Page 1

ЮФ

Model Nos.

213-380

ROTARY TILLER

For one year from date of purchase, MTD Products Inc.

will replace for the original purchaser, free of charge,

F.O.B. factory or authorized service firm, any part or

parts found to be defective in material or workman

ship. All transportation charges on parts submitted

for replacement under this warranty must be paid by

the purchaser. This warranty does not include replace

ment of parts which become inoperative through mis

use, excessive use, accident, neglect, improper main

tenance or alterations by unauthorized persons. This

warranty does not include the engine, motor, battery,

battery charger or any component parts thereof. For

service on these units refer to the applicable manu

facturer's warranty.

The above warranty will apply only to the original

owner and will be effective only if the warranty card

has been properly processed. It will not apply where

the unit has been used commercially.

Warranty service is available through your local au

thorized service dealer or distributor. UNDER NO CIR

CUMSTANCES WILL THE RETURN OF A COMPLETE

UNIT BE ACCEPTED BY THE FACTORY UNLESS PRIOR

WRITTEN PERMISSION HAS BEEN EXTENDED.

213-385 «HI?

1. Your tiller is a precision piece of power equipment.

Exercise extreme caution at all times.

2. Do not attempt to start engine with the clutch con

trol in the engaged or FORWARD position.

3. Stand clear of tines when starting engine. Never

stand in front of, or work on tines while the en

gine is running.

4. NEVER place hands or feet in the vicinity of the

tines while the engine is running.

5. Always stop engine when tiller is not in actual use.

6. Always disconnect spark plug wire during repairs

or refueling operations.

7. Do not fill gas tank while engine is running. Do not

spill gasoline on hot engine.

Your rotary tiller is a precision built machine designed

to take the work out of gardening and other related

chores. It can be used for seed bed preparation, tilling,

cultivating, furrowing, composting and mulching. Like

any other piece of power equipment, it requires a cer

tain amount of care and maintenance. In return for

this, it will give a maximum of service and efficiency.

Read these instructions carefully before assembling or

operating your tiller. Through proper care and opera

tion, you will obtain long, efficient service and trouble

free operation.

MTD PRODUCTS INC

5389 WEST 130th STREET • P. 0. BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-4121

Page 2

ASSEMBLY

HANDLE ASSEMBLY

Your rotary tiller is shipped complete in a single car

ton. The wheels, handle, controls and depth bar are

to be assembled. This is done in the manner described

below.

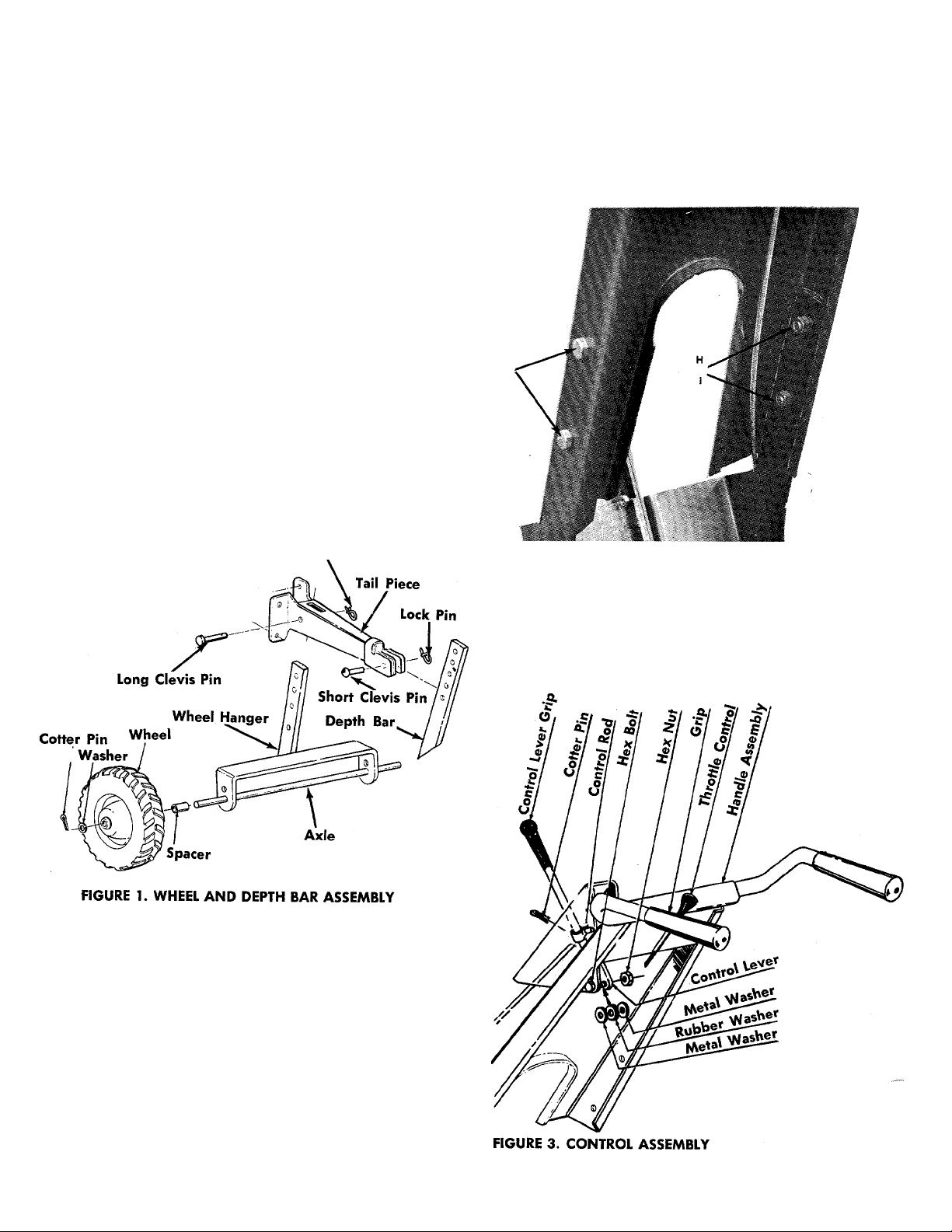

WHEELS

Assemble the axle to the wheel hanger. Place the

spacer over the axle and assemble the wheel, with a

washer on both sides of the wheel, to the axle. See

figure 1. Secure each wheel with a cotter pin.

Place the wheel hanger inside the tailpiece and secure

with the long clevis pin and lock pin. See figure 1.

DEPTH BAR

Assemble the depth bar to the tail piece using the

short clevis pin and lock pin. See figure 1.

Lock Pin

Assemble the handle to the handle brackets with four

cap screws, lockwashers and hex nuts as shown in

figure 2.

FIGURE 2. HANDLE ASSEMBLY

CONTROL LEVER

Place clutch control lever through handle panel. Se

cure in place with hex bolt, flat washers, rubber wash

er and hex nut. See figure 3.

Page 3

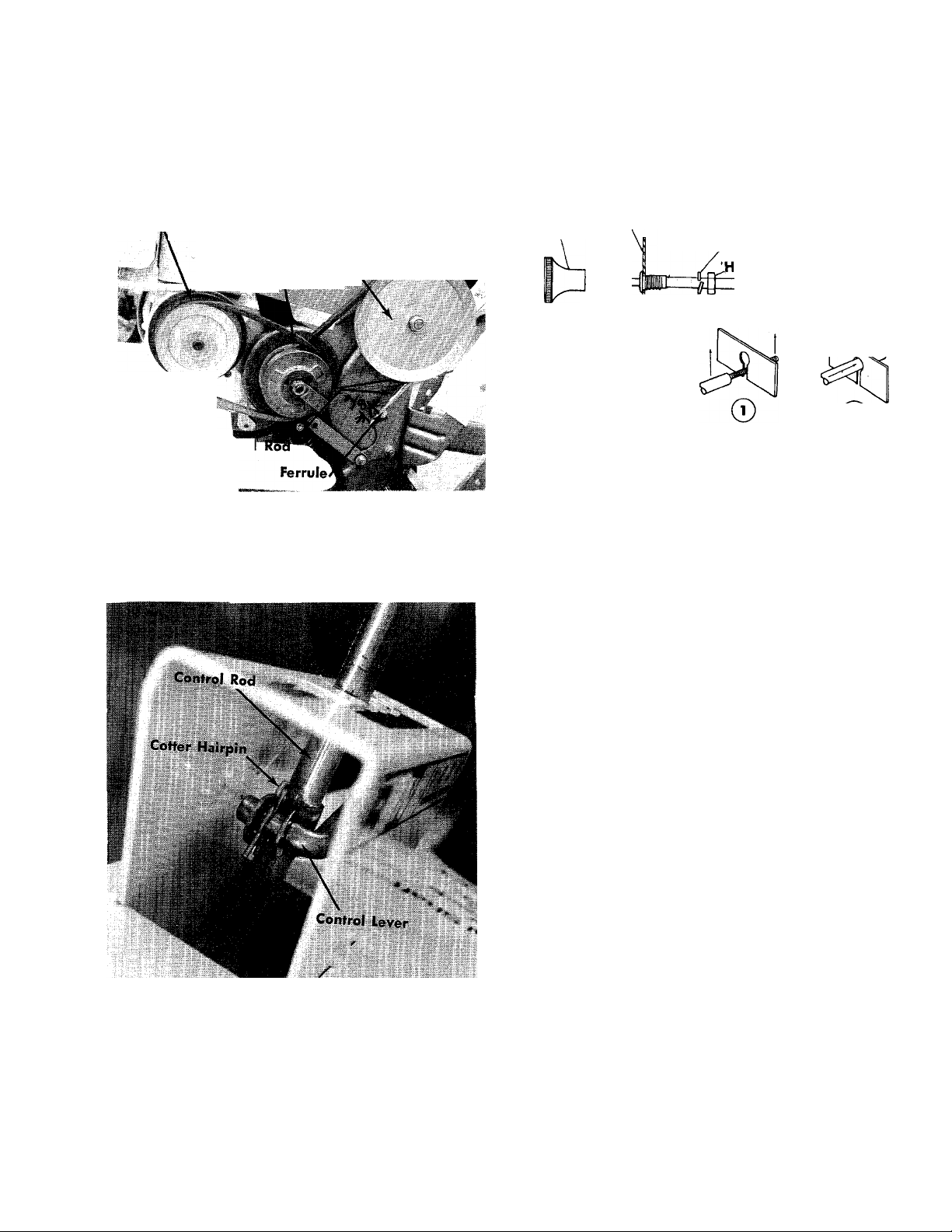

CONTROL ROD

Screw the control rod into the ferrule until it extends

through the ferrule % of an inch. See figure 4.

THROTTLE-Assemble as shown in figure 6.

Engiiis|T»uHey

«a. '

VanSBle Speed Pulley

Control

FIGURE 4. FERRULE ADJUSTMENT

Place the bent end into the control handle as shown

in figure 5 and fasten with a cotter hairpin.

j-J"- ■ Chain Case'^Ej^HI

Pulley

Knob

Handle Panel

Spring Lockwasher

ex Nut

Conduit

©

FIGURE 6. THROTTLE CONTROL

CHECK LIST BEFORE OPERATION

1. Check tiller tines for proper installation. With throt

tle control lever set on STOP position and the con

trol lever set in No. 1 position, slowly crank engine

to determine direction of tine rotation. Be sure all

tines are mounted so the sharpened edges enter

the soil first.

FIGURE 5. CONTROL ROD

CAUTION

With the spark plug wire disconnected

and grounded, place the control lever in

NEUTRAL and pull the recoil starter sev

eral times. THE TINES SHOULD NOT

TURN. If they do, screw the control rod

into the ferrule several more turns as

shown in figure 4.

2. Check all nuts and bolts for proper tightness. This

is especially important during the initial operation

period. Make the same check periodically there

after.

3. Check throttle control for proper setting. Move

throttle control knob to STOP position. Move lever,

to which control wire is fastened at engine, to

CLOSE position and retighten screw to secure throt

tle control wire assembly.

4. Check fuel tank. Clean, fresh, regular gasoline

should be used at all times.

5. Check engine crankcase for proper oil level. The

engine is shipped without oil in the crankcase. Be

sure crankcase is FULL.

STARTING YOUR TILLER

1. Be sure clutch control handle is in NEUTRAL posi

tion.

2. Move throttle control lever to STOP position.

3. Move choke lever, located at the engine, to CHOKE

position. Refer to your engine manual.

Page 4

4. After cranking the engine several times, or as the

engine fires, move the throttle control lever to RUN

position.

5. Use CHOKE as needed to keep engine operating

during warm-up period.

6. Set the throttle control in the FAST position.

7. Move the control lever into the number one posi

tion and the tines will begin rotating. Number four

position will give the maximum tine speed. Tilling

the ground for the first time should be done in the

number one or two position. To pulverize the soil

after it has been tilled, move the control lever to the

number three or four position.

NOTE

The engine must be running to move

the control lever into the faster speeds.

8. To stop engine, move throttle control lever to STOP

position. Keep throttle control lever in STOP posi

tion at all times when tiller is not in use.

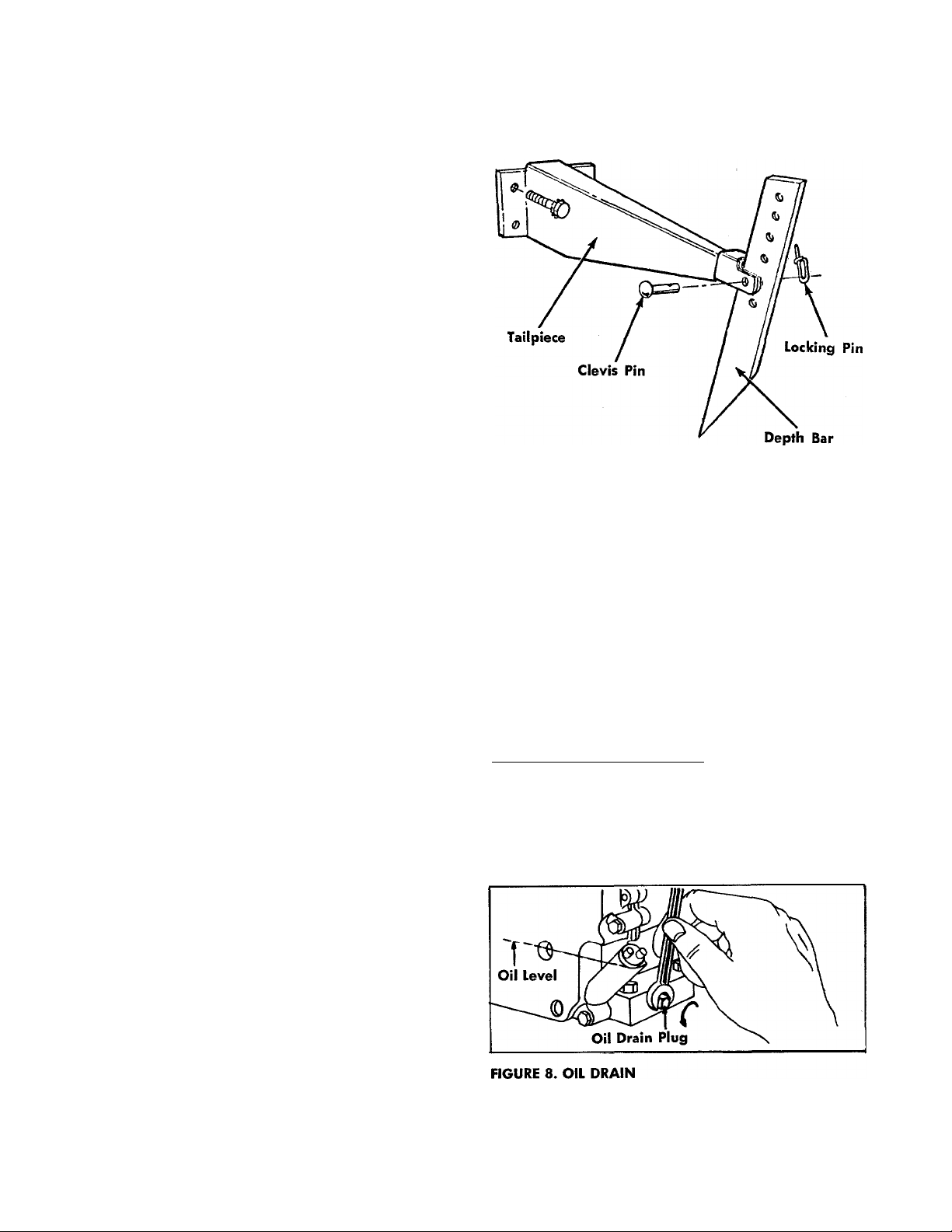

FIGURE 7. DEPTH BAR

11. The wheel height can be adjusted by removing

the long clevis pin for the wheel hanger and rais

ing or lowering the setting. See figure 1.

NOTE

A brief break-in period is essential to

insure maximum engine life. This con

sists of running the engine at half speed

for a period of time required to use one

tank of gasoline. This is necessary on

the initial run only. It is also recom

mended that the oil be changed after

five (5) hours of operation. This allows

for the removal of impurities which

may have accumulated during the breakin period. Subsequent oil changes

should be made as stated in the engine

manual. Always check oil before using

your tiller. Be sure crankcase is full.

9. To reverse the tine rotation to back up or release

an object jamming the tines, pull the control lever

into the REVERSE position.

NOTE

The control lever must be held in the

REVERSE position. When you release the

lever it will go into the NEUTRAL posi

tion.

NOTE

Pick a height that places the handles in

a comfortable position for the operator.

The higher the setting, the deeper you

till.

MAINTENANCE AND lUBRICATION

ENGINE—Service engine in accordance with the en

gine manufacturer's owner's guide. Note: To drain oil

remove oil drain plug and tip tiller forward. Drain oil

while the engine is warm. See engine manual for fil

ling instructions.

1,0. The depth bar acts as a brake for the tiller and con

trols the tilling depth and ground speed. By low

ering the setting of the depth bar, the forward

speed of the tiller is reduced and the tilling depth

of the tines is increased. Raising the settings of

the depth bar increases the forward speed and

reduces the working depth. See figure 7.

THROTTLE—Periodically lubricate throttle control lever

and throttle control wire assembly with a few drops

of light oil (SAE 10 or 20) for ease of operation.

Page 5

AIR CLEANER

CHAIN ADJUSTMENT

1., Remove wing nut and cover.

2. Lift off foam element from support base.

3. Remove metal support tube assembly (screen and

two metal end caps) from foam element by com

pressing foam element. See figure 9.

4. Wash the element in a solvent such as kerosene.

Squeeze dry and blot to remove all kerosene or sol

vent. Saturate element with engine oil. Squeeze

element to distribute and remove excess oil.

5. Insert metal support tube assembly into element so

that end cap without projection enters first. Make

sure metal caps are seated on screen.

IMPORTANT: When support tube is in place, pull rub

ber gasket over shoulder of metal end cap. Rubber gas

ket then forms a protective seal when cover is assem

bled.

6. Install element and cover. Tighten wing nut se

curely. See figure 9.

No chain adjustment is necessary.

BELT ADJUSTMENT

To check the belt adjustment, it is necessary to remove

the belt cover so the belts are exposd as shown in

figure 10.

Start the engine and move the control lever into the

number four position. Stop the engine and remove the

spark plug wire. Remove the belt cover. The belt be

tween the variable speed pulley and the chain case

pulley should move to the outside edge of the variable

speed pulley so the top of the belt is almost flush with

the pulley. If adjustment is necessary, shut off the en

gine and screw the control rod in or out of the ferrule

until the belt is in the proper position.

BELT REPLACEMENT

Step 1. Remove the belt cover so the belts are ex

posed as shown in figure 10.

Step 2. Put the depth bar on the wheel hanger and

place the tip of the depth bar under the vari

able speed pulley bracket as shown in figure

10.

CHAIN CASE LUBRICATION

The chain is permanently lubricated and requires

no further lubrication unless the case is disassembled

for repair.

if the case is disassembled, clean the chain with kero

sene, allow it to dry and work a high temperature

grease, such as Lubriplate No. 310 into the chain.

NOTE

Rear Belt

Déptli Bar

Wheel Hanger

A 4 oz. container of Lubriplate No. 310

is available under part number 727-136.

FIGURE 10. BELT REMOVAL

Page 6

Step 3. Place your foot on the rear of the depth bar

and apply pressure. The belts will go slack.

Step 4-. Remove the REAR belt first and ALLOW IT TO

FORM A LOOP AROUND THE VARIABLE

SPEED PULLEY.

NOTE

By following this order of belt removal,

it is not necessary to remove the belt

guard on the variable speed pulley.

Step 5. Slide the center section of the variable speed

pulley towards the engine.

Step 6. Remove the FORWARD belt from the engine

pulley and the variable speed pulley.

Step 7. Remove the rear belt from the variable speed

pulley.

Step 8. Reassemble with the new belts.

Page 7

58 59 60 61 62 63 64656667

7 8 9 10 12 13 14

45 44 42 40

140

Page 8

139

213-380 AND 213-385

Inner Tine Assembly—L.H.—Complete 4541

Inner Tine Assembly—R.H.—Complete 4542

Outer Tine Assembly-L.H.—Complete 4095

Outer Tine Assembly—R.H.—Complete 4096

Page 9

PARTS LIST FOR TILLER MODELS 213-380 AND 213-385

NO.

COLOR

CODE

DESCRIPTION

Engine

Hex Hd. Cap Scr. 5/16-18 x

NEW

PART

M:

REF.

NO.

1

2

PART

710-380

13/4' 'Lg. (213-385)

710-176

Hex Hd. Cap Scr. 5/16-18 x

23/4" Lg. (213-380)

3

4 710-376

5

6 710-216

4524

4494

Tine Shield

Hex Hd. Cap Scr. 5/16-18 x

1" Lg.*

Engine Spacer Ass'y.

(213-380 Only)

Hex Hd. Cap Scr. %-l 6 x

3/4" Lg.*

7 720-143

714-507

8

711-422 Control Rod

9

10 710-528

11

712-158

12

13

14 4533—438 Handle Assembly

15 4525

16

17 735-126 Rubber Washer* 18 Thd.*

18

19 736-217 Spring Lockwasher % Scr.*

20 712-798

21 4506—438

22 710-152

23 736-217 Spring Lockwasher 3/s Scr.*

24

25

26

27

28

29

30

31 711-231

32 4527—438

33

34

35 711-313

36

1166

746-122

736-264

736-264

4505—438

4507—438

732-194

736-148

710-152

732-194

4328—438

711-510

4451

8929—501

Grip

Cotter Pin 3/32 X 3/4" Lg.*

Hex Hd. Cap Scr. 5/16-18 x

VA" Lg.*

Hex Centerlock Nut 5/16-18

Thd.*

Grip Scr.*

Throttle Control—Cornplete

Control Lever Assembly

Flat Washer*

Flat Washer*

Hex Nut 3/8-16 Thd.*

Handle Mounting Bracket L.H.

Hex Hd. Cap Scr. 3/b-24 x

1" Lg.*

Handle Mounting Brkt R.H.

Tail Piece

Spring Pin

Ext. Lockwasher for 3/&" Scr.*

Hex Hd. Cap Scr. 3/g-24 x

1" Lg.* 65

Spring Pin

Depth Bar

Clevis Pin

Wheel Hanger Brkt. Ass'y. 69

Clevis Pin

Rear Axle

Spacer

Wheel Assembly Complete

PART

COLOR

CODE

NO.

736-160

37

714-115

38

712-236

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60 4516

61

62

63

64

66

67

68

70

71

72 715-120

4474—438

4511—438

736-220

736-224 Dust Pad

742-113

4511—438

742-110

4474—438

710-152

736-169

712-711

710-483

736-119

712-158

4519—438

712-158

736-119

4519—438

710-258

710-252

736-329

712-287

4537 Belt Trap Assembly

710-121

736-921

4523

712-287

711-504 Sprocket Shaft

748-855

4529 Double Sprocket Assembly

717-188

Flat Washer*

Cotter Pin Vs Dia. x 1" Lg.*

Hex Elastic Stop Nut 7/16-20

Thd.

Outer Tine Adapter

Inner Tine Adapter

Dust Pad

Tine—L.H.

Inner Tine Adapter

Tine—R.H.

Outer Tine Adapter

Hex Hd. Cap Scr. 3^-24 x 1"

Lg.*

Spring Lockwasher for 3/b Scr.*

Hex Jam Nut 3/a-24 Thd.*

Hex Hd. Cap Scr. 7/16-20 x

2Va" Lg.*

Spring Lockwasher 5/16

5/16-18 Thd.

Engine Mounting Brk.

Hex Center Locknut 5/16-

Spring Lockwasher 5/16 Scr.*

Engine Mounting Brkt.

Hex Hd. Cap Scr. 14-20 x%"

Lg.*

Hex Hd. Cap Scr. V4-20 x %"

Lg.*

Belt Guard

Spring Lockwasher V4" Scr.*

Hex Nut ’/4-20 Thd.*

Hex Hd. Cap Scr. '/2-2O x %"

Lg.*

Spring Lockwasher Vi" Scr.*

Variable Speed Guiding Brkt.

Hex Nut '/4-20 Thd.*

Flange Bearing

11-2 Teeth Sprocket 3/b Pitch

Spirol Pin 3/16 Dia. X 1" Lg.

Heavy Duty

DESCRIPTION

Hex Centerlock Nut

NEW

PART

* For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally order by part number and size

as shown on parts list.

(438—Polar Blue) When ordering parts If color or finish is important, use the appropriate

color code shown at left. (e.g. Polar Blue finish, 4328 (438).)

Page 10

parts list (CONTINUED)

PART

REF.

NO.

73

750-118 Spacer

74

75 713-149 Roller Chain w/Master Link

76 711-505

77 748-855

78

710-230

79

80 4501—438

81 11021—438 Eccentric Link

82 736-161 Rubber Washer

83 736-703

84 741-155 Ball Bearing % I.D. x ]% O.D.

85 5034

86 736-329 Spring Lockwasher Scr.’*'

87

88 710-258

89

90 5080 Friction Wheel Assembly

91

92

93 712-461

94 4520—438

95 756-167

96 726-106

97

712-221

98 714-115

99

736-204

100

711-392

101 4521—438

102

736-703

103 712-116

104

712-116

105 712-461

106 710-152

107

736-217

108

109

714-133

Foi faster service obtain standard nuts, bolts and washers locally. If these iter»*- cannot be obtained locally order by part number and size

as shown on ports list. \

COLOR

NO.

736-329

754-158

CODE

—

4517—438

714-136 Hi Pro Key *505

4515

7386

Part of Ref. No 70

Pulley Shaft

Flange Bearing

Hex Hd. Cap Scr. ’/4-28 x ’/2"

Variable Speed Brkt. Ass'y.

Housing Ass'y.—L.H. Side

Flat Washer

Bearing Housing—13^ Dia.

Spring Lockwasher Va " Scr.*

Hex Hd. Cap Scr. ’^-20 x %"

Friction Disc

"V"-Belt 21/32 x 35" Lg.

Hex Jam Nut ’/2-I3 Thd.

Variable Speed Belt Guard

8" O.D. x % Split Pulley

Push On Pual Nut (Not Shown)

Hex Elastic Stop Nut %-18

Cotter Pin Va Dia. x 1" Lg.*

Flat Washer

Ferrule

Link Bracket Assembly

Flat Washer 132

Hex Elastic Stop Nut %-24 133

Hex Elastic Stop Nut %-24

Hex Jam Nut ’/a-l 3 Thd.

Hex Hd. Cap Scr. з^-24 x 1"

Spring Lockwasher % Scr.

Flat Washer

Sq. Key 3/16 X l’/2" Lg.*

DESCRIPTION

#35-2 X 363/4" Lg.

Lg-

Lg.*

Special

(Located on Pin at Spring)

Thd.

Thd.

Thd.

Lg. H.T.

Heavy Duty

(213-380)

NEW

PART

REF.

PART

NO.

NO.

714-118 Sq. Key ’/4 X I’/i" Lg.*

no

111 750-166

112

748-180

113

754-157

114 738-138

115

710-380

116 11002

117 711-509

732-232

118

119

712-158

736-119

120

121

122 721-117

123 748-194

124 712-287

125 736-329

126

721-119

127

128

710-118

129

711-506

130 736-119

131

134

135

136

137 736-119

138

139

140 748-147

(438—Polar Bk |Vhen ordering parts if color or finish Is important, use the appropriate

joior code shown at left. (e.g. Polar Blue finish, 4328 (438).)

COLOR

CODE

10843 Variable Speed Pulley Ass'y.

Spacer (For Item #116)

Pivot Slide (For Item #79)

"V"-Belt 21/32 X 28" Lg.—

Shoulder Bolt—Special

Hex Hd. Cap Scr. 5/16-18 x

Spring Bracket

Spring Insert

4530—438

4532

4531

713-150

717-189

715-125

710-258

4530—438

710-118

736-703

4503—438

Cast Bearing Housing Ass'y.

DESCRIPTION

(213-385)

Not Shown

Not Shown

Special

n/4" Lg.*

Variable Drive Spring

Hex Center Locknut 5/16-18

Thd*

Spring Lockwasher 5/16 Scr.*

Oil Seal l’/4" I.D. x 1%" O.D.

Flange Bearing 1’A" I.D. x

l%"O.D.

Hex Center Locknut ’^-20 Thd.*

Spring Lockwasher ’A" Scr.*

Gasket

Engine Pulley Ass'y. (For 213-

380 5 H.P. Only)

Engine Pulley Ass'y. (For 213-

385 8 H.P. Only)

Hex Hd. Cap Scr. 5/16-18

X %" Lg.

Tine Shaft

Spring Lockwasher 5/16 Scr.*

Roller Chain w/Master Link

#40-2 X 34" Lg.

24-2 Teeth Sprocket ’A" Pitch

Spirol Pin % Dia. X 2" Lg.

Heavy Duty

Hex Hd. Cap Scr. ’A-20 x

%" Lg.*

Cast Bearing Housing Ass'y.

Hex Hd. Cap Scr. 5/16-18 x

3/4" Lg.*

Spring Lockwasher 5/16 Scr.*

Flat Washer

Housing Ass'y.—R. H. Side

Bushing

NEW

PART

Page 11

PARTS INFORMATION

DEFECTIVE OR MISSING PARTS must be reported to the

factory immediately. Such claims must include your

model number and date of purchase.

MOWER, TILLER, SNOW THROWER, TRACTOR, TRAIL

BIKE AND MUD BUG PARTS

Mower, tiller, snow thrower, tractor, trail bike and

mud bug parts are available through the authorized

service firms listed below. All orders should specify

the model number of your unit, parts numbers, de-

A 1 Engine & Mower Co.

327 East 9th Street

Salt Lake City, Utah 84102

American Electric Ignition Co.

124 N. W. 8th Street

Oklahoma City, Oklahoma 73102

Auto Electric & Carburetor Co.

2625 4th Avenue, S.

P. O. Box 1948

Birmingham, Alabama 35233

Automotive Equipment Service Co.

3117 Holmes Street

Kansas City, Missouri 64109

Bailey's Rebuild Inc.

1325 E. Madison Street

Seattle, Washington 98102

Brown Equipment Distributor Inc.

110 Beech Street

Corydon, Indiana 47112

Bullard Supply

2409 Commerce Street

Houston, Texas 77003

Catto & Putty, Inc.

P. O. Box 2408

\ 510 Soledad Street

San Antonio, Texas 78205

Center Supply Company

6867 New Hampshire Avenue

Takoma Park, Maryland 20012

Charles B. Wright Co.

309 4th Avenue, South

Nashville, Tennessee 37201

W. B. Clements

400 Salem Avenue

Roanoke, Virginia 24016

Morton B. Collins Co.

300 Birnie Avenue

Springfield, Massachusetts 01107

Dixie Sales Company

P. O. Box 1408

327 Battleground Avenue

Greensboro, North Carolina 27402

East Point Cycle & Key Shop

1617 Whiteway

East Point, Georgia 30044

Gamble Distributors

West End Avenue

Carthage, New York 13619

Garden Equipment Co., Inc.

6600 Cherry Avenue

Long Beach, California 90805

Henzier, Inc.

2015 Lemay Ferry Road

St. Louis, Missouri 63125

Frank E. Ives & Son

1101 Lincoln Avenue

Prospect Park, Pennsylvania 19076

J. W. Jewett Co.

981 Folsom Street

San Francisco, California 94107

Kenton Supply

8216 North Denver Avenue

Portland, Oregon 97217

Kimber's Inc.

115 W. Geddes St.

Syracuse, New York 13204

The Lawnmower Shop

1340 El Camino Real

San Carlos, California 94070

Marr Brothers

423 E. Jefferson

Dallas, Texas 75203

Mathews Auto Electric Co.

420 East 2nd Street

Tulsa Oklahoma 74120

McClure Lawn & Garden Supply

1114 Lexington Avenue

Mansfield, Ohio 44907

Memphis Cycle & Supply Co.

421 Monroe Avenue

Memphis Tennessee 38103

scription of parts and thè quantity of each part re

quired.

BRIGGS & STRATTON, TECUMSEH AND PEERLESS PARTS

AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and

service should be handled by your nearest authorized

engine service firm. Check the yellow pages of your

telephone directory under the listing Engines —

Stratton or Tecumseh Lauson —

Gasoline, Briggs

Power Products.

&

Moz-AII of Florida, Inc.

365 Greco Avenue

Coral Gables, Florida 33146

National Central, Div. of

Joe Sterling, Inc.

Drawer "D" 687 Seville Rd.

Wadsworth, Ohio 44281

Power Equipment Distributor

36463 So. Gratiot Avenue

Mt. Clemons, Michigan 48043

Parts & Sales Inc.

2101 Industrial Pkwy.

Elkhart, Indiana 46514

Parts & Sales Inc.

335 West St. Charles Road

Villa Park, Illinois 60181

Power Lawn & Garden Equip. Co.

2551-2571 J. F. Kennedy Road

Dubuque, Iowa 52001

Raub Supply Company

James & Mulberry Sts.

Lancaster, Pennsylvania 17604

Radco Distributors

2403 Market Street

P. O. Box 3216

Jacksonville, Florida 32206

Richmond Battery & Ignition

P. O. Box 25369 - 957 Myers St.

Richmond, Virginia 23260

Smith Hardware Company

515 N. George Street

Goldsboro, North Carolina 27530

South Denver Lawn Equip. Co.

527 West Evans

Denver, Colorado 80223

Suhren Engine

8330 Earhart Blvd.

New Orleans, Louisiana 70118

Sutton's Lawn Mower Shop

Route 4, Box 343

North Little Rock, Arkansas 72117

Warner Equipment

7520 Lyndale Avenue, So.

Minneapolis, Minnesota 55423

The purpose of warranty is to protect the customer from defects in material and workmanship, defects

which are not detected at the time of manufacture.

Our aim is to build into our product quality and reliability. Considerable emphasis is placed on quality

control in order to assure our customer of satisfactory product performance. To achieve this goal, it is

necessary to gain the cooperation of ail concerned, MTD, our sales force and our customers.

MTD's responsibility is to build a quality product and to back up that product. MTD must build this

quality product at a competitive price. This cannot be achieved without production in quantity. Quantity

production is mass production. In mass production it is always possible for undetected defects to be

present when the product reaches the customer. Our warranty is extended to assure the customer that

any such defects will be corrected.

Use and maintenance are the responsibility of the customer. MTD cannot assume responsibility for con

ditions over which it has no control. MTD's responsibility does not cover misuse, excessive use, accident

neglect, improper maintenance or alterations by unauthorized persons. Satisfactory product performance

can only result when a manufacturer provides and backs up a quality product and the customer follows

through with proper use and proper maintenance of that product. When both the manufacturer and the

customer recognizes and assumes his responsibility, satisfactory product performance and customer sat

isfaction are assured.

FORM NO. 770-4121

WARRANTY PARTS AND SERVICE POLICY

11

PRINTED IN U.S.A.

Loading...

Loading...