Page 1

Owner's Operating

Service Instruction

lOtt

Manual

ASSEMBLY

OPERATION

REPAIR PARTS

rrrrrrnrrrtrrrrrrrrrrtrrrrrrrrrrtrrrrrTrrtrïTTrTrrrrrnrrr^^

Model Nos.

215-390A

215-395A

For one year from date of purchase, MTD Products Inc will replace for the original purchaser, free

of charge, F.O.B. factory or authorized service firm, any part or parts found to be defective in material

or workmanship. All transportation charges on parts submitted for replacement under this warranty

must be paid by the purchaser. This warranty does not include replacement of parts which become

inoperative through misuse, excessive use, accident, neglect, improper maintenance or alterations by

unauthorized persons. This warranty does not inciude the engine, motor, battery, battery charger or any

component parts thereof. For service on these units, refer to the applicable manufacturers warranty.

The above warranty will apply only to the original owner and will be effective only if the warranty

card has been properly processed. It will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. UNDER

NO CIRCUMSTANCES WILL THE RETURN OF A COMPLETE UNIT BE ACCEPTED BY THE

FACTORY UNLESS PRIOR WRITTEN PERMISSION HAS BEEN EXTENDED.

U.t«.k.«.UJ.OtJUUUUIAJIJimg»ftiaaftlH»iitJJQ»eaBeeeeieeaeaiemoaeeeeoinatae»mjp

MTD PRODUCTS INC

PRINTED IN U.S.A.

WARRANTY

5389 WEST 130th STREET • P. 0. BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-5636

Page 2

1. Your tiller is a precision piece of power equipnrient.

Exercise extreme caution at ail times.

2. Do not attempt to start engine with the clutch con

trol in the engaged or FORWARD position.

3. Stand clear of tines when starting engine. Never

stand in front of, or work on tines while the en

gine is running.

4. NEVER place hands or feet in the vicinity of the

tines while the engine is running.

5. Always stop engine when tiller is not in actual use.

6. Always disconnect spark plug wire during repairs

or refueling operations.

7. Do not fill fuel tank while engine is running. Do not

spill gasoline on hot engine.

Your rotary tiller is a precision built machine designed

to take the work out of gardening and other related

chores. It can be used for seed bed preparation, tilling,

cultivating, furrowing, composting and mulching. Like

any other piece of power equipment, it requires a cer

tain amount of care and maintenance. In return for

this, it will give a maximum of service and efficiency.

Read these instructions carefully before assembling or

operating your tiller. Through proper care and opera

tion, you will obtain long, efficient service and trouble

free operation.

NOTE

Your tiller is shipped without oil in the

engine crankcase. See engine manual

for correct type and amount.

ASSEMBLY

Your Rotary Tiller is shipped completely assembled ex

cept for the handle, tine assemblies, depth bar and

wheels. These parts, with the necessary hardware are

easily assembled to the machine, as outlined in this

section.

NOTE

Reference to right hand or left hand

side of machine is from the operating

position.

TOOLS REQUIRED

One Screwdriver

Two 7/16" Wrenches

Two 9/16" Wrenches

Two %" Wrenches

One Pair of Pliers

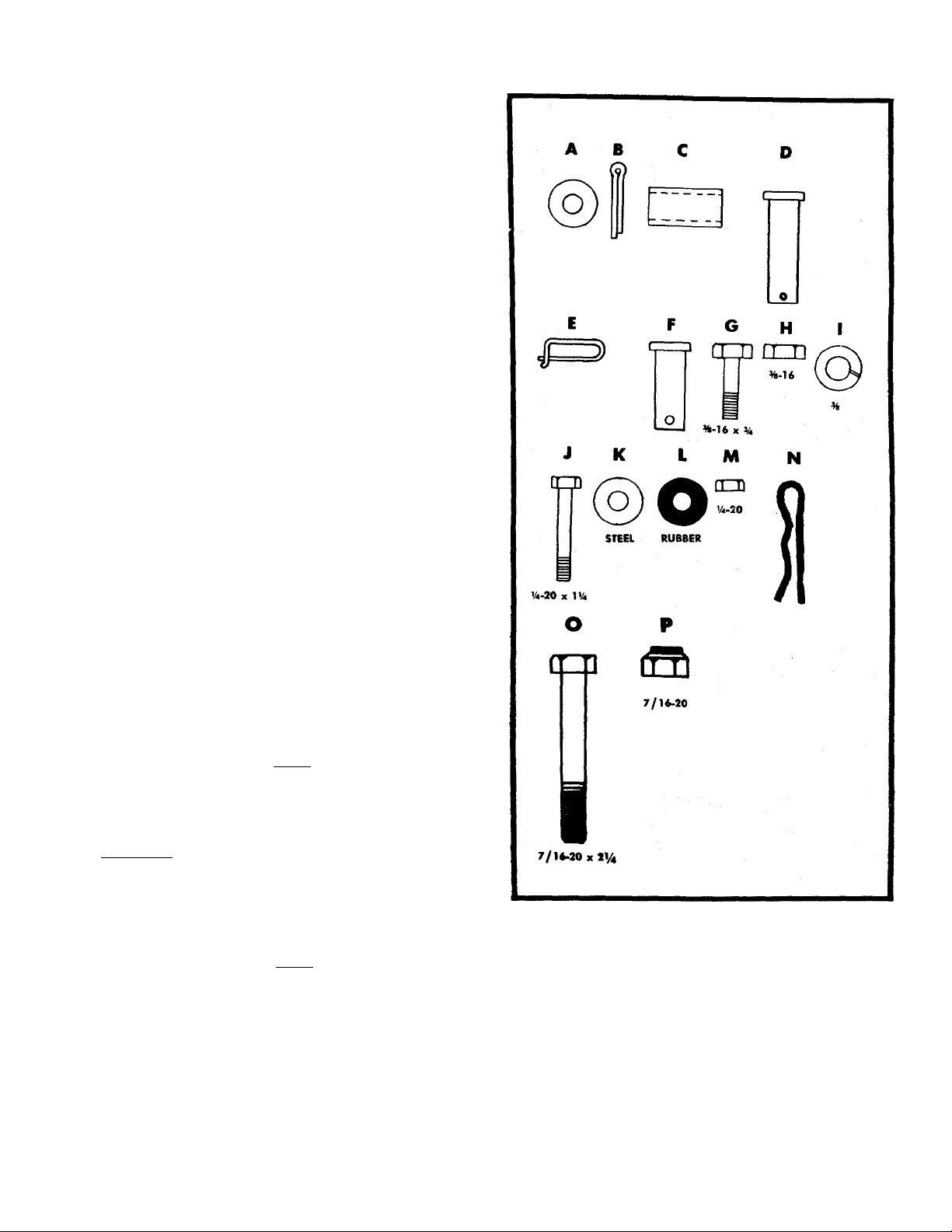

FIGURE 1. HARDWARE SUPPLIED

Wheel end Wheel Hanger Assembly

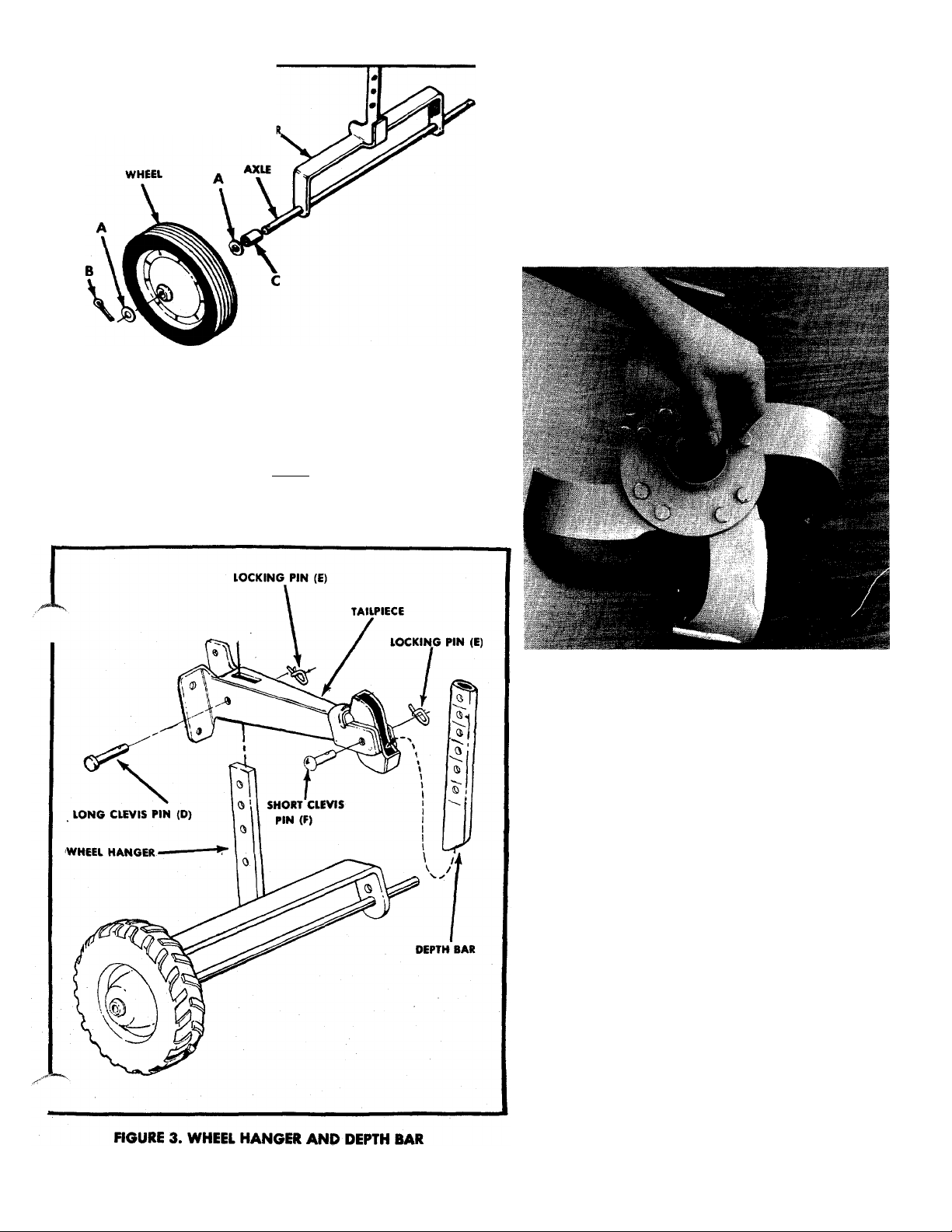

Refer to figure 2.

Step 1. Slide the axle through the wheel hanger.

Step 2. Place the washer A, spacer C, wheel and

washer A on each side of the axle and se

cure each with a cotterpin B as shown.

Page 3

WHEEL

HANGEI

FIGURE 2. WHEEL ASSEMBLY

Step 3. Place the wheel hanger into the tailpiece and

secure with the long clevis pin (D) and locking

pin (E). See figure 3.

NOTE

For the initial set up, use the second

hole from the bottom on the wheel

hanger.

Depth Bar

Refer to figure 3.

Step 1. Attach the depth bar to the tailpiece with the

clevis pin F.

Step 2. Secure the clevis pin F with the locking pin E.

Dust Pad

Install the dust pads in each inner tine assembly. See

figure 4.

FIGURE 4. DUST PADS

Tine Assembly

Step 1. The inner tine assemblies are already assem

bled to the tiller.

Step 2. The outer tine assemblies are inverted on the

tine shaft for shipping purposes only, and

MUST be removed and turned around so that

the sharp edge of the tines enter the soil first.

Secure with bolt O and locknut P. See figure 5.

Page 4

ri-': '

FIGURE 5. OUTER TINE ASSEMBLY

NOTE

Be sure the tines are assembled so the

sharpened edge enters the soil first.

Handle Assembly

Refer to figure 6.

Step 1. Assemble the handle assembly to the handle

mounting brackets with 4 hex bolts G, lockwashers I and hex nuts H.

Step 2. Assemble grips to handle.

nOURE 6. HANDLE ASSEMBLY

CONTROL ASSEMBLY

Page 5

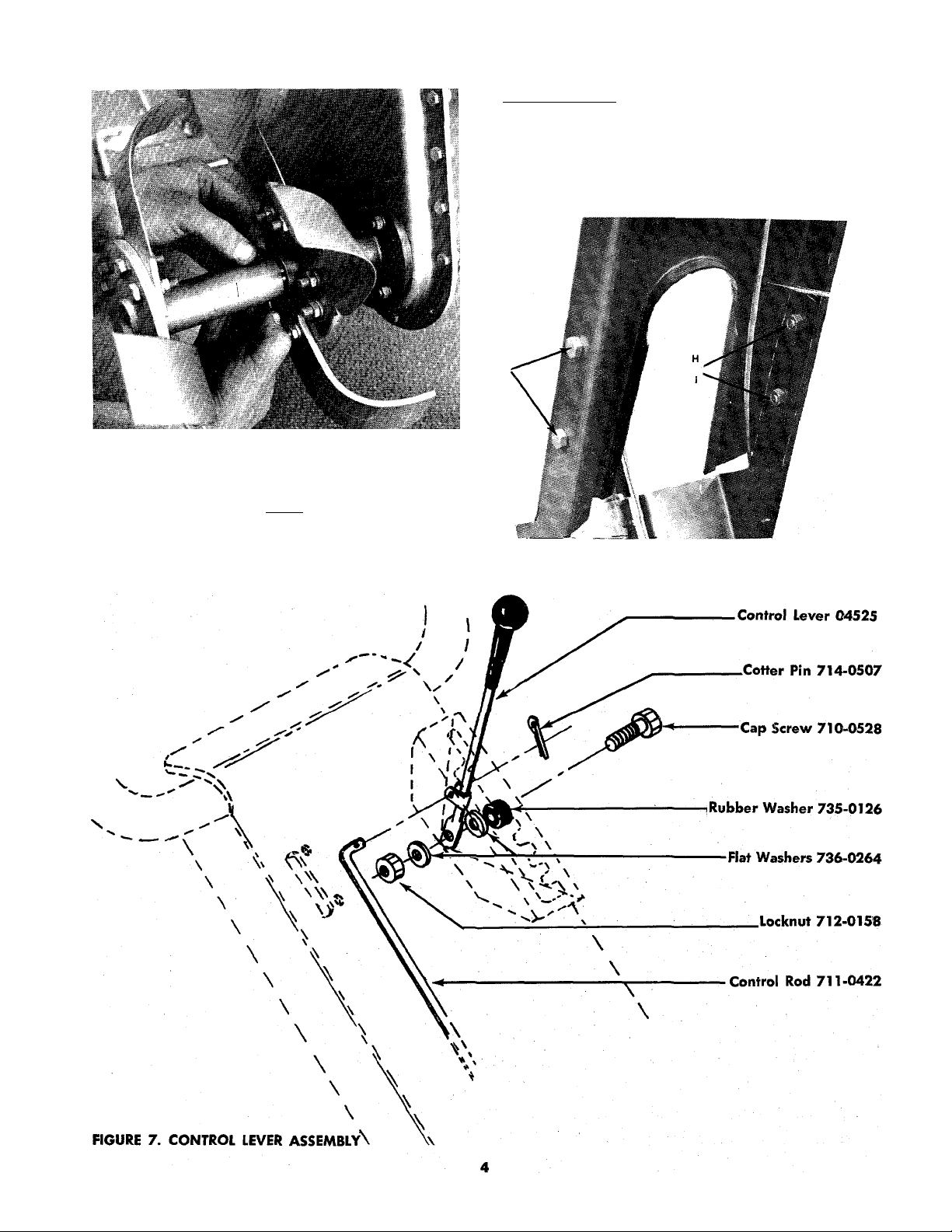

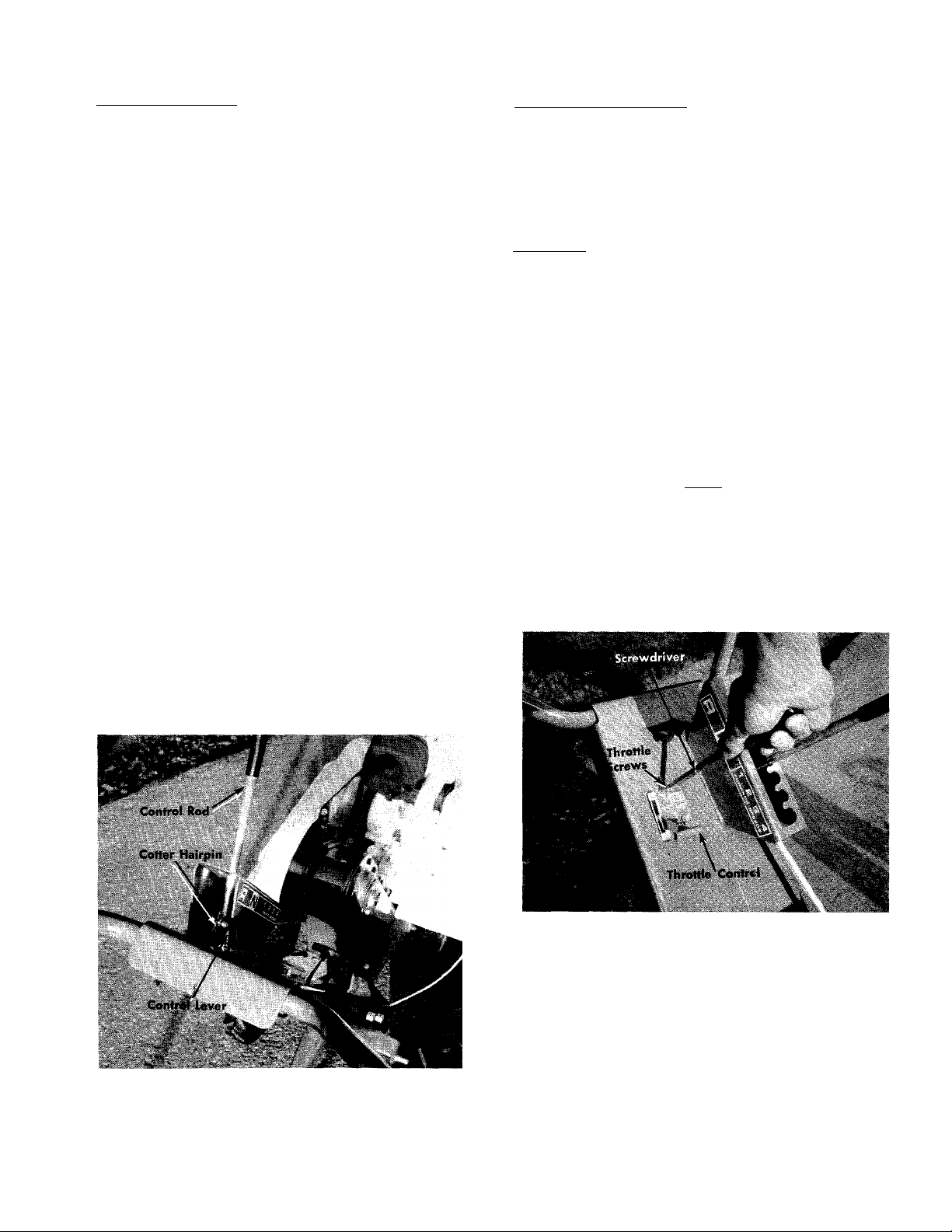

CONTROL ASSEMBLY (See figure 7.)

Throttle Control Assembly

Assemble control lever in box on handle panel as

shown. Be sure control lever is positioned with the

hole in the control rod mounting clevis up (or to

the rear).

2. Insert the "L" shaped end of control rod through

the lower opening of the box. Screw the threaded

end of the control rod into the ferrule on the vari

able speed control. It will extend approximately

3. Insert the "L" shaped end of the control rod into

the control lever and fasten with cotter pin.

4. Remove spark plug wire. Place control lever in neu

tral. Pull recoil starter rope several times. Tines

should not rotate. If tines rotate, adjust control rod

in ferrule until "NEUTRAL" is obtained.

5. Replace spark plug wire.

CAUTION

If the belt cover (Ref. No. 63 on page

12) is removed, you will not have any

neutral. This belt guard contains the

belt trapout meant for around the en

gine pulley. The control rod must be as

sembled exactly as noted above and as

shown in figure 7 or there will be no

neutral and the tiller tines will rotate

as long as the engine runs.

Step 1. Place throttle control in handle and assemble

to handle with the two throttle screws using

a screwdriver. See figure 8.

CONTROLS

The controls on your Rotary Tiller are the control lever,

throttle control and depth bar.

The Control Lever

The Control Lever is released from Neutral by moving

it to the right and allowing the spring tension to pull

the control lever into one of the four forward speeds.

See figure 9.

NOTE

Number 1 position is the slowest tine

rotation speed and number 4 is the

fastest.

Pulling the control lever slowly backwards into Re

verse position reverses the direction of tine rotation.

Reversing should be done at half throttle position.

FIGURE 8. THROmE CONTROL

FIGURE 9. CONTROLS

Page 6

The Throttle Control

The throttle control actuates the butterfly in the carbu

retor which controls the speed of the engine.

NOTE

Always check the throttle cable and

wire at the engine end for a tight con

nection.

To stop the engine, pull the throttle control all the way

back towards you. To start, push the throttle control all

the way forward. See figure 9.

The Depth Bar

The depth bar is used to prevent the tiller from running

on top of the ground instead of tilling. The deeper

you set the depth bar, the deeper you will till. Tilling

depth is from 0 to 8 inches. See figure 10.

WHEEL ADJUSTMENT

The wheel height can be adjusted by removing the

long clevis pin on the wheel hanger and raising or

lowering the setting. The higher the setting the deeper

the tilling depth. See figure 11.

NOTE

Pick a height that places the handles in

a comfortable position for the operator.

TILLING WIDTH ADJUSTMENT

The tilling width is adjustable from 12 inches to 40

inches with the use of the optional extension tines. The

standard tilling width with both the inner and outer

tines is 26 inches. By removing the outer tines you re

duce the tilling width to 12 inches.

FIGURE 11. WHEEL HEIGHT ADJUSTMENT

CHECKING OIL, GASOLINE AND CHAIN CASE

NOTE

When packaged for shipment the ma

chine contains no oil or gasoline. Before

starting the engine, oil must be added

to the engine crankcase and gasoline

to the tank. DO NOT mix oil with gaso

line.

a. Oil

With the tiller on level ground, remove the oil filler

plug from the engine and fill the crankcase with good

quality, SAE 30 type MS engine oil until it overflows.

The crankcase holds approximately 2% pints of oil.

Pour slowly to avoid air locks. Replace the oil filler

plug. See figure 18.

b. Gasoline

Remove the gas cap and fill the tank with FRESH REG

ULAR GRADE GASOLINE. If the gasoline has been in

a metal can for a long period, throw it away and use

fresh gasoline.

c. Chain Case Lubricant

The chain case is sealed and requires no further lubri

cation unless the chain case is disassembled for repair.

Page 7

Step 4. When the engine starts, gradually move the

throttle to the fast position. After engine

warms up (about 2 or 3 minutes) set throttle

at idle position.

Step 5. DO NOT OVERCHOKE ENGINE. Repeated

cranking with throttle at START position will

cause gasoline to flood the intake tube and the

engine. If, after 3 or 4 attempts, the engine

fails to start, place throttle in fast position,

crank the engine several times to clear out

the excess fuel; and then proceed with steps

2, 3 and 4.

STOPPING THE ENGINE

To stop the engine, pull the throttle control all the way

back to STOP position. See figure 9. When the throt

tle control is in the STOP position, a switch blade is

activated to short-circuit the spark plug.

Whenever the tiller is left unattended,

disconnect the spark plug lead and place

the throttle control in the STOP position.

AIR FILTER

The air filter is pre-serviced at the factory and requires

no additional servicing before the initial use of the

tiller, however, the air cleaner should be serviced per

iodically as stated on page 8.

STARTING THE ENGINE

Step 1. With the tiller set on level ground, set the

control lever in NEUTRAL.

Step 2. Set the choke in the START.

Step 3. As illustrated in figure 13, grasp the recoil

starter handle, pull out sharply, and hold it

in the out position. (Do not let cord snap back.)

STOPPING THE TINES

Pull the control lever into the NEUTRAL position. The

tines will not rotate. See figure 9.

OPERATING THE TILLER

Typical operation of the tiller is as follows:

Step 1. Set the clutch control to NEUTRAL.

Step 2. Start the engine.

NOTE

To move the tiller to the work area,

keep the depth bar in the highest posi

tion. With the throttle in the SLOW posi

tion, slowly engage the control lever

into the number 1 position and the tiller

will walk to the work area without dig

ging into the ground.

Step 3. With the clutch control in NEUTRAL, set the

depth bar in one of the lower settings.

NOTE

When several passes must be made

over the same area, lower the depth bar

each time a pass is made.

Step 4. Set the throttle control to fast. (See page 5.)

FIGURE 13. RECOIL STARTER

NOTE

The cord should NOT be pulled out

more than about two feet. If engine

fails to start, allow the cord to wind

back into the housing, then pull out

sharply again. Refer to Step 5.

Step 5. Slowly engage the clutch control to the num

ber 1 position and the tines will begin rotat

ing. Number 4 position will give the maxi

mum tine speed. Tilling the ground for the

first time should be done in the number 1 or 2

position. To pulverize tne soil after it has been

tilled, move the control lever to the number 3

or 4 position.

Page 8

NOTE

This tiller is equipped with a variable

speed pulley making it necessary for

the engine to be running to move

the control lever into the faster speeds.

A downward pressure on the handles

will increase working depth and re

duce the forward speed. An upward

pressure on the handles will reduce the

working depth and increase the for

ward speed. The type of soil and work

ing conditions will determine the actual

setting of the depth bar and the handle

pressure required.

If the tines stop rotating or the belt

slips, stop the engine and examine the

tine area for a rock or some object that

may be jamming the tines and prevent

them from turning. Reversing the tiller

will usually free the object.

Step 2. After the oil has been drained completely

from the crankcase, replace the drain plug and

tighten.

Step 3. With the tiller on level ground, remove the

oil filler plug (See figure 16). Fill the crankcase

until the oil overflows from the oil fill hole.

Fill slowly to avoid air locks. The crankcase

should hold approximately 2% pints of SAÉ

30 type MS engine oil. Replace the oil filler

plug.

CHAIN CASE LUBRICATION

The chain is permanently lubricated and requires no

further lubrication unless the case is disassembled for

repair.

If the case is disassembled, clean the chain with kero

sene, allow it to dry and work a high temperature

grease, such as Lubriplate No. 310 into the chain.

NOTE

If the tines tend to bounce instead of

cutting into the soil, one or more sets

of tines may be on backwards. The

cutting edge of the tines should enter

the soil first.

Step 6. To reverse the direction of rotation of the

tines, pull the control lever into the reverse

position. The control lever must be held in

reverse. See figure 9.

b. Oil Change

To avoid spilling gasoline on your lawn or driveway,

plan to change the oil when the gasoline tank and car

buretor are empty.

After the first two hours of operating a new engine,

drain the oil from the crankcase while the engine is

still hot and refill the crankcase with new oil; there

after change the oil after every 25 hours of operation.

This procedure ensures for minimum wear of engine

parts and provides for virtually trouble-free operation.

To change the oil, proceed as follows:

Step 1. With the machine on level ground, place a

suitable metal container under the oil drain

plug, then remove the drain plug. See figure

12.

NOTE

A 4 oz. container of Lubriplate No. 310

is available under part number 727-0136.

CHAIN ADJUSTMENT

No chain adjustment is necessary.

AIR FILTER

Under normal operating conditions, the air cleaner,

located on top of the carburetor, must be serviced

after every ten hours of use. Under extremely dusty

operating conditions, the air cleaner must be serviced

after every hour of operation. See figure 15.

Step 1. Remove the wing nut and cover.

Step 2. Remove the paper element from the support

base.

Step 3. To clean, tap the paper element (either top or

bottom) on a flat surface or wash in a nonsudsing detergent and flush from the inside

until the water is clear. After washing, air dry

thoroughly before using.

FIGURE 15. AIR CLEANER

Page 9

CLEANING ENGINE AND TINE AREA

Any fuel or oil spilled on the tiller should be wiped

off promptly. Dirt, leaves and other debris must not be

left to accumulate around the cooling fins or the engine

or on any part of the tiller. Clean the under side of the

tine shield after each use. The dirt washes off the tine

easier if washed off immediately instead of after it

dries.

The blower housing is held in place with three screws.

One on the top of the engine and two on the bottom.

See figure 16.

BELTS

Check that belts are free of oil or dirt. Wipe the belts

periodically with a clean rag.

SPARK PLUG

The spark plug gap should be cleaned and reset to a

0.030-inch clearance every 25 hours of engine opera

tion (See figure 17). Spark plug replacement is rec

ommended at the start of each tiller season; check en

gine parts list for correct plug type.

FIGURE 18. GASOLINE FILTER AND SHUT-OFF

BELT ADJUSTMENT

How to adjust:

Step 1. Remove the belt cover as shown in figure 18.

Step 2. Start the engine according to the instructions

on page 7.

Step 3. Tip the tiller back on its wheels until the tines

clear the ground.

Step 4. Move the control lever into number four posi

tion.

NOTE

The inside belt should move to the out

side edge of the variable speed pully

so the top of the belt is almost flush

with the pulley. See figure 19.

Step 5. If adjustment is necessary, adjust the control

rod by screwing it in or out of the ferrule as

necessary. See figure 20.

GASOLINE FILTER AND SHUT-OFF VALVE

Refer to figure 18.

Step 1. Close the shut-off valve.

Step 2. Loosen the thumb screw below the bowl.

Step 3. Remove and clean the screen.

Step 4. Open the shut-off valve to see if gasoline

flows freely from the gasoline tank.

Step 5. Clean the bowl and screen. Use alcohol or

acetone to clean the parts if you find a gum

my, varnish-like substance in the bowl.

Step 6. Reassemble.

Step 7. Open the shut-off valve.

nirew Puii-y

Com

Ferrule^

FIGURE 19. DRIVE SYSTEM

CAUTION

With the belt cover removed your unit

will not have a neutral. The tines will

always turn. You must hold the tines off

the ground either by having someone

else hold the handle down or by placing

the handles under something solid such

as a work bench while you start the en

gine.

Page 10

VARIABLE SPE

PULLEY

Rear Beh

BEIT SHOUIO BE IN THIS

POSITION WITH CONTROL

LEVER IN NO. 4 POSITION

FIGURE 20. VARIABLE SPEED PULLEY

BELT REPLACEMENT

CAUTION

Be careful not to pinch your fingers betv/een the pulley and belt.

Step 1. Remove the belt cover so the belts are ex

posed as shown in figure 19.

CHAIN CAS’E Step 2. Put the depth bar on the wheel hanger and

place the tip of the depth bar under the var

iable speed pulley bracket as shown in figure

21.

Step 3. Place your foot on the rear of the depth bar

and apply pressure. The belts will go slack.

Step 4. Remove the REAR belt first and allow it to

form a loop around the variable speed pulley.

Step 5. Slide the center section of the variable speed

pulley towards the engine. See figure 19.

CENTER SECTION Step 6. Remove the FORWARD belt from the engine

pulley and the variable speed pulley.

NOTE

By following this order of bfelt removal,

it is not necessary to remove the belt

guard on the variable speed pulley.

Step 7. Remove the rear belt from the variable speed

pulley.

Step 8. Reassemble with the new belts.

FIGURE 21. BELT REMOVAL

CARBURETOR ADJUSTMENT See figure 22.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

and load. To adjust:

Step 1. Turn needle valve clockwise until it just closes.

CAUTION

Valve may be damaged by turning too

far.

Step 2. Open needle valve 114 turns counterclockwise.

Step 3. Close the idle valve in the same manner and

open 114 turns.

4. Start the engine.

Step

5. Turn the needle valve in until the engine

Step

misses,

6. Then turn it out past smooth operating point

Step

until the engine runs unevenly.

Step 7. Turn the needle valve mid-point between the

two settings so the engine runs smoothly.

Step 8. Set the throttle in the idle (slow) position and

set the idle speed adjusting screw until a fast

idle is obtained.

St^ 9. With the throttle stilLin the idle position, turn

the idle valve in and out until the engine idles

smoothly.

10

Page 11

ADJUSTING THE CARBURETOR CHOKE

Proper choke and stop switch operation is dependent

upon proper adjustment of remote controls on the

powered equipment.

To Check the Operation of the Choke:

Step 1. Remove the air cleaner.

Step 2. Push the throttle control all the way forward

to the START position. See figure 10. The choke

should be closed.

Step 3. The engine should shut off when the throttle

control is ail the way back. (STOP position.)

To adjust:

Place remote control lever on equipment in fast (high

speed) position. Loosen control casing clamp screw

"B". Move control casing "A" and wire until lever "D"

touches choke operating link at "C". Tighten casing

clamp screw 'B". Replace air cleaner. See figure 24.

OFF-SEASON STORAGE

If the machine is to be inoperative for a period longer

than 30 days, the following precautions are recom

mended:

Step 1. Working outdoors, drain all fuel from the

fuel tank. Use a clean dry cloth to absorb the

small amount of fuel remaining in the tank,

then run the engine until all fuel in carburetor

is exhausted.

WARNING

L;

DO NOT DRAIN FUEL WHILE SMOKING,

OR IF NEAR AN OPEN FIRE.

Step 2. Drain all the oil from the crankcase (this

should be done after the engine has been op

erated and is still warm) and refill the crank

case with clean new oil.

Step 3. Disconnect the spark plug wire and remove

the spark plug from the cylinder. Pour about

six drops of engine oil into the cylinder, and

then pull the recoil starter several times to

spread the oil on the cylinder wall. Replace

the spark plug, but DO NOT connect the wire.

Step 4. Clean the engine and the entire tiller thor

oughly.

Step 5. Wipe tines with oiled rag to prevent rust.

FIGURE 23. CHOKE ADJUSTMENT

11

Page 12

215-390A

215-395A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

12

Page 13

PARTS LIST FOR MODELS 215-390A AND 215-395A

REF.

PART

NO.

20

21

22

23

24

25

26

27

28

29

30

31

32

NO.

1

2

710-0380

710-0176

3

4

5

6

7 720-0143

8

9 711-0422

10 710-0528

11

12

13

14

15

16

17

18

19

04524

710-0376

04494

710-0253

714-0507

712-0158

01166

746-0242

04625-463

04525

736-0264

735-0126

736-0264

736-0217

712-0798

04506-463

710-0152

736-0217

04505-463

04507-463

732-0194

736-0217

710-0152

732-0194

04668-463

711-0231

04527-463

COLOR

CODE

DESCRIPTION

Engine

Hex Hd. Cap Scr. 5/16-18 x

1%" Lg. (215-395A)

Hex Hd. Cap Scr. 5/16-18 x

2%" Lg. (215-390A)

Tine Shield

Hex Hd. Cap Scr. 5/16-18

X 1" Lg.*

Engine Spacer Ass'y. (215-390A)

Only)

Hex Hd. Cap Scr, %-16 x 1.00"

Lg.*

Grip

Cotter Pin 3/32 X %" Lg.*

Control Rod

Hex Hd. Cap Scr. 5/16-18 x

VA" Lg.*

Hex Centerlock Nut 5/16-18

Thd.*

Grip

Throttle Control Ass'y. Comp.

Handle Ass'y.

Control Lever Ass'y.

Flat Washer*

Rubber Washer*

Flat Washer*

L-Washer % Scr.*

Hex Nut %-16 Thd.*

Handle Mtg. Brkt.

Hex Hd. Cap Scr. %-24 x 1"

Lg.*

L-Washer % Scr.*

Handle Mtg. Brkt.

Tail Piece

Spring Pin

L-Wash. %" Scr. H.D.

Hex Hd. Cap Scr. %-24 x 1"

Lg.*

Spring Pin

Depth Bar

Clevis Pin

Wheel Hanger Brkt. Ass'y.

NEW

PART

I

REF.

NO.

49

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

N

70

71

PART

COLOR

NO.

CODE

33

711-0510 Clevis Pin

34

35

36

37

38

39

40 04474-463

41 04511-463 Inner Tine Adapter

42 721-0124

43

44

45 04511-463

46

47

48

50

04451

711-0313

734-0575

736-0108

714-0115

712-0236

721-0125

742-0113

742-011®

04474-463

710-0191 Hex Hd. Cap Scr. %-24 x 1.25"

736-0217

712-0241

710-0483

736-0119

712-0158

04519-463

712-0158

736-0119

04519-463

710-0258

710-0252

04516

736-0329

712-0287

04537

710-0121

736-0921

04523

712-0287

748-0147

710-0180

736-0217

710-0227

Rear Axle

Spacer

Wheel Ass'y. Comp.

Flat Washer*

Cotter Pin Va Dia. x 1" Lg.*

Hex Elastic Stop Nut 7/16-20

Outer Tine Adapter

Dust Pad

Dust Pad

Tine—lA.H

inner Tjhe Adapter

Tine—1^.//

Outer Tine Adapter

L-Washer for % Scr.*

Hex Nut %-24 Thd.*

Hex Hd. Cap Scr. 7/16-20 x

L-Washer 5/16 Scr.*

Hex Center L-Nut 5/16-18 Thd.

Engine Mtg. Brkt.

Hex Center L-Nut 5/16-18 Thd.

L-Washer 5/16 Scr.*

Engine Mtg. Brkt.

Hex Hd. Cap Scr. V4-20 x %" Lg

Hex Hd. Cap Scr. ’A-20 x %" Lg

Belt Guard

L-Washer Va" Scr.*

Hex Nut'/4-20 Thd.*

Belt Trap Ass'y.

Hex Hd. Cap Scr. ’/2-20 x %" Lg

L-Washer '/2" Scr.*

Variable Speed Guiding Brkt.

Hex Nut Va-20 Thd.*

Bushing

Hex Scr. %-24 x .75" Lg.*

L-Wash. %" Scr. H.D.

Hex Wash. Hd. AB-Tapp Scr.

DESCRIPTION

Thd.

2’/4" Lg.*

#8 X .38" Lg.*

NEW

PART

*

*

*For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be obtained lo

cally, order by part number and size as shown on parts list.

(463—^Top Flite Red)

When ordering parts, if color or finish is important, use the appropriate color code

shown at left. (e.g. Top Flite Red finish,04625(463).)

13

Page 14

215-390A

215-395A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

TINE ASSEMBLIES COMPLETE

Inner Tine Assembly—L.H.—Complete 04541

Inner Tine Assembly—R.H.—Complete 04542

Outer Tine Assembly—L.H.—Complete 04095

Outer Tine Assembly—R.H.—Complete 04096

53 52 51 50 49 4d 47 46 4 5 44 43 42 41

14

Page 15

PARTS LIST FOR MODELS 215-390A AND 215-395A

PART COLOR NEW

REF.

NO.

1

2

715-0124

3

748-0181

4

741-0139 Ball Brg. .50 I.D. x 1.38 O.D.

5

750-0144

6

750-0146

7

741-0139

8

748-0177

9

10

11

12

735-0127

13

14 736-0300

15

741-0155

16 05034 Bearing Housing 1% Dia.

17 736-0329 L-Washer 'A" Scr.*

18

710-0258 Hex Hd. Cap Scr. '/4-20 x %" Lg.*

19

714-0136

20

21

22

754-0158

23

712-0461

24

25

756-0167

26

712-0221

27

736-0204

28

736-0329

29

710-0230

30

712-0116

31

712-0116

32

736-0300

33

711-0392

34

711-0422

35

714-0115

36

712-0116

37

735-0127

38

736-0300

39

71 n.n1t R

40

736-0119

41

712-0461

42

710-0152

43 736-0217

44

45

714-0133

714-0118

NO.

10844

04523

04517-463

04501-463

11021-463

05080

04515

04510-463

07386

CODE

Sheave Half with 3 Holes 46 10843

Spring Pin Spiral 5/32 Dia. x

Movable Sheave 390A5 H.P. Only)

Steel Tubing

Spacer .520 I.D. x .692 O.D.

Ball Bearing .50 I.D. x 1.38 O.D. 50 710-0380 Hex Hd. Cap Scr. 5/16-18 x

Sheave Half 1%" Lg.*

Variable Speed Guiding Brkt.

Variable Speed Brkt. Ass'y.

Housing Ass'y.—l-.H. Side

Eccentric Link

Rubber Washer

Flat Washer

Ball Brg. % I.D. X 1% O.D.

Hi Pro Key #505

Friction Wheel Ass'y.

Friction Disc

"V"-Belt 21/32 X 35" Lg. Spec.

Hex Jam Nut '/2-13 Thd.

Variable Speed Belt Guard

8" O.D. x % Split Pulley

Hex Elastic Stop Nut %-18 Thd.

Flat Washer

L-Washer 'A" Scr.*

Hex Hd. Cap Scr. '^-28 x '/2" Lg.

Hex Elastic Stop Nut %-24 Thd

Hex Elastic Stop Nut %-24 The

Flat Washer

Ferrule

Control Rod

Cotter Pin Vs Dia. x 1" Lg.*

Hex Elastic Stop Nut %-24 Thd.

Rubber Washer

FI.-Wash.

Hex Hd. Cap Scr. 5/16-18 x %"

L-Washer 5/16 Scr.*

Hex Jam Nut '/2-13 Thd.

Hex Hd. Cap Scr. %-24 x 1"

Spring L-Wash. % Scr. H.D.

Flat Washer

Sq. Key3/16xl'/2"Lg.* (215-

Sq. Key '/4 X I'A" Lg.* (215-395A)

DESCRIPTION PART

.62“ Lg. 48

Lg. l>]-\Si

Lg. H.T.

390A)

REF.

PART COLOR

NO.

NO.

47

754-0157

49 738-0138

51 11022

52

711-0509

53

732-0232 Variable Drive Spring

54

712-0158

55

736-0119

56

57

721-0117

58

748-0194

59

712-0287

60

736-0329

61

721-0119

62

711-0506

63

713-0150

64 717-0189

65

715-0125

66

710-0258

67 04530-463

68

710-0118

69

736-0119

70

736-0195

71

72

711-0504

73

748-0855

74

75

717-0188

76

715-0120

77

750-0118

78

/y

/ i O-U1^y

80

711-0505

81

748-0855

82

726-0106

83

748-0180

84

750-0166

85

86

730-0158

CODE

04532

04531

04530-463

04503-463

04529

—

04521

Variable Speed Pulley Ass'y.

"V''-Belt21/32 x28" Lg

Engine Pulley Ass'y. (For 215Engine Pulley Ass'y. (For 215-

395A8 H.P. Only)

Shoulder Bolt—Special

Spring Bracket

Spring Insert

Hex Center L-Nut 5/16-18 Thd.*

L-Washer 5/16 Scr.*

Cast Bearing Housing Ass'y.

Oil Seal VA" I.D. x 1%" O.D.

Flange Brg. VA" I.D. x 1%" O.D.

Hex Center L-Nut '^-20 Thd.*

L-Washer '/4" Scr.*

Gasket

Tine Shaft

24-2 Teeth Sprocket '/2'' Pitch

Spirol Pin % Dia. X 2" Lg, H.D.

Hex Hd. Cap Scr. '/4-20 x %" Lg.

Cast Bearing Housing Ass'y.

Hex Hd. Cap Scr. 5/16-18 x

%" Lg.*

L-Washer 5/16 Scr.*

Flat Washer

Housing Ass'y.—R.H. Side

Sprocket Shaft

Flange Bearing

Double Sprocket Ass'y.

11-2 Teeth Sprocket % Pitch

Spirol Pin 3/16 Dia. X 1" Lg. H.D.

Spacer

Part of Ref. No. 74

Pulley Shaft

Flange Bearing

Push Nut

Pivot Slide

Spacer

Link Brkt. Ass'y.

L-Wash. %" Scr.*

DESCRIPTION

________

NEW

PART

Spec.

.|e

i-H'i

- ■

1

1

*For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be obtained lo

cally, order by part number and size as shown on parts list.

(463—Top Flite Red)

When ordering parts, if color or finish is important, use the appropriate color code

shown at left. (e.g. Top Flite Red finish,04625(463).)

15

Page 16

PARTS INFORMATION

DEFECTIVE OR MISSING PARTS must be reported

to the factory immediately. Such claims must include

your model number and date of purchase.

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power

equipment are available through the authorized serv

ice firms listed below. All orders should specify the

model number of your unit, parts numbers, descrip

tion of parts and the quantity of each part required.

A 1 Engine * Mower Co.

327 East 9th Street

Salt Lake City, Utah 84102

Auto Electric A Carburetor Co.

2i25 4th Avenue, S.

P. O. Box 1948

Birmingham, Alabama 35233

Automotive Equipment Service Co.

3117 Holmes Street

Kansas City, Missouri 54109

Bailey's Rebuild Inc.

1325 E. Madison Street

Seattle Washington 98102

Blecicrie, Inc.

7900 Lorain Avenue

Cleveland, Ohio 44102

Brown Equipment Distributor Inc.

? 10 SeMh Street

Corydon, Indiana 47112

Bullard Supply

2409 Commerce Street

Houston, Texas 77003

Catto A Putty, Inc.

P. O. Box 2408

510 Soledad Street

San Antonio, Texas 78205

Center Supply Company

6867 New Hampshire Avenue

Takoma Park, Maryland 20012

Dixie Sales Company

P. O. Box 1408

327 Battleground Avenue

Greensboro, North Carolina 27402

East Point Cycle A Key Shop

1617 Whiteway

East Point, Georgia 30044

\

Gamble Distributors

West End Avenue

Carthage, New York 13619

Garden Equipment Co., Inc.

6600 Cherry Avenue

Long Beach, California 90805

Gardenville Supply, Inc.

Pipersville, Pennsylvania 18947

Henry W. O'Neil & Assoc., Inc.

410 North Goodman Street

Rochester, New York 14609

Henzier, Inc.

2015 Lemay Ferry Road

St. Louis, Missouri 63125

Kenton Supply

8216 North Denver Avenue

Portland, Oregon 97217

KImber's Inc.

115 W. Geddes St.

Syracuse, New York 13204

Marr Brothers

423 E. Jefferson

Dallas, Texas 75203

McClure Lawn A Garden Supply

1114 Lexington Avenue

Mansfield, Ohio 44907

Memphis Cycle A Supply Co.

421 Monroe Avenue

Memphis Tennessee 38103

Morton B. Collins Co.

300 Birnie Avenue

Springfield, Massachusetts 01107

Moz-AII of Florida, Inc.

365 Greco Avenue

Coral Gables, Florida 33146

National Central,

687 Seville Rd.

Wadsworth, Ohio 44281

BRIGGS & STRATTON, TECUMSEH AND PEERLESS

PARTS AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and

service should be handled by your nearest authorized

engine service firm. Check the yellow pages of your

telephone directory under the listing Engines —

Gasoline, Briggs & Stratton or Tecumseh Lauson —

Power Products.

Parts A Sales Inc.

2101 Industrial Pkwy.

Elkhart, Indiana 46514

Power Equipment Distributor

36463 So. Gratiot Avenue

Mt. Clemens, Michigan 48043

Power Lawn A Garden Equip. Co.

2551-2571 J. F. Kennedy Road

Dubuque, Iowa 52001

Radco Distributors

2403 Market Street

P. O. Box 3216

Jacksonville, Florida 32206

Raub Supply Company

James A Mulberry Sts.

Lancaster, Pennsylvania 17604

Richmond Battery A Ignition

P, O. Box 25369 - 957 Myers St.

Richmond, Virginia 23260

R. P. W., Inc.

623 S. 16th Street

Omaha, Nebraska 68102

Smith Hardware Company

515 N. George Street

Goldsboro, North Carolina 27530

South Denver Lawn Equip. Co,

527 West Evans

Denver, Colorado 80223

Suhren Engine

8330 Earhart Blvd.

New Orleans, Louisiana 70118

Sutton's LaWn Mower Shop

Route 4, Box 343

North Little Rock, Arkansas 72117

Warner Equipment

7520 Lyndale Avenue, So.

Minneapolis, Minnesota 55423

Woodson Sales A Service

1702 North Sylvania

Ft. Worth, Texas 76111

♦

♦

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials,

t

defects which are NOT detected at the time of manufacture. It does not provide for the unlimited

and unrestricted replacement of parts. Use and maintenance are the responsibility of the cus

t

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

t

tomer. The manufacturer cannot assume responsibility for conditions over which it has no

control. Simply put, if it's the manufacturer's fault, it's the manufacturer's responsibility; if

it's the customer's fault, it's the customer's responsibility.

CLAIMS AGAINST THE MANUFACTURER'S

WARRANTY INCLUDES

1. Replacement of Missing Parts on new equip

ment.

2. Replacement of Defective Parts within the

warranty period.

3. Repair of Defects within the warranty

period.

All claims MUST be substantiated with the

following information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into

service.

3. Date of failure.

4. Nature of failure.

Loading...

Loading...