Page 1

'Ш

FORM NO. TLP-009

OPERATING INSTRUCTIONS AND SERVICE MANUAL

8 H. P. ROTARY TILLER

MODEL 1850

2 //- 3?o

Original: February 1971

J. G. РЕШУ GGNPm, MG.-I30i AVENE OF THE ШВОШ, HEW YHRE, &T., IHII

Page 2

CONTENTS

Section Paragraph

GENERAL INFORMATION AND ASSEMBLY

1.

1-1. Technical Description

1-2. Preliminary Preparation ....................................... 1-1

1- 3. Assembly ...................................................... 1-1

CONTROLS AND PRELIMINARY CHECKS

2.

2- 1. Controls .............................................................. 2-1

2-2. Wheel Adjustment

2-3. Checking Oik Gasoline, and Gear case... 2-2

OPERATING INSTRUCTIONS

3-1. Starting the Engine _________

3-2.

Stopping the Engine __________

3-3.

Stopping the Tines

..........................................

........

....................................

_____

-

.............

___

_

—

_______________

_________

-----

Page Section Paragraph

1-1

--2-2

—- 3-1

-------

3-1

3-1

MAINTENANCE

4-1.

Crankcase Oil

4-2.

Chain Case Lubricaion

4-3.

Chain Adjustment

4-4.

Air Filter

4-5.

Cleaning Engine and Tine Area

4-6.

Belts .................................................

4-7.

Spark Plug

4-8.

Gasoline Filter and Shut-OfF Valve

4-9,

Belt Adjustment

4-10.

Belt Replacement

4-11.

Adjusting the Carburetor

4-12.

Adjusting the Choke

4-13.

Magneto and Spark Plug Check

4-14.

Off-Season Storage

.......

..........

....................................

___________

..............

................

.........

........

..............................

__________

.............................

..............................

......................

.............

..................

_______

EXPLODED VIEWS AND PARTS LIST

................

___________

.......

.................

................

___________

______

____

........

Page

.....

4-1

.. .. 4-1

.... 4-1

.... 4-1

.... 4-2

.... 4-2

.... 4-2

.... 4-2

.... 4-3

... 4-3

.... 4-4

.... 4-4

.... 4-5

.... 4-5

5-1

Figure

Wheel Assembly

1-1.

Wheel Flanger ------------

1-2.

Handle Assembly

1-3.

Control Assembly

1-4.

Ferrule Adjustment

1-5.

Control Assembly

1-6.

Throttle Assembly

1-7.

2-1.

Controls

Depth Bar

2-2.

Wheel Height Adjustment

2-3.

Oil and Gasoline Fill ............

2-4.

3-1. Recoil Starter

Oil Fill Plug

4-1.

4-2. Oil Drain

________

.............................................

__________

..................

.........

...........

—..........—

-------------

........

....................

..............—--------

--------

--------

-------

-----------------------

------

----------

-------------

__________

--------------------

...................

.....

.....................................

_____________

...........

...................

-----

—.

.......

-------

-----------

______

ILLUSTRATIONS

Page Figi

...... 1-2

____

1-2

____ 1-2

____

1-2

......

1-3

____

1-3

_____

1-3

____

2-1

..........

2-1

-

.......... 2-2

_____

2-2

..........

3-1

_____

4-1

_____

4-1

ure Page

Air Cleaner

4-3.

Spark Plug

4-4.

Gasoline Filter and Shut-Off .........

4-5.

Drive System

4-6.

4-7. Variable Speed Pulley ...............................

Belt Removal

4-8.

Carburetor Adjustment ..................

4-9.

Choke Adjustment

4-10.

Penncraft Tiller Model 1850

5-1.

Penncraft Tiller Model 1850

5-2.

Engine Model 190402-0689-01 ...

5-3.

____________

...................................

----------------------------

-------------------------------------

.........

..........................

___________

.............

..................

.....................

---------

............

.......

_

........

____

........

____

......... 4-3

........

____

.

____

.

.........

.

____

4-1

4-2

4-3

4-3

4-3

4-4

4-5

5-2

5-3

5-5

Page 3

SAFETY RULES

BEFORE TILLING

1. DO NOT operate the equipment when barefooted

Of when wearing open sandals.

2. DO NOT start machine until each control and its

function is understood. See Sections 2 and 3.

3. DO NOT let anyone use the tiller who is unfamiliar

with the controls. Keep children and pets away

from the machine.

4. Check tank for fuel of crankcase for oil level. See

Section 2.

5. Always disconnect the sparkplug wire during re

pairs, refueling, or adjustments except when tun

ing the engine.

6. NEVER refuel with motor running.

7. DO NOT spill gasoline on hot engine.

8. NEVER try to start the engine with the clutch con

trol in any position but NEUTRAL.

9. Stand clear of tines when starting the engine.

10. Never stand in front of or work on tines when the

engine is running. Keep hands and feet clear of

tines.

AFTER TILLING

1. Read and understand all instructions in Sections 2

and 3.

2. NEVER use the tiller in the dark.

3. STOP the engine and remove the spark plug wire

whenever the machine is left unattended.

4. Never leave an operating tiller unattended.

5. If the machine begins to vibrate or produces any

other than normal operating sounds, STOP the

machine immediately and check the cause.

6. Keep children away from the operating tiller at all

times.

7. Know how to stop the tiller instantly.

8. Stop the machine when crossing driveways, roads,

or walkways.

9. If the blades strike any obstructions, STOP the en

gine, remove the spark plug wire, and check for

damage.

Page 4

SECTION I

GENERAL INFORMATION AND ASSEMBLY

1-1. TECHNICAL DESCRIPTION

The Model 1850 Rotary Tiller is equipped wih a

Briggs and Stratton 8 hp, 4-cycle engine and a recoil

starter. The tines are heavy duty slasher type and the

wheels are 10 x 2.50 inches with a rib tread. This til

ler weighs 340 pounds.

The maximum tilling width is 26 inches.

1-2. Preliminary Preparation

Maximum tilling results, equipment performance,

and personal safety depend on correct operation of

the equipment and on proper maintenance of its com

ponents. The operator of this Penncraft rotary tiller

should, therefore, famiarize himself with the machine

and its controls before attempting to operate the

equipment. The two important considerations are:

a. Knowing the location of each control and its

function, as outlined in this manual, to ensure

for most efficient operation of the equipment and

for best performance.

b. Observing the operating instructions and safety

rules at all times to prevent possible injury to

persons and to equipment.

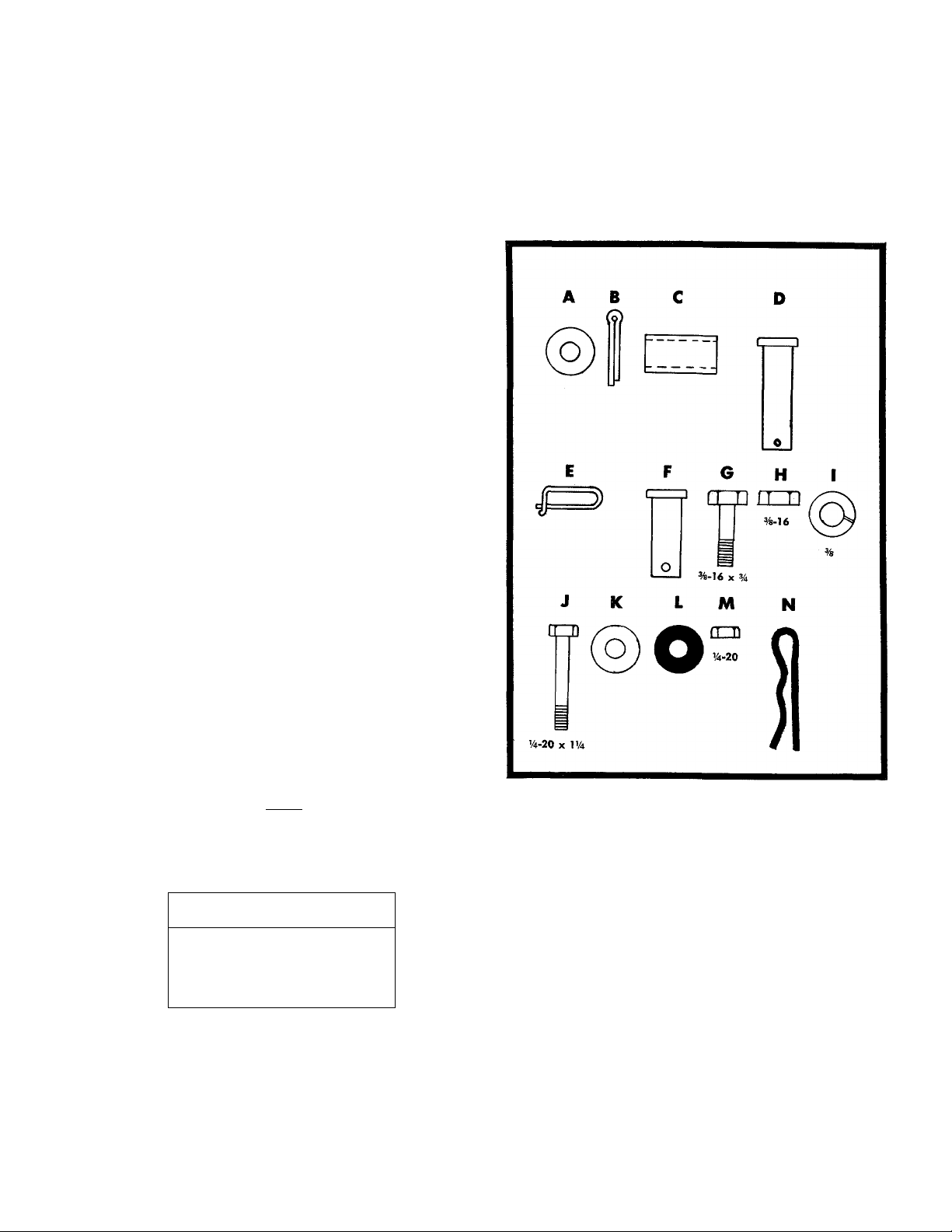

HARDWARE SUPPLIED

1-3. Assembly

The Model 1850 is shipped completely assembleo

except for the handle, depth bar, and wheels. These

parts, with the necessary hardware, are easily assem

bled to the machine, as outlined in this section.

NOTE

Reference to right-hand or left-hand

side of machine is from the operating

position.

TOOLS NEEDED

Two 7/16"

Two 9/16" Wrenches

Wrenches

a. ' heel and Wheel Hanger Assembly

Refer to figure 1-1.

Step 1. Slide the axle through the wheel hanger.

Step 2. Place the washer A, spacer C, wheel, and

washer A on each side of the axle and secure

each with a cotterpin B.

1-1

Page 5

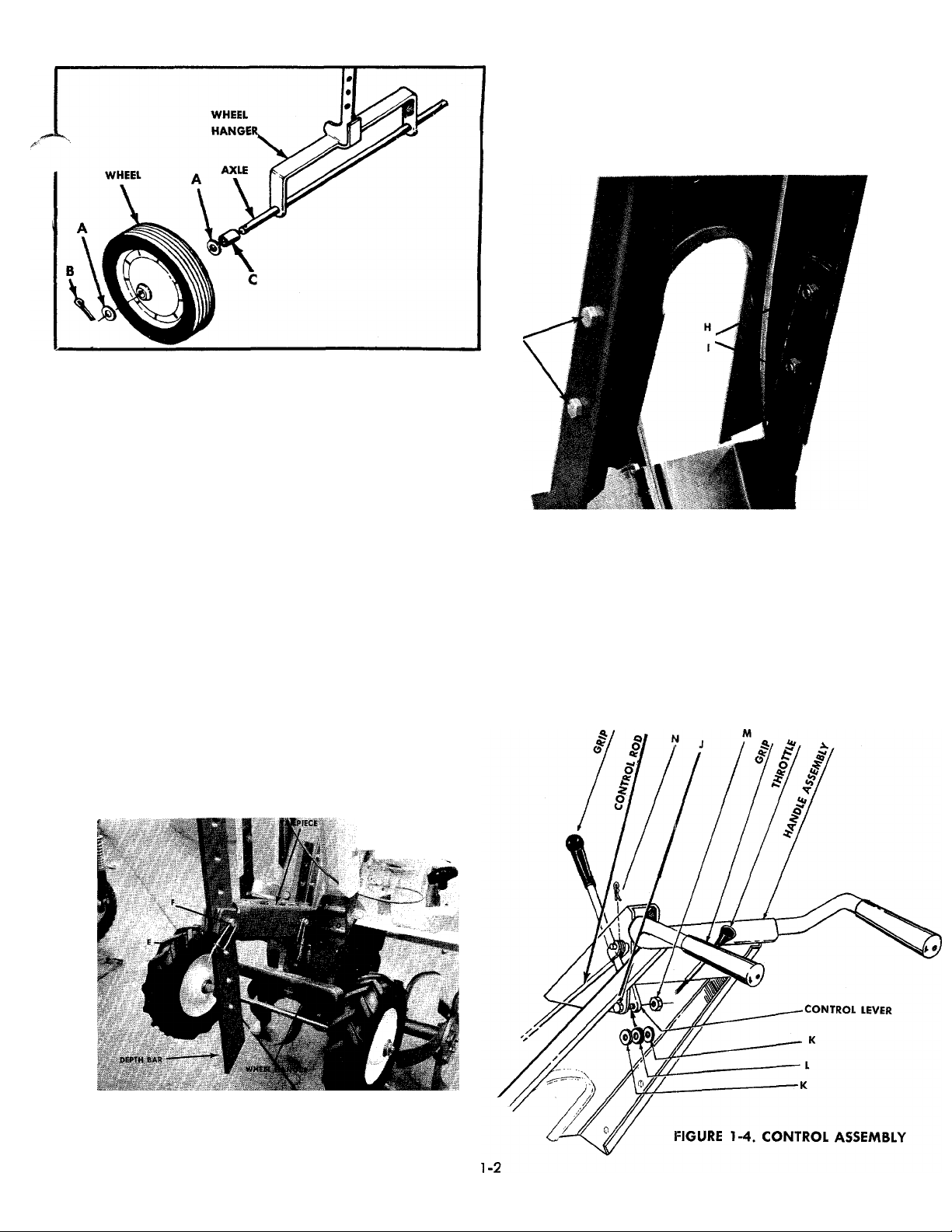

FIGURE 1-1. WHEEL ASSEMBLY

Refer to Figure 1-2.

Step 3. Place the wheel hanger into the tailpiece and

secure with clevis pin D and locking pin E.

c. Handle Assembly

Refer to Figure 1-3.

Assemble the handle to the handle bracket with 4

hex bolts G, lockwashers I and hex nuts H.

b. Depth Bar

Refer to Figure 1-2.

Step 1. Attach the depth bar to the tailpiece with the

clevis pin.

Step 2. Secure the clevis pin F with the locking pin E.

FIGURE 1-3 HANDLE ASSEMBLY

d. Control Assembly

Refer to Figure 1-4.

Step 1. Place the control lever through the handle

assembly.

Step 2. Attach at the bottom with hex bolt J, steel

washer K, rubber washer L and secure with

hex nut M.

FIGURE 1-2. WHEEL HANGER AND DEPTH BAR

Page 6

Refer to Figure 1-5.

Step 3. Screw the control rod into the ferrule until it

extends through the ferrule % of an inch.

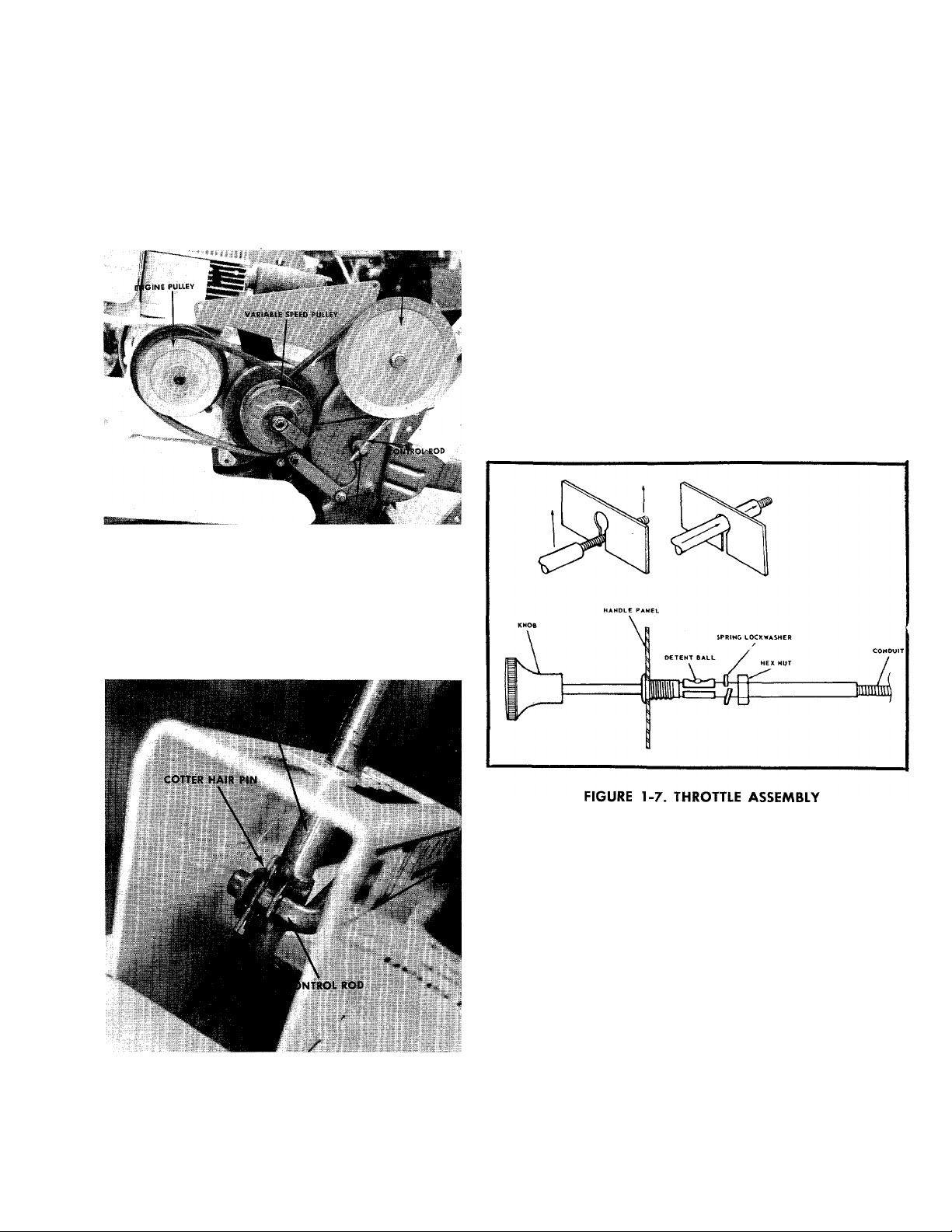

e. Throttle Control Assembly

Step 1. Push the black plastic knob on the throttle

control all the way.

FIGURE 1-5. FERRULE ADJUSTMENT

Refer to Figure 1-6.

Step 4. Place the bent end of control rod into the

control lever and fasten with cotter hairpin N.

Step 2. Pull out the black knob until the detent

clicks twice to allow the spring lockwasher

and the hex nut to pass over the detent

boll to the threads.

Step 3. Slide the spring lockwasher and the hex nut

over the detent ball and thread the hex nut

one or two turns.

Step 4. Place the conduit through the slot in the

handle pandl.

Step 5. Push the throttle control in until it seats.

Step 6. Tighten the hex nut.

FIGURE 1-6. CONTROL ASSEMBLY

1-3

Page 7

SECTION 2

CONTROLS AND TRELIMINARY CHECKS

2-1. CONTROLS

The controls on Model 1850 Rotary Tiller are the

control lever and throttle control.

a. The Control Lever

The Control Lever is released from Neutral by mov

ing it to the right and allowing the spring tension to

pull the control lever into one ot the tour forward

speeds. See Figure 2-1.

NOTE

Number 1 position is the slowest tine

rotation speed and number 4 is the

fastest.

Pulling the control lever backwards into the Reverse

position reverses the direction of tine rotation.

b. The Throttle Control

The throttle control actuates the butterfly in the car

buretor and may be set at stop, slow, fast or choke to

control the speed of the engine.

NOTE

Always check the throttle cable at the

engine end for a tight connection.

To stop the engine, push the throttle control all the

way in. To operate the choke, pull the throttle control

all the way out. See Figure 2-1.

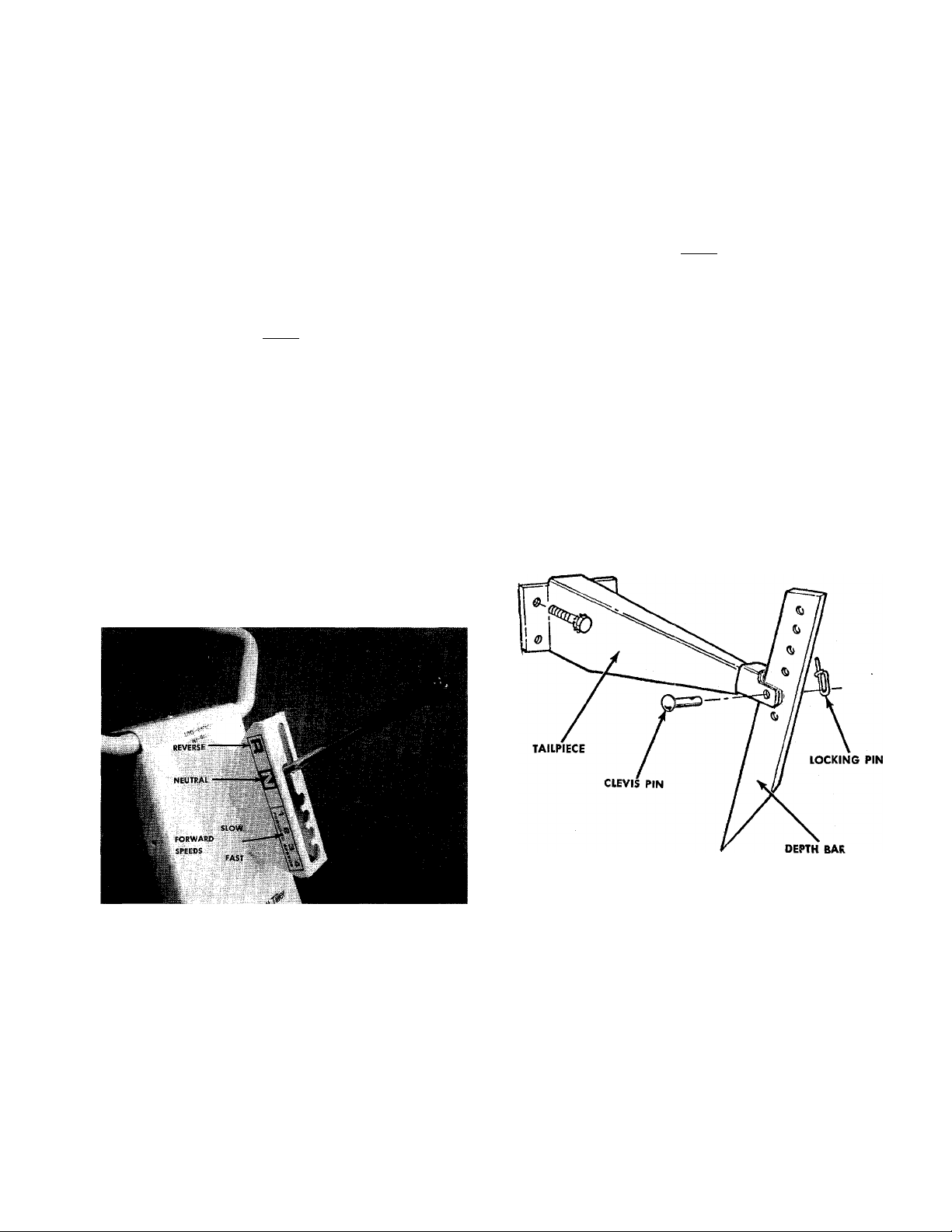

c. The Depth Bar

The depth bar is used to prevent the tiller from run

ning on top of the ground instead of tilling. The deep

er you set the depth bar, the deeper you will till. Tilling

depth is from 0 to 8-inc'hes. See Figure 2-2.

FIGURE 2-1. CONTROLS

FIGURE 2-2. DEPTH BAR

2-1

Page 8

2-2. WHEEL ADJUSTMENT

The wheel height can be adjusted by removing the

long clevis pin on the wheel hanger and raising or

lowering the setting. The higher the setting the deeper

the tilling depth. See Figure 2-3.

NOTE

Pick a height that places the handles in

b. Gasoline

Remove the gas cap and fill the tank with FRESH

REGULAR GASOLINE. If the gasoline has been in a

metal can for a long period, throw it away and use

fresh gasoline.

FIGURE 2-3. WHEEL HEIGHT ADJUSTMENT

2-3. CHECKING OIL, GASOLINE, AND GEAR CASE

NOTE

When packaged for shipment the ma

chine contains no oil or gasoline. Before

starting the engine, oil must be added

to the engine crankcase and gasoline

to the tank. DO NOT mix oil with gaso

line.

a. on

With the tiller on level ground, remove the oil filler

plug and pour 2% pints of good quality, SAE 30 type

MS engine oil into the crankcase. Replace the oil filler

plug.

The chain case is sealed and requires no further

lubrication unless the chain case is disassembled for

repair.

2-2

Page 9

SECTION 3

OPERATINC INSTRUCTIONS

3-1. STARTING THE ENGINE

Step 1. With the tiller set on level ground, set the

control lever in NEUTRAL.

Step 2. Set the throttle control to CHOKE.

Step 3. As illustrated in figure 3-1, grasp the recoil

starter handle, pull out sharply, and hold

it in the out position. (Do not let cord snap

back.)

3-2. STOPPING THE ENGINE

To stop the engine, push the throttle control all the

way in to the STOP position. See Figure 2-1. When the

throttle control is in the STOP position, a switch blade

is activated to short-circuit the spark plug.

WHENEVER THE TILLER IS LEFT UNAT

TENDED, DISCONNECT THE SPARK

PLUG LEAD AND PLACE THE THROHLE

CONTROL IN THE STOP POSITION.

3-3. STOPPING THE TINES

Pull the control lever into the NEUTRAL position. The

tines will not rotate. See Figure 2-1.

3-4. OPERATING THE TILLER

NOTE

The cord should NOT be pulled out

more than about two feet. If engine

fails to start, allow the cord to wind

back Into the housing, then pull out

sharply again. Refer to Step 5.

Step 4. When the engine starts, gradually move

the throttle to the FAST position. After en

gine warms up (about 2 or 3 minutes) set

throttle at IDLE position.

Step 5. DO NOT OVERCHOKE ENGINE. Repeated

cranking with throttle at CHOKE position

will cause gasoline to flood the intake tube

and the engine. If, after 3 or 4 attempts,

the engine fails to start, place throttle in

FAST position, crank the engine several

times to clear out the excess fuel; and then

proceed with steps 2, 3 and 4.

Typical operation of the tiller is as follows:

Step 1. Set the clutch control to NEUTRAL.

Step 2. Start the engine as outlined in paragraph

3-1.

NOTE

To move the tiller to- the work area,

keep the depth bar in the highest posi

tion. With the throttle in the SLOW posi

tion, slowly engage the control lever

into the number 1 position and the tiller

will walk to the work area without dig

ging into the ground.

Step 3. With the clutch control in NEUTRAL, set the

depth bar in one of the lower settings.

NOTE

When several passes must be made

over a certain area, lower the depth bar

each time a pass Is made.

3-1

Page 10

Step 4. Set the throttle control to FAST.

Step 5. Slowly engage the clutch control to the num

ber 1 position and the tines will begin rotat

ing, Number

mum tine speed. Tilling the ground for the

first time should be done in the number 1 or 2

position. To pulverize the soil after it has been

tilled, move the control lever to the number 3

or 4 position.

The engine must be running to move

the control lever into the faster speeds.

A downward pressure on the handles

will increase the working depth and re

duce the forward speed. An upward

pressure on the handles will reduce the

working depth and increase the for

ward speed. The type of soil and work

ing conditions will determine the actual

setting of the depth bar and the handle

pressure required.

4 position will give the maxi

NOTE

NOTE

CAUTION

If the tines stop rotating or the belt

slips, slop the engine and examine the

tine area for a rock or some object that

may be jamming the tines and prevent

them from turning. Reversing the tiller

Will usually free the object.

Step 6. To reverse the direction of rotation of the tines,

pull the control lever into the reverse position.

The control lever must be held in reverse. See

Figure 2-1.

1

3-2

Page 11

4-1. CRANKCASE OIL

SECTION 4

MAINTENANCE

To ensure maximum engine performance, perform

the following periodic maintenance:

a. Oil Check

Check the oil level in the crankcase before each use

of the machine and after every two hours of opration.

The oil level shall be over-flowing at the oil fill plug.

See figure 4-1.

OIL FILL PLUG

Step 1. With the machine on level ground, place a

suitable metal container under the oil drain

plug, then remove the drain plug.

Step 2. After the oil has been drained completely

from the crankcase, replace the drain plug

and tighten.

Step 3. Refill crankcase with 2% pints of SAE 30 en

gine oil (A.P.I. class MS). Pour the oil slowly

to eliminate airlock.

4-2. CHAIN CASE LUBRICATION

The chain is permanently lubricated and requires

no further lubrication unless the case is disassembled

for repair.

If the case is disassembled, clean the chain with

kerosene, allow it to dry and work a high temperature

grease, such as Lubriplate No. 310 into the chain.

NOTE

A 4 oz container of Lubriplate No. 310

is available under part number

727-136.

OIL DRAIN

FIGURE 4-1. OIL FILL PLUG

b. Oil Change

After the first two hours of operating a new engine,

drain the oil (see figure 4-2) from the crankcase while

engine is still hot and refill crankcase with new oil;

thereafter change the oil after every 25 hours of opera

tion. This procedure ensures for minimum wear of engin parts and provides for virtually trouble-free oper

ation. To change the oil, proceed as follows:

4-3. CHAIN ADJUSTMENT

No chain adjustment is necessary.

4-4. AIR FILTER

Under normal operating conditions, the air cleaner,

located on top of the carburetor, must be serviced

after every ten hours of use. Under extremely dusty

operating conditions, the air cleaner must be serviced

after every hour of operation. See Figure 4-3.

Step 1. Remove the wing nut and cover.

Step 2. Lift off foam element from support base.

Step 3. Remove metal support tube assembly (screen

and two metal caps) from foam element by

compressing the foam element.

4-1

Page 12

Step 4. a.Wash foam element in a solvent such as

kerosene or liquid detergent and wafer to

remove dirt.

b. Wrap foam in cloth and squeeze dry.

c. Saturate foam in engine oil, then squeeze

out excess oil.

NOTE

Belt tension is automatically main

tained on the forward and reverse drive

belts by idlers. No adjustment is neces

sary.

NOTE

Use the same oil for the air cleaner that

you use in the engine.

d. Assemble parts and fasten to the car

buretor.

FIGURE 4-3. AIR CLEANER

4-7. SPARK PLUG

The spark plug gap should be cleaned, and reset to

a 0.030-inch clearance every 25 hours of engine oper

ation (see figure 4-4). Spark plug replacement is rec

ommended at the start of each tiller season; check

engine parts list for correct plug type.

FIGURE 4-4. SPARK PLUG

4-5. CLEANING ENGINE AND TINE AREA

Any fuel or oil spilled on the tiller should be wiped

off promptly. Dirt, leaves and other debris must not be

left to accumulate around the cooling fins or the engine

or on any part of the tiller. Clean the under side of the

tine shield after each use. The dirt washs off the tine

easier if washed off immediately instead of after it

dries.

4-6. BELTS

Check that belts are free of oil or dirt. Wipe the belts

periodically with a clean rag.

4-8. GASOLINE FILTER AND SHUT-OFF VALVE.

Refer to Figure 4-5.

Step 1. Close the shut-off valve.

Step 2. Loosen the thumb screw below the bowl.

Step 3. Remove and clean the screen.

Step 4. Open the shut-off valve to see if gasoline

flows freely from the gasoline tank.

Step 5. Clean the bowl and screen. Use alcohol or

acetone to clean the parts if you find a gum

my, varnish-like substance in the bowl.

Step 6. Reassemble.

Step 7. Open the shut-off valve.

4-2

Page 13

FIGURE 4-5. GASOLINE FILTER AND SHUT-OFF

4-9. BELT ADJUSTMENT

To check the belt adjustment, it is necessary to re

move the belt cover so the belts are exposed as shown

in Figure 4-6.

BELT SHOULD BE IN THIS

POSITION WITH CONTROL

LEVER IN NO. 4 POSITION

VARIABLE SPEI

PULLEY

FIGURE 4-7. VARIABLE SPEED PULLEY

4-10. BELT REPLACEMENT

Step 1. Remove the belt cover so the belts are ex

posed as shown in Figure 4-6.

Step 2. Put the depth bar on the wheel hanger and

place the tip of the depth bar under the var

iable speed pulley bracket as shown in Figure

4-8.

FIGURE 4-6. DRIVE SYSTEM

Start the engine and move the control lever into the

number 4 position. The belt closest to the engine

should move to the outside edge of the variable speed

pulley so the top of the belt is almost flush with the

pulley. See Figure 4-7.

FIGURE 4-8. BELT REMOVAL

4-3

Page 14

Step 3. Place your foot on the rear of the depth bar

and apply pressure. The belts will go slack.

Step 4. Remove the REAR belt first and ALLOW IT TO

FORM A LOOP AROUND THE VARIABLE

SPEED PULLEY.

Step 5. Slide the center section of the variable-speed

pulley towards the engine. See Figure 4-7.

Step 6. Remove the FORWARD belt from the engine

pulley and the variable-speed pulley.

NOTE

By following this order of belt removal,

it is not necessary to remove the belt

guard on the varible-speed pulley.

Step 7. Remove the rear belt from the variable-speed

pulley.

Step 8. Reassemble with the new belts.

FIGURE 4-9. CARBURETOR ADJUSTMENT

4-n. ADJUSTING THE CARBURETOR

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature, alti

tude and load.

To Adjust Carburetor:

Turn needle valve clockwise until it just closes. See

Figure 4-9.

CAUTION

Valve may be damaged by turning it in

too far.

Now open needle valve IV2 turns counter-clockwise.

Close idle valve in same manner and open Va to %

turns. This initial adjustment will permit the engine to

be started and warmed up prior to final adjustment.

Final Adjustment;

Turn needle valve in until engine misses (lean mix

ture) then turn it out past smooth operating point until

engine runs unevenly (rich mixture). Now turn needle

valve to the mid-point between rich and lean so the en

gine runs smoothly.

Hold throttle at idle position and set idle speed ad

justing screw until fast idle is obtained (1750 RPM).

Hold throttle in idle position and turn idle valve in

(lean) and out (rich) until engine idles smoothly. Then

reset idle speed adjusting screw so that engine idles

at 1750 RPM. Release throttle—engine should accel

erate without hesitation or sputtering. If engine does

not accelerate properly, the carburetor should be re

adjusted to a slightly richer mixture.

4-12. ADJUSTING CARBURETOR CHOKE

Proper choke and stop switch operation is depend

ent upon proper adjustment of remote controls on the

powered equipment.

To Check The Operation Of The Choke:

Step 1. Remove the air cleaner.

Step 2. Pull the throttle control all the way out to the

CHOKE position. See Figure 2-1. The choke

should be closed.

Step 3. The engine should shut off when the throttle

control is all the way in. (STOP position.)

To Adjust;

Place remote control lever on equipment in FAST

(high speed) position. Loosen control casing clamp

screw "B." Move control casing "A" and wire until lever

"D" touches choke operating link at "C." Tighten cas

ing clamp screw "B." Replace air cleaner. See Figure

4-10.

4-4

Page 15

4-14. OFF-SEASON STORAGE

/■

If the machine is to be inoperative for a period long

er than 30 days, the following precautions are recom

mended;

Step 1. Working outdoors, drain all fuel from the

fuel tank. Use a clean dry cloth to absorb

the small amount of fuel remaining in the

tank, then run the engine until all fuel in

carburetor is exliausted.

|W\RNIN^

DO NOT DRAIN FUEL WHILE SMOKING

OR IF NEAR AN OPEN FIRE.

4-13. MAGNETO AND SPARK PLUG CHECK

WHENEVER CHECKING THE MAGNETO

OR THE SPARK PLUG FOR AN ELECTRI

CAL SPAR.K, USE INSULATED PLIERS TO

HOLD THE SPARK PLUG WIRE OR THE

SPARK PLUG,

a. Magneto Check

Step 1. Disconnect the spark plug wire from the

spark plug, and place throttle control lever in

CHOKE or FAST position.

Step 2. Drain all the oil from the crankcase (this

should be done after the engine has been

operated and is still warm) and refill the

crankcase with clean new oil.

Step 3. Disconnect the spark plug wire and remove

the spark plug from the cylinder. Pour

about six drops of engine oil into the cylin

der, and then pull the recoil starter several

times to spread the oil on the cylinder wall.

Replace the spark plug, but DO NOT con

nect the wire.

Step 4. Clean the engine and the entire tiller thor

oughly.

Step 5. Lubricate the gear cane an indicated in par

agraph 4-2.

Step 6. Wipe tines with oiled rag to prevent rust.

Step 2. Using insulated pliers, hold the wire close

('/4-inch distance) to engine block or cylin

der, then crank the engine several times. A

spark should jump from the wire to the

block or cylinder; if a spark does not occur,

check the wire and the magneto.

b. Spark Plug Check

Step 1. Remove spark plug from cylinder but leave

the wire connected, and set throttle at

CHOKE or FAST position.

Step 2. Using insulated pliers, hold the metal side

of the spark plug in contact with the engine

block, and crank the engine several times.

The spark should jump the gap between

the center and side electrode in the plug.

Step 3. If a spark does not occur, check the elec

trode gap and repeat step 2. If no spark

occurs, replace the plug.

4-5

Page 16

MAINTENANCE LOG

After using and servicing the machine, enter the data on this log for future reference. Change oil after

first 5 hours of operation; thereofter, change oil every 25 hours of operation. Clean the air cleaner every 10

hours; every hour under very dusty conditions. Lubricate all points indicated in figures 4-2, 4-3 and 4-4 every

10 hours.

STARTING

TIME

FINISHING

TIME

OPERATING

TIME

ACCUMULATED

TIME

OIL

CHANGE

AIR

CLEANER

LUBRI

CATION

COMMENTS

4-6

Page 17

SECTION 5

EXPLODED VIEWS

AND

PARTS LIST

5-1

Page 18

FIGURE 5-1. PENNCRAFT TILLER MODEL 1850

5-2

Page 19

FIGURE 5-2. PENNCRAFT TILLER MODEL 1850

5-3

Page 20

PARTS LIST—ROTARY TILLER MODEL 1850

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN IN THIS LIST:

1. The PART NUMBER 2, The PART NAME 3. MODEL NUMBER

DO NOT use Reference Numbers when ordering Repair Parts, always use Part Numbers

Your lawn mower is right hand (R.H.) or- left hand (L.H,| as you ride.

REF.

PART

NO.

NO.

— Engine

1

2

710-380

384-4524

3

4 710-376 Hex Hd. Cap Scr. 5/16-18 x 1 Lg.*

6 710-216

7 720-143 Grip

714-507

8

9 711-422 Control Rod

10 710-106

712-107 Hex Center Lock Nut ’/4-20 Thd.*

11

12 305-1166

746-122 Throttle Control—Complete

13

14 384-4533

310-4525 Control Lever Assembly

15

736-325 Flat Washer^ .20

16

17 736-155 Rubber Washer

736-325 Flat Washer*

18

736-217

19

20 712-798 Hex Nut %-16 Thd.* .20

21 428-4506

22

710-253

23 736-217

428-4505 Handle Mounting Bracket R.H.

24

428-4507 Tail Piece

25

732-194 Spring Pin

26

27

736-148 Ext. Lockwasher for % Scr."^ .20

710-253

28

DESCRIPTION

Hex Hd, Cap Scr, 5 /16-18 x Lg/‘

Tine Shield

Hex Hd. Cap Scr. .20

Cotter Pin 3/32 x% Lg."^

Hex Hd, Cap Scr. x 1 'A Lg. '" .20

Grip .30

Handle Assembly

Spring Lockwasher % Screw"'

Handle Mounting Bracket L.H.

Hex Hd. Cap Scr. %-16x 1 Lg.*

Spring Lockwasher % Scr.*

Hex Hd. Cap Scr, %-16 x 1 Lg.*

29 732-194 Spring Pin

428-4328

30

31 711-231 Clevis Pin

428-4527 Wheel Hanger Bracket

32

Depth Bar 4.80

APPROX.

SELLING

PRICE

.20

.20

.60

.20

.20

2.25

.20

.20

.20

.20

.20

.50

.20

.20

.30

33 711-510 Clevis Pin

34

310-4451

711-313

35

36 501-8929

37

736-160 Flat Washer*

38 714-115

39

712-236 Hex Elastic Stop Nut 7/16-20 Thd.*

428-4474

40

41 428-4511 Inner Tine Adapter

42 736-220

736-224

43

44 742-113

428-4511

45

46 742-110

47

428-4474

710-152

48

49 736-169

50 712-711

51 710-483

52

736-119 Spring Lockwasher 5/l6 Scr.*

53 712-158

54 428-4519

55 712-158

56 736-119

57

428-4519

58

710-258 Hex Hd. Cap Scr. '/4-20 x % Lg.*

59 710-252

60 312-4516

Ó1 736-329

62 712-287

63 312-4537

64

710-121

65 736-921

66 312-4523

67 712-287

68 711-504

69

748-855

70 310-4529

71

717-188 11-2 Tooth Sprocket % Pitch

Rear Axle

Spacer

Wheel Assembly

Cotter Pin Va Dia. x 1 Lg.*

Outer Tine Adapter

Dust Pad

Dust Pad

Tine L. H.

Inner Tine Adapter

Tine R.H.

Outer Tine Adapter

Hex Hd. Cap Scr. %-24 x 1 Lg.*

Spring Lockwasher % Scr.*

Hex Jam Nut %-24 Thd.*

Hex Hd. Cap Scr. 7/16-20 x 2V4 lg.*

Hex Center Lock Nut 5/16-18 Thd.*

Engine Mounting Bracket

Hex Center Lock Nut 5/16-18 Thd.*

Spring Lockwasher 5/16 Scr.*

Engine Mounting Bracket

Hex Hd. Cap Scr. 14-20 x % Lg.*

Belt Guard

Spring Lockwasher '4 Scr.*

Hex Nut '/4-20 Thd.*

Belt Trap Assembly

He < Hd. Cap Scr. '/2-20 x % Lg.*

Spring Lockwasher V2 Scr.*

Variable Speed Guide Bracket

Hex Nut '/4-20 Thd.*

Sprocket Shaft

Flange Bearing

Double Sprocket Assembly

.80

6.00

.20

.20

.20

1.80

1.80

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

1.00

.20

.20

5-4

REF.

PART

NO.

NO.

715-120

72

750-118 Spacer

73

74

713-149

75

711-505

76

77 748-855

710-230

78

428-4517

79

428-4501

80

428-11021 Eccentric Link

81

82 736-161

83 736-703

84 741-155

310-5034

85

736-329

86

736-329

87

710-258

88

714-136

89

310-5080

90

310-4515 Friction Disc

91

754-158

92

712-461

93

428-4520

94

756-167

95

726-106

96

712-221

97

714-115

98

736-204

99

711-392 Ferrule

100

428-4521

101

736-703

102

712-116

103

104 712-116

712-461

105

710-152

106

736-217

107

310-7386

108

714-118

109

310-10843

no

750-166

111

748-180

112

754-157

113

738-138

114

710-380

115

310-11002

116

711-509 Spring Insert

117

732-232 Variable Drive Spring

118

712-158

119

736-119

120

428-4530

121

‘ 721-117 Oil Seal l’/4 X 1%

122

748-194 Flange Bearing 1’4 x VA

123

712-287 Hex Center Lock Nut '/;-20 Thd.*

124

736-329

125

721-119

126

310-4531

127

710-118

128

711 -506

129

736-119

130

713-150

131

717-189

132

715-125

133

710-258

134

428-4530

135

710-118

136

736-119

137

736-703

138

139 428-4503

DESCRIPTION

Spirol Pin 3/I6 Dia, X 1 Lg.—Heavy Duty

Part of Ref. No. 70

Roller Chain w/Master Link ^‘35-2 x 36^/41 Lg.

Pulley Shaft

Flange Bearing

Hex Hd. Cap Scr. ’/4-28 x '/2 Lg.*

Variable Speed Bracket Assembly

Housing Assembly L.H.

Rubber Washer

Flat Washer

Ball Bearing %x 1%

Bearing Housing

Spring Lockwasher Va Scr.*

Spring Lockwasher Va Scr.* .20

Hex Hd. Cap Scr. !^-20 x % Lg.* .20

Hi Pro Key #505

Friction Wheel Assembly 11.50

V-Belt 21/32 x35 Lg. Special

Hex Jam Nut '/2-13 Thd. .20

Variable Speed Belt Guard

8" x W‘ Pulley

Push On Pal Nut (Not Shown) .20

Hex Elastic Stop Nut %-18 Thd. .40

Cotter Pin Va Dia. x 1 Lg. .20

Flat Washer .20

Link Bracket Assembly

Flat Washer

Hex Elastic Stop Nut %-24 Thd.* .20

Hex Elastic Stop Nut %-24 Thd. '' .20

Hex Jam Nut '/2-13 Thd.

Hex Hd. Cap Scr. %-24 x 1 Lg.

(Heat Treated)*

Spring Lockwasher % Scr.* (Heavy Duty) .20

Flat Washer

Square Key Va Sq. x V/2 Lg.*

Variable Speed Pulley Assembly

Spacer (For Item 116) Not Shown

Pivot Slide (For Item 79) Not Shown

V-Belt 21/32 X 28 Lg. Special

Shoulder Bolt Special

Hex Hd. Cap Scr. 5/16-18 x }Va Lg.*

Spring Bracket

Hex Center Lock Nut 5/16-18 Thd.*

Spring Lockwasher 5/16 Scr.*

Cast Bearing Housing Assembly

Spring Lockwasher Va Scr.*

Gasket

Engine Pulley

Hex Hd. Cap Scr, 5/ 16-18 x % Lg.

Tine Shaft

Spring Lockwasher 5/16 Scr.*

Roller Chain w/Master Link #40-2 x 34 Lg.

24-2 Tooth Sprocket l/i" Pitch

Spirol Pin Va Dia. x 2 Lg. (Heavy Duty)

Hex Hd. Cap Scr. Va-20 x % Lg.* .20

Cast Bearing Housing Assembly

Hex Hd. Cap Scr. 5/ 16-18 x % Lg.*

Spring Lockwasher 5/l6 Scr.*

Flat Washer

Housing Assembly R.H. Side

APPROX.

SELLING

PRICE

.20

.50

1.00

.20

.20

.20

.60

.20

.40

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

Page 21

FIGURE 5-3. ENGINE MODEL 190402-0689-01

5-5

Page 22

PARTS LIST ENGINE MODEL 190402-0689-01

PART

REF.

NO.

RING SETS:

NO.

1

390399 Cylinder Assembly

2 295962 Bushing—Cylinder

3 294606 Seal—Oil

211778 Head—Cylinder

5

7

*270430

390321

8

9 *27803

93536 Screw—Sem

10

n 67068 Tube Breather

12

*27750

*27876

*27877

13 93210 Screw—Cylinder Head (2-9/32" Long)

14 93211 Screw—Cylinder Head (2-9/16" Long)

15

16

18 299167 Cover Assy.—Crankcase

21 66768

22

23

24

25 390347

26

93583 Stud—Cylinder Head (2). Used on type

91084 Plug—Oil Drain

93418 Plug—Oil Drain (Hex Socket) Used on

261149

17

29530

19 295964 Bushing—Crankcase Cover

20 298423 Seal—Oil

93585

298260

61760 Key—Flywheel

390348 Piston Assembly—.010" O.S.

390349 Piston Assembly—.020" O.S. 9.60

390350

299569

211637 Ring—Piston, Comp., Top, Std. 1.25

211636 Ring—Piston, Comp., Center, Standard 1.25

211635 Ring—Piston, Oil, Std. 1.25

299570

211649

211650

211651 Ring—Piston, Oil, .010" O.S. 1.25

299571

211653 Ring—Piston, Comp., Top, .020" O.S. 1.25

211654 Ring—Piston, Comp., Center, .020" O.S. 1.25

211655 Ring—Piston, Oil, .020" O.S. 1.25

299572 Ring Set—Piston—.030" O.S. 4.25

211657

211658

211659 King—Piston, Oil, .OSU" O.S. 1.25

27

68546 Lock—Piston Pin .20

28

295840

295841

29

390401

30 222113

31 222114

32

92659 Screw—Connecting Rod

33 390419

34 261055

35

65906 Spring—Intake Valve .30

DESCRIPTION

Note; Requires special tools for installation.

Gasket—Cylinder Head .45

Breather Assembly

Gasket—Valve Cover .20

Gasket—Crankcase Cover—1/64'^ Thick .20

Gasket—Crankcase Cover—.OOS"'"' Thick .20

Gasket—Crankcase Cover—.009" Thick .20

Nos. 0646, 0647

type Nos. 0144, 0652.

Crankshaft

Bearing—Ball 6.35

Note: Requires special tools for installation.

Plug—Oil Filler

Screw—Crankcase Cover Mounting Sem

Flywheel 19.50

Piston Assembly—Std. 9.60

Piston Assembly—.030" O.S.

Ring Set—Piston—Std. 4.25

CONSISTS OF—

Ring Set—Piston—.010" O.S.

CONSISTS OF—

Ring—Piston, Comp., Top, .010" O.S.

Ring—Piston, Comp., Center, .010" O.S. 1.25

Ring Set—Piston—.020" O.S.

CONSISTS OF—

CONSISTS OF—

Ring—Piston, Comp., Top, .030" O.S. 1.25

King—Piston, Comp., Center, O.S.

Pin Assy.—Piston—Std.

Pin Assembly—Piston—.005" O.S.

Rod Assy.—Connecting

Note: For Connecting Rod with .020" unoer-

size Crankpin Bore—Order No. 390773.

Dipper—Connecting Rod 45

Lock—Conn. Rod Screw .20

Valve—Exhaust

Valve—intake 1.70

APPROX.

SELLING

PRICE

36.95 36

1.20

.55

4.95

1.20

.20

.60

.20

.45

.20

.20

.20

38.00

12.95

1.65

.85

.20

.75

.20

9.60

9.60

4.25

1.25

4.25

1.25

1.15

1.15

3.90

.20

3.25

REF.

NO.

40

41

42 93630

45

46

50

51

52

53 93128

54 93208

55

56

57

58

59

60

61 68848

62 93254

63

64

65

66

67 211383 Housing—Rewind Starter Clutch

68 63770

69 66718

70

71 221653 Washer—Retainer

73

100

101

102 f27918

103

104 f230896

105

107 390403

108

111

112 23123

113

114

115

116

117 •¡•23118

118

119 90746

120

121

158

159

164

165

166

167

168

171

180

181

182 221935

PART

NO.

26828

221596

292260

260933

210728 Gear—Cam

211812 Elbow—Intake

*270684 Gasket—Intake Elbow

*27828

295272

295871

294303

66564

230228

66728 Grip-Starter Rope

260414 Spring—Ratchet

230543

93106 Screw—Rewind Starter Housing

298798

298799 Ratchet—Rewind Starter Clutch

221796

220865 Washer—Spring

75

68238

76

390727 Carburetor Assembly (Manual Choke)

90

390404

91

92 390503

23108

93

f292681

94

95

96 62940

9798298826

99

no

93038

91920

26157

61967

93043 Pin—Throttle Stop

99333

299096

62872

62399 Washer—Choke Lever

26155

f390395

f68667 Gasket-Nozzle

•¡•23117

t68677

t230009

92290

295938

27590

220521

390311

93453

230768

66648

222150

92129 Nut—Hex—14-28

290816

69221

DESCRIPTION

Spring—Exhaust Valve

Retainer—Intake Valve

Rotocoil—Exhaust Valve

Retainer—Exhaust Valve Rotocoil (2)

Tappet—Valve

Gasket—Intake Elbow Mtg.

Screw—Carburetor Mounting Sem

Screw—Intake Elbow Mounting Sem

Housing—Rewind Starter

Pulley—Rewind Starter

Spring—Rewind Starter

Rope—Rewind Starter (63" Long)

Pin—Starter Grip

Bumper—Starter Pulley

Screw—Pulley Bumper Mounting Sem

Adapter—Ratchet Spring

Mounting Sem

Clutch Assy.—Rewind Starter

Ball—Clutch

Washer—Starter Clutch Thrust

Screen—Rewind Starter

Washer—Ratchet Sealing

Body Assembly—Upper Carburetor 8.80

Body—Upper Carburetor

Bushing—Throttle Shaft

Valve Assembly Carburetor Idle

Screw—Throttle and Choke Valve Mtg. Sem .20

Valve—Throttle

Shaft and Lever—Throttle

Screw—Machine, Fil. Hd.—8-32 x

Spring—Throttle Adjustment .20

Stop—Throttle

Gasket—Carburetor Body

Float—Carburetor

Pin—Float Hinge

Valve—Fuel Inlet

Body Assembly—Lower Carburetor

Valve—Choke

Spring—Choke Lever

Screw—Choke Lever

Nozzle—Carburetor

Retainer—Needle Valve

Packing-Needle Valve

Nut—Needle Valve Pkng.

Valve—Needle

Screw—Machine, Fil. Hd.—10-32 x W'

Washer—Lock—No. 10 x 1 /16" x 3/64"

Carburetor Overhaul Kit

Filter—Carburetor Drain

Retainer—Carburetor Drain Filter

Pipe Assy.—Air Cleaner

Nut—Wing

Stud—Air Cleaner

Gasket—Air Cleaner Stud

Strap—Air Cleaner Pipe

Tank Assy.—Fuel (4 quart)

Cap—Fuel Tank

Bracket—Fuel Tank

APPROX.

SELLING

PRICE

.80

.25

3.15

.20

.55

5.70

1.60

.20

.20

.20

.20

4.10

2.95

.75

.80

.20

.55

.20

.20

.20

.35

.20

3.00

1.35

.20

.20

.95

.20

.80

.20

.20

19.50

5.20

.25

.25

.20

1.55

.20

.65

.20

.20

.95

.20

.60

6.15

.20

.20

.20

.20

2.00

.20

.35

.20

.20

.40

.20

.20

4.25

.20

.20

2.80

.30

.45

.20

.30

.20

9J0

.30

2.15

______________

5-6

Page 23

PARTS LIST ENGINE MODEL 190402-0689-01

Ref.

No.

183

184

185

187

196

200 221760

201

206

207 26855 Spring—Gov. Control Rod

208

209

216

217 261119

218

219 297656

220

222

227 299165

230

231

240

240A 298090

241

242

243

245

246 298683

247 99665

265

300 390578

302 91242

305 93158 Screw—Sem

306

307

308 221901 Cover—Cylinder Head

333

334

337

340

341 93381

342 65704 Plunger—Breaker Point

Pori

No.

291367

91257 Screw—Machine/ Fil. Hd.—14-20 x V/i" .20

90970

299942

22907 Support—Upper Fuel Tank .60

260872 Link—Governor

230149 Nut—Gov. Control Rod

230841 Rod—Governor Control .30

260695

261122 Link—Choke .20

221198

221551

390670

221559

93064

295984

296005

295913 Valve—Fuel Shut-Off

22547 Screen—Fuel Filter

*68477 Gasket—Fuel Filter Bowl

221535 Clamp—Casing

221898 Shield—Cylinder

93163

298968

93381

298809

26018

Description

Strap Assy.—Fuel Tank

Nut—Square—14-20

Pipe—Fuel (Flexible) ISVa'" Long

Guide—Air .20

Spring—Governor

Spring—Choke Link

Washer—Choke Link .20

Gear—Governor

Washer—Thrust

Plate—Governor Control

Lever Assy.—Governor .65

Washer—Spacer

Screw—Sem

Filter Assembly—Fuel

Filter—Fuel (In Fuel Pipe)

Cover Assembly—Fuel 2.90

Bowl—Fuel Filter

Yoke—Fuel Filter

Muffler—Exhaust 1.95

Locknut—Muffler and Elbow .25

Screw—Cylinder Shield Mtg. Sem .20

Armature Assembly

Screw—Armature Mtg. Sem .20

Plug—Spark {IV2" high—38 M.M.)

Spring—Breaker Arm .20

Screw—Breaker Arm Mounting Sem .20

Approx.

Selling

Price

1.00

.20

.95

.20

.40

.20

.30

.20

1.45

.20

.20

.20

3.95

2.75

.80

.20

.20

.35

.70

.20

.20

.45

.30

7.20

1.10

.30

Ref.

No.

345

346

347

352

353

354

355

356

357

358

362

372

375

521

535

536

552

562

592

601

605

608

614

615

616

621

635

642

643

655

657

682

687

688

689

690

Part

No.

222117

93014

221808

66068

92791

90576

66554

299500

91540

299577

291630

220477

294628

299061

294628

65704

61760

298529

270093

390400

230843

92613

90356

93053

297187

295001

93306

93307

230842

297472

66538

221468

280001

221014

93496

211516

298957

221766

260847

92484

Approx.

description

Cover—Breaker Point .45

Screw—Seni .20

Switch—Stop .20

Washer—Insulating .20

Washer—Lock—Shakeproof (3) .20

Nut-Hex-8-32 (2) .20

Collar—Insulating .20

Wire—Ground .20

Key—Pulley .20

Gasket Set 1.45

Shield—Spark Plug (With Stop Switch) 2.70

Clamp—Condenser .20

Breaker Points and Condenser Set 1.85

Ignition Kit 2.20

INCLUDES-

Point Set 1.85

Plunger .30

Key—Flywheel .20

Shielding—Ignition Cable .65

Element—Air Cleaner 3.05

Cleaner Assy.—Air 4.05

Bushing—Governor Shaft .65

Boit—Governor Lever .20

Nut-Hex-10-24 .20

Clamp—Fuel Pipe .20

Bracket—Guard (Upper) 1.60

Starter Assy.—Rewind 10.95

Cotter—Hair Pin .20

Retainer—E-Ring .20

Crank—Governor .95

Switch—Stop .20

Elbow—Spark Plug .50

Cover—Air Cleaner .85

Cup—Air Cleaner .50

Anchor—Spring .20

Screw—Sem .20

Shield—Starter Clutch .70

Slide—Friction Control .85

Cap—Friction Spring .20

Spring—Friction .20

Screw—Machine^ Fii. Hd.—10-32 x V‘3." .20

Selling

Price

^Included in Gasket Set—Part No. 299577.

flncluded in Carburetor Overhaul Kit—Part No. 295938.

5-7

Loading...

Loading...