Page 1

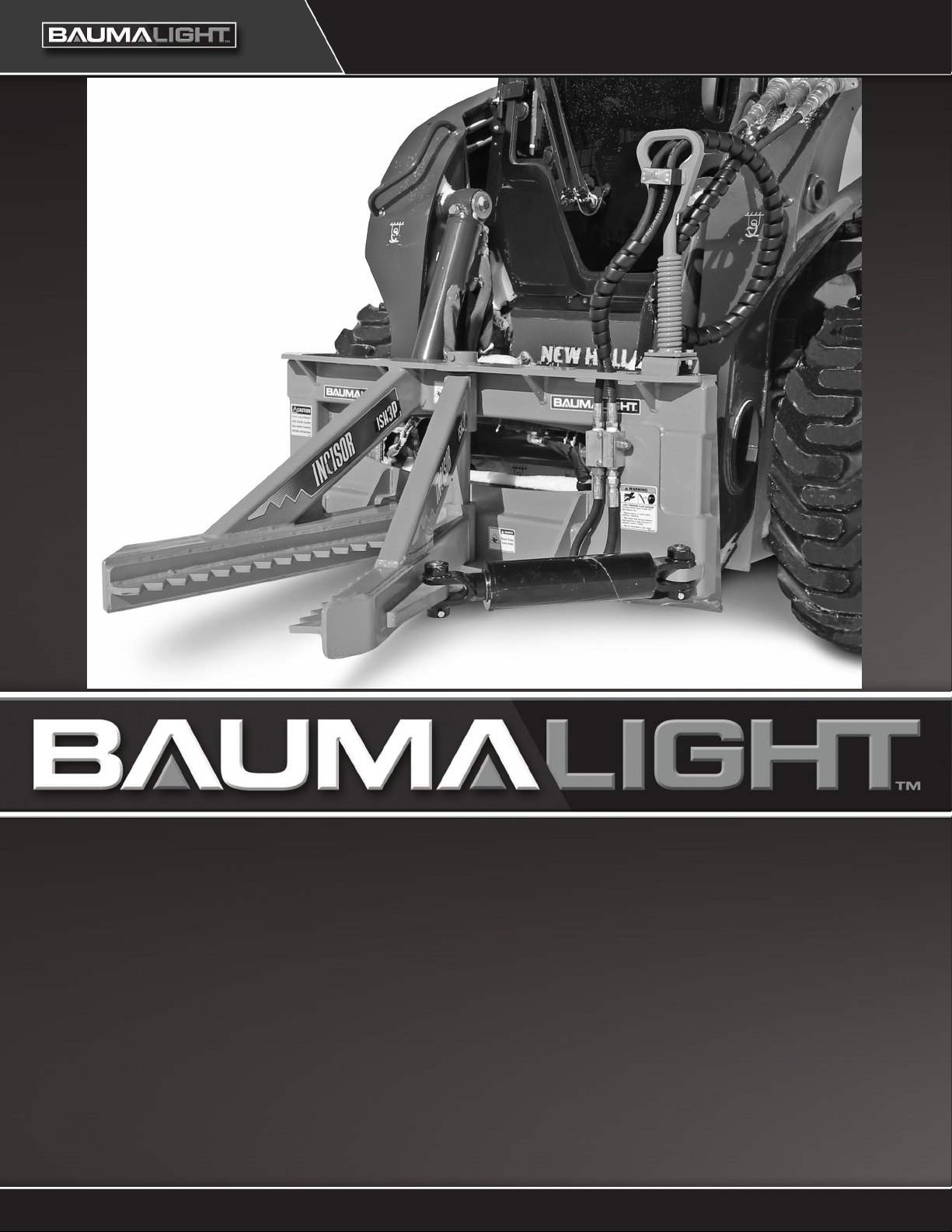

HYDRAULIC TREE PULLER

OPERATOR’S MANUAL

Issue Date: December 2017

Page 2

ii

Page 3

TABLE OF CONTENTS

1 INTRODUCTION ��������������������������������������������������������������������������������������������������������������������������������� 2

1�1 Overview �������������������������������������������������������������������������������������������������������������������������������������� 2

1�2 Intended Use And Foreseeable Misuse ������������������������������������������������������������������������������������ 2

2 SAFETY ������������������������������������������������������������������������������������������������������������������������������������������������ 3

2�1 Safety Alert Symbol And Safety Words ������������������������������������������������������������������������������������ 3

2�2 Operational Hazards ������������������������������������������������������������������������������������������������������������������� 3

Prepare For Emergencies ���������������������������������������������������������������������������������������������������������� 4

Replace Safety Signs ����������������������������������������������������������������������������������������������������������������� 4

Do Not Allow Riders ������������������������������������������������������������������������������������������������������������������� 4

Lower Operating Speed ������������������������������������������������������������������������������������������������������������� 5

Avoid Rollover ���������������������������������������������������������������������������������������������������������������������������� 5

Avoid Powerlines ������������������������������������������������������������������������������������������������������������������������ 5

Detach Tree Puller Safely ����������������������������������������������������������������������������������������������������������� 5

Hazards From Modifying Equipment ���������������������������������������������������������������������������������������� 5

2�3 Maintenance Hazards ����������������������������������������������������������������������������������������������������������������� 7

3 SAFETY SIGNS ����������������������������������������������������������������������������������������������������������������������������������� 8

4 OPERATION �������������������������������������������������������������������������������������������������������������������������������������� 10

4�1 Preparation For Use ����������������������������������������������������������������������������������������������������������������� 10

4�2 Machine Components �������������������������������������������������������������������������������������������������������������� 10

4�3 Attach To Skid Steer ������������������������������������������������������������������������������������������������������������������11

4�4 Detach From Skid Steer ������������������������������������������������������������������������������������������������������������11

4�5 Transporting ������������������������������������������������������������������������������������������������������������������������������ 12

4�6 First Time User Tips ����������������������������������������������������������������������������������������������������������������� 12

4�7 Field Operation ������������������������������������������������������������������������������������������������������������������������� 13

4�8 Relief Valve �������������������������������������������������������������������������������������������������������������������������������� 13

5 SERVICE AND MAINTENANCE ������������������������������������������������������������������������������������������������������ 14

5�1 Lubrication �������������������������������������������������������������������������������������������������������������������������������� 14

5�2 Inspect Hoses ��������������������������������������������������������������������������������������������������������������������������� 14

6 TROUBLESHOOTING ���������������������������������������������������������������������������������������������������������������������� 15

7 WARRANTY ��������������������������������������������������������������������������������������������������������������������������������������� 16

1

Page 4

1 INTRODUCTION

1.1 Overview

Congratulations on your choice of a Baumalight

Incisor Tree Puller to complement your operation.

This equipment has been designed and

manufactured to meet the needs of a discriminating

buyer.

This new and unique design allows us to build it

very economically and makes it a very compact

unit for storage and transport. The enhanced

visibility make the tree puller easy and efcient to

operate. Hydraulic controls are easy to adjust and

operate.

Safe, efcient and trouble free operation of your

tree puller requires that you and anyone else who

will be operating or maintaining the tree puller,

read and understand the Safety, Operation,

Maintenance and Troubleshooting information

contained within the Operator’s Manual.

This manual covers the Baumalight Incisor Tree

Puller. Use the Table of Contents as a guide to

locate required information.

1.2 Intended Use And

Foreseeable Misuse

The tree puller is designed to be used by an

experienced operator. Operator must be trained

in the safe operation of a skid steer and hazards

related to using the tree puller and the safe use of

the tree puller for the intended purpose. Operators

will require personal protective equipment to

reduce the risk from some hazards that cannot be

completely eliminated or controlled by the design

of the tree puller.

Care is required to ensure that the tree puller will

not come in contact with metallic objects, stones or

other materials.

Tree pullers are not designed for use in hazardous

atmospheres where there is a risk of re or

explosion due to ammable gases or vapors.

Use in hazardous, explosive atmospheres is

prohibited. Serious injury or death of the operator

or bystanders may be caused if puller is misused.

Misuse may also cause damage to the machine

carrying the puller.

Keep this manual handy for frequent reference

and to pass on to new operators or owners. Call

your Baumalight dealer, distributor or the factory

if you need assistance, information or additional

copies of the manuals.

OPERATOR ORIENTATION - The directions left,

right, front and rear, as mentioned throughout this

manual, are as seen from the operator’s seat and

facing in the direction of travel.

2

Page 5

2 SAFETY

2.1 Safety Alert Symbol

And Safety Words

You must read, understand and follow the

instructions given by the operating unit

manufacturers, as well as the instructions in this

manual.

The safety information in this manual is denoted

by the safety alert symbol:

^

This symbol means ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^ DANGER

DANGER - Indicates a hazardous

situation, which, if not avoided, WILL

result in death or serious injury�

2.2 Operational Hazards

^ WARNING

Prevent death or serious injury�

Read and understand this manual before

operating tree puller�

Always lower puller to ground, stop

engine and remove key before leaving

operators seat�

Never allow anyone in near tree puller

or in area where tree may fall during

operation�

Travel at a safe speed�

^ WARNING

Prevent death or serious injury from

moving parts�

^ WARNING

WARNING - Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury�

^ CAUTION

CAUTION - Indicates a hazardous

situation, which, if not avoided, could

result in minor or moderate injury�

NOTICE

NOTICE - Indicates a situation that could

result in damage to the equipment or

other property.

Moving parts can crush and dismember�

Disconnect and lockout power source

before adjusting or servicing�

^ WARNING

Use tree puller only for the designed

applications�

Any other use may result in personal

injury, damage to equipment and may

void the warranty�

3

Page 6

^ WARNING

Prepare For Emergencies

Prevent death or serious injury�

Verify tree puller is locked to quick attach

hitch before operation or transport�

^ WARNING

Protect from ying debris.

Wear proper safety glasses, goggles, or

a face shield to protect from debris�

Carefully read all safety messages in this manual

and on equipment safety signs. Keep safety signs

in good condition and replace missing or damaged

safety signs.

New equipment components and repair parts must

include the current safety decal.

Learn how to properly operate equipment.

NEVER operate or work around this equipment

without proper instruction, while fatigued or under

the inuence of alcohol, prescription or non-

prescription medication or if feeling ill.

Keep your equipment in proper working condition.

Know the regulations and laws that apply to you

and your industry. This manual is not to replace

any regulations or laws. Additional information

may be found at: www.asae.org or www.osha.gov.

If you do not understand any part of this manual,

contact Baumalight at 866-820-7603.

• Be prepared in case of emergencies.

• Keep a re extinguisher and rst aid kit close

to the machine.

• Keep emergency phone numbers close to your

phone.

• Know your address so emergency services

can locate you if an emergency arises.

Replace Safety Signs

• Replace missing or damaged safety signs.

• Safety signs are identied in Section 3 of this

manual.

• Replacement safety signs are available from

your Baumalight dealer.

Do Not Allow Riders

• NEVER lift or carry anyone on tree puller.

• NEVER use tree puller as a work platform.

• NEVER allow passengers on tree puller.

4

Page 7

Lower Operating Speed

Detach Tree Puller Safely

Keep tree puller low and move at slow speeds on

rough or uneven terrain.

Avoid Rollover

The equipment may rollover, resulting in death or

serious injury. To help prevent rollover:

• Travel at a slow speed.

• Avoid sharp turns & sudden movement on

slopes.

• Carry tree puller close to the ground.

• Avoid holes, ditches and other obstructions

which may cause equipment to rollover.

• Balance load so weight is evenly distributed

and load is stable.

• Use caution when operating on slopes and do

not operate on excessively steep slopes.

• Do not exceed load capacity of equipment.

Detach tree puller on a rm and level surface. Tree

puller may fall over if detached on unlevel or soft

surface. Be sure people, livestock and pets are

clear of machinery.

Relieve hydraulic pressure before disconnecting

hydraulic hoses.

Raised Attachment

^ WARNING

Crushing hazard�

Raised, unsupported tree puller can fall,

resulting in death or serious injury�

Never enter the area under a raised tree

puller�

A raised tree puller can lower unexpectedly,

resulting in death or serious injury.

Avoid Powerlines

^ DANGER

Prevent electrocution�

Death or serious injury can result if

equipment comes near or contacts

power lines�

Electrocution can occur without direct

contact�

• Check clearance before raising equipment.

DO NOT leave the operator’s seat if any part of the

equipment contacts electric lines or cables.

NEVER enter area under a raised tree puller.

Lower tree puller to ground, engage parking brake,

shut off engine and remove key before servicing.

Hazards From Modifying

Equipment

Do not make any alterations to your tree puller.

Altering may cause your equipment to be unsafe

and may void the manufacturers’ warranty.

5

Page 8

Avoid High Pressure

Fluids

^ WARNING

Pressurized uids can penetrate the

skin�

Hydraulic hoses can fail from age,

damage and exposure�

Use body and face protection while

searching for leaks� A tiny, almost

invisible leak can penetrate the skin,

thereby requiring immediate medical

attention�

Use wood or cardboard to detect

hydraulic leaks, never use your hands�

Escaping uid under pressure can penetrate the

skin causing serious injury.

Avoid Loud Noise

^ WARNING

Prolonged exposure to loud noise can

cause impairment or loss of hearing�

Wear a suitable hearing protective device

such as earmuffs or earplugs to protect

against objectionable or uncomfortable

loud noises�

Prevent the hazard by relieving pressure before

connecting or disconnecting hydraulic lines. Verify

all connections are tight before applying pressure.

Search for leaks with a piece of cardboard or wood.

Protect hands and body from high pressure uids.

If an accident occurs, see a doctor immediately.

Any uid injected into the skin must be surgically

removed within a few hours or serious infection

may result.

Doctors unfamiliar with this type of injury should

reference a knowledgeable medical source.

6

Page 9

2.3 Maintenance Hazards

Before servicing, park machine on a rm and

level surface, set parking brake and place a “Do

Not Operate” tag on control panel. Read and

understand this manual. If you do not understand

any part of the manual, contact Baumalight at 866820-7603.

Always wear face and/or eye protection, safety

shoes, and other protective equipment appropriate

for the job.

Do not make unauthorized modications. Contact

Baumalight at 866-820-7603. Before you weld, cut/

drill holes, or make any other modications.

Always use Baumalight replacement parts.

^ WARNING

Moving parts can crush and cut�

Keep clear of moving components�

^ WARNING

Entanglement hazard�

Keep clear of moving components�

Wear proper protective equipment

appropriate for the job�

^ WARNING

Burn hazard�

Hot and high pressure hydraulic oil�

Allow oil to cool before servicing�

Follow lockout procedure before

servicing�

^ WARNING

Crushing hazard�

Before performing inspections, service

or maintenance:

Park machine on rm, level surface.

Engage parking brake�

Turn engine off and remove key�

Place “Do Not Operate” tag on control

panel�

7

Page 10

3 SAFETY SIGNS

IHS3S

A. MTB-180 Safety Sign

IHS3P

B. MTB-182 Safety Sign

8

Page 11

C. MTB-175 Safety Sign

unsafe

E. MTB-052 Safety Sign

D. MTB-065 Safety Sign

MTB-065

9

Page 12

4 OPERATION

4.1 Preparation For Use

Although the tree puller has been carefully

inspected and checked prior to shipment from

manufacturer, it is recommended that the unit be

thoroughly inspected.

Check all bolts for tightness and remove all

shipping tags, bags, skids, and blocking.

Remove any masking materials afxed during

painting. Inspect equipment to verify that

nameplates and all safety warning, caution signs

and decals provided with the equipment are in

place and clearly visible.

Visually inspect the tree puller before each start up.

Check for loose or missing parts and any damage

that may have occurred during moving or shipping.

Review all skid steer pre-start instructions, and

ensure that all recommended steps and procedures

have been followed.

4.2 Machine Components

A. Hose Holder

B. Relief Valve

C. Clamp Cylinder

D. Pivoting Clamp

E. Stationary Clamp

^ WARNING

Pressurized uids can penetrate the

skin�

Disconnect and lockout power source

before disconnecting and/or connecting

hydraulic hoses�

10

Page 13

4.3 Attach To Skid Steer

4.4 Detach From

Skid Steer

^ WARNING

To prevent injury or machine damage

put transmission in park�

Never position yourself between skid

steer and tree puller�

Only experienced and properly trained

operator’s may operate skid steer and

tree puller�

1. Read and follow all safety instructions.

2. Attach tree puller to skid steer. See skid steer

operator’s manual.

3. Connect hydraulic hoses. Verify hydraulic

hoses are clear of pinch areas and moving

parts.

4. Move to a clear open area to test functions.

^ WARNING

Prevent death or serious injury caused

by unexpected movement:

1� Park skid steer on a level surface�

2� Engage parking brake�

1. Park skid steer on a level surface.

2. Lower tree puller to the ground.

3. Shut off engine and remove key.

4. Disconnect hydraulic hoses.

5. Detach tree puller from skid steer. See skid

steer Operator’s Manual.

11

Page 14

4.5 Transporting 4.6 First Time User Tips

1. Verify all reectors and Slow Moving Vehicle

(SMV) sign are visible.

2. Raise tree puller slightly off ground.

3. Travel at a reasonable and safe speed.

^ WARNING

Always stop engine and remove key

before leaving operators seat�

Operate all functions in an open area with skid

steer at idle to get a good feel for the controls.

Run throttle only at half speed for rst time users.

^ WARNING

Always stop engine and remove key

before leaving operators seat�

12

Page 15

4.7 Field Operation

4.8 Relief Valve

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park skid steer on a level surface�

2� Lower puller to ground�

3� Engage parking brake�

4� Shut off engine and remove key�

^ WARNING

Never operate tree puller when other

people are in the vicinity�

Keep all shields in place�

Do not allow riders on skid steer�

1. Attach tree puller to skid steer. See Attaching/

Detaching in this section.

2. Operate hydraulics to open clamps.

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park skid steer on a level surface�

2� Lower puller to ground�

3� Engage parking brake�

4� Shut off engine and remove key�

Tree puller is equipped with a relief valve to adjust

clamping pressure. If clamping pressure is set

high, clamps may pinch off small brush or trees.

Remove cap (A) and turn relief valve counter

clockwise to decrease clamping pressure.

Turn relief valve clockwise to increase clamping

pressure.

Install cap (A).

3. Position puller so tree is as far into rear of jaw

opening as possible for most clamping power.

4. Position tree puller as low as possible when

clamping tree.

5. Operate hydraulics to raise tree puller and pull

brush/tree from ground.

6. Move skid steer to desired location and operate

hydraulics to open clamps to drop brush/tree.

13

Page 16

5 SERVICE AND

MAINTENANCE

5.1 Lubrication

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park skid steer on a level surface�

2� Lower puller to ground�

3� Engage parking brake�

4� Shut off engine and remove key�

Pump grease into all pivot point lubrication ttings

until adequately lubricated.

5.2 Inspect Hoses

^ WARNING

Pressurized uids can penetrate the

skin�

Hydraulic hoses can fail from age,

damage and exposure�

Use body and face protection while

searching for leaks� A tiny, almost

invisible leak can penetrate the skin,

thereby requiring immediate medical

attention�

Use wood or cardboard to detect

hydraulic leaks, never use your hands�

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park skid steer on a level surface�

2� Lower puller to ground�

3� Engage parking brake�

4� Shut off engine and remove key�

Inspect hydraulic hoses for damage and wear.

Replace damaged or worn hoses before operating

puller.

14

Page 17

6 TROUBLESHOOTING

PROBLEM CHECK SOLUTION

Clamps do not close. Clamps jammed. Remove material from clamps.

Low oil. Check oil level in skid steer. Add oil if

necessary.

Not enough oil ow. Check ow control on skid steer. See

your dealer.

Clamps do not have much power. Low oil. Check oil level in skid steer. Add oil if

necessary.

Oil lter plugged. Replace skid steer oil lter.

Skid steer relief valve not set

properly.

Not enough oil pressure. Check hydraulic pressure on skid steer.

Set relief valve. Pressure should be

3000 psi (207 bar). See your dealer.

See your dealer.

15

Page 18

7 WARRANTY

This product is warranted to be free of defects in materials and workmanship under normal use and

service, for a period of one year from the date of purchase, when operated and maintained in accordance

with the Operating and Maintenance Instructions supplied with this unit. This warranty does not cover

misuse or negligence.

Under no circumstances will the manufacturer be liable for any consequential damage or expense of any

kind, including loss of prots. The manufacturer is under no circumstances liable for skid steer damage

of any kind. The manufacturer is not liable for the maintenance of the product.

This warranty is extended only to the original purchaser. Warranty is void if repairs are attempted by

anyone other than an Authorized Service Center.

If a difculty develops with the product, you should contact your nearest Authorized Repair Center, or

distributor. Only these locations are authorized to make repairs to the product or affect the replacement of

defective parts, which will be done at no charge within a reasonable time after the receipt of the product.

Units or parts should be returned at the customer’s expense to the nearest repair location or Authorized

Service Center. Pack unit in a strong carton and pad tightly to avoid damage. Damage in-transit is not

covered by warranty. Include original purchase receipt with any claim (keeping a copy for your les).

The Manufacturer’s Liability is limited to repair of the product and/or replacement of parts and is given to

the purchaser in lieu of all other remedies including incidental and consequential charges. There are no

warranties, expressed or implied other than those specied herein. For the nearest Authorized Service

Center call the manufacturer.

Please note the following details and le this information in an appropriate place.

Model Number: ___________ S/N:_______________

Date of Purchase: _____________ Owner’s Name__________________________________

16

Page 19

17

Page 20

For parts, specications and the latest machine information please visit our website.

www�baumalight�com

18

MTB MFG INC.

CORPORATE HEADQUARTERS

4575 Powell Rd.,

Wallenstein, Ontario Canada

N0B 2S0

Phone - 519.698.9864

Toll Free - 866.820.7603

Fax - 519.698.1087

www�baumalight�com

Loading...

Loading...