Page 1

OWNEirS GUIDE

• ASSEMBLY • OPERATION • MAINTENANCE • PARTS •

20" and 22"

ROTARY

MOWERS

$1.00

Important:

Read Safety Rules

and Instructions Carefully

WARNING; This unit is equipped with an internal combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by

the operator.

In the State of California the above is required by law (Section 4442 of the California Public

Made ^

in

AMERICA

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 368022, Cleveland, Ohio 44136-9722.

Model Series

113<030A000 thru 113-032D000

113-040A000 thru 113-042D000

113-050A000 thru113-052D000

113-060A000 thru 113-062D000

IMPORTANT!

Record the Model No. and Mfg. Code which

appear on your unit in the space below. You

must have these numbers, along with the date

of purchase, in order to receive warranty or ser

vice.

MEETS ANSI SAFETY STANDARDS

MODEL NO. MFG. CODE

FORM NO. 770-8238H

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL

SAFETY AND/OR PROPERTY OF YOURSELF AND CTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE

▲

ATTEMPTING TO OPERATE YOUR LAWN MOWER. F\ILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL

INJURY. WHEN YOU SEE THIS SYMBOL— Д

Your lawn mower was built to be operated according to tbe rules lor safe operation in this manual. As

DANGER:

A

TRAINING

1. Read this owner’s guide carefully in its entirety befot 3 attempt

ing to assemble or operate this machine. Be compie teiy famiiiar with the controls and the proper use of this mact ine before

operating it. Keep this manual in a safe place for uture and

regular reference and for ordering replacement parts

2. Your rotary mower is a precision piece of power equipment,

not a plaything. Therefore, exercise extreme caution at all

times. Your unit has been designed to perform one job: to

mow grass. Do not use it for any other purpose.

3. Never allow children under 14 years old to operat3 a power

mower. Children 14 years old and over should only operate

mower under close parental supervision. Only peisons well

acquainted with these rules of safe operation should be

allowed to use your mower.

4. Keep the area of operation clear of all persons, particularly

small children and pets. Stop engine when they are in the

vicinity of your mower to help prevent blade contact or thrown

object injury. Although the area of operation shouti be com

pletely cleared of foreign objects, an object may nave been

overlooked and could be accidentally thrown by the mower in

any direction and cause serious personal injury to the operator

or any others allowed in the area.

PREPARATION

1. Thoroughly inspect the area where the equipmeit is to be

used. Remove all stones, sticks, wire, bones and other foreign

objects which could be picked up and thrown by thf mower in

any direction and cause serious personal injury to tfe operator

or any others allowed in the area. Plan your mowing pattern to

avoid discharge of material toward roads, s dewalks,

bystanders and the like.

2. Always wear safety glasses or eye shields during operation or

while performing an adjustment or repair, to protect eyes from

foreign objects that may be thrown from the mad ine in any

direction.

3. Wear sturdy, rough-soled work shoes and close-fit ;ing slacks

and shirts. Shirts and pants that cover the arms and legs and

steel-toed shoes are recommended. Do not wear l( ose fitting

ciothes or jeweiry. They can be caught in moving p irts. Never

operate a unit in bare feet, sandals, or sneakers.

4. Before working with gasoline, extinguish all cigaretes, cigars,

pipes and other sources of ignition. Check the fuel I jvel before

starting the engine. Gasoline is an extremely flammable fuel.

Do not fill the gasoline tank indoors, while the engine is run

ning, or until engine has been allowed to cool for ct least two

minutes after running. Replace gasoline cap securel/ and wipe

off any spilled gasoline before starting the engine as it may

cause a fire or expiosion.

5. Disengage the self-propelled mechanism or drive clutch on

units so equipped before starting the engine.

6. The blade control handle is a safety device. Never attempt to

bypass its operation. Doing so makes the safety de\ ice inoper

ative and may result in personal injury through contact with the

rotating blade. The blade control handle must operjte easily in

both directions and automatically return to the c isengaged

position when released.

7. Never attempt to make a wheel or cutting height idjustment

while the engine is running.

8. Never operate the mower in wet grass. Always be s jre of your

footing. A slip and fall can cause serious personal i ijury. Keep

a firm hold on the handle and walk, never run. Mow only in

daylight or in good artificial light.

with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. If you violate any o' these rules, you may cause serious injury to yourself or others.

SAFE OPERATION PRACTICES

НЕЕ ) ITS WARNING.

OPERATION

5.

7.

10.

11.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at frequent inter

2. Keep all nuts, bolts, and screws tight to be sure the equipment

3. Never store the mower with gasoline in the tank or gas con

4. To reduce fire hazard, keep the engine free of grass, leaves and

5. Check the grass catcher bag frequently for wear or deteriora

A

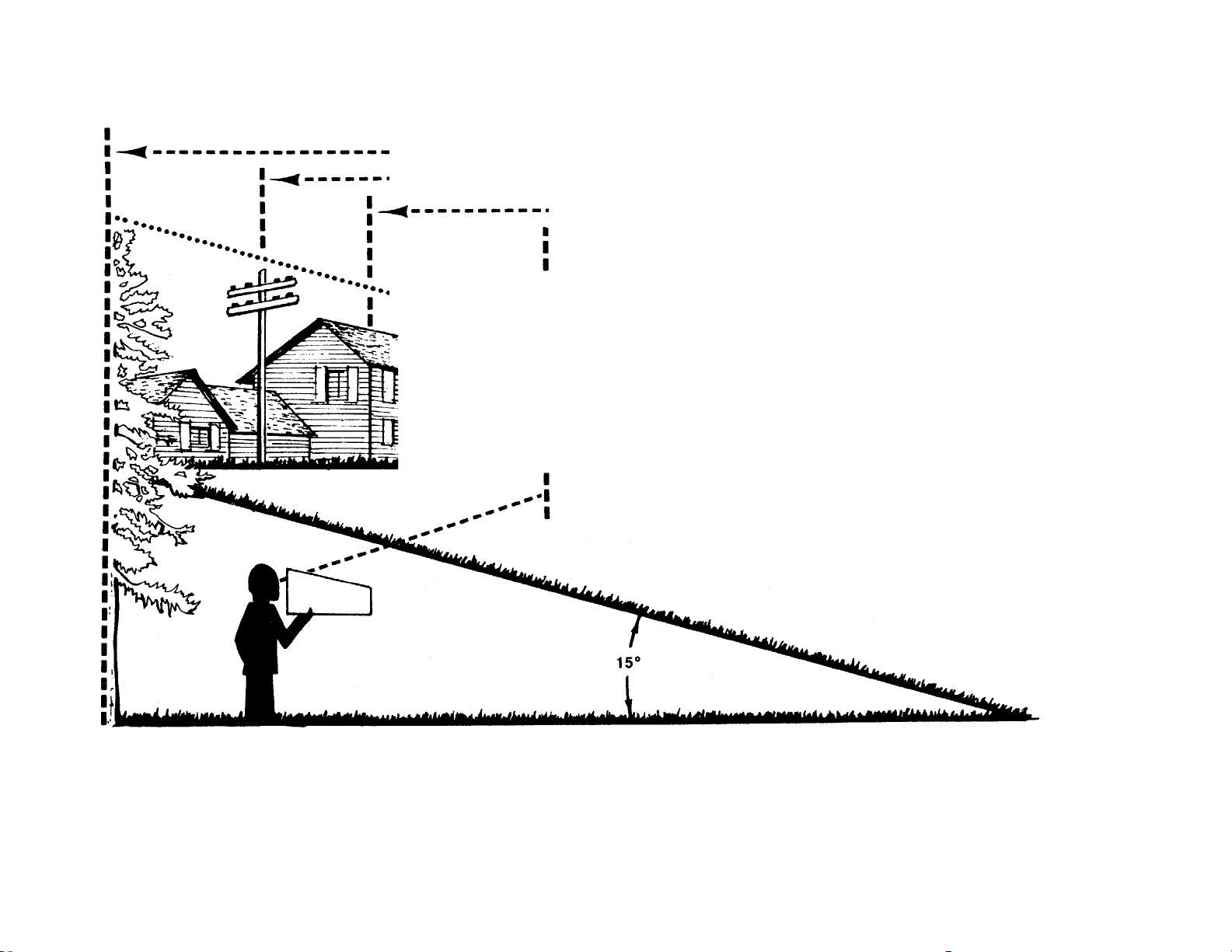

For your safety, use the slope gauge included as part of this

manual to measure slopes before operating this unit on a

sloped or hilly area. If the slope is greater than 15° as shown

on the slope gauge, do not operate this unit on that area or

serious injury couid result.

Do not change the engine governor settings or overspeed the

engine. Excessive engine speeds are dangerous.

Do not put hands or feet near or under rotating parts. Keep

clear of the discharge opening at ail times as the rotating biade

can cause injury.

Stop the blade when crossing gravel drives, walks or roads.

After striking a foreign object, stop the engine, remove the wire

from the spark plug, and thoroughly inspect the mower for any

damage. Repair the damage before restarting and operating the

mower.

If the equipment should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration is gen

erally a warning of troubie.

Shut the engine off and wait until the blade comes to a com

plete stop before removing the grass catcher or unclogging the

chute. The cutting blade continues to rotate for a few seconds

after the engine is shut off. Never place any part of the body in

the blade area until you are sure the blade has stopped rotat

ing.

Before cleaning, repairing or inspecting, make certain the blade

and all moving parts have stopped. Disconnect the spark plug

wire, and keep the wire away from the spark plug to prevent

accidental starting.

Do not run the engine indoors.

Never cut grass by pulling mower toward you. Mow across the

face of slopes, never up-and-down. Exercise extreme caution

when changing direction on slopes. Do not mow excessively

steep slopes. Always be sure of your footing. A slip and fall can

cause serious personal injury.

Never operate mower without proper guards, plates or other

safety protective devices in place.

Muffler and engine become hot and can cause a burn. Do not

touch.

vals for proper tightness. Also visually inspect blade for dam

age (e.g. bent, cracked). Replace with blade which meets origi

nal equipment specifications.

is in safe working condition.

tainers inside of a building where fumes may reach an open

flame or spark (e.g. gas hot water heater). Allow the engine to

cool before storing in any enclosure.

excessive oil.

tion. Replace a worn or damaged bag immediately. For safety

protection, replace only with new bag meeting original equip

ment specifications.

Page 3

------- i---------------------------------------------------------------------

cut Alor.j, ^is Line

--------------------------------------------------------------------^-------------

USE THIS SHEET AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

A POWER POLE

A CORNER OF A BUILDING

7s

OR A FENCE POST

(D

(D

T3

■o

0)

0)

□r

(D

(D

3

0)

(0

fi}

<D

0)

O

(D

C

c

o

—I

<0

(D

<D

3

o

<D

CO

"O

m

O

O

.................

I

u

WARNING

.......

.

SiQp

...i. . -

AC

Do not mow on inclines with a siope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet). A

riding mower couid overturn and cause serious injury, if operating a waik-behind mower on such a slope, it is

extremely difficult to maintain your footing and you couid siip, resulting in serious injury.

Operate RIDiNG mowers up and down slopes, never across the face of slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

Page 4

11

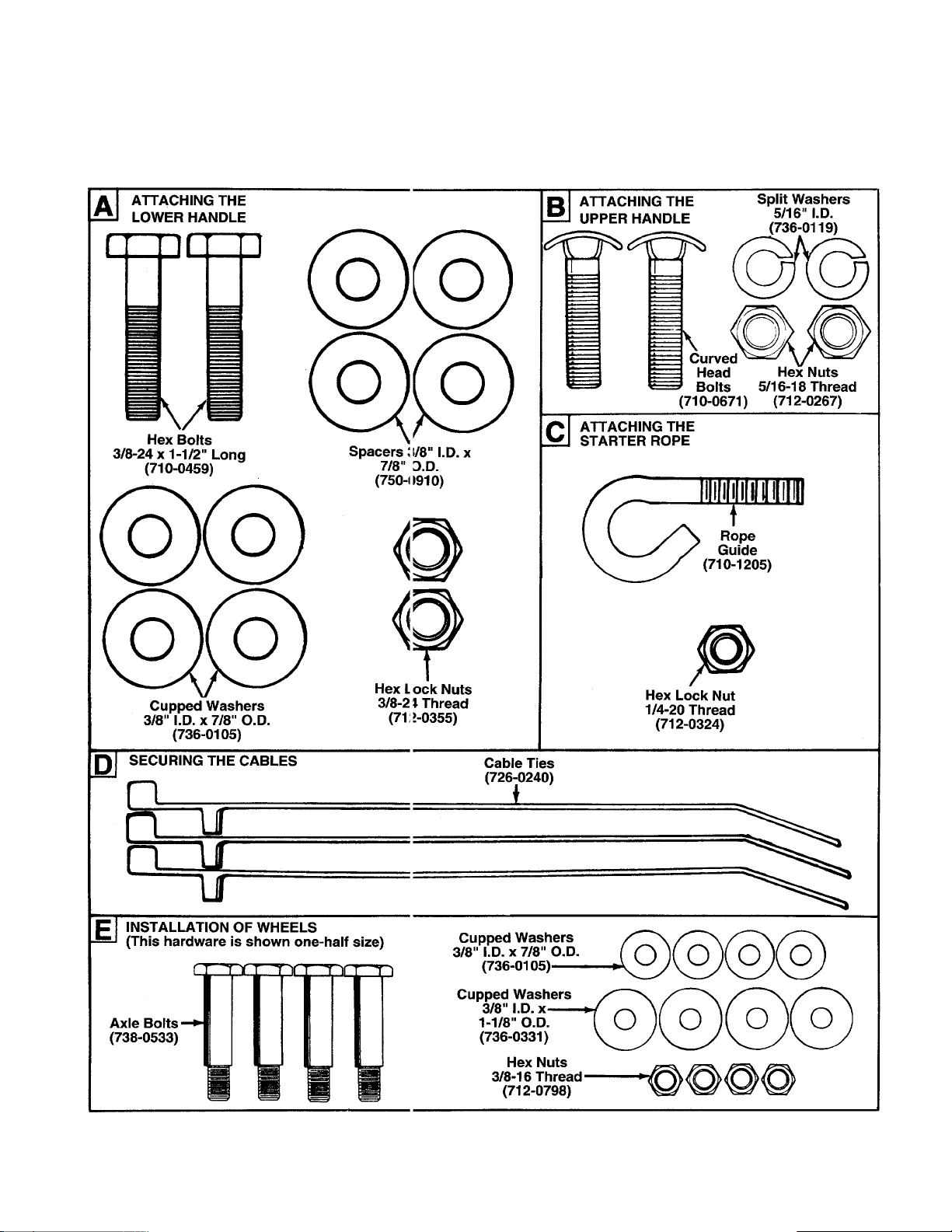

CONTENTS OF HARDWARE PACK

Remove this sheet from your owner’s manual and lay the hardware on the illustration for identification purposes. After assembiy, keep the Slope Gauge which is on the reverse s ide of this sheet for future use.

(Hardware pack may contain extra items which are not used on your unit. Part numbers are shown in parentheses.)

O

c

>

c'

0

INCHES

I I

I

I I I I I I I I I I I I I I I I I I I

I

Page 5

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT GASOLINE

or OIL. After assembly, service engine with gasoiine

and oii as instructed in the separate engine manuai

packed with your unit.

NOTE: Reference to right or left hand side of the mower is

obsen/ed from the operating position.

Toois Required for Assembiy

(1) 1/2" Wrench

(2) 9/16" Wrenches

(1) Phillips Screwdriver

(1) Adjustable Wrench

(Two 6" Adjustable Wrenches may be used instead of the

above.)

Lower

Handle

Use

This

Hole

Rear Baffle

(Models 040 thru

Crowned 1

Side \

(Cupped

i Side

Onhi);.;.

Axle Bolt

Hex Nut

Cupped This',

Washer Hole

FIGURE 1.—Models 040 thru 042 Shown

Use

Hex Nut

Cupped

Washer

Spacer

UNPACKING

1. Remove the lawn mower from the carton by opening

the top flaps and lifting the unit out. Be careful of the

staples. Make certain all parts and literature have been

removed from the carton before the carton is discarded.

2. Disconnect and ground the spark plug wire against the

engine.

3. Stretch out the control cables behind the mower and

place on the floor. Be careful not to bend or kink the

cables at any time during assembly.

4. Remove page four from this manual and lay the contents

of the hardware pack on the illustration for identification.

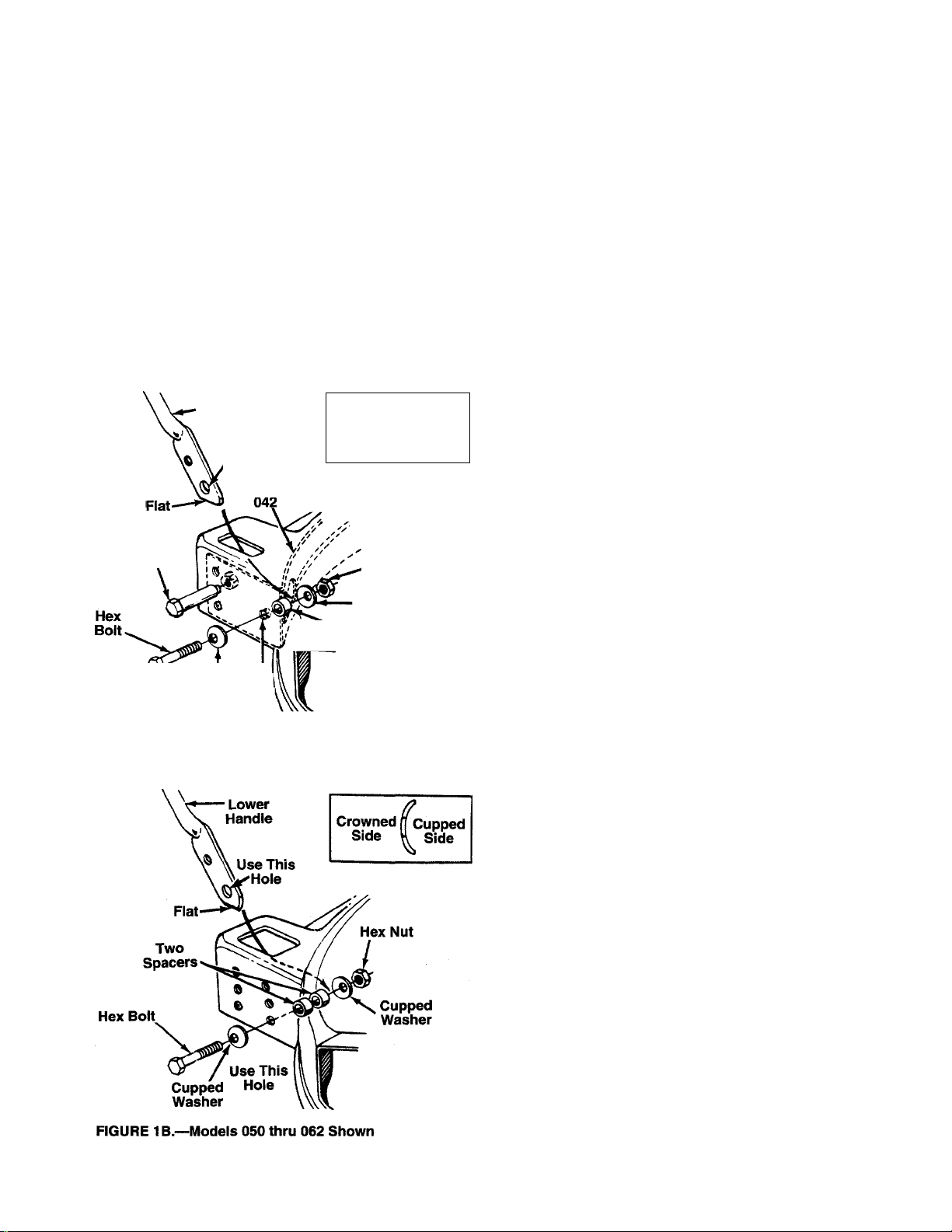

NOTE: ALL MODELS—The handle on your mower can be

adjusted to two different height settings. To raise the height

of the handle attach the lower handle so that the flat part of

the handle is facing downward, as shown in figure 1 and 1B.

To lower the height of the handle rotate handle so that the

flat part of the handle faces upward.

ATTACHING THE LOWER HANDLE (Hardware A)

Models 030 thru 042 only:

1. Raise the rear of the deck and block securely.

2. Models 040 through 042 only: Place the rear baffle in

position inside the rear of the deck. Use one axle bolt

and hex nut on each side of the rear of the deck to

secure baffle temporarily so you can attach the lower

--------

handle. See figure 1.

NOTE: Remove axle bolt and nut when assembling the

wheels, page 7.

3. Insert the ends of the lower handle through the slots in

the rear of the deck.

4. Place one cupped washer on hex bolt (crowned side of

washer goes against the head of the hex boit).

5. Place one spacer between forward hole in baffie (or

deck on Modeis 030 through 032) and bottom hole in

lower handle.

NOTE: Use a screwdriver to pry the handle away from the

baffle slightly in order to insert the spacer. The screwdriver

can also be used to align the holes in the next step.

6. Insert hex bolt through forward hole in deck, baffle

(Models 040 through 042 only), spacer and lower han

dle. Secure with cupped washer (cupped side against

the handle) and hex nut, finger tight only.

7. Repeat steps 4 through 6 to attach the other side of the

handle. Then tighten securely the two bolts and nuts

used to attach the handle.

AHACHING THE LOWER HANDLE (Hardware A)

Models 050 thru 062 only:

1. Raise the rear of the deck and block securely. Insert

the ends of the lower handle through the slots in the

rear of the deck.

2. Place one cupped washer on hex bolt (crowned side of

washer goes against the head of the hex boit).

3. Using the inside set of hoies in the rear of the deck,

insert hex bolt through bottom hole as shown in figure

--------

IB.

4. Place two spacers on hex bolt. Then insert hex bolt

through bottom hole in handie. Secure with cupped

washer (cupped side against the handle) and hex nut,

finger tight only.

5. Repeat steps 2 through 4 to attach the other side of the

handle.

6. Tighten both hex bolts and nuts securely.

Page 6

FIGURE 2.

11

ATTACHING THE UPPER HANDLE (Hardware B)

1. Place the upper handle in position over the lower han

dle. The hole in the side of the blade control handle

(attached to the upper handle) must be on the left side.

- 2. Secure the upper handle to lower handle using the

curved head bolts; spilt washers and hex nuts as

shown in figure 2.

ATTACHING THE CONTROL BOX

One end of the throttle control cable and one end of the

brake cable are attached to the engine. The other ends are

attached to the control box. Attach the control box to the

upper handle as follows.

- 1. Remove the truss machine screw and hex lock nut from

the middle of the control box using a phillips screwdriv

er. Place your finger over the hex lock nut to hold it

inside the control box so you can unscrew the truss

machine screw.

2. Make certain the blade control handle is on top of the

upper handle.

3. Route the control box (with cables attached) under the

lower handle. Make certain the cables are not twisted.

NOTE: If the brake cable Is not attached to the control box,

insert the “Z” end of the cable into the control box as shown

in figure 3. Push the piastic fitting until It locks into the con

trol box.

FIGURE 5.

4. Holding the control box near the left side of the upper

handle (control box must be inside the handle), hook

the “Z” end of the brake cable into the control handle

from the outside to the inside. See figures 3 and 4.

5. Place the control box on the upper handle just below

— the end of the control handle as shown in figure 4.

Secure with hardware removed in step one by placing

hex lock nut into the indent on the inside of the control

box. Screw the truss machine screw into the hex lock

nut.

SECURING THE CABLES (Hardware 0)

Secure the cables to the left side of the handle as follows.

WARNING: When attaching the control

cables, the cables must be routed to avoid

A

1. Insert posts on cable ties into holes provided on the

2. Secure the cables with the cable ties. See figure 5B.

contact with all sharp edges and hot surfaces

to prevent damage to the cables, which will

render the controls inoperative.

inside of the handle, one on the upper handle and two

on the lower handle. The holes may be either on the

inside or outside of the handles. See figure 5A.

Trim excess ends of cable ties.

Page 7

FIGURE 7.

ATTACHING THE STARTER ROPE (Hardware C)

1. The starter rope is inside the top of the engine.

Additional rope may be wound around the starter han

dle. If so, unwind the rope from the handle.

2. With the spark plug wire disconnected and grounded,

depress the blade control handle and pull the rope out

of the engine.

- 3. Place the rope guide around the starter handle, so the

opening in the rope guide is toward the front of the

mower as shown. Insert the rope guide into the right

side of the handle, and secure with hex lock nut.

INSTALLATION OF WHEELS (Hardware E)

The three holes provide three cutting heights for your

mower. Use the same hole location for all four wheels when

assembling. If wheels are to be assembled In the lowest

cutting position (highest hole in the deck), refer to the note

below.

- If your mower has two sets of holes (see figure 7), the front

wheels must be assembled in one of the three holes near

est the front of the deck. The rear wheels must be assem

bled in one of the three holes nearest the rear of the deck.

To assemble the wheels: (See figure 7)

1. Place axle bolt through wheel.

2. Place one smaller cupped washer on axle bolt, with the

cupped side of washer toward the deck (away from

wheel).

3. Secure wheel to deck with one larger cupped washer

on the inside of the deck (cupped side against the

deck) and hex nut. Tighten securely.

4. Assemble the other wheels in the same manner.

NOTE: If the lowest cutting position (highest hole in the

deck) is used, it is necessary to place the larger washer on

the outside of the deck and the smaller washer on the

inside.

FINAL ASSEMBLY OF MOWER

1. The chute deflector on your mower is held in an upright

position by a block for shipping purposes only. This

shipping block must be removed and discarded before

------

the mower is put into operation. See figure 8.

To remove the shipping block, move the spring-loaded

chute toward the engine by pushing above the shipping

block. Remove the block and carefully lower the chute

into operating position, keeping fingers out of the way.

2. Make certain all nuts and bolts are tightened securely.

Page 8

FIGURE 9.

I I

I

CONTROLS OPERATION

TO REDUCE THE RISK OF INJURY. DO NOT

OPERATE MOWER UNLESS REAR TRAILING

SHIELD AND THIS GUARD OR ENTIRE

GRASS CATCHER IS IN ITS PROPER PLACE.

BLADE CONTROL HANDLE

WARNING: This control mechanism is a safe

A

The blade control handle is located on the upper handle of

the mower. See figure 9. The blade control handle must be

depressed in order to operate the unit. Release tfie blade

control handle to stop the engine and blade.

A

ty device. Never attempt to bypass iti opera

tions.

WARNING: The blade will be rotating whenev

er the engine is running.

THROHLE CONTROL

The throttle control is located on the left side of tfie upper

handle or on the engine. It is used to regulate th<; engine

speed. The engine should be started with the engine in the

FAST or START position.

WARNING: The throttle control cannot be

A

used to stop the engine.

RECOIL STARTER

The recoil starter handle is attached to the handle. See fig

ure 9. Stand behind the unit in the operating position to start

the unit.

FIGURE 10.

Keep hands and feet away from the chute area on cutting

deck. See figure 10.

The operation of any iawn mower can result in foreign

objects being thrown into the eyes, which can resuit in

severe eye damage. Always wear safety

glasses or eye shields. We recommend

wide vision safety mask for over specta

cles or standard safety glasses.

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as instructed in

the separate engine manual packed with your mower. Read

instructions carefully.

WARNING: Never fill fuel tank indoors, with

engine running or until the engine has been

A

allowed to cool for at least two minutes after

running.

TO START ENGINE AND ENGAGE BLADE

1. Attach spark plug wire securely to spark plug.

2. Move the throttle control lever all the way forward.

3. Prime engine as instructed in the separate engine man

ual.

4. Standing behind the unit, depress the blade control

handle and hold it against the upper handle as shown

in figure 11.

5. Grasp the recoil starter handle as shown and pull back

rapidly, extending rope fully. Return it slowly to the rope

guide.

6. After engine starts, move throttle control lever to

desired engine speed.

Page 9

FIGURE 11.

NOTE: If any problems are encountered, refer to the

Trouble Shooting Guide on page 16.

TO STOP ENGINE AND BLADE

1. Release the blade control handle to stop the engine

and blade.

WARNING: The blade continues to rotate for a

A

2. Disconnect the spark plug wire and ground it against

few seconds after the engine is shut off.

the engine to prevent accidental starting while equip

ment is unattended.

USING YOUR ROTARY MOWER

Be sure that lawn is clear of stones, sticks, wire, or other

objects which couid damage lawn mower or engine. Such

objects could be accidently thrown by the mower in any

direction and cause serious personal injury to the operator

and others.

For best results, do not cut wet grass because it tends to

stick to the underside of the mower, preventing proper dis

charge of grass clippings, and could cause you to slip and

fall. New grass or thick grass may require a narrower cut.

The best mowing pattern is one that allows the clippings to

discharge towards the uncut part of the lawn. This permits

recutting of the clippings to further pulverize them. When

cutting high weeds, discharge towards cut portion, then

recut at right angles to first direction.

For a healthy lawn, never cut off more than one-third of

the total length of the grass. Lawn should be cut in the fall

as long as there is growth.

This mower is designed to be operated at full throttle to give

you the best cut and do the most effective job of bagging

the cut grass.

ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to lawn mower without first stop

A

CUTTING HEIGHT ADJUSTMENT

Adjustment may be made by removing and moving axle

bolts to desired position. Cutting heights will be raised as

axle bolts are moved to a lower hole and lowered as axle

bolts are moved to a higher hole in the deck. All axle bolts

must be mounted in the same relative position. Cupped

washers must be assembled so that the cupped side of the

washers are against the deck. Refer to figure 7.

THROTTLE CONTROL ADJUSTMENT

If the throttle control requires adjustment or if it has been

replaced, adjust the throttle control as follows.

1. Remove the screw shown in figure 12. Remove the

NOTE: If you have a Tecumseh engine, simply loosen the

screw shown in figure 12 so the cable will move freely

beneath the clamp. It is not necessary to remove the screw

and clamp completely.

2.

3.

FIGURE 12A.—Briggs and Stratton Engine

ping engine and disconnecting spark plug

wire.

cable clamp from the cable.

Push the throttle control lever on the handle all the way

forward as far as it will go, then back it off one “click.”

Make certain the throttle control lever remains in this

position.

Push the control lever on the engine as far toward the

rear of the engine as it will go. Secure the cable in this

position with the cable clamp and screw.

Control Lever

On Engine

J

Cable

Clamp

A

WARNING: If you strike a foreign object, stop

the engine. Remove wire from spark plug,

thoroughly inspect the mower for any dam

age, and repair the damage before restarting

and operating the mower. Extensive vibration

of the mower during operation is an indication

of damage. The unit should be promptly

inspected and repaired.

Control

Lever

On Engine

FIGURE 12B.—Tecumseh Engine

Page 10

11

HANDLE HEIGHT ADJUSTMENT

The handle on your mower can be adjusted to two (iifferent

height settings. Refer to the note on page 5 for instructions.

CARBURETOR ADJUSTMENTS

WARNING; If any adjustments are madi; to the

engine while the engine is running (e g. car

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, ¡iltitude

and load. Refer to the separate engine manual pad :ed with

your mower for carburetor adjustment information.

NOTE: A dirty air cleaner will cause an engine to rui i rough.

Be certain air cleaner is clean and attached to the carbure

tor before adjusting carburetor. Refer to the separate ■ engine

manual.

A

Blade Control—Lubricate the pivot points on ths blade

control handle and the brake cable at least once a season

with light oil. See figure 13. The blade control must operate

freely in both directions.

FIGURE 13.

Chute Deflector—The torsion spring and pivot point should

be lubricated periodically with light oil to prevent an / rust or

binding. Deflector must work freely.

Wheels—^The wheels require no lubrication. Howevsr, if the

wheels are removed for any reason, lubricate the surface of

the axle bolt and the inner surface of the wheel with light oil.

A 4 oz. plastic bottle of light oil lubricant is availabi 3. Order

part number 737-0170. Engine oil may also be used

Engine—Follow engine manual for lubrication instructions.

buretor), keep clear of ail moving parts. Be

careful of heated surfaces and muffler.

LUBRICATION

WARNING: Always stop engine and discon

nect spark plug wire before cleaning, lubricat

ing or doing any kind of work on lawn inower.

_____

MAINTENANCE

WARNING: Be sure to disconnect and ground

A

NOTE: When tipping the unit, empty the fuel tank e nd keep

engine spark plug side up.

the spark plug wire before perform ng any

repairs or maintenance.

TROUBLE SHOOTING

Refer to page 16 of this manual for trouble shooting infor

mation.

CUTTING BLADE

When removing the cutting blade for sharpening or replace

ment, protect hands by using heavy gloves or a rag to grasp

the cutting blade. Remove the bolt and bell washer which

hold the blade and adapter to the engine crankshaft.

Remove the blade and adapter from the crankshaft.

If the blade or blade adapter needs replacing, remove the

two small bolts, lock washers and nuts which hold the blade

to the adapter.

WARNING: Periodically inspect the blade

A

When sharpening the blade, follow the original angle of

grind as a guide. It Is extremely important that each cut

ting edge receives an equal amount of grinding to prevent

an unbalanced blade. An unbalanced blade will cause

excessive vibration when rotating at high speeds, may

cause damage to the mower and could break, causing per

sonal injury.

It is recommended that the blade always be removed from

the adapter for the best test of balance.

The blade can be tested by balancing it on a round shaft

screwdriver. Remove metal from the heavy side until it bal

ances evenly.

Before reassembling the blade and the blade adapter to the

unit, lubricate the engine crankshaft and the inner surface of

the blade adapter with light oil. Lubricating the bolt holes,

bolts and inner surface of the nuts with light oil is also rec

ommended. A 4 oz. plastic bottle of light oil lubricant is

available. Order part number 737-0170. Engine oil may also

be used.

When replacing the blade, be sure to install the blade with the

side of the blade marked “Bottom” (or with part number) fac

ing the ground when the mower is in the operating position.

Blade Mounting Torque

Center Bolt: 450 in. lbs. min., 600 in. lbs. max.

Blade Adapter Bolts: 200 in. lbs. min., 350 in. lbs. max.

To Insure safe operation of your unit, all nuts and bolts must

be checked periodically for correct tightness.

adapter for cracks, especially if you strike a

foreign object. Replace when necessary.

DECK

The underside of the mower deck should be cleaned after

each use to prevent a buildup of grass clippings, leaves, dirt

or other matter. If this debris Is allowed to accumulate, it will

invite rust and corrosion, and may cause an uneven dis

charge of grass clippings at the next cutting.

The deck may be cleaned by tilting the mower and scraping

clean with a suitable tool (make certain the spark plug wire

is disconnected).

ENGINE

Refer to the separate engine manual for engine mainte

nance instructions.

10

Page 11

Maintain engine oil as instructed in the separate engine

manual packed with your unit. Read and follow instructions

carefully.

Service air cleaner every 25 hours under normal condi

tions. Clean every few hours under extremely dusty condi

tions. Poor engine performance and flooding usually indi

cates that the air cleaner should be serviced. To service the

air cleaner, refer to the separate engine manual packed with

your unit.

The spark plug should be cleaned and the gap reset once

a season. Spark plug replacement is recommended at the

start of each mowing season; check engine manual for cor

rect plug type and gap specifications.

Clean the engine regularly with a cloth or brush. Keep the

cooling system (blower housing area) clean to permit proper

air circulation which is essential to engine performance and

life. Be certain to remove all grass, dirt and combustible

debris from muffler area.

NOTE: The use of any accessory on this Rotary Mower other than those manufactured by the mower manufacturer is not

recommended. GRASS CATCHER model 190-086 is available as optional equipment for the mowers shown in this manual.

OFF-SEASON STORAGE

The following steps should be taken to prepare lawn mower

for storage.

1. Clean and lubricate mower thoroughly as described in

the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

3. Coat mower’s cutting blade with chassis grease to pre

vent rusting.

4. Store mower in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment in an

unventiiated or metal storage shed, care should be taken to

rust-proof the equipment. Using a light oil or silicone, coat

the equipment, especially cables and all moving parts.

WARNING: To reduce the risk of injury, do not operate mower uniess rear traiiing shieid and guard or

A

NOTE: Under normal usage bag material is subject to wear and should be checked periodically. Be sure any replacement

bag complies with the mower manufacturer’s recommendations. For replacement bags, use only factory authorized replace

ment bag part number 764-0271.

entire grass catcher is in its proper piace.

11

Page 12

! I

Models 030 thru 042

CODE: N notates a new part (not previously existing).

COLOR: A three digit number is the color code. Specify color

code if color or finish is important when ordering parts, [i.e.,

(part no.)-638 for Red Finish]

Color Codes

436—Radiant Yellow

460—Green Flake

483—Charcoal Gray

498—Yellow 650—Red Metallic

499—Beige 657—Teal

629—Silver Flake 663—Dark Teal

637—Black

638—Red

640—Green

646—CM Blue

NOTE

This instruction manu

al covers various mod

els, and all specifica

tions shown do not

necessarily apply to

your model. Specifica

tions subject to change

without notice or obli

gation.

12

Page 13

Models 030 thru 042

PARTS LIST FOR MODELS 030 THRU 042 ROTARY MOWERS

REF.

NO.

1

10

11

12 712-0241 Hex Nut 3/8-24 Thd.

13 731-1034

14 710-0605 Oval C-Sunk Scr. 41 747-0710

15 710-0599 Self-Tap Scr. 1/4-20 x .5" Lg. 42

16

17 712-0324 Hex L-Nut 1/4-20 Thd,

18 782-0030 20" Deck Ass’y.

19 710-0654A Hex Wash. Hd. Scr. 3/8-16 x 47

20 17098

21 731-0872A Rear Flap 16.69" Lg.

22

23

24

25 736-0119 L-Wash. 5/16" l.D.*

26 712-0267 Hex Nut 5/16-18 Thd.*

PART

NO.

■k*

2

742-0620

3 782-5006 Baffle (040 Series Only) X 1.38" Lg.

4

710-1044

5 753-0484 Blade Adapter Kit (Keyed)

6

7

8

9

**

736-0105

736-0331

712-0798

710-1055

736-0169

736-0329

726-0240

749-0928

747-1205 Rope Guide 52

CODE

Wheel Ass’y. Complete

N 20" Blade

Hex Bolt 3/8-24 X 1.5" Lg.

Axle Bolt

Bell-Wash. .380" l.D. x .88" 37 746-0842

Bell-Wash. .39" l.D. x 1.13" 746-0844

Hex Nut 3/8-16 Thd.* (Tecumseh)

Hex Bolt 3/8-24 X 1" Lg.

L-Wash. 3/8" l.D.* 746-0552

Chute Deflector Ass’y.

L-Wash. 1/4" l.D.*

Hinge Clip

Cable Tie

N

Lower Handle 51 746-0875

DESCRIPTION

1"Lg.

REF.

NO.

27 749-0538C Upper Handle

28

29 710-0459 Hex Bolt 3/8-24 x 1.5" Lg.

30

36

38 746-0553

39 732-0593 Torsion Spring

40 17032 Adapter Plate

43

45 750-0910 Spacer

46 712-0355 Hex L-Nut 3/8-24 Thd.

48

49 736-0501

50

53 811-00185

PART

NO.

710-0671

747-0824

736-0452 Bell-Wash. .39" l.D.

736-0270 Bell-Wash. 1/4" l.D.

—

751-0568 Casing Clamp (B&S)

710-1237

712-0324

746-0876 Throttle Lever

CODE DESCRIPTION

Curved Carriage Bolt 5/16-18

Control Handle

Throttle Control Wire—51" (B&S)

Throttle Control Wire—39"

Control Cable—36" (B&S)

Control Cable—49" (Tec.)

Hinge Pin

Engine

Hex Wash. Hd. Scr. #10-32 x

.62" Lg. (B&S)

Spring Wash. .66" l.D.

Hex L-Nut 1/4-20 Thd.

Throttle Body

Throttle Box Comp. (Incl. Ref.

14, 49, 50,51,52)

*For faster service obtain standard nuts, boits and washers localiy.

if these items cannot be obtained iocaily, order by part number

and size as shown on parts iist.

‘WHEEL CHART

Tread***

Rib 734-1170 (7")

Diamond

‘Tread Type: Rib ; Diamond

The engine is not under warranty by the mower manufacturer. . .If repairs or senrice is needed on the

engine, please contact your nearest authorized engine service outlet. Check the “Yellow Pages” of your

telephone book under “Engines-Gasoline.”

Ass’y. Comp. Axle Bolt

738-0533

734-1169 (8")

734-1779 (7")

734-1780 (8")

738-0533

i

Find It Fast

In The

Yellow Pages

13

Page 14

Models 050 thru 0(>3

CODE: N notates a new part (not previously existing).

COLOR: A three digit number is the color code. Specify color

code if coior or finish is important when ordering parts, [i.e.,

(part no.)-638 for Red Finish]

Color Codes

436—Radiant Yeliow 638—Red

460—Green Fiake

483—Charcoal Gray 646—CM Blue

498—Yellow 650—Red Metallic

499—Beige

629—Silver Flake 663—Dark Teal

637—Black

640—Green

657—Teal

NOTE

This instruction manu

al covers various modeis, and ail specifica

tions shown do not

necessarily apply to

your model. Specifica

tions subject to change

without notice or obiigation.

14

Page 15

Models 050 thru 063

PARTS LIST FOR MODELS 050 THRU 063 ROTARY MOWERS

REF.

NO.

10

11 736-0169

12

13

14 746-0876 Throttle Lever

18

19

20 17098 Hinge Clip

21

22 726-0240 Cable Tie 52

23

24 710-1205

25 736-0119

PART

NO.

1

2 742-0620 N 20" Blade 27

3

4

5

6

7 736-0105 Bell-Wash. .380" I.D. x .88" 32

8

9

**

742-0622 N 22" Blade

712-0324

710-1044

753-0484

**

736-0331 Bell-Wash. .39" I.D. x 1.13" 34

712-0798

710-1055 Hex Bolt 3/8-24 x1"Lg.

712-0241 Hex Nut 3/8-24 Thd.

746-0842 Throttle Wire 51 “ Lg.

746-0844 Throttle Wire 39" Lg. (Tec.)

17038 20" Deck Ass’y.

17043 22" Deck Ass’y. 46

710-0654A Hex Wash. Hd. Scr. 3/8-16 x

731-0872A

749-0928 N Lower Handle

CODE

DESCRIPTION

Wheel Ass’y. Complete

Hex L-Nut 1/4-20 Thd.

Hex Bolt 3/8-24 X 1.5” Lg.

Blade Adapter Kit (Keyed) 30 747-0824 Control Handle

Axle Bolt 31 712-0324

Hex Nut 3/8-16 Thd.* 35

L-Wash. 3/8" I.D.*

1" Lg.

Rear Flap 16.69" Lg.

Rope Guide

L-Wash. 5/16” I.D.*

REF.

NO.

PART

NO.

26 712-0267

749-0538C Upper Handle

28 710-0671 Curved Carriage Bolt 5/16-18

29 710-0459 Hex Bolt 3/8-24 x 1.5" Lg.

736-0501 Spr. Wash. .66” I.D.

746-0875

710-0605 Oval C-Sunk Scr.

38

746-0550 Control Cable—39” (B&S)

746-0552

39 751-0568 Casing Clamp (B&S)

40 710-1237

43

45

48 731-1034

49

50 17032 Adapter Plate

51

53

54

—

750-0910 Spacer .391" I.D. x .375" Lg.

712-0355 Hex L-Nut 3/8-24 Thd.

732-0593 Torsion Spring

747-0710 Hinge Pin

710-0599 Hex Self-Tap Scr. 1/4-20 x .5”

736-0270 Bell-Wash. 1/4" I.D.

811-00185 Throttle Box Comp. (Incl. Ref.

CODE

DESCRIPTION

Hex Nut 5/16-18 Thd.*

X 1.38" Lg.

Hex L-Nut 1/4-20 Thd.

Throttle Body

Control Cable—49” (Tec.)

Hex Wash. Hd. Scr. #10-32 x

.62” Lg.

Engine

Chute Deflector Ass’y.

14, 31,32, 34, 35)

*For faster service obtain standard nuts, boits and washers locally.

If these items cannot be obtained locally, order by part number

and size as shown on parts list.

‘WHEEL CHART

Tread“*

Rib 734-1170 (7")

Diamond

‘Tread Type: Rib ; Diamond

The engine is not under warranty by the mower manufacturer. . .If repairs or sen/ice is needed on the

engine, please contact your nearest authorized engine service outlet. Check the “Yellow Pages” of your

telephone book under “Engines-Gasoline.”

Ass’y. Comp. Axle Bolt

734-1169 (8”)

734-1779 (7")

734-1780 (8”)

738-0533

738-0533

Find It Fast

In The

Yellow Pages

15

Page 16

TROUBLI: SHOOTING GUIDE

Trouble Possible Cause(s) Corrective Action

11

Engine fails to start

Engine runs erratic

Engine overheats 1. Engine oil level low.

Occasional skip

(hesitates) at high speed

1. Blade control handle disengaged.

2. Spark plug wire disconnected.

3. Throttle control lever not In FAST

or START posit on.

4. Fuel tank empty, or stale fuel.

5. Blocked fuel lina (if so equipped).

6. Faulty spark pli g.

7. Engine flooded.

1. Unit running in START position.

2. Spark plug wire loose.

3. Blocked fuel lina (if so equipped)

or stale fuel.

4. Vent in gas cap plugged.

5. Water or dirt in 'uel system.

6. Dirty air cleanei.

7. Carburetor out' )f adjustment.

2. Air flow restrict« d.

3. Carburetor not .idjusted properly.

1. Spark plug gap too close.

2. Carburetor idle mixture adjustment

improperly set.

1. Engage blade control handle.

2. Connect wire to spark plug.

3. Move throttle lever to FAST or

START position.

4. Fill tank with clean, fresh gasoline.

5. Clean fuel line.

6. Clean, adjust gap or replace.

7. Remove spark plug, dry the plug, and

crank engine with plug removed and

throttle in off position. Replace spark

plug, connect wire and resume starting

procedures.

1. Move throttle lever to FAST position.

2. Connect and tighten spark plug wire.

3. Clean fuel line; fill tank with clean,

fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6. Clean air cleaner.t

7. Adjust carburetor.)-

1. Fill crankcase with proper oil.

2. Remove blower housing and clean.t

3. Adjust carburetor.t

1. Adjust gap to .030”.

2. Adjust carburetor.t

Idles poorly

Excessive vibration

Mower will not

discharge grass

Uneven cut

fRefer to separate engine manual packed with your unit.

Note: For repairs beyond the minor adjustments listed above, please contact your local authorized service dealer.

1. Spark plug foulad, faulty or gap

too wide.

2. Carburetor impioperly adjusted.

3. Dirty air cleanei.

1. Cutting blade Icose or unbalanced.

2. Bent cutting blade.

1. Engine speed too low.

2. Wet grass.

3. Excessively high grass.

1. Wheels not positioned correctly.

2. Dull blade.

1. Reset gap to .030” or replace

spark plug.

2. Adjust carburetor.t

3. Clean air cleaner.f

1. Tighten blade and adapter.

Balance blade.

2. Replace blade.

1. Set throttle between 3/4 and full throttle.

2. Do not mow when grass is wet; wait

until later to cut.

3. Mow once at a high cutting height, then

mow again at desired height or make a

narrower cutting swath (1/2 width).

1. Place all four wheels in same height

position.

2. Sharpen or replace blade.

For Replacement Parts, Contact:

SERVICE DEPARTMENT • P.O BOX 368022 • CLEVELAND, OHIO 44136-9722

Loading...

Loading...