Page 1

Operator's Manual

CRRFr MRN

REVOLUTION

ZERO TURN RiDiNG MOWER

Model No. 247.28933

For answers to your questions about this product,

call 1-800-659-5917.

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-04608

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

ESPANOL, p. 58

1/7/2009

Page 2

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-8

SafetyLabels......................... Page9

Assembly........................... Page10

Operation........................ Pages11-17

Service&Maintenance.............. Pages18-29

Off-SeasonStorage................... Page30

Troubleshooting...................... Page31

PartsList......................... Pages32-53

RepairProtectionAgreement............ Page57

Espadol............................. Page58

ServiceNumbers................... BackPage

Craftsman Limited Warranty

Two Years on Riding Equipment

Whenoperatedand maintainedaccordingto allsuppliedinstructions,ifthis ridingequipmentfailsduetoa defectin materialorworkmanship

withintwoyearsfromthedateorpurchase,call1-800-4-MY-HOME®toarrangefor freerepair.

Duringthefirstyearofpurchase,therewillbe nochargeforwarrantyserviceinyourhome.Foryourconvenience,in-homewarrantyservicewill

stillbeavailableafterthefirstyearof purchase,butatripchargewillapply.Thischargewillbe waivedif youtransportthe ridingequipmenttoan

authorizedCraftsmandrop-offlocation.Forthenearestauthorizedlocation,call 1-800-4-MY-HOME®.

90 Days on Battery

Forninety(90)daysfromdateofpurchase,ifthebatteryincludedwiththisridingequipmentisdefectiveinmaterialorworkmanship(ourtesting

provesitwill notholdacharge),it willbe replacedfreeofchargein yourhome.

This warranty covers ONLYdefects in material andworkmanship. Searswill NOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedtoblades,sparkplugs,aircleaners,belts,andoil filters.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthatbendtheframeor crankshaft,or over-speedingthe engine.

• Repairsnecessarybecauseof operatornegligence,includingbut notlimitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethe propergradeandamountofengineoil,failuretokeepthedeckclearofflammabledebris,orfailuretomaintainthe

ridingequipmentaccordingtotheinstructionscontainedin theoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).In general,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearof theexteriorfinishes,or productlabelreplacement.

All ridingequipmentandbatterywarrantycoverageis voidif thisproductis everusedforcommercialor rentalpurposes.

Thiswarrantyappliesonlywhilethisproductiswithinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalso haveotherrightswhichvaryfromstatetostate.

Sears, RoebuckandCo.,Hoffman Estates, IL 60179

GrossHP: 22

EngineOil: SAE30

Fuel: UnleadedGasoline

SparkPlug: Champion®RC12YC

Engine: Briggs& StrattonIntekV-Twin

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultinpersonalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthepartofthe operatorcanresultin serious

injury.Thismachineiscapableof amputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorother reproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknownto theStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplacefor futureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsoldtooperatethis machine.

Children14yearsoldandovershouldreadandunderstandthe

operationinstructionsandsafetyrulesinthismanualandshould

betrainedandsupervisedbya parent.

• Neverallowadultstooperatethismachinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhileitis in operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentistobe used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownbytheblade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatterntoavoiddischargeof materialtoward

roads,sidewalks,bystandersandthe like.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardtheoperator.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandonthemachine.

SAVE THESE INSTRUCTIONS!

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperforminganadjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycanbe caughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beawareofthemowerandattachmentdischargedirectionand

do notpointitatanyone.Donotoperatethemowerwithoutthe

dischargecoverorentiregrasscatcherinitsproperplace.

Donot puthandsor feetnearrotatingpartsorunderthecutting

deck.Contactwiththe blade(s)can amputatehandsandfeet.

A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfortrafficwhenoperatingnearorcrossingroadways.This

machineisnotintendedforuseonanypublicroadway.

• Donot operatethemachinewhile undertheinfluenceofalcohol

or drugs.

• Mowonlyindaylightorgoodartificiallight.

Nevercarrypassengers.

• Disengageblade(s)beforeshiftingintoreverse.Backupslowly.

Alwayslookdownandbehindbeforeandwhile backingtoavoida

back-overaccident.

3

Page 4

• Slowdownbeforeturning.Operatethemachinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometoacompletestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

Neverleavea runningmachineunattended.Alwaysturnoff

blade(s),setparkingbrake,stopengineandremovekeybefore

dismounting.

Useextracarewhenloadingorunloadingthe machineintoa

trailerortruck.Thismachineshouldnot bedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loador unloadproperly.

Mufflerandenginebecomehotandcancauseaburn.Do not

touch.

Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtreebranches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthemachine,whichcould

resultinseriousinjury.

Disengageallattachmentclutchesanddepressthebrakepedal

completelybeforeattemptingtostart engine.

Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donotattemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpilesofdryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfirehazard.

Useonlyaccessoriesandattachmentsapprovedforthis machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththeapprovedaccessoryorattachment.

Fora list ofapprovedaccessoriesandattachments,call 1-800-

659-5917.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilitytooperatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

If situationsoccurwhicharenot coveredinthismanual,usecare

andgoodjudgment.Contact1-800-659-5917forinformationand

assistance.

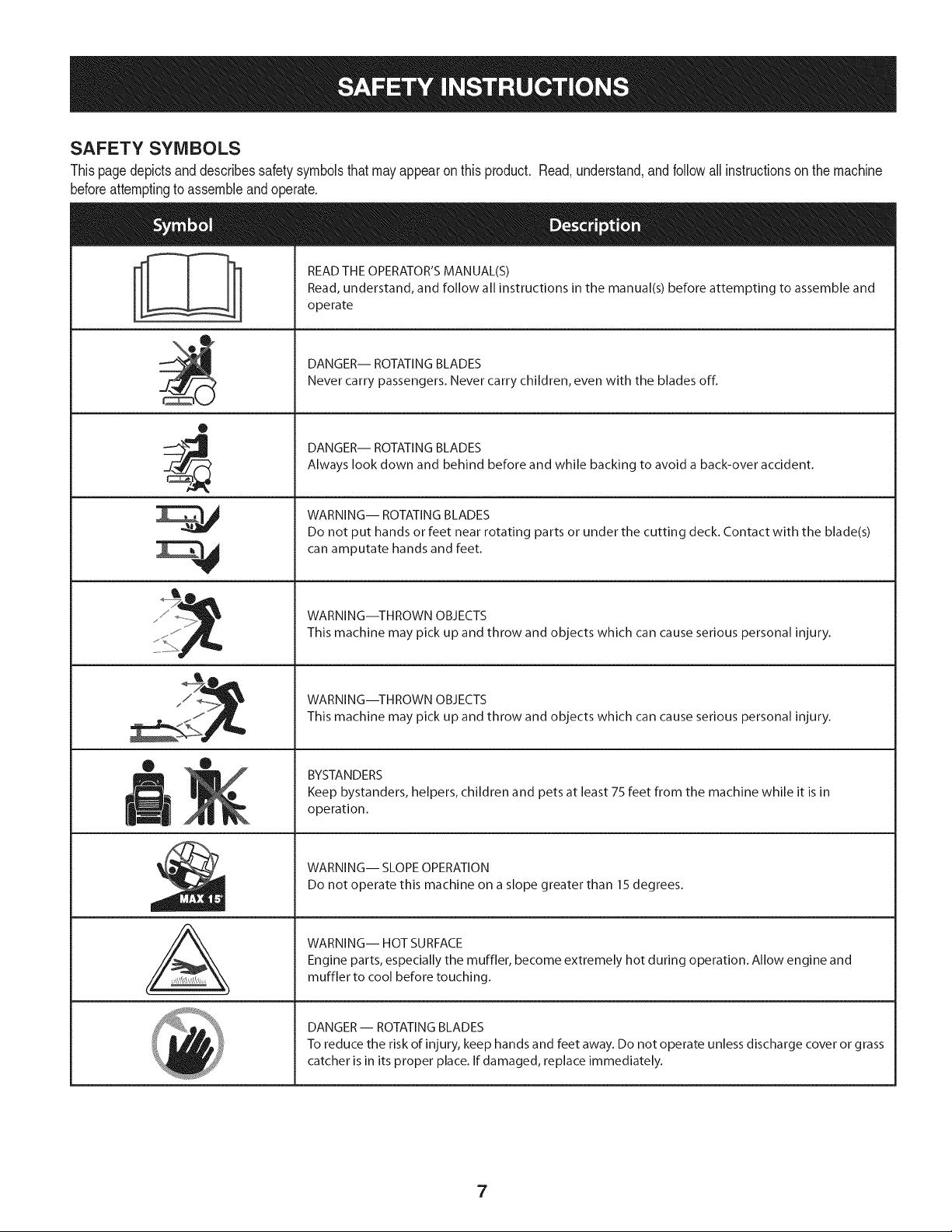

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossofcontrolandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackupthe slopeor if youfeeluneasyon

it, do notmowit.

Foryoursafety,usetheSlopeGuideincludedaspartof this manual

to measureslopesbeforeoperatingthismachineona slopedor hilly

area.Iftheslopeisgreaterthan15degreesasshownonthe Slope

Guide,do notoperatethismachineonthatareaor seriousinjurycould

result.

Do:

o

Mowupanddownslopes,not across.Exerciseextremecaution

whenchangingdirectionon slopes.

• Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

Useslowspeed.Choosea lowenoughspeedsettingsothat

youwill nothavetostopor shiftwhileon theslope.Tiresmay

losetractionon slopeseventhoughthe brakesarefunctioning

properly.Alwayskeepmachineingearwhen goingdownslopes

totakeadvantageofenginebrakingaction.

• Followthemanufacturer'srecommendationsforwheelweights

or counterweightsto improvestability.Forrecommendations,call

1-800-659-5917.

• Useextracarewithgrasscatchersor otherattachments.These

canchangethestabilityofthe machine.

Keepallmovementonthe slopesslowandgradual.Donotmake

suddenchangesinspeedor direction.Rapidengagementor

brakingcouldcausethefrontofthemachinetoliftandrapidlyflip

overbackwardswhichcouldcauseseriousinjury.

• Avoidstartingorstoppingona slope.Iftireslosetraction,disen-

gagetheblade(s)andproceedslowlystraightdowntheslope.

DoNot:

• Donot turnon slopesunlessnecessary;then,turnslowlyand

graduallydownhill,ifpossible.

• Donot mowneardrop-offs,ditchesorembankments.The mower

couldsuddenlyturnoverif a wheelisovertheedgeofa cliff,

ditch,or if an edgecavesin.

• Donot try tostabilizethemachinebyputtingyourfooton the

ground.

• Donot usea grasscatcheronsteepslopes.

• Donot mowon wetgrass.Reducedtractioncouldcausesliding.

• Donot attempttocoastdownhill.Over-speedingmaycausethe

operatortolosecontrolofthemachineresultingin seriousinjury

or death.

• Donot towheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5degrees.Whengoing

downhill,theextraweighttendstopushthetractorandmay

causeyouto loosecontrol.(e.g.tractormayspeedup,braking

and steeringabilityare reduced,attachmentmayjack-knifeand

causetractorto overturn).

4

Page 5

CHILDREN

Tragicaccidentscanoccurifthe operatorisnotalert tothepresence

ofchildren.Childrenareoftenattractedto themachineandthemowing

activity.Theydo notunderstandthedangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthe mowingareaand inwatchfulcare ofa

responsibleadultotherthantheoperator.

• Bealertandturnmachineoff ifachildentersthe area.

• Beforeandwhilebacking,lookbehindanddownfor small

children.

Nevercarrychildren,evenwiththeblade(s)shutoff.Theymay

falloffandbeseriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionof a child

whomayrunintothe machine.

Toavoidback-overaccidents,alwaysdisengagethecutting

blade(s)beforeshiftingintoReverse.Ifequipped,the"Reverse

CautionMode"(bladesoperatewhilemachineridesinreverse)

shouldnotbe usedwhenchildrenorothersarearound.

Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedto preventunauthorized

operation.

Neverallowchildrenunder14yearsofagetooperatethis machine.

Children14andovershouldreadandunderstandtheinstructionsand

safeoperationpracticesinthismanualandon themachineandshould

betrainedandsupervisedbyan adult.

TOWING

Towonlywitha machinethathasa hitchdesignedfor towing.Do

notattachtowedequipmentexceptat thehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.Forrecommendations,

call1-800-659-5917.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Alwaysuseextracautionwhentowingwitha machinecapableof

makingtightturns(e.g."zero-turn"ride-onmower). Makewide

turnstoavoidjack-knifing.

Travelslowlyandallowextradistancetostop.

Donotcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

on yourselforyour clotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

Neverfillcontainersinsidea vehicleoron a truckortrailer bed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthe truck

or trailerandrefuelitontheground.Ifthis isnot possible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

Keepthenozzleincontactwiththe rimofthe fueltankor

containeropeningatalltimesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

Neverremovegascapor addfuelwhiletheengineis hotor run-

ning.Allowengineto coolatleasttwominutesbeforerefueling.

Neveroverfillfuel tank.Filltanktonomorethan1/2inchbelow

bottomoffillernecktoallowspaceforfuel expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff the engineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlightasonawaterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

Allowa machineto coolatleastfiveminutesbeforestoring.

Page 6

GeneralService

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertainthe

blade(s)andallmovingpartshavestopped.Disconnectthespark

plugwireandgroundagainsttheenginetopreventunintended

starting.

• Periodicallychecktomakesurethebladescometocomplete

stopwithinapproximately(5)fivesecondsafteroperatingthe

bladedisengagementcontrol.Ifthebladesdonotstopwithinthe

thistimeframe,yourmachineshouldbeservicedprofessionally

byanauthorizedSearsParts&RepairCenter.

• Checkbrakeoperationfrequentlyasitissubjectedtowearduring

normaloperation.Adjustandserviceasrequired.

• Checktheblade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)

fordamage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useofpartswhichdonot

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepallnuts,bolts,andscrewstighttobesuretheequipmentis

insafeworkingcondition.

• Nevertamperwiththesafetyinterlocksystemorothersafety

devices.Checktheirproperoperationregularly.

• Afterstrikingaforeignobject,stopthe engine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothe machine

whilethe engineis running.

• Grasscatchercomponentsandthe dischargecoverare subject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo notmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donot changetheenginegovernorsettingsorover-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofthe engine.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

• Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andthe U.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasanAverageUsefulLifeof seven(7)years,or270hours

ofoperation.Attheendofthe AverageUsefulLife,buyanew

machineor havethemachineinspectedannuallybya Searsor

otherqualifiedservicedealerto ensurethatall mechanicaland

safetysystemsareworkingproperlyandnotwornexcessively.

Failuretodosocanresultinaccidents,injuriesor death.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonornearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any).

Ifa sparkarresteris used,itshouldbe maintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveisrequired

bylaw (Section4442of theCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarresterforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

6

Page 7

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct.Read,understand,andfollowallinstructionson the machine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

DANGER-- ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

0

DANGER-- ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s)

can amputate hands and feet.

A

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in

operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER-- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

7

Page 8

Sightandholdthis levelwith averticaltree...

|

|

|

!

!

|

|

or acorner of a building...

,_ or afencepost

|

|

#Old ',

!

|

0o

_. :,uog dotto,_'.

"T,"_ _Presen_ts

alo

, ._ _lOpe_

|

I

15 °

Use this page as a guideto determine slopes whereyou may not operate safely.

Donot operateyourlawnmoweron suchslopes.Do notmowoninclineswitha slopeinexcessof 15degrees(a riseofapproximately2-1/2feetevery10feet). A ridingmower

couldoverturnandcauseseriousinjury.Operateridingmowersupanddownslopes,neveracrossthefaceofslopes.

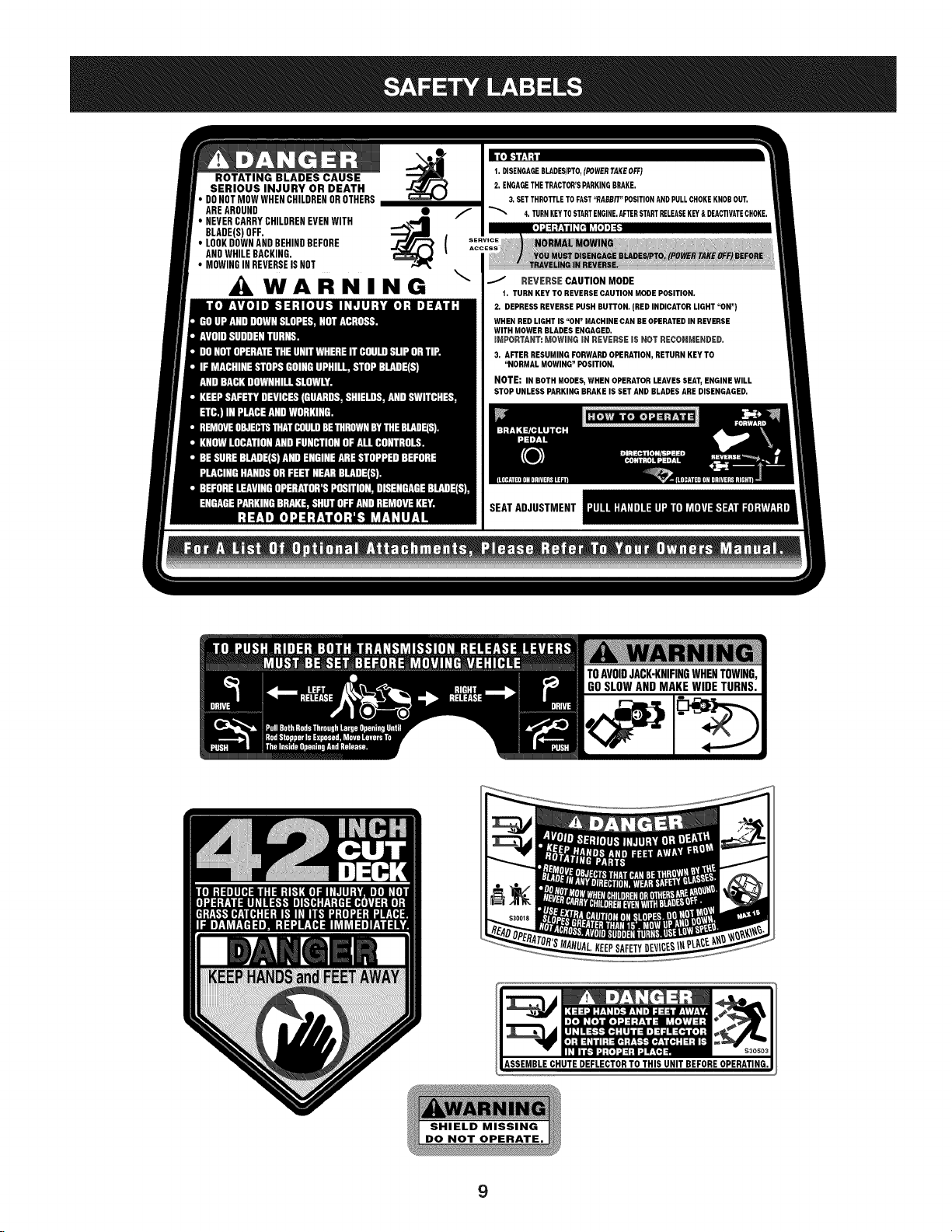

Page 9

ROTATING BLADES CAUSE

SERIOUS INJURY OR DEATH

DONOTMOWWHENCHILDRENDROTHERS

AREAROUND

• NEVERCARRYCHILDRENEVENWITH

BLADE(S)OFF.

• LOOKDOWNANDBEHINDBEFORE

ANDWHILEBACKING.

* MOWINGINREVERSEISNOT

_WARNING

1.DISENGAGEBLADES/PTO,(POWERTAKEOFF)

2, ENGAGETHETRACTOR'SPARKINGBRAKE.

3.SETTHROTTLETOFAST"RABBIT"POSITIONANDPULLCHOKEKNOBOUT.

;. TURNKEYTOSTARTENGINE.AFTERSTARTRELEASEKEY&DEACTIVATECHOKE.

REVERSE CAUTION MODE

t. TURN KEYTO REVERSECAUTIONMODEPOSITION,

2, DEPRESSREVERSEPUSHBUTTON,(RED INDICATORLIGHT "ON")

WHENREDLIGHTIS "ON" MACHINECANBEOPERATEDIN REVERSE

WITHMOWERBLADESENGAGED.

mMPORTANT:MOWING iN REVERSEiS NOT RECOMMENDED.

3, AFTERRESUMINGFORWARDOPERATION,RETURNKEYTO

"NORMALMOWING"POSITION,

NOTE: IN BOTH MODES,WHEN OPERATORLEAVESSEAT,ENGINEWILL

STOPUNLESSPARKINGBRAKEIS SETANDBLADESAREDISENGAGED,

9

Page 10

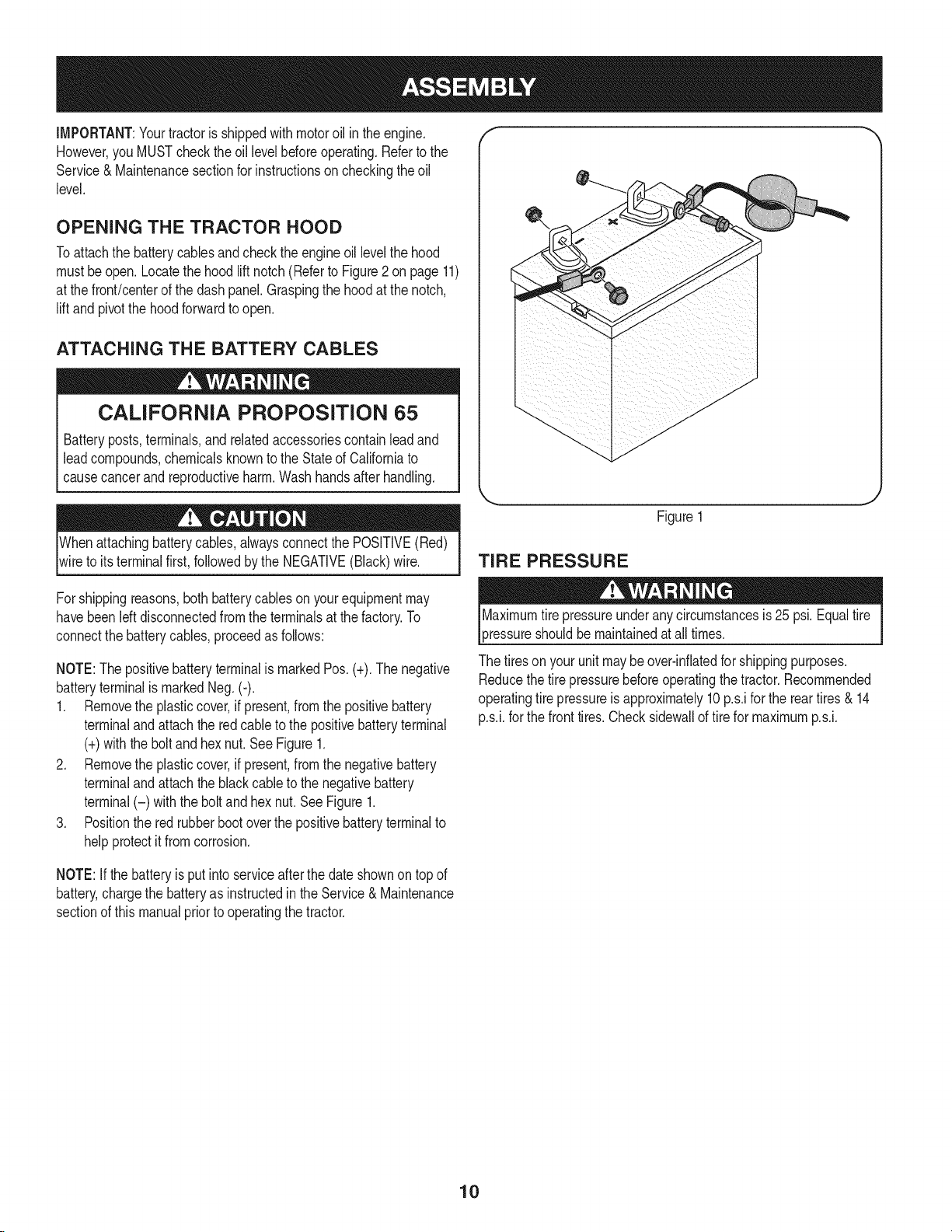

IMPORTANT:Yourtractorisshippedwithmotoroil in theengine.

However,youMUSTcheckthe oil levelbeforeoperating.Referto the

Service& Maintenancesectionforinstructionson checkingtheoil

level.

OPENING THE TRACTOR HOOD

Toattachthebatterycablesandchecktheengineoil levelthehood

mustbeopen. Locatethe hoodlift notch(Referto Figure2on page11)

atthe front/centerofthe dashpanel.Graspingthehoodat thenotch,

lift andpivotthehoodforwardtoopen.

ATTACHING THE BATTERY CABLES

CALIFORNIA PROPOSITION 65

Batteryposts,terminals,andrelatedaccessoriescontainleadand

leadcompounds,chemicalsknownto theStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

Whenattachingbatterycables,alwaysconnectthePOSITIVE(Red)

wireto its terminalfirst,followedby theNEGATIVE(Black)wire.

Figure1

TIRE PRESSURE

Forshippingreasons,bothbatterycablesonyourequipmentmay

havebeenleftdisconnectedfromtheterminalsatthefactory.To

connectthebatterycables,proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegative

batteryterminalis markedNeg.(-).

1. Removethe plasticcover,if present,fromthe positivebattery

terminaland attachthe redcableto the positivebatteryterminal

(+)withthebolt andhexnut.See Figure1.

2. Removethe plasticcover,if present,fromthe negativebattery

terminaland attachtheblackcabletothenegativebattery

terminal(-) withthe boltandhexnut.SeeFigure1.

3. Positionthe redrubberbootoverthepositivebatteryterminalto

helpprotectit fromcorrosion.

NOTE:If thebatteryisputintoserviceafterthedateshownon topof

battery,chargethebatteryas instructedinthe Service& Maintenance

sectionofthis manualpriortooperatingthetractor.

3ressureshouldbemaintainedatall times.

Thetiresonyourunitmaybeover-inflatedforshippingpurposes.

Reducethetirepressurebeforeoperatingthe tractor.Recommended

operatingtirepressureisapproximately10p.s.iforthe reartires & 14

p.s.i,forthe fronttires.Checksidewalloftirefor maximump.s.i.

10

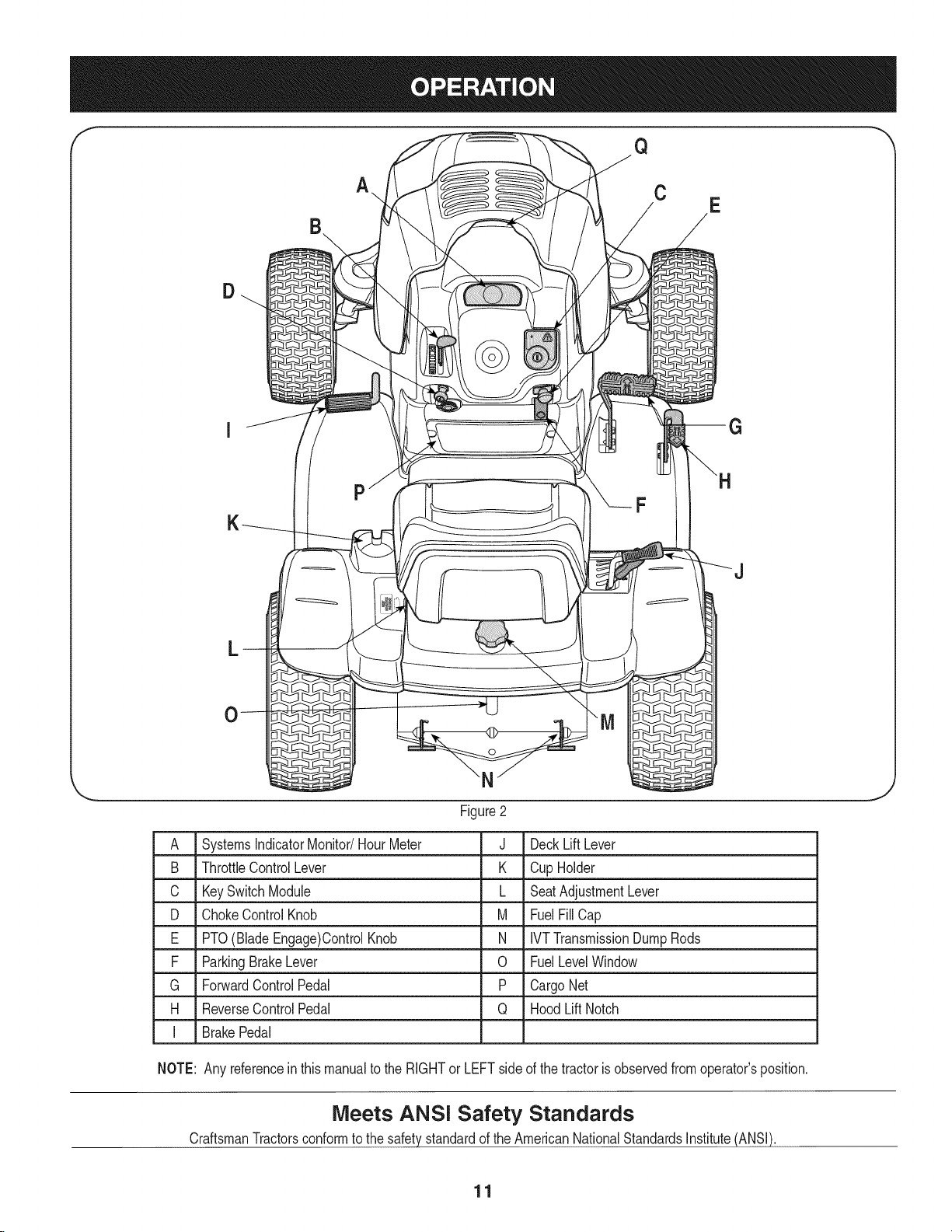

Page 11

f

Q

A

\

C

E

P

K

L--

A SystemsIndicatorMonitor/HourMeter

B ThrottleControlLever

C KeySwitchModule

D ChokeControlKnob

E PTO(BladeEngage)ControlKnob

F ParkingBrakeLever

G ForwardControlPedal

H ReverseControlPedal

I BrakePedal

F

J

Figure2

J DeckLiftLever

K CupHolder

L SeatAdjustmentLever

M FuelFillCap

N IVTTransmissionDumpRods

0 FuelLevelWindow

P CargoNet

Q HoodLiftNotch

NOTE: Any referenceinthismanualtotheRIGHTorLEFTside ofthe tractorisobservedfromoperator'sposition.

Meets ANSI Safety Standards

CraftsmanTractorsconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

11

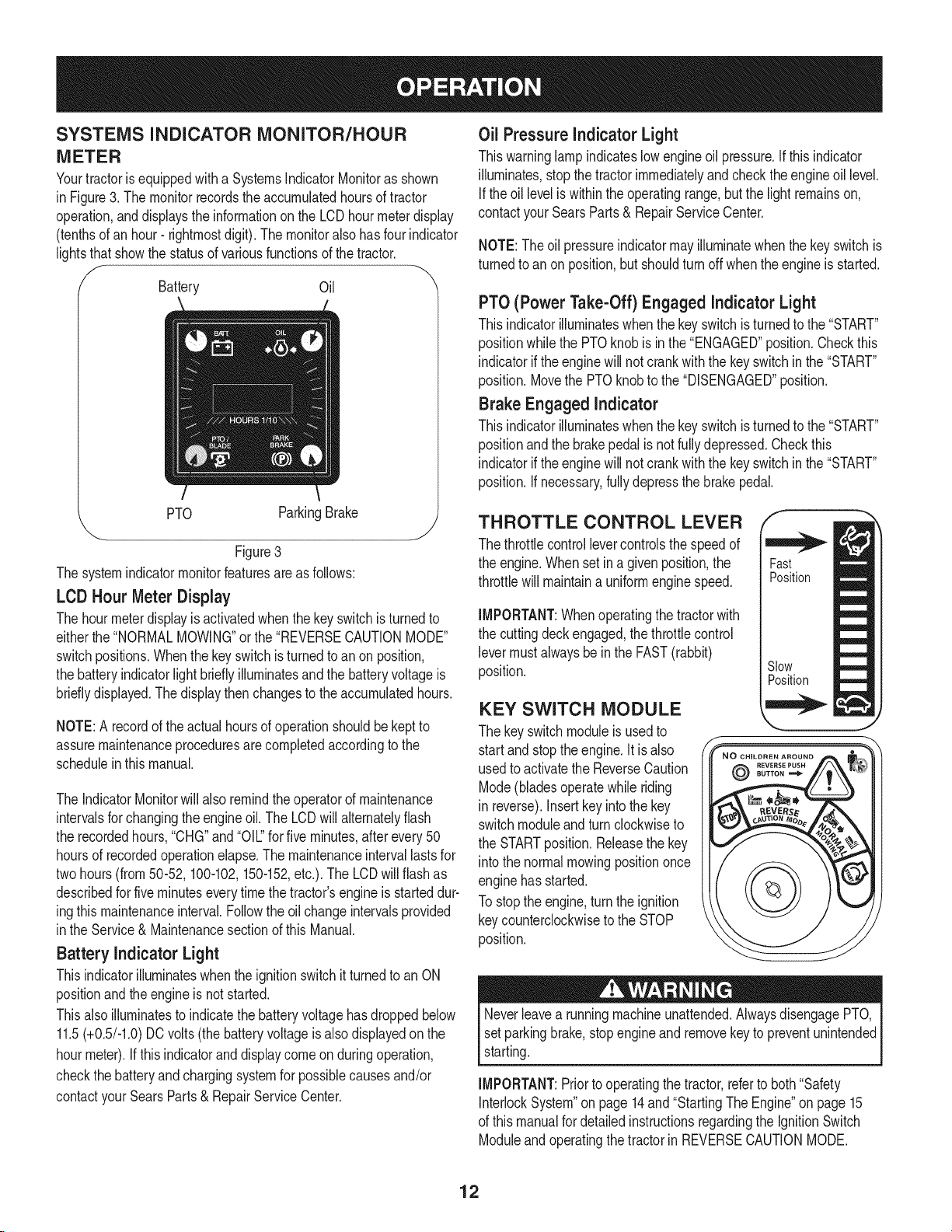

Page 12

SYSTEMS iNDiCATOR MONITOR/HOUR

METER

Yourtractorisequippedwitha SystemsIndicatorMonitoras shown

in Figure3.Themonitorrecordstheaccumulatedhoursoftractor

operation,anddisplaystheinformationontheLCDhourmeterdisplay

(tenthsofan hour- rightmostdigit).The monitoralsohasfour indicator

lightsthat showthestatusofvariousfunctionsof thetractor.

Battery Oil

Oil PressureindicatorLight

Thiswarninglampindicateslowengineoil pressure.Ifthisindicator

illuminates,stopthetractorimmediatelyandchecktheengineoil level.

Iftheoilleveliswithintheoperatingrange,butthelight remainson,

contactyourSearsParts& RepairServiceCenter.

NOTE:The oilpressureindicatormayilluminatewhenthe keyswitchis

turnedto an onposition,butshouldturnoff whentheengineisstarted.

PTO(Power Take-Off) Engaged indicatorLight

Thisindicatorilluminateswhenthekeyswitchisturnedtothe"START"

positionwhilethe PTOknobisinthe"ENGAGED"position.Checkthis

indicatorif theenginewillnotcrankwiththekeyswitchinthe"START"

position.Movethe PTOknobtothe"DISENGAGED"position.

Brake Engaged indicator

Thisindicatorilluminateswhenthekeyswitchisturnedtothe"START"

positionandthebrakepedalisnotfullydepressed.Checkthis

indicatoriftheenginewillnotcrankwiththekeyswitchinthe"START"

position.If necessary,fullydepressthebrakepedal.

PTO ParkingBrake

"-.. j

Figure3

Thesystemindicatormonitorfeaturesareasfollows:

LCD Hour Meter Display

Thehourmeterdisplayis activatedwhenthe keyswitchisturnedto

eitherthe"NORMALMOWING"orthe"REVERSECAUTIONMODE"

switchpositions.Whenthekeyswitchis turnedto anon position,

thebatteryindicatorlight brieflyilluminatesandthe batteryvoltageis

bridly displayed.Thedisplaythenchangesto theaccumulatedhours.

NOTE:A recordoftheactualhoursofoperationshouldbekeptto

assuremaintenanceproceduresarecompletedaccordingtothe

scheduleinthismanual.

TheIndicatorMonitorwillalsoremindtheoperatorofmaintenance

intervalsforchangingtheengineoil.The LCDwillalternatelyflash

therecordedhours,"CHG"and"Oil" for fiveminutes,afterevery50

hoursof recordedoperationelapse.The maintenanceintervallastsfor

twohours(from50-52,100-102,150-152,etc.).The LCDwillflashas

describedforfiveminuteseverytimethe tractor'sengineisstarteddur-

ingthis maintenanceinterval.Followthe oilchangeintervalsprovided

inthe Service& Maintenancesectionof thisManual.

Battery indicator Light

ThisindicatorilluminateswhentheignitionswitchitturnedtoanON

positionandtheengineis notstarted.

Thisalsoilluminatesto indicatethebatteryvoltagehasdroppedbelow

11.5(+0.5/-1.0)DCvolts(the batteryvoltageisalsodisplayedonthe

hourmeter).Ifthisindicatorand displaycomeonduringoperation,

checkthe batteryandchargingsystemforpossiblecausesand/or

contactyourSearsParts& RepairServiceCenter.

THROTTLE CONTROL LEVER

Thethrottlecontrollevercontrolsthespeedof

theengine.Whenset inagivenposition,the

throttlewill maintaina uniformenginespeed.

IMPORTANT:Whenoperatingthetractorwith

thecuttingdeckengaged,thethrottlecontrol

levermustalwaysbeintheFAST(rabbit)

position.

Fast

Position

Slow

Position

KEY SWITCH MODULE

Thekeyswitchmoduleisusedto

startandstoptheengine.Itisalso

usedto activatetheReverseCaution

Mode(bladesoperatewhileriding

in reverse).Insertkeyintothekey

switchmoduleandturn clockwiseto

theSTARTposition.Releasethe key

intothenormalmowingpositiononce

enginehasstarted.

Tostopthe engine,turntheignition

keycounterclockwiseto theSTOP

position.

Neverleavea runningmachineunattended.AlwaysdisengagePTO,

setparkingbrake,stopengineand removekeyto preventunintended

starting.

IMPORTANT:Priorto operatingthetractor,referto both"Safety

InterlockSystem"on page14and"StartingThe Engine"on page15

ofthis manualfordetailedinstructionsregardingthe IgnitionSwitch

ModuleandoperatingthetractorinREVERSECAUTIONMODE.

@

12

Page 13

NevermovethekeyintotheStartpositionwhiletheengineis

running.Doingsomaycausedamagetoyourengine'sstarter.

CHOKE CONTROL

Thechokecontrolknobislocatedonthe lowerIdt sideofthedash

paneland isactivatedby pullingoutward.Activatingthe chokecontrol

closesthechokeplateonthecarburetorandaidsinstartingthe

engine.

PTO (BLADE ENGAGE) CON-

TROL KNOB

Toengagethe electricPTOand providepowerto

thecuttingdeck,pulloutwardonthePTOcontrol

knob.PushtheknobinwardtodisengagethePTO

andstopthecuttingdeck.

NOTE:The PTOControlKnobmustbe inthe

disengaged(OFF)positionwhenstartingthe

engine.

F PTO

o I

BRAKE PEDAL

Thebrakepedalislocatedatthe frontoftheleft runningboardandis

usedforquickstops,or settingtheparkingbrake.Thispedalmustbe

fullydepressedtoactivatethesafetyinterlockswitchwhen startingthe

tractor.

DECK LIFT LEVER

Thedeckliftleverislocatedintherightfenderandisusedtochange

thecuttingheightof themowerdeck.Thecuttingheightsrangefrom

1-1/2"to 4".Eachofthesix indexnotchesrepresentanapproximately

1/2"adjustmentto thedeckheight.

1. To use,graspthe lift leverhandleandpullslightlyupward(rear-

ward)while pivotingtheleverinwardandoutof its indexnotch.

2. Movethe liftleverasnecessaryto placeinthe notchbestsuited

foryourapplication.

Afterchangingthecuttingheightofthedeck,youmustcheckthe

positionofthedeckfrontgaugewheels.Theyshouldbeapproximately

1/2-inchabovethegroundwhenthetractorisona smooth,flatsurface

suchasa driveway.Referto "Service& Maintenance"laterinthis

manual.

PARKING BRAKE LEVER

NOTE:Theparkingbrakemustbesetifthe operator ,_,_%,

leavestheseatwiththeenginerunning;otherwisethe

enginewillautomaticallyshutoff.

1. Tosettheparkingbrake,fullydepressthebrake

pedaland pushthe bottomofparkingbrakelever

inward.Seetheimagetotherightforparkingbrake

identification.Holdtheleverinwhileremovingyour

footfromthebrakepedal.Bothparkingbrakelever

andbrakepedalwill staydepressed.

2. Toreleasetheparkingbrake,depressthebrakepedalslightly.

Theparkingbrakeleverwillthenreturntoits originalposition.

IMPORTANT:Alwayssettheparkingbrakewhenleavingthetractor

unattended.

tL )

FORWARD CONTROL PEDAL

Theforwardcontrolpedalis locatedonthe rightsideofthetractor,at

thefrontof the rightrunningboard.Depressthe forwardcontrolpedal

tocausethe tractortotravelinthe forwarddirection.Theforward

groundspeedof thetractorisdirectlyaffectedbythedistancethe

pedalisdepressed.Thefurtherthepedalisdepressed,thefasterthe

tractorwilltravel.Thetractorwillslowandthe pedalwillreturnto its

originalpositionwhenreleased.

REVERSE CONTROL PEDAL

Thereversecontrolpedalis locatedinthe rightfrontrunningboard

rearwardoftheforwardcontrolpedal.Depressthe reversecontrol

pedaltocausethetractorto travelin reverse.Thefurtherthepedalis

depressed,the fasterthetractorwilltravel.Thetractorwillslowand

thepedalwill returntoitsoriginalpositionwhenreleased.

CUP HOLDER

Thetractor'scupholderis locatedon thefendertothe left oftheseat.

SEAT ADJUSTMENT LEVER

Theseatadjustmentleverisontheleftside oftheseat.Usethis lever

toadjusttheseatforwardor rearwardtoacomfortableoperating

position.Seethe"Service&Maintenance"sectionlaterin thismanual

forinstructions.

FUEL FILL CAP AND FUEL LEVEL

WINDOW

Thefuelfillcapis locatedinthecenterofthe rearfender.Pivot

theseatforwardtofullyaccessthefuelfill capandfillthefuel

tank.

1. Turnthefill capapproximately1/4turnandpull upwardto

remove.

2. Pushthecapdownwardonthefueltankfillneckandturn

1/4turn clockwisetotighten.

Theleveloffuelinthe fueltankcanbeviewedthroughthefuel

levelwindowinthe rearhitchplate.

CARGO NET

Convenientlylocatedon thetractor'sdashpanel,thecargo netcan be

usedto storepersonalitemswhileoperatingthelawntractor.

IVT (INFINITELY VARIABLE TRANSMISSION)

DUMP RODS

TheIVTtransmissiondumprodsare locatedatthebackof thetractor

abovethe rearhitchplate.Whenengaged,theseleversopena dump

valveineachtransmissionwhichallowsthetractorto bemanually

pushedshortdistances.Seethe"Service& Maintenance"sectionlater

inthismanualfor instructions.

13

Page 14

Avoid Serious injury or Death

• Goupanddownslopes,notacross.

Avoidsuddenturns.

Donotoperatetheunitwhereitcouldslip ortip.

If machinestopsgoinguphill,stopbladesandbackdownhill

slowly.

• Donotmowwhenchildrenorothersarearound.

• Nevercarrychildren,evenwithbladesoff.

• Lookdownandbehindbeforeandwhilebacking.

• Keepsafetydevices(guards,shields,andswitches)inplace

andworking.

• Removeobjectsthatcouldbethrownbythe blades.

• Knowlocationandfunctionofallcontrols.

• Besurebladesandengineare stoppedbeforeplacinghandsor

feetnearblades.

• Beforeleavingoperator'sposition,stoptractor,disengage

blades,engageparkingbrake,shutengineoff,and removekey.

Read Operator's Manual

OIL AND GAS FILL-UP

0il

IMPORTANT:Yourtractorisshippedwithmotoroil in theengine.

However,youMUSTcheckthe oil levelbeforeoperating.Seethe

"ServiceandMaintenance"section.

Gasoline

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuel machine

indoorsorwhiletheengineishotor running.Extinguishcigarettes,

cigars,pipes,andothersourcesofignition.

NOTE: Purchasegasolinein smallquantities.Donotusegasolineleft

overfromthe previousseason,tominimizegumdepositsinthe fuel

system.

• Donot overfillfueltank.Filltankto nomorethan1/2inchbelow

bottomof fillernecktoallowspaceforfuelexpansion.

• Neverremovegascapor addfuelwhiletheengineis hotor run-

ning.Allowenginetocoolatleasttwominutesbeforerefueling.

• Ifgasolineis spilled,wipeitoff the engineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

1. Turntheengineoffandletenginecoolatleast2minutesbefore

removingthefuel cap.Thegasolinetankis underthe rearfender,

withthefuelfillcaplocatedinthe centeroftherearfender.

Thefuelcapistetheredtothetractorto preventitsloss.Donot

attemptto removethecapfromthetractor.

2. Fillthe fueltankwithgasoline.

3. Reinstallthe fuelcap.

SAFETY INTERLOCK SYSTEM

Thesafetyinterlocksystemis designedforsafeoperationofthetrac-

tor.If thissystemshouldevermalfunction,donot operatethetractor,

immediatelycontactyourSearsParts& RepairServiceCenter.

• Thesafetyinterlocksystempreventstheenginefromstarting

unlesstheparkingbrakeisengagedandthe PTOknobis inthe

disengaged(OFF)position.

• Thesafetyinterlocksystemwillautomaticallyshutoffthe engineif

theoperatorleavestheseatbeforeengagingtheparkingbrake.

• Thesafetyinterlocksystemwillautomaticallyshutoffthe engine

if theoperatorleavesthetractor'sseatwiththePTO(Blade

Engage)knobengaged,regardlessofwhethertheparkingbrake

is engaged.

• WiththeignitionkeyintheNORMALMOWINGposition,the

electricPTOclutchwill automaticallyshutoff ifthe PTOknobis in

theengaged(ON) positionandthe drivepedalisdepressedfor

Reversetravel.

Tamperingwithor attemptingto bypasstheSafetyInterlockSwitches

in anywaywillvoidyourtractor'swarranty.Donot operatethetractor

if the interlocksystemis malfunctioning.

REVERSE CAUTION MODE

• Thisengineiscertifiedtooperateon unleadedgasoline.For best

results,fillthe fueltankwithonlyclean,fresh,unleadedgasoline

witha pumpstickeroctaneratingof87or higher.

• Gasohol(upto 10%ethylalcohol,90%unleadedgasolineby

volume)isanapprovedfuel.Othergasoline/alcoholblends,such

asE85,arenotapproved.

• MethylTertiaryButylEther(MTBE)andunleadedgasolineblends

(uptoamaximumof 15%MTBEbyvolume)areapprovedfuels.

Othergasoline/etherblendsarenotapproved.

• Fillfueltankoutdoorsorin well-ventilatedarea.

Useextremecautionwhileoperatingthetractorinthe REVERSE

CAUTIONMODE.Alwayslookdownandbehindbeforeandwhile

backing.Donotoperatethe tractorwhenchildrenorothersare

around.Stopthetractorimmediatelyif someoneentersthearea.

TheREVERSECAUTIONMODEpositionofthekeyswitchmodule

allowsthetractortobeoperatedinreversewiththeblades(PTO)

engaged.

14

Page 15

IMPORTANT:Mowingin reverseisnotrecommended.

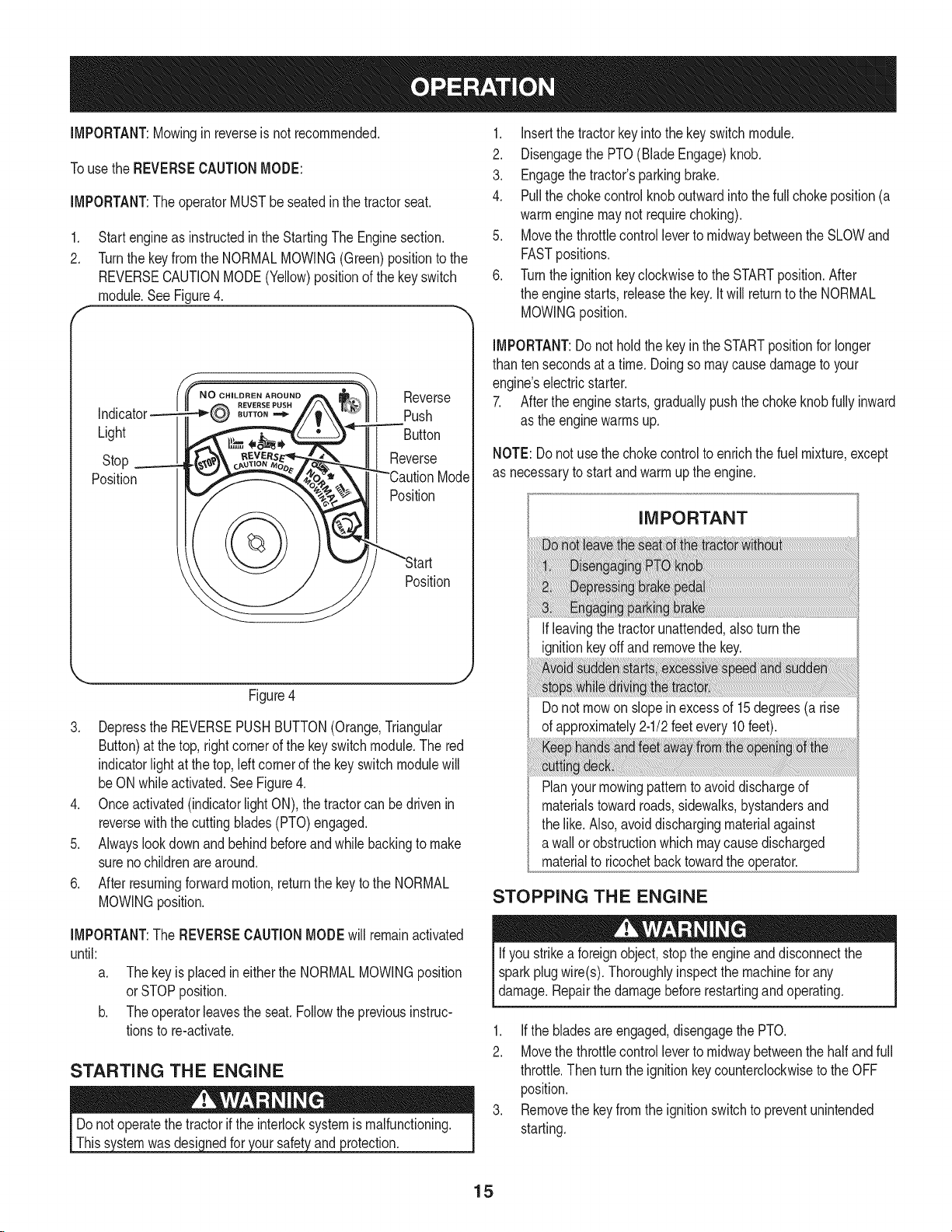

Touse theREVERSECAUTIONMODE:

IMPORTANT:TheoperatorMUSTbe seatedin the tractorseat.

1. Startengineas instructedin the StartingTheEnginesection.

2. TurnthekeyfromtheNORMALMOWING(Green)positionto the

REVERSECAUTIONMODE(Yellow)positionofthe keyswitch

module.SeeFigure4.

N O CHILDREN AROUND

BUTTON

Light

Stop

Position

Reverse

Push

Button

Reverse

Mode

Position

Position

1, Insertthetractorkeyintothekeyswitchmodule,

2. DisengagethePTO(BladeEngage)knob.

3. Engagethetractor'sparkingbrake.

4. Pullthechokecontrolknoboutwardintothe fullchokeposition(a

warmenginemaynotrequirechoking).

5. MovethethrottlecontrollevertomidwaybetweentheSLOWand

FASTpositions.

6. Turnthe ignitionkeyclockwisetothe STARTposition.After

theenginestarts, releasethekey.Itwillreturntothe NORMAL

MOWINGposition.

IMPORTANT:Do notholdthekeyinthe STARTpositionfor longer

thantensecondsata time.Doingso maycausedamageto your

engine'selectricstarter.

7. Afterthe enginestarts,graduallypushthechokeknobfully inward

asthe enginewarmsup.

NOTE:Donotusethechokecontrolto enrichthefuel mixture,except

as necessarytostartandwarmuptheengine.

IMPORTANT

J

Figure4

3. DepresstheREVERSEPUSHBUTTON(Orange,Triangular

Button)atthe top,rightcornerofthekeyswitchmodule.Thered

indicatorlightatthe top,leftcornerofthe keyswitchmodulewill

beONwhileactivated.SeeFigure4.

4. Onceactivated(indicatorlightON),thetractorcanbedrivenin

reversewiththecuttingblades(PTO)engaged.

5. Alwayslookdownand behindbeforeandwhilebackingto make

surenochildrenarearound.

6. Afterresumingforwardmotion,returnthekeytothe NORMAL

MOWINGposition.

IMPORTANT:The REVERSECAUTIONMODEwill remainactivated

until:

a. Thekeyis placedin eitherthe NORMALMOWINGposition

orSTOPposition.

b. Theoperatorleavestheseat.Followthepreviousinstruc-

tionstore-activate.

STARTING THE ENGINE

wasdesic )rotection.

If leavingthetractorunattended,alsoturnthe

ignitionkeyoff and removethekey.

Donot mowon slopeinexcessof 15degrees(a rise

ofapproximately2-1/2feetevery10feet).

Planyourmowingpatternto avoiddischargeof

materialstowardroads,sidewalks,bystandersand

thelike.Also,avoiddischargingmaterialagainst

a wallor obstructionwhichmaycausedischarged

materialto ricochetbacktowardtheoperator.

STOPPING THE ENGINE

Ifyoustrikea foreignobject,stopthe engineanddisconnectthe

sparkplugwire(s).Thoroughlyinspectthemachineforany

damage.Repairthedamagebeforerestartingandoperating.

1. Ifthebladesareengaged,disengagethePTO.

2. Movethethrottlecontrollevertomidwaybetweenthehalfandfull

throttle.Thenturn theignitionkeycounterclockwisetotheOFF

position.

3. Removethe keyfromtheignitionswitchtopreventunintended

starting.

15

Page 16

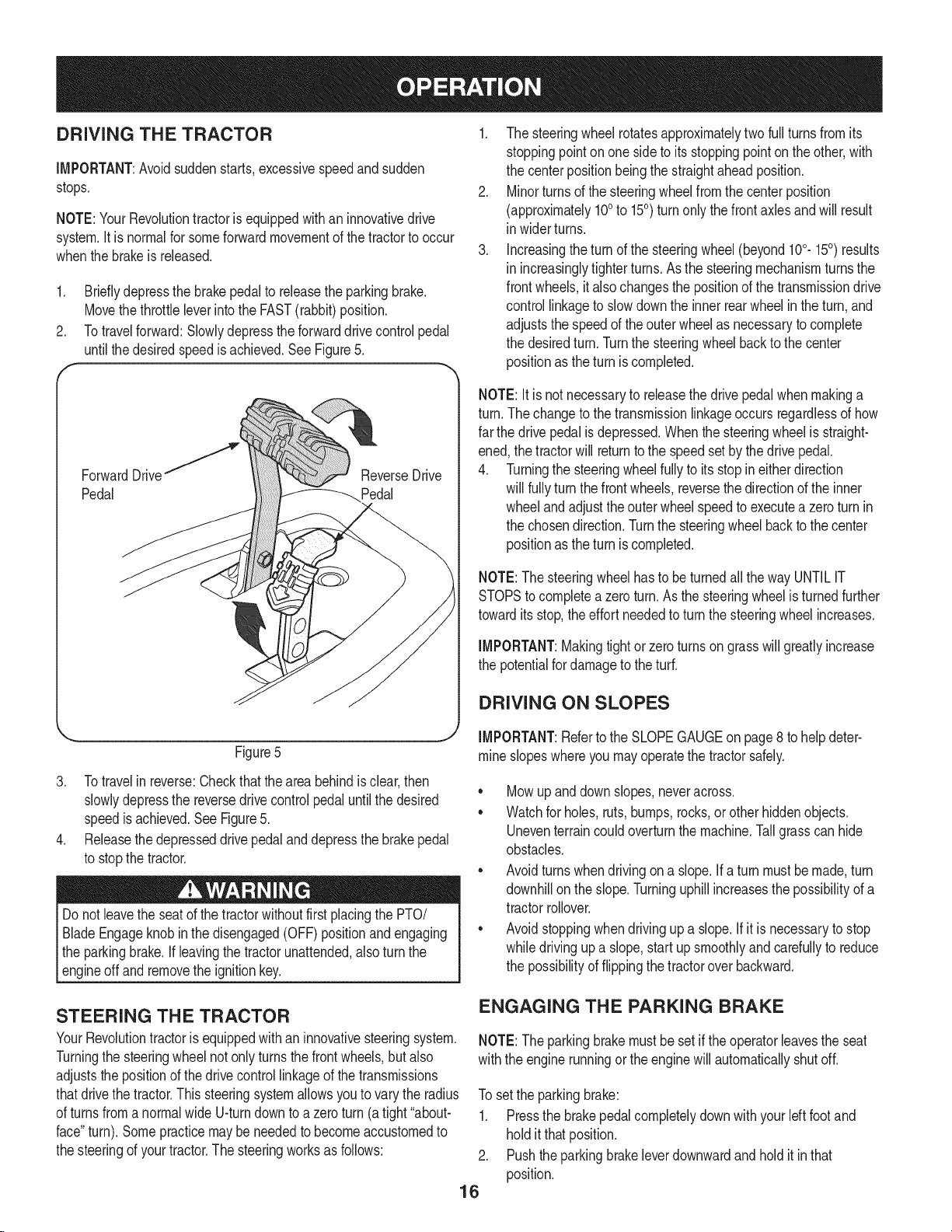

DRiViNG THE TRACTOR

iMPORTANT:Avoidsuddenstarts,excessivespeedandsudden

stops.

NOTE:YourRevolutiontractorisequippedwithan innovativedrive

system.Itis normalforsomeforwardmovementofthetractortooccur

whenthe brakeis released.

.

Brieflydepressthebrakepedalto releasethe parkingbrake.

MovethethrottleleverintotheFAST(rabbit)position.

2.

Totravelforward:Slowlydepresstheforwarddrivecontrolpedal

untilthe desiredspeedisachieved.SeeFigure5.

ForwardDrivef

Pedal

1. The steeringwheel rotatesapproximatelytwofullturnsfromits

stoppingpointonone sidetoitsstoppingpointonthe other,with

thecenterpositionbeingthe straightaheadposition.

2. Minorturnsof thesteeringwheelfromthe centerposition

(approximately100to 150) turnonly thefrontaxlesandwillresult

in widerturns.

3. Increasingtheturnofthesteeringwheel(beyond100.150) results

in increasinglytighterturns.Asthesteeringmechanismturnsthe

frontwheels,it alsochangesthepositionofthetransmissiondrive

controllinkagetoslowdowntheinnerrearwheelin theturn,and

adjuststhe speedof theouterwheelasnecessaryto complete

thedesiredturn.Turnthesteeringwheelbacktothe center

positionasthe turniscompleted.

NOTE:Itisnotnecessaryto releasethedrivepedalwhenmakinga

turn.Thechangetothetransmissionlinkageoccursregardlessofhow

farthe drivepedalisdepressed.Whenthesteeringwheelis straight-

ened,the tractorwill returntothespeedsetby thedrivepedal.

4. Turningthesteeringwheelfullytoits stopineitherdirection

willfullyturnthefrontwheels,reversethedirectionoftheinner

wheelandadjusttheouterwheelspeedtoexecutea zeroturn in

thechosendirection.Turnthe steeringwheelbackto thecenter

positionasthe turniscompleted.

NOTE:The steeringwheelhasto beturnedallthewayUNTILIT

STOPStocompleteazeroturn.Asthesteeringwheelisturnedfurther

towardits stop,theeffortneededtoturnthesteeringwheelincreases.

Figure5

3. Totravelin reverse:Checkthattheareabehindisclear,then

slowlydepressthe reversedrivecontrolpedaluntilthe desired

speedis achieved.SeeFigure5.

4. Releasethedepresseddrivepedalanddepressthebrakepedal

tostopthetractor.

Donotleavetheseatof thetractorwithoutfirstplacingthePTO/

BladeEngageknobin thedisengaged(OFF)positionandengaging

theparkingbrake.If leavingthetractorunattended,alsoturnthe

_engne offand removethe gnton key.

STEERING THE TRACTOR

YourRevolutiontractorisequippedwithan innovativesteeringsystem.

Turningthe steeringwheelnotonlyturnsthefrontwheels,butalso

adjuststhepositionofthe drivecontrollinkageofthetransmissions

thatdrivethe tractor.Thissteeringsystemallowsyouto varythe radius

ofturnsfromanormalwideU-turndowntoa zeroturn (a tight"about-

face"turn).Somepracticemaybe neededtobecomeaccustomedto

thesteeringofyourtractor.Thesteeringworksasfollows:

IMPORTANT:Makingtightor zeroturnsongrasswill greatlyincrease

thepotentialfordamageto theturf.

DRIVING ON SLOPES

IMPORTANT:Referto theSLOPEGAUGEonpage8 to helpdeter-

mineslopeswhereyoumayoperatethe tractorsafely.

• Mowupanddownslopes,neveracross.

• Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

• Avoidturnswhendrivingon a slope,if a turnmustbemade,turn

downhillonthe slope.Turninguphillincreasesthe possibilityofa

tractorrollover.

• Avoidstoppingwhendrivingup a slope,if itis necessarytostop

whiledrivingupa slope,start upsmoothlyandcarefullyto reduce

thepossibilityof flippingthetractoroverbackward.

ENGAGING THE PARKING BRAKE

NOTE:The parkingbrakemustbe setiftheoperatorleavestheseat

withtheenginerunningor theenginewill automaticallyshutoff.

Tosettheparkingbrake:

1. Pressthe brakepedalcompletelydownwithyourIdt footand

holdit thatposition.

2. Pushtheparkingbrakeleverdownwardandholdit in that

position.

16

Page 17

3. Removeyourfootfromthebrakepedal.

4. Releasepressurefromtheparkingbrakelever.

Aftercompletingstep3,thebrakepedalshouldremaininthe down

position.Ifit doesn't,the parkingbrakeis notengaged.Repeatsteps

1-4toengagethe parkingbrake.

Todisengagetheparkingbrake,lightlypressthe brakepedal.

Neverleavea runningmachineunattended.AlwaysdisengagePTO,

setparkingbrake,stopengineand removekeyto preventunintended

starting.

2. Shutengineoffand removethekey.

Doingsowillminimizethe possibilityofhavingyourlawn"browned"by

hotexhaustfromyourtractor'srunningengine.

MOVING THE TRACTOR MANUALLY

Ifforanyreasonthetractorwillnot driveoryouwishtomovethe

tractor,engagethetwo transmissiondumprodstomanuallymovethe

tractorshortdistances.

IMPORTANT:Nevertowor dragthetractorwiththerearwheelsonthe

ground.Evenwiththedumprodsengaged.Doingsowill damagethe

transmissions.

ENGAGING THE PTO

EngagingthePTOtransferspowertothe cuttingdeckor other

(separatelyavailable)attachments.ToengagethePTO:

1. Movethe throttlecontrollevertotheFAST(rabbit)position.

2. PullthePTO/BladeEngageknoboutwardintothe engaged(ON)

position.

NOTE:Alwaysoperatethetractorwiththe throttleleverin theFAST

(rabbit)positionforthemostefficientuseofthe cuttingdeckorother

(separatelyavailable)PTOdrivenattachments.

MOWING

Tohelpavoidbladecontactor a thrownobjectinjury,keepbystand-

ers,helpers,childrenandpetsatleast75feetfromthemachine

whileit is inoperation.Stopmachineifanyoneentersthearea.

ThistractorisequippedwithoneofCraftsman'shighqualitycutting

decks.Thefollowinginformationwillbehelpfulwhenusingthecutting

deckwithyourtractor.

• Donot mowathighgroundspeed,especiallyif a mulchkitor

grasscollectoris installed.

• Forbestresultsitis recommendedthatthefirsttwolapsbecut

withthedischargethrowntowardsthecenter.Afterthefirsttwo

laps,reversethedirectiontothrowthe dischargeto theoutside

forthe balanceofcutting.Thiswillgivea betterappearancetothe

lawn.

• Donotcut thegrasstooshort.Shortgrassinvitesweedgrowth

andyellowsquicklyindryweather.

• Mowingshouldalwaysbedonewiththeengineat fullthrottle.

• Underheavierconditionsitmaybenecessaryto go backoverthe

cutareaa secondtimetogeta cleancut.

• Donotattempttomowheavybrushandweedsandextremelytall

grass.Yourtractorisdesignedto mowlawns,notclearbrush.

• Keepthebladessharpandreplacethebladeswhenworn.Refer

tothe "Service& Maintenance"sectionofthis manualforproper

bladesharpeninginstructions.

IMPORTANT:Whenstoppingthetractorfor anyreasonwhileona

grasssurface,always:

1. Engagethe parkingbrake.

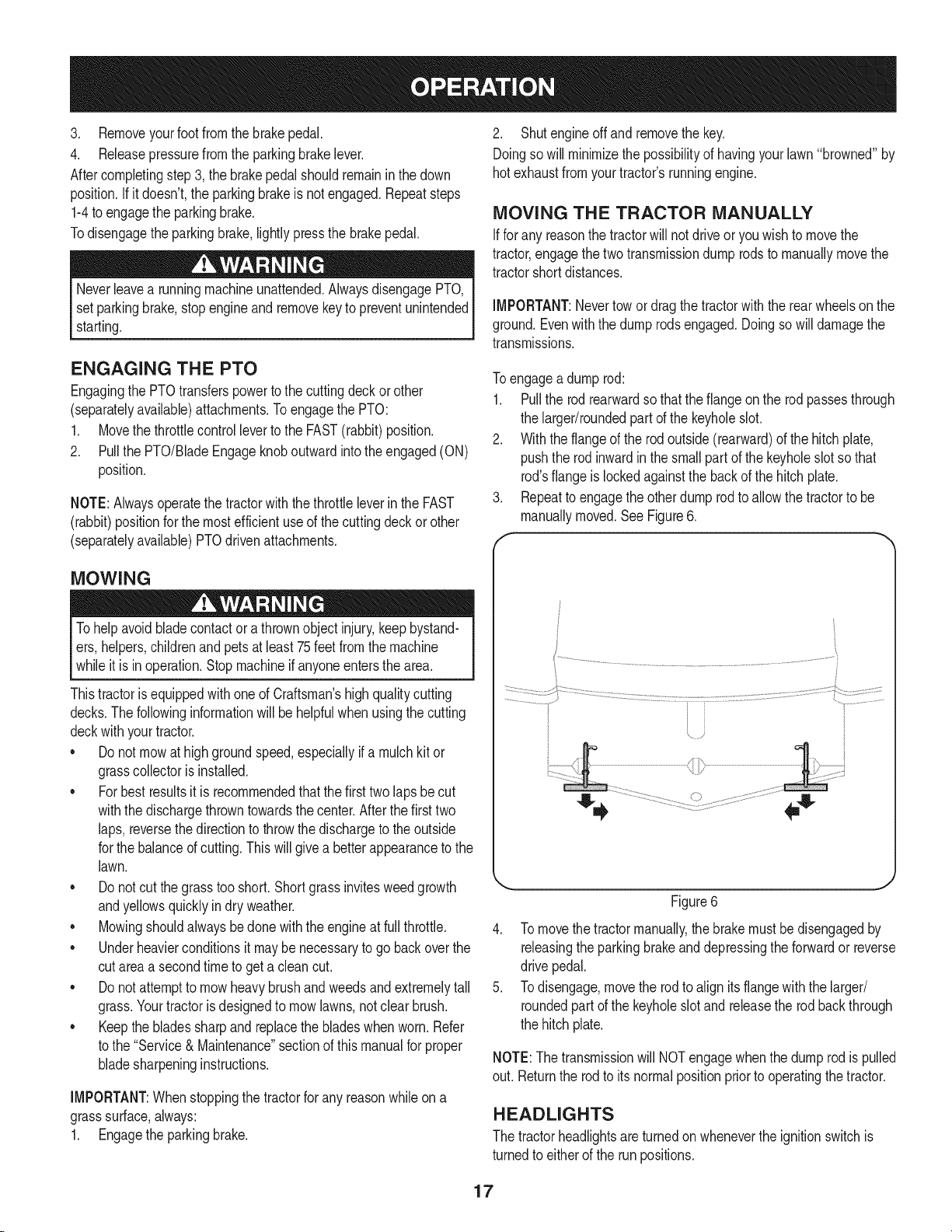

Toengagea dump rod:

1. Pullthe rodrearwardso thattheflangeontherodpassesthrough

thelarge#roundedpartd thekeyholeslot.

2. Withtheflangeoftherodoutside(rearward)ofthe hitchplate,

pushthe rodinwardinthesmallpartofthe keyholeslotso that

rod'sflangeis lockedagainstthebackofthe hitchplate.

.

Repeattoengagetheotherdumprodto allowthetractortobe

manuallymoved.SeeFigure6.

f

...............................f_J

Figure6

4. Tomovethetractormanually,thebrakemustbedisengagedby

releasingthe parkingbrakeanddepressingthe forwardor reverse

drivepedal.

5. Todisengage,movetherodtoalign itsflangewiththe larger/

roundedpartd the keyholeslotand releasetherodbackthrough

thehitchplate.

NOTE:Thetransmissionwill NOTengagewhenthedump rodispulled

out. Returnthe rodto itsnormalpositionpriorto operatingthetractor.

HEADLIGHTS

Thetractorheadlightsare turnedonwheneverthe ignitionswitchis

turnedto eitherof therunpositions.

17

Page 18

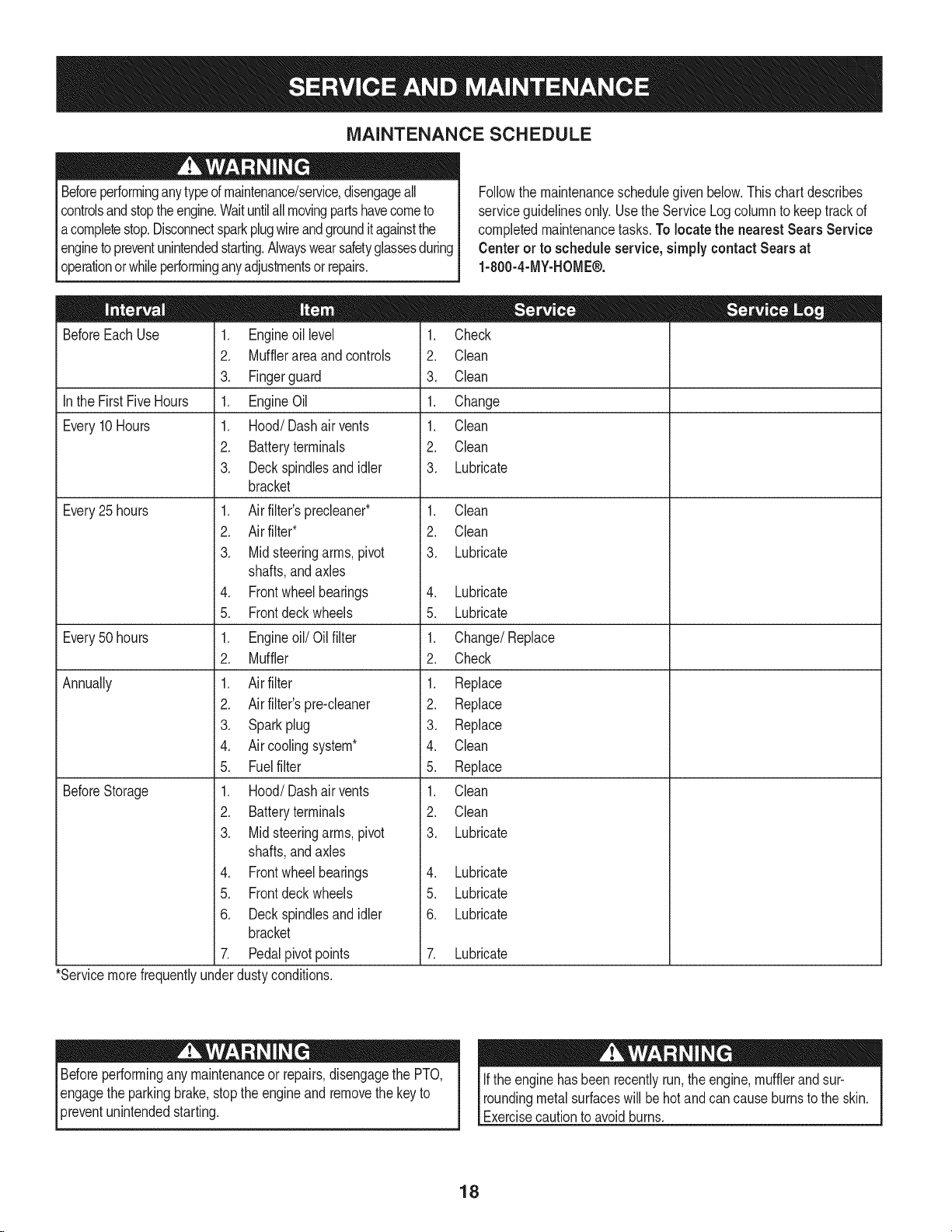

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

BeforeEachUse

Inthe FirstFiveHours

Every10Hours

1. Engineoil level

2. Mufflerareaandcontrols

3. Fingerguard

1. EngineOil

1. Hood/Dashairvents

2. Batteryterminals

3. Deckspindlesandidler

1. Check

2. Clean

3. Clean

1. Change

1. Clean

2. Clean

3. Lubricate

bracket

Every25 hours

1. Air filter'sprecleaner*

2. Air filter*

3. Midsteeringarms,pivot

1. Clean

2. Clean

3. Lubricate

shafts,andaxles

4. Lubricate

5. Lubricate

1. Change/Replace

2. Check

1. Replace

2. Replace

3. Replace

4. Clean

5. Replace

1. Clean

2. Clean

3. Lubricate

Every50 hours

Annually

BeforeStorage

4. Frontwheelbearings

5. Frontdeckwheels

1. Engineoil/Oil filter

2. Muffler

1. Air filter

2. Air filter'spre-cleaner

3. Sparkplug

4. Air coolingsystem*

5. Fuelfilter

1. Hood/Dashairvents

2. Batteryterminals

3. Midsteeringarms,pivot

shafts,andaxles

4. Frontwheelbearings

5. Frontdeckwheels

6. Deckspindlesandidler

4. Lubricate

5. Lubricate

6. Lubricate

bracket

7. Pedalpivotpoints

7. Lubricate

*Servicemorefrequentlyunderdustyconditions.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.Tolocatethe nearest Sears Service

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

Beforeperformingany maintenanceor repairs,disengagethePTO,

engagetheparkingbrake,stoptheengineandremovethekeyto

3reventunintendedstarting.

Iftheenginehasbeen recentlyrun,theengine,mufflerandsur-

roundingmetalsurfaceswillbehotand cancauseburnsto theskin.

Exercisecautionto avoidburns.

18

Page 19

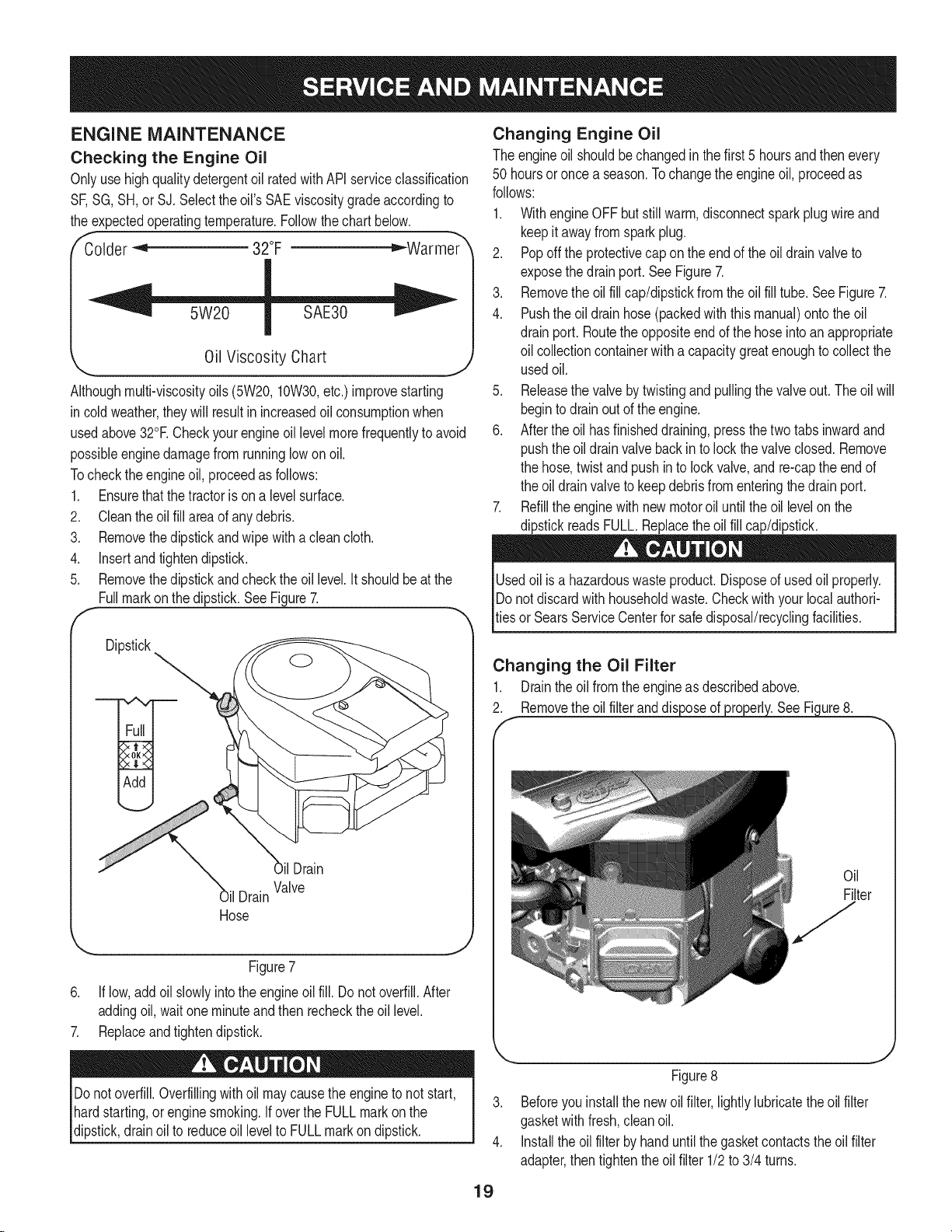

ENGINE MAINTENANCE

Checking the Engine Oil

Onlyuse highqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,SH,or SJ, Selecttheoil'sSAEviscositygradeaccordingto

theexpectedoperatingtemperature.Followthechartbelow.

f_older _ 32°F _Warmer _

Oil Viscosity Chart

Althoughmulti-viscosityoils (5W20,10W30,etc.)improvestarting

in coldweather,theywill resultinincreasedoil consumptionwhen

usedabove32°RCheckyourengineoillevelmorefrequentlytoavoid

possibleenginedamagefromrunninglowonoil.

Tochecktheengineoil,proceedasfollows:

1. Ensurethatthetractorisona levelsurface.

2. Cleantheoil fillareaofanydebris.

3. Removethedipstickandwipewithacleancloth.

4. Insertandtightendipstick.

5. Removethedipstickandcheckthe oil level.It shouldbeatthe

Fullmarkonthedipstick.SeeFigure7.

F

Dipstick

Changing Engine Oil

Theengineoil shouldbechangedinthefirst5 hoursandthenevery

50 hoursoroncea season.Tochangetheengineoil, proceedas

follows:

1. WithengineOFFbut stillwarm,disconnectsparkplugwireand

keepit awayfromsparkplug.

2. Popoff theprotectivecapon theendoftheoil drainvalveto

exposethedrainport.SeeFigure7.

3. Removethe oilfillcap/dipstickfromtheoil fill tube.SeeFigure7.

4. Pushtheoil drainhose(packedwiththis manual)ontotheoil

drainport. Routethe oppositeendofthehoseintoan appropriate

oil collectioncontainerwithacapacitygreatenoughtocollectthe

usedoil.

5. Releasethevalvebytwistingandpullingthe valveout.Theoilwill

begintodrainoutoftheengine.

6. Aftertheoil hasfinisheddraining,pressthetwotabsinwardand

pushtheoil drainvalvebackinto lockthevalveclosed.Remove

thehose,twist andpushinto lockvalve,and re-captheendof

theoil drainvalvetokeepdebrisfromenteringthe drainport.

7. Refilltheenginewithnewmotoroil untiltheoil levelonthe

dipstickreadsFULL.Replacetheoil fillcap/dipstick.

Usedoil isahazardouswasteproduct.Disposeofusedoil properly.

IDonotdiscardwithhouseholdwaste.Checkwithyourlocal authori-

[tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

Changing the Oil Filter

1. Draintheoil fromtheengineasdescribedabove.

2. Removetheoilfilteranddis ure8.

OilDrain

Valve

il Drain

Hose

Figure7

6. If low,addoil slowlyintotheengineoilfill. Donotoverfill.After

addingoil,waitoneminuteand thenrechecktheoillevel.

7. Replaceandtightendipstick.

Donotoverfill.Overfillingwithoil maycausetheengineto notstart,

hardstarting,orenginesmoking.If overtheFULLmarkonthe

dipstick,drainoil to reduceoilleveltoFULLmarkondipstick.

Oil

Filter

Figure8

3. Beforeyouinstallthenewoilfilter,lightlylubricatetheoilfilter

gasketwithfresh,cleanoil.

4. Installtheoil filterbyhanduntilthe gasketcontactstheoil filter

adapter,thentightentheoilfilter 1/2to3/4 turns.

19

Page 20

5. Addoilasdescribedabove.

6. Startandruntheengine.Astheenginewarmsup,checkforoil

leaks.

7. Stoptheengineandchecktheoillevel.ItshouldbeattheFULL

markonthedipstick.

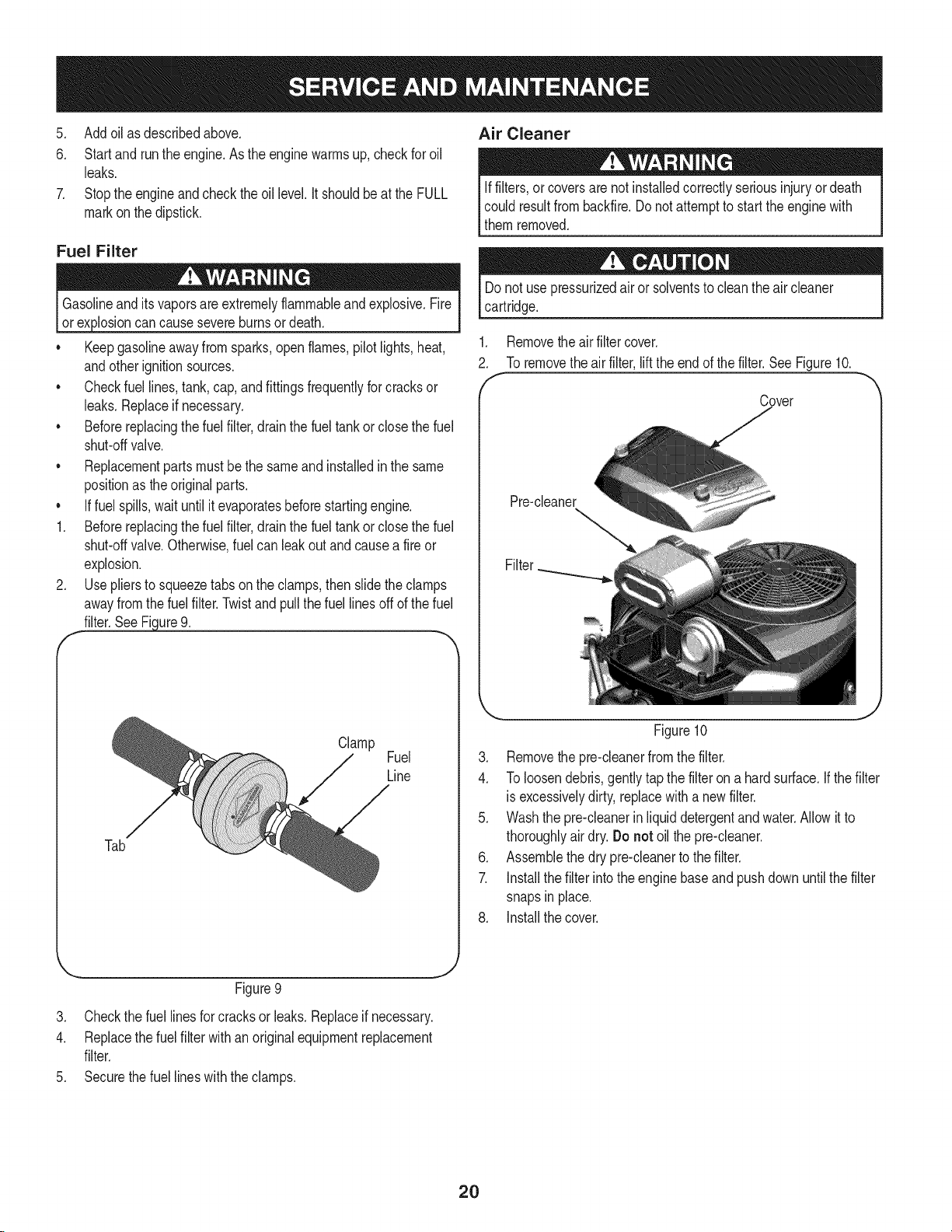

Fuel Filter

3losioncan causesevereburnsor death.

Keepgasolineawayfromsparks,openflames,pilotlights,heat,

andotherignitionsources.

Checkfuellines,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Beforereplacingthefuelfilter,drainthefueltankor closethe fuel

shut-offvalve.

Replacementpartsmustbethesameand installedinthe same

positionastheoriginalparts.

o

Iffuelspills,waituntilitevaporatesbeforestartingengine.

1.

Beforereplacingthefuelfilter,drainthefueltankor closethe fuel

shut-offvalve.Otherwise,fuel canleakoutandcauseafireor

explosion.

.

Usepliersto squeezetabsonthe clamps,thenslidetheclamps

awayfromthefuel filter.Twistand pullthefuellinesoff ofthefuel

filter.SeeFigure9.

f

Air Cleaner

Iffilters,or coversarenotinstalledcorrectlyseriousinjuryordeath

couldresultfrombackfire.Donotattemptto startthe enginewith

themremoved.

Donot usepressurizedair or solventstocleanthe aircleaner

cartridge.

.

Removethe airfiltercover.

2.

Toremovetheairfilter,lifttheendof thefilter.SeeFigure10.

f

Cover

Pre-cleaner

Filter

Clamp

Fuel

Line

Tab

Figure9

3. Checkthefuellinesforcracksorleaks.Replaceifnecessary.

4. Replacethefuelfilterwithan originalequipmentreplacement

filter.

5. Securethefuellineswiththeclamps.

Figure10

3. Removethe pre-cleanerfromthefilter.

4. Toloosendebris,gentlytapthe filteron a hardsurface.If thefilter

is excessivelydirty,replacewithanewfilter.

5. Washthepre-cleanerinliquiddetergentandwater.Allowit to

thoroughlyair dry.Do not oilthepre-cleaner.

6. Assemblethedrypre-cleanertothefilter.

7. Installthefilterintotheenginebaseand pushdownuntilthe filter

snapsin place.

8. Installthecover.

J

2O

Page 21

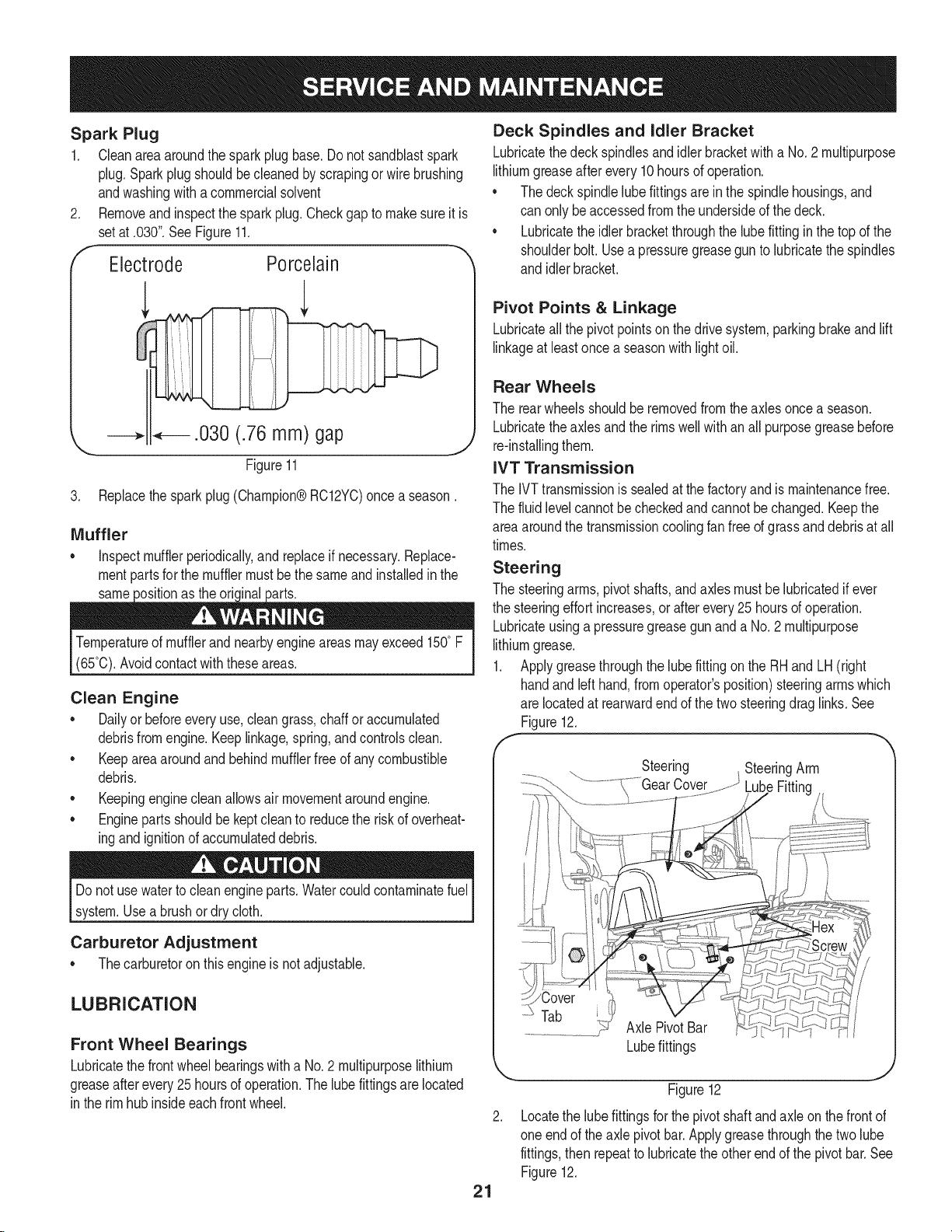

Spark Plug

1. Cleanareaaroundthesparkplugbase.Donotsandblastspark

plug.Sparkplugshouldbecleanedby scrapingorwirebrushing

andwashingwitha commercialsolvent

2. Removeandinspectthesparkplug.Checkgaptomakesureit is

setat.030".SeeFigure11.

f- -._

Electrode Porcelain

3. Replacethesparkplug(Champion®RC12YC)oncea season.

Muffler

o inspectmufflerperiodically,and replaceifnecessary.Replace-

mentpartsforthemufflermustbethe sameand installedin the

same the oric

Temperatureof mufflerandnearbyengineareasmayexceed150°F

(65°0).Avoidcontactwiththeseareas.

Clean Engine

o Dailyor beforeeveryuse,cleangrass,chaff oraccumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustible

debris.

Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbekeptcleanto reducetheriskofoverheat-

ingandignitionofaccumulateddebris.

Deck Spindles and Idler Bracket

Lubricatethedeckspindlesandidlerbracketwitha No.2 multipurpose

lithiumgreaseafterevery10hoursof operation.

• Thedeckspindlelubefittingsareinthe spindlehousings,and

canonly beaccessedfromthe undersideof thedeck.

• Lubricatetheidlerbracketthroughthelubefitting inthetopof the

shoulderbolt.Usea pressuregreaseguntolubricatethespindles

and idlerbracket.

Pivot Points & Linkage

Lubricateallthepivotpointsonthedrivesystem,parkingbrakeandlift

linkageatleastonceaseasonwithlightoil.

Rear Wheels

Therearwheelsshouldberemovedfromtheaxlesoncea season.

Lubricatetheaxlesandtherimswellwithan all purposegreasebefore

re-installingthem.

IVT Transmission

TheIVTtransmissionissealedatthefactoryandis maintenancefree.

Thefluidlevelcannotbecheckedandcannotbe changed.Keepthe

areaaroundthetransmissioncoolingfanfreeofgrassanddebrisatall

times.

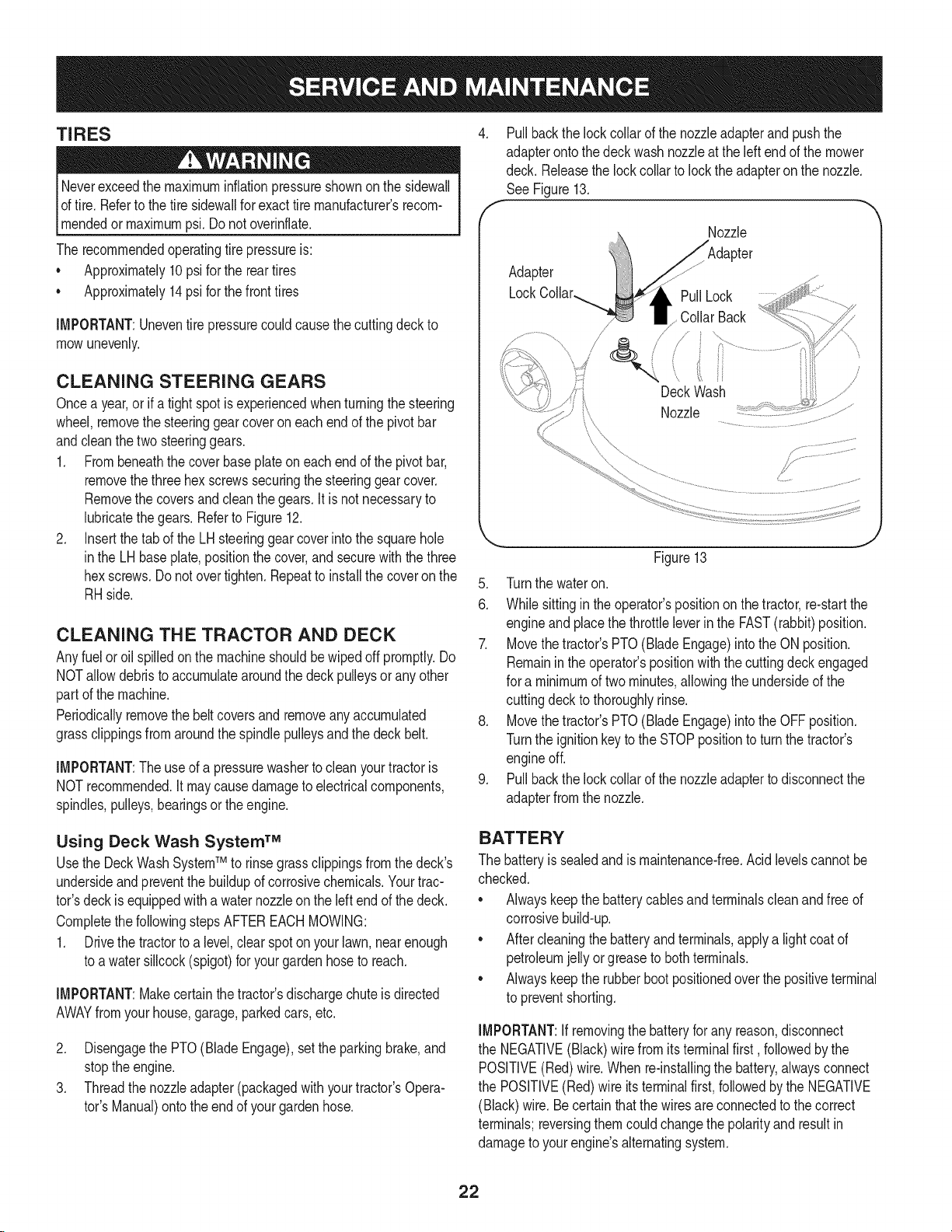

Steering

Thesteeringarms,pivotshafts,andaxlesmustbelubricatedif ever

thesteeringeffortincreases,or afterevery25 hoursofoperation.

Lubricateusingapressuregreasegunanda No.2 multipurpose

lithiumgrease.

1. Applygreasethroughthelubefittingonthe RHandLH (right

handandleft hand,fromoperator'sposition)steeringarmswhich

are locatedat rearwardendofthetwo steeringdraglinks.See

Figure12.

f

Steering SteeringArm

LubeFitting

Donot usewatertocleanengineparts.Watercouldcontaminatefuel

system.Usea brushordrycloth.

Carburetor Adjustment

Thecarburetoronthisengineisnotadjustable.

LUBRICATION

Front Wheel Bearings

Lubricatethefrontwheelbearingswitha No.2 multipurposelithium

greaseafterevery25hoursofoperation.Thelubefittingsarelocated

in therimhubinsideeachfrontwheel.

Tab

AxlePivotBar

Lubefittings

Figure12

Locatethelubefittingsforthe pivotshaftandaxleonthe frontof

oneendof theaxle pivotbar.Applygreasethroughthe twolube

fittings,then repeattolubricatetheother endof thepivotbar.See

Figure12.

21

Page 22

TIRES

Neverexceedthe maximuminflationpressureshownont!e sidewall

oftire.Refertothetiresidewallforexacttire manufacturers recom-

_mendedor maxmumps. Donotovernfate.

Therecommendedoperatingtire pressureis:

• Approximately10psifor thereartires

Approximately14psifor thefronttires

IMPORTANT:Uneventire pressurecouldcausethe cuttingdeckto

mowunevenly.

CLEANING STEERING GEARS

Oncea year,or ifa tightspotisexperiencedwhenturningthe steering

wheel,removethesteeringgearcoveroneachendofthepivotbar

andcleanthe twosteeringgears.

1. Frombeneaththecoverbaseplateon eachendofthe pivotbar,

removethethreehexscrewssecuringthesteeringgearcover.

Removethe coversandcleanthegears.Itisnot necessaryto

lubricatethegears.RefertoFigure12.

2. Insertthe tabof theLHsteeringgearcoverintothesquarehole

inthe LHbaseplate,positionthecover,andsecurewiththethree

hexscrews.Donot overtighten.Repeatto installthecoveronthe

RHside.

CLEANING THE TRACTOR AND DECK

Anyfuel oroil spilledonthemachineshouldbewipedoff promptly.Do

NOTallowdebristoaccumulatearoundthedeckpulleysor anyother

partof themachine.

Periodicallyremovethe beltcoversandremoveany accumulated

grassclippingsfromaroundthespindlepulleysandthedeckbelt.

IMPORTANT:The useof a pressurewasherto cleanyourtractoris

NOTrecommended,itmaycausedamageto electricalcomponents,

spindles,pulleys,bearingsortheengine.

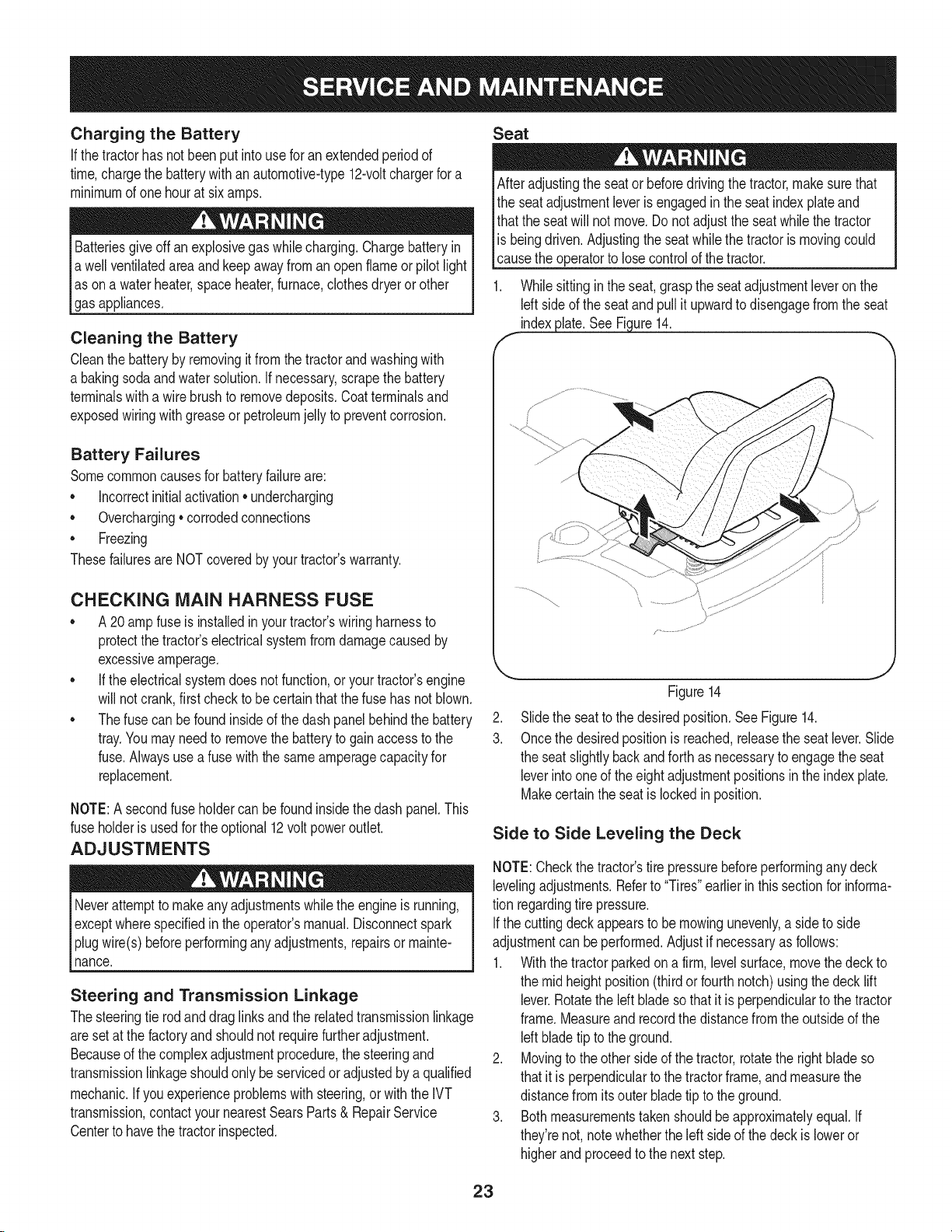

4. Pullbackthelockcollarofthenozzleadapterandpushthe

adapterontothedeckwashnozzleattheleftendofthemower

deck.Releasethelockcollartolockthe adapteronthenozzle.

See Figure13.

f

Nozzle

Adapter

PullLock

Collar Back

/

/

f,

Deck Wash

Nozzle

Figure13

5. Turnthe wateron.

6. Whilesittingin theoperator'spositionon the tractor,re-startthe

engineand placethethrottleleverintheFAST(rabbit)position.

7. Movethetractor'sPTO(BladeEngage)intotheON position.

Remainintheoperator'spositionwiththe cuttingdeckengaged

fora minimumoftwominutes,allowingtheundersideofthe

cuttingdeckto thoroughlyrinse.

8. Movethetractor'sPTO(BladeEngage)intotheOFFposition.

Turnthe ignitionkeytotheSTOPpositiontoturnthe tractor's

engineoff.

9. Pullbackthelockcollarofthenozzleadaptertodisconnectthe

adapterfromthe nozzle.

Using Deck Wash System TM

UsetheDeckWashSystemTM to rinsegrassclippingsfromthe deck's

undersideandpreventthebuildupofcorrosivechemicals.Yourtrac-

tor'sdeckis equippedwitha waternozzleonthe leftendof thedeck.

Completethe followingstepsAFTEREACHMOWING:

1. Drivethetractortoalevel,clearspotonyour lawn,nearenough

toa watersillcock(spigot)foryourgardenhoseto reach.

IMPORTANT:Makecertainthetractor'sdischargechuteisdirected

AWAYfromyourhouse,garage,parkedcars, etc.

2. DisengagethePTO(BladeEngage),settheparkingbrake,and

stoptheengine.

3. Threadthenozzleadapter(packagedwithyourtractor'sOpera-

tot'sManual)ontotheendof yourgardenhose.

BATTERY

Thebatteryissealedand ismaintenance-free.Acidlevelscannotbe

checked.

Alwayskeepthebatterycablesandterminalscleanandfreeof

corrosivebuild-up.

Aftercleaningthebatteryandterminals,applya lightcoatof

petroleumjellyorgreaseto bothterminals.

Alwayskeepthe rubberbootpositionedoverthepositiveterminal

to preventshorting.

IMPORTANT:If removingthe batteryforanyreason,disconnect

the NEGATIVE(Black)wirefromitsterminalfirst, followedby the

POSITIVE(Red)wire.Whenre-installingthebattery,alwaysconnect

the POSITIVE(Red)wire itsterminalfirst,followedbytheNEGATIVE

(Black)wire.Becertainthatthewiresareconnectedtothecorrect

terminals;reversingthemcouldchangethepolarityandresultin

damagetoyourengine'salternatingsystem.

22

Page 23

Charging the Battery

If thetractorhasnotbeenputintouse foranextendedperiodof

time,chargethe batterywithanautomotive-type12-voltchargerfora

minimumof onehourat sixamps.

Batteriesgiveoffan explosivegaswhilecharging.Chargebatteryin

awellventilatedareaandkeepawayfromanopenflameorpilot light

asonawaterheater,spaceheater,furnace,clothesdryerorother

gasappliances.

Cleaning the Battery

Cleanthe batterybyremovingitfromthetractorandwashingwith

a bakingsodaandwatersolution.Ifnecessary,scrapethebattery

terminalswitha wirebrushtoremovedeposits.Coatterminalsand

exposedwiringwithgreaseorpetroleumjellytopreventcorrosion.

Battery Failures

Somecommoncausesforbatteryfailureare:

• Incorrectinitialactivation•undercharging

• Overcharging• corrodedconnections

• Freezing

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

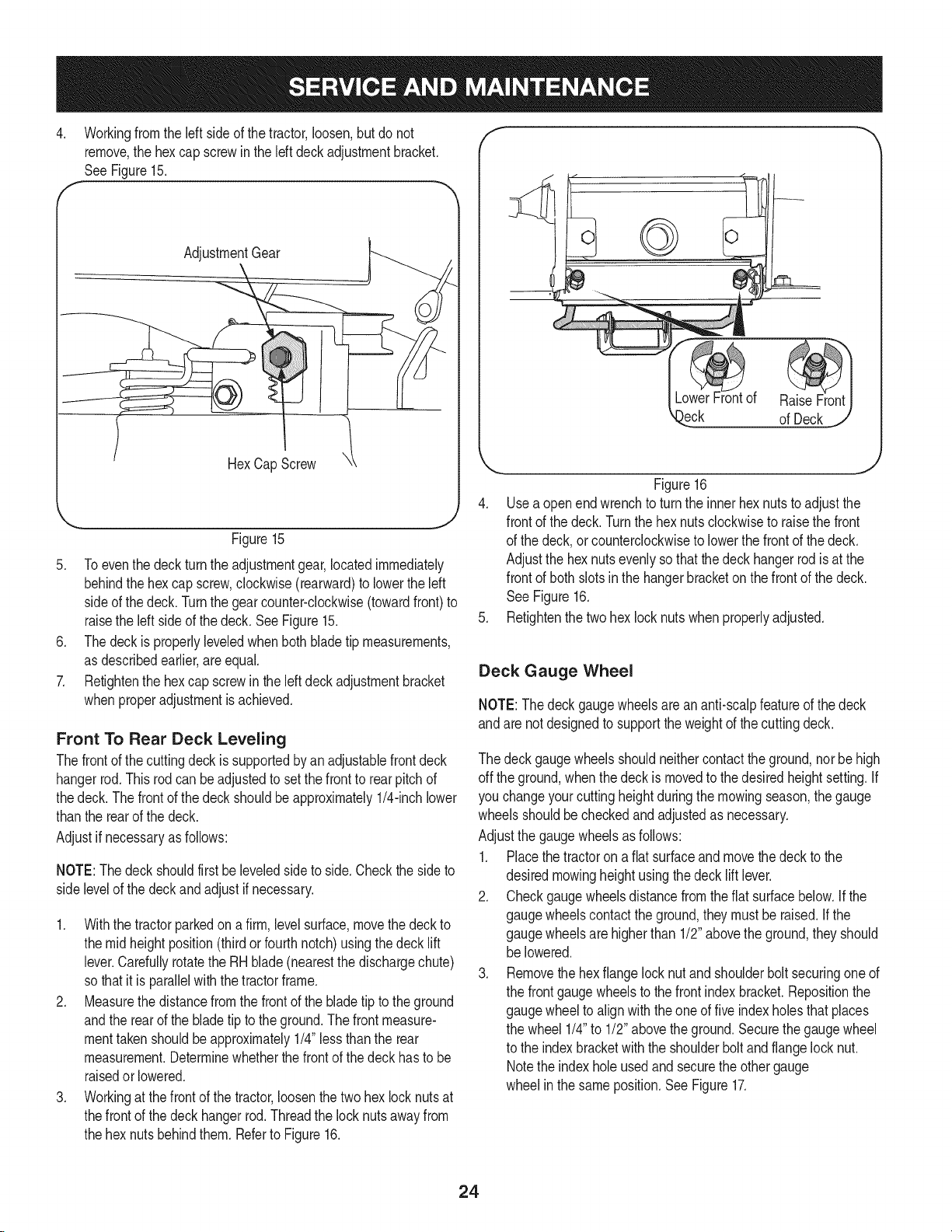

Seat

Afteradjustingtheseator beforedrivingthetractor,makesurethat

theseatadjustmentleveris engagedin the seatindexplateand

thattheseatwillnotmove.Donotadjustthe seatwhilethetractor

is beingdriven.Adjustingtheseatwhilethetractorismovingcould

causetheoperatorto losecontrolofthetractor.

1. Whilesittingintheseat,graspthe seatadjustmentleveronthe

Idt sideofthe seatandpullit upwardtodisengagefromtheseat

indexplate.SeeFigure14.

f

CHECKING MAIN HARNESS FUSE

• A20ampfuseis installedin yourtractor'swiringharnessto

protectthetractor'selectricalsystemfromdamagecausedby

excessiveamperage.

• Iftheelectricalsystemdoesnotfunction,oryourtractor'sengine

willnotcrank,firstchecktobecertainthatthefuse hasnotblown.

• Thefusecan befoundinsideof thedashpanelbehindthebattery

tray.Youmayneedto removethebatterytogainaccesstothe

fuse.Alwaysusea fusewiththesameamperagecapacityfor

replacement.

NOTE:A secondfuseholdercanbe foundinsidethedash panel.This

fuseholderisusedfortheoptional12voltpoweroutlet.

ADJUSTMENTS

Neverattemptto makeanyadjustmentswhiletheengineis running,

exceptwherespecifiedintheoperator'smanual.Disconnectspark

plugwire(s)beforeperforminganyadjustments,repairsormainte-

nance.

Steering and Transmission Linkage

Thesteeringtie rodanddraglinksandthe relatedtransmissionlinkage

aresetatthefactoryandshouldnotrequirefurtheradjustment.

Becauseofthecomplexadjustmentprocedure,the steeringand

transmissionlinkageshouldonlybe servicedoradjustedbya qualified

mechanic.If youexperienceproblemswith steering,or withthe IVT

transmission,contactyournearestSearsParts& RepairService

Centertohavethetractorinspected.

Figure14

2. Slidetheseattothedesiredposition.SeeFigure14.

3. Oncethedesiredpositionis reached,releasetheseatlever.Slide

theseatslightlybackandforthasnecessaryto engagetheseat

leverintooneoftheeightadjustmentpositionsinthe indexplate.

Makecertaintheseatislockedin position.

Side to Side Leveling the Deck

NOTE:Checkthetractor'stirepressurebeforeperforminganydeck

levelingadjustments.Referto"Tires"earlierinthissectionfor informa-

tionregardingtirepressure.

Ifthecuttingdeckappearstobe mowingunevenly,a sideto side

adjustmentcanbeperformed.Adjustif necessaryas follows:

1. Withthetractorparkedona firm, levelsurface,movethedeckto

themid heightposition(thirdorfourthnotch)usingthedecklift

lever.Rotatetheleft bladeso thatit isperpendiculartothetractor

frame.Measureandrecordthedistancefromtheoutsideofthe

leftbladetiptotheground.

2. Movingtotheothersideofthetractor,rotatetheright bladeso

thatit isperpendiculartothetractorframe,andmeasurethe

distancefromits outerbladetipto theground.

3. Bothmeasurementstakenshouldbeapproximatelyequal.If

they'renot,notewhethertheleftside ofthedeckis loweror

higherandproceedtothenextstep.

23

Page 24

4. Workingfromtheleftsideof thetractor,loosen,butdonot

remove,the hexcapscrewin theleftdeckadjustmentbracket.

SeeFigure15.

AdjustmentGear

HexCapScrew

Figure15

5. Toeventhedeckturntheadjustmentgear,locatedimmediately

behindthehexcapscrew,clockwise(rearward)to lowertheleft

sideof thedeck.Turnthegearcounter-clockwise(towardfront)to

raisethe left sideofthedeck.SeeFigure15.

6. Thedeckis properlyleveledwhenbothbladetip measurements,

asdescribedearlier,areequal.

7. Retightenthe hexcap screwin theleftdeckadjustmentbracket

whenproperadjustmentisachieved.

Front To Rear Deck Leveling

Thefrontof thecuttingdeckissupportedbyanadjustablefrontdeck

hangerrod.This rodcanbeadjustedtosetthefrontto rearpitchof

thedeck. Thefrontofthedeckshouldbeapproximately1/4-inchlower

thanthe rearofthedeck.

Adjustifnecessaryasfollows:

NOTE:Thedeckshouldfirstbeleveledsideto side.Checkthesideto

sidelevelofthedeckandadjustif necessary.

1. Withthetractorparkedonafirm,levelsurface,movethedeckto

themidheightposition(thirdor fourthnotch)usingthedeck lift

lever.Carefullyrotatethe RHblade(nearestthedischargechute)

sothatitis parallelwiththe tractorframe.

2. Measurethedistancefromthefrontof thebladetiptotheground

andtherearofthebladetipto theground.The frontmeasure-

menttakenshouldbeapproximately1/4"lessthanthe rear

measurement.Determinewhetherthefrontofthe deckhasto be

raisedorlowered.

3. Workingatthefrontof thetractor,loosenthe twohexlocknutsat

thefrontof thedeckhangerrod.Threadthelocknutsawayfrom

thehexnutsbehindthem.Referto Figure16.

f

)eck ofDeck

Figure16

4. Usea openendwrenchtoturntheinnerhexnutsto adjustthe

frontofthedeck.Turnthehexnutsclockwisetoraisethefront

ofthe deck,orcounterclockwiseto lowerthefrontofthe deck.

Adjustthe hexnutsevenlysothatthedeckhangerrod isat the

frontofbothslotsinthe hangerbracketon the frontofthe deck.

See Figure16.

5. Refightenthe twohexlocknutswhenproperlyadjusted.

Deck Gauge Wheel

NOTE:The deckgaugewheelsareananti-scalpfeatureofthe deck

andare notdesignedto supporttheweightofthecuttingdeck.

Thedeckgaugewheelsshouldneithercontacttheground,norbehigh

off theground,whenthedeckismovedtothedesiredheightsetting.If

youchangeyourcuttingheightduringthe mowingseason,thegauge

wheelsshouldbecheckedandadjustedas necessary.

Adjustthegaugewheelsasfollows:

1. Placethetractorona fiatsurfaceandmovethe decktothe

desiredmowingheightusingthe decklift lever.

2. Checkgaugewheelsdistancefromtheflat surfacebelow.Ifthe

gaugewheelscontacttheground,theymustberaised.Ifthe

gaugewheelsare higherthan1/2"abovethe ground,theyshould

be lowered.

3. Removethe hexflangelocknutandshoulderboltsecuringoneof

thefrontgaugewheelstothefrontindexbracket.Repositionthe

gaugewheelto alignwiththeoneoffiveindexholesthatplaces

thewheel 1/4"to 1/2"abovetheground.Securethegaugewheel

tothe indexbracketwiththe shoulderboltandflangelocknut.

Notetheindexholeusedandsecuretheothergauge

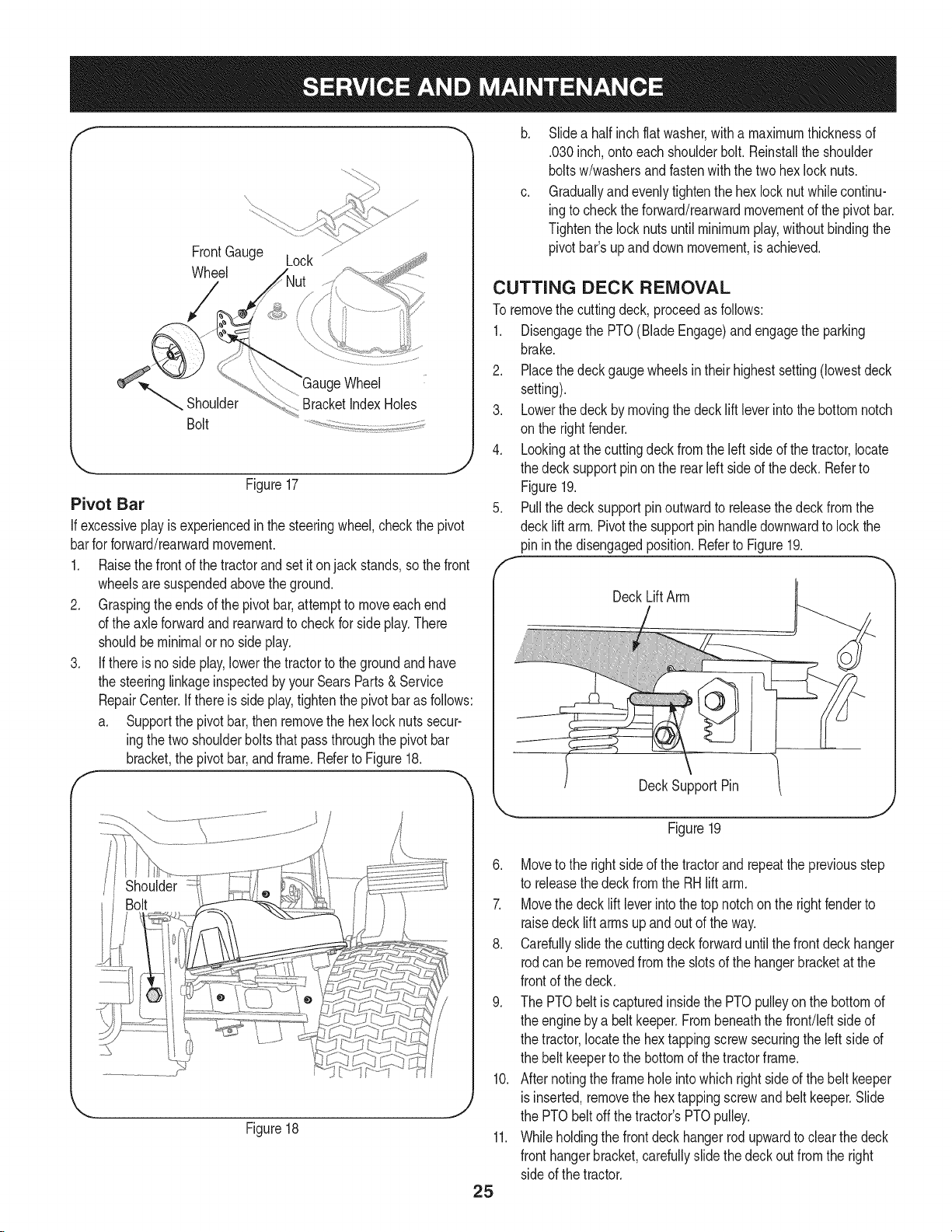

wheelin the sameposition.SeeFigure17.

24

Page 25

f

FrontGauge Lock ............

Wheel

Wheel

Shoulder BracketIndexHoles

Bolt

'_. j

Figure17

Pivot Bar

If excessiveplay isexperiencedin thesteeringwheel,checkthe pivot

barforforward/rearwardmovement.

1. Raisethe frontofthetractorand setitonjackstands,sothefront

wheelsaresuspendedabovetheground.

2. Graspingtheendsof thepivotbar,attempttomoveeachend

ofthe axleforwardandrearwardtocheckfor sideplay.There

shouldbeminimalornosideplay.

3. If thereis no sideplay,lowerthetractortothegroundandhave

thesteeringlinkageinspectedbyyourSearsParts& Service

RepairCenter.Ifthereis sideplay,tightenthepivotbarasfollows:

a. Supportthepivotbar,thenremovethehexlocknutssecur-

ingthetwoshoulderboltsthatpassthroughthe pivotbar

bracket,thepivotbar,andframe.RefertoFigure18.

b. Slidea halfinchflatwasher,witha maximumthicknessof

.030inch,onto eachshoulderbolt.Reinstalltheshoulder

boltsw/washersandfastenwiththetwohexlock nuts.

c. Graduallyandevenlytightenthehexlocknut whilecontinu-

ingtochecktheforward/rearwardmovementofthe pivotbar.

Tightenthelocknutsuntilminimumplay,withoutbindingthe

pivotbar'supanddownmovement,isachieved.

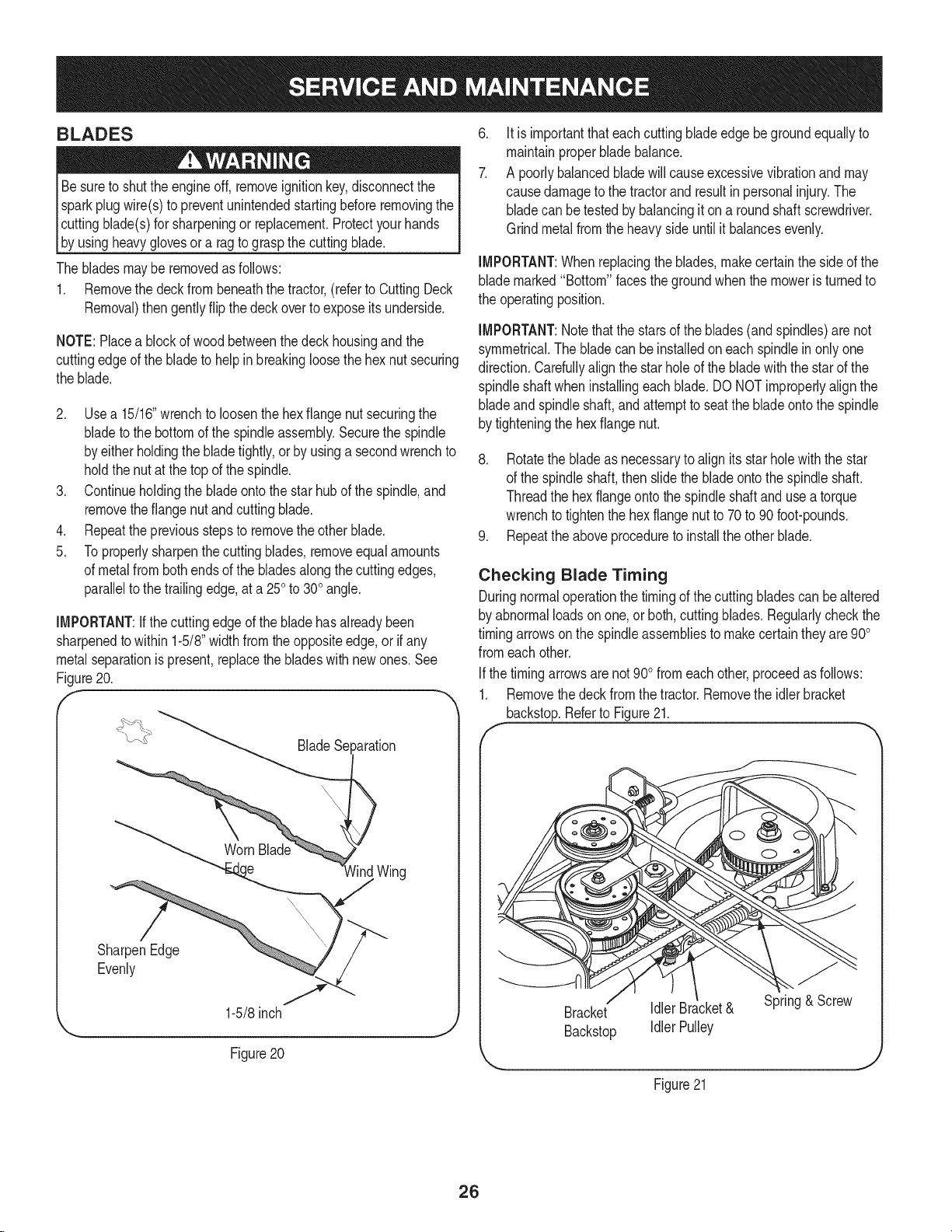

CUTTING DECK REMOVAL

Toremovethecuttingdeck,proceedasfollows:

1. DisengagethePTO(BladeEngage)andengagethe parking

brake.

2. Placethedeckgaugewheelsin theirhighestsetting(lowestdeck

setting).

3. Lowerthedeck bymovingthe decklift leverintothe bottomnotch

on therightfender.

4. Lookingatthecuttingdeckfromtheleftsideof thetractor,locate

thedecksupportpinontherearleftside ofthedeck.Referto

Figure19.

5. Pullthedecksupportpinoutwardtoreleasethedeckfromthe

decklift arm.Pivotthesupportpinhandledownwardto lockthe

pininthedisengagedposition.RefertoFigure19.

DeckLiftArm

Figure18

DeckSupportPin

Figure19

6. Moveto therightsideofthe tractorandrepeatthe previousstep

to releasethedeckfromtheRHlift arm.

7. Movethedecklift leverintothetopnotchon therightfenderto

raisedeckliftarmsupandoutof theway.

8. Carefullyslidethecuttingdeckforwarduntilthefrontdeckhanger

rodcanbe removedfromthe slotsof thehangerbracketat the

frontofthedeck.

9. ThePTObeltiscapturedinsidethePTOpulleyonthebottomof

theengineby a beltkeeper.Frombeneaththefront/leftsideof

thetractor,locatethe hextappingscrewsecuringtheleftsideof

thebelt keepertothebottomofthetractorframe.

10. Afternotingtheframeholeintowhichrightsideofthebelt keeper

isinserted,removethehextappingscrewandbelt keeper.Slide

thePTObeltoffthetractor'sPTOpulley.

11. Whileholdingthe frontdeckhangerrodupwardtoclearthedeck

fronthangerbracket,carefullyslidethedeckout fromtheright

sideof thetractor.

25

Page 26

BLADES

Besureto shutthe engineoff,removeignitionkey,disconnectthe

sparkplugwire(s)topreventunintendedstartingbeforeremovingthe

cuttingblade(s)forsharpeningor replacement.Protectyourhands

b_ usng heavygovesor a ragtograspthecuttng bade.

Thebladesmayberemovedas follows:

1. Removethe deckfrombeneaththetractor,(referto CuttingDeck

Removal)then gentlyflipthedeckoverto exposeitsunderside.

NOTE:Placea blockofwoodbetweenthedeck housingandthe

cuttingedgeof the bladeto helpin breakingloosethehexnut securing

theblade.

2. Usea 15/16"wrenchtoloosenthehexflangenutsecuringthe

bladetothe bottomof thespindleassembly.Securethespindle

byeitherholdingthebladetightly,orbyusinga secondwrenchto

holdthenutatthetopofthe spindle.

3. Continueholdingthebladeontothestarhubofthespindle,and

removetheflangenutandcuttingblade.

4. Repeatthepreviousstepstoremovetheotherblade.

5. Toproperlysharpenthecuttingblades,removeequalamounts

ofmetalfrombothendsofthebladesalongthecuttingedges,

paralleltothe trailingedge,ata250to300angle.

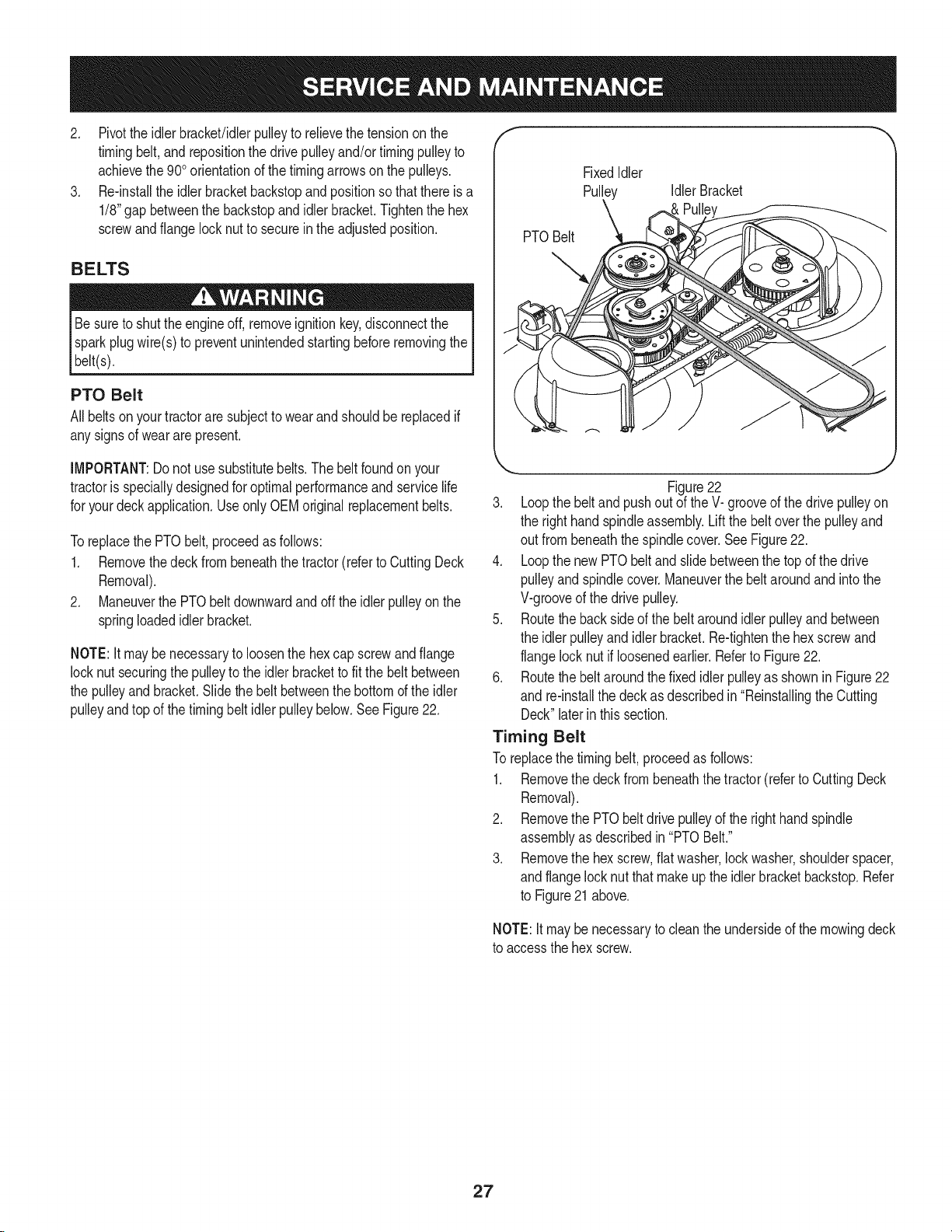

iMPORTANT:ifthecuttingedgeofthebladehasalreadybeen

sharpenedto within1-5/8"widthfromtheoppositeedge,or ifany

metalseparationis present,replacethebladeswith newones.See

Figure20.

f

_aration

.

Itis importantthateach cuttingbladeedgebegroundequallyto

maintainproperbladebalance.

7.

A poorlybalancedbladewillcauseexcessivevibrationandmay

causedamageto thetractorand resultin personalinjury.The

bladecanbetestedbybalancingit ona roundshaftscrewdriver.

Grindmetalfromtheheavysideuntilit balancesevenly.

iMPORTANT:Whenreplacingtheblades,makecertainthesideofthe

blademarked"Bottom"facesthegroundwhenthemoweris turnedto

theoperatingposition.

iMPORTANT:Notethatthe starsoftheblades(andspindles)arenot

symmetrical.The bladecanbeinstalledoneachspindlein onlyone

direction.Carefullyalignthestarholeof thebladewiththe starofthe

spindleshaftwheninstallingeachblade.DO NOTimproperlyalignthe

bladeandspindleshaft,andattempttoseatthe bladeontothe spindle

bytighteningthehexflange nut.

8. Rotatethebladeasnecessarytoalignits starholewiththestar

ofthe spindleshaft,thenslidethebladeontothespindleshaft.

Threadthe hexflangeontothe spindleshaftandusea torque

wrenchtotightenthe hexflangenutto 70to 90foot-pounds.

9. Repeattheaboveproceduretoinstalltheotherblade.

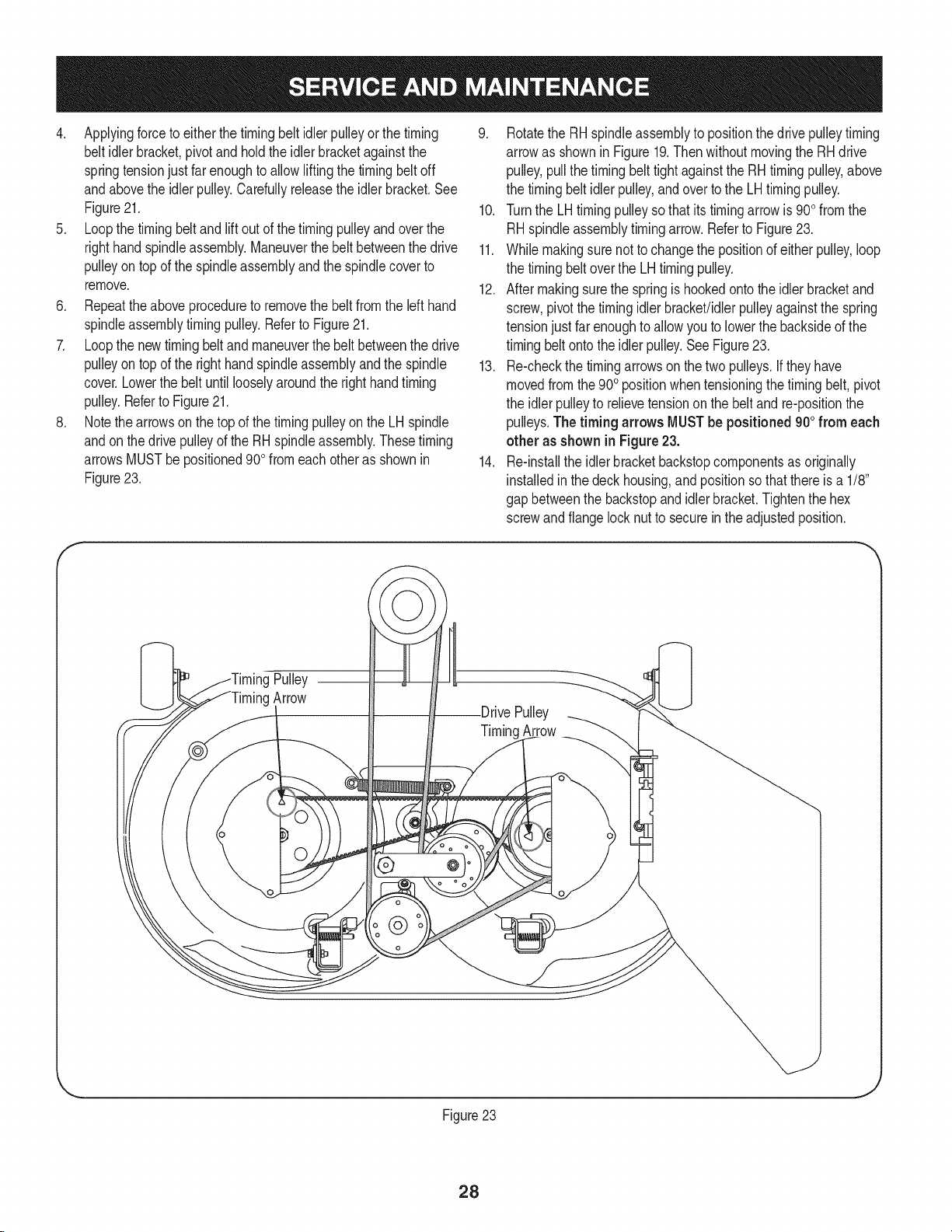

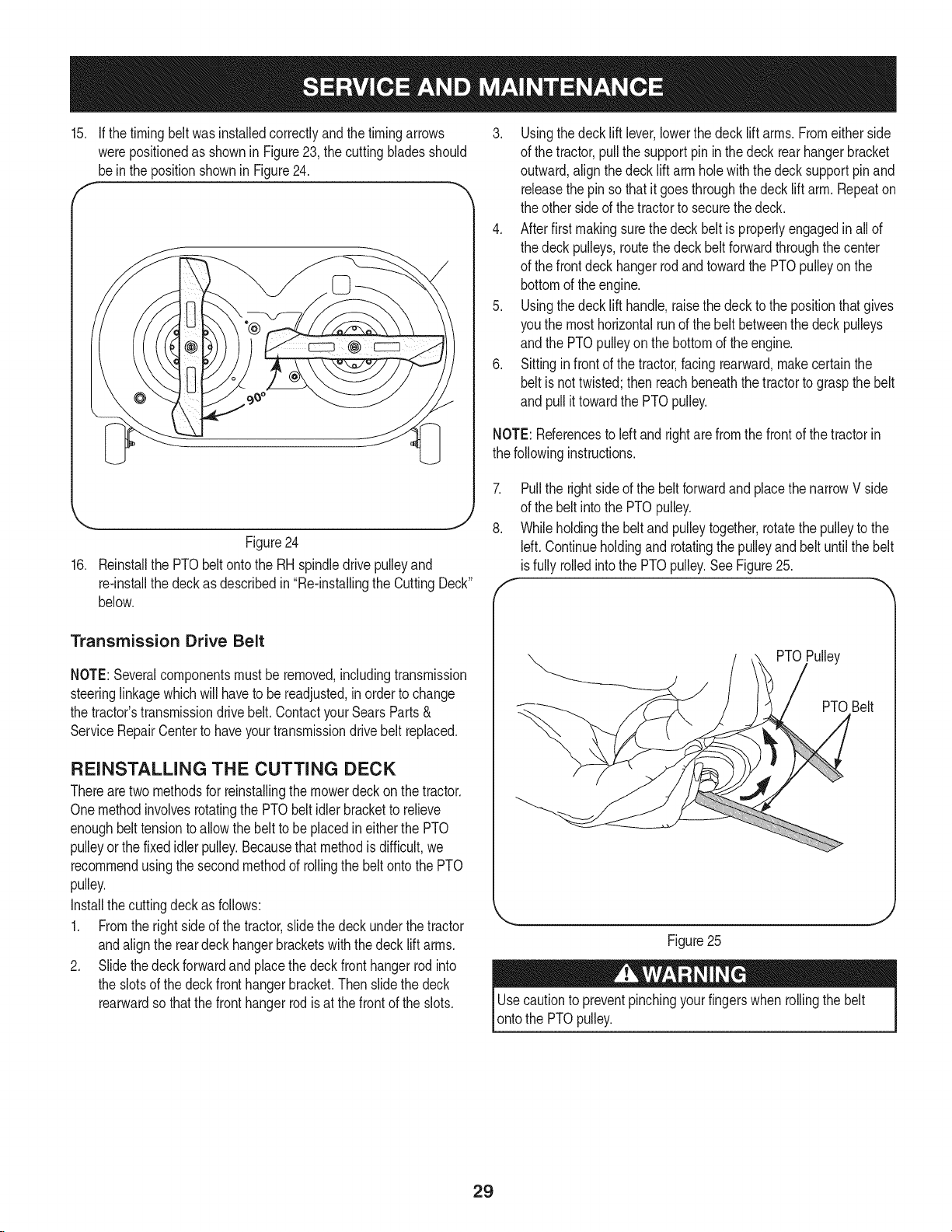

Checking Blade Timing

Duringnormaloperationthetimingofthecuttingbladescan bealtered

byabnormalloadsonone,orboth,cuttingblades.Regularlycheckthe

timingarrowsonthespindleassembliestomakecertaintheyare900

fromeachother.

Ifthetimingarrowsarenot900fromeachother,proceedasfollows:

1. Removethe deckfromthetractor.Removetheidlerbracket

backstop.Referto Figure21.