Page 1

Operator’s Manual

42cc Gas Chain Saw

Model

MTD1425NAV

MTD1642AVCC

MTD1842AVCC

English

IMPORTANT: READ SAFETY RULES

AND INSTRUCTIONS CAREFULLY

P/N 9096-310545 © 2005

PRINTED IN TAIWAN

Page 2

INTRODUCTION

S/N :

ITEM :

MODEL :

THANK YOU

Thank you for buying this quality product. This modern

outdoor power tool will provide many hours of useful

service. You will find it to be a great labor-saving device.

This operator’s manual provides you with easy-tounderstand operating instructions. Read the whole

manual and follow all the instructions to keep your new

outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS

AND SPECIFICATIONS

All information, illustrations, and specifications in this

manual are based on the latest product information

available at the time of printing. We reserve the right to

make changes at any time without notice.

Copyright© 2004 MTD SOUTHWEST INC, All Rights

Reserved.

SERVICE INFORMATION

Service on this unit both within and after the warranty

period should be performed only by an authorized and

approved service dealer.

For service call 1-800-668-1238 to obtain a list of

authorized service dealers near you.

DO NOT RETURN THE UNIT TO THE RETAILER.

PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

Before beginning, locate the unit’s model plate. It lists

the model and serial numbers of your unit. Refer to the

sample plate below and copy the information for future

reference.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . .2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . .3

Oil and Fuel Information

Starting/Stopping Instructions . . . . . . . . . . . . . . . .10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . .11

Maintenance and Repair Instructions . . . . . . . . . . .13

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . .20

Notas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

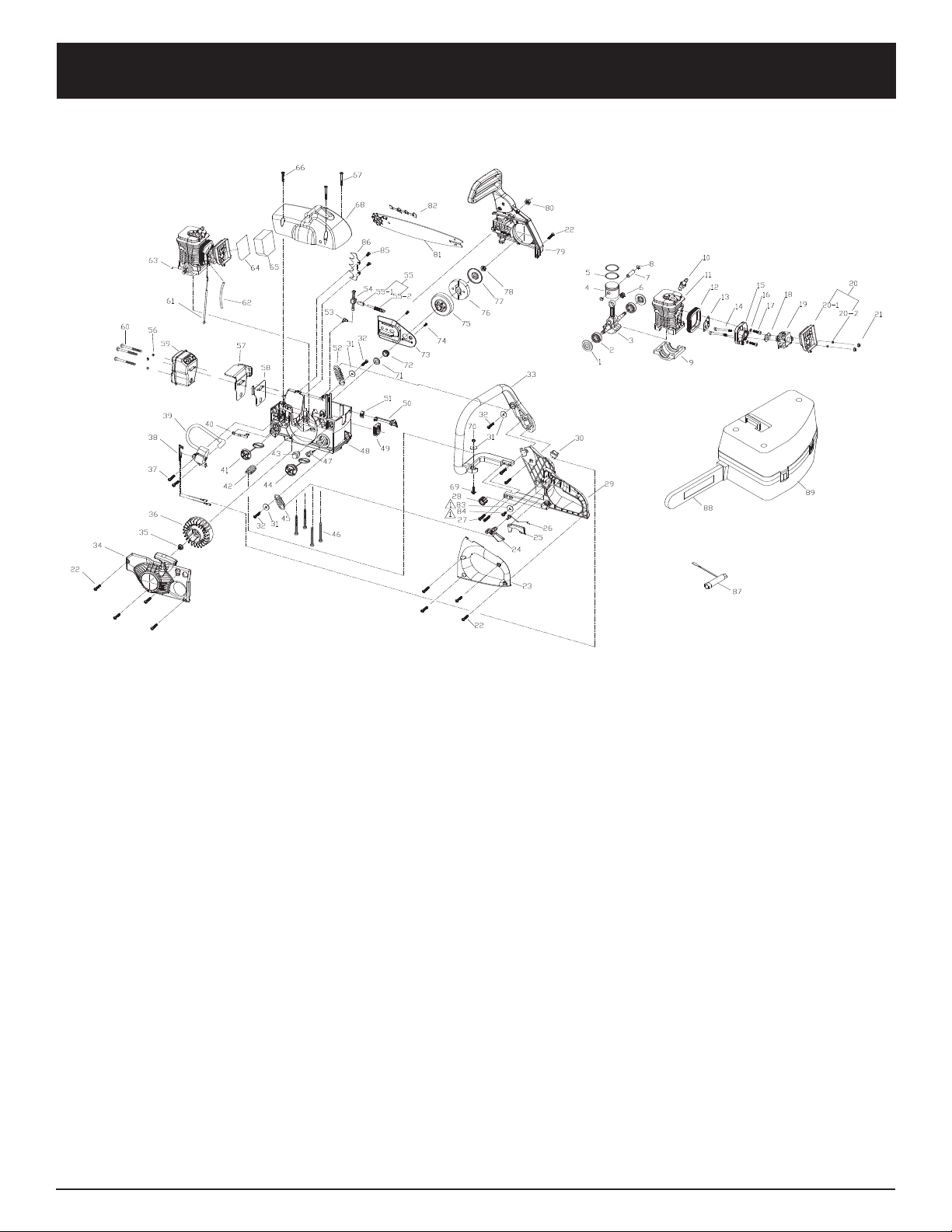

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-23

Warranty Information . . . . . . . . . . . . . . . . . . . . . . .24

. . . . . . . . . . . . . . . . . . . . . .9

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the

states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public

Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal

combustion engines operated on forest brush and/or

grass-covered areas be equipped with a spark arrestor,

maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention

of fire. Check with your state or local authorities for

regulations pertaining to these requirements. Failure to

follow these requirements could subject you to liability or

a fine. This unit is factory equipped with a spark

arrestor

SERVICE DEALER to install the

. If it requires replacement, ask your LOCAL

Spark Arrestor Kit.

Copy the model and parent

part number here:

Copy the serial number

here:

Make sure you carefully read and understand this manual

before starting or operating this equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S.

PATENTS. OTHER PATENTS PENDING.

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS

PRODUCT CONTAINS CHEMICALS

KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

2

Page 3

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

their explanations, deserve your careful attention

and

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING

SAFETY ALERT:

warning or caution. Attention is required in

order to avoid serious personal injury. May

be used in conjunction with other symbols

or pictographs.

NOTE: Advises you of information or instructions vital to

the operation or maintenance of the equipment.

Read the Operator’s Manual(s) and follow all

warnings and safety instructions.

Failure to do so can result in serious injury to the

operator and/or bystanders.

Indicates

danger,

FOR QUESTIONS, CALL 1-800-668-1238

SYMBOL MEANING

DANGER:

result in serious injury to yourself or to

others. Always follow the safety precautions

to reduce the risk of fire, electric shock and

personal injury.

WARNING:

result in injury to yourself and others.

Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

CAUTION:

result in property damage or personal injury

to yourself or to others. Always follow the

safety precautions to reduce the risk of fire,

electric shock and personal injury.

Failure to obey a

safety warning will

Failure to obey a

safety warning can

Failure to obey a

safety warning may

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS

BEFORE OPERATING

WARNING:

quick, easy to handle and efficient tool; if

used improperly or without the due

ecautions it could become a danger

pr

tool. For pleasant and safe work,always

strictly comply with the safety rules that

follow and throughout this manual.

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

Do not operate this unit when tired, ill or under the

•

influence of alcohol, drugs or medication.

Only responsible individuals who are familiar with the

•

instructions may operate the chain saw (no one under

the age of 16). Provide parental supervision at all times

• Inspect the unit before use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in

place and secure. Replace parts that are cracked,

chipped or damaged in any way.

• Know the controls and know how to stop the chain

saw quickly.

Carry the chain saw with the engine stopped, the

•

guide bar and saw chain to the rear, and the muffler

away from your body.

•

When transporting your chain saw, use the

appropriate guide-bar scabbard (sheath).

If correctly used,

the chain saw is a

ous

WHILE OPERATING

• Keep all parts of your body away from the chain when

the engine is running.

• Never start or run the unit inside a closed room or

building. Breathing exhaust fumes can kill. Operate

this unit only in a well ventilated outdoor area.

• Wear safety glasses or goggles that are marked as

meeting ANSI Z87.1-1989 standards. Also wear

ear/hearing protection when operating this unit. Wear

a face or dust mask if the operation is dusty. Long

sleeve shirts are recommended.

Wear heavy, long pants, boots or safety footwear and

•

protective gloves. Do not wear loose clothing, jewelry,

short pants, sandals or go barefoot. Secure hair above

shoulder level.

• Use the unit only in daylight or good artificial light.

.

• Avoid accidental starting. Be in the starting position

whenever pulling the starter rope. The operator and

unit must be in a stable position while starting. See

Starting/Stopping

• Before you start the engine, make sure that the saw’s

chain is not contacting anything. Do not cut near

electrical cables or power lines.

• Keep all parts of your body away from the chain when

the engine is running.

Do not start cutting until you have a clear work area,

•

secure footing, and a planned retreat path from the

falling tree.

Instructions

.

3

Page 4

RULES FOR SAFE OPERATION

• Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw’s chain stops moving

when the throttle control trigger is released.

Shut off the engine before setting the chain saw down.

•

• Use extreme caution when cutting small-sized brush

and saplings because slender material may catch the

chain saw and whip towards you or pull you off

balance.

• When cutting a limb that is under tension, be alert for

springback so that you will not be struck when the

tension in the wood fibers is released

• Do not cut through nails, rods in the tree, railroad ties

or pallets. Inspect a tree that you are going to cut for

foreign objects that could cause injury or damage to

your chain saw.

• After striking a foreign object, stop the engine and

thoroughly inspect for damage. Repair as necessary.

• Keep the handles dry, clean and free of the oil/fuel

mixture

• We do not recommend using the chain saw in a tree or

on a ladder.

• All chain saw service, other that the items listed in this

instruction manual maintenance instructions, should be

performed by competent chain saw service personnel.

• Use the right tool. Only use this chain saw for its

intended purpose, to cut wood.

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on all handles or grips.

• Apply chain brake prior to any repositioning of the

operator in the cutting area. As an additional safety

precaution, apply the chain brake prior to setting down

the saw.

Never touch the chain or attempt to service the saw

•

while the engine is running. Make sure all moving parts

have stopped. Allow the chain saw to cool, as the

chain can be hot.

• Check the bar and chain at frequent intervals for

proper adjustment. Make sure the bar and chain are

properly tightened and sharpened. Visually inspect for

damage. Repair any damage before restarting or

operating the chain saw.

KICKBACK SAFETY PRECAUTIONS

WARNING:

or tip of the guide bar touches an object, or

when the wood closes in and pinches the

saw chain in the cut. Tip contact in some

cases may cause a lightning-fast reverse

reaction, kicking the guide bar up and back

towards the operator. Pinching the saw chain

along the top of the guide bar may push the

guide bar rapidly back toward the operator.

Either of these reactions may cause you to

lose control of the saw , which could r esult in

serious personal injury .

Do not rely exclusively upon the safety

devices built into your saw. As a chain saw

user, you should take several steps to keep

your cutting jobs free from accident or injury.

• With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents. Be alert to the

potential for kickback at all times.

• Keep a good firm grip on the saw with both hands, the

right hand on the rear handle and the left hand on the

front handle, when the engine is running. Use a firm grip

with thumbs and fingers encircling the chain saw

handles. A firm grip will help you reduce kickback and

maintain control of the saw. Don’t let go.

• Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of the guide bar

contact a log, branch, fence, or any other obstruction

that could be hit while you are operating the saw.

• Always cut with the engine running at full speed. Fully

squeeze the throttle trigger and maintain a steady

cutting speed.

• Use only the correct original equipment manufacturer

replacement bars, chains and other parts and

accessories. These are available from your authorized

service dealer. Use of any unauthorized parts or

accessories could lead to serious injury to the user, or

damage to the unit, and will void your warranty.

• Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

• Use only the replacement guide bars and low kickback

chains specified for your saw to avoid injury.

KICKBACK may

occur when the nose

4

Page 5

RULES FOR SAFE OPERATION

OTHER SAFETY PRECAUTIONS

• Do not operate a chain saw with one hand! Serious

injury to the operator, helpers, bystanders, or any

combination of these persons may result from onehanded operation. A chain saw is intended for twohanded use.

• Do not operate a chain saw if you are fatigued.

• Use safety footwear; snug-fitted clothing; protective

gloves; and eye, hearing, and head protection devices.

• Do not allow other persons to be near the chain saw

when starting or cutting with the chain saw. Keep

bystanders and animals out of the work area.

• Do not remove, damage or de-activate any of the

safety devices. Never use a damaged, modified, or

improperly repaired or assembled chain saw. Check

their proper operation regularly. Only use bars and

chains of the length indicated in the table herein.

• Never carry out operations or repairs on your own that

are other than routine maintenance. For information,

contact specialized and authorized workshops only.

• If your chain saw is no longer usable, dispose of it

properly without damaging the environment by

handing it in to your local dealer who will arrange for

its correct disposal.

• Use caution when felling a tree. Make sure you have

planned an escape path when felling, and keep all

bystanders away.

• Be alert; stop the machine if anyone enters the cutting

area, which is usually 3 to 4 feet around the operator.

• Use caution when working in a crew to avoid injury to

a fellow worker who may enter the cutting area.

• Only loan your saw to experienced users who are

completely familiar with saw operation and correct

use. Give other users this manual, which they should

read before using the saw. Provide them the operating

instructions.

Shut off the engine before setting down the saw. Do

•

not leave the engine running unattended.

• Never store the unit, with fuel in the tank, inside a

building where fumes may reach an open flame or

spark.

• Allow the engine to cool before storing or transporting

the chain saw over long distances. For example, let

the engine cool before placing the chain saw in an

automobile. Also, be sure to secure the unit while

transporting.

• Store the unit in a dry area, locked up, located up high

and located out of the reach of children to prevent

unauthorized use or damage.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

• Do not use the unit in the rain, in a storm or in

inclement weather. Wait until the storm danger has

passed before operation of this product.

FUEL SAFETY

WARNING:

vapors can explode if ignited. Take the

following precautions:

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Always stop the engine and allow it to cool before

filling the fuel tank. Never remove the cap of the fuel

tank, or add fuel, when the engine is hot. Never

operate the unit without the fuel cap securely in place.

Loosen the fuel tank cap slowly to relieve any pressure

in the tank.

• Add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Slowly remove the fuel

cap only after stopping engine. Do not smoke while

fueling or mixing fuel. Wipe up any spilled fuel from the

unit immediately.

• Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapors dissipate.

• Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not

smoke. Keep sparks and open flames away from the

area while adding fuel or operating the unit.

Gasoline is highly

flammable, and its

SAVE THESE

INSTRUCTIONS

5

Page 6

RULES FOR SAFE OPERATION

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning, or

caution. May be used in conjunction

with other symbols or pictographs.

• WARNING - READ OPERATOR'S

MANUAL

Read the Operator’s Manual(s) and

follow all warnings and safety

instructions. Failure to do so can

result in serious injury to the

operator and/or bystanders.

• WEAR EYE, HEARING AND

HARDHAT PROTECTION

WARNING: Thrown objects and

loud noise can cause severe eye

injury and hearing loss. Wear eye

protection meeting ANSI Z87.1-1989

standards and ear protection when

operating this unit. Wear a hard hat.

Use a full face shield when needed.

SYMBOL MEANING

• ON/OFF CONTROL

ON / START / RUN

• ON/OFF CONTROL

OFF OR STOP

• GUIDE BAR WARNING:

Contact of the guide bar tip with any

object should be avoided. Tip

contact may cause the guide bar to

move suddenly upward and

backward, which may cause serious

injury.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator's manual for the

proper type of oil.

• USE BOTH HANDS

Always use both hands while

operating the chain saw. Never use

only one hand to operate the saw.

Avoid bar nose contact.

This product has been tested at a

computed kickback angle (CKA) of

no greater than 45 degrees.

6

Page 7

RULES FOR SAFE OPERATION

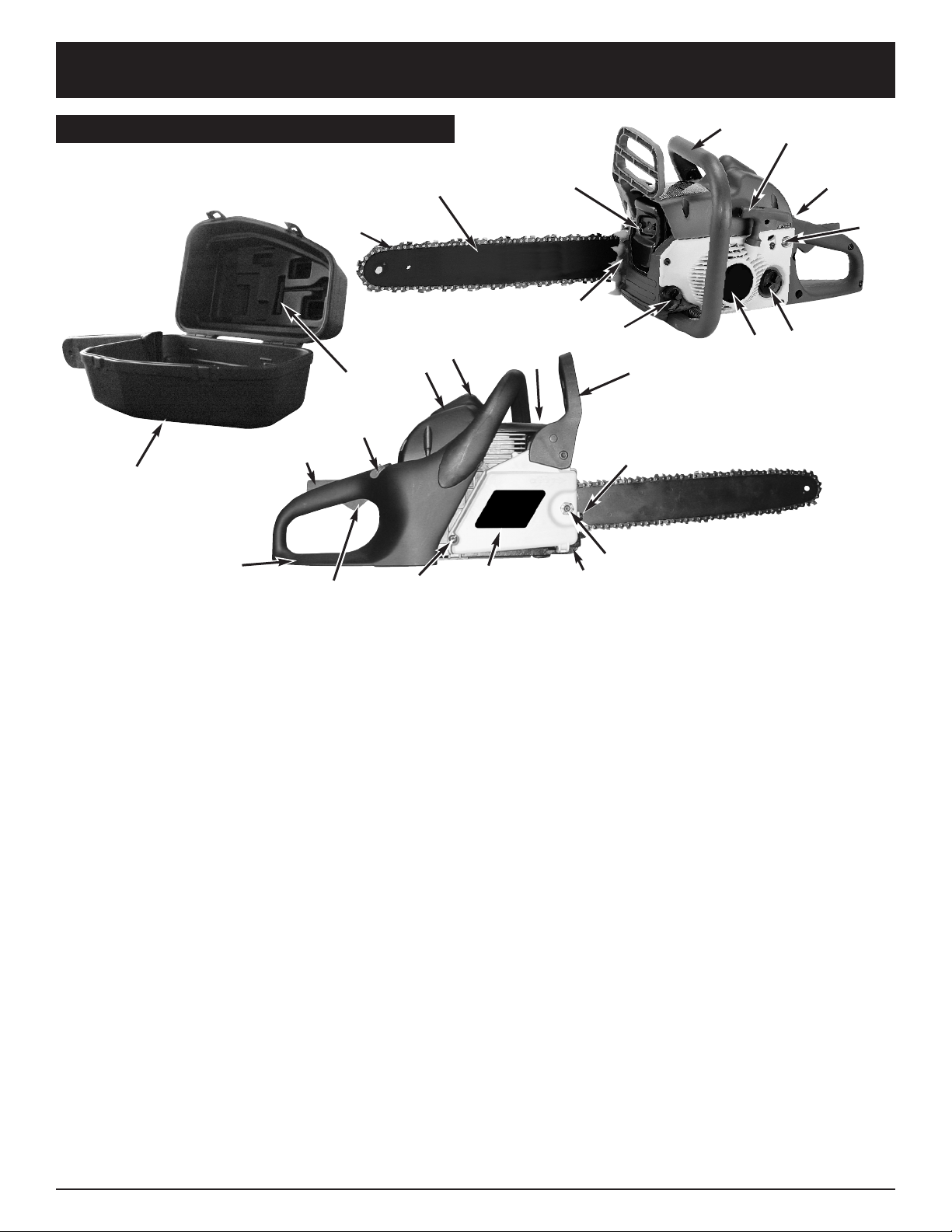

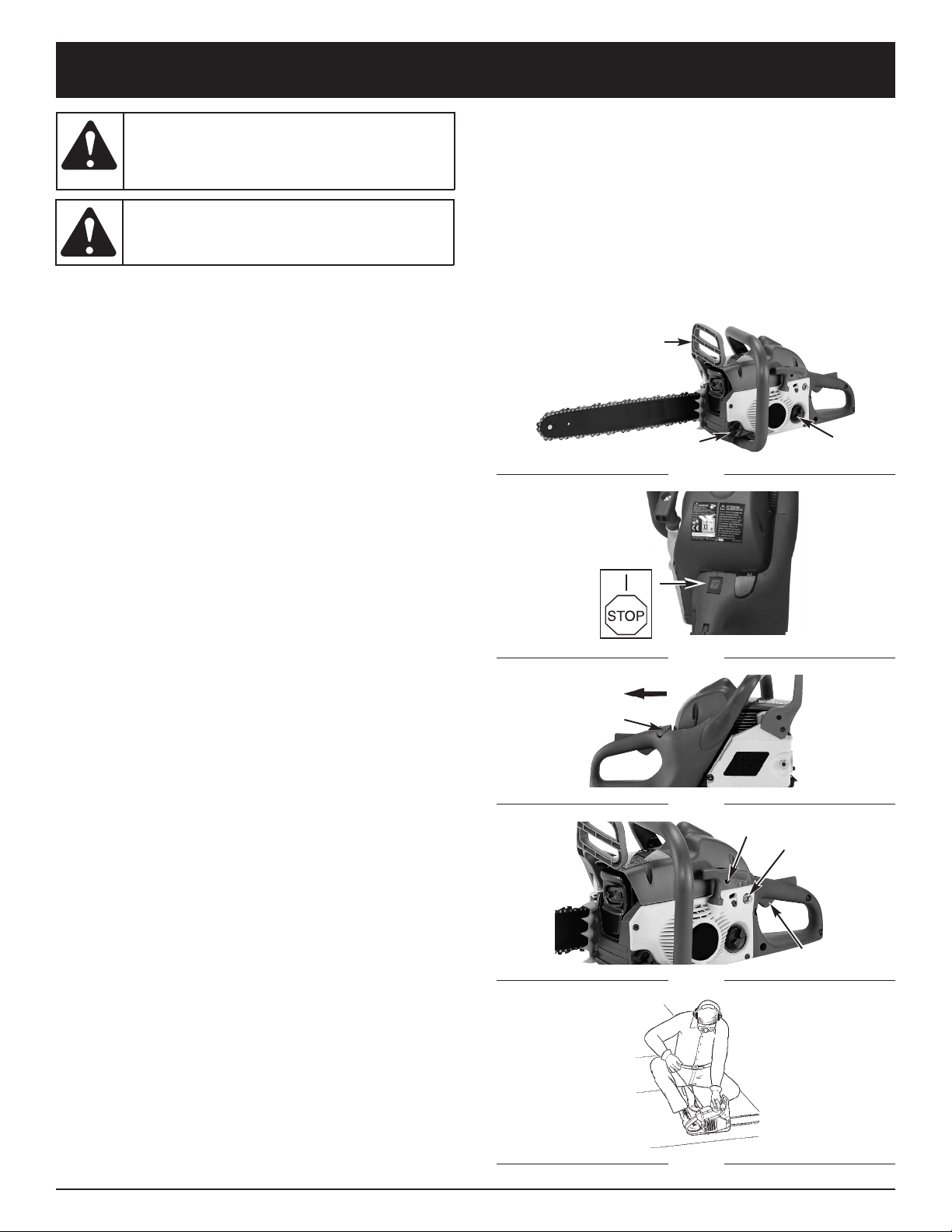

KNOW YOUR UNIT

11

26

15

19

CHAIN SAW COMPONENTS

1. GUIDE BAR

2. SAW CHAIN

3. SAW CHAIN ADJUSTMENT SCREW

4. SPARK ARRESTER SCREEN

5. CHAIN BRAKE®LEVER /HAND GUARD

6. FRONT HANDLE

7. STARTER HANDLE

8. SPARK PLUG

AIR CLEANER COVER

9.

STOP SWITCH

10.

11. SAFETY LATCH

12. OIL TANK CAP

13. STARTER COVER

14. FUEL TANK CAP

15. REAR HANDLE / BOOT LOOP

16. PRIMER BULB

17. BLUE CHOKE LEVER

BAR RETAINING NUT

18.

THROTTLE / TRIGGER

19.

20. CHAIN CATCHER

21. MUFFLER SHIELD

22. CLUTCH COVER

23. BUCKING SPIKE

24. CLUTCH COVER RETAINING SCREW

25. SCREWDRIVER / WRENCH

CARRY CASE (Available on some models)

26.

2

25

17

24

6

1

8

9

22

4

23

12

21

5

3

18

20

13

7

10

16

14

SAFETY FEATURES

Numbers preceding the descriptions correspond with the

numbers above to help you locate the safety feature.

2 LOW KICKBACK SAW CHAIN helps significantly

reduce kickback, or the intensity of kickback, due to

specially designed depth gauges and guard links.

4 SPARK ARRESTER SCREEN retains carbon and

other flammable particles over 0.023 inches (0.6mm)

in size from engine exhaust flow. Compliance with

local, state and federal laws and/or regulations

governing the use of a spark arrester screen is the

user’s responsibility. See Safety Precautions for

additional information.

5 CHAIN BRAKE

operator’s left hand in the event it slips off the front

handle while saw is running.

CHAIN BRAKE

5

reduce the possibility of injury due to kickback by

stopping a moving saw chain in milliseconds. It is

activated by the CHAIN BRAKE®lever.

10 STOP SWITCH immediately stops the engine when

tripped. Stop switch must be pushed to ON position

to start or restart engine.

11 SAFETY LATCH prevents accidental acceleration of

the engine. Throttle trigger (19) cannot be squeezed

unless the safety latch is depressed.

CHAIN CATCHER reduces the danger of injury in the

20

event saw chain breaks or derails during operation.

The chain catcher is designed to intercept a whipping

chain.

®

LEVER / HAND GUARD protects the

®

is a safety feature designed to

7

Page 8

RULES FOR SAFE OPERATION

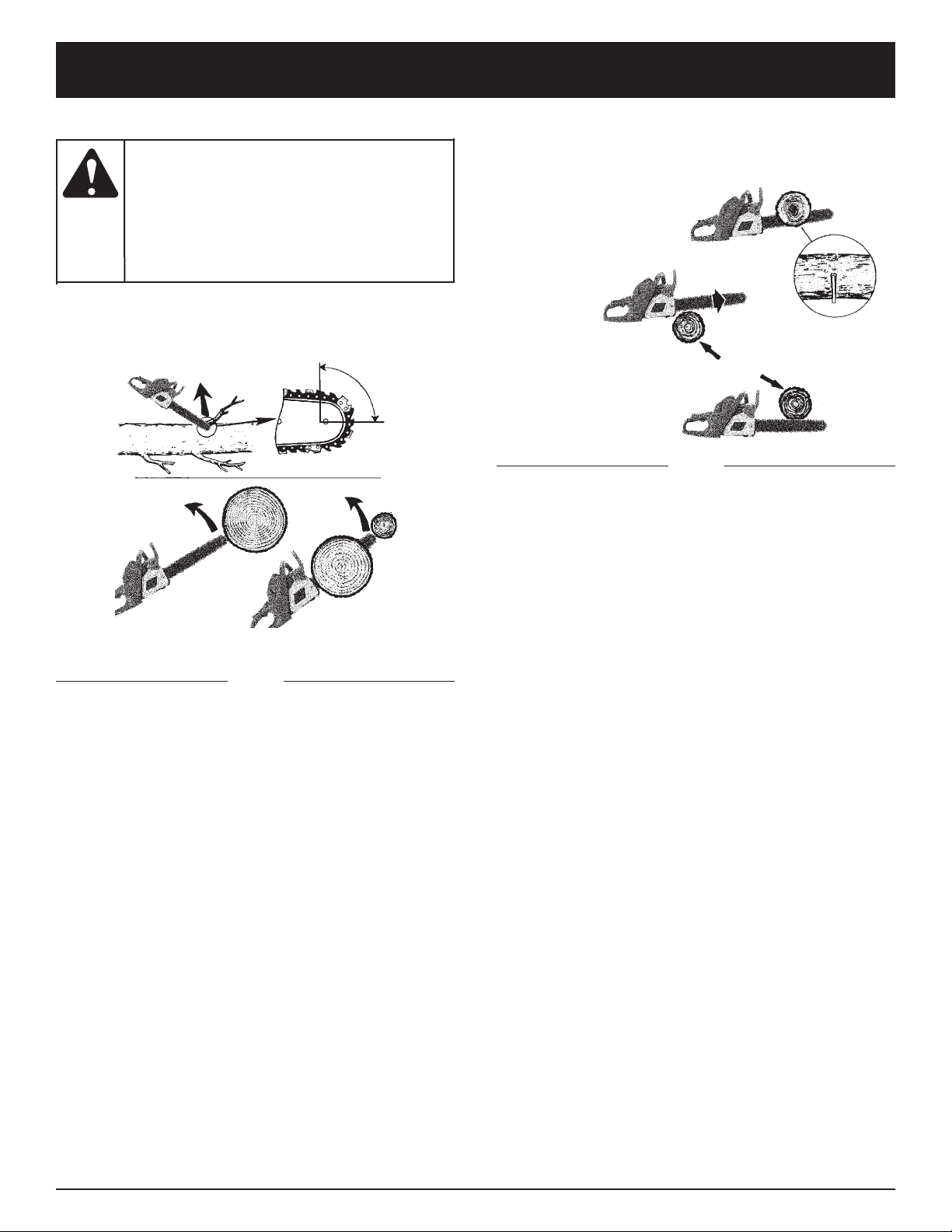

KICKBACK SPECIFICS

WARNING:

control of the chain saw and result in serious

or fatal injury to the saw operator or to

anyone standing close by . Always be alert.

Rotational kickback and pinch-kickback are

major chain saw operational dangers and

the leading cause of most accidents.

Beware of:

Rotational Kickback

A

A

A = Kickback path

B = Kickback reaction zone

Fig. 1

Kickback can lead

to dangerous loss of

B

A

KICKBACK SPECIFICS

Beware of:

Pinch Kickback (The push and pull reactions)

A

B

B

A = Pull

B = Solid objects

C = Push

C

Fig. 2

KICKBACK may occur when the NOSE or TIP of the

guide bar touches an object, or when wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse reaction, kicking the guide bar up and back

toward the operator.

PINCHING the saw chain along the BOTTOM of the

guide bar may PULL the saw forward away from the

operator. PINCHING the saw chain along the TOP of the

guide bar may PUSH the guide bar rapidly back toward

the operator.

Any of these reactions may cause you to lose control of

the saw, which could result in serious personal injury.

8

Page 9

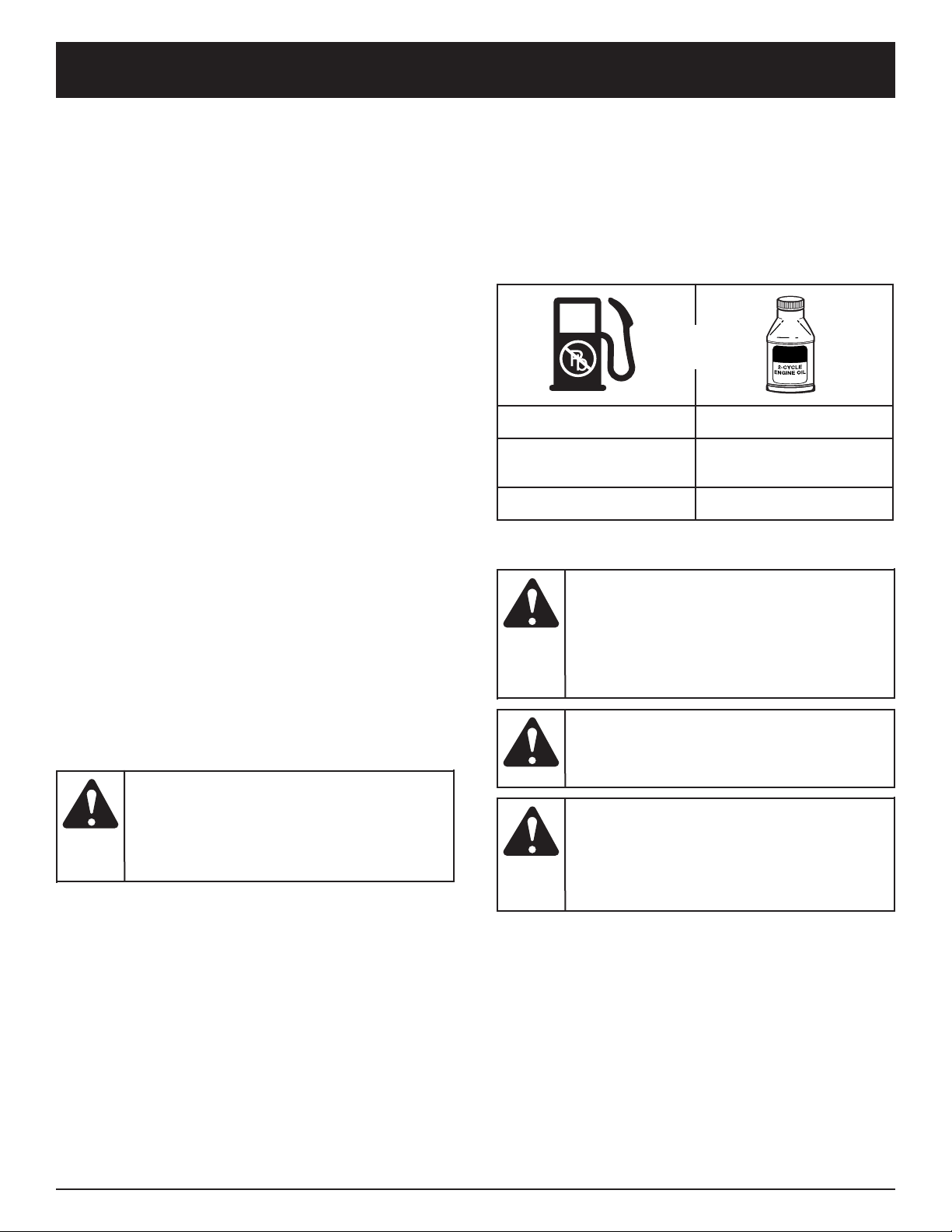

OIL AND FUEL INFORMATION

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons

for the unit not running properly. Be sure to use fresh,

clean unleaded fuel. Follow the instructions carefully for

the proper fuel/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and

oxygenates such as ethanol, methanol, or MTBE (ether).

Alcohol-blended fuel absorbs water. As little as 1%

water in the fuel can make fuel and oil separate. It forms

acids when stored. When using alcohol-blended fuel,

use fresh fuel (less than 60 days old).

Using Blended Fuels

If you choose to use a blended fuel, or its use is

unavoidable, follow recommended precautions:

• Always use the fresh fuel mix explained in your

operator's manual

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing

the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with your unit

contains a fuel additive which will help inhibit corrosion

and minimize the formation of gum deposits. It is

recommended that you use our 2-cycle oil with this unit.

If unavailable, use a good 2-cycle oil designed for

air-cooled engines along with a fuel additive, such as

STA-BIL®Gas Stabilizer or an equivalent. Add 0.8 oz.

(23 ml.) of fuel additive per gallon of fuel according to the

instructions on the container. NEVER add fuel additives

directly to the unit's fuel tank.

oper engine

CAUTION:

maximum reliability, pay strict attention to

the oil and fuel mixing instructions on the

2-cycle oil container. Using improperly mixed

fuel can severely damage the engine.

For pr

operation and

Thoroughly mix the proper ratio of 2-cycle engine oil

with unleaded gasoline in a separate fuel can. Use a 40:1

fuel/oil ratio. Do not mix them directly in the engine fuel

tank. See the table below for specific gas and oil mixing

ratios.

NOTE: One gallon (3.8 liters) of unleaded gasoline mixed

with one 3.2 oz. (95 ml.) bottle of

2-cycle oil makes a 40:1 fuel/oil ratio.

+

UNLEADED GAS 2 CYCLE OIL

1 GALLON US

(3.8 LITERS)

1 LITER 25 ml

MIXING RATIO - 40:1

WARNING:

flammable. Ignited Vapors may explode.

Always stop the engine and allow it to cool

before filling the fuel tank. Do not smoke

while filling the tank. Keep sparks and open

flames at a distance from the area.

WARNING:

from fuel spray. Never operate the unit

without the fuel cap secur

WARNING:

ipe up any spilled fuel

outdoor ar

immediately

ignition for spilt fuel. Do not star

until fuel vapors dissipate.

ea. W

. Avoid creating a source of

3.2 FL. OZ.

(95 ml)

Gasoline is

extremely

Remove fuel cap

slowly to avoid injury

ely in place

Add fuel in a clean,

well ventilated

.

t the engine

NOTE: Dispose of the old fuel/oil mix in accordance to

Federal, State and Local regulations.

9

Page 10

STARTING/STOPPING INSTRUCTIONS

WARNING:

Operate this unit only

in a well- ventilated

outdoor area. Carbon monoxide exhaust

fumes can be lethal in a confined area.

WARNING:

Never operate the saw

without the bar and

chain properly installed.

STARTING INSTRUCTIONS

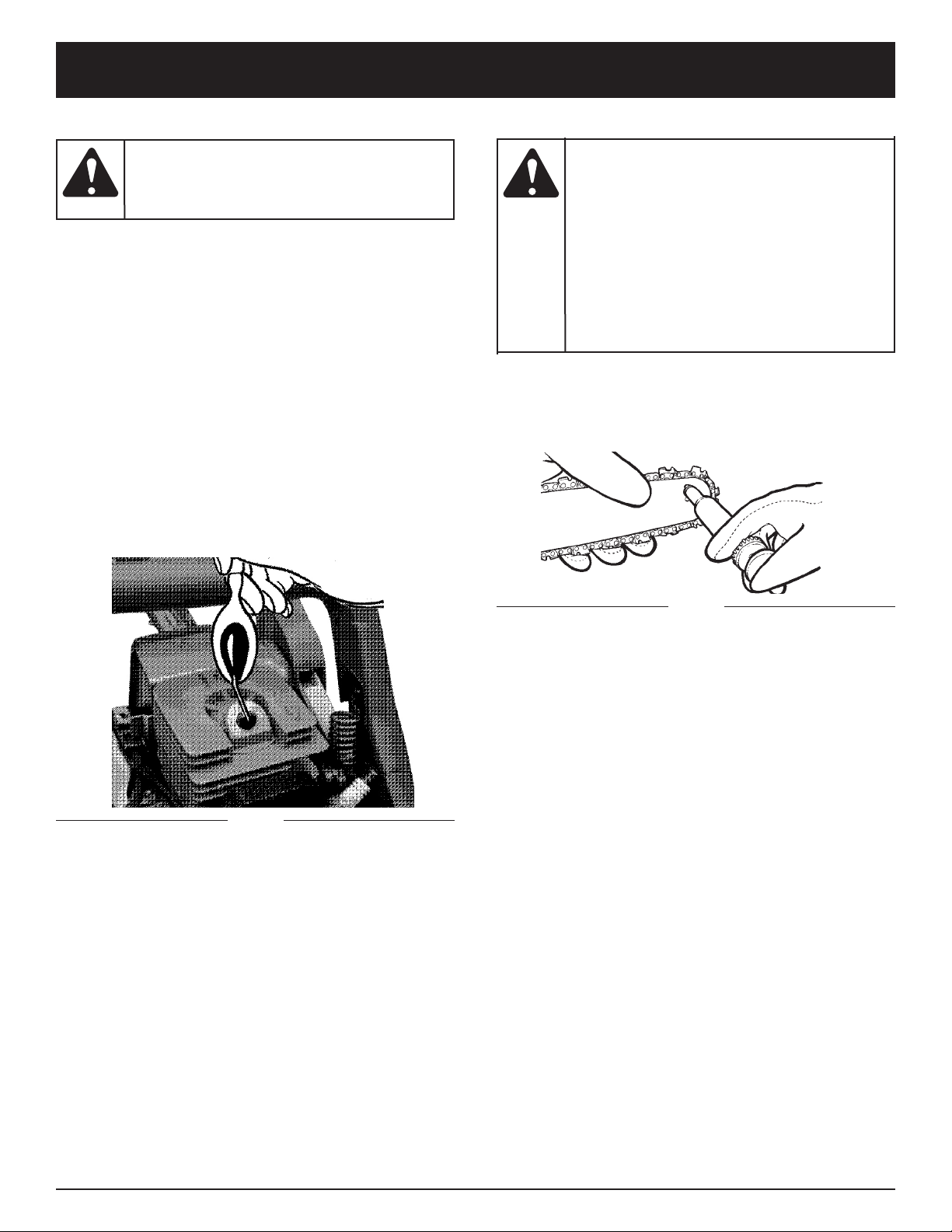

1. Mix gas with oil. Fill fuel tank (A, Fig. 3) with fuel/oil

mixture. See Oil and Fuel Mixing Instructions.

2. Fill the oil tank (B) with correct chain and bar oil (Fig. 3).

3. Be certain the Chain Brake®is disengaged (C) before

starting unit (Fig. 3).

NOTE: see page 15 fig. 24.

4. Press red STOP switch to the “I” ON position (Fig. 4).

5. Pull the blue lever (D) out as far as it will go until the

blue lever stays out (Fig. 5). This advances the

throttle so you do not have to hold the trigger while

starting.

6. Fully press and release the primer bulb (E) 10 times,

slowly. Some amount of fuel should be

primer bulb (Fig. 6). If you can’t see fuel in the bulb,

press and release the bulb as many times as it takes

before you can see fuel in it.

7. Place the saw on a firm flat surface. Hold saw firmly

as shown (Fig. 7).

8.

Pull the rope with a controlled and steady motion 4

times. Then move the blue lever (D) all the way in (Fig. 6).

9. Hold saw firmly and pull rope until saw starts. This

could take 4 more pulls.

10. Let the saw warm up for 10 seconds. Depress and

release trigger (F) for idle (Fig. 6).

NOTE: In some cases due to operating conditions

11. If engine fails to start, repeat these instructions.

NOTE: When starting a warm engine:

1. make sure switch is on

2. pull blue choke all the way out and then push it back

3. push primer10x or until you see fuel in the bulb

4. pull rope until engine starts

5. depress and release trigger for idle

(altitude,temperature, etc)your chain saw may

need a slight adjustment to the idle speed.

1. locate idle adjustment screw(G). (fig. 6)

2. if saw will not idle-turn screw clockwise 1/4 to1/2

turn-saw should idle

3. If chain turns while idling turn screw

counterclockwise until chain stops.

in-This advances the throttle so you do not have to

hold trigger during starting

visible in the

STOPPING INSTRUCTIONS

1. Release the throttle trigger as soon as the cut is

completed, allowing the engine to idle. If you run the

saw at full throttle without a cutting load,

unnecessary wear can occur to the chain, bar, and

engine. It is recommended that the engine not be

operated for longer than 30 seconds at full

throttle.

2. Stop the engine before setting the saw down after

cutting.

NOTE: For emergency stopping, simply activate the

Chain Brake

®

and move the STOP switch down.

C

B

Fig. 3

Fig. 4

D

Fig. 5

G

E

F

Fig. 6

A

10

Fig. 7

Page 11

OPERATING INSTRUCTIONS

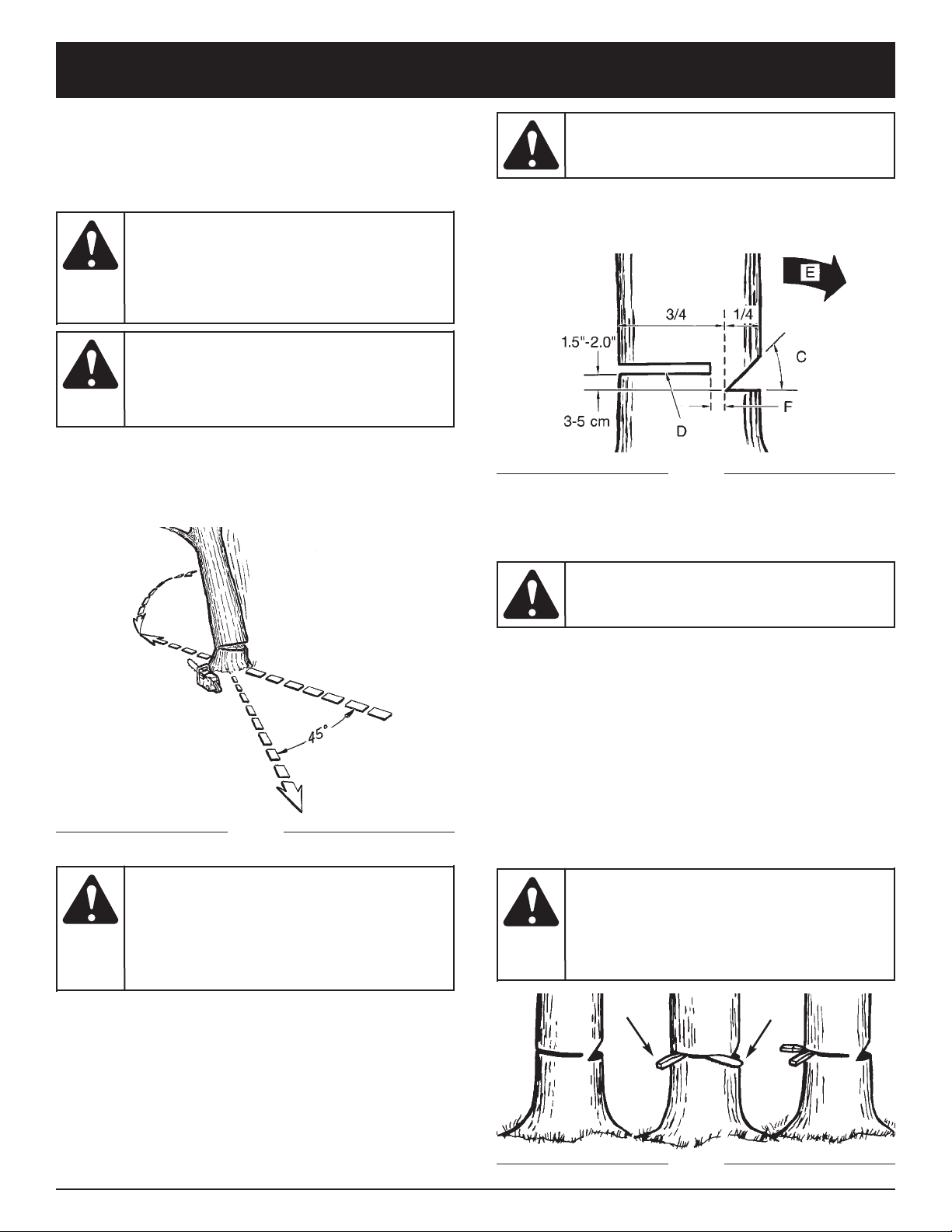

FELLING

Felling is the term for cutting down a tree. Small trees up

to 6-7 inches (15-18cm) in diameter are usually cut in a

single cut. Larger trees require notch cuts. Notch cuts

determine the direction the tree will fall.

WARNING:

and cleared as necessary before cuts are

started. The retreat path should extend

back and diagonally to the rear of the

expected line of fall, as illustrated in Fig. 8.

CAUTION:

chain saw operator should keep on the

uphill side of the terrain, as the tree is likely

to roll or slide downhill after it is felled.

NOTE: Direction of fall (B) is controlled by the notching

cut. Before any cuts are made, consider the

location of larger branches and natural lean of the

tree to determine the way the tree will fall.

A retreat path (A)

should be planned

If felling a tree on

sloping ground, the

WARNING:

notched.

Make the felling cut (D) from the other side of the tree

and 1.5 - 2.0 inches (3-5 cm) above the edge of the

notch (C) (Fig. 9).

Fig. 9

Never saw completely through the trunk. Always leave a

hinge. The hinge guides the tree. If the trunk is completely

cut through, control over the felling direction is lost.

Never walk in front of

a tree that has been

B

A

Fig. 8

WARNING:

changing winds or if there is a danger to

property. Consult a tree professional.Do not

cut down a tree if there is a danger of

striking utility wires; notify the utility

company befor

Normally felling consists of 2 main cutting operations,

notching (C) and making the felling cut (D).

Start making the upper notch cut (C) on the side of the

tree facing the felling direction (E). Be sure you don t

make the lower cut too deep into the trunk.

The notch (C) should be deep enough to create a hinge

(F) of sufficient width and strength. The notch should be

wide enough to direct the fall of the tree for as long as

possible.

e making any cuts.

Do not cut down a

tree during high or

WARNING:

the area for bystanders, animals or obstacles.

Insert a wedge or felling lever in the cut well before the

tree becomes unstable and starts to move. This will

prevent the guidebar from binding in the felling cut if you

have misjudged the falling direction. Make sure no

bystanders have entered the range of the falling tree

before you push it over.

Felling Cut:

1. Use wooden or plastic wedges (G) to prevent binding

the bar or chain (H) in the cut. Wedges also control

felling (Fig. 10).

2. When diameter of wood being cut is greater than the

bar length, make 2 cuts as shown (Fig. 11).

WARNING:

hinge, the tree should begin to fall. When

tree begins to fall, remove saw from cut,

stop engine, put chain saw down, and

leave ar

ea along r

G

Fig. 10

Before making the

final cut, always recheck

As the felling cut

gets close to the

eat path (Fig. 8).

etr

H

11

Page 12

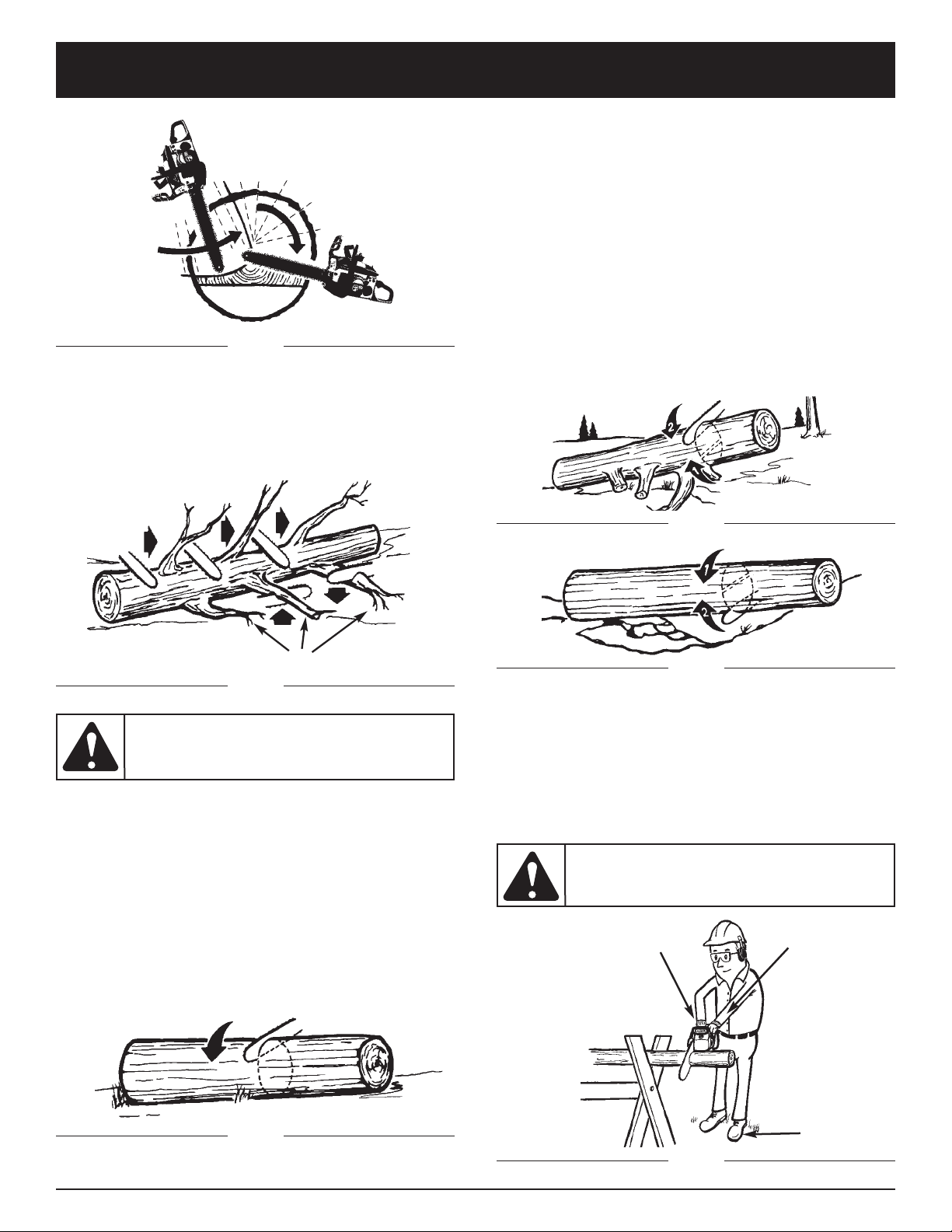

OPERATING INSTRUCTIONS

Fig. 11

LIMBING

Limbing a tree is the process of removing the branches

from a fallen tree. Do not remove supporting limbs (A)

until after the log is bucked (cut) into lengths (Fig. 12).

Branches under tension should be cut from the bottom

up to avoid binding the chain saw.

When bucking on a slope, always stand on the uphill side.

1. Log supported along entire length: Cut from top

(overbuck), being careful to avoid cutting into the

ground (Fig. 13).

2. Log supported on 1 end: First, cut from bottom

(underbuck) 1/3 diameter of log to avoid splintering.

Second, cut from above (overbuck) to meet first cut

and avoid pinching (Fig. 14).

3. Log supported on both ends: First, overbuck 1/3

diameter of log to avoid splintering. Second, underbuck

to meet first cut and avoid pinching (Fig. 15).

NOTE: The best way to hold a log while bucking is to use

a sawhorse. When this is not possible, the log

should be raised and supported by the limb

stumps or by using supporting logs. Be sure the

log being cut is securely supported.

Fig. 14

A

Fig. 12

WARNING:

tree trunk.

Never cut tree limbs

while standing on a

BUCKING

Bucking is cutting a fallen log into lengths. Make sure

you have a good footing and stand uphill of the log when

cutting on sloping ground. If possible, the log should be

supported so that the end to be cut off is not resting on

the ground. If the log is supported at both ends and you

must cut in the middle, make a downward cut halfway

through the log and then make the undercut. This will

prevent the log from pinching the bar and chain. Be

careful that the chain does not cut into the ground when

bucking as this causes rapid dulling of the chain.

Fig. 15

BUCKING USING A SAWHORSE

For personal safety and ease of cutting, the correct

position for vertical bucking is essential (Fig. 16).

A. Hold the saw firmly with both hands and keep the

saw to the right of your body while cutting.

B. Keep the left arm as straight as possible.

C. Keep weight on both feet.

CAUTION:

chain and bar are being properly lubricated.

A

While the saw is

cutting, be sure the

B

Fig. 13

C

Fig. 16

12

Page 13

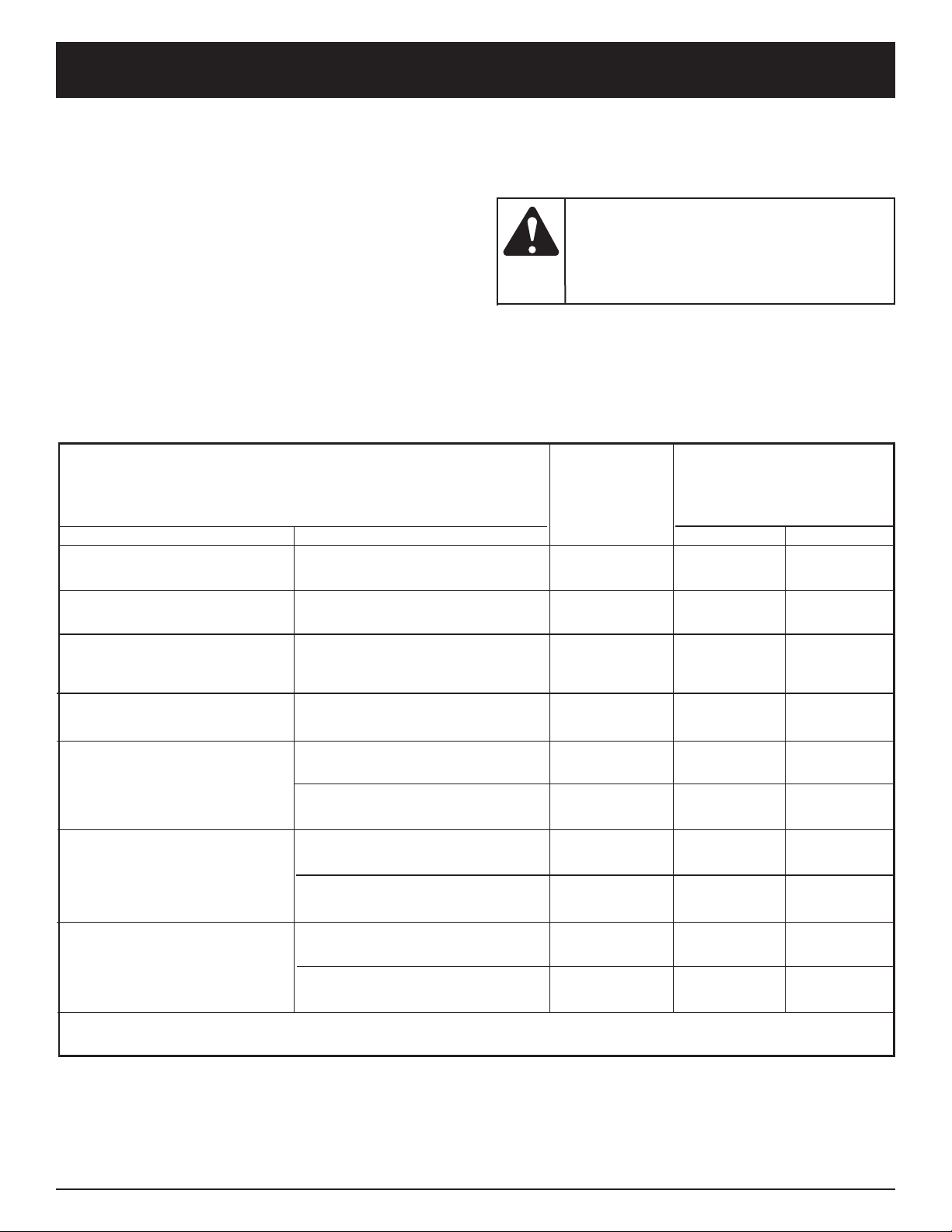

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should

also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about

these procedures take your unit to any non-road

engine repair establishment, individual or

authorized service dealer.

NOTE: Maintenance, replacement, or repair of the

emission control devices and system may be

performed by any non-road engine repair

establishment, individual or authorized service

dealer.

WARNING:

To prevent serious

injury, never perform

maintenance or repairs with unit running.

Always service and repair a cool unit.

Disconnect the spark plug wire to ensure that

the unit cannot start.

A good preventive maintenance program of regular inspection and care will increase life and improve performance of

your chain saw. This maintenance checklist is a guide for such a program.

Cleaning, adjustment, and part replacement may be required, under certain conditions, at more frequent intervals than

those indicated.

MAINTENANCE CHECKLIST

LISTES DES VERIFICATIONS D’ENTRETIEN

LISTA DE VERIFICACION DEL MANTENIMIENTO

ITEM / PIECE / PARTE

SCREWS / NUTS / BOLTS

VIS / ECROUS / BOULONS

TORNILLOS / TUERCAS / PERNOS

AIR FILTER

FILTRE A AIR

FILTRO DE AIRE

FUEL FILTER / OIL FILTER

FILTRE ESSENCE / FILTRE A HUILE

FILTRO DEL COMBUSTIBLE /

FILTRO DE ACEITE

SPARK PLUG

BOUGIE

BUJIA DE ENCENDIDO

SPARK ARRESTER SCREEN

ECRAN PARE-ETINCELLES

PANTALLA DEL PARACHISPAS

FUEL HOSES

DURITS D’ESSENCE

MANGUERAS DE COMBUSTIBLE

CHAIN BRAKE®COMPONENTS

COMPOSANTS DE CHAIN BRAKE

COMPONENTES DEL CHAIN BRAKE

*Recommended for Maintenance by an Authorized Service Center Technician.

*Il est recommandé de confier ces opérations à un technicien agréé.

*Recomendamos que el Centro de Servicio Autorizado proporcione el mantenimiento.

®

®

ACTION / ACTION / ACCION

INSPECT / TIGHTEN

INSPECTER / RESSERRER

INSPECCIONAR / APRETAR

CLEAN OR REPLACE

NETTOYER OU REMPLACER

LIMPIAR O REEMPLAZAR

REPLACE

REMPLACER

REEMPLAZAR

CLEAN / ADJUST / REPLACE

NETTOYER / REGLER / REMPLACER

LIMPIAR / AJUSTAR / REEMPLAZAR

INSPECT

INSPECTER

INSPECCIONAR

REPLACE AS REQUIRED

REMPLACER SUIVANT LES BESOINS

REEMPLAZAR SEGUN SE REQUIERA

INSPECT

INSPECTER

INSPECCIONAR

*REPLACE AS REQUIRED

*REMPLACER SUIVANT LES BESOINS

*REEMPLAZAR SEGUN SE REQUIERA

INSPECT

INSPECTER

INSPECCIONAR

*REPLACE AS REQUIRED

*REMPLACER SUIVANT LES BESOINS

*REEMPLAZAR SEGUN SE REQUIERA

EACH USE

CHAQUE

USAGE

CADA USO

✔

✔

✔

✔

HOURS OF

OPERATION

HEURES

D’OPERATION

HORAS DE OPERACION

10

20

✔

✔

✔

✔

13

Page 14

MAINTENANCE AND REPAIR INSTRUCTIONS MAINTENANCE AND REPAIR INSTRUCTIONS

REMOVING AND INST ALLING THE GUIDE BAR

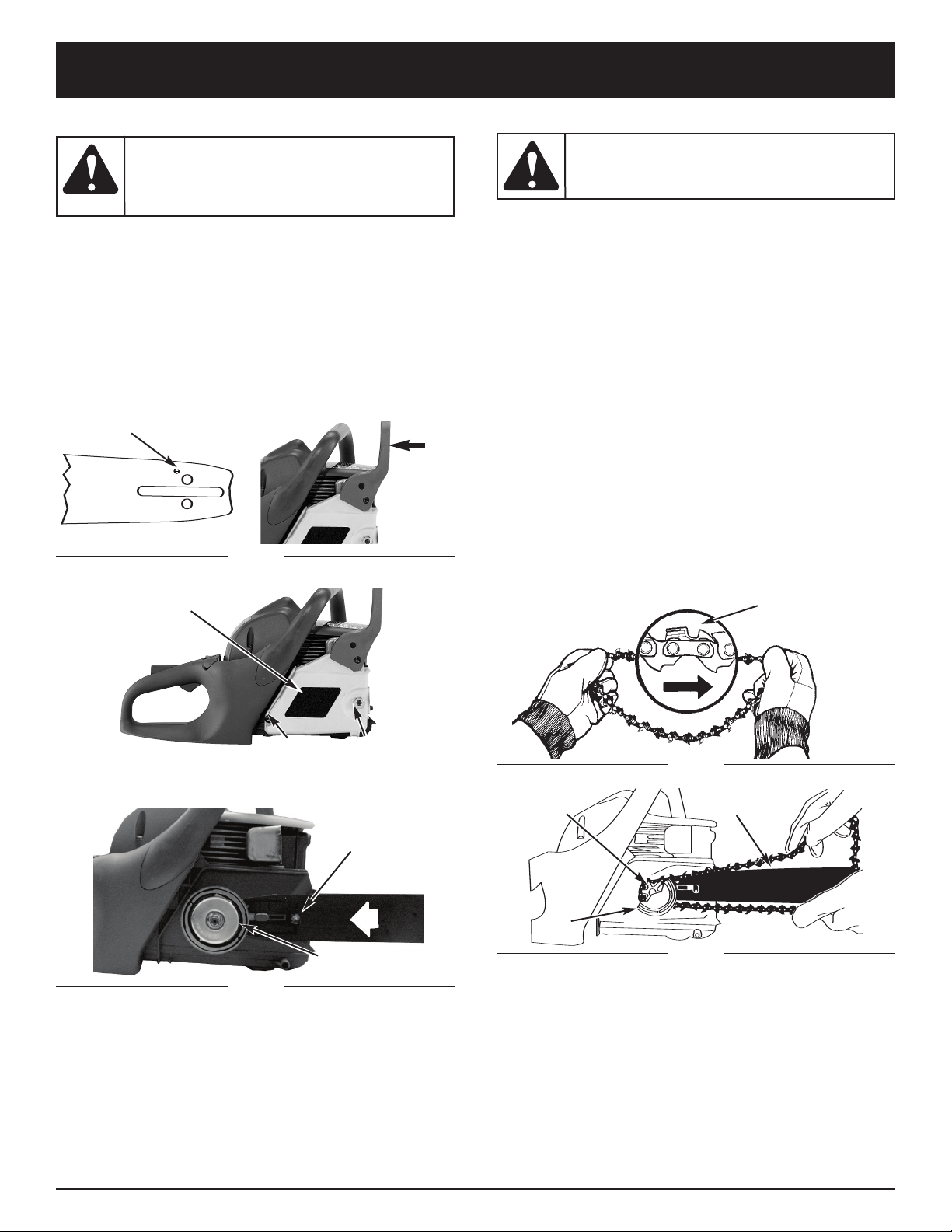

CAUTION:

USE THE ORIGINAL STYLE BAR with the oil

passage hole (A) as illustrated in Fig. 17.

1. Make sure the Chain Brake®lever is pulled back into

the DISENGAGED position (Fig. 17).

2. Remove the bar retaining nut (B1) and the screw (B2)

at rear of clutch cover (C). Remove clutch cover (C)

by pulling straight out, some force may be required.

(Fig. 18). Remove bar and chain.

3. To install bar, place the slotted end of the guide bar

over the bar bolt (F). Slide guide bar behind clutch

drum (G) until the guide bar stops (Fig. 19).

A

Fig. 17

To ensure the bar and

chain receive oil, ONLY

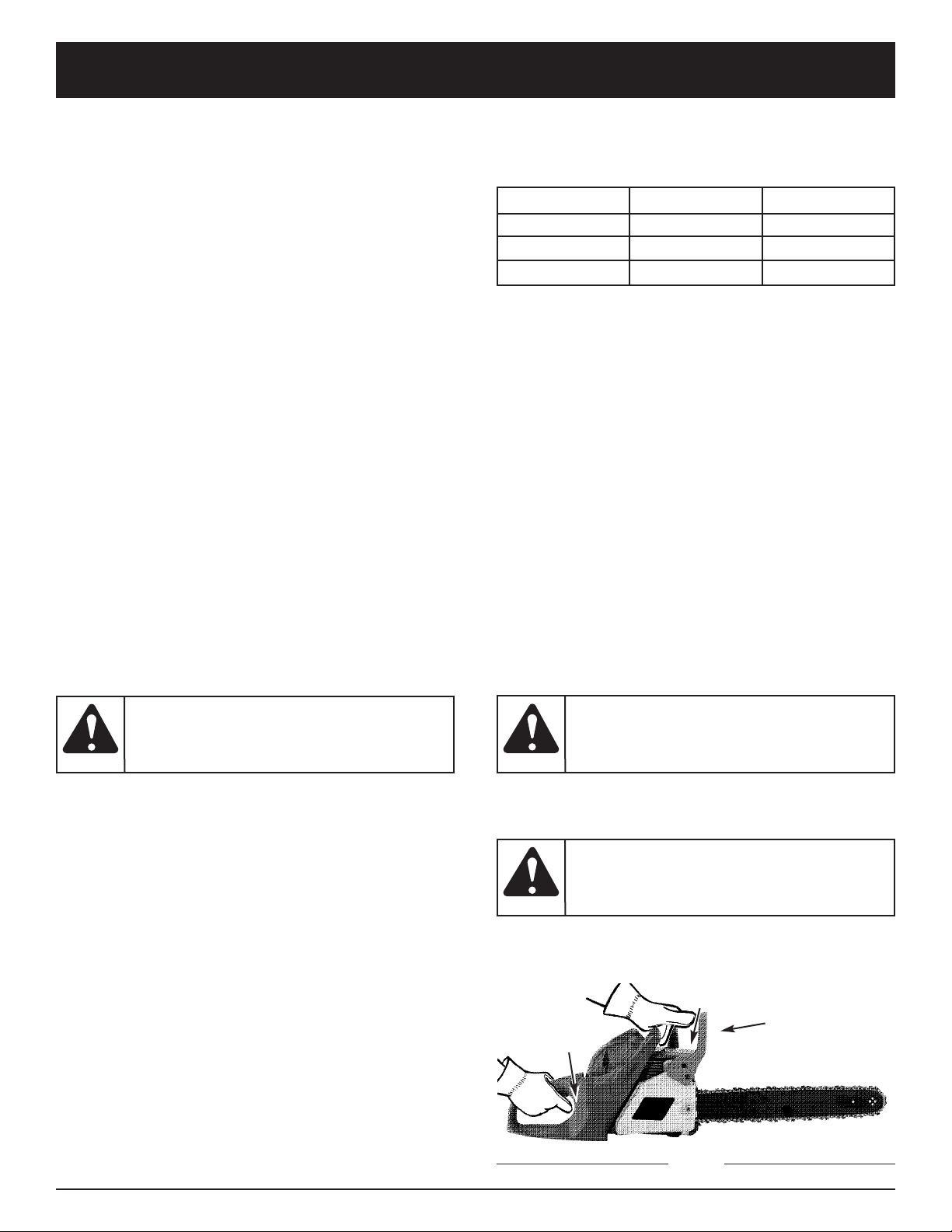

INSTALLING A CHAIN

WARNING:

when handling the saw chain.

1. Spread chain out in a loop with cutting edges (A)

pointing CLOCKWISE around loop (Fig. 20).

2. Slip the chain around the sprocket (B) behind the

clutch (C). Make sure the links fit between the

sprocket teeth (Fig. 21).

3. Guide the drive links into the groove (D) and around

the end of the bar (Fig. 21).

NOTE: The saw chain may droop slightly on the lower

part of bar. This is normal.

4. Pull guide bar forward until chain is snug. Ensure all

drive links are in the bar groove.

5. Install the clutch cover. Make sure the chain does

not slip off of the bar. Install the bar retaining nut

hand tight and follow tension adjustment instructions

in the next section. Replace screw at rear of clutch

cover.

NOTE: The guide bar retaining nut is installed only hand

tight at this point because saw chain adjustment

is required. Follow instructions in Saw Chain

Tension Adjustment.

Always use

protective gloves

C

B2

Fig. 18

Fig. 19

B1

Fig. 20

B

F

C

G

Fig. 21

A

D

14

Page 15

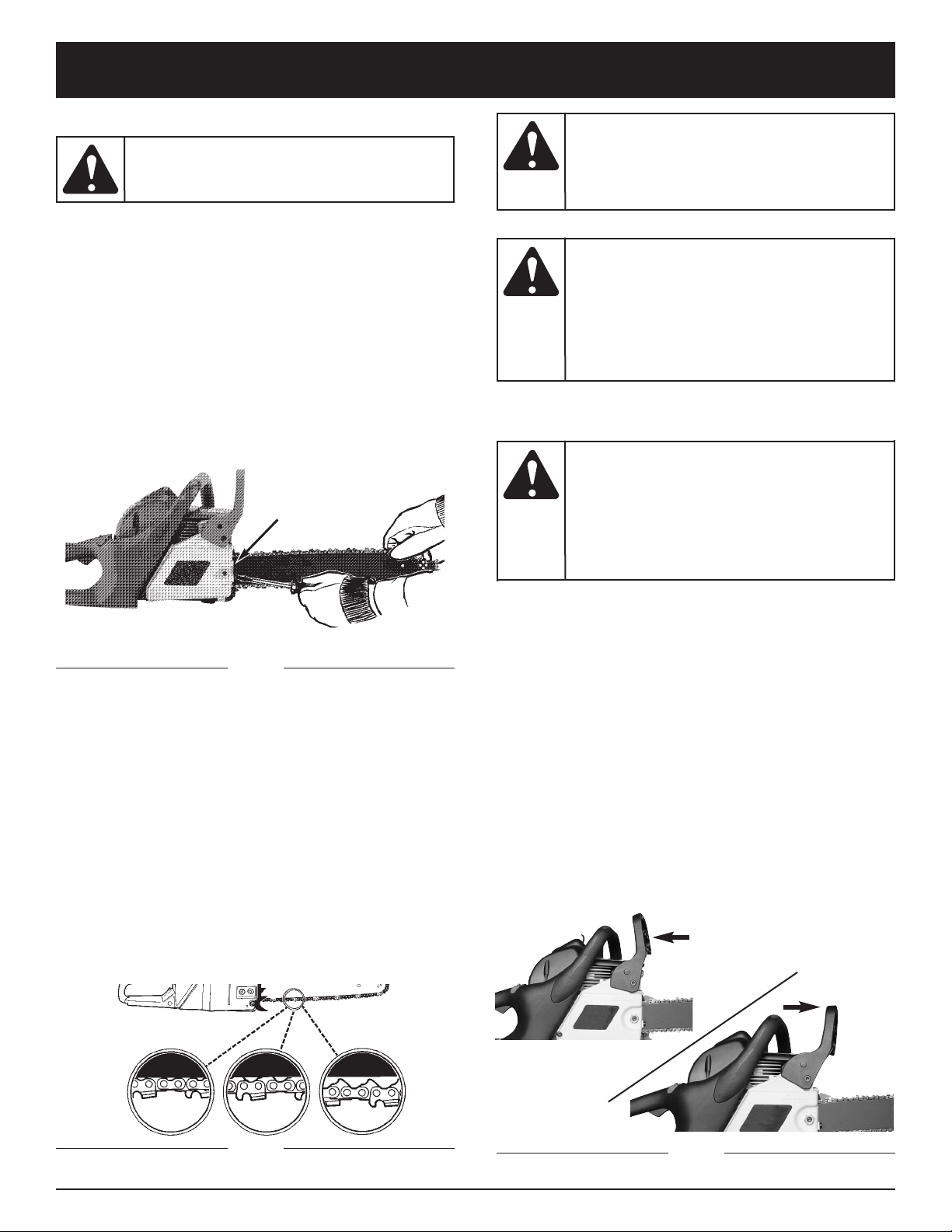

SAW CHAIN TENSION ADJUSTMENT

WARNING:

when handling the saw chain.

Proper tension of saw chain is extremely important and

must be checked before starting, as well as during any

cutting operation.

Taking the time to make needed adjustments to the saw

chain will result in improved cutting performance and

prolonged chain life.

To adjust the saw chain:

1. Loosen bar nut, hold nose of guide bar up and turn

adjustment screw (D) CLOCKWISE to increase chain

tension. Turning screw COUNTERCLOCKWISE will

decrease amount of tension on chain. Ensure the cha i n

fits snugly all the way around the guide bar (Fig. 22).

Always use

protective gloves

CAUTION:

adjustment after as few as 5 cuts. This is normal

with a new chain, and the interval between

future adjustments will lengthen quickly.

CAUTION:

TIGHT, the sprocket, bar, chain, and

crankshaft bearings will wear more rapidly.

Study Fig. 23 for information concerning

correct cold tension (A), correct warm

tension (B), and as a guide for when saw

chain needs adjusdjtment (C).

A new saw chain

stretches, requiring

saw chain is TOO

LOOSE or TOO

CHAIN BRAKE MECHANICAL TEST

D

Fig. 22

2. After making adjustment, and while still holding nose

of bar in the uppermost position, tighten the bar

retaining nut securely. Chain has proper tension

when it has a snug fit all around and can be pulled

around by gloved hand.

NOTE: If chain is difficult to rotate on guide bar or if it

binds, too much tension has been applied. This

requires minor adjustment as follows:

A.

Loosen the bar retaining nut so it is finger tight.

Decrease tension by turning the bar adjustment

screw COUNTERCLOCKWISE slowly. Move chain

back and forth on bar. Continue to adjust until chain

rotates freely, but fits snugly. Increase tension by

turning bar adjustment screw CLOCKWISE.

B. When saw chain has proper tension, hold nose of bar

in uppermost position and tighten the bar retaining

nut securely.

WARNING:

reduce the possibility of injury due to

kickback; however, it cannot provide the

intended measure of protection if the saw is

operated carelessly.

Always test the Chain Brake

your saw and periodically while on the job.

Your chain saw is equipped with a Chain Brake®that

reduces possibility of injury due to kickback. The brake

is activated if pressure is applied against brake lever

when, as in the event of kickback, operator’s hand

strikes the lever. When the brake is actuated, chain

movement stops abruptly.

To Test the Chain Brake®:

1. The Chain Brake®is DISENGAGED (chain can move)

when BRAKE LEVER IS PULLED BACK AND

LOCKED (A, Fig. 24).

2. The Chain Brake®is ENGAGED (chain is stopped)

when brake lever is in forward position. You should

not be able to move chain (B, Fig. 24).

NOTE: The brake lever should snap into both positions.

If strong resistance is felt, or lever does not move

into either position, do not use your saw. Take it

immediately to a Authorized Service Center for

repair. Call 1-800-520-5520 for more information.

The purpose of the

Chain Brake

®

®

is to

before using

A

A

B

Fig. 23

B

C

Fig. 24

15

Page 16

MAINTENANCE AND REPAIR INSTRUCTIONS

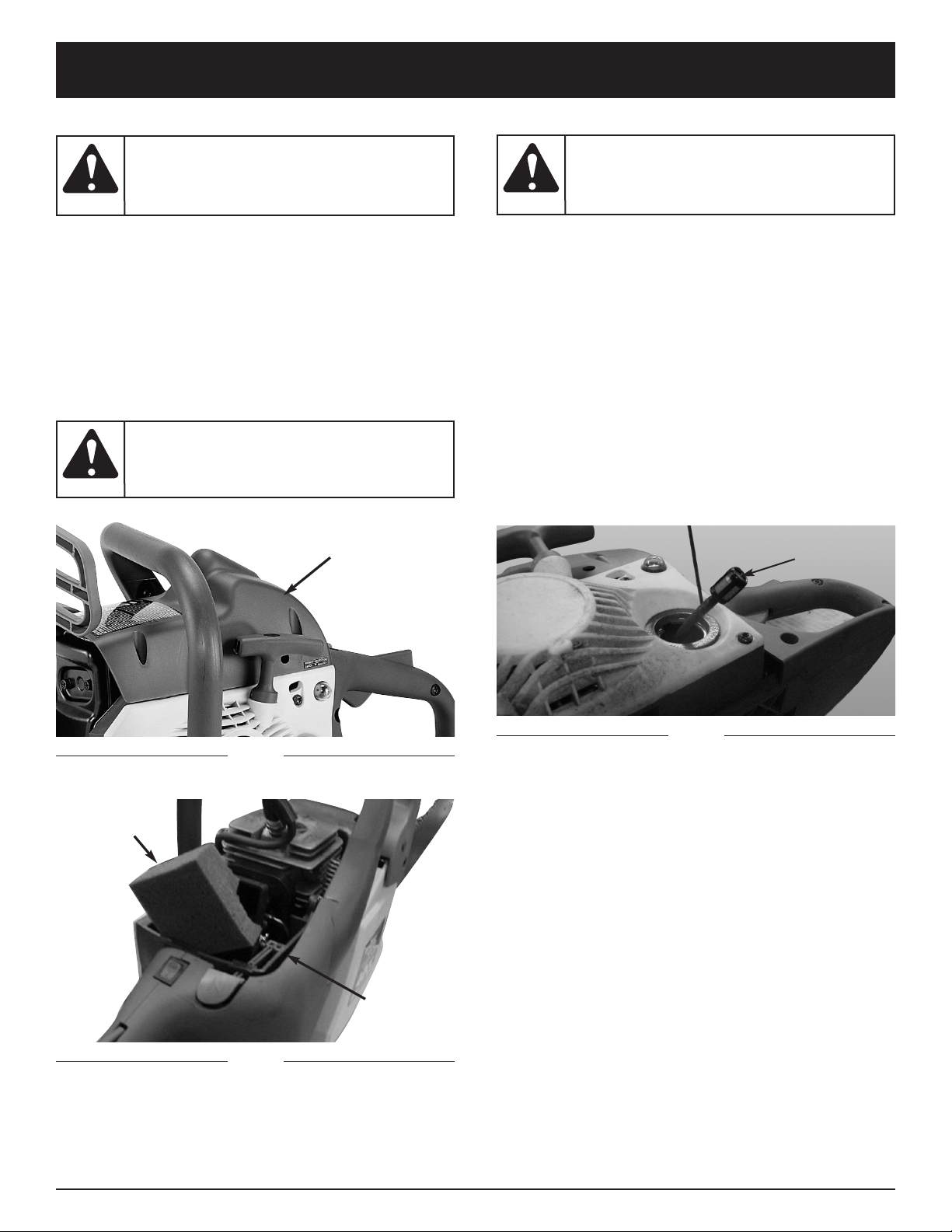

AIR FILTER

CAUTION:

Dust and dirt wil be drawn into engine and

damage it. Keep the air filter clean.

1. Remove the top cover (A) by loosening the cover

retaining screws. Cover will lift off (Fig. 25).

2. Lift the air filter (B) out of air-box (C) (Fig. 26).

3. Clean air filter. Wash filter in clean, warm, soapy

water. Rinse in clear, cool water. Air dry completely.

NOTE: It is advisable to have a supply of spare filters.

4. Install air filter. Install engine / air filter cover. Make

sure cover fits properly. Tighten the cover retaining

screws securely.

WARNING:

always turn your unit off and allow it to cool

before you clean or service it.

Never operate saw

without the air filter.

o avoid serious

T

personal injury ,

A

FUEL FILTER

CAUTION:

The fuel filter should be replaced after each 20

hours of use. Drain fuel tank before changing.

1. Remove the fuel tank cap.

2. Bend a piece of soft wire.

3. Reach into fuel tank opening and hook fuel line.

Carefully pull the fuel line toward the opening until

you can reach it with your fingers.

NOTE: Do not pull hose completely out of tank.

4. Lift filter (A) out of tank (Fig. 27).

5. Pull filter off with a twisting motion. Discard filter.

6. Install new filter. Insert end of filter into tank opening.

Make sure filter sits in bottom corner of tank. Use a

long handle screwdriver to aid in filter placement if

necessary.

7. Fill tank with fresh fuel / oil mixture. See Oil and Fuel

Information page 9. Install fuel cap.

Never operate saw

without the fuel filter.

A

Fig. 27

Fig. 25

B

C

Fig. 26

16

Page 17

MAINTENANCE AND REPAIR INSTRUCTIONS

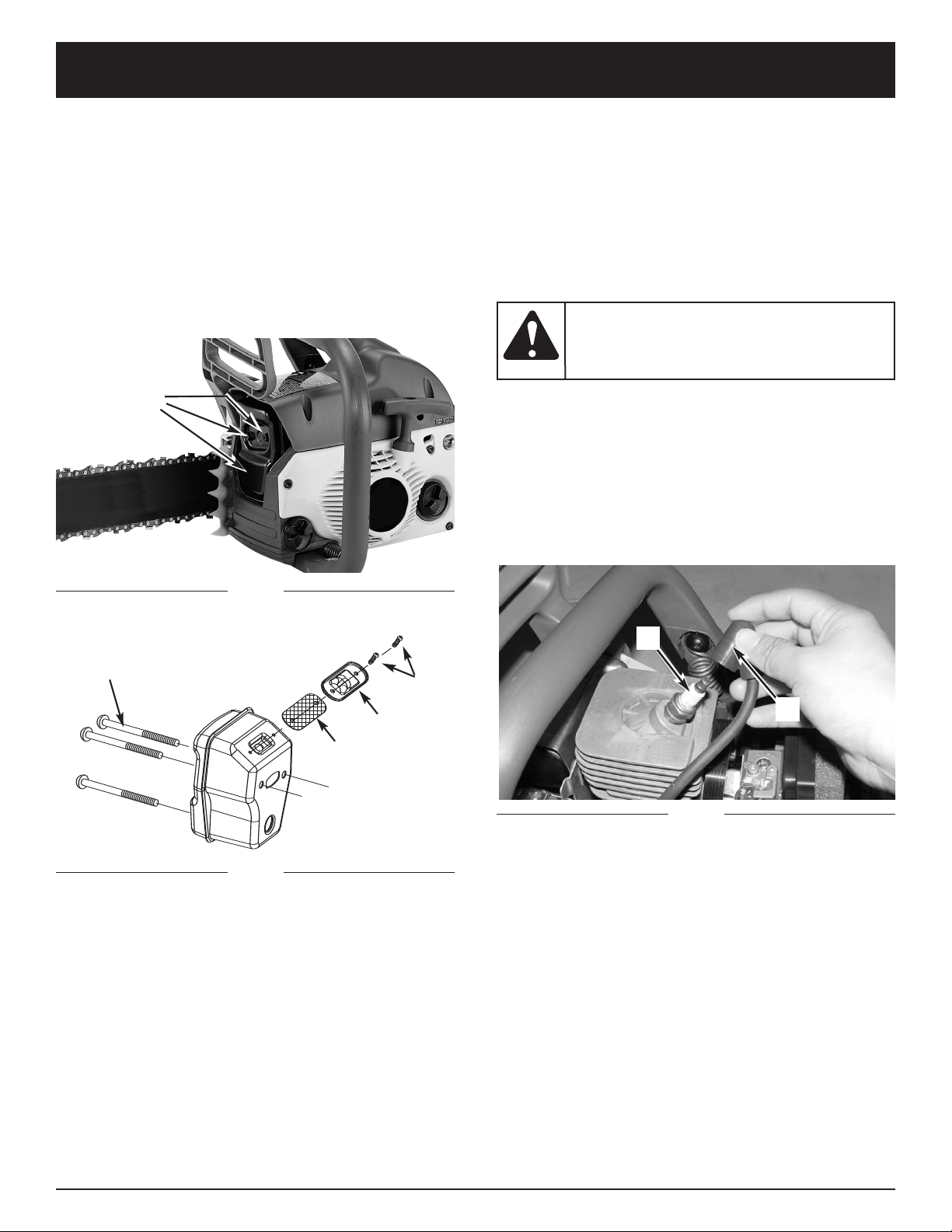

SPARK ARRESTER SCREEN

NOTE: A clogged spark arrester screen will dramatically

reduce engine performance.

Remove the 3 bolts (A) and pull muffler out. (Fig. 28).

1.

2. Remove the 2 screws (B) that hold the spark arrester

cover (C) (Fig. 29).

3. Discard the used spark arrester screen (D) and

replace it with a new one.

4. Reasemble the muffler components and install the

muffler to the cylinder. Tighten securely.

A

SPARK PLUG

NOTE: For efficient operation of saw engine, spark plug

must be kept clean and properly gapped.

Push STOP switch down.

1.

2. Remove air cleaner cover.

3. Disconnect the wire connector (G) from the spark plug

(H) by pulling and twisting at the same time (Fig. 30).

4. Remove spark plug with spark plug socket wrench.

DO NOT USE ANY OTHER TOOL.

WARNING:

electrodes. Grit in the engine could damage

the cylinder.

5. Check electtrode gaps with wire feeler gauge and set

gaps to .025” (.635mm) if necessary.

6. Reinstall a new spark plug.

NOTE: A resistor spark plug must be used for

replacement (part no. 9295-310502).

NOTE: This spark ignition system meets all requirements

of the Canadian Interferen-Causing Equipment

Regulations.

Do not sand blast,

scrape or clean

Fig. 28

H

A

B

G

Fig. 29

C

D

Fig. 30

CARBURETOR ADJUSTMENT

The carburetor was pre-set at the factory for optimum

performance. If further adjustments are necessary,

please take your unit to the nearest Authorized Service

Center listed in the Yellow Pages. Call 1-800-345-8746

for more information.

17

Page 18

MAINTENANCE AND REPAIR INSTRUCTIONS

STORING A CHAIN SAW

CAUTION:

Never stor

saw for longer than

30 days without performing the following

procedures.

Storing a chain saw for longer than 30 days requires

storage maintenance. Unless the storage instructions are

followed, fuel remaining in the carburetor will evaporate,

leaving gum-like deposits. This could lead to difficult

starting and result in costly repairs.

1. Remove the fuel tank cap slowly to release any

pressure in tank. Carefully drain the fuel tank.

2. Start the engine and let it run until the unit stops to

remove fuel from carburetor.

3. Allow the engine to cool (approx. 5 minutes).

4. Using a spark plug wrench, remove the spark plug.

5. Pour 1 teaspoon of clean 2-cycle oil into the

combustion chamber. Pull starter rope slowly several

times to coat internal components. Replace spark

plug (Fig. 31).

NOTE: Store the unit in a dry place and away from

possible sources of ignition such as a furnace,

gas hot water heater, gas dryer, etc.

e a chain

Sprocket Tip Lubrication

CAUTION:

The spr

your new saw has

ocket tip on

been pre-lubricated at the factory. Failure to

lubricate the guide bar sprocket tip as

explained below will result in poor

performance and seizure, voiding the

manufacturer’s warranty.

Lubrication of the sprocket tip is

recommended after 10 hours of use or

once a week, which ever occurs first.

Always thoroughly clean guide bar sprocket

tip before lubrication.

The Lube Gun (optional) is recommended for applying

grease to the guide bar sprocket tip. The Lube Gun is

equipped with a needle nose tip which is necessary for

the efficient application of grease to the sprocket tip.

Fig. 31

REMOVING A UNIT FROM STORAGE

1. Remove spark plug.

2. Pull starter rope briskly to clear excess oil from

combustion chamber.

3. Clean and gap spark plug or install a new spark plug

with proper gap.

4. Prepare unit for operation.

5. Fill fuel tank with proper fuel / oil mixture. See Oil

and Fuel Information.

GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar (railed bar which

supports and carries the saw chain) sprocket tip is

required. Proper maintenance of the guide bar, as

explained in this section, is essential to keep your saw in

good working condition.

Fig. 32

To lubricate the sprocket tip:

1. Move the STOP switch down.

NOTE: It is not necessary to remove the saw chain to

2. Clean the guide bar sprocket tip.

3. Using the Lube Gun (optional), insert tip of lube gun

4.

lubricate the guide bar sprocket tip. Lubrication

can be done on the job.

into the lubrication hole and inject grease until it

appears at outside edge of sprocket tip (Fig. 32).

Rotate saw chain by hand. Repeat lubrication procedure

until the entire sprocket tip has been greased.

SAW CHAIN / BAR LUBRICATION

Adequate lubrication of the saw chain is essential at all

times to minimize friction with the guide bar.

Never starve the bar and chain of oil. Running the saw

with too little oil will decrease cutting efficiency, shorten

saw chain life, cause rapid dulling of chain, and cause

excessive wear of bar from overheating. Too little oil is

evidenced by smoke, bar discoloration or pitch build-up.

NOTE: Saw chain stretches during use, particularly when

it is new, and it will occasionally be necessary to

adjust and tighten it. New chain will require

adjustment after about 5 minutes of operation.

AUTOMATIC OILER

Your chain saw is equipped with an automatic gear driven

oiler system. The oiler automatically delivers the proper

amount of oil to the bar and chain. As the engine speed

increases, so does the oil flow to the bar pad. There is no

flow adjustment. The oil reservoir will run out at

approximately the same time as the fuel supply runs out.

18

Page 19

MAINTENANCE AND REPAIR INSTRUCTIONS

GUIDE BAR MAINTENANCE:

Most guide bar problems can be prevented merely by

keeping the chain saw well maintained.

Insufficient guide bar lubrication and operating the saw

with chain that is too tight will contribute to rapid bar wear.

To help minimize bar wear, the following guide bar

maintenance procedures are recommended.

BAR WEAR - Turn guide bar frequently at regular

intervals (for example, after 5 hours of use), to ensure

even wear on top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and

carry the chain) should be cleaned if saw has been used

heavily or if saw chain appears dirty. Rails should always

be cleaned every time saw chain is removed.

OIL PASSAGES - Oil passages on the bar should be

cleaned to ensure proper lubrication of the bar and chain

during operation.

NOTE: The condition of the oil passages can be easily

checked. If the passages are clear, the chain will

automatically give off a spray of oil within

seconds of starting the saw. Your saw is

equipped with an automatic oiler system.

CHAIN MAINTENANCE

Chain Tension

Check the chain tension frequently and adjust as often as

necessary to keep the chain snug on the bar, but loose

enough to be pulled around by hand.

Breaking in a New Saw Chain

A new chain and bar will need chain readjustment after

as few as 5 cuts. This is normal during the break-in

period, and the interval between future adjustments will

begin to lengthen quickly.

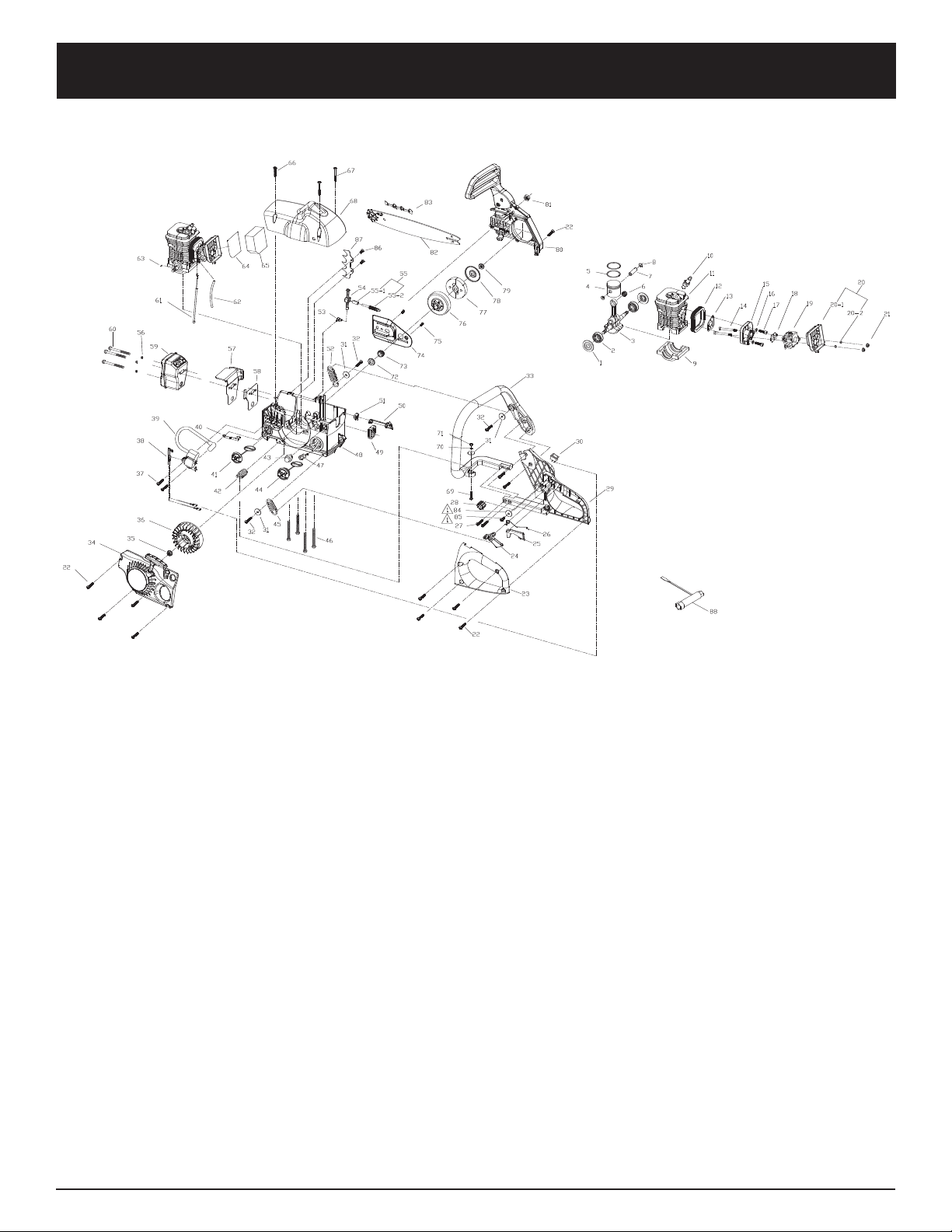

CHAIN REPLACEMENT INFORMATION

There may be other quality equivalent replacement

components for achieving kickback protection.

Bar Length Drive Links

14” Bar 49 DL

16” Bar 54 DL

18” Bar 60 DL

Part Number

6220-210803

6220-210816

6220-210805

INERTIA CHAIN BRAKE®ACTION

NOTE: THIS SAW IS EQUIPPED WITH AN INERTIA

CHAIN BRAKE. IF THE SAW KICKS BACK

WHILE IN USE, THE INERTIA OF THE MOVING

SAW WILL ACTIVATE THE BRAKE. A BRAKE

BAND AROUND THE CLUTCH DRUM

ACTIVATES AND STOPS THE MOVING CHAIN.

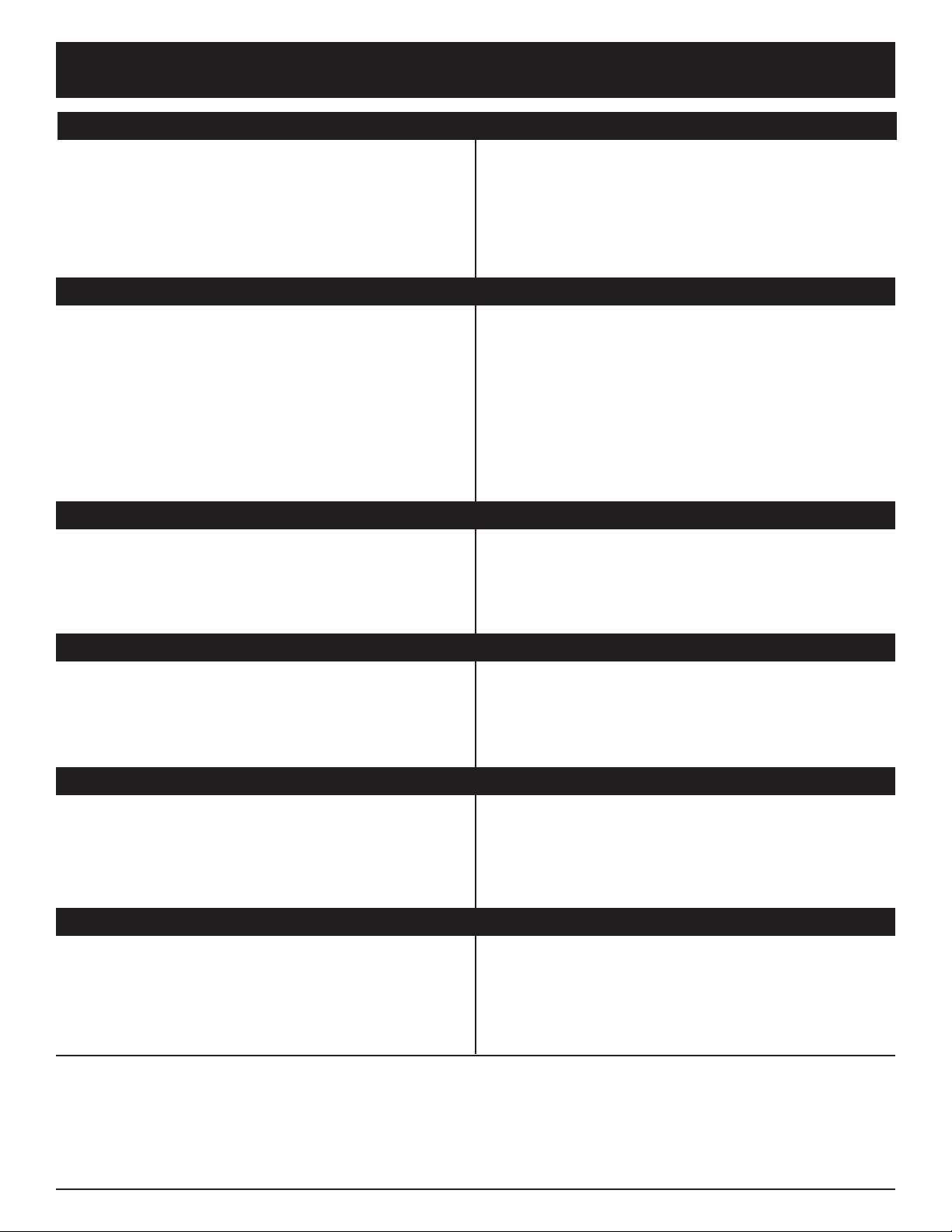

CHAIN BRAKE®OPERATIONAL TEST

Test the Chain Brake®periodically to ensure proper

function.

Perform a Chain Brake®test prior to initial cutting,

following extensive cutting, and definitely following any

Chain Brake®service. Test the Chain Brake:

1. Place saw on a clear, firm, flat surface.

2. Start engine.

3. Grasp the rear handle (A) with your right hand (Fig. 33).

4. With your left hand, hold the front handle (B) [not

Chain Brake

5. Squeeze the throttle trigger to 1/3 throttle, then

immediately activate the Chain Brake®lever (C) (Fig. 33).

®

lever (C)] firmly (Fig. 33).

WARNING:

removed from a loop of chain. This could

cause damage to the sprocket.

Never have more

than 3 links

Chain Lubrication

Always make sure the automatic oiler system is working

properly. Keep the oil tank filled with Genuine Factory

Parts Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cutting

operations is essential to minimize friction with the guide bar.

Never starve the bar and chain of lubricating oil. Running

the saw dry or with too little oil will decrease cutting

efficiency, shorten saw chain life, cause rapid dulling of

chain, and lead to excessive wear of bar from

overheating. Too little oil is evidenced by smoke or bar

discoloration.

Chain Sharpening

Chain sharpening requires special tools to ensure that

cutters are sharpened at the correct angle and depth. For

the inexperienced chain saw user, we recommend that

the saw chain be professionally sharpened by the

nearest Authorized Service Center. If you feel

comfortable sharpening your own saw chain, special

tools are available from your Authorized Service Center.

Activate the Chain

WARNING:

deliberately. Keep the chain from touching

anything; don’t let the saw tip forward.

6. Chain should stop abruptly. When it does,

immediately release the throttle trigger.

WARNING:

and take your unit to the nearest Authorized

Service Center for service.

7. If Chain Brake®functions properly, turn the engine off

and return the Chain Brake®to the DISENGAGED

position.

B

A

®

Brake

If chain does not

stop, tur

slowly and

n engine of

C

f

19

Fig. 33

Page 20

TROUBLESHOOTING

UNIT WON’T START OR STARTS BUT WILL NOT RUN

CAUSE ACTION

Incorrect starting procedures Follow instructions in the Starting/Stopping section

Incorrect carburetor mixture adjustment setting Have carburetor adjusted by Authorized Service Center

Fouled spark plug Clean / gap or replace plug

UNIT STARTS, BUT ENGINE HAS LOW POWER

CAUSE ACTION

Fuel filter is plugged Replace the fuel filter

Incorrect lever position Move to RUN position

Dirty spark arrester screen Replace spark arrester screen.

Dirty air filter

Incorrect carburetor mixture adjustment setting Have carburetor adjusted by Authorized Service Center

ENGINE HESITATES

Remove, clean and reinstall filter.

CAUSE ACTION

Incorrect carburetor mixture adjustment setting Have carburetor adjusted by Authorized Service Center

NO POWER UNDER LOAD

CAUSE ACTION

Incorrect carburetor mixture adjustment setting Have carburetor adjusted by Authorized Service Center

RUNS ERATICALLY

CAUSE ACTION

Incorrectly gapped spark plug Clean / gap or replace plug

SMOKES EXCESSIVELY

CAUSE ACTION

Incorrect carburetor mixture adjustment setting

Incorrect fuel mixture Use properly mixed fuel (40:1 mixture)

Have carburetor adjusted by Authorized Service Center

If further assistance is required, contact your authorized service dealer.

Call 1-800-345-8746 for more information.

20

Page 21

NOTES

21

Page 22

MODEL MTD1425NAV

ELTTORHT ,ELBAC205013-010916

R

EHSAW

1

2

-50-BFW9

1

3

G

NIRAEB ,PAC205013-75191

EPIP LEUF405013-921926

WERCS5

2

6.

0-

6

1

/

8Y

BKKS

92

3

GNIRAEB101026-BD92

YEK FFURDOOW100013-12293

6

TNORF ,E

LD

NA

H305013

-

8

60

9

3

3Y’SSA DOR/KNAR

C

505013-82293

HSE

M

2

05013-381946Y’SSA GNISUOH RE

TRATS

8

15

0

1

3-

8

2

29

4

3

NOTSIP

205013-09

294

RIA ,RETLIF105013-252956T

UN4

2

-61/5-

BAN

953NO

TSIP ,

GNIR205013-98195

WERCS1-61/8-YBKKS966LE

EHWYLF

1

0

50

13

-

9

61

9

6

3

N

OTSIP ,RE

LL

OR

014101K-

BN9

6

WERC

S

4.1-61/8YBKKS97

6

W

ER

C

S

0

2-

5

0-BEGS

9

73

NO

TSIP ,NIPHC-5.43-01-CP97

DUORHS905013-710986Y’S

SA

ERI

W

3

0

50

1

3-

0

1

0983

GNIR

3.01-AC

9

8

F105013-27

099

WERCS81-50YBKKS99

6Y’SS

A NOIT

ING

I

HC-20

50

1

3

-8

8

29

9

3

KNA

RC ,ESAC

TUN50-BAN907ETALP EVITCUDNOC105013-150904GULP KRAPS205013-592901

F

10

5

0

13

-29291

1

TLEF105013-75191

7

Y’SSA PA

C

L

IO

7

0

20

1

3-

8

2

29

14R

EDNILY

C

MR

OW3

05013-370927

Y’SSA

GNIRP

S

415013-8229

2

4

ROTAL

OSI ,REBBUR

205013-210

9

2

1

TSUD-ITNA ,PAC805013-710937REMIRP200013-241934RECAPS505013-280931

WERCS80-40BBADS647Y’SSA PAC LEUF602013-822944WERCS06-50-BDTS941

Y’SSA MUR

D

515013-822957

GN

IRP

S

605013

-4

2

0954RO

TERU

BRA

C

,ROTA

LOSI

40

5

0

13

-

2

80

95

1

Y’SSA HCTULC825013-822967W

ERC

S55-60-BAFS964

REH

SAW GNIRPS60-BSW

66

1

TSUD-ITNA ,PAC105013-770977RETLIF305013-281974WERCS52-60-BCAS971

TUN90-CHN987Y’SSA GNISUOH565013-822984RECAPS605013-280981

Y’SSA TIK EKAR

B

715013-822997ELBAC ,R

EDLOH

30

5

01

3

-2

1

09

9

4

ROTE

R

UB

RA

C

10

5

0

13

-

78

2

99

1

TUN81-61/5-ZAN908EKOHC ,REVEL015013-411905Y/SSA RETLIF RIA015013-822902

18" BARF335013-0409

16" BAR9040-310532F

18LEVEL EKOHC ,REDLOH405013-210915TUN50-ZHN912

18" CHAIN

508012-0226

16" CHAIN

6220-210816

2

8

GNIRP

S

705013-420925WERCS526.0-41/01YBKGS92

2

REHSAW31-5.4-BFW938

ROTCENNOC201013-421935TRAP TFEL ,ELDNA

H

105013-860932

WERCS01-40-BBKKS948

EPIP LIO105013-310945ELTTORHT ,REGGIRT205013-820942

WERCS5.0-61/8YBKKS958

Y’SSA PMUP625013-822955ESAELER ,REGGIRT105013-820952

RE

PMU

B DEKIP

S105013-72

2968

REH

SAW60-BSW665 GNIRPS

405013-42

096

2

HCNERW102013-240978

ELFFAB205013-280975WERCS86.0-41/01YBKKS972

REVOC RAB412013-710988

ELFFAB105013-280985 REBBUR101013-720982

ESAC YRRAC102013-021998

Y’SSA RELFFUM465013-822995RAER ,ELDNAH205013-860992

WERCS07-60-BDXS906HCTIWS105013-220903

No. Parts No. Description No. Parts No. Description No. Parts No. Description

ELTTORHT ,ELBAC205013-010916

R

EHSAW

1

2

-50-BFW9

1

3

G

NIRAEB ,PAC205013-75191

EPIP LEUF405013-921926

WERCS5

2

6.

0-

6

1

/

8Y

BKKS

92

3

GNIRAEB101026-BD92

YEK FFURDOOW100013-122936TNORF ,ELDNAH305013-860933Y’SSA DOR/KNARC505013-82293

HSEM205013-381946

Y

’SSA GNISUOH

R

ET

RATS2

0

9

0DM-

8

2

29

4

3

NOTSIP

205013-09

294

RIA ,RETLIF105013-252956T

UN4

2-61/5-BAN953NOTSIP ,GNIR205013-98195

WERCS1-61/8-YBKKS966LEEHWYLF105013-961963NOTSIP ,RELLOR014101K-BN96

WERCS4.1-61/8YBKKS976WERCS02-50-BEGS973NOTSIP ,NIPHC-5.43-01-CP97

DUORHS905013-710986Y’SSA

ERI

W305013-01

0983

GNIR

3.01-AC

9

8

F105013-27099 WERCS91-50-BKKS996Y’SSA NOITINGIHC-105013-882993KNARC ,ESAC

REHSAW GNIRPS50-BSW607ETALP EVITCUDNOC105013-150904GULP KRAPS205013-592901

F

105013-29291

1

TUN50-BAN917Y’SSA PAC LIO

7

02013-822914REDNILYC

TLEF105013-75192

7

ETALP XIF3001DM-3409

24

ROTAL

OSI ,REBBUR

205013-210921

MROW305013-370937REMIRP200013-241934RECAPS505013-280931

TSUD-ITNA ,PAC805013-710947Y’SSA PAC LEUF602013-822944WERCS06-50-BDTS941

WERCS80-40BBADS657ETALP XIF2001DM-340954ROTERUBRAC ,ROTA

LOSI

405013-280951

Y’SSA MURD515013-822967WERCS55-60-BAFS964REHSAW GNIRPS60-BSW661

Y’SSA HCTULC825013-822977RETLIF305013-281974WERCS52-60-BCAS971

TSUD-ITNA ,PAC105013-770987Y’SSA GNISUOH115013-822984RECAPS605013-280981

TUN90-CHN997ELBAC ,REDLOH305013-210994ROTERUBRA

C

105013-782991

Y’SSA TIK EKARB715013-822908)EULB DTM( EKOHC ,REVEL015013-411905Y/SSA RETLIF RIA015013-822902

TUN81-61/5-ZAN918LEVEL EKOHC ,REDLOH405013-210915TUN50-ZHN912

RAB

1

35013-040928

ETALP XI

F1001DM-340925WERCS526.0-41/01YBKGS92

2

NIAHC308012-022638ROTCENNOC201013-421935TRAP TFEL ,ELDNA

H

105013-860932

REHSAW31-5.4-BFW948EPIP LIO105013-310945ELTTORHT ,REGGIRT205013-820942

WERCS01-40-BBKKS958Y’SSA PMUP625013-822955ESAELER ,REGGIRT105013-820952

WERCS5.0-61/8YBKKS968

REH

SAW60-BSW665 GNIRPS

405013-42

096

2

REPMUB DEKIPS105013-722978ELFFAB205013-280975WERCS86.0-41/01YBKKS972

HCNERW102013-240988ELFFAB105013-280985 REBBUR101013-720982

Y’SSA RELFFUM745013-822995RAER ,ELDNAH205013-860992

WERCS07-60-BDXS906HCTIWS105013-220903

No. Parts No. Description No. Parts No. Description No. Parts No. Description

22

Page 23

PARTS LISTPARTS LIST

ELTTORHT ,ELBAC205013-010916

R

EHSAW

1

2

-50-BFW9

1

3

G

NIRAEB ,PAC205013-75191

EPIP LEUF405013-921926

WERCS5

2

6.

0-

6

1

/

8Y

BKKS

92

3

GNIRAEB101026-BD92

YEK FFURDOOW100013-12293

6

TNORF ,E

LD

NA

H305013

-

8

60

9

3

3Y’SSA DOR/KNAR

C

505013-82293

HSE

M

2

05013-381946Y’SSA GNISUOH RE

TRATS

8

15

0

1

3-

8

2

29

4

3

NOTSIP

205013-09

294

RIA ,RETLIF105013-252956T

UN4

2

-61/5-

BAN

953NO

TSIP ,

GNIR205013-98195

WERCS1-61/8-YBKKS966LE

EHWYLF

1

0

50

13

-

9

61

9

6

3

N

OTSIP ,RE

LL

OR

014101K-

BN9

6

WERC

S

4.1-61/8YBKKS97

6

W

ER

C

S

0

2-

5

0-BEGS

9

73

NO

TSIP ,NIPHC-5.43-01-CP97

DUORHS905013-710986Y’S

SA

ERI

W

3

0

50

1

3-

0

1

0983

GNIR

3.01-AC

9

8

F105013-27

099

WERCS81-50YBKKS99

6Y’SS

A NOIT

ING

I

HC-20

50

1

3

-8

8

29

9

3

KNA

RC ,ESAC

TUN50-BAN907ETALP EVITCUDNOC105013-150904GULP KRAPS205013-592901

F

10

5

0

13

-29291

1

TLEF105013-75191

7

Y’SSA PA

C

L

IO

7

0

20

1

3-

8

2

29

14R

EDNILY

C

MR

OW3

05013-370927

Y’SSA

GNIRP

S

415013-8229

2

4

ROTAL

OSI ,REBBUR

205013-210

9

2

1

TSUD-ITNA ,PAC805013-710937REMIRP200013-241934RECAPS505013-280931

WERCS80-40BBADS647Y’SSA PAC LEUF602013-822944WERCS06-50-BDTS941

Y’SSA MUR

D

515013-822957

GN

IRP

S

605013

-4

2

0954RO

TERU

BRA

C

,ROTA

LOSI

40

5

0

13

-

2

80

95

1

Y’SSA HCTULC825013-822967W

ERC

S55-60-BAFS964

REH

SAW GNIRPS60-BSW

66

1

TSUD-ITNA ,PAC105013-770977RETLIF305013-281974WERCS52-60-BCAS971

TUN90-CHN987Y’SSA GNISUOH565013-822984RECAPS605013-280981

Y’SSA TIK EKAR

B

715013-822997ELBAC ,R

EDLOH

30

5

01

3

-2

1

09

9

4

ROTE

R

UB

RA

C

10

5

0

13

-

78

2

99

1

TUN81-61/5-ZAN908EKOHC ,REVEL015013-411905Y/SSA RETLIF RIA015013-822902

18" BARF335013-0409

16" BAR9040-310532F

18LEVEL EKOHC ,REDLOH405013-210915TUN50-ZHN912

18" CHAIN

508012-0226

16" CHAIN

6220-210816

2

8

GNIRP

S

705013-420925WERCS526.0-41/01YBKGS92

2

REHSAW31-5.4-BFW938

ROTCENNOC201013-421935TRAP TFEL ,ELDNA

H

105013-860932

WERCS01-40-BBKKS948

EPIP LIO105013-310945ELTTORHT ,REGGIRT205013-820942

WERCS5.0-61/8YBKKS958

Y’SSA PMUP625013-822955ESAELER ,REGGIRT105013-820952

RE

PMU

B DEKIP

S105013-72

2968

REH

SAW60-BSW665 GNIRPS

405013-42

096

2

HCNERW102013-240978

ELFFAB205013-280975WERCS86.0-41/01YBKKS972

REVOC RAB412013-710988

ELFFAB105013-280985 REBBUR101013-720982

ESAC YRRAC102013-021998

Y’SSA RELFFUM465013-822995RAER ,ELDNAH205013-860992

WERCS07-60-BDXS906HCTIWS105013-220903

No. Parts No. Description No. Parts No. Description No. Parts No. Description

MODEL MTD1642AVCC / MTD1842AVCC

23

Page 24

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by MTD LLC

with respect to new merchandise purchased and used in

the United States and Canada, its possessions and

territories.

MTD LLC warrants this product against defects in material

and workmanship for a period of one (1) year commencing

on the date of original purchase and will, at its option, repair

or replace, free of charge, any part found to be defective in

material or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water or damage because

of other peril or natural disaster. Damage resulting from the

installation or use of any accessory or attachment not

approved by MTD LLC for use with the product(s) covered

by this manual will void your warranty as to any resulting

damage. This warranty is limited to ninety (90) days from

the date of original retail purchase for any MTD product that

is used for rental or commercial purposes, or any other

income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is

available, WITH PROOF OF PURCHASE THROUGH

YOUR LOCAL AUTHORIZED SERVICE DEALER. To locate

the dealer in your area, visit our website at www.troybilt.com,

check for a listing in the Yellow Pages, call 1-800-668-

1238 or write to

0019

.

This limited warranty does not provide coverage in

the following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments,

Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting

Line, Inner Reels, Starter Pulley, Starter Ropes, Drive

Belts

C. MTD LLC does not extend any warranty for products

sold or exported outside of the United States of

America and Canada , its possessions and

territories, except those sold through MTD’s

authorized channels of export distribution.

MTD LLC

design of any MTD Product without assuming any

obligation to modify any product previously manufactured.

P.O. Box 361131, Cleveland, OH 44136-

reserves the right to change or improve the

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind MTD LLC During the period of the

Warranty, the exclusive remedy is repair or

replacement of the product as set forth above. (Some

states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to

you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

LLC shall not be liable for incidental or consequential

loss or damages including, without limitation,

expenses incurred for substitute or replacement lawn

care services, for transportation or for related

expenses, or for rental expenses to temporarily

replace a warranted product. (Some states do not allow

limitations on how long an implied warranty lasts, so the

above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold.

Alteration of the safety features of the product shall void

this Warranty. You assume the risk and liability for loss,

damage, or injury to you and your property and/or to

others and their property arising out of the use or misuse

or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This warranty

gives you specific legal rights, and you may also have

other rights which vary from state to state.

To locate your nearest service dealer dial

1-800-668-1238.

MTD LLC

P.O. Box 361131

Cleveland, OH 44136-0019

24

Page 25

Page 26

S/N :

ITEM :

MODEL :

Manuel de L’utilisateur

Modèle De Scie De

Chaîne Du Gaz 42cc

MTD1425NAV

MTD1642AVCC

MTD1842AVCC

French

IMPORTANT: Lisez les règles et les instructions

de sûreté soigneusement

P/N 9096-310545 © 2005

IMPRIME AUX TAIWAN

Page 27

INTRODUCTION

S/N :

ITEM :

MODEL :

TOUS NOS REMERCIEMENTS

Nous vous remercions d'avoir acheté ce produit de

qualité. Cet outil mécanique de plein air moderne est

conçu pour vous rendre service pendant longtemps. Il

vous sauvera beaucoup de temps comme vous pourrez

vous en rendre compte. Ce manuel de l'utilisateur

comporte un mode d'emploi facile à comprendre. Prenez

soin de lire le manuel au complet et suivez toutes ses

instructions à la lettre afin de conserver votre nouvel outil

mécanique de plein air en excellent état de

fonctionnement.

RÉFÉRENCES, ILLUSTRATIONS ET

SPÉCIFICATIONS RELATIVES AU PRODUIT

Toutes les informations, illustrations et spécifications

contenues dans ce manuel tiennent compte des dernières

informations techniques disponibles au moment de

mettre sous presse. Nous nous réservons le droit d'y

apporter des modifications à tout moment, sans préavis.

Copyright© 2004 MTD SOUTHWEST INC., Tous droits

réservés.

NFORMATIONS D’ENTRETIEN

Tout entretien effectué sur cet appareil pendant et après

la période de garantie doit être fait par un concessionnaire agréé uniquement.

Obtenez la liste des concessionnaires agréés appelez le

1-800-668-1238.

NE RETOURNEZ PAS L'APPAREIL AU

DÉTAILLANT CHEZ QUI VOUS L'AVEZ

ACHETÉ. TOUT SERVICE SOUS GARANTIE

NÉCESSITE UNE PREUVE D'ACHAT.

Avant d'assembler votre nouvel équipement, repérez la

plaque signalétique de l'appareil et copiez ses

informations dans l'espace ci-dessous. Ces informations

sont essentielles si vous désirez obtenir de l'aide auprès

de notre service technique ou d'un distributeur agréé. Un

exemple de plaque signalétique est présenté ci-dessous.

Numéro de série

Numéro de modèle

Numéro de pièce mère

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . .26

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . .27

Informations sur l'huile et le carburant

Instructions de démarrage et d'arrêt . . . . . . . . . . .34

Mode d'emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Entretien et réparations . . . . . . . . . . . . . . . . . . . . .37

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Notas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Liste des Pièces . . . . . . . . . . . . . . . . . . . . . . . . . . .46-47

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

. . . . . . . . . .33

PARE-ÉTINCELLES

REMARQU E : à l'intention des utilisateurs opérant

dans les terres forestières des États-Unis et dans les

états de Californie, du Maine, de l'Orégon et de

Washington. Toutes les terres forestières des États-Unis

et de l'état de Californie (Codes sur les ressources

publiques 4442 et 4443), de l'Orégon et de Washington

exigent de par la loi que certains moteurs à combustion

interne utilisés dans des zones couvertes de taillis ou

d'herbe soient équipés d'un pare-étincelles en parfait état

de fonctionnement, ou qu'ils soient conçus, équipés et

entretenus pour la prévention des incendies. Renseignezvous auprès des autorités de votre province ou de votre

municipalité concernant la réglementation en vigueur.

Vous pourriez être passible d'une amende ou être tenu