Page 1

Safety • Operation • Maintenance • Storage • Troubleshooting

OPERATOR’S MANUAL

179cc and 208cc

Horizontal Shaft OHV Snow Engines

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY BEFORE OPERATION

PRINTED IN U.S.A. MTD Products Ltd., P. O. Box 1386, KITCHENER, ONTARIO N2G 4J1

769-03333

9/11/2007

Page 2

This Operator’s Manual is an important part of your new engine. It will help you prepare and maintain the unit for best

performance. Please read and understand what it says.

Table of Contents

Safe Operation Practices .........................................3

Operating the Engine ...............................................5

Maintaining the Engine ............................................9

Troubleshooting ......................................................12

This Operator’s Manual may cover a range of engine models. Characteristics and features discussed and/or illustrated in this manual may not be

applicable to all engine models. MTD LLC reserves the right to change product specifications, designs, and equipment without notice and without

incurring obligation.

This manual covers the operation and maintenance of your

engine. All information in this publication is based on the latest

product information available at the time of printing.

No part of this publication may be reproduced without written

permission.

This manual should be considered a permanent part of the

engine and should remain with it if it is resold.

WARNING: The engine is designed to give safe and dependable service if operated according to instructions. Read

and understand the Operator’s Manual before operating the engine. Failure to do so could result in personal injury or

equipment damage.

Pay special attention to safety messages and notes printed in

this manual and on the engine itself. A safety message alerts

you to potential hazards that could hurt you or others.

WARNING: Indicates a strong possibility of

severe personal injury or death if instructions

are not followed. Each safety message is

preceded by a safety symbol.

NOTE: Gives helpful information.

IMPORTANT: Indicates a possibility of equipment or property damage if instructions are

not followed.

Customer Support

Visit www.mtdcanada.ca or call a Customer Support Representative at 1-800-668-1238.

2

Page 3

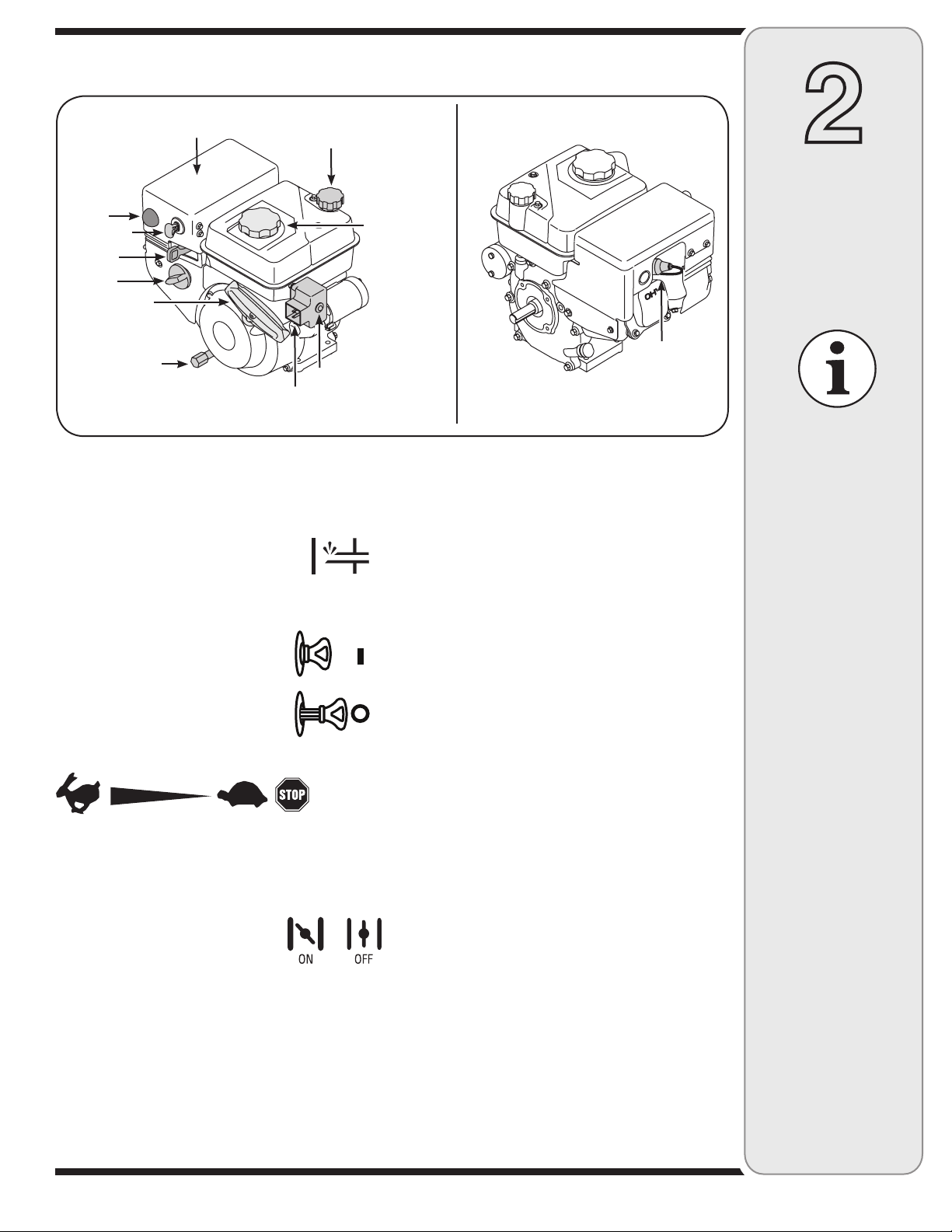

Engine Components

Muffler

Primer

Ignition Key

Throttle

Choke

Starter Handle

Oil Drain

Electric Switch Box*

* Optional

Figure 2-1: Front and rear views of the engine.

Read this section before starting the engine. It is important to familiarize yourself with the controls on the engine. Refer

to “Starting the Engine” section for detailed operating instructions.

Primer

Depressing primer forces fuel directly into

engine’s carburetor to aid in cold-weather

starting.

Ignition Key

The ignition key is a safety device.

Insert key and snap in place; do not

turn ignition key. Pull the key out

halfway to stop the engine. Remove

key when the unit is not in use.

Throttle

Oil Filler Cap/Dipstick

Fuel Fill Cap

Electric start button*

PRIMER

Spark Plug

Oil Drain

Removing the oil drain plug will drain the oil from the

engine. Refer to the Maintenance section in this manual

for instructions on changing the oil.

Oil Filler Cap/Dipstick

Remove oil cap to check oil level. Refer to “Pre-Operation

Check” section for checking oil and “Maintaining Your

Engine” section for adding oil instructions.

Fuel Fill Cap

Remove gas cap to add fuel. Unit runs on automotive

unleaded gas.

2

Operating

the

Engine

IMPORTANT: This engine

is shipped without gasoline or oil in the engine.

Running the engine with

insufficient oil can cause

serious engine damage

and void the engine

warranty.

Specifications are

subject to change without

notification or obligation.

Images my not reflect your

exact model and are for

reference purposes only.

The throttle control regulates the speed of the engine

and will shut off the engine when moved into the STOP

position.

Choke

Activating the choke closes the choke

plate on the carburetor and aids in

starting the engine. For information

on choke usage, see “Starting The

Engine.”

Starter Handle

This motor is fitted with a recoil action pull start and a

mitten grip handle for easy access while wearing gloves

or mittens.

Electric Start (if equipped)

Electric Switch Box

Requires the use of a three-prong outdoor extension cord

and a 120V power source/wall outlet.

Electric Start Button

Pressing the electric starter button engages the engine’s

electric starter when plugged into a 120V power source.

3

Page 4

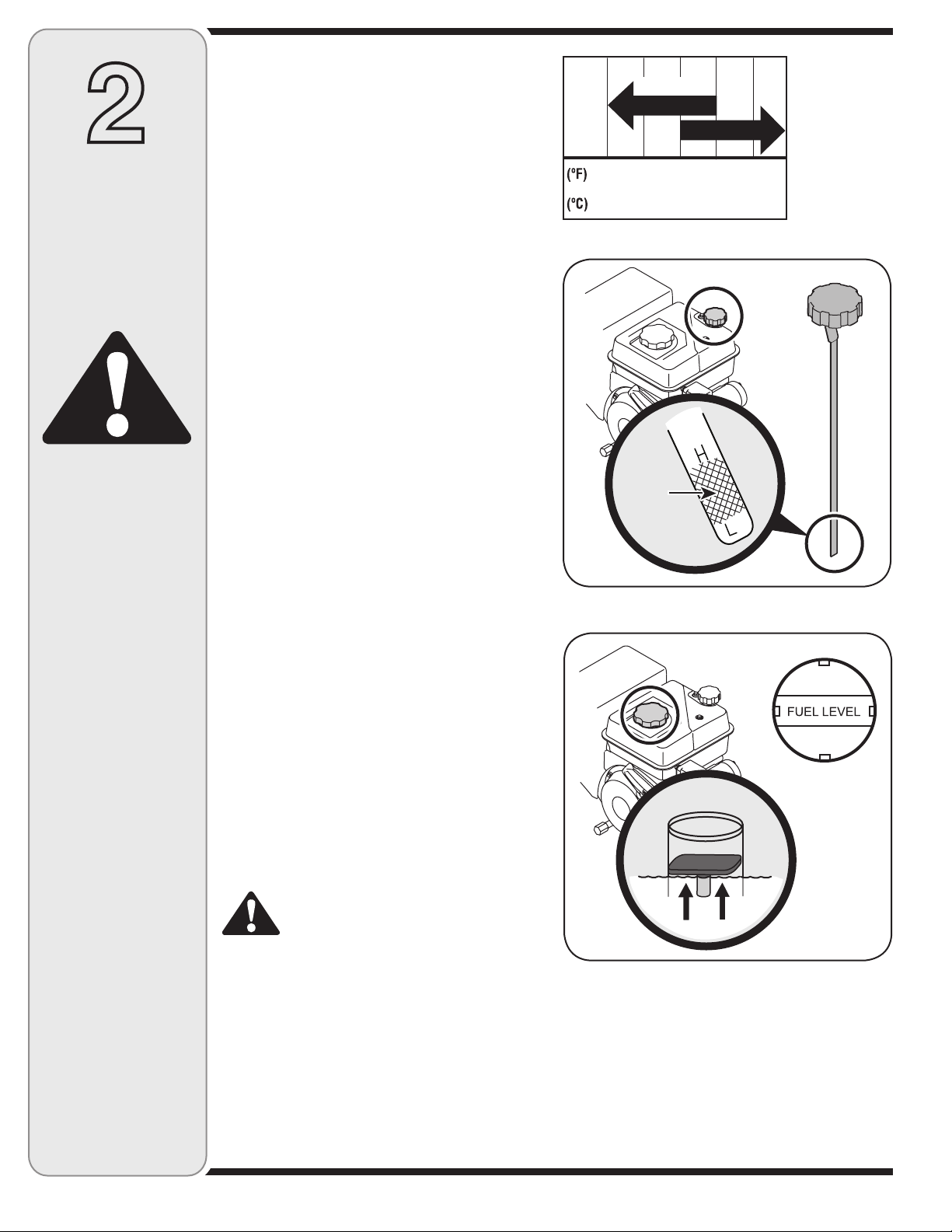

2

Pre-Operation Check

IMPORTANT: This engine is shipped without gasoline or oil in the engine. Running the engine with

insufficient oil can cause serious engine damage

and void the engine warranty.

Synthetic

0W-30

5W-30

Operating

the

Engine

WARNING

WARNING: Gasoline is

extremely flammable and

is explosive under certain

conditions.

WARNING: Always keep

hands and feet clear of

equipment moving parts.

Do not use a pressurized

starting fluid. Vapors are

flammable.

Oil Recommendations

Before starting engine, fill with oil, refer to viscosity

chart in Figure 2-2. Engine oil capacity is 600 ml. Do not

over-fill. Use a 4-stroke, or an equivalent high detergent,

premium quality motor oil certified to meet or exceed

U.S. automobile manufacturer’s requirements for service

classification SG, SF. Motor oils classified SG, SF will

show this designation on the container.

IMPORTANT: DO NOT use nondetergent oil or

2-stroke engine oil. It could shorten the engine’s

service life.

Checking Oil Level

IMPORTANT: Be sure to check the engine on a level

surface with the engine stopped.

Remove the oil filler cap/dipstick and wipe the

1.

dipstick clean, Figure 2-3.

Insert the cap/dipstick into the oil filler neck, but do

2.

not screw it in.

Remove the oil filler cap/dipstick. If the level is low,

3.

slowly add oil until oil level registers between high

(H) and low (L), Figure 2-3.

Replace and tighten cap/dipstick firmly before

4.

starting engine.

IMPORTANT: Do not overfill. Overfilling with oil may

cause smoking, hard starting, or spark plug fouling.

-40º

0º 20º 40º-20º

-30º -20º -10º 0º

Figure 2-2: Oil Viscosity Chart

Fill

between

high

and low

marks

Figure 2-3: Checking the oil level.

Fuel Recommendations

Use automotive gasoline (unleaded or low leaded to

minimize combustion chamber deposits) with a minimum

of 87 octane. Gasoline with up to 10% ethanol or 15%

MTBE (Methyl Tertiary Butyl Ether) can be used. Never

use an oil/gasoline mixture or dirty gasoline. Avoid

getting dirt, dust, or water in the fuel tank. DO NOT use

E85 gasoline.

WARNING: Gasoline is extremely flammable and is explosive under certain

conditions.

Refuel in a well-ventilated area with the engine

•

stopped. Do not smoke or allow flames or sparks

in the area where the engine is refueled or where

gasoline is stored.

Do not overfill the fuel tank. After refueling, make

•

sure the tank cap is closed properly and securely.

Be careful not to spill fuel when refueling. Spilled

•

fuel or fuel vapor may ignite. If any fuel is spilled,

make sure the area is dry before starting the engine.

Avoid repeated or prolonged contact with skin or

•

breathing of vapor.

Fuel Level Indicator

Top View

Figure 2-4: The fuel level indicator

Checking the Fuel Level

IMPORTANT: Before refueling, allow engine to cool

two minutes.

Clean around fuel fill before removing cap to fuel.

1.

A fuel level indicator is located in the fuel tank. Fill

2.

tank until fuel reaches the fuel level indictor, Figure

2-4. Be careful not to overfill.

4

Page 5

Starting the Engine

WARNING: Always keep hands and

feet clear of moving parts. Do not use

a pressurized starting fluid. Vapors are

flammable.

2

NOTE: Allow the engine to warm up for a few minutes after starting. The engine will not develop full

power until it reaches operating temperatures.

Engines with Electric Starters

WARNING: The electric starter is

equipped with a grounded three-wire

power cord and plug, and is designed

to operate on 120 volt AC household

current. It must be used with a properly grounded

three-prong receptacle at all times to avoid the

possibility of electric shock. Follow all instructions

carefully prior to operating the electric starter.

WARNING: DO NOT use electric starter

in rain.

Determine that your home’s wiring is a three-wire

1.

grounded system. Ask a licensed electrician if you

are unsure. If you have a grounded three-prong

receptacle, proceed as follows. If you do not have

the proper house wiring, DO NOT use the electric

starter under any conditions.

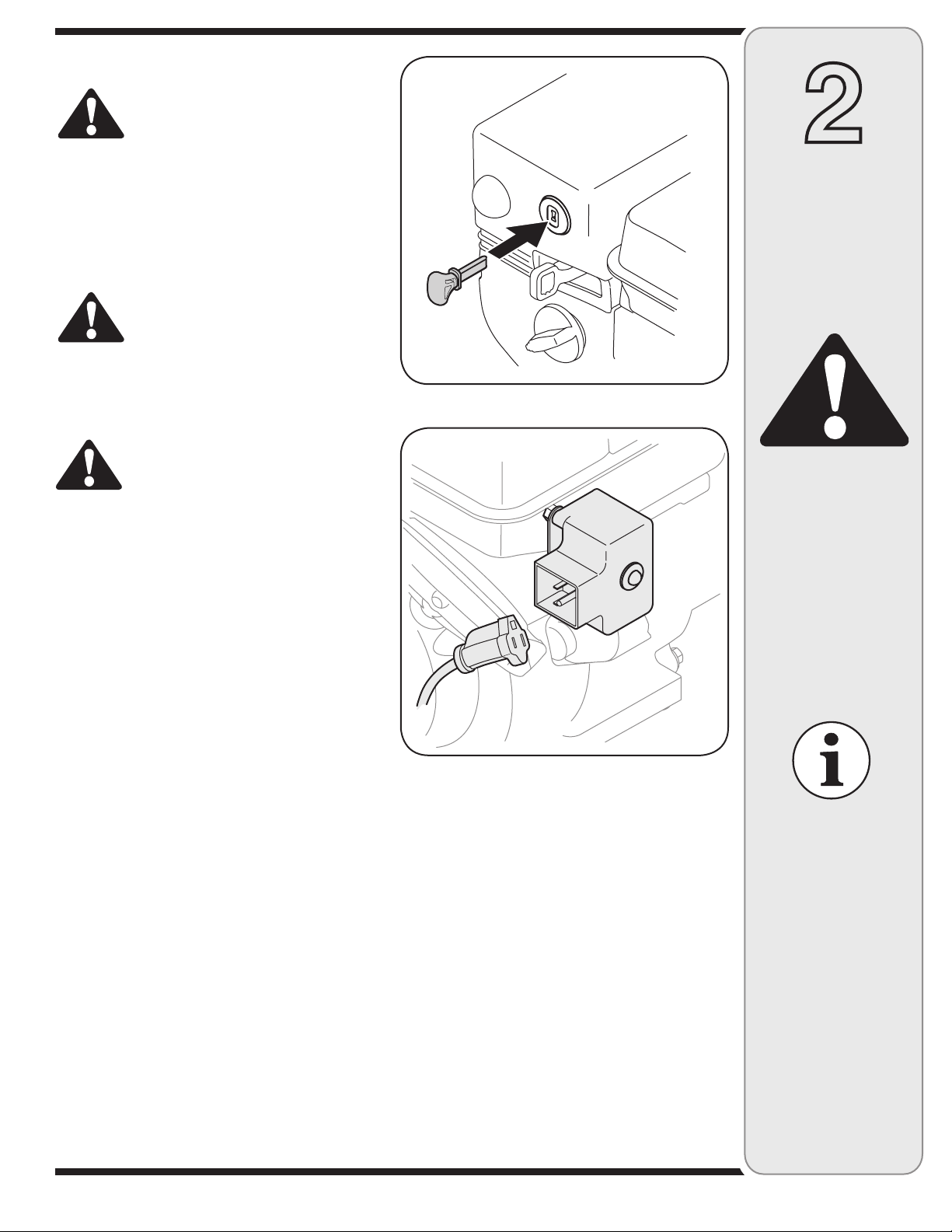

Insert ignition key fully into slot, Figure 2-5. Make

2.

sure it snaps into place. DO NOT turn ignition

key. The engine cannot start unless the key is

inserted into ignition switch.

Plug the extension cord into the electric switch box

3.

located on the engine, Figure 2-6. Plug the other

end of extension cord into a three-prong 120-volt,

grounded, AC outlet in a well-ventilated area.

Move throttle control, Figure 2-1, to FAST (rabbit)

4.

position.

Move choke to the ON position (cold engine start).

5.

If engine is warm, place choke in OFF position,

Figure 2-1.

Push primer three to five (3-5) times, making sure

6.

to cover vent hole when pushing, Figure 2-1. If

engine is warm, push primer only once. Always

cover vent hole when pushing. Cool weather may

require priming to be repeated.

Push starter button to start engine, Figure 2-1.

7.

Once the engine starts, immediately release

starter button. Electric starter is equipped with

thermal overload protection; system will temporarily

shut-down to allow starter to cool if electric starter

becomes overloaded.

Figure 2-5: The ignition key is a safety device.

Figure 2-6: Plug cord into electric switch box on engine.

As the engine warms, slowly rotate the choke control

8.

to OFF position. If the engine falters, restart engine

and run with choke at half-choke position for a short

period of time, and then slowly rotate the choke into

OFF position.

After engine is running, disconnect power cord from

9.

electric starter. When disconnecting, always unplug

the end at the wall outlet before unplugging the

opposite end from the engine.

Operating

the

Engine

WARNING

WARNING: The optional

electric starter is equipped

with a grounded three-wire

power cord and plug, and is

designed to operate on 120

volt AC household current.

It must be used with a properly grounded three-prong

receptacle at all times to

avoid the possibility of

electric shock.

IMPORTANT: This engine

is shipped without gasoline or oil in the engine.

Running the engine with

insufficient oil can cause

serious engine damage and

void the engine warranty.

5

Page 6

2

Operating

the

Engine

WARNING

WARNING: To avoid

unsupervised engine

operation, never leave the

engine unattended while

running. Turn the engine

off after use and remove

ignition key

Engines with Starter Handle

(non-electric start)

IMPORTANT: Do not pull the starter handle with

engine running.

Insert ignition key fully into slot, Figure 2-4. Make

1.

sure it snaps into place. DO NOT turn ignition key.

The engine cannot start unless the key is inserted

into ignition switch.

Move throttle, Figure 2-1, control to FAST (rabbit)

2.

position.

Move choke, Figure 2-1, to the ON position (cold

3.

engine start). If engine is warm, place choke in OFF

position.

Push primer three to five (3-5) times, making sure to

4.

cover vent hole when pushing, Figure 2-1. If engine

is warm, push primer only once. Always cover vent

hole when pushing. Cool weather may require

priming to be repeated.

Pull gently on the starter handle until it begins to

5.

resist, then pull quickly and forcefully to overcome

the compression. Do not release the handle and allow it to snap back. Return rope SLOWLY to original

position. If required, repeat this step.

As the engine warms, slowly rotate the choke

6.

control to OFF position. If the engine falters, restart

engine and run with choke at half-choke position

for a short period of time, and then slowly rotate the

choke into OFF position.

Stopping the Engine

WARNING: To avoid unsupervised engine operation, never leave the engine

unattended while running. Turn the

engine off after use and remove ignition key

Run engine for a few minutes before stopping to help dry

off any moisture on the engine.

Move throttle control to STOP position.

1.

Remove the ignition key. Removing the key will

2.

reduce the possibility of unauthorized starting of the

engine while equipment is not in use. Keep the key

in a safe place. The engine cannot start without

the ignition key.

Wipe any moisture away from the controls on the

3.

engine.

IMPORTANT: Do not allow

the starter handle to snap

back against the engine.

Return it gently to prevent

damage to the starter.

6

Page 7

WARNING: Shut off the engine before

performing any type of maintenance.

To prevent accidental start-up, disconnect the spark plug boot.

IMPORTANT: If engine must be tipped to transport

equipment or to inspect, keep spark plug side of engine up. Transporting or tipping engine with spark

plug down may cause smoking, hard starting, spark

plug fouling, or oil saturation of air cleaner.

Periodic inspection and adjustment of the engine is

essential if high level performance is to be maintained.

Regular maintenance will also ensure a long service life.

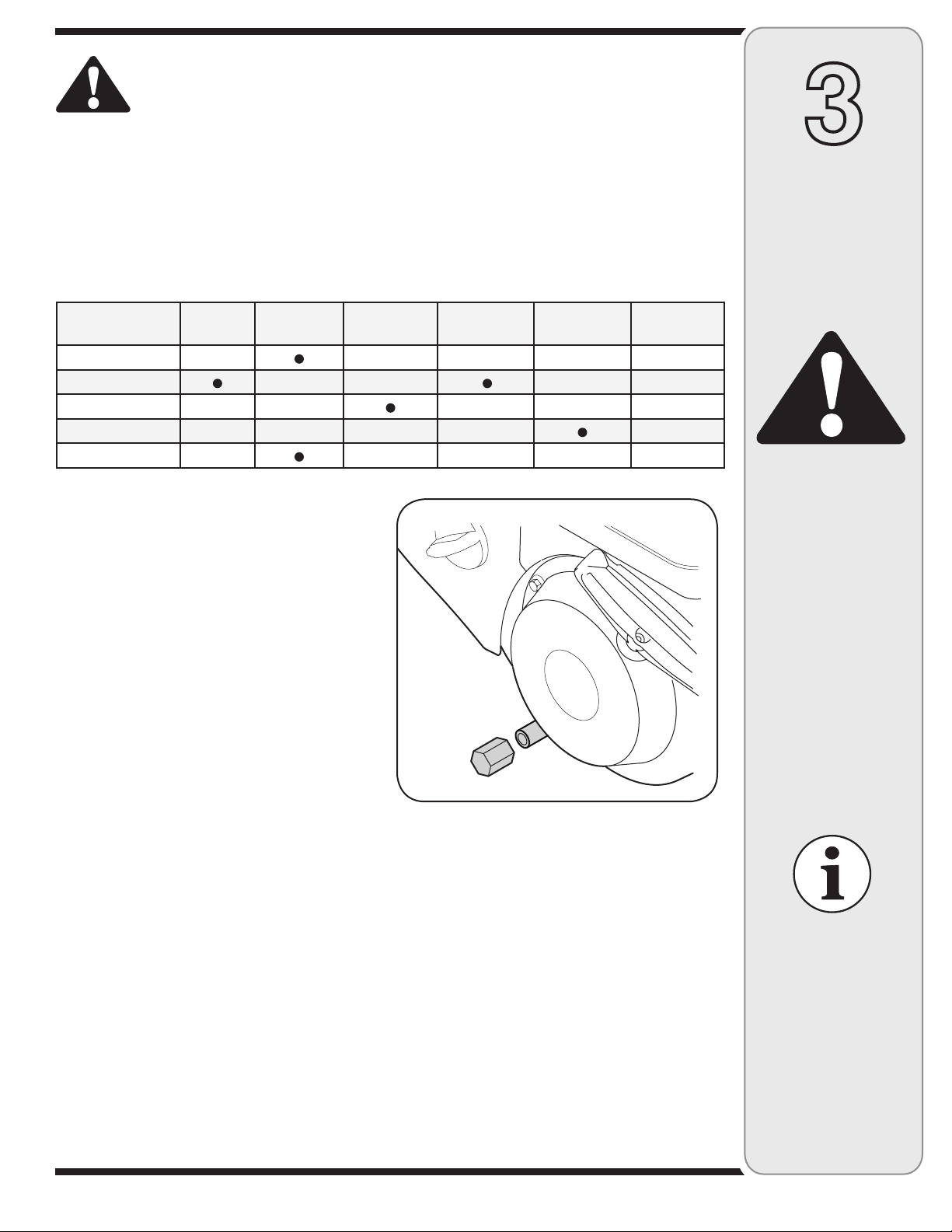

The required service intervals and the type of maintenance to be performed are described in the table below.

Follow the hourly or calendar intervals, whichever occur

first. More frequent service is required when operating in

adverse conditions.

3

Maintaining

the

Maintenance Schedule

Tasks First 5

Hrs.

Check engine oil

Change engine oil

Check spark plug

Service spark plug

Clean exhaust area

Each Use or

Every 5 Hrs.

Every Season

or 25 Hrs.

Every Season

Oil Service

Check oil level regularly.

•

Be sure correct oil level is maintained. Check every

•

five hours or daily before starting engine. See oil

checking procedure in the Operation section.

Oil Change

IMPORTANT: Be sure to check engine on a level

surface with the engine stopped. Drain the oil while

the engine is still warm to assure rapid and complete

draining.

Drain fuel from tank by running engine until the fuel

1.

tank is empty. Be sure fuel fill cap is secure.

Place suitable oil collection container under oil drain

2.

plug.

Remove oil drain plug, Figure 3-1.

3.

Tip engine to drain oil into the container. Used oil

4.

must be disposed of at a proper collection center.

Reinstall the drain plug and tighten it securely.

5.

Refill with the recommended oil and check the oil

6.

level, refer to Operation section for instructions.

Reinstall the oil filler cap/dipstick securely.

7.

IMPORTANT: Used motor oil may cause skin cancer

if repeatedly left in contact with the skin for prolonged periods. Although this is unlikely unless you

handle used oil on a daily basis, it is still advisable

to thoroughly wash your hands with soap and water

as soon as possible after handling used oil.

Oil

Drain

Plug

Figure 3-1: Remove the oil drain plug to drain oil from engine.

NOTE: Please dispose of used motor oil in a manner

that is compatible with the environment. We suggest

you take it in a sealed container to your local service

station for reclamation. Do not throw it in the trash or

pour it on the ground.

or 50 Hrs.

Oil Drain

Every Season

or 100 Hrs.

Engine

Service Dates

WARNING

WARNING: Shut off the

engine before performing

any type of maintenance.

To prevent accidental

start-up, disconnect the

spark plug boot.

Before tipping engine or

equipment to drain oil,

drain fuel from tank by

running engine until fuel

tank is empty.

IMPORTANT: Be sure to

check engine on a level

surface with the engine

stopped. Drain the oil

while the engine is still

warm to assure rapid and

complete draining.

7

Page 8

Spark Plug Service

3

Maintaining

the

Engine

WARNING

DO NOT check for spark

with spark plug removed.

DO NOT crank engine

with spark plug removed.

If the engine has been

running, the muffler will

be very hot. Be careful

not to touch the muffler.

WARNING: DO NOT check for spark

with spark plug removed. DO NOT

crank engine with spark plug removed.

WARNING: If the engine has been running, the muffler will be very hot. Be

careful not to touch the muffler.

To ensure proper engine operation, the spark plug must

be properly gapped and free of deposits.

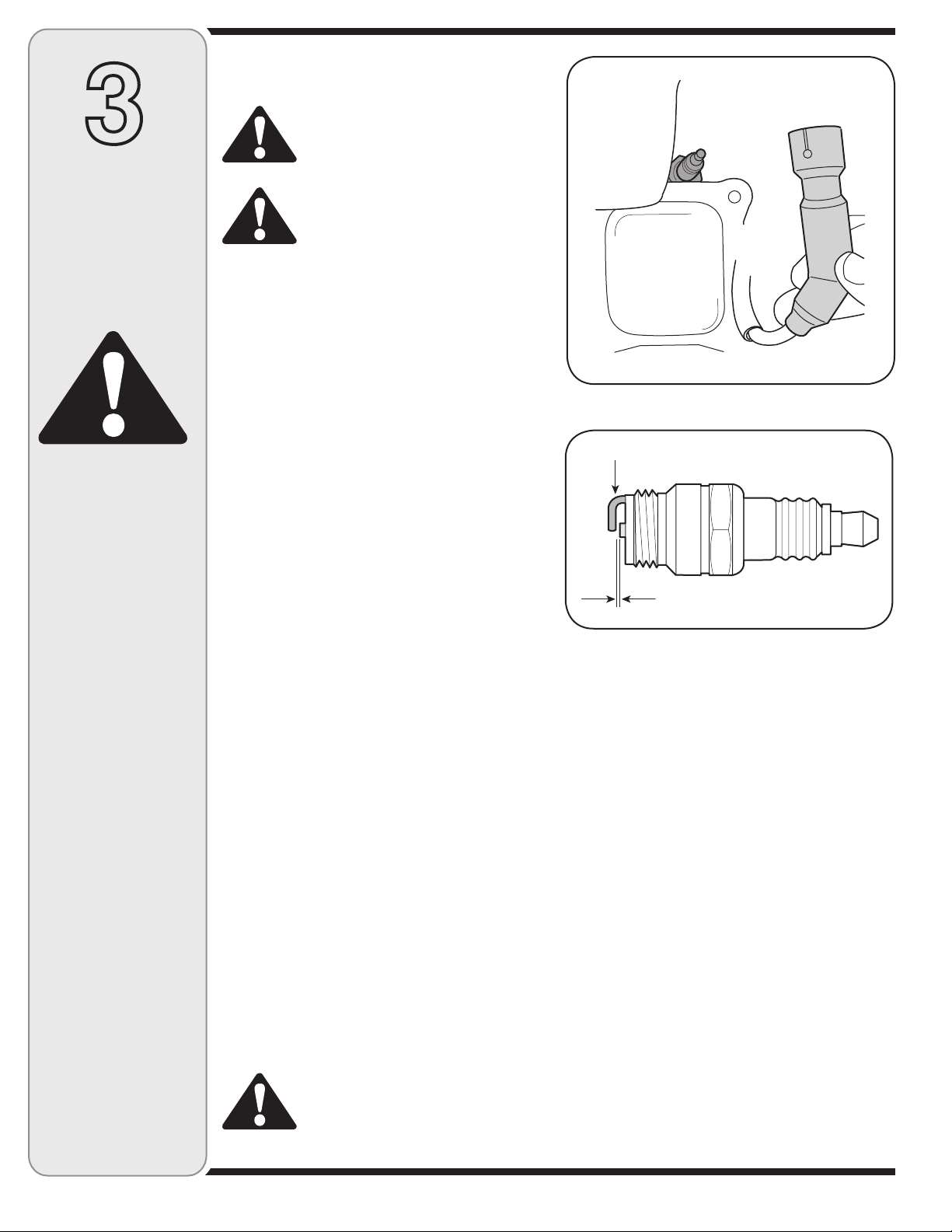

Remove the spark plug boot and use a spark plug

1.

wrench to remove the plug, Figure 3-2.

Visually inspect the spark plug. Discard the spark

2.

plug if there is apparent wear, or if the insulator is

cracked or chipped. Clean the spark plug with a wire

brush if it is to be reused.

Measure the plug gap with a feeler gauge. Correct

3.

as necessary by bending side electrode, Figure 3-3.

The gap should be set to 0.02-0.03 inches (0.60-

0.80 mm).

Check that the spark plug washer is in good condi-

4.

tion and thread the spark plug in by hand to prevent

cross-threading.

After the spark plug is seated, tighten with a spark

5.

plug wrench to compress the washer.

NOTE: When installing a new spark plug, tighten

1/2 turn after the spark plug seats to compress the

washer. When reinstalling a used spark plug, tighten

1/8-1/4 turn after the spark plug seats to compress

the washer.

Spark Plug

Spark Plug Boot

Figure 3-2: The spark plug and boot.

Electrode

0.02-0.03 in.

0.60-0.80 mm

Figure 3-3: Use a feeler gauge to measure the plug gap.

IMPORTANT: The spark plug must be tightened

securely. An loose spark plug can become very hot

and can damage the engine.

Cleaning the Engine

If the engine has been running, allow it to cool for at least

half an hour before cleaning. Periodically remove dirt

build-up from engine.

IMPORTANT: Do not spray engine with water to

clean because water could contaminate fuel. Using

a garden hose or pressure washing equipment can

also force water into the muffler opening. Water that

passes through the muffler can enter the cylinder,

causing damage.

WARNING: Accumulation of debris

around muffler could cause a fire.

Inspect and clean before every use.

8

Page 9

Storage

Engines stored over 30 days need to be drained of fuel to prevent deterioration and gum from forming in fuel system

or on essential carburetor parts. If the gasoline in your engine deteriorates during storage, you may need to have the

carburetor, and other fuel system components, serviced or replaced.

Remove all fuel from tank by running engine until it stops from lack of fuel.

1.

Change oil. See Oil Change section.

2.

Remove spark plug and pour approximately 1 oz. (30 ml) of clean engine oil into the cylinder. Pull the recoil

3.

starter several times to distribute the oil, and reinstall the spark plug.

Clean debris from around engine, and under, around, and behind muffler. Apply a light film of oil on any areas that

4.

are susceptible to rust.

Store in a clean, dry and well ventilated area away from any appliance that operates with a flame or pilot light,

•

such as a furnace, water heater, or clothes dryer. Avoid any area with a spark producing electric motor, or where

power tools are operated.

If possible, avoid storage areas with high humidity.

•

Keep the engine level in storage. Tilting can cause fuel or oil leakage.

•

Removing From Storage

Check your engine as described in the Pre-Operation Check section in this manual.

1.

If the fuel was drained during storage preparation, fill the tank with fresh gasoline. If you keep a container of

•

gasoline for refueling, make certain it contains only fresh fuel. Gasoline oxidizes and deteriorates over time,

causing hard starting.

If the cylinder was coated with oil during storage preparation, the engine will smoke briefly at startup. This is

•

normal.

3

Maintaining

the

Engine

WARNING

Accumulation of debris

around muffler could

cause a fire. Inspect and

clean before every use.

IMPORTANT: Do not

spray engine with water

to clean because water

could contaminate fuel.

Using a garden hose

or pressure washing

equipment can also force

water into the air cleaner

or muffler opening. Water

in the air cleaner will soak

the paper element, and

water that passes through

the element or muffler

can enter the cylinder,

causing damage.

9

Page 10

4

Trouble-

shooting

For repairs beyond the

minor adjustments listed

here, contact an authorized service dealer.

Troubleshooting

For repairs beyond the minor adjustments listed here, contact an authorized service dealer.

Problem Cause Solution

Engine fails to start Engine flooded from excessive

Engine runs erratically Spark plug wire loose

Engine overheats Engine oil level low1. Fill engine with proper amount of

1.

priming

Spark plug wire disconnected

2.

Fuel tank empty or stale fuel

3.

Engine not choked

4.

Faulty spark plug

5.

Engine not primed

6.

Ignition key installed improperly

7.

Throttle in stop position

8.

1.

Spark plug scorched, defective, or

2.

electrode gap set incorrectly

Stale fuel

3.

Unit running with choke on

4.

Water or dirt in fuel system

5.

Wait at least ten minutes before

1.

starting

Connect wire to spark plug

2.

Fill tank with clean, fresh gasoline

3.

Choke engine

4.

Clean, adjust gap, or replace

5.

Prime engine 3-5 times

6.

Insert ignition key all the way

7.

Move throttle to FAST/RUN position

8.

Connect and tighten spark plug wire

1.

Re-adjust electrode gap or change

2.

spark plug

Fill tank with clean, fresh gasoline

3.

Move choke to off

4.

Drain fuel tank. Refill with fresh fuel.

5.

1.

engine oil.

10

Page 11

MTD LLC (MTD), The United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

The U. S. EPA and MTD are pleased to explain the emissions control system warranty on your model year 2005 and later small off-road engine.

New small off-road engines must be designed, built and equipped to meet the stringent anti-smog standards. MTD must warranty the emission

control system on your engine for the period of time listed below, provided there has been no abuse, neglect or improper maintenance of your small

off-road engine.

Your emission control system may include parts such as the carburetor, air cleaner, ignition system, exhaust system, and other associated emission-related components.

Where a warrantable condition exists, MTD will repair your small off-road engine at no cost to your including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emission-related part on your engine is defective, the part will be repaired or

replaced by MTD.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual. MTD

recommends that you retain all your receipts covering maintenances on your small off-road engine, but MTD can not deny warranty solely for the

lack of receipts or for your failure to ensure the performance to all scheduled maintenance.

As the small off-road engine owner, you should however be aware that MTD may deny your warranty coverage if your small off-road engine or part

has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to an Authorized MTD Service Dealer as soon as a problem exists. The warranted

repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact a MTD Service Representative at 1-800-668-1238

and address is MTD Products Ltd., P. O,. Box 1386, 97 Kent Avenue, Kitchener, Ontario Canada N2 G 4J1.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGINES:

This section applies to 1995 and later small off-road engines. The warranty period begins on the date the engine or equipment is delivered to an

ultimate purchaser.

(a) General Emissions Warranty Coverage

MTD must warrant to the ultimate purchaser and each subsequent purchaser that the engine is:

(1) Designed, built, and equipped so as to conform with all applicable regulations adopted by the Air Resources Board pursuant to its authority in

Chapters 1 and 2,Part 5, Division 26 of the Health and Safety Code; and

(2) Free from defects in materials and workmanship that cause the failure of a warranted part to be identical in all material respects to the part as

described in the engine manufacturer’s application for certification for a period of two years.

(b) The warranty on emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written instructions required by Subsection (c)

must be warranted for the warranty period defined in Subsection (a)(2). If any such part fails during the period of warranty coverage, it must be

repaired or replaced by MTD according to Subsection (4) below. Any such part repaired or replaced under the warranty must be warranted for

the remaining warranty period.

(2) Any warranted part that is scheduled only for regular inspection in the written instructions required by Subsection (c) must be warranted for

the warranty period defined in Subsection (a)(2). A statement in such written instructions to the effect of “repair or replace as necessary” will

not reduce the period of warranty coverage. Any such part repaired or replaced under warranty must be warranted for the remaining warranty

period.

(3) Any warranted part that which is scheduled for replacement as required maintenance in the written instructions required by Subsection (c)

must be warranted for the period of time prior to the first scheduled replacement point for that part. If the part fails prior to the first scheduled

replacement, the part must be repaired or replaced by MTD according to Subsection (4) below. Any such part repaired or replaced under

warranty must be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no charge to the owner at a

warranty station.

(5) Notwithstanding the provisions of Subsection (4) above, warranty services or repairs must be provided at all MTD distribution centers that

are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact defective, provided that

such diagnostic work is performed at a warranty station.

11

EPA-1-CA

Page 12

(7) The engine manufacturer is liable for damages to other engine components proximately caused by a failure under warranty of any warranted

part.

(8) Throughout the engine’s warranty period defined in Subsection (a)(2), MTD will maintain a supply of warranted parts sufficient to meet the

expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to the

owner. Such use will not reduce the warranty obligations of MTD.

(10) Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any non-exempted add-on or

modified parts shall be grounds for disallowing a warranty claim made in accordance with this article. The engine manufacturer shall not be

liable under this article to warrant failures of warranted parts caused by the use of non-exempted add-on or modified part.

(c) MTD will include a copy of the following emission warranty parts list with each new engine, using those portions of the list applicable to the

engine.

(1) Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

(2) Air Induction System

• Air cleaner

• Intake manifold

(3) Ignition System

• Spark plug(s)

• Magneto Ignition System

(4) Exhaust System

(5) Miscellaneous Items Used in Above System

• Vacuum, temperature , position, time sensitive valves and switches

• Connectors and assemblies

12

EPA-1

Page 13

EPA-1-CA

12

• Raccords et ensembles

• Soupapes de dépression, thermocontacts, soupapes de positionnement et à action minutée et interrupteurs

(5) Divers articles utilisés dans le système ci-dessus

(4) Système d’échappement

• Système d’allumage à magnéto

• Bougie(s)

(3) Système d’allumage

• Tubulure d’admission

• Filtre à air

(2) Système d’admission de l’air

• Pompe à carburant0

• Carburateur et pièces internes

• Système d’enrichissement du carburant pour démarrages à froid

(1) Système de dosage du carburant

avec chaque moteur neuf utilisant les parties de la liste qui s’appliquent au moteur.

(c) MTD fournira une copie de la liste suivante des pièces du système antipollution sous garantie

modifiée non exemptée.

moteur ne sera pas tenu, en vertu de cet article, de garantir les pièces garanties si leur défaillance a été causée par l’utilisation d’une pièce complémentaire ou

pièce complémentaire ou modifiée non exemptée sera suffisant pour rejeter une demande d’application de la garantie en vertu de cet article. Le fabricant du

(10) Les pièces complémentaires ou modifiées qui ne sont pas exemptées par le « Air Resources Board » ne peuvent toutefois pas être utilisées. L’emploi de toute

les obligations de garantie de MTD.

(9) Toute pièce de remplacement peut être utilisée pour l’entretien ou la réparation sous garantie et doit être fournie gratuitement au propriétaire. Ceci ne limite pas

Page 14

EPA-1-CA

11

stipulée au paragraphe (a)(2).

(8) MTD s’engage à conserver un stock de pièces garanties suffisant pour satisfaire la demande prévue pour ces pièces pendant la période de garantie du moteur

garantie.

(7) Le fabricant du moteur est tenu responsable des dégâts aux autres pièces du moteur susceptibles d’avoir été causés par la panne sous garantie d’une pièce

une station technique autorisée à offrir les services sous garantie.

(6) Les diagnostics permettant d’établir qu’une pièce garantie est défectueuse doivent être effectués sans frais pour le propriétaire, à condition d’être réalisés par

cessionnaires MTD autorisés à entretenir les moteurs en question.

(5) Nonobstant les termes du paragraphe (4) ci-dessus, les services ou réparations sous garantie doivent être effectués dans tous les centres de distribution/con-

sans frais pour le propriétaire.

(4) La réparation ou le remplacement de toute pièce garantie en vertu de la garantie énoncée dans cet article doit être effectuée par une station technique agréée,

de la période de garantie avant le premier intervalle de remplacement prévu de la pièce.

réparée ou remplacée par MTD conformément au paragraphe (4) ci-dessous. Toute pièce réparée ou remplacée sous garantie doit être garantie pour le solde

pour la période précédant le premier remplacement prévu. Si la pièce tombe en panne avant le premier intervalle de remplacement prévu, la pièce doit être

(3) Toute pièce garantie pour laquelle les instructions écrites du paragraphe (c) prévoient le remplacement dans le cadre d’un entretien requis doit être garantie

de garantie. Toute pièce réparée ou remplacée en vertu de la garantie doit être garantie pour le solde de la période de garantie.

garantie spécifiée dans le paragraphe (a)(2). La mention dans les instructions écrites de « réparer ou remplacer selon le besoin » ne raccourcit pas la période

(2) Toute pièce garantie pour laquelle les instructions écrites du paragraphe (c) prévoient seulement une inspection régulière doit être garantie pour la période de

le solde de la période de garantie.

réparée ou remplacée par MTD conformément au paragraphe (4) ci-dessous. Toute pièce réparée ou remplacée en vertu de la garantie doit être garantie pour

être garantie pour la période de garantie spécifiée dans le paragraphe (a)(2). Si une telle pièce tombe en panne pendant la période de garantie, elle doit être

(1) Toute pièce garantie pour laquelle les instructions écrites du paragraphe (c) ne prévoient pas le remplacement dans le calendrier des entretiens requis doit

(b) La garantie des pièces du système antipollution sera interprétée comme suit :

demande de certification du fabricant du moteur, pour une période de deux ans.

(2) est exempt de tout vice de matière et de fabrication susceptible de causer la défaillance d’une pièce garantie, en tous points identique à la pièce décrite dans la

dans les Chapitres 1 et 2, Partie 5, Division 26 du Code de la santé et de la sécurité ; et

(1) a été conçu, construit et équipé conformément à tous les règlements applicables, adoptés par le « Air Resources Board », en vertu de son autorité, et énoncés

MTD doit garantir à l’acheteur au détail initial et à chaque acheteur successif que le moteur :

(a) Protection offerte par la garantie du système antipollution

est livré à l’acheteur au détail initial.

Cette section concerne les petits moteurs hors route fabriqués en 1995 et ultérieurement. La période de garantie commence le jour où le moteur ou l’équipement

FABRIQUÉS EN 1995 ET ULTÉRIEUREMENT

TERMES DE LA GARANTIE DESc PETITS MOTEURS HORS ROUTE

appelant le 1-800-668-1238 ou en écrivant à MTD Products Ltd., P. O. Box 1386, Kitchener, Ontario Canada N2G 4J1.

Pour toute question concernant vos droits et responsabilités en vertu de cette garantie, adressez-vous au représentant des services techniques de MTD en

devraient être effectuées dans un délai raisonnable ne dépassant pas 30 jours.

Le propriétaire est tenu de présenter le petit moteur hors route à une station technique agréée dès l’apparition d’un problème. Les réparations sous garantie

pièces a fait l’objet d’abus, de négligence, d’un entretien incorrect ou de modifications non approuvées.

Le propriétaire du petit moteur hors route doit toutefois savoir que MTD peut refuser d’honorer la garantie si le petit moteur hors route ou l’une quelconque de ses

cause de l’absence de reçus ou à cause du manquement à effectuer l’entretien requis.

conserver tous les reçus se rapportant à l’entretien du petit moteur hors route. Toutefois, MTD ne peut pas refuser les réclamations sous garantie uniquement à

Le propriétaire de tout petit moteur hors route est tenu de respecter le calendrier des entretiens requis énoncés dans la notice d’utilisation. MTD recommande de

RESPONSABILITÉS DU PROPRIÉTAIRE :

remplacée par MTD.

Le système antipollution est garanti pour une période de deux ans. Toute pièce annexe du système antipollution du moteur jugée défectueuse sera réparée ou

GARANTIE DU FABRICANT :

nécessaires, si la situation est couverte par la garantie.

MTD s’engage à effectuer, sans frais pour le propriétaire, les réparations du petit moteur hors route, y compris les diagnostics, les pièces et la main d’œuvre

système antipollution.

Le système antipollution peut inclure les pièces suivantes : carburateur, filtre à air, système d’allumage, système d’échappement et autres pièces annexes du

moteur pour la durée stipulée ci-dessous, à condition que le petit moteur hors route n’ait pas fait l’objet d’abus, de négligence ou d’un entretien incorrect.

moteurs hors route neufs doivent être conçus, fabriqués et équipés conformément aux normes antipollution strictes. MTD doit garantir le système antipollution du

C’est avec plaisir que l’U.S. EPA et MTD présentent la garantie du système antipollution du petit moteur hors route fabriqués en 2005 et ultérieurement. Les petits

(Droits et obligations du propriétaire en vertu de la garantie)

Déclaration de garantie du système antipollution

MTD LLC (MTD) et l’Agence de protection de l’environnement des États-Unis (U.S. EPA)

Page 15

10

recommandée.

Le moteur surchauffe. 1. Le niveau d’huile est bas. 1. Versez la quantité d’huile à moteur

fraîche.

le plein avec une essence propre et

5. Videz le réservoir de carburant. Faites

4. Fermez le volet de départ.

propre et fraîche.

3. Faites le plein avec une essence

remplacez-la.

2. Ajustez l’écartement de la bougie ou

1. Branchez et serrez le fil de la bougie.

Rapide/Marche.

8. Placez l’obturateur à la position

contact.

7. Enfoncez complètement la clé de

6. Amorcez 3 à 5 fois le moteur.

remplacez la bougie.

5. Nettoyez et ajustez l’écartement ou

4. Fermez le volet de départ.

propre et fraîche.

3. Faites le plein avec une essence

2. Branchez le fil de la bougie.

remettre en marche.

1. Attendez 10 minutes au moins avant de

-

système.

5. Présence d’eau ou de saleté dans le

4. Le volet de départ est fermé.

3. L’essence est éventée.

fectueuse ou l’écartement est incorrect.

2. La bougie est endommagée, dé

1. Le fil de la bougie est desserré.

8. L’obturateur est en position Arrêt.

enfoncée.

7. La clé de contact n’est pas bien

6. Le moteur n’a pas été amorcé.

5. La bougie est défectueuse.

4. Le volet de départ n’est pas utilisé.

l’essence est éventée.

3. Le réservoir de carburant est vide ou

2. Le fil de la bougie est débranché.

amorçage répété.

1. Le moteur est noyé en raison d’un

façon irrégulière.

Le moteur tourne de

pas.

Le moteur ne démarre

énumérés ici.

que les réglages mineurs

pour toute réparation autre

station technique agréée

Adressez-vous à une

des pannes

Détection

Problème Cause Solution

4

Adressez-vous à une station technique agréée pour toute réparation autre que les réglages mineurs énumérés ici.

Détection des pannes

Page 16

9

moteur.

endommager ainsi le

dans le silencieux et

la cartouche et pénétrer

détrempé, peut atteindre

d’un élément en papier

par l’intermédiaire

du silencieux. L’eau,

à air ou dans l’ouverture

forcer l’eau dans le filtre

sous pression peut aussi

équipement de lavage

tuyau d’arrosage ou d’un

l’essence. L’emploi d’un

risque de contaminer

avec un jet d’eau qui

toyez pas le moteur

IMPORTANT : Ne net-

avant chaque emploi.

Examinez-le et nettoyez-le

peut causer un incendie.

autour du silencieux

L’accumulation de débris

AVERTISSEMENT

du moteur

Entretien

fait normal.

• Si le cylindre a été enduit d’huile pour le remisage, le moteur dégagera de la fumée à la mise en route. C’est tout à

causera des démarrages difficiles.

l’essence dans tout contenant est propre et fraîche. L’essence a tendance à s’oxyder et à se détériorer, ce qui

• Si le carburant a été vidé avant de remiser la tondeuse, faites le plein avec de l’essence fraîche. Vérifiez que

1. Vérifiez le moteur en suivant les instructions dans le chapitre « Avant l’emploi » dans cette notice d’utilisation.

Remise en service

• Placez le moteur sur une surface plane car toute inclinaison risque de causer une fuite d’huile ou d’essence.

• Dans la mesure du possible, évitez de remiser la tondeuse dans un local très humide.

produire des étincelles sont utilisés.

rifère, chauffe-eau ou sèche-linge). Évitez tout endroit où un moteur électrique ou des outils électriques pouvant

• Remisez le moteur dans un local propre, sec et bien aéré, loin de tout appareil à veilleuse ou flamme nue (calo-

parties susceptibles de rouiller avec une légère couche d’huile.

4. Retirez les débris d’herbe et autres qui se trouvent autour du moteur et aux alentours du silencieux. Recouvrez les

le démarreur à lanceur pour bien répartir l’huile et replacez la bougie.

3. Retirez la bougie et versez environ une (1) once (30 mL) d’huile à moteur dans le cylindre. Tirez plusieurs fois sur

2. Changez l’huile. Voir la section « Vidange d’huile ».

1. Videz le carburant du réservoir en laissant tourner le moteur jusqu’à ce qu’il tombe en panne d’essence.

3

carburateur et les autres pièces par une station technique.

le moteur se détériore pendant le remisage, il sera peut-être nécessaire de faire examiner, et peut-être remplacer, le

formation de gomme dans les canalisations d’essence ou sur les pièces principales du carburateur. Si l’essence dans

Un moteur remisé pendant plus de 30 jours doit être vidé de tout carburant pour empêcher toute détérioration et toute

Remisage

Page 17

8

avant chaque emploi de la tondeuse.

un incendie. Examinez et nettoyez

débris autour du silencieux peut causer

AVERTISSEMENT : L’accumulation de

trer dans le cylindre et endommager le moteur.

air ou dans l’ouverture du silencieux, la faire pénésous pression peut aussi forcer l’eau dans le filtre à

d’un tuyau d’arrosage ou d’un équipement de lavage

d’eau qui risque de contaminer l’essence. L’emploi

IMPORTANT : Ne nettoyez pas le moteur avec un jet

avec une brosse ou de l’air comprimé.

le dispositif de protection et les alentours du silencieux

souvent les débris accumulés sous le moteur. Nettoyez

au moins une demi-heure avant de le nettoyer. Éliminez

Si le moteur a fonctionné, laissez-le refroidir pendant

Nettoyage du moteur

Gaine de la bougie

0,60 - 0,80 mm

0,02 - 0.03 po

Bougie

Figure 3-3: Mesurez l’écartement avec une jauge d’écartement.

Électrode

Figure 3-2: Gaine de la bougie.

endommager le moteur.

bougie mal serrée peut chauffer excessivement et

IMPORTANT : La bougie doit être serrée à fond. Une

pour comprimer la rondelle.

1/8e à ¼ de tour quand la bougie est bien en place,

primer la rondelle. Si la bougie est usagée, faites de

un demi-tour quand elle est bien en place, pour comREMARQUE : Serrez la bougie neuve en lui donnant

clé à bougie pour comprimer la rondelle.

5. Quand la bougie est bien installée, serrez-la avec une

filets.

filetez la bougie à la main pour éviter de déformer les

4. Vérifiez que la rondelle de la bougie est en bon état et

entre 0,020 et 0,030 po (0,60 et 0,80 mm).

de côté. Voir la Figure 3-3. L’écartement doit mesurer

d’écartement. Ajustez au besoin en pliant l’électrode

3. Mesurez l’écartement de la bougie avec une jauge

voulez l’utiliser à nouveau.

Nettoyez la bougie avec une brosse à bougie si vous

paraît usée ou si l’isolateur est fendu ou écaillé.

2. Examinez soigneusement la bougie. Jetez-la si elle

bougie pour la démonter. Voir la Figure 3-2.

1. Dégagez la gaine de la bougie et utilisez une clé à

doit pas être encrassée.

l’écartement de la bougie doit être correct et la bougie ne

Pour assurer le bon fonctionnement du moteur,

le toucher.

arrêté. Faites très attention de ne pas

sera chaud si le moteur vient d’être

AVERTISSEMENT : Le silencieux

bougie n’est pas installée.

Ne faites pas tourner le moteur si la

de la bougie si celle-ci est débranchée.

AVERTISSEMENT : Ne vérifiez pas l’état

de ne pas le toucher.

rêté. Faites très attention

le moteur vient d’être arsilencieux sera chaud si

AVERTISSEMENT : Le

installée.

si la bougie n’est pas

pas tourner le moteur

débranchée. Ne faites

bougie si celle-ci est

vérifiez pas l’état de la

AVERTISSEMENT : Ne

AVERTISSEMENT

du moteur

Entretien

3

Page 18

plus facilement

pour que l’huile coule

moteur est encore chaud

l’huile pendant que le

une surface plane. Videz

l’équipement est sur

moteur à l’arrêt quand

IMPORTANT: Vérifiez le

d’essence.

ce qu’il tombe en panne

moteur tourner jusqu’à

réservoir en laissant le

vider l’huile, videz le

ou l’équipement pour

Avant d’incliner le moteur

gaine de la bougie.

accidentel, débranchez la

Pour éviter un démarrage

d’effectuer tout entretien.

Arrêtez le moteur avant

AVERTISSEMENT :

AVERTISSEMENT

7

ne la déversez pas sur le sol.

pourra la recycler. Ne la jetez pas dans les ordures et

dans un contenant fermé, à une station service qui

Nous vous conseillons de remettre l’huile usagée,

selon les règlements protégeant l’environnement.

REMARQUE : Veuillez disposer de l’huile usagée

Figure 3-1: Enlevez le bouchon de vidange de l’huile pour vider

l’huile

vidange de

Bouchon de

l’huile

Vidange de

7. Resserrez le capuchon/jauge à huile.

tionnement » pour plus de renseignements.

le niveau d’huile. Consultez le chapitre « Fonc-

6. Faites le plein avec l’huile recommandée et vérifiez

le à fond.

5. Replacez le bouchon de vidange de l’huile et serrez-

à un centre de recyclage.

Remettez l’huile usagée dans un récipient approprié

4. Videz l’huile en tournant le moteur sur le côté.

3. Retirez le bouchon de vidange de l’huile. Figure 3-1.

vidange de l’huile.

2. Placez un récipient approprié sous le bouchon de

que le capuchon est bien serré.

jusqu’à ce qu’il tombe en panne d’essence. Vérifiez

1. Videz le réservoir en laissant le moteur tourner

l’huile coule plus facilement

pendant que le moteur est encore chaud pour que

l’équipement est sur une surface plane. Videz l’huile

IMPORTANT : Vérifiez le moteur à l’arrêt quand

Vidange de l’huile

contact.

de l’eau et du savon dès que possible après tout

toutefois recommandé de se laver les mains avec

en cas de manipulation quotidienne de l’huile. Il est

prolongé avec la peau. Ceci est peu probable, sauf

le cancer de la peau en cas de contact répété et

IMPORTANT : L’huile à moteur usagée peut causer

heures

ou toutes les 100

Dates d’entretien

Chaque saison

heures

ou toutes les 50

Chaque saison

heures

ou toutes les 25

Chaque saison

les 5 heures

tion ou toutes

Chaque utilisa-

heures

premières

dans le chapitre « Fonctionnement ».

mettre le moteur en marche. Lisez les instructions

Vérifiez toutes les 5 heures ou chaque jour avant de

• Assurez-vous de maintenir l’huile au niveau correct.

• Vérifiez souvent le niveau d’huile.

Vidange de l’huile

Nettoyage du silencieux

Entretien de la bougie

Vérification de la bougie

moteur

Vidange de l’huile à

de l’huile à moteur

Vérification du niveau

Tâches Cinq

du moteur

Entretien

3

Calendrier des opérations d’entretien

à air par de l’huile.

l’encrassement de la bougie ou la saturation du filtre

provoquer de la fumée, des démarrages difficiles,

dans des conditions difficiles.

tervalles plus courts sont nécessaires en cas d’utilisation

horaires ou autres, selon ce qui survient d’abord. Des indans le tableau ci-dessous. Respectez les intervalles

mandés et les opérations à effectuer sont répertoriés

longue durée de vie. Les intervalles d’entretien recomL’entretien régulier du moteur garantira également sa

sont essentiels pour obtenir des performances optimales.

Une inspection et des réglages périodiques du moteur

débranchez la gaine de la bougie.

éviter un démarrage accidentel,

avant d’effectuer tout entretien. Pour

AVERTISSEMENT : Arrêtez le moteur

l’inclinaison du moteur du côté de la bougie peut

avec la bougie reste sur le dessus. Le transport ou

brins d’herbe, assurez-vous que le côté du moteur

transport, pour une inspection ou pour enlever les

IMPORTANT : Si le moteur doit être incliné pour le

Page 19

6

répétez l’opération.

revenir LENTEMENT à sa position initiale. Au besoin,

qu’elle ne frappe pas le moteur. Laissez la poignée

er » la compression. Ne lâchez pas la poignée pour

puis tirez rapidement et fermement pour « surmontjusqu’à ce que vous sentiez une légère résistance,

5. Tirez doucement sur la poignée du démarreur

plusieurs fois.

Par temps froid, il peut être nécessaire d’amorcer

sur l’amorceur. Recouvrez toujours le trou d’aération.

Si le moteur est chaud, appuyez seulement une fois

attention de bien couvrir le trou d’aération. Figure 2-1.

4. Appuyez sur l’amorceur de trois à cinq fois en faisant

placez le volet de départ à la position OFF.

rage d’un moteur froid). Si le moteur est chaud,

3. Placez le volet de départ à la position ON (démar-

position Rapide (Lapin).

2. Placez la commande de l’obturateur, Figure 2-1, à la

pas bien enfoncée dans le commutateur d’allumage.

Le moteur ne peut pas démarrer tant que la clé n’est

Vérifiez qu’elle s’emboîte bien. NE la tournez PAS.

1. Placez la clé de contact dans la fente. Figure 2-4.

reur quand le moteur tourne.

IMPORTANT : Ne tirez pas sur la poignée du démar-

(démarreur non électrique)

Moteurs à démarreur à lanceur

moteur.

3. Essuyez toute condensation sur les commandes du

lieu sûr. Le moteur ne peut pas démarrer sans la clé.

l’équipement n’est pas utilisé. Rangez la clé dans un

élimine le risque d’un démarrage non autorisé quand

2. Retirez la clé de contact. Le fait de retirer la clé

STOP.

1. Déplacez la commande de l’obturateur à la position

sur le moteur.

avant de l’arrêter pour éliminer toute humidité accumulée

Laissez le moteur tourner pendant quelques minutes

il tourne. Arrêtez-le après l’emploi et retirez la clé.

jamais le moteur sans surveillance quand

utilisation non surveillée, ne laissez

AVERTISSEMENT : Pour éviter toute

Arrêt du moteur

commande lentement vers la position OFF.

départ à la position intermédiaire. Déplacez ensuite la

et laissez-le tourner brièvement avec le volet de

position OFF. Si le moteur cale, remettez-le en marche

lentement la commande du volet de départ vers la

6. Au fur et à mesure que le moteur chauffe, tournez

débrancher du démarreur même.

toujours la rallonge de la prise murale avant de la

la rallonge du démarreur électrique. Débranchez

9. Quand le moteur tourne régulièrement, débranchez

OFF.

ensuite la commande lentement vers la position

volet de départ à la position intermédiaire. Déplacez

marche et laissez-le tourner brièvement avec le

la position OFF. Si le moteur cale, remettez-le en

lentement la commande du volet de départ vers

8. Au fur et à mesure que le moteur chauffe, tournez

surcharge.

pour permettre au démarreur de refroidir en cas de

thermique. Le système sera provisoirement arrêté

d’un dispositif de protection en cas de surcharge

moteur tourne. Le démarreur électrique est équipé

le moteur, Figure 2-1. Lâchez le bouton dès que le

7. Enfoncez le bouton du démarreur pour faire démarrer

plusieurs fois.

Par temps froid, il peut être nécessaire d’amorcer

sur l’amorceur. Recouvrez toujours le trou d’aération.

Si le moteur est chaud, appuyez seulement une fois

attention de bien couvrir le trou d’aération. Figure 2-1.

6. Appuyez sur l’amorceur de trois à cinq fois en faisant

2

démarreur.

d’endommager le

doucement pour éviter

le moteur. Ramenez-la

du démarreur frapper

laissez pas la poignée

IMPORTANT : Ne

l’emploi et retirez la clé.

il tourne. Arrêtez-le après

sans surveillance quand

laissez jamais le moteur

surveillée du moteur, ne

éviter toute utilisation non

AVERTISSEMENT : Pour

AVERTISSEMENT

du moteur

Fonctionnement

Page 20

5

si le système ne convient pas.

3 fiches mise à la masse. N’utilisez PAS le démarreur

volet de départ à la position OFF. Figure 2-1.

d’un moteur froid). Si le moteur est chaud, placez le

5. Placez le volet de départ à la position ON (démarrage

position Rapide (Lapin).

4. Placez la commande de l’obturateur, Figure 2-1, à la

garantie.

le moteur et annuler la

gravement endommager

d’huile insuffisante peut

moteur avec une quantité

ni huile. L’utilisation du

est expédié sans essence

IMPORTANT : Le moteur

120 volts mise à la masse dans un endroit bien aéré.

extrémité de la rallonge dans une prise de C.A. de

électrique sur le moteur, Figure 2-6. Branchez l’autre

3. Branchez la rallonge dans la boîte de commutation

d’allumage.

n’est pas bien enfoncée dans le commutateur

Le moteur ne peut pas démarrer tant que la clé

Vérifiez qu’elle s’emboîte bien. NE la tournez PAS.

2. Placez la clé de contact dans la fente. Figure 2-5.

sur le moteur.

Figure 2-6: Branchez la rallonge dans la boîte de commutation

démarreur par temps de pluie.

AVERTISSEMENT : N’utilisez pas le

démarreur électrique.

les instructions avant d’utiliser le

électrique. Suivez attentivement toutes

pour éviter tout risque de décharge

une prise à 3 fiches mise à la masse

volts. Il doit toujours être branché dans

dans une prise de C. A. normale de 120

mis à la masse et d’une fiche à brancher

trique est équipé d’un cordon à 3 fils

AVERTISSEMENT : Le démarreur élec-

Procédez comme suit si vous disposez d’une prise à

appel à un électricien licencié en cas de doute.

comprend un système à 3 fils mis à la masse. Faites

1. Vérifiez que l’installation électrique de votre domicile

démarreur électrique

Moteurs équipés d’un

décharge électrique.

pour éviter tout risque de

à 3 fiches mise à la masse

être branché dans une prise

120 volts. Il doit toujours

prise de C. A, normale de

fiche à brancher dans une

mis à la masse et d’une

équipé d’un cordon à 3 fils

démarreur électrique est

AVERTISSEMENT : Le

sont inflammables.

d’allumage sous pression. Les vapeurs

mouvement. N’utilisez pas de liquide

les mains et les pieds des pièces en

AVERTISSEMENT : N’approchez jamais

moteur

certaines températures.

n’atteint sa puissance maximale qu’à partir de

quelques minutes après le démarrage. Le moteur

REMARQUE : Laissez le moteur chauffer pendant

AVERTISSEMENT

du moteur

Fonctionnement

2

Mise en marche du

attention de ne pas déborder.

le carburant atteigne l’indicateur, Figure 2-4. Faites

Figure 2-5: La clé de contact est un dispositif de sécurité.

le réservoir. Remplissez le réservoir jusqu’à ce que

2. Un indicateur du niveau du carburant se trouve dans

plein.

avant de retirer le bouchon d’essence pour faire le

1. Nettoyez les alentours du goulot de remplissage

moins deux minutes avant de faire le plein

IMPORTANT : Laissez le moteur refroidir pendant au

burant

Vérification du niveau de car-

d’essence.

avec la peau et ne respirez pas les vapeurs

Évitez tout contact répété ou prolongé de l’essence

•

en marche.

éclaboussures ont séché avant de mettre le moteur

d’essence peuvent s’enflammer. Vérifiez que les

faisant le plein. Les éclaboussures et les vapeurs

Faites attention de ne pas renverser d’essence en

•

Page 21

carburant

du niveau de

de l’indicateur

Vue du dessus

Niveau de carburant

place et serré à fond.

sage). Vérifiez ensuite que le bouchon est bien en

doit pas y avoir d’essence dans le goulot de remplisNe remplissez pas excessivement le réservoir (il ne

vous remisez l’essence.

tondeuse pendant que vous faites le plein ou là où

aucune flamme nue ou étincelle à proximité de la

le moteur est arrêté. Ne fumez pas et n’autorisez

Faites le plein dans un endroit bien aéré quand

haut et bas.

repères

entre les

Remplissez

4

•

•

Figure 2-4: Indicateur du niveau de carburant.

d’exploser dans certaines situations.

produit très inflammable qui risque

AVERTISSEMENT : L’essence est un

réservoir. N’utilisez pas une essence E85.

la saleté, de la poussière ou de l’eau pénétrer dans le

d’essence ou une essence sale. Évitez de laisser de

être utilisée). N’utilisez jamais un mélange d’huile et

d’éthanol ou 15% de MTBE (méthyl-ter-butyléther) peut

de 87 minimum. Une essence contenant jusqu’à 10%

la chambre de combustion) ayant un indice d’octane

faible teneur en plomb pour minimiser les dépôts dans

Utilisez une essence automobile (sans plomb ou à

le carburant

Recommandations concernant

bougies.

des démarrages difficiles ou l’encrassement des

Une quantité excessive d’huile causera de la fumée,

IMPORTANT : Ne remplissez pas excessivement.

moteur en marche.

4. Vissez la jauge à huile à fond avant de mettre le

sur la jauge à huile. Figure 2-3.

d’huile se trouve entre les repères haut (H) et bas (L)

ajoutez lentement de l’huile jusqu’à ce que le niveau

3. Sortez la jauge à huile. Si le niveau d’huile est bas,

Figure 2-3: Vérification du niveau d’huile

sage de l’huile sans la visser.

2. Enfoncez la jauge à huile dans le goulot de remplis-

jauge à huile. Voir la Figure 2-3.

1. Enlevez le capuchon/jauge à huile et essuyez la

vérifier le niveau d’huile.

sur une surface plane et d’arrêter le moteur avant de

IMPORTANT : Assurez-vous de placer la tondeuse

mables.

Les vapeurs sont inflamd’allumage sous pression.

N’utilisez pas de liquide

pièces en mouvement.

mains et les pieds des

N’approchez jamais les

AVERTISSEMENT :

situations.

d’exploser dans certaines

très inflammable qui risque

L’essence est un produit

AVERTISSEMENT :

AVERTISSEMENT

Vérification du niveau d’huile

durée de vie du moteur.

gente ou pour moteur à 2 temps. Elle peut abréger la

IMPORTANT : N’utilisez pas une huile non déter-

d’huile correspondants).

les classifications SG et SF (qui figurent sur les bidons

établis par les fabricants automobiles américains pour

ou équivalente, satisfaisant ou surpassant les critères

détergente de première qualité pour moteur à 4 temps

sez pas excessivement. Utilisez une huile hautement

2-2. Le carter a une capacité de 600 mL. Ne remplis-

Figure 2-2: Tableau de viscosité de l’huile

-30º -20º -10º 0º

0º 20º 40º-20º

-40º

5W-30

0W-30

Synthétique

marche. Consultez le tableau de viscosité à la Figure

Faites le plein d’huile avant de mettre le moteur en

l’huile

Recommandations concernant

teur et annuler la garantie.

d’huile insuffisante gravement endommager le moni huile. L’utilisation du moteur avec une quantité

IMPORTANT : Le moteur est expédié sans essence

du moteur

Fonctionnement

2

Vérification initiale

Page 22

3

courant de 120 volts.

du moteur s’il est branché dans une prise de

électrique enclenche le démarreur électrique

Le fait d’appuyer sur le bouton de démarrage

Bouton de démarrage électrique

volts.

pour l’extérieur et une prise de courant de 120

Elle exige l’utilisation d’une rallonge à 3 fiches

Boîte de commutation électrique

échéant)

Démarreur électrique (le cas

seulement.

à titre de référence

et sont proposées

votre modèle exact

ne pas représenter

illustrations peuvent

obligation. Les

sans préavis ni

être modifiées

techniques peuvent

Les caractéristiques

garantie.

moteur et annuler la

endommager le

peut gravement

d’huile insuffisante

une quantité

du moteur avec

huile. L’utilisation

sans essence ni

moteur est expédié

IMPORTANT : Le

plomb.

machine utilise une essence automobile sans

Enlevez le capuchon pour faire le plein. La

burant

Capuchon du réservoir de car-

concerne l’huile à utiliser.

l’emploi » et « Entretien du moteur » pour ce qui

l’huile. Consultez le chapitre « Vérification avant

Enlevez le capuchon pour vérifier le niveau de

Capuchon/jauge d’huile

concernant la vidange de l’huile.

notice d’utilisation pour plus de renseignements

Consultez le chapitre « Entretien » dans cette

l’huile permet de vider l’huile du moteur.

Le fait d’enlever le bouchon de vidange de

AMORCEUR

Vidange de l’huile

poignée facile à tenir avec des gants ou moufles.

Ce moteur est équipé d’un démarreur à lanceur à grosse

Poignée du démarreur

FERMÉ OUVERT

pour des instructions détaillées.

Consultez le chapitre « Mise en marche du moteur »

rateur et de faciliter les démarrages.

Il permet de fermer le volet du carbu-

Volet de départ

si la commande est placée à la position « STOP ».

Il permet de régler le régime du moteur et arrête celui-ci

Obturateur

quand la machine n’est pas utilisée.

pour arrêter le moteur. Retirez la clé

la tourner. Sortez la clé à mi-distance

positif de sécurité. Insérez la clé sans

La clé de contact est en fait un dis-

Clé de contact

par temps froid.

du moteur pour faciliter les démarrages

carburant directement dans le carburateur

Le fait d’appuyer sur l’amorceur projette le

Amorceur

commandes du moteur. Consultez le chapitre « Mise en marche du moteur » pour des instructions détaillées.

Lisez attentivement ce chapitre avant de mettre le moteur en marche. Il est important de vous familiariser avec les

Figure 2-1: Vues avant et arrière du moteur.

* En option

du moteur

Fonctionnement

2

Bougie

carburant

réservoir de

Bouchon du

électrique*

Bouton du démarreur

Capuchon/Jauge à huile

Silencieux

Pièces du moteur

Boîte de commutation électrique

Vidange de l’huile

démarreur

Poignée du

Volet de départ

Obturateur

Clé de contact

Amorceur

Page 23

2

Visit www.mtdcanada.ca or call a Customer Support Representative at 1-800-668-1238.

Service à la clientèle

de ces instructions peut entraîner des blessures corporelles ou des dégâts matériels.

Veuillez lire et bien comprendre la notice d’utilisation avant de mettre le moteur en marche. Le non respect

AVERTISSEMENT : Ce moteur fonctionnera de façon fiable et sécuritaire si les instructions sont suivies.

dégâts à l’équipement ou autres dégâts

IMPORTANT : Il indique la possibilité de

utiles.

REMARQUE : Elle fournit des renseignements

symbole de sécurité.

consigne de sécurité est accompagnée d’un

les instructions ne sont pas suivies. Toute

possibilité de blessure grave ou fatale si

AVERTISSEMENT : Il indique une forte

d’autres personnes.

risques potentiels qui pourraient vous blesser ou blesser

moteur même. Une consigne de sécurité vous avertit de

sécurité et remarques figurant dans cette notice ou sur le

Faites particulièrement attention aux consignes de

Depannage .............................................................12

Entretien du moteur .................................................9

Utilisation du moteur ................................................5

Consignes de sécurité .............................................3

moteur et doit l’accompagner s’il est vendu.

Cette notice d’utilisation fait partie intégrale et permanente du

d’utilisation sans autorisation écrite.

Il est interdit de reproduire tout ou partie de cette notice

sa publication.

plus récents concernant le produit, disponibles au moment de

dans cette publication s’appuient sur les renseignements les

l’entretien de votre moteur. Tous les renseignements fournis

Cette notice d’utilisation explique le fonctionnement et

l’équipement sans préavis ni obligation.

ne pas s’appliquer à tous les modèles de moteurs. MTD LLC se réserve le droit de modifier les caractéristiques techniques du produit, son design et

Cette notice d’utilisation couvre une variété de modèles de moteurs. Les caractéristiques mentionnées et/ou représentées dans cette notice peuvent

Table des matières

comprendre les instructions.

le moteur de manière à obtenir les meilleures performances possible. Veuillez la lire attentivement afin de bien

Cette notice d’utilisation est une pièce importante de votre nouveau moteur. Elle vous aidera à préparer et à entretenir

Page 24

9/11/2007

769-03333

DE SÉCURITÉ ET LES INSTRUCTIONS AVANT D’UTILISER LA MACHINE.

IMPORTANT: VEUILLEZ LIRE ATTENTIVEMENT LES CONSIGNES

PRINTED IN U.S.A. MTD Products Ltd., P. O. Box 1386, KITCHENER, ONTARIO N2G 4J1

à arbre horizontal et soupapes en tête, pour souffleuses

3

and 208 cm

3

Moteurs de 179 cm

NOTICE D’UTILISATION

Sécurité • Fonctionnement • Entretien • Remisage • Détection des problèmes

Loading...

Loading...