Page 1

10*

ROTARY TILLER

FOR

GARDEN TRACTORS

Model Nos.

192-766,193-966-760

and 193-967-7^0

For one year from date of purchase, MTD Products Inc,

will replace for the original purchaser, free of charge, F.O.B.

factory or authorized service firm, any part or parts found to

be defective in material or workmanship. All transportation

charges on parts submitted for replacement under this war

ranty must be paid by the purchaser. This warranty does not

include replacement of parts which become inoperative

through misuse, excessive use, accident, neglect, improper

maintenance or alterations by unauthorized persons. This

warranty does not include the engine, motor, battery, bat

tery charger or any component parts thereof. For service on

these units refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner

and will be effective only if the warranty card has been pro

perly processed. It will not apply where the unit has been

used commercially.

Warranty service is available through your local author

ized service dealer or distributor. UNDER NO CIRCUM

STANCES WILL THE RETURN OF A COMPLETE UNIT

BE ACCEPTED BY THE FACTORY UNLESS PRIOR

WRITTEN PERMISSION HAS BEEN EXTENDED.

Your rotary tiller is a precision built machine designed to

to take the work out of gardening and other related chores. It

can be used for seed b<Kj preparation, titling, cultivating, fur

rowing, composting and mulching. Like any other piece of

power equipment, it n»quires a certain amount of care and

maintenance. In return For this, it will give a maximum of ser

vice and efficiency. Read these instructions carefully before

assembling or operating your tiller. Through proper care and

operation, you will obtain long, efficient service and trouble

free operation.

1. Your tiller is a precision piece of power equipment. Exer

cise extreme caution at all times.

2. Do not attempt to start engine with the clutch control in

engages or "Forward" position.

3. Stand clear of tines when starting engine. Never stand in

front of, or work on tines while the engine is running.

4. NEVER place hands or feet in the vicinity of the tines

while the engine is running.

5. Always stop engine iMien tiller is not in actual use.

6. Always disconnect spark plug wire during repairs or re

fueling operations.

7. Do not fill gas tank white engine is running. Do not spill

gasoline on hot engine.

MTD PRODUCTS INC

5389 WEST 130th STREET

P.O.BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-3844

Page 2

192- 766 Tiller Attachment is for 10, 12, and 14 HP Tractors built before

1971.

193- 966 Tiller Attachment is for the 1971 through 1973 10, 14, 15 and 16

HP Tractors. (Models 141-760, 141-960, 142-760, 142-960, 143-860 and

143-960).

193-967 Tiller Attachment is for the Hydrostatic Tractors. (Model 141-900,

142,990 and 143-990).

ASSEMBLY INSTRUCTIONS FOR

MODELS

193-966 and 193-967. (Refer to Fig. 2)

1. Assemble outer tine assemblies complete to the

inner tine assemblies complete with four spirol

pins 5/16 diameter x 2-1/2^’ long Heavy Duty.

(Ref. 28).

2. Assemble pivot bracket assembly (Ref. 24) to the

power input side of the gear case with two bolts

5/8-11 X 1-1/2” long (Ref. 67) and lockwashers

5/8 diameter (Ref. 25).

3. Assemble other pivot bracket assembly (Ref. 24)

to the right hand side of gear case.

4. Assemble the universal drive shaft assembly (Ref.

26). To the gear case with spirol pin (Ref. 22).

Drive pin into the shaft with a hammer. The end of

the universal drive shaft assembly with the square

head set screw attaches to the power take off on

tractor.

5. Assemble cover bracket (Ref. 20) to cover bracket

assembly (Ref. 5) with one carriage bolt 1-1/2” long

(Ref. 15).

6. Assemble cover bracket assembly (Ref. 5) to cover

assembly (Ref. l)with six carriage bolts 5/16—18x1”

long (Ref. 4) lockwashers 5/16 diameter (Ref. 6) and

nuts 5/16-18 thread (Ref. 7). Assemble bolts and

nuts loose until all six are started, then tighten.

ASSEMBLY INSTRUCTIONS

FOR MODEL

192-766. (Refer to Figs. 1 and 2)

1. Assemble outer tine assemblies complete to the

inner tine assemblies complete with four spirol

pins 5/16 diameter x 2-1/2’’ long Heavy Duty.

(Ref. 28).

2. Assemble flat bracket L.H. (Ref. 69) to the power

input side of the gear case with two bolts

5/8—11 X 1-1/2” long (Ref. 67) and lockwashers

5/8 diameter (Ref. 25).

3. Assemble offset bracket R.H. (Ref. 68) to the right

hand side of the gear case with two bolts

5/8-11 X 1-1/2” long (Ref. 67) and lockwashers 5/8

diameter (Ref. 25).

4. Assemble the universal drive shaft assembly (Ref.

26) to the gear case with spirol pin (Ref. 22).

Drive pin into the shaft with a hammer. The end

of the universal drive shaft assembly with the

square head set screw attaches to the power take

off on the tractor.

5. Assemble cover bracket (Ref. 5) to the cover

assembly (Ref. l)with sixcarriage bolts 5/16—18x1”

long (Ref. 4), lockwashers 5/16 diameter (Ref. 6)

and nuts 5/16—18 thread (Ref. 7). Assemble

bolts and nuts loose until all six are started, then

tighten.

7. Assemble cover and bracket assembly to gear case

with four bolts 1/2-13 X 7/8 long. (Ref. 9) and lock

washers 1/2 diameter (Ref. 10). Assemble bolts

loose until- all four are started, then tighten.

8. Remove the solid pipe plug in the hole above the

input shaft in the gear case and replace it with the

vented pipe plug (Ref. 21). Refer to Figure 2 for

proper location of the vented plug. This vented plug

allows the gear case to breathe.

9. The lubricant level in the gear case should be

checked after it is attached to the tractor.

6. Assemble cover and bracket assembly to the gear

case with four bolts 1/2—13 x 7/8 long (Ref. 9) and

lockwashers 1/2 diameter (Ref. 10). Assemble bolts

loose until all four are started, then tighten.

7. Remove the solid pipe plug in the hole above the

input shaft in the gear case and replace it with the

vented pipe plug (Ref. 21). Refer to Figure 2 for

proper location of the vented plug. This vented

plug allows the gear case to breathe.

8. The lubricant level in the gear case should be

checked after it is attached to the tractor.

Page 3

ATTACHING YOUR ROTARY TILLER TO YOUR

TRACTOR (Models 193-966 and 193-967)

1. Before attaching your rotary tiller to your tractor, be

sure the rear wheels on the tractor are all the way

into the minimum rear wheel width. Refer to your

tractor manual.

2. Remove the draw bar assembly from the three point

hitch of your tractor by removing the two cotterhairpins.

3. Place the rotary tiller behind the tractor in the

approximate position shown in Fig. 2.

4. Attach universal drive shaft (Ref. 26) to the tractor

power take off. Tighten set screw (Ref. 27).

5. Move the lift lever on the tractor until the draft bar

assemblies line up with pivot brackets (Ref. 24).

6. Assemble pivot brackets (Ref. 24) to the rear of the

tractor with washers and cotter-hairpins.

ATTACHING YOUR ROTARY TILLER TO YOUR

TRACTOR (Model 192-766).

1. Before attaching your rotary tiller to your tractor, be

sure the rear wheels on the tractor are all the way

into the minimum rear wheel width. Refer to your

tractor manual.

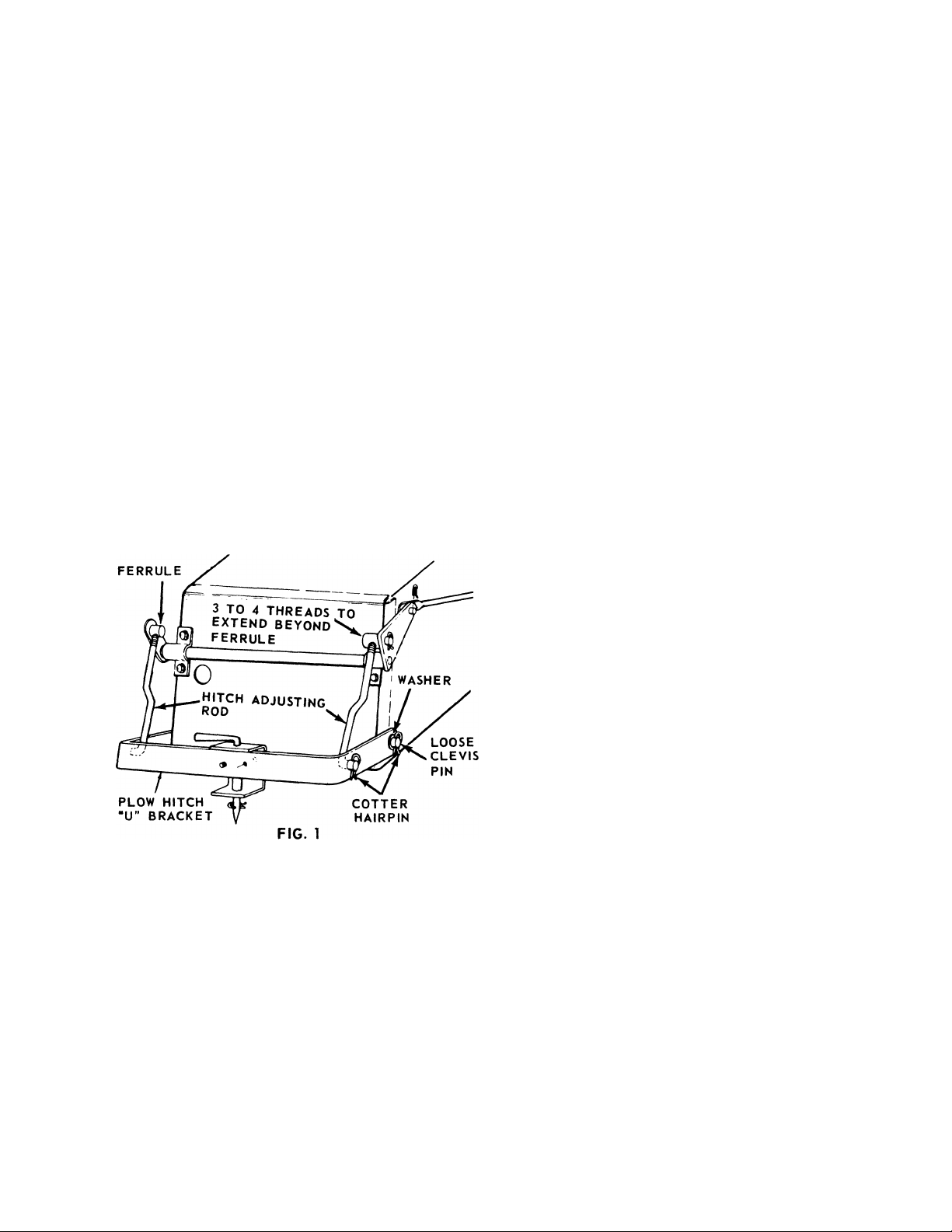

Remove the part of the plow hitch from your

2.

tractor by removing the two cotter-hairpins on the

loose clevis pins and the two cotter-hairpins from

the hitch adjusting rods. Refer to Fig. 1.

Lift the rotary tiller with the lift h^^adle on the tractor

to transport it to and from the work area. Use caution

when transporting the rotary tiller since your ground

clearance has been reduced.

The entire tiller unit is offset to the left to allow

closer tilling with the left side.

NOTE: BE SURE THE POWER TAKE OFF HANDLE

IS IN THE ‘‘OFF” POSITION BEFORE STARTING

THE TRACTOR ENGINE. Refer to the tractor manual

for proper position of the PTO handle.

GENERAL ROTARY TILLER OPERATION

ALWAYS shut the engine off when removing a stone or

anything that becomes entangled in the tines.

All large stones or rocks should be removed from the

area before you begin tilling.

Tilling can be done with or without the outer tine

assemblies. You can till 32!/2” wide with the outer tines

and 17” wide with only the inner tines.

Use rear wheel weights when tilling. Part number

191-776.

Maximum tilling depth is approximately 10” depending

on the type of soil. This CANNOT be accomplished in

one pass. Maximum tilling depth may be only 2-1/2”

on extremely hard soil on the first pass.

The more passes you make with the tiller over the same

area, the deeper you can till and the finer you pulverize

the soil. Change directions as often as you can to level

out the ground and to prevent furrows.

When tilling, the tiller will push the tractor and the

transmission on the tractor will hold the tractor back.

For easy lifting of the rotary tiller from the ground, shut

off the power by disengaging the PTO handle and

continue to drive the tractor forward. The tines will

climb out of the hole when you pull the lift lever

handle back.

3. Adjust the hitch adjusting rods until 3 or 4 threads

extend beyond the rear hitch ferrule.

4. Place the rotary tiller behind the tractor in the

approximate position shown in Fig. 2.

5. Attach universal drive shaft (Ref. 26) to the tractor

power take off. Tighten set screw (Ref. 27).

6. Assemble brackets (Ref. 68 & 69) to the rear of the

tractor with the loose clevis pins, washers and

cotter-hairpins.

CHECK LUBRICANT LEVEL at this time. The gear

case is lubricated at the factory but should be checked

for proper lubricant level before each operation. Remove

plug (Ref. 61) on side of gear case. Lubricant should

be at this level, if not, fill through the vented pipe plug

hole (Ref. 21) with SAE 140 oil until the lubricant over

flows through the hole in the side of the gear case.

Replace the pipe plugs. BE SURE THE VENTED PIPE

PLUG IS IN THE OIL FILL HOLE. Refer to Fig. 3.

LUBRICATION

Gear Case - Lubricated with three quarts of SAE 140

oil. It is lubricated at the factory. Be sure to check

the lubricant level before each use.

To check the oil level, remove plug (Ref. 61) on the

side of the gear case. See Fig. 3. Lubricant should be

at this level. If not, fill through the vented pipe plug

hole (Ref. 21) until it overflows through the hole in

the side of the gear case. Replace both plugs. BE

SURE THE VENTED PIPE PLUG IS IN THE OIL

FILL HOLE.

Grease Fittings — There are three grease fittings on

the universal drive shaft assembly. Lubricate after

each 25 hours of use with an automotive multi-purpose

type grease. Apply grease with grease gun provided

with your tractor. Lubricate until the old grease is

pushed through and clean grease appears.

Page 4

Used on Gear driven Tractors

ROTARY TILLER 192-766, 193-966 and 193-967

FOR MODEL

192-766

FIG. 2

901-10507

OUTER TINE ASS Y.

L M(COMPLETE)

901-1050 6

OUTER TINE

ASSY. RH

(COMPLETE)

Page 5

ROTARY TILLER 192-766, 193-966 and 193-967

Oil level should be checked when the tiller Is

mounted on the tractor with the tines touching

the ground.

Place a 6 inch block under the front of the case

to check oil level with the tiller off the tractor.

FIG. 3

Page 6

PARTS LIST FOR TILLER ATTACHMENT MODELS 192-766, 193-966 and 193-967

Ref.

No.

10

11

12 742-110

13

14

15 710-431

16

17

18

19 10501

20

21

22 715-118

23

24

25 736-158

26 717-149

27 710-357

28 715-113

29 714-123

30

31

32

33

Part

No.

1 9844A

2

714-111

3 9846

4

710-276

5

10981

6 736-119

712-267

7

8 9850

710-365

9

736-921

712-267

742-113

10502

712-711

736-169

710-113

10984

737-102

712-798

10982

717-184

711-451

719-145

736-124

721-109

Color

Code

Cover Assembly

Cotter Pin 3/32 Dia. x V Lg.*

Cover Flap Assembly

Carriage Bolt 5/16—18 x V’ Lg. *

Cover Bracket Assembly

Spring Lockwasher 5/16 Scr. *

Hex Nut 5/16-18 Thread *

Rod

Hex Hd.Cap Scr.1/2-13 x 7/8" Lg.*

Spring Lockwasher 1/2—13 Thread *

Hex Nut 5/16-18 Thread *

Tine R.H. Slasher

Tine L.H. Slasher

Extension - Tine

Carriage Bolt 3/8—16 x 1-1/2”Lg.*

Hex Nut 3/8-24 Thread ^

Spring Lockwasher 3/8 Scr. *

Hex Hd.Cap Scr.3/8—24 x 1-5/8"' Lg.*

Mounting Tine 52

Cover Bracket (966 and 967 only)

Square Hd. Pipe Plug w/Vent 3/8 Thd.

Spirol Pin 5/16 X 1-3/4" Lg. *

Hex Nut 3/8-16 Thread *

Pivot Bracket Assembly

(966 and 967 only)

Spring Lockwasher 5/8 Scr. *

Universal Drive Shaft Assembly

(766 and 966 only)

Universal Drive Shaft Assembly

(967 only) 63

Square Hd.Set Scr.3/8-16 x 1/2" Lg.* 64

Spirol Pin 5/16"Dia.x 2-1/2"Lg. 65

Heavy Duty

Square Key 5/16 x 2" Lg. *

Shaft

Tiller Gear Case - L.H.

Felt Dust Pad - Small

Oil Seal 1-1/4 I.D. x 2.004 O.D.

DESCRIPTION

9841

9842

Color

Code

DESCRIPTION

Oil Seal 1-1/4 I.D. x 2.004 O.D.

Thrust Bearing

Truarc Snap Ring No.5100-125

Needle Bearing 1.25 I.D. x 1.625 O.D.

Thrust Bearing 1.25 I.D. x 1.927 O.D.

Thrust - Race 1.25 I.D. x .030

Sprocket 13 Teeth

Square Key 5/16 x 1-1/4 Lg. *

Square Key 5/16 x 1-3/4 Lg. *

Worm Gear Shaft

Spirol Pin 1/4 X 1" Lg.

Timken Roller Bearing 3/4" Bore

Spacer

Worm

Key Hi Pro No.HP 505 3/4" *

Worm Shaft

Gasket - Worm

Case Cover

Gasket - Gear Case

Tiller Gear Case - R.H.

Clevis Pin (966 and 967 only)

Hex Locknut 5/8—18 Thread *

Hex Hd. Cap Scr.5/8-11 x 1-1/2"Lg.

Bracket - L.H. (Not xhown

For 192-766 only)

Bracket-R.H. For 192-766 only)

Input Shaft Seal

Ref.

No.

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

53

54

55

56

57

58

59

60

61

62

66

67

68

69

70

Part

No.

721-110

742-126 Needle Bearing 1-1/4 I.D.x 1.625 O.D.

748-159

716-116

717-148 Sprocket - 25 Teeth

713-119 Chain w/master Link No. 60 x 39 lg.

741-127

741-130 Thrust - Race 1.25 I.D. x 1.23

741-128

741-129

717-146 Worm Wheel

717-147

714-125

714-124

711-325

715-108

741-107

711-329

717-145

711-328 Spacer

714-314

711-324

721-108

711-327

736-329 Spring Lockwasher 1/4" Scr. *

710-206 Hex Hd.Cap Scr. 1/4-20 x 7/8"Lg. *

721-111 Oil Seal 3/4 I.D. x 1.503 O.D.

737-103 Square Hd. Pipe Plug 3/8 Thread *

721-107

710-380 Hex Hd. Cap Scr.5/16-18 x 1-3/4" Lg.*

719-146

711-497

712-923

710-367

11566

* For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order

by part number and size as shown on the parts list.

NOTE: Parts shown on drawings that do not have reference numbers are tractor parts. Refer to your tractor manual.

Page 7

ASSEMBLY INSTRUCTiONS FOR BOOSTER SPRINGS 732-246

(USED WITH TILLER ATTACHMENTS 192-766 and 193-966)

Booster springs may be used with any accessories which can be attached at the rear of the tractor.

NOTE: Booster springs cannot be used when using the 42'' mowing deck attachment.

1. Remove any attachment which may be on the tractor,

2. Pull the lift lever all the way back to disengaged position,

3. Remove cotter pin, flat washer and pull rod from clevis pin at location shown in figure 1.

4. Hook one end of spring on clevis pin as shown in figure 1.

5. Place the pull rod, flat washer and cotter pin back on the clevis pin as shown in figure 1.

6. With a screwdriver or tube (as shown in figure 2), extend spring forward and hook over the welded clevis pin

on the frame. (See figure 2)

COTTER PIN

714-117

7. Secure the spring with a flat washer (310-7387) and a cotter pin (714-117), which is provided with the springs.

(See figure 1)

WASHER

310-7387

CLEVIS PIN

Figure 1

TUBE

COTTER PIN

Figure 2

Page 8

PARTS INFORMATION

DEFECTIVE OR MISSING PARTS must be reported to the

fiictory immediately. Such claims must include your

model number and date of purchase.

MOWER, TILLER, SNOW THROWER, TRACTOR, TRAIL

BIKE AND MUD BUG PARTS

Mower, tiller, snow thrower, tractor, trail bike and

mud bug parts are available through the authorized

service firms listed below. All orders should specify

the model number of your unit, parts numbers, de

A 1 Engine & Mower Co.

327 East 9th Street

Sait Lake City, Utah 84102

American Electric Ignition Co.

124 N. W. 8th Street

Oklahoma City, Oklahoma 73102

Auto Electric & Carburetor Co.

2625 4th Avenue, S.

P. O. Box 1948

Birmingham, Alabama 35233

Automotive Equipment Service Co.

3117 Holmes Street

Kansas City, Missouri 64109

Bailey's Rebuild Inc.

1325 E. Madison Street

Seattle, Washington 98102

Brown Equipment Distributor Inc.

110 Beech Street

Corydon, Indiana 47112

Bullard Supply

2409 Commerce Street

Houston, Texas 77003

Catto & Putty, Inc.

P. O. Box 2408

510 Soiedad Street

San Antonio, Texas 78205

Center Supply Company

6867 New Hampshire Avenue

Takoma Park, Maryland 20012

Charles B. Wright Co.

309 4th Avenue, South

Nashville, Tennessee 37201

W. B. Clements

400 Salem Avenue

Roanoke, Virginia 24016

Morton B. Collins Co.

300 Birnie Avenue

Springfield, Massachusetts 01107

Dixie Sales Company

P. O. Box 1408

327 Battleground Avenue

Greensboro, North Carolina 27402

East Point Cycle & Key Shop

1617 Whiteway

East Point, Georgia 30044

Gamble Distributors

West End Avenue

Carthage, New York 13619

Garden Equipment Co., Inc.

6600 Cherry Avenue

Long Beach, California 90805

HenzIer, Inc.

2015 Lemay Ferry Road

St. Louis, Missouri 63125

Frank E. Ives & Son

1101 Lincoln Avenue

Prospect Park, Pennsylvania 19076

J. W. Jewett Co.

981 Folsom Street

San Francisco, California 94107

Kenton Supply

8216 North Denver Avenue

Portland, Oregon 97217

Kimber's Inc.

115 W. Geddes St.

Syracuse, New York 13204

The Lawnmower Shop

1340 El Camino Real

San Carlos, California 94070

Marr Brothers

423 E. Jefferson

Dallas, Texas 75203

Mathews Auto Electric Co.

420 East 2nd Street

Tulsa Oklahoma 74120

McClure Lawn & Garden Supply

1114 Lexington Avenue

Mansfield, Ohio 44907

Memphis Cycle & Supply Co.

421 Monroe Avenue

Memphis Tennessee 38103

scription of parts and the quantity of each part re

quired.

BRIGGS & STRATTON, TECUMSEH AND PEERLESS PARTS

AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and

service should be handled by your nearest author-ized

engine service firm. Check the yellow pages of your

telephone directory under the listing Engines —

Gasoline, Briggs

Power Products.

Stratton or Tecumseh Lauson —

&

Moz-AII of Florida, Inc.

365 Greco Avenue

Coral Gables, Florida 33146

National Central, Div. of

Joe Sterling, Inc.

Drawer "D" 687 Seville Rd.

Wadsworth, Ohio 44281

Power Equipment Distributor

36463 So. Gratiot Avenue

Mt. Clemons, Michigan 48043

Parts & Sales Inc.

2101 Industrial Pkwy.

Elkhart, Indiana 46514

Parts & Sales Inc.

335 West St. Charles Road

Villa Park, Illinois 60181

Power Lawn & Garden Equip. Co.

2551-2571 J. F. Kennedy Road

Dubuque, Iowa 52001

Raub Supply Company

James & Mulberry Sts.

Lancaster, Pennsylvania 17604

Radco Distributors

2403 Market Street

P. O. Box 3216

Jacksonville, Florida 32206

Richmond Battery & Ignition

P. O. Box 25369 - 957 Myers St.

Richmond, Virginia 23260

Smith Hardware Company

515 N. George Street

Goldsboro, North Carolina 27530

South Denver Lawn Equip. Co.

527 West Evans

Denver, Colorado 80223

Suhren Engine

8330 Earhart Blvd.

New Orleans, Louisiana 70118

Sutton's Lawn Mower Shop

Route 4, Box 343

North Little Rock, Arkansas 72117

Warner Equipment

7520 Lyndale Avenue, So.

Minneapolis, Minnesota 55423

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty Is to protect the customer from defects in material and workmanship, defects

which are not detected at the time of manufacture.

Our aim is to build into our product quality and reliability. Considerable emphasis is placed on quality

control in order to assure our customer of satisfactory product performance. To achieve this goal, it is

necessary to gain the cooperation of ail concerned, MTD, our sales force and our customers.

MTD^s responsibility is to build a quality product and to back up that product. MTD must build this

quality product at a competitive price. This cannot be achieved without production in quantity. Quantity

production is mass production. In mass production it is always possible for undetected defects to be

present when the product reaches the customer. Our warranty is extended to assure the customer that

any such defects will be corrected.

Use and maintenance are the responsibility of the customer. MTD cannot assume responsibility for con

ditions over which it has no control. MTD's responsibility does not cover misuse, excessive use, accident

neglect, improper maintenance or alterations by unauthorized persons. Satisfactory product performance

can only result when a manufacturer provides and backs up a quality product and the customer follows

through with proper use and proper maintenance of that product. When both the manufacturer and the

customer recognizes and assumes his responsibility, satisfactory product performance and customer sat

isfaction are assured.

FORM NO. 770-3844

8

PRINTED IN U.S.A.

j

Loading...

Loading...