Page 1

OWNERS

MANUAL

75

8 H.P.

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

REAR TINE

TILLER

Model Number

214-412-000

Important:

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Thank you for purchasing an

American built product.

FORM NO. 770-3189

Page 2

INDEX

Safe Operation Practices

Assembly...............................................................4

Controls.................................................................8

Operation.............................................................11

How To Use YourTiller

Adjustments

........................................................

......................................

.......................................

r

LIMITEiD WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective n material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for any parts submitted for replacement under this warran

ty must be paid by the purchaser ur less such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, mo or, battery, battery chargeror component parts thereof.

Please refer to the applicable man jfacturer’s warranty on these items.

11

13

3

Lubrication .........................................................14

Maintenance

Off-Season Storage

Illustrated Parts.......................................18, 20, 22

Parts List.................................................19, 21, 23

Parts Information...............................................Back Cover

......................................................

............................................

14

16

♦

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distri Dutor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will r ot be accepted by the factory unless prior written per

mission has been extended by MT ).

♦

♦

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

V

WARNING

This unit is equipped with an internal con bustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is

equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator.

j

♦

♦

♦

♦

♦

♦

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws, federal laws apply on federal lands. A spark arrester muffler is

available at your nearest engine authorized service center.

Page 3

I WARNING \

To reduce the potential for any injury, comply with the following safety instructions. Faiiure to compiy with

the instructions may resuit in personai injury.

SAFE OPERATION PRACTICES FOR TILLERS

1. It is suggested that this manuai be read in its

entirety before attempting to assembie or

operate this unit. Keep this manuai in a safe

piace for future reference and for ordering

repiacement parts.

2. Your tiiier is a precision piece of power equip

ment, not a piaything. Therefore, exercise ex

treme caution at aii times.

3. Read this Owner’s Manual carefully. Be

thoroughly familiar with the controls and the

proper use of the equipment.

4. Never allow children to operate a power tiller.

Only persons well acquainted with these rules

of safe operation should be allowed to use

your tiller.

5. Keep the area of operation clear of all per

sons, particularly small children and pets.

6. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

7. Do not wear loose fitting clothing that could

get caught on the tiller.

8. Do not start the engine unless the shift lever

is in the neutral (N) position.

9. Do not stand in front of the tiller while starting

the engine.

10. Do not filace. feet and hands on or near the

tines when starting the engine or while the

engine is running.

11. Never attempt to make a wheel or depth bar

adjustment while the engine is running.

14. Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do

not fill gasoline tank indoors, when the engine

is running, or while the engine is still hot.

Wipe off any spilled gasoline before starting

the engine as it may cause a fire or explosion.

15. Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

16. Be careful not to touch the muffler after the

engine has been running. It is hot.

17. Do not change the engine governor settings

or overspeed the engine. Excessive engine

speeds are dangerous.

18. Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

19. Use caution when tilling near buildings and

fences. Rotating tines can cause damage or

injury.

20. Before attempting to remove rocks, bricks and

other objects from tines, stop the engine and

be sure the tines have stopped completely.

Disconnect the spark plug wire and ground to

prevent accidental starting.

21. Check the tine and engine mounting bolts at

frequent intervals for proper tightness.

22. Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working condi

tion.

12. Do not leave the tiller unattended with the

engine running.

13. Do not walk in front of the tiller while the

engine is running.

23. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any

enclosure.

Page 4

Depth iar

Adjustrr ent

Plate

ASSEMBLY

NOTE

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

separate engine manual for proper

fuel and engine oil recommenda

tions.

-Contents of Hardware Pack: (See Figure 1)

A (1) Belleville Washer 3/8" I.D.

B (1) Compression Spring

0 (1) Hex Lock Nut 3/8-24 Thread

D (1) Hairpin Cotter

E (2) Shoulder Bolts

F (2) Belleville Washers V2" I.D.

G (2) Flat Washers V2" I.D.

H (2) Hex Top Lock Nuts 3/8-16 Thread

J (1) Ferrule

K (1) Hex Jam Nut 3/8-24 Thread

L (1) Handle Adjustment Lever

M (1) Hex Bolt 1/4-20 X 1.75" Long

N (1) Hex Lock Nut 1/4-20 Thread

O (1) Spring

P (1) Hex Bolt 3/8-16 X 1.75" Long

Q (1) Spacer .38" Long

R (2) Flat Washers 3/8" I.D.

S (2) Hex Nuts 3/8-16Thread

T (2) Hex Lock Nuts 3/8-16 Thread

U (1) Spacer .18" Long

V (1) Hex Bolt 3/8-16 X 1.5" Long

W (2) Flat Washers 1/4" I.D.

X (4) Belleville Washers 5/16" I.D.

Y (4) Hex Nuts 5/16-18 Thread

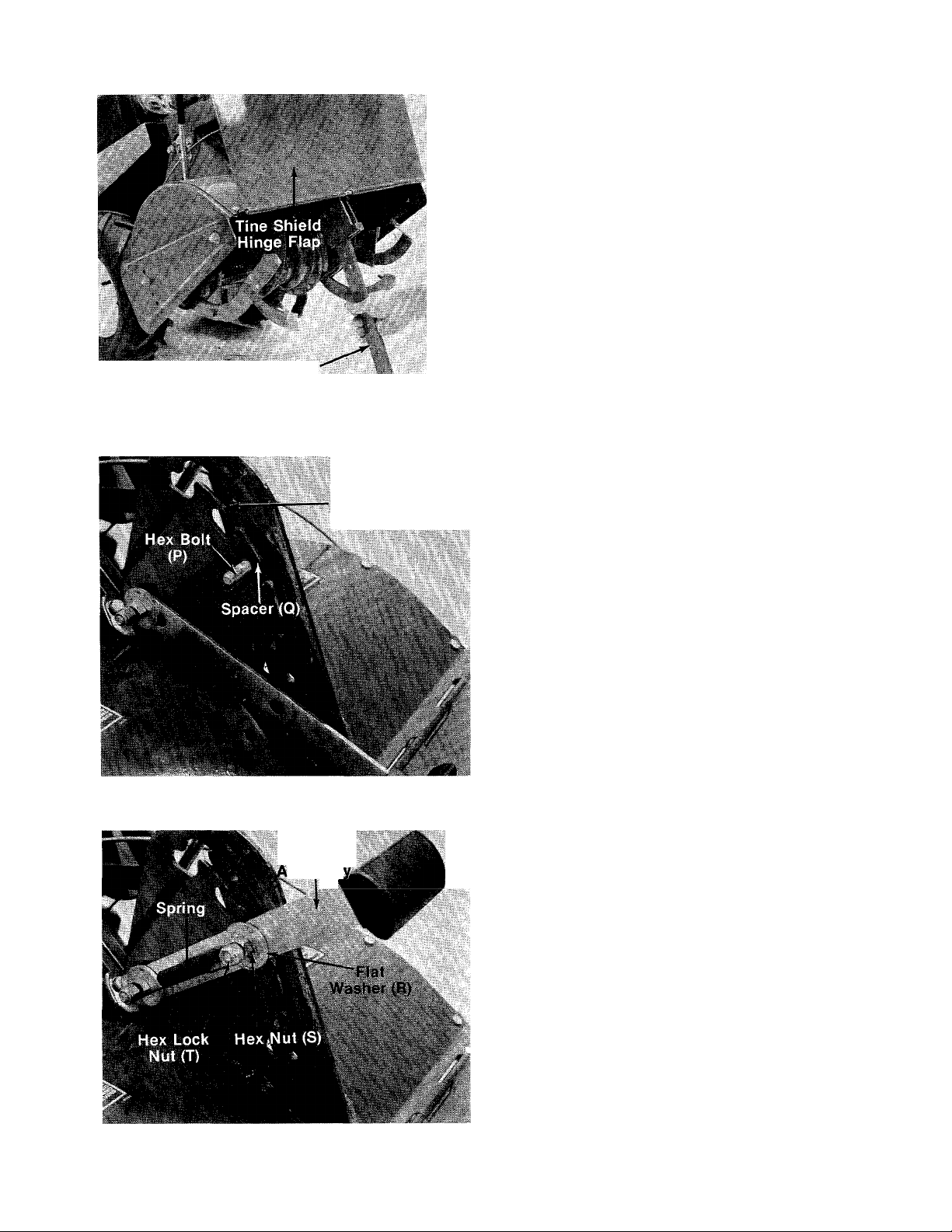

■DEPTH BAR INSTALLATION

1. Grease the depth bar adjustment slots with an

automotive chassis grease.

2. Place hex bolt (V) through the hole in the

depth bar adjustment plate as shown in figure

2. The head of the bolt must be to the right

side of the tiller. Place smaller spacer (U) on

the hex bolt.

FIGURE 3.

¡*■1

NOTE

The right and left side of your tiller

is determined from operator’s posi

tion.

■3. Place slot in depth bar handle assembly over

the spacer and hex bolt. Secure with flat

washer (R) and hex nut (S), tightening secure

ly. Place one end of spring (O) onto the bolt.

Thread hex lock nut (T) on the bolt until the

two nuts are approximately 1/8" apart. See

figure 3.

Page 5

FIGURE 4.

Raise the tine shield hinge flap assembly. In

sert the depth bar assembly up through the

-tine shield assembly as shown in figure 4.

Depth Bar

Assembly

Depth Bar

Assembly

5. Place hex bolt (P) through depth bar assembly

and through notches in depth bar adjustment

plate. Head of hex bolt must be to right side of

the tiller. Place spacer (Q) on hex bolt. See

— figure 5.

FIGURE 5.

FIGURE 6.

Depth Bar

Handle

ssembi

6. Place hole in depth bar handle assembly over

the spacer and hex bolt. Secure with flat

washer (R) and hex nut (S), tightening secure

ly, then backing off one turn. Handle must be

able to pivot freely. See figure 6.

Place end of spring onto hex bolt. Thread hex

lock nut (T) on the bolt until the two nuts are

approximately 1/8" apart. See figure 6.

Page 6

Assemble

in this

order

Assemble the side shields to the tine shield as

-shown in figure 7, using belleville washers (X)

(cupped side against the side shields) and hex

nuts (Y). Side shields will be adjusted up or down

as the depth bar is adjusted, as described in the

Operation section.

HANDLE ASSEMBLY

1. Place the handle assembly in position on the

tiller so that the holes in handle line up with

holes in mounting bracket.

2. Place flat washer (G) and belleville washer (F)

over shoulder on shoulder bolt (E). Place

shoulder bolt through handle mounting holes.

Secure with hex top lock nut (H) from the in-

-----

side of handie. See figure 8.

FIGURE 8.

Hex Bolt (M)

Ra. \

Washer (W) V'

Handle , ,

Adjustment (N) Handle

Rod Adjustment

FIGURE 9.

Lever

%

3. To assemble the handle adjustment lever (L),

hook handle adjustment rod (already on han

dle) into lever. Hook to the outside.

Place a flat washer (W) on either side of the

4.

handle inside of the handle adjustment lever.

Secure with hex bolt (M) and lock nut (N). See

figure 9. Do not over tighten. Handle adjust

ment lever must pivot freely.

Page 7

THROTTLE CONTROL INSTALLATION

Assemble the throttle control to the handle panel

as follows.

1. Hold the throttle control assembly beneath

the handle panel. Turn the control sideways

and insert the lever up through the wide por

tion of the slot on the handle panel. See figure

■10A.

2. After the end of the lever is through the slot,

turn and then tip the control forward as shown

in figure 8B to slide it through the slot.

NOTE

The lever must be all the way to the

back of the control housing as

shown in figure 10B.

'Belleville

Washer (A)

Compression

Spring (B)

3. Push the control back into the slot in the han

dle panel and press in place. Be certain the

—control is locked securely into the slot.

GEAR SHIFT ROD INSTALLATION

1. Assemble notched edge of gear shift lever so

notch faces forward. Place gear shift lever

through slot in handle panel. Place bottom

hole in gear shift lever over weld stud. Secure

with belleville washer (A), compression spring

------

(B) and hex lock nut (C). See figure 11.

Tighten hex lock nut until nut is flush with

2.

stud. See figure 11.

FIGURE 11.

Page 8

FIGURE 12.

3. Thread hex jam nut (K) on one end of gear shift

rod. Then thread gear shift rod into ball joint

on the top of pivot horn assembly 10 to 12

complete turns, approximately I/2 inch. See

—figure 12. Lock hex jam nut against ball joint.

4. Thread ferrule (J) on other end of gear shift

— rod. See figure 13.

5. Secure ferrule in gear shift lever as shown in

figure 13 with hairpin cotter (D).

Hairpin

Cotter (D)

errule (J)

Gear Shift ^bd

in Front of

Gear Shift Lever

FIGURE 13.

Gear Shift Rod Adjustment

A

Service engine with oil and gasoline

before making this adjustment.

Refer to the separate engine

manual packed with your tiller.

1. Place the gear shift lever in “NEUTRAL” (N)

position.

2. Place the tine engagement lever in the

disengaged position. See figure 22.

3. Place wheel engagement lever in the

disengaged position. See figure 23.

4. Place the throttle in the “START” position.

CAUTION

After all assembly is completed,

the gear shift rod must be ad

justed prior to initial operation.

5. Move choke lever down (if engine is cold). See

figure 17.

6. Start the engine.

7. Engage the gear shift lever through the five

gears with the engine running and return to

“NEUTRAL” (N).

8. Stop the engine.

9. Remove the hairpin from ferrule and pull out

of gear shift lever.

10. Place gear shift lever in first gear (and pull

lever to rear of slot). Adjust the ferrule to fit

gear shift lever, and replace the hairpin.

11. Repeat steps 6 through 10 to make the final

adjustment.

Page 9

CONTROLS—Location and Use

Gearshift Lever

The gear shift lever is located in the center of han

dle panel.

Hl^ note

The engine must be running to

move the gear shift lever. Shifting

gears with the engine off will

cause damage to the clutch control

rod.

1. Forward (1 thru 5)—Move the lever to the left

and forward for each gear. See figure 14.

»

- V

J

aw

FIGURE 15.

Throttle Control

The throttle control lever is located on the right

hand side of handle panel and controls the engine

speed.

1. Start—Push throttle control lever forward

(down) to start position. See figure 16.

2. Stop—Pull lever back (upward) to stop the

engine.

■''V

FIGURE 14.

A. Use (1) first and (2) second gears when

breaking the sod for the first time.

B. Use (3) third and (4) fourth gears when till

ing soil which has been tilled before.

C. Use (5) fifth gear for pulverizing soil or for

transporting the tiller.

CAUTION

Use first speed only when operating

the tiller for the first time.

2. Neutral (N)—Move lever to detent marked

“N.”

3. Reverse (R)—Raise up on the handles to lift

the tines out of the ground and pull the gear

shift lever back (upward) slowly to obtain

reverse. Always use caution when using the

reverse. When using reverse, if gear shift lever

is released it will snap back into neutral (N).

See figure 15.

m

FIGURE 16.

Choke

The choke is located on the engine just below the

air cleaner. To choke the engine, move the choke

lever down. See figure 17.

Page 10

FIGURE 17.

Handle Adjustment Lever

The handle adjustment lever is located (»n the

right hand handle bar. See figure 18.

Squeeze up on handle adjustment lever anc place

the handle in one of nine (9) positions. See figures

19, 2C and 21.

If the locking pin does not withdraw from the han

dle positioner assembly or if the locking pin does

not seat securely into the holes in the handl 5 posi

tioner assembly, adjustment is required. Refer to

Adjustment Section on page 13.

Handle has three vertical

positions in the center

FIGURE 19.

Handle has three vertical

positions to the right

FIGURE 18.

Right Hand

Handle Bar

'V

'Hafndl'e

Adjustments .r ^

¡. ‘ •*

i-*

iM

ilH!

FIGURE 20.

FIGURE 21.

10

'W,

Handle has three vertical

positions to the left

'•ts ■

'■f i

■I' 1

Page 11

^ WARNING I

(D

Before using the tiller, check to be

certain the tines are assembled

properly (sharp edge of the tines

must enter the soil first). Refer to

Operation Section.

Wheel Engagement

Lever (Disengaged/

Position)

\ WARNING \

The gear shift lever must be in

Neutral (N) position before engaging

or disengaging the tine and wheel

engagement levers.

Tine Engagement Lever

The tine engagement lever is located on the left

side of tiller.

To engage tines, move the lever outward. To

disengage tines, move the lever inward. See figure

22.

NOTE

It may be necessary to slightly

engage gear shift lever to align the

gears.

jagement

(Engaged

sition)

FIGURE 23.

OPERATION

^^CAUTION

Engine is shipped without oil.

BEFORE STARTING

1. Before operating tiller for the first time or if

tines have been removed and reassembled for

any reason, check to be certain the tines are

assembled correctly. The sharp edge of the

tines must enter the soil first as shown in

figure 24. (Figure 24 illustrates the left hand

tines, viewed from the left hand side of the

tiller. Right hand tines rotate in the same

direction as the left hand tines.)

»ment S

■

as

FIGURE 22.

Wheel Engagement Lever

The wheel engagement lever is located on the

right side of tiller.

To engage wheels, move the lever outward. To

disengage or stop wheels, move lever inward. See

figure 23.

FIGURE 24.

2. Fill crankcase with oil as instructed in the

separate engine manual packed with your

unit.

3. Fill fuel tank with clean, fresh, lead-free, lowlead or regular grade leaded gasoline.

4. Open fuel shut-off valve.

11

Page 12

TO START ENGINE

^ WARNING ^

BE SURE NO ONE IS STANDING IN

FRONT OF THE TILLER WHILE THE

ENGINE IS RUNNING OR BEING

STARTED.

1. Place the gear shift lever in “NEUTRAL” (N)

position. See figure 14.

2. Place the tine engagement lever ii the

disengaged position. See figure 22.

3. Place the wheel engagement lever in the

disengaged position. See figure 23.

4. Place the throttle control lever in “S' ART”

position.

5. Move choke lever down to choke engin i. See

figure 17.

NOTE

A warm engine may not require

choking.

6. Stand at side of tiller. Grasp the starter t andle

and pull out rapidly. Return it slowly :o the

engine. Repeat as necessary.

7. After engine starts, move choke lever gradual

ly to “OFF” position.

Refer to engine manual for additional engine Infor

mation.

TO STOP ENGINE

1. Move throttle control to “OFF” positior.

2. Disconnect spark plug wire and ground

vent accidentally starting while equipment is

unattended.

1

o pre

HOW TO USE YOUR

TILLER

A. Forward speeds: First and second speeds are

generally used for tilling sod or soil which has

not been tilled before. Third and fourth speeds

are usually used for fine tilling or cultivating.

The fifth speed is for pulverizing soil or for

transporting the tiller. The soil conditions in

your area will determine the speed you will

want to use.

IMPORTANT

Do not shift gears unless the engine

is running. If the engine should stall

while in gear, you must proceed as

follows;

1. ) Disconnect and ground the spark plug wire

against the engine.

2. ) Move tine and wheel engagement levers to

the disengaged position.

3. ) Pull the recoil starter rope, and at the same

time pull back on gear shift lever. Pull the

rope out as many times as it takes to move

the gear shift lever into neutrai (N) position.

Do Not force shift lever back into neutral at

any time.

4. ) Move the gear shift lever through the for

ward speeds, neutral and reverse. Readjust

control rod if necessary.

B. Neutral (N): The neutral detent on the handle

panel is used when starting and stopping the

tiller and going from a forward speed to

reverse.

C. Reverse (R) Gear; The reverse gear is a dead-

man type. If you put the tiller into reverse to

back up or to unclog the tines, and you let go

of gear shift lever, the reverse motion will stop.

Reverse will only work when you pull the gear

shift lever back and hold it in that position.

Raise the handles and lift the tines out of the

ground before putting the tiller in reverse gear.

I WARNING ^

When operating the tiller for the

first time, use the depth bar setting

that gives 1 inch of tilling depth

(second slot from the bottom).

Refer to figure 25. Use first speed

only.

Your tiller has a variable speed pulley which

allows you to change gears, First (1) through Fifth

(5), without stopping. The gear shift le>er is

located on the top center of handle panel. There

are Five (5) forward speeds. Neutral (N and

Reverse (R).

A

CAUTION

Placing the tiller in reverse with the

tines in the ground will cause pre

mature wear of the reversing disc.

TILLING

Tilling depth is controiled by the depth bar which

can be adjusted to five different settings. See

figure 25. Adjust the side shields as shown in

figure 25 as you adjust the depth bar. Be certain

spark plug wire is disconnected and grounded

against the engine.

1. When using the tiller for the first time, use the

second adjustment slot from the bottom (1 " of

tilling depth). See figure 25.

12

Page 13

2. When breaking up sod and for shallow cultiva

tion, use the setting which gives 1" of tilling

depth (second slot from the bottom). Place

the side shields in their lowest position. For

further depth, raise the depth bar and side

shields and make one or two more passes

over the area.

3. When tilling loose soil, depth bar may be

raised to the top slot to give the deepest till

ing depth. Raise the side shields to their

highest position.

4. To transport tiller, lower the depth bar (use

bottom adjustment slot).

\ WARNING j

Engage wheel drive before engaging

the tine engagement lever.

NOTE

To transport tiller, do not engage

the tine engagement lever. Engage

the wheels only.

For best results, it is recommended the garden be

tilled twice (lengthwise, then widthwise) to

pulverize the soil.

ADJUSTMENTS

HANDLE ADJUSTMENT LEVER (See Figure 26)

Use This

Position

First Time

DEPTH BAR

Hole for Lowest

Side

Shield I

SIDE SHIELDS

Use This

Position,

Use This Hole

for Highest Position

NOTE

Figure 26 is viewed from the bottom

of handle panel.

Position A. Use if not enough free play.

Position B. Normal setting.

Position C. Use if pin will not withdraw complete

ly from bracket.

To make the adjustment, loosen hex lock nut and

reposition the rod in Position A, B or C. See figure

tti

■■ ■

tion A

ition B

ition C

FIGURE 25.

To adjust the depth bar, lift up on the tiller

handles. Pull the depth bar handle assembly and

move the depth bar to desired setting. Release the

handle. See figure 25.

To operate the tiller:

1. Select the depth bar setting.

2. Start engine as instructed on page 12.

3. Engage wheel and tine engagement levers.

4. Move gear shift lever to first speed position

(wheels and tines will be moving).

FIGURE 26.

CONTROL BRACKET ADJUSTMENT

When the belt has become worn and/or stretched

or the friction wheel has become worn, make the

following adjustment.

Move the control bracket to the bottom hole on

the pivot horn assembly and readjust the gear

shift rod. See figure 27.

13

Page 14

Pivot Hor,

Assembly

FIGURE 27.

THROTTLE CONTROL CABLE ADJUSTMENT

1. Place the throttle control lever in “STOP”

position.

2. Loosen the casing clamp screw and move the

throttle control wire in as far as possible. See

figure 28.

3. Tighten the casing clamp screw.

Never make unnecessary adjustments. The fac

tory settings are correct for most applications. If

adjustments are needed, refer to the separate

engine manual packed with your tiller.

LUBRICATION

TRANSMISSION

The transmission is lubricated and sealed at the

factory. It requires no additional lubrication

unless the transmission is disassembled. To fill

with grease, lay the left half of the transmission

on its side, add 28 ounces of Plastilube #0 grease

and assemble the right half to it. This grease can

be purchased from your nearest service dealer.

(Order Part No. 737-0133.)

DEPTH BAR ADJUSTMENT SLOTS

Clean and grease the depth bar adjustment slots

at least once a season with an automotive chassis

grease.

PIVOT POINTS

Lubricate all pivot points and linkages at least

once a season with light oil.

FIGURE 28.

CARBURETOR ADJUSTMENT

^ WARNING \

If any adjustments are made to the

engine while the engine is running,

(e.g. carburetor), disengage all

clutches and tines. Keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Throt le

Win

Conti ol

MAINTENANCE

WARNING

(S)

Disconnect the spark plug wire and

ground it against the engine before

performing any repairs or main

tenance.

^ IMPORTANT

If for any reason the tines are re

moved from the tiller, be certain the

tines are reassembled so that the

sharp edge of the tines enter the

soil first. Refer to item number

one under “Operation.”

ENGINE OIL

After the first two hours of operating a new

engine, drain the oil from the crankcase while the

engine is still hot and refill the crankcase with

new oil; thereafter change the oil after every 25

hours of operation.

To avoid spilling gasoline on your lawn or

driveway, plan to change the oil when the gasoline

tank and carburetor are empty.

To change the oil, refer to the separate engine

manual.

14

Page 15

Check oil level every eight hours of operation. Be

sure level is maintained full to point of overflow

ing.

AIR CLEANER

Under normal operating conditions, the air

cleaner, located on top of the carburetor, must be

serviced after every ten hours of use. Under ex

tremely dusty operating conditions, the air

cleaner must be serviced after every hour of

operation.

To service the air cleaner, refer to the separate

engine manual packed with your tiller.

A

Never run your engine without air cleaner com

pletely assembled.

CAUTION

Grommet

FIGURE 29.

LIMITED TORQUE CLUTCH

If the limited torque clutch is disassembled for

any reason, reassemble as shown on page 22.

Filter

Valve

CLEANING ENGINE AND TINE AREA

Any fuel or oil spilled on the tiller should be wiped

off promptly. Dirt, leaves and other debris must

not be left to accumulate around the cooling fins

or the engine or on any part of the tiller. Clean the

underside of the tine shield after each use. The

dirt washes off the tines easier if washed off im

mediately instead of after it dries.

SPARK PLUG

The spark plug should be cleaned and the gap

reset every 25 hours of engine operation. Spark

plug replacement is recommended at the start of

each tiller season; check engine manual for cor

rect plug type and gap specification.

FUEL SHUT-OFF VALVE AND FILTER

The valve and filter is located on the bottom of the

gasoline tank located on top of the tiller.

Turn the valve knob in to shut off the fuel flow.

Turn the valve knob out to operate the tractor. See

figure 29.

The entire valve can be pulled out to clean the

filter. When reassembling, place the rubber grom

met into the gasoline tank first, then push the

valve all the way in.

\ WARNING \

NOTE

Torque setting is 550 to 650 in. lbs.

If you do not have a torque wrench, proceed as

follows:

1. Run the first nut on until it touches the spring

bell washer.

2. Mark nut and plate with a scrib line.

3. Tighten nut 3/4 of a turn clockwise.

4. Then lock in place with the second hex jam

nut.

BELT REPLACEMENT

A

Do not use an off-the-shelf belt.

Your tiller has been engineered with belts made of

special material (Kevlar Tensile) for longer life and

better performance. They should not be replaced

with an off-the-shelf belt.

If belt replacement is required, order belt or belts

by part number from your nearest authorized

dealer.

Part No. 754-0220 Part No. 754-0268

5/8" X 27" Short Belt 5/8" x 51" Long Belt

Front (Short) Belt Removal

1. Remove belt cover by removing the four self

tapping screws and flat washers. See figure

30.

CAUTION

Only use factory approved parts if

repairs are needed on the gasoline

tank, grommet, valve or gasoline

line.

15

, CAUTION

A

Muffler may be hot in the area

of belt cover. Only remove the belt

cover when engine is cool.

Page 16

Self-Tapping

Screws

Self-Tappin}

Screws

FIGURE 30.

2. Place gear shift lever in neutral position Hoid

friction disc with one hand. Remove three hex

bolts and lock washers which hold the friction

disc to the variable speed pulley. See figure

31. Lift belt off the variable speed pulle/.

Lift up on the idler pulley by hand, and remove

3.

the belt from beneath the idler pulley. Lift belt

off the transmission pulley and variable speed

pulley. See figure 32.

FIGURE 32.

NOTE

Upon reassembly of friction disc,

tighten the three bolts equally.

FIGURE 31.

3. Remove the hex bolt and internal lock u/asher

which holds the belt guard to the engir e. See

figure 31. Remove the belt guard. Remc ve and

replace the belt.

4. Reassemble in reverse order with the new

belt.

■i^NOTE

Be certain to assemble the new rear

belt in the second groove on the variabie speed pulley.

TIRE CHAINS

It may be necessary to move the right hand wheel

assembly to the extreme outside position when

using tire chains. See iilustration below.

Rear (Long) Belt Removal

1. Follow step numbers 1 and 2 under “Front

Belt Removal.”

2. Place the gear shift lever in one of the f Drward

gears (as far forward as possible).

16

Page 17

OFF SEASON STORAGE

If the tiller is to be inoperative for a period longer

than 30 days, the following precautions are recom

mended. Keep your tiller in a weatherproof dry

area. If stored for over 30 days the following steps

will protect the essential engine parts from gum

deposits.

1. Working outdoors, drain all fuel from the fuel

tank. Use a clean dry cloth to absorb the small

amount of fuel remaining in the tank, then run

the engine until all fuel in carburetor is ex

hausted.

5. Wipe tines with oiled rag to prevent rust.

CAUTION

A

When storing any type of power

equipment in an unventilated or

metal storage shed, care should be

taken to rust proof the equipment.

Using a light oil or silicone, coat the

equipment, especially any springs,

bearings and cables.

t. WARNING {

DO NOT DRAIN FUEL WHILE

SMOKING, OR IF NEAR AN OPEN

FIRE.

2. Drain all the oil from the crankcase (this

should be done after the engine has been

operated and is still warm) and refill the

crankcase with clean new oil.

3. Disconnect the spark plug wire and remove

the spark plug from the cylinder. Pour about

six drops of engine oil into the cylinder, and

then pull the recoil starter several times to

spread the oil on the cylinder wall. Replace

the spark plug, but DO NOT connect the wire.

4. Clean the engine and the entire tiller

thoroughly.

TILLER WINTERIZING INSTRUCTIONS FOR USE WITH SNOW BLADE:

1. For cold weather (below 32°F.), drain oil from

tiller engine crankcase and replace with SAE

10W or 10W-20 detergent oil.

2. Replace any remaining fuel on hand or in the

engine fuel tank with a fresh supply of winter

grade fuel. Winter fuels contain additives for

faster starts. Keep fuel tank full.

NOTE

It may be necessary to enrich the

carburetor idle and high speed jets

1/8 to 1/4 turn (counterclockwise) for

good performance.

3. In the spring of the year, before the tilling sea

son, be sure to change engine oil back to SAE

30W detergent oil.

17

Page 18

TROUE LE SHOOTING CHART

SYMPTOM

POS ilBLE CAUSE(S)

Engine fails to start 1. Check ft el tank for gas.

2. Spark plug lead wire

discor nected.

3. Faulty spark plug.

Hard starting or loss of

1. Spark plug wire loose.

power

2. Dirty air cleaner.

Engine overheats

1. Carburetor not adjusted

propel ly.

2. Air flow restricted.

3. Engine c il level low.

Controls do not engage

Belts worn and/or

stretched.

SOLUTION

1. Fill tank if empty.

2. Connect lead wire.

3. Spark should jump gap between

control electrode and side elec

trode. If spark does not jump,

replace the spark plug.

1. Connect and tighten spark plug

wire.

2. Clean air cleaner as described in

engine manual.

1. Adjust carburetor. See engine

manual.

2. Remove blower housing and clean

as described in the engine

manual.

3. Fill crankcase with the proper oil.

Make control bracket adjustment.

See adjustment section of manual.

NOTE: For repairs beyond the minor adjust nents listed above, please contact your local service dealer.

18

Page 19

NOTES

19

Page 20

Model 412

20

Page 21

Model 412

REF.

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

PARTS LIST

1 710-0136 Hex Bolt 1/4-20 X 1.75" Lg.*

2 749-0268

720-0180

3

712-0107 Hex Cent. L-Nut V4-20 Thd.

4

14844

5

04831

6

7 749-0269

04810

8

9 714-0149

Handle—R.H.

Grip

Clutch Grip

Handie Panei Ass’yHandle—L.H.

Clutch Handle Ass’yHairpin Cotter

10 736-0105 Belleville Wash. .38" I.D.

11

732-0193

Compression Spring .88"

O.D. X .81" Lg.

712-0214 Hex Cent. L-Nut 3/8-24 Thd.

12

13 747-0278 Gear Shift Rod

14 14734 Pivot Horn Ass’y.

15 736-0290 FI-Wash. .630 I.D. x 1.0" O.D.

X .063

714-0474 Cotter Pin 1/8" Dia. x .75"

16

Lg-*

17

15381

Tine Shield Ass’y.

18 710-0344 Hex Bolt 3/8-16 x 1.5" Lg.*

750-0527

19

Spacer .38 I.D. x .50 O.D. x

.18 Lg.

20 750-0528 Spacer .38 I.D. x .50 O.D. x

.38 Lg.

21 14843 Depth Bar Handle Ass’y.

w/Knob

22

711-0198

23 712-0798

24

712-0130 Hex Ins. L-Nut 3/8-16 Thd.

736-0227

25

Ferrule

Hex Nut 3/8-16 Thd.*

FI-Wash. .38 I.D. x 1.50 O.D. x

.13

26 712-0798 Hex Nut 3/8-16 Thd.*

27 732-0416 Spring—Depth Bar

28 712-0130

747-0252

29

Hex Ins. L-Nut 3/8-16 Thd.

Hinge Rod

30 04804 Tine Shield Hinge Flap

Ass’y.

31 15389 Side Cover Tine Shield—L.H.

15388 Side Cover Tine Shield—R.H.

(Not Shown)

14731 Depth/Drag Bar Ass’y.

32

710-0347

33

Hex Bolt 3/8-16 X 1.75" Lg.*

34 710-0604 Hex Wash. Hd. Self-Tap Scr.

5/16-18 X .62" Lg.

712-0292 Speed Nut

35 710-0830 Hex Bolt 3/8-24 x 3.0" Lg.

36 736-0169 L-Wash. 3/8" I.D.*

37 710-0623 Hex Wash. Hd. Self-Tap Scr.

38 738-0258 Shoulder Bolt .50" Dia. x .25"

Lg.

39 04841

Control Bracket

40 712-0116 Hex Ins. L-Nut 3/8-24 Thd.

41

736-0169 L-Wash. 3/8" I.D.*

42 736-0169 L-Wash. 3/8" I.D.*

43 736-0105 Belleville Wash.

*For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

FOR MODEL 412 TILLER

REF.

NEW

PART

NO.

44

45

PART

NO.

710-0623

712-0241

COLOR

CODE

46 736-0169

47

711-0679

48

15295 Tine Adapter Ass’y.

49 15387 LH. Tine Ass’y. Comp.

15386 R.H. Tine Ass’y. Comp.

50 710-0192

51 736-0169 L-Wash. 3/8" I.D.*

52 712-0241

53 742-0244

54

742-0243 Tine—L.H.

55 714-0149 Hairpin Cotter

56 15385 Chain Case Ass’y. Comp.

57

712-0267

58 736-0119

59 14744

60 712-0130 Hex Ins. L-Nut 3/8-16 Thd.

736-0119

61

62 710-0601

723-0156

63

747-0254

64

712-0158

65

748-0516

66

67

04819 Pivot Handle Link

736-0289 Bushing Wash.

68

712-0267

69

736-0119

70

738-0143

71

72 736-0253

714-0474

73

732-0132

74

75 711-0663 Locking Pin

76 712-0221

77 712-0181

78 04812

748-0150

79

80 736-0192

81 04792

82

710-0458

83 747-0255

84 831-0692

85

710-0118

86 746-0502

87

712-0711

88 15390

736-0170

89

712-0267

90

736-0173

91

92

710-0191 Hex Bolt 3/8-24 x .75" Lg.

When ordering parts, if color or finish is important use the ap

propriate color code shown above, (e.g. Top Flite Red—04820

(463).)

21

DESCRIPTION

Hex Wash. Hd. Self-Tap Scr.

Hex Nut 3/8-24 Thd.*

L-Wash. 3/8" Scr.*

Clevis Pin

(Not Shown)

Hex Bolt 3/8-24 x 1.25" Lg.*

Hex Nut 3/8-24 Thd.*

Tine—R.H.

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16" I.D.*

Handle Positioner Ass’y.

L-Wash. 5/16" I.D.*

Hex Wash. Hd. Self-Tap Scr.

Rod End 3/8-24 Thd.

Lower Handle Control Rod

Hex Nut 5/16-18 Thd.*

Pivot Handle Brg.

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16" I.D.*

Shid. Bolt .500" Dia. x .660

Belleville Wash. .505" I.D. x

1.00" O.D.

Cotter Pin 1/8" Dia. x .75"

Lg.*

Compression Spring

Hex Ins. L-Nut 5/8-16 Thd.

Hex Top L-Nut 3/8-16 Thd.

Pivot Brkt. Ass’y.

Sleeve Brg. .50" I.D. x .62"

O.D. X 1.12" Lg.

FI-Wash. .50" I.D. x 1.00"

O.D. X .090

Handle Mtg. Brkt. Ass’y.

Carriage Bolt 5/16-18 x 1.75"

Lg.*

Handle Lock Rod

Throttle Control Box Ass’y.

Hex Bolt 5/16-18 X .75" Lg.*

Throttle Control Wire

Hex Jam Nut 3/8-24 Thd.

Side Shield

Bell-Wash.

Hex Nut 5/16-18 Thd.

FI-Wash. 1/4" I.D.

(463—Top Flite Red)

(447—Patina Silver)

NEW

PART

N

N

Page 22

Model 412

16 15 1

NOTE: The engine is not under warranty by

the tiiler manufacturer.. . If repairs or service

is needed on the engine; please contact your

nearest authorized engine ^

service outlet. Check the Find It Fast

“Yellow Pages” of your In The

telephone book under “En- Yellow Pages

gines—Gasoline.”

----------------------------

IMPORTANT

The chain case must be assembled to the

frame with 3/4" hex bolt, lock washer and

beileville washer as shown.

22

Page 23

Model 412 PARTS LIST FOR MODEL 412 TILLER

NEW

REF.

NO.

PART

NO.

1 723-0365

2 710-0876

3 736-0119

4

736-0231

15727

5

COLOR

CODE

DESCRIPTION

Gas Cap 53 736-0105

Hex L-Bolt 5/16-24 x 1.5" Lg. 54

L-Wash. 5/16" I.D.*

FI-Wash. 5/16" I.D. X 1.125"

O.D.

Friction Disc Ass’y. N

PART

REF.

NO.

55 710-0623

56 734-0806

6 710-0191 Hex Bolt 3/8-24 x 1.25" Lg.

7

761-0189

Friction Pad 57

8 738-0372 Shoulder Spacer 58 712-0116 Hex Ins. L-Nut 3/8-24 Thd.

9 14740 Idler Bracket 59

10 756-0225

11

717-0343

12

712-0130 Hex Ins. L-Nut 3/8-16 Thd. .75" Lg.

Fl-ldler2.75" Dia.

Variable Speed Ass’y.

60 736-0119 L-Wash. 5/16" I.D.*

61 710-0601

13 754-0220 “V”-Belt 5/8" X 27.0" Lg. 62 715-0139

14

714-0118

Sq. Key 1/4" X 1.50" Lg.*

15 726-0153 Cable Tie 63 747-0265

16

751-0225

17

18

710-0380

19 14826

—

Gas Tank 64 720-0143 Grip

Engine 65

Hex Bolt 5/16-18 X 1.75" Lg.*

Belt Cover Support Ass’y-

66

67

20 736-0114 Internal L-Wash. Va" I.D. 719-0237

21

710-0121 Hex Bolt 1/2-20 X .75" Lg. Shown)

22 756-0296 Engine Pulley Ass’y. 68

23

24

05080

750-0381

Friction Wheel Ass’y.

69

Spacer 04859

25 736-0119 L-Wash. 5/16" I.D.*

26 710-0621 Hex Bolt 5/16-18 X .50" Lg.* 70

28

741-0155

Ball Bearing 71 717-0382

29 05034 Bearing Housing 1-3/8" O.D. 72

30 736-0329

L-Wash. 1/4" I.D.* 74

31 712-0138 Hex Nut 1/4-28 Thd.* 75

32 712-0324 Hex Ins. L-Nut V4-20 Thd. 76

33 04837

Variable Speed Brkt. Ass’y.

77 736-0319

34 710-0106 Hex Bolt 1/4-20 X 1.25" Lg.* 78

35 738-0380

36 714-0115

37 736-0237 Fi-Wash. .686" I.D. X 1.25"

14741 —452

38

39

736-0119

40 712-0267

41

712-0214 Hex Cent. L-Nut 3/8-24 Thd.

42

723-0340

43

736-0326

44

712-0206

45

736-0169

Shid. Bolt 1/2" Dia. x .25" Lg. 79

Cotter Pin 1/8" Dia. x 1.0" 80

Lg.*

81 754-0268

82 736-0169

O.D.

Frame Ass’y.

83

84 756-0410

L-Wash. 5/16" I.D.* 85 710-0195

Hex Nut 5/16-18 Thd.* 86 710-0599

87

Weight 88 15290

FI-Wash. .50" I.D. x 1.0" O.D. 89

Hex Nut 1/2-13 Thd.* 90 736-0119

L-Wash. 3/8" I.D.*

91

46 04860 Weight Mtg. Brkt. 92 751-0171

47

710-0496

Hex Bolt 1/2-13 X 4.50" Lg.*

93

48 710-0152 Hex Bolt 3/8-24 x 1.00" Lg.* 94 751-0173

49

712-0130

50

736-0329

51 712-0138

52 732-0384 Spring Idler Bracket

Hex Ins. L-Nut 3/8-16 Thd.

L-Wash. 1/4" I.D.*

Hex Cent. L-Nut V4-28 Thd.

95

96 748-0296

97

98

PART

NO.

COLOR

CODE

DESCRIPTION

Belleville Wash. 3/8" I.D.

736-0169

L-Wash. 3/8" I.D.*

Hex Self-Tap Scr. 3/8-16 x

.75" Lg.

Wheel Ass’y. Comp.—R.H.

734-0807

Wheel Ass’y. Comp.—L.H.

(Not Shown)

710-0191 Hex Bolt 3/8-24 x 1.25" Lg.*

* ^ am %

Chain Case Ass’y. Comp.

Hex Tap Tite Scr. 5/16-18 x

Headed Spiral Pin 3/16 x

13/16" Lg.

Engagement Lever

741-0862

732-0863

Ball Detent .250" Dia.

Compression Spring

719-0238 Shift Housing—R.H.

Shift Housing—L.H. (Not

721-0162

04858

Gasket—Shift Housing

Shift Yoke Ass’y.—R.H.

Shift Yoke Ass’y.—L.H. (Not

Shown)

717-0383

Clutch Dog

Clutch Dog Driver

04841

15287

710-0314

736-0171

Control Brkt.

Shroud Belt Cover

Hex Bolt 7/16-20 x 1.00" Lg.

L-Wash. 7/16" I.D.

FI-Wash. .44 I.D. x 1.38" O.D.

04836

710-0230

736-0329

Friction Disc

Hex Bolt 1/4-28 X .50" Lg.

L-Wash. 1/4" I.D.*

“V”-Belt 5/8" X 51" Lg.

L-Wash. 3/8" I.D.*

710-0344

Hex Bolt 3/8" X 1.50" Lg.*

Input Pulley—Chain Case

Hex Bolt 1/4-28 X .62" Lg.

Hex Wash. Hd. Self-Tap Scr.

736-0173

FI-Wash. 1/4" I.D.

Tank Mounting Brkt.

710-0118

Hex Bolt 5/16-18 X .75" Lg.*

L-Wash. 5/16" I.D.*

735-0149

Bushing—Gas Line

Shut-Off Valve

723-0157

Clamp Gas Line

Gas Line 141/2" Lg.

15291

Brace

Floating Disc

736-0352

712-0331

Spring Bell-Wash.

Hex Jam Nut 1.0-14

NEW

PART

N

23

Page 24

Model 412

NOTE: Use 28 ounces of

Plastilube #0 grease. Order

part no. 737-0133.

24

Page 25

Model 412

REF.

NO.

10

11 721-0163

12 15383

15

20

21

22

23

24 719-0237

25 710-0601

27 717-0383

28

PART

NO.

1 741-0155

15384

2

738-0379

3

4 714-0122

750-0379

5

717-0210

6

7 750-0378

8 14899

736-0350

9

741-0381

05034

13

14 736-0329

712-0138 i

721-0192

16

17 736-0219

18 736-0169

712-0214

19

04859

04858

721-0162

741-0862

732-0863

719-0238

717-0382

COLOR

CODE

PARTS LIST FOR CHAIN CASE ASSEMBLY 15385

REF.

DESCRIPTION

Ball Bearing .62" I.D. x 1.38"

O.D. X .44

Chain Case R.H. Half

Input Shaft .62" Dia.

Sq. Key 3/16" x 3/16" x .75"

Lg.

NEW

PART

NO.

29 721-0102

30

31

32

33 14746

34

PART

NO.

712-0138

736-0329

741-0229

713-0313

Spacer .637" I.D. x .781" O.D.

X .85" Lg.

35 750-0352

Sprocket 9 Tooth x .62"

Shaft

Spacer .637" I.D. x .781"

36 04823

37

713-0250

O.D. X 1.44" Lg.

Tine Shaft Ass’y.

FI-Wash. 1.28" I.D. x 1.62"

39 717-0512

40

750-0563

O.D.

Flange Bearing 1.25" I.D.

Gasket—Housing

41

717-0511

42 748-0184

Chain Case L.H. Half

Bearing Housing 1-3/8" O.D.

43 750-0374

L-Wash. 1/4" I.D.*

Hex Nut 1/4-28 Thd.

44

741-0189

Seal 1.25" i.D.

Belleville Wash.

45 736-0259

L-Wash. 3/8" I.D.*

Hex Cent. L-Nut 3/8-24 Thd.

Shift Yoke Ass’y.—L.H.

46 04835

47 713-0312

Shift Yoke Ass’y.—R.H. (Not

Shown)

48 750-0314

Gasket—Shift Housing

Ball Detent .250 Dia.

Compression Spring

Shift Housing —L.H.

Shift Housing—R.H. (Not

Shown) 53

49 710-0195

50 736-0219

51 710-0629

52 736-0159

736-0119

Hex Tap-Tite 5/16-18 x .75" 54 710-0627

Lg.

Clutch Dog

Clutch Dog Driver

55 756-6297^*°

56 721-0165

57

714-0139

COLOR

CODE

DESCRIPTION

Seal 1.0" I.D. x 1.38" O.D.

Hex Nut V4-28 Thd.*

L-Wash. 1/4" I.D.*

Flange Brg. 1.00" I.D.

Sprocket Brg. Sleeve Ass’y.

#50 Chain—5/8" Pitch x 50

Links—Endless

Stepped Spacer 1.0" I.D. x

1.75" O.D.

Clutch Shaft Ass’y.

#420 Chain 1/2" Pitch x

58 Links—Endless

Gear Bearing—Sleeve Ass’y.

Spacer 1.25" I.D. x 2.0"

O.D. X .68" Lg.

Sprocket and Gear Ass’y.

Flange Brg. .628" I.D. x .753"

O.D.

Hub Sleeve .38" I.D. x .625"

O.D.

Flange Brg. 1.00" I.D. x

1.188" O.D.

FI-Wash. 1.0" I.D. x 1.62"

O.D.

Axle Shaft Ass’y.

#420 Chain Vz" Pitch 46

Links—Endless

Spacer 1.0" I.D. x 2.0"

O.D.

Hex Bolt 1/4-28 X .62" Lg.

Belleville Wash.

Hex Bolt 3/8-24 x 2.75" Lg.*

FI-Wash. 5/16" I.D.

L-Wash. 5/16" I.D.*

Hex L-Bolt 5/16-24 x .75" Lg.

Input Pulley—Chain Case

Cap Plug .250" Dia.

Sq. Key 3/16" x 2.0" Lg.

NEW

PART

nr.

Heavy Duty Rear Tine Garden Tiller Attachments Available for All-Season Use

31-0106 Depth Gauge Wheels (Pair)

31-0107 6-Tine Cultivator (Must be used with

31-0106 Depth Gauge Wheels)

31-0110 8" Furrower Opener

31-0111 15" Sweep Cultivator

31-0114 Wheel Weights (Pair)

31-0116 32" Leveling/Snow Blade (Must be used

with 31-0121 Front Hitch Mount)

31-0121 Front Hitch Mount (For 32" Blade)

Note: Attachments are available through your local dealer or from the factory:

Agri-Fab Inc., 303 W. Raymond Street, Sullivan, Illinois 61951 (217) 728-4334

31-0144 “V”-Bar Cultivating Kit

Kit Includes: “V”-Bar Frame, 4-Point

Cultivating Tines, Hiller/Furrower,

Depth Gauge Wheels (Pair).

To use these

necessary to:

1.

Remove the tine shield hinge flap assembly.

2.

Remove the depth bar assembly (except when

using the 8" furrower opener and 15" sweep

cultivator).

3.

Remove the tines.

25

attachments on the tiller, it

IS

Page 26

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorized

firms listed below. All orders should specify the model num jer of

your unit, part numbers, description of parts and the quantity of

each part required.

Sfjrvice

NOTE: If any parts are found to be missing or d ifective upon assembly of this unit

that immediate repiacement can be made.

ALABAMA

Auto Electric & Carburetor Co.

ARKANSAS

Sutton’s Lawn Mower Shop . ..

CALIFORNIA

Billious'

COLORADO

FLORIDA

GEORGIA

ILLINOIS LYONS

INDIANA

IOWA

LOUISIANA

MARYLAND

MASSACHUSETTS

MICHIGAN

MINNESOTA

MISSISSIPPI

MISSOURI

NEW JERSEY

NEW MEXICO

NEW YORK

........................................

Spitzer Industrial Products Co.

Radco Distributors

Small Eng. Dist............................

East Point Cycle & Key

Keen Edge Co.............................

Parts & Sales Inc

Power Lawn & Garden Equip. . . . 2551 J.F. Kennedy ..

Suhren Engine Co

Center Supply Co

Morton B. Collins Co

Lorenz Service Co.......................

Power Equipment Dist.................

Hance Distributing Inc

Biloxi Sales 8. Service, Inc

Automotive Equip. Service ...

Ross-Frazier Supply Co

Henzier, Inc

Lawnmower Parts Inc

Spitzer Eng. & Parts

Gamble Dist., Inc.........................

......................

...............

........................

.......................

........................

...................

.................

..........

..............

.................................

.................

....................

BIRMINGHAM

.. 2625 4th Ave.S

NORTH LITTLE ROCK

. . 5301 Roundtop Drive

Box 368, Rt. 4

PORTERVILLE

.. 75 North D Street .., . )3257

DENVER

. . 6601 N.

Washington St

JACKSONVILLE

. . 4909 Victor St.

Box 5459

OPA LOCKA

. . 2351 N.W. 147th St. . .33054

EAST POINT

.. 2834 Church St

.. 8615 Ogden Ave. . ..

ELKHARÎ

. . 2101 Industrial Pkwy.

DUBUQUE

NEW ORLEANS

. . 8330 Earhart Blvd. ..

ТАКОМА PARK

.. 6867 New Hampshire

Ave

.............................

SPRINGFIELD

. . 300 Birnie Ave

LANSING

.. 2500 S. Pennsylvania .38910

MOUNT CLEMENS

. . 340 Hubbard

HOPKINS

. . 420 Excelsior Ave. W. .1,5343

BILOXI

.. 506 Caillavet St

KANSAS CITY

. . 3117 Holmes St

ST. JOSEPH

.. 8th and Monterey ... .(4503

ST. LOUIS

BELLMAWR

.. 717 Creek Rd

ALBUQUERQUE

.. 1023ThirdAve. N.W. .<7103

CARTHAGE

. . West End Ave

............

............

............

...................

...........

............

...............

...........

..........

..............

.............

. 55233

. ^2117

.30229

.12207

.:I0344

.30534

.36516

. 12001

. ’0118

.30912

.111107

.. 18043

.; 19533

.<4109

.<3125

.(8030

.13619

BRIGGS AND STRATTON,

AND SERVICE

Briggs & Stratton, Tecumseh

should be handled by your nearest authorized engine service firm.

listing Engines—Gasoline,

Lauson.

NORTH CAROLINA

OHIO

OKLAHOMA

OREGON PORTLAND

PENNSYLVANIA HARRISBURG

TENNESSEE

TEXAS

UTAH

A-1 Engine & Mower Co...

VIRGINIA

WASHINGTON

WISCONSIN

Automotive Supply Co. .. ... 123 S. Lin wood Ave.

Check the yellow pages of your telephone directory under the

Smith Hardware Co

Dixie Sales Company .... .. . 335 N. Green

Stebe’s Mid-State Mower Supply . Box 366, 71 High St... .43112

Bleckrie, Inc

National Central

Burton Supply Co

Victory Motors, Inc

Kenton Supply Co

EECO Inc

Thompson Rubber Co. ... ... 5222-24 N. Fifth St.... .19120

Bluemont Co

Frank Roberts & Sons . .. . . . R.D.2.............................

Scranton Auto Ignition Co.

Master Repair Service ... . . . 2000 Western Ave. . . .

American Sales & Service, Inc. ... 3035-43 Bellbrook . . .

Marr Brothers, Inc

Woodson Sales Corp

Bullard Supply Co

Engine House inc

RBI Corp

Bailey’s Inc

Horst Dist

............................

.............................

............................

.............

........................

..................

................

..............

...............

.......................

...............

...............

................

..........................

TECUMSEH AND PEERLESS

and Peerless parts and

Briggs & Stratton or Tecumseh

write to advise the factory so

GOLDSBORO

... 515 N. George St

GREENSBORO

CARROLL

CLEVELAND

.. . 7900 Lorain Ave

WADSWORTH

... 687 Seville Rd

YOUNGSTOWN

... 1301 Logan Ave.

Box 929

MUSKOGEE

. . . 605 S. Cherokee

. . . 8216 N. Denver Ave. ..

. . . 4021 N. 6th St...............

PHILADELPHIA

PITTSBURGH

... 11125 Frankstown Rd.

PUNXSUTAWNEY

SCRANTON

... 1133-35 Wyoming Ave. 18509

KNOXVILLE

MEMPHIS

DALLAS

. . . 423 E. Jefferson

..........

FORT WORTH

. . . 1702 N. Sylvania

HOUSTON

. . . 2409 Commerce St. ..

SAN ANTONIO

. . . 8610 Botts Lane

P.O. Box 17867

SALT LAKE CITY

... 439 E. 900 So................. .84111

ASHLAND

... 101 Cedar Ridge Dr. . .

SEATTLE

... 141414th Ave

APPLETON

P.O. Box 798 ............... .54911

CHILTON

.. . 444 N. Madison

...........

...............

............

................

.......................

..........

...........

..........

...........

.................

.............

PARTS

service

.27530

.27402

.44102

.44281

.44501

.74401

.97217

.17110

.15235

.15767

-

.37921

.38116

.75203

.76111

.77003

.78217

.23005

.98122

.53014

WARRANTY F ARTS AND SERVICE POLICY (0783)

The purpose of warranty is to protect the customer from d efects in workmanship and materials, defects which are NOT detected at the

time of manufacture. It does not provide for the unlimited and unrestricted replacement of parts. Use and maintenance are the respon

sibility of the customer. The manufacturer cannot assume responsibility for conditions over which it has no control. Simply put, if it’s

the manufacturer’s fault, it’s the manufacturer’s responsibility; if it’s the customer’s fault, it’s the customers’s responsibility.

CLAIMS AGAINST THE MANUFACTURER’S WARRANTY

INCLUDES:

1. Replacement of Missing Parts on new equipment. 1. Model Number of unit involved.

2. Replacement of Defective Parts within the warranty pe iod. 2. Date unit was purchased or first put into service.

3. Repair of Defects within the warranty period. 3. Date of failure.

MTD PRODUCTS INC

P.O. BOX 36900

All claims MUST be substantiated with the following

information:

4. Nature of failure.

CLEVELAND, OHIO 44136

Loading...

Loading...