Page 1

OUTER’S

MANUAL

22"HI-WHEEL

ROTARY

MOWER

.75

Model Number

112-530A

Important:

Read Safety Rules and

Instructions Carefully

Thank you for purchasing an

American built product.

PRINTED IN U.S.A.

FORM NO. 770-1775

Page 2

INDEX

Safe Operation Practices........................................3

Assembly Instructions............................................4

Operation..................................................................7

Adjustments.............................................................8

Lubrication.............................................................10

r

LIMITED WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for any parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

Maintenance ..........................................................10

Off-Season Storage...............................................12

Illustrated Parts...........................................15,16,18

Repair Parts List

Parts Information

.........................................

....................................

Back Cover

15,17,19

♦

♦

♦

t

♦

♦

t

♦

♦

♦

♦

♦

♦

V

The equipment which you have just purchased does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by law to be in effective working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

J

} WARNING \

TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

♦

♦

♦

♦

♦

♦

Page 3

^ WARNING I

To reduce the potential for any injury, comply with the foiiowing safety instructions. Faiiure to comply with

the instructions may resuit in personai injury.

SAFE OPERATION PRACTICES

TRAiNING

1. It is suggested that this manual be read in its

entirety before attempting to assemble or

operate this unit. Keep this manual in a safe

place for future reference and for ordering

replacement parts.

2. Your rotary mower is a precision piece of

power equipment, not a plaything. Therefore,

exercise extreme caution at all times.

3. Read this Owner’s Manual carefully. Be

thoroughly familiar with the controls and the

proper use of the equipment.

4. Never allow children to operate a power

mower. Only persons well acquainted with

these rules of safe operation should be al

lowed to use your mower.

5. Keep the area of operation clear of all per

sons, particularly small children and pets.

Stop engine when they are in the vicinity of

your mower. Although the area of operation

should be completely cleared of foreign ob

jects, a small object may have been over

looked and could be accidently thrown by the

mower in any direction and cause injury.

PREPARATION

1. Thoroughly inspect the area where the equip

ment is to be used. Remove all stones, sticks,

wire, bones and other foreign objects which

could be picked up and thrown by the mower

in any direction and cause injury.

2. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

3. Do not wear loose fitting clothing that could

get caught on the mower.

4. Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do

not fill the gasoline tank indoors, while the

engine is running, or while the engine is still

hot. Wipe off any spilled gasoline before start

ing the engine as it may cause a fire or explo

sion.

5. Disengage the self-propelled mechanism or

drive clutch on units so equipped before start

ing the engine.

6. Never attempt to make a wheel or cutting

height adjustment while the engine is run

ning.

7. Mow only in daylight or in good artificial light.

8. Never operate the equipment in wet grass.

Always be sure of your footing. Keep a firm

hold on the handle and walk, never run.

OPERATION

1. Do not change the engine governor settings

or overspeed the engine. Excessive engine

speeds are dangerous.

2. Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at

all times as the rotating blade can cause in

jury.

3. Stop the blade when crossing gravel drives,

walks or roads. 3

FOR WALK-BEHIND MOWERS

4. After striking a foreign object, stop the

engine, remove the wire from the spark plug,

and thoroughly inspect the mower for any

damage. Repair the damage before restarting

and operating the mower.

5. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately

for the cause. Vibration is generally a warning

of trouble.

6. Stop the engine whenever you leave the

mower, before cleaning the mower housing,

and when making any repairs or inspections.

7. When cleaning, repairing or inspecting, make

certain the blade and all moving parts have

stopped. Disconnect the spark plug wire, and

keep the wire away from the plug to prevent

accidental starting.

8. Before attempting to unclog the mower or

discharge chute, stop the engine and be sure

the blade has stopped completely. The cut

ting blade continues to rotate for a few

seconds after the engine is shut off. Never

place any part of the body in the blade area un

til you are sure the blade has stopped rotating.

Disconnect the spark plug wire and keep the

wire away from the plug to prevent accidental

starting.

9. Do not run the engine indoors.

10. Shut the engine off and wait until the blade

comes to a complete stop before removing

the grass catcher or unclogging chute.

11. Mow across the face of slopes, never up-anddown. Exercise extreme caution when chang

ing direction on slopes. Do not mow ex

cessively steep slopes.

12. Always disconnect electric mowers (line

operated) before cleaning, repairing or ad

justing.

13. Never operate mower without proper guards,

plates or other safety protective devices in

place.

14. Keep washout ports and other mower-housing

service openings closed when mowing.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at

frequent intervals for proper tightness.

2. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working condi

tion.

3. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any

enclosure.

4. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

5. Check the grass catcher bag frequently for

wear or deterioration. For safety protection,

replace only with new bag meeting original

equipment specifications.

Page 4

0 0 00 0©

FIGURE 1.

Lower

Handle

FIGURE 2.

ASSEMBLY INSTRUCTIONS

NOTE

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

operating section of this manual for

proper fuel and engine oil recom

mendations.

Loose Parts in Carton:

(1) Lower Handle

(1) Lower Handle Support—Left Hand

Lower Handle Support—Right Hand

(1)

Upper Handle Assembly

(1)

Hardware Pack

(1)

Control Rod

(1)

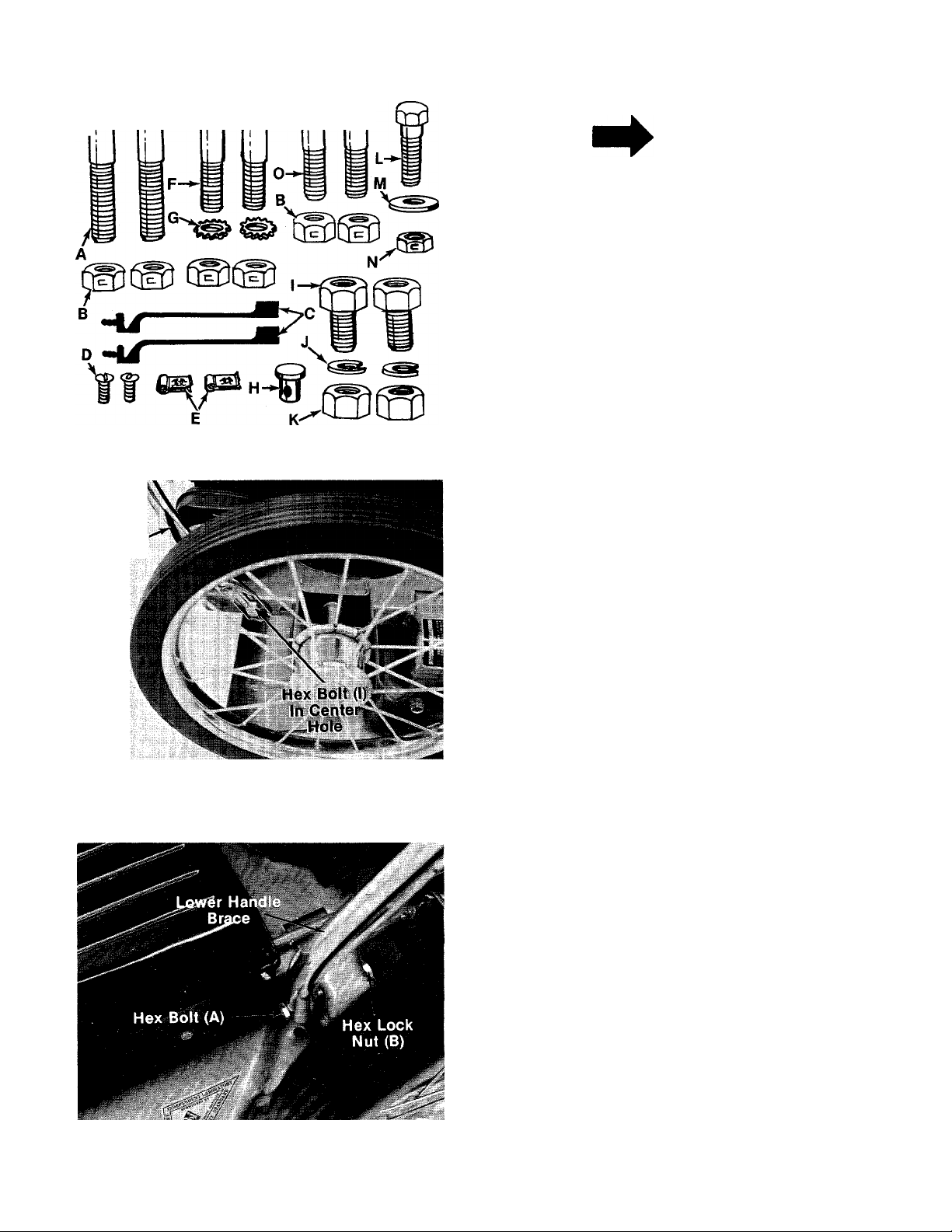

Contents of Hardware Pack: (See Figure 1)

Hex Bolts V4-20 x 2.50" Long

A

(2)

Hex Center Lock Nuts V4-20 Thread

B

(6)

Cable Ties

C

(2)

Truss Machine Screws #10-24 x .38" Long

D

(2)

Speed Nuts #10-24

E

(2)

Hex Bolts V4-20 x 1.50" Long

F

(2)

External Lock Washers

G

(2)

H

Ferrule

(1)

Hex Bolts 3/8-16 X .62" Long

I

(2)

J

Q (2)

Remove the lawn mower, loose parts, hardware

pack and literature from the carton. Make certain

all parts and literature have been removed before

the carton is discarded.

Extend throttle control assembly which is at

tached to the rear of the mower and place on the

floor. Be careful not to bend or kink control wire.

HANDLE ASSEMBLY

1. Assemble lower handle to frame assembly by

Lock Washers 3/8" I.D.

(2)

Hex Nuts 3/8-16 Thread

K

(2)

Hex Bolt 1/4-28 X .75" Long

L

(1)

Flat Washer .510 I.D. x .750 O.D.

M (1)

Hex Center Lock Nut Va-ZS Thread

N (1)

Hex Bolt 1/4-20 X 1.25" Long

O (2)

Lockout Lever Assembly (Not Shown)

P (1)

Hand Grips (Not Shown)

lining up hole in lower handle with center hole

in frame assembly. See figure 2. Secure using

hex bolts (I), lock washers (J) and hex nuts (K)

on the inside of frame. Two 9/16" wrenches

are required.

FIGURE 3.

2. Fasten bottom of left and right hand lower

------

handle supports to frame using hex bolts (A)

and hex lock nuts (B). See figure 3.

Page 5

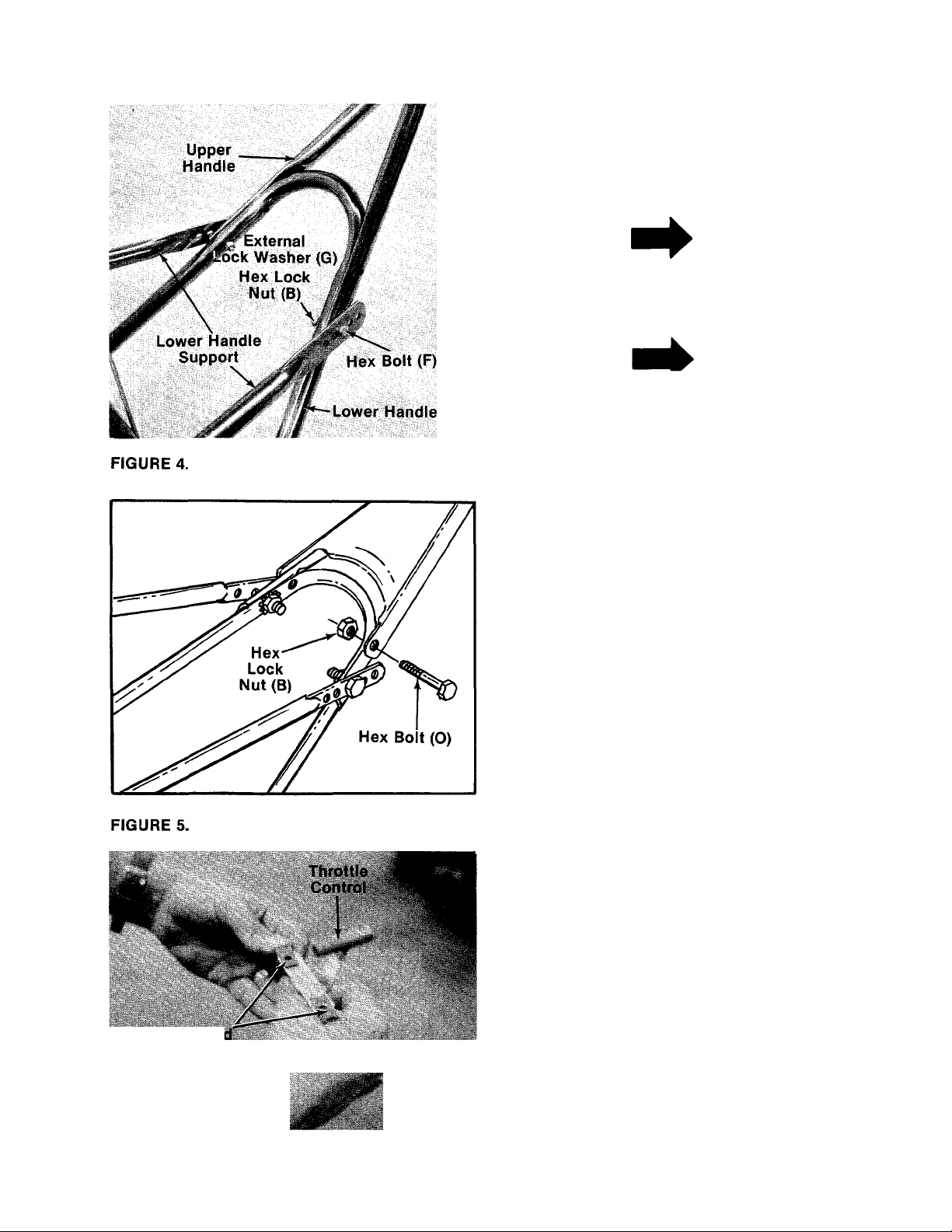

Hold upper handle assembly In position over

lower handle. Select one of five holes in lower

handle support. Fasten lower handle support

to upper and lower handle using hex bolt (F),

external lock washer (G) and hex lock nut (B).

-Do not tighten. See figure 4.

NOTE

The five holes in the lower

handle support allow handle

height adjustment. See adjust

ment section.

NOTE

Figure 4 is shown with the handle

panel removed for clarity only. It is

not necessary to remove the handle

panel when assembling the handle.

Spee

Nuts (E)

4. Secure handle panel, upper handle and lower

handle with hex bolts (O) and hex lock nuts (B)

as shown in figure 5.

5. Tighten securely all nuts and bolts used in

handle assembly.

6. Slip hand grips onto the ends of the upper

handle. They will slip on more easily if you

first soak them in warm, soapy water.

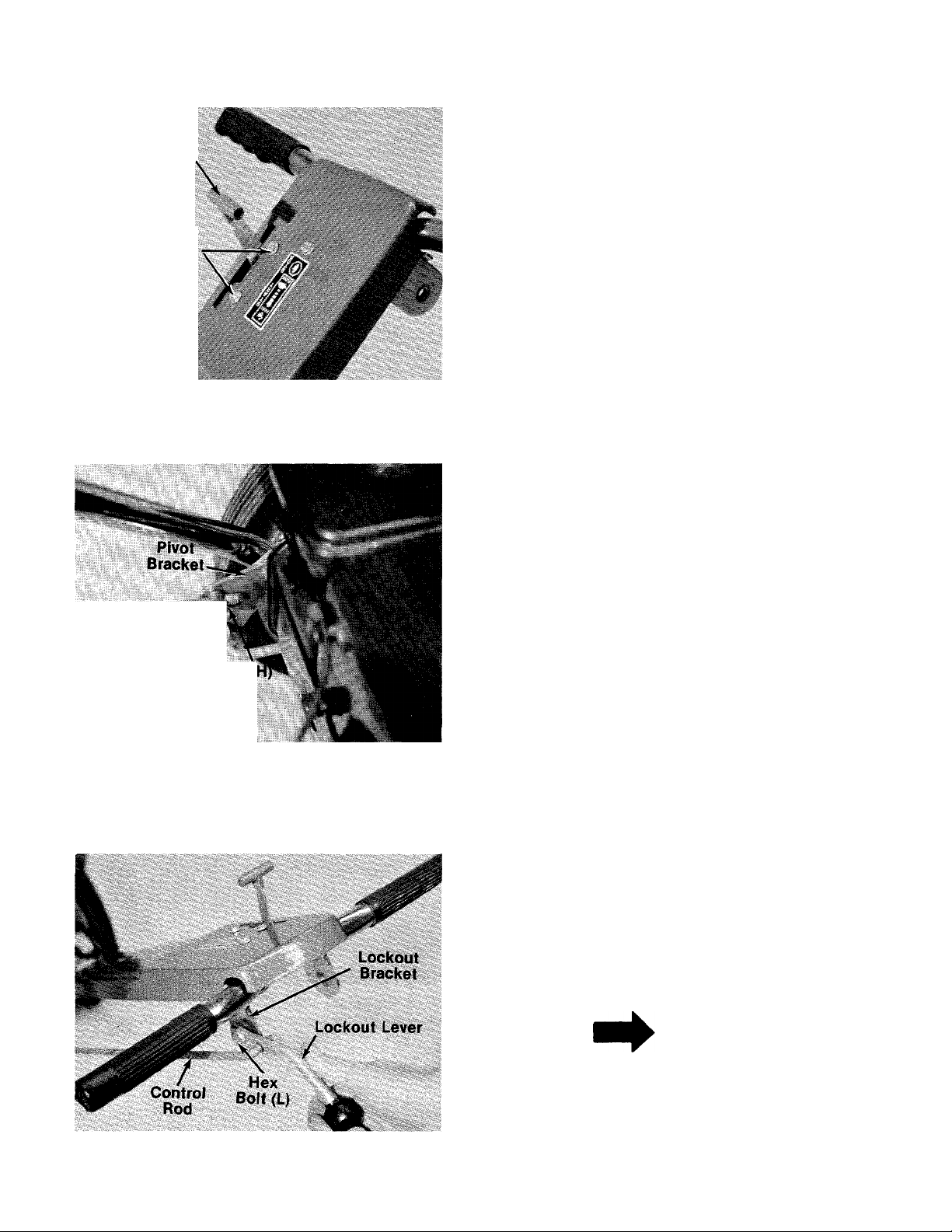

THROTTLE CONTROL INSTALLATION

1. Slide speed nuts (E), flat side up, onto the

------

throttle control assembly. See figure 6.

FIGURE 6.

Page 6

Screws (D)

FIGURE?.

Control

Rod

Throttle

Control

f

Ferrule (

2. Place throttle control up through slot provided

in handle panel. Secure with two screws (D).

— See figure 7.

3. Secure throttle control wire to handle using

cable ties (C).

CONTROL ROD INSTALLATION

1. Pull pivot bracket up as far as it will go. See

-----

figure 8. Place ferrule (H) through hole in pivot

bracket. Thread control rod into ferrule ap

proximately one-half inch.

FIGURE 8.

FIGURES.

2. Hook control rod into hole provided in lockout

lever assembly (O). Hold lockout lever in a

raised position as shown in figure 9. Thread

control rod in or out of ferrule as necessary

until hole in lockout lever lines up with hole in

— lockout bracket. See figure 9.

3. When correct adjustment is reached, secure

lever to bracket using hex bolt (L), flat washer

(M) and hex lock nut (N).

NOTE

Check control rod adjustment. A

slight pressure should be needed to

operate lockout lever. Too much

pressure can break lever assembly

or control rod. Readjust control

rod if pressure is too great.

Page 7

OPERATION

Caution

Oo Not ^^rat# Ufi^

âll Safetf ^a«te'^ In H»ir

Use SAE 30 oil. If not available, use SAE

10W-30 oil.

Place the engine level. Remove oil filler plug.

See figure 10. FILL THE OIL SUMP TO POINT

OF OVERFLOWING. Pour slowly. Capacity

1 3/4 pints.

FIGURE 10.

Keep hands and feet away from the chute area on

cutting deck.

HI^note

For shipping purposes your mower

is set with the wheeis in a low cut

ting height position. For best

results, raise the cutting position

until it is determined which height

is best for your lawn. See adjust

ment section.

BEFORE STARTING ENGINE

1. Before starting engine, lubricate the blade

spindle assembly. Refer to lubrication sec

tion.

2. Check lockout control lever for proper opera

tion. If too great a pressure is needed to

operate this control, damage can be done to

the mechanism and the rod. Readjust so only

slight pressure is needed to operate the blade

engaging control. See control rod installation

section of assembly instructions.

3. Fill sump with oil using a high quality

detergent oil classified “For Service SC, SD,

SE or MS.” Nothing should be added to the

recommended oil.

4. Fill fuel tank using clean, fresh regular grade

automotive gasoline. Fill tank completely!

DO NOT MIX OIL WITH GASOLINE.

TO START ENGINE

1. Move lockout lever to “OFF” position. See

figure 11.

2. Move throttle control lever to “CHOKE” posi

tion. See figure 11.

Lockout

Lever

Throttle

Control

FIGURE 11.

3. Crank engine. Move throttle control to

“FAST” position as soon as engine fires. Use

choke as needed to keep engine running dur

ing warm up period.

Page 8

4. Put blade into motion by moving lockout lever

to “ON” position.

To engage the blade with the engine run

ning. ..

a. Move the throttle control lever to “FAST”

position.

b. Engage the blade engagement handle

(lockout lever) SLOWLY.

c. Adjust engine speed.

TO STOP

1. The blade is stopped by moving the lockout

lever to the “OFF” position.

2. The engine is stopped by moving the throttle

control lever to “STOP” position.

3. Disconnect the spark plug wire and ground

against the engine to prevent accidental start

ing while equipment is unattended.

A brief break-in period is essential to insure max

imum engine and mower life. This consists of run

ning the engine at half speed for a period of time

required to use one tank of gasoline. It is also

recommended to change crankcase oil after the

first five hours of operation or as operating condi

tions dictate. Always check oil before operating

the mower. BE SURE CRANKCASE IS FULL.

Proper lubrication must be maintained at all

times.

Appropriate clothing should be worn when cutting

brush or heavy weeds. Safety shoes and safety

glasses are highly recommended.

Be sure that lawn is clear of stones, sticks, wire,

or other objects which could damage lawn mower

or engine. For best results and to insure more

even grass distribution, do not mow when lawn is

excessively wet.

New grass, thick grass or wet grass may require a

narrower cut. Blade speeds should be adjusted to

the condition of the lawn.

The best mowing pattern is one that allows the

clippings to discharge towards the uncut part of

the lawn. This permits recutting of the clippings

to further pulverize them. When cutting high

weeds, discharge towards cut portion then recut

at right angles to first direction.

For best results, cut off one-third or less of the

total length of the grass. Lawn should be cut in

the fall as long as there is growth.

ADJUSTMENTS

CAUTION

A

Do not at any time make any adjust

ment to lawn mower without first

stopping engine and disconnecting

spark plug wire.

CONTROL ROD ADJUSTMENT

To adjust the control rod, remove the lockout lever

from the lockout bracket. Then refer to Control

Rod Installation on page 6.

HANDLE ADJUSTMENT

The handle may be adjusted to five different posi

tions. To adjust, remove the nut and bolt on the

lower handle support. Reassemble in desired

hole. See figure 12. When the handle height is

changed, it is necessary to readjust the control

rod.

IMPORTANT

If you strike a foreign object, stop

the engine. Remove wire from spark

plug, thoroughly inspect the mower

for any damage, and repair the

damage before restarting and

operating the mower.

USING YOUR ROTARY MOWER

For best results, do not cut wet grass because it

tends to stick to the underside of the mower,

preventing proper discharge of grass clippings. If

wet grass must be cut, reduce walking speed to

help distribute the clippings more effectively.

Lowest

Position

FIGURE 12.

Page 9

CUTTING HEIGHT

The mower can be adjusted to four different cut

ting heights. Cutting height adjustment is made

by removing and moving axie bolts to the desired

positions. Ail axle bolts must be mounted in the

same relative position to the deck. When wheels

are mounted to the deck, the bellevMIe washers

must be assembled with the cupped side towards

the deck. This is necessary to prevent the axle

bolts from loosening. When assembling the rear

wheel, bellevMIe washers are placed against the

threaded hole in the frame. See figure 13.

i. t

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all

clutches and blades. Keep clear of

all moving parts and be careful of

heated surfaces and muffler.

CARBURETOR ADJUSTMENTS (See Figure 15)

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Initial Adjustment:

Turn needle valve clockwise to close it. Then open

2 turns. This initial adjustment will permit the

engine to be started and warmed up before mak

ing final adjustment.

Beileviile

Washer

Axle Bolt

FIGURE 13.

THROTTLE

If adjustment becomes necessary, the throttle

control wire assembly can be reset as follows:

1. Loosen, but do not remove, screw securing

throttle control wire assembly at engine. See

figure 14.

2. Move throttle control lever on handle to

“CHOKE” position.

3. Move lever, to which control wire is fastened

at engine, to full open position. Retighten

screw to secure throttle control wire

assembly.

Final Adjustment:

With engine running at normal operating speed

(approximately 3000 RPM without load), turn nee

dle valve clockwise until engine starts to lose

speed (lean mixture). Then slowly turn needle

valve counterclockwise past the point of

smoothest operation, until engine just begins to

run unevenly. This mixture will give best perform

ance under load.

To check adjustment, move engine control from

SLOW to FAST speed. If engine tends to stall or

die out, it usually indicates that the mixture is

slightly lean. It may be necessary to open the nee

dle valve slightly to provide a richer mixture. This

richer mixture may cause a slight unevenness in

idling.

FIGURE 14. FIGUREIS.

Page 10

LUBRICATION

IMPORTANT

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of

work on lawn mower.

Wheels—Unit is provided with ball bearing

wheels. Lubricate at least once a season with light

oil. To lubricate the rear wheels, remove the oil

caps and add several drops of oil. See figure 16.

Also, if the wheels are removed for any reason,

lubricate the surface of the axle bolt and the inner

surface of the wheel with light oil. A 4 oz. plastic

bottle of light oil lubricant is available. Order part

number 737-0170. Engine oil may also be used.

Blade Spindle Assembly—The blade spindle

assembly is equipped with a grease fitting. Use

grass discharge chute for access to the fitting

located under the deck. Use multi-purpose grease.

Lubricate PRIOR to initial use and every 25 hours

thereafter.

MAINTENANCE

CUTTING BLADE

A. Removal for Sharpening or Replacement

\ WARNING J

Be sure to disconnect and ground

the spark plug wire before working

on the cutting blade to prevent

accidental engine starting.

FIGURE 16.

Protective Shield—The pivot points on the protec

tive shield should be lubricated periodically with

light oil to prevent any rust or binding.

Chute Deflector—The torsion spring and pivot

point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must

work freely.

Engine—Follow engine manual for lubrication in

structions. Check oil level before each use.

Throttle—Periodically lubricate throttle control

lever and throttle wire assembly with a few drops

of light oil for ease of operation.

Friction point between idler bracket assembly

(Ref. No. 9 on page 15) and deck should be

greased once each season with a multi-purpose

grease.

1. Remove the large bolt and lock washer which

holds the blade and adapter to the blade spin

dle.

2. Remove the blade and adapter from the spin

dle. Be careful not to lose the key on the spin

dle.

3. If the blade or blade adapter needs replacing,

remove the two small bolts, lock washers and

nuts which hold the blade to the adapter.

B. Sharpening

Remove the cutting blade by following the direc

tions of the preceding section.

When sharpening the blade, follow the original

angle of grind as a guide. It is extremely important

that each cutting edge receives an equal amount

of grinding to prevent an unbalanced blade. An un

balanced blade will cause excessive vibration

when rotating at high speeds, may cause damage

to the mower and could break, causing injury.

The blade can be tested for balance by balancing

it on a round shaft screwdriver. Remove metal

from the heavy side until it balances evenly.

NOTE

It is recommended that the blade

always be removed from the adapter

for the best test of balance.

10

Page 11

C. Reassembly

Before reassembling the blade and the blade

adapter to the unit, lubricate the spindle and the

inner surface of the blade adapter with light oil.

Lubricating the bolt holes, bolts and inner surface

of the nuts with light oil is also recommended. A 4

oz. plastic bottle of light oil lubricant is available.

Order part number 737-0170. Engine oil may also

be used.

When replacing the blade, be sure to install the

blade with the side of the blade marked “Bottom”

(or with part number) facing the ground when the

mower is in the operating position. Make certain

key is in place on the blade spindle.

Blade Mounting Torque

3/8" Dia. Bolt 375 in. lb. min., 450 in. lb. max.

5/16" Dia. Bolt 150 in. lb. min., 250 in. ib. max.

To insure safe operation of your unit, ALL nuts

and bolts must be checked periodically for correct

tightness.

DECK

The underside of mower deck should be cleaned

after each period of use as grass clippings, leaves,

dirt and other matter will accumulate. This ac

cumulation of grass clippings, etc., is undesirable

as it will invite rust and corrosion and may cause

an uneven discharge of grass clippings at the next

cutting.

The deck may be cleaned by tilting the mower for

ward or on its side and scraping clean with a

suitable tool or by washing with a stream of water

from a garden hose.

CAUTION

A

Do not direct the stream of water at

a hot engine as damage to the

engine may result.

AIR CLEANER

Clean air cleaner and re-oil element every 25 hours

under normal conditions. Clean every few hours

under extremely dusty conditions. Poor engine

performance and flooding usually indicates that

the air cleaner should be serviced. See figure 17.

To service air cleaner:

1. Remove screw.

2. Remove air cleaner carefully to prevent dirt

from entering carburetor.

3. Take air cleaner apart and clean.

a. WASH foam element in kerosene or a liq

uid detergent and water to remove dirt.

b. DRY foam completeiy by wrapping and

squeezing in a cloth.

c. SOAK foam with engine oil. Squeeze to

distribute and remove excess oil.

4. Reassemble parts and fasten to carburetor.

Assemble

Stud O"® o* These

Low Points^^^^

Screen

Towards>^^$.S;S^^P“P

Narrow

Edge of

'Element

Assemble Element So

Lip Extends Over Edge

of Air Cleaner Body

Lip Wiil Form

Protective Seai

When Cover Is

Assembled

ENGINE OIL

Check oil level before starting engine and after

every 5 hours of operation or each period of use.

Add oil as necessary to keep level FULLTO POINT

OF OVERFLOWING. Before removing oil fill plug,

clean area around plug to prevent dirt from enter

ing oil fill hole. Engine should be in a level posi

tion when checking oil.

Change oil after first 5 hours of operation.

Thereafter change every 25 hours. Change oil

while engine is warm. Oil may be drained from oil

drain by tipping unit on its side. See figure 10. Oil

capacity 13/4 pints.

FIGURE 17.

SPARK PLUG

The spark plug should be cleaned (see figure 18)

and the gap reset to a 0.030-inch clearance once a

season (see figure 19). Spark plug replacement is

recommended at the start of each mowing

season; check engine manual for correct plug

type.

11

Page 12

Clean

Electrode

13. Position belt bracket on idler pulley to clear

the tightened belt. Secure belt bracket in posi

tion. See drawing on page 13.

14. Replace blade spindle cover.

NOTE

To insure safe operation of your

unit, ALL nuts and bolts must be

checked periodically for correct

tightness.

OFF-SEASON STORAGE

FIGURE 18.

.030"

ler Gauge

FIGURE 19.

BELT REPLACEMENT

Belt replacement may be made as follows:

1. Remove blade spindle cover.

2. Remove front belt guard.

3. Remove blade tension spring.

4. Loosen belt on bracket of idler bearing

assembly.

5. Remove bracket lever assembly.

6. Remove damaged or worn belt.

7. Place new belt on engine pulley. Do not bend

belt guard pins. Belt should be inside of pins.

8. Work belt to front and mount on blade spindle

pulley. Replace front belt guard.

9. Replace brake lever assembly.

10. Slip belt on idler pulley between pulley and

belt bracket.

11. Replace blade tension spring.

12. Move blade lockout handle to “ON” position.

The following steps should be taken to prepare

lawn mower for storage.

1. Clean and lubricate mower thoroughly as

described in the lubrication instructions.

2. Refer to engine manual for correct engine

storage instructions.

3. Coat mower’s cutting blade with chassis

grease to prevent rusting.

4. Place blocks under deck to raise tires clear of

floor.

5. Store mower in a dry, clean area.

12

Page 13

Brake Shoe 754-0647

BLADE IDLER BRACKET ASSEMBLY DETAIL

Rivet 728-0649

Idler Bracket Assembly 12278

Idler Bearing 756-0199

Hex Lock Nut

712-0262

BELT WEAR

Belt clips improperly positioned will cause

premature belt wear. The belt clip must complete

ly clear the belt when the belt is tightened. It

should also assist in freeing the belt from the

blade spindle pulley when the belt is loose. This

may be checked by removing the blade spindle

cover.

The use of any accessory on this rotary mower

other than those manufactured by the mower

manufacturer is not recommended.

GRASS CATCHER Model 004 is available as optional equipment for the

mower shown in this manual.

Beit Ciip

04563

NOTE

\ WARNING }

1. The mower should not be operated without the entire grass catcher

or chute deflector in place.

2. The mower should not be operated without the protective shield on

the rear of the deck in place.

NOTE

Under normal usage bag material is subject to wear and should be

checked periodically. Be sure any replacement bag complies with the

mower manufacturer’s recommendations.

For replacement bags, use only factory authorized replacement bag No.

764-0176.

13

Page 14

cup Must Not Touch ;

Where Blade Is

ngaged.

■s.-.

14

Page 15

Model 530

26

------

/

REF.

NO.

1

2 09373

3

4

5

6

7

8

9 12278

10

11

^12

13

14

15

PART

NO.

732-0158

09371

712-0262

04563

736-0300

756-0199

12581

712-0287

736-0329

736-0170

712-0123

756-0206

07386

COLOR

CODE

-462

PARTS LIST FOR M(

DESCRIPTION

Blade Tension Spring

Control Rod

Brake Lever

Hex Ins. Jam Nut 3/8-24 Thd.

Belt Clip

FI-Wash.

Flat Idler w/Flange

Frame Ass’y.

Idler Brkt. Ass’y. w/Brake

Shoe

Hex Nut 1/4-20 Thd.*

L-Wash. 1/4" Scr.*

Special L-Wash. 5/16" Scr.

Hex Nut 5/16-24 Thd.*

Engine Pulley 4.00" O.D.

FI-Wash. .406" I.D. x 1.25"

O.D. X .164

DDEL 530 F

NEW

REF.

PART

NO.

16 736-0169

17 710-0152

18

19

20 09925 Sheave Ass’y.—4" Dia.

21 736-0921

22 712-0200

23 736-0463

24

25

26

15

OTARY MOWER

PART

NO.

COLOR

CODE

DESCRIPTION

L-Wash. 3/8" Scr.*

Hex Scr. 3/8-24 x 1.00" Lg.

H.T.

712-0181

08324

—462 Belt Guard

Hex Top L-Nut 3/8-16 Thd.

(Blade Spindle)

L-Wash. 1/2" Scr.*

Hex Ins. Nut 1/2-20 Thd.

FI-Wash. .296 I.D. x .62"

O.D. X .059

738-0234 Shoulder Bolt .500" Dia.

X .295

754-0109

726-0111

“V”-Belt 1/2" X 43" Lg.

Push Cap

NEW

PART

Page 16

Model 530

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

16

Page 17

Model 530

1EF.

NO.

10

PART

COLOR

NO.

CODE

1

2 726-0188

3

4 710-0136

5

6 712-0526

7

8

9

—

Engine

Cable Tie

07861 Clamp Bracket

Hex Bolt V4-20 X 1.75" Lg.*

08376

Lockout Brkt. Ass’y- 28

Speed Nut #10-24

712-0107 Hex Center L-Nut V4-20 Thd.

08378

Clamp Bracket

09354 Upper Handle (2-Req’d)

720-0157

Grip

PARTS LIST FOR MODEL 530 ROTARY MOWER

DESCRIPTION

11 736-0222 Ext. L-Wash. V4" I.D.

12 08373

Lockout Lever Ass’y- with 35 710-0227

Plastic Ball

711-0180 Control Rod

13

14 736-0108

FI-Wash. .510 I.D. x .750

O.D.

712-0117 Hex Cent. L-Nut V4-28 Thd.

15

712-0107 Hex Center L-Nut V4-20 Thd.

16

17 710-0106

18 710-0606

712-0107 Hex Center L-Nut V4-20 Thd.

19

08327 Lower Handle Support—L.H.

20

21 712-0181

22 738-0234

09372 Pivot Bracket

23

24 710-0412

Hex Bolt 1/4-20 X 1.25" Lg.*

Hex Bolt 1/4-20 X 1.50" Lg.* 41

Hex Top L-Nut 3/8-16 Thd.

Shid. Bolt .500" Dia. x .295

Hex Bolt 1/4-28 X .75" Lg.

Grade 5

NEW

PART

REF.

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

25 711-0179 Adjustable Ferrule

26 710-0209 Hex Sems Bolt 3/8-16 x .62"

Lg.

27 09362

712-0107

29 710-0102

30

08328 Lower Handle Support—R.H.

31

710-0158 Hex Bolt 5/16-24 x 1.25"

32

714-0365

Lower Handle

Hex Center L-Nut V4-20 Thd.

Hex Bolt 1/4-20 X 2.50" Lg.*

#6 Hi-Pro Key 5/32 x 5/8 Dia.

33 746-0171 Throttle

34

11815 —462 Control Panel

Hex Wash. Hd. AB-Tap Scr.

#8 X .38" Lg.

36 710-0192

37

08325 —462 Belt Trap Ass’y.

38 736-0169

39 712-0798

40

710-0209

Truss Mach. Scr. #10-24 x .38

L-Wash. 3/8" I.D.*

Hex Nut 3/8-16 Thd.*

Hex Sems Bolt 3/8-16 x .62"

Lg.

12593 Pivot Mounting Bracket

42 710-0117

Hex Bolt 5/16-24 x 1.00"

Lg.-H.T.

43

736-0119

44 712-0123

L-Wash 5/16" I.D.*

Hex Nut 5/16-24 Thd.*

NEW

PART

'For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

NOTE; The engine is not under warranty by

the mower manufacturer ... If repairs or

service is needed on the engine, please

contact your nearest author

ized engine service outlet.

Check the “Yellow Pages” of

your telephone book under

“Engines—Gasoline.”

Find It Fast

In the

Yellow Pages

(462—Red Flake)

When ordering parts, if color or finish is important use the ap

propriate color code shown above, (e.g. Red Flake

Finish—11815 (462).)

NOTE

This instruction manual covers various models

and all specifications shown do not neces

sarily apply to your model. Specifications sub

ject to change without notice or obligation.

17

Page 18

Model 530

18

Page 19

Model 530

,£F.

PART

NO.

1

710-0116 Hex Bolt 5/16-18 X 2.00" Lg.*

2

710-0158 Hex Bolt 5/16-24 x 1.25" Lg.*

3 12581 —462

4

710-0209 Hex Sems Bolt 3/8-16 x .62"

NO.

COLOR

CODE

Frame Ass’y-

PARTS LIST FOR MODEL 530 ROTARY MOWER

DESCRIPTION

Lg.*

710-0567

5

Hex Sems Bolt V4-28 x 5/8"

Lg.

6 712-0271 Hex Sems Nut V4-20 Thd.

7 12422 —462

11197

8

Deck Ass’y.—22 in.

Protective Shield Ass’y.—

Comp.

9 718-0132

Oil Cap

10 741-0113 Ball Brg. .504 I.D. x 1.38 Dia.

11

738-0114 Shoulder Bolt .498" Dia. x

4.755"

12

11679

13 732-0253

14

726-0106

—462

Chute Deflector Ass’y.

Torsion Spring

Push Cap

15 11130 —462 Adapter Plate

16 711-0555 Pivot Pin

17

10769

18 734-0439

Blade Adapter Kit

16" Rear Wheel Ass’y.—

Comp.

19 734-0180 16" Rear Wheel—Less Tire

734-0392

Semi Pneumatic Tire 16 x

1.75

741-0267

.1 710-0427

22

734-0643 Front Wheel Ass’y. Comp.

23 736-0105

24 738-0251

Ball Brg. 3/8" I.D.

Hex Bolt 3/8-16 x 2.00" Lg.*

Belleville Washer

Blade Spindle

NEW

PART

REF.

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

25 714-0365 #6 Hi-Pro Key 5/32 X 5/8" Dia

26 712-0123 Hex Nut 5/16-18 Thd.*

27 736-0119 L-Wash. 5/16" Scr.*

28 742-0125 22" Blade

710-0117 Hex Bolt 5/16-24 X 1.00" H.T.

29

30 710-0459 Hex Bolt 3/8-24 X 1.50" Lg.

H.T.

31 736-0217 L-Wash. 3/8" Scr. H.D.

32

07919 Scalp Plate

33 10769 Blade Adapter Kit

34 712-0123

Hex Nut 5/16-24 Thd.*

35 736-0119 L-Wash. 5/16" Scr.*

36 712-0267

37

736-0119 L-Wash. 5/16" Scr.*

38 712-0123

39 12281

712-0267

40

41

736-0119 L-Wash. 5/16" Scr.*

42

08253 Bearing Housing

43

741-0919 Ball Bearing

Hex Nut 5/16-18 Thd.*

Hex Nut 5/16-18 Thd.*

Blade Reinforcement Plate

Hex Nut 5/16-18 Thd.*

44 08253 Bearing Housing

45 710-0192

Truss Hd. Mach. Scr. 10-24 x

.38 Lg.

46 08295 —452 Blade Spindle Cover

47

48

712-0526

11679

—462

Speed Nut #10-24

Chute Deflector Ass’y.—

Comp.

49 710-0289

50 750-0434

51 741-0484

Hex Bolt 1/4-20 X .50" Lg.*

Spacer

Ball Bearing Vz" I.D.

NEW

PART

*For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

(462—Red FlaKe)

When ordering parts, if coior or finish is important, use the ap

propriate color code shown at left. (e.g. Red Flake

Finish—11815(462).)

The engine is not under warranty by the mower manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine service outlet. Check the “Yellow Pages” of

your telephone book under “Engines — Gasoline.”

Find It Fast

In The

Yellow Pages

19

Page 20

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PART?:

Parts and service for all MTD manufactured power equipment are AND SERVICE

available through the authorized service firms listed below. All Briggs & Stratton, Tecumseh and Peerless parts and serv.

orders should specify the model number of your unit, part should be handled by your nearest authorized engine service firm,

numbers, description of parts and the quantity of each part re- Check the yellow pages of your telephone directory under the

quired. listing Engines—Gasoline, Briggs & Stratton or Tecumseh

NOTE; If any parts are found to be missing or defective upon assembly of this unit, write to advise the factory so

that immediate replacement can be made.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co. . .. 2625 4th Ave. S

ARKANSAS FORT SMITH

Mity Mite Motors, Inc......................4515 S. 16th St............72901

Sutton’s Lawn Mower Shop

CALIFORNIA PORTERVILLE

Billious

COLORADO DENVER

FLORIDA JACKSONVILLE

GEORGIA EAST POINT

ILLINOIS LYONS

INDIANA ELKHART

IOWA DUBUQUE

LOUISIANA NEW ORLEANS

MARYLAND TAKOMA PARK

MASSACHUSETTS SPRINGFIELD

MICHIGAN LANSING

MINNESOTA HOPKINS

MISSISSIPPI BILOXI

MISSOURI KANSAS CITY

NEW JERSEY BELLMAWR

NEW MEXICO ALBUQUERQUE

NEW YORK CARTHAGE

.........................................

Spitzer Industrial Products Co. . . . 6601 N. Washington St.,

Radco Distributors

Small Eng. Dist.,

East Point Cycle & Key

Keen Edge Co................................8615 Ogden Ave..........60534

Parts & Sales Inc

Power Lawn & Garden Equip

Suhren Engine Co

Center Supply Co..........................

Morton B. Collins Co

Lorenz Service Co.......................... 2500 S. Pennsylvania . .48910

Power Equipment Dist

Hance Distributing Inc

Biloxi Sales & Service, Inc

Automotive Equip. Service

Ross-Frazier Supply Co

Henzier, Inc....................................2015 Lemay Ferry Rd. .63125

Lawnmower Parts Inc

Spitzer Eng. & Parts....................... 1023 Third St. N.W... .87103

Gamble Dist., Inc............................West End Ave

.........................

............................

..................

...........................

..........................

......................

...................

...................

.................

....................

NORTH LITTLE ROCK

...........

Rt. 4, Box 368

75 North D Street

60x29114

4909 Victor St.,

80x5459

OPA LOCKA

2351 N.W. 147th St. . . .33054

2834 Church St

2101 Industrial Pkwy.. .46514

........

2551 J.F. Kennedy . . . .52001

8330 Earhart Blvd

6867 New Hampshire

Ave

.............................

300 Birnie Ave

MOUNT CLEMENS

340 Hubbard...............48043

420 Excelsior Ave. W. .55343

.............

506 Caillavet St

............

3117HolmesSt

ST. JOSEPH

8th and Monterey

ST. LOUIS

717 Creek Rd

..............

.............

.............

..................

....................

...........

.......

............

..........

.............

........

..............

..............

35233

72117

93257

80229

32207

30344

70118

20012

01107

39533

64109

64503

08030

13619

Lauson.

NORTH CAROLINA GOLDSBORO

Smith Hardware Co

Dixie Sales Company

OHIO CARROLL

Stebe’s Mid-State Mower Supply . 71 High St., Box 366 .. .43112

Bleckrie, Inc

National Central

Burton Supply Co...........................1301 Logan Ave.,

OKLAHOMA MUSKOGEE

Victory Motors, inc

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA HARRISBURG

EECOInc........................................ 4021 N.6thSt

Thompson Rubber Co

Bluemont Co

Frank Roberts & Sons

TENNESSEE KNOXVILLE

Master Repair Service

American Sales & Service, Inc. . . . 3035-43 Bellbrook . .. .381 lo

TEXAS DALLAS

Marr Brothers, Inc

Woodson Sales Corp

Bullard Supply Co

UTAH SALT LAKE CITY

A-1 Engine & Mower Co

VERMONT BURLINGTON

Vermont Hdwe. Co. Inc..................180 Flynn Ave..............05401

VIRGINIA ASHLAND

RBI Corp

WASHINGTON SEATTLE

Bailey’s inc

WEST VIRGINIA CHARLESTON

Young’s, Inc.................................... 233 Virginia St., E

WISCONSIN MARSHFIELD

Power Pac

........................................

.....................................

......................................

.......................

....................

...................................

.............................

.........................

..........................

....................

..................................

..................

..................

..........................

.....................

..........................

................

515 N. George St

GREENSBORO

335 N. Green

CLEVELAND

7900 Lorain Ave..........44102

WADSWORTH

687 Seville Rd

YOUNGSTOWN

Box 929 .......................44501

605 S. Cherokee

8216 N. Denver Ave. . . .97217

PHILADELPHIA

5222-24 N. Fifth St 19120

PITTSBURGH

11125 Franksfown Rd. . 15235

PUNXSUTAWNEY

R.D. 2

...........................

2000 Western Ave

MEMPHIS

423 E. Jefferson..........75203

FORT WORTH

1702 N. Sylvania

HOUSTON

2409 Commerce St. . . .77003

437 E. 9th St

Lake Ridge Park,

101 Cedar Run Dr

1414 14th Ave

301 E. 29th St.. ..........

.........

..............

............

........

...............

......

........

...............

........

.............

......

27530

27402

44281

74401

17110

15767

37T

76111

84111

23005

98102

25301

54449

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected at the

time of manufacture. It does not provide for the unlimited and unrestricted replacement of parts. Use and maintenance are the respon

sibility of the customer. The manufacturer cannot assume responsibiiity for conditions over which it has no control. Simply put, if it’s

the manufacturer’s fault, it’s the manufacturer’s responsibility; if it’s the customer’s fault, it’s the customer’s responsibility.

CLAIMS AGAINST THE MANUFACTURER’S WARRANTY

INCLUDES:

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty period.

3. Repair of Defects within the warranty period.

All claims MUST be substantiated with the following

information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

MTD PRODUCTS • P.O.BOX 36900 • CLEVELAND, OHIO 44136

Loading...

Loading...