MTD 197-987A User Manual

OWNER’S MANUAL

TEN CENTS

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Important:

Instructions Carefully

Model Nos.

197-987A

197-989A

40” TILLER

ATTACHMENT

PRINTED IN U.S.A.

FORM NO. 770-7179

Your new tiller attachment comes unassembled from

the factory. You will need two adjustable wrenches

and one hammer to complete the assembly of your

tiller.

LIST OF CONTENTS IN HARDWARE PACK.

(See figure 1)

A (4) Hex Screws 5/8-11 x 1-1/2" long

B (6) Lockwashers for 5/8" screw

C (4) Hex Screws 1/2-13 x 1-1/4" long

D (4) Lockwashers for 1/2" screw

E (4) Spring pins 3/8" Dia. x 2" long

F (3) Hair pin cotters for 5/8" Dia.

G (2) Link Clevis Pins

H (2) Hex Lock Nuts 5/8-18 Thread

I (1) Clevis Pin 5/8" Dia. x 2" long

J (4) Hex Screws 5/16-24 x 3/4" long

K (4) Lockwashers for 5/16" screw

L (4) Hex Nuts 5/16-24 Thread

M (2) Hair Pin Cotters for 3/8" Dia.

N (2) Clevis Pins 3/8" Dia. x 1-1/4" long

O (1) Spring Pin 5/16" Dia. x 1-3/4" long

P (1) Square Head Pipe Plug-Vented

Q (10) Carriage Bolts 5/16-18 x 1" long

R (10) Lockwashers for 5/16" Screw

S (10) Hex Nuts 5/16-18 Thread

REPLACE WITH VENTED PIPE PLUG (P)

_ADJUStABLE

WRENCH

FIGURE 2

3. With an adjustable wrench remove the pipe plug

and replace with vented pipe plug (P) provided in

hardware parts pack. See figure 2.

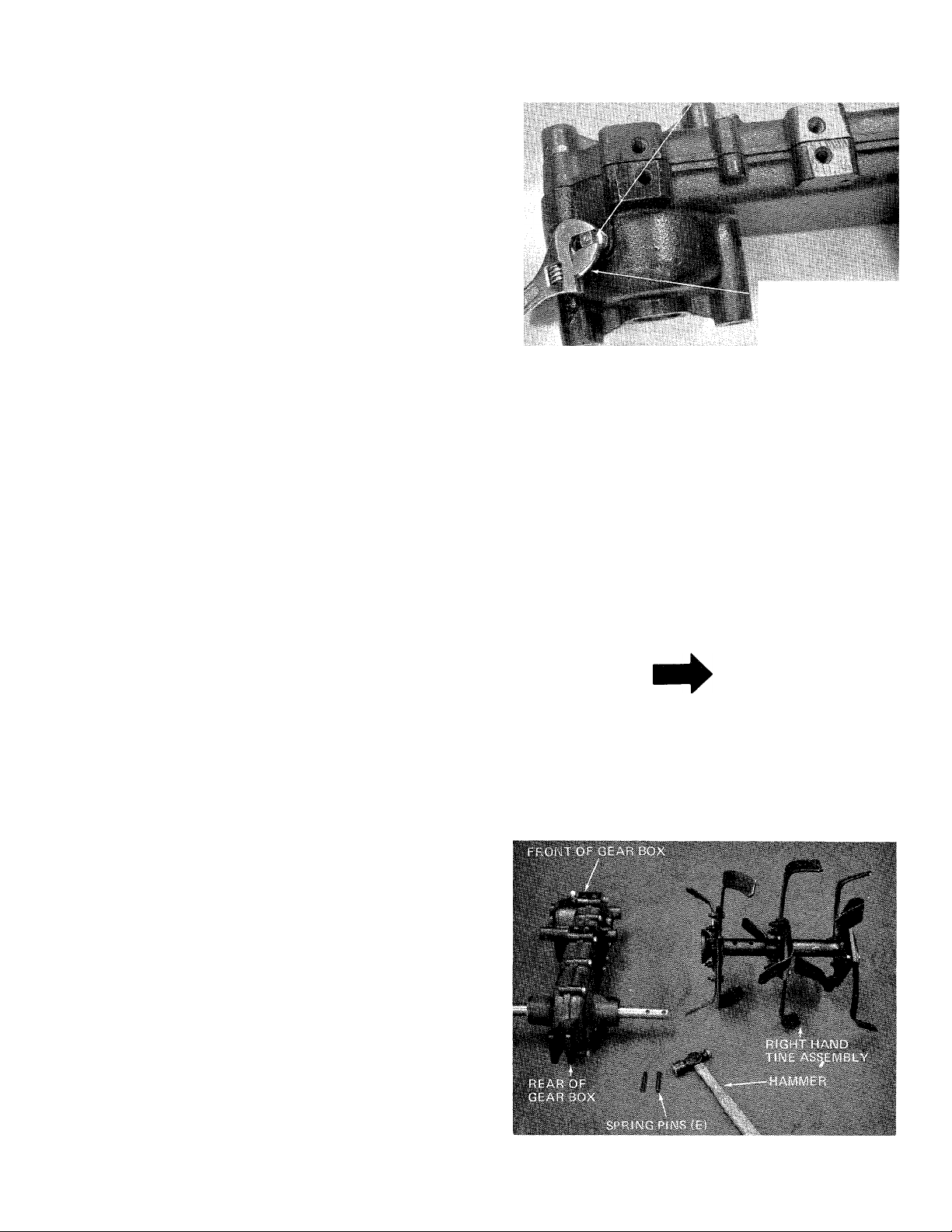

4. Assemble the right and left hand tine assemblies

to gear box, with four spring pins (E). A hammer

is required. See note below before continuing.

■I

■

' I

IB

FIGURE 1

ASSEMBLY INSTRUCTIONS

1. Remove the tiller, all loose parts and hardware

parts pack from the carton before discarding the

carton.

NOTE

Right and left hand is determined

from behind the gear box. The sharp

edge of the tines must enter the soil

first. See figures 3 and 4.

2. Place the gear box so that the pipe plug is up, as

shown in figure 2.

FIGURES

FIGURE 4

FIGURE 6

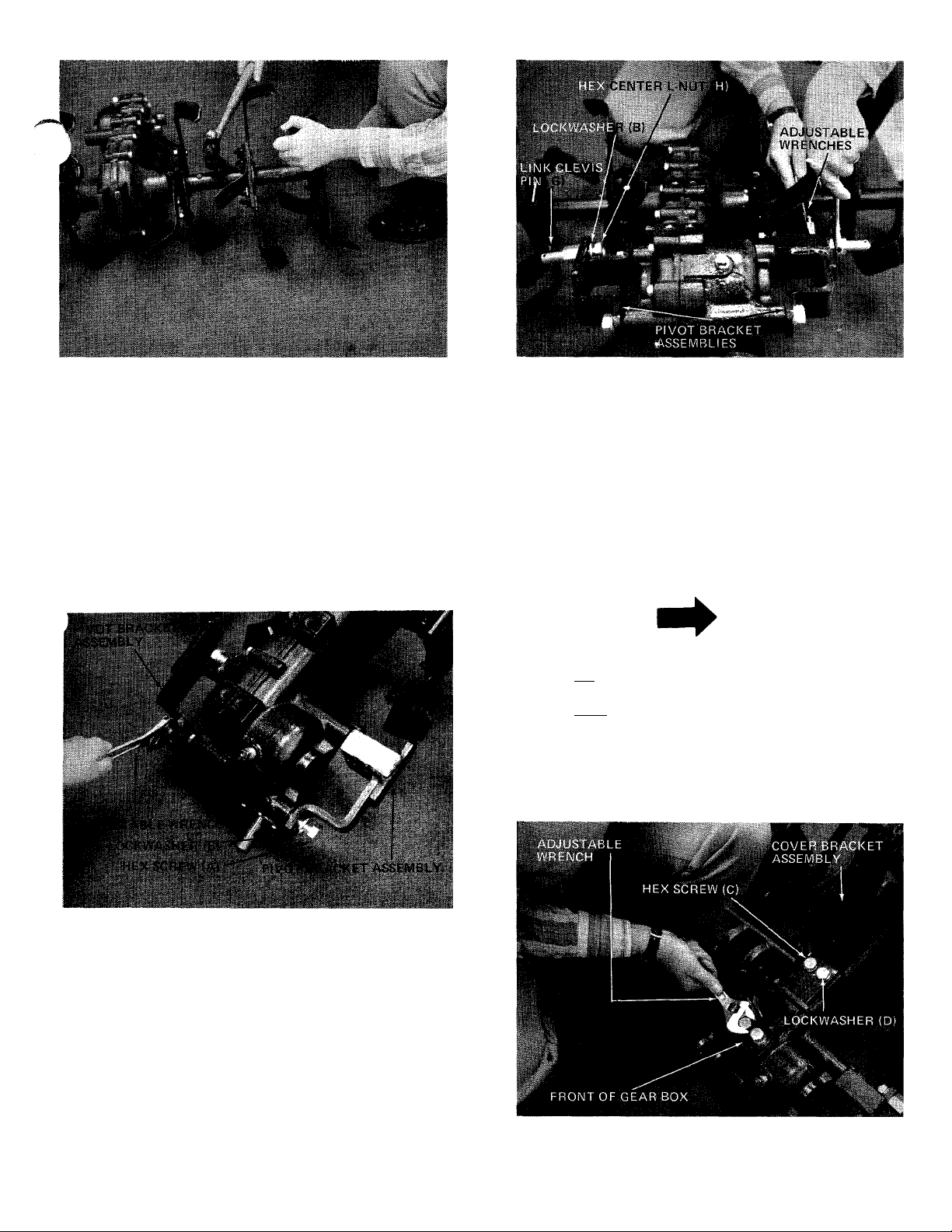

5. Install tiller pivot bracket assemblies. An adjust

able wrench is required. Place pivot bracket in

position on gear box as shown in figure 5. Secure

with four hex screws (A) and lockwashers (B).

See figure 5.

Install cover bracket assembly to gear box (as

shown in figure 7) using four hex screws 1/2-13 x

1-1/4" (C) and 1/2" lockwashers (D). An adjust

able wrench is required.

NOTE

All hex screws should be hand tight

ened. When _aiL screws are in place,

then tighten with adjustable wrench.

FIGURES

Insert link clevis pins (G) through outside holes

j.

of pivot bracket assemblies. Using two adjustable

wrenches, tighten link clevis pins in place with

lockwashers 5/8" (B) and hex center lock nuts

5/8-18 (H). See figure 6.

FIGURE 7

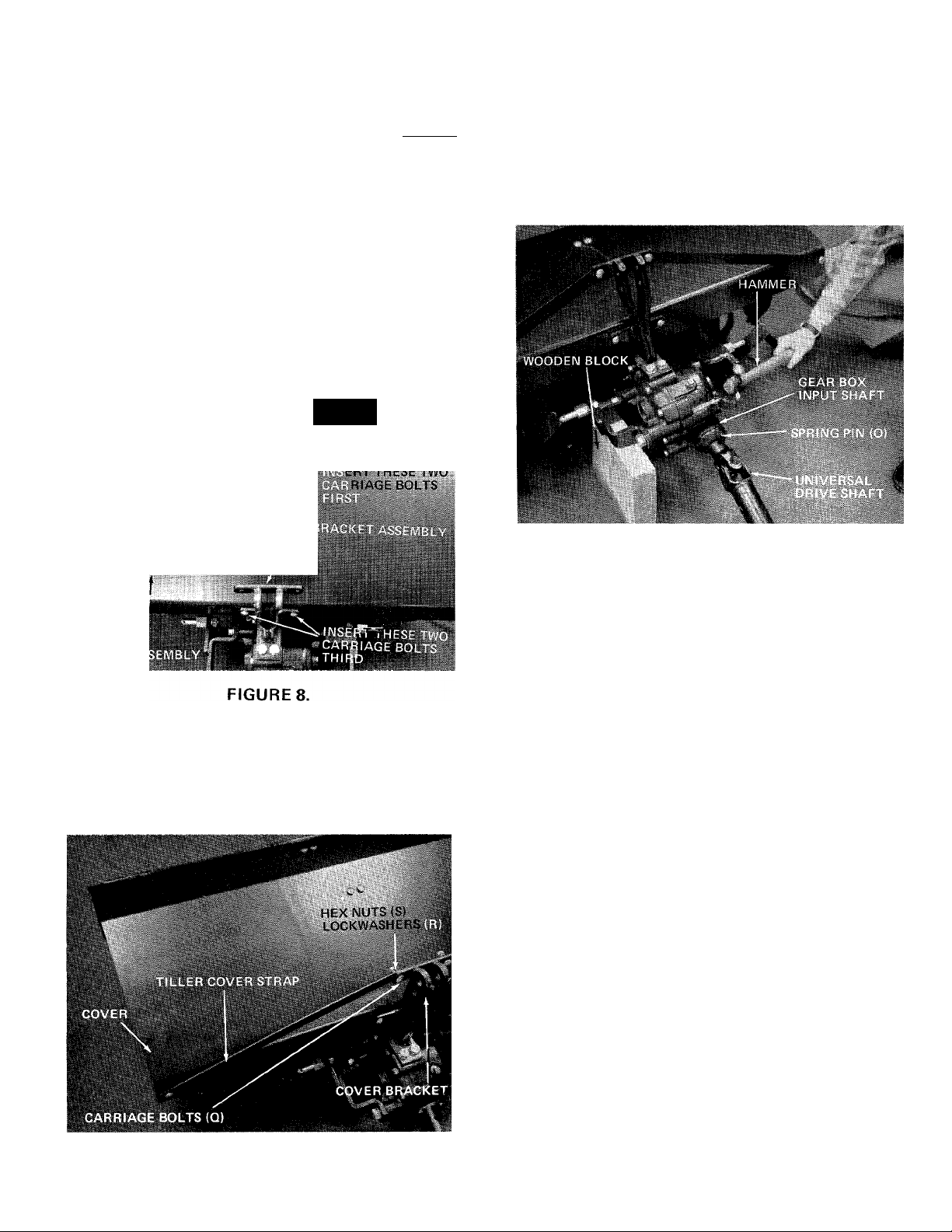

8. Place tiller cover assembly in position on the tiller

cover bracket as shown in figure 8. Using six 1"

carriage bolts (Q), six 5/16" lockwashers (R) and

six 5/16-18 hex nuts (S) start by hand. Do Not

Tighten.

a. Place two of the carriage bolts in the top

center of the cover first. See figure 8.

b. Place the next two carriage bolts in the rear

of the cover as shown in figure 8.

c. Place two more carriage bolts in the front of

the cover as shown in figure 8.

d. Do not tighten any of the six bolts in step 8

until step 9 is completed.

CAHhl

-SECOND

10. Using an adjustable wrench, tighten ail ten

carriage bolts used in steps 8 and 9.

11. Block up the front of the tiller so that the input

shaft is clear of the ground. Place the universal

drive shaft in position on input shaft of gear box

and secure with spring pin (0). See figure 10.

A hammer is required.

9. Using the four remaining carriage bolts (Q),

lockwashers (R) and hex nuts (S), assemble tiller

cover straps to cover bracket and cover. See figure

9.

FIGURE 10.

ATTACHING TILLER TO

TRACTOR

1. Before attaching the rotary tiller to the tractor,

be sure the rear wheels on the tractor are all the

way into the minimum rear wheel width. Refer to

your tractor manual.

2. Raise the undercarriage on the tractor, by pulling

the lift lever back.

FIGURE 9.

3. Remove the locking clip on each side of the

tractor. See figure 11.

4. Turn locking clips around and reassemble to

tractor as shown in figure 12. Be sure the locking

4 clip is under edge of undercarriage.

Loading...

Loading...