MTD 13BL78ST299 Owner’s Manual

perator's

nual

I:RnFrSMRN°

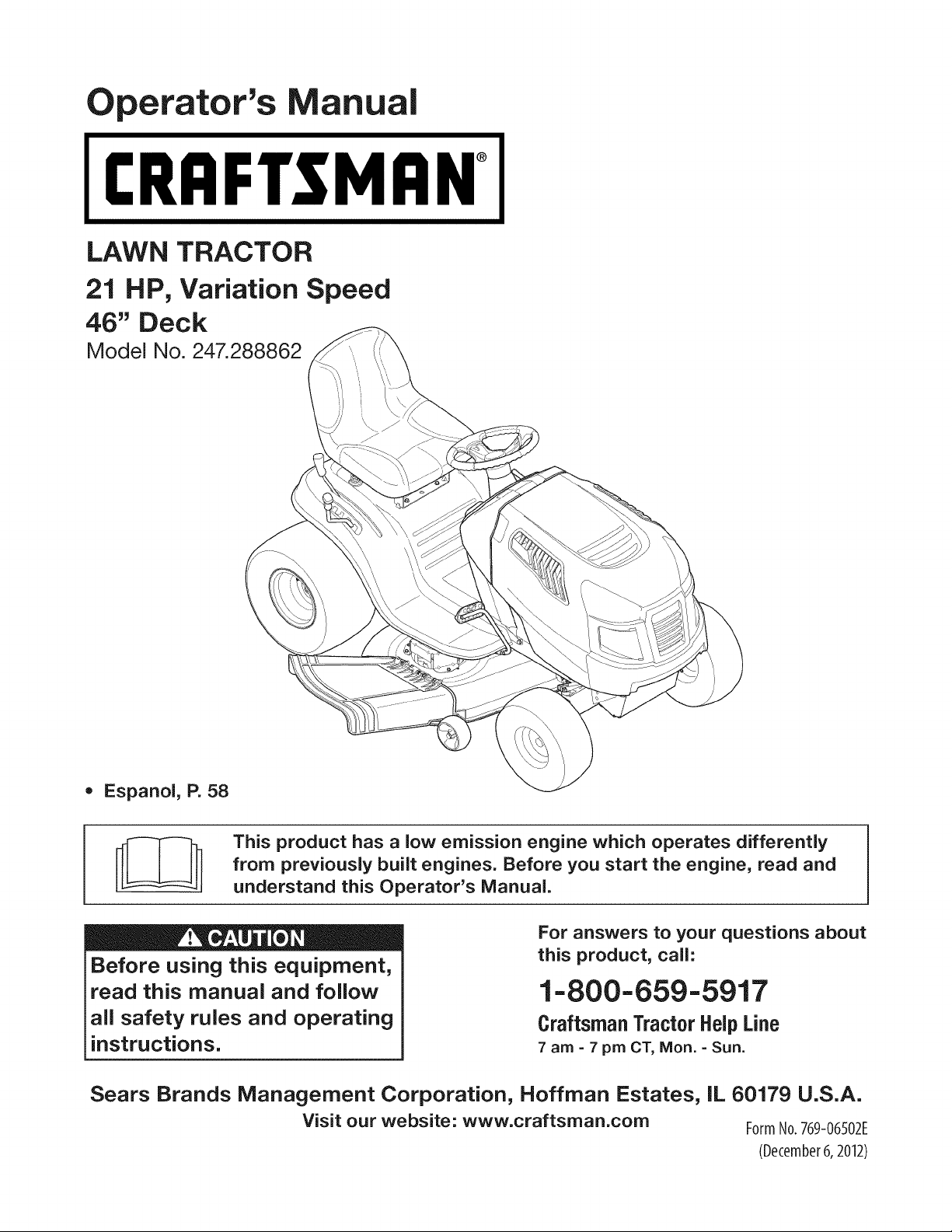

LAWN TRACTOR

21 HP, Variation Speed

46" Deck

Model No. 247.288862

• Espanol, P. 58

This product has a low emission engine which operates differently

from previously built engines. Before you start the engine, read and

understand this Operator's Manual.

For answers to your questions about

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com FormNo.769-06502E

this product, call:

1-800=659=5917

CraftsmanTractorHelpLine

7 am = 7 pm CT, Mort. =Sun.

(December6,2012)

Warranty Statement .......................................................... 2

Safety Instructions ............................................................ 3

Slope Gauge ..................................................................... 8

Assembly ........................................................................... 9

Operation ........................................................................ 11

Service and Maintenance .............................................. 17

Off-Season Storage ........................................................ 26

Trou bleshooting .............................................................. 27

Labels ............................................................................. 28

Parts List ......................................................................... 30

Espa_ol ............................................................................ 58

Service Numbers ............................................. Back Cover

CRAFTSMAN FULL WARRANTY

FORTWOYEARSfromthedateofpurchase,all non-expendablepartsofthis ridingequipmentarewarrantedagainstanydefectsinmaterialor

workmanship.Adefectivenon-expendablepartwill receivefreein-homerepairorreplacementif repairisunavailable.

BATTERYLIMITEDWARRANTY

FOR90 DAYSfromthe dateofpurchase,thebattery(an expendablepart)ofthis ridingequipmentiswarrantedagainstanydefectsinmaterialor

workmanship.Anewbatterywillbesuppliedfreeof charge.Youareresponsibleforthelaborcostof batteryinstallation.

ADDITIONALLIMITEDWARRANTIES

inthefollowingadditionalwarranties,youare responsibleforthe laborcostof partinstallationafterthe secondyearfromthedateof purchase.

FORFiVEYEARSfromthedateof purchase,theframeofthis ridingequipmentiswarrantedagainstanydefectsinmaterialorworkmanship.A

newframewill be suppliedfreeof charge.

FORTENYEARSfromthe dateofpurchase,thefrontaxleof thisridingequipmentiswarrantedagainstanydefectsinmaterialorworkmanship.

A newfrontaxlewill be suppliedfreeofcharge.

FORASLONGASIT iSUSEDbytheodginalownerafterthetenthyearfromthedateofpurchase,thecastironfrontaxle(ifequipped)ofthisriding

equipmentiswarrantedagainstanydefectsinmaterialorworkmanship.Withproofofpurchase,a newcastironfrontaxlewillbesuppliedfreeofcharge.

WARRANTYSERVICE

Forwarrantycoveragedetailsto obtainfreerepairor replacement,call 1-800-659-5917orvisit thewebsite: www.craftsman.com

inallcasesabove,ifpart repairor replacementisimpossible,theridingequipmentwillbe replacedfree ofchargewiththesameor anequivalent

model.

Alloftheabovewarrantycoverageisvoidif thisridingequipmentis everusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

ThiswarrantycoversONLYdefectsin materialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableparts(exceptbattery)thatcanwearout fromnormalusewithinthe warrantyperiod,includingbutnot limitedtoblades,spark

plugs,air cleaners,belts,andoil filters.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireorwheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnot limitedto damagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthatbendtheframe,axleassemblyorcrankshaft,or over-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethepropergradeandamountofengineoil, failuretokeepthedeckclearofflammabledebris,orfailureto maintainthe

ridingequipmentaccordingto theinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandweard theexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyoumayalso haveotherrightswhichvaryfromstateto state.

Sears BrandsManagement Corporation, Hoffman Estates,IL 60179

EngineOil: SAE30

Fuel: UnleadedGasoline

SparkPlug: Champion®RC12YC

Engine: Briggs& Stratton

© SEARSBRANDS,LLC 2

Model Number:

Serial Number:

Dateof Purchase:

Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsoldto operatethismachine.

Children14yearsoldandovershouldreadandunderstandthe

operationinstructionsandsafetyrulesinthismanualandshould

betrainedandsupervisedbyaparent.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhile itisin operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentisto be used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownby the blade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatternto avoiddischargeofmaterialtoward

roads,sidewalks,bystandersandthelike.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardthe operator.

Your Responsibility--Restrict theuseof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVE THESE INSTRUCTIONS!

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycanbe caughtinmovable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beawareofthemowerandattachmentdischargedirectionand

do notpointit at anyone.Donotoperatethemowerwithoutthe

dischargecoverorentiregrasscatcherin its properplace.

Donot puthandsorfeetnearrotatingpartsor underthe cutting

deck.Contactwiththe blade(s)canamputatehandsandfeet.

A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfortrafficwhenoperatingnearorcrossingroadways.This

machineis notintendedforuseonanypublic roadway.

• Donotoperatethemachinewhileundertheinfluenceofalcohol

or drugs.

• Mowonly indaylightorgoodartificiallight.

Nevercarrypassengers.

• Disengageblade(s)beforeshiftingintoreverse.Backupslowly.

Alwayslookdownandbehindbeforeandwhilebackingtoavoida

back-overaccident.

3

• Slowdownbeforeturning.Operatethemachinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometoa completestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

Neverleavea runningmachineunattended.Alwaysturnoff

blade(s),setparkingbrake,stopengineandremovekeybefore

dismounting.

Useextracarewhenloadingorunloadingthemachineintoa

trailerortruck.Thismachineshouldnotbedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loador unloadproperly.

Mufflerandenginebecomehotandcancausea burn.Donot

touch.

Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtree branches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthemachine,whichcould

resultinseriousinjury.

Disengageallattachmentclutchesanddepressthebrakepedal

completelybeforeattemptingto startengine.

Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donot attemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpiles ofdryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfirehazard.

Useonlyaccessoriesandattachmentsapprovedfor this machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththe approvedaccessoryorattachment.

Fora list ofapprovedaccessoriesandattachments,call 1-800-

659-5917.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilityto operatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

If situationsoccurwhicharenotcoveredinthismanual,usecare

andgoodjudgment.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossof controlandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeor if youfeeluneasyon

it, do notmowit.

Foryoursafety,usetheSlopeGuideincludedaspartofthis manual

to measureslopesbeforeoperatingthismachineona slopedor hilly

area.Iftheslopeisgreaterthan15degreesasshownonthe Slope

Guide,do notoperatethis machineonthatareaor seriousinjurycould

result.

Do:

o

Mowupanddownslopes,notacross.Exerciseextremecaution

whenchangingdirectionon slopes.

• Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscanhide

obstacles.

Useslowspeed.Choosea lowenoughspeedsettingsothat

youwill nothaveto stopor shiftwhileon the slope.Tiresmay

losetractionon slopeseventhoughthe brakesarefunctioning

properly.Alwayskeepmachineingearwhengoingdownslopes

totakeadvantageof enginebrakingaction.

• Followthemanufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersor otherattachments.These

canchangethestabilityofthe machine.

Keepallmovementontheslopesslowandgradual.Donotmake

suddenchangesinspeedor direction.Rapidengagementor

brakingcouldcausethefrontofthe machinetolift andrapidlyflip

overbackwardswhichcouldcauseseriousinjury.

• Avoidstartingorstoppingona slope.Iftireslosetraction,disen-

gagetheblade(s)andproceedslowlystraightdownthe slope.

DoNot:

• Donotturnon slopesunlessnecessary;then,turnslowlyand

graduallydownhill,ifpossible.

• Donotmowneardrop-offs,ditchesorembankments.Themower

couldsuddenlyturnoverifa wheelis overtheedgeof a cliff,

ditch,or ifan edgecavesin.

• Donottry tostabilizethemachinebyputtingyourfooton the

ground.

• Donotusea grasscatcheronsteepslopes.

• Donotmowon wetgrass.Reducedtractioncouldcausesliding.

• Donotattempttocoastdownhill.Over-speedingmaycausethe

operatortolosecontrolofthe machineresultinginseriousinjury

or death.

• Donottowheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendstopushthe tractorandmay

causeyouto loosecontrol(e.g.tractormayspeedup,brakingand

steeringabilityarereduced,attachmentmayjack-knifeandcause

tractorto overturn).

4

CHILDREN

Tragicaccidentscanoccuriftheoperatorisnotalerttothe presence

ofchildren.Childrenareoftenattractedtothemachineandthe mowing

activity.Theydo notunderstandthedangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthemowingareaand inwatchfulcareof a

responsibleadultotherthantheoperator.

• Bealertandturnmachineoff ifachildentersthearea.

• Beforeandwhilebacking,lookbehindanddownforsmall

children.

Nevercarrychildren,evenwiththeblade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionof a child

whomayrunintothe machine.

Toavoidback-overaccidents,alwaysdisengagethe cutting

blade(s)beforeshiftingintoReverse.Ifequipped,the"Reverse

CautionMode"(bladesoperatewhilemachineridesinreverse)

shouldnotbe usedwhenchildrenor othersarearound.

Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedtopreventunauthorized

operation.

Neverallowchildrenunder14yearsofagetooperatethismachine.

Children14andovershouldreadandunderstandthe instructionsand

safeoperationpracticesinthismanualandon the machineandshould

betrainedandsupervisedbyanadult.

TOWING

Towonlywitha machinethathasahitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Alwaysuseextracautionwhentowingwithamachinecapableof

makingtightturns(e.g."zero-turn"ride-onmower). Makewide

turnstoavoidjack-knifing.

Travelslowlyandallowextradistancetostop.

Donotcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonly anapprovedgasolinecontainer.

Neverfill containersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthe truck

or trailerandrefueliton theground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

Keepthenozzleincontactwiththerim ofthefueltankor

containeropeningat all timesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

Neverremovegascapor addfuelwhilethe engineis hotorrun-

ning.Allowengineto coolat leasttwominutesbeforerefueling.

Neveroverfillfueltank. Filltanktono morethan1/2inchbelow

bottomoffillernecktoallowspaceforfuelexpansion.

• Replacegasolinecap andtightensecurely.

• Ifgasolineisspilled,wipeitoff the engineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight as ona waterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

Allowa machineto coolatleastfiveminutesbeforestoring.

GeneralService

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertainthe

blade(s)andallmovingpartshavestopped.Disconnectthespark

plugwireandgroundagainsttheenginetopreventunintended

starting.

• Periodicallychecktomakesurethebladescometocomplete

stopwithinapproximately(5)fivesecondsafteroperatingthe

bladedisengagementcontrol.Ifthebladesdonotstopwithinthe

thistimeframe,yourmachineshouldbeservicedprofessionally

byaSearsorotherqualifiedservicedealer.

• Checkbrakeoperationfrequentlyasitissubjectedtowearduring

normaloperation.Adjustandserviceasrequired.

• Checktheblade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)

fordamage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useofpartswhichdonot

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepallnuts,bolts,andscrewstighttobesuretheequipmentis

insafeworkingcondition.

• Nevertamperwiththesafetyinterlocksystemorothersafety

devices.Checktheirproperoperationregularly.

• Afterstrikingaforeignobject,stoptheengine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothe machine

whilethe engineis running.

• Grasscatchercomponentsandthedischargecoverare subject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo not meettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donotchangetheenginegovernorsettingsorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

• Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andthe U.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasanAverageUsefulLifeofseven(7)years,or 270hours

ofoperation.AttheendoftheAverageUsefulLife,buy anew

machineor havethemachineinspectedannuallybya Searsor

otherqualifiedservicedealerto ensurethatall mechanicaland

safetysystemsareworkingproperlyandnot wornexcessively.

Failuretodosocanresultinaccidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththe governorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

Ifa sparkarrestoris used,it shouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

6

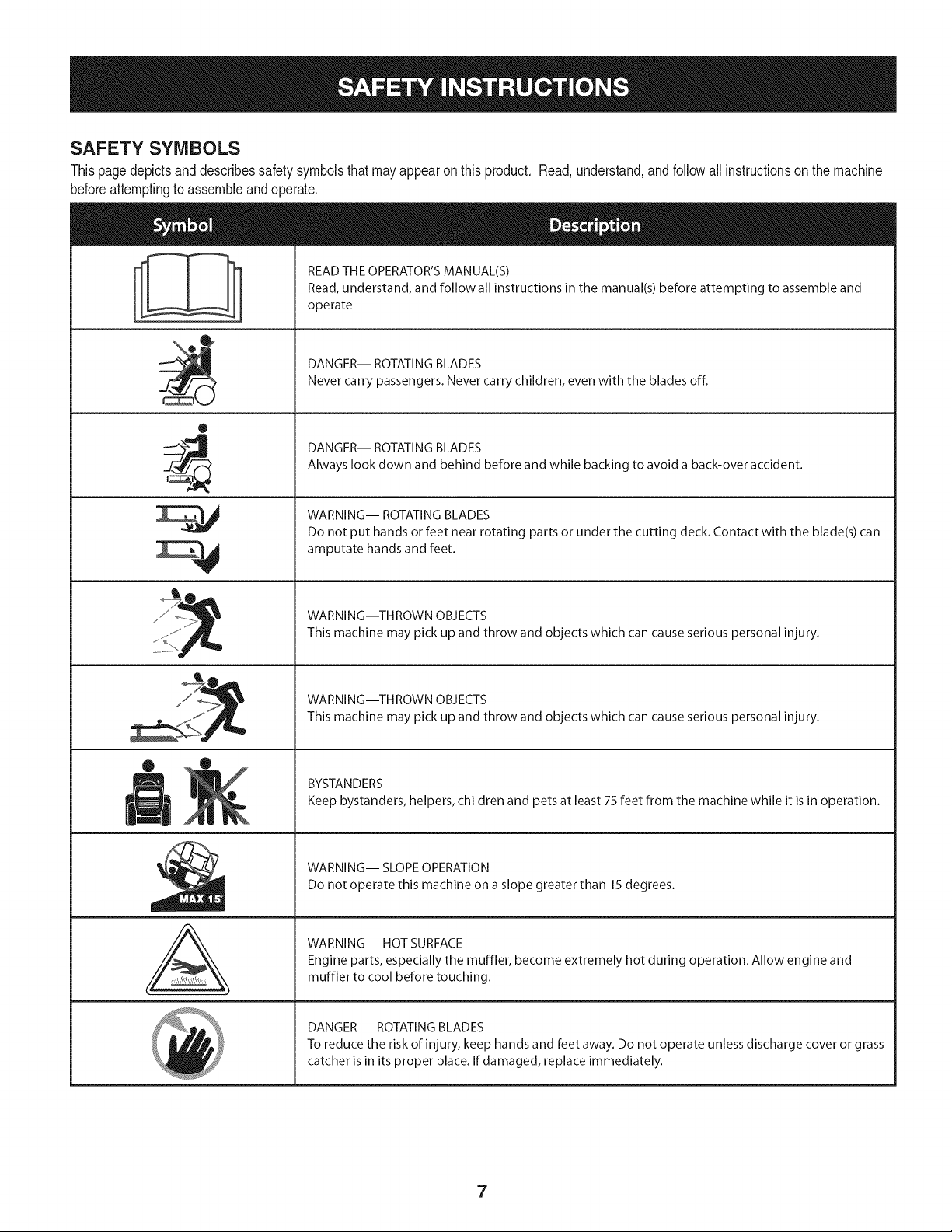

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthis product.Read,understand,andfollowallinstructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

DANGER-- ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

0

DANGER-- ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s) can

amputate hands and feet.

A

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER-- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

7

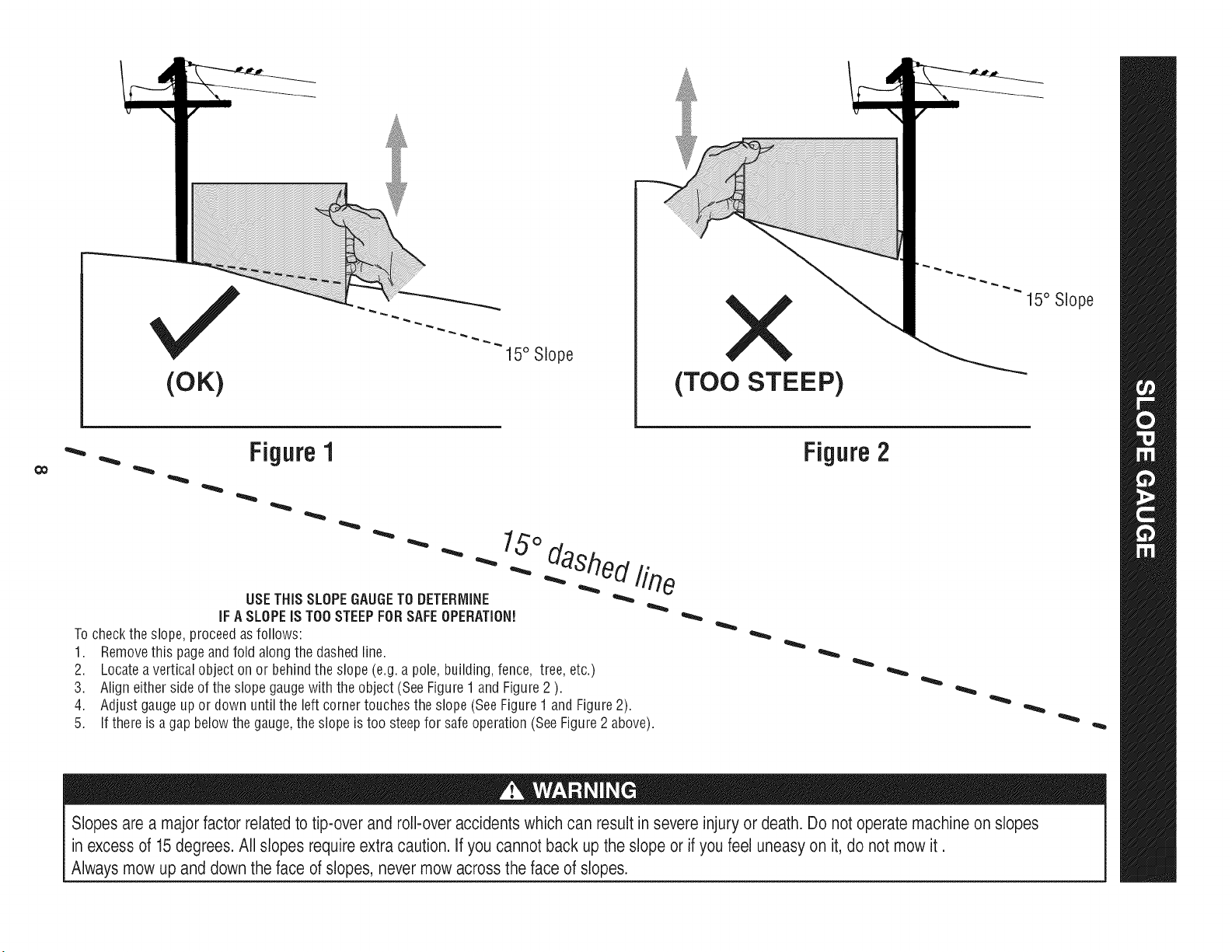

15° Slope

15° Slope

X

(OK)

'_. _ Figure1

(TOO STEEP)

Figure2

15°

dashedline

USETHISSLOPEGAUGETODETERMINE

IFA SLOPEISTOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfoldalongthedashedline.

2. Locateaverticalobject onor behindtheslope (e.g.a pole,building,fence, tree,etc.)

3. Align eithersideoftheslope gaugewith the object(SeeFigure1and Figure2).

4. Adjust gaugeupor down untilthe left cornertouchesthe slope(SeeFigure1and Figure2).

5.

If thereisagap belowthegauge,theslopeis too steepfor safeoperation(SeeFigure2 above).

Slopesare a majorfactor relatedto tip-over androll-over accidents whichcan resultin severe injury or death. Do not operatemachine on slopes

in excess of 15degrees.All slopesrequire extra caution. Ifyou cannotback up theslope orif you feeluneasyon it, do not mow it.

Always mowup and down theface ofslopes, never mowacrossthe faceof slopes.

IM PORTANT: Yourtractorisshippedwithmotoroilintheengine.However,

youMUSTchecktheoillevelbeforeoperating.RefertotheService&Maintenance

sectionforinstructionsoncheckingtheoillevel.

NOTE:Any referenceinthismanualtotheRIGHTorLEFTsideof the

tractoris observedfromoperator'sseatpositionfacingforwardtowards

thefrontof tractor.

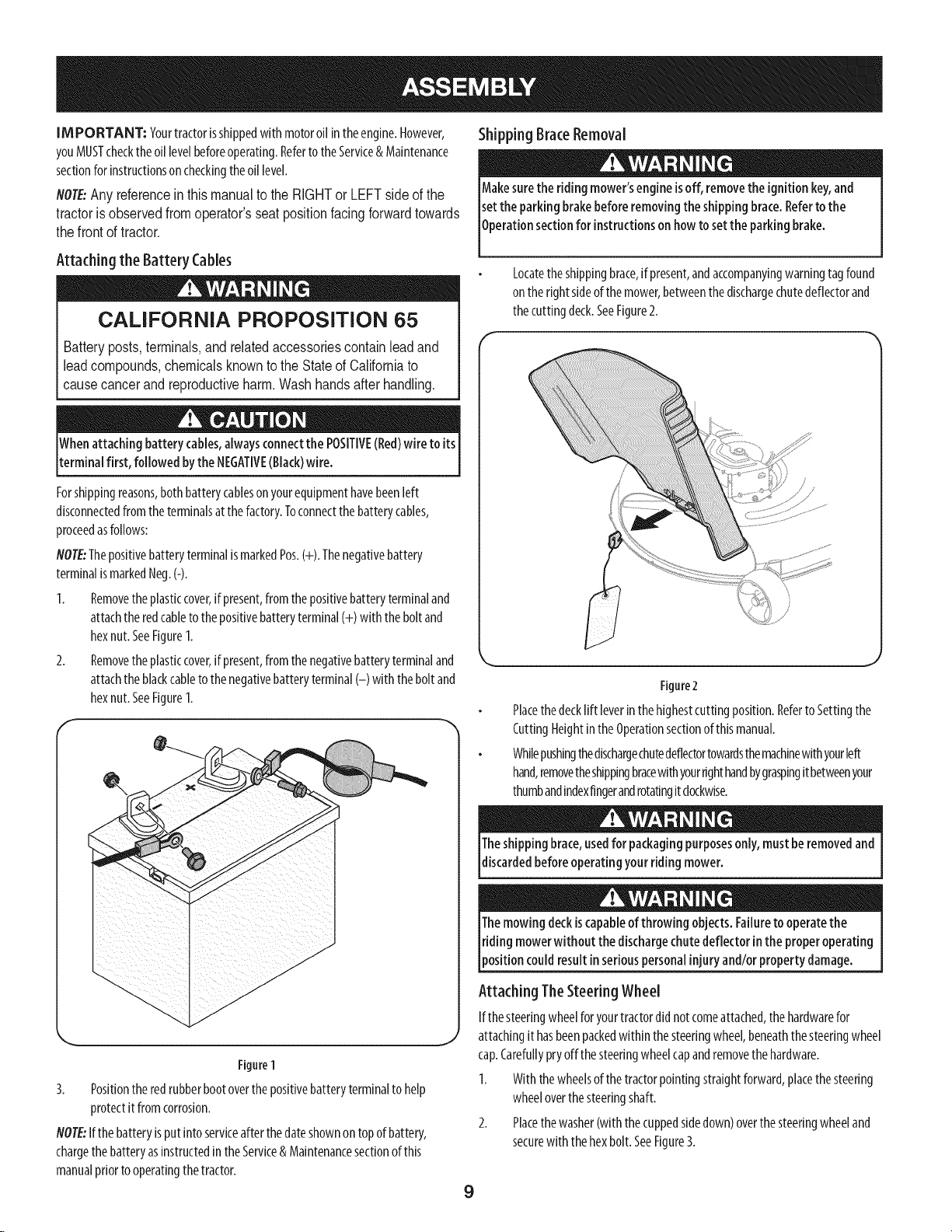

Attaching the Battery Cables

CALIFORNIA PROPOSITION 65

Batteryposts,terminals,andrelatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

Whenattachingbatterycables,alwaysconnectthe POSITIVE([ted)wire toits

terminalfirst, followed bythe NEGATIVE(Black)wire.

Forshippingreasons,bothbatterycablesonyourequipmenthavebeenleft

disconnectedfromtheterminalsat thefactory.Toconnectthe batterycables,

proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegativebattery

terminalismarkedNeg.(-).

1. Removetheplasticcover,ifpresent,fromthepositivebatteryterminaland

attachtheredcabletothepositivebatteryterminal(+) with theboltand

hexnut.SeeFigure1.

2. Removetheplasticcover,ifpresent,fromthenegativebatteryterminaland

attachtheblackcabletothenegativebatteryterminal(-) withtheboltand

hexnut.SeeFigure1.

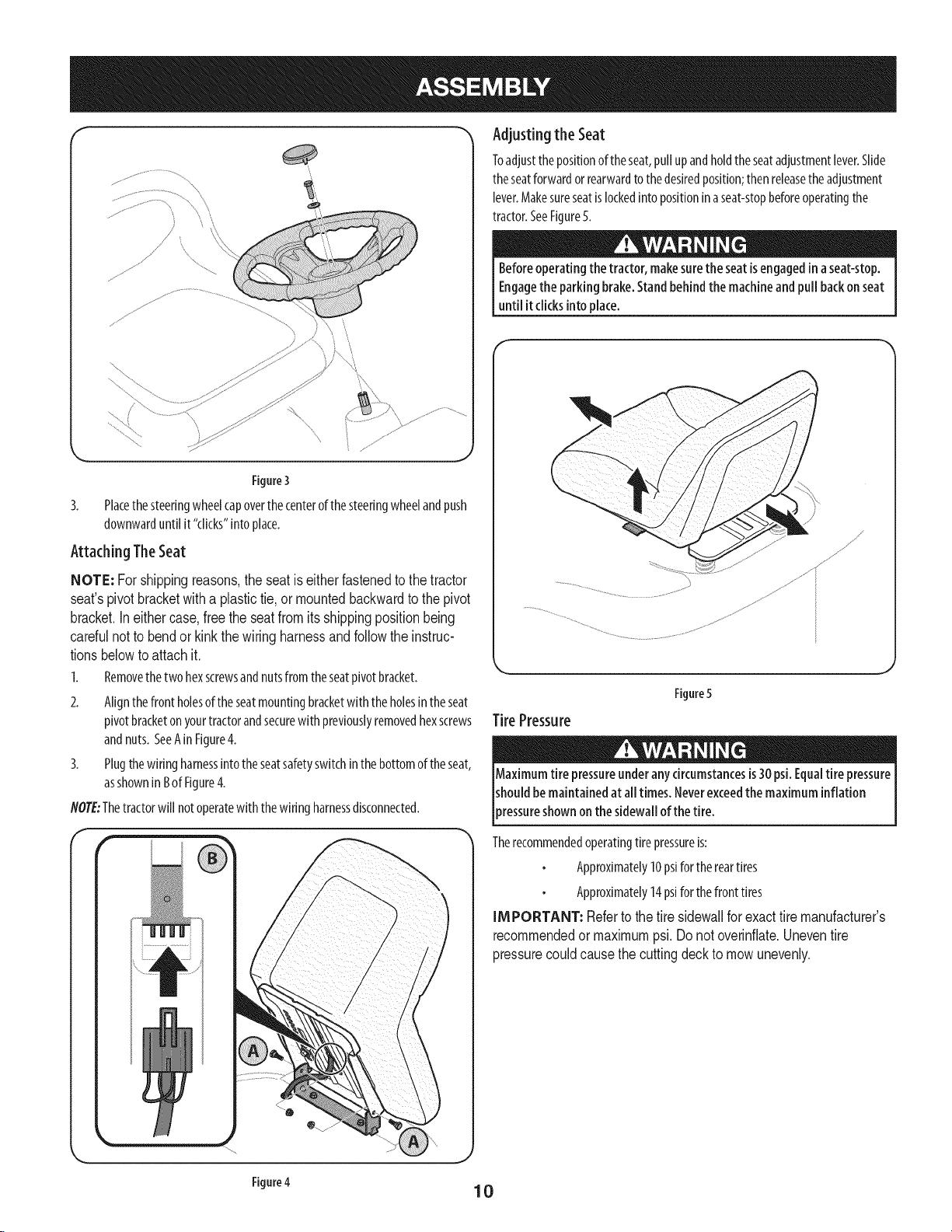

Shipping BraceRemoval

Makesurethe ridingmower'sengineisoff, removethe ignition key,and

setthe parkingbrakebeforeremovingthe shipping brace.Refertothe

0perat on sectonfor nstructonsonhowtosetthe parkngbrake.

Locatetheshippingbrace,ifpresent,andaccompanyingwarningtagfound

ontherightsideofthemower,betweenthedischargechutedeflectorand

thecuttingdeck.SeeFigure2.

Figure2

Placethedecklift leverin thehighestcutting position.RefertoSettingthe

CuttingHeightintheOperationsectionofthismanual.

Whilepushingthedischargechutedeflectortowardsthemachinewithyourleft

hand,removetheshippingbracewithyourrighthandbygraspingitbetweenyour

thumbandindexfingerandrotatingitclockwise.

/

/

/

j-

/

/

/

/

/

f

./

/

/-

/

\ J

Figure1

3. Positiontheredrubberbootoverthe positivebatteryterminaltohelp

protectitfromcorrosion.

NOTE:Ifthe batteryisput intoserviceafterthedateshownontopofbattery,

chargethe batteryasinstructedin theService& Maintenancesectionofthis

manualpriortooperatingthetractor.

Theshippingbrace,usedforpackagingpurposesonly,must beremovedand

discardedbeforeoperatingyourridingmower.

Themowingdeckiscapableof throwing objects. Failuretooperatethe

[riding mowerwithout the dischargechutedeflector inthe properoperating

[positioncouldresultinseriouspersonalinjuryand/orproperty damage.

Attaching TheSteeringWheel

Ifthesteeringwheelforyourtractordidnotcomeattached,thehardwarefor

attachingithasbeenpackedwithinthesteeringwheel,beneaththesteeringwheel

cap.Carefullypryoff thesteeringwheelcapandremovethehardware.

I. Withthewheelsofthetractorpointingstraightforward,placethesteering

wheeloverthesteeringshaft.

2. Placethewasher(with thecuppedsidedown)overthesteeringwheeland

securewith thehexbolt.SeeFigure3.

9

f

\

Figure3

3.

Placethesteeringwheelcapoverthecenterofthesteeringwheelandpush

downwarduntilit"clicks"intoplace.

Attaching TheSeat

NOTE: Forshippingreasons,theseatiseitherfastenedto thetractor

seat'spivotbracketwitha plastictie,or mountedbackwardtothe pivot

bracket.Ineithercase,free theseatfromitsshippingpositionbeing

carefulnotto bendor kinkthewiringharnessandfollowtheinstruc-

tionsbelowtoattachit.

1. Removethetwohexscrewsandnutsfromtheseatpivotbracket.

2. Alignthefrontholesoftheseatmountingbracketwiththeholesintheseat

pivotbracketonyourtractorandsecurewithpreviouslyremovedhexscrews

andnuts.SeeAinFigure4.

3. Plugthewiringharnessintotheseatsafetyswitchinthebottomoftheseat,

asshowninBofFigure4.

flOTE:Thetractorwillnotoperatewiththewiringharnessdisconnected.

Adjusting the Seat

Toadjustthepositionoftheseat,pull upandholdtheseatadjustmentlever.Slide

theseatforwardorrearwardto thedesiredposition;thenreleasetheadjustment

lever.Makesureseatislockedintopositioninaseat-stopbeforeoperatingthe

tractor.SeeFigure5.

Beforeoperatingthe tractor, makesuretheseatisengagedin a seat-stop.

Engagethe parkingbrake.Standbehindthe machineand pull backonseat

until itclicksintoplace.

_,, ,J

Figure5

Tire Pressure

Maximumtire pressureunderanycircumstancesis30psi.Equaltire pressure

shouldbemaintainedat alltimes. Neverexceedthemaximum inflation

)ressureshownonthe sidewallofthe tire.

Figure4

Therecommendedoperatingtirepressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT: Refertothe tire sidewallforexacttiremanufacturer's

recommendedormaximumpsi.Donot overinflate.Uneventire

pressurecouldcausethecuttingdeckto mowunevenly.

10

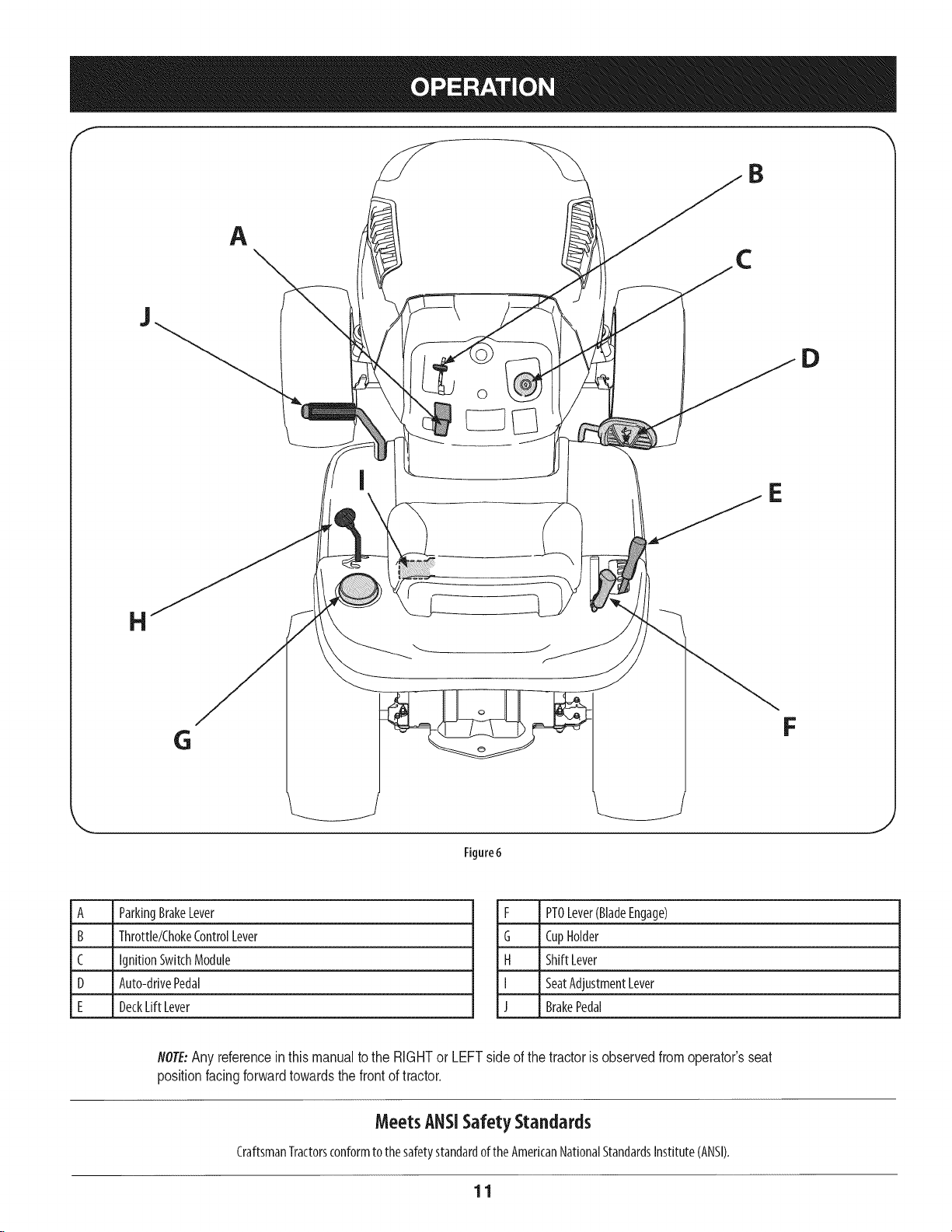

f

B

A

.I

D

©

E

H

G

A ParkingBrakeLever

B ThrotNe/ChokeControlLever

C IgnitionSwitchModule

D Auto-drivePedal

E DeckLiftLever

flOTE:Any referenceinthismanualtotheRIGHTorLEFTside of thetractoris observedfromoperator'sseat

positionfacingforwardtowardsthefrontoftractor.

F

Figure6

F PTOLever(BladeEngage)

G CupHolder

H ShiftLever

I SeatAdjustmentLever

J BrakePedal

MeetsANSiSafetyStandards

CraftsmanTractorsconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

11

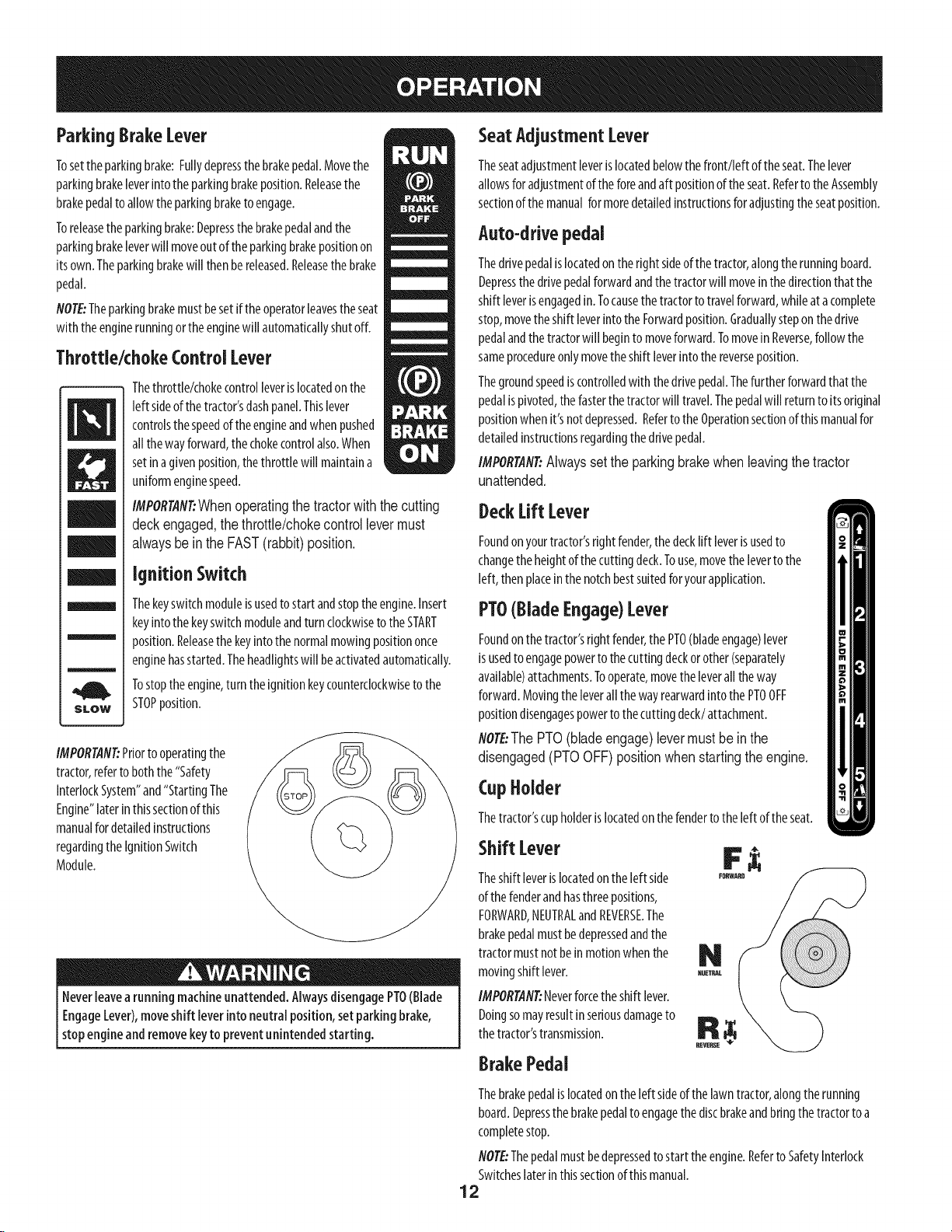

ParkingBrakeLever

SeatAdjustment Lever

Tosettheparkingbrake:Fullydepressthebrakepedal.Movethe

parkingbrakeleverintotheparkingbrakeposition.Releasethe

brakepedaltoallowtheparkingbraketoengage.

Toreleasetheparkingbrake:Depressthebrakepedalandthe

parkingbrakeleverwillmoveoutoftheparkingbrakepositionon

itsown.Theparkingbrakewill thenbereleased.Releasethebrake

pedal.

NOTE:Theparkingbrakemustbesetiftheoperatorleavestheseat

with theenginerunningortheenginewill automaticallyshutoff.

Throttle/chokeControlLever

Thethrottle/chokecontrolleverislocatedonthe

leftsideofthetractor'sdashpanel.Thislever

controlsthespeedoftheengineandwhenpushed

m

m

allthewayforward,thechokecontrolalso.When

setinagivenposition,thethrottle will maintaina

uniformenginespeed.

IMPOR@N#Whenoperating the tractor with the cutting

deck engaged, the throttle/choke control lever must

always be inthe FAST (rabbit) position.

ignitionSwitch

mlmmmml

mmmmmmm

SLOW

IMPORTANT:Priortooperatingthe

tractor,refertoboththe"Safety

InterlockSystem"and"StartingThe

Engine"laterinthissectionofthis

manualfordetailedinstructions

regardingtheIgnitionSwitch

Module.

Neverleavearunning machineunattended.AlwaysdisengagePTO(Blade

EngageLever),moveshift leverintoneutralposition,setparkingbrake,

stopengineandremovekeyto prevent unintendedstarting.

Thekeyswitchmoduleisusedtostart andstoptheengine.Insert

keyintothekeyswitchmoduleandturnclockwisetotheSTART

position.Releasethe keyintothe normalmowingpositiononce

enginehasstarted.Theheadlightswill beactivatedautomatkally.

Tostoptheengine,turntheignitionkeycounterclockwiseto the

STOPposition.

Theseatadjustmentleverislocatedbelowthefront/left oftheseat.Thelever

allowsforadjustmentof theforeandaft positionof theseat.Referto theAssembly

sectionofthemanualformoredetailedinstructionsforadjustingtheseatposition.

Auto-drivepedal

Thedrivepedalis locatedontherightsideofthetractor,alongtherunningboard.

Depressthedrivepedalforwardandthetractorwill moveinthedirectionthatthe

shiftleverisengagedin.Tocausethetractortotravelforward,whileatacomplete

stop,movetheshift leverintotheForwardposition.Graduallysteponthedrive

pedalandthetractorwill begintomoveforward.TomoveinReverse,follow the

sameprocedureonlymovetheshiftleverintothereverseposition.

Thegroundspeediscontrolledwith thedrivepedal.Thefurtherforwardthatthe

pedalispivoted,thefasterthetractorwilltravel.Thepedalwill returnto itsoriginal

positionwhenit'snotdepressed.RefertotheOperationsectionofthis manualfor

detailedinstructionsregardingthedrivepedal.

IMPOR@NT_Always set the parking brake when leaving the tractor

unattended.

DeckLiftLever

Foundonyourtractor'srightfender,thedecklift leverisusedto

changetheheightofthecuttingdeck.Touse,movethelevertothe

left, thenplaceinthenotchbestsuitedforyourapplication.

PTO(Blade Engage)Lever

Foundonthetractor'srightfender,thePTO(bladeengage)lever

isusedto engagepowertothecuttingdeckorother(separately

available)attachments.Tooperate,movetheleveralltheway

forward.Movingthe leverallthewayrearwardintothe PTOOFF

positiondisengagespowertothecuttingdeck/attachment.

NOTE:ThePTO (blade engage) lever must be inthe

disengaged (PTO OFF) position when starting the engine.

CupHolder

Thetractor'scupholderislocatedonthefendertotheleftof theseat.

Shift Lover

Theshiftleverislocatedon theleftside

ofthefenderandhasthreepositions,

FORWARD,NEUTRALandREVERSE.The

brakepedalmustbedepressedandthe

tractormustnotbeinmotionwhenthe

movingshiftlever.

IMPORTAN_Neverforcetheshiftlever.

Doingsomayresultinseriousdamageto

thetractor'stransmission.

REVERSE

BrakePedal

Thebrakepedalislocatedontheleftsideofthelawntractor,alongtherunning

board.Depressthebrakepedaltoengagethediscbrakeandbringthetractortoa

completestop.

NOTE:Thepedalmustbedepressedtostarttheengine.Referto SafetyInterlock

Switcheslaterin thissectionof thismanual.

12

Gasand OilFill-up

Oil

IMPORTAfl#Yourtractorisshippedwith motoroilintheengine.However,you

MUSTchecktheoillevelbeforeoperating.Becarefulnottooverfill.

Forinstructionsonhowtochecktheengineoil,refertoCheckingTheEngineOilin

theServiceandMaintenancesectionofthismanual.

Gasoline

Thegasolinetankislocatedunderthehood.Donotoverfill.

Useextremecarewhen handling gasoline.Gasolineisextremelyflammable

andthe vaporsareexplosive.Neverfuelmachineindoorsorwhile the

engineishotor running. Extinguishcigarettes,cigars,pipes,andother

sourcesof gnt on.

NOTE:Purchasegasolineinsmallquantities.Donotusegasolineleft overfromthe

previousseason,to minimizegumdepositsinthefuelsystem.

Thisengineiscertifiedtooperateonunleadedgasoline.Forbestresults,fill

thefueltankwith onlyclean,fresh,unleadedgasolinewith apumpsticker

octaneratingof 87orhigher.

Gasohol(upto10%ethylalcohol,90%unleadedgasolinebyvolume)isan

approvedfuel.Othergasoline/alcoholblends,suchasE85,arenotapproved.

MethylTertiaryButylEther(MTBE)andunleadedgasolineblends(uptoa

maximumof 15%MTBEbyvolume)areapprovedfuels.Othergasoline/ether

blendsarenotapproved.

Fillfueltankoutdoorsorinwell-ventilatedarea.

Donotoverfillfueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Neverremovegascaporaddfuelwhiletheengineishotor running.Allow

engineto coolatleasttwo minutesbeforerefueling.

Ifgasolineisspilled,wipeit off theengineandequipment.Movemachineto

anotherarea.Wait5minutesbeforestartingtheengine.

ToAddGasoline

1. Turntheengineoffandletenginecoolatleast2minutesbeforeremoving

thefuelcap.Thegasolinetankislocatedunderthehood.Removethefuel

capbyturningitcounterclockwise.

2. Fillthefueltankwithgasoline.Useonlyclean,fresh(nomorethan30days

old),unleadedgasoline.Filltanktonomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

3. Reinstallthefuelcap.

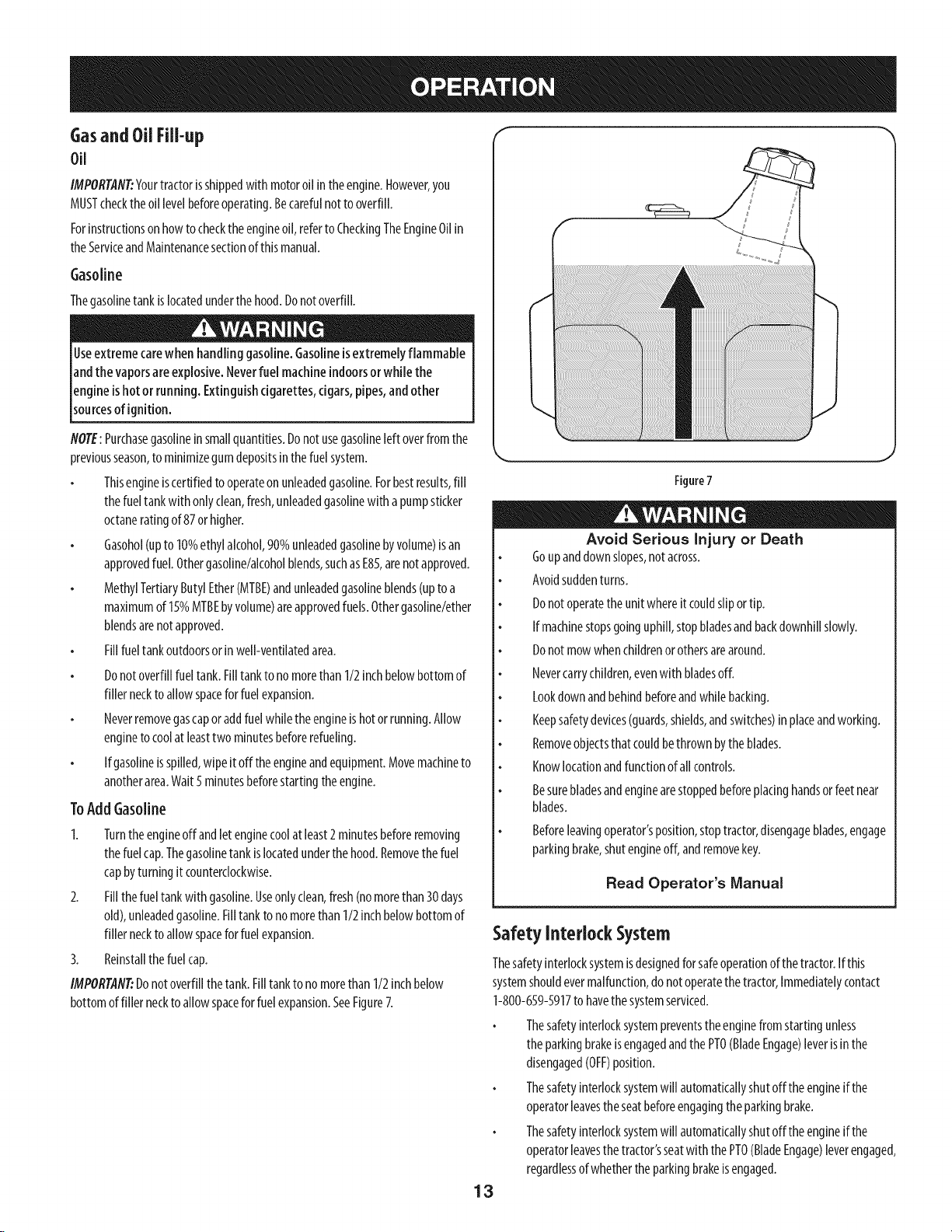

IMPORTAN_Donotoverfillthetank.Filltanktonomorethan 1/2inchbelow

bottomoffiller necktoallowspaceforfuelexpansion.SeeFigure7.

Figure7

Avoid Serious Injury or Death

Goupanddownslopes,notacross.

Avoidsuddenturns.

Donotoperatetheunitwhereitcouldsliportip.

Ifmachinestopsgoinguphill,stopbladesandbackdownhillslowly.

Donotmowwhenchildrenorothersarearound.

Nevercarrychildren,evenwith bladesoff.

Lookdownandbehindbeforeandwhilebacking.

Keepsafetydevices(guards,shields,andswitches)inplaceandworking.

Removeobjectsthat couldbethrownbytheblades.

Knowlocationandfunctionofallcontrols.

Besurebladesandenginearestoppedbeforeplacinghandsorfeet near

blades.

Beforeleavingoperator'sposition,stoptractor,disengageblades,engage

parkingbrake,shutengineoff,andremovekey.

Read Operator's Manual

Safety Interlock System

Thesafetyinterlocksystemisdesignedfor safeoperationofthetractor.Ifthis

systemshouldevermalfunction,do notoperatethetractor,Immediatelycontact

1-800-659-5917to havethesystemserviced.

Thesafetyinterlocksystempreventstheenginefromstartingunless

theparkingbrakeisengagedandthePTO(BladeEngage)leverisinthe

disengaged(OFF)position.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavestheseatbeforeengagingtheparkingbrake.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavesthetractor'sseatwiththe PTO(BladeEngage)leverengaged,

regardlessofwhethertheparkingbrakeisengaged.

13

Theenginewill automaticallyshutoffif thePTO(BladeEngage)leveris

movedintotheengaged(ON)positionwith theshiftleverinReverse.

Ignition Switch

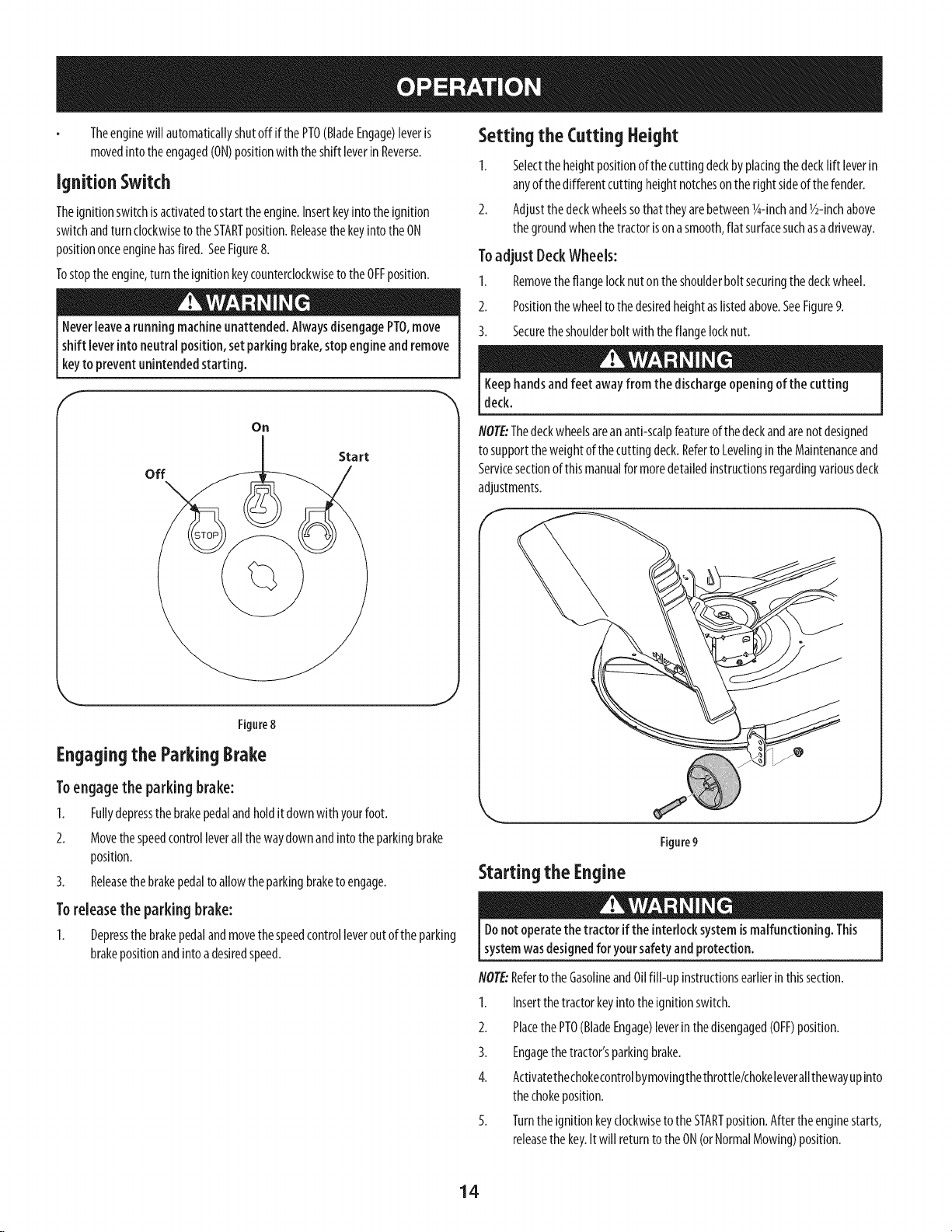

Theignitionswitchisactivatedto starttheengine.Insertkeyintotheignition

switchandturnclockwiseto theSTARTposition.ReleasethekeyintotheON

positiononceenginehasfired. SeeFigure8.

Tostoptheengine,turntheignitionkeycounterclockwiseto theOFFposition.

Neverleavearunning machineunattended.AlwaysdisengagePTO,move

shift leverintoneutral position,set parkingbrake,stopengineandremove

keyto preventunintendedstarting.

f

On

Start

off

Setting the Cutting Height

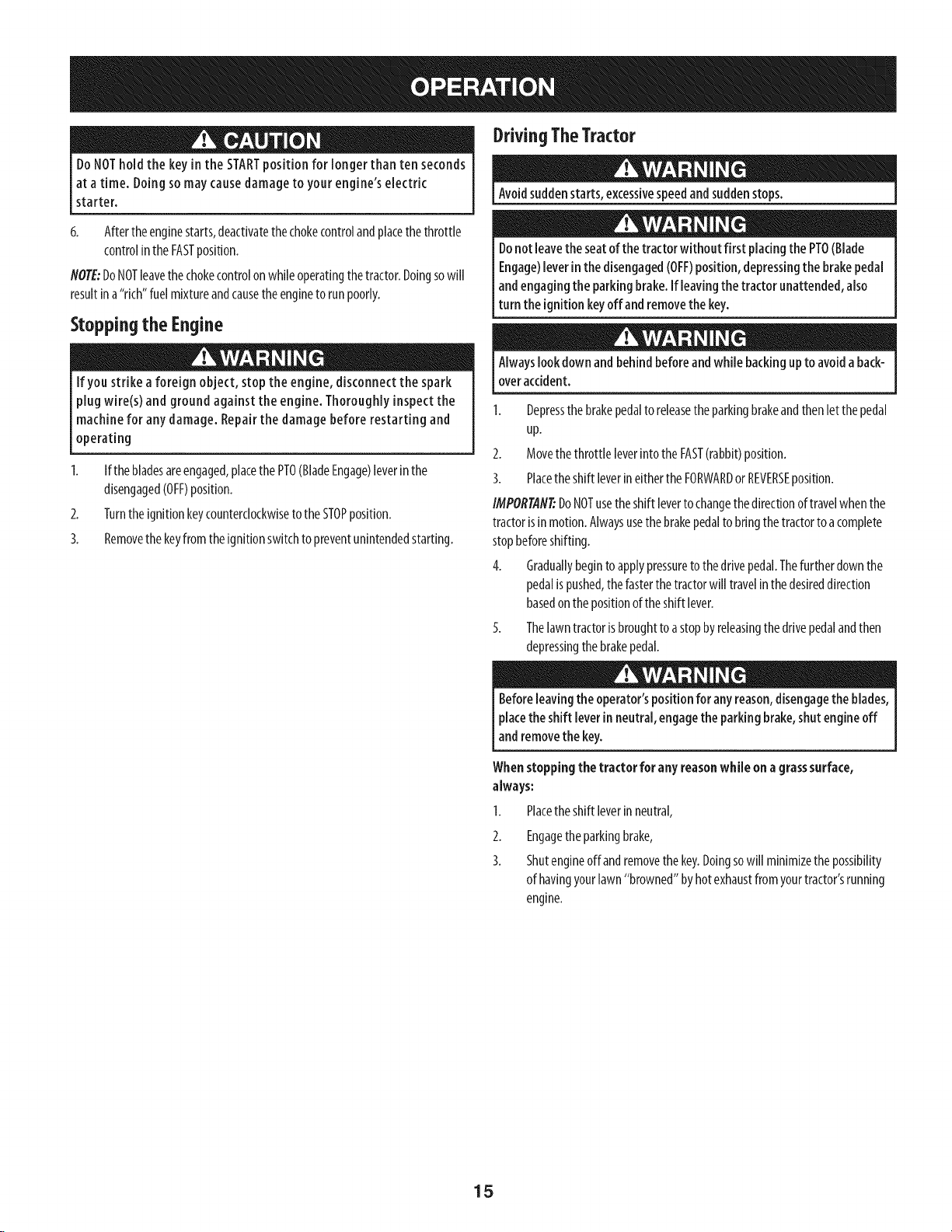

1. Selecttheheightpositionof thecuttingdeckbyplacingthedecklift leverin

anyofthedifferentcutting heightnotchesontherightsideofthefender.

2. Adjustthe deckwheelssothattheyarebetweenl_-inchand1/2-inchabove

thegroundwhenthetractorisonasmooth,flatsurfacesuchasadriveway.

Toadjust DeckWheels:

1. Removetheflangelocknutontheshoulderbolt securingthedeckwheel.

2. Positionthewheeltothedesiredheightaslistedabove.SeeFigure9.

3. Securetheshoulderboltwith theflangelocknut.

Keephandsandfeet awayfrom the dischargeopening of the cutting

deck.

NOTE:Thedeckwheelsareananti-scalpfeatureofthedeckandarenotdesigned

tosupporttheweightof thecuttingdeck.RefertoLevelingintheMaintenanceand

Servicesectionof thismanualformoredetailedinstructionsregardingvariousdeck

adjustments.

Figure8

Engagingthe ParkingBrake

Toengagethe parking brake:

1. Fullydepressthe brakepedalandholditdownwith yourfoot.

2. Movethespeedcontrolleverallthewaydownandintotheparkingbrake

position.

3. Releasethebrakepedalto allowtheparkingbraketoengage.

Toreleasethe parking brake:

1. Depressthebrakepedalandmovethespeedcontrolleveroutof theparking

brakepositionandintoadesiredspeed.

J

Figure9

Starting the Engine

Donotoperatethetractor if the interlocksystemismalfunctioning.This

systemwasdesignedforyoursafetyandprotection.

NOTE:Referto theGasolineandOilfill-up instructionsearlierinthissection.

1. Insertthetractorkeyintotheignitionswitch.

2. PlacethePTO(BladeEngage)leverinthedisengaged(OFF)position.

3. Engagethetractor'sparkingbrake.

4. Activatethechokecontrolbymovingthethrottle/chokeleverallthewayupinto

thechokeposition.

5. TurntheignitionkeyclockwisetotheSTARTposition.Aftertheenginestarts,

releasethekey.Itwill returntotheON(orNormalMowing)position.

14

DoNOTholdthe key inthe STARTposition for longerthan ten seconds

at atime. Doingsomay causedamageto your engine's electric

starter.

6. Aftertheenginestarts,deactivatethechokecontrolandplacethethrottle

controlin theFASTposition.

NOTE:DoNOTleavethechokecontrolonwhileoperatingthetractor.Doingsowill

resultina"rich"fuelmixtureandcausetheengineto runpoorly.

Stopping the Engine

If you strike aforeign object, stop the engine, disconnect the spark

plug wire(s) and ground against the engine. Thoroughly inspect the

machine for anydamage. Repairthe damage before restartingand

operating

Ifthebladesareengaged,placethe PTO(BladeEngage)leverinthe

disengaged(OFF)position.

2.

Turntheignitionkeycounterclockwiseto theSTOPposition.

3.

Removethekeyfromtheignitionswitchtopreventunintendedstarting.

DrivingTheTractor

Avoidsuddenstarts,excessivespeedandsuddenstops.

Donotleavethe seatofthe tractor without first placingthe PTO(Blade

Engage)leverinthe disengaged(OFF)position,depressingthebrakepedal

andengaging the parkingbrake.Ifleavingthe tractor unattended,also

turn the ignitionkeyoffand removethe key.

Alwayslookdownand behindbeforeandwhile backinguptoavoidaback-

overaccident.

1. Depressthebrakepedaltoreleasetheparkingbrakeandthenletthepedal

up.

2. MovethethrottleleverintotheFAST(rabbit)position.

3. PlacetheshiftleverineithertheFORWARDor REVERSEposition.

IMPORTAN_DoNOTusetheshiftlevertochangethedirectionoftravelwhenthe

tractorisin motion.Alwaysusethebrakepedaltobringthetractorto acomplete

stopbeforeshifting.

4. Graduallybegintoapplypressureto thedrivepedal.Thefurtherdownthe

pedalispushed,thefasterthetractorwilltravelinthedesireddirection

basedonthepositionoftheshift lever.

5. Thelawntractorisbroughttoastopbyreleasingthedrivepedalandthen

depressingthebrakepedal.

Beforeleavingthe operator'spositionfor anyreason,disengagethe blades,

placethe shift leverin neutral,engagethe parkingbrake,shutengineoff

andremovethe key.

Whenstoppingthe tractor for anyreasonwhile on agrasssurface,

always:

I.

Placetheshiftleverinneutral,

2.

Engagetheparkingbrake,

3.

Shutengineoffand removethekey.Doingsowill minimizethepossibility

ofhavingyourlawn"browned"byhotexhaustfromyourtractor'srunning

engine.

15

DrivingOnSlopes

RefertotheSLOPEGAUGEintheSafetyInstructionssectionofthe manualto help

determineslopeswhereyoumayoperatethistractorsafely.

Donotmowon inclineswith aslopeinexcessof 15degrees(ariseof

approximately2-1/2feetevery10feet).Thetractorcouldoverturn and

causeseriousinjury.

Mowupanddownslopes,NEVERacross.

Exerciseextremecautionwhenchangingdirectiononslopes.

Watchfor holes,ruts,bumps,rocks,orotherhiddenobjects.Uneventerrain

couldoverturnthemachine.Tallgrasscanhideobstacles.

Avoidturnswhendrivingonaslope.Iraturnmustbemade,turndownthe

slope.Turningupaslopegreatlyincreasesthechanceof arollover.

Avoidstoppingwhendrivingupaslope.If it isnecessarytostopwhile

drivingupaslope,startupsmoothlyandcarefullytoreducethe possibility

offlippingthetractoroverbackward.

Engaging the Blades

Engagingthe PTO(BladeEngage)transferspowertothecuttingdeckorother

(separatelyavailable)attachments.Toengagetheblades,proceedasfollows:

1. Movethethrottle/chokecontrollevertotheFAST(rabbit)position.

2. GraspthePTO(BladeEngage)leverandpivotit allthewayforwardintothe

engaged(ON)position.

3. Keepthethrottleleverinthe FAST(rabbit)positionfor themostefficientuse

ofthecutting deckorother(separatelyavailable)attachments.

NOTE:Theenginewillautomaticallyshutoff ifthe PTOisengagedwith theshift

leverinpositionforreversetravelwiththeignitionkeyintheONposition.

Mulching

Amulchkitisavailableasanattachment.Mulchingisaprocessof recirculating

grassclippingsrepeatedlybeneaththecuttingdeck.Theultra-fineclippingsare

thenforcedbackintothe lawnwheretheyactasanaturalfertilizer.

Amulchkitcanbepurchasedthroughtheretaillocationinwhichyoupurchased

thistractor.Formoreinformation,simplycontactSearsat 1-800-659-5917.

Mowing

Tohelpavoid bladecontactor athrown object injury,keepbystanders,

helpers,childrenandpetsat least75feet from the machinewhile it isin

operation.Stopmachineifanyoneentersthearea.

Thefollowinginformationwill behelpfulwhenusingthecuttingdeckwith your

tractor:

Planyour mowing patterntoavoiddischargeof materialstowardroads,

sidewalks,bystandersandthe like.Also,avoiddischargingmaterial against

awall or obstructionwhich maycausedischargedmaterialto ricochetback

towardthe operator.

Donotmowat highgroundspeed,especiallyira mulchkitorgrasscollector

isinstalled.

Forbestresultsit isrecommendedthatthefirsttwo lapsbecutwith the

dischargethrowntowardsthecenter.Afterthefirst twolaps,reversethe

directiontothrowthedischargetotheoutsideforthebalanceof cutting.

Thiswill giveabetterappearanceto thelawn.

Donotcutthegrasstooshort.Shortgrassinvitesweedgrowthandyellows

quicklyindryweather.

Mowingshouldalwaysbedonewiththeengineatfullthrottle.

Underheavierconditionsit maybenecessarytogobackoverthecutareaa

secondtimeto getacleancut.

DoNOTattemptto mowheavybrushandweedsandextremelytall grass.

Yourtractorisdesignedtomowlawns,NOTclearbrush.

Keepthebladessharpandreplacethebladeswhenworn.Referto Cutting

Bladesin theServicesectionof thismanualforproperbladesharpening

instructions.

Headlights

ThelampsareONwheneverthetractor'sengineisrunning.

Thelampsturn OFFwhentheignitionkeyismovedto theSTOPposition.

Usingthe Deck Lift Lever

Toraisethecuttingdeck,movethedecklift leverto the left,then placeit inthe

notchbestsuitedfor yourapplication.RefertoSettingTheCuttingHeightearlierin

thissection.

16

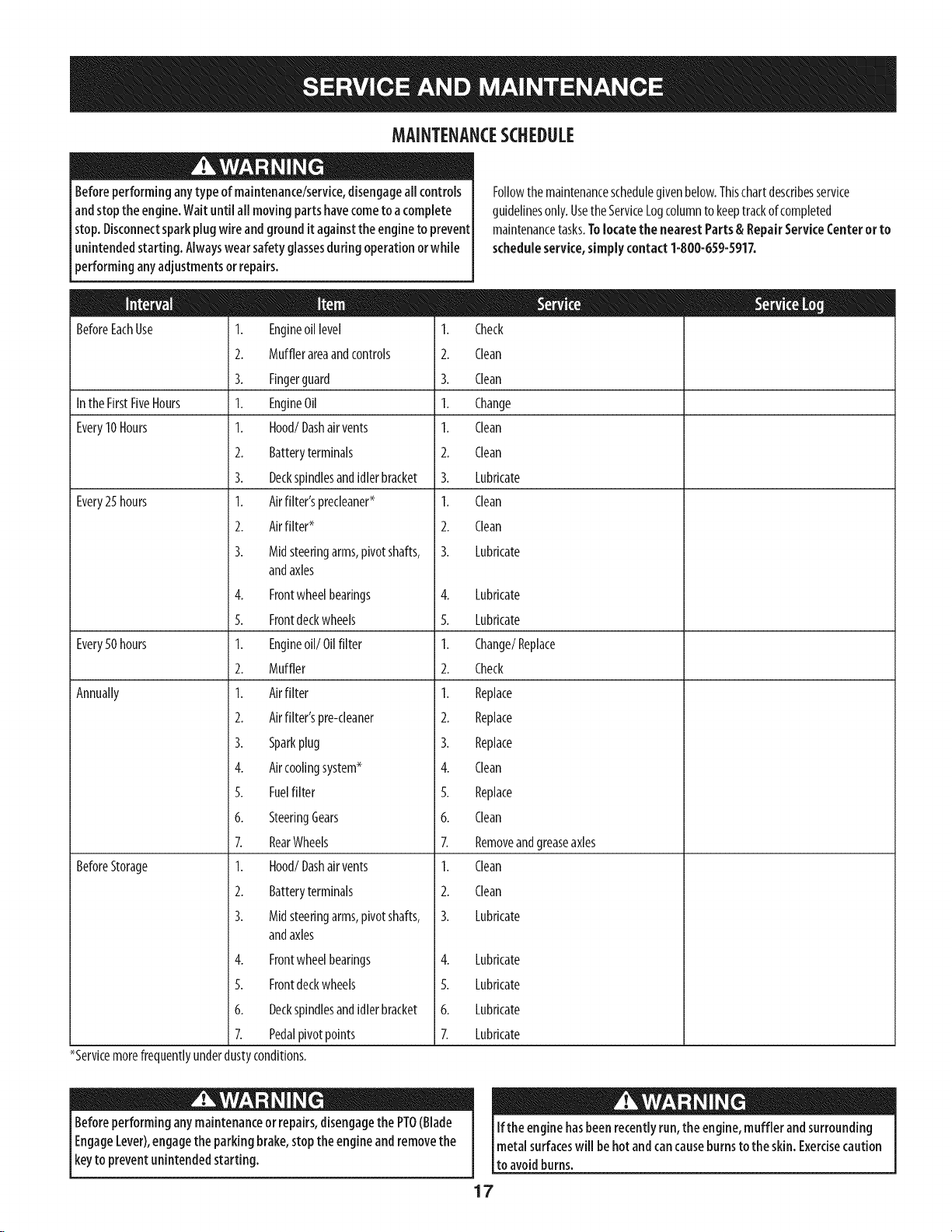

MAINTENANCESCHEDULE

Beforeperforming anytypeofmaintenance/service,disengageallcontrols

andstopthe engine.Waituntil all movingparts havecometoa complete

stop.Disconnectsparkplugwire andgroundit againstthe engineto prevent

unintendedstarting. Alwayswearsafetyglassesduring operationorwhile

performing anyadjustmentsor repairs.

BeforeEachUse 1. Engineoil level 1.

2. Mufflerareaandcontrols 2.

3. Fingerguard 3.

Inthe FirstFiveHours 1. EngineOil 1.

Every10Hours I. Hood/Dashair vents I.

2. Batteryterminals 2.

3. Deckspindlesandidlerbracket 3.

Every25 hours 1. Airfilter'sprecleaner* 1.

2. Airfilter* 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings 4.

5. Frontdeckwheels 5.

Every50 hours 1. Engineoil/Oil filter 1.

2. Muffler 2.

Annually 1. Airfilter 1.

2. Airfilter'spre-cleaner 2.

3. Sparkplug 3.

4. Aircoolingsystem* 4.

5. Fuelfilter 5.

6. SteeringGears 6.

7. RearWheels 7.

BeforeStorage 1. Hood/Dashairvents 1.

2. Batteryterminals 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings

5. Frontdeckwheels

6. Deckspindlesandidlerbracket

7. Pedalpivotpoints

*Servicemorefrequentlyunderdustyconditions.

4. Lubricate

5. Lubricate

6. Lubricate

7. Lubricate

Followthe maintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumnto keeptrackofcompleted

maintenancetasks.Tolocate the nearest Parts & RepairServiceCenteror to

scheduleservice,simply contact1-800-659-5917.

Check

Clean

Clean

Change

Clean

Clean

Lubricate

Clean

Clean

Lubricate

Lubricate

Lubricate

Change/Replace

Check

Replace

Replace

Replace

Clean

Replace

Clean

Removeandgreaseaxles

Clean

Clean

Lubricate

Beforeperforminganymaintenanceorrepairs,disengagethePTO(Blade

EngageLever),engagethe parking brake,stopthe engineandremovethe

keyto preventunintendedstarting.

Ifthe enginehasbeenrecentlyrun,the engine,muffler andsurrounding

metalsurfaceswill behot andcancauseburnsto the skin. Exercisecaution

to avoidburns.

17

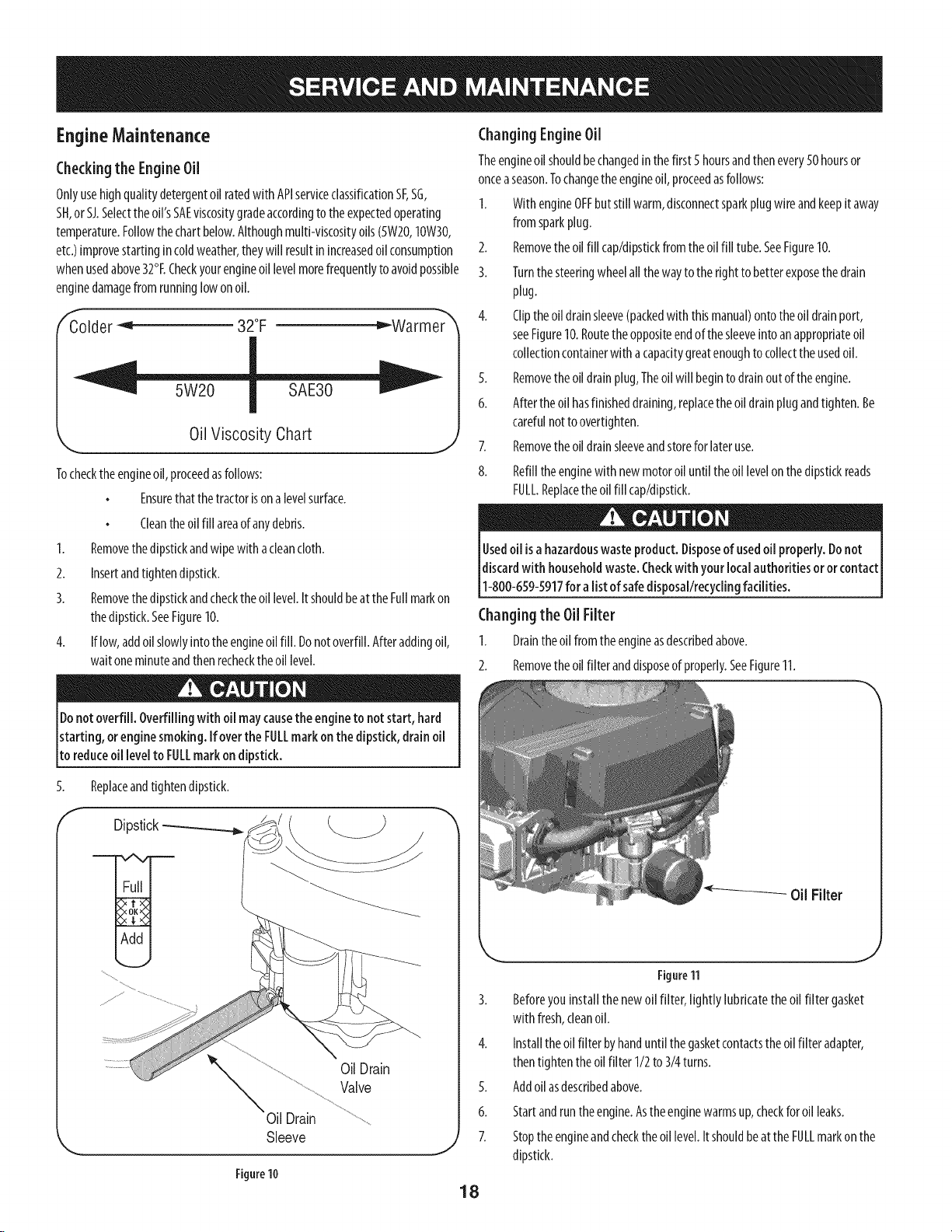

Engine Maintenance

Checkingthe EngineOil

OnlyusehighqualitydetergentoilratedwithAPIserviceclassificationSF,SG,

SH,or SJ.Selecttheoil'sSAEviscositygradeaccordingto theexpectedoperating

temperature.Followthechartbelow.Althoughmulti-viscosityoils(5W20,10W30,

etc.)improvestartingin coldweather,theywill resultinincreasedoilconsumption

whenusedabove32°I.Checkyourengineoillevelmorefrequentlyto avoidpossible

enginedamagefromrunninglowonoil.

f

Colder _'_ 32°F _Warmer

Oil Viscosity Chart

Tochecktheengineoil,proceedasfollows:

Ensurethatthetractorisonalevelsurface.

Cleantheoilfill areaofanydebris.

1. Removethedipstickandwipewith acleancloth.

2. Insertandtightendipstick.

3. Removethedipstickandchecktheoillevel.ItshouldbeattheFullmarkon

thedipstick.SeeFigure10.

4. Iflow,addoilslowlyintotheengineoilfill. Donotoverfill.Afteraddingoil,

waitoneminuteandthenrechecktheoillevel.

J

ChangingEngineOil

Theengineoilshouldbechangedin thefirst 5hoursandthenevery50hoursor

onceaseason.Tochangetheengineoil,proceedasfollows:

I. WithengineOFFbutstillwarm,disconnectsparkplugwireandkeepitaway

fromsparkplug.

2. Removetheoilfill cap/dipstkkfromtheoilfill tube.SeeFigure10.

3. Turnthesteeringwheelallthewaytothe righttobetterexposethedrain

plug.

4. Cliptheoildrainsleeve(packedwith thismanual)ontotheoil drainport,

seeFigure10.Routetheoppositeendofthesleeveintoanappropriateoil

collectioncontainerwith acapacitygreatenoughtocollecttheusedoil.

5. Removetheoildrainplug,Theoilwill begintodrainoutof theengine.

6. Aftertheoil hasfinisheddraining,replacetheoildrainplugandtighten.Be

carefulnottoovertighten.

7. Removetheoildrainsleeveandstoreforlateruse.

8. Refilltheenginewith newmotoroiluntiltheoil levelonthedipstickreads

FULL.Replacetheoilfill cap/dipstkk.

Usedoil isa hazardouswasteproduct. Disposeof usedoil properly. Donot

discardwith householdwaste.Checkwith your localauthoritiesor or contact

1-800-659-5917for alist of safedisposal/recyclingfacilities.

Changingthe Oil Filter

I. Draintheoilfromtheengineasdescribedabove.

2. Removetheoilfilteranddisposeofproperly.SeeFigure11.

Donotoverfill. Overfillingwith oil maycausethe engineto notstart, hard

starting, orenginesmoking.If overthe FULLmark onthedipstick,drain oil

to reduceoil levelto FULLmarkondipstick.

5.

Replaceandtightendipstick.

f

Dipstick

OilDrain

Valve

Oil Drain

Sleeve

Figure10

Figure11

3. Beforeyouinstallthenewoil filter, lightly lubricatetheoil filter gasket

with fresh,cleanoil.

4. Installtheoilfilter byhanduntil thegasketcontactsthe oilfilteradapter,

thentightentheoilfilter 1/2to3/4turns.

5. Addoilasdescribedabove.

6. Startandruntheengine.Astheenginewarmsup,checkforoil leaks.

7. Stoptheengineandchecktheoillevel.ItshouldbeattheFULLmarkonthe

J

dipstick.

18

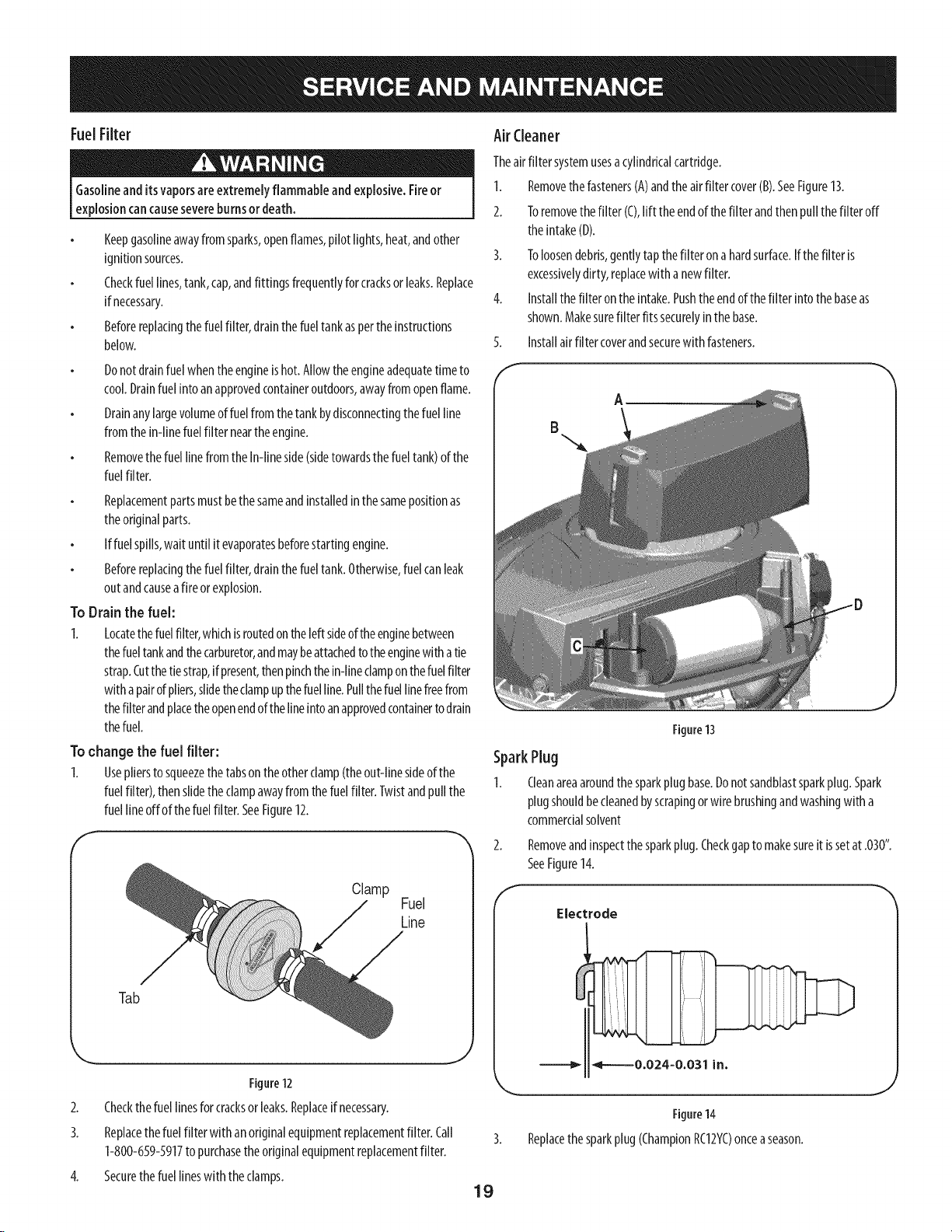

FuelFilter

Gasolineanditsvaporsare e×tremelyflammable andexplosive.Fireor

explosioncancausesevereburnsordeath.

Keepgasolineawayfromsparks,openflames,pilotlights,heat,andother

ignitionsources.

Checkfuellines,tank,cap,andfittingsfrequentlyforcracksor leaks.Replace

if necessary.

Beforereplacingthefuelfilter,drainthefueltankaspertheinstructions

below.

Donotdrainfuelwhentheengineishot.Allowtheengineadequatetimeto

cool.Drainfuelintoanapprovedcontaineroutdoors,awayfromopenflame.

Drainanylargevolumeoffuelfromthetankbydisconnectingthefuel line

fromthe in-linefuelfilter neartheengine.

Removethefuellinefromthe In-lineside(sidetowardsthefueltank)ofthe

fuelfilter.

Replacementpartsmustbethesameandinstalledinthesamepositionas

theoriginalparts.

Iffuelspills,wait untilit evaporatesbeforestartingengine.

Beforereplacingthefuelfilter,drainthefueltank.Otherwise,fuelcanleak

outandcauseafireorexplosion.

To Drain the fuel:

1. Locatethefuelfilter,whichisroutedontheleft sideoftheenginebetween

thefueltankandthecarburetor,andmaybeattachedtotheenginewith atie

strap.Cutthetie strap,if present,thenpinchthein-lineclamponthefuelfilter

withapairofpliers,slidetheclampupthefuelline.Pullthefuellinefreefrom

thefilterandplacetheopenendofthelineintoanapprovedcontainertodrain

thefuel.

Tochange the fuel filter:

1. Useplierstosqueezethetabsontheotherclamp(theout-linesideofthe

fuelfilter),thenslidetheclampawayfromthefuelfilter.Twistandpullthe

fuellineoff ofthefuelfilter.SeeFigure12.

Clamp

Fuel

Line

AirCleaner

Theairfilter systemusesacylindricalcartridge.

1. Removethefasteners(A)andtheairfiltercover(B).SeeFigure13.

2. Toremovethefilter (C),lift theendofthefilter andthenpullthefilter off

theintake(D).

3. Toloosendebris,gentlytapthefilter onahardsurface.If thefilter is

excessivelydirty, replacewith a newfilter.

4. Installthefilteronthe intake.Pushtheendofthefilter intothebaseas

shown.Makesurefilterfitssecurelyin thebase.

Installairfilter coverandsecurewith fasteners.5.

f

A

Figure13

SparkPlug

1.

Cleanareaaroundthesparkplugbase.Donotsandblastsparkplug.Spark

plugshouldbecleanedbyscrapingorwirebrushingandwashingwith a

commercialsolvent

Removeandinspectthesparkplug.Checkgaptomakesureit issetat.030".

SeeFigure14.

f

Electrode

Tab

Figure12

2. Checkthefuellinesforcracksorleaks.Replaceifnecessary.

3. Replacethefuelfilterwith anoriginalequipmentreplacementfilter. Call

1-800-659-5917to purchasetheoriginalequipmentreplacementfilter.

4. Securethefuellineswiththeclamps.

J

Figure14

Replacethesparkplug(ChampionRC12YC)onceaseason.

19

Muffler

Temperatureof muffler andnearbyengineareasmayexceed150° F(65°C).

Avoidcontactwith theseareas.

Inspectmufflerperiodically,andreplaceifnecessary.Replacementparts

forthemufflermustbethesameandinstalledinthesamepositionasthe

originalparts.

Clean Engine

Dallyorbeforeeveryuse,cleangrass,chafforaccumulateddebrisfrom

engine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeof anycombustibledebris.

Keepingenginecleanallowsairmovementaroundengine.

Enginepartsshouldbekeptcleantoreducethe riskofoverheatingand

ignitionofaccumulateddebris.

re-installingthebattery,alwaysconnectthePOSITIVE(Red)wire toitsterminal

first, followedbytheNEGATIVE(Black)wire.Becertainthat thewiresareconnected

tothecorrectterminals;reversingthem couldchangethepolarityandresultin

damageto yourengine'salternatingsystem.

CleaningBattery

Cleanthebatterybyremovingitfromthetractorandwashingwith abakingsoda

andwatersolution.Ifnecessary,scrapethebatteryterminalswith awirebrushto

removedeposits.Coatterminalsandexposedwiringwith greaseorpetroleumjelly

topreventcorrosion.

Battery Failures

Somecommoncausesfor batteryfailureare:

Incorrectinitialactivation

Overcharging

Freezing

Undercharging

Corrodedconnections

Donotusewater to cleanengineparts.Watercouldcontaminatefuel

system.Usea brushordry cloth.

CarburetorAdjustment

Thecarburetoronthisengineisnotadjustable.

Lubrication

Beforelubricating, repairing,orinspecting,alwaysdisengagePTO(Blade

EngageLever),moveshift leverinto neutral position,set parkingbrake,stop

engneandremovekeyto preventun ntendedstart ng.

Pivot Points& Linkage

Lubricateallthepivotpointsonthedrivesystem,parkingbrakeandlift linkageat

leastonceaseasonwith lightoil.

RearWheels

Therearwheelsshouldberemovedfromtheaxlesonceaseason.Lubricatethe

axlesandtherimswellwith anall-purposegreasebeforere-installingthem.

Front Axles

Eachendofthetractor'sfrontpivotbarmaybeequippedwith agreasefitting.

Lubricatewith agreasegunafterevery25hoursoftractoroperation.

Battery

Thebatteryissealedandismaintenance-free.Acidlevelscannotbechecked.

Alwayskeepthebatterycablesandterminalscleanandfreeofcorrosive

build-up.

Aftercleaningthebatteryandterminals,applya lightcoatofpetroleumjelly

orgreaseto bothterminals.

Alwayskeeptherubberbootpositionedoverthepositiveterminaltoprevent

shorting.

IM PORTANT: Ifremovingthebatteryforanyreason,disconnecttheNEGATIVE

(Black)wirefromitsterminalfirst,followedbythePOSITIVE(Red)wire.When

2O

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

Cleaningthe EngineAndDeck

Anyfueloroilspilledonthemachineshouldbewipedoff promptly.DoNOTallow

debristoaccumulatearoundthecoolingfinsoftheengineoronanyotherpartof

themachine.

IMPORTANT: TheuseofapressurewashertocleanyourtractorisNOT

recommended.It maycausedamageto electricalcomponents,spindles,pulleys,

bearingsortheengine.

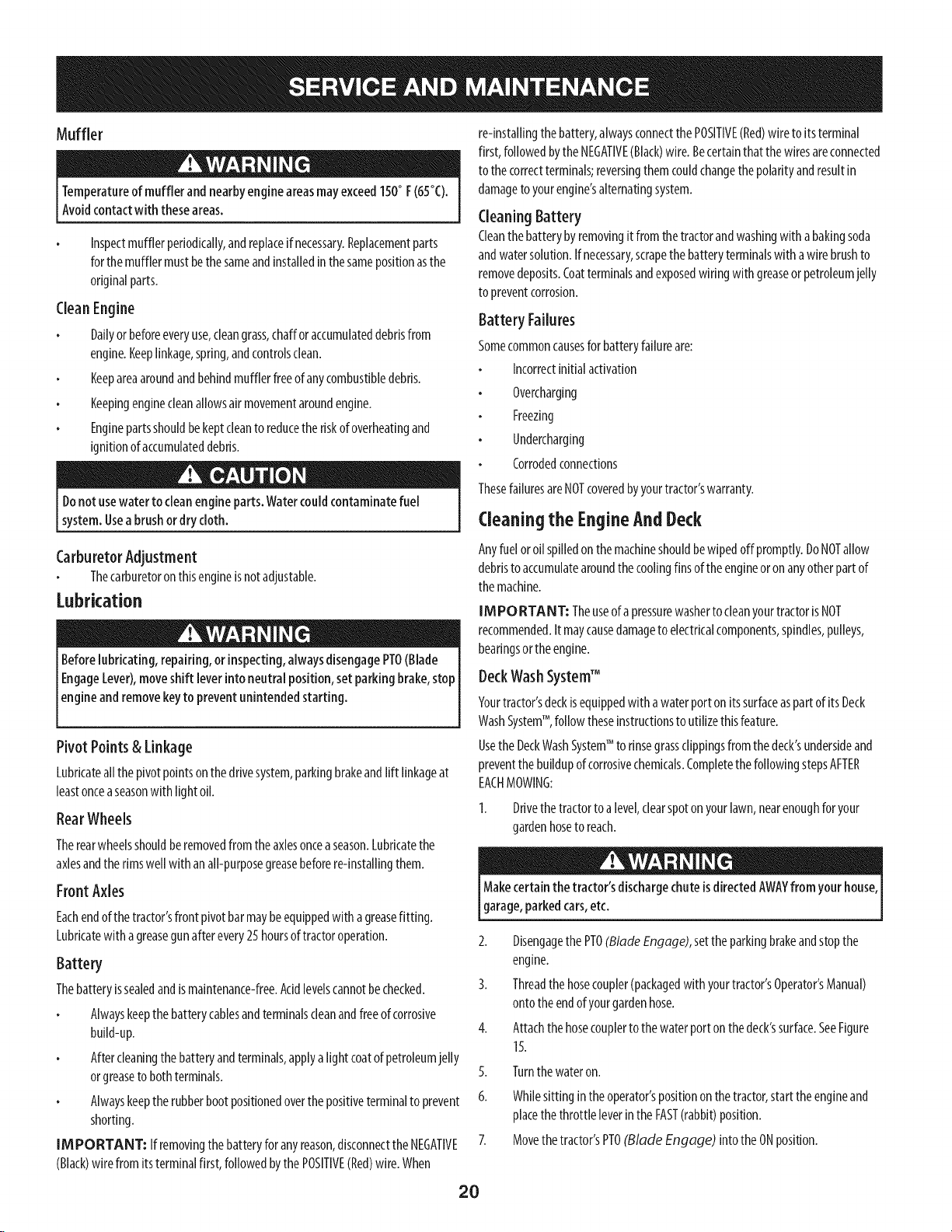

DeckWashSystemTM

Yourtractor'sdeckisequippedwith awaterportonitssurfaceaspartofitsDeck

WashSystem%followtheseinstructionstoutilizethisfeature.

UsetheDeckWashSystemTM to rinsegrassclippingsfromthedeck'sundersideand

preventthebuildupofcorrosivechemicals.CompletethefollowingstepsAFTER

EACHMOWING:

Drivethetractortoa level,clearspotonyourlawn,nearenoughforyour

gardenhosetoreach.

Makecertainthe tractor'sdischargechuteisdirectedAWAYfromyourhouse,

garage,parkedcars,etc.

2. Disengagethe PTO(BladeEngage),settheparkingbrakeandstopthe

engine.

3. Threadthe hosecoupler(packagedwith yourtractor'sOperator'sManual)

ontotheendofyourgardenhose.

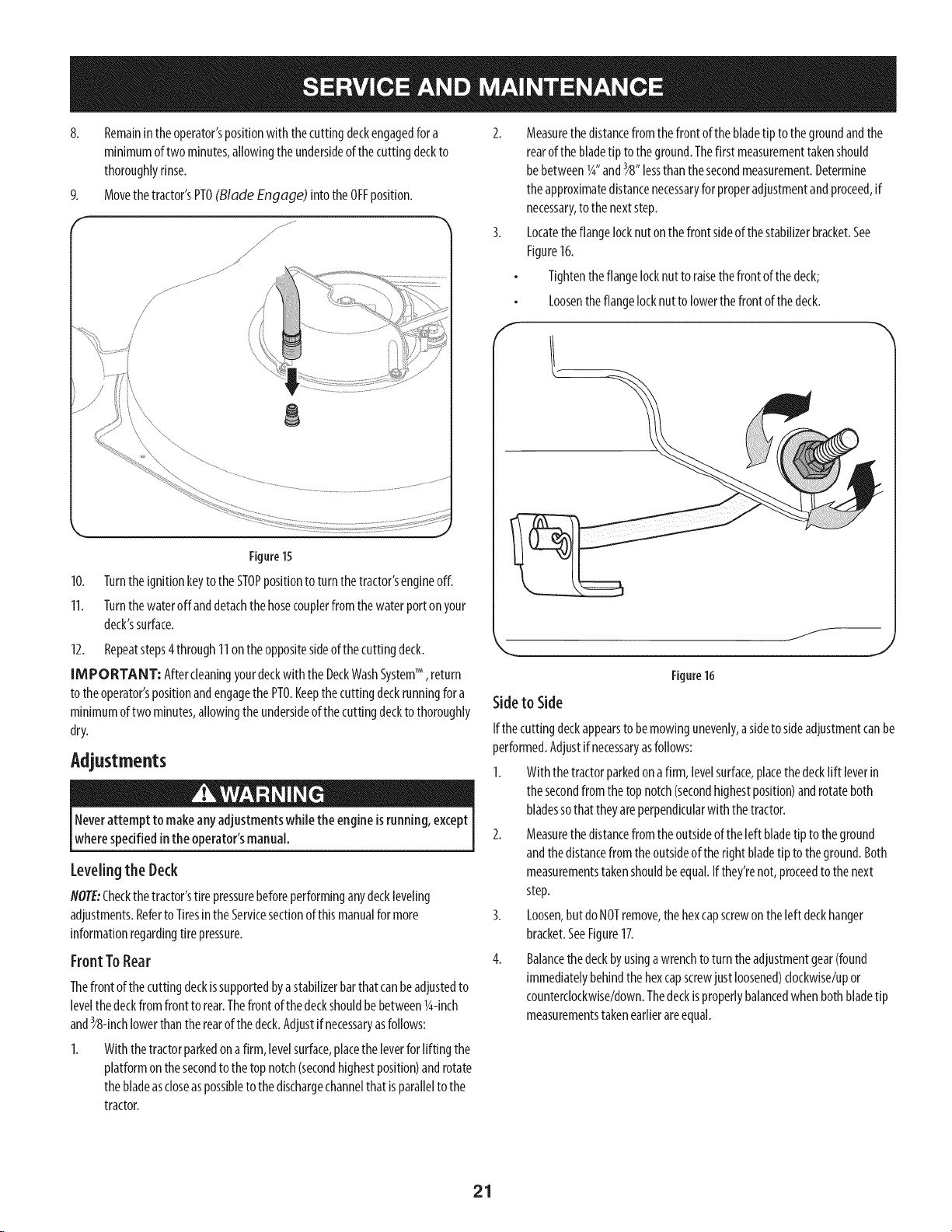

4. Attachthehosecouplertothewaterportonthedeck'ssurface.SeeFigure

15.

5.

Turnthewateron.

6.

Whilesittingintheoperator'spositiononthetractor,starttheengineand

placethethrottle leverintheFAST(rabbit)position.

Movethetractor'sPTO(Blade Engage) intotheONposition.

8.

Remainintheoperator'spositionwiththecuttingdeckengagedfor a

minimumoftwominutes,allowingtheundersideofthecuttingdeckto

thoroughlyrinse.

Movethetractor'sPTO(Blade Engage) intotheOFFposition.

\

Figure15

10. TurntheignitionkeytotheSTOPpositiontoturnthetractor'sengineoff.

11. Turnthewateroffanddetachthehosecouplerfromthewaterportonyour

deck'ssurface.

12. Repeatsteps4through11ontheoppositesideofthecuttingdeck.

IMPORTANT: Aftercleaningyourdeckwith the DeckWashSystemTM , return

totheoperator'spositionandengagethePTO.Keepthecuttingdeckrunningfora

minimumoftwo minutes,allowingtheundersideofthecuttingdeckto thoroughly

dry.

Adjustments

Neverattempt to makeanyadjustmentswhiletheengineisrunning,except

wherespecifiedinthe operator'smanual.

Levelingthe Deck

NOTE:Checkthetractor'stire pressurebeforeperforminganydeckleveling

adjustments.Referto Tiresin theServicesectionof thismanualformore

informationregardingtirepressure.

Front ToRear

Thefrontofthecuttingdeckissupportedbyastabilizerbarthatcanbeadjustedto

levelthedeckfromfrontto rear.Thefrontofthedeckshouldbebetween1g-inch

3

andY8-inchlowerthantherearofthedeck.Adjustif necessaryasfollows:

1. Withthetractorparkedona firm, levelsurface,placetheleverforliftingthe

platformonthesecondto thetop notch(secondhighestposition)androtate

thebladeascloseaspossibletothedischargechannelthat isparalleltothe

tractor.

2. Measurethedistancefromthefrontof thebladetiptothegroundandthe

rearofthebladetip totheground.Thefirst measurementtakenshould

bebetweenlg"and_8"lessthanthesecondmeasurement.Determine

theapproximatedistancenecessaryfor properadjustmentandproceed,if

necessary,tothenextstep.

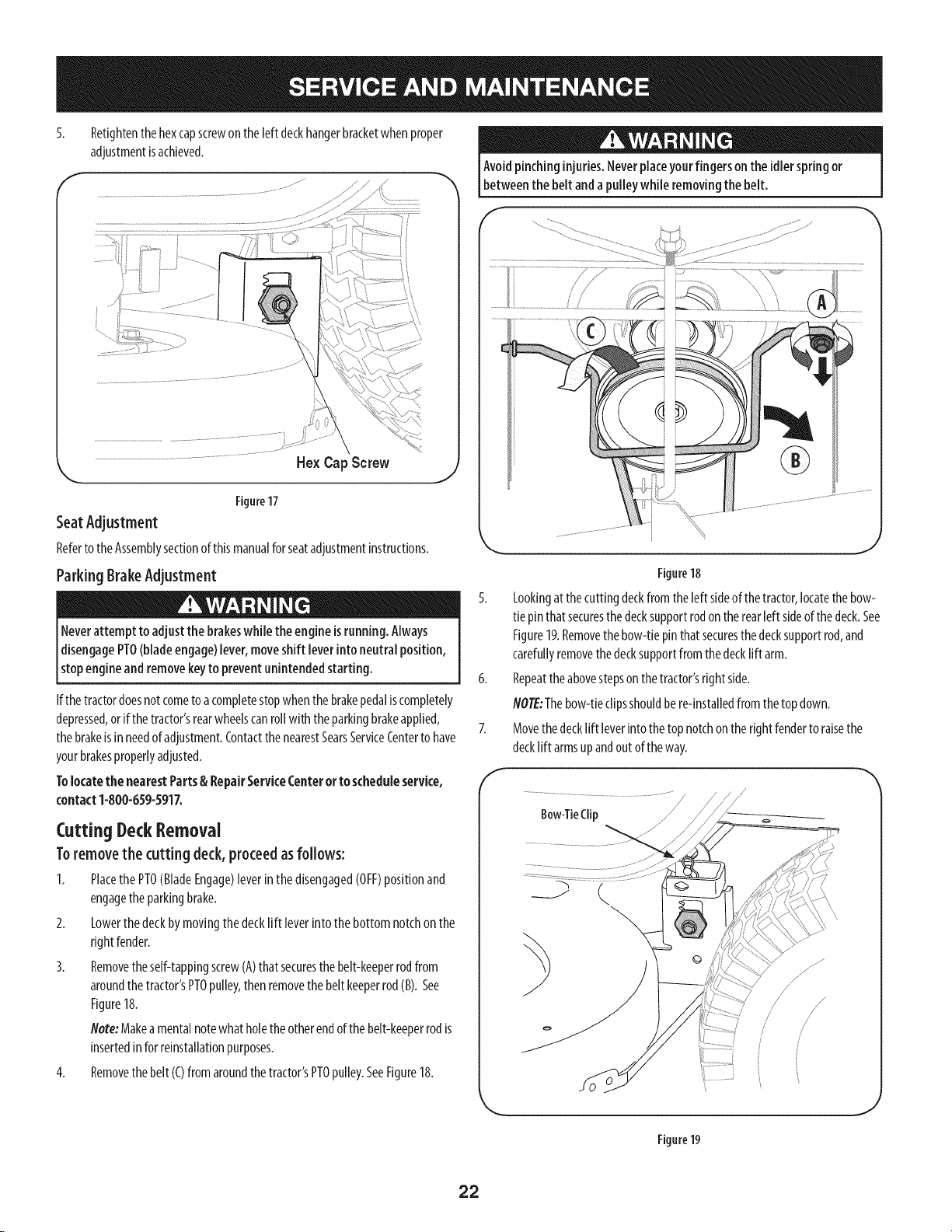

3. Locatetheflangelocknutonthefrontsideofthestabilizerbracket.See

Figure16.

Tightentheflangelocknutto raisethefrontofthedeck;

Loosentheflangelocknutto lowerthefrontofthedeck.

f__

,,_. J

Figure16

Sideto Side

Ifthecuttingdeckappearstobemowingunevenly,asidetosideadjustmentcanbe

performed.Adjustifnecessaryasfollows:

1. Withthetractorparkedonafirm,levelsurface,placethedeckliftleverin

thesecondfromthetopnotch(secondhighestposition)androtateboth

bladessothattheyareperpendicularwith thetractor.

2. Measurethedistancefromtheoutsideoftheleftbladetipto theground

andthedistancefromtheoutsideoftheright bladetip totheground.Both

measurementstakenshouldbeequal.Ifthey'renot,proceedtothenext

step.

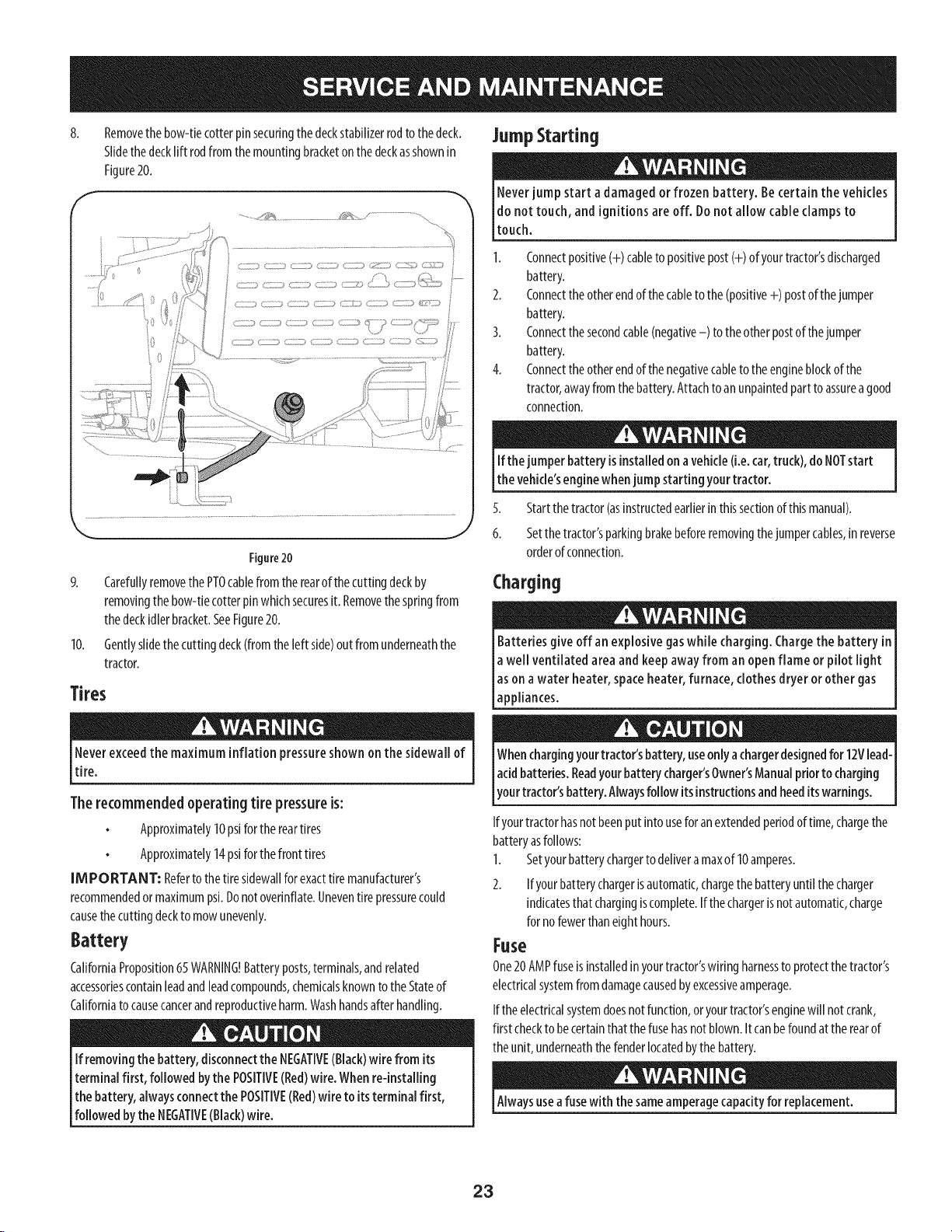

3. Loosen,but doNOTremove,the hexcapscrew onthe leftdeck hanger

bracket.See Figure17.

4. Balancethe deckby usinga wrenchto turn the adjustment gear (found

immediatelybehindthe hex capscrewjust loosened)dockwise/up or

counterclockwise/down.Thedeck isproperlybalancedwhen both bladetip

measurements taken earlierare equal.

21

5.

Retightenthehexcapscrewontheleft deckhangerbracketwhenproper

adjustmentisachieved.

Avoidpinchinginjuries.Neverplaceyourfingers onthe idlerspringor

betweenthe beltand apulleywhile removingthe belt.

f

Hex Cap Screw

J

Figure17

SeatAdjustment

RefertotheAssemblysectionofthismanualfor seatadjustmentinstructions.

Parking BrakeAdjustment

Neverattempt toadjustthe brakeswhilethe engineisrunning. Always

disengagePTO(bladeengage)lever,moveshift leverintoneutralposition,

stopengineandremovekeyto prevent unintendedstarting.

Ifthetractordoesnotcometoacompletestopwhenthe brakepedaliscompletely

depressed,orifthetractor'srearwheelscanrollwiththeparkingbrakeapplied,

thebrakeisinneedof adjustment.ContactthenearestSearsServiceCenterto have

yourbrakesproperlyadjusted.

Tolocatethe nearestParts& RepairService(enter orto scheduleservice,

contact1-800-659-5917.

Cutting DeckRemoval

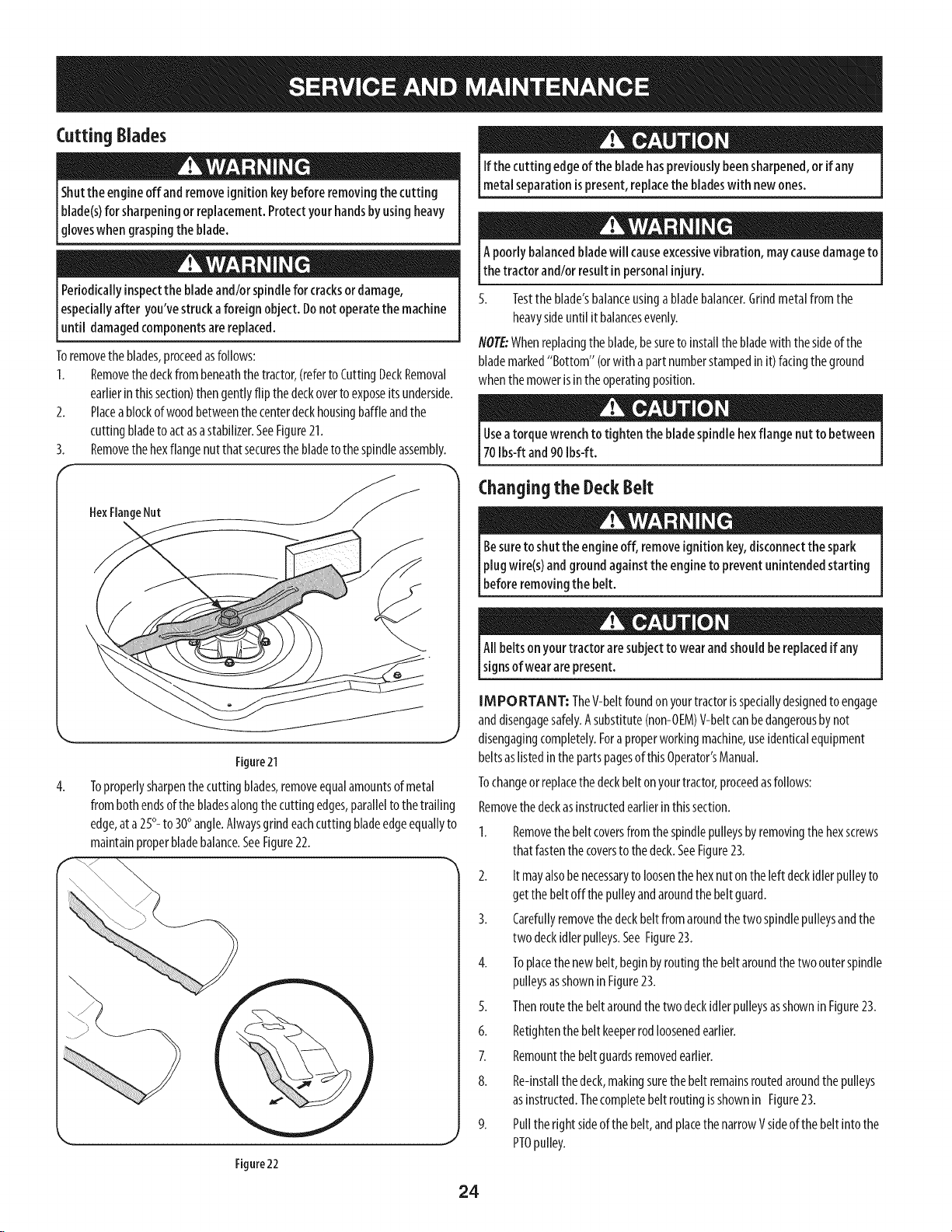

Toremovethe cuttingdeck, proceedasfollows:

I. Placethe PTO(BladeEngage)leverinthe disengaged(OFF)positionand

engagethe parkingbrake.

2. Lowerthedeckbymovingthedecklift leverintothebottomnotchon the

rightfender.

3. Removetheself-tappingscrewCA)thatsecuresthebelt-keeperrodfrom

aroundthetractor'sPTOpulley,then removethebeltkeeperrod(B).See

Figure18.

Note:Makeamentalnotewhatholetheotherendofthebelt-keeperrodis

insertedinfor reinstallationpurposes.

4. Removethebelt(C)fromaroundthetractor'sPTOpulley.SeeFigure18.

Figure18

5. Lookingatthecuttingdeckfromtheleftsideofthetractor,locatethebow-

tiepinthat securesthedecksupportrodon therearleftsideofthedeck.See

Figure19.Removethebow-tiepinthatsecuresthedecksupportrod,and

carefullyremovethedecksupportfromthedeckliftarm.

6. Repeattheabovestepsonthetractor'srightside.

NOTE:Thebow-tieclipsshouldbere-installedfromthetopdown.

7. Movethedecklift leverintothetopnotchontheright fendertoraisethe

decklift armsupandoutoftheway.

f

Bow-TieClip

22

J

Figure19

8. Removethebow-tiecotterpinsecuringthedeckstabilizerrodtothedeck. JUllIIpStarting

Slidethedecklift rodfromthemountingbracketon thedeckasshownin

Figure20.

f

.........._y,_ _ ....................

i o

Figure20

CarefullyremovethePTOcablefromtherearofthecuttingdeckby

removingthebow-tiecotterpinwhichsecuresit. Removethespringfrom

thedeckidlerbracket.SeeFigure20.

10.

Gentlyslidethecuttingdeck(fromtheleft side)outfromunderneaththe

tractor.

Tires

Neverjump start adamagedor frozen battery. Becertain the vehicles

do not touch, and ignitions are off. Do not allow cableclampsto

touch.

1. Connectpositive(+) cableto positivepost(+)of yourtractor'sdischarged

battery.

2. Connecttheotherendofthecabletothe(positive+)postofthejumper

battery.

3. Connectthesecondcable(negative-) to theotherpostofthejumper

battery.

4. Connecttheotherendofthenegativecabletotheengineblockofthe

tractor,awayfromthebattery.Attachtoanunpaintedparttoassureagood

connection.

Ifthejumper batteryis installedona vehicle(i.e.car,truck),doNOTstart

the vehicle'senginewhenjumpstartingyourtractor.

5. Startthetractor(asinstructedearlierinthissectionof thismanual).

6. Setthetractor'sparkingbrakebeforeremovingthejumpercables,in reverse

orderofconnection.

Charging

Batteries

awell ventilated areaand keepawayfrom anopen flame or pilot light [

asonawater heater,spaceheater,furnace, clothes dryer orother gas [

lapp ances. J

giveoff an explosive gaswhile charging. Chargethe battery in [

e

Neverexceedthe maximum inflation pressureshown on the sidewall of

tire.

Therecommended operating tire pressureis:

Approximately10psifor thereartires

Approximately14psifor thefronttires

IMPORTANT: Refertothetiresidewallforexacttiremanufacturer's

recommendedormaximumpsi.Donotoverinflate.Uneventirepressurecould

causethecuttingdeckto mowunevenly.

Battery

CaliforniaProposition65WARNING!Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductiveharm.Washhandsafterhandling.

Ifremovingthe battery, disconnectthe NEGATIVE(Black)wirefrom its

terminalfirst, followed bythe POSITIVE(Red)wire. Whenre-installing

the battery,alwaysconnectthe POSITIVE(Red)wire toits terminal first,

followedbythe NEGATIVE(Black)wire.

Whenchargingyourtractor'sbattery,useonlyachargerdesignedfor 12Vlead-

[acidbatteries.Readyourbatterycharger'sOwner'sManualpriortocharging

[yourtractorsbattery.Alwaysfollow itsinstructionsandheeditswarnings.

Ifyourtractorhasnotbeenputintouseforanextendedperiodoftime,chargethe

batteryasfollows:

1. Setyourbatterychargerto delivera maxof 10amperes.

2. Ifyourbatterychargerisautomatic,chargethebatteryuntilthecharger

indicatesthatchargingiscomplete.If thechargerisnotautomatic,charge

fornofewerthaneighthours.

Fuse

One20AMPfuseisinstalledinyourtractor'swiringharnesstoprotectthetractor's

electricalsystemfromdamagecausedbyexcessiveamperage.

Iftheelectricalsystemdoesnotfunction,oryourtractor'senginewillnotcrank,

firstcheckto becertainthatthefusehasnotblown.Itcanbefoundattherearof

theunit,underneaththefenderlocatedbythebattery.

Alwaysuseafusewith thesameamperagecapacityfor replacement.

23

CuttingBlades

Shutthe engineoffand removeignitionkeybeforeremovingthe cutting

blade(s)for sharpeningor replacement.Protectyour handsbyusingheavy

[g oveswhengraspngthe b ade.

Periodicallyinspectthe bladeand/orspindlefor cracksor damage,

Iespeciallyafter you'vestruckaforeign object. Donot operatethe machine

[until damagedcomponentsarereplaced.

Toremovetheblades,proceedasfollows:

1. Removethedeckfrombeneaththetractor,(refertoCuttingDeckRemoval

earlierinthissection)thengentlyflipthedeckoverto exposeitsunderside.

2. Placeablockofwoodbetweenthecenterdeckhousingbaffleandthe

cuttingbladetoactasastabilizer.SeeFigure21.

3. Removethehexflangenutthatsecuresthe bladeto thespindleassembly.

HexFlangeNut

Ifthe cuttingedge ofthe bladehaspreviouslybeensharpened,orif any

metalseparationispresent,replacethe bladeswith newones.

Apoorlybalancedbladewill causeexcessivevibration, maycausedamageto

the tractor and/orresultin personalinjury.

5. Testtheblade'sbalanceusingabladebalancer.Grindmetalfromthe

heavysideuntilit balancesevenly.

NOTE:Whenreplacingtheblade,besureto installthebladewith thesideofthe

blademarked"Bottom" (orwitha partnumberstampedinit)facingtheground

whenthemowerisintheoperatingposition.

Useatorquewrenchtotighten the bladespindlehexflange nut to between

70Ibs-ftand 90Ibs-ft.

Changingthe DeckBelt

Besureto shutthe engineoff, removeignitionkey,disconnectthe spark

plugwire(s)andgroundagainstthe engineto prevent unintendedstarting

beforeremovingthe belt.

Figure21

4.

Toproperlysharpenthecuttingblades,removeequalamountsofmetal

frombothendsofthe bladesalongthecuttingedges,paralleltothetrailing

edge,ata25°-to 30° angle.Alwaysgrindeachcuttingbladeedgeequallyto

maintainproperbladebalance.SeeFigure22.

\

Figure22

All beltsonyourtractor aresubjectto wear andshouldbereplacedif any

signsofwearare present.

IMPORTANT: TheV-beltfoundonyourtractorisspeciallydesignedto engage

anddisengagesafely.Asubstitute(non-OEM)V-beltcanbedangerousbynot

disengagingcompletely.Foraproperworkingmachine,useidenticalequipment

beltsaslistedinthe partspagesof thisOperator'sManual.

Tochangeorreplacethedeckbeltonyourtractor,proceedasfollows:

Removethedeckasinstructedearlierinthissection.

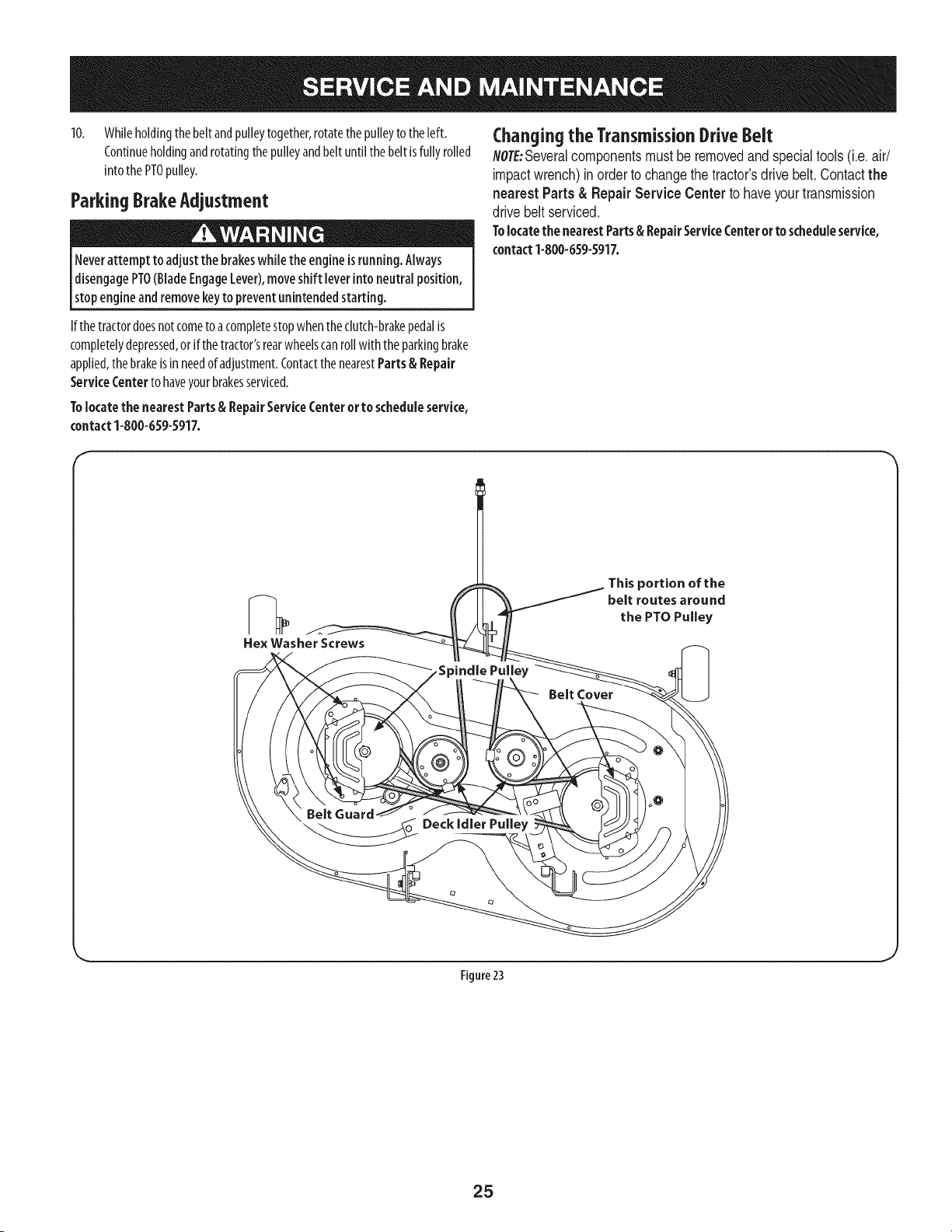

1. Removethebeltcoversfromthespindlepulleysbyremovingthehexscrews

thatfastenthecoversto thedeck.SeeFigure23.

2. Itmayalsobenecessaryto loosenthehexnutontheleft deckidlerpulleyto

getthebeltoffthe pulleyandaroundthebeltguard.

3. Carefullyremovethedeckbeltfromaroundthetwospindlepulleysandthe

twodeckidlerpulleys.SeeFigure23.

4. Toplacethenewbelt,beginbyroutingthebeltaroundthetwoouterspindle

pulleysasshownin Figure23.

5. Thenroutethe beltaroundthetwodeckidlerpulleysasshowninFigure23.

6. Retightenthe beltkeeperrodloosenedearlier.

7. Remountthe beltguardsremovedearlier.

8. Re-installthedeck,makingsurethebeltremainsroutedaroundthepulleys

asinstructed.Thecompletebeltroutingisshownin Figure23.

9. Pulltherightsideofthebelt,andplacethenarrowVsideofthebeltintothe

PTOpulley.

24

10. Whileholdingthebeltandpulleytogether,rotatethepulleyto theleft.

Continueholdingandrotatingthepulleyandbeltuntilthebeltisfully rolled

intothePTOpulley.

ParkingBrakeAdjustment

Neverattempt toadjustthe brakeswhile theengineisrunning.Always

disengagePTO(BladeEngageLever),moveshift [everintoneutralposition,

stopengineandremovekeyto preventunintendedstarting.

Ifthetractordoesnotcometoacompletestopwhentheclutch-brakepedalis

completelydepressed,orif thetractor'srearwheelscanrollwith theparkingbrake

applied,thebrakeisinneedofadjustment.Contactthe nearestParts& Repair

ServiceCenterto haveyourbrakesserviced.

Tolocate the nearestParts&RepairServiceCenterorto scheduleservice,

contact1-800-659-5917.

F

(:hanging the TransmissionDrive Belt

NOTE:Several components must be removed and special tools (i.e. air/

impact wrench) in order to change the tractor's drive belt. Contact the

nearest Parts & Repair Service Center to have your transmission

drive belt serviced.

Tolocatethe nearestParts& RepairService(:enteror to scheduleservice,

contact1-800-659-5917.

Figure23

25

J

Neverstorelawn tractor with fuel in tank indoorsorin poorlyventilated

areaswherefuel fumes mayreachanopen flame,spark,or pilot light ason

afurnace,waterheater,clothesdryer,or gasappliance.

PreparingTheEngine

IM PORTANT: Fuelleft inthefueltankduringwarmweatherdeterioratesand

will causeseriousstartingproblems.

Topreventgumdepositsfromforminginsidetheengine'scarburetorandcausing

possiblemalfunctionoftheengine,thefuelsystemmustbeeithercompletely

emptied,orthegasolinemustbetreatedwithastabilizertopreventdeterioration.

I. Ifusingafuelstabilizer:

a. Readtheproductmanufacturer'sinstructionsandrecommendations.

b. Addtoclean,freshgasolinethecorrectamountofstabilizerforthe

capacityofthefuelsystem.

c. Fillthefueltankwith treatedfuelandruntheenginefor2-3minutesto

getstabilizedfuelintothecarburetor.

2. Ifemptyingthefuelsystem:

a. Donotdrainfuelwhentheengineishot.Allowtheengineadequate

timetocool.Drainfuelintoanapprovedcontaineroutdoors,awayfrom

openflame.

b. Drainanylargevolumeoffuelfromthetankbydisconnectingthe

fuellinefromthe in-linefuelfilter neartheengine.Seethecomplete

instructionsforDrainingTheFuellaterin thissection.

Gasolineisextremelyflammableand canbeexplosiveundercertain

conditions.Draingasolinebeforestoringthe equipment for extended

periods.Drainfuelonly intoan approvedcontaineroutdoors,awayfrom

anopenflame. Allowengineto cool.Extinguishcigarettes,cigars,pipes,

andothersourcesof ignition prior to draining fuel. Storegasolinein an

approvedcontainerinsafelocation.

DrainingTheFuel

1. Locatethefuelfilter,whichislocatedontheleftsideoftheengine,andmay

beattachedtotheenginewith atiestrap.

2. Cutthetiestrap,if present,thenpinchthe in-lineclamponthefuelfilter

with apairofpliers,slidetheclampupthefuelline.

3. Pullthefuellinefreefromthefilterandplacetheopenendof thelineinto

anapprovedcontainerto drainthefuel.

PreparingThelawn tractor

Cleanandlubricatetractorthoroughlyasdescribedinthelubrication

instructions.

2. Donotuseapressurewasherorgardenhoseto cleanyourunit.

3. Storemowerinadry,cleanarea.Donotstorenexttocorrosivematerials,

suchasfertilizer.

c. Reconnectthefuellineandruntheengineuntilit startstofalter,then

usethechoketokeeptheenginerunninguntilall fuelinthecarburetor

hasbeenexhausted.

d. Disconnectthefuellineanddrainanyremaininggasolinefromthe

system.

Gasolineisatoxicsubstance.Disposeofgasolineproperly.Contactyour

localauthoritiesforapproveddisposalmethods.

3. Removethesparkplugandpourone(1)ounceofengineoil throughthespark

plugholeintothecylinder.Crankthe engineseveraltimestodistributethe

oil. Replacethesparkplug.

26

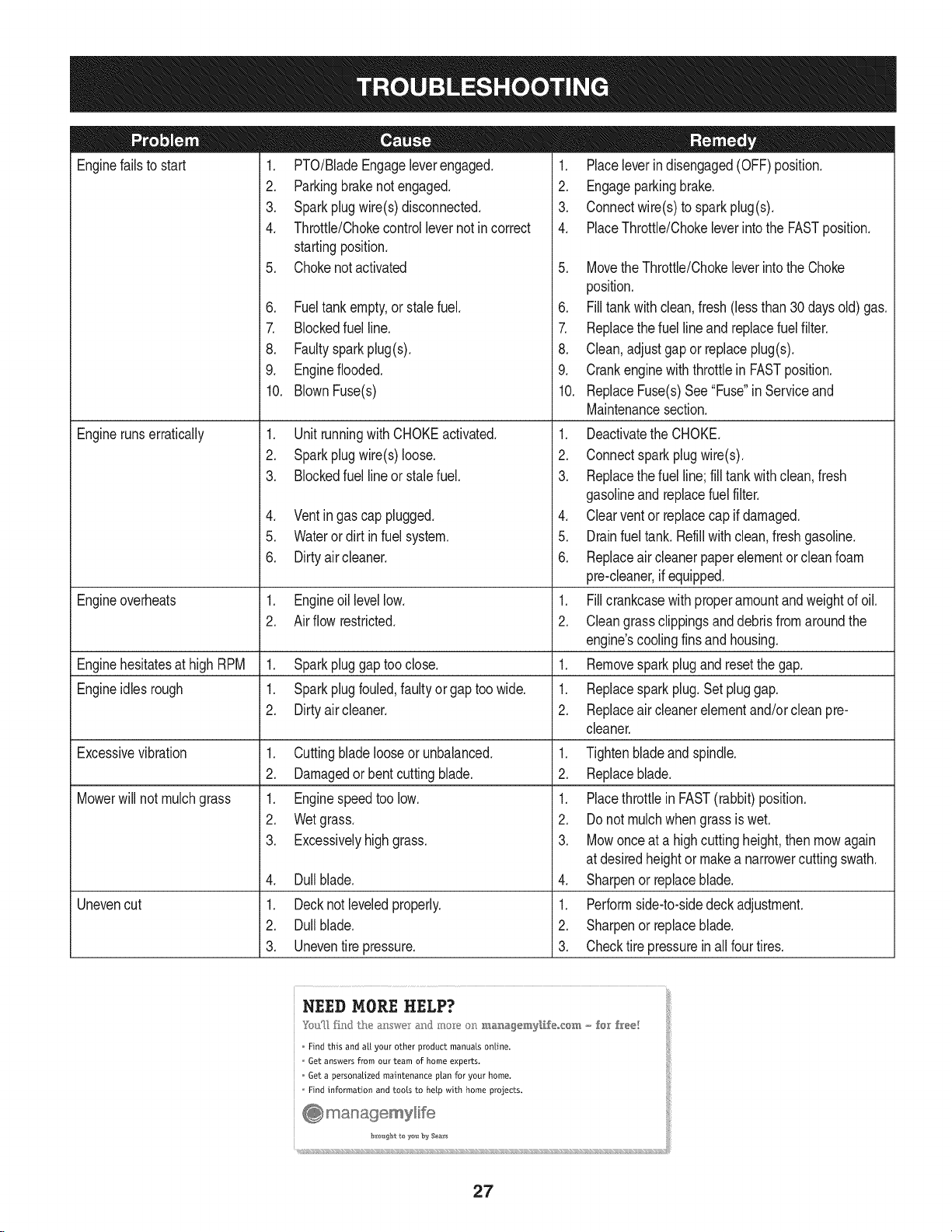

Enginefailstostart

1. PTO/BladeEngageleverengaged.

2. Parkingbrakenotengaged.

3. Sparkplugwire(s)disconnected.

4. Throttle/Chokecontrollevernotincorrect

4. PlaceThrottle/Chokeleverintothe FASTposition.

startingposition.

5. Chokenotactivated

6. Fueltankempty,orstalefuel.

7. Blockedfuel line.

8. Faultysparkplug(s).

9. Engineflooded.

10. BlownFuse(s)

Enginerunserratically

1. UnitrunningwithCHOKEactivated.

2. Sparkplugwire(s)loose.

3. Blockedfuel lineor stalefuel.

4. Ventingascap plugged.

4. Clearventorreplacecapifdamaged.

5. Wateror dirtin fuelsystem.

6. Dirtyair cleaner.

Engineoverheats 1. Engineoillevellow. 1.

2. Air flowrestricted. 2.

Enginehesitatesat high RPM 1. Sparkpluggaptoo close. 1.

Engineidlesrough 1. Sparkplugfouled,faultyor gaptoowide. 1.

2. Dirtyair cleaner. 2.

Excessivevibration

1. Cuttingbladelooseor unbalanced.

2. Damagedorbent cuttingblade.

Mowerwillnot mulchgrass

1. Enginespeedtoolow.

2. Wetgrass.

3. Excessivelyhighgrass.

Unevencut

4. Dullblade.

1. Decknot leveledproperly.

4. Sharpenor replaceblade.

2. Dullblade.

3. Uneventire pressure.

1. Placeleverindisengaged(OFF)position.

2. Engageparkingbrake.

3. Connectwire(s)to sparkplug(s).

5. MovetheThrottle/Chokeleverintothe Choke

position.

6. Filltankwithclean,fresh(lessthan30daysold)gas.

7. Replacethe fuellineandreplacefuelfilter.

8. Clean,adjustgapor replaceplug(s).

9. Crankenginewiththrottlein FASTposition.

10. ReplaceFuse(s)See"Fuse"in Serviceand

Maintenancesection.

1. Deactivatethe CHOKE.

2. Connectsparkplugwire(s).

3. Replacethe fuelline;filltankwithclean,fresh

gasolineandreplacefuelfilter.

5. Drainfueltank.Refillwithclean,freshgasoline.

6. Replaceair cleanerpaperelementorcleanfoam

pre-cleaner,ifequipped.

Fillcrankcasewithproperamountandweightof oil.

Cleangrassclippingsanddebrisfromaroundthe

engine'scoolingfinsandhousing.

Removesparkplugandresetthegap.

Replacesparkplug.Setpluggap.

Replaceair cleanerelementand/orcleanpre-

cleaner.

1. Tightenbladeandspindle.

2. Replaceblade.

1. Placethrottlein FAST(rabbit)position.

2. Donotmulchwhengrassiswet.

3. Mowonceat a highcuttingheight,thenmowagain

atdesiredheightor makea narrowercuttingswath.

1. Performside-to-sidedeckadjustment.

2. Sharpenor replaceblade.

3. Checktirepressureinallfourtires.

NEED MORE HELP?

Find this and a[[ your other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance ptan for your home.

Find information and tools to help with home projects.

27

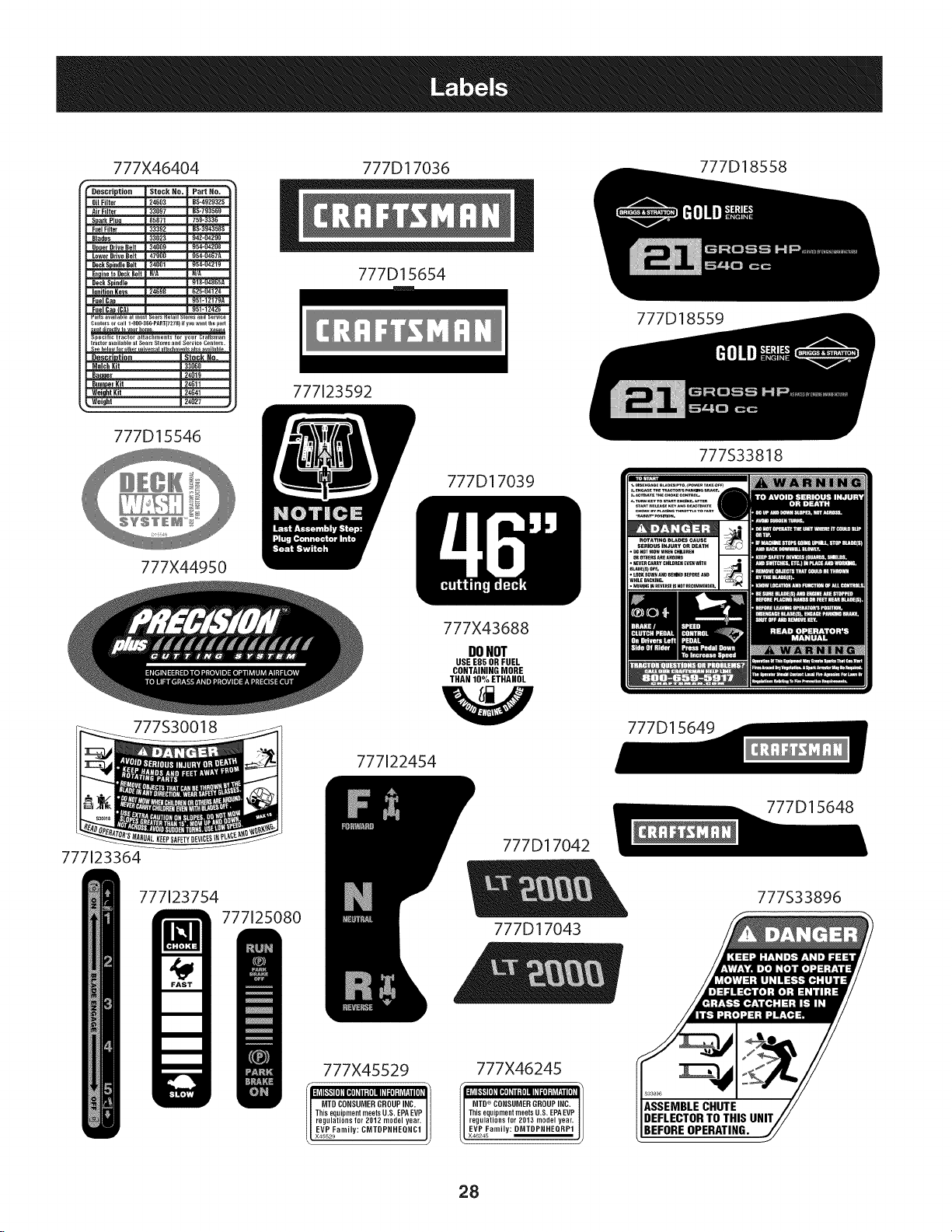

777X46404 777D18558

777D17036

777D15654

Ce.tersorcall1-800-366-PART(7278)ifyo.wanttilepart

i specmc tractor attachlnent_ lot yo.r Crattslnan

tractoravailableatSearsStoresandServiceCenlers.

Seebelowfor otheru,i_e_al atladlmentsal_oavailahlem

Descr|_tjon Stock Ho.

BumperKit | 24011

WeightKit [ 24041

_.Weight | 24027 ,