Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Troubleshooting • Warranty

OperatOr’s Manual

123cc OHV Horizontal Shaft Engine

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-06051F

(September 25, 2015)

Page 2

To The Owner

Thank You

This Operator’s Manual is an important part of your new engine. It will help you prepare and maintain the engine for the best

performance. Please read and understand the contents before operating the engine.

Table of Contents

1

Safe Operation Practices ........................................ 3

Safety Labels............................................................ 5

Set-Up ....................................................................... 6

Controls & Features ................................................. 9

Operation ................................................................11

Maintenance ..........................................................14

Troubleshooting .................................................... 20

Replacement Parts .................................................21

Warranty ................................................................ 22

Spanish ................................................................... 24

Record Product Information

Before operating your new engine, please locate the model plate on the engine and record the information in the provided area

below. This information will be necessary, should you seek technical support via our web site or with your local dealer.

Model NuMber/Serial NuMber

/

Customer Support

Please do NOT return the machine to the retailer or dealer without first contacting our Customer Support Department.

If you have difficulty with this product or have any questions regarding the controls, operation, or maintenance of this

engine, you can seek help from the experts. Choose from the options below:

◊ Visit us on the web at www.mtdproducts.com

See How-to Maintenance and Parts Installation Videos at www.mtdparts.com/KnowledgeCenter

◊ Call a Customer Support Representative at (800) 800-7310 or (330) 220-4683

◊ Write us at MTD LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

2

Page 3

Important Safe Operation Practices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate the equipment. Failure to

comply with these instructions may result in personal injury. When you see this symbol.

HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

DANGER! This machine was built to be operated according to the safe operation practices

in this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing foreign objects. Failure to observe the following safety

instructions could result in serious injury or death.

2

Training

1. Read, understand and follow all instructions on the engine

and in the manual(s) before attempting to assemble and

operate. Keep this manual in a safe place for future and

regular reference and for ordering replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the engine and disengage them quickly.

3. Never allow children under 14 years of age to operate the

engine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and be trained and supervised by an adult.

4. Never allow adults to operate the machine without proper

instruction.

5. Keep the area of operation clear of all persons, particularly

small children and pets. Stop machine if anyone enters the

area.

Preparation

1. Thoroughly inspect the area where the equipment is to

be used. Remove all stones, sticks, wire and other foreign

objects which could be tripped over and cause personal

injury.

2. Wear sturdy, rough-soled work shoes and close fitting

slacks and shirts. Loose fitting clothes or jewelry can be

caught in the moving parts. Never operate the machine in

bare feet or sandals.

3. Disengage clutch levers and shift (if equipped) into neutral

(“N”) before starting the engine.

4. Never leave the engine running while unattended.

5. Never attempt to make any adjustments while the engine

is running, except where specifically recommended in the

operator’s manual.

Safe Handling of Gasoline:

To avoid personal injury or property damage, use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself and/or your clothes which can

ignite. Wash your skin and change clothes immediately.

1. When adding fuel, turn engine OFF and let engine cool at

least 2 minutes before removing the gas cap.

2. Fill fuel tank outdoors or in well ventilated area.

3. Use only an approved gasoline container.

4. Never fill containers inside a vehicle or on a truck or trailer

bed with a plastic liner. Always place containers on the

ground away from your vehicle before filling.

5. If possible, remove gas-powered equipment from the truck

or trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

6. Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do

not use a nozzle lock-open device.

3

Page 4

7. Do not overfill fuel tank. Fill tank to full as indicated by the

fuel level indicator installed inside of the fuel tank. Do not

over-fill to allow space for fuel expansion. On some models,

a fuel level indicator may NOT be present, in this instance,

fill the tank no more than 1/2 inch below the bottom of the

filler neck to allow space for fuel expansion.

8. Replace fuel cap and tighten until the cap ratchets.

9. If gasoline is spilled, wipe it off the engine and the

equipment. Move the machine to another area. Wait five

minutes before starting the engine.

10. To reduce fire hazards, keep the machine free of grass ,

leaves or other debris build up. Clean up oil or fuel spillage

and remove any fuel-soaked debris.

11. Keep gasoline away from sparks, open flames, pilot lights,

heat, and other ignition sources.

12. Never fuel equipment indoors because flammable vapors

will accumulate in the area.

13. Extinguish all cigarettes, cigars, pipes, and other sources of

ignition.

14. Check fuel line, tank, cap, and fittings frequently for cracks

or leaks. Replace if necessary.

Operation

1. When starting the engine, make sure spark plug, muffler,

and fuel cap are in place.

2. Do not crank engine with spark plug removed.

3. If fuel spills, wait until it evaporates before starting engine.

4. Allow muffler, engine cylinder, and fins to cool before

touching.

5. Keep children away from hot or running engines. They can

suffer burns from a hot muffler.

6. Remove accumulated combustibles from muffler and

cylinder area.

7. Operate equipment with all guards in place.

8. Keep hands and feet away from rotating parts.

9. Tie up long hair and remove jewelry.

10. Do not wear loose-fitting clothing, dangling drawstrings or

items that could become caught.

11. When starting the engine, pull cord slowly until resistance

is felt, then pull rapidly (if not electric start).

12. Remove all external equipment/engine loads before

starting engine.

13. Direct coupled equipment components such as, but not

limited to blades, impellers, pulleys, sprockets, etc., must

be securely attached.

Maintenance & Storage

1. Keep the engine in safe working order

2. Allow the engine to cool at least five minutes before

storing. Never tamper with safety devices. Check their

proper operation regularly.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the engine in safe working condition.

Visually inspect the engine for any damage.

4. Before cleaning, repairing or inspecting; stop the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire and ground it against the

engine to prevent unintended starting.

5. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

6. Maintain and replace safety and instruction labels as

necessar y.

7. Always refer to the operator’s manual for important details

if the machine is to be stored for an extended period of

time.

8. If the fuel tank has to be drained, do this outdoors.

9. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

Spark Arrestor

WARNING! This machine is equipped with an

internal combustion engine and should not be used

on or near any unimproved forest-covered, brush

covered or grass-covered land unless the engine’s

exhaust system is equipped with a spark arrestor

meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrestor for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

4 Section 2 — important Safe operation practiceS

Page 5

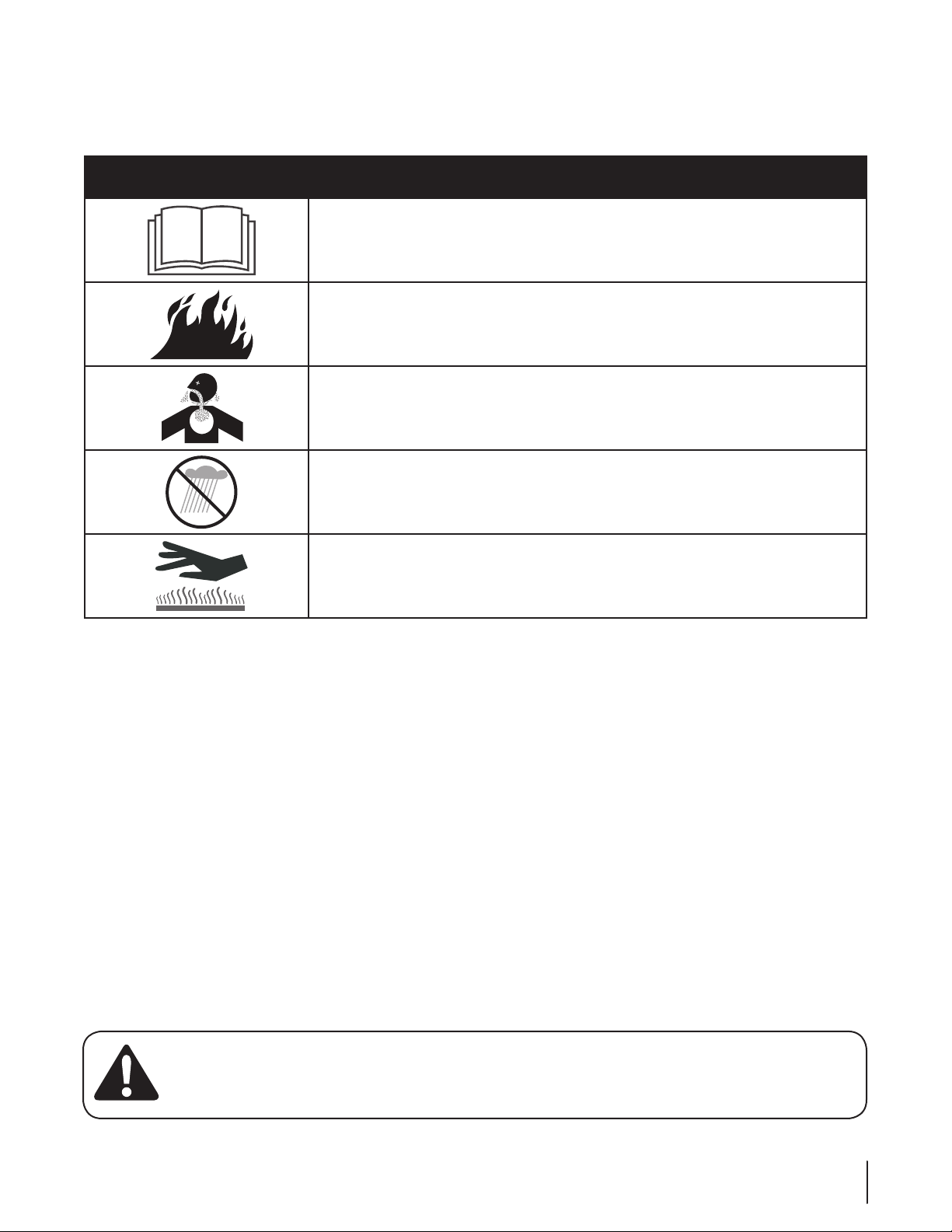

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING— ELECTRICAL SHOCK

Do not use the engine’s electric starter in the rain.

WARNING— HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING! Your Responsibility — Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

5Section 2 — important Safe operation practiceS

Page 6

Upper Level

Set-Up

3

Gas & Oil

IMPORTANT: The engine is shipped without gasoline in the

engine. See the following instructions for adding gasoline.

IMPORTANT: Some engines are shipped with oil already in

the engine, others without oil already in the engine. It is very

important to check the oil level before operating the engine and

to add oil if necessary. Running the engine with insufficient oil

can cause serious engine damage and void the engine warranty

Before starting engine, fill with motor oil, capacity is 600

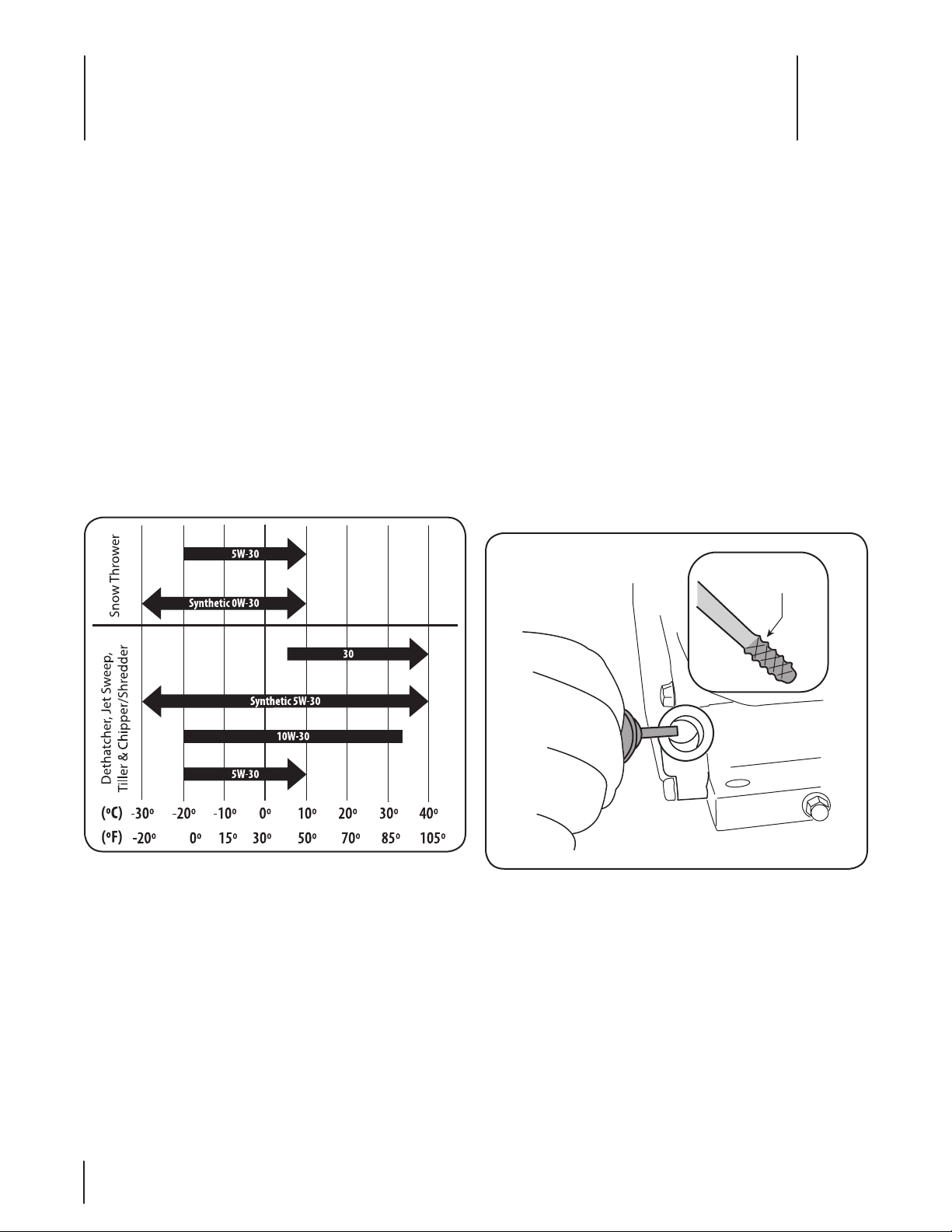

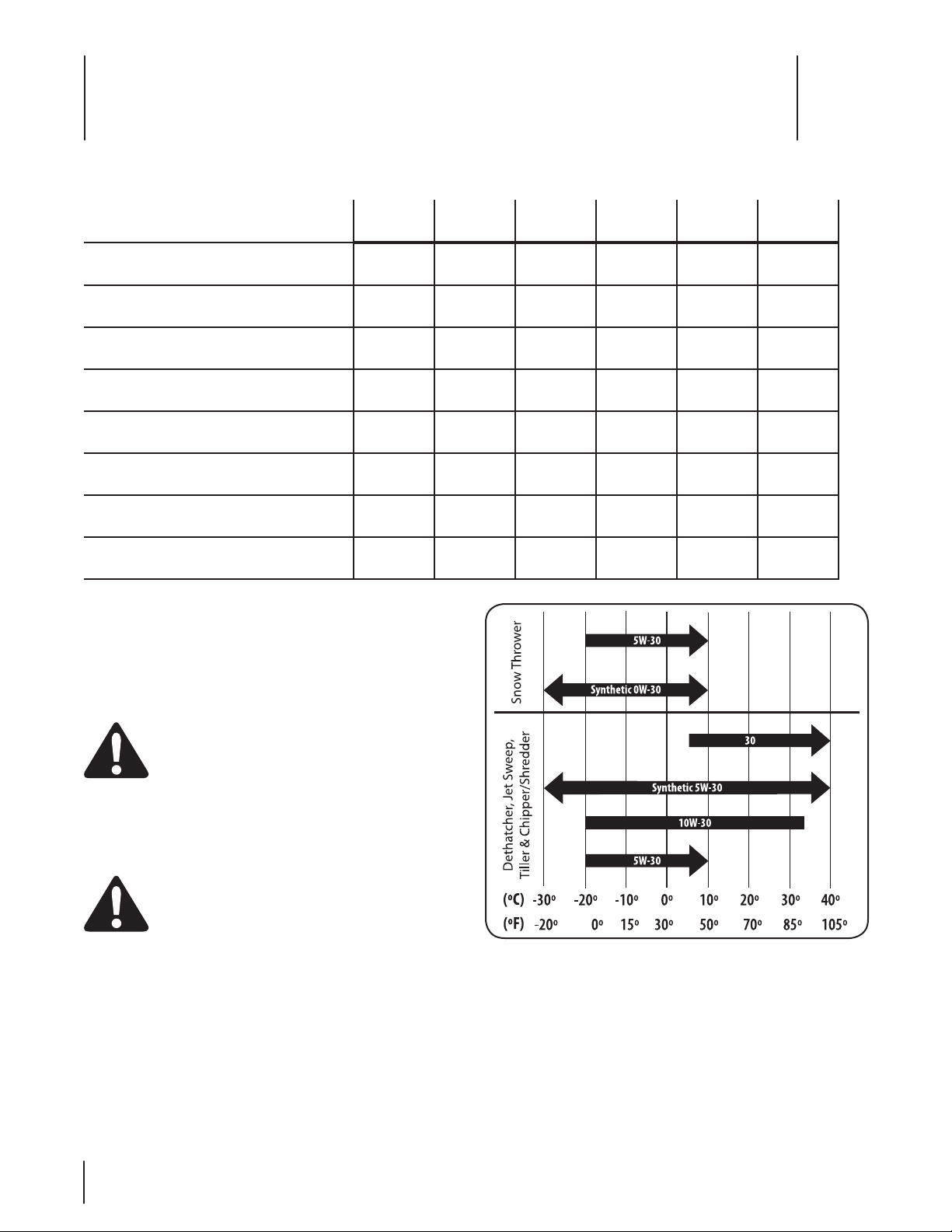

ml/20 oz. Refer to the viscosity chart (Figure 3-1) for oil

recommendations. Do not over-fill. Use a 4-stroke, or an

equivalent high detergent, premium quality motor oil certified to

meet or exceed U.S. automobile manufacturer’s requirements for

service classification of a minimum level SJ (higher letter ratings

are acceptable such as SL and SM grades). Motor oil will display

this designation on the container.

NOTE: Do not use non-detergent oil or 2-stroke engine oil. It

could shorten the engine’s service life.

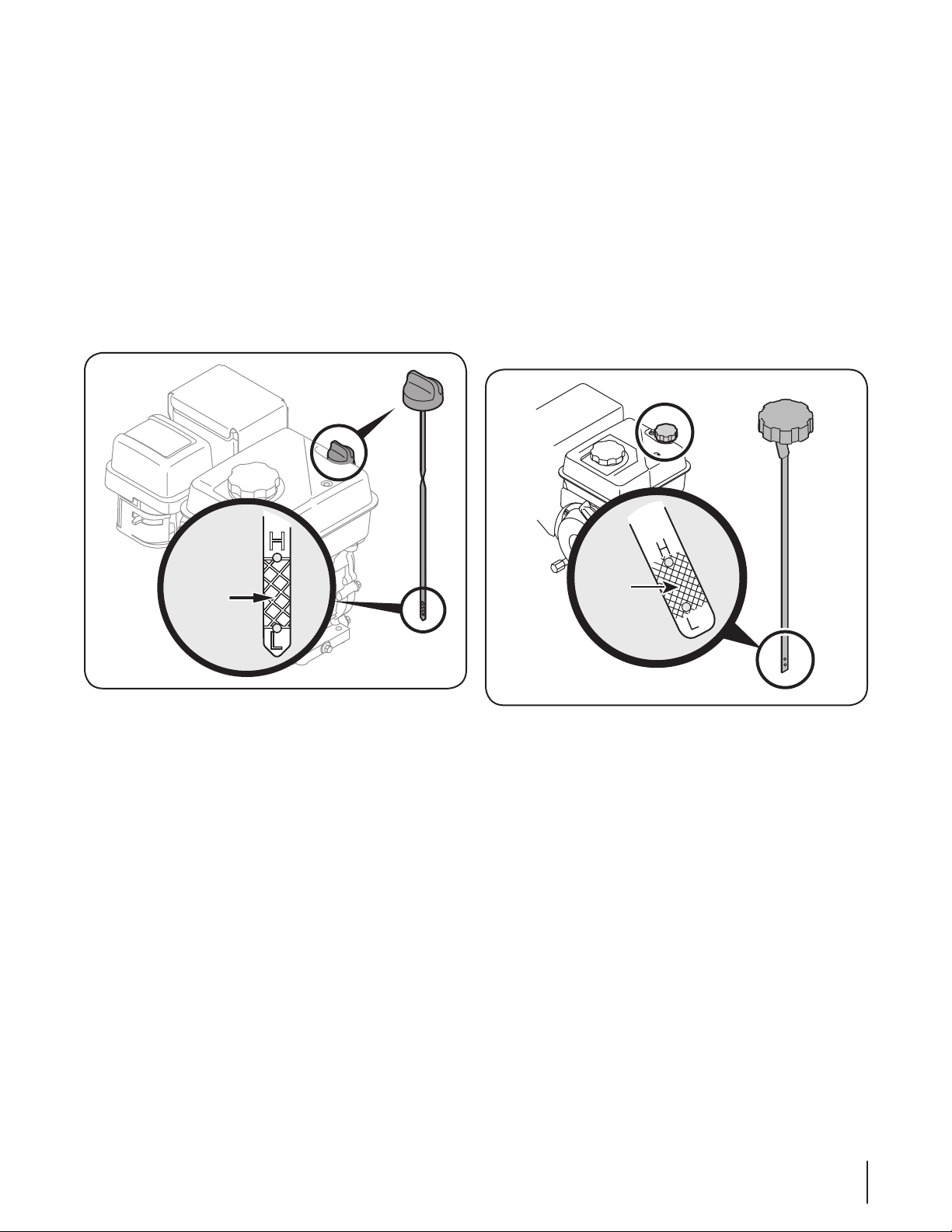

Checking Oil Level On Engines with Dipstick on Engine Block

NOTE: Be sure to check the oil while on a level surface with the

engine stopped.

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating

hours when engine is warm. Check oil level more

frequently during engine break-in.

• Keep oil level near or slightly below the upper level

mark on the dipstick or to point of overflow on

engines without dipstick. See Figure 3-2.

• Be sure oil fill cap/plug is tightened securely.

1. Remove the oil filler cap/dipstick and wipe the dipstick

clean. See Figure 3-2.

2. Insert the cap/dipstick into the oil filler neck, but do not

screw it in.

3. Remove the oil filler cap/dipstick. If the level is low, slowly

add oil until oil level registers between high (H) and low (L),

Figure 3-2.

Figure 3-1

Checking the Oil

This manual covers several different engine models. Instructions

for checking the oil with various different oil cap/dipstick

configurations follow. Refer to the instructions that pertain to the

particular engine model that you have.

6

Figure 3-2

4. Replace and tighten cap/dipstick firmly before starting

engine.

NOTE: Do not overfill. Overfilling with oil may cause smoking,

hard starting, or spark plug fouling.

NOTE: DO NOT allow oil level to fall below the “L” mark on the

dipstick. Doing so may result in equipment malfunctions or

damage.

NOTE: some engines are equipped with a dipstick or oil fill plug.

NOTE: To change the oil on your engine, see the Maintenance

Section of this manual.

Page 7

Fill

between

high

and low

marks

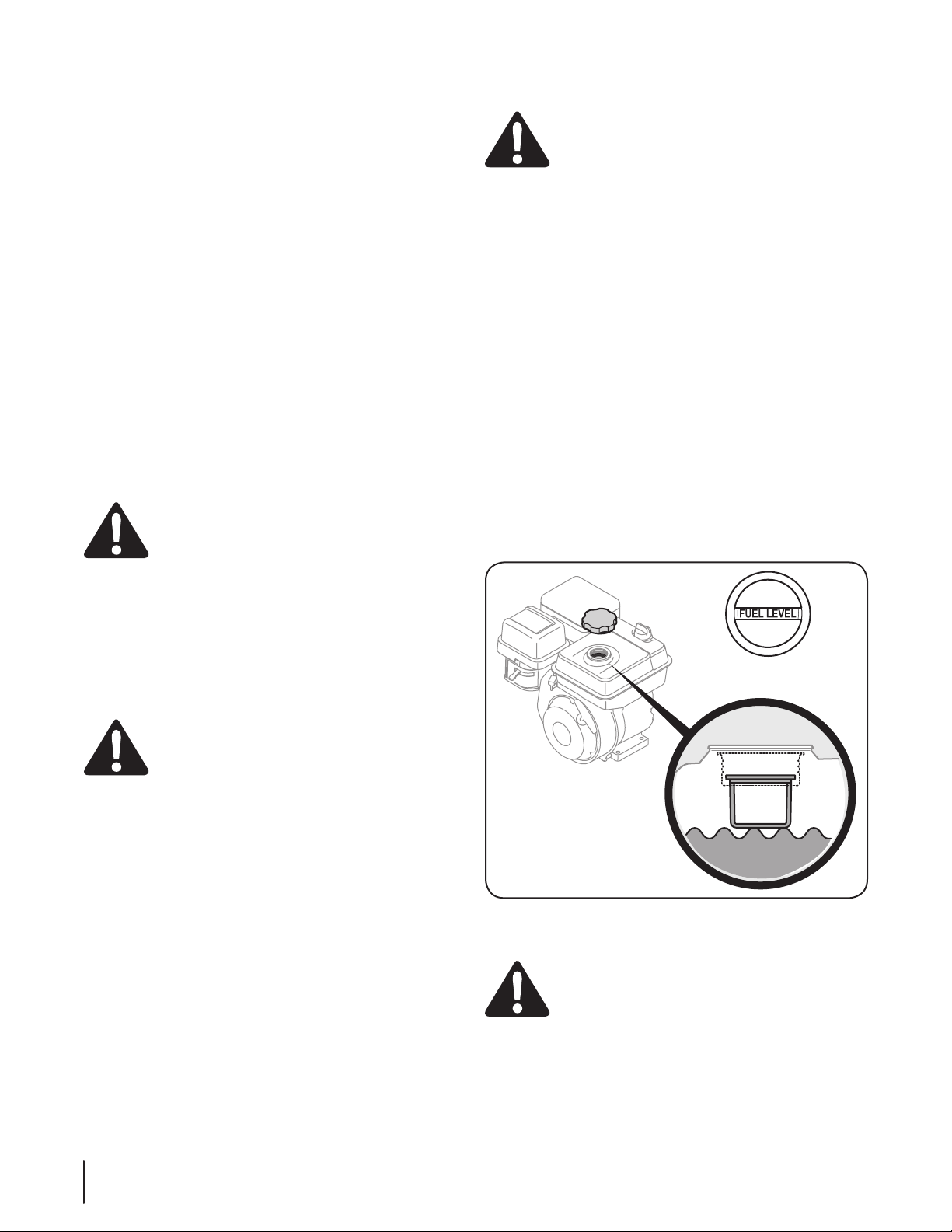

Checking Oil Level on Engines with Quarter-Turn Oil Fill Caps

Fill

between

high

and low

marks

NOTE: Be sure to check the oil while on a level surface with the

engine stopped.

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating

hours when engine is warm. Check oil level more

frequently during engine break-in.

• Keep oil level between “H” and “L” marks on dipstick.

See Figure 3-3.

• Be sure oil fill cap/plug is tightened securely when

checking.

1. Remove the oil filler cap/dipstick and wipe the dipstick

clean. See Figure 3-3.

Checking Oil Level on Engines with Threaded Oil Fill Caps

NOTE: Be sure to check the oil while on a level surface with the

engine stopped.

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating

hours when engine is warm. Check oil level more

frequently during engine break-in.

• Keep oil level between “H” and “L” marks on dipstick.

See Figure 3-4.

• Be sure to rest oil fill cap on the threads when

checking. Do not tighten down oil fill cap when

checking the oil on threaded oil fill cap engines.

1. Remove the oil filler cap/dipstick and wipe the dipstick

clean. See Figure 3-4.

Figure 3-3

2. Insert the cap/dipstick into the oil filler neck, and tighten

the cap until seated.

3. Remove the oil filler cap/dipstick. If the level is low, slowly add

oil until oil level registers between high (H) and low (L), Figure

3-3.

4. Replace and tighten cap/dipstick firmly before starting

engine.

NOTE: Do not overfill. Overfilling with oil may cause smoking,

hard starting, or spark plug fouling.

NOTE: DO NOT allow oil level to fall below the “L” mark on the

dipstick. Doing so may result in equipment malfunctions or

damage.

NOTE: To change the oil on your engine, see the Maintenance

Section of this manual.

Figure 3-4

2. Insert the cap/dipstick into the oil filler neck, but do not

screw it in.

3. Remove the oil filler cap/dipstick. If the level is low, slowly

add oil until oil level registers between high (H) and low (L),

Figure 3-4.

4. Replace and tighten cap/dipstick firmly before starting

engine.

NOTE: Do not overfill. Overfilling with oil may cause smoking,

hard starting, or spark plug fouling.

NOTE: DO NOT allow oil level to fall below the “L” mark on the

dipstick. Doing so may result in equipment malfunctions or

damage.

NOTE: To change the oil on your engine, see the Maintenance

Section of this manual.

7Section 3 — Set-Up

Page 8

Filling Oil Sump

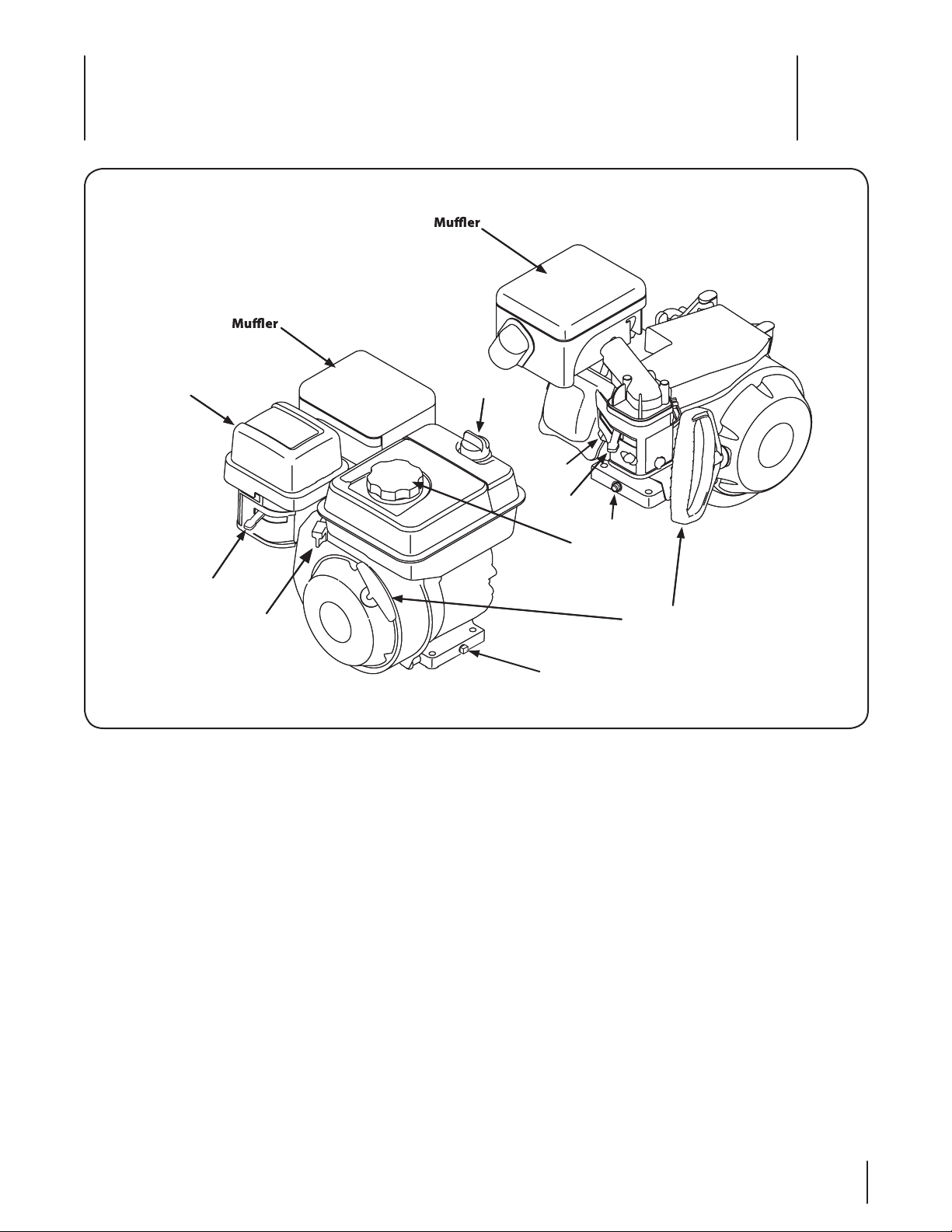

Fuel Level Indicator

Top View

1. Be sure the engine is upright and level.

2. Remove the oil fill cap dipstick from oil filler tube by

rotating counter-clockwise and lifting the dipstick out of

the engine. Wipe the dipstick clean with a shop rag.

3. Insert oil fill cap dipstick back into oil filler tube. On

threaded oil cap/dipstick units, do not screw the cap on to

check, just rest cap on threads to gain proper reading. On

quarter-turn cap units, tighten down the cap to check the

oil level. Refer to the proceeding instructions based on the

engine model that you have for more detailed information

regarding checking the oil level.

4. Remove the oil fill cap/dipstick from the oil filler tube. Note

the oil level and if the oil reading on the dipstick is below

the “L” mark, slowly add oil to reach the “H” level.

5. Insert oil fill cap/dipstick back into oil filler tube. Tighten by

rotating the cap clockwise until firmly seated.

6. Wipe away any spilled oil.

NOTE: To change the oil, see Checking and Changing Oil

instructions in the Maintenance Section of this manual.

Fuel Recommendations

CAUTION: Operating the engine with E15 or E85

fuel, an oil/gasoline mixture, dirty gasoline, or

gasoline over 30 days old that hasn’t been fuel

stabilizing additive may result in damage to your

engine’s carburetor. Subsequent damage would not

be covered under the manufacturer’s warranty.

Use automotive gasoline (unleaded or low leaded to minimize

combustion chamber deposits) with a minimum of 87 octane.

Gasoline with up to 10% ethanol (E10) or 15% MTBE (Methyl

Tertiary Butyl Ether) can be used. Never use an oil/gasoline

mixture or dirty gasoline. Avoid getting dirt, dust, or water in the

fuel tank. DO NOT use E15 or E85 gasoline.

Adding Fuel

WARNING! An adult should fuel this engine. NEVER

allow children to refuel this engine. Gasoline (fuel)

vapors are highly flammable and can explode. Fuel

vapors can spread and be ignited by a spark or flame

many feet away from engine. To prevent injury or

death from fuel fires, follow these instructions:

• DO NOT use leaded fuel.

• Fuel must be fresh and clean. NEVER use fuel left over

from last season or stored for long periods.

• NEVER mix oil with fuel.

• DO NOT use fuel containing Methanol (Wood

Alcohol)

1. Before refueling, allow the engine to cool for two minutes.

2. Be sure engine is outdoors and in a well-ventilated area.

3. Clean area around the fuel fill cap and remove the fuel fill

cap.

4. Using an approved red GASOLINE container, add fuel

slowly, being careful to avoid spilling.

NOTE: On tanks with a fuel level indicator, fill the tank until

the fuel reaches the “fuel full” indicator mark. See Figure

3-5. All other tanks, fill tank until the fuel reaches a ⁄ inch

below the bottom of the filler neck to allow space for fuel

expansion. Be careful not to overfill.

WARNING! Gasoline is extremely flammable and is

explosive under certain conditions.

• Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks in the area where

the engine is refueled or where gasoline is stored.

• Do not overfill the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

• Be careful not to spill fuel when refueling. Spilled fuel or

fuel vapor may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

• Avoid repeated or prolonged contact with skin or

breathing of vapor.

8 Section 3— Set-Up

Figure 3-5

5. Replace the fuel cap and tighten securely.

WARNING! Wipe up spilled fuel before starting

engine. If fuel is spilled DO NOT start engine. Move

machine away from area of spillage. Avoid creating

any source of ignition until fuel vapors are gone.

Page 9

Oil Fill

Fuel Fill

Air Filter

Choke

Choke

Recoil Starter

Handle

Oil Fill

Fuel Fill

Air Filter

Choke

Throttle

Oil Drain

Oil Drain

Choke

Oil Fill/

Dipstick

Recoil Starter

Handle

Controls and Features

4

NOTE: Engine models may vary in features and/or location of

controls. The following is to serve as a general reference. Always

supplement this information with the operator’s manual that

is included with the product for more information regarding

specific controls and their location.

Choke Control

Activating choke control by sliding it all the way to the right

closes the choke plate on carburetor and aids in starting engine.

For information on choke usage, see “Starting The Engine”.

The image above corresponds with the label on the engine

identifying the Choke control.

Recoil Starter & Starter Handle

This motor is fitted with a recoil action pull start and a mitten

grip handle for easy access while wearing gloves or mittens.

Figure 4-1

Ignition Key

NOTE: The existence and location of an ignition key may vary by

product. Refer to your product operator’s manual for specific key

inclusion and/or location information.

Insert the key, if so equipped, and snap it into place; do not turn

the key to attempt to start/stop the unit. Pull the key out halfway

to stop the engine. Remove key when the unit is not in use.

Oil Fill

On some models the oil fill is located at the top of the engine, as

seen in the lower portion of Figure 4-1. On some other models, it

is located on the bottom of the engine block as seen in the upper

portion of Figure 4-1. Remove oil cap to add oil. Refer to “PreOperation Check” section for checking oil and “Maintaining Your

Engine” section for adding oil instructions.

9

Page 10

Fuel Cap

The location of the fuel cap may vary based on engine model.

On some models, it appears as part of the units shroud, on

others, the fuel tank is located on top of the engine. Refer to your

product operator’s manual for detailed information regarding

the location of the fuel tank. Remove the fuel cap to add fuel.

These engines operate on automotive unleaded gas.

Oil Drain

The oil drain is located at the base of the engine block and is

used to drain the motor oil from the engine.

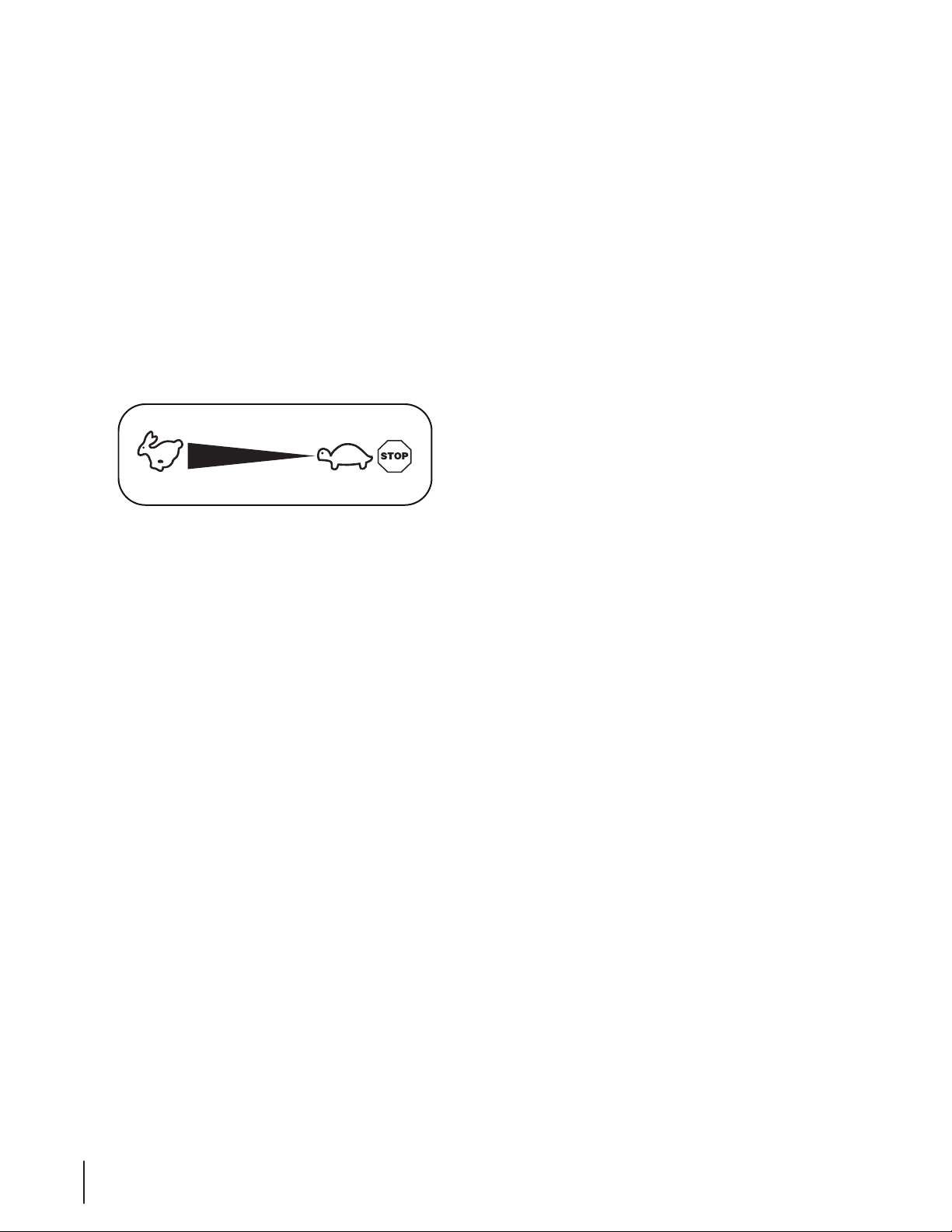

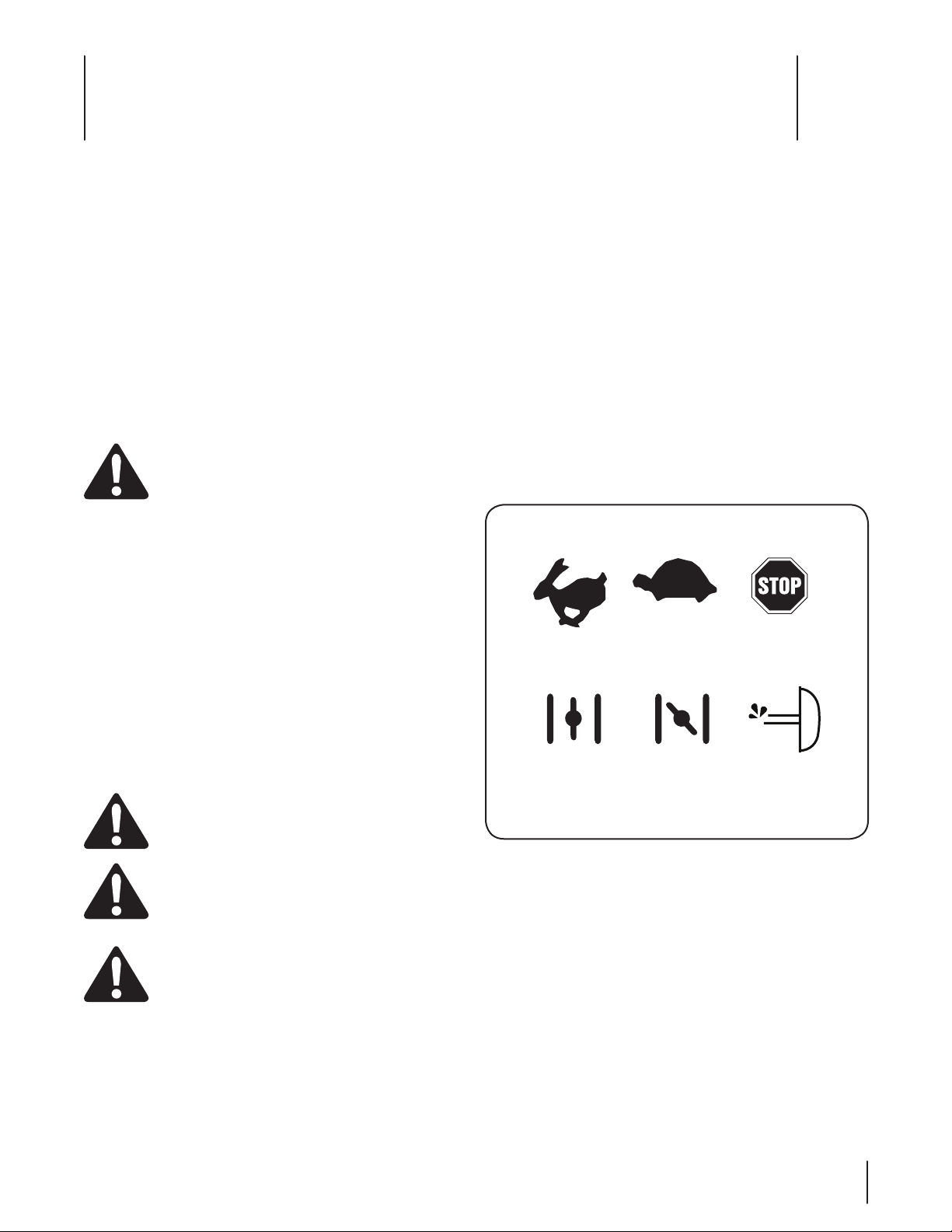

Throttle Control

The presence of a throttle control may vary by engine model. If

present, it regulates the speed of the engine (Rabbit being the

fastest, Turtle being the slowest) and will shut off the engine

when pushed to the STOP position.

If a throttle control is not present, then the engine is set to always

run at maximum performance speed once started.

10 Section 4— controlS and FeatureS

Page 11

ChokeRun

Fast Slow/Idle Engine Off

Primer

Operation

5

Pre-Operation Check

IMPORTANT: The engine is shipped without gasoline in the

engine. See the Set-Up Section of this manual for instructions on

adding gasoline.

IMPORTANT: Some engines are shipped with oil already in

the engine, others without oil already in the engine. It is very

important to check the oil before operating the engine and

to add if necessary. See the Set-Up Section of this manual for

instructions on checking and adding oil.

For your safety, and in order to maximize the service life of this

equipment, it is very important to check its condition before you

operate this engine. Make certain to service, correct or fix any

problem that might be identified before attempting to operate

this engine.

WARNING! Improperly maintaining this engine, or

failure to correct any problem before operation can

cause a malfunction which could result in serious

injury or even death.

Always perform a pre-operation inspection before

each operation, and correct any problem.

Before you start the engine, always check the following items:

1. Fuel Recommendations (See Set Up Section)

2. Checking Oil Level (See Set Up Section)

3. Air filter (if equipped) (See Maintenance Section)

4. General Overall Inspection. Check for any fluid leaks or

discharges, and loose or damaged parts.

5. Check the owner’s manual provided with the equipment

that is powered by this engine. Review the owner’s manual

for any precautions and procedures that should be

followed before starting the engine.

• DO NOT put flammable liquids into carburetor.

• DO NOT operate engine or pull on starter rope

with spark plug removed. Fuel can spray from

spark plug hole and ignite.

NOTE: Allow the engine to warm up for a few minutes after

starting. The engine will not develop full power until it reaches

operating temperatures.

NOTE: Familiarize yourself with the engine symbols shown in

Figure 5-1 before attempting to start this engine. If this engine

is remotely controlled by the equipment it is powering, be sure

to familiarize yourself with the equipment Operator’s Manual as

well.

NOTE: The following starting instructions are for several different

types of engines. In order to locate the instructions that apply to

your engine, first determine what type of starter you have. If you

have an electric starter, see Engines With Electric Starters. If you

have a manual recoil starter, see Engines with Recoil Starters later

in this section.

Starting the Engine

WARNING! Always keep hands and feet clear of

moving parts. Do not use a pressurized starting

fluid. Vapors are flammable.

WARNING! An adult should start the engine. Only

allow children to start the engine if an adult has

determined they are experienced and capable of

such operation.

WARNING! If you are unable to start this engine

after following instructions in this manual, contact

you authorized MTD Service Dealer. To avoid serious

burn injuries or damage to your engine, DO NOT

attempt to start or troubleshoot this engine in any

other way. for example:

• DO NOT use starting fluid.

• DO NOT spray flammable vapors into the

carburetor.

Figure 5-1

11

Page 12

Engines With Electric Starters

If you have a manual recoil starter, see Engines with Recoil

Starters later in this section.

WARNING! DO NOT pull the starter handle while

the engine is running.

WARNING! Some electric starters are equipped

with a 120V A.C. Three-Wire Power Plug designed

to operated on a 120V A.C. household current using

a standard 3-pronged, grounded extension cord. It

must be properly grounded at all times to avoid the

possibility of injury or death from electrical shock.

a. Determine if your house wiring has a Ground Fault

Interrupted (G.F.I.) Three-Wire Grounded System; if

you are not sure, ask a Licensed Electrician.

b. If your house wiring does not have a G.F.I. Three-

Wire Grounded System, DO NOT USE THIS ELECTRIC

STARTER UNDER ANY CONDITION.

c. If your house wiring is grounded and a G.F.I.

three-Prong Wall Receptacle is not available at the

location where your starter will be used, one must

be installed by a Licensed Electrician BEFORE USING

THE ELECTRIC STARTER!

1. To avoid carbon monoxide poisoning, be sure engine is

outdoors in a well-ventilated area.

2. Be sure fuel valve, if present (see equipment Operator’s

Manual instructions) is open and all switches are on.

3. Plug an extension cord into the outlet located on the

engine’s surface. Plug the other end of extension cord

into a three-prong 120-volt, grounded, AC outlet in a wellventilated area.

CAUTION: The extension cord can be any length,

but must be rated for 15 amps at 125 volts, grounded

and rated for outdoor use.

IMPORTANT: When connecting the power cord, always

connect the power cord to the switch box on the engine

first; then into the outlet.

4. Move engine speed control, if equipped, in the “Fast”

position.

5. If equipped, set the choke control to the “FULL CHOKE”

position. On units WITHOUT a choke control, a primer bulb

will be present. Prime engine 5-7 times.

IMPORTANT: DO NOT operate an electric starter for

more than 5 seconds during each attempt.

NOTE: If restarting a warm engine after a short shutdown,

move the engine speed control (if equipped) the “FAST”

position and move the choke control to the “NO CHOKE”

position.

6. Push the starter button to start the engine.

NOTE: If the engine fails to start after 3 attempts, repeat

steps 1 through 8.

7. When the engine starts:

• Release the starter button.

• Move the choke control to 1/2 “CHOKE” position

until the engine runs smoothly.

• Next, move the choke control to the NO CHOKE

position.

8. Move the engine speed control (if equipped) to the desired

speed in the “RUN” range.

NOTE: If the engine starts but falters when the choke

control is moved to the “NO CHOKE” position:

• Momentarily move choke control back to “FULL

CHOKE” position.

• Next, move the choke control to “!/2 CHOKE”

position until engine runs smoothly.

• Finally, move the choke control to the NO

CHOKE position.

If the engine dies after choke control is moved to “NO

CHOKE” position, repeat steps 5 through 10 to restart

engine.

9. If the engine fails to start after 3 attempts in the “NO

CHOKE” position, move the choke control to “FULL CHOKE”

position and start engine.

NOTE: When disconnecting the power cord, always

disconnect the power cord from the outlet first; then

disconnect the power cord from the switch box on the

engine.

10. Disconnect the power cord form the outlet.

11. Disconnect the power cord form the switch box on the

engine.

12. If engine does not start after following steps 1 through

12, contact your Authorized MTD Service Dealer. DO NOT

attempt to troubleshoot this engine in any other way.

Engines with Recoil Starters

If you have an electric starter, see Engines with Electric Starters

earlier in this section.

WARNING! DO NOT pull starter rope with engine

running. Doing so may VOID YOUR WARRANTY.

1. To avoid carbon monoxide poisoning, be sure engine is

outdoors in a well-ventilated area.

2. Be sure fuel valve, if present (see equipment Operator’s

Manual instructions) is open and all switches are on.

3. Move the engine speed control, if equipped, to the “FAST”

position.

4. If equipped, set the choke control to the “FULL CHOKE”

position. On units WITHOUT a choke control, a primer bulb

will be present. Prime engine 5-7 times.

NOTE: If restarting a warm engine after a short shutdown,

move the engine speed control (if equipped) the “FAST”

position and move the choke control to the “NO CHOKE”

position.

WARNING! When pulling the starter rope, the

rope can unexpectedly jerk back toward the engine

causing serious injury. To avoid this risk, carefully

follow these instructions:

12 Section 5— operation

Page 13

5. Grasp the starter cord handle.

• Pull rope out slowly until you feel drag.

• Without allowing the rope to retract, continue

pulling the rope with one rapid full arm stroke.

• Return the rope slowly to the original position.

NOTE: Following the instructions listed in the steps above

avoids potential damage to the recoil mechanism.

If the recoil starter handle is frozen and will not operate the

engine, proceed as follows:

• Pull as much rope out of the starter as possible.

• Release the starer handle and let it snap back

against the starter to break up ice’; these two

steps should only be done when the starter is

frozen.

6. If the engine fails to start after 3 attempts repeat steps 1

through 7 and try again.

7. When the engine starts:

• Move the choke control to 1/2 “CHOKE” position

until the engine runs smoothly.

• Next, move the choke control to the NO CHOKE

position.

8. Move the engine speed control (if equipped) to the desired

speed in the “RUN” range.

NOTE: If the engine starts but falters when the choke

control is moved to the “NO CHOKE” position:

• Momentarily move choke control back to “FULL

CHOKE” position.

• Next, move the choke control to “1/2 CHOKE”

position until engine runs smoothly.

• Finally, move the choke control to the NO

CHOKE position.

If the engine dies after choke control is moved to “NO CHOKE”

position, repeat steps 3 through 10 to restart engine.

9. If the engine fails to start after 3 attempts in the “NO

CHOKE” position, move the choke control to “FULL CHOKE”

position and start engine.

10. If engine does not start after following steps 1 through

11, contact your Authorized MTD Service Dealer. DO NOT

attempt to troubleshoot this engine in any other way.

Stopping the Engine & Short Term Storage

Stop engine in accordance with the equipment Operator’s

Manual.

WARNING! To avoid unsupervised engine

operation, especially by children, NEVER leave the

engine unattended while running. Always turn off

the engine after use and remove the ignition key, if

equipped.

WARNING! NEVER store the engine with fuel in the

fuel tank inside a building with potential sources of

ignition such as hot water tank and space heaters,

clothes drivers, electric motors, etc.

Stopping The Engine

1. If operating the engine in the snow or rain, run the engine

for a few minutes to help dry off any moisture.

2. Move the equipment control, if present (see Equipment

Owner’s Manual), engine control lever or ignition switch to

“STOP” or “OFF” position.

3. Remove ignition key, if provided (see equipment Operator’s

Manual).

NOTE: Removing the key will reduce the possibility of

unauthorized starting of the engine while equipment is not

in use.

WARNING! NEVER store the engine with fuel in the

fuel tank inside a building with potential sources of

ignition such as hot water tank and space heaters,

clothes dryers, electric motors, etc.

After the Engine is Stopped

WARNING! To prevent the possible freeze-up of

engine controls, follow instructions with engine

STOPPED, listed below:

1. Wipe all snow and moisture from the engine control lever

and choke areas.

2. Move the equipment control, if present, (see equipment

Operator’s Manual), engine control lever or ignition switch

back and forth several times and leave the control in the

“STOP” or “OFF” position.

3. Move the engine choke back and forth several times and

leave in the “FULL CHOKE” position.

4. Be sure the Fuel Shut-Off Valve, , if present, is off.

13Section 5 — oper ation

Page 14

Maintenance

Maintenance Schedule

6

First 5 Hours

Check Engine Oil Level

Change Engine Oil

Check Air Cleaner (If so equipped)

Service Air Cleaner (If so equipped)

Check Spark Plug

Replace Spark Plug

Clean Engine Shroud (If so equipped)

Clean around muer

Periodic inspection and adjustment of the engine is essential if

high level performance is to be maintained. Regular maintenance

will also ensure a long service life. The required service intervals

and the kind of maintenance to be performed are described

in the table above. Follow the hourly or calendar intervals,

whichever occur first. More frequent service is required when

operating in adverse conditions.

P P

Each Use or

Every 5 Hrs.

P

P

P

P

Every Season

or 25 Hours

P

Every Season

or 50 Hours

Every Season

or 100 Hours

P

P

Service

Dates

WARNING! Shut off the engine before performing

any maintenance. To prevent accidental start-up,

disconnect the spark plug boot.

NOTE: If engine must be tipped to transport equipment or to

inspect or remove grass, keep spark plug side of engine up.

Transporting or tipping engine spark plug down may cause

smoking, hard starting, spark plug fouling, or oil saturation of air

cleaner.

WARNING! If the engine has been running, the

muffler will be very hot. Be careful not to touch the

muffler.

Checking and Changing the Engine Oil

Oil Recommendations

Refer to the viscosity chart (Figure 6-1) for oil recommendations.

Do not over-fill. Use a 4-stroke, or an equivalent high detergent,

premium quality motor oil certified to meet or exceed

U.S. automobile manufacturer’s requirements for service

classification of a minimum level SF or SG (higher letter ratings

are acceptable such as SJ, SL and SM grades). Motor oil will

display this designation on the container.

14

Figure 6-1

NOTE: Do not use non-detergent oil or 2-stroke engine oil. It

could shorten the engine’s service life.

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating hours

when the engine is warm.

Page 15

Oil

Drain

• Change the oil after the first 5 operating hours and every

Spark Plug

Spark Plug

Boot

50 operating hours thereafter. Engine should still be warm

but NOT hot from recent use.

Oil Fill Cap/Dipstick

WARNING! Before tipping engine or equipment to

drain oil, drain fuel from tank by running engine

until fuel tank is empty.

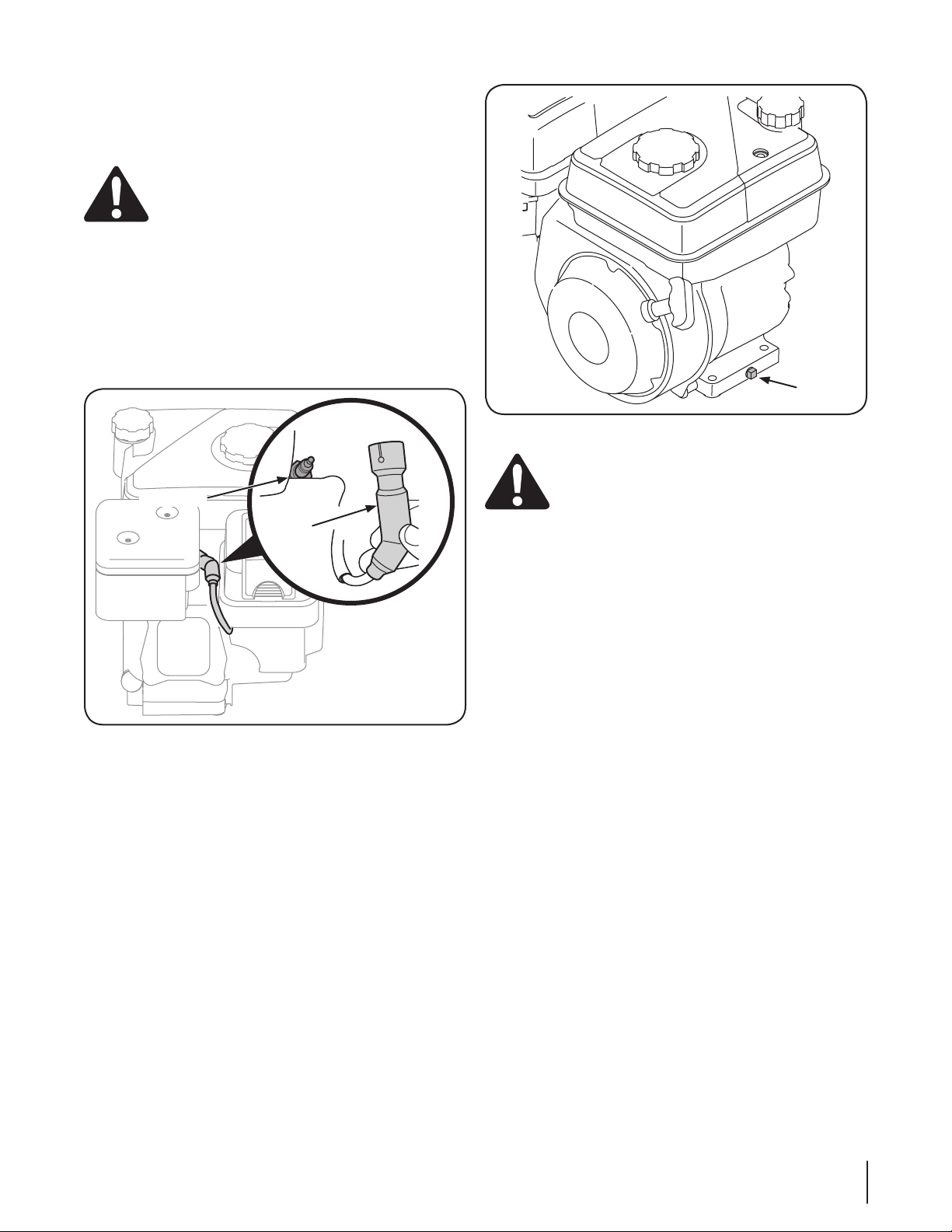

1. Carefully disconnect the spark plug wire and keep it away

from the spark plug. Refer to Figure 6-2 for spark plug

location.

• Keep the disconnected spark plug wire securely

away from the metal parts where arcing could

occur.

• Carefully attach the spark plug wire to the

grounding post, if provided.

Figure 6-2

2. Be sure that the fuel fill cap is on and securely tightened.

3. Be sure to find correct oil drain plug location, if present

(see the equipment Operator’s Manual instructions for

additional information).

4. Clean area around the oil drain plug.

5. Place an approved recyclable oil container under the oil

drain plug.

6. Remove the Oil drain plug. See Figure 6-3.

Figure 6-3

WARNING! Used motor oil may cause skin cancer

if repeatedly left in contact with the skin for

prolonged periods. Although this is unlikely unless

you handle used oil on a daily basis, it is still

advisable to thoroughly wash your hands with soap

and water as soon as possible after handling used

oil.

7. Tip engine to position the oil flow, so it will drain from the

lowest point on the engine.

8. Drain the oil into an approved recyclable oil container.

NOTE: Please dispose of used motor oil in a manner that is

compatible with the environment. We suggest you take it in a

sealed container to your local service station for reclamation.

Do not throw it in the trash or pour it on the ground.

9. Install the oil drain plug and tighten securely.

10. Clean area around the oil drain plug.

11. Remove the oil fill cap dipstick.

12. Fill with the recommended Oil. See Figure 6-1.

NOTE: DO NOT overfill oil filler. Doing so may result in oil

carry-over to the equipment and cause malfunction or

damage.

NOTE: DO NOT allow oil level to fall below and “L” mark on

dipstick. Doing so may result in equipment malfunction or

damage.

13. Wipe away any spilled oil.

14. Check the oil level by installing the Oil Fill Cap/Dipstick.

• For threaded Oil Fill Cap/Dipstick models, rest

the cap on the threads, do not tighten down the

cap to check the oil level.

• For quarter-turn Oil Fill Cap/Dipstick models,

tighten down the cap to check the oil level.

NOTE: See the Set-Up section earlier in this manual for

detailed instructions on identifying and checking the oil on

each of these specific engine models.

15Section 6 — Maintenance

Page 16

15. Remove the oil filler cap/dipstick. If the level is low, slowly

Air

Filter

Air Filter

Cover

Foam

Element

0.02-0.03 in.

0.60-0.80 mm

Electrode

add oil until oil level registers between high (H) and low (L),

Figure 3-2 and Figure 3-3 in the Set-Up section.

16. Repeat Steps 14 & 15 to be sure that the correct oil level has

been achieved.

17. Once the proper oil level has been confirmed, install the Oil

Fill Cap/Dipstick. Tighten securely

18. Carefully disconnect spark plug wire from grounding post,

if present.

19. Carefully reconnect the spark plug wire to the spark plug.

NOTE: It is advisable to recheck the oil level after you have

operated the engine for a short while, and the normal engine

operating temperature has been achieved.

WARNING! If the engine has been running, the

muffler, engine head and spark plug will be very hot.

Be careful not to touch any of these components

until they have cooled.

Air Filter (If so equipped)

NOTE: Not all engines have air filters, such as engines used for

snow throwers. Service the air filter if one is present.

Paper filters cannot be cleaned and must be replaced once a

year; more often if used in extremely dusty conditions.

Spark Plug Service

WARNING! DO NOT check for spark with spark

plug removed. DO NOT crank engine with spark

plug removed.

Check the spark plug yearly or every 100 operating hours. To

ensure proper engine operation, the spark plug must be properly

gapped and free of deposits.

1. Remove the spark plug boot.

2. Clean the area around the spark plug.

3. Use a spark plug wrench to remove the plug.

WARNING! If the engine has been running, the

muffler will be very hot. Be careful not to touch the

muffler.

2. Visually inspect the spark plug. Discard the spark plug

if there is apparent wear, or if the insulator is cracked or

chipped. Replace the plug if the electrodes are pitted,

burned or fouled with deposits.

4. Clean the spark plug with a wire brush if it is to be reused.

5. Measure the plug gap with a feeler gauge. Correct as

necessary by bending side electrode. See Figure 6-5. The

gap should be set to 0.030 in. (0.76mm).

WARNING! Never use gasoline or low flash point

solvents for cleaning the air cleaner element. A fire

or explosion could result.

NOTE: Never run the engine without the air cleaner. Rapid

engine wear will result.

1. Press the tab on the air filter cover and lift the cover. See

Figure 6-4.

2. Replace paper element when dirty or damaged. Clean

foam element or replace when damaged.

3. To clean foam element, separate it from the paper element

and wash in liquid detergent and water. Allow to dry

thoroughly before using. Do not oil the foam element.

Figure 6-4

Figure 6-5

6. Check that the spark plug washer is in good condition

7. Thread the spark plug in by hand to prevent crossthreading.

8. After the spark plug is seated, tighten with a spark plug

wrench to compress the washer.

NOTE: When installing a new spark plug, tighten ⁄ turn

after the spark plug seats to compress the washer. When

reinstalling a used spark plug, tighten ⁄-⁄ turn after the

spark plug seats to compress the washer.

NOTE: The spark plug must be securely tightened. An

improperly tightened spark plug can become very hot and

may damage the engine.

16 Section 6— Maintenance

Page 17

Adjustments

DO NOT make any engine adjustments. Factory settings are

satisfactory for most conditions. If adjustments are needed,

contact your Authorized MTD Servicing Dealer.

Carburetor

If you think you carburetor needs adjusting, see your nearest

Authorized MTD Servicing Dealer. Engine performance should

NOT be affected at altitudes up to 7,000 feet (2,134 meters). For

operation at higher elevations, contact your Authorized MTD

Servicing Dealer

Cleaning the Engine

If the engine has been running, allow it to cool for at least half

an hour before cleaning. Periodically remove dirt build-up from

the engine. Clean around the muffler. Clean with a brush or

compressed air.

NOTE: Do not spray engine with water to clean because water

could contaminate fuel. Using a garden hose or pressure washing

equipment can also force water into the air cleaner or muffler

opening. Water in the air cleaner will soak the paper element,

and water that passes through the element or muffler can enter

the cylinder, causing damage.

WARNING! Accumulation of debris around muffler

could cause a fire. Inspect and clean before every

use.

Engine Speed

WARNING! To avoid serious injury or death, DO

NOT modify engine in any way. Tampering with the

governor setting can lead to a runaway engine and

cause it to operate at unsafe speeds. NEVER tamper

with the factory setting of the engine governor.

WARNING! Running the engine faster than the

speed set at the factory can be dangerous and will

VOID THE ENGINE WARRANTY.

Removing Snow from the Engine

After each use, remove snow from the following areas:

• Oil Fill Cap Dipstick

• Fuel Fill Cap

• Recoil Starter/Flywheel Screen

• Linkage

• Guards

• Spark Plug Connection (if visible).

• Electric Starter Switch Box, if present (see the

equipment Operator’s Manual instructions).

NOTE: See the equipment Operator’s Manual instructions

for proper location of fuel fill cap and control lever.

1. Removing snow will ease operation of the recoil starter

rope and reduce the risk of water contamination when

opening the fuel fill cap.

Transporting Your Engine

WARNING! NEVER transport this engine inside of

another vehicle or in any enclosed space if there is

any gasoline in the tank. Fuel vapor or spilled fuel

may ignite.

WARNING ! If there is fuel in the fuel tank, close

the fuel valve, if equipped, and transport the engine

upright in an open vehicle, such as an open trailer or

open bed of a pickup truck.

If you DO NOT have an open vehicle and have to transport

the engine upright in a closed vehicle, follow these steps for

emptying the fuel tank before transporting:

1. Empty fuel tank by using a commercially available suction

device designed for use with gasoline.

WARNING! DO NOT pour fuel from the engine or

siphon fuel by mouth.

2. Drain fuel into an approved red gasoline container, being

careful to avoid spilling.

3. Run the engine until remaining fuel is consumed.

WARNING! NEVER leave the engine unattended

when it is running and NEVER run the engine in an

enclosed area.

Storing Your Engine

Short-Term/Seasonal Storage

Clean Engine

If the engine has been running, allow it to cool for at least half an

hour before cleaning.

Before servicing the engine, remove the carburetor cover and/or

blower housing. Discard the dirt and debris from the following

areas:

• Cooling Fins

• Air Intake Screen or Recoil Starter/Flywheel

Guard Areas

• Spark Plug Connection

• Levers

• Linkage Area

• Guards

• Carburetor

• Head

Removing debris will insure adequate cooling, correct engine

speed and reduce the risk of fire.

NOTE: Do not spray engine with water to clean because water

could contaminate fuel. Using a garden hose or pressure washing

equipment can also force water into the air cleaner or muffler

opening. Water in the air cleaner will soak the paper element,

and water that passes through the element or muffler can enter

the cylinder, causing damage.

17Section 6 — Maintenance

Page 18

WARNING! Accumulation of debris around muffler

could cause a fire. Inspect and clean before every

use.

Fuel Storage

1. To prevent serious injury from fuel fires, empty fuel tank

by running engine until it stops from lack of fuel. DO NOT

attempt to pour fuel from engine.

2. Run the engine while waiting until the remaining fuel is

consumed.

WARNING! NEVER store engine with fuel in the

fuel tank inside a building with potential sources of

ignition such as hot water heater, space heater,

clothes dryer, electric motor, etc. Failure to do so

may result in an explosion and result in death or

serious injury.

NOTE: If engine fuel stored in the gas tank and/or an approved

gas container is to be unused without gasoline stabilizer for more

than 15-30 days, prepare it for short-term/seasonal storage. See

Fuel Treatment later in this section.

NOTE: If engine fuel is to be stored for more than one season,

without gasoline stabilizer, it will gradually deteriorate. Also, if

it is stored in the engine’s gas tank without gasoline stabilizer it

is likely that your carburetor will have gum deposits, a clogged

fuel system and will VOID YOUR WARRANTY. Prepare the fuel for

extended storage.

Fuel System

To avoid stale fuel and carburetor problems, treat the fuel system

in the following manner:

NOTE: Always follow mix ratio found on the stabilizer container.

Failure to do so may result in equipment damage.

NOTE: It is NOT necessary to drain stabilized gas from carburetor.

Fuel Treatment

1. Add a gasoline stabilizer according to the manufacturer’s

instructions.

2. Run engine at least 10 minutes after adding the stabilizer to

allow it to reach the carburetor.

WARNING! NEVER store the engine with the fuel in

the fuel tank inside a building with potential sources

of ignition such as a hot water heater, space heater,

clothes dryer, electric motor, etc.

NOTE: Instead of using a fuel preservative/stabilizer, you can

empty the fuel tank as described in Extended Storage —

Draining the Fuel.

Extended Storage

Draining the Fuel

NOTE: Clean debris from the engine before draining fuel from

the carburetor.

NOTE: If you have prepared your fuel for short-term storage it

is NOT necessary to drain fuel that contains stabilizer from your

carburetor.

WARNING! To avoid severe injury or death, DO

NOT pour fuel from engine or siphon fuel by mouth.

WARNING! NEVER leave the engine unattended

when it is running and NEVER run the engine in an

enclosed area.

3. Begin servicing the cylinder bore as per the following

instructions.

Oil Cylinder Bore

WARNING! When lubricating cylinder bore, fuel

may spray from the spark plug hole. To prevent

serious injury from fuel fires, follow these instructions:

1. Carefully disconnect the spark plug wire and keep it away

from the spark plug.

• Keep the disconnected spark plug wire securely

away from the metal parts where arcing could

occur.

• Carefully attach the spark plug wire to the

grounding post, if provided.

• Disconnect the battery at the negative terminal first, if the

engine is equipped with a D.C. electric starter.

• Turn off all the engine switches.

• Remove the ignition key, if provided.

2. Remove the spark plug.

3. Squirt 1oz. (30ml) of clean engine oil into the spark plug

hole.

4. Cover the spark plug hole with a rag to prevent fuel from

spraying from the spark plug hole when the starter rope is

pulled.

NOTE: for engines equipped with a recoil starter, proceed to

Step 5. For engines equipped with electric starters, proceed

to Step 6.

5. Grasp the starter cord handle:

• Pull the starter cord handle out slowly using a full

arm stroke.

• Repeat once. This will distribute the oil

throughout the cylinder to prevent corrosion

during storage.

• Proceed to Step 7.

6. Push starter button or turn ignition switch key to “START”:

position. Immediately releases the starter button or turn the

ignition switch key to the “OFF” position. This will distribute

the oil throughout the cylinder to prevent corrosion during

storage.

7. Remove the rag from spark plug hole and Install spark plug.

8. Carefully disconnect the spark plug wire from the grounding

post, if provided.

9. Connect the spark plug wire plug wire to the spark plug.

18 Section 6— Maintenance

Page 19

Oil

Change the oil if NOT changed within the last 3 months. See

Checking and Changing the Oil earlier in this section.

Off-Season Storage

CAUTION: Failure to use a fuel stabilizing additive

or completely run the engine until it’s out of fuel

before off-season storage may result in damage to

your engine’s carburetor. Subsequent damage

would not be covered under the manufacturer’s

warranty.

Engines stored between 30 and 90 days need to be treated with

a gasoline stabilizer and engines stored over 90 days need to be

drained of fuel to prevent deterioration and gum from forming

in fuel system or on essential carburetor parts. If the gasoline in

your engine deteriorates during storage, you may need to have

the carburetor, and other fuel system components, serviced or

replaced.

1. Remove all fuel from tank by running engine until it stops

from lack of fuel.

WARNING! Never leave engine unattended while

it is running.

2. Change the oil. See Changing the Oil earlier in this section.

3. Remove the spark plug and pour approximately a ⁄-ounce

of engine oil into the cylinder. Replace spark plug and

crank it slowly to distribute oil.

4. Clean debris from around the engine and the muffler.

Touch up any damaged paint, and coat other areas that

may rust with a light film of oil.

5. Store in a clean, dry and well ventilated area away from any

appliance that operates with a flame or pilot light, such

as a furnace, water heater, or clothes dryer. Also avoid any

area with a spark producing electric motor, or where power

tools are operated.

6. If possible, also avoid storage areas with high humidity,

because that promotes rust and corrosion.

7. Keep the engine level in storage. Tilting can cause fuel or

oil leakage.

Removing From Storage

1. Check your engine as described in the Pre-Operation Check

section of this manual.

2. If the fuel was drained during storage preparation, fill the

tank with fresh gasoline. If you keep a container of gasoline

for refueling, make certain it contains only fresh fuel.

Gasoline oxidizes and deteriorates over time, causing hard

starting.

3. If the cylinder was coated with oil during storage

preparation, the engine will smoke briefly at startup. This

is normal.

19Section 6 — Maintenance

Page 20

Troubleshooting

Problem Cause Remedy

7

Engine Fails to start 1. Engine flooded

2. Spark plug wire disconnected

3. Fuel tank empty or stale fuel

4. Engine not choked

5. Faulty spark plug

6. Throttle, if so equipped, in the stop position

Engine runs erratically 1. Spark plug wire loose

2. Spark plug scorched, defective or electrode

gap is set incorrectly

3. Stale fuel

4. Engine running with choke on

5. Water or dirt in fuel system

Engine overheats 1. Engine oil level low 1. Fill engine with proper amount of engine oil

1. Wait at least 10 minutes before starting

2. Connect wire to spark plug

3. Fill tank with clean, fresh gasoline

4. Choke engine

5. Clean, adjust gap or replace

6. Move throttle to FAST/Run position

1. Connect and tighten spark plug wire

2. Re-adjust electrode gap or change

3. Fill tank with clean, fresh gasoline

4. Move choke to off

5. Drain fuel tank. Refill with fresh fuel

20

Page 21

Replacement Parts

Component Part Number and Description

8

951-10292 Spark Plug

951-10794 Air Cleaner (161-VHA)

N/A Air Cleaner Kit (161-JWA)

951-10917A Fuel Cap Assembly (161-VHA)

751-10487A Fuel Cap Assembly (161-JWA)

N/A Key (161-VHA)

731-05632 Key (161-JWA)

Phone (800) 800-7310 or (330) 220-4683 to order replacement parts or a complete Parts Manual (have your full model number and

serial number ready). Parts Manual downloads are also available free of charge at www.mtdproducts.com.

21

Page 22

FEDERAL and/or CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

MTD Consumer Group Inc, the United States Environmental Protection Agency (EPA), and for those products certified for sale in the state

of California, the California Air Resources Board (CARB) are pleased to explain the emission control system (ECS) warranty on your 20152016 small off-road spark-ignited engine and equipment (outdoor equipment). In California, new outdoor equipment must be designed,

built and equipped to meet the State’s stringent anti-smog standards (in other states, outdoor equipment must be designed, built, and

equipped to meet the U.S. EPA small off-road spark ignition engine regulations). MTD Consumer Group Inc must warrant the ECS on your

outdoor equipment for the period of time listed below, provided there has been no abuse, neglect, or improper maintenance of the outdoor

equipment.

Your ECS may include parts such as the carburetor, fuel-injection system, ignition system, catalytic converter, fuel tanks, fuel lines, fuel caps,

valves, canisters, filters, vapor hoses, clamps, connectors, and other associated emission-related components.

Where a warrantable condition exists, MTD Consumer Group Inc will repair your outdoor equipment at no cost to you including diagnosis,

parts, and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emission control system is warranted for two years. If any emission-related part on your outdoor equipment is defective, the part will be

repaired or replaced by MTD Consumer Group Inc.

OWNER’S WARRANTY RESPONSIBILITIES:

As the outdoor equipment owner, you are responsible for performance of the required maintenance listed in your owner’s manual. MTD

Consumer Group Inc recommends that you retain all receipts covering maintenance on your outdoor equipment, but MTD Consumer Group Inc

cannot deny warranty solely for the lack of receipts.

As the outdoor equipment owner, you should however be aware that MTD Consumer Group Inc may deny you warranty coverage if your

outdoor equipment or a part has failed due to abuse, neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your outdoor equipment to MTD Consumer Group Inc’s distribution center or service center as soon as

the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question

regarding your warranty coverage, you should contact the MTD Consumer Group Inc Service Department at 1-800-800-7310 or at

http://support.mtdproducts.com.

GENERAL EMISSIONS WARRANTY COVERAGE:

MTD Consumer Group Inc warrants to the ultimate purchaser and each subsequent purchaser that the outdoor equipment is: (1) designed,

built, and equipped so as to conform with all applicable regulations; and (2) free from defects in materials and workmanship that cause the

failure of a warranted part for a period of two years.

The warranty period begins on the date the outdoor equipment is delivered to an ultimate purchaser or first placed into service.

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied is warranted for

the warranty period stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by MTD

Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the

remainder of the period.

2. Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty period

stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

3. Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied is warranted for the

period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled replacement, the part

will be repaired or replaced by MTD Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

4. Repair or replacement of any warranted part under the warranty provisions herein must be performed at a warranty station at no charge

to the owner.

5. Notwithstanding the provisions herein, warranty services or repairs will be provided at all of our distribution centers that are franchised to

service the subject engines or equipment.

6. The outdoor equipment owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emissionrelated warranted part, provided that such diagnostic work is performed at a warranty station.

7. MTD Consumer Group Inc is liable for damages to other engine or equipment components proximately caused by a failure under

warranty of any warranted part.

8. Throughout the off-road engine and equipment warranty period stated above, MTD Consumer Group Inc will maintain a supply of

warranted parts sufficient to meet the expected demand for such parts.

9. Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to

the owner. Such use will not reduce the warranty obligations of MTD Consumer Group Inc.

Page 23

10. Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any non-exempted add-on or

modified parts by the ultimate purchaser will be grounds for disallowing a warranty claim. MTD Consumer Group Inc will not be liable to

warrant failures of warranted parts caused by the use of a non-exempted add-on or modified part.

WARRANTED PARTS:

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if MTD

Consumer Group Inc demonstrates that the outdoor equipment has been abused, neglected, or improperly maintained, and that such abuse,

neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part. That notwithstanding, any adjustment

of a component that has a factory installed, and properly operating, adjustment limiting device is still eligible for warranty coverage. Further,

the coverage under this warranty extends only to parts that were present on the off-road equipment purchased.

The following emission warranty parts are covered (if applicable):

1. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts (or fuel injection system)

• Fuel pump

• Fuel tank

2. Air Induction System

• Air cleaner

• Intake manifold

3. Ignition System

• Spark plug(s)

• Magneto ignition system

4. Exhaust System

• Catalytic converter

• SAI (Reed valve)

5. Miscellaneous Items Used in Above System

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

6. Evaporative Control

• Fuel hose

• Fuel hose clamps

• Tethered fuel cap

• Carbon canister

• Vapor lines

050790 Rev. D

Page 24

Medidas importantes de seguridad • Conguración • Funcionamiento • Mantenimiento

• Solución de problemas • Garantía

Manual del OperadOr

del MOtOr

Motor de 123cc con eje horizontal y válvulas en cabeza

ADVERTENCIA

LEA Y RESPETE TODAS LAS NORMAS DE SEGURIDAD E INSTRUCCIONES INCLUIDAS EN ESTE

MANUAL ANTES DE PONER EN FUNCIONAMIENTO ESTA MÁQUINA.

SI NO RESPETA ESTAS INSTRUCCIONES PUEDE PROVOCAR LESIONES PERSONALES.

MTD LLC. APARTADO POSTAL 361131 CLEVELAND, OHIO 44136-0019

Impreso en Estados Unidos de América

Page 25

Al propietario

1

Gracias

Este Manual del Operador es una parte importante de su nuevo motor. Le ayudará a preparar y mantener la unidad para obtener los

mejores resultados. Antes de operar el motor lea cuidadosamente y comprenda todo el manual.

Índice

Medidas importantes de seguridad .................... 26

Etiquetas de seguridad ......................................... 28

Conguración ........................................................ 29

Controles y Características ................................... 32

Funcionamiento .................................................... 34

Mantenimiento ...................................................... 37

Solución de problemas ......................................... 43

Piezas De Repuesto ............................................... 44

Declaración de Emisiones/Garantía .................... 47

Registro de información de producto

Antes de operar su motor nuevo, por favor localice su placa de

modelo y registre la información en el área situada a la derecha.

Si tiene que solicitar soporte técnico a través de nuestro sitio

web o de un distribuidor de servicio local, necesitará esta

información.

NúMero de Modelo / NúMero de Serie

/

Asistencia al Cliente

Por favor, NO devuelva la máquina al minorista o distribuidor sin ponerse en contacto primero con el Departamento de

Asistencia al Cliente.

En caso de tener problemas con este producto o de tener dudas con respecto a los controles, funcionamiento o

mantenimiento de este motor, puede solicitar la ayuda de expertos. Elija entre las opciones que se presentan a continuación:

◊ Visite nuestro sitio web en www.mtdproducts.com

Ver Vídeos demostrativos de instalación de mantenimiento y piezas en www.mtdparts.com/ KnowledgeCenter

◊ Llame a un representante de Asistencia al Cliente al (800) 800-7310 ó (330) 220-4683

◊ Escríbanos a MTD LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

25

Page 26

Medidas importantes de seguridad

¡ADVERTENCIA! La presencia de este símbolo indica que se trata de instrucciones de

seguridad importantes que debe respetar para evitar poner en riesgo su seguridad personal

y/o material y la de los demás. Lea y siga todas las instrucciones de este manual antes de

poner en funcionamiento este equipo. Si no respeta estas instrucciones puede provocar

lesiones personales. Cuando vea este símbolo. TENGA EN CUENTA LA ADVERTENCIA.

PROPOSICIÓN 65 DE CALIFORNIA

¡ADVERTENCIA! El escape del motor de este producto, algunos de sus componentes y

algunos componentes del vehículo contienen o liberan sustancias químicas que el estado

de California considera que pueden producir cáncer, defectos de nacimiento u otros

problemas reproductivos.

¡PELIGRO! Esta máquina está diseñada para ser utilizada respetando las normas de seguridad

contenidas en este manual. Al igual que con cualquier tipo de equipo motorizado, un descuido o

error por parte del operador puede producir lesiones graves. Esta máquina es capaz de amputar

dedos, manos y pies y de arrojar objetos extraños con gran fuerza. De no respetar las

instrucciones de seguridad siguientes se pueden producir lesiones graves o la muerte.

2

Capacitación

1. Lea, entienda y cumpla todas las instrucciones incluidas en

el motor y en los manuales antes de montarlo y utilizarlo.

Guarde este manual en un lugar seguro para consultas

futuras y periódicas, así como para solicitar repuestos.

2. Familiarícese con todos los controles y con el uso adecuado

de los mismos. Sepa cómo detener el motor y desactivar

los controles rápidamente.

3. No permita nunca que los niños menores de 14 años

utilicen este motor. Los niños de 14 años en adelante deben

leer y entender las instrucciones de operación y normas

de seguridad contenidas en este manual y en el motor y

deben ser entrenados y supervisados por un adulto.

4. Nunca permita que los adultos operen la máquina sin

recibir antes la instrucción apropiada.

5. Mantenga el área de operación despejada de personas,

particularmente de niños pequeños y mascotas. Detenga la

máquina si alguien se acerca.

Preparativos

1. Inspeccione minuciosamente el área donde utilizará el

equipo. Quite las piedras, palos, alambres y otros objetos

extraños con los que se pueda tropezar y provocar lesiones

personales.

2. Utilice zapatos de trabajo resistentes, de suela fuerte, así

como pantalones y camisas ajustados. Las prendas sueltas

y las alhajas se pueden enganchar en las piezas móviles.

Nunca opere la máquina descalzo o con sandalias.

3. Antes de arrancar el motor, desenganche las palancas del

embrague y desplácelas (en caso de haber) a la posición

neutral (“N”).

4. Nunca deje el motor en marcha sin vigilancia.

5. Nunca intente realizar ajustes mientras el motor está

en marcha, excepto en los casos específicamente

recomendados en el manual del operador.

Manejo seguro de la gasolina:

Para evitar lesiones personales o daños materiales sea

sumamente cuidadoso al manipular la gasolina. La gasolina es

sumamente inflamable y sus vapores pueden causar explosiones.

Si se derrama gasolina encima o sobre la ropa se puede lesionar

gravemente ya que se puede incendiar. Lávese la piel y cámbiese

de ropa de inmediato.

1. Cuando agregue combustible, APAGUE el motor y déjelo

enfriar por lo menos 2 minutos antes de sacar la tapa del

combustible.

2. Llene el tanque de combustible al aire libre o en un área

bien ventilada.

3. Utilice sólo los recipientes para gasolina autorizados.

4. Nunca llene los recipientes en el interior de un vehículo

o camión o caja de remolque con recubrimiento plástico.

Coloque siempre los recipientes en el piso y lejos del

vehículo antes de llenarlos.

5. Si es posible, retire el equipo a gasolina del camión o

remolque y llénelo en el suelo. Si esto no es posible, llene el

equipo en un remolque con un contenedor portátil, en vez

de con una boquilla dispensadora de gasolina.

6. Mantenga la boquilla de llenado en contacto con el

borde del depósito de combustible o con la abertura del

recipiente en todo momento, hasta terminar la carga. No

utilice un dispositivo para abrir/cerrar la boquilla.

26

Page 27

7. No llene demasiado el tanque de combustible. Llene

el tanque completo indicado por el indicador de nivel

de combustible instalado en el interior del depósito de

combustible. No más de relleno para dejar espacio para

la expansión del combustible. En algunos modelos, un

indicador de nivel de combustible no puede estar presente,

en este caso, llenar el tanque sin pulgada más de 1 / 2 por

debajo de la parte inferior de la boca de llenado para dejar

espacio para la expansión del combustible.

8. Reemplace la tapa de combustible y apriete hasta que la

tapa de trinquetes.

9. Limpie el combustible que se haya derramado sobre el

motor y el equipo. Traslade la máquina a otra zona. Espere

cinco minutos antes de encender el motor.

10. Para reducir el riesgo de incendio mantenga la máquina

limpia de pasto, hojas y de la acumulación de otros

desechos. Limpie los derrames de aceite o combustible y

saque todos los residuos embebidos de combustible.

11. Mantenga la gasolina alejada de chispas, llamas expuestas,

llamas piloto, calor, y otras fuentes de ignición.

12. Nunca cargue combustible en el equipo en interiores

porque se acumulan vapores inflamables en el área.

13. Apague todos los cigarrillos, cigarros, pipas y otras fuentes

de ignición.

14. Verifique frecuentemente la línea de combustible, el

depósito, el tapón, y los accesorios buscando rajaduras o

pérdidas. Reemplácelos de ser necesario.

Funcionamiento

1. Al arrancar el motor, asegúrese de que la bujía, el silenciador

y la tapa del combustible están en su lugar.

2. No dé arranque al motor si no está la bujía de encendido.

3. Si se derrama combustible, espere hasta que se evapore

antes de encender el motor.

4. Permita que el silenciador, el cilindro del motor, y las aletas

se enfríen antes de tocarlos.

5. Mantenga a los niños alejados de los motores en marcha o

calientes. Pueden sufrir quemaduras por el contacto con un

silenciador caliente.

6. Extraiga el combustible acumulado en el silenciador y el

cilindro.

7. Haga funcionar el equipo con todos los protectores

colocados.

8. Mantenga las manos y los pies alejados de las piezas

giratorias.

9. Átese el cabello si lo lleva largo y no use alhajas.

10. No use ropa demasiado holgada, con cordones colgantes o

partes que se puedan enganchar.

11. Para encender el motor, jale de la cuerda lentamente hasta

que sienta resistencia, luego jale rápidamente (Si no es de

arranque eléctrico).

12. Antes de arrancar el motor, retire todos los equipos