Page 1

OWNERS

MANUAL

75

20" & 22"

ROTARY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Important:

MOWERS

Model Numbers

114-073-000

114-074-000

114-083-000

114-084-000

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Thank you for purchasing an

American buiit product.

FORM NO. 770-3143

Page 2

INDEX

Safe Operation Practices

Assembly.................................................................. 4

Controls.....................................................................7

Operation...................................................................7

Adjustments...............................................................8

Lubrication.................................................................9

..........................................

Г

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of orig nal retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free cf charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for г ny parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, imp oper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manifacturer’s warranty on these items.

LIMITED WARRANTY

3

Maintenance .............................................................9

Off-Season Storage

Trouble Shooting Chart

Illustrated Parts...................................................16,17

Parts Information

................................................

...........................................

......................................

Back Cover

12

15

i

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

This warranty will not apply where he unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distrit utor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will n ct be accepted by the factory unless prior written per

mission has been extended by MT[>.

This warranty gives you specific leqai rights. You may also have other rights which vary

from state to state.

V

WARNING

t

This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is

equipped with a spark arrester meeting ap clicable local or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator.

j

♦

♦

♦

♦

♦

♦

J

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester muffler is

available at your nearest engine authorized service center.

Page 3

I W AR NI NG }

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply

with the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR WALK-BEHIND MOWERS

TRAINING

1. Read this owner’s manual carefully in its en

tirety before attempting to assemble or

operate this machine. Be completely familiar

with the controls and the proper use of this

machine before operating it. Keep this manual

in a safe place for future and regular reference

and for ordering replacement parts.

2. Your rotary mower is a precision piece of

power equipment, not a plaything. Therefore,

exercise extreme caution at all times.

3. Never allow children to operate a power

mower. Only persons well acquainted with

these rules of safe operation should be al

lowed to use your mower.

4. Keep the area of operation clear of all per

sons, particularly small children and pets.

Stop engine when they are in the vicinity of

your mower. Although the area of operation

should be completely cleared of foreign ob

jects, an object may have been overlooked

and could be accidently thrown by the mower

in any direction and cause serious personal

injury to the operator or any others allowed in

the area.

PREPARATION

1. Thoroughly inspect the area where the equip

ment is to be used. Remove all stones, sticks,

wire, bones and other foreign objects which

could be picked up and thrown by the mower

in any direction and cause serious personal

injury to the operator or any others allowed in

the area.

2. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

3. Do not wear loose fitting clothing that could

get caught on the mower.

4. Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do

not fill the gasoline tank indoors, while the

engine is running, or while the engine is still

hot. Wipe off any spilled gasoline before start

ing the engine as it may cause a fire or explo

sion.

5. Disengage the self-propelled mechanism or

drive clutch on units so equipped before start

ing the engine.

6. The blade control handle is a safety device.

Never attempt to bypass its operation. Doing

so makes the safety device inoperative and

may result in personal injury through contact

with the rotating blade. The blade control han

dle must operate easily in both directions.

7. Never attempt to make a wheel or cutting

height adjustment while the engine is run

ning.

8. Mow only in daylight or in good artificial light.

9. Never operate the equipment in wet grass.

Always be sure of your footing. A slip and fall

can cause serious personal injury. Keep a firm

hold on the handle and walk, never run. g

OPERATION

1. Do not change the engine governor settings

or overspeed the engine. Excessive engine

speeds are dangerous.

2. Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at

all times as the rotating blade can cause in

jury.

3. Stop the blade when crossing gravel drives,

walks or roads.

4. After striking a foreign object, stop the

engine, remove the wire from the spark plug,

and thoroughly inspect the mower for any

damage. Repair the damage before restarting

and operating the mower.

5. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately

for the cause. Vibration is generally a warning

of trouble.

6. Shut the engine off and wait until the blade

comes to a complete stop before removing

the grass catcher or unclogging the chute.

The cutting blade continues to rotate for a few

seconds after the engine is shut off. Never

place any part of the body in the blade area un

til you are sure the blade has stopped rotating.

7. Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have

stopped. Disconnect the spark plug wire, and

keep the wire away from the spark plug to pre

vent accidental starting.

8. Do not run the engine indoors.

9. Mow across the face of slopes, never up-anddown. Exercise extreme caution when chang

ing direction on slopes. Do not mow ex

cessively steep slopes. Always be sure of

your footing. A slip and fall can cause serious

personal injury.

10. Always disconnect electric mowers (line

operated) before cleaning, repairing or ad

justing.

11. Never operate mower without proper guards,

plates or other safety protective devices in

place.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at

frequent intervals for proper tightness.

2. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working condi

tion.

3. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any en

closure.

4. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

5. Check the grass catcher bag frequently for

wear or deterioration. For safety protection,

replace only with new bag meeting original

equipment specifications.

Page 4

SAFE OPERATION PRACTICES (Continued)

BLADE BRAKEICLUTCH MAINTENANCE

NOTE: Any required repair work on the biade

brake/clutch should be performed by an author- 3.

ized service dealer. If you cannot locate an author

ized service dealer, contact the manufact jrer as

set forth on your copy of the Owner’s Registration

Card.

1. The blade brake/clutch hand control is a safe

ty device. Never attempt to bypass its opera

Doing so makes the safety device in

tion.

operative and may result in personal injury

through contact with the rotating blade. This 4.

hand control must operate freely in both direc

tions.

2. Striking a solid object can cause daniage to

the blade brake/clutch or to the engine crank

shaft. Extensive vibration of the mowei during

operation is an indication of damage and the

unit should be promptly inspected and

repaired.

A leak in the lower engine crankshaft oil seal

could expose the blade brake/clutch friction

pads to excess oil resulting in blade or brake

slippage, which could increase the stopping

time of the blade. Oil collection on the floor

beneath the mower during storage may be an

indication of an oil seal leak. The unit should

be checked by an authorized service dealer.

Periodically inspect the inner control cable in

the area where it attaches to the hand control.

If the cable becomes frayed, it could cause

the blade brake/clutch to operate improperly.

Also, be careful to avoid pinching the blade

brake/clutch control cable when storing the

handle.

NOTE

This unit is'shipped WITHOUT GAS

OLINE or OIL. After assembly, see

separate engine manual for proper

fuel and engine oil recommenda

tions.

ww

-B

FIGURE 1.

Lower Handle-

у

4

Hairpin i

Cotter (A)

in Inner

Hole

,_F

Handle

Bracket

ASSEMBLY

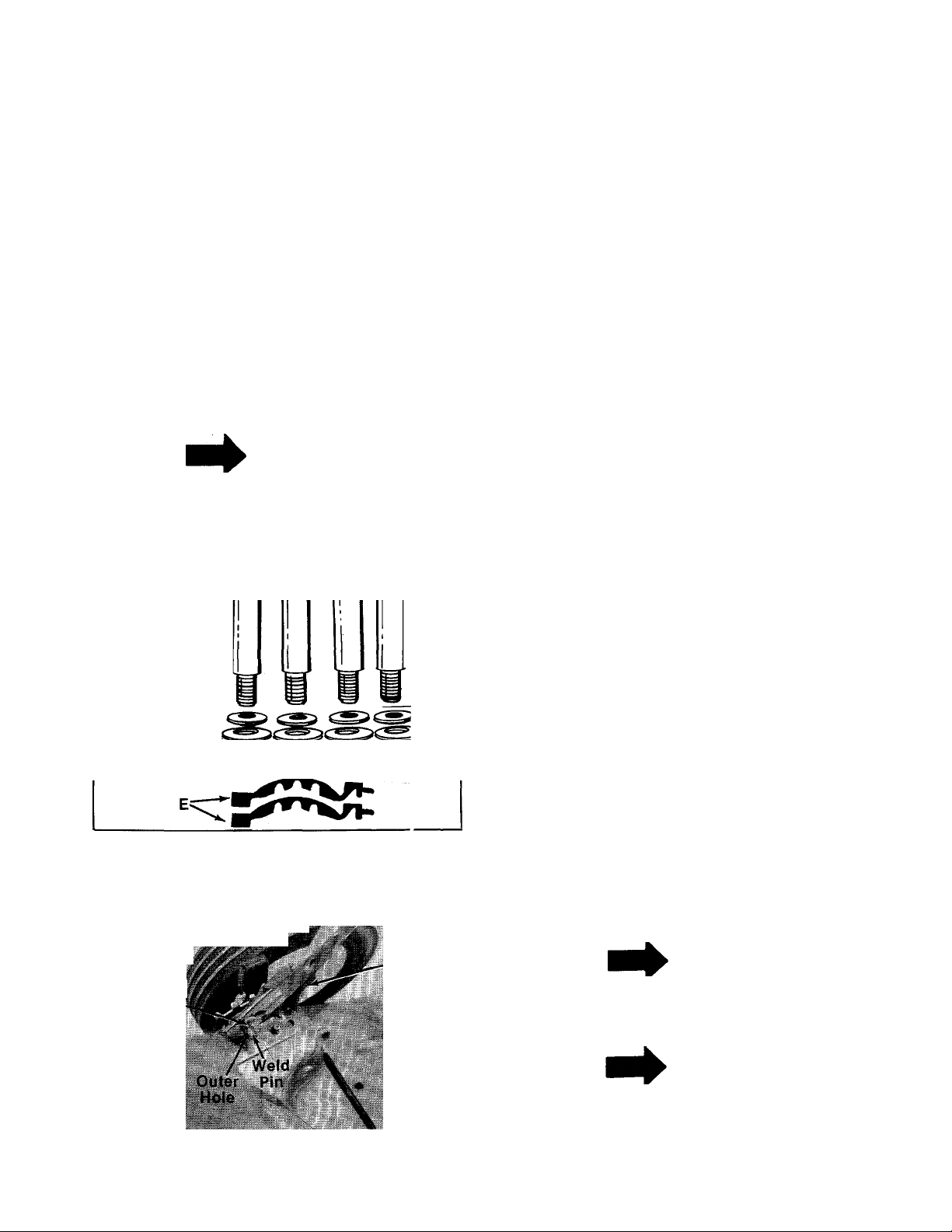

Contents of hardware pack: (See figure 1)

A (2) Hairpin Cotters

В (2) Curved Carriage Bolts 1.38" Long

C (2) Lock Washers 5/16" I.D.

D (2) Hex Nuts 5/16-18 Thread

E (2) Cable Ties

F (4) Shoulder Bolts*

— G (4) Belleville Washers 3/8" I.D. x 7/8" O.D.*

H (4) Belleville Washers 3/8" I.D. x 1-1/8" O.D.*

I (4) Hex Nuts 3/8-16 Thread*

*Units with wheeis not assembied.

1. Remove the iawn mower, ioose parts, hard

ware pack and iiterature from the carton.

Make certain all parts and literature have been

removed before the carton is discarded.

2. Extend the throttle control cable (attached to

the upper handle) and the blade brake/clutch

cable (attached to the blade brake/clutch

beneath the deck) and place on the floor. Be

careful not to bend or kink control cables.

3. Place lower handle in position over weld pins

in handle mount brackets on deck. Make cer

tain the instruction label on the lower handle

can be read from the operating position.

Secure by placing two hairpin cotters (A) in in-

------

ner hole on weld pins. See figure 2.

NOTE

It may be "necessary to bend the

ends of the lower handle outward

slightly to obtain a snug fit against

the bracket.

NOTE

FIGURE 2.

There are two (2) holes in the handle

mount brackets. Place hairpin cot

ter in the inner hole for operation.

The outer hole is for storage.

Page 5

Curved

Carri

Bolt

FIGURE 3.

Lock Washer (C)

X Nut <D)

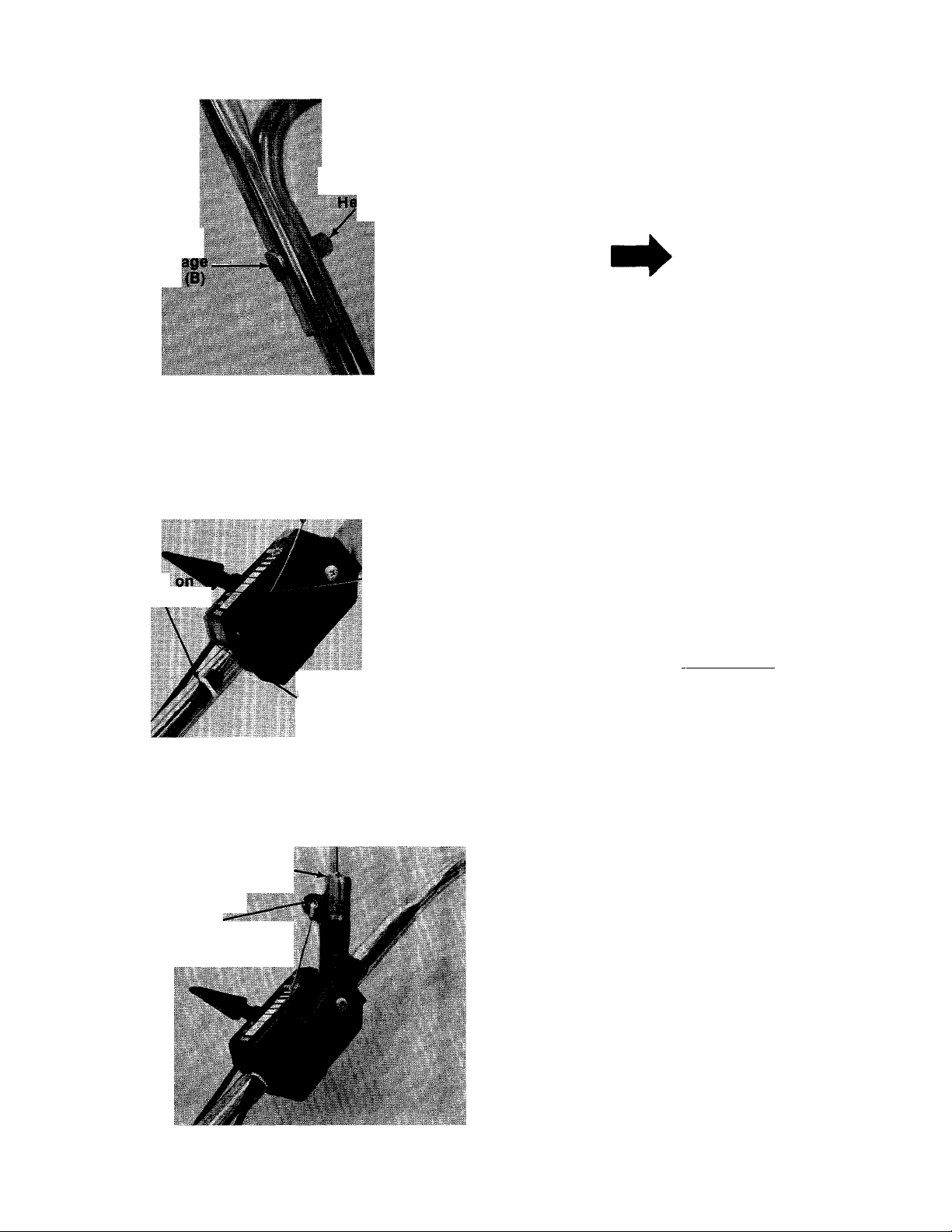

4. Place upper handle in position over lower han

dle. Control housing should be on the right

side of the handie. Secure upper handle with

two curved carriage bolts (B), lock washers (C)

■and hex nuts (D). See figure 3.

NOTE

Reference to ieft or right side of

machine is determined from oper

ator’s position at the handle facing

forward.

"Z" End of Blade

Brake/Clutch Cable.

Flange

Plastic Fitting

FIGURE 4.

Blade Control

Handle

“Z” End of

Blade Brake/Clutch

Cable

Upper Hole

on Bottom

of Housing

/

.Slot

5. Route the blade brake/clutch cable under the

lower handle. Place end of cable into the up

per hole on the bottom of the control housing,

and through the slot on the side of the hous

ing as shown. The angie of the flange on the

plastic fitting must be positioned downward

— as shown in figure 4. Be careful not to bend or

kink the cable.

\ WARNING \

The cable must be assembled as

shown for proper blade brake/

clutch operation.

6. Snap the plastic fitting on the end of the cable

into the control housing.

7. Hook the “Z” end of the blade brake/clutch

cable into the hoie in the blade brake/clutch

— control handle. See figure 5. If additional

slack is needed in order to hook the cable into

the handle, proceed as follows.

FIGURE 5.

Page 6

FIGURE 6.

FIGURE 7.

a. Hook the “Z” end of the cable into notch

provided in the biade controi handle. See

—figures.

b. Push release lever (see figure 12), then

squeeze blade control handle against up

per handle.

c. Release the blade control handle, unhook

the cable from the notch and hook it into

the hole in the blade control handle.

8. Remove the engine shroud if the unit is so

equipped. Replace it after attaching the throt

tle control cable.

9. Place the throttle control lever on the handle

in “Fast” position.

10.--Push the throttle control lever on the engine

to the full open position (as far toward the out

side of the unit as it will go) as shown in figure

------

7.

11. Hook the “Z” end of the throttle control cable

into the hole in the control lever on the

engine.

12. Remove the screw on the cable clamp shown

in figure 7. Slip the control casing under the

clamp. With the throttle lever on the engine

still in the full open position, replace and

tighten the screw to secure the throttle con

trol cable.

FIGURE 8.

13. Secure throttle control cable and blade

brake/clutch cable to upper and lower handles

-----

with cable ties (E) provided. See figure 8.

Page 7

Washer (

Shoulder

Bolt (F)

FIGURE 9.

Belleville

Belleville

Washer

n Use These Holes “ For Front Wheel

Hex Nut (I)

(G) s

Front Wheel

14. Units without height adjustment brackets—If the wheels on your mower are not already assembled, proceed as follows. The front wheels must be assembled in one of the three holes nearest the front of the deck. See figure

9. The rear wheels must be assembled in one

of the three holes nearest the rear of the deck.

The three holes provide three cutting heights

for your mower. Use the same hole location

for all four wheels when assembling. If wheels

are to be assembled in the lowest cutting

position (highest hole in the deck), refer to the

note below.

------

To assemble the wheels (see figure 9):

A. Place shoulder bolt (F) through wheel.

B. Place one belleville washer 7/8" O.D. (G) on

shoulder bolt, with the cupped side of

washer toward the deck (away from wheel).

C. Secure wheel to deck with one belleville

washer 1-1/8" O.D. (H) on the inside of the

deck (cupped side against the deck) and

hex nut (I).

NOTE

If the lowest cutting position (high

est hole in the deck) is used, it is

necessary to place the 1-1/8" washer

on the outside of the deck and the

7/8" washer on the inside.

15. Check all nuts and bolts for correct tightness.

A

Please note that the chute deflector

on your mower is in an upright posi

tion. It is held in that position by a

shipping block. This block is used

for shipping purposes only. It must

be removed and discarded before

your mower is put into operation.

■See figure 10.

CAUTION

Page 8

CONTROLS

THROTTLE CONTROL

The throttle is located on the right side of handle.

It controls engine speed. See figure 11.

Throttle

Control

OPERATION

Caution

Do Not Operate Mower Unless This

Guard Or Entire Grasscatcher Is In

Its Proper Place.

FIGURE 11.

BLADE BRAKE/CLUTCH CONTROL

WARNING

THIS CONTROL MECHANISM IS A

SAFETY DEVICE. NEVER ATTEMPT

TO BYPASS ITS OPERATIONS

The blade brake/clutch control is located on the

upper handle of the mower. The clutch handle

engages and disengages the blade.

To engage the blade, pull the side release lever

away from the unit. See figure 12. Pull the clutch

control handle against the upper handle. Release

side lever.

Release the clutch control handle to stop the

blade from turning.

-W -4.

.

...M_

.......

FIGURE 12.

.

Blade

Brake/Clutch

Control

Handle

FIGURE 13.

Keep hands and feet away from the chute area on

cutting deck. Seejigure 13.

NOTE

For shipping purposes your mower

is set with the wheels in a low cut

ting height position. For best re

sults raise the cutting position un

til it is determined which height is

best for your lawn. See cutting

height adjustment.

BEFORE STARTING

1. Fill sump with oil, as instructed in the

separate engine manual packed with your

unit.

2. Fill fuel tank, using clean, fresh, lead-free,

low-lead or regular grade leaded gasoline. Fill

tank completely!

DO NOT MIX OIL WITH GASOLINE.

3. Attach spark plug wire to spark plug.

START ENGINE

1. Move throttle control lever to “START” posi

tion.

2. With the blade brake/clutch control released,

crank engine by pulling recoil starter with a

quick firm pull. Do not pull out so far that rope

stops with a jerk as this will cause rope

failure. Do not allow rope and handle to snap

back into place.

3. After two or three full firm pulls on recoil, or

as soon as engine starts, move throttle con

trol to desired engine speed.

Page 9

TO STOP ENGINE

1. Move throttle control lever to “STOP” posi

tion.

2. Disconnect spark plug wire from spark plug

and ground against the engine to prevent ac

cidental starting while equipment is unat

tended.

TO ENGAGE THE BLADE

1. Start engine as instructed above. Allow the

engine to warm up for one minute before at

tempting to engage the blade.

2. To engage the blade, pull the side release

lever away from the unit. Pull the blade

brake/clutch control handle down against the

upper handle. Release the side lever. See

figure 12.

NOTE

IMPORTANT

If you strike a foreign object, stop

the engine. Remove wire from spark

plug, thoroughly inspect the mower

for any damage, and repair the

damage before restarting and

operating the mower.

Striking a solid object can cause

damage to the blade brake/clutch or

to the engine crankshaft. Extensive

vibration of the mower during opera

tion is an indication of damage. The

unit should be promptly inspected

and repaired.

ADJUSTMENTS

If a warm engine falters or stalls

when attempting to engage the

blade, refer to Carburetor Adjust

ment Section of this owner’s

manual.

3. Release the blade brake/clutch control handle

to stop the blade from turning.

USING YOUR ROTARY MOWER

Be sure that lawn is clear of stones, sticks, wire,

or other objects which could damage lawn mower

or engine. Such objects could be accidently

thrown by the mower in any direction and cause

serious personal injury to the operator and others.

Operate a new engine at intermediate speeds and

light load for the first few hours as you would a

new automotive engine.

For best results, do not cut wet grass because it

tends to stick to the underside of the mower,

preventing proper discharge of grass clippings,

and could cause you to slip and fall. New grass,

thick grass or wet grass may require a narrower

cut. Blade speed should be adjusted to the condi

tion of the lawn.

The best mowing pattern is one that allows the

clippings to discharge towards the uncut part of

the lawn. This permits recutting of the clippings

to further pulverize them. When cutting high

weeds, discharge towards cut portion, then recut

at right angles to first direction.

A

Do not at any time make any adjust

ment to lawn mower without first

stopping engine and disconnecting

spark plug wire.

CUTTING HEIGHT ADJUSTMENT

Units Without Height Adjustment Brackets

An adjusting plate and thumb lever at each wheel

position provides cutting height adjustment. Each

adjusting plate has nine height positions. Height

of cut will be changed when the thumb lever is

moved from one position to another. Simply

depress thumb lever towards wheel and move

wheel and lever assembly to desired position. All

wheels must be placed in the same relative posi

tion, See figure 14.

CAUTION

For best results, cut off one-third or less of the

total length of the grass. Lawn should be cut in

the fall as long as there is growth.

This mower is designed to be operated at full

throttle to give you the best cut and do the most

effective job of bagging the cut grass.

FIGURE 14.

Page 10

Units Without Height Adjustment Brackets

Adjustment may be made by removing and moving

axie boits to desired position. Cutting heigt ts wili

be raised as axie boits are moved to a iowur hoie

and iowered as axie bolts are moved to a higher

hole in the deck. All axle bolts must be mounted in

the same relative position. The front wheels must

be assembled in one of the three holes nearest

the front of the deck. The rear wheels mjst be

assembled in one of the three holes neare st the

rear of the deck. Belleville washers must be

assembled on the inside and outside of th(S deck

so that the cupped side of the washers are £ gainst

the deck. Refer to assembly instructions o i page

7.

Needle Valve

FIGURE 15.

LUBRICATION

THROTTLE

If adjustment becomes necessary, the tirottle

control wire assembly can be reset as follows:

1. Loosen, but do not remove, screw securing

throttle control wire assembly at engine.

Refer to figure 7.

2. Move throttle control lever on handle to

“FAST” position.

3. Move control lever on engine to full open posi

tion. Retighten screw to secure thrott e con

trol wire assembly.

CARBURETOR ADJUSTMENTS

t. warning \

(D

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage ail

clutches and blades. Keep clear of

all moving parts. Be careful of

heated surfaces and muffler.

Minor carburetor adjustment may be reqLired to

compensate for differences in fuel, tempfirature,

altitude and load. Refer to the separate engine

manual packed with your mower.

IMPORTANT

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of

work on lawn mower.

Blade Brake/Clutch—Lubricate the pivot points

on the blade brake/clutch handle and the cable at

least once a season with light oil. The control

must operate freely in both directions.

Chute Deflector—The torsion spring and pivot

point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must

work freely.

Wheels—Mower may be provided with ball bear

ing wheels. Lubricate at least once a season with

light oil. Also, if the wheels are removed for any

reason, lubricate the surface of the axle bolt and

the inner surface of the wheel with light oil. A 4 oz.

plastic bottle of light oil lubricant is available.

Order part number 737-0170. Engine oil may also

be used.

Engine—Follow engine manual for lubrication in

structions.

Throttle—Periodically lubricate throttle control

lever and throttle wire assembly with a few drops

of light oil for ease of operation.

MAINTENANCE

NOTE

If a warm engine falters or stalls

when attempting to engage the

blade, the carburetor mixture should,

be adjusted 1/8 turn richer (counter

clockwise). See figure 15.

The carburetor should be adjusted with the air

cleaner in place and the blade control handle in

the blade disengaged position.

10

WARNING

I

Be sure to disconnect and ground

the spark plug wire before perform

ing any repairs or maintenance.

CAUTION

A

When tipping the unit, empty the

fuel tank and keep engine spark plug

side up.

Page 11

CUTTING BLADE

To remove the cutting blade for sharpening or

replacement, remove the two hex nuts and lock

washers which hold the blade to the blade

brake/clutch. See figure 16.

FIGURE 16.

When sharpening the blade, follow the original

angle of grind as a guide. It is extremely important

that each cutting edge receives an equal amount

of grinding to prevent an unbalanced blade. An un

balanced blade will cause excessive vibration

when rotating at high speeds, may cause damage

to the mower and could break, causing personal

injury.

The blade can be tested for balance by balancing

it on a round shaft screwdriver. Remove metal

from the heavy side until it balances evenly.

When replacing the blade, be sure to install the

blade with the side of the blade marked “Bottom”

(or with part number) facing the ground when the

mower is in the operating position.

Blade Mounting Torque

Make certain that the center bolt which secures

the blade brake/clutch and the two hex nuts which

secure the blade are tightened to between 350

inch pounds (minimum) and 600 inch pounds

(maximum).

To insure safe operation of your unit, all nuts and

bolts must be checked periodically for correct

tightness.

DECK

The underside of mower deck should be cleaned

after each period of use as grass clippings, leaves,

dirt and other matter will accumulate. This ac

cumulation of grass clippings, etc., is undesirable

as it will invite rust and corrosion and may cause

an uneven discharge of grass clippings at the next

cutting.

The deck may be cleaned by tilting the mower for

ward or on its side and scraping clean with a

suitable tool or by washing with a stream of water

from a garden hose.

CAUTION

A

Do not direct the stream of water at

a hot engine as damage to the

engine may result.

ENGINE OIL

Check oil level before starting and after every 5

hours of operation. ADD oil as necessary to keep

level to full mark on dipstick. Before removing

dipstick, clean area around dipstick to prevent dirt

from entering oil fill tube. Engine should be in a

level position when checking oil.

Change oil after first 5 hours of operation.

Thereafter change every 25 hours. Change oil

while engine is warm. Oil may be drained thru oil

fill opening by tipping the unit on its side. Oil

capacity I-V4 pints.

AIR CLEANER

Service air cleaner every 25 hours under normal

conditions. Clean every few hours under extreme

ly du^ty conditions. Poor engine performance and

flooding usually indicates that the air cleaner

should be serviced.

To service air cleaner, refer to the separate engine

manual packed with your mower.

SPARK PLUG

The spark plug should be cleaned and the gap

reset once a season. Spark plug replacement is

recommended at the start of each mowing

season: check engine manual for correct plug

type and gap specifications.

BLADE BRAKE/CLUTCH

This unit is equipped with a blade brake/clutch. If

for some reason the blade brake/clutch becomes

inoperative, it is suggested that all repair work on

the blade brake/clutch be performed by an

authorized service dealer. The unit should be in

spected by an authorized service deaier if any of

the following conditions are noticed.

1. Frayed clutch control cable.

2. Leaking oil seal (oil collection on the floorduring mower storage).

3. Extensive vibration of the unit.

Blade Brake/Clutch Removal

1. Disconnect the spark plug wire and ground it

against the engine block.

2. Empty fuel tank and drain oil from crankcase.

3. Remove the cable ties which secure control

cables to the handle.

4. Disconnect the “Z” fitting on the blade

brake/clutch cable from the clutch control

handle.

11

Page 12

5. Remove one truss machine screw on the in

side of the control housing as shown ir figure

17.

6. Loosen the truss machine screw on the out

side of the control housing until tf e two

halves of control housing can be separated

enough for the control cable to be freer. Slide

the blade brake/clutch cable out of the control

housing.

7. Retighten the truss machine screws on the

control housing.

.^.

w

Tru! S ■ *'

Machine

Screw

Control Cable

10. Remove the center bolt as follows.

a. Insert a screwdriver into the slot provided

in the blade brake/clutch housing where

the control cable enters housing. See

figure 19.

b. Place a 9/16" wrench on the center bolt.

Turn the wrench slowly until the screw

driver catches in a groove provided inside

the clutch. The screwdriver will now keep

the clutch from turning, and the center bolt

and two belleville washers may be re

moved.

IMPORTANT

Upon reassembly, be certain to

tighten center bolt to between 350

and 600 in. lbs.

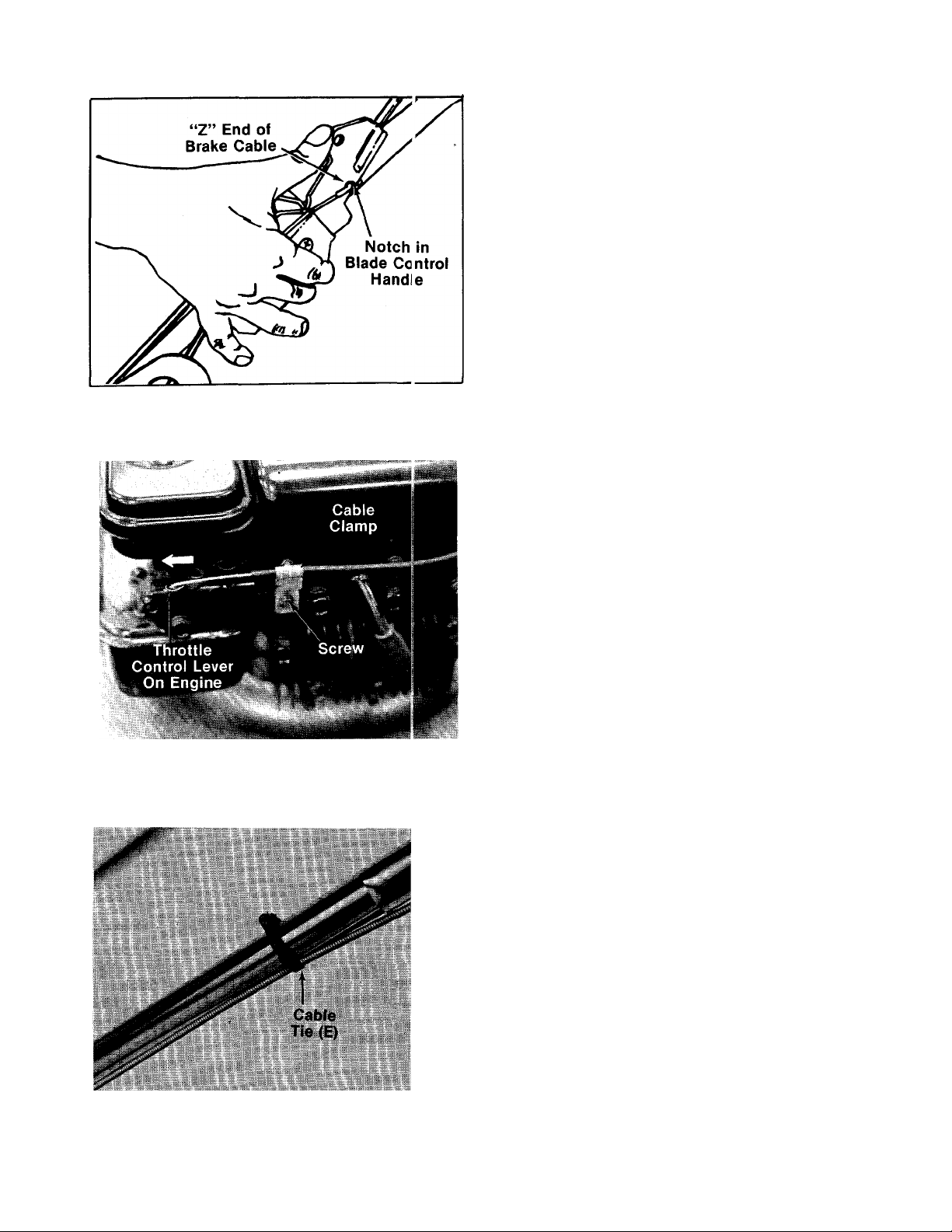

FIGURE 17

Disconnect the throttle control cable from the

8.

engine by loosening screw on engine and

disconnecting the “Z” fitting. See figure 18.

FIGURE 18.

9. Tip the mower on its side. Remove tie blade

by removing two hex nuts and lock washers.

Refer to figure 16.

FIGURE 19.

11. Support the engine with one hand. Remove

the three self-tapping screws which secure

the deck and blade brake/clutch to the engine.

A Vz" socket wrench is required. See figure

20.

NOTE

When reassembling, tighten he>:

nuts to between 350 and 600 in. Ibu.

FIGURE 20.

12

Page 13

12. Slide the blade brake/clutch cable through the

hole in the deck as you lift off the engine and

blade brake/clutch. Be careful not to kink con

trol cable.

13. Remove blade brake/clutch from engine

crankshaft.

Blade Brake/Clutch Installation

1. Place the new blade brake/clutch on engine

crankshaft. Line up holes on blade

brake/clutch with mounting holes on engine.

2. Place the two belleville washers onto

crankshaft. Cupped side of washers must be

against the blade brake/clutch. Secure with

hex bolt finger tight only.

3. Place cable through engine mounting hole on

deck.

4. Reverse steps 1 through 12 of preceding sec

tion for reassembly.

OFF-SEASON STORAGE

The following steps should be taken to prepare

lawn mower for storage.

1. Clean and lubricate mower thoroughly as

described in the lubrication instructions.

2. Refer to engine manual for correct engine

storage instructions.

3. Coat mower’s cutting blade with chassis

grease to prevent rusting.

4. Store mower in a dry, clean area.

CAUTION

A

When storing any type of power

equipment in an unventiiated or

metal storage shed, care should be

taken to rust proof the equipment.

Using a light oil or silicone, coat the

equipment, especially the bearings

and cables.

HANDLE STORAGE

The handle can be stored in an upright position to

take less space. Move hairpin cotters to outer hole

on weld pins (see figure 2). Grasp the lower handle

at the bottom and push inward slightly. Tip the

handle forward. It will lock in this position.

Reverse this procedure to place the handle in the

operating position.

A

Be careful not to kink or pinch blade

brake/clutch cable when storing the

handle.

CAUTION

13

Page 14

NOTE

The use of an^ accessory on this Rotary Mower

other than those manufactured by the mower

manufacturer is not recommended.

GRASS CATCHER Model 003 is available as optional equipment for the

mower shown in this manual.

WARNING

J

(D

1. DO NOT operate the rr ower without the entire grass catcher or chute

deflector in place.

2. DO NOT operate the mower without the protective shield on the rear

of the deck in place.

I

Under normal usage bag material is subject to wear and should be

checked periodically. Be sure any replacement bag complies with the

mower manufacturer’s recommendations.

For replacement bags, use only factory authorized replacement bag No.

764-0176.

NOTE

14

Page 15

Trouble Shooting Chart

Problem

1 Engine fails to start

2 Hard starting or A Spark plug wire loose

loss of power plug wire.

Cause

A Check fuel tank for gas

B Spark plug lead wire discon

nected

C Throttle control lever not in

the starting position

D Faulty spark plug

E Carburetor improperly ad-

Justed, engine flooded

F Old stale gasoline

B Carburetor improperly

adjusted engine manual.

C Dirty air cleaner

Remedy

A Fill tank if empty.

B Connect lead wire.

C Move throttle lever to start

position.

D Spark should jump gap be

tween control electrode and

side electrode. If spark does

not jump, replace the spark

plug.

E Remove spark plug, dry the

plug, crank engine with plug

removed, and throttle in off po

sition. Replace spark plug and

lead wire and resume starting

procedures.

F Drain and refill with fresh

gasoline.

A Connect and tighten spark

B Adjust carburetor. See separate

C Clean air cleaner as described

in separate engine manual.

3 Operation erratic

4 Occasional skip

(hesitates) at high

speed

5 Idles poorly A Spark plug fouled, faulty, or

6 Engine overheats A Carburetor not adjusted

A Dirt in gas tank

B Dirty air cleaner

C Water in fuel supply

D Vent in gas cap plugged

E Carburetor improperly

adjusted

A Carburetor idle speed too

slow

B Spark plug gap too close

C Carburetor idle mixture ad-

justment improperly set

gap too wide

B Carburetor improperly

adjusted

C Dirty air cleaner

properly

B Air flow restricted

C Engine oil level low

A Remove the dirt and fill tank

with fresh gas.

B Clean air cleaner as described

in separate engine manual.

C Drain contaminated fuel and

fill tank with fresh gas.

D Clear vent or replace gas cap.

E Adjust carburetor. See

separate engine manual.

A Adjust carburetor. See

separate engine manual.

B Adjust to .030".

C Adjust carburetor. See

separate engine manual.

A Reset gap to .030" or replace

spark plug.

B Adjust carburetor. See

separate engine manual.

C Clean air cleaner as described

in separate engine manual.

A Adjust carburetor. See

separate engine manual.

B Remove blower housing and

clean as described in separate

engine manual.

C Fill crankcase with the proper

oil.

7 Excessive vibration

Note: For repairs beyond the minor adjustments iisted above contact your iocal authorized service deaier.

A Cutting blade loose or

unbalanced

B Bent blade

15

A Tighten blade. Balance blade.

B Replace blade.

Page 16

Models 073, 074, 083 and 084

Meets CPSC Blade Safety Requirements

61 ◄Hub Caps (Optional)

45

Color

Red

Orange

Black

Gray

Part No.

731-0124

731-0254

731-0354

731-0355

Page 17

PARTS LIST FOR MODELS 073, 074, 083

AND 084 ROTARY MOWERS

REF.

NO.

2

3

5

6 742-0220

7 746-0473

8

9

10

11

12

PART

718-0145

◄ Hub Cap

4

NO.

* *

* *

COLOR

CODE

DESCRIPTION

Grip 41 720-0190

Wheel Ass’y. Comp. 43

Bearing

20" Blade (073 & 074) 44

742-0222 22" Blade (083 & 084) 45

Throttle Control Wire—39"

749-0373 Lower Handle (Chrome)

749-0372

—

Lower Handle (Painted) 47

Engine 48 732-0396

751-0369 Casing Clamp

710-0227

12935

Hex AB-Tap Scr. #8 x .38" Lg. 49 741-0124 Ball Brg. .669" I.D. x 1.574"

Handle Mount Brkt. Ass’y.—

NEW

REF.

PART

NO.

42

46 717-0482

N

NO.

COLOR

CODE

DESCRIPTION

PART

Spring Lever Knob

732-0401

710-0818

711-0719

Lock Out Spring

Hex Cent. L- Bolt 3/8-24

X 2.00" Lg.

Lock Pin .75" Dia. x 1.80

712-0328 Special Hex Nut 5/16-24 Thd.

Blade Brake Clutch Ass’y.

Comp.

14300

Clutch Blade Housing Ass’y.

Comp. Spring .35" O.D. x

2.00" Lg.

O.D.

L.H. 50 14304 Clutching Cone

12936

Handle Mount Brkt. Ass’y.—

R.H. (Not Shown)

13

710-0603

Hex Wash. Hd. B-Tap Scr. 53

5/16-18 X .50" Lg.

14

15

14846

710-0776

Retaining Strip

Hex Wash. Hd. AB-Tap Scr. 55

1/4" X .62" Lg. 56 732-0397

17 731-0575

14578

18

14579

Rear Flap Ass’y.

Height Adj. Ass’y.—R.H.t

Height Adj. Ass’y.—L.H.f

(Not Shown)

19 15261

20 15262

21 14832

738-0507

22

712-0798 Hex Nut 3/8-16 Thd.*

23

736-0331 Bell-Wash. .39" I.D. x 1.13" 63

24

Height Adj. Platef

Pivot Barf

Spring Lever w/Knobt

Shld. Bolt .500" Dia. x .375f 61

O.D. (073 & 083)

736-0356

Bell-Wash. .39" I.D. x 1.4"

O.D. (074 & 084)

14944 Chute Deflector Ass’y. Comp.

25

26 11130

Deflector Hinge Plate 738-0102

51 14305 Brake Cup Cone

52

14306 Clutch Housing

710-0875

Hex Wash. TT-Tap Cl.-Scr.

1/4-20 X .75" Lg.

N

54

719-0256

Fan Adapter

731-0520 Ball Block

Extension Spring .35" O.D. x

1.75" Lg.

57

736-0333 FI-Wash. .690" I.D. x 1.060"

O.D.

58 741-0326

746-0402 Clutch Cable—42"

59

60

736-0105 Bell-Wash. .400" I.D. x .88"

Steel Ball .500" Dia.

O.D.

736-0169 L-Wash. 3/8" I.D.*

62

726-0219 Snap On Scr. #8 x .38 Tap

64

731-0656

736-0105

Engine Shroudf

Bell-Wash. .400" I.D. x .88"

O.D.

65 738-0213

Axle Bolt (Used w/o Height

Adj.)

Axle Bolt (Used w/Height

27 711-0555 Pivot Pin Adj.)

726-0106 Cap Speed Nut Va" Rod 66 710-0796 Truss Mach. Hi-B Tap Scr.

28

29 732-0253

30 710-0289 Hex Bolt 1/4-20 X .50" Lg.*

712-0287 Hex Nut 1/4-20 Thd.* 68 731-0523

31

32 736-0329 L-Wash. 1/4" I.D.*

33 14995 20" Deck Ass’y.

14998

710-0654

34

714-0104

35

726-0192 Cable Tie

36

710-0671

37

753-0361

38

7-12-0267

39

736-0119

W

Torsion Spring #12 X 1.50" Lg.

67

726-0135 Cap Speed Nut 5/16" Rod

Control Panel Half

22" Deck Ass’y.

Hex Wash. Hd. TT-Tap Scr.

3/8-16 X 1.00" Lg.

Intern. Cot. Pin 5/16" Dia.

Curved Carriage Bolt 5/16-18

X 1.38" Lg.

Kit—Control Housing Comp.

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16" I.D.*

69 731-0524

70 731-0526

71

731-0528 Throttle Control Lever

72

749-0536 Upper Handle (Chrome)

749-0538

73

731-0610

74

14320

75

777-3456

76

777-3453

—

8073-000-4

—

8074-000-4

Control Disc Pin

Clutch Panel Half

Upper Handle (Painted)

Control Handle Ass’y.

Control Handle Ass’y.f

Control Label—Throttle

Instruction Label —Handle

Hardware Pack (073)

Hardware Pack (074, 083 &

084)

NEW

PART

N

fOptional Parts

Plastic Rim

Size

7 X 1.5

8 X 1.75

734-0841

734-0840

734-1161

734-1162

Size

7 X 1.5

8 X 1.75

7YT:5

8 X 1.75

**WHEEL CHART

Tread Type

Twinline

734-0639

734-0643

734-0876

734-0661

Waffle

734-0637

734-0645

734-0893

734-0812

17

Steel Rim

Bearinas

Ball Brgs. 3/8" I.D.-741-0267, V2" I.D.-741-0484,

Spacer-750-0434 (Use Axle Bolt 710-0347)

V2" I.D. Plastic Brg.-741-0262

(2 per Wheel)

Page 18

NOTE

This instruction manuai covers various modeis

and ail specifications shown do not neces

sarily apply to your model. Specifications sub

ject to change without notice or obiigation.

*For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

NOTE; The engine is not under warranty by

the mower manufacturer.. .If repairs or

service is needed on the engine, please

contact your nearest authorized engine service outlet. Find It Fast

Check the “Yellow Pages” of In The

your telephone book under Yellow Pages

“Engines—Gasoline.”

(462—Red Flake)

When ordering parts, if color or finish is important use the ap

propriate color code shown above, (e.g. Red Flake

Finish—10292 (462).)

-----------------------------

-

18

Page 19

PARIS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorizec service

firms listed below. All orders should specify the model n jmber of

your unit, part numbers, description of parts and the quantity of

each part required.

NOTE: If any parts are found to be missing or defective upon assembly of this unit, write to advise the factory so

that immediate replacement can be nr ade.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co. ... 2625 4th Ave. S..........................

ARKANSAS NORTH LITTLE ROCK

Sutton’s Lawn Mower Shop................... 5301 Roundtop Drivs

CALIFORNIA PORTERVILLE

Billious

COLORADO DENVER

FLORIDA JACKSONVILLE

GEORGIA EAST POINT

ILLINOIS LYONS

INDIANA ELKHART

IOWA DUBUQUE

NEW YORK CARTHAGE

...................................................

Spitzer Industrial Products Co. ... 6601 N.

Radco Distributors

Small Eng. Dist

East Point Cycle & Key

Keen Edge Co

Parts & Sales Inc........................................2101 Industrial Pkw /..

Power Lawn & Garden Equip

LOUISIANA MEW ORLEANS

Suhren Engine Co

MARYLAND TAKOMA PARK

Center Supply Co.................................... 6867 New Hampshi 'e

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

MICHIGAN LANSING

Lorenz Service Co................................... 2500 S. PennsyIvan ia .

Power Equipment Dist

MINNESOTA HOPKINS

Hance Distributing Inc............................. 420 Excelsior Ave. W.

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc

MISSOURI KANSAS CITY

Automotive Equip. Service

Ross-Frazier Supply Co...........................8th and Monterey ....

Henzier, Inc

NEW JERSEY BELLMAWR

Lawnmower Parts Inc

NEW MEXICO ALBUQUERQUE

Spitzer Eng. & Parts

Gamble Dist., Inc

Red Fox Parts Dist

..................................

......................................

.........................

.......................................

................

...................................

...............................

............................

....................

.....................

.............................................

............................

..............................

................................

................................

Box 368, Rt. 4

75 North D Street ....

Washington St

4909 Victor St.

Box 5459

OPA LOCKA

2351 N.W. 147th St. ..

2834 Church St..................

8615 Ogden Ave

2551 J.F. Kennedy ..

8330 Earhart Blvd. ..

Ave

..................................

300 Birnie Ave

MOUNT CLEMENS

340 Hubbard

506 Caillavet St................

3117 Holmes St

ST. JOSEPH

ST. LOUIS

2015 Lemay Ferry Fid.

717 Creek Rd....................

1023Third Ave. N.V\/. .

West End Ave..................

SCHOHARIE

Rt. 30 P.O. Box 527 ....

.................

..................

.........................

...............

................

...................

..............

35233

72117

93257

80229

32207

33054

30344

60534

46516

52001

,70118

20912

01107

48910

48043

55343

39533

64109

64503

63125

08030

87103

13619

12157

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS

AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service

should be handled by your nearest authorized engine service firm

Check the yellow pages of your telephone directory under tl

listing Engines—Gasoline, Briggs & Stratton or Tecumse.

Lauson.

NORTH CAROLINA GOLDSBORO

Smith Hardware Co

Dixie Sales Company

OHIO CARROLL

Stebe’s Mid-State Mower Supply . Box 366, 71 High St... .43112

Bleckrie, Inc........................................... 7900 Lorain Ave

National Central..................................... 687 Seville Rd

Burton Supply Co

OKLAHOMA MUSKOGEE

Victory Motors, Inc

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA HARRISBURG

EECOInc

Thompson Rubber Co

Bluemont Co.......................................11125 Frankstown Rd.. 15235

Frank Roberts & Sons

Scranton Auto Ignition Co

TENNESSEE KNOXVILLE

Master Repair Service .......................... 2000 Western Ave

American Sales & Service, Inc. ... 3035-43 Bellbrook .... 381

TEXAS DALLAS

Marr Brothers, Inc

Woodson Sales Corp

Bullard Supply Co.................................. 2409 Commerce St. ... 77003

Engine House Inc......................................8610 Botts Lane

................................................

...............................

............................

..................................

.................................

.................................

.................................

..........................

......

.......................................

.................................

GREENSBORO

CLEVELAND

WADSWORTH

YOUNGSTOWN

PHILADELPHIA

PITTSBURGH

PUNXSUTAWNEY

SCRANTON

1133-35 Wyoming Ave. 18509

MEMPHIS

FORT WORTH

HOUSTON

SAN ANTONIO

515 N. George St................27530

335 N. Green

1301 Logan Ave.

Box 929

605 S. Cherokee

8216 N. Denver Ave. . . .97217

4021 N.6thSt

5222-24 N. Fifth St

R.D.2

423 E. Jefferson

1702 N. Sylvania

P.O. 60x17867

.....................

.................

....................

............................

.....................

...................................

UTAH SALT LAKE CITY

A-1 Engine & Mower Co

........................

439 E. 900 So...................84111

VIRGINIA ASHLAND

RBI Corp................................................101 Cedar Ridge Dr. .. .23005

WASHINGTQN SEATTLE

Bailey’s Inc.............................................1414 14th Ave

....................

WISCONSIN APPLETON

Automotive Supply Co...........................123 S. Linwood Ave.

P.O. Box 798

...................

CHILTON

Horst Dist

...............................................

444 N. Madison

.................

...............

.......

.............

...........

...........

.................

27402

44102

44281

44501

74401

17110

19120

15767

37921

75203

76111

78217

98122

54911

53014

WARR/tNTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer

time of manufacture. It does not provide for the un

sibility of the customer. The manufacturer cannot.

the manufacturer’s fault, it’s the manufacturer’s res

from defects in workmanship and materials, defects which are NOT detected at the

imited and unrestricted replacement of parts. Use and maintenance are the responissume responsibility for conditions over which it has no control. Simply put, if it’s

ponsibility; if it’s the customer’s fault, it’s the customers’s responsibility.

CLAIMS AGAINST THE MANUFACTURER’S WARR \NTY

INCLUDES:

1. Replacement of Missing Parts on new equipme

2. Replacement of Defective Parts within the warr

3. Repair of Defects within the warranty period.

MTD PRODUCTS INC

It.

anty period.

P.O. BOX 36900

(0783)

All claims MUST be substantiated with the following

information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

CLEVELAND, OHIO 44136

Loading...

Loading...