MTD 17AK2ACS099 Owner’s Manual

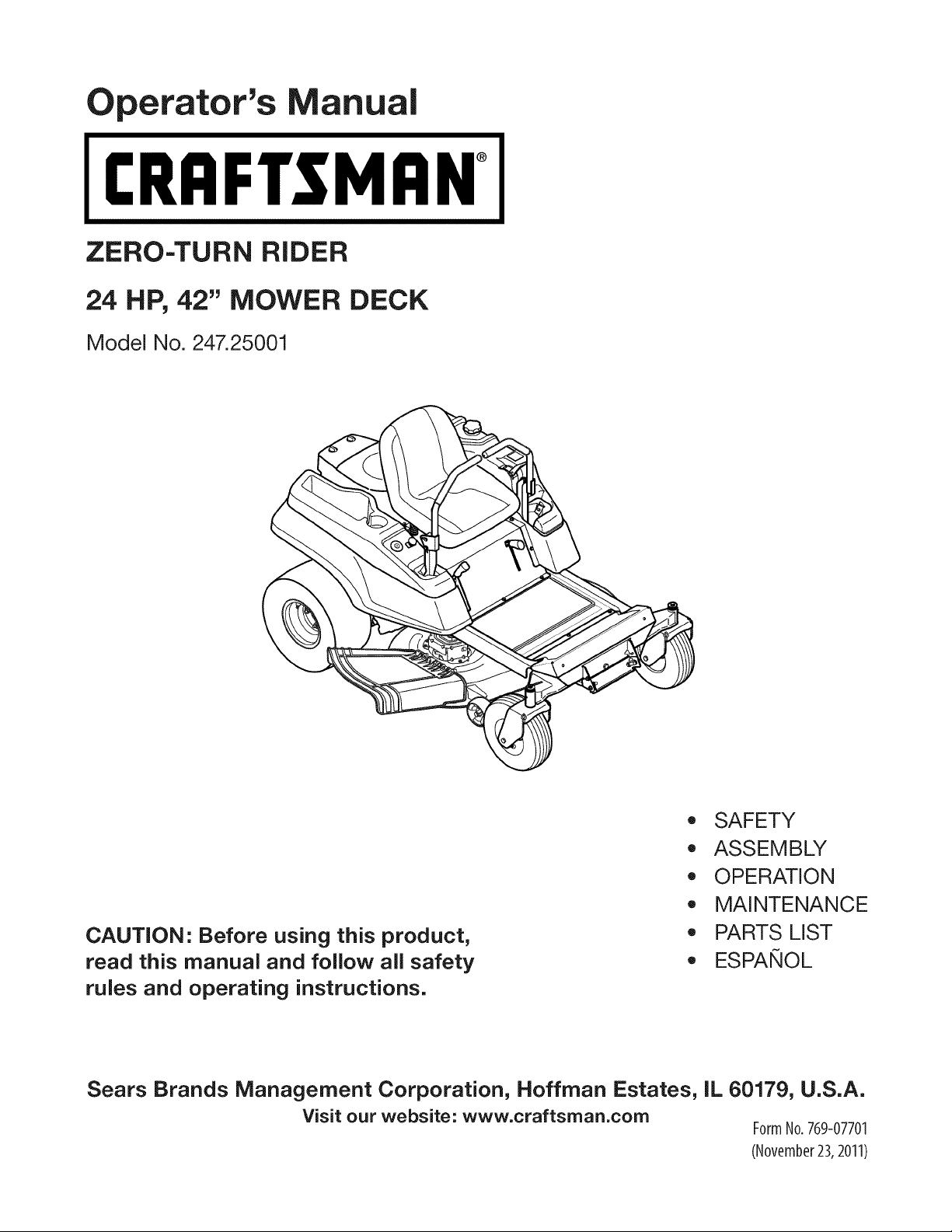

perator_s nual

I:RRFrSMRN°

ZERO=TURN RIDER

24 Hi:), 42" MOWER DECK

Model No. 247,25001

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions,

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

PARTS LIST

o ESPANOL

FormNo.769-07701

(November23,2011)

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Pages 3-8

Assembly .................................................. Pages 9-12

Operation .................................................... Pages 13-21

Service and Maintenance ......................... Pages 22-33

Parts List ..................................................... Pages 37-61

Labels ....................................................... Page 62

Repair Protection Agreement ................... Page 68

Espa_ol ..................................................... Page 69

Service Numbers ...................................... Back Cover

Off-Season Storage .................................. Page 34

Troubleshooting ........................................ Page 35-36

CRAFTSMAN FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,all non-expendablepartsofthis ridingequipmentarewarrantedagainstanydefectsin materialor

workmanship.A defectivenon-expendablepartwill receivefreein-homerepairorreplacementif repairisimpossible.

FOR90 DAYSfromthedateofpurchase,thebattery(anexpendablepart)ofthis ridingequipmentis warrantedagainstany defectsinmaterialor

workmanship(ourtestingprovesthat it willnotholda charge).A defectivebatterywillreceivefreein-homereplacement.

WARRANTYSERVICE

Forwarrantycoveragedetailsto obtainfree repairor replacement,call1-800-659-5917or visitthe website: www.craftsman.com

Inallcasesabove,if part repairor replacementis impossible,theridingequipmentwillbe replacedfreeofchargewiththesameor anequivalent

model.

Allofthe abovewarrantycoverageis voidif thisridingequipmentis everusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

ThiswarrantycoversONLYdefectsin materialandworkmanship.Warrantycoveragedoes NOTinclude:

• Expendableparts(exceptbattery)thatcanwear outfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoblades,spark

plugs,air cleaners,belts,andoilfilters.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

• Tirereplacementor repaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,or improperoperationormaintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto damagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthatbendthe frame,axleassemblyor crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethe propergradeand amountof engineoil,failuretokeepthedeckclearofflammabledebris,orfailuretomaintainthe

ridingequipmentaccordingto theinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedor oxidized(stale). Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

o

Normaldeteriorationandwearofthe exteriorfinishes,or productlabelreplacement.

o

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands ManagementCorporation, Hoffman Estates,IL 60179

EngineOil: SAE30

Fuel: UnleadedGasoline

SparkPlug: RC12YC

Engine: Briggs& StrattonTwinPlatinumProfessional

© KCDIRLLC 2

ModelNumber

Serial Number

Dateof Purchase

Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failureto complywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandshouldbetrainedandsupervisedbyan adult.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhile itis in operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentistobe used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownbythe blade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatterntoavoiddischargeof materialtoward

roads,sidewalks,bystandersandthe like.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardtheoperator.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperforminganadjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycan becaughtin movable

parts.Neveroperatethis machinein barefeetor sandals.

• Beawareof themowerandattachmentdischargedirectionand

Your Responsibility--Restrictthe useof thispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon the machine.

SAVE THESE INSTRUCTIONS!

do notpointitat anyone.Donot operatethemowerwithoutthe

dischargecoverorentiregrasscatcherinits properplace.

• Donotputhandsor feetnearrotatingpartsor underthecutting

deck.Contactwiththe blade(s)can amputatehandsandfeet.

A missingordamageddischargecovercan causebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfor trafficwhenoperatingnearorcrossingroadways.This

machineis notintendedforuseonanypublic roadway.

• Donotoperatethemachinewhile undertheinfluenceofalcohol

or drugs.

• Mowonlyindaylightorgoodartificiallight.

Nevercarrypassengers.

• Backup slowly.Alwayslookdownandbehindbeforeandwhile

backingto avoida back-overaccident.Beawareand payatten-

tionto thesafetysystemfunctionthatstopspowertothe blades

whendrivingin reverse.Ifnotfuctioningproperly,contactan

authorizeddealerfor safetysysteminspectionand repair.

• Slowdownbeforeturning.Operatethe machinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometo acompletestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

• Neverleavearunningmachineunattended.Alwaysturnoff

blade(s),placedrivecontrollevers inneutral,setparkingbrake,

stopengineand removekeybeforedismounting.

• Useextracarewhenloadingor unloadingthemachineintoa

traileror truck.Thismachineshouldnotbe drivenupor down

ramp(s),becausethemachinecouldtipover,causingserious

personalinjury.Themachinemustbepushedmanuallyon

ramp(s)toloadorunloadproperly.

3

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.

• Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtree branches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthe machine,whichcould

resultinseriousinjury.

• Disengageallattachmentclutches,setthe parkingbraketothe

'on'positionandmovethe RHand LHdrivecontrolleverstothe

neutralpositionbeforeattemptingto startthe engine.

Yourmachineisdesignedto cutnormalresidentialgrassof a

heightnomorethan10".Donotattemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpilesof dryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfire hazard.

• Useonlyaccessoriesandattachmentsapprovedfor this machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththe approvedaccessoryorattachment.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilitytooperatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

• If situationsoccurwhicharenot coveredinthismanual,usecare

andgoodjudgment.ContacttheCraftsmanHelpLineat1-800-

659-5917for assistance.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossof controlandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeorifyoufeeluneasyon

it, do notmowit.

Foryoursafety,usetheslopegaugeincludedaspartofthismanual

to measureslopesbeforeoperatingthis machineona slopedor hilly

area.Ifthe slopeis greaterthan15degreesasshownonthe slope

gauge,donot operatethismachineonthatareaor seriousinjurycould

result.

Do:

o

Mowacrossslopes,notupanddown.Exerciseextremecaution

whenchangingdirectionon slopes.

Watchfor holes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscan hide

obstacles.

Useslowspeed.Choosea lowenoughspeedsothatyouwillnot

haveto stopwhileon the slope.Avoidstartingor stoppingon a

slope.Ifthetiresareunableto maintaintraction,disengagethe

bladesandproceedslowlyandcarefullystraightdowntheslope.

Followthe manufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersorotherattachments.These

canchangethestabilityof the machine.

• Keepallmovementontheslopesslowandgradual.Donot

makesuddenchangesinspeedor direction.Rapidacceleration

or decelerationcouldcausethefrontof themachineto lift and

rapidlyrollover backwards,whichcouldcauseseriousinjury.

DoNot:

• Donotturnonslopesunlessnecessary;thenturn slowlyuphill

and useextracarewhileturning.

• Donotmowneardrop-offs,ditchesorembankments.Themower

couldsuddenlyturnoverif a wheelis overthe edgeofa cliff,

ditch,or if an edgecavesin.

• Donottry tostabilizethemachinebyputtingyourfooton the

ground.

• Donotuseagrasscatcheron steepslopes.

• Donotmowon wetgrass.Reducedtractioncouldcausesliding.

• Donottowheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendsto pushthe ridingmowerand

maycauseyouto loosecontrol(e.g.ridingmowermayspeed

up,brakingandsteeringabilityare reduced,attachmentmay

jack-knifeandcauseridingmowertooverturn).

4

CHILDREN

Tragicaccidentscanoccurifthe operatorisnotalert tothe presence

ofchildren.Childrenareoftenattractedto themachineandthe mowing

activity.Theydo notunderstandthe dangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthe mowingareaand inwatchfulcare ofa

responsibleadultotherthantheoperator.

• Bealertandturnmachineoff ifa childentersthearea.

• Toavoidback-overaccidents,alwayslookbehindanddownfor

smallchildren.

• Nevercarrychildren,evenwiththeblade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionofa child

whomayrunintothe pathof themachine.

• Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedtopreventunauthorized

operation.

Neverallowchildrenunder14yearsofageto operatethismachine.

Children14andovershouldreadandunderstandtheinstructionsand

safeoperationpracticesinthismanualandon themachineandshould

betrainedandsupervisedbyan adult.

TOWING

Towonlywitha machinethathasa hitchdesignedfortowing.Donot

attachtowedequipmentexceptat thehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfortowed

equipmentandtowingonslopes.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Travelslowlyandallowextradistancetostop.

Donot shiftto neutralandcoastdownhill.

Donottowheavypullbehindattachments(e.g.loadeddumpcart,

lawnroller,etc.)onslopesgreaterthan5 degrees.Whengoingdown

hill,the extraweighttendsto pushtheridingmowerandmaycause

youto loosecontrol(e.g.ridingmowermayspeedup,brakingand

steeringabilityare reduced,attachmentmayjack-knifeandcause

ridingmowerto overturn).

SERVICE

SafeHandlingof Gasoline:

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyour clotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Neverfillcontainersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthe truck

or trailerandrefueliton theground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthenozzleincontactwiththerimof thefueltankor

containeropeningat all timesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

• Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegascap or addfuelwhiletheengineis hotor run-

ning.Allowengineto coolatleasttwominutesbeforerefueling.

• Neveroverfill fueltank. Filltankto no morethan1/2"belowbottom

offiller necktoallowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineor fuelcontainerinsidewherethereisan

openflame,sparkor pilotlightas ona waterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

• Allowa machineto coolat leastfiveminutesbeforestoring.

GeneralService

• Neverrunan engineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertainthe

blade(s)andall movingpartshavestopped.Disconnectthe spark

plugwireandgroundagainsttheengineto preventunintended

starting.

• Periodicallychecktomakesurethebladescometocompletestop

withinapproximately(5) fivesecondsafteroperatingtheblade

disengagementcontrol,ifthebladesdonotstopwithinthethis

timeframe,aveyourmachineservicedprofessionallyby Searsor

anotherqualifieddealer.

• Regularlycheckthesafetyinterlocksystemforproperfunction,as

describedlaterinthis manual.Ifthe safetyinterlocksystemdoes

notfunctionproperly,haveyourmachineservicedprofessionally

bySearsoranotherqualifieddealer.

• Checkthe blade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)for

damage(e.g.,excessivewear,bent,cracked). Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useof partswhichdo not

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepall nuts,bolts,andscrewstighttobesuretheequipmentis

in safeworkingcondition.

• Nevertamperwiththesafetyinterlocksystemorothersafety

devices.Checktheirproperoperationregularly.

• Afterstrikingaforeignobject,stopthe engine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothe machine

whilethe engineis running.

• Grasscatchercomponentsandthedischargecoveraresubject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo notmeetthe originalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donotchangethe enginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

• Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsfor gas,oil,etc. to

protecttheenvironment.

• Accordingto theConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or270hoursof

operation.At theendof theAverageUsefulLifehavethe machine

inspectedannuallyby Searsoranotherqualifieddealerto ensure

thatall mechanicalandsafetysystemsareworkingproperlyand

notworn excessively.Failuretodo socan resultinaccidents,

injuriesordeath.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththe governorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

Notice RegardingEmissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonor nearanyunimprovedforest-covered,

brush-coveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

Ifa sparkarrestoris used,it shouldbe maintainedin effectiveworking

orderbythe operator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablethroughyournearest

engineauthorizedservicedealeror contacttheservicedepartment,

RO.Box361131Cleveland,Ohio44136-0019.

6

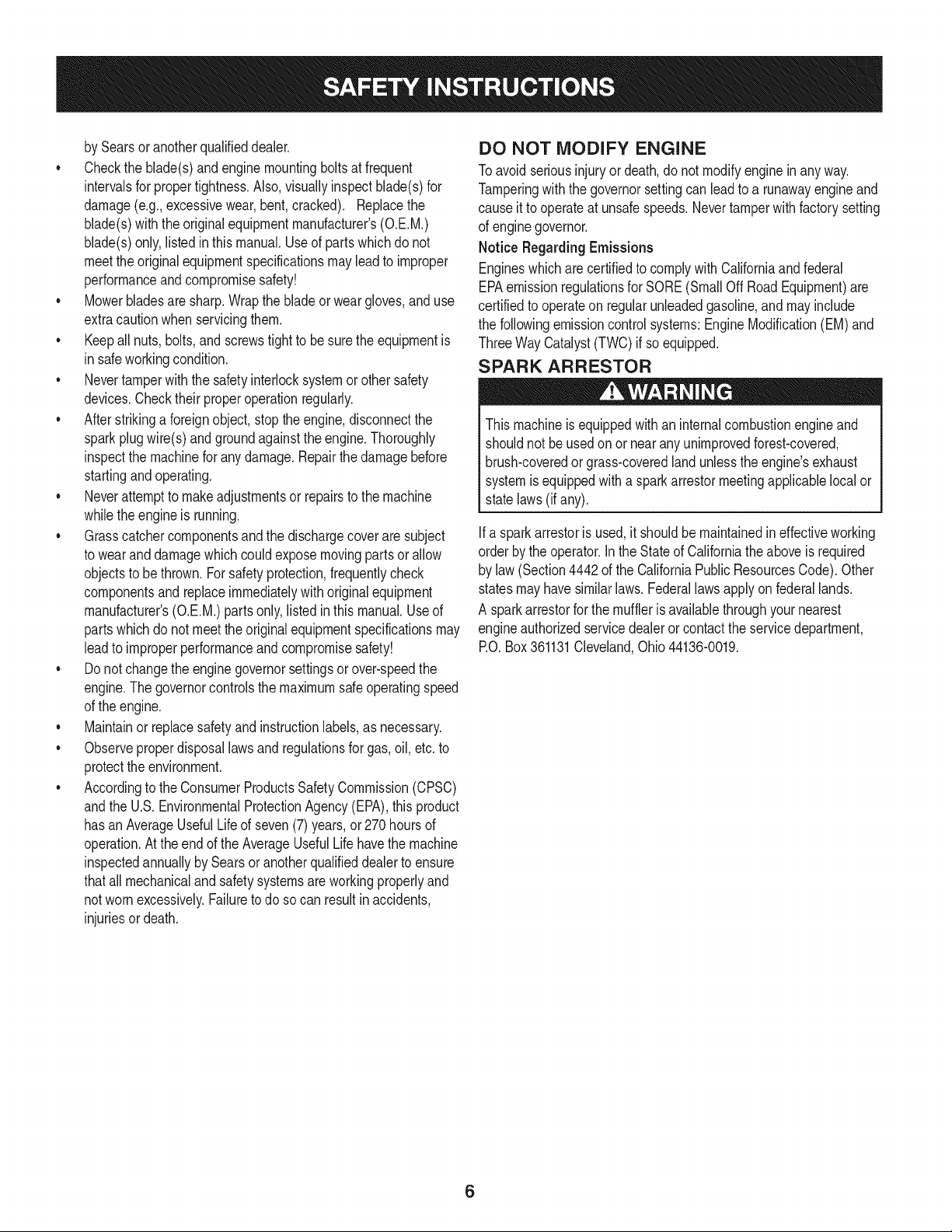

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthis product.Read,understand,andfollowallinstructionson themachine

beforeattemptingtoassembleandoperate.

READTHEOPERATOR'SMANUAL(S)

Read,understand,andfollowall instructionsinthemanual(s)beforeattemptingto assembleand

operate

WARNING--ROTATINGBLADES

Donot puthandsor feetnearrotatingpartsor underthecuttingdeck.Contactwiththeblade(s)can

amputatehandsandfeet.

sJ / _

®

WARNING--THROWNOBJECTS

Thismachinemaypickupandthrowandobjectswhichcancauseseriouspersonalinjury.

WARNING--THROWNOBJECTS

Thismachinemaypickupandthrowandobjectswhichcancauseseriouspersonalinjury.

BYSTANDERS

Keepbystanders,helpers,childrenandpetsatleast75feetfromthemachinewhileitis inoperation.

WARNING--SLOPEOPERATION

Donot operatethismachineona slopegreaterthan15degrees.

DANGER-- ROTATINGBLADES

Toreducetheriskof injury,keephandsandfeetaway.Donotoperateunlessdischargecoveror grass

catcheris in itsproperplace.Ifdamaged,replaceimmediately.

7

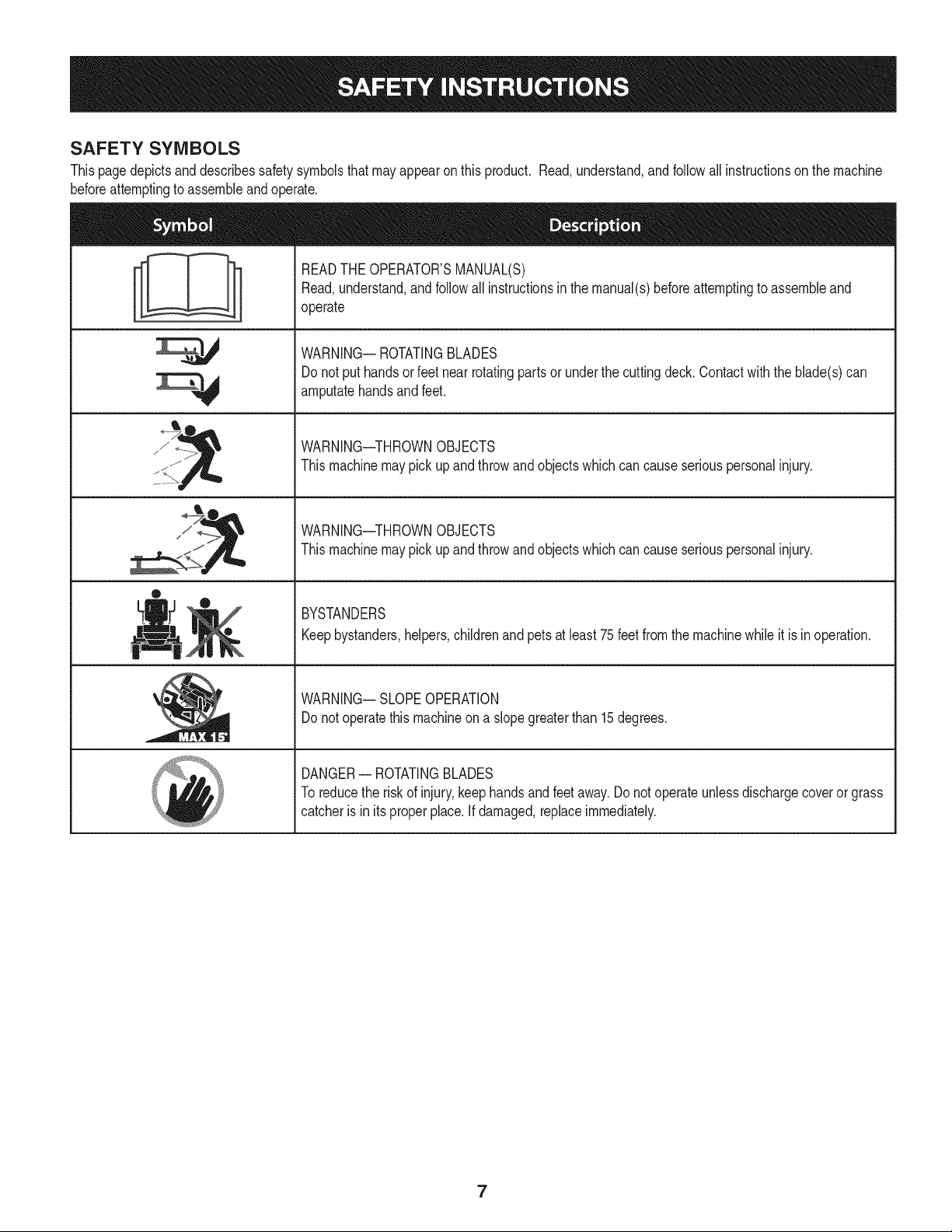

15° Slope

15° Slope

X

(OK)

'_. _ Figure1

(TOO STEEP)

Figure2

15°

dashedline

USETHISSLOPEGAUGETODETERMINE

IFA SLOPEIS TOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfoldalongthedashedline.

2. Locateaverticalobjectonor behindtheslope(e.g.apole,building,fence, tree,etc.)

3. Align eithersideoftheslopegaugewiththeobject(SeeFigure1andFigure2 ).

4. Adjust gaugeupor downuntilthe leftcornertouchestheslope(SeeFigure1and Figure2).

5.

If thereis agap belowthe gauge,theslopeis too steepfor safeoperation(SeeFigure2 above).

Slopesare a majorfactor relatedtotip-over and roll-overaccidents whichcan resultin severeinjuryordeath. Do not operatemachine on slopes

in excess of 15degrees.All slopesrequireextracaution. Ifyou cannotbackup theslope or if you feeluneasyon it,do not mowit.

Always mow across thefaceof slopes,never mowupand downthe face of slopes.

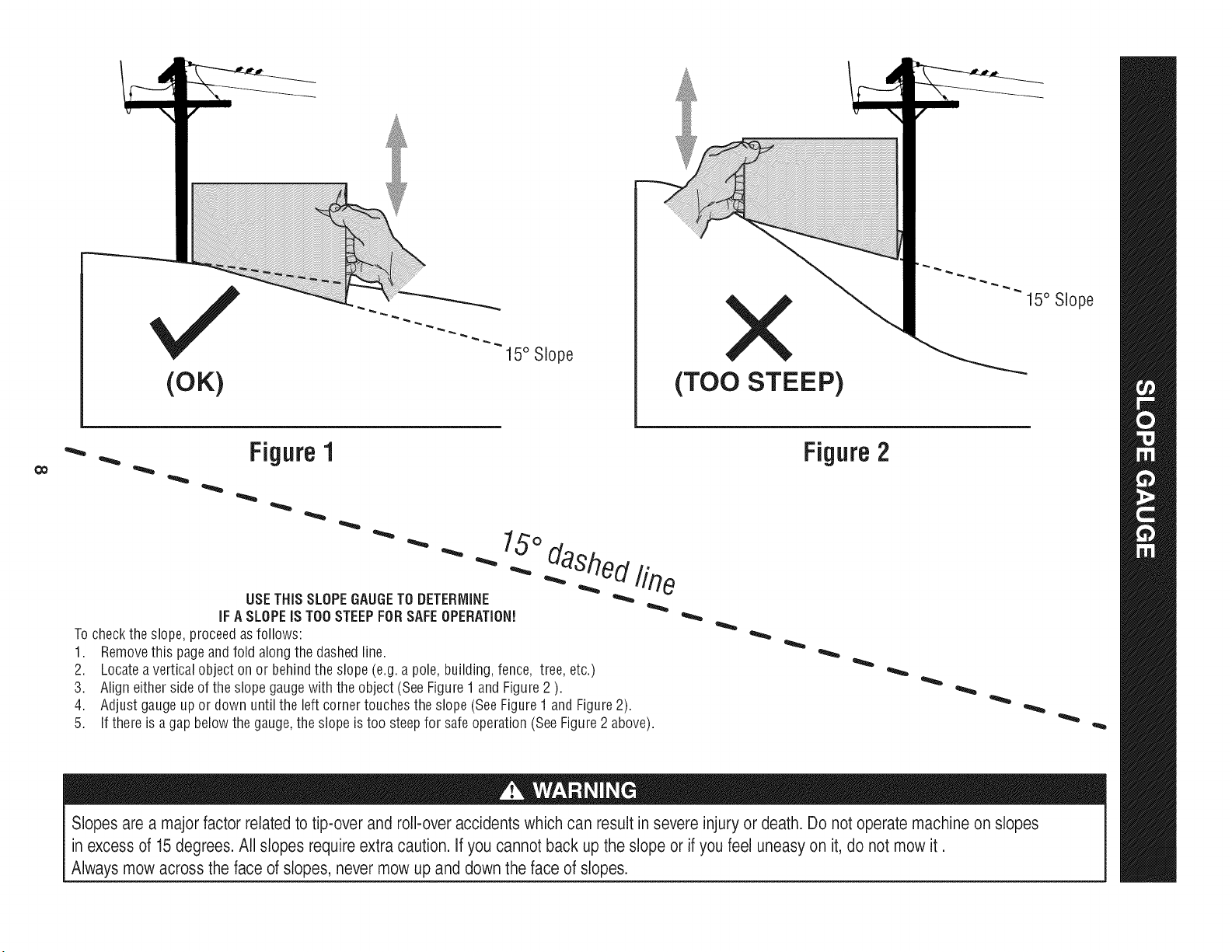

SET-UP

Moving The Riding mower Manually

Yourridingmower'stransmissionisequippedwithahydrostaticrelief

valveforoccasionswhenitisnecessaryto movethe ridingmower

manually.Openingthisvalvepermitsthefluidinthe transmissionto

bypassitsnormalroute,allowingthereartiresto "freewheel."Toopen

thehydrostaticreliefvalve,proceedasfollows:

1. Locatethehydrostaticbypassrodintherearoftheridingmower.

SeeFigure1.

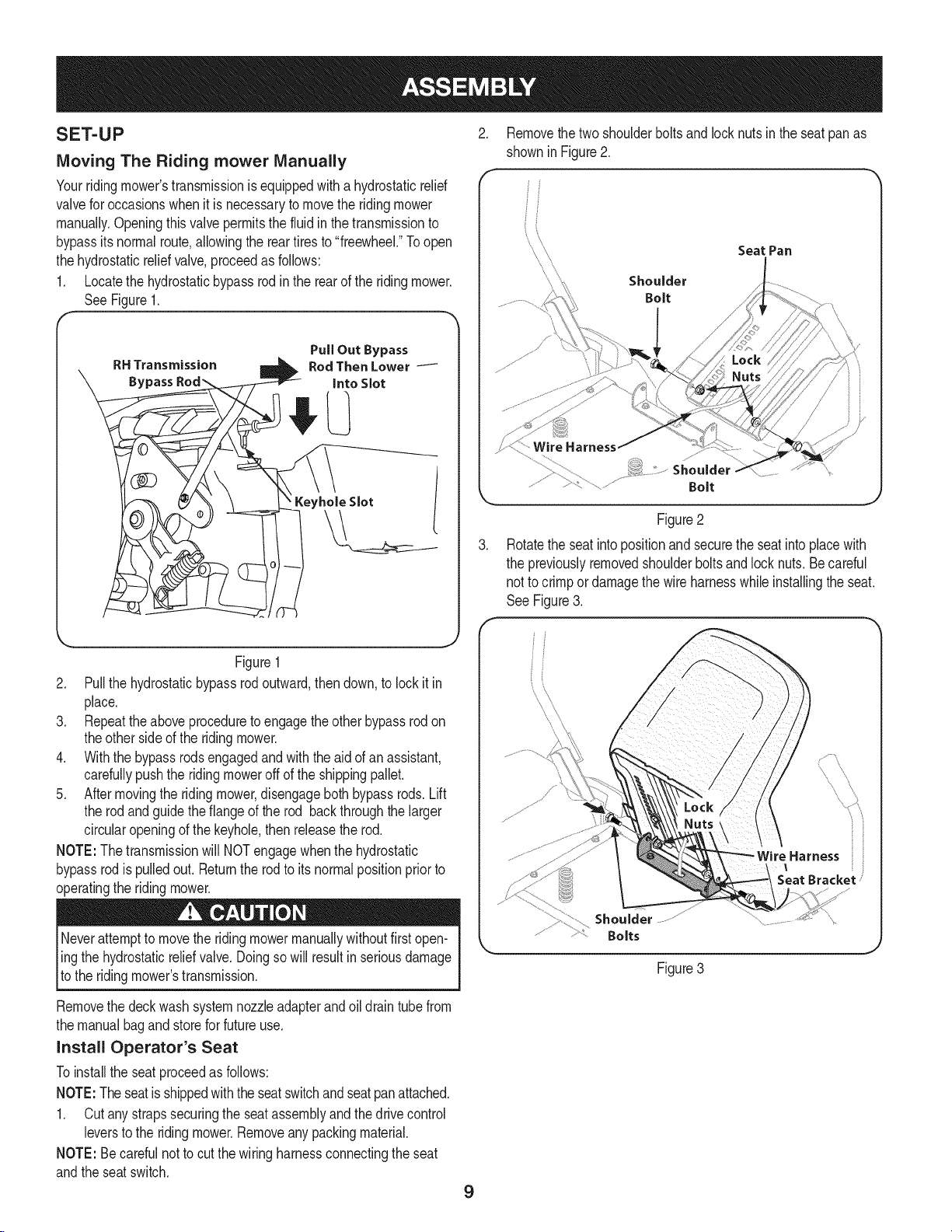

Removethetwoshoulderboltsandlocknutsin theseatpanas

showninFigure2.

Seat Pan

Shoulder

Bolt

RH Transmission

Bypass

RodThenLower

IntoSlot

Keyhole Slot

Figure1

2. Pullthehydrostaticbypassrodoutward,thendown,tolockit in

place.

3. Repeattheaboveproceduretoengagetheotherbypassrodon

theother sideof the ridingmower.

4. Withthe bypassrodsengagedandwiththeaidofanassistant,

carefullypushtheridingmoweroffof theshippingpallet.

5. Aftermovingthe ridingmower,disengagebothbypassrods.Lift

therodandguidethe flangeof therod backthroughthe larger

circularopeningof thekeyhole,then releasetherod.

NOTE:The transmissionwillNOTengagewhenthehydrostatic

bypassrodis pulledout. Returnthe rodto itsnormalpositionpriorto

operatingthe ridingmower.

PullOut Bypass

Shoulder

Bolt

Figure2

.

Rotatetheseatintopositionandsecuretheseatintoplacewith

thepreviouslyremovedshoulderboltsand locknuts.Becareful

notto crimpordamagethewireharnesswhileinstallingtheseat.

See Figure3.

iHarness ii

Seat Bracket /

Neverattemptto movetheridingmowermanuallywithoutfirstopen-

ling thehydrostaticr,elief valve.Doingsowill resultinseriousdamage

[to theridingmowers transmission.

Removethedeckwashsystemnozzleadapterandoildraintubefrom

themanualbagandstoreforfutureuse.

Install Operator's Seat

Toinstallthe seatproceedasfollows:

NOTE:Theseatisshippedwiththe seatswitchandseatpanattached.

1. Cutanystrapssecuringtheseatassemblyandthedrivecontrol

leverstothe ridingmower.Removeanypackingmaterial.

NOTE:Becarefulnottocut thewiringharnessconnectingtheseat

andtheseatswitch.

Shoulder

Bolts

Figure 3

9

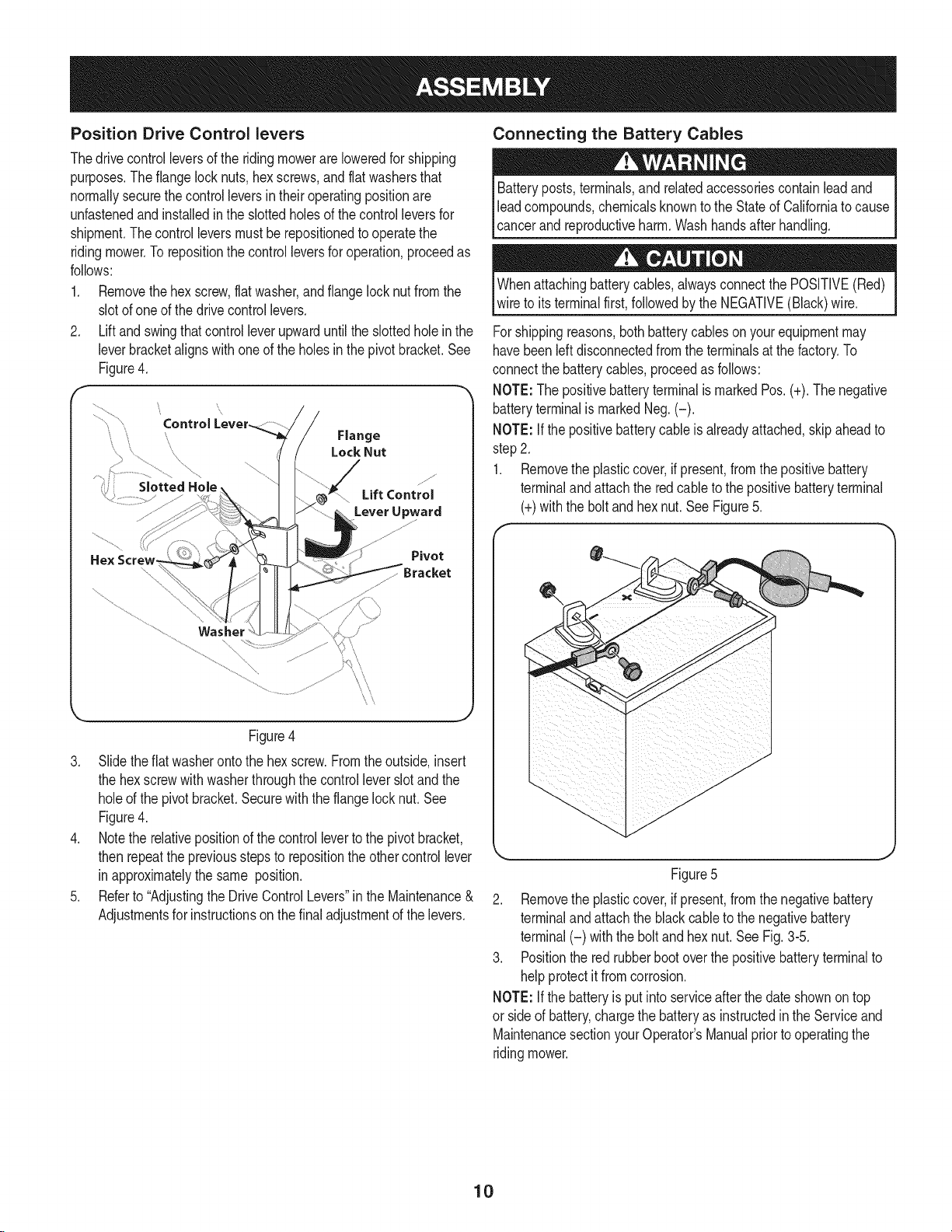

Position Drive Control levers

Thedrivecontrolleversof theridingmowerareloweredforshipping

purposes.Theflangelocknuts,hex screws,andflatwashersthat

normallysecurethe controlleversintheiroperatingpositionare

unfastenedandinstalledintheslottedholesofthecontrolleversfor

shipment.Thecontrolleversmustbe repositionedtooperatethe

ridingmower.Torepositionthecontrolleversforoperation,proceedas

follows:

1. Removethehexscrew,flat washer,andflangelocknutfromthe

slotofoneof thedrivecontrollevers.

2. Liftand swingthatcontrolleverupwarduntiltheslottedholeinthe

leverbracketalignswithoneof theholesinthepivotbracket.See

Figure4.

\

SlottedHole

Pivot

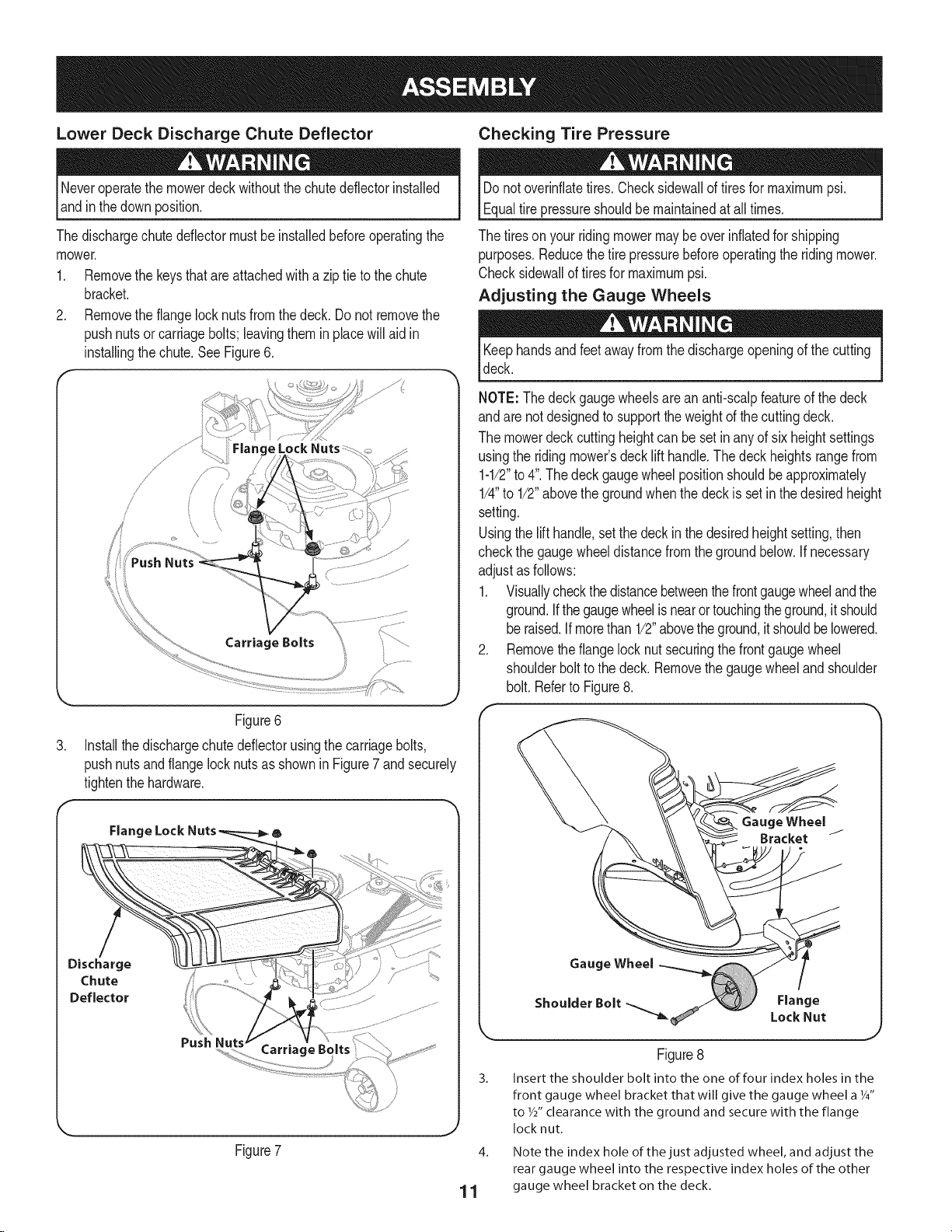

Connecting the Battery Cables

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknownto theStateof Californiato cause

cancerand reproductiveharm.Washhandsafterhandling.

Whenattachingbatterycables,alwaysconnectthePOSITIVE(Red)

wireto itsterminalfirst,followedby theNEGATIVE(Black)wire.

Forshippingreasons,bothbatterycableson yourequipmentmay

havebeenleftdisconnectedfromtheterminalsatthe factory.To

connectthe batterycables,proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegative

batteryterminalismarkedNeg.(-).

NOTE:If the positivebatterycable isalreadyattached,skipaheadto

step2.

1. Removetheplasticcover,ifpresent,fromthe positivebattery

terminalandattachthe redcableto thepositivebatteryterminal

(+)withtheboltandhexnut.SeeFigure5.

/

\

\\

\\

Figure4

3. Slidetheflatwasherontothe hexscrew.Fromtheoutside,insert

thehexscrewwithwasherthroughthecontrolleverslotandthe

holeofthe pivotbracket.Securewiththe flangelocknut.See

Figure4.

4. Notethe relativepositionofthecontrollevertothepivotbracket,

thenrepeatthepreviousstepsto repositiontheothercontrollever

inapproximatelythe same position.

5. Referto"AdjustingtheDriveControlLevers"intheMaintenance&

Adjustmentsforinstructionsonthefinaladjustmentofthelevers.

Figure5

2. Removetheplasticcover,ifpresent,fromthe negativebattery

terminalandattachthe blackcableto thenegativebattery

terminal(-) withtheboltand hexnut.SeeFig.3-5.

3. Positiontheredrubberbootoverthe positivebatteryterminalto

helpprotectitfromcorrosion.

NOTE:If the batteryisputintoserviceafterthe dateshownon top

or sideof battery,chargethebatteryasinstructedinthe Serviceand

MaintenancesectionyourOperator'sManualpriortooperatingthe

ridingmower.

10

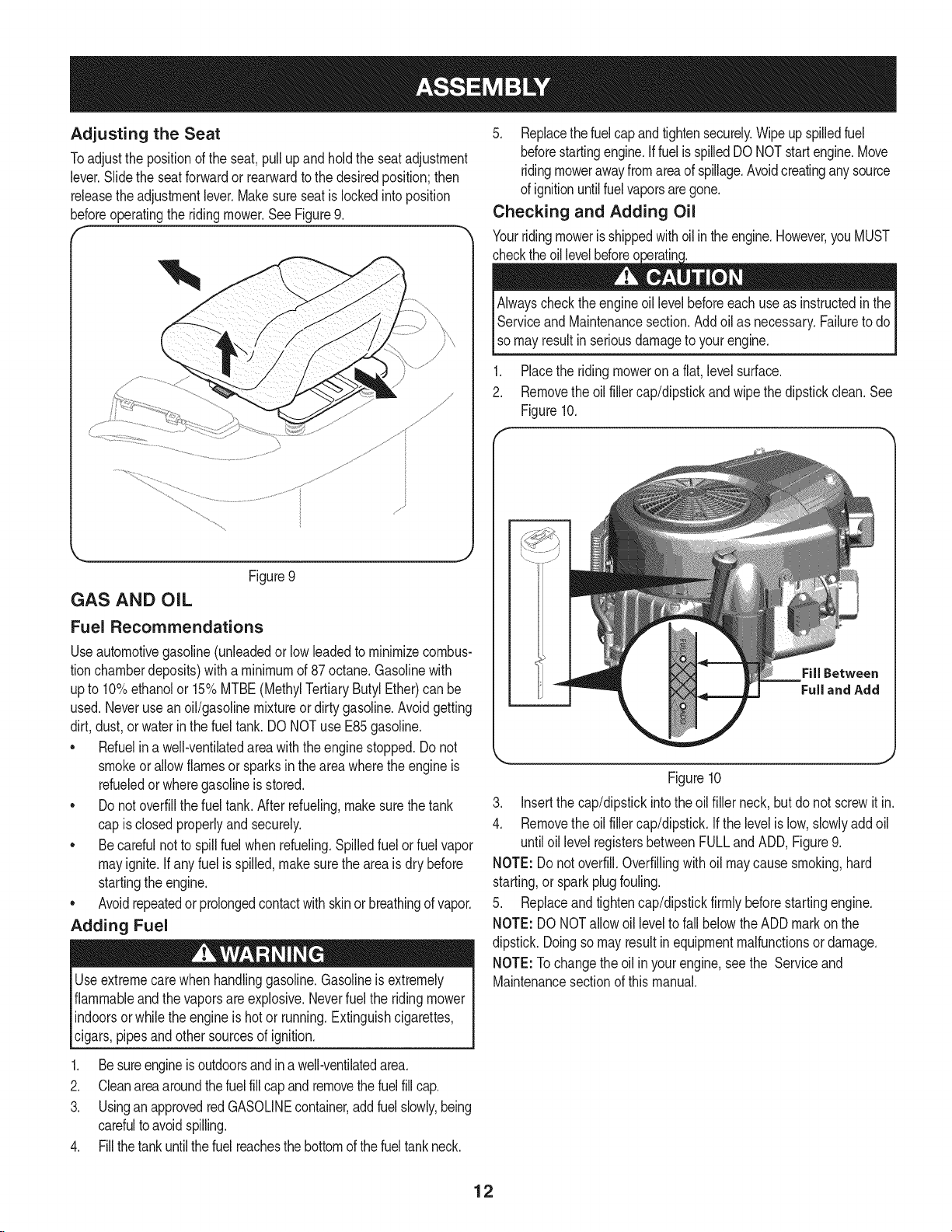

Lower Deck Discharge Chute Deflector Checking Tire Pressure

Neveroperatethemowerdeckwithoutthechutedeflectorinstalled

andinthedownposition.

Thedischargechutedeflectormustbe installedbeforeoperatingthe

mower.

1. Removethe keysthatareattachedwitha zip tieto thechute

bracket.

2. Removetheflangelocknutsfromthedeck.Donotremovethe

pushnutsor carriagebolts;leavingthemin placewill aidin

installingthe chute.SeeFigure6.

,//

/

/

/

/

/

Carriage Bolts

Donot overinflatetires.Checksidewallof tiresformaximumpsi.

Equaltire pressureshouldbemaintainedatall times.

Thetiresonyour ridingmowermaybe overinflatedfor shipping

purposes.Reducethetirepressurebeforeoperatingtheridingmower.

Checksidewallof tiresfor maximumpsi.

Adjusting the Gauge Wheels

Keephandsandfeetawayfromthe dischargeopeningof thecutting

deck.

NOTE:Thedeckgaugewheelsarean anti-scalpfeatureof the deck

andare notdesignedtosupportthe weightofthe cuttingdeck.

Themowerdeckcuttingheightcanbe setinanyof sixheightsettings

usingthe ridingmower'sdecklift handle.Thedeckheightsrangefrom

1-1/2"to4".The deckgaugewheelpositionshouldbeapproximately

1/4"to 1/2"abovethegroundwhenthedeckissetin thedesiredheight

setting.

Usingthelifthandle,setthedeckinthedesiredheightsetting,then

checkthe gaugewheeldistancefromthegroundbelow.If necessary

adjustasfollows:

1. Visuallycheckthedistancebetweenthefrontgaugewheelandthe

ground.Ifthe gaugewheelisnearortouchingtheground,itshould

be raised.If morethan1/2"abovetheground,itshouldbelowered.

2. Removetheflangelocknutsecuringthefrontgaugewheel

shoulderbolttothe deck.Removethegaugewheelandshoulder

bolt. RefertoFigure8.

Figure6

3. Installthedischargechutedeflectorusingthecarriagebolts,

pushnutsandflangelocknutsasshownin Figure7 andsecurely

tightenthehardware.

Flange Lock 6

Discharge

Chute

Deflector

Push

Carriage Bc

Figure7

Gauge Wheel

Gauge Wheel

ShoulderBolt_ LockNut

Flange

Figure8

3_

Insert the shoulder bolt into the one of four index holes in the

front gauge wheel bracket that will give the gauge wheel a Y4"

to W' clearance with the ground and secure with the flange

J

1 1 gauge wheel bracket on the deck.

locknut.

4. Note the index hole of the just adjusted wheel, and adjust the

rear gauge wheel into the respective index holes of the other

Adjusting the Seat

Toadjustthe positionofthe seat,pullupand holdthe seatadjustment

lever.Slidetheseatforwardor rearwardto thedesiredposition;then

releasetheadjustmentlever.Makesureseatislockedintoposition

beforeoperatingthe ridingmower.See Figure9.

5. Replacethefuelcapandtightensecurely.Wipeupspilledfuel

beforestartingengine.IffuelisspilledDONOTstartengine.Move

ridingmowerawayfromareaof spillage.Avoidcreatinganysource

ofignitionuntilfuelvaporsaregone.

Checking and Adding Oil

Yourridingmoweris shippedwithoilintheengine.However,youMUST

m J

Figure9

GAS AND OIL

Fuel Recommendations

Useautomotivegasoline(unleadedor low leadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruse anoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterin the fueltank. DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineis stored.

Donotoverfillthefuel tank.Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

Becarefulnotto spillfuelwhenrefueling.Spilledfuelor fuelvapor

mayignite.Ifanyfuel isspilled,makesuretheareais drybefore

startingtheengine.

Avoidrepeatedorprolongedcontactwithskinor breathingof vapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthe ridingmower

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesand othersourcesofignition.

checkthe engineoil levelbeforeeachuseasinstructedinthe IAlways

Serviceand Maintenancesection.Addoilas necessary.Failuretodo I

[so mayresut nser ousdamagetoyourengne. J

1. Placetheridingmoweron a flat,levelsurface.

2. Removetheoilfillercap/dipstickandwipethedipstickclean.See

Figure10.

Figure10

3. Insertthecap/dipstickintothe oilfillerneck,butdonot screwit in.

4. Removetheoilfillercap/dipstick.Ifthe levelislow,slowlyaddoil

untiloillevel registersbetweenFULLandADD,Figure9.

NOTE:Do notoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmly beforestartingengine.

NOTE:DO NOTallowoil leveltofall belowthe ADDmarkonthe

dipstick.Doingsomayresultinequipmentmalfunctionsor damage.

NOTE:Tochangetheoil inyourengine,seethe Serviceand

Maintenancesectionof thismanual.

I

1. Besureengineisoutdoorsandin awell-ventilatedarea.

2. Cleanareaaroundthefuelfillcapandremovethefuelfillcap.

3. Usingan approvedredGASOLINEcontainer,addfuelslowly,being

carefulto avoidspilling.

4. Fillthetankuntilthefuelreachesthebottomofthefueltankneck.

12

Deck Lift

Deck Height Handle

Throttle/Choke Control

Hour Meter/

indicator Panel

SeatAdjustmentLever

FuelTankCap

Parking

O

H

// _ / -PTOSwitch

LH Drive RH Drive nition Switch

Control Lever Control Lever

Cup Holder

Storage Tray

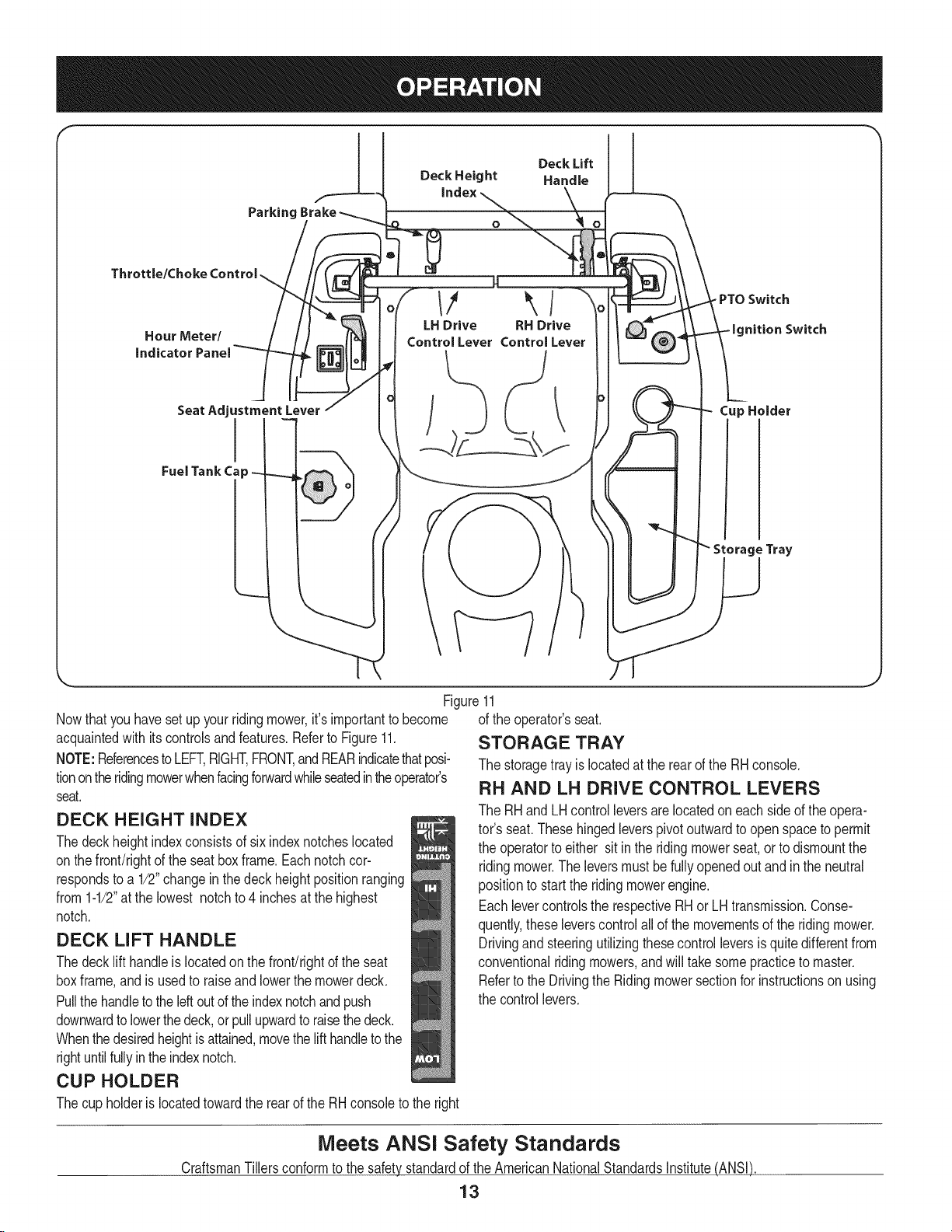

Figure11

Nowthat youhavesetup yourridingmower,it'simportanttobecome ofthe operator'sseat.

acquaintedwith itscontrolsandfeatures.Referto Figure11.

NOTE:ReferencestoLEFT,RIGHT,FRONT,andREARindicatethatposi-

tionontheridingmowerwhenfacingforwardwhileseatedintheoperator's

seat.

DECK HEIGHT iNDEX

Thedeckheightindexconsistsof sixindexnotcheslocated

onthefront/rightof theseatboxframe.Eachnotchcor-

respondsto a 1/2"changeinthedeck heightpositionranging

from1-1/2"atthe lowestnotchto 4inchesatthehighest

notch.

DECK LiFT HANDLE

Thedecklift handleis locatedon the front!rightof the seat

boxframe,andisusedto raiseand lowerthemowerdeck.

Pullthehandletotheleftoutoftheindexnotchandpush

STORAGE TRAY

Thestoragetrayislocatedatthe rearofthe RHconsole.

RH AND LH DRIVE CONTROL LEVERS

TheRHandLH controlleversarelocatedon eachsideofthe opera-

tor'sseat.Thesehingedleverspivotoutwardtoopenspacetopermit

theoperatortoeither sitin theridingmowerseat,orto dismountthe

ridingmower.Theleversmustbefullyopenedoutand intheneutral

positionto starttheridingmowerengine.

Eachlevercontrolsthe respectiveRHorLH transmission.Conse-

quently,theseleverscontrolallof themovementsof theridingmower.

Drivingand steeringutilizingthesecontrolleversis quitedifferentfrom

conventionalridingmowers,andwill takesomepracticetomaster.

Refertothe Drivingthe Ridingmowersectionfor instructionsonusing

thecontrollevers.

downwardto lowerthedeck,orpullupwardto raisethedeck.

Whenthedesiredheightisattained,movethelifthandleto the

rightuntilfullyintheindexnotch.

CUP HOLDER

Thecup holderislocatedtowardtherearofthe RHconsoletotheright

Meets ANSi Safety Standards

CraftsmanTillersconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI)

13

iGNiTiON SWITCH

Theignitionswitchis locatedon

theRHconsoleto therightofthe

operator'sseat.Theignitionswitch

hasthree positions.

STOP_ -- Theengineandelectri-

calsystemisturnedoff.

RUN_ -- Theridingmowerelectricalsystemisenergized.

START_ -- Thestartermotorwillturnovertheengine.Releasethe

keyimmediatelywhentheenginestarts

NOTE:Topreventaccidentalstartingand/or batterydischarge,

removethe keyfromtheignitionswitchwhenthe ridingmowerisnot

inuse.

RUN_ I

POWER TAKE-OFF (PTO) SWITCH

ThePTOswitchislocatedonthe RHconsoletothe rightof theopera-

tor'sseat.ThePTOswitchoperatestheelectricPTOclutchmounted

onthebottomoftheenginecrankshaft.Pullthe switchknobupward

toengagethe PTOclutch,or pushtheknob downwardto disengage

theclutch.The PTOswitchmustbeinthe"disengaged"positionwhen

startingtheengine.

TRANSMiSSiON BYPASS RODS

Thetransmissionbypassrods(onefor eachthe RHandLHtransmis-

sion)arelocatedbeneaththeframeplatform,justinsideeach rear

wheel.

Whenengaged,the two rodsopena bypasswithinthe hydrostatic

transmissions,whichallowstheridingmowerto be pushedshort

distancesby hand.Referto theAssemblysectionforinstructionson

usingthe bypassfeature.

Nevertowyourridingmower.Towingthe ridingmowerwiththe rear

wheelsonthe groundmaycauseseveredamageto thetransmissions.

SEAT ADJUSTMENT LEVER

Theseatadjustmentleverislocatedbelowthefront!leftoftheseat.

Theleverallowsforadjustmentoftheforetoaft positionofthe

operator'sseat.Referto Serviceand Maintenanceforinstructionson

adjustingthe seatposition.

FUEL TANK CAP

Thefuel tankcapislocatednearthemiddleoftheLHconsole.Turn

thefill capapproximately1/4turnandpull upwardtoremove.Thefuel

capistetheredto the ridingmowerto preventitsloss.Do notattempt

toremovethecapfromthe ridingmower.

Pushthecapdownwardonthe fueltankfill neckand turnapproxi-

mately1/4turnclockwisetotightenAlwaysre-installthe fuelcap tightly

ontothe fueltankafter removing.

Neverfillthe fueltankwhentheengineis running.Ifthe engineis

hotfrom recentlyrunning,allowtocoolforseveralminutesbefore

refueling.Highlyflammablegasolinesplashingontoa hot engine

couldcausea fire.

HOUR METER/INDICATOR

PANEL

Thehourmeter/indicatorpanelislocatedonthe

LHconsoletotheIdtd theoperator'sseat.

Hour Meter Features

Thehourmeterrecordsthehoursthatthe

ridingmowerhasbeenoperatedinthedigital

display(tenthsofanhour-- rightmostdigit).

NOTE:Thehourmeterisactivatedwhenevertheignitionswitchisturned

totheRUN_ position.Keepa recordof theactualhoursof operation

toassureallmaintenanceproceduresarecompletedaccordingtothe

instructionsintheServiceandMaintenancesectionof thismanual.

Whenkeyis turnedto theRUN_ position,thebatteryindicatorlight

brieflyilluminatesandthebatteryvoltageis brieflydisplayed.The

displaythenchangestotheaccumulatedhours.

TheIndicatorMonitorwillalsoremindtheoperatorofmaintenanceinter-

valsforchangingtheengineoil.TheLCDwillalternatelyflash,CHG;OIL

andtherecordedhoursforfiveminutesafterevery50hoursof recorded

operation.Themaintenanceintervallastsfortwohours(from50-52,100-

102,150-152,etc.).TheLCDwillflashasdescribedforfiveminutesevery

timetheridingmower'sengineisstartedduringthismaintenanceinterval.

FollowtheoilchangeintervalsprovidedintheServiceandMaintenance

sectionofthisoperator'smanual.

indicator Panel Features

Battery Indicator

Illuminatesandthe batteryvoltageisdisplayedbrieflywhenthe ignition

switchitturnedtothe RUN_ position.

Illuminatesto indicatethe batteryvoltagehasdroppedbelow11.5(+0.5/-

1.0)volts,andthevoltageis displayedonthe hourmeter.Ifthisindicator

anddisplaycomeonduringoperation,checkthebatteryandcharging

systemforpossiblecausesand/orcall1-800-659-5917to schedule

ridingmowerinspectionservicefromSearsParts& Repair.

Oil PressureIndicator (if EngineSo Equipped)

Thiswarninglampindicateslowengineoilpressure.Iftheindicatorcomes

onwhiletheengineis running,stoptheengineimmediatelyandcheckfor

possiblecauses.Donotruntheenginewhilethisindicatorisilluminated.

Call1-800-659-5917toscheduleservicefromSearsParts& Repair.

NOTE:Theoil_ressureindicatormayilluminatewhentheignitionswitch

isin the RUN0 position,butshouldturnoffwhentheengineisstarted.

PTOEngagedIndicator

ThisindicatorilluminateswhenthePTOswitchis pulledupwardinthe

ENGAGEDpositionandtheignitionswitchisturnedtothe START

position.Checkthisindicatoriftheenginewillnotcrankwiththeignition

switchinthe START_ position.Ifnecessary,movethePTOswitchto

theDISENGAGEDposition.

ParkingBrake Engaged Indicator

Thisindicatorilluminateswhenthe parkingbrakeisin the DISEN-

GAGEDpositionandtheignitionswitchisturnedtothe START

position.Checkthis indicatoriftheenginewill notcrankwiththe

ignitionswitchinthe START_ position.Ifnecessary,movethe

parkingbraketo theENGAGEDposition.

Thisindicatoralsoilluminateswhentheignitionswitchisturnedtothe

START_ positionandtheRHand/orLHdrivecontrolleversare in

a positionotherthanthefullyout in neutralposition.Movethe control

leversfullyoutward.

14

THROTTLE/CHOKE CONTROL

Thethrottle/chokecontrolislocatedonthe LHconsoleto

theleftof theoperator'sseat.Whensetina givenposition,a

uniformenginespeedwill bemaintained.

Pushthethrottle/chokecontrolhandleforwardtoincrease

theenginespeed.Theridingmowerisdesignedtooperate

withthethrottle/chokecontrolintheFAST_ position

whentheridingmoweris beingdrivenandthemowerdeck

isengaged.

Pullthethrottle/chokecontrolhandlerearwardtodecrease

theenginespeed.

Whenstartingtheengine,pushthecontrolhandlefully

forwardintothe CHOKEI'_,1position.

Afterstartingandwarmingtheengine,movethe controlhandle

rearwarduntilyoufeel it movepastthechokedetent.

PARKING BRAKE ENGAGEMENT LEVER

Theparkingbrakeengagementleveris locatedonthefront/

leftofthe seatboxframe,andis usedtoengagethe parking

brake.

Pulltheleverfullyupwardandtothe left;thenlowerintothe

short"J"slottoengagethe brake.

Pulltheleverupoutof the"J"slotandto theright;then lower

completelyto disengagetheparkingbrake.

NOTE:Ifthe LHandRHdrivecontrolleversarenotfully

openedoutto eachsidein theneutralpositionwhenengag-

ingtheparkingbrake,theenginewill stop.The parkingbrake

mustbe placedin theengagedpositionwhenstartingthe

ridingmowerengine.

GENERAL SAFETY

• RECEIVEINSTRUCTION-- Entirelyreadthisoperator'smanual.

Learnto operatethismachineSAFELY.Donot riskINJURYor

DEATH.Allowonlythosewho havebecomecompetentin its

usageto operatethisridingmower.

• Beforestartingtheengineor beginningoperation,be familiarwith

thecontrols.Theoperatorshouldbein theoperator'sseat.The

PTOswitchmustbein thedisengagedposition,theparkingbrake

engaged,andthe RHand LHdrivecontrolleversmovedfully

outwardin theneutralposition.

• Keepallshieldsin place.Keepawayfrommovingparts.

• NORIDERS!Keepall peopleandpetsa safedistanceaway.

Lookbehindanddowntobothsidesoftheridingmowerbefore

andwhilebackingup.

• DONOTdirectthemowerdischargeatpeople.

• Avoidslopeswherepossible.Neveroperateon slopesgreater

than15°.Slopeswitha greaterinclinepresentdangerousoperat-

ing conditions.Ridingmowerscanbe rolledover.

• Beforeleavingtheoperator'sseat:ShutoffthePTO,move

the RHand LHdrivecontrolleversfullyoutwardin the neutral

position,engagetheparkingbrake_:_, shutoff theengineand

removethe ignitionkey.Waitforall movementto stopbefore

servicingorcleaning.

• Operatethedrivecontrolleverssmoothlyandavoidanysudden

movementsofthe leverswhenstartingandstopping.Keepafirm

gripon thecontrollevers.

• Becarefulwhenoperatingnearroadways.Stoptheridingmower

motionandwaitforvehiclestopassbeforeoperatingalongthe

road.

• Donotoperatetheridingmowerwiththe mowerdeckremoved.

Removalofthe deckwillchangethebalanceofthe ridingmower,

andcouldcontributetoa ridingmowerrollover.

• Avoidoperationontractionsurfacesthatare unstable;use

extremecautionif thesurfaceis slippery.

• Slowdown beforeturningandcometo a completestopbefore

anyzeroturnmaneuver.

• Donotstoptheridingmoweror parktheridingmowerover

combustiblematerialssuchasdry grass,leaves,debris,etc.

• Donotfillthefueltankwhentheengineis runningor whilethe

engineishot.Allowtheengineseveralminutesto coolbefore

refueling.Tightenthe fuelcap securely.

15

BEFORE OPERATING YOUR RiDiNG MOWER

• Beforeyouoperatetheridingmower,studythismanualcarefully

tofamiliarizeyourselfwiththeoperationofallthe instrumentsand

controls.Ithasbeenpreparedtohelpyouoperateandmaintain

yourridingmowerefficiently.

• Thisengineiscertifiedtooperateonlyonclean,fresh,unleadedregu-

largasoline.Forbestresults,fill thefueltankwithonlyclean,fresh,

unleadedgasolinewithapumpstickeroctaneratingof87orhigher.

• Unleadedgasolineis recommendedbecauseitleavesless

combustionchamberdepositsand reducesharmfulexhaust

emissions.Leadedgasolineis notrecommendedand mustnotbe

usedwhereexhaustemissionsareregulated.

NOTE:Purchasegasolineinsmallquantities.Donotusegasolineleftover

fromthe previousseason,tominimizegumdepositsinthefuelsystem.

• Gasohol(upto 10%ethylalcohol,90% unleadedgasolineby

volume)isanapprovedfuel.Othergasoline/alcoholblendsare

notapproved.

• MethylTertiaryButylEther(MTBE)andunleadedgasolineblends

(uptoa maximumof 15%MTBEbyvolume)areapprovedfuels.

Othergasoline/etherblendsarenotapproved.

• Checktheengineoil level.

• Cleantheair cleanerelementif necessary.

• Checkthetireinflationpressures.

• Adjusttheseatforoperator'smaximumcomfort,visibilityandfor

maintainingcompletecontrolofthe ridingmower.

SAFETY iNTERLOCK SYSTEM

Thisridingmowerisequippedwitha safetyinterlocksystemforthe

protectionoftheoperator.Ifthe interlocksystemshouldevermalfunc-

tion,donotoperatetheridingmower.Call 1-800-659-5917to schedule

servicefromSearsParts& Repair.

• Thesafetyinterlocksystempreventstheenginefromcranking

orstartingunlessthe RHand LHdrivecontrolleversaremoved

fullyoutwardto eachsidein theneutralposition,theparking

brakeisengaged,andthe PTOis disengaged.

• Toavoidsuddenmovementwhendisengagingthe parkingbrake,

thesafetyinterlocksystemwillshutoffthe engineifthe RHand/

or LHdrivecontrolleversare movedto a positionotherthan

thefullyout intheneutralpositionwhenthe parkingbrakeis

engaged.

• Thesafetyinterlocksystemwillshutofftheengineiftheoperator

leavestheseatbeforeengagingthe parkingbrake.

• Thesafetyinterlocksystemwillshutofftheengineiftheoperator

leavestheseatwiththe PTOengaged,regardlessof whetherthe

parkingbrakeisengaged.

NOTE:The PTOswitchmustbe movedto the"OFF"positionto restart

theengine.

• Thesafetyinterlocksystemwillshutoffthe PTOandthe mower

bladeswillstopif bothdrivecontrolleversare movedintothe

reverseposition.ThePTOwillre-engagewhenoneor bothof the

leversaremovedbacktoeither theneutralorforwardposition.

STARTING THE ENGINE

Thisridingmowerisequippedwitha safetyinterlocksystemdesignee

forthe protectionofthe operator.Donotoperatethe ridingmowerif

anypartofthe interlocksystemis malfunctioning.Periodicallycheck

thefunctionsofthe interlocksystemforproperoperation.

Forpersonalsafety,theoperatormustbesittingintheridingmower

seatwhenstartingtheengine.

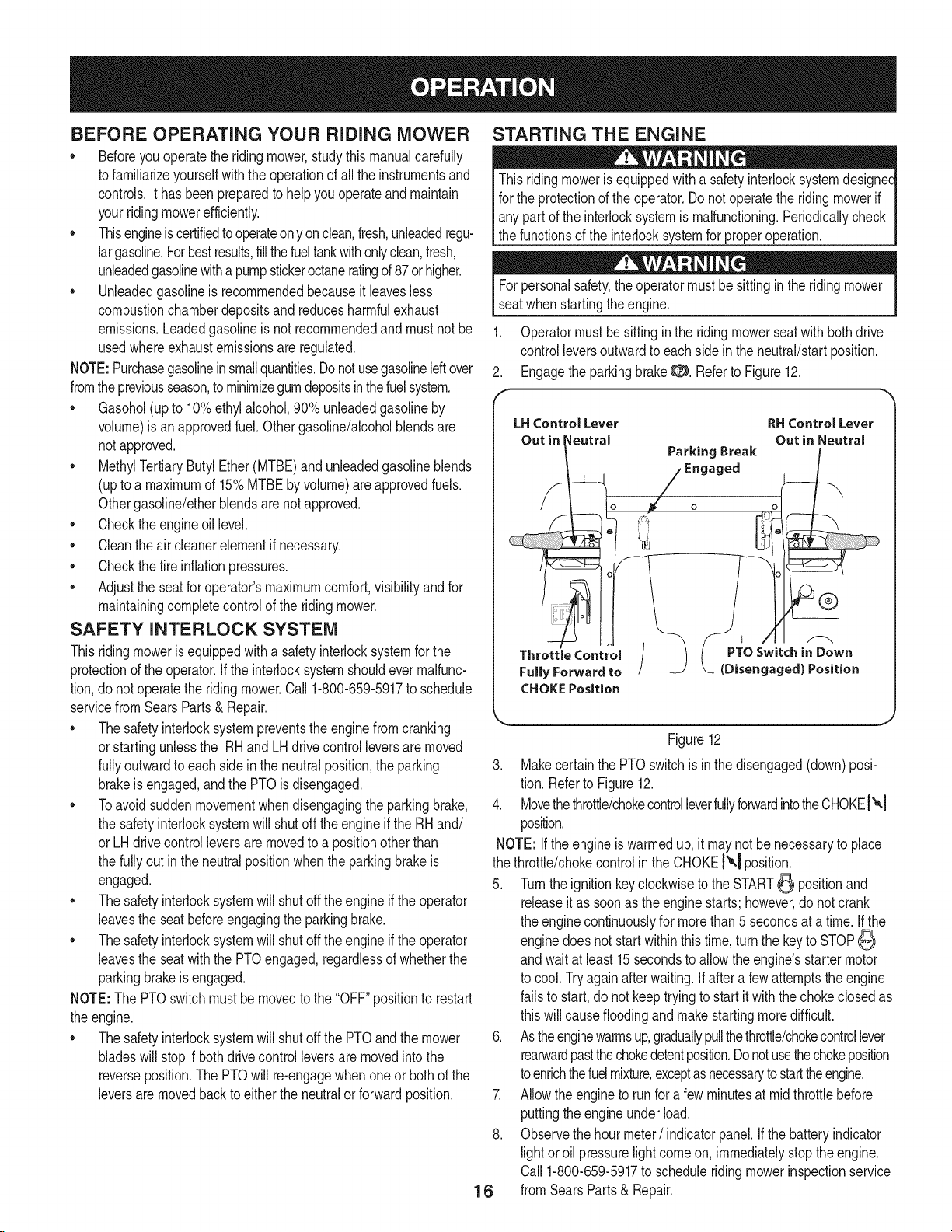

1. Operatormustbesittinginthe ridingmowerseatwithbothdrive

controlleversoutwardto eachsidein theneutral/startposition.

2. EngagetheparkingbrakeO. Referto Figure12.

LHControlLever RHControlLever

Outin I_eutral Out in Neutral

ParkingBreak

-- Engaged

ThrottleControl / ( PTOSwitchinDown

FullyForwardto / __ (Disengaged)Position

CHOKEPosition

Figure12

3. MakecertainthePTOswitchisin the disengaged(down)posi-

tion. Referto Figure12.

4. Movethethrottle/chokecontrolleverfullyforwardintotheCHOKEt"°,1

position.

NOTE:Iftheengineiswarmedup,it maynotbe necessarytoplace

thethrottle/chokecontrolinthe CHOKE!'_1position.

5. Turnthe ignitionkeyclockwisetotheSTART_ positionand

releaseitassoonasthe enginestarts;however,do not crank

theenginecontinuouslyfor morethan5 secondsata time.If the

enginedoesnot startwithinthis time,turnthe keytoSTOP

andwaitat least15secondstoallowtheengine'sstartermotor

tocool.Tryagainafterwaiting.Ifaftera fewattemptstheengine

failstostart,do not keeptryingto startit withthechokeclosedas

thiswillcausefloodingandmakestartingmoredifficult.

6. Astheenginewarmsup,graduallypullthethrottle/chokecontrollever

rearwardpastthechokedetentposition.Donotusethechokeposition

toenrichthefuelmixture,exceptasnecessarytostarttheengine.

7. Allowtheengineto runfora fewminutesatmidthrottlebefore

puttingtheengineunderload.

8. Observethehourmeter/ indicatorpanel.Ifthe batteryindicator

lightoroil pressurelightcomeon,immediatelystoptheengine.

Call1-800-659-5917toscheduleridingmowerinspectionservice

16

fromSearsParts& Repair.

ColdWeatherStarting

Whenstartingtheengineattemperaturesnearorbelowfreezing,

ensurethecorrectviscositymotoroilisusedintheengineandthe

batteryisfullycharged.Starttheengineasfollows:

1. Besurethebatteryisingoodcondition.Also,awarmbatteryhas

muchmorestartingcapacitythanacoldbattery.

2. Usefreshwintergradefuel.Wintergradegasolinehashighervolatility

toimprovestarting.Donotusegasolineleftoverfromsummer.

3. FollowthepreviousinstructionforStartingtheEngine.

UsingJumper CablesTo Start Engine

Batteriescontainsulfuricacidandproduceexplosivegasses.Make

certaintheareaiswellventilated,wearglovesandeyeprotection,

land avod sparksor famesnearthe battery.

Ifthe batterychargeis notsufficienttocranktheengine,rechargethe

battery.Ifa batterychargeris unavailableandtheridingmowermust

be started,the aidof aboosterbatterywillbenecessary.Connectthe

boosterbatteryasfollows:

1. Connecttheendofonecabletothedisabledridingmowerbat-

tery'spositiveterminal;thenconnecttheotherendof thatcableto

theboosterbattery'spositiveterminal.

2. Connectoneendof theothercabletotheboosterbattery's

negativeterminal;thenconnecttheotherendofthatcableto

the frameof thedisabledridingmower,asfarfromthe batteryas

possible.

3. Startthedisabledridingmowerfollowingthe normalstarting

instructionspreviouslyprovided;thendisconnectthejumper

cablesin theexact reverseorderof theirconnection.

4. Havetheridingmower'selectricalsystemcheckedand repaired

assoonaspossibleto eliminatethe needforjump starting.

STOPPING THE ENGINE

1. Placethe PTOswitchinthe OFFposition.

2. Movethe RHand LHdrivecontrolleversfullyoutwardin the

neutralposition.

3. EngagetheparkingbrakeO.

4. Movethethrottle/chokecontroltomidwaybetweentheSLOW"_

andFAST_ positions.

5. Turntheignitionkeytothe STOP_ positionand removethekey

fromtheignitionswitch.

NOTE:Alwaysremovethe keyfromtheignitionswitchtopreventacci-

dentalstartingor batterydischargeiftheequipmentisleft unattended.

PRACTICE OPERATION (INITIAL USE)

Operatinga zero-turnridingmowerisnotlikeoperatingaconventional

typeridingridingmower.Becausea zeroturnridingmoweris more

maneuverable,gettingusedtooperatingthecontrolleverstakessome

practice.

Westronglyrecommendthatyoulocatea reasonablylarge,levelandopen

"practicearea"wheretherearenoobstructions,pedestrians,oranimals.You

shouldpracticeoperatingthendingmowerforaminimumof30minutes.

Carefullymove-- orhaveanexperiencedusermove--the ridingmower

tothepracticearea.Whenperformingthe practicesession,the PTO

shouldnotbeengaged.Whilepracticing,operatetheridingmower

atapproximately1/2to 3/4throttleandat lessthanfull speedinboth

forwardandreverse.

Carefullypracticemaneuveringtheridingmowerandproceedto driveas

describedin thefollowingDrivingtheRidingmowerForwardsection.

17

DRIVING THE RIDING MOWER

Avoidsuddenstarts,excessivespeedandsuddenstops. ]

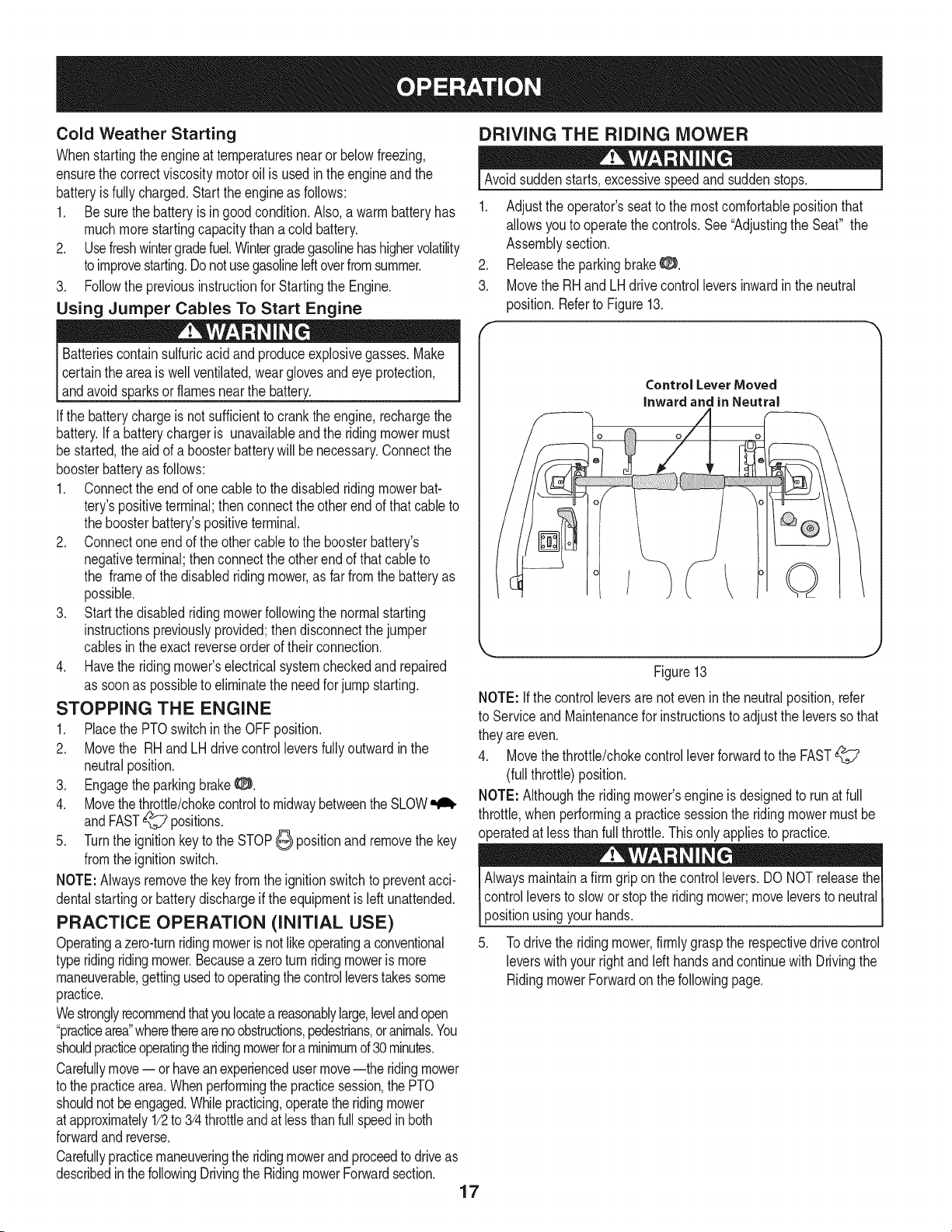

1. Adjusttheoperator'sseattothe mostcomfortablepositionthat

allowsyouto operatethecontrols.See"AdjustingtheSeat" the

Assemblysection.

2. Releasetheparkingbrake_:_.

3. MovetheRHand LHdrivecontrolleversinwardin theneutral

position.Referto Figure13.

Control Lever Moved

inward and in Neutral

/

Figure13

NOTE:Ifthe controlleversarenoteven intheneutralposition,refer

to ServiceandMaintenancefor instructionstoadjustthe leverssothat

theyareeven.

4. Movethethrottle/chokecontrolleverforwardtothe FAST

(fullthrottle)position.

NOTE:Althoughtheridingmower'sengineisdesignedto runat full

throttle,whenperforminga practicesessiontheridingmowermustbe

operatedatlessthanfullthrottle.Thisonlyappliesto practice.

Alwaysmaintainafirm griponthe controllevers.DONOTreleasethe

controlleversto slowor stopthe ridingmower;moveleversto neutral

positionusingyour hands.

5. Todrive theridingmower,firmlygrasptherespectivedrivecontrol

leverswithyourrightandleft handsandcontinuewithDrivingthe

RidingmowerForwardon thefollowingpage.

Q

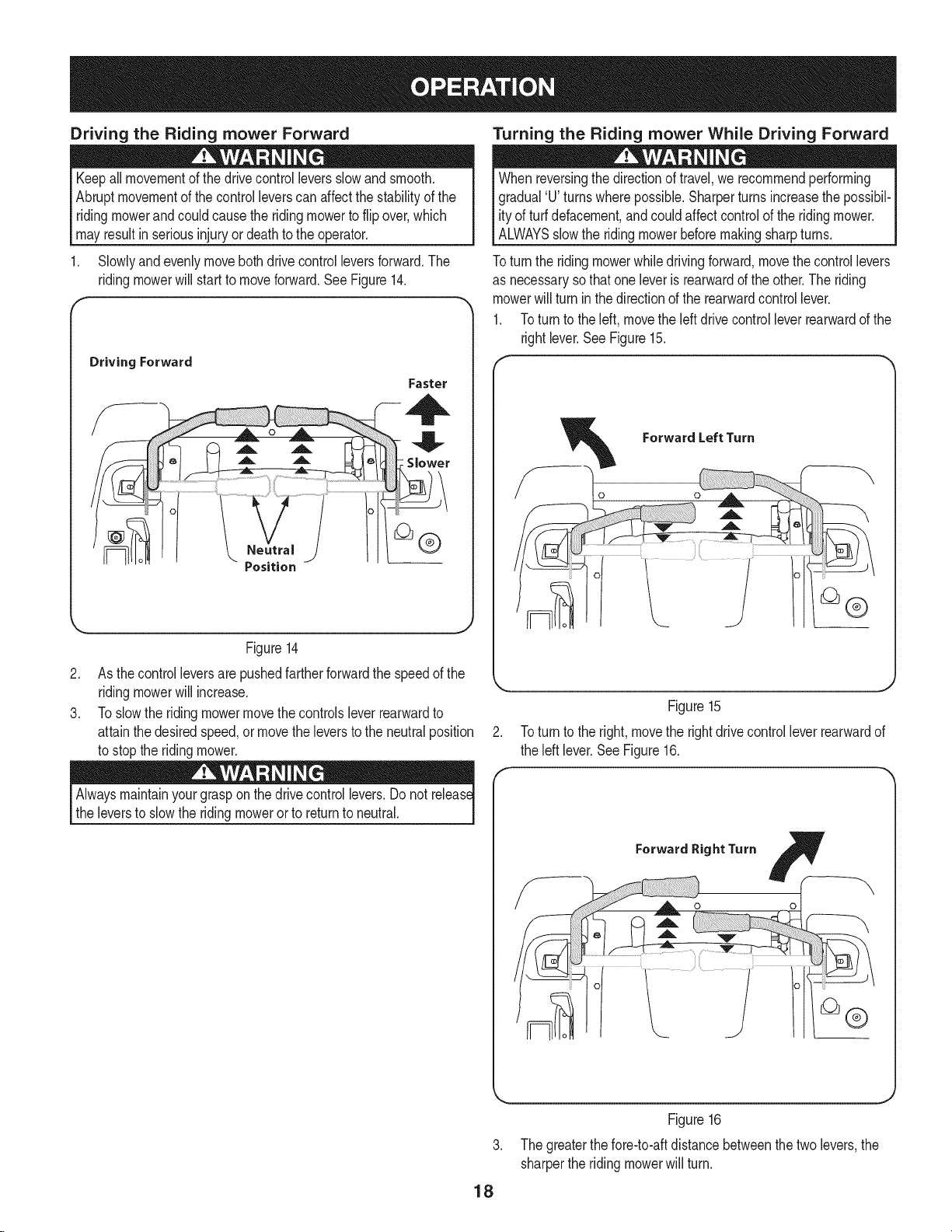

Driving the Riding mowerForward

Turning the Riding mower While Driving Forward

Keepall movementof thedrivecontrolleversslowandsmooth.

Abruptmovementofthe controlleverscanaffectthe stabilityofthe

ridingmowerandcouldcausetheridingmowerto flipover,which

mayresultin seriousinjury ordeathto theoperator.

Slowlyandevenlymovebothdrive controlleversforward.The

ridingmowerwill startto moveforward.SeeFigure14.

r

Driving Forward

Faster

Whenreversingthedirectionof travel,werecommendperforming

gradual'U' turnswherepossible.Sharperturnsincreasethepossibil-

ity ofturfdefacement,andcouldaffectcontrolofthe ridingmower.

ALWAYSslowtheridingmowerbeforemakingsharpturns.

Toturn theridingmowerwhiledrivingforward,movethecontrollevers

as necessarysothat oneleveris rearwardd the other.The riding

mowerwill turninthe directionof the rearwardcontrollever.

1. Toturntotheleft,movetheleftdrivecontrolleverrearwardofthe

rightlever.SeeFigure15.

Figure14

2. Asthecontrolleversarepushedfartherforwardthespeedofthe

ridingmowerwill increase.

3. Toslowthe ridingmowermovethecontrolsleverrearwardto

attainthedesiredspeed,ormovetheleverstotheneutralposition

tostopthe ridingmower.

Alwaysmaintainyourgraspon the drivecontrollevers.Donot release

the leversto slowthe ridingmowerorto returntoneutral.

Figure15

2. Toturn tothe right,movetherightdrivecontrollever rearwardof

theleft lever.SeeFigure16.

W

ForwardRightTurn F

-oZ-

Figure16

3. Thegreaterthefore-to-aftdistancebetweenthetwolevers,the

sharpertheridingmowerwillturn.

18

4. Toexecutea"zeroturn"movetheturnsidedrivecontrolleverto

theinwardneutralposition,whilemovingtheothercontrollever

forward.

NOTE:Makingazeroturnongrasswillgreatlyincreasethepotential

fordefacementoftheturf.

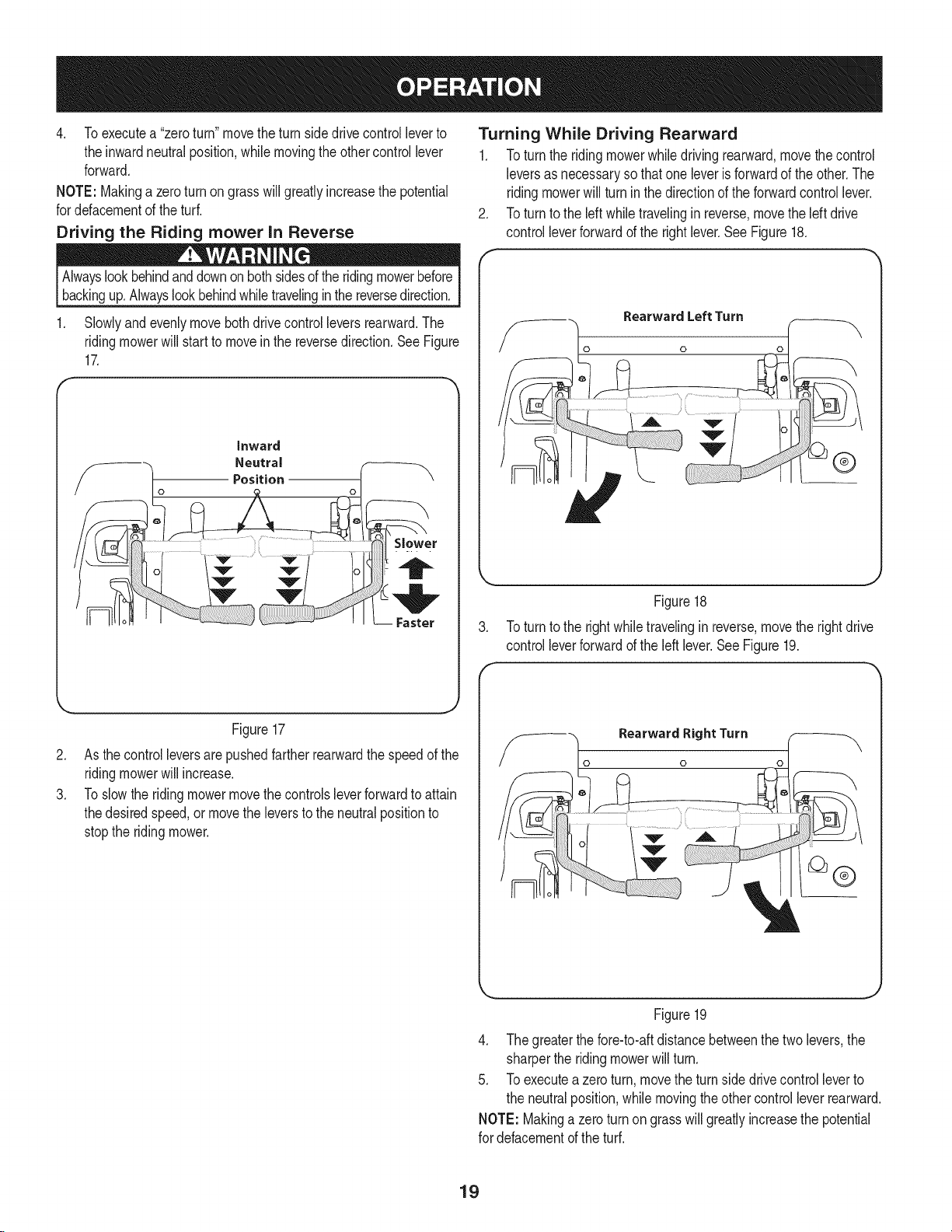

Driving the Riding mower in Reverse

Turning While Driving Rearward

1. Toturntheridingmowerwhiledrivingrearward,movethecontrol

leversasnecessaryso thatoneleverisforwardofthe other.The

ridingmowerwillturninthedirectionof theforwardcontrollever.

.

Toturn tothe leftwhiletravelinginreverse,movethe left drive

controlleverforwardofthe rightlever.See Figure18.

F

1. Slowlyandevenlymovebothdrivecontrolleversrearward.The

ridingmowerwill startto moveinthe reversedirection.SeeFigure

17.

Figure17

.

Asthecontrolleversarepushedfartherrearwardthe speedof the

ridingmowerwill increase.

3.

Toslowthe ridingmowermovethecontrolsleverforwardto attain

thedesiredspeed,or movetheleversto theneutralpositionto

stoptheridingmower.

Rearward Left Turn

0

Figure18

.

Toturn tothe rightwhiletravelinginreverse,movetherightdrive

controlleverforwardoftheleft lever.SeeFigure19.

f

Rearward Right Turn

0

®

Figure19

4. Thegreaterthefore-to-aftdistancebetweenthetwolevers,the

sharperthe ridingmowerwillturn.

5. Toexecutea zeroturn,movethe turnsidedrivecontrolleverto

theneutralposition,whilemovingtheother controlleverrearward.

NOTE:Makinga zeroturnon grasswill greatlyincreasethepotential

fordefacementoftheturf.

19

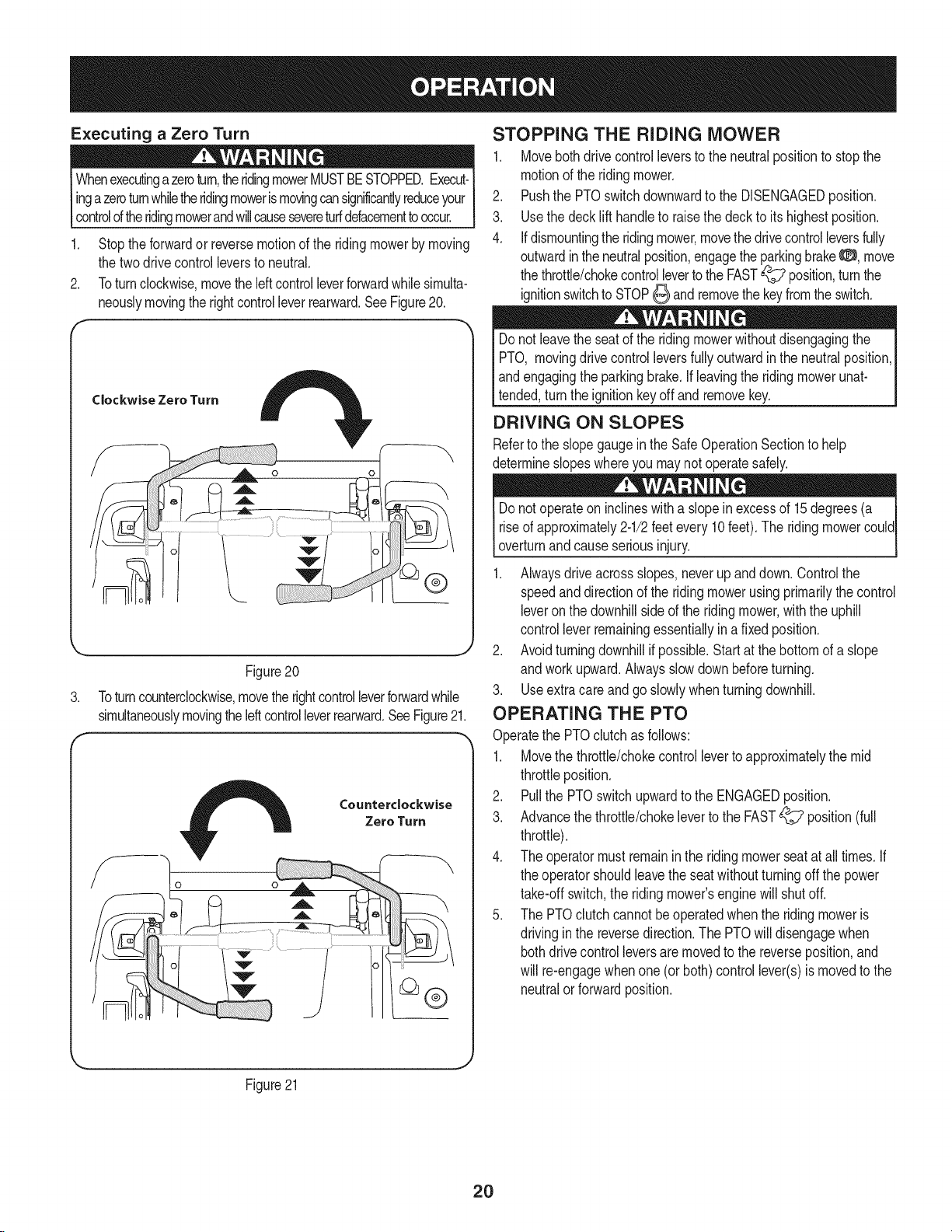

Executing a Zero Turn

ingazeroturnwhiletheridingmoweris movingcansignificantlyreduceyour

Whenexecutingazeroturn,theridingmowerMUSTBESTOPPED.Execut-

controloftheridingmowerandwillcausesevereturfdefacementtooccur.

1. Stoptheforwardor reversemotionoftheridingmowerbymoving

thetwodrivecontrolleverstoneutral.

2. Toturnclockwise,movetheleftcontrolleverforwardwhilesimulta-

neouslymovingtherightcontrolleverrearward.SeeFigure20.

Clockwise Zero Turn

Figure20

.

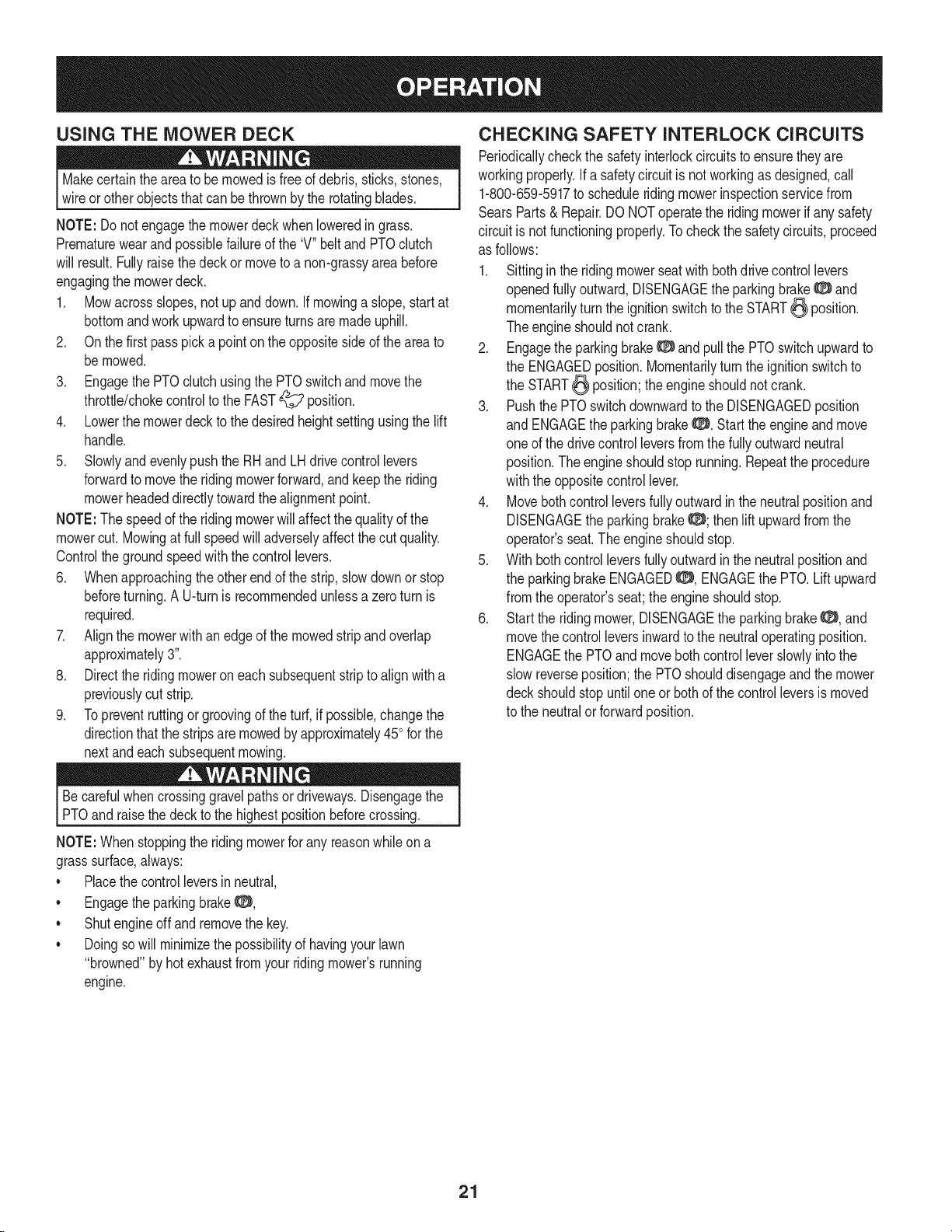

Toturncounterclockwise,movetherightcontrolleverforwardwhile

simultaneouslymovingtheleftcontrolleverrearward.SeeFigure21.

r

Counterclockwise

Zero Turn

STOPPING THE RIDING MOWER

1. Movebothdrivecontrolleverstothe neutralpositiontostopthe

motionof theridingmower.

2. Pushthe PTOswitchdownwardtothe DISENGAGEDposition.

3. Usethedecklift handleto raisethe decktoitshighestposition.

4. Ifdismountingtheridingmower,movethe drivecontrolleversfully

outwardintheneutralposition,engagethe parkingbrakeO, move

thethrottle/chokecontrollevertothe FAST_ position,turnthe

ignitionswitchto STOP_ andremovethekeyfromtheswitch.

Donot leavetheseatofthe ridingmowerwithoutdisengagingthe

PTO, movingdrivecontrolleversfullyoutwardin the neutralposition,

andengagingthe parkingbrake,if leavingtheridingmowerunat-

tended,turnthe ignitionkeyoffand removekey.

DRIVING ON SLOPES

Referto theslopegaugeinthe SafeOperationSectiontohelp

determineslopeswhereyoumaynot operatesafely.

Donot operateoninclineswitha slopein excessof15degrees(a

riseof approximately2-1/2feetevery10feet).The ridingmowercould

overturnandcauseseriousinjury.

1. Alwaysdriveacrossslopes,neverupanddown.Controlthe

speedanddirectionof theridingmowerusingprimarilythe control

leveronthedownhillsideofthe ridingmower,withtheuphill

controlleverremainingessentiallyina fixedposition.

2. Avoidturningdownhillif possible.Startat thebottomof a slope

andworkupward.Alwaysslowdownbeforeturning.

3. Useextracareandgo slowlywhenturningdownhill.

OPERATING THE PTO

Operatethe PTOclutchas follows:

1. Movethe throttle/chokecontrollevertoapproximatelythemid

throttleposition.

2. Pullthe PTOswitchupwardtothe ENGAGEDposition.

3. Advancethethrottle/chokelevertotheFAST_? position(full

throttle).

4. Theoperatormustremainintheridingmowerseatatalltimes.If

theoperatorshouldleavetheseatwithoutturningoffthe power

take-offswitch,theridingmower'senginewillshutoff.

5. ThePTOclutchcannotbeoperatedwhenthe ridingmoweris

drivingin the reversedirection.ThePTOwilldisengagewhen

bothdrivecontrolleversaremovedtothe reverseposition,and

willre-engagewhenone(or both)controllever(s)is movedto the

neutralorforwardposition.

Figure21

2O

USING THE MOWER DECK

l Makecertaintheareato be mowedisfreeof debris,sticks,stones,

wireorother objectsthatcan bethrownbythe rotatingblades. ]

NOTE:Donotengagethe mowerdeckwhenloweredingrass.

Prematurewearand possiblefailureofthe 'V" beltand PTOclutch

willresult.Fullyraisethe deckormovetoa non-grassyareabefore

engagingthe mowerdeck.

1. Mowacrossslopes,notupanddown.Ifmowinga slope,startat

bottomandworkupwardtoensureturnsaremadeuphill.

2. Onthefirst passpicka pointon the oppositesideof theareato

be mowed.

3. Engagethe PTOclutchusingthe PTOswitchandmovethe

throttle/chokecontrolto theFAST_ position.

4. Lowerthemowerdecktothe desiredheightsettingusingthelift

handle.

5. Slowlyandevenlypushthe RHandLHdrivecontrollevers

forwardtomovethe ridingmowerforward,andkeepthe riding

mowerheadeddirectlytowardthealignmentpoint.

NOTE:The speedof theridingmowerwill affectthequalityof the

mowercut.Mowingatfullspeedwilladverselyaffectthecut quality.

Controlthegroundspeedwiththecontrollevers.

6. Whenapproachingtheotherendof thestrip, slowdownor stop

beforeturning.AU-turnis recommendedunlessa zeroturn is

required.

7. Alignthe mowerwithan edgeof themowedstripandoverlap

approximately3".

8. Directthe ridingmoweroneachsubsequentstripto alignwitha

previouslycut strip.

9. Topreventruttingor groovingof theturf, ifpossible,changethe

directionthatthe stripsare mowedbyapproximately450for the

nextandeachsubsequentmowing.

CHECKING SAFETY iNTERLOCK CiRCUiTS

Periodicallycheckthesafetyinterlockcircuitstoensuretheyare

workingproperly.If a safetycircuitis notworkingasdesigned,call

I

1-800-659-5917to scheduleridingmowerinspectionservicefrom

SearsParts& Repair.DONOToperatethe ridingmowerifany safety

circuitis notfunctioningproperly.Tocheckthe safetycircuits,proceed

asfollows:

1. Sittingin theridingmowerseatwithbothdrivecontrollevers

openedfullyoutward,DISENGAGEthe parkingbrake0 and

momentarilyturn theignitionswitchtothe START_ position.

Theengineshouldnotcrank.

2. Engagetheparkingbrake0 andpullthePTOswitchupwardto

the ENGAGEDposition.Momentarilyturnthe ignitionswitchto

theSTART_ position;theengineshouldnotcrank.

3. PushthePTOswitchdownwardtotheDISENGAGEDposition

and ENGAGEtheparkingbrake0. Starttheengineandmove

oneofthe drivecontrolleversfromthe fullyoutwardneutral

position.Theengineshouldstoprunning.Repeattheprocedure

withtheoppositecontrollever.

4. Movebothcontrolleversfullyoutwardinthe neutralpositionand

DISENGAGEtheparkingbrake0; then liftupwardfromthe

operator'sseat.The engineshouldstop.

5. Withbothcontrolleversfullyoutwardintheneutralpositionand

theparkingbrakeENGAGED0, ENGAGEthe PTO.Liftupward

fromtheoperator'sseat;theengineshouldstop.

6. Startthe ridingmower,DISENGAGEtheparkingbrake0, and

movethecontrolleversinwardtothe neutraloperatingposition.

ENGAGEthe PTOand movebothcontrolleverslowlyintothe

slowreverseposition;thePTOshoulddisengageandthemower

deckshouldstopuntiloneor bothof thecontrolleversis moved

tothe neutralorforwardposition.

Becarefulwhencrossinggravelpathsor driveways.Disengagethe

PTOandraisethedeckto thehighestpositionbeforecrossing.

NOTE:Whenstoppingtheridingmowerfor anyreasonwhileona

grasssurface,always:

• Placethecontrolleversinneutral,

• Engagethe parkingbrake8,

• Shutengineoff andremovethekey.

• Doingso willminimizethe possibilityof havingyourlawn

"browned"byhotexhaustfromyourridingmower'srunning

engine.

l

21

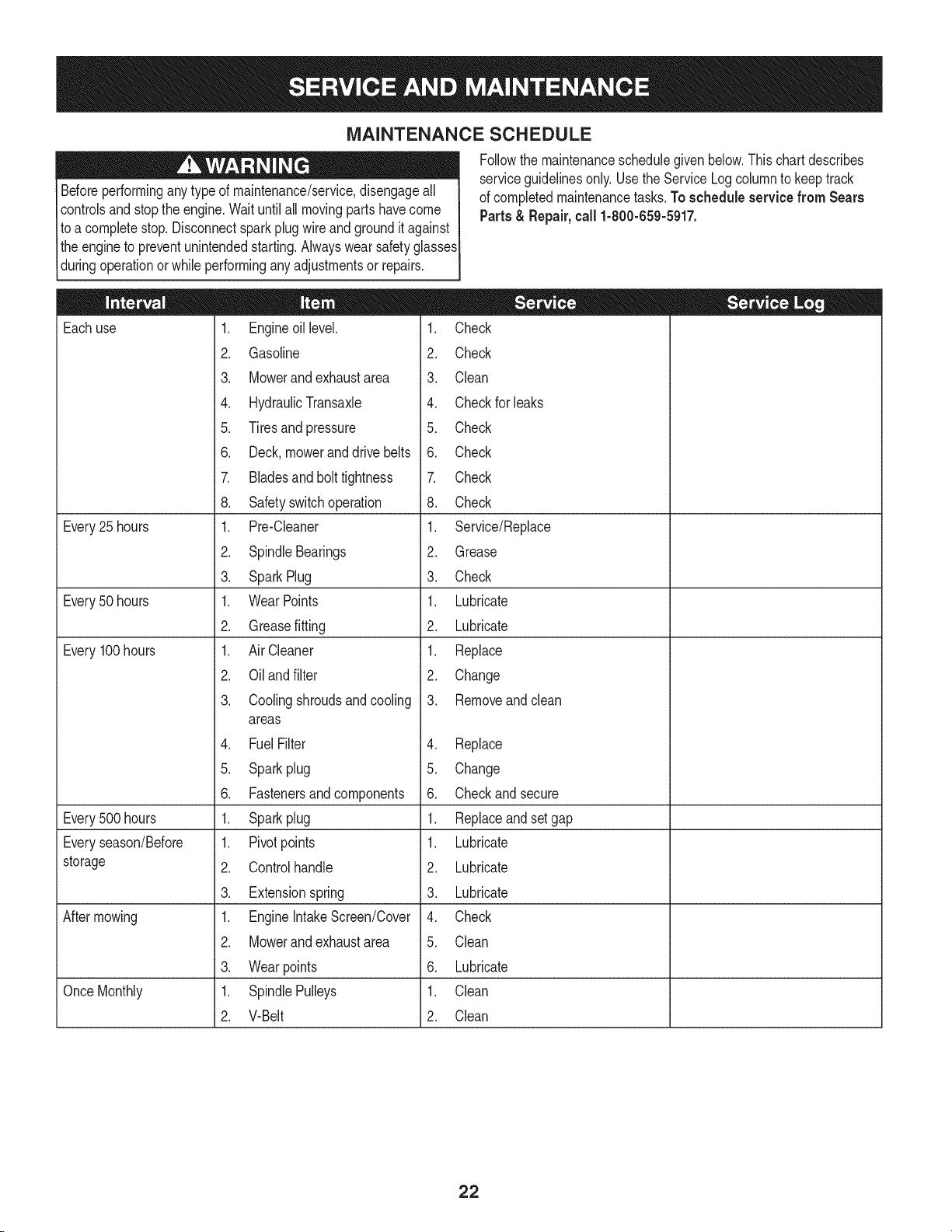

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstopthe engine.Waituntilall movingpartshavecome

toacompletestop.Disconnectsparkplugwireand grounditagainst

theengineto preventunintendedstarting.Alwayswearsafetyglasses

duringoperationorwhile performingany adjustmentsor repairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrack

ofcompletedmaintenancetasks.To schedule service from Sears

Parts& Repair,call 1-800-659-5917.

Eachuse

Every25 hours

Every50 hours

Every100hours

Every500 hours

Everyseason/Before

storage

Aftermowing

OnceMonthly

1. Engineoillevel.

2. Gasoline

3. Mowerand exhaustarea

4. HydraulicTransaxle

5. Tiresand pressure

6. Deck,moweranddrivebelts

7. Bladesandbolttightness

8. Safetyswitchoperation

1. Pre-Cleaner

2. SpindleBearings

3. SparkPlug

1. WearPoints

2. Greasefitting

1. AirCleaner

2. Oilandfilter

3. Coolingshroudsandcooling

areas

4. FuelFilter

5. Sparkplug

6. Fastenersand components

1. Sparkplug

1. Pivotpoints

2. Controlhandle

3. Extensionspring

1. EngineIntakeScreen/Cover

2. Mowerand exhaustarea

3. Wearpoints

1. SpindlePulleys

2. V-Belt

1. Check

2. Check

3. Clean

4. Checkfor leaks

5. Check

6. Check

7. Check

8. Check

1. Service/Replace

2. Grease

3. Check

1. Lubricate

2. Lubricate

1. Replace

2. Change

3. Removeandclean

4. Replace

5. Change

6. Checkandsecure

1. Replaceandsetgap

1. Lubricate

2. Lubricate

3. Lubricate

4. Check

5. Clean

6. Lubricate

1. Clean

2. Clean

22

Beforeperforminganymaintenanceor repairs,disengagethe PTO,

movethedrivecontrolleversfullyoutwardintheneutralposition,

engagetheparkingbrake,stoptheengineand removethekeyto

preventunintendedstarting.

ENGINE MAINTENANCE

Thoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandlingusedoil.

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withengineon levelground,theoil must

beto FULLmarkon dipstick.

2. Refertothe Assemblysectionofthismanualforinstructionson

checkingtheoil.

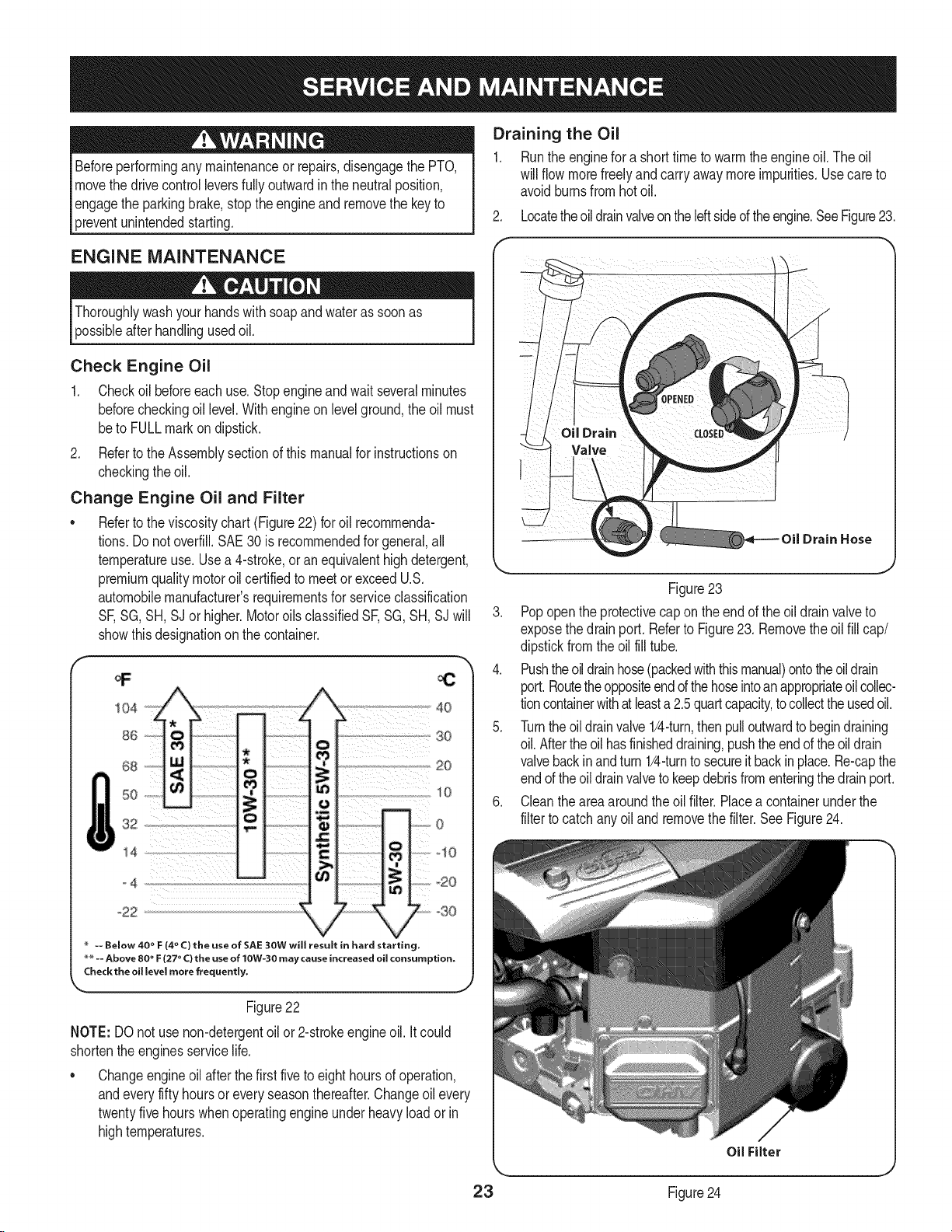

Change Engine Oil and Filter

• Refertothe viscositychart(Figure22)foroil recommenda-

tions.Do notoverfill.SAE30 isrecommendedfor general,all

temperatureuse.Usea 4-stroke,or anequivalenthighdetergent,

premiumqualitymotoroilcertifiedtomeetor exceedU.S.

automobilemanufacturer'srequirementsfor serviceclassification

SF,SG,SH,SJ or higher.MotoroilsclassifiedSF,SG,SH,SJ will

showthisdesignationon thecontainer.

4O

a6 .

50

_4

°22

iU L:F ¸3o

i...................................................................20

C

C

>

10

_20

0

-30

Draining the Oil

1. Runthe enginefor a shorttimetowarmthe engineoil.The oil

willflowmorefreelyandcarryawaymoreimpurities.Usecareto

avoidburnsfromhotoil.

2. Locatetheoildrainvalveontheleftsideoftheengine.SeeFigure23.

Figure23

3. Popopentheprotectivecapon theendof theoildrainvalveto

exposethedrainport.Referto Figure23.Removetheoilfill cap/

dipstickfromtheoil fill tube.

4. Pushtheoildrainhose(packedwiththismanual)ontotheoildrain

port.Routetheoppositeendd thehoseintoanappropriateoilcollec-

tioncontainerwithatleasta2.5quartcapacity,to collecttheusedoil.

5. Turntheoildrainvalve1/4-turn,thenpulloutwardtobegindraining

oil.Aftertheoil hasfinisheddraining,pushtheendoftheoildrain

valvebackin andturn1/4-turntosecureitbackinplace.Re-capthe

endoftheoildrainvalvetokeepdebrisfromenteringthedrainport.

6. Cleantheareaaroundtheoil filter.Placeacontainerunderthe

filtertocatchanyoiland removethefilter.See Figure24.

-- Below 40 ° F (4 ° C) the use of SAE 30W will result in hard starting.

** -- Above 80 ° F (27 ° C) the use of 10W-30 may cause increased oil consumption,

Check the oil level more frequently,

Figure22

NOTE:DOnotusenon-detergentoil or2-strokeengineoil. it could

shortentheenginesservicelife.

o Changeengineoilafterthefirstfivetoeighthoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoilevery

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

23 Figure24

7. Placethe newfilterinan openpanwiththe opensidefacingup.

Fillwith newoil untilthe oil reachedthebottomofthe threads.

Waittwo minutesfortheoil to beabsorbedbythefiltermaterial.

8. Applya thinfilmof cleanoiltothe rubbergasketonthefilter.

9. Carefullyinstallthenewfilter.

10. Refilltheenginewiththerecommendedoil andchecktheoil

level;referto CheckingandAddingOilin theAssemblySection.

11.

Reinstalltheoilfillercap/dipsticksecurely.

12.

Reconnectsparkplugwire.

Air Filter and Pre=Cleaner

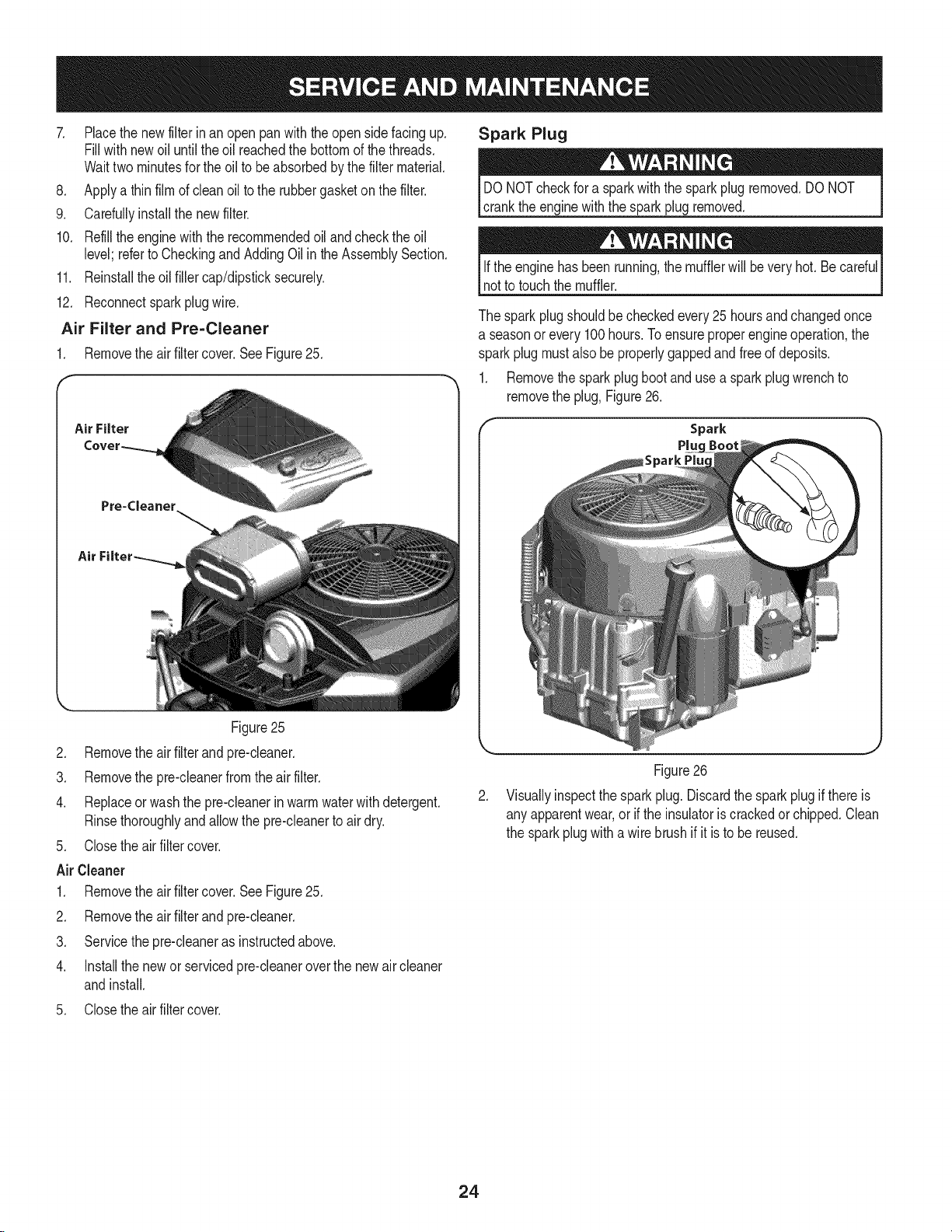

1. Removetheair filtercover.SeeFigure25.

Spark Plug

DONOTcheckfora sparkwiththe sparkplugremoved.DONOT

cranktheenginewiththe sparkplugremoved.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becardul

notto touchthemuffler.

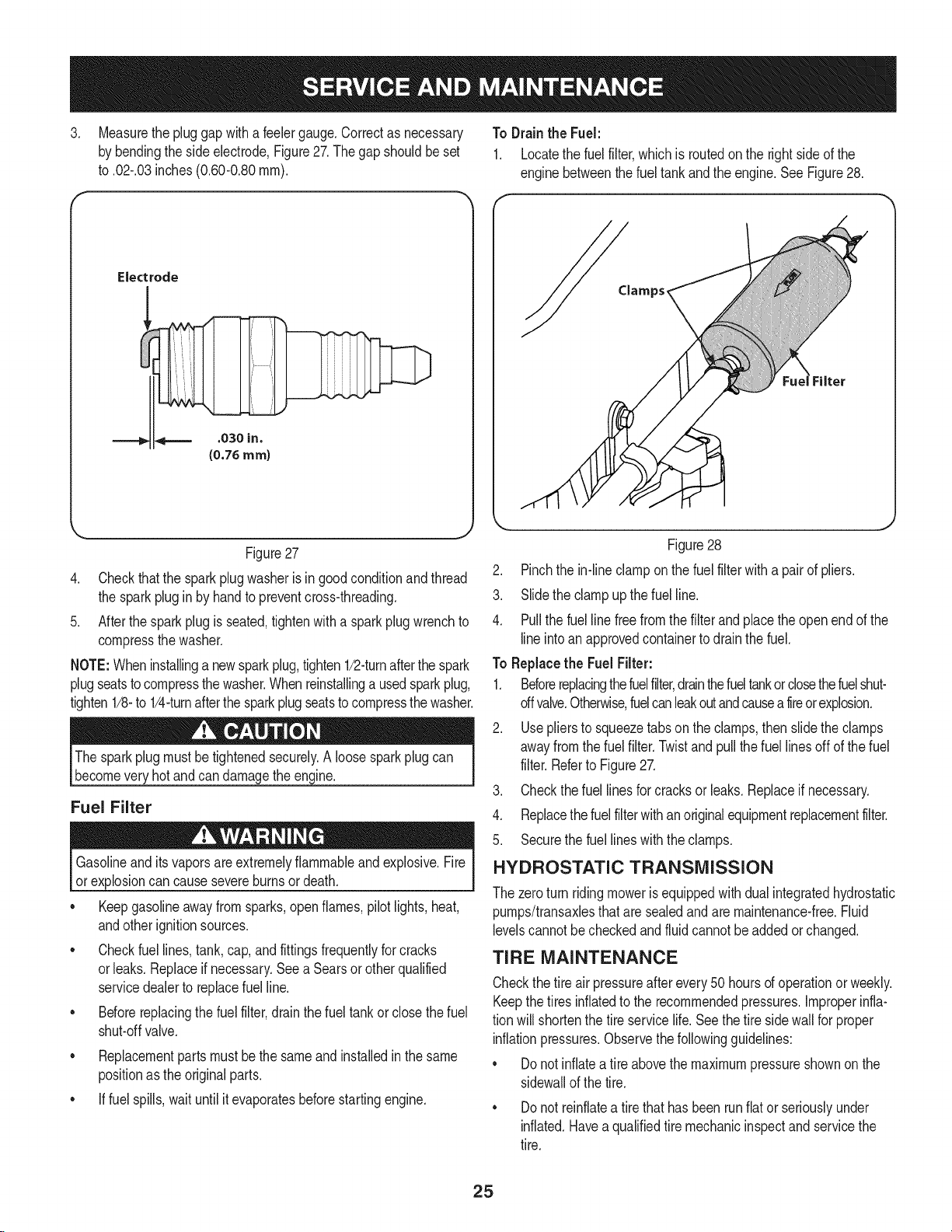

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonor every100hours.Toensureproperengineoperation,the

sparkplugmustalsobe properlygappedandfreeofdeposits.

1. Removethesparkplugboot andusea sparkplugwrenchto

removethe plug,Figure26.

Air Filter

Pre=Cleaner

Air

Figure25

2. Removetheair filterand pre-cleaner.

3. Removethe pre-cleanerfromthe air filter.

4. Replaceor washthe pre-cleanerinwarmwaterwithdetergent.

Rinsethoroughlyandallowthepre-cleanerto air dry.

5. Closetheairfiltercover.

AirCleaner

1. Removetheair filtercover.SeeFigure25.

2. Removetheair filterand pre-cleaner.

3. Servicethepre-cleaneras instructedabove.

4. Installthe newor servicedpre-cleaneroverthe newair cleaner

andinstall.

5. Closetheairfiltercover.

Spark

Pluc

Figure26

2. Visuallyinspectthe sparkplug.Discardthesparkplugifthereis

anyapparentwear,or if theinsulatoris crackedorchipped.Clean

thesparkplugwitha wire brushif it is tobe reused.

24

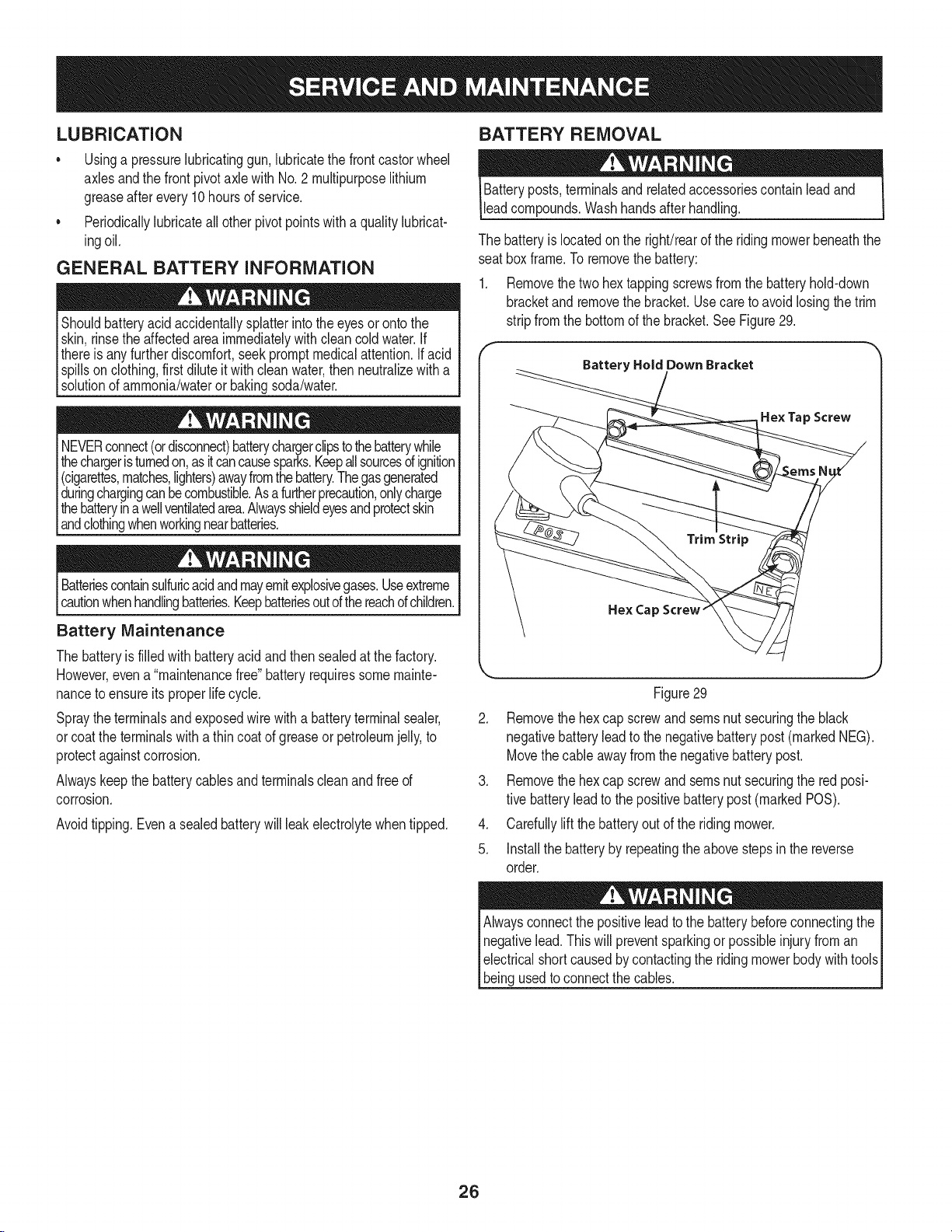

3. Measurethe pluggapwitha feelergauge.Correctas necessary To Drain the Fuel:

bybendingthesideelectrode,Figure27.Thegapshouldbeset 1. Locatethe fuelfilter,whichis routedontheright sideof the

to.02-.03inches(0.60-0.80ram). enginebetweenthe fueltankandthe engine.SeeFigure28.

Electrode

Clamps_

.030 in.

(0.76ram)

Figure27

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthe washer.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthespark

plugseatstocompressthewasher.Whenreinstallinga usedsparkplug,

tighten1/8-to1/4-turnafterthe sparkplugseatstocompressthewasher.

Thesparkplugmustbetightenedsecurely.A loosesparkplugcan

becomevery hotandcandamagetheengine.

Fuel Filter

Gasolineanditsvaporsareextremelyflammableandexplosive.Fire

or explosioncan causesevereburnsor death.

• Keepgasolineawayfromsparks,openflames,pilotlights,heat,

andotherignitionsources.

• Checkfuellines,tank,cap,andfittingsfrequentlyforcracks

orleaks.Replaceif necessary.SeeaSearsorotherqualified

servicedealerto replacefuelline.

• Beforereplacingthe fuelfilter,drainthefueltankor closethefuel

shut-offvalve.

• Replacementpartsmustbethesameandinstalledinthesame

positionasthe originalparts.

• If fuelspills,waituntilit evaporatesbeforestartingengine.

Figure28

2. Pinchthein-lineclamponthefuel filterwitha pairof pliers.

3. Slidetheclampup thefuelline.

4. Pullthefuel linefreefromthe filterandplacetheopenendofthe

lineintoanapprovedcontainerto drainthefuel.

To Replacethe FuelFilter:

1. Beforereplacingthefuelfilter,drainthefueltankorclosethefuelshut-

offvalve.Otherwise,fuelcanleakoutandcauseafireorexplosion.

2. Usepliersto squeezetabson theclamps,thenslidethe clamps

awayfromthefuelfilter.Twistandpullthe fuellinesoffof thefuel

filter.Referto Figure27.

3. Checkthefuellinesforcracksorleaks.Replaceifnecessary.

4. Replacethefuelfilterwithanoriginalequipmentreplacementfilter.

5. Securethefuellineswiththeclamps.

HYDROSTATIC TRANSMISSION

Thezeroturnridingmoweris equippedwithdualintegratedhydrostatic

pumps/transaxlesthatare sealedandare maintenance-free.Fluid

levelscannotbecheckedandfluidcannotbeaddedorchanged.

TIRE MAINTENANCE

Checkthetireairpressureafterevery50 hoursofoperationorweekly.

Keepthetires inflatedtotherecommendedpressures.Improperinfla-

tionwill shortenthetireservicelife.Seethe tiresidewallfor proper

inflationpressures.Observethefollowingguidelines:

• Donotinflatea tireabovethemaximumpressureshownon the

sidewallof thetire.

• Donotreinflatea tirethathas beenrunflator seriouslyunder

inflated.Haveaqualifiedtiremechanicinspectandservicethe

tire.

25

LUBRiCATiON

Usinga pressurelubricatinggun, lubricatethefrontcastorwheel

axlesandthefrontpivotaxlewith No.2 multipurposelithium

greaseafterevery10hoursof service.

Periodicallylubricateallotherpivotpointswitha qualitylubricat-

ingoil.

GENERAL BATTERY iNFORMATiON

Shouldbatteryacidaccidentallysplatterintotheeyesor ontothe

skin,rinsetheaffectedareaimmediatelywithcleancold water.If

thereis anyfurtherdiscomfort,seekpromptmedicalattention.Ifacid

spillsonclothing,firstdiluteit withcleanwater,thenneutralizewitha

solutionofammonia/wateror bakingsoda/water.

NEVERconnect(ordisconnect)batterychargerclipstothebatterywhile

thechargeris turnedon,asitcancausesparks.Keepallsourcesofignition

(cigarettes,matches,lighters)awayfromthebattery.Thegasgenerated

duringchargingcanbecombustible.Asafurtherprecaution,onlycharge

thebatteryina wellventilatedarea.Alwaysshieldeyesandprotectskin

_andcothngwhenworkngnearbatteres.

BATTERY REMOVAL

leadcompounds.Washhandsafterhandling.

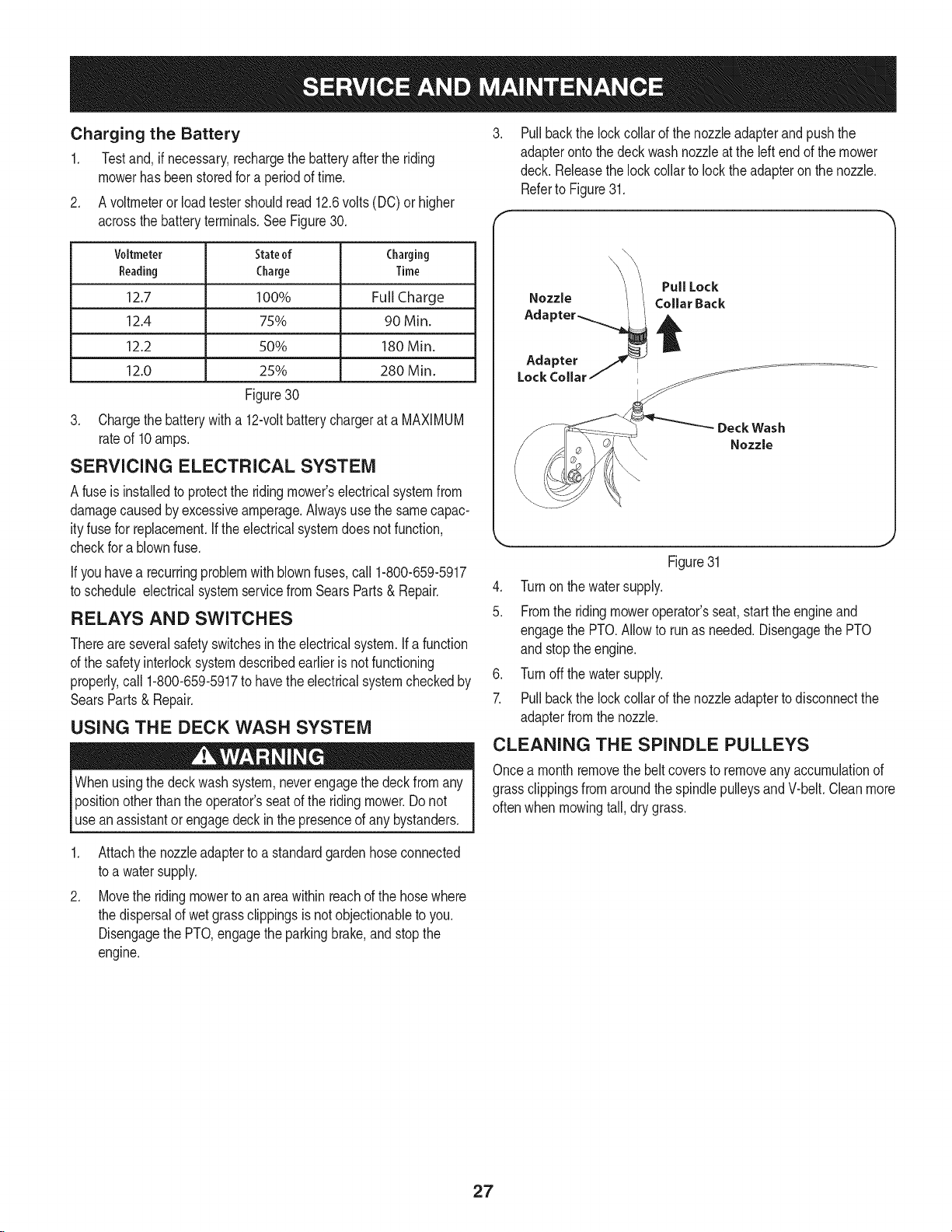

Thebatteryislocatedonthe right/rearofthe ridingmowerbeneaththe

seatboxframe.Toremovethebattery:

1. Removethetwohextappingscrewsfromthebatteryhold-down

bracketandremovethebracket.Usecareto avoidlosingthetrim

stripfromthebottomof thebracket.SeeFigure29.

f

Battery Hold Down Bracket

Hex Tap Screw

Batteriescontainsulfuricacidandmayemitexplosivegases.Useextreme

cautionwhenhandlingbatteries.Keepbatteriesoutofthereachofchildren.

Battery Maintenance

Thebatteryisfilled withbatteryacidandthensealedatthefactory.

However,evena "maintenancefree"batteryrequiressomemainte-

nanceto ensureitsproperlife cycle.

Spraytheterminalsandexposedwirewitha batteryterminalsealer,

orcoattheterminalswitha thincoatof greaseorpetroleumjelly,to

protectagainstcorrosion.

Alwayskeepthebatterycablesandterminalscleanandfreeof

corrosion.

Avoidtipping.Evena sealedbatterywillleak electrolytewhentipped.

Hex Cap Screw"

Figure29

2. Removethehexcapscrewandseresnutsecuringtheblack

negativebatteryleadto thenegativebatterypost(markedMEG).

Movethecable awayfromthenegativebatterypost.

3. Removethehexcapscrewandseresnutsecuringtheredposi-

tive batteryleadto thepositivebatterypost(markedPOS).

4. Carefullyliftthe batteryoutofthe ridingmower.

5. Installthebatteryby repeatingtheabovestepsinthe reverse

order.

Alwaysconnectthepositiveleadtothe batterybeforeconnectingthe

negativelead.Thiswillpreventsparkingor possibleinjuryfroman

electricalshortcausedbycontactingthe ridingmowerbodywithtoolsI

Ibengusedtoconnectthecabes. j

26

Charging the Battery

1. Testand,ifnecessary,rechargethebatteryaftertheriding

mowerhasbeenstoredfor a periodoftime.

2. A voltmeterorloadtestershouldread12.6volts(DC)or higher

acrossthebatteryterminals.SeeFigure30.

Voltmeter Stateof Charging

Reading Charge Time

12.7 100% FullCharge

12.4 75% 90 Min.

12.2 50% 180 Min.

12.0 25% 280 Min.

Figure30

3. Chargethebatterywitha 12-voltbatterychargerataMAXIMUM

rateof 10amps.

SERViCiNG ELECTRICAL SYSTEM

A fuseisinstalledto protecttheridingmower'selectricalsystemfrom

damagecausedbyexcessiveamperage.Alwaysusethe samecapac-

ityfusefor replacement.Ifthe electricalsystemdoes notfunction,

checkfor a blownfuse.

If youhavea recurringproblemwithblownfuses,call1-800-659-5917

toschedule electricalsystemservicefromSearsParts& Repair.

RELAYS AND SWITCHES

Thereareseveralsafetyswitchesintheelectricalsystem.Ifa function

ofthe safetyinterlocksystemdescribedearlieris notfunctioning

properly,call 1-800-659-5917to havetheelectricalsystemcheckedby

SearsParts& Repair.

USING THE DECK WASH SYSTEM

Whenusingthedeckwashsystem,neverengagethedeckfromany

positionotherthantheoperator'sseatof theridingmower.Donot

usean assistantorengagedeckin thepresenceofanybystanders.

Pullbackthelockcollarofthe nozzleadapterandpushthe

adapterontothedeckwashnozzleat theleftendofthemower

deck.Releasethelockcollarto locktheadapteron thenozzle.

Referto Figure31.

Deck Wash

Nozzle

Figure31

4. Turnonthe watersupply.

5. Fromthe ridingmoweroperator'sseat,starttheengineand

engagethePTO.Allowto runas needed.Disengagethe PTO

and stoptheengine.

6. Turnoffthe watersupply.

7. Pullbackthelockcollarofthenozzleadaptertodisconnectthe

adapterfromthe nozzle.

CLEANING THE SPINDLE PULLEYS

Oncea monthremovethebeltcoverstoremoveanyaccumulationof

grassclippingsfromaroundthe spindlepulleysandV-belt.Cleanmore

oftenwhenmowingtall,dry grass.

Attachthe nozzleadaptertoa standardgardenhoseconnected

toa watersupply.

,

Movetheridingmowertoan areawithinreachof thehosewhere

thedispersalofwetgrassclippingsisnotobjectionableto you.

Disengagethe PTO,engagethe parkingbrake,andstopthe

engine.

27

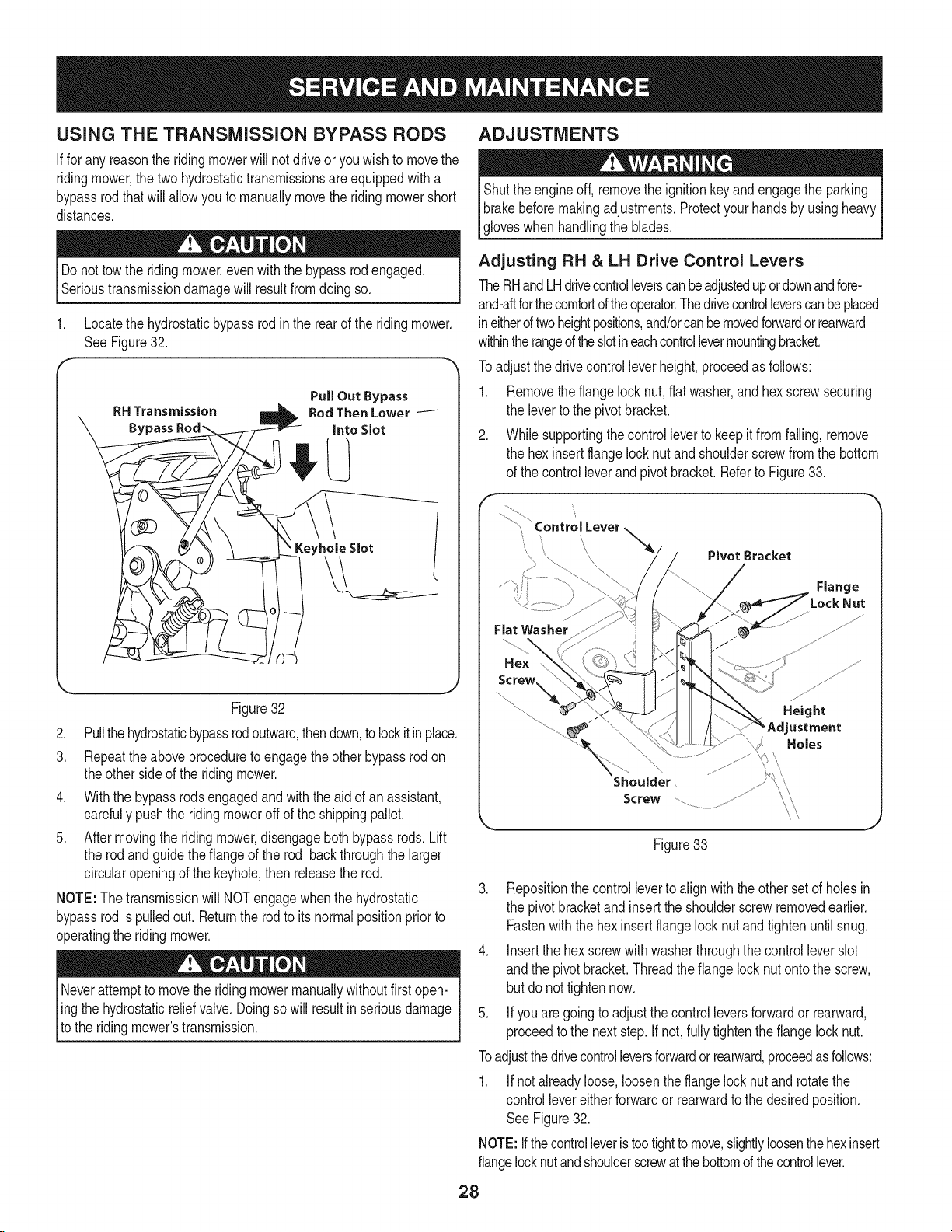

USING THE TRANSMiSSiON BYPASS RODS

Ifforany reasonthe ridingmowerwillnot driveor youwishtomovethe

ridingmower,thetwohydrostatictransmissionsareequippedwitha