Page 1

Owner's Operating

Service Instruction

lOtfc

Manual

ASSEMBLY OPERATION REPAIR PARTS

Model Nos.

215-370A

215-375A

rrrrrrrrrsTrrryrrrrrrrrrrrr^^

WARRANTY

For one year from date of purchase, MTD Products Inc will replace for the original purchaser, free

of charge, F.O.B. factory or authorized service firm, any part or parts found to be defective in material

or workmanship. Alt transportation charges on parts submitted for replacement under this warranty

must be paid by the purchaser. This warranty does not include replacement of parts which become

inoperative through misuse, excessive use, accident, neglect, improper maintenance or alterations by

unauthorized persons. This warranty does not include the engine, motor, battery, battery charger or any

component parts thereof. For service on these units, refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner and will be effective only if the warranty

card has been properly processed. It will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. UNDER

NO CIRCUMSTANCES WILL THE RETURN OF A COMPLETE UNIT BE ACCEPTED BY THE

FACTORY UNLESS PRIOR WRITTEN PERMISSION HAS BEEN EXTENDED.

MTD PRODUCTS INC

PRINTED IN U.S.A. FORM NO. 770-5634

• 5389 WEST 130th STREET . P. 0. BOX 2741 CLEVELAND OHIO 44111

Page 2

1. Your tiller is a precision piece of power equipment.

Exercise extreme caution at all times.

2. Do not attempt to start engine with the clutch con

trol in the engaged or FORWARD position.

3. Stand clear of tines when starting engine. Never

stand in front of, or work on tines while the en

gine is running.

4. NEVER place hands or feet in the vicinity of the

tines while the engine is running.

5. Always stop engine when tiller is not in actual use.

6. Always disconnect spark plug wire during repairs

or refueling operations.

7. Do not fill gas tank while engine is running. Do not

spill gasoline on hot engine.

Your rotary tiller is designed to take the work out of

gardening and other related chores. It can be used

for seed bed preparation, tilling, cultivating, furrow

ing, composting and mulching. Like any other piece

of power equipment, it requires a certain amount of

care and maintenance. In return for this, it will give

a maximum of service and efficiency. Read these in

structions carefully before assembling or operating

your tiller. Through proper care and operation, you

will obtain long, efficient service and trouble-free

operation.

NOTE

The engine is shipped without oil in

the crankcase. See engine manual for

correct type and amount.

ASSEMBLY

Your rotary tiller is shipped complete in a single ca^

ton. The outer tines, wheels, handle, controls, depti

bar and tailpiece are to be assembled. This is done ir

the manner described below.

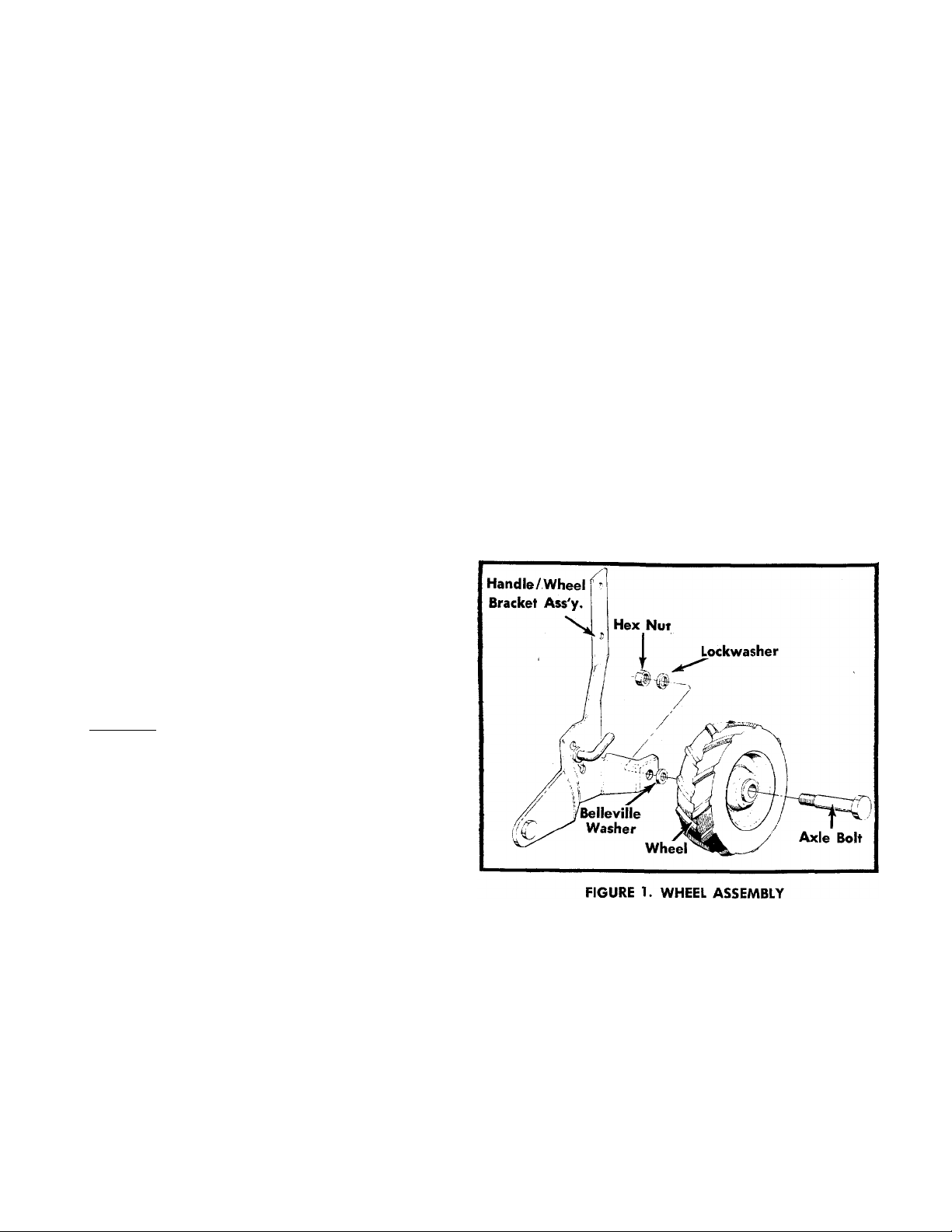

WHEELS

Insert axle bolt into wheel place Belleville washer on

threaded part of axle bolt. Crown of washer should be

positioned towards the wheel. Insert axle bolt in wheel

mounting hole of handle/wheel bracket assembly and

fasten with lockwasher and hex nut. See figure 1.

TINE ASSEMBLY

Step 1. The inner tine assemblies are already assem

bled to the tiller.

Step 2. The outer tine assemblies are inverted on the

Step 3. Remove the outer tine assembly and turn

tine shaft and MUST be removed and turned

around.

around so that the sharp edge of the tines

enter the soil first. Secure with bolt and lock

nut. See page 14.

Page 3

HANDLE ASSEMBLY

CONTROL ROD

Assemble the handle to the bracket with four cap

screws, washers and hex nuts. See figure 2.

Hex Nuts and Lockwashers

Hex Cap Sere'

FIGURE 2. HANDLE ASSEMBLY

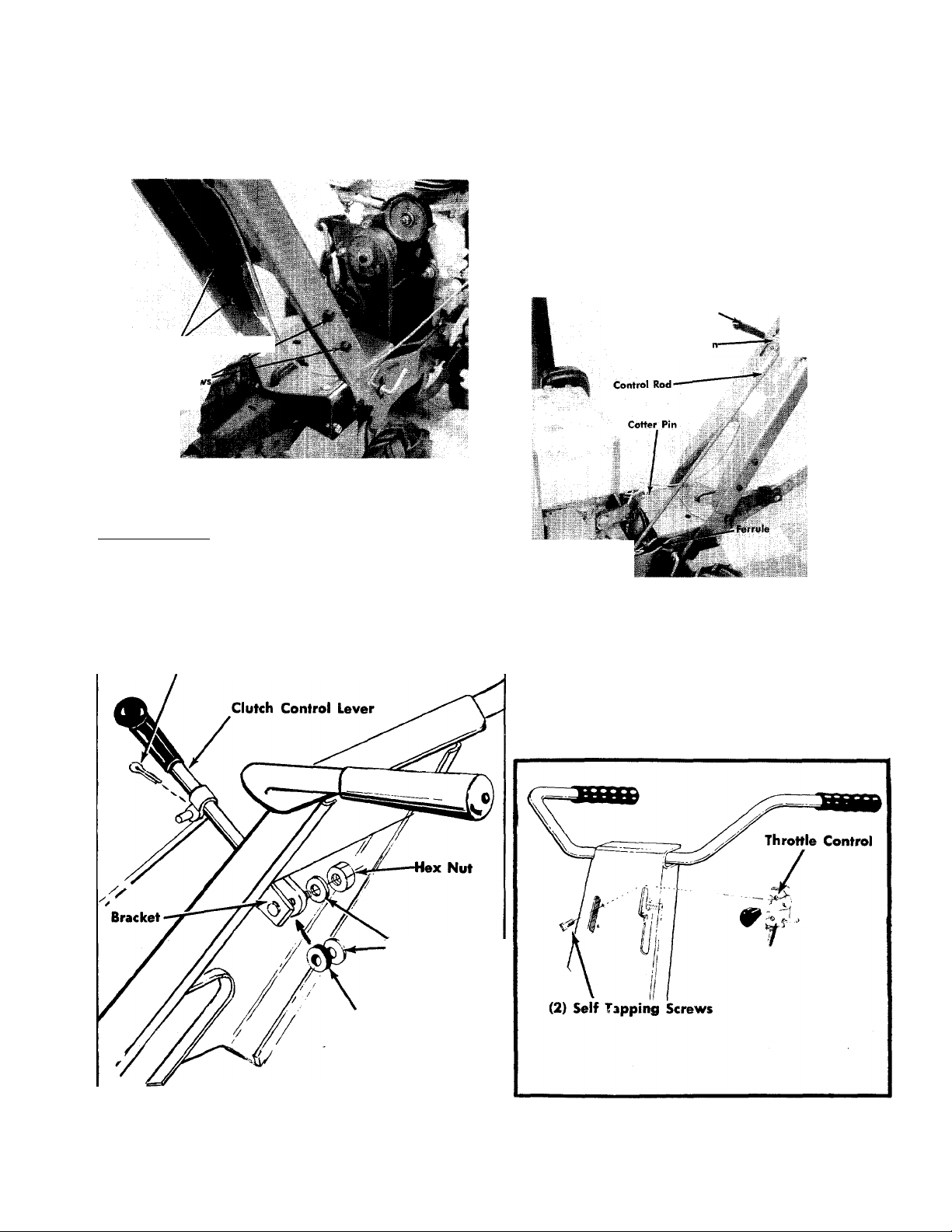

CLUTCH CONTROL

Place the clutch control lever through the handle pan

el and attach it to the bracket using a screw and hex

nut with two metal washers and a rubber washer

between the bracket and clutch control as shown in

figure 3.

Cotter Pin

Place the clutch control lever in neutral as shown in

figure 4. Screw the ferrule onto the control rod so that

approximately

the ferrule. Assemble the ferrule to the pivot idler

bracket and secure with a cotter pin.

Adjust the ferrule location on the control rod so both

the forward and reverse belts are slack with the clutch

control lever in the NEUTRAL position. Secure with a

cotter pin.

Va inch of threads are showing below

Clutch Control Lever

Cotter Pi

2

f

FIGURE 4. CONTROL ROD

THROTTLE

Assemble throttle control as shown in figure 5.

Flat Washers

Rubber Washer

FIGURE 3. CLUTCH CONTROL FIGURE 5. THROTTLE CONTROL

Page 4

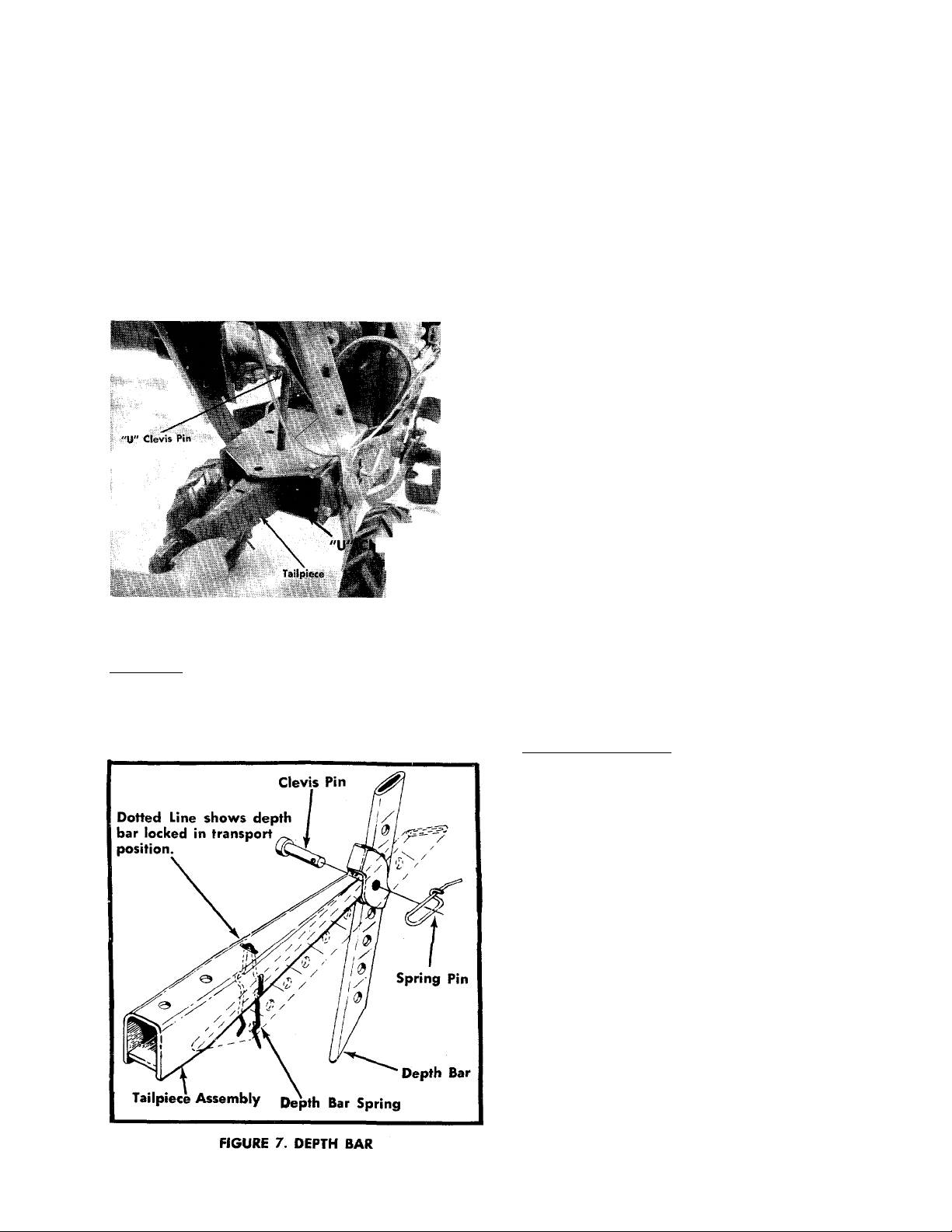

TAILPIECE

CHECK LIST BEFORE OPERATION

Attach the tailpiece to tiller with "U" clevis pin and

secure with spring pin. See figure 7.

NOTE

The "U" channel bracket assembly has

been assembled loose so that the tail

piece can be easily assembled to the

unit. After assembly of tail piece tighten

nuts and bolts tightly. See figure 6.

annel Bracket

fembly

FIGURE 6. TAILPIECE

DEPTH BAR

Attach the depth bar to the tailpiece with a clevis

pin and secure with the spring pin. See figure 8,

1. Remove spark plug wire from spark plug and '

ground. Check tiller tines for proper installatior

With throttle control lever set on STOP position ano

the clutch control handle set in FORWARD position,

slowly crank engine to determine direction of tine

rotation. Be sure all tines are mounted so the sharp

ened edges enter the soil first.

2. Place the clutch control lever in the NEUTRAL po

sition. Slowly crank engine. The tines should

not rotate. If they do, readjust control rod.

3. Check all nuts and bolts for correct tightness. This is

especially important during the initial operation

period. Make the same check periodically there

after.

4. Check throttle control for proper setting. Move

throttle control knob to STOP position. Move lever,

to which control wire is fastened at engine, to

CLOSE position and retighten screw to secure throt

tle control wire assembly.

5. Check gear case for proper lubricant level. With til

ler on a level surface, lubricant level should be up

to the front pipe plug opening. This can be checked

by removing front pipe plug. Maintain correct lu

bricant level with Molilube SAE 140 gear oil or

equivalent. The gear case holds five (5) ounces of

lubricant.

6. Fill fuel tank. Clean, fresh, regular grade gasoline

should be used at all times.

7. Check engine crankcase for proper oil level. The en

gine is shipped without oil in the crankcase. Be

sure crankcase is FULL. See engine manual.

STARTING YOUR TILLER

1. Be sure clutch control lever is in NEUTRAL posi

tion.

2. Move throttle control lever to STOP position.

3. Move choke lever, located at the engine, to CHOKE

position. Refer to your engine manual.

4. Pull the starter rope to start the engine. More than

one pull may be required the first time. When the

engine fires, move the throttle control lever to RUN

position.

5. Use Choke as needed to keep engine operating

during warm-up period.

6. Adjust throttle .control lever for desired operating

speed.

7. Check and make sure tines do not turn in NEUTR/

position.

8. To stop engine, move throttle control lever to STOP

position. Keep throttle control lever in STOP posi

tion at all times when tiller is not in use.

Page 5

NOTE

NOTE

A brief break-in period is essential to

insure maximum engine life. This con

sists of running the engine at half speed

for a period of time required to use one

tank of gasoline. This is necessary on

the initial run only. It is also recom

mended that the oil be changed after

five (5) hours of operation. This allows

for the removal of impurities which

may have accumulated during the breakin period. Subsequent oil changes

should be made as stated in the engine

manual. Always check oil before using

your tiller especially during the break-in

period. Be sure oil level is adequate.

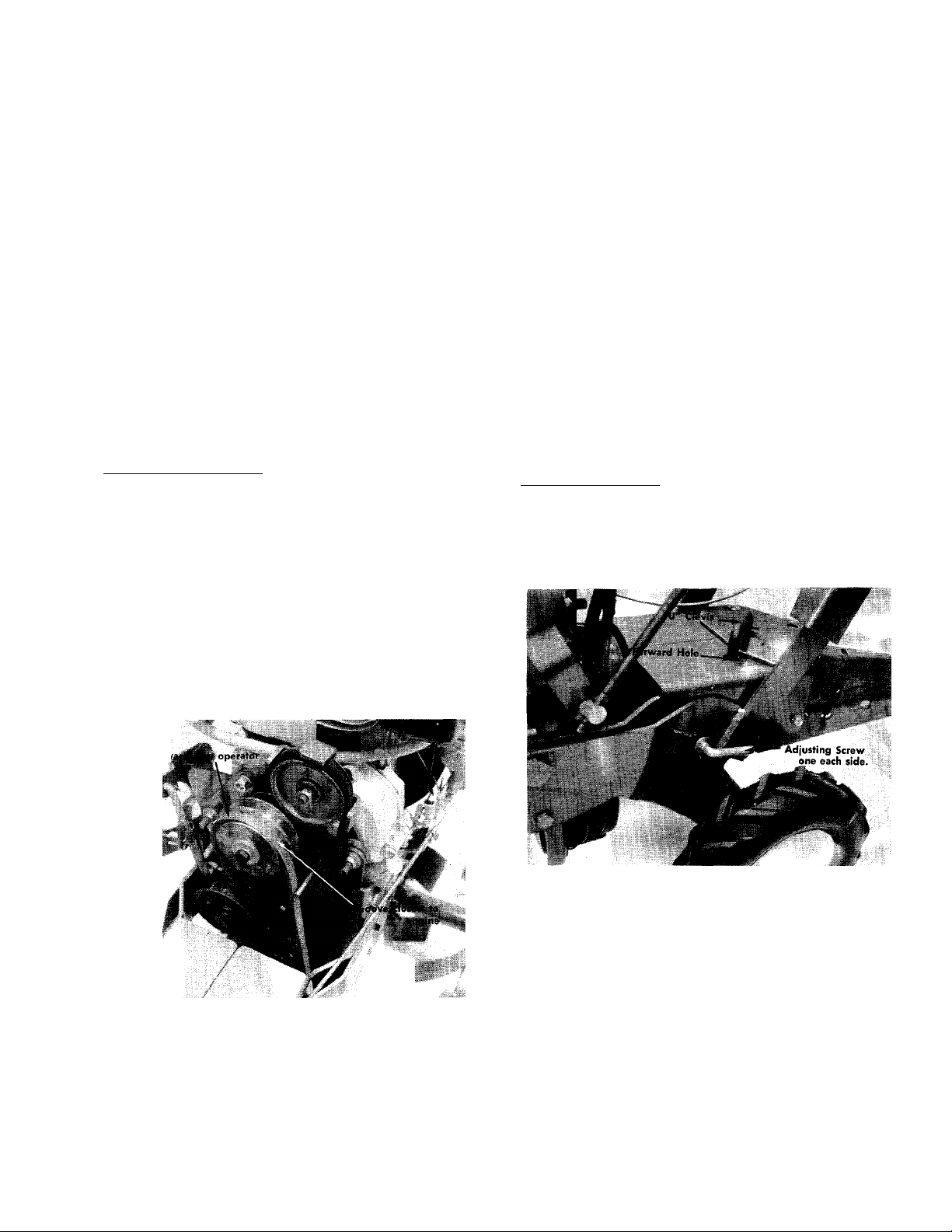

TWO SPEED ADJUSTMENT

Your tiller can be operated in two speed ranges. See

figure 8.

The forward drive belt can be in either the high speed

groove or the low speed groove. The soil condition

determines the best speed range for your tiller.

To change belt from one groove to the other, shut off

the engine remove the spark plug wire and ground,

pull the clutch control lever into REVERSE with your

left hand and move the belt on the upper pulley to

the other groove. Repeat with the lower pulley.

The Low Speed Groove for the 5 H.P.

tiller is the groove closest to the engine.

The Low Speed Groove for the 8 H.P.

tiller is the groove towards the oper

ator. See figure 8.

The High Speed Groove for the 5 H.P.

tiller is the groove towards the operator.

The High Speed Groove for the 8 H.P.

tiller is the groove closest to the engine.

See figure 8.

HANDLE ADJUSTMENT

The handle may be adjusted to five different heights

by loosening the adjusting screw (and pulling it out

enough to clear the notches) on each side of the handle

and pivoting the handle up or down. See figure 9.

Groove tow

FIGURE 8. TWO SPEED ADJUSTMENT

FIGURE 9. HANDLE ADJUSTMENT

TAILPIECE ADJUSTMENT

The tailpiece can be made stationary or free floating.

To be free floating simply lift the "U" clevis and rotate

"U" clevis to engage forward hole and push down.

See figure 9. See figure 2 for stationary position.

Page 6

OPERATING INSTRUCTIONS

For your own convenience and safety, observe all safe

ty suggestions shown on page 2. Your tiller

is not a toy, it is a precision piece of power equipment.

Treat it as such.

It is important to recognize the fact that the forward

and penetrating action of the rotary tiller is obtained

from the rotating action of the tines in the soil. The

depth bar acts as a brake for the tiller and controls the

depth and speed at which the machine will operate. By

lowering the setting of the depth bar, the forward

speed of the machine is reduced and the working

depth of the tines is increased. Raising the setting of

the depth bar increases the forward speed and reduces

the working depth. When soil conditions are severe

and several passes must be made over a certain area,

the depth bar si.tting should be lowered each time a

pass is made. Further control of tilling depth and travel

speed can be obtained by variation of pressure on the

handle or the throttle setting. A downward pressure

on the handles will increase the working depth and

reduce the forward speed. An upward pressure on

the handles will reduce the working depth and in

crease the forward speed. The type of soil and working

conditions will determine the actual setting of the

depth bar and the handle pressure required.

ADJUSTMENTS

Belts. Belt slack is taken up by a spring loaded idler

pulley. Because of this, belt aojustment is not required.

Clutch. No adjustment of the lower clutch rod is re

quired. This is done automatically by the spring loaded

idler.

NOTE

Belt and clutch adjustments can be

made with the adjustable control rod.

Throttle. If adjustment becomes necessary, the throttle

control wire assembly can be reset as follows:

1. Loosen, but do not remove, screw securing throttle

control wire assembly at engine.

2. Move throttle control knob to STOP position.

3. Move lever, to which control wire is fastened at en

gine, to STOP position and retighten screw to se

cure throttle control wire assembly.

Tines. The standard width of cut is 26". Because of

the various types of work the tiller may be put to,

variation in the tilling widths may be necessary. This

can be accomplished in a number of ways.

NOTE

If the tines tend to bounce instead of

cutting into the soil, one or more sets

of tines may be on backwards. The

cutting edge of the tines should enter

the soil first.

1. Tine engagement and forward travel is achieved by

moving the clutch control lever to FORWARD po

sition. Tine rotation and forward motion are stopped

by moving the clutch control handle to NEUTRAL

position. Reverse tine action and reverse travel mo

tion can be maintained by HOLDING the clutch con

trol handle in REVERSE position. Releasing the han

dle stops reverse operation automatically.

2; The throttle control lever adjusts the engine speed.

It also gives finger tip control of the carburetor and

magneto stop switch. With the throttle control knob

pushed completely forward, the carburetor is in

START position. Pulling the knob back slightly ad

justs the engine speed to FAST. Pulling- the knob

back further reduces the engine speed to SLOW.

When the knob is pulled completely back, the mag

neto stop switch grounds out the spark and stops

the engine.

3. With the depth bar positioned out of ground

engagement position, self propelled transporting

of the tiller is easily achieved. With no pressure

on the handles and the throttle control set for SLOW

engine speed, move the clutch control handle to

the FORWARD position and let the tiller gently pro

pel itself.

1. Standard tine arrangement________________________________26"

2. Remove both outer tine assemblies

3. Remove tines that point outward from outer

tine assemblies. Tines may be interchanged

with opposite sides _____________________________________ 20"

4. Add tine extensions to standard arrangement __ 40"

NOTE

When adjusting tines, be sore the cut

ting edges enter the soil first.

A6AINTENANCE AND LUBRICATION

Engine. Service engine in accordance with the engine

manufacturer's owner's guide.

NOTE

To drain oil remove oil filler plug and

tip tiller on its side. Drain oil while the

engine is warm. See engine manual for

filling instructions.

Throttle. Periodically lubricate throttle control lever

and throttle control wire assembly with a few drops

of light oil (SAE 10 or 20) for ease of operation.

---------------------

12"

Page 7

Gear Case. Proper lubricant level should be up to

the front pipe plug. Check with tiller on a level sur

face. Add lubricant through vented pipe plug hole.

Add enough to bring level up to front pipe plug hole.

Use Mobilube SAE 140 gear oil or equivalent. Gear

case should be maintained with five (5) ounces of lu

bricant.

TILLER GEAR CASE BEARING ADJUSTMENT CAP (Small)

If the bearing adjustment cap on the worm shaft is

over-tightened the bearings on the worm shaft can

seize during operation.

The cap should protrude approximately 1 /32" to

1/16" from the gear case.

5. Remove oil seals from gear case and bearing cap.

6. Remove all burrs from holes in tine shaft.

7. Dip oil seals in lubricant and then insert one in

gear case and one in bearing cap.

8. Wipe tine shaft clean of filings and lubricate be

fore assembling with bearings and worm wheel

in gear case. Insert shaft slowly to prevent seals

from catching in holes in shaft.

9. Replace bearing cap.

CAUTION

REPLACING TILLER GEAR CASE OIL SEALS

1. Drain lubricant.

2. Remove tine assemblies.

3. Remove bearing cap. (See reference 24, pages 10

and 11.)

4. Remove bearings, worm wheel and tine shaft. Do

not remove bearing races'.

Do not damage oil seals. The open

flanges face to the outside of the gear

case.

10. Tighten bearing cap, retighten screws evenly.

11. Replace tine assemblies and add lubricant. (See

gear case above.)

Page 8

BELT REMOVAL

FORWARD DRIVE

Page 9

BELT REMOVAL

REVERSE DRIVE

Page 10

Maintain with five(5)ounces of lubricant.

1

2

3

4

5

ó

7

8

9

10

11

PART

716- 0119

721-0100

748-0106

717- 0226

737- 0102

741-0107

711-0469

738- 0170

717-0167

716-0101

735-0100

REF.

NO.

12

714-0474

13

714-0126

14

*For fitter »rvic* obtain standard nuts and bolti locally. If thaw Items

cannot bo obtalnad locally, ordar by part numbar and siza at shown

on tha part$ list.

NO.

10583

COLOR

CODE

Snap Ring for .750" Dia. Shaft

Oil Seal-—.750" Shaft

Sleeve Brg. .752" I.D.

Gear Case

Sq. Hd. Pipe Plug with Vent %"

Thd.

Roller Brg. .750" Bore

Spacer .755" I.D. x 1.265" O.D.

Worm Shaft %" Dia.

Worm

Snap Ring for .750" Dia. Shaft

O-Ring 2.12 X 2.38

Brg. Adjustment Cap

Cotter Pin Va" Dia. x .75" Lg.*

#9 Hi-Pro Key 3/16 x%" Dia

Hdn.

DESCRIPTION

NEW

PART

REF.

NO.

737'

15

72\-

16

741.

17

711.

18

711.

19

714

20

716-

21

717.

22

735.

23

717-

24

736-

25

710-

26

10

PART

NO.

■0103

■0102

■0108

■0131

■0133

■0103

■0102

■0105

•0101

0227

0119

0371

COLOR

CODE

Sq. Hd. Pipe Plug %" Thd.

Oil Seal Double Lip 1" Shaft

Roller Brg. 1" Bore

Spacer 1.005 I.D. x 1.390 O.D.

Tine Shaft 1" Dia.

#91 Woodruff Key 14" x%" Dia

Snap Ring for 1" Shaft

Worm Wheel

O-Ring 3.62 X 3.88

Bearing Cap—Bolt-on Type

L-Wash. 5/16" Scr.*

Hex Scr. 5/16-18 X.88" Lg.^

DESCRIPTION

Special

NEW

PART

Page 11

Maintain withfive(5)ounces of lubricant.

PARTS LIST FOR GEAR CASE ASSEMBLY 04499 FOR 215-375A

REF.

NO.

1

2

3

4

5

PART

716-0119

721-0100

748-0106

717-0279

737-0102

NO.

COLOR

CODE

DESCRIPTION

Snap Ring for .750" Dia. Shaft 15

Oil Seal—.750" Shaft

Sleeve Brg. .752" I.D.

Gear Case

Sq. Hd. Pipe Plug with Vent %'

Thd. 20

741-0107

6

711-0469

7

8

738-0170

9

717-0180 Worm 24

10

716-0101

n

735-0100

12 10583

13

714-0474 Cotter Pin Va" Dia. x .75" Lg.*

14

714-0126

*

*For faster service obtain standard nuts and bolts locally. If these Items

cannot be obtained locally, order by part number and slxe as shown

on the parts list.

Roller 8rg. .750" Bore

Spacer .755" I.D. x 1.265" O.D

Worm Shaft %" Dia.

Snap Ring for .750" Dia. Shaft

O-Ring 2.12 X 2.38

Brg. Adjustment Cap Special

#9 Hi-Pro Key 3/l6x%" Dia

Hdn.

NEW

PART

REF.

NO.

16

17

18

19

-21 716-0116

'22

23

25

26

11

PART

NO.

COLOR

CODE

DESCRIPTION

737-0103 Sq. Hd. Pipe Plug %" Thd.

721-0117

748-0194

736-0246

Oil Seal Double Lip 1.25" Shaft

Flange Brg. 1.25" Shaft

FI. Wash. 1.25 I.D. x 2.00" O.D.

711-0499 Tine Shaft 1.25" Dia.

714-0135

#91 Woodruff Key V4"

Snap Ring for 1.25" Shaft

717-0181

735-0101

717-0280

736-0119

710-0371

Worm Wheel

O-Ring 3.62 X 3.88

Bearing Cap

L-Wash. 5/16" Scr.*

Hex Scr. 5/16-18 X.88" Lg.-

NEW

PART

Page 12

215-370A

215-375A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

12

Page 13

PARTS LIST FOR MODEL 215-370A AND 215-375A

REF.

NO.

PART

1

2

3

736-0253 Belleville Wash. .505 I.D. x

COLOR

CODE

NO.

01166

04626—458

DESCRIPTION

Grip

Handle Ass'y.

1.00 O.D.

4

746-0244

9

04638—458

Throttle Control Ass'y-—Comp.

Handle/Wheel Brkt. Ass'y.—

R.H.

10

11

12

736-0169

712-0798

04637—458

L-Wash. %" Scr.*

Hex Nut %-16 Thd.*

Handle/Wheel Brkt. Ass'y.—

LH.

13

14

15

16

712-0394

736-0253

710-0584

738-0239

Hex Cent. L-Nut '/2-13 Thd.*

Bell-Wash. .505 I.D.

Adj. Screw

Shoulder Scr. %" Dia. x .222"

Lg-

17

738-0240

Shoulder Scr. %" Dia. x 2.75"

Lg.

18

19

20

21

22

23

24

25

26

27

741-0116

734-0573

732-0194

711-0231

736-0119

712-0267

04589—458

04668—458

732-0290

732-0194

Flange Brg. wth Flats .631 I.D.

Wheel Ass'y.—Comp.

Spring Pin

Clevis Pin .50" Dia.

L-Wash. 5/16" Scr.*

Hex Nut 5/16-18" Thd.*

Tail Piece Ass'y.

Depth Bar

Depth Bar Spring

Spring Pin

NEW

PART

N

N

—

28

29

30

32

33

PART

NO.

712-0267

736-0119

04631

710-0152

04633—458

710-019B

COLO

R

CODE

DESCRIPTION

Hex Nut 5/16-18" Thd.*

L-Wash. 5/16" Scr.*

—458 "U" Channel Brkt. Ass'y.

Hex Scr. %-24 x 1.00" Lg.*

Tiller Frame

Hex Sems Scr. 5/16-18 x .75"

REF.

NO.

31

Lg.*

35

36

04586—458 "U" Channel Plate

710-0451 Carriaqe Bolt 5/16-18 x.75"

Lg.*

37

38

04602

715-0133

"U" Clevis Pin .500" Dia.

Spring Pin Spiral 5/32 Dia. x

.875" Lg.

39

736-0190

40

712-0239

41

712-0214

42

736-0148

43

711-0392

44

711-0610

45

720-0143

46

735-0126

47

736-0159

48

49

04392

712-0158

50 710-0160

714-0104

51

Ext. L-Wash. ’/2" Scr.*

Hex Cnt. L-Nut '/2-20 Thd.*

Hex Cnt. L-Nut %-24 Thd.*

Ext. L-Wash. %" Scr.*

Ferrule

Control Rod

Grip

Rubber Washer

FI. Wash. .344" I.D. x .87" O.D.

Clutch Control Lever I

Hex Cent. L-Nut 5/16-18 Thd.

Hex AB-Tapp Scr. #8 x .62"

Int. Cotter Pin 3/32x5/16"

Dia.

52

53

710-0253

04634—458

Hex Scr. %-16x 1.00"Lg.*

Mg. Plate Ass'y.

NEW

PART

215-370A 5 H.P. Only

Inner Tine Assembly—L.H.—Complete—742-0150

Inner Tine Assembly—R.H.—Complete—742-0151

Outer Tine Assembly—L.H.—Complete—742-0153

Outer Tine Assembly—R.H.—Complete—742-0152

215-375A 8 H.P. Only

Inner Tine Assembly—L.H.—Complete— 742-0159

Inner Tine Assembly—R.H.—Complete—742-0160

Outer Tine Assembly—L.H.—Complete— 742-0161

Outer Tine Assembly—R.H.—Complete—742-0162

*For faster service, obtain standard nuts, bolts and washers locally. If these items cannot

be obtained locally, order by part number and size, as shown on parts list.

OPTIONAL TINE EXTENSION

215-370A(5 H.P. Only)

Order Part No. 295-166A

OPTIONAL TINE EXTENSION

215-375A(8 H.P. Only)

Order Part No. 295-166A

13

Page 14

215-370A

215-375A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

14

Page 15

PARTS LIST FOR MODELS 215-370A AND 215-375A

PART

NO.

COLOR

CODE

DESCRIPTION

REF.

NO.

Engine

714-0139

Sq. Key 3/16x3/16x2.00" Lg.

(215-370A1

714-0114

Sq. Key ’/4 X Va x 2.00" Lg.

(215-375A)

738-0183

736-0232

Sh. Scr. .50" Dia. x .215" Lg.

Wave Wash. .530 I.D. x .78

O.D. x.013

712-0181

9

736-0253

04644^58

04634—458

Pivot Idler Brkt.

Hex Top L-Nut %-16 Thd.*

Mtg. plate Ass'y.

Belleville Wash. .505 I.D. x

1.00" O.D.

10

710-0121

11

738-0183

12

13

04643

04641

15 712-0181

16

04639

17 736-0300

712-0116

18

19 756-0225

Hex Scr. '/2-20 X .75" Lg. Spec.

Sh. Scr. .50" Dia. x .215" Lg.

Idler Brkt. Link

Reverse Idler Brkt. Ass'y.

Hex Top L-Nut %-16 Thd.*

Idler Brkt. Ass'y.

Fl.-Wash. .385" I.D. x .875 O.D.

Hex Ins. L-Nut %-24 Thd.

Fl-ldler with Flange 3.12 O.D.

X.75

20

756-0224

756-0222

21

712-0116

22

736-0133

736-0169

23

24 710-0539

25

04646

26 712-0116

27

710-0118

28 736-0119

29

736-0231

30 756-0219

756-0220

754-0154

31

754-0190

32

754-0189

33

756-0178

34

712-0116

35

736-0300

36

736-0300

37

714-0111

38

736-0119

39

712-0267

40

747-0140

41

736-0300

42

714-0111

714-0111

43

732-0296

44

710-0342

45

710-0198

46

48

04664

04649

49

or faster service obtain standard nuts and bolts locally. If these items

cannot be obtained locally, order by part number and size as shown

on the parts list.

04648-458

Engine Pulley 3.75" Dia.

(215-370A)

Engine Pulley (214-375A)

Hex Ins. L-Nut %-24 Thd.

FI-Wash. .406 I.D. x 1.250 O.D.

L-Wash. %" Scr.*

Hex Scr. %-24 x 1.75" Lg. H.T.

Idler Disc

Hex Ins. L-Nut %-24 Thd.

Hex Scr. 5/16-18 X .75" Lg.*

L-Wash. 5/16" Scr.*-

FI-Wash. .344 I.D. x 1.125 O.D.

Gear Box Step Pulley 5.5" Dia.

(215-370A) I

Gear Box Step Pulley(215-375A)

V-Belt ’/2 X 37" Lg. (215-370A)

(Forward)

V-Belt ’/2 X 39" Lg. (215-375A)

(Forward)

V-Belt '/2" X 44" Lg. (Reverse)

P-FI.-ldler 2.75 O.D.

Hex Ins. L-Nut %-24 Thd.

Fl.-Wash. .385 I.D. x .870" O.D.

Fl.-Wash. .385 I.D. x .870" O 0.

Cotter Pin 3/32 X 1.00" Lg.*

L-Wash. 5/16" Scr.*

Hex Nut 5/16-18 Thd.*

Clutch Rod

FI -Wash. .385 I.D. x .870 O.D.

Cotter Pin 3/32 X 1.00" Lg.*

Cotter Pin 3/32 X 1.00" Lg.*

Ext. Spring

Hex Scr. %-16 X 1.25" Lg.*

Hex Sems Scr. 5/16-18 x .75" Lg.

Belt Retainer (215-370A)

Belt Retainer (215-375A)

Belt Guard

NEW

PART

N

REF.

NO.

50

51

52

PART

NO.

736-0119

712-0267

710-0253

53 714-0126

54 736-0169

55 712-0798

56 04498

57

710-0459

710-0483

58 742-0150

742-0159

59

742-0151

742-0160

742-0152

60

742-0162

61

742-0153

742-0161

72I-OI2K

65

66

721-0120

721-0124

67

712-0116

712-0236

68

712-0798

69

736-0169

70

71

712-0123

72

736-0119

73

74

710-0253

75

711-0392

76

77

710-0409

78

710-0151

710-0483

79 04611

736-0264

80

710-0621

81

82 712-0158

accessories shown do not neces

sarily apply to your model tiller.

The engine is not under war

15

ranty by the tiller manufac

turer.

COLOR

CODE

L-Wash. 5/16" Scr.*

Hex Nut 5/16-18 Thd.*

Hex Scr. %-16 X 1.00" Lg.*

(215-375A)

#9 Hi-Pro Key 3/16 X %" Dia.

Hdn.

L-Wash. %" Scr.*

Hex Nut %-16 Thd.*

Gear Case Ass'y. Comp.

(215-370A)

04499

Gear Case Ass'y. Comp.

(215-375A)

Hex Scr. %-24xl.50" Lg. H.T.

(215-370A)

Hex Scr. 7/16-20x2.25" Lg.

Inner Tine Ass'y.—L.H.

(215-370A)

Inner Tine Ass'y.—L.H.

(215-375A)

Inner Tine Ass'y.—R.H.

(215-37OA)

Inner Tine Ass'y.—R.H.

(215-375A)

Outer Tine Ass'y.—R.H.

(215-370A)

Outer Tine Ass'y.—R.H.

(215-375A)

Outer Tine Ass'y.—L.H.

(215-370A)

Outer Tine Ass'y.—L.H.

(215-375A)

Foam Seal 2.25 I.D. x 2.94 O.D.

Foam Seal 1.25 I.D. x 2.12 O.D.

(215-370A)

Foam Seal 1.62 I.D. x 2.12 O.D.

(215-375A)

Hex Ins. :L-Nut %-24 Thd.

(215-370A)

Hex Ins. L-Nut 7/16-20 Thd.

(215-375A)

Hex Nut %-16 Thd.* (215-375A)

L-Wash. %" Scr.* (215-375A)

04647

Support Arm

Hex Nuts/ 16-24 Thd.*

L-Wash. 5/16" Scr.*

04633-458

Tiller Frame

Hex Scr. %-16x 1.00" Lg.*

(215-375A)

Ferrule

04599

Tine Shield

Hex Scr. 5/16-24 x 1.75*

Hex Scr. %-24 x 2.00" Lg.

(215-370A)

Hex Scr. 7/16-20x2.25" Lg.

(215-375A)

Reinforcement Plate

FI-Wash. .344 I.D. x .625 O.D.

Hex Scr. 5/16-18 X .50" Lg.*

Hex Cnt. L-Nut 5/16-18 Thd.*

NOTE: This bistruction manual

eovon various oMdais cmsl sril

DESCRIPTION

contact your nearest authorized

NEW

PART

N

N

N

N

N

N

N

N

N

if repairs or service is

needed on the engine, please

engine service outlet. Check

steeiiFaii Pages" of your

the "Yellow

fvtspiipiM booir

JkuBmi

Page 16

PARTS INFORMATION

DEFECTIVE OR MISSING PARTS must be reported

to the factory immediately. Such claims must include

your model number and date of purchase.

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power

equipment are available through the authorized serv

ice firms listed below. All orders should specify the

model number of your unit, parts numbers, descrip

tion of parts and the quantity of each part required.

A 1 Engine ft Mower Co.

327 East 9th Street

Salt Lake City, Utah 84102

Auto Electric ft Carburetor Co.

2 S25 4th Avenue, S.

P. O. Box 1948

Birmingham, Alabama 35233

Automotive Equipment Service Co.

3117 Holmes Street

Kansas City, Missouri 64109

Bailey's Rebuild Inc.

1325 E. Madison Street

Seattle Washington 98102

Bleckrie, Inc,

7900 Lorain Avenue

Cleveland, Ohio 44102

Brown Equipment Distributor Inc.

110 Beech Street

Corydon, Indiana 47112

Bullard Supply

2409 Commerce Street

Houston, Texas 77003

Catto ft Putty, Inc.

P. O. Box 2408

510 Soledad Street

San Antonio, Texas 78205

Center Supply Company

6867 New Hampshire Avenue

Takoma Park, Maryland 20012

Dixie Sales Company

P. O. Box 1408

327 Battleground Avenue

Greensboro, North Carolina 27402

East Point Cycle ft Key Shop

1617 Whiteway

East Point, Georgia 30044

Gamble Distributors

West End Avenue

Carthage, New York 13619

Garden Equipment Co., Inc.

6600 Cherry Avenue

Long Beach, California 90805

Gardenvilie Supply, Inc.

Pipersville, Pennsylvania 18947

Henry W. O'Neil & Assoc., Inc.

410 North Goodman Street

Rochester, New York 14609

Henzier, Inc.

2015 Lemay Ferry Road

St. Louis, Missouri 63125

Kenton Supply

8216 North Denver Avenue

Portland, Oregon 97217

Kimber's Inc.

115 W. Geddes St.

Syracuse, New York 13204

Marr Brothers

423 E. Jefferson

Dallas, Texas 75203

McClure lawn ft Garden Supply

1114 Lexington Avenue

Mansfield, Ohio 44907

Memphis Cycle ft Supply Co.

421 Monroe Avenue

Memphis Tennessee 38103

Morton B. Collins Co.

300 Birnie Avenue

Springfield, Massachusetts 01107

Moz-AII of Florida, Inc.

365 Greco Avenue

Coral Gables, Florida 33146

Nationjii Central

687 Seville Rd.

Wadsworth, Ohio 44281

BRIGGS & STRATTON, TECUMSEH AND PEERLESS PARTS AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and

service should be handled by your nearest authorized

engine service firm. Check the yellow pages of your

telephone directory under the listing

Engines —

Gasoline, Briggs & Stratton or Tecumseh Lauson —

Power Products.

Parts ft Sales Inc.

2101 Industrial Pkwy.

Elkhart, Indiana 46514

Power Equipment Distributor

36463 So. Gratiot Avenue

Mt. Clemens, Michigan 48043

Power Lawn ft Garden Equip. Co.

2551-2571 J. F. Kennedy Road

Dubuque, Iowa 52001

Radco Distributors

2403 Market Street

P. O. Box 3216

Jacksonville, Florida 32206

Raub Supply Company

James & Mulberry Sts.

Lancaster, Pennsylvania 17604

Richmond Battery & Ignition

P. O. Box 25369 - 957 Myers St.

Richmond, Virginia 23260

R. P. W., Inc.

623 S. 16th Street

Omaha, Nebraska 68102

Smith Hardware Company

515 N. George Street

Goldsboro, North Carolina 27530

South Denver Lawn Equip. Co.

527 West Evans

Denver, Colorado 80223

Suhren Engine

8330 Earhart Blvd.

New Orleans, Louisiana 70118

Sutton's LaWn Mower Shop

Route 4, Box 343

North Little Rock, Arkansas 72117

Warner Equipment

7520 Lyndale Avenue, So.

Minneapolis, Minnesota 55423

Woodson Sales & Service

1702 North Sylvania

Ft. Worth, Texas 76111

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

t

The purpose of warranty is to protect the customer from defects in workmanship and materials,

defects which are NOT detected at the time of manufacture. It does not provide for the unlimited

end unrestricted replacement of parts. Use and maintenance are the responsibility of the cus

tomer. The manufacturer cannot assume responsibility for conditions over which it has no

control. Simply put, if it's the manufacturer's fault, it's the manufacturer's responsibility; if

it's the customer's fault, it's the customer's responsibility.

CLAIMS AGAINST THE MANUFACTURER'S WARRANTY INCLUDES

1. Replacement of Missing Parts on new equip- 1. Model Number of unit involved.

ment.

2. Replacement of Defective Parts within the

warranty period.

3. Repair of Defects within the warranty

period.

WARRANTY PARTS AND SERVICE POLICY

All claims MUST be substantiated with the

following information:

2. Date unit was purchased or first put into

service.

3. Date of failure.

4. Nature of failure.

♦

♦

♦

I

I

t

t

t

♦

♦

♦

♦

Loading...

Loading...