MTD 215-386-000 User Manual

OUTDOOR POWER EQUIPMENT

for all seasons

.75

5 H.P.

FOUR SPEED

CHAIN DRIVE

TILLER

Model Number

215-386-000

Important:

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Thank you for purchasing

an American-built product.

FORM NO. 770-4081

INDEX

Safe Operation Practices.............................................3

Assembly Instructions.................................................4

Operation .....................................................................8

How to Use YourTiller..................................................9

Adjustments

Lubrication

Maintenance

...............................................................

................................................................

..............................................................

Instructions given with this symbol are for per

A

sonal saf(!ty. Be sure to follow them.

r

LIMITED WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges foi any parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, irrproper maintenance, alterations, or unless the unit has

been operated and maintained in c.ccordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

11

1.1

12

Off-Season Storage....................................................13

Trouble Shooting Chart

Parts for Chain Case..................................................15

Illustrated Parts.....................................................16,18

Parts Lists..............................................................17,19

Parts Information........................................Back Cover

.............................................

14

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or disti ibutor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by M 'D.

♦

♦

This warranty gives you specific egal rights. You may also have other rights which vary

from state to state.

V

AC WARNING f

This unit is equipped with an internal conbustion engine and should not be used on or near any unim

proved forest-covered, brush-covered oi grass-covered land unless the engine’s exhaust system is

equipped with a spark arrester meeting a|iplicable local or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code), ether states may have similar laws. Federal laws apply on federal lands. A spark arrester muffler Is

available at your nearest engine authoriz id service center.

♦

♦

♦

♦

♦

♦

A i WARNING^J

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply

with the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR TILLERS

1. It is suggested that this manual be read in its

entirety before attempting to assemble or

operate this unit. Keep this manual in a safe

piace for future reference and for ordering

replacement parts.

2. Your tiller is.a precision piece of power equip

ment, not a piaything. Therefore, exercise ex

treme caution at all times.

3. Read this Owner’s Manual carefully. Be

thoroughly familiar with the controls and the

proper use of the equipment.

4. Never allow children to operate a power tiller.

Only persons well acquainted with these rules

of safe operation should be allowed to use

your tiller.

N.

5. No one should operate this unit while intoxi

cated or while taking medication that impairs

the senses or reactions.

6. Keep the area of operation clear of all per

sons, particularly small children and pets.

14. Do not waik in front of the tiiier while the

engine is running.

15. Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do

not fill gasoline tank indoors, when the engine

is running, or whiie the engine is stiil hot.

Wipe off any spilled gasoline before starting

the engine as it may cause a fire or expiosion.

16. Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

17. Be careful not to touch the muffler after the

engine has been running. It is hot.

18. Do not change the engine governor settings

or overspeed the engine. Excessive engine

speeds are dangerous.

19. Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

7. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

8. Do not wear loose fitting clothing that could

get caught on the tiller.

9. Do not start the engine unless the shift lever

is in the neutral (N) position.

10. Do not stand in front of the tiller while starting

the engine.

11. Do not place feet and hands on or near the

tines when starting the engine or while the

engine is running.

N 12. Never attempt to make a wheel or depth bar

adjustment while the engine is running.

13. Do not leave the tiller unattended with the

engine running.

20. Use caution when tilling near buildings and

fences. Rotating tines can cause damage or

injury.

21. Before attempting to remove rocks, bricks and

other objects from tines, stop the engine and

be sure the tines have stopped completely.

Disconnect the spark plug wire and ground to

prevent accidental starting.

22. Check the tine and engine mounting bolts at

frequent intervals for proper tightness.

23. Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working condi

tion.

24. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open fiame or spark. Allow the

engine to cool before storing in any

enclosure.

ASSEMBLY

Handle

Panel Assembly

Tail Piece

Depth Bar

FIGURE 1.

Shift Lever

Tiller

Hardware P ick

Control Ro J

INSTRUCTIONS

NOTE

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

operating sectipn of this manual for

proper fuel and engine oil recom

mendations.

Before any step is undertaken, the instructions for

that step should be read thoroughly.

-Tools Required (See Figufe 1)

1. (1) V2" Socket, Open or Box Wrench

2. (2) 9/16" Socket, Open or Box Wrench

3. (1) V4 " Flat Screwdriver

Parts in Carton (See Figure 1)

Tiller

Handle Panel Assembly

Depth Bar

Tailpiece

Control Rod

Hardware Pack

Shift Lever

FIGURE 2.

-Contents of Hardware Pack (See Figure 2)

A (1) “U”-Clevis Pin

B (1) Internal Cotter Pin

C (2) Hairpin Cotters

D (1) Adjustment Ferrule

E (1) Flat Washer 5/16" I.D.

F (1) Belleville Washer 5/16" I.D.

G 0) Compression Spring

H (1) Hex Lock Nut 5/16-18 Thread

J (1) Clevis Pin

K (1) Spring Pin

L (6) Hex Bolts 3/8-16 x 1.00" Long

M (2) Belleville Washers 3/8" I.D.

N (6) Lock Washers 3/8" I.D.

O (6) Hex Nuts 3/8-16 Thread

P (2) Hand Grips (Not Shown)

1. Tailpiece Installation

Slide the tailpiece into the chassie. Secure with

-“U”-Clevis (A) and internal cotter pin (B). See

figure 3.

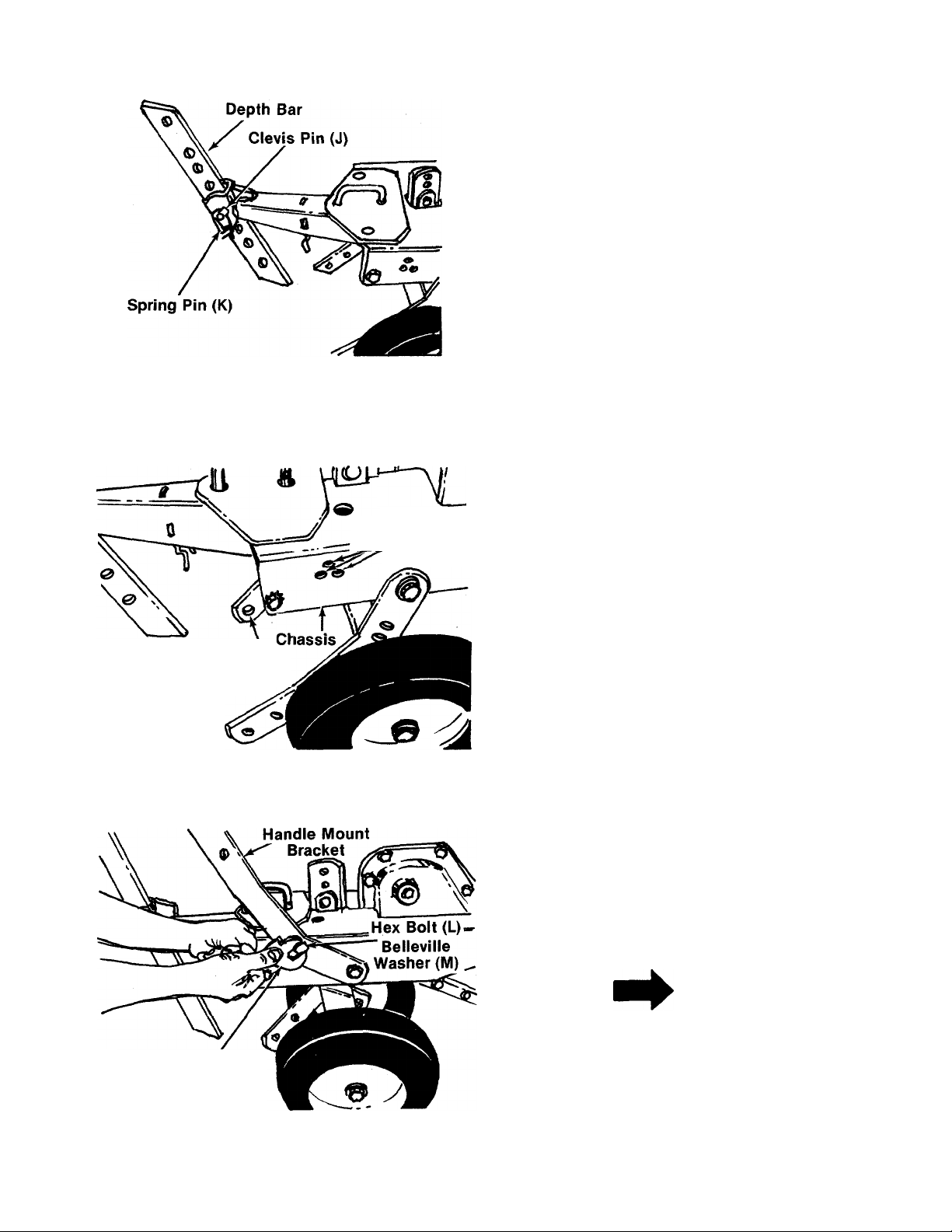

FIGURE 4.

2. Depth Bar Installation

Slide the depth bar into the tailpiece to desired

depth. Secure with clevis pin (J) and spring pin (K).

■See figure 4.

Handle Mount

FIGURE 5.

Brackets \

Three Handle

Mount Locations

3. Attaching Handle Mount Brackets

For shipping purposes, the handle mounting

■ brackets are pivoted down. See figure 5. Pull han

dle mount brackets up and select height position

for the handle by lining up one of the holes in the

handle mount brackets with desired hole in

chassis. See figure 5.

Place hex bolt (L) and belleville washer (M)

(cupped side against the handle mount bracket)

through handle mount bracket and chassis.

Secure with lock washer (N) and hex nut (O) on the

■inside of chassis. See figure 6.

9/16" or

Adjustable Wrench

FIGURE 6.

NOTE

This tiller is a variable speed unit.

Any movement in the handle (after

assembly) may change your speed.

The handle mount brackets must be

as tight as possible. See figure 6.

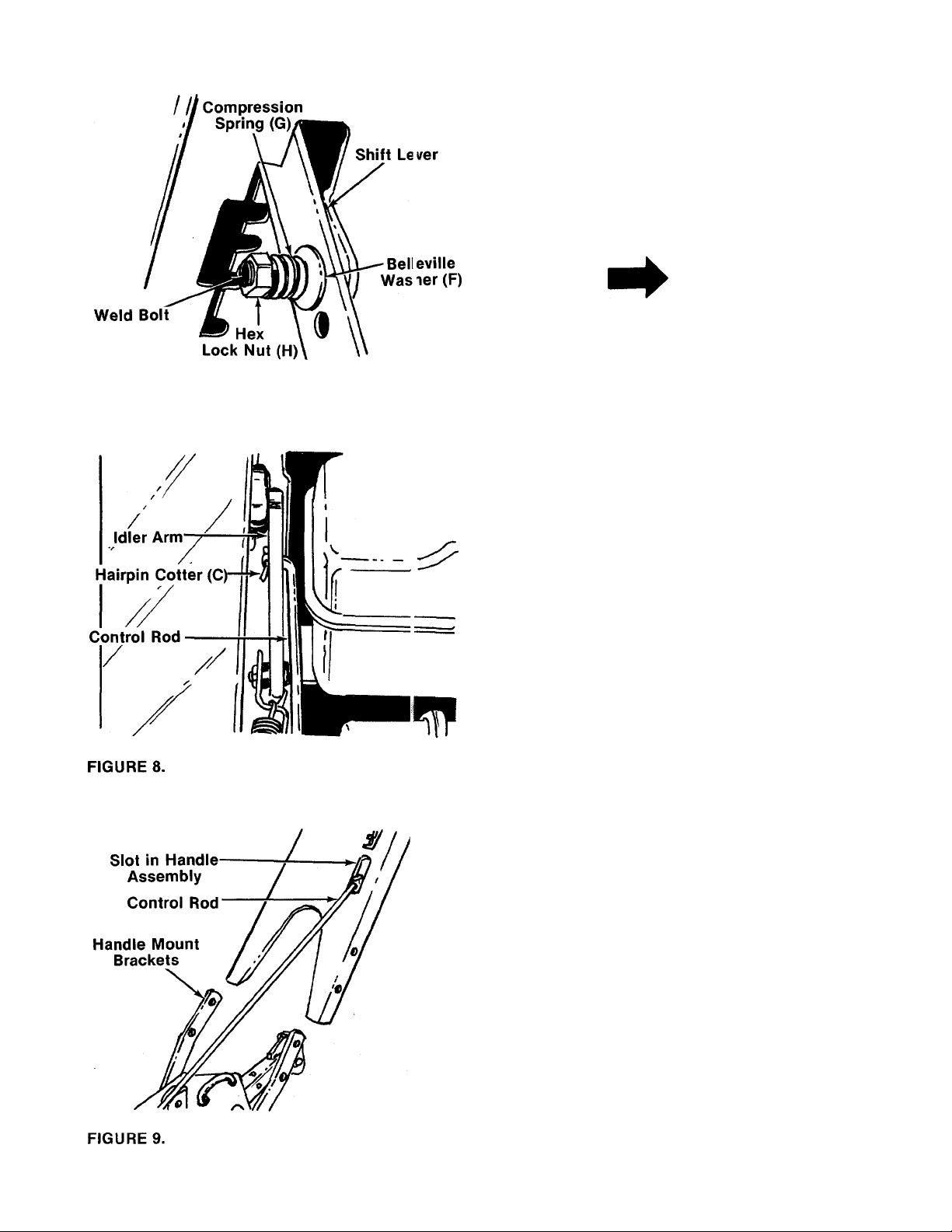

FIGURE 7.

4. Shift Lever Installation

The shift lever is mounted to the handle panel in

the following manner.

A. Place the top hole of the shift lever over weld

-------

bolt on handle panel. See figure 7.

B Place belleville washer (F) and spring (G) over

weld bolt as shown in figure 7.

C. Secure with hex lock nut (H). See figure 7.

NOTE

Thighten hex lock nut just to the

point the spring starts to compress.

5. Handle Panel Installation

Thread adjustment ferrule (D) on end of control

rod. Hook the other end of control rod into the tab

on idler arm. Secure with hairpin cotter (C). See

-figure 8.

Slip other end of control rod with ferrule attached

through the slot in handle panel. Then slide the

handle assembly down over the handle mount

-brackets on the chassis. See figure 9.

Loading...

Loading...