Page 1

OWNEirSGUM

ASSEMBLY • OPERATION • MAINTENANCE • PARTS

20" and 22"

ROTARY

$1.00

MOWERS

Model Series

111-070R000 thru 111-078R000

111-080R000 thru 111-089R000

111-200R000 thru 111-206R000

111-220R000 thru 111-226R000

(Models 072R and 082R Shown)

Important: Read Safety Rules and Instructions Carefully

WARNING: This unit is equipped with an internal combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order

by the operator.

In the State of California the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

in

AMERICA

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 360900, Cleveland, Ohio 44136.

SOPFLEMeJir SHEET /*A!ISÙ

n0'ûgi.-ûûû

PRINTED IN U.S.A.

FORM NO. 770-7500F

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTR JCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY

AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

A

TO OPERATE YOUR LAWN MOWER. FAILURE TO CON PLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN,

YOU SEE THIS SYMBOL- A HEED ITS WARMING.

RULES FOR SAFE OPERATION

A

DANGER: with any type of power equ ipment, carelessness or error on the part of the operator can result In serious

Your lawn mower was bull I to be operated according to the rules for safe operation In this manual. As

A

TRAINING

1. Read this owner’s guide carefully In Its entirety before attempting

A-

to assemble or operate this machine. Be completely f< miliar with

the controls and the proper use of this machine befoni operating

it. Keep this manual in a safe place for future and reguL r reference

and for ordering replacement parts.

2. Your rotary mower is a precision piece of power equi iment, not

a plaything. Therefore, exercise extreme caution at all 1 mes. Your

unit has been designed to perform one job: to mow grass. Do

not use it for any other purpose.

3. Never allow children under 14 years old to operate a po\ ler mower.

Children 14 years old and over should only operate mi iwer under

close parental supervision. Only persons well acquaintec with these

rules of safe operation should be allowed to use yoi ir mower.

4. Keep the area of operation clear of all persons, particularly small

children and pets. Stop engine when they are in the vicinity of

your mower to help prevent blade contact or throwr object in

jury. Although the area of operation should be complel ely cleared

of foreign objects, an object may have been overlook» and could

be accidently thrown by the mower in any direction and cause

serious personal injury to the operator or any others allowed in

the area.

PREPARATION

Thoroughly inspect the area where the equipment is lo be used.

Remove all stones, sticks, wire, bones and other fore gn objects

which could be picked up and thrown by the mower ir any direc

tion and cause serious personal injuiy to the operator oi any others

allowed in the area. Plan your mowing pattern to avok discharge

of material toward roads, sidewalks, bystanders and the like.

2. Always wear safety glasses or eye shields during operat on or while

performing an adjustment or repair, to protect eyes frDm foreign

objects that may be thrown from the machine in am direction.

3. Wear sturdy, rough-soled work shoes and close-fitting slacks and

shirts. Shirts and pants that cover the arms and legs and steel

toed shoes are recommended. Do not wear loose fitt ng clothes

or jewelry. They can be caught in moving parts. Nei er operate

a unit in bare feet, sandals, or sneakers.

4. Before working with gasoline, extinguish all cigarettes, c gars, pipes

and other sources of ignition. Check the fuel level before starting

the engine. Gasoline is an extremely flammable fuel. Do not fill

the gasoline tank Indoors, while the engine, is running, or until

engine has been allowed to cool for at least two mi lutes after

running. Replace gasoline cap securely and wipe off any spilled

gasoline before starting the engine as it may causî a fire or

explosion.

5. Disengage the self-propelled mechanism or drive dut ;h on units

so equipped before starting the engine.

6. The blade control handle is a safety device. Never attemi t to bypass

its operation. Doing so makes the safety device inop jrative and

may result in personal injury through contact with 1 ie rotating

blade. The blade control handle must operate easily in both direc

tions and automatically return to the disengaged pos:ition when

released.

7. Never attempt to make a wheel or cutting height adjus ment while

the engine is running.

8. Never operate the mower in wet grass. Always be s ire of your

footing. A slip and fall can cause serious personal injury. Keep

a firm hold on the handle and walk, never run. Mow onl; ' in daylight

or in good artificial light.

injury. If you violate any o’ these rules, you may cause serious injury to yourself or others.

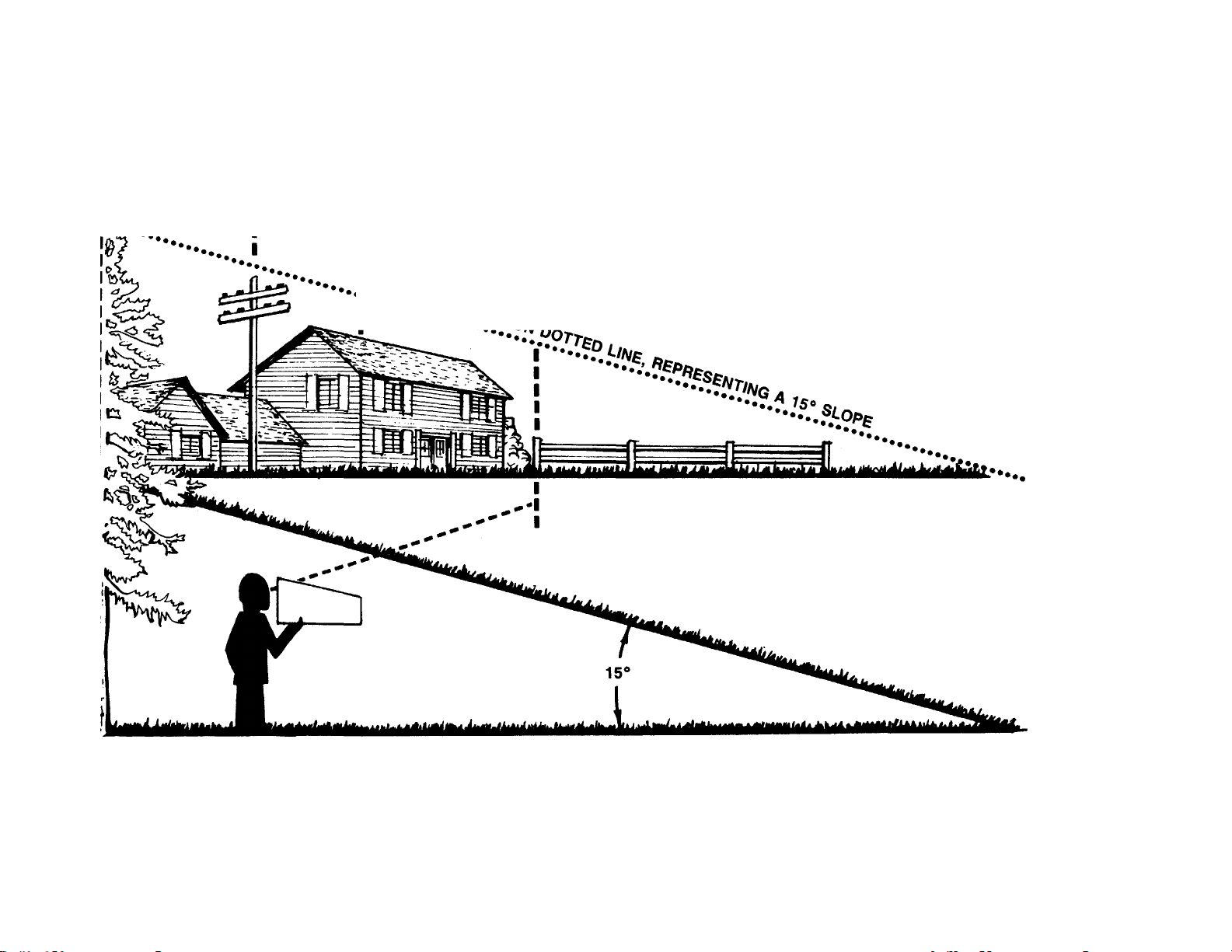

For your safety, use the slope gauge included as part of this manual

to measure slopes before operating this unit on a sloped or hilly

area. If the slope is greater than 15° as shown on the slope gauge,

do not operate this unit on that area or serious injury could result.

OPERATION

Do not change the engine governor settings or overspeed the

engine. Excessive engine speeds are dangerous.

2.

Do not put hands or feet near or under rotating parts. Keep clear

of the discharge opening at all times as the rotating blade can

cause injury.

Stop the blade when crossing gravel drives, walks or roads.

After striking a foreign object, stop the engine, remove the wire

from the spark plug, and thoroughly inspect the mower for any

damage. Repair the damage before restarting and operating the

mower.

5.

If the equipment should start to vibrate abnormally, stop the engine

and check immediately for the cause. Vibration is generally a warn

ing of trouble.

Shut the engine off and wait until the blade comes to a complete

stop before removing the grass catcher or unclogging the chuteThe cutting blade continues to rotate for a few seconds after

engine is shut off. Never place any part of the body in the bk

area until you are sure the blade has stopped rotating.

7.

Before cleaning, repairing or inspecting, make certain the blade

and all moving parts have stopped. Disconnect the spark plug wire,

and keep the wire away from the spark plug to prevent accidental

starting.

Do not run the engine indoors.

Never cut grass by pulling mower toward you. Mow across the

face of slopes, never up-and-down. Exercise extreme caution when

changing direction on slopes. Do not mow excessively steep slopes.

Always be sure of your footing. A slip and fali can cause serious

personal injury.

10.

Never operate mower without proper guards, plates or other safety

protective devices in place.

11.

Muffler and engine become hot and can cause a burn. Do not

touch.

MAINTENANCE AND STORAGE

Check the blade and engine mounting bolts at frequent intervals

for proper tightness. Also visually inspect blade for damage (e.g.

bent, cracked). Replace with blade which meets original equip

ment specifications.

Keep all nuts, bolts, and screws tight to be sure the equipment

is in safe working condition.

Never store the mower with gasoline in the tank or gas containers

inside of a building where fumes may reach an opan flame or spark

(e.g. gas hot water heater). Allow the engine to cool before stor

ing In any enclosure.

To reduce fire hazard, keep the engine free of grass, leaves and

excessive oil.

Check the grass catcher bag frequently for wear or détériorât

Replace a worn or damaged bag immediately. For safety prott.

tion, replace only with new bag meeting original equipment

specifications.

Page 3

--------

j------------------------------------------------------------------------------------------------------------------OUT Mio jns Line-------------------------------------------------------------------------------------------------------------------------- I

USE THIS SHEET AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

----------------------

----------------

^---------------------------------A CORNER OF A BUILDING

I

..........

A POWER POLE

.

OR A FENCE POST

T3

o

o

0)

CO

0)

zr

(D

(D

S'

CD

(0

w

■D

(D

O

D

O

(D

C

n

C

-t

(D

“T

(D

(D

(D

3

o

0

WARNING

AC

Do not mow on inclines with a slope in excess of IS degrees (a rise of approximately 2V2 feet every 10 feet). A

riding mower could overturn and cause serious injury. If operating a waik-behind mower on such a slope, it is

extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RIDING mowers up and down slopes, never across the face of slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

Page 4

CONTENTS OF HARDWARE PACK

Remove this sheet from your owner’s manual £ nd lay the hardware on the illustration for identification purposes.

After assembly, keep the Slope Gauge which is on the reverse side of this sheet for future use.

(Hardware pack may contain extra items which are not used on your unit—

Part numbeis are shown in parentheses.)

ATTACHING THE

LOWER HANDLE

Hairpin—«

Clips

(714-0104)

ATTACHING THE

STARTER ROPE

Rope Guide

(710-1205)

Hex Lock Nut

V4-2O Thread

(712-0324)

ATTACHING THE CABLE BRACKET AI>1D

(OPTIONAL) THROTTLE CONTROL Spring Washer

R ATTACHING THE

UPPER H I^NDLE

Curved

Head Be lts

(710-06/1)

Split Was hers

5/16" I D.

(736-0119)

Hex Nuts

5/16-18 Tliread

(712-021)7)

1/4" I.D.

Cable ^ (736-0175)

Bracket

(17174)

\

O

Upper-

Handle

Rope

Guide

Lower

Handle

Handle

Mounting

Brackets

Blade Control

Handle

Chute

Deflector

(Models 072R and

082R Shown)

PARTS IDENTIFICATION

Hex Nut

Vt-20 Thread

(712-0287)

Throttle

Control

(Optional)

Engine

\ Hex Bolt

V4-20 X 1-7/8" Long

(710-1216)

1-----Hex Bolt

1/4-20 X 1" Long

(710-0597)

(Used With No

Remote Throttle)

O

c

>

—1

3"

«■

I-

5'

(D

SECURING THE CABLES

n

n

n

I > 111111111111111111111

0

INCHES

LI

U

If

Cable Ties

(726-0240)

f

Page 5

ASSEMBLY INSTRUCTIONS

This owner’s guide covers various modeis of

mowers. Foiiow only those instructions which per

tain to your unit.

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, service engine

with gasoline and oil as instructed in the separate

engine manual packed with your unit.

NOTE: Reference to right or left hand side of the

mower is observed from the operating position.

Tools Required for Assembly

(1) Pair of Pliers

(1) 1/2" Wrench*

(2) 7/16" Wrenches*

*Or two 6" Adjustable Wrenches

Lower

Handle

Handle

Mounting

Bracket

Hairpin

Clip

FIGURE 1.

Hole in Blade

Control Handle

UNPACKING

1. Remove the lawn mower from the carton by open

ing the top flaps and lifting the unit out. Be careful

of the staples. Make certain all parts and literature

have been removed from the carton before the car

ton is discarded.

2. Disconnect the spark plug wire and move away

from the spark plug.

Stretch out all control cables and place on the floor.

3.

Be careful not to bend or kink the cables at any

time during assembly.

4.

Remove page four from this manual and lay the

contents of the hardware pack on the illustration

for identification.

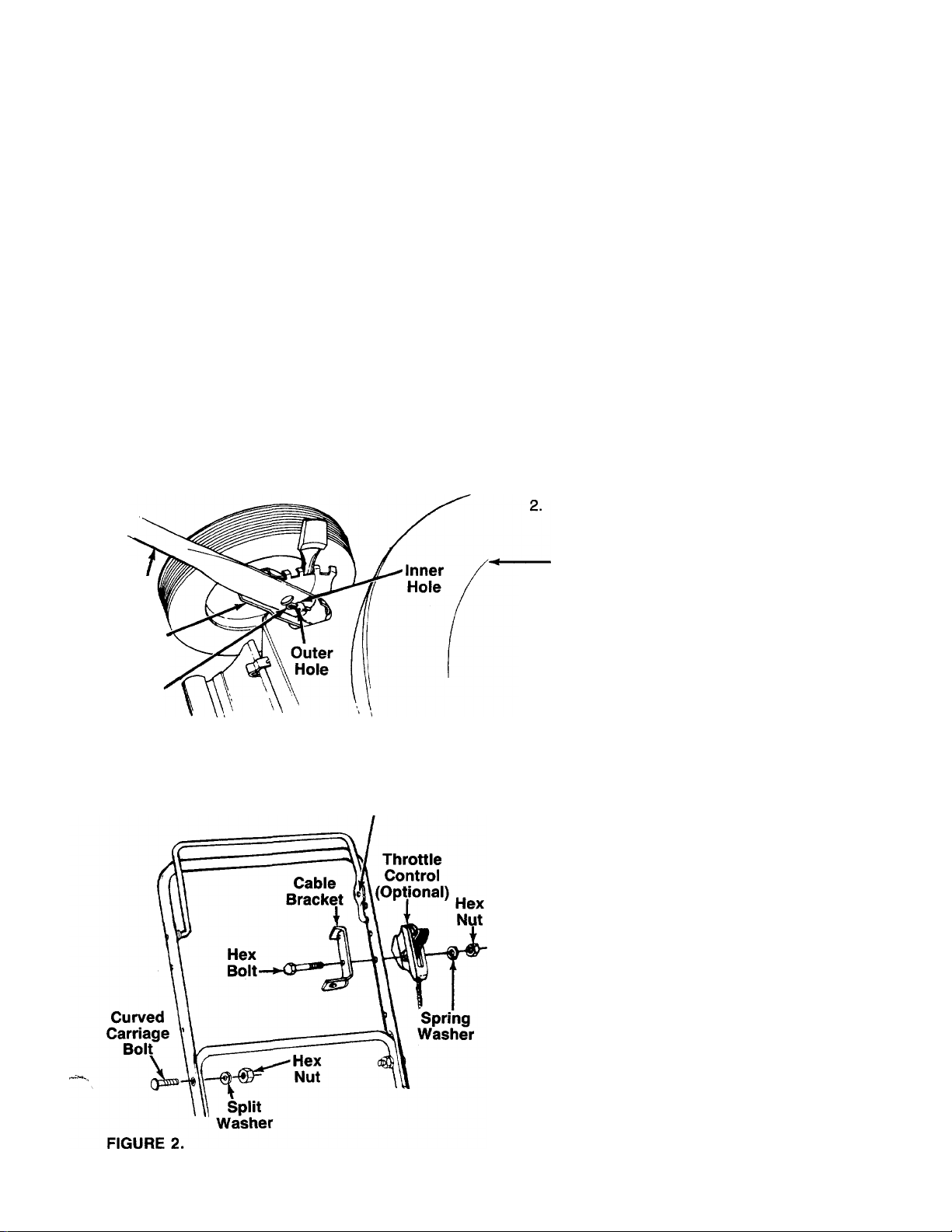

AHACHING THE LOWER HANDLE (Hardware A)

1. Attach the lower handle by placing the bottom

holes in the lower handle over the weld pins on the

handle mounting brackets extending through the

rear of the deck.

Using a pair of pliers, squeeze one leg of the lower

handle against the handle mounting bracket. In

sert the hairpin clip into the inner hole on the weld

pin. See figure 1. Repeat on other side.

NOTE: There are two (2) holes in the handle mounting

brackets. Place the hairpin clip in the inner hole for

operation. Outer hole is for storage.

ATTACHING THE UPPER HANDLE (Hardware B)

1. Place the upper handle in position over the lower

handle. The hole in the side of the blade control

handle (attached to the upper handle) must be on

the left side.

2. Secure the upper handle to the lower handle us

ing the curved head bolts, split washers and hex

nuts as shown in figure 2.

AHACHING THE CABLE BRACKET AND THRDTTLE CDNTRDL (Hardware D) (Dptional)

If your mower is equipped with a remote throttle con

trol, it is already attached to the engine. Attach the

cable bracket and throttle control to the left side of up

per handle as follows. See figure 2.

NOTE: If your mower does not have a remote throttle

control, attach the cable bracket using the 1" long hex

bolt provided and following steps 2 and 4 only.

1. Route the throttle control cable inside the handle

mounting bracket and beneath the lower handle.

2.

Place cable bracket against left side of upper han

dle, lining up the hole in the bracket with the bot

tom hole in upper handle. Place 1/4" hex bolt

through cable bracket and handle, from the inside

to the outside.

3.

Place throttle control on the hex bolt (outside of

the upper handle), with the throttle lever facing

upward.

Page 6

“Z”

FIGURE 3.

\\ ) ‘V

Hole in

Bracket

Plastic Fitting

-Blade

Control

Handle

4. Secure with spring washer (cupped side against

the throttie control) and hex nut.

ATTACHING THE BRAKE CABLE

1. The brake cable is attached to the engine, and has

a “Z” fitting on the loose end. Route the brake

cable below the lower handle. Place end of cable

through the hole in the bracket as shown in figure

-3. Push the plastic fitting until it locks into the hole

in the bracket.

WARNING: Brake cable must be assem

bled as shown for proper blade brake

A

2. Hook the “Z” end of the brake cable into the hole

operation.

in the blade control handle from the inside to the

outside as shown in figure 3.

SECURING THE CABLES (Hardware E)

Secure all cables to the left side of the handle as

follows.

1. Insert posts on cable ties into holes provided on

the handles, one on the upper handle and two on

the lower handle. The holes may be either on the

inside or outside of the handles. See figure 4A.

2. Secure the cables with the cable ties. See figure

-------

4B.

3. Trim excess ends of cable ties.

FIGURE 5.

FIGURE 6.—Optional Hub Caps

ATTACHING THE STARTER ROPE (Hardware C)

1. The starter rope is inside the top of the engine. Ad

ditional rope may be wound around the starter han

dle. If so, unwind the rope from the handle.

2. With the spark plug wire disconnected and

grounded, depress the blade control handle and

pull the rope out of the engine.

—3. Place the rope guide around the starter handle, so

the rope guide is positioned as shown (bends

downward slightly). Insert the rope guide through

the side of the upper handle, and secure with hex

lock nut.

INSTALLATION OF HUB CAPS (Optional)

1. If your mower is equipped with hub caps which

have four tabs, line up the tabs on the hub caps

with the holes in the wheels. Push to lock in

position.

2. If your mower is equipped with 2" wide tires, place

hub caps in position against the inner hub of the

wheel. Press firmly around the center portion of

hub cap in a circular motion, similar to installing

-------

a lid on a round, plastic container. See figure 6.

The hub caps are flexible and will snap over the

3V2" diameter wheel hubs.

NOTE: It may be helpful to place the hub caps In hot

tap water for several minutes to make them pliable

before installing, especially if the temperature is less

than 60°F.

Page 7

FINAL ASSEMBLY OF MOWER

1. The chute deflector on your mower is held in an

upright position by a block for shipping purposes

only. This shipping block must be removed and

discarded before the mower is put into operation.

-------

See figure 7.

To remove the shipping block, move the spring-

loaded chute toward the engine by pushing above

the shipping block. Remove the block and carefully

lower the chute into operating position, keeping

fingers out of the way.

2. Make certain all nuts and bolts are tightened

securely.

BLADE CONTROL HANDLE

WARNING: This control mechanism is a

safety device. Never attempt to bypass its

A

operations.

CONTROLS

The blade control handle is located on the upper han

dle of the mower. See figure 8. The biade control han

dle must be depressed in order to operate the unit.

Release the blade control handle to stop the engine and

blade.

A

THROTTLE CONTROL (Optional)

The throttle control is located on the side of the upper

handie or on the engine. It is used to regulate the

engine speed.

A

RECOIL STARTER

The recoii starter handle is attached to the handle. See

figure 8. Stand behind the unit in the operating posi

tion to start the unit.

WARNING: The blade will be rotating

whenever the engine is running.

WARNING: The throttle control cannot be

used to stop the engine.

Page 8

OPERATION

TO REDUCE THE RISK OF INJURY, DO NOT

OPERATE MOWER UNLESS REAR TRAILING

SHIELD AND THIS GUARD OR ENTIRE

GRASS CATCHER IS IN ITS PROPER PLACE.

FIGURE 9.

Keep hands and feet away from the chute area on

cutting deck. See figure 9.

The operation of any lawn mower can result in

foreign objects being thrown into the eyes, which

can result in severe eye dainage.

Always wear safety glasses nr eye

shields. We recommend wide vision

safety mask for over spectacles or

standard safety glasses.

Metal Loop

on Spark

Plug Wire

Rubber Boot

FIGURE 10.

2. Open fuel shut-off valve if so equipped. Refer to

the separate engine manual.

3. Move throttle control lever all the way forward.

4. Tecumseh engines only: Prime engine as in

structed in the separate engine manual.

5. Standing behind the unit, depress the blade con

trol handle and hold it against the upper handle

as shown. See figure 11.

6. Grasp the recoil starter handle and pull back rapid

ly, extending rope fully. Return it slowly to the rope

guide bolt.

7. After engine starts, move throttle control to desired

engine speed.

NOTE: if any probiems are encountered, refer to the

Troubie Shooting Guide on page 16.

NOTE: For shipping purposes your mower is set with

the wheeis in a iow cutting height position. For best

resuits raise the cutting position untii it is determined

which height is best for your iawn. See cutting 'leight

adjustment section.

GAS AND OIL FILL-UP

Service the engine with gasoiine and oii as instructed

in the separate engine manual packed with your

mower. Read instructions carefully.

WARNING: Never fill fuel tank indoors,

with engine running or until the engii le has

A

been allowed to cool for at least two

minutes after running.

TO START ENGINE AND ENGAGE BLADE

1. Attach spark plug wire to spark plug. If jnit is

equipped with a rubber boot over the end of the

spark plug wire, make certain the metal loop on

the end of the spark plug wire (inside the ubber

boot) is fastened securely over the metal tip on the

spark plug. See figure 10.

FIGURE 11.

TO STOP ENGINE AND BLADE

1. Release the blade control handle to stop the

engine and blade.

WARNING: The blade continues to rotate

for a few seconds after the engine is shut

A

2. Disconnect the spark plug wire and ground it

off.

against the engine to prevent accidental starting

while equipment is unattended.

Page 9

USING YOUR ROTARY MOWER

Be sure that lawn is clear of stones, sticks, wire, or other

objects which could damage lawn mower or engine.

Such objects could be accidently thrown by the mower

in any direction and cause serious personal injury to

the operator and others.

For the best results, do not cut wet grass because it

tends to stick to the underside of the mower, prevent

ing proper discharge of grass clippings, and could

cause you to slip and fall. New grass, thick grass or

wet grass may require a narrower cut. Blade speed

should be adjusted to the condition of the lawn.

The best mowing pattern is one that allows the clippings

to discharge towards the uncut part of the lawn. This

permits recutting of the clippings to further pulverize

them. When cutting high weeds, discharge towards cut

portion, then recut at right angles to first direction.

For best results, cut off one-third or less of the total

length of the grass. Lawn should be cut in the fall as

long as there is growth.

This mower is designed to be operated at full throttle

to give you the best cut and do the most effective job

of bagging the cut grass.

WARNING: If you strike a foreign object,

stop the engine. Remove wire from spark

A

plug, thoroughly inspect the mower for any

damage, and repair the damage before

restarting and operating the mower. Exten

sive vibration of the mower during opera

tion is an indication of damage. The unit

should be promptly inspected and

repaired.

FIGURE 12.

THROTTLE CONTROL ADJUSTMENT

If the throttle control (optional) needs adjustment or if

it has been replaced, adjust as follows.

Briggs & Stratton Quantum Engi.ies:

1. Remove the screw shown in figure 13. Remove the

cable clamp from the cable.

2. Push the throttle control lever on the handle all the

way forward to CHOKE position. Make certain the

throttle control lever remains in this position.

3. Push the control lever on the engine as far toward

the rear of the engine as it will go. Secure the cable

in this position with the cable clamp and screw.

Cable

Clamp

ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to lawn mower without first

A

CUTTING HEIGHT ADJUSTMENT

An adjusting plate and thumb lever at each wheel posi

tion provides cutting height adjustment. Each adjusting

plate has nine height positions. Height of cut will be

changed when the thumb lever is moved from one hole

to another. Simply depress the lever towards wheel and

move wheel and lever assembly to desired position. All

wheels must be placed in the same relative position.

See figure 12.

stopping engine and disconnecting spark

plug wire.

FIGURE 13.—Briggs & Strattoh Quantum Engines

Briggs & Stratton Standard and Sprint Engines

and all Tecumseh Engines (all other models):

1. Loosen (do not remove) the screw on the cable

clamp so that the cable will move freely under the

clamp. See figure 14.

2. Place the throttle control lever on the handle all the

way forward to START position.

3. Place the control lever on the engine in the full

open position by pushing it as far toward the out

side (Briggs and Stratton engine) or rear

(Tecumseh engine) of the engine as it will go.

Tighten the screw on the cable clamp to secure

the cable in this position.

Page 10

Control

Lever

On Engine

FIGURE 14A.—Briggs & Stratton Standard Engine

Blade Control—Lubricate the pivot points on the blade

control handle and the brake cable at least once a

season with light oil. See figure 15. The blade control

must operate freely in both directions.

Chute Deflector—The torsion spring and pivot point

should be lubricated periodically with light oil to pre

vent any rust or binding. Deflector must work freely.

Wheels—Mower may be provided with ball bearing

wheels. Lubricate at least once a season with light oil.

Also, if the wheels are removed for any reason,

lubricate the surface of the axle bolt and the inner sur

face of the wheel with light oil. A 4 oz. plastic bottle

of light oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

Engine—Follow engine manual for lubrication in

structions.

Throttle—Periodically lubricate throttle control lever

and throttle wire assembly with a few drops of light oil

for ease of operation.

FIGURE 14B.—Tecumseh Engines

CARBURETOR ADJUSTMENTS

WARNING: If any adjustments are made to

the engine whiie the engine is running (e.g.

A

Minor carburetor adjustments may be requ red to

compensate for differences in fuel, tempe ature,

altitude and load. To adjust carburetor, refer to the

separate engine manual packed with your mcwer.

NOTE: A dirty air cleaner will cause an engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Refer to the

separate engine manual.

carburetor), keep ciear of ali moving parts.

Be carefui of heated surfaces and nr uffier.

LUBRICATION

WARNING: Always stop engine and

disconnect spark plug wire before clean

A

ing, iubricating or doing any kind of work

on lawn mower.

MAINTENANCE

WARNING: Be sure to disconnect and

ground the spark plug wire before perform-

Ai

iing any repairs or maintenance.

NOTE: When tipping the unit, empty the fuel tank and

keep engine spark plug side up.

TROUBLE SHOOTING

Refer to page 16 of this manual for trouble shooting

information.

CUTTING BLADE

When removing the cutting blade for sharpening or

replacement, protect hands by using heavy gloves or

a rag to grasp the cutting blade. Remove the bolt and

bell washer which hold the blade and adapter to the

engine crankshaft. Remove the blade and adapter from

the crankshaft.

If the blade or blade adapter needs replacing, remove

the two small bolts, lock washers and nuts which hold

the blade to the adapter.

WARNING: Periodically inspect the blade

adapter for cracks, especially if you strike

A

a foreign object. Replace when necessary.

10

Page 11

When sharpening the blade, follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds,

may cause damage to the mower and could break,

causing personal injury.

It is recommended that the blade always be removed

from the adapter for the best test of balance.

The blade can be tested by balancing it on a round shaft

screwdriver. Remove metal from the heavy side until

it balances evenly.

Before reassembling the blade and the blade adapter

to the unit, lubricate the engine crankshaft and the inner

surface of the blade adapter with light oil. Lubricating

the bolt holes, bolts and inner surface of the nuts with

light oil is also recommended. A 4 oz. plastic bottle of

light oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

When replacing the blade, be sure to install the blade

with the side of the blade marked “Bottom” (or with

part number) facing the ground when the mower is in

the operating position.

Blade Mounting Torque

Center Bolt and Blade Adapter Bolts:

375 in. lb. min., 450 in. lb. max.

To insure safe operation of your unit, all nuts and bolts

must be checked periodically for correct tightness.

DECK

The underside of the mower deck should be cleaned

after each use to prevent a buildup of grass clippings,

leaves, dirt or other matter. If this debris is allowed to

accumulate, it will invite rust and corrosion, and may

cause an uneven discharge of grass clippings at the

next cutting.

The deck may be cleaned by tilting the mower and

scraping clean with a suitable tool (make certain the

spark plug wire is disconnected).

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each mowing season; check

engine manual for correct plug type and gap

specifications.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to per

mit proper air circulation which is essential to engine

performance and life. Be certain to remove all grass,

dirt and combustible debris from muffler area.

OFF-SEASON STORAGE"

The following steps should be takfin to prepare lawn

mower for storage.

1. Clean and lubricate mower thoroughly as de

scribed in the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

3. Coat mower’s cutting blade with chassis grease

to prevent rusting.

4. Store mower in a dry, clean area.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rust-proof the equipment. Using a light oil or

silicone, coat the equipment, especially cables and all

moving parts.

HANDLE STORAGE

The handle may be placed in an upright position for

storage. Move hairpin clips to outer hole on weld pins.

See figure 1. Press inward on the bottom of the lower

handle and push forward. The handle will lock In this

position.

To place the handle in the operating position, remove

the starter rope from the rope guide bolt. Grasp the

lower handle at the bottom, press inward slightly and

tip the handle backward. Place the hairpin clips in the

inner holes. With the spark plug wire disconnected and

grounded, depress the blade control handle and pull

the starter rope out from the engine. Slip the starter

rope into the rope guide bolt.

NOTE: The use of any accessory on this Rotary Mower other than those manufactured by the mower manufacturer is

not recommended. GRASS CATCHER Model 086 is available as optional equipment for the mowers shown in this manual.

WARNING: To reduce the risk of injury, do not operate mower unless rear trailing shield and guard or

A

NOTE: Under normal usage bag material is subject to wear and should be checked periodically. Be sure any replace

ment bag complies with the mower manufacturer’s recommendations. For replacement bags, use only factory authorized

replacement bag No. 764-0271.

entire grass catcher is in its proper place.

11

Page 12

Models 070R thru 089R

‘For faster service obtain standard nuts, bolts and washers locally.

If these items cannot be obtained locally, order by part number and

size as shown on parts list.

CODE: N notates a new part (not previously existing). A three digit

number is the color code. Specify color code if color or finish is

important when ordering parts as shown below, [i.e., 638 for Red

^ Finish].

Color Codes

456—Radiant Tangerine 629—Silver Flake

460—Green Flake

483—Charcoal Gray

498—Yellow

499—Beige 640—Green

621—Brilliant Fire Mist 646—CM Blue

630—Metallic Blue

637—Black

638—Red

NOTE; The engine is not under warranty by

the mower manufacturer.. .If repairs or

service is needed on the engine, please

contact your nearest author

ized engine service outlet.

Check the ‘‘Yellow Pages” of

your telephone book under

‘‘Engines—Gasoline.”

Find It Fast

In The

Yellow Pages

Optional Hub Caps

Description Part No.

Gray (for “S” Wave Wheels)

Beige (for ”S” Wave Wheels)

Red (with 4 tabs)

Black (with 4 tabs)

12

731-0981A

731-0982A

731-0124

731-0354

^30

^30

Page 13

PARTS LIST FOR MODELS 070R THRU 089R ROTARY MOWERS

1

PART

NO.

747-0748

CODE DESCRIPTION

Control Handle Ass’y- (Std.)

731-1135 Control Handle Ass’y. w/PlastIc

2

736-0270 Bell-Wash. Va" I.D.

3 17174

Cable Brkt.

4 710-1216 N Hex Bolt 1/4-20 X 1.875" Lg.*

710-0597

Hex Bolt 1/4-20 X 1" Lg.* 47

REF.

NO.

41 710-0429

42 751-0369

43

44 735-0639

46

(Used without Throttle Control) 48

5 736-0175 Spr. Wash. 1/4" I.D. 49 14832

712-0287

6

749-0756A

8

Hex Nut 1/4-20 Thd.*

Upper Handle 51 15261A

N

Rope Guide

50 15262B Pivot Bar

52

L-Wash. 5/16" I.D.* 53 14578

712-0267

710-0671

Hex Nut 5/16-18 Thd.* R.F. & L.R.

Curved Carriage Bolt 5/16-18

X 1.38" Lg.

726-0240 Cable Tie 54

749-0372B

Lower Handle

Hairpin Cotter 746-0820

17098

Hinge Clip

731-0872 Rear Flap

17189 Handle Bracket Ass’y.—L.H.

17188

Handle Bracket Ass’y.—R.H. 079R)

Bell-Wash. .39" I.D. x 1.38"

Hex Nut 3/8-16 Thd.*

L-Wash. 3/8" I.D.* 746-0832

712-0241

17036 638 20" Deck Ass’y.

Hex Nut 3/8-24 Thd.*

55 746-0553.

17046 638 22" Deck Ass’y.

Blade Adapter Kit (Keyed)

753-0485

Blade Adapter Kit (Splined) 746-0550

Bell-Wash. .39" I.D. (Used

w/Keyed Adapter) 746-0557

736-0453

Bell-Wash. .46" I.D. (Used

w/Splined Adapter) 746-0552

Hex Bolt 3/8-24 x 1.5" Lg.

(Used w/Keyed Adapter)

710-0757

Hex Bolt 7/16-20 X 1.5" Lg. 57 710-0654A

(Used w/Splined Adapter)

20" Blade 60 731-1034

742-0522

22" Blade 61

Hex L-Nut 1/4-20 Thd. 62 17032

12894A

__

Cable Clampt

Engine

63 747-0710

64

Iref.

■So.

10 747-1205

11 736-0119

12

13

14

15

16 714-0104

17

18

19

20

21 736-0356

22 712-0798

26 710-1055 Hex Bolt 3/8-24 x 1" Lg.*

27 736-0169

28

. 29

jO 753-0484

31 736-0452

32 710-1044

33 742-0520

37 712-0324

38

39

PART

NO.

CODE

DESCRIPTION

Hex B-Tap Scr. #10 x .38"t

Cable Clampt

710-0227

*■ *

736-0105

738-0507B

Hex AB-Tap Scr. #8 x .38"t

Spark Plug Boot (Optional)

Axle Bolt

Bell-Wash. .400" I.D. x .88"

ShId. Bolt .50" Dia. x .357"

Spring Lever Ass’y. w/Knob

* *

Height Adj. Plate

Wheel Ass’y. Comp.

Height Adi. Ass’y. Comp.—

14579 Height Adj. Ass’y. Comp.—

L.F. & R.R.

746-0801

Throttle Control Ass’y. Comp.—

51.62"t

Throttle Cofitrol Ass’y. Comp.—

49.62"tt

746-0830

Throttle Control Ass’y. Comp.—

38.62" (071R, 073R, 075R,

746-0831

Throttle Control Ass’y. Comp.—

41.62" (081R, 083R, 085R,

089R)

Throttle Control Ass’y. Comp.—

45.62" (077R, 087R)

Control Cable—36" (070R,

072R, 074R, 076R, 078R,

084R, 086R, 088R)

Control Cable—39"

(080R, 082R)

Control Cable—47"

(077R, 087R)

Control Cable—49" (071R,

073R, 075R, 079R, 081R,

083R, 085R, 089R)

Hex L-Wash. Hd. Scr.

3/8-16 X 1.0" Lg.

Chute Deflector Ass’y.

732-0593

Torsion Spring

Adapter Plate

Hinge Pin

710-0599

Hex Self-Tap Scr. V4-20 x .5" Lg.

tModels 070R, 072R, 080R & 082R Only

ttModels 074R, 076R, 078R, 084R, 086R & 088R Only

•WHEEL CHART

Wheels w/o Bearings Wheels With Bearings

Tread*** Ass’y. Comp. Axle Bolt Tread*** Ass’y. Comp. Bearings

•

Waffle

Rib

Bar

734-1162A (8")

734-1161A (7")

734-1169 (8")

734-1170 (7")

734-1608 (8")

738-0102

738-0102 Waffle

738-0144

738-0144

738-0102 “S” Wave 734-1513A Ball Brg. Va" I.D.-741-0180 (2 per Wheel)

•Tread Type: Waffle |

“T” Tread

734-0645

734-0924

734-0812

734-1259

734-1260

; Rib

Ball Brgs.; 3/8" I.D.-741-0267, Va" I.D.-741-0484, Spacer-750-0434

Ball Brg. Va" I.D.-741-0180 (2 per Wheel)

Plastic Brg. Va" I.D.-741-0262 (2 per Wheel)

Ball Brgs.: 3/8" I.D.-741-0267, Va" I.D.-741-0484, Spacer-750-0434

Ball Brg. Va" I.D.-741-0180 (2 per Wheel)

Bar

“T” Tread ; "S” Wave

13

Axle Bolt

710-1020

738-0102

738-0102

710-1020

738-0102

738-0102

Page 14

Models 200R thru 226R

*For faster service obtain standard nuts, bolts and washers I scally.

If these items cannot be obtained locally, order by part numt er and

size as shown on parts list.

CODE: N notates a new part (not previously existing). A thn le digit

number is the color code. Specify color code if color or f nish is

important when ordering parts as shown below. [I.e., 6381 or Red

Finish].

NOTE: The engine is not under warranty by

the mower manufacturer... If repairs or

service is needed on the engine, piease

contact your nearest author

ized engine service outlet.

Check the “Yellow Pages" of

your telephone book under

“Engines—Gasoline.”

**Optional Hub Caps

Description Part No.

Find It Fast

In The

Yellow Pages

Gray (5-1/2" Dia.)

Beige (5-1/2" Dia.)

Gray (3-1/2" Dia.)

Black (1-1/2" Dia.)

Red (1-3/8" Dia.)

731-0981A

731-0982A

720-0249

720-0251

731-0342

Page 15

Models 200R thru 226R

PARTS LIST FOR MODELS 200R THRU 226R ROTARY MOWERS

Iref.

TO.

PART

NO.

1 747-0748

731-1135 Control Handle Ass’y. w/Plastic

* *

2

3 712-0324 Hex L-Nut V4-20 Thd. 3/8-16 X 1.00" Lg.

* *

5

7

742-0520 20" Blade 53 714-0104 Intern. Cot. Pin 5/16" Dia.

742-0522

8 746-0820

CODE DESCRIPTION

Control Handle Ass’y- (Std.)

Wheel Ass’y.—Comp. 45

Axle Bolt 52 749-0756A

22" Blade

N

Throttle Control Ass’y. Comp.— 55

REF.

49.6 (204R, 206R, 224R,

226R)

746-0801 Throttle Control Ass’y. Comp.—

51.62" (200R, 202R, 220R, 58 736-0119 L-Wash. 5/16" I.D.*

ol5(p

222R)

746-0830 Throttle Control Ass’y. Comp.— 60 710-0429

0^15'

3^^’ (203R, 223R)

9 749-0372B Lower Handle 62 710-0227

10

11

—

710-1216

Engine 65

N

Hex Bolt 1/4-20 X 1.875" Lg.* 70 735-0639 Spark Plug Boot (Optional)

12 712-0287 Hex Nut 1/4-20 Thd.* 72 738-0507B

13

736-0175

14

17174 Cable Mtg. Bracket 80 15262B

15

736-0169

Spr. Wash. .265" I.D. x .562"

L-Wash. 3/8" I.D.*

16 712-0241 Hex Nut 3/8-24 Thd. 82

18 710-1055 Hex Bolt 3/8-24 x 1.0" Lg. 84 14578

19

682-3001

20 682-3000

N Wheel Brkt. Ass’y.—L.H.

N

Wheel Brkt. Ass’y.—R.H.

28 712-0798 Hex Nut 3/8-16 Thd.*

U29

736-0105 Bell-Wash. .40" I.D. x .88"

33

710-1044

Hex Bolt 3/8-24 x 1.5" Lg. O.D.

(Used w/Keyed Adapter)

710-0757 Hex Bolt 7/16-20 X 1.5" Lg.

(Used w/Splined Adapter)

753-0484

35

Blade Adapter Kit (Keyed) 89 17032 Adapter Plate

753-0485 Blade Adapter Kit (Splined) 90

36 736-0452 Beil-Wash. .39" I.D. (Used 91

w/Keyed Adapter 93 731-1034

736-0453 Bell-Wash. .46" I.D. (Used 97

w/Splined Adapter)

38 17098

40

731dtfii8l{

43

746-0553 Control Cable—36" (Slii,

.

------

746*0727-

'

T

^9 N

^ 0537

Hinge Clip 99

Rear Flap Ass’y. 102

2S№, 204R, 206R, -2^,

224R, 226R)

N

Control Cable ■ 77

1^)

V^tM0dels|ffR,^j)2R.^22SR4g2g,p¿fc

PART

NO.

44

NO.

682-0200

682-0220 638/N

710-0654A

CODE DESCRIPTION

638/N

20" Deck Ass’y.

22" Deck Ass’y.

Hex Wash. Hd. TT-Tap Scr.

Upper Handle

54

726-0240 Cable Tie

710-0671

56

710-1205

57 712-0267

12894A

59

Curved Carriage Bolt 5/16-18

X 1.38" Lg.

N

Rope Guide

Hex Nut 5/16-18 Thd.*

Cable Clampt

Hex B-Tap Scr. #10 x .38" Lg.t

751-0369

61

Cable Clampt

Hex AB-Tap Scr. #8 x .38" Lg.f

** Naf

ZMÙUJA)

Wheel Bearing S££ eMtr Zolo

Shoulder Bolt .50" Dia.

14832

79

Spring Lever Ass’y. w/Knob

Pivot Bar

15261A

81

Height Adj. Plate

736-0356 Bell-Wash. .39" I.D. x 1.38"

Front Height Adj. Ass’y.

Comp.—R.H.

14579

Front Height Adj. Ass’y.

Comp.—L.H. (Not Shown)

86 736-0270 Bell-Wash. .285" I.D. x .75"

87

710-0599 Hex Wash. Hd. Tap Scr.

1/4-20 X .5" Lg.

88 747-0710 Hinge Pin

732-0593 Torsion Spring

* W

Hub Cap

Chute Deflector Ass’y. Comp.

736-0232

Wave Washer .53" I.D. (Used

w/Ball Brg. Wheels)

736-^72A ÙT SUM

720-0226

- ....

----

TTTVTx

/ Ff-WastTrT&T-'HrBT'xH-rO^i

Foam Grip (Optional)

Wheels w/o Bearings

Tread***

Diamond 634-004 (7")

Bar

‘S” Wave 734-1512A (8") 738-0102

Waffle 734-1162A (8") 738-0102 T” Tread 734-1259

Rib 734-1169 (8")

Ass’y. Comp. Axie Boit

738-0102

734-1655 (8")

734-1608 (8")

***Tread Type; Waffle |

738-0102

738-0102

738-0144

Tread*

S” Wave 734-1513B

Waffle 734-0645

Ass’y- Comp.

(Gray)

734-1517B

(Beige)

734-1260

Rib

Wheels With Bearings

Bearings

Ball Brg. V2" I.D.-741-0180 (2 per Wheel)

Ball Brg. Vz" I.D.-741-0180 (2 per Wheel)

Ball Brgs. 3/8" I.D.-741-0267, Vz" I.D.-741-0484, Spacer-750-0434

Ball Brgs. 3/8" I.D.-741-0267, Vz" I.D.-741-0484, Spacer 750-0434

Ball Brg. Vz" I.D.-741-0180 (2 per Wheel)

Bar

“T” Tread

; “S” Wave Sffll ; Diamond

15

Axle Bolt

738-0102

738-0102

710-1020

710-1020

738-0102

Page 16

TROUBLE SHOOTING GUIDE

Trouble

Engine fails to start

Engine runs erratic

Engine overheats

Possible Cause(s)

1. Blade control handle disengaged.

2. Spark plug wire disconnected.

3. Throttle control lover not in CHOKE

or START position.

4. Fuel shut-off valve closed (if so

equipped).

5. Fuel tank empty, or stale fuel.

6. Blocked fuel line

7. Faulty spark pluc.

8. Engine flooded.

1. Unit running in CHOKE or START

position.

2. Spark plug wire iDOse.

3. Blocked fuel line or stale fuel.

4. Vent in gas cap plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

1. Engine oil level low.

2. Air flow restrictec.

3. Carburetor not adjusted properly.

Corrective Action

1. Engage blade control handle.

2. Connect wire to spark plug.

3. Move throttle lever to CHOKE or

START position.

4. Open fuel shut-off valve.

5. Fill tank with clean, fresh gasoline.

6. Clean fuel line.

7. Clean, adjust gap or replace.

8. Remove spark plug, dry the plug, and

crank engine with plug removed and

throttle in off position. Replace spark

plug, connect wire and resume starting

procedures.

1. Move throttle lever to FAST

position.

2. Connect and tighten spark plug wire.

3. Clean fuel line; fill tank with clean,

fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6. Clean air cleaner.f

7. Adjust carburetor.!

1. Fill crankcase with proper oil.

2. Remove blower housing and clean.!

3. Adjust carburetor.!

Occasional skip

(hesitates) at high speed

Idies poorly

Excessive vibration 1. Cutting blade loose or unbalanced.

Mower will not

discharge grass

Uneven cut 1. Wheels not positioned correctly.

tRefer to separate engine manual packed with your unit.

1. Carburetor idle speed too slow.

2. Spark plug gap too close.

3. Carburetor idle rr ixture adjustment

improperly set.

1. Spark plug fouled faulty or gap too wide.

2. Carburetor impro serly adjusted.

3. Dirty air cleaner.

2. Bent cutting blad b.

1. Engine speed toe low.

2. Wet grass.

3. Excessively high grass.

2. Dull blade.

1. Adjust carburetor.!

2. Adjust gap to .030".

3. Adjust carburetor.!

1. Reset gap to .030" or replace spark plug.

2. Adjust carburetor.!

3. Clean air cleaner.!

1. Tighten blade and adapter.

Balance blade.

2. Replace blade.

1. Set throttle between 3/4 and full throttle.

2. Do not mow when grass is wet; wait until

later to cut.

3. Mow once at a high cutting height, then

mow again at desired height or make a

narrower cutting swath (1/2 width).

1. Place all four wheels in same

height position.

2. Sharpen or replace blade.

Note: For repairs beyond the minor adjustments list 3d above, contact your local authorized service dealer.

REPLACEMENT PARTS • P.O. BOX 360900 • CLEVELAND, OHIO 44136

Loading...

Loading...