Page 1

10 CENTS

Model No. 110-530

ROTARY MOWER

For one year from date of purchase, MTD Products, Inc.,

will replace for the original purchaser, free of charge, F.O.B.

factory or authorized service firm, any part or parts found to

be defective in material or workmanship. All transportation

charges on parts submitted for replacement under this war

ranty must be paid by the purchaser. This warranty does not

include replacement of parts which become inoperative

through misuse, excessive use, accident, neglect, improper

maintenance or alterations by unauthorized persons. This

warranty does not include the engine, motor, battery, bat

tery charger or any component parts thereof. For service on

these units refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner

and will be effective only if the warranty card has been pro

perly processed. It will not apply where the unit has been

used commercially.

Warranty service is available through your local author

ized service dealer or distributor. UNDER NO CIRCUM

STANCES WILL THE RETURN OF A COMPLETE UNIT

BE ACCEPTED BY THE FACTORY UNLESS PRIOR

WRITTEN PERMISSION HAS BEEN EXTENDED.

Your rotary mower is a precision piece of power equip

ment, not a plaything. Therefore exercise extreme caution

at all times.

1. Remove all sticks, stones, wire and other hazardous items

from lawn before mowing. Such items are dangerous to

both the mower and individuals in the vicinity of the

mower.

2. Always disconnect spark plug cable during repairs or re

fueling operations.

3. Always start engine from side opposite discharge chute.

4. NEVER place hands or feet under mower or near dis

charge chute while engine is running.

5. Do not tilt mower at extreme angle while engine is run

ning. Cut grass on hills and banks sideways, not up and

down.

6. Always stop engine when not cutting grass.

7. Do not fill gas tank while engine is running. Do not spill

gasoline on hot engine.

8. Keep children and pets away from area at all times during

mowing operation. Never allow mower to discharge grass

toward any person.

9. Do not attempt to start engine while mower is resting in

high grass.

10. Check all nuts and bolts, particularly the blade bolts, for

tightness. This is especially important during the initial

operation period. Make this same check periodically

thereafter.

NOTE: Should excessive vibration develop, check your blade

and crankshaft immediately. Do not operate mower with an

unbalanced blade, a damaged blade or a damaged crankshaft.

M:TD FROIDXJCTS II^TC • saa? west noth st. • p.o. box 274i .

CLEVELAND, OHIO 44111

FORM NO. 770-2393A

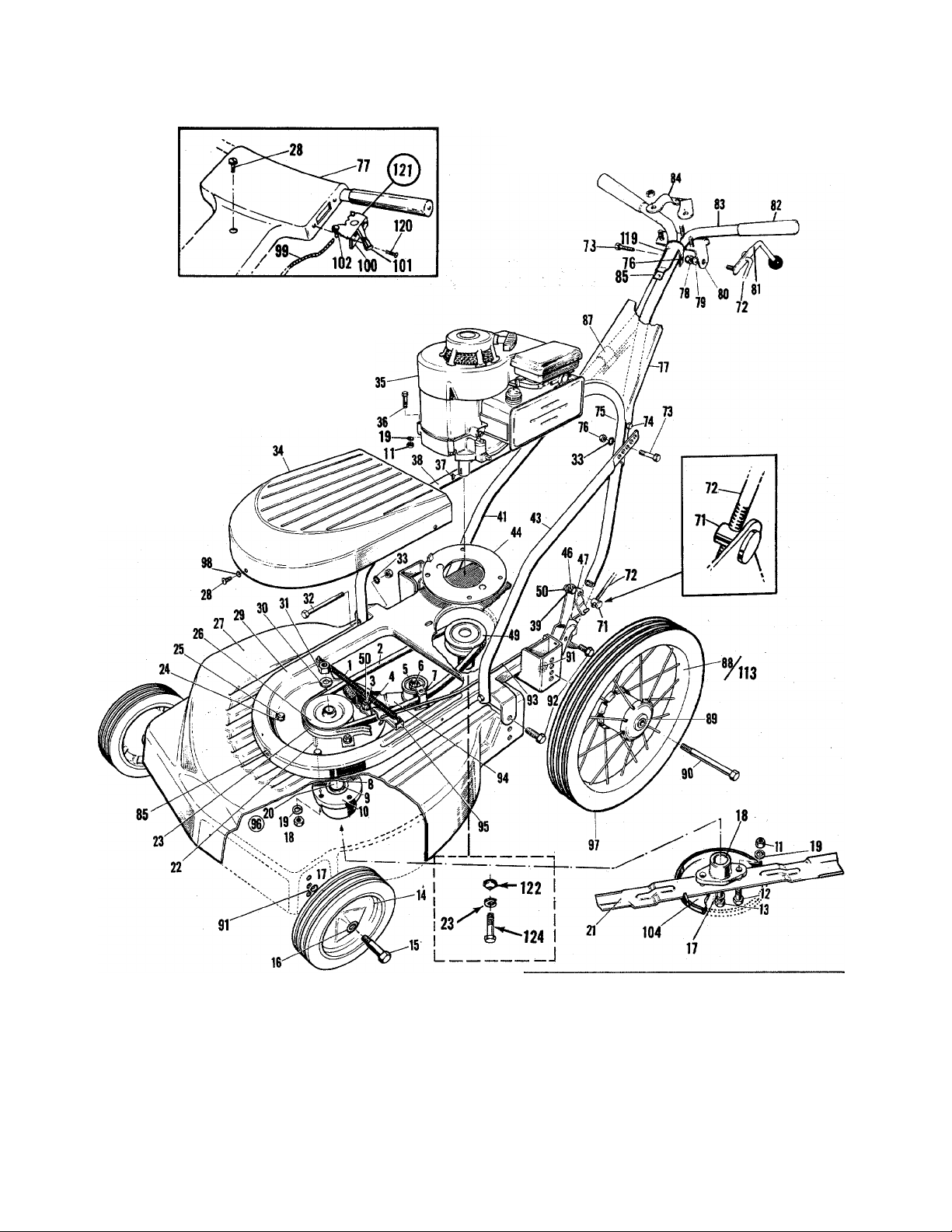

Page 2

NOTE: Set screws in pulleys are treated with a nut

and bolt sealant. Remove with Allen wrench while

applying heat with a small torch. Sealant disintegrates

at 400°

Blade Spindle Detail on page “G

Blade Idler Detail on page “F"

110-530

NOTE; To engage the blade with the engine running..

1. Move the throttle control lever to “FAST* position.

2. Engage the blade engagement lever SLOWLY.

3. Adjust engine speed.

FORM NO. 770-2393B

NOTE: This instruction manual covers various

models and all accessories shown do not neces

sarily apply to your model mower.

MTD PRODUCTS INC extends its warranty only

on the mower. If repairs or service is needed on

the engine, please contact

your nearest authorized en

gine service outlet. Check

the “Yellow Pages” of

Find it Fast

tn The

'Yellow Pages'

your telephone book under

“Engines — Gasoline”

Page 3

PARTS LIST FOR ROTARY MOWER MODEL NO. 110-530

Ref.

No.

Part

No.

1

732-158

2 754-109

736-300 Flat Washer - 3/8 I.D.

3

Blade Tension Spring

VBelt - 1/2x43 *

NAME OF PART

4 710-373 Shoulder - Special

5 756-370

Idler Bearing Assembly

6 712-372 Centerlock - Hex Nut — 5/16—18 thread *

310-7353 Bracket — Belt 77

7

711-212

8

9 741-120

719-120

10

712-123 Hex Nut - 5/16-24 thread *

11

12

710-117

Sleeve

Bearing - Upper

Spindle Housing

Hex Head Cap Screw (heat treated) —

5/16-24 X 1 long

710-113 Hex Hd.Cap Sew. 3/8-24 x 1-5/8 long *

13

501-9383

14

738-213 Axle Bolt - 5/8 length thread

15

741-114

16

17

736-169

18 748-100

19

736-119

711-240 Spindle

20

312-7581 Blade - 22’« 93

21

710-122

22

312 8324

23

712-123

24

710-122

25

26

27

28

29

3-9925

395-8756

710-473

395-8280 Frame Assembly

Wheel Ass’y - 8” Waffle - B.B. 85 712-526 Speed Nut - 10-24 thread *

Ball Bearing

Spring Lockwasher - 3/8 screw *

Blade Adapter

Spring Lockwasher — 5/16 screw *

Hex Hd. Cap Sew. 5/16—24 x 1 long *

Belt Guard

Hex Nut — 5/16—24 thread* 96

HexHd. Cap Sew. 5/16—24 x 1 long *

Pulley - 4”

Deck Assembly — 22” 99

Truss Hd. Mach. Sew. 10-24 x 1/2 long * 100

30 736-921 Spring Lockwasher - 1/2 screw * 102

712-922 Hex Jam Nut - 1/2-20 thread *

31

710-102 Hex Hd.Cap Sew. 1/4-20 x 2-1/2 long *

32

33 736-222 Ext. Lockwasher — 1/4 screw *

34 395-8295 Blade Spindle Cover

35

—

36 710-158

714-365

37

38 310-8328

39 736-108

310-8334

41

310-8327 Handle Support — Lower L.H.

43

310-8325

44

738-234

46

Engine

Hex Hd. Cap Sew. 5/16-24 x 1-1/4 long *

Key - Hi Pro #505 *

Handle Support - Lower R. H.

Flat Washer — 33/64 I.D. *

Handle - Lower H. W.

Belt Trap Assembly

Pivot Screw

47 310-9372 Pivot Bracket

756-110 Pulley - Engine

49

50

51

712-430

300-8809

Elastic Stop Nut — 3/8—16 thread *

Reinforcement Plate

Ref.

No.

Part

No.

NAME OF PART

71 711-179 Ferrule

72 711-180

Control Rod

73 710-606 Hex Hd.Cap Sew. 1/4—20 x 1-1/2 long *

74 710-106 Hex Hd.Cap Sew. 1/4-20 x 1-1/4 long *

75 712-287 Hex Nut — 1/2—20 thread *

76

712-107 Centerlock - Hex Nut — 1/4—20 thread *

395-9366

712-324

78

736-325

79

80 310-8376

310-8373

81

Control Panel

Elastic Stop Nut — 1/4—20 thread *

Flat Washer - .265 I.D. *

Lockout Bracket Assembly

Lockout Lever Assembly

82 305-7072 Grip — White

83 310-9364

84

310-8378 Clamp Bracket

746-145

87

734-180

88

741-113

89

90 738-114

736-105

91

710-209

92

310-9373

94

310-8298

310-9371

95

901-7805

97

734-179

98

736-147

732-139

310-8508

101

305-7470

901-7627

104

312-7919

no 710-938

Handle - Upper

Cable Clip

Wheel Assembly — 16” less tire

Ball Beating

Axle Bolt

Belleville Washer

SEMS Hex Hd. Cap Sew. 3/8-16 x 5/8 Ig.*

Control Rod

Idler Bracket Assembly

Brake Lever

Blade Spindle Ass’y —Complete H.W.

Tire - Rib Tread 16 x 1.75

Ext. Lockwasher - # 10 screw *

Conduit 8s Wire 37-1/2 x 39-13/16

Control Bracket Assembly — Throttle

Knob

Ferrule Assembly — Complete

Anti Scalp Plate — 8-1/2”

Allen Set Screw — 1/4-28 x 1/4 long*

(not shown)

741-107

111

Bearing—Lower-Blade Spindle

113 502-8761 Wheel Ass’y Complete

736-154 Washer

114

115 721-105

737-479

116

Seal

Zerk Fitting

117 728-649 Rivet

754-647 Brake Shoe

118

119 310-8378

120 710-148

121 310-8357

122 736-112

123 736-169

710-152

124

718-132

Clamp Bracket

Thread Cut Screw #8—32 x 3/8 Ig.*

Throttle Control - Complete

Belleville Washer

Lockwasher 3/8 Screw. *

Hex Head Cap Screw 3/8 — 24 x 1 Ig. *

Plastic Cap — Rear Wheel (not shown)

*For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

FORM NO. 770-2393C

Page 4

ASSEMBLY INSTRUCTIONS

8. Fasten control panel to upper handle with cap screws and

locknuts at lower holes and truss head screw through upper

hole. Tighten all nuts and bolts.

5. Assemble speed nut to clamp bracket. Assembly clamp,

bracket to upper handles with long yellow bolt and nut as

shown.

2. Assemble upper handle parts with cap

screws and locknuts as shown —^

BLADE SPINDLE COVER

7. Assemble throttle control to

handle panel with two sheet

metal screws.

j 6. Assemble lockout bracket

assembly to upper handle.

/ A / Tighten nuts

securely.

4. Assemble upper handles and lower handle

supports to lower handle assembly with

cap screws and locknuts. Position sup

ports for most convenient height.

Use lower holes only.

3. Attach lower handle supports to frame assembly

with cap screws, lockwashers and hex nuts

9. Blade Engagement Assemblya. Remove Blade Spindle Cover by removing three screws.

b. Move brake lever to rear position so belt is slack.

c. Insert ferrule into blade bracket assembly from the left.

d. Screw rod into ferrule.

e. Assemble control handle to control rod as shown.

f. Adjust control rod. A slight pressure should be needed to operate lockout lever.

Too much pressure can break lever assembly or control rods. Readjust control

rods if pressure is too great.

g. Replace Blade Spindle Cover.

FORM N0.770 1847D

Page 5

OPERATION

1. Before starting engine, check LUBRICATION

INSTRUCTIONS.

2. Check lockout control handle for proper operation.

If too great a pressure is needed to operate these

controls, damage can be done to both the mechanism

and the rods. Readjust so only slight pressure is

needed to operate the blade engaging control. See

ASSEMBLY INSTRUCTIONS Step 9.

3. Service engine with gasoline and oil. See engine

instructions for complete care and maintenance of

engine. READ DIRECTIONS CAREFULLY.

4. Be sure engine crankcase is filled to capacity with

proper grade of oil.

5. Move control handle to “OFF” position.

6. Move throttle control lever to “Choke” position.

7. Crank engine. Move throttle control lever to “Fast”

position as soon as engine fires. Use choke as

needed to keep engine running during warm up period.

8. Put blade into motion by moving blade control handle

to “On” position.

3. Cutting height adjustment is made by removing and

moving axle bolts to the desired positions. Cutting

height will be raised as axle bolts are moved to

lower mounting holes and lowered as axle bolts are

moved to higher mounting holes. All axle bolts must

be mounted in the same relative position to the deck.

When wheels are mounted to the deck, the crown

shape washers must be assembled with the crown

away from the deck. This is necessary to prevent

the axle bolts from loosening.

4. If throttle adjustment becomes necessary, the throttle

control wire may be rèset as follows:

a. Loosen, but do not remove, screw securing throttle

control wire assembly at engine.

b. Move throttle control lever on handle to “Choke”

position.

c. Move lever to which control wire is fastened to

engine to full choke position. Retighten screw to

secure throttle control wire assembly.

LUBRICATION

Important: Always stop engine and disconnect spark

plug wire before cleaning, lubricating or doing any kind

of work on the lawn mower.

To engage the blade with the engine running . . .

a. Move the throttle control lever to “Fast” position.

b. Engage the blade engagement handle SLOWLY.

c. Adjust engine speed.

9. A brief break-in period is essential to insure maxi

mum engine and mower life. This consists of running

the engine a half speed for a period of time required

to use one tank of gasoline. It is also recommended

to change crankcase oil after the first five hours of

operation or as operating conditions dictate. Always

check oil before operating the mower. BE SURE

CRANKCASE IS FULL.

10. Proper lubrication must be maintained at all times.

11. Appropriate clothing should be worn when cutting

brush or heavy weeds. Safety shoes and safety

glasses are highly recommended.

12. The engine is stopped by moving the throttle control

lever to “STOP” position.

ADJUSTMENT

1. Wheel bearings are ball bearings. Use SAE 30

engine oil.

2. Throttle — Periodically lubricate throttle control

lever and entire length of throttle wire assembly

with a few drops of SAE 30 engine oil for ease of

operation.

3. Engine — Follow engine manual for lubrication

instructions. Check oil level before each mowing.

4. Friction point between idler bracket assembly (Ref.

No.94) and deck should be greased once each season

with a multi-purpose grease.

5. ' Blade Spindle Assembly — The Blade Spindle

Assembly is equipped with a grease fitting. Use

grass discharge chute for access to the fitting

located under the deck. Use multi-purpose grease.

Lubricate PRIOR to initial use and every 25 hours

thereafter. CAUTION: Be sure spark plug wire is

disconnected and grounded.

1. Handles may be adjusted by changing the position

of the lower support mounting holes. When this

change is made, it may also be necessary to check

the adjustment of the control rod. See Step 9 in

ASSEMBLY INSTRUCTIONS.

2. Control rod adjustment is made as shown in ASSEM

BLY INSTRUCTIONS Step 9.

MAINTENANCE

Important: Always stop engine and disconnect spark

plug wire before cleaning, lubricating or doing any kind

of work on the lawn mower.

1. Cutting Blade — Remove all nuts and bolts holding

the blade to the blade hub.

FORM N0.770-1847E

Page 6

When sharpening blade, follow the original angle of

of grind as a guide. It is extremely important that

each cutting edge receives an equal amount of grind

ing to prevent an unbalanced blade. An unbalanced

blade will cause excessive vibration when rotating

at high speeds and may cause damage to the mower.

Upon reassembling, make certain all parts

are

assembled properly and tightened securely.

2. Deck — The underside of mower deck should be

cleaned after each period of use as grass clippings,

leaves, dirt and other matter accumulates. This

accumulation of grass clippings, etc. is undesirable

as it will invite rust and corrosion and may cause

an uneven discharge of grass clippings at next

cutting.

The deck may be cleaned by tilting the mower back

ward or on its right side and scraping clean with a

suitable tool or by washing with a stream of water

from a garden hose. CAUTION; Do not direct the

stream of water at a hot engine as damage to the

engine may result.

3. Belt replacement may be made as follows:

a. Remove blade spindle cover.

b. Remove front belt guard.

c. Remove blade tension spring.

d. Loosen belt on bracket of idler bearing assembly.

e. Remove brake lever assembly.

f. Remove damaged or worn belt.

g. Place new belt on engine pulley. Do not bend

belt guard pins. Belt should be inside of pins.

h. Work belt to front and mount on blade spindle

pulley. Replace front belt guard.

i. Replace brake lever assembly.

j. Slip belt on idler pulley between pulley and belt

bracket.

k. Replace blade tension spring.

l. Move blade lockout handle to “ON” position.

m. Position belt bracket on idler pulley to clear the

tightened belt. Secure belt bracket in position.

See Drawing page “C”.

n. Replace blade spindle cover.

4. Storage — The following steps should be taken to

prepare lawn mower for storage:

a. Clean and lubricate mower thoroughly as describ

ed in the preceding instructions.

b. Refer to engine manual for correct engine storage

instructions.

c. Coat mower's cutting blade with multi-purpose

grease to prevent rusting.

d. Place blocks under deck to raise tires clear of

floor.

e. Store mower in a dry, clean area.

USING YOUR ROTARY MOWER

For best results do not cut wet grass because it tends

to stick to the underside of the mower, thus preventing

proper discharge of grass clippings. If wet grass must

be cut, reduce engine speed to help distribute the

clippings more effectively.

New grass should be treated as wet grass, otherwise a

normal walking speed is about the right pace for

efficient mowing.

The best mowing pattern is one that allows the clippings

to discharge towards the uncut part of thé lawn. This

permits recutting of the clippings to further pulverize

them. When cutting high weeds, discharge towards cut

portion then recut at right angle to first direction.

Lawns should be cut in fall as long as there is growth.

BLADE IDLER BRACKET ASSEMBLY DETAIL

BRAKE SHOE 754-647 (118)

BELT WEAR

Belt clips improperly positioned

will cause premature belt wear.

The belt clip must completely

clear the belt when the belt is

tightened. It should also assist in freeing the

belt from the blade spindle pulley when the belt

is loose. This may be checked by removing the

blade spindle cover.

FORM NO. 770-1847F

RIVET 728-649 (117)

IDLER BRACKET ASSEMBLY (94)

IDLER BEARING (5)

756-370

HEX LOCK NUT (6)

712-372

BELT CLIP (7)

310-7353

Page 7

'ì

NOTE: PARTS SHOWN

IN DOTTED LINES

NOT INCLUDED

IN ASSEMBLY.

736-154 114

BEARING 11/16

741-120

BEARING 3/4

741-107 111

SEAL

721-105 115

41

^ ' 714-365 37

REINFORCEMENT PLATE

300-8809 51

ZERK FITTING

737-479 116

SPINDLE HOUSING

719-120 10

CAUTION: 1. Bearing races must be firmly seated in Spindle Housing.

'2. Zerk Fitting should face Discharge Chute of Deck.

3. Lubricate every 8 to 10 hours with Shell General Purpose

Grease or Equivalent.

KEY

SPINDLE

711-240 20

KEY

'714-365 37

BLADE SPINDLE

ASSEMBLY

901-7805

736-119 19

HEX NUT

712-123 11

SPINDLE ASSEMBLY

DECjK 27

736-119 19

HEX NUT

712-123 11

ZERK FITTING

737-479 116

Z

o

Page 8

FORM NO. 770-1847H

PRINTED IN U.S.A.

Loading...

Loading...