Page 1

10 CENTS

ROTARY MOWER

For one year from date of purchase, MTD Products, Inc.,

will replace for the original purchaser, free of charge, F.O.B.

factory or authorized service firm, any part or parts found to

be defective in material or workmanship. All transportation

charges on parts submitted for replacement under this war

ranty must be paid by the purchaser. This warranty does not

include replacement of parts which become inoperative

through misuse, excessive use, accident, neglect, improper

maintenance or alterations by unauthorized persons. This

warranty does not include the engine, motor, battery, bat

tery charger or any component parts thereof. For service on

these units refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner

and will be effective only if the warranty card has been pro

perly processed. It will not apply where the unit has been

used commercially.

Warranty service is available through your local author

ized service dealer or distributor. UNDER NO CIRCUM

STANCES WILL THE RETURN OF A COMPLETE UNIT

BE ACCEPTED BY TH| FACTORY UNLESS PRIOR

WRITTEN PERMISSION HAS BEEN EXTENDED.

Your rotary mower is a precision piece of power equip

ment, not a plaything. Therefore exercise extreme caution

at ail times.

1. Remove all sticks, stones, wire and other hazardous items

from lawn before mowing. Such items are dangerous to

both the mower and individuals in the vicinity of the

mower.

2. Always disconnect spark plug cable during repairs or re

fueling operations.

3. Always start engine from side opposite discharge chute.

4. NEVER place hands or feet under mower or near dis

charge chute while engine is running.

5. Do not tilt mower at extreme angle while engine is run

ning. Cut grass on hills and banks sideways, not up and

down.

6. Always stop engine when not cutting grass.

7. Do not fill gas tank while engine is running. Do not spill

gasoline on hot engine.

8. Keep children and pets away from area at all times during

mowing operation. Never allow mower to discharge grass

toward any person.

9. Do not attempt to start engine while mower is resting in

high grass.

10. Check all nuts and bolts, particularly the blade oolts, for

tightness. This is especially important during the initial

operation period. Make this same check periodically

11. While operating the mower, if any foreign object is struck,

stop the mower and inspect for damage. Do not restart

or operate the mower until all damage has been repaired.

WARMING: Should excessive vibrotioo develop, check your blode ond

crankshaft immediately. Do not operate mower with on unbalanced

blade, a damaged blade or a damaged crankshaft.

MTID FROIDXJCTS INC

• 5389 west noth ST. • P.O. B0 X 274I • CLEVELAND, OHIO 441II

FORM NO. 2799A

Page 2

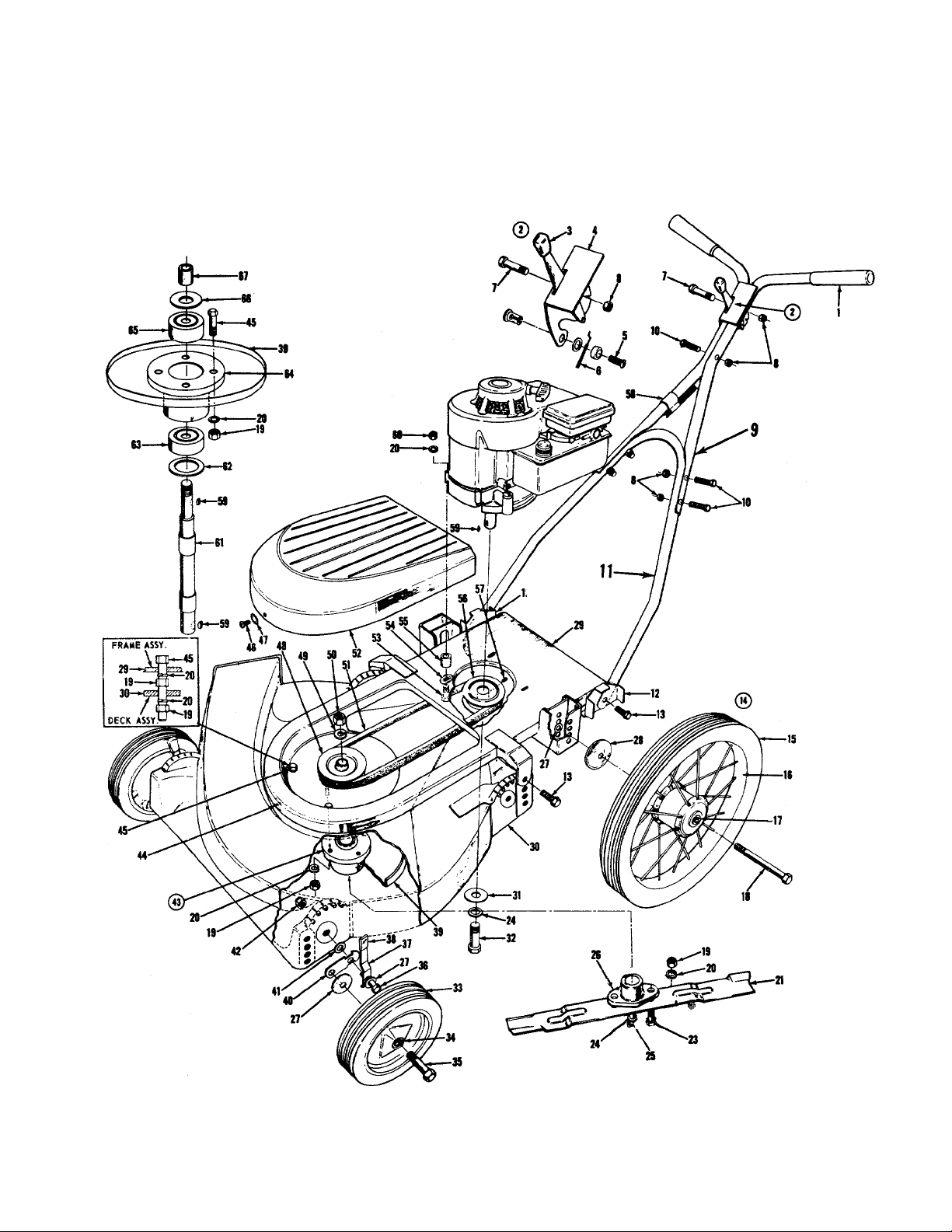

no - 500

NOTE: Set screw in engine

pulley is treated with a nut

and bolt sealant. Apply heat

with a torch or solder gun

(400°) to remove.

FORM NO. 770-2799B

Page 3

PARTS LIST FOR MODEL NO. 110-500

Raf.

No.

1

2 310-8846 Throttle Control - Complete

3

4 310-8841

5

6

7

8

9

10

11

12

13

14

15 734-237

16

17

18

19 712-123

20

21

23 710-117

24

25 710-113 HexHd. Cap Sew. 3/8—24 x 1-5/8 Ig.

26

27

28

79

30

31

32 710-152

33

34

35

Port

No.

305-7072

305-7470 Knob +

901-7627 Ferrule Assembly +

732-139

710-606

712-107 Hex Centerlock Nut 1/4—20 thread *

310-9364

710-106

310-8334

310-9060 Handle Bracket 46

710-209

501-9184 Wheel Assembly — Rear

734-238

748-147

738-114

736-119

312-8125

736-169

748-100 Blade Adapter

736-105

736-112

347-9169

347-9069

310-7386

SlO-9392

305-7006

738-213 Axle Bolt

Grips — White

Throttle Control Bracket + 38

Conduit and Wire +

HexHd. Cap Sew. 1/4-20 x 1-1/2 Ig. *

Handle — Upper (2 Req’d)

HexHd. Cap Sew. 1/4—20 x 1-1/4 Ig. * 44 712-526

Handle - Lower

Sems HexHd. Cap Sew. 3/8—16x5/8 Ig. *

Tire-Rib Tread 14” dia. x 1-3/4”

Wheel Assembly — Rear . Tire

Flange Bearing (2 Req’d Per Wheel)

Axle Bolt — Rear

Hex Nut 5/16 — 24 thread *

Spring Lockwasher 5/16 Screw *

Blade - 21”

HexHd. Cap Sew. 5/16—24 x 1 Ig.

(Heat Treated)

Spring Lockwasher — 3/8” Screw *

(Heat Treated)

Belleville Washer 63

Belleville Washer

Frame Assembly

Deck Assembly

Washer

HexHd. Cap Sew. 3/8—24 x 1 Ig.

Wheel Assembly — Front

Fortiflex Bearing

DESCRIPTION

Ref.

No.

36

37

39 347 -8809

40

41 736-133

42

43

45 710-116

47

48

49

50 712-922

51

52 347 -8295 Blade Soindle Cover

53 710-158

54 736-170

55

56 756-121

57 710-938

58 746-145

59

60

61

62 721-105

64

65 741-120

66 736-154

67

Port

No.

710-191

310-8835

305-7520

310-7492

712-116

901-7805

710-473

736-147

310-9925

736-921

754-116

711-250

714-365

712-267

711-240

741-107

719-120

711-212

Hex Hd. Cap Sew. 3/8-24 x 1-1/4 Ig.

(Heat Treated)

Sluing Lever Assembly

Knob - Red

Blade Reinforcement Plate

Wheel Pivot Bai

Flat Washer 3/8 ID *

Elastic Stop Nut 3/8—24 thread *

Blade Spindle Ass’y — Complete

Speed Nut

HexHd. Cap Sew. 5/16-18 x 2 Ig. *

Truss Hd. Mach. Sew. #10-24 x 1/2 Ig. *

External Lockwasher #10 Screw ♦

Pulley — 4” dia. — 1/2” bore

Spring Lockwasher — 1/2” screw *

Hex Jam Nut 1/2 — 20 thread ♦

V-Belt42” X 1/2” ♦

HexHd. Cap Sew. 5/16-24 x 1-1/4 Ig.

Lockwasher — Special

Spacer

Pulley — Engine — 4” dia.

Allen Set Sew. Cup Pt. 1/4—28 x 1/4 Ig.*

Cable Clip

Key-Hi Pro # HP 505 * A

Hex Nut 5/16-18 thread *

Spindle A

Seal A

Timken Bearing —3/4 Bore — lower A

Spindle Housing A

Timken Bearing — 11/16 Bore —upper A

Flat Washer A

Sleeve A

DESCRIPTION

* For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

+ Included in Part No. 310-8846 Control-Throttle (complete).

A Included in Part No. 901-7805 Blade Spindle Ass’y (complete).

ASSEMBLY

Your new mower is shipped completely assembled with the

exception of the handle.

1. Remove lawn mower and all parts from carton. Make

certain that all loose parts and literature are removed

from carton before carton is discarded.

2. Extend throttle control assembly, which is attached to

rear of mower and place on floor. CAUTION: Do not bend

or kink control wire.

3. (a) Snap lower handle into position on two lugs which

extend from the handle brackets mounted on the rear

of the frame assembly®

(b) Assemble the two upper handle parts with cap screws

and locknuts provided in parts bag. The yellow cap

screw should be used to attach throttle control assem

bly to upper handle as shown in diagram. Do not

tighten nuts.

(c) Attach upper handle assembly to lower handle with

cap screws and locknuts. Tighten all nuts.

(d) Secure control wire to lower handle with cable clips.

4. Check blade bolts for proper tightness.

5. See initial belt adjustment under Adjustment Section on

page U .

OPERATION

NOTE: For shipping purposes your mower is set with the

v/heels in a low cutting height position. For best results

raise the cutting position until it is determined which

height is best for your lawn. See adjustments.

1. Service engine with gas and oil. See Engine Manual pack

ed with lawn mower for complete instructions for the care

and maintenance of engine. Read Directions Carefully.

2. When ready to start engine, place throttle control lever,

on handle, in “Choke” position and start engine in

accordance with instructions in Engine Manual. After

engine starts, move throttle control lever, on handle, to

desired engine speed. The engine is stopped by placing

control lever on handle in the “Stop” position.

3. Be sure that lawn is clear of stones, sticks, wire or other

objects which could damage lawn mower or engine. For

best results and to insure more even grass distribution,

do not mow when lawn is excessively wet.

FORM NO. 770-2799C

Page 4

ADJUSTMENTS

CAUTION: Do not at any time make any adjustment to lawn

mower without first stopping engine and disconnecting spark

plug wire.

CUTTING HEIGHT - An adjusting plate and thumb lever at

each front wheel position provides cutting height adjustment.

Each adjusting plate has five holes. Height of cut will be

changed when the thumb lever is moved from one hole to

another. Simply depress thumb lever towards wheel and move

wheel and lever assembly to desired position. Cutting height

will be raised as lever is moved toward front and lowered as

lever is moved toward rear.

Adjustment may be made to the rear wheels by removing and

moving wheel studs to desired position. Cutting heists will

be raised as wheel studs are moved to a lower hole and

lowered as wheel studs are moved to a higher hole in the

deck. All wheels must be positioned in relative height of

cut positions.

THROTTLE - If adjustment becomes necessary, the throttle

control wire assembly can be reset as follows:

1. Loosen, but do not remove, screw securing throttle control

wire assembly at engine.

2. Move throttle control lever on handle to ‘“CHOKE”

position.

3. Move lever, to which control wire is fastened at engine,

to full choke position and retighten screw to secure

throttle control wire assembly.

BELT ADJUSTMENT - After the first one-half hour of

operation the slack in the belt must be taken up. After this

initial adjustment the belt will require only checking after

every 25 hours of operation. To tighten the belt, remove the

three truss head machine screws (46) and lockwashers (47)

and remove the blade spindle cover (52) Loosen the three

hex nuts (60) holding the engine to the frame assembly (29)

and pull the engine back until the belt (51) has a 1/4”

deflection when depressed by hand. Tighten the hex nuts

(60) and reassemble shroud.

MAINTENANCE

CUTTING BLADE - The blade may easily be removed for

grinding or replacement as follows:

1. Remove bolt and lock washer holding blade and hub

assembly to blade spindle.

2. Remove blade and hub assembly from blade spindle.

3. Remove two bolts, lock washers and nuts holding blade

to blade hub.

When sharpening blade, follow the original angle of grind as

a guide. It is extremely important that each cutting edge

receives an equal amount of grinding to prevent an unbalanced

blade. An unbalanced blade will cause excessive vibration

when rotating at high speeds and may cause damage to the

mower.

Upon reassembly, make certain all parts are assembled

properly and listened securely.

DECK - The underside of mower deck should be cleaned

after each period use as grass clippings, leaves, dirt and

other matter will accumulate. This accumulation of grass

clippings, etc., is undesirable as it will invite conosion and

may cause an uneven discharge of grass clippings at the

next cutting.

The deck may be cleaned by tilting the mower forward or on

its left side and scraping clean with a suitable tool or by

washing with a stream of water from a garden hose.

CAUTION: Do not direct the stream of water at a hot engine

as damage to the engine may result.

STORAGE - The following steps should be taken to prepare

lawn mower for storage.

1. Clean and lubricate mower thoroughly as described in the

preceding instructions.

2. Refer to Engine Manual for correct engine storage

instructions.

3. Coat mower’s cutting blade with chassis grease to prevent

rusting.

4. Place blocks under d’ck to raise tires clear of floor.

5. Store mower in a dry clean area.

LUBRICATION

IMPORTANT: Always stop engine and disconnect spark plug

wire before cleaning, lubricating or doing any kind of work on

lawn mower.

WHEELS - Front wheel bearings of Fortiflex require no

lubrication. Rear wheels of Lifetime graphoil bearings

require little lubrication. A light film of oil applied to these

bearings will reduce normal friction.

THROTTLE - Periodically lubricate throttle control lever

and throttle wire assembly with a few drops of light oil

(S.A.E. No. 10 or 20) for ease of operation.

ENGINE - Follow Engine Manual for lubrication instruction.

USING YOUR ROTARY MOWER

For best results do not cut wet grass because it tends to

stick to underside of the mower thus preventing proper

discharge of grass clippings. If wet grass must be cut reduce

engine speed and walking speed to help distribute the

clippings more effectively.

New grass should be treated as wet grass, otherwise a

normal walking speed is about the right pace for efficient

mowing.

The best mowing pattern is one that allows the clippings to

discharge towards the uncut part of the lawn. This permits

recutting of the clippings to further pulverize them. When

cutting high weeds, discharge towards cut portion then recut

at right angles to first direction.

Lawn should be cut in the fall as long as there is growth.

FORM NO. 770-27990

PRINTED IN U.S.A.

Loading...

Loading...