Page 1

OWNEirS GUIDE

ASSEMBLY • OPERATION • MAINTENANCE • PARTS

$1.00

Oi "

^ * Model Numbers

ROTARY 110-516R000

MOWERS 110-518R000

QTi C/mtE«.- [MMDj

on 0/mfER.-(2orr)

Important: Read Safety Rules and Instructions Carefully

PRINTED IN U.S.A.

FORM NO. 770-7046E

Page 2

INDEX

Slope Gauge.....................................................................3

Contents of Hardware Pack

Rules for Safe Operation.................................................5

Assembly

Controls

Operation........................................................................11

Adjustments....................................................................12

Lubrication

Maintenance

Off-Season Storage........................................................14

Trouble Shooting Guide

Illustrated Parts..............................................................16

Repair Parts List......................................................17, 18

Parts Information

A

..........................................................................

..........................................................................

.....................................................................

...................................................................

...........................................

The use of any accessory on this Rotary Mower other than those manufactured by the mower manufacturer

is not recommended.

WARNING: DO NOT operate the nower without the entire grass catcher or chute defiector in piace. DO NOT operate the mower without the protective shield on the rear of the deck in place.

NOTE: Under normal usage bag material is subject to wear and should be checked periodically. Be sure

any replacement bag complies with the m 3wer manufacturer’s recommendations. For replacement bags,

use only factory authorized replacement t ag.

............................................

................................................

Bad: Cover

4

6

10

13

13

15

Dear Customer,

So often throughout the year we are all in a

rush to meet our daily obligations.

However, we at MTD Products Inc are tak

ing a quick moment out to say.. .

“Thank you for your business.’’

Sincerely,

MTD PRODUCTS INC

INSTRUCTIONS GIVEN WITH THIS SYM

BOL ARE FOR PERSONAL SAFETY. BE

A

SURE TO FOLLOW THEM.

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with

a spark arrester meeting applicable local or . itate laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal I iws apply on federal lands. A spark arrester for the muffler is available

through your nearest engine authorized se vice dealer.

Page 3

--UUIMK ^nisLine-

USE THIS SHEET AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

A-

-----------------

^------------------

....

....................

CO

.

.

................

......

A POWER POLE

----------------

A CORNER OF A BUILDING

I

I —

!

................................................

........

OR A FENCE POST

n--------------f

..

.........

ii

..............................

......

o

0

n

(0

(/>

3-

o

o

0)

(A

0)

(D

■D

0>

O

O

C

•NN

c

(D

C/>

m

O

O

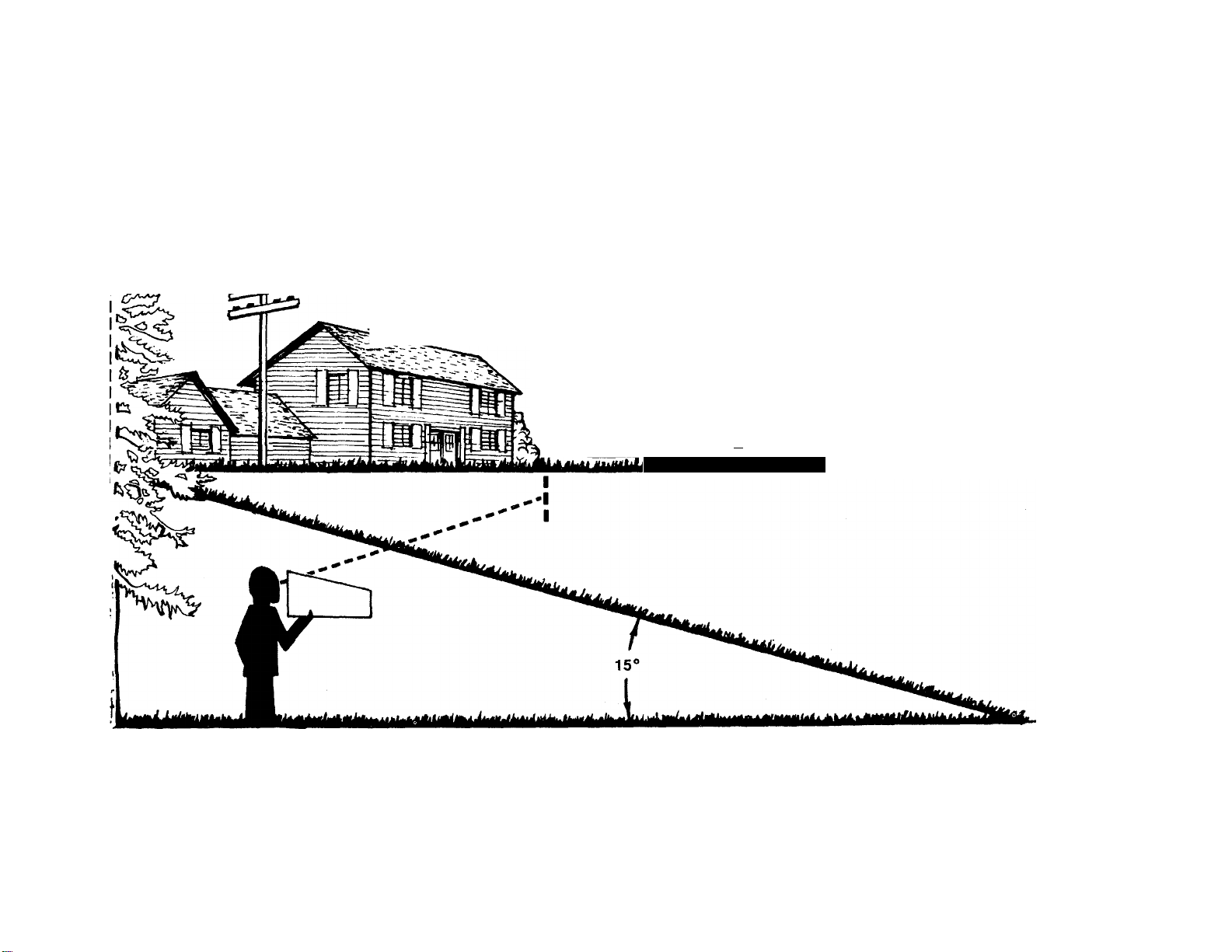

AC WARNING I

Do not mow on inclines with a slope in excess of IS degrees (a rise of approximately 2V2 feet every 10 feet). A

riding mower couid overturn and cause serious injury. If operating a waik-behind mower on such a slope, it is

extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RIDING mowers up and down slopes, never across the face of slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

(D

(D

—t

O

3

o

o

Page 4

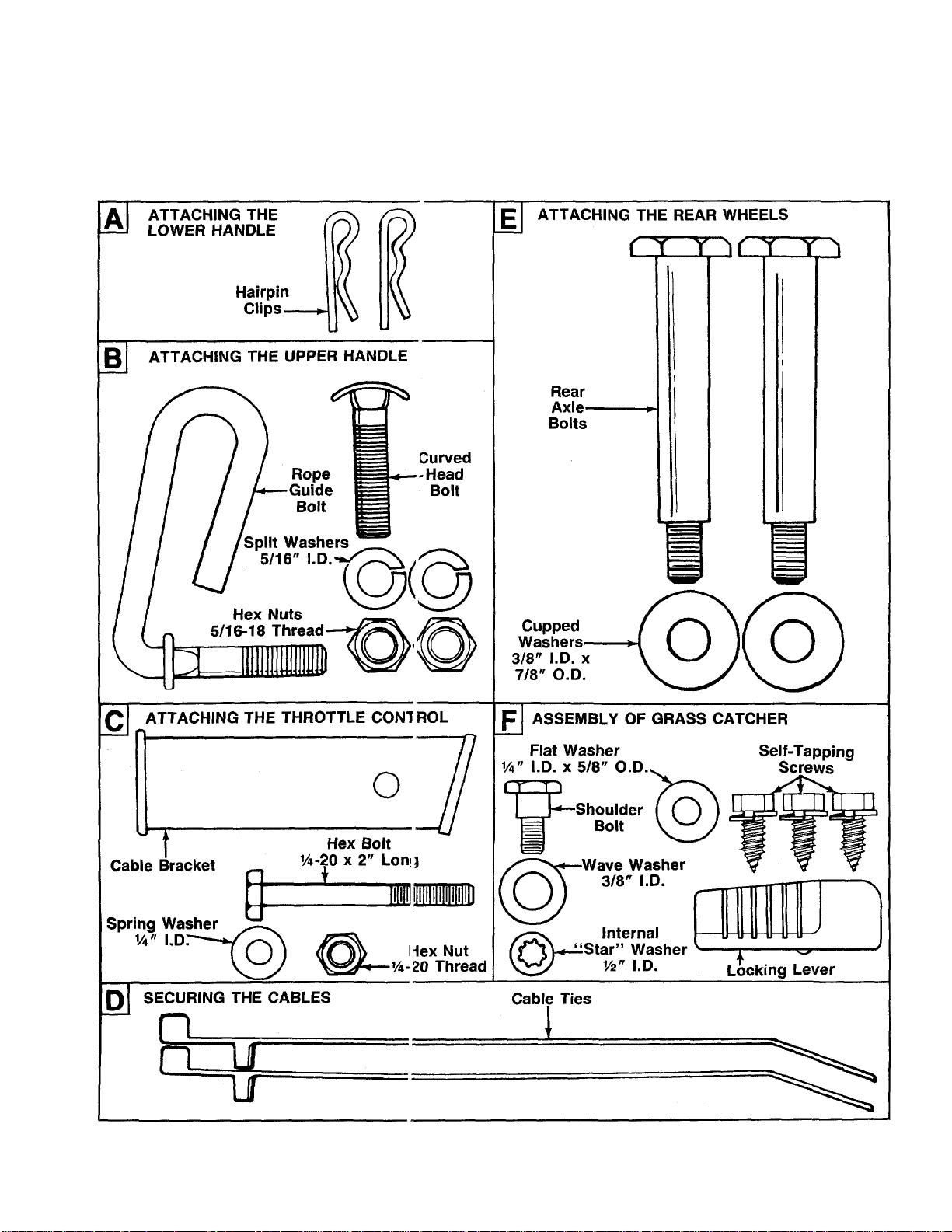

CONTENTS OF HARDWARE PACK

Remove this sheet from your owner’s manual and lay the hardware on the illustration for identification purposes.

After assembly, keep the Slope Gauge whicf is on the reverse side of this sheet for future use.

(Hardware pack may contain extra items which are not used on your unit.)

o

c

>

3-

M

<D

I I I I I I

0

INCHES

Itili

1

I

I I I

I

I I I

I

I

I

Page 5

A

IMPORTANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY

AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE AHEMPTING

TO OPERATE YOUR LAWN MOWER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN

YOU SEE THIS SYMBOL- ^ HEED ITS WARNING.

DANGER

Ai

Your lawn mower was built to be operated according to the rules for safe operation in this manual. As

with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. If you violate any of these rules, you may cause serious injury to yourself or others.

A

A

TRAINING

Read this owner’s guide carefully in its entirety before attempting

to assemble or operate this machine. Be completely familiar with

the controls and the proper use of this machine before operating

it. Keep this manual in a safe place for future and regular reference

and for ordering replacement parts.

2. Your rotary mower Is a precision piece of power equipment, not

a plaything. Therefore, exercise extreme caution at all times.

3. Never allow children to operate a power mower. Only persons well

acquainted with these rules of safe operation should be allowed

to use your mower.

4. Keep the area of operation clear of all persons, particularly small

children and pets. Stop engine when they are in the vicinity of

your mower to help prevent blade contact or thrown object in

jury. Although the area of operation should be completely cleared

of foreign objects, an object may have been overlooked and could

be accidently thrown by the mower in any direction and cause

serious personal injury to the operator or any others allowed in

the area.

PREPARATION

1. Thoroughly inspect the area where the equipment is to be used.

Remove all stones, sticks, wire, bones and other foreign objects

which could be picked up and thrown by the mower in any direc

tion and cause serious personal injury to the operator or any others

allowed in the area.

2. Always wear safety glasses or eye shields during operation or while

performing an adjustment or repair, to protect eyes from foreign

objects that may be thrown from the machine in any direction.

3. Wear sturdy, rough-soled work shoes and close-fitting slacks and

shirts to avoid entanglement in the moving parts. Never operate

a unit in bare feet, sandais, or sneakers.

4. Check the fuel before starting the engine. Gasoline is an extreme

ly flammable fuel. Do not fill the gasoline tank indoors, while the

engine is running, or until engine has been allowed to cool for

two minutes after running. Replace gasoline cap securely and wipe

off any spilled gasoline before starting the engine as it may cause

a fire or explosion.

5. Disengage the self-propelled mechanism or drive clutch on units

so equipped before starting the engine.

6. The blade control handle is a safety device. Never attempt to bypass

its operation. Doing so makes the safety device inoperative and

may result in personal injury through contact with the rotating

blade. The blade control handle must operate easily in both

directions.

7. Never attempt to make a wheel or cutting height adjustment while

the engine is running.

8. Never operate the equipment in wet grass. Always be sure of your

footing. A slip and fall can cause serious personal injury. Keep

a firm hold on the handle and walk, never run. Mow only in daylight

or in good artificial light.

9. For your safety, use the slope gauge included as part of this manual

to measure slopes before operating this unit on a sloped or hilly

area. If the slope is greater than 15“ as shown on the slope gauge,

do not operate this unit on that area or serious injury could result.

OPERATION

1.

Do not change the engine governor settings or overspeed the

engine. Excessive engine speeds are dangerous.

2.

Do not put hands or feet near or under rotating parts. Keep clear

of the discharge opening at all times as the rotating blade can

cause injury.

Stop the blade when crossing gravel drives, walks or roads.

After striking a foreign object, stop the engine, remove the wire

from the spark plug, and thoroughly inspect the mower for any

damage. Repair the damage before restarting and operating the

mower.

If the equipment should start to vibrate abnormally, stop the engine

and check immediately for the cause. Vibration is generally a warn

ing of trouble.

Shut the engine off and wait until the blade comes to a complete

stop before removing the grass catcher or unclogging the chute.

The cutting blade continues to rotate for a few seconds after the

engine is shut off. Never place any part of the body in the blade

area until you are sure the blade has stopped rotating.

7.

Before cleaning, repairing or inspecting, make certain the blade

and all moving parts have stopped. Disconnect the spark plug wire,

and keep the wire away from the spark plug to prevent accidental

starting.

Do not run the engine indoors.

Mow across the face of slopes, never up-and-down. Exercise ex

treme caution when changing direction on slopes. Do not mow

excessively steep slopes. Always be sure of your footing. A slip

and fall can cause serious personal injury.

10.

Never operate mower without proper guards, plates or other safety

protective devices in place.

11.

Do not operate this mower with the chute door open, unless the

complete grass catcher or chute deflector is properly mounted

on the mower.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at frequent intervals

for proper tightness.

2. Keep all nuts, bolts, and screws tight to be sure the equipment

is in safe working condition.

3. Never store the equipment with gasoline in the tank inside of a

building where fumes may reach an open flame or spark. Allow

the engine to cool before storing in any enclosure.

4. To reduce fire hazard, keep the engine free of grass, leaves, or

excessive grease.

5. Check the grass catcher bag frequently for wear or deterioration.

For safety protection, replace only with new bag meeting original

equipment specifications.

Page 6

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, service engine

with gasoline and oil as instructed in the separate

engine manual packed with your unit.

NOTE: Reference to right or left hand side jf the

mower is observed from the operating posi ion.

Tools Required for Assembly

(1) Pair of Pliers

(1) 1/2" Wrench*

(2) 7/16" Wrenches*

(1) Adjustable Wrench

*Or two 6" Adjustable Wrenches

UNPACKING

1. Remove the lawn mower from the carton by open

ing the top flaps and lifting the unit out. Be careful

of the staples. Make certain all parts and literature

have been removed from the carton before the car

ton is discarded.

2. Disconnect and ground the spark plug wire against

the engine. Check beneath the deck for any card

board packaging. Remove if present.

3. Stretch out all control cables and place on the floor.

Be careful not to bend or kink the cables at any

time during assembly.

4. Remove page four from this manual and lay the

contents of the hardware pack on the illustration

for identification.

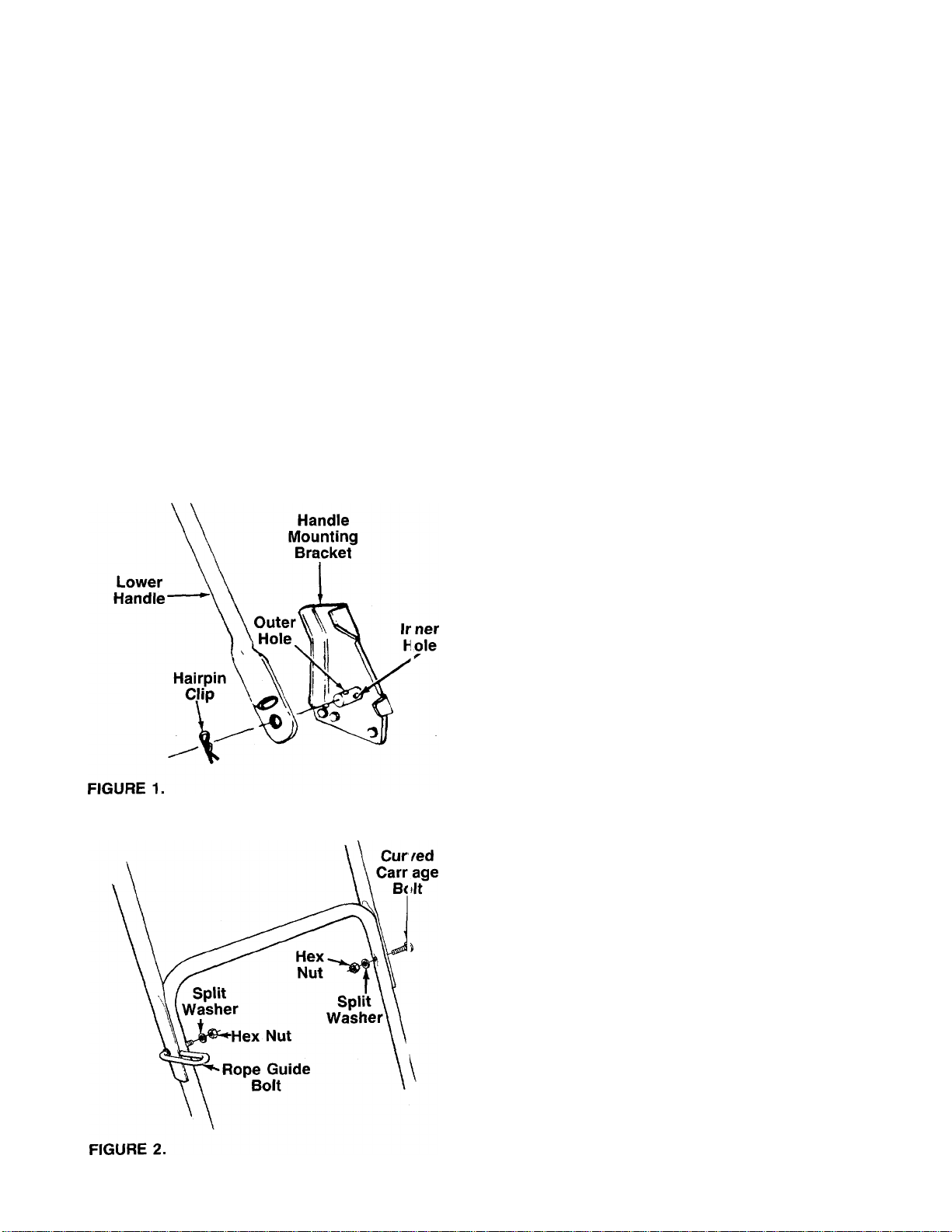

ATTACHING THE LOWER HANDLE (Hardware A)

1. Attach the lower handle by placing the bottom

holes in the lower handle over the weld pins on the

handle mounting brackets on the rear of the deck.

2. Using a pair of pliers, squeeze one leg of the lower

handle against the handle mounting bracket. In

sert the hairpin clip into the inner hole on the weld

-------

pin. See figure 1. Repeat on other side.

NOTE: There are two (2) holes in the handle mounting

brackets. Place the hairpin clip in the inner hole for

operation. Outer hole is for storage.

ATTACHING THE UPPER HANDLE (Hardware B)

1. Place the upper handle in position over the lower

handle. The blade control handle (attached to the

upper handle) must be facing up.

NOTE: The right hand side of the handle will be secured

with the rope guide boit. However, left handed operators

may assemble the rope guide bolt to the left side of the

handle for easier starting by foliowing steps 2 and 3 and

reversing the ieft and right hand instructions.

2. Secure the left hand side of upper handle using

the curved head bolt, split washer and hex nut as

-------

shown in figure 2.

Insert the rope guide bolt through the right hand

3.

side of upper and lower handle from the outside

in. Secure with split washer and hex nut, finger

tight only at this time.

Page 7

AHACHING THE THROHLE CONTROL (Hardware C)

The throttle control is attached to the engine. Attach

the throttle control to the left side of upper handle as

-follows. See figure 3.

1. Route the throttle control cable inside the handle

mounting bracket and beneath the lower handle.

2. Place cable bracket against left side of upper han

dle, lining up the hole in the bracket with the bot

tom hole in upper handle. Place 1/4" hex bolt

through cable bracket and handle, from the inside

to the outside.

3. Place throttle control on the hex bolt (outside of

the upper handle), with the throttle lever facing up

ward. Secure with spring washer (cupped side

against the throttle control) and hex nut.

ATTACHING THE BRAKE CABLE

1. The brake cable is attached to the engine, and has

a “Z” fitting on the loose end. Route the brake

cable below the lower handle. Place end of cable

through the hole in the bracket as shown in figure

-------

4. Be careful not to bend or kink the cable at any

time. Push the plastic fitting until it locks into the

hole in the bracket.

WARNING: Brake cable must be assem

bled as shown for proper blade brake

A

2. Hook the “Z” end of the brake cable into the hole

operation.

in the blade control handle from the inside to the

outside as shown in figure 4.

SECURING THE CABLES (Hardware D)

Secure both cables to the left side of the handle as

follows.

1. Insert posts on cable ties into holes provided on

the lower handle. The holes may be either on the

-------

inside or outside of the handles. See figure 5A.

2. Secure the cables with the cable ties. See figure

5B.

3. Trim excess ends of cable ties.

ATTACHING THE STARTER ROPE

1. The starter rope is inside the top of the engine. Ad

ditional rope may be wound around the starter han

dle. If so, unwind the rope from the handle.

2.

With the spark plug wire disconnected and

grounded, depress the blade control handle and

pull the rope out of the engine.

3.

Slip the starter rope into the rope guide bolt as

—shown in figure 6.

4. Tighten the hex nut on the rope guide bolt

securely.

Page 8

ATTACHING THE REAR WHEELS (Hardware E)

-Assemble the rear wheels as follows. See figure 7.

1. Move the wheel height adjusters so the deck is in

the lowest cutting position.

2. Lift the rear of the unit up and block securely.

3. Insert axle bolt through one rear wheel. Place

cupped washer on axle bolt (crowned side of

washer goes against the wheel).

4. Thread axle bolt into rear hole of pivot bar. Tighten

securely.

5. Assemble other rear wheel in the same manner.

INSTALLATION OF HUB CAPS (Optional)

1. If your mower is equipped with front hub caps

which have four tabs, line up the tabs on the hub

caps with the holes in the wheels. Push to lock in

position.

2. If your mower is equipped with 2" wide tires, place

front hub caps in position against the inner hub of

the wheel. Press firmly around the center portion

of hub cap in a circular motion, similar to install

ing a lid on a round, plastic container. See figure

-------

8. The hub caps are flexible and will snap over the

3V2" diameter wheel hubs.

FIGURE 8.—Optional Hub Caps

FINAL ASSEMBLY OF MOWER

Make certain all nuts and bolts are tightened securely.

ASSEMBLY OF GRASS CATCHER (Hardware F)

NOTE; Make certain the grass bag is turned right side

out before assembling (warning label will be on the

outside).

There are three holes in the rear frame. With the

1.

holes on the upper side as shown in figure 9A, in

sert one end of the rear frame into the cloth chan

nel on the edge of the grass catcher bag. Feed all

the material on one side of the frame, then work

■it around the frame. See figure 9B.

FIGURE 9.

Page 9

2. Slide the ends of the front frame assembly into the

—ends of the rear frame as shown in figure 10A.

3. Secure front of bag to front frame by slipping

plastic channels on sides and bottom of bag over

frame. See figure 10B.

4. Attach the hardtop cover to the grass catcher as

—follows. See figure 11.

a. Place the cover in position on top of the grass

catcher. Press the rear frame into the channel

on the rear of the cover (beneath the rear

handle).

b. Slide the notches on the sides of the cover over

the front catcher frame.

c. Attach rear of cover to frame using the flat

washer and one self-tapping screw as shown

in figure 11. Attach the sides of the cover to

frame with the other two self-tapping screws.

Assemble the locking lever as follows:

a. Place wave washer on shoulder bolt (crowned

side of washer goes against the head of bolt).

b. Insert shoulder bolt up through hole in hardtop

-----

cover as shown in figure 12. Place “star”

washer over shoulder bolt.

c. Thread shoulder bolt into the grass catcher

locking lever, using a 9/16" socket wrench. Do

not overtighten. Locking lever must be able to

pivot.

Page 10

FIGURE 13.

Rear

Deflector

AHACHING BAG TO MOWER

Lift the rear deflector on the mower. Place the hooks

on the grass catcher over the pins on the back of the

mower. See figure 13. Release the rear deflector. Turn

the locking lever to the locked position to secure the

-rear deflector. See figure 13, inset.

To remove the grass catcher, turn the locking lever to

the unlocked position and lift the rear deflector on the

mower. Lift the grass catcher up, over the pins on the

back of the mower. Release the deflector.

BLADE CONTROL HANDLE

WARNING

THIS CONTROL MECHANISM IS /

SAFETY DEVICE NEVER ATTEMP

TO BYPASS ITS operation;

Throttle

Control

C:ONTROLS

The blade control handle is located on the upper han

dle of the mower. See figure 14. The blade control han

dle must be depressed in order to operate the unit.

Release the blade control handle to stop the engine and

blade.

A

THROTTLE CONTROL

The throttle control is located on the side of the upper

handle. It is used to regulate the engine speed.

A

RECOIL STARTER

The recoil starter handle is attached to the handle. See

figure 14. Stand behind the unit in the operating posi

tion to start the unit.

WARNING: The blade will be rotating whenever the engine is running.

WARNING: The throttle control cannot be used to stop the engine.

10

Page 11

OPERATION

TO REDUCE THE RISK OF INJURY. DO NOT

OPERATE MOWER UNLESS REAR TRAILING

SHIELD AND THIS GUARD OR ENTIRE

GRASS CATCHER IS IN ITS PROPER PLACE.

FIGURE 15.

Keep hands and feet away from the chute area on cut

ting deck. See figure 15.

The operation of any lawn mower can result in

foreign objects being thrown into the eyes, which

can resuit in severe eye damage.

Aiways wear safety glasses or eye

shields. We recommend wide vision

safety mask for over spectacles or

standard safety glasses.

NOTE: For shipping purposes your mower is set with

the wheels in a low cutting height position. For best

resuits raise the cutting position untii it is determined

which height is best for your lawn. See cutting height

adjustment section.

Metal Loop

on Spark

Piug Wire

Rubber Boot

FIGURE 16.

2. Open fuel shut-off valve. See figure 17.

3. Move throttle control lever all the way forward.

4. Standing behind the unit, depress the blade con

trol handle and hold it against the upper handle

as shown. See figure 18.

5. Grasp the recoil starter handle and pull back rapid

ly, extending rope fully. Return it slowly to the rope

guide bolt.

6. After engine starts, move throttle control to desired

engine speed.

NOTE: If any problems are encountered, refer to the

Trouble Shooting Guide on page 15.

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as instructed

in the separate engine manual packed with your

mower. Read instructions carefully.

WARNING: Never fill fuel tank indoors,

with engine running or until the engine has

▲

been allowed to cool for at least two

minutes after running.

TO START ENGINE AND ENGAGE BLADE

1. Attach spark plug wire to spark plug. If unit is

equipped with a rubber boot over the end of the

spark plug wire, make certain the metal loop on

the end of the spark plug wire (inside the rubber

boot) is fastened securely over the metal tip on the

spark plug. See figure 16.

FIGURE 18.

TO STOP ENGINE AND BLADE

1. Release the blade control handle to stop the

engine and blade.

11

Page 12

WARNING: The blade continues to rotate

for a few seconds after the engine is shut

A

2. Disconnect the spark plug wire and ground it

USING YOUR ROTARY MOWER

A

Be sure that lawn is clear of stones, sticks, wire, o other

objects which could damage lawn mower or e igine.

Such objects could be accidently thrown by the r lower

in any direction and cause serious personal injury to

the operator and others.

For the best results, do not cut wet grass becc use it

tends to stick to the underside of the mower, pr aventing proper discharge of grass clippings, and could

cause you to slip and fall. New grass, thick grass or

wet grass may require a narrower cut. Blade speed

should be adjusted to the condition of the lawi.

For best results, cut off one-third or less of th a total

length of the grass. Lawn should be cut in the fall as

long as there is growth.

This mower is designed to be operated at full t irottle

to give you the best cut and do the most effect! t/e job

of bagging the cut grass.

off.

against the engine to prevent accidental starting

while equipment is unattended.

WARNING: Never operate your unit

without either the rear deflector or (>ntire

grass catcher assembly in place.

FIGURE 19.

THROTTLE CONTROL ADJUSTMENT

If the carburetor choke does not close fully or if the

throttle control has been replaced, adjust the throttle

control as follows.

1.

Remove the screw shown in figure 20. Remove the

cable clamp from the cable.

2.

Push the throttle control lever on the handle all the

way forward to CHOKE position. Make certain the

throttle control lever remains in this position.

Push the control lever on the engine as far toward

the rear of the engine as it will go. Secure the cable

in this position with the cable clamp and screw.

Cable

Clamp

WARNING: If you strike a foreign object,

A

stop the engine. Remove wire from spark

plug, thoroughly inspect the mower f }r any

damage, and repair the damage before

restarting and operating the mower. I Exten

sive vibration of the mower during < iperation is an indication of damage. The unit

should be promptly inspected and

repaired.

ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to lawn mower withoit first

A

CUTTING HEIGHT ADJUSTMENT

An adjusting plate and thumb lever at each whe ?l posi

tion provides cutting height adjustment. Each ac justing

plate has nine height positions. Height of cut will be

changed when the thumb lever is moved from one hole

to another. Simply depress the lever towards whnel and

move wheel and lever assembly to desired posil ion. All

wheels must be placed in the same relative position.

See figure 19.

stopping engine and disconnecting spark

plug wire.

FIGURE 20.

CARBURETOR ADJUSTMENTS

WARNING: If any adjustments are made to

the engine while the engine is running (e.g.

A

Minor carburetor adjustments may be required to

compensate for differences in fuei, temperature,

altitude and ioad. To adjust carburetor, refer to the

separate engine manual packed with your mower.

NOTE: A dirty air cleaner will cause an engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Refer to the

separate engine manual.

carburetor), keep ciear of aii moving parts.

Be carefui of heated surfaces and muffler.

12

Page 13

LUBRICATION

WARNING: Always stop engine and

disconnect spark plug wire before clean

A

Blade Control—Lubricate the pivot points on the blade

control handle and the brake cable at least once a

season with light oil. See figure 21. The blade control

must operate freely in both directions.

FIGURE 21.

Discharge Chute Deflector—The torsion spring and

pivot point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must work

freely.

Wheels—Mower may be provided with ball bearing

wheels. Lubricate at least once a season with light oil.

Also, if the wheels are removed for any reason,

lubricate the surface of the axle bolt and the inner sur

face of the wheel with light oil. A 4 oz. plastic bottle

of light oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

Engine—Follow engine manual for lubrication in

structions.

Throttle—Periodically lubricate throttle control lever

and throttle wire assembly with a few drops of light oil

for ease of operation.

ing, lubricating or doing any kind of work

on lawn mower.

MAINTENANCE

CUTTING BLADE

When removing the cutting blade for sharpening or

replacement, protect hands by using heavy gloves or

a rag to grasp the cutting blade. Remove the bolt and

bell washer which hold the blade and adapter to the

engine crankshaft. Remove the blade and adapter from

the crankshaft.

If the blade or blade adapter needs replacing, remove

the two small bolts, lock washers and nuts which hold

the blade to the adapter.

WARNING: Periodically inspect the blade

adapter for cracks, especially if you strike

A

When sharpening the blade, follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds,

may cause damage to the mower and could break,

causing personal injury.

It is recommended that the blade always be removed

from the adapter for the best test of balance.

The blade can be tested by balancing it on a round shaft

screwdriver. Remove metal from the heavy side until

it balances evenly.

Before reassembling the blade and the blade adapter

to the unit, lubricate the engine crankshaft and the inner

surface of the blade adapter with light oil. Lubricating

the bolt holes, bolts and inner surface of the nuts with

light oil is also recommended. A 4 oz. plastic bottle of

light oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

When replacing the blade, be sure to install the blade

with the side of the blade marked “Bottom” (or with

part number) facing the ground when the mower is in

the operating position.

Blade Mounting Torque

Center Bolt and Blade Adapter Bolts:

375 in. lb. min., 450 in. lb. max.

To insure safe operation of your unit, all nuts and bolts

must be checked periodically for correct tightness.

a foreign object. Replace when necessary.

WARNING: Be sure to disconnect and

ground the spark plug wire before perform

A

NOTE: When tipping the unit, empty the fuel tank and

keep engine spark plug side up.

TROUBLE SHOOTING

Refer to page 15 of this manual for trouble shooting

information.

ing any repairs or maintenance.

DECK

The underside of the mower deck should be cleaned

after each use to prevent a buildup of grass clippings,

leaves, dirt or other matter. If this debris is allowed to

accumulate, it will invite rust and corrosion, and may

cause an uneven discharge of grass clippings at the

next cutting.

The deck may be cleaned by tilting the mower and

scraping clean with a suitable tool (make certain the

spark plug wire is disconnected).

13

Page 14

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as instructed in the seaarate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under norm il con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should k e ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the ga|) reset

once a season. Spark plug replacement is lecom-

mended at the start of each mowing season; check

engine manual for correct plug type and gap

specifications.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to per

mit proper air circulation which is essential to engine

performance and life. Be certain to remove aii grass,

dirt and combustible debris from muffler area

OFF-SEASON STORACiE

The following steps should be taken to prepaie lawn

mower for storage.

1. Clean and lubricate mower thoroughly as de

scribed in the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

3. Coat mower’s cutting blade with chassis grease

to prevent rusting.

4. Store mower in a dry, clean area.

NOTE: When storing any type of power equipment in

an unventiiated or metai storage shed, care shouid be

taken to rust-proof the equipment. Using a light oil or

silicone, coat the equipment, especially cables and all

moving parts.

HANDLE STORAGE

The handle may be placed in an upright position for

storage. Move hairpin clips to outer hole on weld pins.

See figure 1. Press outward on the bottom of the lower

handle and push forward. The handle will lock in this

position.

To place the handle in the operating position, remove

the starter rope from the rope guide bolt. Grasp the

lower handle at the bottom, press outward slightly and

tip the handle backward. Place the hairpin clips in the

inner holes. With the spark plug wire disconnected and

grounded, depress the blade control handle and pull

the starter rope out from the engine. Slip the starter

rope into the rope guide bolt.

14

Page 15

TROUBLE SHOOTING GUIDE

Trouble

Engine fails to start 1. Blade control handle disengaged.

Engine runs erratic

Engine overheats

2. Spark plug wire disconnected.

3. Throttle control lever not in CHOKE

or START position.

4. Fuei shut-off valve closed.

5. Fuel tank empty, or stale fuel.

6. Blocked fuel line.

7. Faulty spark plug.

8. Engine flooded.

1. Unit running in CHOKE or START

position.

2. Spark plug wire loose.

3. Blocked fuel line or stale fuel.

4. Vent in gas cap plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

1. Engine oil level low.

2. Air flow restricted.

3. Carburetor not adjusted properly.

Possible Cause(s) Corrective Action

1. Engage blade control handle.

2. Connect wire to spark plug.

3. Move throttle lever to CHOKE or

START position.

4. Open fuel shut-off valve.

5. Fill tank with clean, fresh gasoline.

6. Clean fuel line.

7. Clean, adjust gap or replace.

8. Remove spark plug, dry the plug, and

crank engine with plug removed and

throttle in off position. Replace spark

plug, connect wire and resume starting

procedures.

1. Move throttle lever to FAST

position.

2. Connect and tighten spark plug wire.

3. Clean fuel line; fill tank with clean,

fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6. Clean air cleaner.t

7. Adjust carburetor.f

1. Fill crankcase with proper oil.

2. Remove blower housing and clean.t

3. Adjust carburetor.f

Occasional skip

(hesitates) at high speed

Idles poorly

Excessive vibration 1. Cutting blade loose or unbalanced.

Mower will not

discharge grass

Uneven cut

tRefer to separate engine manual packed with your unit.

1. Spark plug gap too close.

2. Carburetor idle mixture adjustment

improperly set.

1. Spark plug fouled, faulty or gap too wide.

2. Carburetor improperly adjusted.

3. Dirty air cleaner.

2. Bent cutting blade.

1. Engine speed too low.

2. Wet grass.

3. Excessively high grass.

1. Wheels not positioned correctly.

2. Dull blade.

1. Adjust gap to .030".

2. Adjust carburetor.f

1. Reset gap to .030" or replace spark plug.

2. Adjust carburetor.f

3. Clean air cleaner.f

1. Tighten blade and adapter.

Balance blade.

2. Replace blade.

1. Set throttle between 3/4 and full throttle.

2. Do not mow when grass is wet; wait until

later to cut.

3. Mow once at a high cutting height, then

mow again at desired height or make a

narrower cutting swath (1/2 width).

1. Place all four wheels in same

height position.

2. Sharpen or replace blade.

Note: For repairs beyond the minor adjustments listed above, contact your local authorized service dealer.

15

Page 16

Models 516R and 518R

r\Y{-}(aG( CAfJ

3"

This instruction manuai covers various

models and all specifications shown

do not necessarily apply to your

model. Specifications subject to

change without notice or obligation.

!5 (p F'/loMT VOHC..

7^/- 0 5 ^ St, Fi4sTi c 8/?CS

78 2-o/oq is,ocr

73/_

^ 3p Uu4V £

"ih- 0/0£^ 8£7c

Page 17

PARTS LIST FOR MODELS 516R AND 518R ROTARY MOWERS

REF.

iNO.

PART

NO.

1

747-0748

731-1135 N

CODE DESCRIPTION

N Control Handle Ass’y. (Std.)

Control Handle Ass’y- (Deluxe)

2 720-0226 Foam Grip (Optional)

17174 N Cable Brkt.

3

REF.

NO.

PART

NO.

52 710-0654A

CODE DESCRIPTION

Hex L-Wash. Hd. Scr.

3/8-16 X 1" Lg.

53

16998 638 21" Deck Ass’y.

54 17014

Chute Baffle

4 710-0501 Hex Bolt 1/4-20 X 2.0" Lg. 55 17003 Retaining Strip 14.25" Lg.

736-0175

5

712-0287

6

749-0438B N

8

746-0821 N

12

710-0842B Rope Guide Bolt

13

14 736-0119

712-0267 Hex Nut 5/16-18 Thd.* 63 741-0484

15

746-0554 N

16

17 726-0240

710-0671 Curved Carriage Bolt 5/16-18

18

19 749-0504C

22 735-0639

27

—

29 734-1661

30 734-1653

710-1055 N Hex Bolt 3/8-24 x 1" 80

31

32 736-0169

712-0241 Hex Nut 3/8-24 Thd.

33

34 731-0858

35 714-0104 Int. Cotter Pin 5/16" Dia. Comp.—L.H. (Not Shown)

36 726-0106

37 747-0698B N Hinge Pin 17.75" Lg.

750-0566 Spacer .255" I.D. 85 17488 N Pivot Bar—R.H.

38

732-0577A Torsion Spring—L.H.

39

40 711-0805

41 736-0169 L-Wash. 3/8" I.D.*

42 712-0711 Hex Jam Nut 3/8-24 Thd. 88

732-0578A Torsion Spring—R.H.

43

44 12297A N

710-1017 Torx Mach. AB-Tap Scr. У4 x

45

46 731-0970B N

47

731-0931

12296A N Handle Brkt. Ass’y.—R.H. 92 720-0224

48

710-0892 Hex L-Wash. AB-Tap Scr. 93

49

50 736-0356 Bell-Wash. .39" I.D. 95 738-0137

712-0798 Hex Nut 3/8-16 Thd.* 96 731-0564

51

Spr. Wash. 1/4" I.D.

Hex Nut 1/4-20 Thd. 57

Upper Handle

Throttle Control Ass’y. Comp.—

56.6"

L-Wash. 5/16" I.D.* 62

Control Cable—40.5"

Cable Tie

X 1.38" Lg.

N Lower Handle

Spark Plug Boot (Optional)

Engine

N Wheel Ass’y. Comp.—Steel Rim

N Wheel Ass’y. Comp.—Plastic

Rim

L-Wash. 3/8" I.D.

Seal—Extrusion

Cap Speed Nut 83

Shid. Pin 3/8-24 x 1.43" Lg. 86

Handle Brkt. Ass’y.—L.H.

.62" Lg. 89

Deflector Plug

Corner Plug

1/4 X .62" Lg. 94

56

731-0669

731-0859

58

731-0856 Hardtop Handle

Rear Flap 17.30" Lg.

Rear Chute Deflector

59 731-0857A Hardtop Bag Cover

60 749-0736A Rear Catcher Frame

61

747-0693B

Front Catcher Frame

764-0252 Grass Bag

Bearing Vz" I.D. (2 Per Wheel)

64

738-0+t7d M81 ShId. Bolt .498" Dia. x 2.475"

65

736-0463 FI-Wash. .281" I.D.

72

736-0453 Bell-Wash. .46" I.D.

73 742-0306A N

74

753-0485 Blade Adapter Kit

21" Blade

75 710-0757 Hex Bolt 7/16-20 x 1.5" Lg.

76

15261A Height Adj. Plate

77

15262B Pivot Bar

78

14832 Spring Lever Ass’y. w/Knob

79

738-0507B

Shid. Bolt .50" Dia. x .357"

736-0105 Bell-Wash. .38" I.D. x .88" O.D.

81 731-0981A Hub Cap (Optional)

82

14578 Height Adj. Ass’y. Comp.—R.H.

14579 Height Adj. Ass’y.

84

★ *

14764C

17489

Front Wheel Ass’y. Comp.

Index Plate

N

Pivot Bar—L.H. (Not Shown)

720-0190 Spring Lever Knob

87

732-0417A Spring Lever

17490

N

Rear Height Adj. Ass’y.

Comp.—R.H.

17491

* *

N

Rear Height Adj. Ass’y.

Comp.—L.H. (Not Shown)

Front Axle Bolt

90 736-0232 Wave Wash. .53" I.D. x .78"

O.D.

Grass Catcher Locking Knob

736-0498 Internal L-Wash. V4" I.D.

736-0286

Wave Washer 3/8" I.D.

Shid. Bolt .342" Dia. x .268"

Plug

Wheels w/o Bearings

Tread“* Ass’y. Comp. Axle Bolt Tread*“

Waffle

Rib

Bar

734-1162A (8")

734-1161A (7")

734-1169 (8")

734-1170 (7")

734-1608 (8")

738-0102

738-0102

738-0144

738-0144

738-0102

‘"Tread Type: Waffle : Rib ; Bar

Waffle

“T” Tread

“S” Wave

*‘FRONT WHEEL CHART

Ass’y. Comp.

734-0645

734-0924

734-0812

734-1259

734-1260

734-1513ДВ

Ball Brgs.: 3/8" I.D.-741-0267, V2" I.D.-741-0484, Spacer-750-0434

Ball Brg. V2" 1.D.-741-0180 (2 per Wheel)

Plastic Brg. V2" I.D.-741-0262 (2 per Wheel)

Ball Brgs.: 3/8" I.D.-741-0267, V2" I.D.-741-0484, Spacer-750-0434

Ball Brg. 1/2" I.D.-741-0180 (2 per Wheel)

Ball Brg. V2" I.D.-741-0180 (2 per Wheel)

17

Wheels With Bearings

Bearings

: “T” Tread

Axle Bolt

710-1020

738-0102

738-0102

710-1020

738-0102

710-1020

‘S” Wave

Page 18

*For faster service obtain standard nuts, boits and washers ocaily.

If these items cannot be obtained locally, order by part numi )er and

size as shown on parts iist.

NOTE: The engine is not under warranty by

the mower manufacturer. ..If repairs or

service is needed on the engine, piease

contact your nearest author

ized engine service outiet.

Check the “Yeilow Pages” of

your telephone book under

“Engines—Gasoline.”

Find It Fast

In The

Yellow Pages

CODE: N notates a new part (not previously existing). A three digit

number is the color code. Specify color code as shown below if

color or finish is important when ordering parts, [i.e., -638 for Red

Finish].

Color Codes

456—Radiant Tangerine

460—Green Flake

483—Charcoal Gray 637—Black

498—Yellow

499—Beige

621—Brilliant Fire Mist

629—Silver Flake

630—Metallic Blue

638—Red

640—Green

646—CM Blue

18

Page 19

"N

Page 20

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorized service firms listed

below. All orders should specify the model number of your unit, part

numbers, description of parts and the quantity of each part req jired.

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS AND

SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service should be

handled by your nearest authorized engine service firm. Check the yellow

pages of your telephone directory under the listing Engines—Gasoline,

Briggs & Stratton or Tecumseh Lauson.

NOTE: If any parts are found to be missing or defitctive upon assembly of this unit, write to advise the factory so that

immediate replacement can be made.

ARKANSAS NORTH LITTLE ROCK

Sutton’s Lawn Mower Shop

CALIFORNIA

Billious

...............................................

COLORADO

Spitzer Industrial Products Co. . . 6601 N.

FLORIDA

Radco Distributors

............................

...........

5301 Roundtop Drive

Box 368, Rt. 4

PORTERVILLE

. . 75 North D Street ....

DENVER

Washington St

JACKSONVILLE

. . 4909 Victor St.

Box 5459

...................

...................

..........................

HIALEAH

Small Eng. Dist

..................................

ILLINOIS

Keen Edge Co

.................................

INDIANA

Parts & Sales Inc...............................

IOWA

Power Lawn & Garden Equip..

MARYLAND

Center Supply Co

............................

MASSACHUSETTS

Morton B. Collins Co.......................

MICHIGAN

Power Equipment Dist

....................

MINNESOTA

Hance Distributing Inc

....................

MISSOURI

Oscar Wilson Engine & Parts

. . 7995 W. 26th Court . .. .13016

LYONS

. . 8615 Ogden Ave

.................

ELKHART

.. 2101 Industrial Pkwy.

Box 277

.............................

DUBUQUE

.. 2551 J.F. Kennedy. . . .

BELTSVILLE

. . 6802 Industrial Dr.

#208 ...................................

SPRINGFIELD

.. 300 Birnie Ave.......................

MOUNT CLEMENS

.. 340 Hubbard

........................

PLYMOUTH

. . 12795 16th Ave. North

EARTH CITY

4159 Shoreline Dr

...........

KANSAS CITY

Automotive Equip

3117 Holmes St

.................

Service

..........

NEW YORK CARTHAGE

Gamble Dist., Inc

...........................

West End Ave.

Box 389

..........................

.’2117

.1)3257

. : 10229

.:!2207

. >0534

. 16516

. 52001

. 20705

. 51107

.18043

.55441

83045

84109

13619

NORTH CAROLINA

Dixie Sales Company

......................

OHIO

Stebe’s Mid-State Mower Supply

Bleckrie, Inc

National Central...............................

Burton Supply Co............................

.....................................

PENNSYLVANIA

EECO Inc

Bluemont Co

Frank Roberts & Sons

Scranton Auto Ignition Co..............

..........................................

....................................

....................

TENNESSEE

Ace Distributors...............................

Chilton Air Cooled Engine..............

TEXAS

Marr Brothers, Inc

...........................

UTAH

Powered Products

............

...............

VIRGINIA

RBI Corp...........................................

WASHINGTON

Equip. Northwest.............................

WISCONSIN

Wisconsin Magneto Inc

PUERTO RICO

Island Distribution Center

..................

..............

BROWNS SUMMIT

5920 Summit Ave............27214

CARROLL

Box 366, 71 High St... .43112

CLEVELAND

7900 Lorain Ave.............44102

WADSWORTH

687 Seville Rd

...............

YOUNGSTOWN

1301 Logan Ave.

Box 929

........................

HARRISBURG

4021 N. 6th St

................

PITTSBURGH

11101 Frankstown Rd. .15235

PUNXSUTAWNEY

R.D. 2.............................15767

SCRANTON

1133-35 Wyoming Ave. .18509

KNOXVILLE

2103 Magnolia

...............

NASHVILLE

319 4th Ave. S

...............

DALLAS

423 E. Jefferson

.............

SALT LAKE CITY

1661 N. Beck St

.............

ASHLAND

101 Cedar Ridge Dr. . . .23005

SEATTLE

1410 14th Ave

...............

MILWAUKEE

4727 N. Teutonia St. . . .53209

RAMEY

102 N. St

.......................

44281

44501

17110

37917

37210

75203

84116

98122

00604

WARRANTS PARTS AND SERVICE POLICY

(0689)

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected at the time

of manufacture. It does not provide for the unlimited and un estricted replacement of parts. Use and maintenance are the responsibility of the

customer. The manufacturer cannot assume responsibility fo ' conditions over which it has no control. Simply put, if it’s the manufacturer’s fault,

it’s the manufacturer’s responsibility; if it’s the customer’s ault, it’s the customer’s responsibility.

CLAIMS AGAINST THE MANUFACTURER’S WARRANTY

INCLUDES:

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty f eriod.

3. Repair of Defects within the warranty period.

All claims MUST be substantiated with the following

information:

1. Model Number, Serial Number and/or Date Code of unit in

volved.

2. Date unit was purchased.

3. Date of Failure.

4. Nature of Failure.

MTD PRODUCTS INC • P.O BOX 360900 • CLEVELAND, OHIO 44136

Loading...

Loading...