Page 1

OPERATOR’S MANUAL

Single-Stage

Snow Thrower

Models

140

150

E150

E162

E172

Model E172 Shown

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning:

brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above

is required by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department,

P.O. Box 368022 Cleveland, Ohio 44136-9722.

PRINTED IN U.S.A.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered,

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

FORM NO

770-10000E.fm

.

(8/2001)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices .........................................................................................3

Assembling Your Snow Thrower .............................................................................................. 5

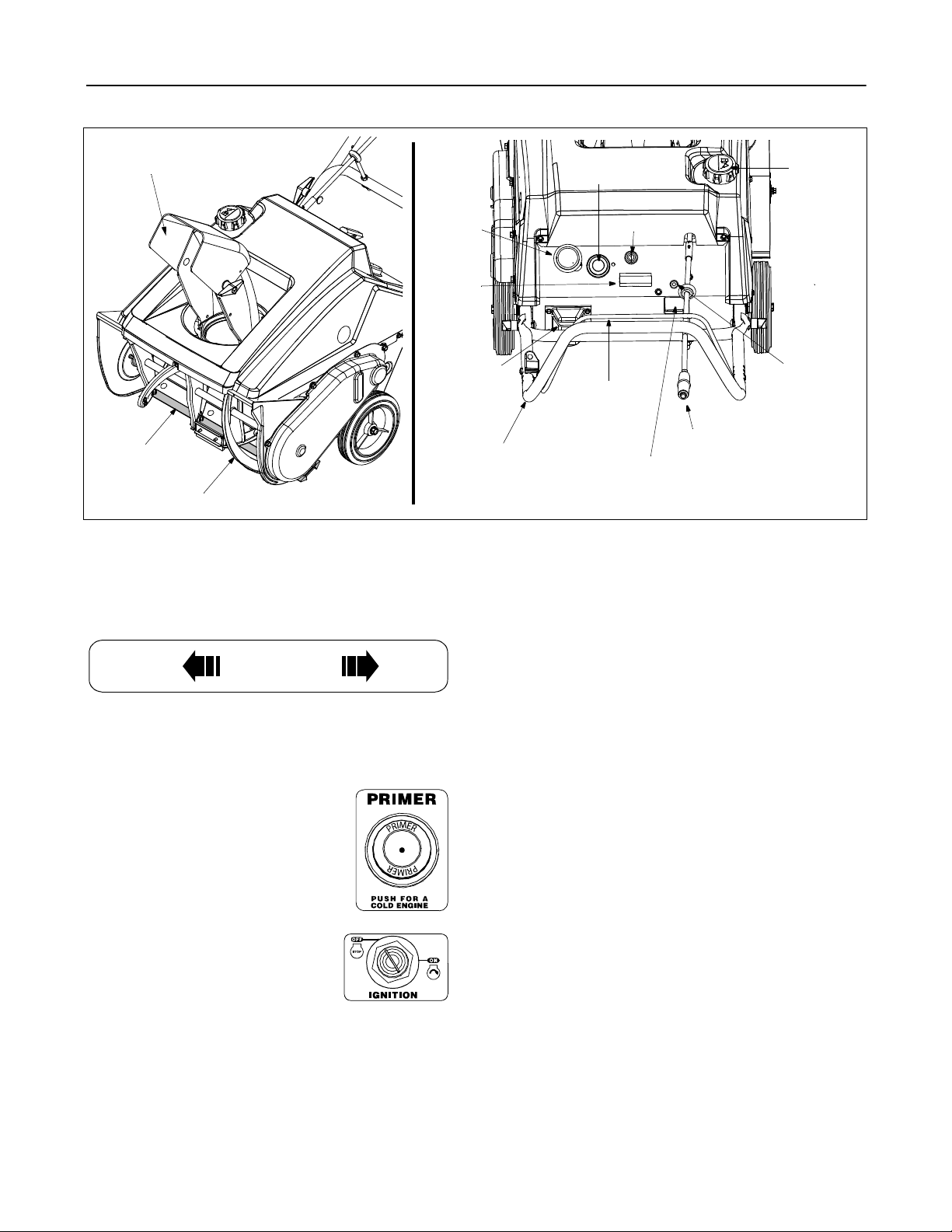

Know Your Snow Thrower........................................................................................................ 7

Operating Your Snow Thrower.................................................................................................8

Making Adjustments.................................................................................................................9

Maintaining Your Snow Thrower ..............................................................................................10

Off-Season Storage .................................................................................................................11

Troubleshooting .......................................................................................................................11

Accessories & Kits ...................................................................................................................12

Parts List ..................................................................................................................................14

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new snow thrower. It will help you to assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new snow thrower, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on the

model plate is very important if you need help from our Customer Support Department or an

authorized dealer.

• You can locate the model number by standing behind the unit in the operating position and looking down at

the dash panel. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space below.

(Model Number)

(Serial Number)

MTD PRODUCTS INC

CLEVELAND, OHIO 44136

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating,

specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed

separately with your unit for more information.

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Support Department.

Call 1- (330) 220-4MTD (4683) or 1- (800) 800-7310 to reach a Customer Support representative.

Please have your unit’s model number and serial number ready when you call. See previous section

to locate this information. You will be asked to enter the serial number in order to process your call .

For more details about your machine, visit our website at www.mtdproducts.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger the

personal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate this machine. Failure to comply with these instructions may result in personal injury. When you

see this symbol—heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals

known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with

any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This

machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to

be used. Remove all door mats, newspapers, sleds,

boards, wires and other foreign objects which could be

tripped over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing which could become entangled in moving

parts. Wear footwear which will improve footing on

slippery surfaces.

4. Use a grounded three wire extension cord and receptacle

for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all clutch levers before starting the engine.

7. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator’s manual.

8. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

9. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than

½ inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

Operation

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or discharge chute. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller clutch lever is a safety device. Never

bypass its operation. Doing so, makes the machine

unsafe and may cause personal injury.

3. The clutch levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged discharge

chute. Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

6. Do not operate machine while under the influence of

alcohol or drugs.

3

Page 4

7. Muffler and engine become hot and can cause a burn. Do

not touch.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while

operating on slopes.

10. Plan your snow throwing pattern to avoid discharge

towards windows, walls, cars etc. To avoid property

damage or personal injury caused by a ricochet.

11. Never direct discharge at children, bystanders and pets

or allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or

light. Always be sure of your footing and keep a firm hold

on the handles. Walk, never run.

14. Disengage power to the auger/impeller when

transporting or not in use.

15. Never operate machine at high transport speeds on

slippery surfaces. Look down and behind and use care

when in reverse.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug and ground it against

the engine. Inspect thoroughly for damage. Repair any

damage before starting and operating.

17. Disengage all clutch levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the discharge chute, making any

adjustments, or inspections.

18. Never put your hand in the discharge or collector

openings. Always use a clearing tool to unclog the

discharge opening.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. If situations occur which are not covered in this manual,

use care and good judgment. Contact your dealer or

telephone 1-800-800-7310 for assistance and the name

of your nearest servicing dealer.

Maintenance And Storage

1. Never tamper with safety devices. Check their proper

operation regularly.

2. Disengage all clutch levers and stop engine. Wait until

the auger/impeller come to a complete stop. Disconnect

the spark plug wire and ground against the engine to

prevent unintended starting before cleaning, repairing, or

inspecting.

3. Check bolts, and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer’s (O.E.M.) parts only. “Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!”

6. Check clutch controls periodically to verify they engage

and disengage properly and adjust, if necessary. Refer to

the adjustment section in this operator’s manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator’s manual for proper

instructions on off-season storage.

Your Responsibility:

• Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine.

DANGER

NEVER PUT HAND IN CHUTE. CONTACT WITH

ROTATING PARTS CAN AMPUTATE FINGERS

AND HANDS.

DO NOT UNCLOG DISCHARGE CHUTE WHILE

ENGINE IS RUNNING.

SHUT OFF ENGINE AND REMAIN BEHIND

HANDLES UNTIL ALL MOVING PARTS HAVE

STOPPED BEFORE UNCLOGGING.

READ OPERATOR'S MANUAL.

4.

GRAVEL SURFACES.

USE EXTRA CAUTION WHEN OPERATING ON

NEVER DIRECT DISCHARGE AT BYSTANDERS.

3.

AVOID INJURY FROM

ROTATING AUGER KEEP HANDS, FEET

AND CLOTHING AWAY.

TO AVOID THROWN OBJECTS INJURIES,

UNCLOGGING OR SERVICING MACHINE.

MOVING PARTS HAVE STOPPED BEFORE

AND REMAIN BEHIND HANDLES UNTIL ALL

2.

DISENGAGE CLUTCH LEVERS, STOP ENGINE,

HANDS AND FEET.

CONTACT WITH AUGER CAN AMPUTATE

KEEP AWAY FROM ROTATING AUGER

1.

4

Page 5

SECTION 2: ASSEMBLING YOUR SNOW THROWER

NOTE: This Operator’s Manual covers several models.

Snow thrower features vary by model. Not all

features discussed in this manual are applicable to all

snow thrower models.

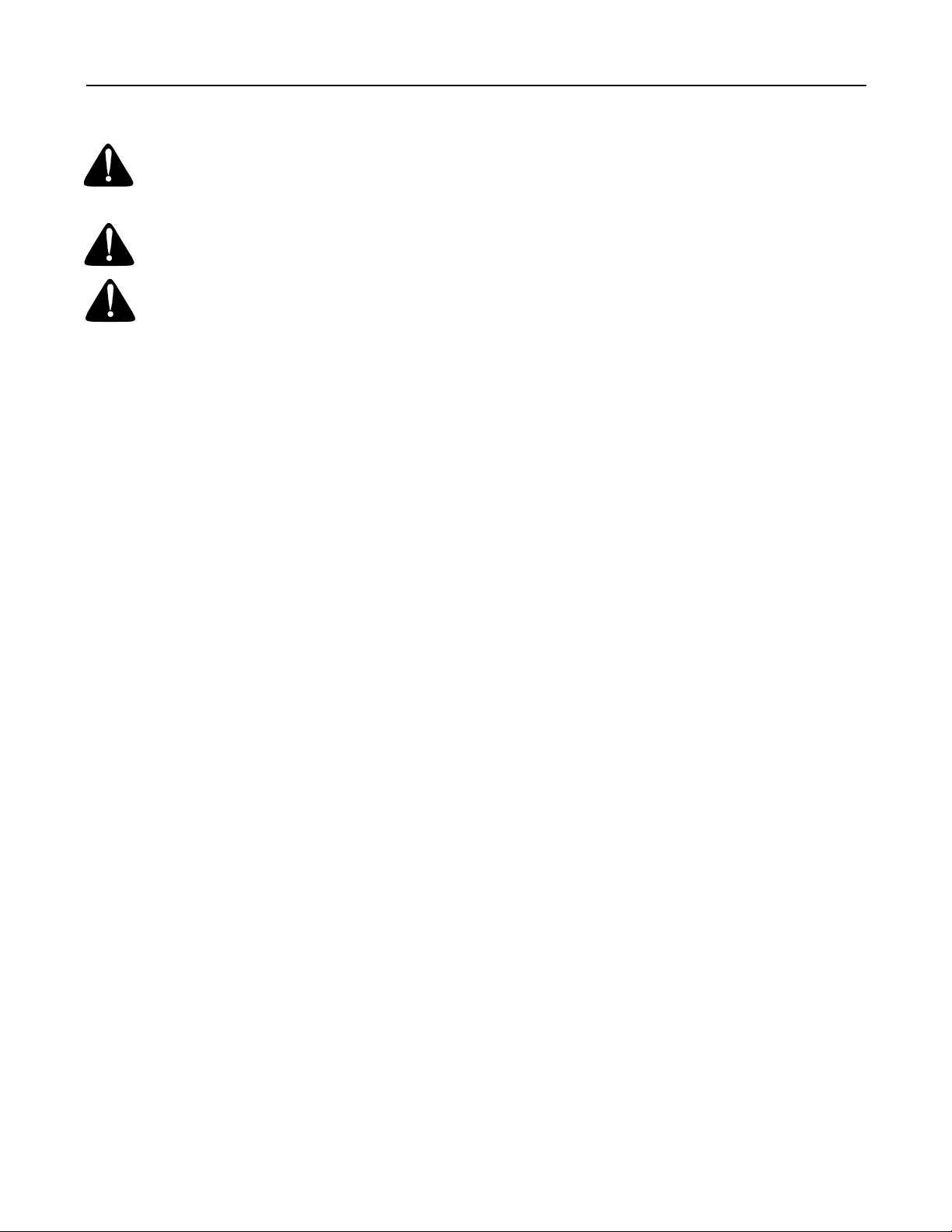

Contents of Carton

Before beginning installation, remove all parts from the

carton and compare them to Figure 1. Carton contents

are listed below with part numbers in parentheses.

• Two

Ignition Keys (725-0201, 725-1341B†)

† An ignition key with a plastic cover is included with

select models only. Two standard ignition keys are

included with all other models.

On Models So Equipped:

• Extended Chute Directional Control Assembly

(747-0737, 720-0201A & 726-0100)

• One Cotter Pin (714-0507)

• One Saddle Washer (736-0415)

• Two Hex Nuts (712-3010)

• One Eye Bolt (747-0697) w/ Grommet (735-0234)

Wing Knob

• Tighten the wing knobs to secure the handle in

place.

Upper Handle

Wing Knob

Figure 2

Ignition Key w/ Plastic Cover

Standard Ignition Key

Cotter Pin

Saddle Washer

Hex Nuts

Eye Bolt

Extended Chute

Directional Control Assembly

Figure 1

NOTE: All references to left or right side of the snow

thrower is from the operating position only.

†

WARNING: Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

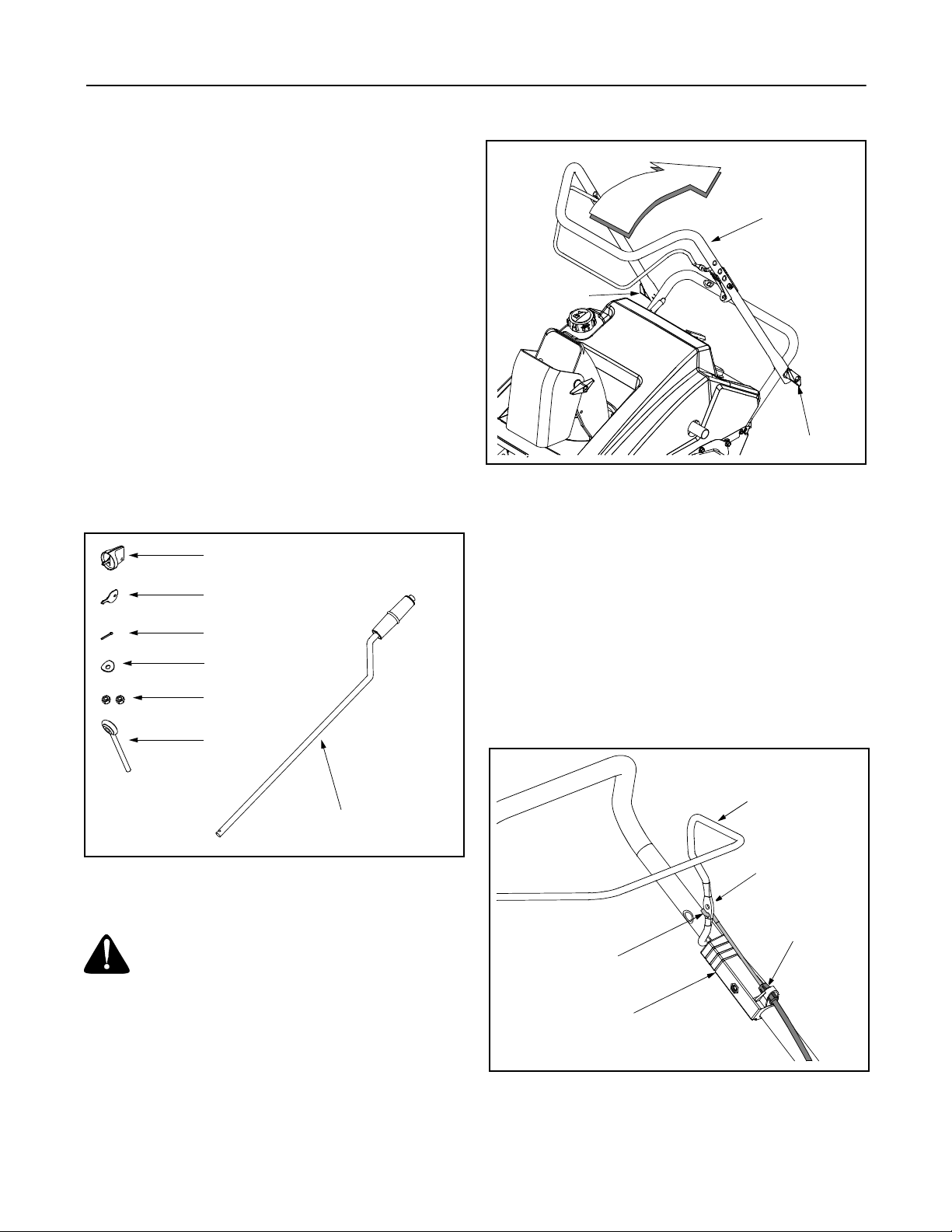

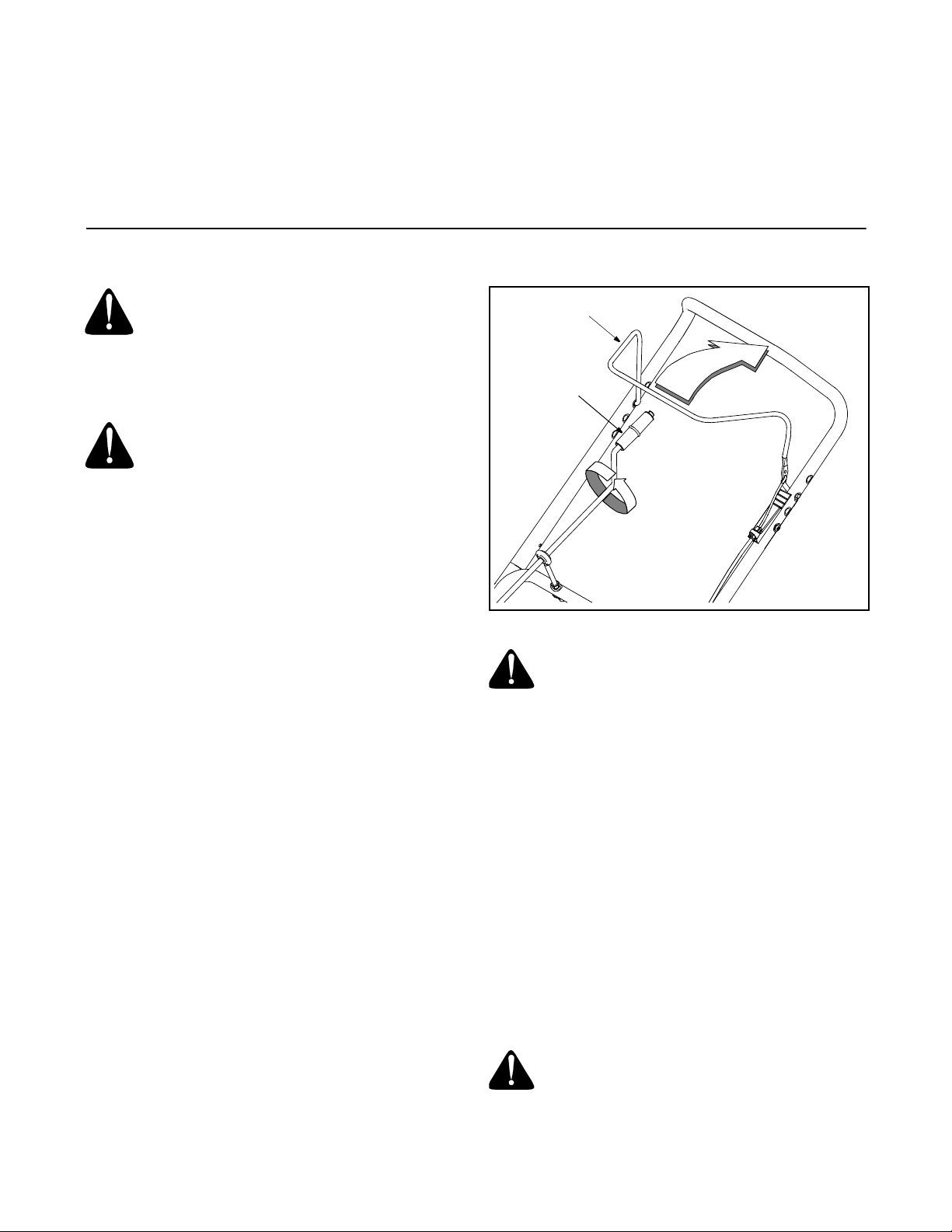

Attaching the Control Cable

The control cable may already be attached to the

control handle. If it’s not, complete the following steps

to attach it to the snow thrower housing.

• Route the control cable over the crossbar where

the lower handle meets the upper handle.

• Pivot the control handle forward and insert the end

of the control cable into the bottom hole in the

control handle, from the outside to the inside, as

shown in Figure 3.

Control Handle

Upper Hole

Plastic Fitting

End of Cable

In Bottom Hole

Positioning the Upper Handle

• Remove packing material, if present, and loosen

the wing knobs found on each side of the handle.

• Making sure not to pinch or crimp the cable in the

process, pivot the upper handle into the operating

position as illustrated in Figure 2 until it clicks into

place.

Control Housing

Figure 3

• Push the plastic fitting into the control housing until

it clicks in place

5

Page 6

NOTE: The upper hole in the control handle provides

for adjustment in belt and cable tension. Refer to page

9 of this manual for instructions.

Eye Bolt

Installing the Chute Directional Control’s

Eye Bolt

To install the upper crank of the chute directional

control, proceed as follows:

• Thread one of the hex nuts (they are

interchangeable) included in the snow thrower’s

hardware pack all the way onto the eye bolt.

• Insert the eye bolt into the hole found in the lower

handle’s crossbar. See Figure 4.

• Fasten the eye bolt to the crossbar with the saddle

washer (cupped side UP) and the other hex nut as

illustrated in Figure 4. Do NOT tighten at this time.

(on models so equipped)

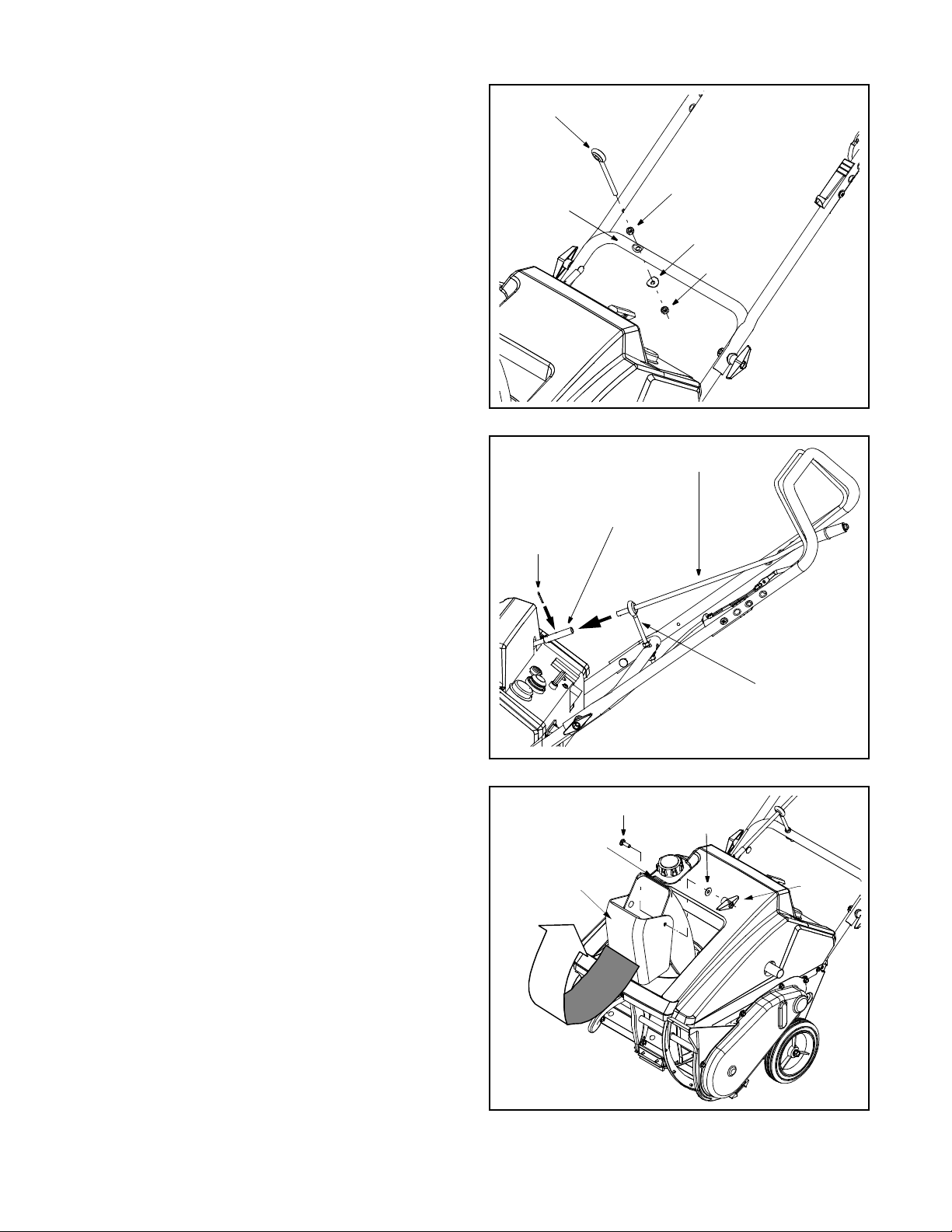

Installing the Extended Chute

Directional Control

• Insert the chute directional control through the

eyebolt and into the coupler found in the top right

area of the snow thrower’s shroud. See Figure 5.

• Rotate the chute directional control to align the hole

in the coupler with the hole in the chute directional

control, and insert the cotter pin through both holes.

Bend the ends of cotter pin in opposite directions to

secure it in place. See Figure 5.

• Thread the eye bolt’s lower hex nut upward or

downward to adjust the height of the eye bolt so

that the chute directional control does not bind in

the coupler when operated.

• Fininsh by threading the upper hex nut downward

against the crossbar and tightening securely.

(on models so equipped)

Cross Bar

Hex Nut

Saddle Washer

Hex Nut

Figure 4

Chute Directional Control

Coupler

Cotter Pin

Eye Bolt

Assembling the Discharge Chute

For shipping reasons, the snow thrower has been

packaged with the upper chute pivoted all the way

down. To pivot it upward, proceed as follows:

• Turn the chute directional control until the chute

opening is facing straight ahead.

• Remove the wing knob, flat washer and carriage

bolt from the upper chute. See Figure 6.

• Pivot the upper chute upward over the lip on the

lower chute so that there is NO gap between the

upper chute and the lower chute. See Figure 6.

• Resecure with the hardware just removed.

Lower Chute Lip

Upper Chute

Front

6

Figure 5

Carriage Bolt

Figure 6

Flat

Washer

Wing

Knob

Page 7

SECTION 3: KNOW YOUR SNOW THROWER

Discharge Chute

Spark

Plug

Cover

Starter

Handle

Choke Lever

Shave Plate

Auger

IMPORTANT:

This unit runs on a mixture of gasoline

and oil. Do NOT operate the snow thrower without first

reading the Tecumseh Engines operator’s manual for

instructions regarding proper fuel and engine oil.

Choke Lever

OFF CHOKE

Activating the choke control closes the choke plate on

the carburetor and aids in starting the engine. Refer to

the engine manual packed with the snow thrower for

more detailed instructions regarding the choke.

ON

Primer

Depressing the primer forces fuel

directly into the engine’s carburetor to

aid in cold-weather starting. Refer to

the engine manual packed with the

snow thrower for more detailed

instructions regarding the primer.

Ignition Key

The ignition key must be present

and placed in the “ON” position for

the engine to start.

Starter Handle

The starter handle is used to manually start the engine.

Stopping Engine

• Turn ignition key to OFF position and remove it

from the snow thrower.

Primer

Ignition Key

Upper Handle

Control Handle

Chute Directional Control

Electric Starter Plug

(If So Equipped)

(If So Equipped)

Electric Starter Button (If so equipped)

Pressing the electric starter button engages the

engine’s electric starter when plugged into a 120V

power source

Electric Starter Plug (If so equipped)

Requires use of a two-prong outdoor extension cord

(packed with the snow thrower) and a 120V power

source/wall outlet.

Spark Plug Cover

Remove the spark plug cover to access the engine’s

spark plug located beneath it.

Chute Directional Control

Located on right side of dash panel, the chute

directional control determines the direction that snow

will be discharged. Crank it clockwise to discharge

snow to the left; counterclockwise to discharge snow to

the right.

Auger

When engaged, the augers rotation picks up snow that

enters the auger housing and throws it out the

discharge chute. The rubber paddles on the augers

also aid in propelling the snow thrower as they come in

contact with the pavement.

Auger Control Handle

Located on the upper handle, the auger control handle

is used to engage and disengage drive to the auger.

Squeeze the control handle against the upper handle to

engage the auger; release it to disengage.

Fuel Cap

Electric

Starter

Button

7

Page 8

Discharge Chute

The pitch of the discharge chute controls the angle at

which the snow is thrown. Loosen the wing knob on the

side of the discharge chute before pivoting the

discharge chute upward or downward. Retighten the

knob once the desired position has been achieved.

Shave Plate

The shave plate scrapes along the pavement as the

snow thrower is propelled, allowing the snow close to

the pavement’s surface to be discharged.

SECTION 4: OPERATING YOUR SNOW THROWER

WARNING: Before starting the engine,

read, understand, and follow all instructions

and warnings on the machine and in this

manual before operating.

Fuel And Oil Mixture

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish cigarettes,

cigars, pipes and other sources of ignition.

Your snow thrower is equipped with a two-cycle

engine that requires a mixture of gasoline and two

cycle engine oil at a ratio of 50:1. Refer to the

Tecumseh Engines operator’s manual for detailed

instructions regarding oil and gasoline for your snow

thrower’s engine.

• A plastic cup is placed inside the fuel fill opening on

the fuel tank (beneath the fuel cap) to keep debris

out during product assembly. Remove and discard

this cup before filling up the tank.

IMPORTANT:

the fuel cap securely in place on the fuel tank.

Do NOT operate the snow thrower without

Starting the Engine

• Refer to the Tecumseh Engines manual packed

with the snow thrower for detailed instructions

regarding starting the engine.

Operating the Snow Thrower

• Loosen the wing knob found on the left side of the

discharge chute and pivot the upper chute upward

or downward to the desired pitch. Retighten the

wing knob before operating the snow thrower.

• Crank the chute directional control to position the

discharge chute opening in the desired direction.

See Figure 7.

NOTE: For more efficient snow clearing, discharge

snow downwind whenever possible.

Control Handle

Chute

Directional Control

Figure 7

WARNING: Never operate the snow thrower

with bystanders in front of or near the

discharge chute opening.

• Engage the auger by squeezing the control handle

against the upper handle. See Figure 7.

• Lift up slightly on the handle to allow the rubber

paddles on the auger to contact the pavement and

propel the snow thrower forward.

IMPORTANT:

will result in premature wear on the rubber auger

paddles. Resulting wear would not be covered by

warranty.

• As the snow thrower starts to move, maintain a firm

hold on the handle, and guide the snow thrower

along the path to be cleared.

• Release the auger control handle to stop the snow

throwing action and the forward motion.

Excessive upward pressure on the handle

Stopping the Engine

WARNING: Muffler, engine and surrounding

areas become hot and can cause a burn. Do

not touch.

8

Page 9

• After clearing snow, allow the engine to run for an

extra few minutes before storing to help dry any

moisture on the engine.

• To stop the engine: Turn the ignition key

counterclockwise to the OFF position. Refer to

Ignition Key on page 7. Remove the key form the

snow thrower’s ignition switch before storing.

SECTION 5: MAKING ADJUSTMENTS

WARNING: NEVER attempt to make any

adjustments while the engine is running, except

where specified in the operator’s manual.

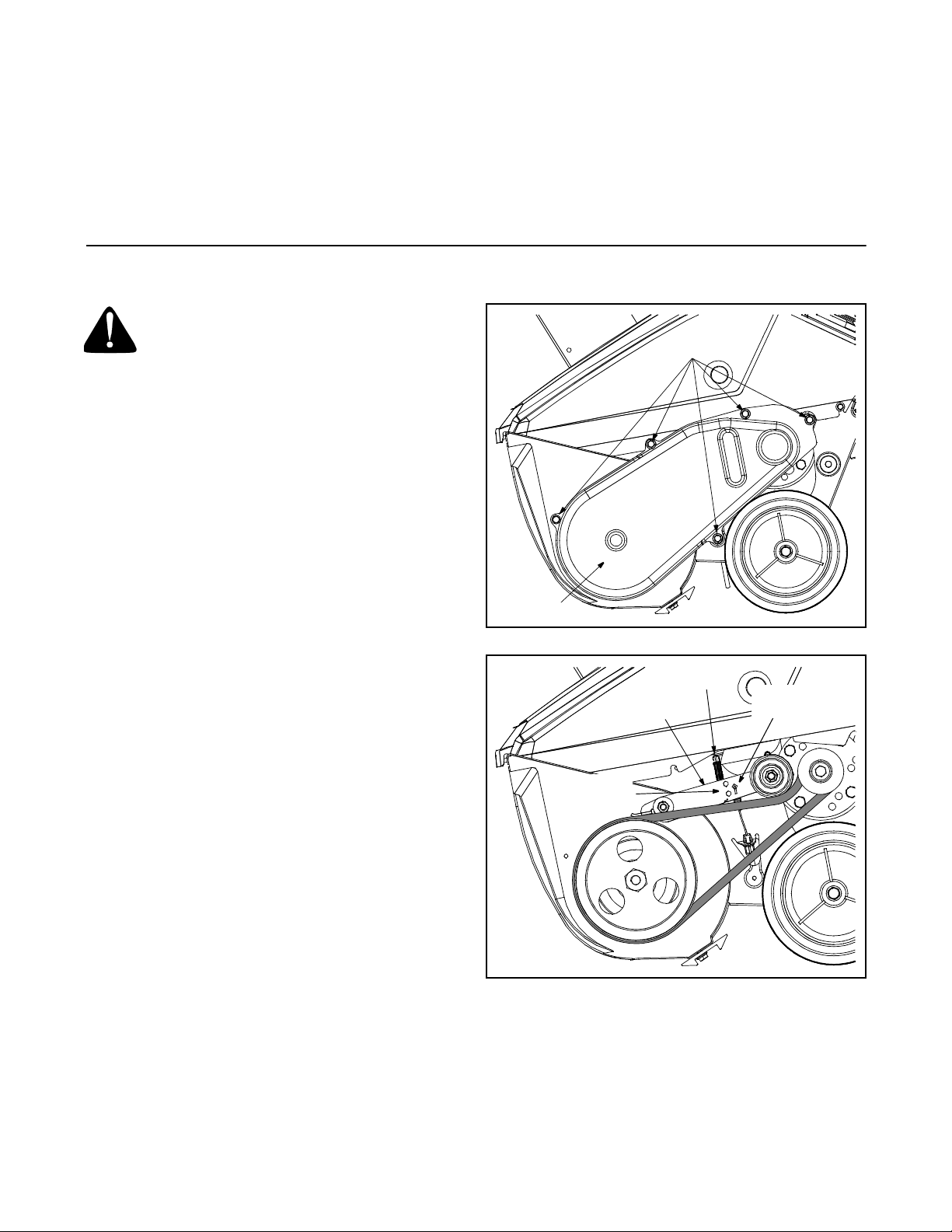

Control Cable & Belt Tension

As a result of both the control cable and the drive belt

stretching due to wear, periodic adjustments may be

necessary.

If the auger seems to hesitate when rotating while the

engine maintains a constant speed, an adjustment is

necessary. Proceed as follows:

IMPORTANT:

engine can not be started without it.

• Wipe all the snow and any moisture which has

formed, from the unit.

• Move the choke lever back and forth several times.

Keep the ignition key in a safe place. The

Hex Screws

The upper hole in the control handle provides for an

adjustment in cable tension. To adjust, disconnect the

end of control cable from the bottom hole in the control

handle and reinsert it in the upper hole. Refer to Figure

3 . Test the snow thrower to see if there is a noticeable

difference.

If additional adjustment is required, proceed as follows.

• Remove the belt cover from the left side of the

snow thrower’s auger housing by unthreading the

five hex screws which secure it in place. See Figure

8.

There are three adjustment holes provided in the idler

bracket assembly. To adjust, proceed as follows:

• Move the extension spring (found on the end of the

control cable) from the low position to the middle

position on the idler bracket. See Figure 9.

NOTE: Be careful not to lose the idler spring when

moving the clutch cable spring. See Figure 9.

• If the extension spring is already found in the

middle position on the idler bracket, move it from

the middle position to the high position.

• Reattach the belt cover with the five hex screws

removed earlier.

Belt Cover

Adjustment

Idler Bracket

Holes

Figure 8

Idler Spring

Control Cable

Spring

Figure 9

9

Page 10

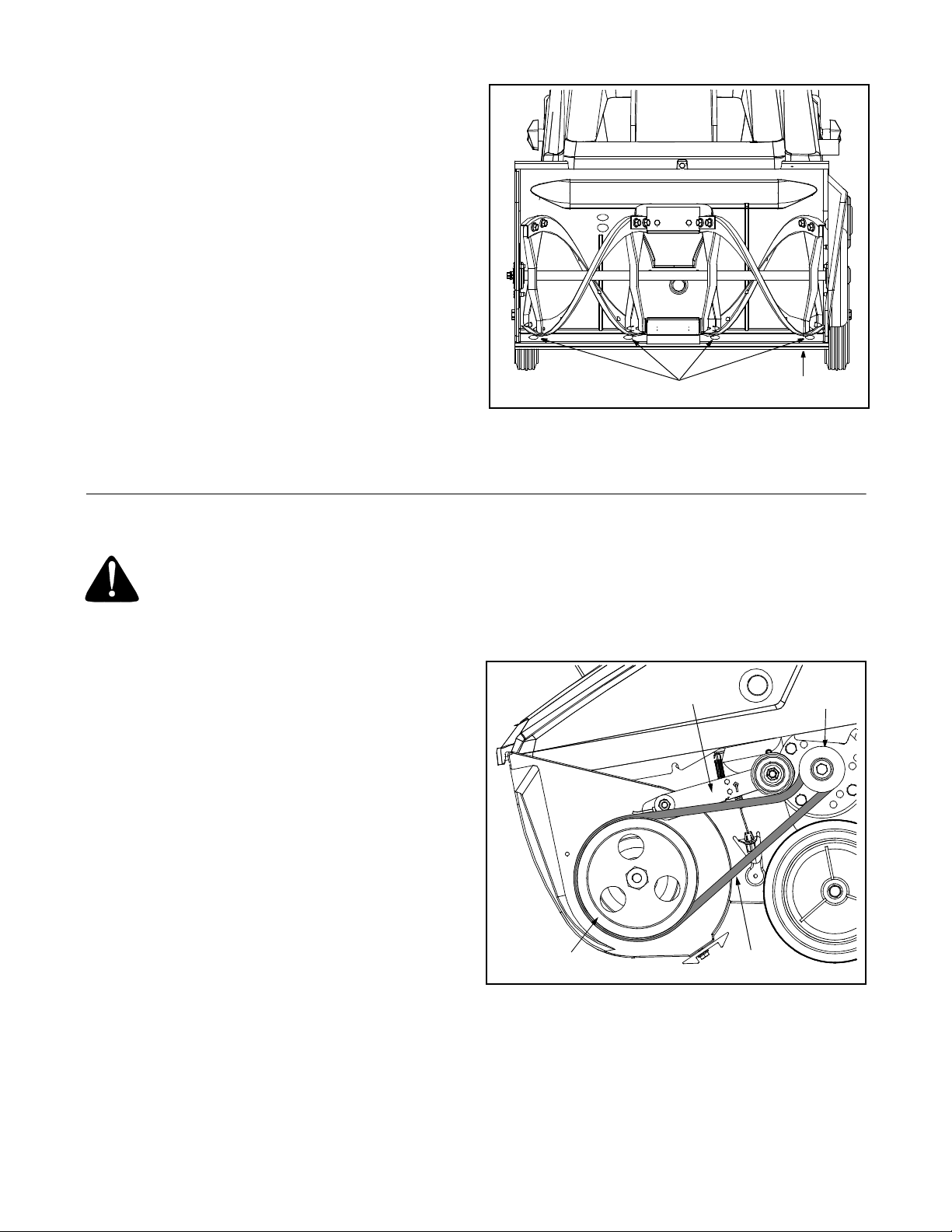

Shave Plate

• To check the adjustment of the shave plate, place

the unit on a level surface. The wheels, shave plate

and augers should all contact the level surface.

Note that if the shave plate is adjusted too high,

snow may blow under the housing. If the shave

plate wears out excessively, or the unit will not selfpropel, the shave plate may be adjusted too low.

NOTE: On new units or units with a new shave plate

installed, the augers may be slightly off the ground.

• To adjust, tip the snow thrower back so that it rests

on the handle. Loosen the lock nuts from the

carriage bolts which secure the shave plate to the

housing. See Figure 10.

• Move the shave plate to desired position and

retighten the nuts and bolts. Make certain all four

nuts are securely tightened.

SECTION 6: MAINTAINING YOUR SNOW THROWER

Carriage Bolts

Figure 10

Shave Plate

WARNING: Before servicing, repairing, or

inspecting, disengage all clutch levers and

stop engine. Wait until all moving parts have

come to a complete stop. Disconnect spark

plug wire and ground it against the engine to

prevent unintended starting.

Engine

Refer to the Tecumseh Engines manual packed with

the snow thrower for detailed instructions regarding all

engine-related maintenance.

Lubrication

• Lubricate pivot points on the control handle and the

extension spring at the end of the clutch cable with

a light oil once every season and before storage of

the snow thrower at the end of the season.

Hardware

Check the engine and snow thrower frequently for

loose or missing hardware, and tighten or replace as

necessary.

• Remove the belt cover from the left side of the

snow thrower’s auger housing by unthreading the

five hex screws which secure it in place. Refer to

Figure 8.

• Gently grasp the idler bracket and pivot it upward to

ease tension on the drive belt. See Figure 11.

Engine

Pulley

Auger Pulley

Idler Bracket

Drive Belt

Figure 11

Replacing the Drive Belt

The snow thrower’s drive belt is subject to wear and

should be replaced if any signs of cracking, shredding

or rotting is present. To change the drive belt, proceed

as follows:

• Install the replacement drive belt by following the preceding steps in reverse order.

• While holding the idler bracket up, carefully slip the

drive belt off the engine pulley. See Figure 11.

• Carefully release the idler bracket and allow it to

pivot downward.

• Carefully slip the drive belt off the auger pulley,

freeing it from the snow thrower. See Figure 11.

10

Page 11

• Reattach the belt cover with the five hex screws

removed earlier.

Replacing the Shave Plate

The shave plate is subject to wear and should be

checked periodically. There are two wearing edges and

the shave plate can be reversed after one side wears

out. To replace (or reverse) the shave plate, proceed as

follows:.

NOTE: Call 1-800-800-7310 for information regarding

price and availability of Shave Plate Kit 753-0451or

contact an authorized MTD Service Dealer in your

area).

• Remove the four carriage bolts and hex lock nuts

which secure it to the snow thrower’s auger

housing. Refer to Figure 10.

• Install the new shave plate (or reverse the existing

one, if both sides are not yet worn), making sure the

heads of the carriage bolts are on the inside of the

housing. The lock nuts should be on the outside of

the housing.

• Adjust the shave plate as instructed in the Making

Adjustments section on page 10 of this manual.

• Tighten the nuts securely before operating the

snow thrower.

Replacing the Auger’s Rubber Paddles

The snow thrower auger’s rubber paddles are subject

to wear and should be replaced if any signs of

excessive wear is present.

IMPORTANT:

to wear to the point where the metal auger itself can

come in contact with the pavement. Doing so can result

in serious damage to your snow thrower.

NOTE: Call 1-800-800-7310 for information regarding

the price and availability of Rubber Paddle Kit 753-0613

or contact an authorized MTD Service Dealer in your

area).

To change the rubber paddles, proceed as follows:

• Remove the existing rubber paddles by

unthreading the self-tapping screws which secure

them to the auger.

IMPORTANT:

securing the rubber paddles to the auger. Note their

location for ease in reassembling.

• Secure the replacement rubber paddles to the

auger using the hardware removed earlier.

Do NOT allow the auger’s rubber paddles

There are two different styles of screws

SECTION 7: OFF-SEASON STORAGE

WARNING: Never store engine with fuel in

tank indoors or in enclosed, poorly ventilated

areas where fuel fumes may reach an open

flame, spark or pilot light as on a furnace,

water heater, clothes dryer, or other gas

appliance.

• Clean snow thrower thoroughly.

• Lubricate as instructed in the Maintaining Your Snow

Thrower section on page 10 of this manual.

• Refer to the Tecumseh Engines manual packed

with the snow thrower for detailed instructions

regarding all engine-related storage instructions.

• Store the snow thrower in a clean, dry area.

• Place blocks under the front of the auger housing

so that the snow thrower is not resting on the

rubber auger paddles. The rubber can become

misshaped if it supports the weight of the snow

thrower for several months of storage.

NOTE: When storing any type of power equipment in

an poorly ventilated or metal storage shed, care should

be taken to rustproof the equipment, especially springs,

cables and all moving parts.

11

Page 12

SECTION 8: TROUBLESHOOTING GUIDE

Problem Cause Remedy

Engine fails to start 1. Key not in ignition switch or not in ON position.

2. Fuel tank empty, or stale fuel

3. Blocked fuel line

4. Spark plug wire disconnected

5. Faulty spark plug

Engine runs erratic 1. Unit running on choke

2. Fuel line blocked, or stale fuel

3. Water or dirt in fuel system

4. Carburetor out of adjustment

Loss of power 1. Spark plug wire loose

2. Vent in fuel cap plugged

3. Engine exhaust pipe plugged.

Excessive vibration 1. Loose parts or damaged auger 1. Stop engine immediately and disconnect

Unit fails to self-propel 1. Drive cable out of adjustment

2. Drive belt damaged

Unit fails to discharge

snow

1. Discharge chute clogged

2. Foreign object lodged in auger

3. Drive cable out of adjustment

4. Drive belt or damaged

1. Insert key and turn to ON position

2. Fill tank with clean fresh gasoline/oil

mixture as specified in the engine manual.

3. Clean fuel line

4. Connect wire to spark plug.

5. Clean spark plug, readjust gap, or replace.

1. Move choke lever to off position.

2. Clean fuel line and fill tank with fresh, clean

gasoline.

3. Refer to engine manual on remedy.

4. Refer to engine manual.

1. Connect and tighten spark plug wire.

2. Clear vent.

3. Remove obstruction from exhaust pipe.

spark plug wire. Check for possible

damage. Tighten all bolts and nuts. Repair

as needed. If the problem persists, take unit

to an authorized MTD service dealer.

1. Adjust the control cable as instructed on

page 9 of this manual.

2. Inspect the drive belt for damage and

replace if necessary as instructed on page

10 of this manual.

1. Stop engine immediately and disconnect

spark plug wire. Clean discharge chute and

the auger housing.

2. Stop engine immediately and disconnect

spark plug wire. Remove object.

3. Adjust the control cable as instructed

on page 9 of this manual.

4. Inspect the drive belt for damage and

replace if necessary as instructed on page

10 of this manual.

SECTION 9: ACCESSORIES & KITS

The following accessories and kits are available for single-stage, two-stroke snow throwers. See the retailer

from which you purchased your snow thrower, an authorized MTD Service Dealer or phone (800) 800-7310 for

information regarding price and availability.

MODEL DESCRIPTION

OEM-390-694 Electric Start Kit

(fits models with a two-cycle Te cu ms eh 3 HP or 3.5 HP engine)

OEM-390-996 Electric Start Kit

(fits models with a two-cycle Te cu ms eh 4.5 HP – 5 HP engine)

OEM-737-0325 MTD two-cycle snow thrower oil (contains six 2.6 oz. bottles)

753-0451 Shave Plate (includes replacement shave plate and hardware)

753-0613 Auger Rubber Paddle Kit (includes replacement rubber paddles and hardware)

12

Page 13

NOTES

13

Page 14

SECTION 10: PARTS LIST

12

11

20

5

1

3

7

1

5

10

21

23

6

7

8

17

16

4

2

25

18

22

2

2

29

19

24

37

22

8

38

18

13

27

6

2

39

36

8

34

35

30

31

9

14

33

32

9

31

9

14

Page 15

Models 140, 150, E150, E162 & E172

REF.

NO.

1 710-0276 Splined Carriage Screw, 5/16-18 x 1.0

2 710-3015 Hex Cap Screw, 1/4-20 x.75

3 712-3068 Hex Lock Nut, 5/16-18

4 731-0851A Chute Flange Keeper

5 731-0915B Lower Chute, 5.0

6 731-0921 Upper Chute, 5.0

7 736-0159 Washer, .349 x .879 x .063

8 720-0284 Wingnut Knob, 5/16-18

9 710-1268 Screw, #10-16 x .375

10 712-3027 Hex Flange Lock Nut, 1/4-20

11 710-0451 Carriage Bolt, 5/16-18 x .75

12 726-0100 Push Cap, 3/8

13 720-0201A Knob, 1.0 x 3.2

14 731-1765 Shroud, Black—Models E162 & E172

15 735-0234 Rubber Grommet, .44 x .94 x .50

16 736-0185 Flat Washer, .375 x .738 x .063

17 714-0104 Internal Cotter Pin, .072 x 1.12

18 736-0451 Saddle Washer, .320 x .93

19 747-0697 Eyebolt, .70

20 747-0737 Upper Chute Crank

21 750-0785 Spacer, .382 x .50 x 1.12

22 712-3010 Hex Nut, 5/16-18

23 714-0507 Cotter Pin, 3/32 x .75

24 715-0138 Rolled Pin, 1/8 x .63

25 684-0126 Chute Crank Assembly

26 749-0705 Upper Handle

27 747-0946 Auger Bail (Control Handle)

28 749-0796B Lower Handle

29 736-0119 Lock Washer, 5/16

30 731-1087 Shroud, Black—Models 150 & E150

31 736-0400 Flat Washer, .194 x .62 x .063

32 731-0702 Shroud, Black—Model 140

33 710-1003 Screw, #10-16 x .625

34 747-0956 Auger Bail (Control Handle), Gullwing-style

35 749-0711A Upper Handle, Gullwing-style

— 720-0295 Foam Grip, 22” (not included with handle)

36 725-0157 Cable Tie

37 746-0883 Control (Cable) Housing

38 712-0324 Nylon Hex Lock Nut, 1/4-20

39 710-1270 Machine Screw, 1/4-20 x 1.31

PA RT

NO. DESCRIPTION

NOTE: Snow thrower features/components vary by model. NOT all parts listed above and pictured on the previous page are standard equipment.

15

Page 16

Models 140, 150, E150, E162 & E172

29

74

26

12

64

32

66

38

52

33

49

53

27

7

50

28

57

35

37

65

18

1

50

20

5

68

40

11

6

17

25

21

16

69

2

5

6

55

71

58

67

2

47

34

62

42

54

56

7

61

41

3

45

60

13

15

31

14

22

19

4

70

23

8

9

43

24

7

22

30

6

4

59

22

73

72

51

72

44

73

16

46

36

10

63

48

39

Page 17

Models 140, 150, E150, E162 & E172

REF.

NO.

1 684-0054A Dash Assembly—Model E162

2 750-0589 Spacer, .325 x .625 x .88—Model 140

3 710-1003 Screw, #10-16 x .625

4 710-1090 Hex Flange Screw, 5/16-18 x 1.25

5 710-1268 Screw, #10-16 x .375

6 710-1652 Self-tapping Screw, 1/4-20 x .625

7 712-3010 Hex Nut, 5/16-18

8 754-0101A Drive Belt—Model 150, E150, E162, E172

9 756-0416B Pulley Half-.625 x 2.25

10 756-0475 Auger Drive Pulley

11 734-1176 Wheel Assembly, 7 x 1.5

12 725-0201 Ignition Key

13 725-1341B Ignition Key w/ Plastic Cover

14 725-1346 Ignition Nut, 5/8-32—Model E162, E172

15 725-1347 Ignition Switch Cap

16 725-1425 Ignition Switch

17 784-5178A Chute Crank Bracket—Model 140

18 731-1089A Choke Cover

19 731-1133C Spark Plug Cap

20 7510009630 Recoil Handle (Standard)

21 751-0535 Fuel Line Hose

22 736-0119 Lock Washer, 5/16

23 750-0716 Spacer, .630 x .88 x .680

24 736-0225 Internal Lock Washer, 5/8 x 1.058 x .046

25 751-0352 Gas Tank, 1 qt—Model 140

26 751-0353 Fuel Cap for 751-0352

27 751-0540A Gas Tank, 2 qt.—Model 150, E150,

28 751-0800 Fuel Cap for 751-0540A (50:1 Red Print)

29 7510009636 Recoil Handle (Mitten Grip)

30 723-0354 Primer Tube

31 751-0354 Primer Bulb

32 684-0114A Auger Housing Assembly

33 710-0167 Screw, 1/4-20 x .50

34 710-0191 Cap Screw, 3/8-24 x 1.25

35 710-0323 Trus Machine Screw, 5/16-18 x .75

PA RT

NO. DESCRIPTION

(Includes Plastic Cup for Mitten Grip)

684-0056 Dash Assembly—Model 140

(Includes Plastic Sleeve for Starter Rope)

684-0160 Dash Assembly—Model 150, E150, E172

(Includes Plastic Sleeve for Starter Rope)

754-0367 Drive Belt—Model 140

712-0252 Jam Nut, 5/8-32—Model 140, 150, E150

E162, E172

REF.

NO.

36 710-0352 Hex Index Washer Screw, 1/4-14 x .375

37 710-0451 Carriage Bolt, 5/16-18 x .75

38 710-0642 Self-tapping Screw 1/4-20 x .75

39 710-0773 Self-tapping Screw 3/8-16 x .50

40 710-0896 Self-tapping Screw, 1/4-14 x .625

41 710-1005 Self-tapping Screw, 1/4-14 x .50

42 710-0848A Axle, .35 x .5 x 20.75

43 712-0116 Jam Lock Nut, 3/8-24

44 712-3027 Hex Flange Lock Nut, 1/4-20

45 784-5177 Engine Support Bracket—Model 140

46 731-1033 Shave Plate, 2.66 x 19.88

47 732-0357A Extension Spring, .33 x 1.12

48 736-0108 Flat Washer, .51 x .75 x .033

49 736-0176 Flat Washer, .265 x .938 x .120

50 736-0242 Belleville Washer, .340 x .872

51 736-0326 Flat Washer, .51 x 1.0 x .125

52 736-0329 Lock Washer, 1/4

53 741-0475 Plastic Bushing

54 741-0600 Ball Bearing, 17mm x 40mm x 12mm

55 746-0910A Cable, 41.78” (includes end spring)

56 748-0234 Shoulder Spacer

57 726-0205 Hose Clamp, .49

58 741-0475 Plastic Bushing, .38

59 756-0313 Flat Idler Pulley, 1.88 x .50 x 2.12

60 710-0895 Hi-Lo Self-tapping Screw, 1/4-15 x .75

61 784-5174 Bearing Cup

62 784-5175B Brake Idler Bracket

63 784-5176 Belt Cover

64 784-5485 Solid Shaft Auger Assembly

65 784-5720 Chute Crank Bracket

66 629-02536 110V Extension Cord, 2-prong

67 705-5139A Fuel Tank Support Bracket—Model 150,

68 710-0157 Hex Cap Screw, 5/16-24 x .75

69 710-3013 Hex Cap Screw, 1/4-20 x .50

70 710-3025 Hex Cap Screw, 5/16-24 x .625

71 726-0152 Self-adhesive Clamp, .5 (for starter cable)

72 731-0782 Rubber Paddle

73 731-0780A Rubber Paddle/Spiral

74 784-5344 Chute Crank Assembly—Model 140

PART

NO. DESCRIPTION

E150, E162 & E172

—Model 150, E150, E162, E172

710-0805 Hex Cap Screw, 5/16-18 x 1.50

—Model 140

IMPORTANT:

For a proper

working machine, use

Factory Approved Parts.

V-belts are designed to

engage and disengage

safely. A substitute (non

OEM) V-belt can be

dangerous by not

disengaging completely.

NOTE: Snow thrower features/components vary by model. NOT all parts listed above and pictured on the previous page are standard equipment.

17

Page 18

ÍNDICE

Contenido Página

Medidas importantes de seguridad .......................................................................... 3

Montaje de la Máquina quitanieve........................................................................... 5

Conozca las propiedades de la máquina quitanieve................................................ 7

Funcionamiento de la máquina quitanieve............................................................... 8

Realización de ajustes............................................................................................. 9

Mantenimiento de la máquina quitanieve................................................................. 10

Almacenamiento fuera de temporada ...................................................................... 11

Guía para la solución de problemas de la máquina quitanieve ................................ 11

Lista de las piezas.................................................................................................... 12

BÚSQUEDA DEL NÚMERO DE MODELO

Este manual de operación es una parte importante de la nueva máquina quitanieve. Le ayudará a montar, preparar

y mantener la unidad para obtener los mejores resultados. Por favor lea y comprenda el contenido del manual.

Antes de comenzar el montaje de la máquina quitanieve nueva, por favor encuentre la placa del

modelo del equipo y copie la información contenida en la misma en el espacio provisto a

continuación. La información contenida en la placa del modelo es muy importante en caso de

necesitar ayuda de nuestro Departamento de Asistencia al Cliente o de un distribuidor autorizado.

• Para encontrar el número de modelo párese detrás de la unidad en posición de operación y mire hacia abajo

donde está el panel de instrumentos. A continuación se explica un ejemplo de placa de modelo. Para

referencias futuras, por favor copie el número de modelo y el número de serie del equipo en el espacio a

continuación.

(Número de modelo)

CLEVELAND, OHIO 44136

(Número de serie)

MTD PRODUCTS INC

Copie el número del modelo en este espacio:

Copie el número de serie en este espacio:

SERVICIO TELEFÓNICO DE ASISTENCIA AL CLIENTE

En caso de tener problemas para ensamblar este producto o de tener dudas con respecto a los controles,

funcionamiento o mantenimiento del mismo, por favor comuníquese con el Departamento de asistencia al cliente.

Llame al 1- (330) 220-4MTD (4683) o 1- (800)-800-7310 para comunicarse con un representante de

asistencia al cliente. Por favor cuando llame tenga a la vista el número de modelo y el número de

serie de su unidad. Consulte la sección anterior para obtener esta información. Se le solicitará que

ingrese el número de serie para poder procesar su llamada.

18

Page 19

SECCIÓN 1: MEDIDAS IMPORTANTES DE SEGURIDAD

ADVERTENCIA: La presencia de este símbolo indica que se trata de instrucciones importantes de seguridad

que debe respetar para evitar poner en riesgo su seguridad personal y / o material y de otras personas. Lea y siga

todas las instrucciones contenidas en este manual antes de intentar poner esta máquina en funcionamiento. De no

hacerlo puede ocasionar lesiones. Cuando encuentre este símbolo —respete la advertencia que aparece a

continuación del mismo.

DVERTENCIA: El escape del motor de este producto, algunos de sus componentes y algunos componentes del

vehículo contienen o emiten productos químicos que el estado de California considera que pueden producir cáncer,

defectos de nacimiento u otros problemas reproductivos.

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las reglas de seguridad contenidas en este

manual. Al igual que con todos los equipos eléctricos si el operador es descuidado o comete errores puede ocasionar

lesiones graves. Esta máquina puede amputar manos y pies y arrojar objetos. De no respetar las instrucciones de

seguridad siguientes se pueden producir lesiones graves o la muerte.

Capacitación

1. Lea, comprenda y respete todas las instrucciones que figuran

en la máquina o en este(os) manual(es) antes de proceder al

montaje y operación del equipo. Guarde este manual en un

lugar seguro para referencias futuras y regulares y para solicitar

repuestos.

2. Familiarícese con todos los controles y con el uso adecuado de

los mismos. Sepa cómo detener la máquina y cómo

desengranar los controles rápidamente.

3. Nunca permita que niños menores de 14 años operen esta

máquina. Los niños de 14 años y más deben leer y comprender

las instrucciones de operación y las reglas de seguridad

contenidas en este manual y deben ser capacitados y

supervisados por uno de los padres.

4. Nunca permita que adultos sin conocimientos acerca de la

máquina operen la misma.

5. Los objetos arrojados por la máquina pueden producir lesiones

graves. Planifique el patrón en el que va a ir arrojando nieve

para evitar que la descarga de material se realice hacia los

caminos, los observadores, etc.

6. Mantenga a los observadores, ayudantes, mascotas y a los

niños por lo menos a 75 pies de la máquina mientras la misma

está en funcionamiento. Detenga la máquina si alguien entra en

la zona.

7. Sea precavido para evitar patinarse o caerse especialmente

cuando opera la máquina en reversa.

Preparativos

1. Revise minuciosamente la zona donde se utilizará el equipo.

Saque todos los felpudos, diarios, trineos, tablas, cables y otros

objetos extraños con los que podría tropezar o que podrían ser

arrojados por la barrena / motor.

2. Para protegerse los ojos utilice siempre anteojos o antiparras

de seguridad mientras opera la máquina o mientras la ajusta o

repara. Los objetos arrojados que rebotan pueden lesionar

gravemente la vista.

3. No opere la máquina sin la vestimenta adecuada para estar al

aire libre en invierno. No utilice alhajas, bufandas largas u otras

prendas sueltas que podrían enredarse en las partes móviles.

Utilice un calzado antideslizante para las superficies

resbaladizas.

4. Use un cordón prolongador y un tomacorriente de tres cables

con conexión a tierra para todas las unidades con motores con

encendido eléctrico.

5. Ajuste la altura de la caja del tomacorriente para limpiar la grava

o las superficies con piedras trituradas.

6. Desengrane todas las palancas de embrague antes de arrancar

el motor.

7. Nunca trate de realizar ningún ajuste mientras el motor está en

marcha, excepto cuando lo recomiende específicamente el

manual de operación.

8. Deje que el motor y la máquina se adapten a la temperatura

exterior antes de comenzar a sacar la nieve.

9. Sea sumamente cuidadoso al manipular la gasolina para evitar

lesiones o daños. La gasolina es altamente inflamable y los

vapores son explosivos. Se puede lesionar gravemente si

derrama gasolina sobre usted o sobre la ropa ya que se puede

encender. Lave la piel y cámbiese de ropa de inmediato.

a. Utilice sólo recipientes para gasolina aprobados.

b. Apague todos los cigarrillos, cigarros, pipas y otras

fuentes de combustión.

c. Nunca cargue combustible en la máquina en un espacio

cerrado.

d. Nunca saque la tapa del gas ni agregue combustible

mientras el motor está caliente o en marcha.

e. Deje que el motor se enfríe por lo menos dos minutos

antes de volver a cargar combustible.

f. Nunca recargue el tanque de combustible. Llene el

tanque no más de 1/2 pulgada por debajo de la base del

cuello del filtro para dejar espacio para la dilatación del

combustible.

g. Vuelva a colocar la tapa de la gasolina y ajústela bien.

h. Limpie la gasolina derramada sobre el motor y el

equipo. Traslade la máquina a otra zona. Espere 5

minutos antes de encender el motor.

i. Nunca almacene la máquina o el recipiente de

combustible en un espacio cerrado donde haya fuego,

chispas o luz piloto (por ejemplo, hornos, calentadores

de agua, calefactores, secadores de ropa, etc.).

j. Deje que la máquina se enfríe 5 minutos por lo menos

antes de almacenarla.

Funcionamiento

1. No ponga las manos o los pies cerca de las piezas rotatorias, en

la caja de la barrena / motor o en el canal de descarga. El

contacto con las piezas rotatorias puede producir la amputación

de manos y pies.

2. La palanca del embrague de la barrena / motor es un dispositivo

de seguridad. Nunca pase por alto su funcionamiento. De

hacerlo la operación de la máquina es riesgosa y puede

ocasionar lesiones.

3. Las palancas del embrague deben funcionar bien en ambas

direcciones y regresar automáticamente a la posición de

desengrane cuando se las suelta.

4. Nunca opere la máquina si falta un canal de descarga o el

mismo está dañado. Mantenga todos los dispositivos de

seguridad en su lugar y en funcionamiento.

19

Page 20

5. Nunca encienda el motor en espacios cerrados o en una zona

poco ventilada. El escape del motor contiene monóxido de

carbono, un gas inodoro y letal.

6. No opere la máquina estando bajo los efectos del alcohol o de

drogas.

7. El silenciador y el motor se calientan y producen una

quemadura. No los toque.

8. Sea sumamente precavido cuando opere la máquina sobre una

superficie con grava o cuando la cruce. Manténgase alerta por

si se presentan peligros ocultos o tráfico.

9. Tenga cuidado cuando cambie de dirección o cuando opere la

máquina en pendientes.

10. Planifique el patrón en el que va a ir arrojando nieve para evitar

que la descarga de material se produzca hacia las ventanas, las

paredes, los autos, etc. para evitar daños materiales o lesiones

producidas por los rebotes.

11. Nunca dirija la descarga hacia los niños, los observadores y a

las mascotas ni deje que nadie se pare delante de la máquina.

12. No sobrecargue la capacidad de la máquina tratando de sacar

la nieve muy rápidamente.

13. Nunca opere esta máquina si no tiene buena visibilidad o

iluminación. Siempre debe estar seguro de que está bien

afirmado y sostenga bien las manijas. Camine, nunca corra.

14. Corte la corriente a la barrena / motor cuando transporte la

máquina o cuando la misma no está en uso.

15. Nunca opere la máquina a alta velocidad de desplazamiento

sobre superficies resbaladizas. Mire hacia abajo y hacia atrás y

tenga cuidado cuando la use en reversa.

16. Si la máquina comenzara a vibrar de manera anormal, detenga

el motor, desconecte la bujía y póngala de manera que haga

masa contra el motor. Inspeccione la máquina minuciosamente

para ver si está dañada. Repare todos los daños antes de

encender y operar la máquina.

17. Desengrane todas las palancas de embrague y detenga el

motor antes de dejar la posición de operación (detrás de las

manijas). Espere a que la barrena / motor se detenga por

completo antes de destapar el canal de descarga, de realizar

ajustes o inspecciones.

18. Nunca ponga las manos en las aberturas de descarga o de

recolección. Utilice siempre una herramienta de limpieza para

destapar la abertura de descarga.

19. Use sólo uniones y accesorios aprobados por el fabricante (por

ejemplo, pesas para las ruedas, cadenas para los neumáticos,

cabinas, etc.).

20. Si se presentan situaciones que no están previstas en este

manual sea cuidadoso y use el sentido común. Comuníquese

con su distribuidor o llame al teléfono 1-800-800-7310 por

ayuda y para obtener el nombre del distribuidor más cercano.

Mantenimiento y almacenamiento

1. Nunca manipule los dispositivos de seguridad de manera

imprudente. Controle periódicamente que funcionen de forma

adecuada.

2. Desengrane todas las palancas de embrague y detenga el

motor. Espere a que la barrena / motor se detenga por

completo. Desconecte el cable de la bujía y póngalo de manera

que haga masa contra el motor para evitar que se encienda de

manera accidental antes de limpiar, reparar o revisar la

máquina.

3. Controle frecuentemente que todos los pernos y tornillos estén

bien ajustados para comprobar que la máquina se encuentra en

condiciones seguras de operación. Además realice una

inspección visual de la máquina para controlar si la misma está

dañada.

4. No cambie la configuración del regulador del motor ni acelere

demasiado el mismo. El regulador controla la velocidad máxima

segura de operación del motor.

5. Las placas de raspado y los zapatos anti deslizantes de que se

usan con la máquina quitanieves se desgastan y se dañan. Para

su seguridad controle frecuentemente todos los componentes y

reemplácelos solamente por repuestos originales del fabricante

(O.E.M.). “¡Si usa piezas que no cumplen con las

especificaciones del equipo original puede obtener resultados

incorrectos y comprometer la seguridad!”

6. Revise los controles del embrague periódicamente para

verificar que engranen y desengranen adecuadamente y

ajústelos si es necesario. Consulte las instrucciones que figuran

en la sección sobre ajustes incluida en este manual de

operación.

7. Mantenga o reemplace las etiquetas de seguridad e

instrucciones según sea necesario.

8. Respete las leyes y reglamentaciones referentes a la

disposición correcta de gas, aceite, etc. para proteger el medio

ambiente.

9. Antes de almacenar la máquina enciéndala unos minutos para

sacar la nieve que haya quedado en la misma y para evitar así

que se congele la barrena / motor.

10. Nunca almacene la máquina o el recipiente de combustible en

un espacio cerrado donde haya fuego, chispas o luz piloto como

por ejemplo, calentadores de agua, hornos, secadores de ropa,

etc.

11. Consulte siempre el manual de operación por las instrucciones

adecuadas para el almacenamiento fuera de temporada.

Su responsabilidad:

• Sólo permita que usen esta máquina eléctrica las personas que

lean, comprendan y respeten las advertencias y las

instrucciones que aparecen en este manual y en la máquina.

DANGER

NEVER PUT HAND IN CHUTE. CONTACT WITH

ROTATING PARTS CAN AMPUTATE FINGERS

AND HANDS.

DO NOT UNCLOG DISCHARGE CHUTE WHILE

ENGINE IS RUNNING.

SHUT OFF ENGINE AND REMAIN BEHIND

HANDLES UNTIL ALL MOVING PARTS HAVE

STOPPED BEFORE UNCLOGGING.

20

AVOID INJURY FROM

ROTATING AUGER KEEP HANDS, FEET

AND CLOTHING AWAY.

READ OPERATOR'S MANUAL.

4.

GRAVEL SURFACES.

USE EXTRA CAUTION WHEN OPERATING ON

NEVER DIRECT DISCHARGE AT BYSTANDERS.

3.

TO AVOID THROWN OBJECTS INJURIES,

UNCLOGGING OR SERVICING MACHINE.

MOVING PARTS HAVE STOPPED BEFORE

AND REMAIN BEHIND HANDLES UNTIL ALL

2.

DISENGAGE CLUTCH LEVERS, STOP ENGINE,

HANDS AND FEET.

CONTACT WITH AUGER CAN AMPUTATE

KEEP AWAY FROM ROTATING AUGER

1.

Page 21

SECCIÓN 2: MONTAJE DE LA MÁQUINA QUITANIEVE

NOTA: Este manual de operación trata distintos modelos. Las

características técnicas de la máquina quitanieve varían según

los modelos. No todas las características técnicas tratadas en este

manual son aplicables a todos los modelos de máquinas quitanieve.

Contenido de la caja

Antes de comenzar la instalación saque todas las piezas de la caja y

compárelas con Figure 1. El contenido de la caja es enunciado a

continuación con el número de las piezas entre paréntesis.

•Dos

†Se incluye una llave de encendido con una cubierta plástica con

modelos seleccionados únicamente. Dos llaves de encendido

convencionales se incluyen con todos los otros modelos.

Llaves de encendido (725-0201, 725-1341B†)

Para los modelos equipados de esa manera:

• Montaje del control direccional del canal extendido

(747-0737, 720-0201A y 726-0100)

• Un pasador de chaveta (714-0507)

• Uno arandela acopada (736-0415)

• Dos tuercas de maleficio (712-3010)

•Uno cerrojo de ojo (747-0697) con ojal (735-0234)

Llave de encendido con cubierta plástica

Llave de encendido convencional

Pasador de chaveta

Arandela acopada

Tuercas de maleficio

Cerrojo de ojo

†

Perilla a mariposa

Colocación del cable de control

Es posible que el cable de control ya esté unido a la manija de

control. De no ser así siga estos pasos para conectarlo a la caja de la

máquina quitanieve.

• Dirija el cable de control sobre la barra transversal donde la

manija inferior se encuentra con la superior.

• Gire la manija de control hacia adelante e inserte el extremo del

cable de control en el agujero de la base en la manija de

control, desde afuera hacia adentro, como se indica en Figure 3.

Manija superior

Perilla a mariposa

Figura 2

Canal extendido

Montaje del control direccional

Figura 1

NOTA:

máquina quitanieve se hacen observando la misma desde la posición

de operación.

Las referencias a los lados derecho o izquierdo de la

ADVERTENCIA: Desconecte el cable de la bujía

y póngalo de manera que haga masa contra el motor para

evitar que se encienda de manera accidental.

Colocación de la manija superior

• Retire el material de embalaje si hubiera y afloje las perillas a

mariposa que se encuentran a ambos lados de la manija.

• Gire la manija superior hasta la posición de operación cuidando

de no apretar o doblar el cable en el proceso, como se indica en

la ilustración • hasta que quede en su lugar.

• Ajuste las perillas a mariposa para ajustar la manija en su lugar.

Manija de control

Agujero superior

Accesorio plástico

Extremo del cable

En el agujero de la base

Caja del control

Figura 3

• Empuje el accesorio plástico dentro de la caja del control hasta

que haga ruido de que quedó en su lugar

NOTA: El agujero superior de la manija de control prevé el ajuste

de la tensión de la correa y del cable. Consulte la página 9 de este

manual por las instrucciones.

21

Page 22

Instalación del perno de ojo canal pour control

direccional (en modelos equipados de esa

manera)

Instalar a la manivela superior de el control direccional del canal a,

proceda de la siguiente manera:

• El hilo uno de los loco de maleficio (ellos son permutables)

incluídos en paquete de hardware del lanzador de nieve toda la

manera sobre el cerrojo de ojo.

• Encarte el cerrojo de ojo en el agujero encontrado en la barra

enfadada de la manija inferior . Ver Figura 4.

• Sujetar el cerrojo de ojo a el barra enfadada con el arandela

acopada ( Lado ahuecado ENCIMA de) y otra tuerca de

maleficio como ilustrado en Figura 4. No apriétese en este

tiempo.

Instalación del canal extendido

Control direccional

Cerrojo de Ojo

Barra Enfadada

Tuerca de Maleficio

Arandela Acopada

Tuerca de Maleficio

(en modelos equipados de esa manera)

• Inserte el control direccional del canal a través del perno de ojo

y hacia el interior del acoplador que se encuentra en la zona

superior derecha del recubrimiento de la máquina quitanieve.

Ver Figura 5.

• Gire el control direccional del canal para alinear el agujero del

acoplador con el del control direccional del canal e inserte el

pasador de chaveta a través de ambos agujeros. Doble los

extremos del pasador de chaveta en direcciones opuestas para

ajustarlo en su lugar. Ver Figura 5.

• El hilo el cerrojo de ojo sobre el que la tuerca de maleficio

inferior hacia arriba o hacia abajo ajustar la altura del ojo echa el

cerrojo para que la tolva el control direccional no ate en el

acoplador cuando manejado.

• Bien apriete ambos tuerca de maleficio.

Montaje del canal de descarga

Por razones de envío, la máquina quitanieve ha sido embalada con el

canal superior girado completamente hacia abajo. Para girarlo hacia

arriba proceda de la siguiente manera:

• Gire el control direccional del canal hasta que la abertura del

canal quede mirando derecho hacia adelante.

• Saque la perilla a mariposa, la arandela plana y el bulón del

carro del canal superior. Ver Figura 6.

• Gire el canal superior hacia arriba sobre el borde del canal

inferior de manera que NO quede ningún espacio entre el canal

superior y el inferior. Ver Figura 6.

• Vuelva a unirlos con los elementos de ferretería que sacó

anteriormente.

Pasador de chaveta

Acoplador

Bulón del carro

Borde del

canal inferior

Canal superior

Figura 4

Control direccional del canal

Perno de ojo

Figura 5

Plana

Arandela

A mariposa Perilla

22

Frente

Figura 6

Page 23

SECCIÓN 3: CONOZCA LAS PROPIEDADES DE LA MÁQUINA QUITANIEVE

Canal de descarga

Bujía

Cubierta

Arrancador

Manija

de obturación

Placa de raspado

IMPORTANTE:

Barrena

Esta unidad funciona con una mezcla de

Manija superior

gasolina y aceite. NO ponga en funcionamiento la máquina

quitanieve sin leer antes el Manual de operación Tecumseh

para conocer las instrucciones referentes al combustible y al

aceite para motor adecuados.

Palanca de obturación

OFF

Al activar el control de obturación se cierra la placa de obturación del

carburador y ayuda a encender el motor. Consulte el manual del

motor que viene embalado con la máquina quitanieve para conocer

las instrucciones completas referentes a la obturación.

CHOKE

(obturación) (encendido)(apagado)

ON

Cebador

Al presionar el cebador se envía combustible

directamente al carburador del motor para

ayudar al encendido cuando el clima es frío.

Consulte el manual del motor que viene

embalado con la máquina quitanieve para

conocer las instrucciones completas referentes

al cebador.

Llave de encendido

La llave de encendido debe estar presente y

en la posición “ON” (encendido) para que

arranque el motor.

Manija del arrancador

La manija del arrancador se utiliza para

arrancar el motor manualmente.

Detención del motor

• Gire la llave de encendido a la posición OFF (apagado) y

sáquela de la máquina quitanieve.

Botón del arrancador eléctrico (Si está equipado de esa manera)

Si oprime el botón del arrancador eléctrico se engrana el arrancador

eléctrico del motor cuando se lo enchufa a una fuente de energía de

120V

Cebador

Llave de encendido

Palanca

Manija de control

Control direccional del canal

Enchufe del arrancador eléctrico

(Si está equipado de esa manera)

Arrancador Botón

(Si está equipado

de esa manera)

Enchufe del arrancador eléctrico

(Si está equipado de esa manera)

Es necesario usar un cordón prolongador para exteriores de dos

espigas (embalado junto con la máquina quitanieve) y una fuente de

energía / tomacorriente de pared de 120V.

Cubierta de la bujía

Saque la cubierta de la bujía para acceder a la bujía del motor que se

encuentra debajo de ella.

Control direccional del canal

El control direccional del canal está ubicado en el lado derecho del

panel de instrumentos y determina la dirección en que se descargará

la nieve. Gírelo en sentido de las agujas del reloj para descargar la

nieve hacia la izquierda y en sentido contrario a las mismas para

descargarla hacia la derecha.

Barrena

Cuando está engranada, la rotación de la barrena levanta la nieve la

cual ingresa a la caja de la barrena y es arrojada hacia afuera por el

canal de descarga. Las paletas de caucho de la barrena también

ayudan a impulsar la máquina quitanieve al ponerse en contacto con

el pavimento.

Manija de control de la barrena

La manija de control de la barrena está ubicada en la manija superior

y se usa para engranar y desengranar la transmisión de la barrena.

Apriete la manija de control contra la manija superior para engranar

la barrena, aflójela para desengranarla.

Canal de descarga

La inclinación del canal de descarga controla el ángulo con el que se

arroja la nieve. Afloje la perilla a mariposa del costado del canal de

descarga antes de girar el canal de descarga hacia arriba o hacia

abajo. Vuelva a ajustar la perilla después de alcanzar la posición

deseada.

Placa de raspado

La placa de raspado raspa contra el pavimento a medida que se

impulsa la máquina quitanieve permitiendo que se descargue la

nieve que está cerca de la superficie del pavimento.

Tapa de l

combustible

Eléctrico

23

Page 24

SECCIÓN 4: FUNCIONAMIENTO DE LA MÁQUINA QUITANIEVE

ADVERTENCIA: Antes de encender el motor,

lea, comprenda y respete todas las instrucciones y

advertencias que figuran en la máquina y en este manual

antes de operar el equipo.

Mezcla de combustible y aceite

ADVERTENCIA: Sea sumamente cuidadoso al

manipular la gasolina. La gasolina es altamente

inflamable y los vapores son explosivos. Nunca cargue

combustible en la máquina en un espacio cerrado o

cuando el motor está caliente o en marcha. Apague todos

los cigarrillos, cigarros, pipas y otras fuentes de

combustión.

La máquina quitanieve está equipada con un motor de dos ciclos

que necesita una mezcla de gasolina y de aceite para motores de

dos ciclos en una proporción de 50:1. Consulte el manual de

operación Tecumseh para motores para conocer las instrucciones

completas en lo referente al aceite y la gasolina para el motor de la

máquina quitanieve.

• Se coloca una cubeta plástica en la abertura de carga del

tanque de combustible (debajo de la tapa del combustible) para

evitar que ingresen escombros durante el montaje del producto.

Saque la cubeta y tírela antes de llenar el tanque.

IMPORTANTE: NO opere la máquina quitanieve sin antes ajustar

bien la tapa del combustible en su lugar en el tanque de combustible.

Encendido del motor

• Consulte el manual de operación Tecumseh para motores

embalado con la máquina quitanieve para conocer las

instrucciones completas referentes al encendido del motor.

Funcionamiento de la máquina quitanieve

• Afloje la perilla a mariposa que se encuentra en el costado del

canal de descarga y gire el canal superior hacia arriba o hacia

abajo hasta alcanzar la inclinación deseada. Vuelva a ajustar la

perilla a mariposa antes de poner la máquina quitanieve en

funcionamiento.

• Gire el control direccional del canal para poner la abertura del

canal de descarga en la dirección deseada. Ver Figura 7.

NOTA: Si desea quitar nieve de manera más eficiente,

descárguela a favor del viento cuando sea posible.

ADVERTENCIA: Nunca opere la máquina

quitanieve cuando haya observadores delante o cerca de

la abertura del canal de descarga.

• Para engranar la barrena apriete la manija de control contra la

manija superior. Ver Figura 7.

• Levante apenas la manija para permitir que la paleta de caucho

de la barrena toque el pavimento e impulse la máquina

quitanieve hacia adelante.

Manija de control

Canal

Control direccional

Figura 7

NOTA:

excesiva las paletas de caucho de la barrena se desgastarán

prematuramente. El desgaste resultante no estará cubierto por la

garantía.

• A medida que la máquina quitanieve comienza a moverse,

• Suelte la manija de control de la barrena para que la máquina

Si la presión hacia arriba que se ejerce sobre la manija es

sostenga firmemente la manija y guíe la máquina a lo largo del

camino que desea limpiar.

deje de arrojar nieve y de desplazarse hacia adelante.

Detención del motor

ADVERTENCIA: El silenciador, el motor y las

zonas que los rodean pueden calentarse y causar

quemaduras. No los toque.

• Después de sacar la nieve, deje el motor en funcionamiento

unos minutos más antes de guardar la máquina para ayudar a

que se seque la humedad del motor.

• Para detener el motor: Gire la llave de encendido en sentido

contrario a las agujas del reloj a la posición OFF (apagado).

Consulte la sección sobre

Saque la llave del interruptor de encendido de la máquina

quitanieve antes de almacenarla.

IMPORTANTE:

Mantenga la llave de encendido en un lugar

seguro. No se puede encender el motor sin ella

• Limpie la nieve y seque la humedad de la máquina.

• Mueva la palanca de obturación hacia atrás y hacia adelante

varias veces.

la llave de encendido en la página 23.

24

Page 25

SECCIÓN 5: REALIZACIÓN DE AJUSTES

ADVERTENCIA: NUNCA trate de realizar

ajustes mientras el motor está en marcha, excepto

cuando así lo especifique el manual de operación.

Tensión del cable de control y de la banda de

transmisión

Es posible que necesite realizar ajustes periódicos debido al

estiramiento del cable de control y de la banda de transmisión

ocasionado por el desgaste de los mismos.

Si la barrena parece trabarse cuando gira mientras que el motor

mantiene una velocidad constante, es necesario realizar un ajuste.

Proceda de la siguiente manera:

El agujero superior de la manija de control tiene en cuenta el ajuste

de la tensión del cable. Para realizar el ajuste, desconecte el extremo

del cable de control del agujero inferior de la manija de control e

insértelo en el agujero superior. Consulte Figura 3 . Pruebe la

máquina quitanieve para controlar si se logra una diferencia

apreciable.

Si necesita ajustar la máquina nuevamente proceda de la siguiente

manera.

• Saque la cubierta de la banda del costado izquierdo de la caja

de la barrena de la máquina quitanieve para lo cual debe

desenroscar los cinco tornillos con cabeza hexagonal que la

sujetan en su sitio. Ver Figura 8.

Hay tres agujeros de ajuste en el montaje del soporte intermedio.

Para realizar los ajustes proceda de la siguiente manera:

• Mueva el resorte de extensión (que se encuentra en el extremo

del cable de control) de la posición baja a la posición media

del soporte intermedio. Ver Figura 9.

NOTA: Tenga cuidado de no soltar el resorte intermedio cuando

mueva el resorte del cable del embrague. Ver Figura 9.

• Si el resorte de extensión ya se encuentra en la posición media

en el soporte intermedio, cámbielo de la posición media a la

alta .

• Vuelva a colocar la cubierta de la banda con los cinco tornillos

con cabeza hexagonal que sacó anteriormente.

Cubierta de la banda

Soporte intermedio

Agujeros de

ajuste

Tornillos de cabeza hexagonal

Figura 8

Resorte intermedio

Resorte

del cable

de control

Placa de raspado

• Para controlar el ajuste de la placa de raspado coloque la

unidad en una superficie nivelada . Las ruedas, la placa de

raspado y las barrenas deben tocar la superficie nivelada.

Fíjese que si la placa de raspado está demasiado alta la nieve

puede volar debajo de la caja. Si la placa de raspado se

desgasta de manera excesiva o si la unidad no se auto propulsa

es posible que la placa de raspado esté muy baja.

NOTA: En las unidades nuevas o en las que tienen una placa de