Page 1

Operator’s Manual

Electric Chain saws

Model MTD1416NT

English

IMPORTANT: READ SAFETY RULES

AND INSTRUCTIONS CAREFULLY

P/N 6096-211304©2005

PRINTED IN CHINA

Page 2

INTRODUCTION

S/N :

ITEM :

MODEL :

THANK YOU

Thank you for buying this quality product. This modern

outdoor power tool will provide many hours of useful

service. You will find it to be a great labor-saving device.

This operator’s manual provides you with easy-tounderstand operating instructions. Read the whole

manual and follow all the instructions to keep your new

outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS

AND SPECIFICATIONS

All information, illustrations, and specifications in this

manual are based on the latest product information

available at the time of printing. We reserve the right to

make changes at any time without notice.

Copyright© 2004 MTD SOUTHWEST INC, All Rights

Reserved.

SERVICE INFORMATION

Service on this unit both within and after the warranty

period should be performed only by an authorized and

approved service dealer.

For service call 1-800-668-1238 to obtain a list of

authorized service dealers near you. For more details

about your unit, visit our website at

www.yardmachines.com.

DO NOT RETURN THE UNIT TO THE RETAILER.

PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

Before beginning, locate the unit’s model plate. It lists

the model and serial numbers of your unit. Refer to the

sample plate below and copy the information for future

reference.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . .2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . .3

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starting/Stopping Instructions . . . . . . . . . . . . . . . .10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . .11

Maintenance and Repair Instructions . . . . . . . . . . .13

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . .19

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Warranty Information . . . . . . . . . . . . . . . . . . . . . . .21

Copy the model and parent

part number here:

Copy the serial number

here:

Make sure you carefully read and understand this manual before starting or operating this equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS. OTHER PATENTS PENDING.

2

Page 3

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

their explanations, deserve your careful attention

and

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING

SAFETY ALERT:

warning or caution. Attention is required in

order to avoid serious personal injury. May

be used in conjunction with other symbols

or pictographs.

NOTE: Advises you of information or instructions vital to

the operation or maintenance of the equipment.

Read the Operator’s Manual(s) and follow all

warnings and safety instructions.

Failure to do so can result in serious injury to the

operator and/or bystanders.

Indicates

danger,

FOR QUESTIONS, CALL 1-800-668-1238

SYMBOL MEANING

DANGER:

result in serious injury to yourself or to

others. Always follow the safety precautions

to reduce the risk of fire, electric shock and

personal injury.

WARNING:

result in injury to yourself and others.

Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

CAUTION:

result in property damage or personal injury

to yourself or to others. Always follow the

safety precautions to reduce the risk of fire,

electric shock and personal injury.

Failure to obey a

safety warning will

Failure to obey a

safety warning can

Failure to obey a

safety warning may

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS

BEFORE OPERATING

ectly used,

r

WARNING:

quick, easy to handle and efficient tool; if

used improperly or without the due

precautions it could become a dangerous

tool. For pleasant and safe work,always

strictly comply with the safety r

follow and thr

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Only responsible individuals who are familiar with the

instructions may operate the chain saw (no one under

the age of 16). Provide parental supervision at all times

Inspect the unit before use. Replace damaged parts.

•

Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped or damaged

in any way.

Know the controls and know how to stop the chain

•

saw quickly.

oughout this manual.

If cor

the chain saw is a

ules that

• Carry the chain saw with the motor stopped, and with

the guide bar and saw chain to the rear.

• When transporting your chain saw, use the

appropriate guide-bar scabbard (sheath).

WHILE OPERATING

• Keep all parts of your body away from the chain when

the motor is running.

• Wear safety glasses or goggles that are marked as

meeting ANSI Z87.1-1989 standards. Also wear

ear/hearing protection when operating this unit. Wear

a face or dust mask if the operation is dusty. Long

sleeve shirts are recommended.

Wear heavy, long pants, boots or safety footwear and

•

protective gloves. Do not wear loose clothing, jewelry,

short pants, sandals or go barefoot. Secure hair above

.

shoulder level.

Use the unit only in daylight or good artificial light.

•

Before you start the motor, make sure that the saw’s

•

chain is not contacting anything. Do not cut near

electrical cables or power lines.

Do not start cutting until you have a clear work area,

•

secure footing, and a planned retreat path from the

falling tree.

3

Page 4

RULES FOR SAFE OPERATION

• Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw’s chain stops moving

when the throttle control trigger is released.

Use extreme caution when cutting small-sized brush

•

and saplings because slender material may catch the

chain saw and whip towards you or pull you off

balance.

• When cutting a limb that is under tension, be alert for

springback so that you will not be struck when the

tension in the wood fibers is released

• Do not cut through nails, rods in the tree, railroad ties

or pallates. Inspect a tree that you are going to cut for

foreign objects that could cause injury or damage to

your chain saw.

• After striking a foreign object, stop the motor and

thoroughly inspect for damage. Repair as necessary.

• We do not recommend using the chain saw in a tree or

on a ladder.

• All chain saw service, other that the items listed in this

instruction manual maintenance instructions, should be

performed by competent chain saw service personnel.

• Use the right tool. Only use this chain saw for its

intended purpose, to cut wood.

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on all handles or grips.

• Apply chain brake prior to any repositioning of the

operator in the cutting area. As an additional safety

precaution, apply the chain brake prior to setting down

the saw.

• Never touch the chain or attempt to service the saw

while the motor is running. Make sure all moving parts

have stopped. Allow the chain saw to cool, as the

chain can be hot.

Check the bar and chain at frequent intervals for

•

proper adjustment. Make sure the bar and chain are

properly tightened and sharpened. Visually inspect for

damage. Repair any damage before restarting or

operating the chain saw.

WARNING:

KICKBACK may

occur when the nose

or tip of the guide bar touches an object, or

when the wood closes in and pinches the

saw chain in the cut. Tip contact in some

cases may cause a lightning-fast reverse

reaction, kicking the guide bar up and back

towards the operator. Pinching the saw chain

along the top of the guide bar may push the

guide bar rapidly back toward the operator.

Either of these reactions may cause you to

lose control of the saw , which could r esult in

serious personal injury .

Do not rely exclusively upon the safety

devices built into your saw. As a chain saw

user, you should take several steps to keep

your cutting jobs free from accident or injury.

KICKBACK SAFETY PRECAUTIONS

• With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents. Be alert to the

potential for kickback at all times.

• Keep a good firm grip on the saw with both hands, the

right hand on the rear handle and the left hand on the

front handle, when the motor is running. Use a firm grip

with thumbs and fingers encircling the chain saw

handles. A firm grip will help you reduce kickback and

maintain control of the saw. Don’t let go.

• Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of the guide bar

contact a log, branch, fence, or any other obstruction

that could be hit while you are operating the saw.

• Always cut with the motor running at full speed. Fully

squeeze the throttle trigger and maintain a steady

cutting speed.

• Use only the correct original equipment manufacturer

replacement bars, chains and other parts and

accessories. These are available from your authorized

service dealer. Use of any unauthorized parts or

accessories could lead to serious injury to the user, or

damage to the unit, and will void your warranty.

• Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

• Use only the replacement guide bars and low kickback

chains specified for your saw to avoid injury.

4

Page 5

RULES FOR SAFE OPERATION

OTHER SAFETY PRECAUTIONS

• Do not operate a chain saw with one hand! Serious

injury to the operator, helpers, bystanders, or any

combination of these persons may result from onehanded operation. A chain saw is intended for twohanded use.

• Do not operate a chain saw if you are fatigued.

• Use safety footwear; snug-fitted clothing; protective

gloves; and eye, hearing, and head protection devices.

• Do not allow other persons to be near the chain saw

when starting or cutting with the chain saw. Keep

bystanders and animals out of the work area.

• Do not remove, damage or de-activate any of the

safety devices. Never use a damaged, modified, or

improperly repaired or assembled chain saw. Check

their proper operation regularly. Only use bars and

chains of the length indicated in the table herein.

• Never carry out operations or repairs on your own that

are other than routine maintenance. For information,

contact specialized and authorized workshops only.

• If your chain saw is no longer usable, dispose of it

properly without damaging the environment by

handing it in to your local dealer who will arrange for

its correct disposal.

• Use caution when felling a tree. Make sure you have

planned an escape path when felling, and keep all

bystanders away.

• Be alert; stop the machine if anyone enters the cutting

area, which is usually 3 to 4 feet around the operator.

• Use caution when working in a crew to avoid injury to

a fellow worker who may enter the cutting area.

• Only loan your saw to experienced users who are

completely familiar with saw operation and correct

use. Give other users this manual, which they should

read before using the saw. Provide them the operating

instructions.

• Shut off the motor before setting down the saw. Do

not leave the motor running unattended.

Store the unit in a dry area, locked up, located up high

•

and located out of the reach of children to prevent

unauthorized use or damage.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

• Do not use the unit in the rain, in a storm or in

inclement weather. Wait until the storm danger has

passed before operation of this product.

ELECTRICAL SAFETY WARNINGS

• Since the tool is double-insulated, a 2-wire extension

cord (an extension cord without a ground) may be

used. A 3-wire extension cord (an extension cord with

a ground) that uses a NEMA type connector (parallel

blade, U ground) is recommended. Extension cords are

available from your local retailer. Use only roundjacketed extension cords approved for outdoor use.

• This tool is double-insulated. Repair or replace

damaged cords.

• To reduce the risk of electrical shock, this unit has a

polarized plug (one blade is wider than the other). This

unit will fit with a polarized plug in one way only. If the

plug does not fit fully into the unit, reverse the plug. If it

still does not fit, use a cord with the correct

connection. Do not modify the unit in any way.

WARNING:

only SW-A, SOW-A, STW-A, STOW-A, SJW-A,

SJOW-A, SJTW-W or SJTOW-A cord types.

To reduce the risk of

electrical shock, use

5

Page 6

RULES FOR SAFE OPERATION

ELECTRICAL SAFETY WARNINGS (CONT’D)

• CORD SETS: Make sure your cord set is in good

condition, with a cord that is heavy enough to carry the

current that your unit will draw. An undersized cord set

will cause a drop in line voltage resulting in a loss of

power, as well as overheating. The table shown below

illustrates the correct size to use depending on the

cord length and nameplate amperage rating. If in

doubt, use the next heavier size line gauge. The

smaller the gauge number, the heavier the cord. To

prevent the cord from disconnecting from the unit, use

the cord hook shown in the Starting/Stopping

Instructions.

• Ground Fault Circuit Interrupter (GFCI) protection

should be provided on the circuit(s) or outlet(s) that will

be used for the unit. Use receptacles with built-in GFCI

protection for an extra measure of safety.

• Avoid dangerous environments. Never operate your unit in

damp or wet conditions. Moisture is a shock hazard.

• Inspect all extension cords and the unit power connection

periodically. Look closely for deterioration, cuts or cracks in

the insulation. Also inspect the connections for damage.

Repair or replace the cords if any defects appear.

• Do not handle the plug or the unit with wet hands.

• Examine the electrical switches. Do not use the chain

saw if the switches do not properly turn on and off. Do

not attempt to make any repairs to the electric

switches. Take your saw to an Authorized Service

Center.

• Keep the cord away from the cutting area and to

position cord so that it will not be caught on branches,

and the like, during cutting.

• Use an extension cord heavy enough to carry the

current the tool will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power

and overheating.

• This electric powered saw is classified by CSA as a

Class 2C saw. It is intended for infrequent use by

homeowner’s, cottagers and campers, and for such

general applications such as clearing, pruning, cutting

firewood, etc. It is not intended for prolonged use. If

the intended use involves prolonged periods of

operation, this may cause circulatory problems in the

user’s hands due to vibration. It may be appropriate to

use a saw having an anti-vibration feature.

Minimum Gauge Wire

Saw Model

MTD1416NT 13.5 110 / 120 16 Gauge 16 Gauge 14 Gauge

Ampere

Rating

Volts AC

25 ft. / 7.5m 50 ft. / 15m 100 ft. / 30m

Length of Power Cord

SAVE THESE INSTRUCTIONS

6

Page 7

RULES FOR SAFE OPERATION

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

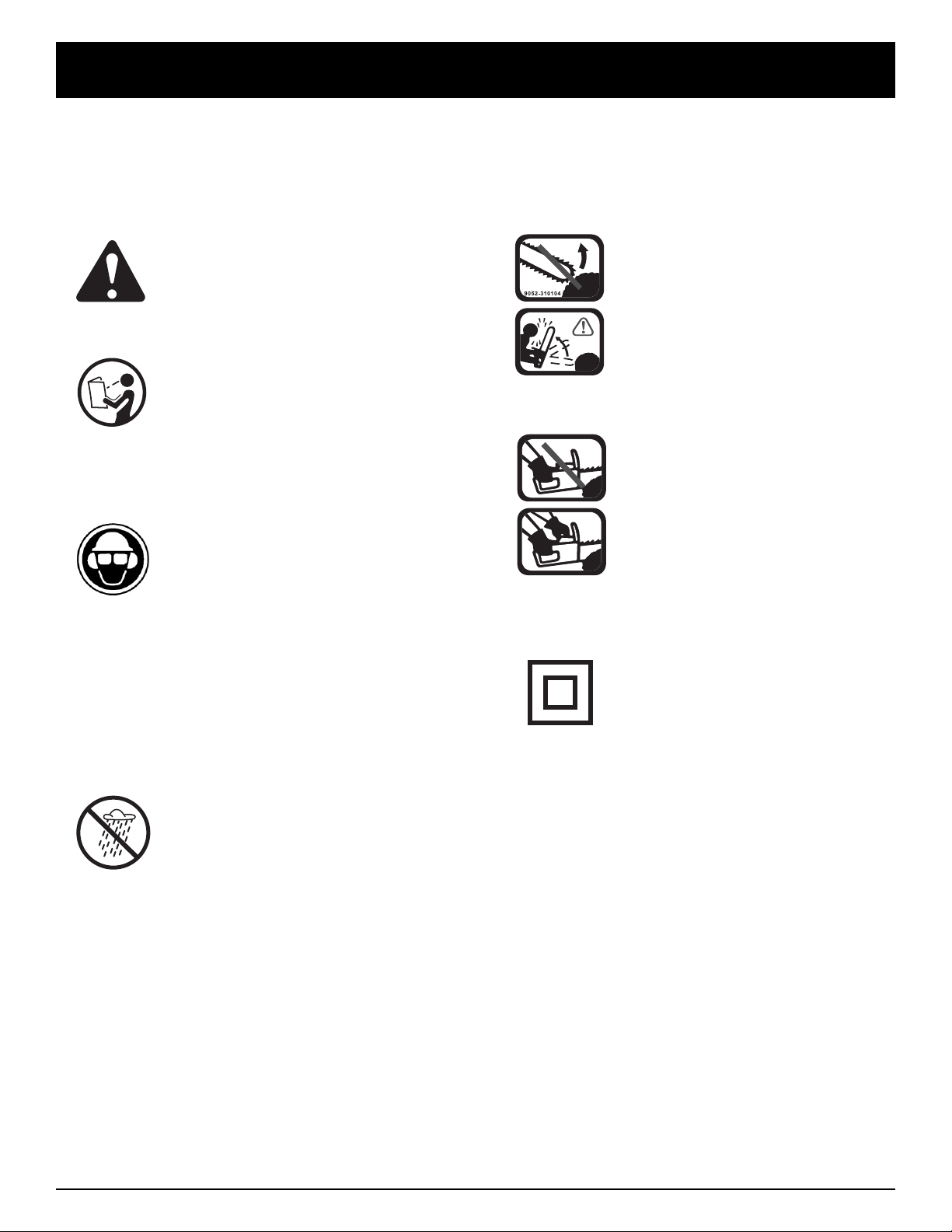

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning, or

caution. May be used in conjunction

with other symbols or pictographs.

• WARNING - READ OPERATOR'S

MANUAL

Read the Operator’s Manual(s) and

follow all warnings and safety

instructions. Failure to do so can

result in serious injury to the

operator and/or bystanders.

• WEAR EYE, HEARING AND

HARDHAT PROTECTION

WARNING:Thrown

objects and loud noise can cause

severe eye injury and hearing loss.

Wear eye protection meeting ANSI

Z87.1-1989 standards and ear

protection when

operating this unit. Wear a hard hat.

Use a full face shield when needed.

SYMBOL MEANING

• GUIDE BAR WARNING:

Contact of the guide bar tip with any

object should be avoided. Tip

contact may cause the guide bar to

move suddenly upward and

backward, which may cause serious

injury.

• USE BOTH HANDS

Always use both hands while

operating the chain saw. Never use

only one hand to operate the saw.

Avoid bar nose contact.

• DOUBLE INSULATED

Two systems of insulation are

provided instead of grounding.

There is no grounding provided

and no means of grounding should

be added to this unit.

• DO NOT USE IN THE RAIN

WARNING:Avoid

dangerous environments. Never

operate your unit in the rain, or in

damp or wet conditions. Moisture is

a shock hazard.

7

Page 8

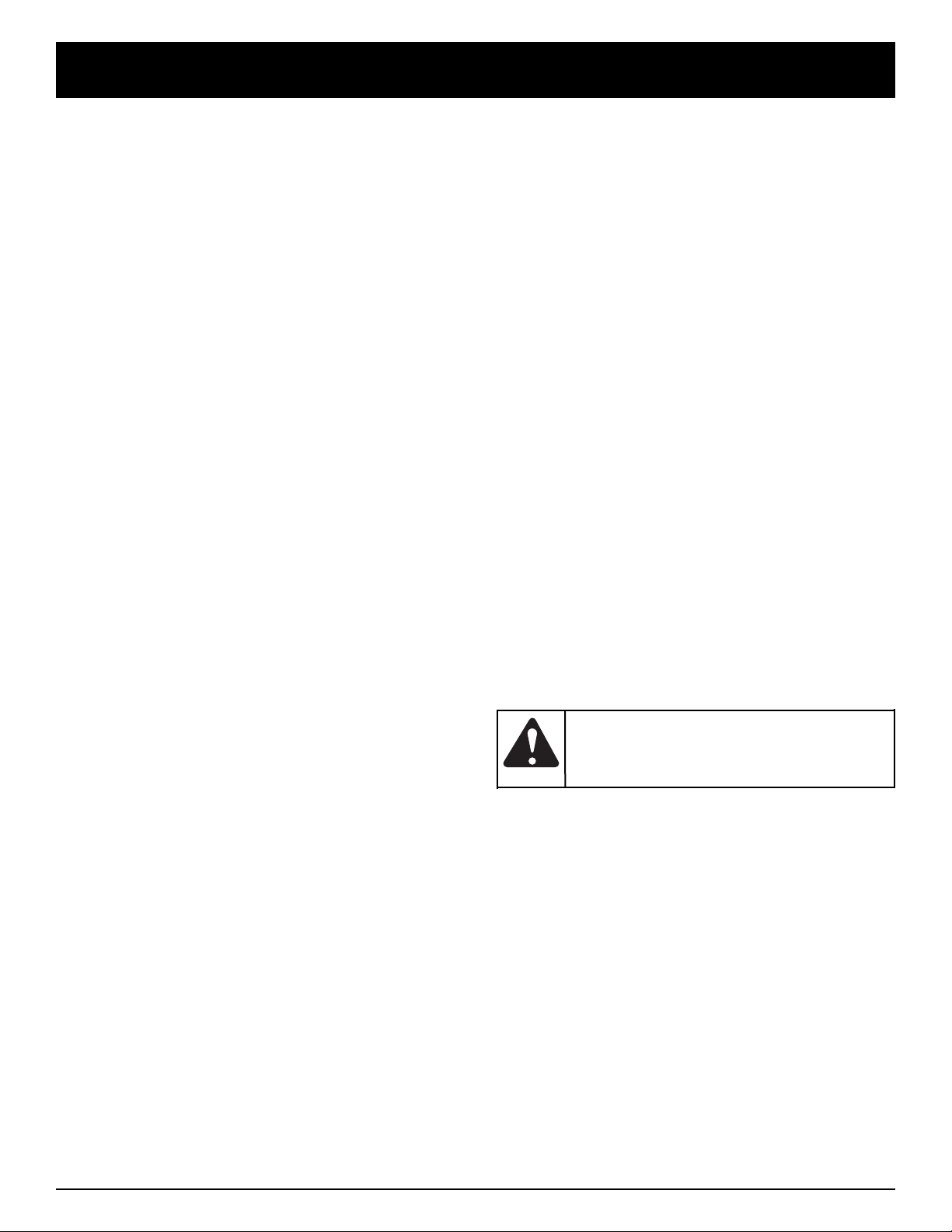

KNOW YOUR UNIT

RULES FOR SAFE OPERATION

20

18

16

9

14

2

3

5

17

4

6

19

11

10

1

8

15

7

12

13

CHAIN SAW COMPONENTS

1. REAR HANDLE

2. OIL TANK CAP

3. TRIGGER START/STOP SWITCH

4. SPROCKET COVER

5. BAR BOLT KNOB

6. CHAIN TENSION RING

7. ELECTRIC MOTOR

8. ELECTRIC CORD

9. CHAIN BRAKE® LEVER / HAND GUARD

LOCK / OFF BUTTON

10.

11. FRONT HANDLE

12. GUIDE BAR

13. SAW CHAIN

14. SPIKES

REAR HAND GUARD

15.

16. SPROCKET

17. OIL TANK WINDOW

18. CORD RETAINER

CHAIN CATCHER

19.

CARRY CASE (Available on some models)

20.

SAFETY FEATURES

Numbers preceding the descriptions correspond with the

numbers above to help you locate the safety feature.

3 TRIGGER START / STOP SWITCH stops saw motor

when released.

7 ELECTRIC MOTOR is double insulated for added

safety.

CHAIN BRAKE® LEVER / HAND GUARD protects the

9

operator’s left hand in the event it slips off the front

handle while saw is running.

10 LOCK / OFF BUTTON prevents accidental

acceleration of the saw motor. The trigger cannot be

squeezed unless lock/off button is depressed.

13 LOW KICKBACK SAW CHAIN helps significantly

reduce kickback, or the intensity of kickback, due to

specially designed depth gauges and guard links.

CHAIN CATCHER reduces the danger of injury in the

19

event saw chain breaks or derails during operation.

The chain catcher is designed to intercept a whipping

chain.

8

Page 9

RULES FOR SAFE OPERATION

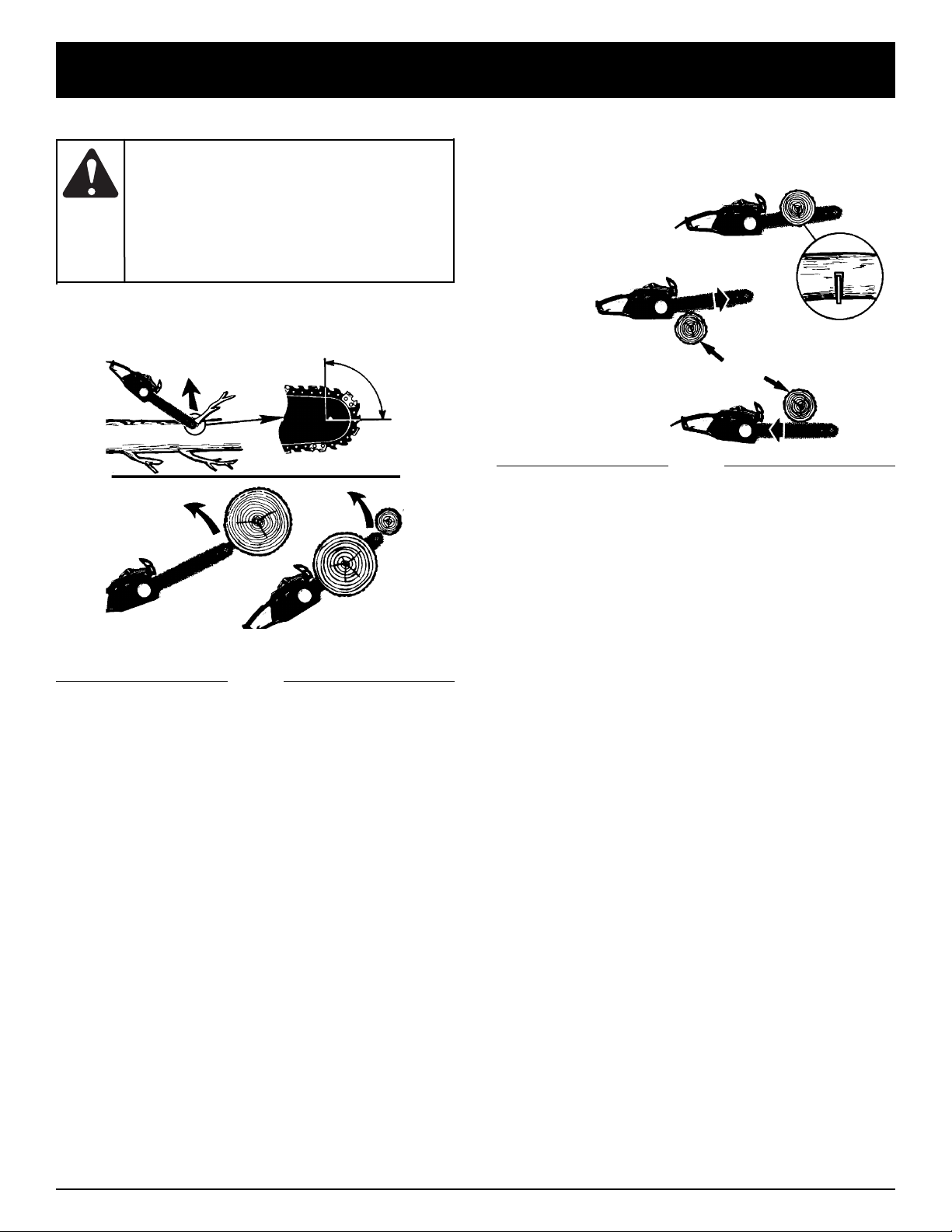

KICKBACK SPECIFICS

WARNING:

control of the chain saw and result in serious

or fatal injury to the saw operator or to

anyone standing close by . Always be alert.

Rotational kickback and pinch-kickback are

major chain saw operational dangers and

the leading cause of most accidents.

Beware of:

Rotational Kickback

A

A

A = Kickback path

B = Kickback reaction zone

Fig. 1

Kickback can lead

to dangerous loss of

B

A

KICKBACK SPECIFICS

Beware of:

Pinch Kickback

A

B

B

A = Pull

B = Solid objects

C = Push

Fig. 2

KICKBACK may occur when the NOSE or TIP of the

guide bar touches an object, or when wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse reaction, kicking the guide bar up and back

toward the operator.

PINCHING the saw chain along the BOTTOM of the

guide bar may PULL the saw forward away from the

operator. PINCHING the saw chain along the TOP of the

guide bar may PUSH the guide bar rapidly back toward

the operator.

Any of these reactions may cause you to lose control of

the saw, which could result in serious personal injury.

C

9

Page 10

STARTING/STOPPING INSTRUCTIONS

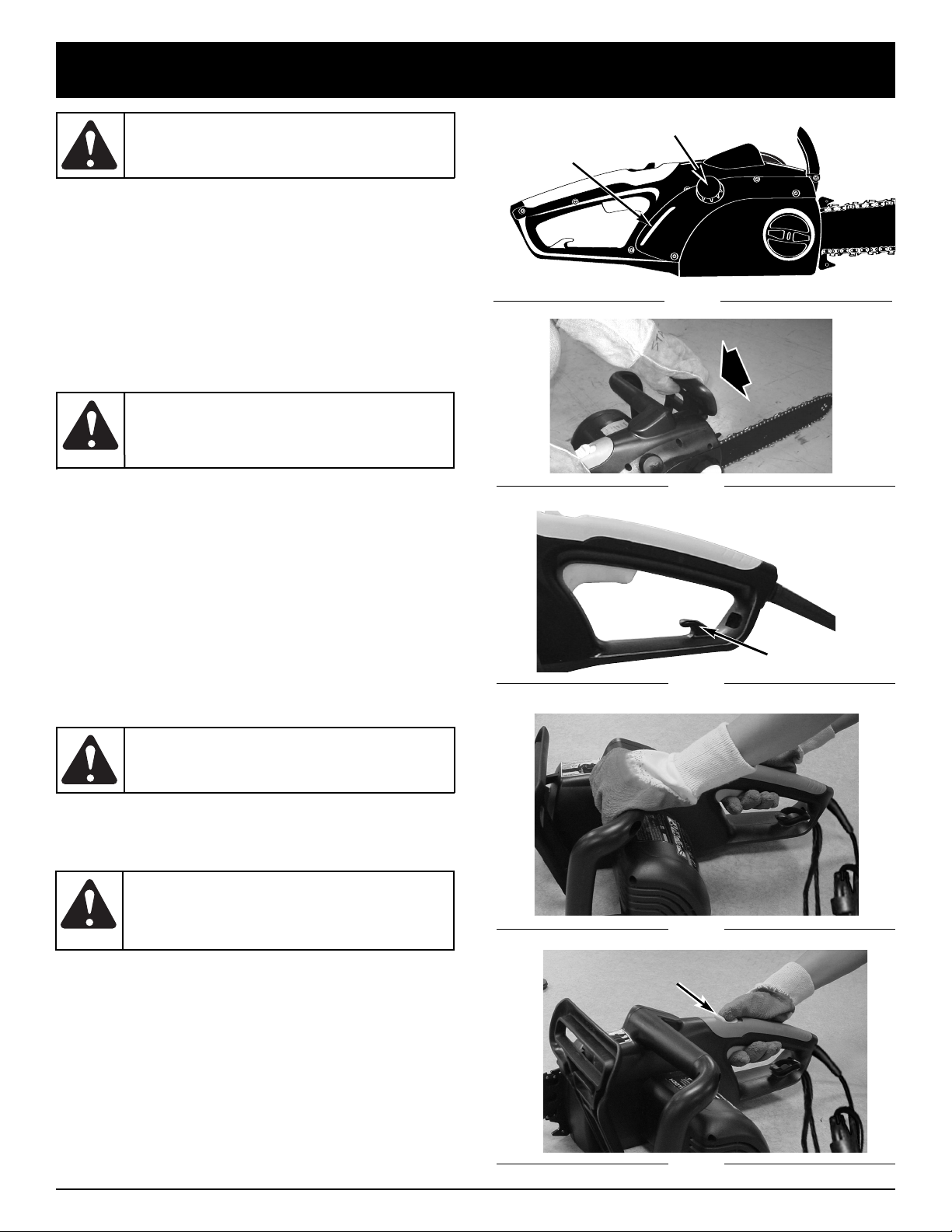

WARNING:

chain properly installed.

Never operate the saw

without the bar and

STARTING INSTRUCTIONS

1. Fill the oil tank with correct chain and bar oil (Fig. 3).

Use a funnel, wipe up any spills and make sure no dirt

gets into the tank.

NOTE: The saw chain requires lubrication when in use to

NOTE: Your chain saw is equipped with an Automatic

2. Be certain the Chain Brake® is disengaged before

3. Hook the extension cord to the extension cord retainer

minimize friction with the guide bar. The oil tank

holds 4.5 ozs of oil, enough to lubricate the chain

for 12-15 minutes of sawing. We recommend

using original equipment manufacturer Bar and

Sprocket Oil, which contains additives to reduce

friction wear and reduce resin residue formations.

CAUTION:

checked during operation to avoid starving

the bar and chain of lubrication.

Oiler system and is the ONLY source of

lubrication for the bar and chain.

starting unit (Fig. 4). Disengage it by pulling backward

toward the motor.

(A) (Fig. 5) that is built into the rear handle. This will

prevent the cord from pulling out of the handle. Double

the extension cord, about a foot from the end, and

insert it through the hole at the end of the handle.

Hook the loop formed by doubling the cord over the

tab. Gently tug on the cord to ensure that it is firmly

retained in the saws handle. Plug the receptacle end of

the extension cord into the tool’s power supply cord.

The oil tank level

should be frequently

Oil Tank

Oil Cap

Inspection Spot

Fig. 3

A

Fig. 4

A

Fig. 5

WARNING:

size and type for your saw.

4. Grip the saw with both hands, left hand holding the

front /handle (DO NOT HOLD CHAIN BRAKE®) and

the right hand holding the rear handle. Thumbs and

fingers should encircle both handles (Fig. 6).

WARNING:

not come in contact with the guide bar and

saw chain.

With your right thumb, depress the LOCK/OFF button

5.

(C) on the top of the rear handle, and at the same

time squeeze the trigger. To stop the saw, release the

trigger (Fig. 7).

NOTE: It is not necessary to maintain pressure on the

LOCK/OFF button once the trigger is squeezed

and the motor is running. The LOCK/OFF button

is a safety device to avoid accidental starting.

Ensure the extension

cord is of the proper

Make sure the

extension cord does

STOPPING INSTRUCTIONS

The saw motor will automatically stop when the trigger is

released. To restart the motor, you will have to depress

the LOCK/OFF button and squeeze the trigger.

Fig. 6

C

Fig. 7

10

Page 11

OPERATING INSTRUCTIONS

FELLING

Felling is the term for cutting down a tree. Small trees up

to 6-7 inches (15-18cm) in diameter are usually cut in a

single cut. Larger trees require notch cuts. Notch cuts

determine the direction the tree will fall.

WARNING:

and cleared as necessary before cuts are

started. The retreat path should extend

back and diagonally to the rear of the

expected line of fall, as illustrated in Fig. 8.

CAUTION:

chain saw operator should keep on the

uphill side of the terrain, as the tree is likely

to roll or slide downhill after it is felled.

NOTE: Direction of fall (B) is controlled by the notching

cut. Before any cuts are made, consider the

location of larger branches and natural lean of the

tree to determine the way the tree will fall.

A retreat path (A)

should be planned

If felling a tree on

sloping ground, the

WARNING:

notched.

Make the felling cut (D) from the other side of the tree

and 1.5 - 2.0 inches (3-5 cm) above the edge of the

notch (C) (Fig. 9).

Fig. 9

Never saw completely through the trunk. Always leave a

hinge. The hinge guides the tree. If the trunk is completely

cut through, control over the felling direction is lost.

Never walk in front of

a tree that has been

B

A

Fig. 8

WARNING:

changing winds or if there is a danger to

property. Consult a tree professional.Do not

cut down a tree if there is a danger of

striking utility wires; notify the utility

company befor

Normally felling consists of 2 main cutting operations,

notching (C) and making the felling cut (D).

Start making the upper notch cut (C) on the side of the

tree facing the felling direction (E). Be sure you don t

make the lower cut too deep into the trunk.

The notch (C) should be deep enough to create a hinge

(F) of sufficient width and strength. The notch should be

wide enough to direct the fall of the tree for as long as

possible.

e making any cuts.

Do not cut down a

tree during high or

WARNING:

the area for bystanders, animals or obstacles.

Insert a wedge or felling lever in the cut well before the

tree becomes unstable and starts to move. This will

prevent the guidebar from binding in the felling cut if you

have misjudged the falling direction. Make sure no

bystanders have entered the range of the falling tree

before you push it over.

Felling Cut:

1. Use wooden or plastic wedges (G) to prevent binding

the bar or chain (H) in the cut. Wedges also control

felling (Fig. 10).

2. When diameter of wood being cut is greater than the

bar length, make 2 cuts as shown (Fig. 11).

WARNING:

hinge, the tree should begin to fall. When

tree begins to fall, remove saw from cut,

stop motor

ea along r

ar

, put chain saw down, and leave

eat path (Fig. 8).

etr

G

Fig. 10

Before making the

final cut, always recheck

As the felling cut

gets close to the

H

11

Page 12

OPERATING INSTRUCTIONS

Fig. 11

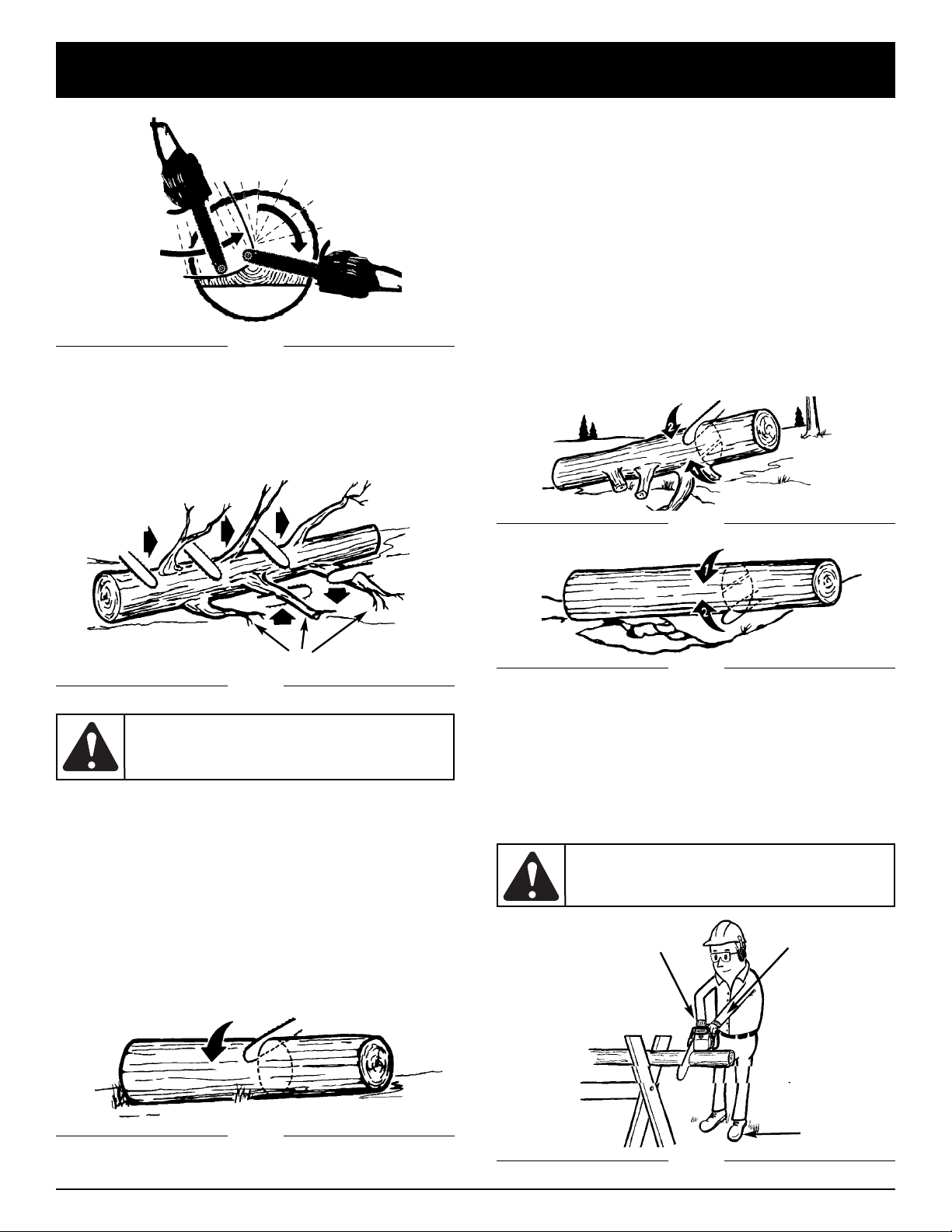

LIMBING

Limbing a tree is the process of removing the branches

from a fallen tree. Do not remove supporting limbs (A)

until after the log is bucked (cut) into lengths (Fig. 12).

Branches under tension should be cut from the bottom

up to avoid binding the chain saw.

When bucking on a slope, always stand on the uphill side.

1. Log supported along entire length: Cut from top

(overbuck), being careful to avoid cutting into the

ground (Fig. 13).

2. Log supported on 1 end: First, cut from bottom

(underbuck) 1/3 diameter of log to avoid splintering.

Second, cut from above (overbuck) to meet first cut

and avoid pinching (Fig. 14).

3. Log supported on both ends: First, overbuck 1/3

diameter of log to avoid splintering. Second, underbuck

to meet first cut and avoid pinching (Fig. 15).

NOTE: The best way to hold a log while bucking is to use

a sawhorse. When this is not possible, the log

should be raised and supported by the limb

stumps or by using supporting logs. Be sure the

log being cut is securely supported.

Fig. 14

A

Fig. 12

WARNING:

tree trunk.

Never cut tree limbs

while standing on a

BUCKING

Bucking is cutting a fallen log into lengths. Make sure

you have a good footing and stand uphill of the log when

cutting on sloping ground. If possible, the log should be

supported so that the end to be cut off is not resting on

the ground. If the log is supported at both ends and you

must cut in the middle, make a downward cut halfway

through the log and then make the undercut. This will

prevent the log from pinching the bar and chain. Be

careful that the chain does not cut into the ground when

bucking as this causes rapid dulling of the chain.

Fig. 15

BUCKING USING A SAWHORSE

For personal safety and ease of cutting, the correct

position for vertical bucking is essential (Fig. 16).

A. Hold the saw firmly with both hands and keep the

saw to the right of your body while cutting.

B. Keep the left arm as straight as possible.

C. Keep weight on both feet.

CAUTION:

chain and bar are being properly lubricated.

A

While the saw is

cutting, be sure the

B

Fig. 13

C

Fig. 16

12

Page 13

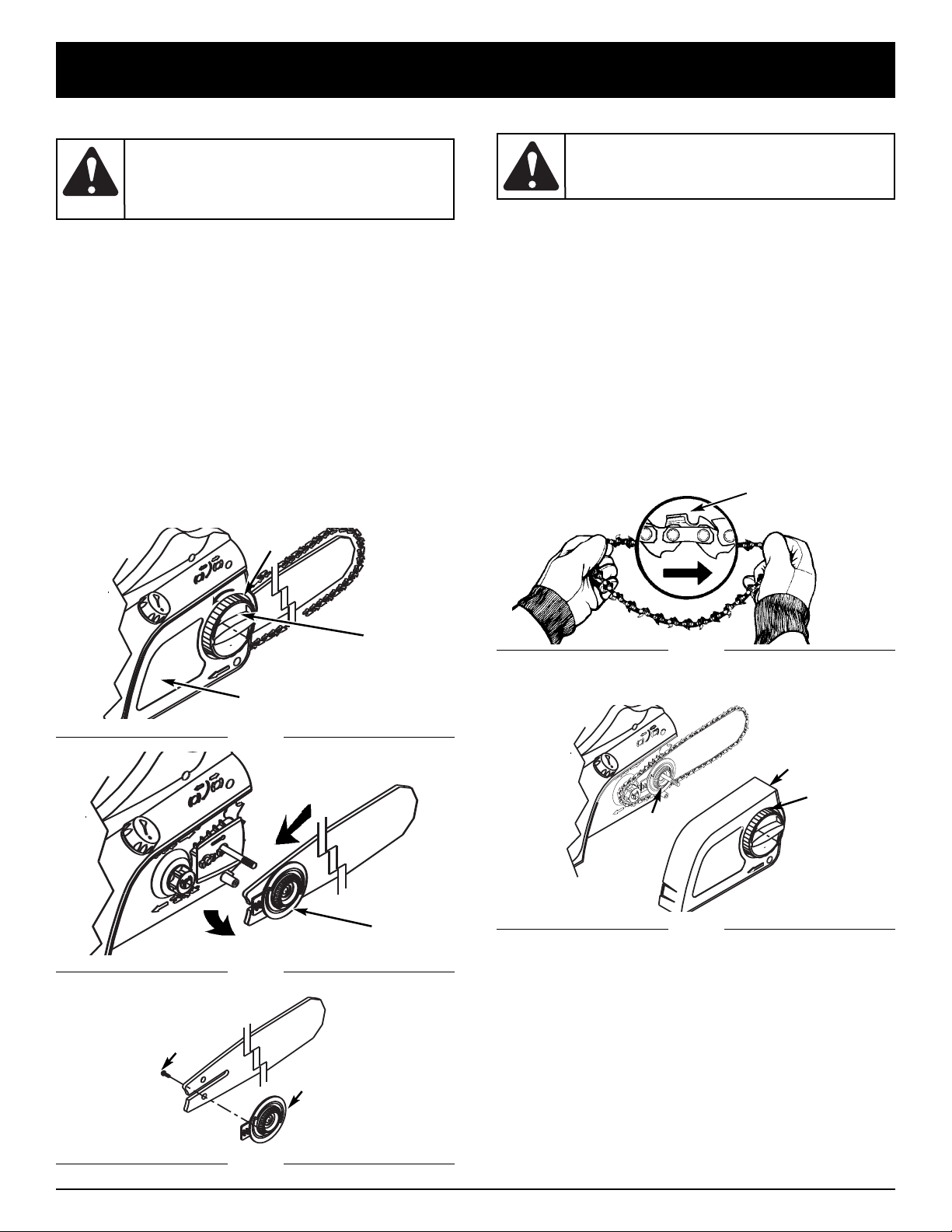

MAINTENANCE AND REPAIR INSTRUCTIONS

INSTALL THE GUIDE BAR

CAUTION:

source before checking or adjusting the

chain saw tension.

These instructions are for replaciing a bar. The unit is

fully assembled when shipped.

Note: Always wear heavy gloves when handling the saw

chain.

1. Place the power unit on a flat surface.

2. Loosen knob (B) slightly by turning knob counterclockwise and then turn the chain tension ring (C)

counter-clockwise to relieve chain tension (Fig. 17).

3. To remove the sprocket cover (A), turn knob (B)

counter-clockwise. (Fig. 17)

4. Remove saw chain from around the guide bar and

the sprocket. Slide the guide bar, with tension plate

(D) attached, from the unit. (Fig. 18)

5. Remove screw (C) from the tension plate (D) to

remove it from the old bar and attach it to the new

bar. (Fig. 19)

Disconnect the chain

saw from power

C

INSTALL THE SAW CHAIN

WARNING:

when handling the saw chain.

1. Spread the chain out with the cutting edges (E) of

the chain pointing in the DIRECTION OF ROTATION

(Fig. 20).

2. To fit the chain links into the groove on the guide bar,

turn the tension plate (D) counter-clockwise to the

end. Install the chain and bar on the power unit, turn

the tension plate (D) clockwise and then put the side

cover (A) on (Fig. 21).

3. Turn the knob clockwise, adjust the chain tension

ring (F) and then tighten the knob. See Saw Chain

Tension Adjustment P14.

4. After running the chain saw even for just 1 hour,

retensioning of the chain may be needed. Follow the

tension adjustment instructions in the next section.

Always use

protective gloves

E

B

A

Fig. 17

D

Fig. 18

C

D

Fig. 20

A

F

D

Fig. 21

Fig. 19

13

Page 14

MAINTENANCE AND REPAIR INSTRUCTIONS

SAW CHAIN TENSION ADJUSTMENT

WARNING:

when handling the saw chain.

Proper tension of saw chain is extremely important and

must be checked before starting, as well as during any

cutting operation.

Taking the time to make needed adjustments to the saw

chain will result in improved cutting performance and

prolonged chain life.

NOTE: A new chain and bar will need readjustment after

as few as 5 cuts. This is normal during the breakin period, and the interval between future

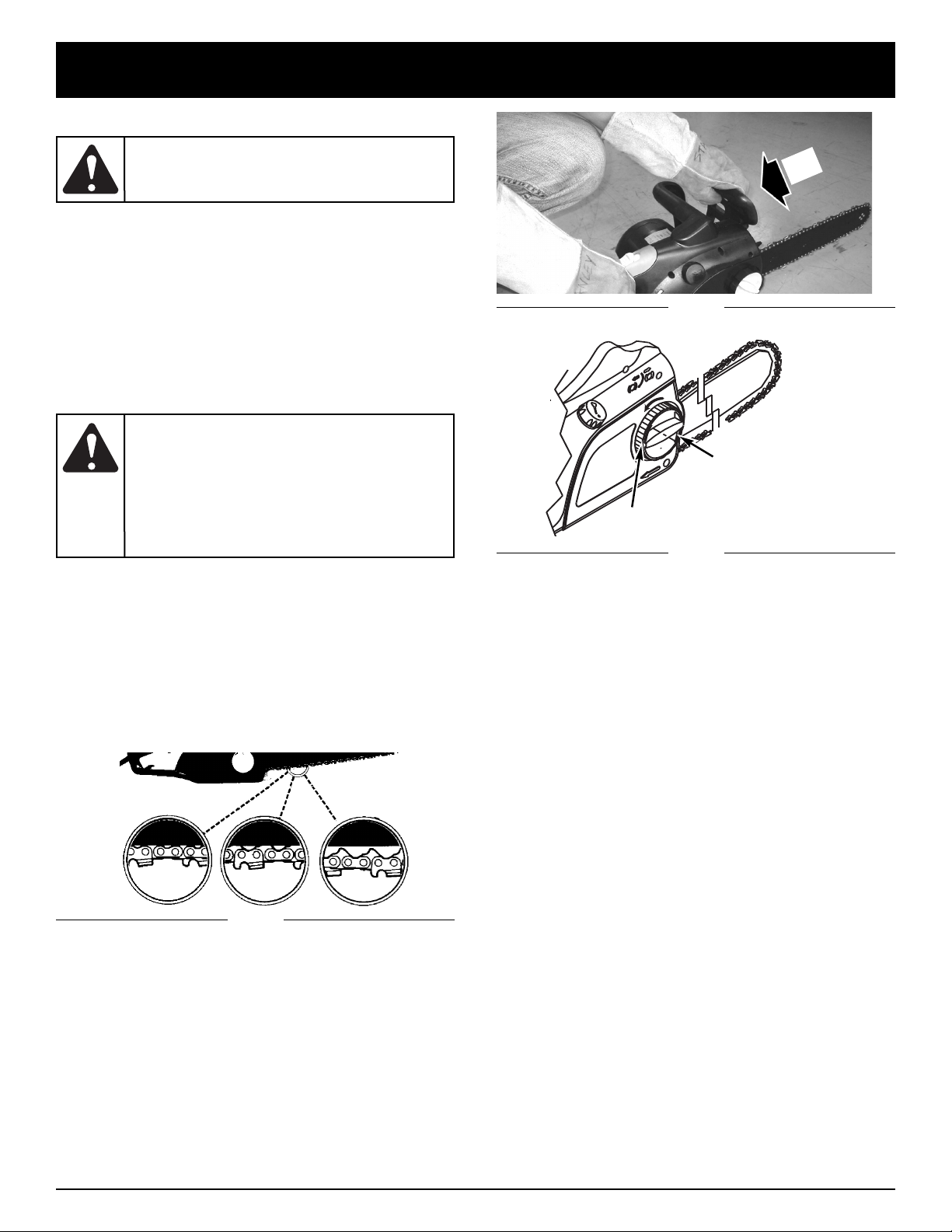

adjustments will lengthen quickly (Fig. 22).

CAUTION:

TIGHT, the sprocket, bar, chain, and

crankshaft bearings will wear more rapidly.

Study Fig. 22 for information concerning

correct cold tension (A), correct warm

tension (B), and as a guide for when saw

chain needs adjustment (C).

To adjust the saw chain:

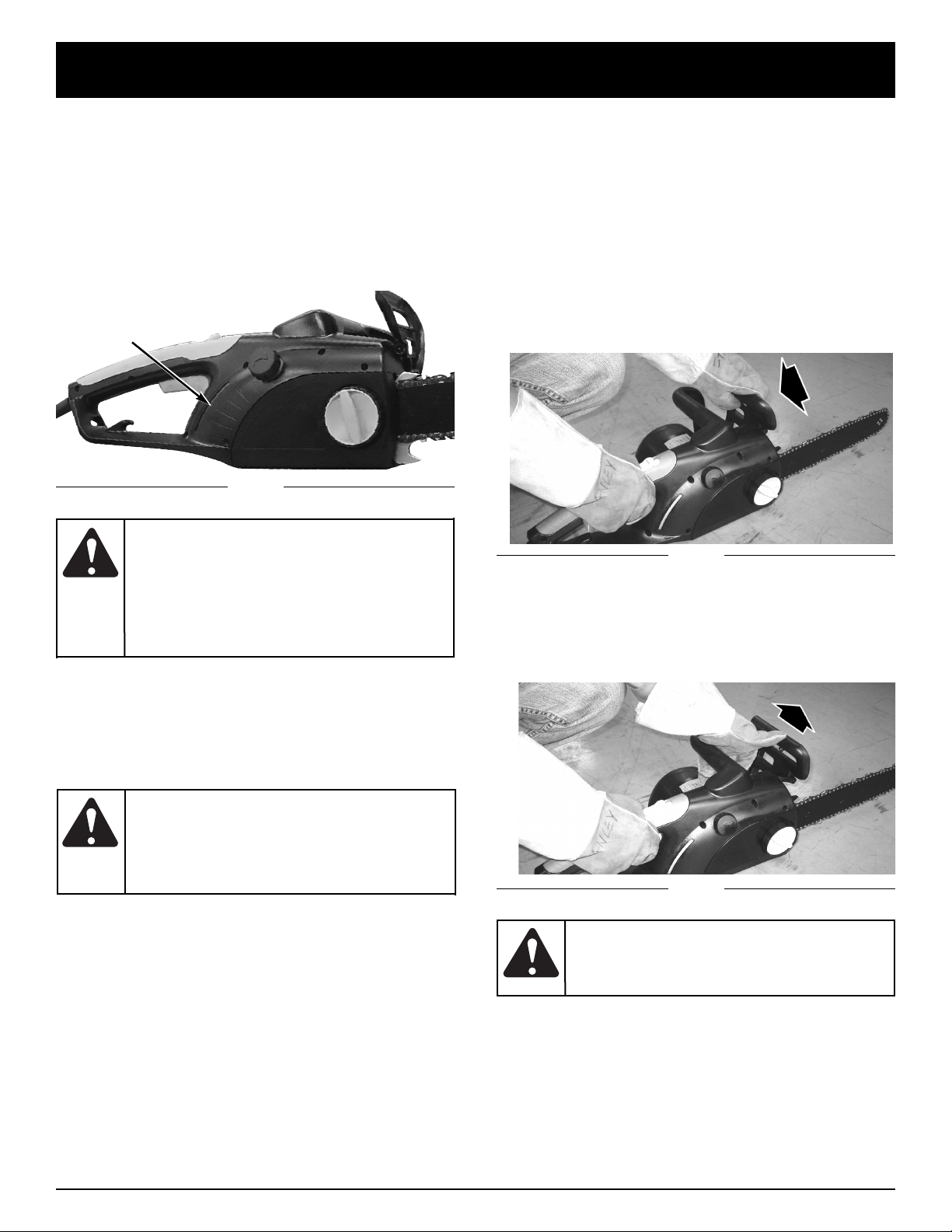

NOTE: Make sure the Chain Brake® is disengaged.

Disengage the Chain Brake® (D) by pulling it backward

(Fig. 23).

1. Tensioning the chain can be accomplished with

relative ease. Turn bar bolt knob (E) counter clock

wise. Then turn ring (F) counter clock wise to loosen

chain or clock wise to tighten chain (Fig. 24).

Always use

protective gloves

If saw chain is TOO

LOOSE or TOO

D

Fig. 23

E

F

Fig. 24

2. After adjustment and while wearing heavy duty work

gloves, move the saw chain back and forth on the

guide bar to be sure the chain moves freely and is in

proper mesh with sprocket.

NOTE: If the chain is difficult to rotate or if it binds on the

guide bar, too much tension has been applied

and must be adjusted as described in step 1.

3. While applying tension to the chain, hold the tip of

the bar up and then tighten the bar bolt knob (E).

A

B

Fig. 22

C

14

Page 15

MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN AND BAR LUBRICATION

Adequate lubrication of the saw chain during cutting operations is essential to minimize friction with the guide bar.

Your chain saw is equipped with an automatic oiler

system. The oiler automatically delivers the proper amount

of oil to the bar and chain. There is no flow adjustment.

You can check the oil tank level using the inspection slot

(D) provided on the right side of the saw. The tank is full

when oil is at the top of the slot (Fig. 25).

D

Fig. 25

CAUTION:

lubrication oil. Running the saw DRY or with

TOO LITTLE OIL will decrease cutting

efficiency, shorten chain saw life, and cause

rapid dulling of the chain and excessive

wear of the bar from overheating. Too little

is evidenced by smoke or bar discoloration.

Never starve the bar

and chain of

The Chain Brake® is a safety feature which is activated if

pressure is applied against the guard or when, in the

event of kickback, the operator’s hand strikes the lever.

When the Chain Brake® is activated, chain movement

abruptly stops and the power supply to the motor is

immediately cut off.

The purpose of the Chain Brake® is to reduce the

possibility of injury due to kickback. The Chain Brake®

cannot, however, provide the measure of intended

protection if the saw is carelessly operated.

The Chain Brake® is disengaged (chain can move) when

the brake is pulled back and locked. This is the normal

running position (Fig. 26).

Fig. 26

The Chain Brake® is engaged (chain cannot move) when

the brake is in forward position (Fig. 27).

NOTE: The motor will not start if the Chain Brake® is in

the engaged position.

NOTE: The saw chain stretches during use, particularly

when it is new, and occasional adjustment will be

needed. A new chain requires more frequent

adjustment during the break-in period. This is

normal. See Section Saw Chain Tension

Adjustment for instructions.

WARNING:

you are cutting, as well as wear the bar and

chain. A chain that is too tight can damage

the saw. Either situation, chain too loose or

too tight, could cause serious personal injury .

A loose chain can

jump off the bar while

CHAIN BRAKE® / HAND GUARD

This chain saw is equipped with chain brake/hand guard.

The Hand Guard protects your left hand in the event it

slips off the front handle.

Fig. 27

CAUTION:

for star

normal operation

ting and stopping the saw during

The Chain Brake®

should not be used

15

Page 16

MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN BRAKE® TEST

Before cutting with your saw, the Chain Brake® should

be tested as follows:

Make sure the Chain Brake® is disengaged (Fig. 26).

A.

B. Place the saw on a firm, flat, dry surface that is clear

of any debris. Do not let the saw come in contact

with any objects.

C. Plug the unit into the power source.

D. Grasp the front handle (not the Chain Brake®/Hand

Guard Lever) with your left hand. Thumb and fingers

should encircle the handle.

E. Grasp the rear handle with your right hand. Thumb

and fingers should encircle the handle.

F. Depress the LOCK/OFF button with your right thumb.

Squeeze the trigger with your index finger (Fig. 7).

G. While the motor is running, activate the Chain

Brake® by rolling your left hand forward against the

lever.

H. Chain and motor should stop abruptly.

WARNING:

when the Chain Brake® is engaged, take

the saw to the nearest Authorized Service

Center. Do not use the saw if the Chain

Brake® is not in proper working order.

If the chain and

motor fail to stop

EXTENSION CORDS

When using an electric chain saw, plug it into the

extension cord only when you are ready to cut wood.

Connect the extension cord to a 110/120 voltage outlet.

Refer to the Electrical Safety Warnings section.

CAUTION:

overloaded.

WARNING:

damp environment. Do not expose the saw to

rain, snow or sleet. Moistur

cuits. Replace or r

cir

frayed extension cords before using your saw.

Keep the cord away from the cutting area and

position the cord so that it will not be caught

on branches or other objects during cutting.

A cord that is hot to

the touch is

Do not operate your

chain saw in a wet or

e will cause shor

epair any damaged or

t

DOUBLE INSULATION

WHEN SERVICING, USE ONLY IDENTICAL

REPLACEMENT PARTS.

Information

Do not use if the cord or plug is damaged. Your

appliance is double insulated to help protect against

electric shock. Double insulation construction consists of

2 separate “layers” of electrical insulation.

Appliances built with this insulation system are not

intended to be grounded. As a result, the extension cord

used with your appliance can be plugged into any

conventional 120 volt electrical outlet.

Normal safety precautions must be observed when

operating an electrical appliance. The double insulation

system is only for added protection against injury resulting

from a possible internal electrical insulation failure.

our double

WARNING:

has no serviceable parts inside. Do not

attempt to repair it yourself. For service

information, dial 1-800-668-1238.

In this double insulated appliance, 2 systems of insulation,

instead of grounding, are provided. No grounding means

is provided on a double insulated appliance, nor should a

means for grounding be added to the appliance. No

serviceable parts are inside. A double insulated appliance

is marked with the words, “DOUBLE INSULATION” or

“DOUBLE INSULATED.” The symbol (square within a

square) may also be marked on the appliance.

Maintenance

1. Place switch in OFF position and unplug the power

supply before the appliance is serviced, cleaned, or

maintenance is performed.

2. Keep the air intake clean and air vents free of debris

to avoid overheating the motor.

3. Clean with a damp sponge and mild soap. Do not

squirt with a water hose or douse with water or other

liquids.

4. Inspect the saw chain for proper tension before each

use and frequently during cutting. Sharpen as required.

Clean the guide bar and bar pad to ensure free path

5.

for oil.

6. No motor lubrication is necessary. The motor is

equipped with lifetime lubricated bearings.

7. If the saw does not operate, turn switch to OFF

position and disconnect the extension cord, first from

the power supply, then from the saw. Check the

power supply for blown fuses or tripped circuit

breakers. If it still does not operate, contact a

Product Service Department. Call 1-800-520-520 for

more information.

Do not attempt to repair it yourself. No serviceable

parts are inside.

Y

insulated appliance

16

Page 17

MAINTENANCE AND REPAIR INSTRUCTIONS

GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar is required. Proper

maintenance of the guide bar, as explained in this

section, is essential to keep your saw in good working

condition.

WARNING:

disconnected before performing any

maintenance on your saw.

Sprocket Tip Lubrication

CAUTION:

been pre-lubricated at the factory. Failure to

lubricate the guide bar sprocket tip as

explained below will result in poor

performance and seizure, voiding the

manufacturer’s warranty.

Lubrication of the sprocket tip is

recommended after each saw use. Always

thoroughly clean guide bar sprocket tip

before lubrication.

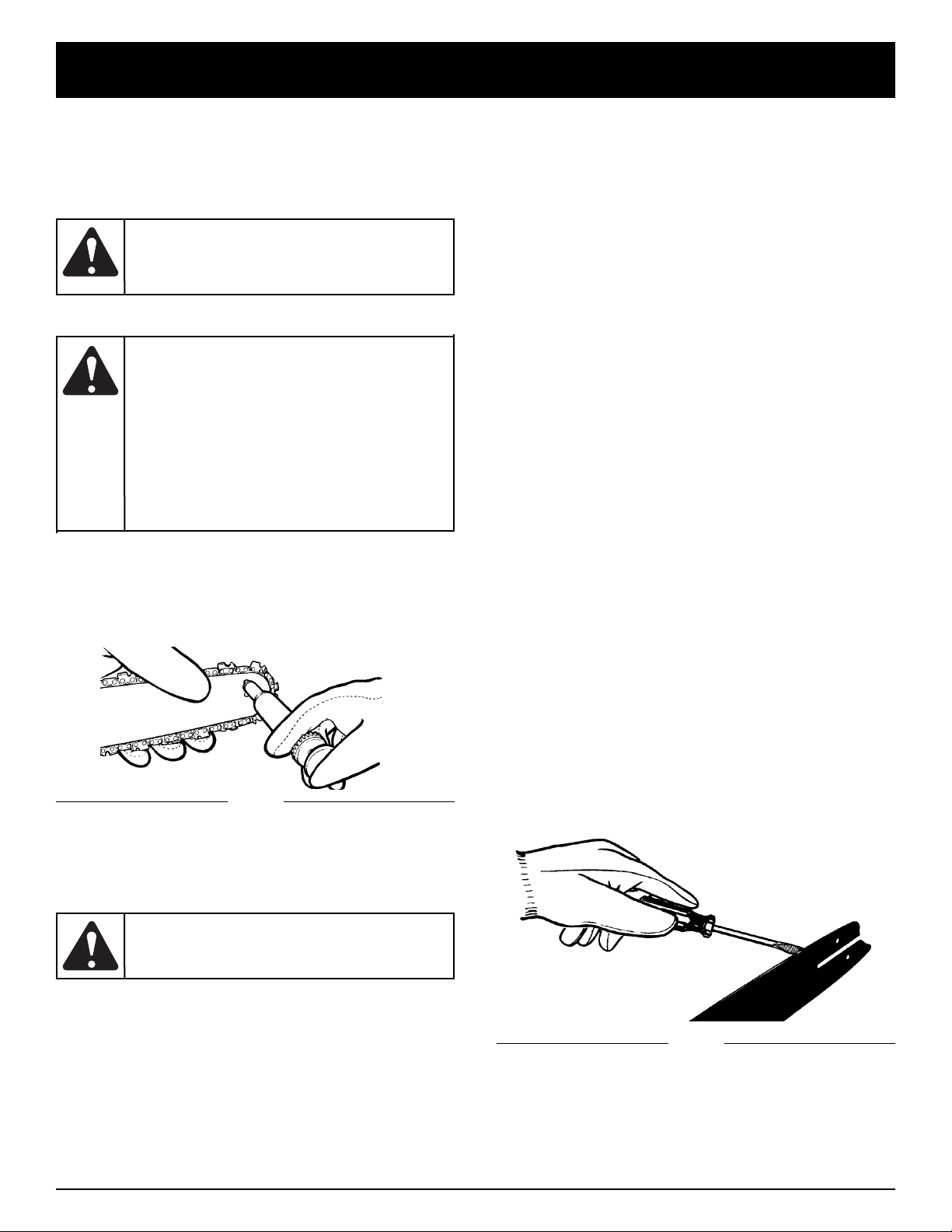

The Lube Gun (optional) is recommended for applying

grease to the guide bar sprocket tip. The Lube Gun is

equipped with a needle nose tip which is necessary for

the efficient application of grease to the sprocket tip.

Fig. 28

Ensure that the

power cord is

The sprocket tip on

your new saw has

Maintenance Procedures

Most guide bar problems can be prevented merely by

keeping the chain saw well maintained. Incorrect filing

and non-uniform cutter and depth gauge settings cause

most guide bar problems, primarily resulting in uneven

bar wear. As the bar wears unevenly, the rails widen,

which may cause chain clatter and difficulty in making

straight cuts.

Insufficient guide bar lubrication and operating the saw

with chain that is too tight will contribute to rapid bar wear.

To help minimize bar wear, the following guide bar

maintenance procedures are recommended:

BAR WEAR - Turn guide bar frequently at regular

intervals (for example, after 5 hours of use), to ensure

even wear on top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and

carry the chain) should be cleaned if saw has been used

heavily or if saw chain appears dirty. Rails should always

be cleaned every time saw chain is removed.

OIL PASSAGES - Oil passages on the bar should be

cleaned to ensure proper lubrication of the bar and chain

during operation. This can be done using a soft wire

small enough to insert into the oil discharge hole.

NOTE: The condition of the oil passages can be easily

checked. If the passages are clear, the chain will

automatically give off a spray of oil within

seconds of starting the saw. Your saw is

equipped with an automatic oiler system.

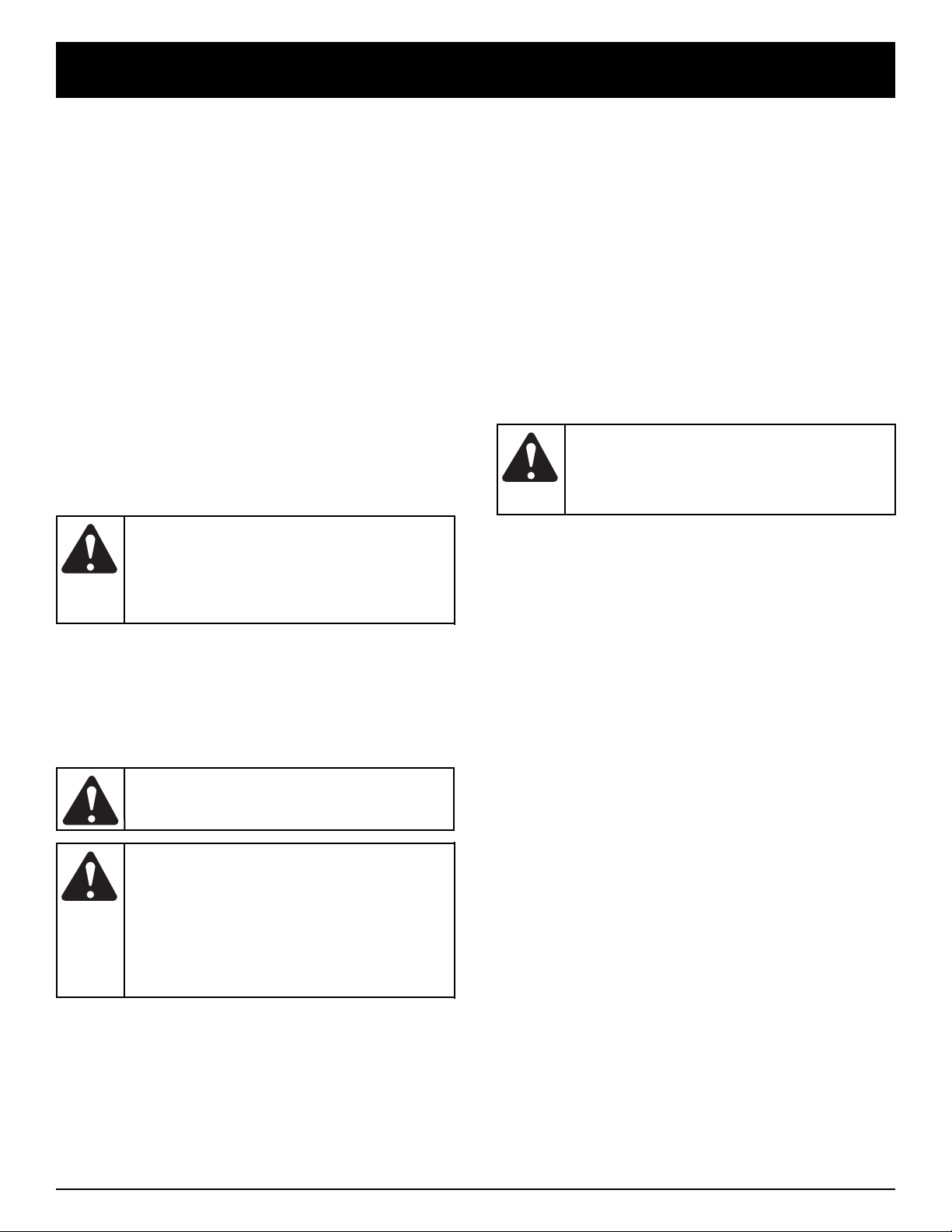

Cleaning Bar Rails

1. Remove sprocket cover, bar and chain. Refer to the

Install the Guide Bar/Saw Chain section.

2. Using a screwdriver, putty knife, wire brush or other

similar instrument, clear residue from the rails on the

guide bar. This will keep the oil passages open to

provide proper lubrication to the bar and chain (Fig. 29).

3. Reinstall the bar, chain, sprocket cover and bar bolt

knob. See Section Install the Guide Bar / Saw Chain

for more information.

To lubricate the sprocket tip:

Unplug the chain saw from the power source.

1.

NOTE: It is not necessary to remove the saw chain to

2. Clean the guide bar sprocket tip.

3.

4. Make sure that the Chain Brake® is deactivated.

lubricate the guide bar sprocket tip. Lubrication

can be done on the job.

WARNING:

when handling the saw chain.

Using the Lube Gun (optional), insert tip of lube gun

into the lubrication hole and inject grease until it

appears at outside edge of sprocket tip (Fig. 28).

Rotate saw chain by hand. Repeat lubrication

procedure until the entire sprocket tip has been

greased.

Always use

protective gloves

Fig. 29

17

Page 18

MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN MAINTENANCE

WARNING:

specialized training for dealing with

kickback (see Safety Precautions), always

use a low-kickback saw chain, which

significantly reduces the danger of

kickback. Low-kickback saw chain does

not completely eliminate kickback. A lowkickback or “safety chain”, should never be

regarded as total protection against injury.

A low-kickback saw chain should always be used in

conjunction with other kickback protection devices such

as the Chain Brake®/Hand Guard furnished with your unit.

Always use a replacement saw chain designed as “lowkickback” or a saw chain which meets the low-kickback

performance requirements of ANSI (American National

Standards Institute).

A standard saw chain (a chain which does not have the

kickback reducing guard links) should only be used by an

experienced professional chain saw operator.

What is a Low-Kickback Saw Chain?

A low-kickback saw chain is a chain which has met the

kickback performance requirements of ANSI B175.1.

By keeping the Chain Brake® and saw chain in good

working condition and correctly serviced as

recommended in this manual, you will be able to

maintain the safety system of your chain saw over the life

of the product.

Chain Tension

Check the chain tension frequently and adjust as often as

necessary to keep the chain snug on the bar, but loose

enough to be pulled around by hand.

Breaking in a New Saw Chain

A new chain and bar will need chain readjustment after

as few as 5 cuts. This is normal during the break-in

period, and the interval between future adjustments will

begin to lengthen quickly.

Over a period of time, however, the moving parts of the

saw chain will become worn, resulting in what is called

CHAIN STRETCH. This is normal. When it is no longer

possible to obtain correct chain tension adjustment, a

link will have to be removed to shorten the chain. See

your Authorized Service Center to have this repair

performed.

Unless you have

experience and

WARNING:

removed from a loop of chain. This could

cause damage to the sprocket.

Never have mor

than 3 links

e

Chain Lubrication

Always make sure the automatic oiler system is working

properly. Keep the oil tank filled with Genuine Factory

Parts Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cutting

operations is essential to minimize friction with the guide bar.

Never starve the bar and chain of lubricating oil. Running

the saw dry or with too little oil will decrease cutting

efficiency, shorten saw chain life, cause rapid dulling of

chain, and lead to excessive wear of bar from

overheating. Too little oil is evidenced by smoke or bar

discoloration.

Chain Sharpening

Chain sharpening requires special tools to ensure that

cutters are sharpened at the correct angle and depth. For

the inexperienced chain saw user, we recommend that

the saw chain be professionally sharpened by the

nearest Authorized Service Center. If you feel

comfortable sharpening your own saw chain, special

tools are available from your Authorized Service Center.

WARNING:

inoperative any safety device furnished with

your unit. The Chain Brake® / Hand Guard

and low-kickback saw chain are major

safety features provided for your protection.

Never remove,

modify or make

CHAIN REPLACEMENT INFORMATION

There may be other quality equivalent replacement

components for achieving kickback protection.

Bar Length Drive Links

16” Bar 55 DL

Part Number

49M1655P753

18

Page 19

TROUBLESHOOTING

UNIT WILL NOT START

CAUSE ACTION

Unit is unplugged Check cord to make sure it is plugged into an electrical outlet

GFCI in outlet has tripped (if used) Reset GFCI

If further assistance is required, contact your authorized service dealer.

In Canada call :1-800-668-1238 , In US call :1-866-747-9816 for more information.

SPECIFICATIONS / FEATURES

Peak H.P. .................................................................................................................................................................. 3 .5HP

Approximate Weight (with bar and chain) ..........................................................................................9.7 lbs. (MTD1416NT)

Features:

Chain Brake / Hand Guard

Double Insulated

CSA-c-us-Listed

Trigger Lock / Off

Chain Catcher

19

Page 20

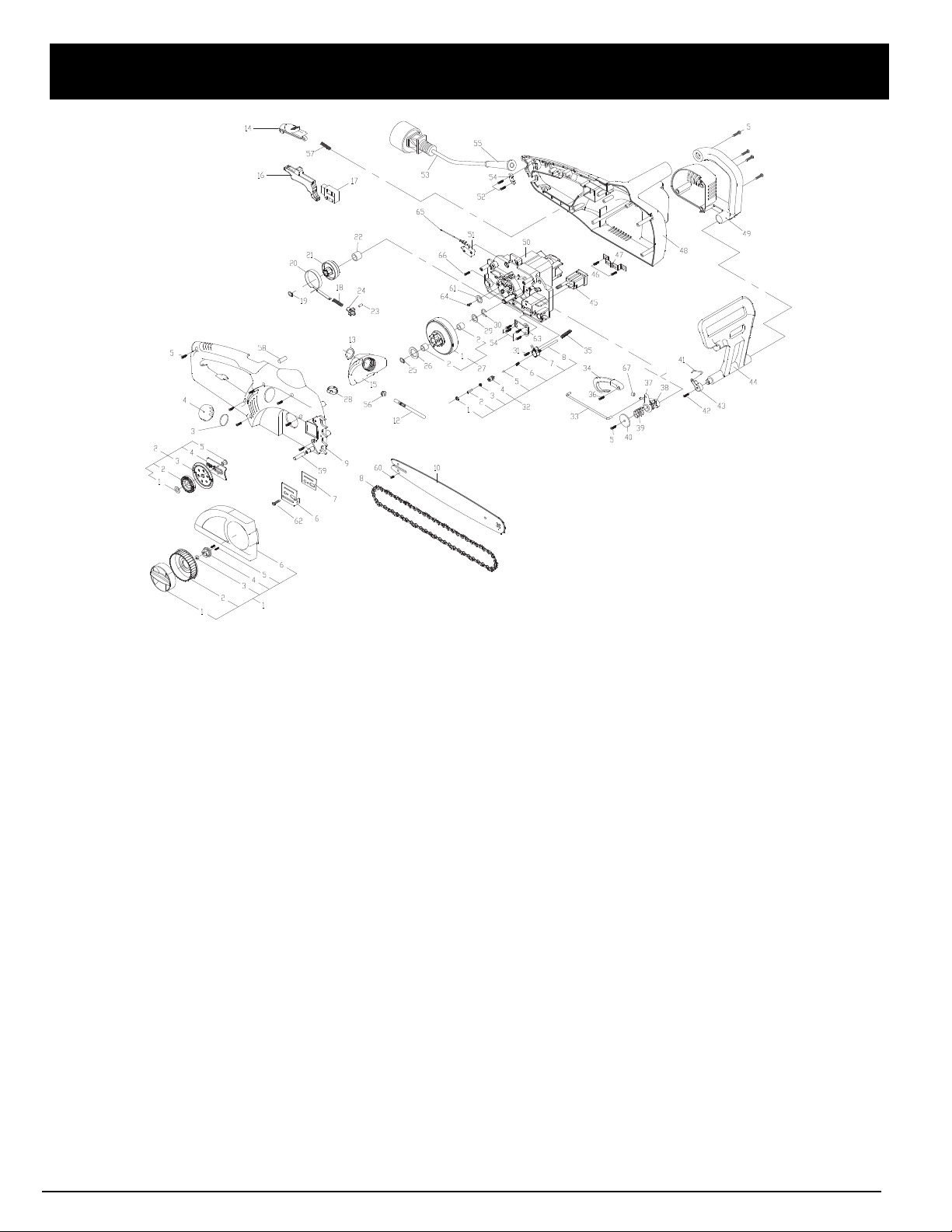

PARTS LIST

No. Parts No. Description No. Parts No. Description

1 6228-211403 HOUSING (R) 35 6024-211507 SPRING

2 6228-211504 CHAIN COVER ASS'Y 36 6SQABB04-20 SCREW

3 6012-210501 WASHER 37 6181-211501 CLUTCH

4 6017-210103 OIL COVER 38 6181-211502 CLUTCH

5 6SDABB04-18 SCREW 39 6024-211503 SPRING

6 6043-211302 ADJUSTMENT PLATE 40 6014-211501 WASHER

7 6050-211301 OIL WASHER 41 6154-211301 CONNECTING BAR

8 6220-210201 CHAIN 42 6SQABB4.5-30 SCREW

9 6038-211505 HOUSING (R) 43 6154-211504 CONNECTOR

10 9040-3101124 BAR 44 6017-211503 FRONT-HAND GUARD

12 6228-211506 OIL PIPE ASS'Y 45 6228-211303 FIXED ASS'Y

13 6076-210503 WASHER 46 6SDABB04-16 SCREW

14 6056-211502 SWITCH BUTTON 47 6079-211503 SPRING

15 6066-211501 OIL TANK 48 6038-211506 HOUSING (L)

16 6028-211502 TRIGGER 49 6086-211501 REAL COVER

17 6022-211502 SWITCH 50 6228-211301 MOTOR GEAR BOX ASS'Y

18 6024-211301 SPRING 51 6022-211501 SWITCH

19 6CY-08 RING 52 6SDABB04-10 SCREW

20 6079-211501 SPRING, BRAKE 53 6011-211502 POWER CORD

21 6073-211501 GEAR 54 6043-840001 STRAIN RELIEF

22 6059-210201 ADJUSTMENT COVER 55 6059-855001 CORD GUARD

23 6115-211502 PIN 56 6012-211501 RUBBER STOP

24 6154-211502 CONNECTION 57 6024-211506 SPRING

25 6CG-9.5 C RING 58 6PC05-14.7 PIN

26 6014-210502 WASHER 59 6PC4.4-35 PIN

27 6228-210104 GEAR BEARING ASS'Y 60 6SQAB-04-06 SCREW

28 6077-211501 COVER 61 6WFB-03-12 WASHER

29 6057-210102 WASHER 62 6SDABB03-15 SCREW

30 6CC-10 C RING 63 6158-211502 PLATE

31 6SDABB03-18 SCREW 64 6SLABB03-06 SCREW

32 6228-210105 OIL PUMP ASS'Y

65 6010-211301 WIRE

33 6188-211501 PULL BAR

66 6SDABB04-14 SCREW

34 6114-211501 PULL PLATE 67 6124-TH0101 SLEEVE

20

Page 21

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by MTD

LLC (“MTD”) with respect to new merchandise purchased and

used in the United States and Canada, its possessions and

territories.

MTD warrants this product against defects in material and

workmanship for a period of two (2) years commencing on the

date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in

material or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not

been subject to misuse,

abuse,commercial use, neglect, accident, improper

maintenance, alteration, vandalism, theft, fire, water or

damage because of other peril or natural disaster. Damage

resulting from the installation or use of any accessory or

attachment not approved by MTD for use with the product(s)

covered by this manual will void your warranty as to any

resulting damage. This warranty is limited to ninety (90) days

from the date of original retail purchase for any MTD product

that is used for rental or commercial purposes, or any other

income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in your

area, please check for a listing in the Yellow Pages or contact

the Customer Service Department of MTD LLC by calling

1-866-747-9816 or writing to P.O. Box 361131, Cleveland

OH 44136-0019 or if in Canada call 1-800-668-1238. No

product returned directly to the factory will be accepted

unless prior written permission has been extended by the

Customer Service Department of MTD LLC.

This limited warranty does not provide coverage in the

following cases:

A. Guide ,Bar ,Chain.

B. MTD does not extend any warranty for products sold or

exported outside of the United States of America and

Canada, its possessions and territories, except those

sold through MTD’s authorized channels of export

distribution.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind MTD. During the period of the

Warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

shall not be liable for incidental or consequential loss or

damages including, without limitation, expenses

incurred for substitute or replacement lawn care

services, for transportation or for related expenses, or

for rental expenses to temporarily replace a warranted

product.

an implied warranty lasts, so the above limitation may not

apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of the safety features of the product shall void this

Warranty. You assume the risk and liability for loss,

damage, or injury to you and your property and/or to others

and their property arising out of the use or misuse or

inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This warranty

gives you specific legal rights, and you may also have other

rights which vary from state to state.

To locate your nearest service dealer dial 1-866-747-9816

in the United States or 1-800-668-1238 in Canada.

(Some states do not allow limitations on how long

(Some states do not

MTD reserves the right to change or improve the design of

any MTD Product without assuming any obligation to

modify any product previously manufactured.

MTD LLC

P.O. Box 361131

Cleveland, OH 44136-0019

21

Page 22

Manuel de L’utilisateur

S/N :

ITEM :

MODEL :

Tronçonneuses

Electriques

Modèle MTD1416NT

Francais

IMPORTANT: READ SAFETY RULES

AND INSTRUCTIONS CAREFULLY

MANUEL IMPORTANT À NE PAS JETER

P/N 6096-211304©2005

IMPRIMÉ AUX CHINE

Page 23

INTRODUCTION

S/N :

ITEM :

MODEL :

TOUS NOS REMERCIEMENTS

Nous vous remercions d'avoir acheté ce produit de

qualité. Cet outil mécanique de plein air moderne est

conçu pour vous rendre service pendant longtemps. Il

vous sauvera beaucoup de temps comme vous pourrez

vous en rendre compte. Ce manuel de l'utilisateur

comporte un mode d'emploi facile à comprendre. Prenez

soin de lire le manuel au complet et suivez toutes ses

instructions à la lettre afin de conserver votre nouvel outil

mécanique de plein air en excellent état de

fonctionnement.

RÉFÉRENCES, ILLUSTRATIONS ET

SPÉCIFICATIONS RELATIVES AU PRODUIT

Toutes les informations, illustrations et spécifications

contenues dans ce manuel tiennent compte des dernières

informations techniques disponibles au moment de

mettre sous presse. Nous nous réservons le droit d'y

apporter des modifications à tout moment, sans préavis.

Copyright© 2004 MTD SOUTHWEST INC., Tous droits

réservés.

INFORMATIONS D’ENTRETIEN

Tout entretien effectué sur cet appareil pendant et après

la période de garantie doit être fait par un concessionnaire agréé uniquement. Obtenez la liste des

concessionnaires agréés appelez le 1-800-668-1238.

Pour de plus amples informations à propos de votre

appareil, visitez www.yardmachines.com.

NE RETOURNEZ PAS L'APPAREIL AU DÉTAILLANT

CHEZ QUI VOUS L'AVEZ ACHETÉ. TOUT SERVICE

SOUS GARANTIE NÉCESSITE UNE PREUVE D'ACHAT.

Avant d'assembler votre nouvel équipement, repérez la

plaque signalétique de l'appareil et copiez ses

informations dans l'espace ci-dessous. Ces informations

sont essentielles si vous désirez obtenir de l'aide auprès

de notre service technique ou d'un distributeur agréé. Un

exemple de plaque signalétique est présenté ci-dessous.

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . .23

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . .24

Familiarisez-vous avec votre appareil . . . . . . . . . .29

Instructions de démarrage et d'arrêt . . . . . . . . . . .31

Mode d'emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Entretien et réparations . . . . . . . . . . . . . . . . . . . . .34

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . .40

Charactéristiques . . . . . . . . . . . . . . . . . . . . . . . . . .40

Liste des Pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Numéro de série

Prenez soin de lire et de bien comprendre ce manuel avant de démarrer ou de faire fonctionner cet équipement.

CE PRODUIT EST COUVERT PAR UN OU PLUSIEURS BREVETS AMÉRICAINS, ET D’AUTRES SONT EN INSTANCE.

Numéro de modèle

Numéro de pièce mère

Copiez le numéro de

modèle / pièce mère ici :

Copiez le numéro

de série ici :

23

Page 24

CONSIGNES DE SÉCURITÉ

Les symboles de sécurité attirent votre attention sur

des dangers potentiels. Ces symboles et leurs détails

explicatifs méritent que vous les lisiez et compreniez

bien. Les avertissements de sécurité ne peuvent éviter

les dangers de par eux-mêmes. Les consignes ou

mises en garde qu'ils donnent ne remplacent pas des

mesures préventives appropriées contre les accidents.

SYMBOLE SIGNIFICATION

ALERTE DE SÉCURITÉ:

indique un danger, un avertissement ou une

mise en garde. Soyez vigilant afin d'éviter toute

blessure grave. Ce symbole peut être combiné

à d'autres symboles ou pictogrammes.

REMARQUE: donne des informations ou des

Lisez le(s) manuel(s) de l'utilisateur et suivez tous

Vous pourriez à défaut entraîner des blessures

SI VOUS AVEZ DES QUESTIONS, APPELEZ LE

instructions vitales pour le fonctionnement ou

l'entretien de l'équipement.

les aver

tissements et consignes de sécurité.

graves pour vous ou d'autres personnes.

1-800-668-1238

SYMBOLE SIGNIFICATION

DANGER:

causer dommages matériels ou blessures

graves pour tous. Respectez les consignes de

sécurité afin de réduire les risques d'incendie,

d'électrocution et de blessures.

le non-respect d’un

avertissement peut

AVERTISSEMENT:

avertissement peut causer dommages matériels

ou blessures graves pour tous. Respectez les

consignes de sécurité afin de réduire les risques

d'incendie, d'électrocution et de blessures.

MISE EN GARDE:

d’un avertissement peut causer dommages

matériels ou blessures graves pour tous.

Respectez toujours les consignes de sécurité

afin de réduire les risques d'incendie,

d'électrocution et de blessures.

le nonrespect d’un

le nonrespect

• IMPORTANTES CONSIGNES DE SÉCURITÉ •

LIRE TOUTES LES INSTRUCTIONS

AVANT UTILISATION

AVERTISSEMENT:

correctement la tronçonneuse, vous aurez un

instrument de travail rapide, pratique et

efficace ; utilisé de façon non correcte ou

sans adopter les précautions nécessaires, cet

ument pour

instr

que votr

respectez scrupuleusement les mesures de

sécurité reportées ici et au cours du manuel.

• Veuillez lire les instructions avec soin. Familiarisezvous avec les commandes et l'utilisation correcte de

cet appareil.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou

sous l'effet de l'alcool, de drogues ou de médicaments.

•

Ne laissez pas les enfants faire fonctionner l’appareil. Ne

laissez jamais des adultes qui ne se sont pas familiarisés

avec les instructions utiliser l’appareil. Ne laissez jamais

des adultes n'ayant jamais reçu les instructions

nécessaires faire fonctionner l’appareil.

Inspectez l'appareil avant utilisation. Remplacez les

•

pièces endommagées. Assurez-vous que les fixations

sont solidement en place. Remplacez les pièces de

l'accessoire de coupe qui sont fendillées, ébréchées ou

endommagées.

Connaissez la fonction des commandes et sachez

•

comment arrêter la tronçonneuse rapidement.

Quand vous transportez votre tronçonneuse, veuillez

•

utiliser le protège-lame approprié.

e travail soit toujours agréable et sûr

rait s’avérer dangereux. Pour

Si vous

utilisez

,

• Après avoir arrêté le moteur, transporter la tronçonneuse

par sa poignée avant, le guide-chaîne et chaîne dirigés

vers l’arrière.

PENDANT L'UTILISATION DE L'APPAREIL

• Portez des lunettes de sécurité conformes aux normes

ANSI Z87.1-1989 ainsi que des protège-oreilles durant

l'utilisation de l'appareil. Portez un masque facial ou

antipoussières si vous travaillez dans un lieu

poussiéreux. Il est recommandé de porter des

chemises à manches longues.

Portez des pantalons épais et longs, des bottes et des

•

gants. Ne marchez pas pieds nus et ne portez pas les

articles suivants : vêtements lâches, bijoux, pantalons

courts, sandales. Relevez les cheveux au-dessus du

niveau des épaules.

• N'utilisez l'appareil qu'en plein jour ou avec un bon

éclairage artificiel.

• Avant d’entreprendre l’abattage, veuiller à vous tenir

sur une surface stable afin de ne pas perdre

l’équilibre, vérifier que votre zone de travail et voie de

retraite sont sans obstacle.

• Rester à l’écart de la chaîne lorsque le moteur est en

marche.

•

Avant de faire démarrer le moteur, s’assurer que la

chaîne de la tronçonneuse ne puisse pas entrer en

contact avec quoi que ce soit.

• Ne jamais utiliser une tronçonneuse endommagée,

mal ajustée, non complètement ou incorrectement

montée. S’assurer qu’il y a arrêt de la chaîne quand la

gâchette est relâchée.

24

Page 25

CONSIGNES DE SÉCURITÉ

• Etre extrêmement prudent lors de la coupe de petits

buissons et arbustes car les matériaux plus fins

peuvent «s’attraper» dans la chaîne et être projetés

dans votre direction ou vous faire perdre l’équilibre.

• Pendant la coupe d’un tronc ou d’une branche en

tension, faites attention à ne pas vous faire surprendre

par le relâchement instantané de la tension du bois.

• Ne coupez pas à travers des clous, des tiges de fer dans

l’arbre, des traverses de chemin de fer ou des palettes.

Inspectez l’arbre que vous allez couper pour voir s’il ne

renferme pas d’objets étrangers qui pourraient vous

blesser ou endommager la tronçonneuse.

• Si vous rencontrez un objet étranger, coupez le

moteur et inspectez soigneusement la tronçonneuse

pour voir si elle n’est pas endommagée. Réparez si

nécessaire.

• Nous déconseillons l’utilisation de la tronçonneuse

dans un arbre ou sur une échelle.

• Tous autres services d’entretien de la tronçonneuse, à

l’exception de ceux indiqués dans le manuel d’utilisation

et d’entretien, doivent être accomplis par un personnel

de réparation de tronçonneuse compétent.

• Utiliser le bon outil. Ne couper que du bois. Ne pas

utiliser la tronçonneuse à des fins pour lesquelles ellen

n’apas été conçue. Ne jamais utilser la tronçonneuse

pour couper plastique, maçonnerie, ou tout autre

matériel n’étant pas pour la construction.

• Ne vous étirez pas trop loin. Gardez toujours une

bonne assise et votre équilibre.

• Tenez toujours la tronçonneuse à deux mains lorsque

vous l’opérez. Tenez toujours fermement toutes les

poignées ou prises.

• Engagez le frein de chaîne lorsque vous vous déplacez

dans la zone de coupe. Comme précaution

supplémentaire, engagez le frein de chaîne avant de

déposer la tronçonneuse par terre.

• Ne touchez jamais la chaîne et n’essayez jamais de

travailler à la tronçonneuse lorsque le moteur tourne.

Assurez-vous que toutes les pièces mobiles soient

bien arrêtées. Laissez la tronçonneuse refroidir car la

chaîne peut être chaude.

• Vérifiez le guide-chaîne et la chaîne régulièrement et

ajustez si nécessaire. Assurez-vous que le guidechaîne et la chaîne soient bien serrés et que la chaîne

soit bien aiguisée. Inspectez visuellement pour tout

dommage. Réparez tout dommage avant d’utiliser ou

de remettre la tronçonneuse en marche.

AVERTISSEMENT:

Les rebonds

peuvent se

produire si la tête du guide-chaîne touche un

objet, ou si le bois se resserre sur la chaîne

de la tronçonneuse dans la coupe. Si un

contact a lieu avec la tête du guide-chaîne, la

tronçonneuse peut, en l’espace d’une

seconde, être projetée de manière

incontrôlée dans un mouvement en arc, en

direction de l’opérateur. Coincer la chaîne le

long de la partie supérieure du guide-chaîne

peut pousser le guide-chaîne peut pousser le

guide-chaîne vers l’arrière, vers l’opérateur.

Chacune de ces réactions peut vous faire

perdre contrôle de la tronçonneuse et peut

entraîner de sérieuses blessures.

Ne comptez pas exclusivement sur les

dispositifs de sécurité qui équipent votre

onçonneuse. Vous devriez prendre

tr

plusieurs mesures pour éviter tout accident

ou toute blessure lorsque vous vous servez

de votr

e tronçonneuse.

ATTENTION AUX REBONDS

• El hecho de tener unos conocimientos básicos de el

rebote puede ayudarle a reducir o eliminar el elemento

sorpresa. Las sorpresas súbitas contribuyen a la

ocurrencia de accidentes.

• Sujete la sierra firmemente con ambas manos cuando

el motor esté en marcha. Coloque su mano derecha

en la empuñadura posterior y la mano izquierda en la

empuñadura frontal con los pulgares y los dedos

rodeando las empuñaduras de la sierra de cadena. El

hecho de agarrar firmemente la unidad y de mantener

su brazo izquierdo firme le ayudará a reducir el rebote

y a mantener el control de la sierra.

• Scier toujours le moteur à plein régime.

• Ne pas scier au delà de la hauteur des épaules; ne pas

se pencher trop en avant.

• Suivre les instructions du fabricant pour l’affûtage et

l’entretien de la tronçonneuse.

• Asegúrese de que el área en que esté cortando se

encuentre libre de obstrucciones. No deje que el borde

de la barra de guía entre en contacto con leños, ramas,

cercas o cualquier otro tipo de obstrucción que se

pueda golpear mientras usted esté operando su sierra.

25

Page 26

CONSIGNES DE SÉCURITÉ

• Votre secteur de travail doit être libre d’obstacle.

S’assurer que la pointe du guide-chaîne n entre pas en

contact de branches, troncs ou autres surfaces

pendant son fonctionnement.

• N’utiliser que des chaînes et guide-chaînes

recommandés par le fabricant ou leur équivalent.

AUTRES PRÉCAUTIONS DE SÉCURITÉ

• Ne pas utiliser la tronçonneuse d’une seule main! De

graves blessures à l’opérateur, toute personne l’aidant

ou spectateurs pourraient en résulter. Un tronçonneuse

est conçue pour être utilisée des deux mains.

• Ne vous servez pas d’une tronçonneuse si vous êtes

fatigué.

• S’habiller de maniere appropriee: Ne pas porter de

vêtements trop amples ou de bijoux cars ils risquent

de vous gêner et de se faire prendre dans une partie

mobile de l’appareil. L’utilisation des élastiques et des

semelles antidérapantes est recommandée pour tout

travail à l’extérieur. Les cheveux longs doivent être

protégés par un casque ou autre protection.

• Vetements et equipement recommandes: Porter des

chaussures, gants et lunettes de protection, des habits

moulants, des protecteurs d’oreilles et un casque.

• Ne laissez personne se trouver à proximité quand

vous faites démarrar ou utilisez votre tronçonneuse.

• Ne pas enlever, endommager ou désactiver tout

dispositif de sécurité. Ne jamais utiliser une

tronçonneuse endommagée, modifiée, mal entretenue

ou mal remontée. Vérifier régulièrement son bon

fonctionnement. N’utilisez que le guide-chaîne et la

chaîne de longueur appropiée tel qu’indiqué dans le

tableau ci-dedans.

• Ne faites jamais de réparations par vous-même en

dehors de l’entretien de routine. Pour plus de

renseignements, contactez uniquement des ateliers

de réparation spécialisés et agréés.

• Si votre tronçonneuse ne marche plus, ne

l'abandonnez pas dans la nature ! Appelez votre

revendeur habituel, qui saura résoudre la situation.

• Faites attention lorsque vous faites tomber un arbre.

Assurez-vous que vous avez prévu une voie pour

vous échapper lorsque vous faites tomber l’arbre, et

maintenez les curieux à l’écart.

• Soyez sur vos gardes, arrêtez la machine si quelqu’un

entre dans la zone de coupe qui se situe généralement

à environ 3 ou 4 pieds de l’opérateur.

• Faites attention lorsque vous travaillez en équipe pour

éviter toute blessure a un équipier qui pourrait entrer

dans la zone de coupe.

• Ne prêtez votre tronçonneuse qu’à des personnes

expertes qui sachent la faire fonctionner correctement.

Donnez-leur aussi le manuel avec le mode d’emploi à

lire avant de commencer à travailler.

• Arrêtez le moteur avant de déposer la tronçonneuse

par terre. Ne laissez pas tourner le moteur sans

surveillance.

• Rangez l'appareil dans un endroit verrouillé et sec, ou

élevé et sec, hors de portée des enfants, pour éviter

une utilisation indésirable ou un accident.

• Ne trempez et n'arrosez jamais l'appareil avec de l'eau

ou tout autre liquide. Gardez les poignées sèches,

propres et exemptes de débris. Nettoyez après chaque

usage. Voir les sections

• Conservez ces instructions. Consultez-les souvent et

servez-vous en pour instruire d'autres usagers. Si vous

prêtez l'appareil à quelqu'un, prêtez-lui également ces

instructions.

• Ne pas utiliser la machine dans la pluie, au cours d’un

orage ou par mauvais temps. Attendez que la fin de

l’orage avant d’opérer ce produit.

Nettoyage et Entreposage.

AVER TISSEMENTS DE SÉCURITÉ ÉLECTRIQUE

• Comme cet outil comporte une isolation double, il est

donc possible d’utiliser des rallonges à 2 conducteurs

(rallonges sans terre). Cependant, il est tout à fait

possible d’utiliser des rallonges à 3 conducteurs

(rallonges avec fil de terre), qui comportent des fiches

de type NEMA (fiches parallèles, fiche terre en forme

de U). Ces rallonges sont disponibles auprès de votre

revendeur local. Veillez à n’utiliser que des rallonges à

section circulaire, approuvées pour une utilisation

extérieure.

AVERTISSEMENT:

risque de choc électrique, utilisez uniquement

des rallonges électriques approuvées pour une

utilisation extérieure., comme par exemple les

rallonges à cordons de typeSW-A, SO W- A, S TW A, STOW-A, SJW-A, SJOW-A, SJTW-W ou SJTOW.

Pour

réduire le

26

Page 27

CONSIGNES DE SÉCURITÉ

• Pour réduire le risque de choc électrique, cet appareil

est pourvu d’une fiche polarisée (une lame est plus

large que l’autre). Cet appareil ne peut être inséré dans

une prise polarisée que d’une seule manière. S’il n’est

pas possible d’insérer entièrement la fiche dans la

prise, essayez de brancher la fiche dans l’autre sens.

Si malgré tout, il n’est pas possible d’insérer la fiche,

remplacez le cordon par un cordon qui comporte les

bonnes fiches. Ne modifiez cet appareil en aucun cas.

• CORDONS DE BRANCHEMENTS : Assurez vous que

votre cordon de branchement est en bon état, avec un

cordon pouvant supporter la courant électrique que

votre unité va tirer. Un cordon sous dimensionné

causerait une chute de tension en ligne et ainsi une

perte de puissance ainsi qu’une surchauffe. Le tableau

ci-dessous illustre la jauge correcte à utiliser en fonction

de la longueur du cordon et de l’ampérage nominal sur

la plaque constructeur. En cas de doute, utilisez la jauge

supérieure suivante. Plus le numéro de jauge est faible,

et plus le cordon est lourd. Pour éviter que le cordon ne

se débranche de l’unité, utilisez le crochet à cordon

décrit dans Instruction de démarrage / arrêt.

• Le(s) circuit(s) électrique(s) ou la(les) prise(s)

d’alimentation de cet outil de jardinage doit(doivent)

comporter une protection de type GFCI (qui coupe le

circuit en cas de défaut de terre). Il existe des prises

qui comportent une protection GFCI, et que l’on peut

utiliser dans ce cas de figure.

• Cet outil comporte une isolation double. Pour toutes

les réparations, utilisez uniquement des pièces de

rechange identiques. Tout cordon électrique

endommagé doit être réparé ou remplacé.

• Ne touchez pas la fiche ou l’appareil lui même si vos

mains sont mouillées.

• Écartez le cordon de la zone de coupe et placez-le de

façon à ce qu’il ne se prenne pas dans les branches

pendant la coupe.

• Procédez à une inspection périodique de vos rallonges

électriques et de la fiche de raccord de votre appareil.

Examinez plus particulièrement l’isolation qui ne doit