MTA TAEevo Tech 101, TAEevo Tech 051, TAEevo Tech 081, TAEevo Tech 020, TAEevo Tech 121 Operating And Maintenance Manual

...

TAEevo Tech

WATER CHILLERS

OPERATING AND MAINTENANCE MANUAL

TAEevo Tech 015÷802 60 Hz UL

DDOMA00417

Original instructions in Italian language (Service)

OPERATING AND MAINTENANCE MANUAL

- User’s quick guide

TAEevo Tech 015÷802 60 Hz UL

1

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

USER’S QUICK GUIDE

ATTENTION

MODIFICATION OF AN UL LISTED PRODUCT

MTA chillers feature an electrical cabinet designed and wired in compliance with the UL508A standard for electrical

enclosures. The UL compliance allows this MTA equipment to meet local code requirements in most locations in the US and

Canada. When a UL Listed product is modified, retrofitted or altered in any way after it leaves the factory, it is necessary to

verify if the product continues to meet the applicable certification safety requirements.

If a modification made to the product in the field (outside of the MTA factory) does NOT affect the electrical characteristics

of the panel installed on the machine, then the UL Listing is not affected and th e UL label that was placed on the p roduct at

the factory can remain. Some examples include:

- Making the remote ON / OFF connection (to terminals provided in the panel)

- Making the alarm relay connection (to terminals provided in the panel)

- Making remote terminal connection (to terminals provided in the panel)

- Replacement of panel components with equal components

If a modification made in the field DOES affect the electrical characteristics of the panel installed on the machine, it is not

possible for UL to confirm that the product continues to meet the applicable certification safety requirements. In this case

the field modifications must be specifically inspected and recertified by the appropriate UL agency. Some examples include:

- Replacement of panel components with components that are different than those originally supplied

- Replacement of motors (or other current-drawing devices) that involve the change of components inside the panel

- Addition of devices not provided for by MTA

- Addition of electrical loads not foreseen by MTA

In this case it is the responsibility of the AUTHORITY HAVING JURISDICTION to assess the acceptability of modifications

and/or to determine if modifications are significant enough to require a member of the UL field engineering services staff to

evaluate and/or recertify the modified product. Anyone directly involved with a product (including manufacturers, owners,

contractors, and regulatory authorities) can request a Field Evaluation.

For further clarification, contact MTA USA or visit the UL’s Web site at www.ul.com/field.

ATTENTION

Before starting units of this type, ensure that all personnel inv olved have read and understood Chapter 2 “Safety” and

follow the procedures set down in Chapter 6 “Starting”.

ATTENTION

When first starting after a stop of several days, ensure that the casing heating element of each compressor is switched

on for at least 12 hours before pressing the start button.

ATTENTION

The pressure l imiting valve is factory set, according to the pump nominal flow operating at a standard voltage of 460V/

3Ph/60Hz.

Before using the unit it is necessary to set the limiting valve according to the plant nominal flow and accordin g to the power

supply.

Units in the TAEevo Tech range are equipped with an electronic controller that manages correct operation of the appliance on

the basis of signals read on the analogue and digital inputs.

This quick guide contains a list of the main functions of the electronic board. For more detailed information consult Chapter7

“Electronic controller”.

OPERATING AND MAINTENANCE MANUAL

- User’s quick guide

TAEevo Tech 015÷802 60 Hz UL

2

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

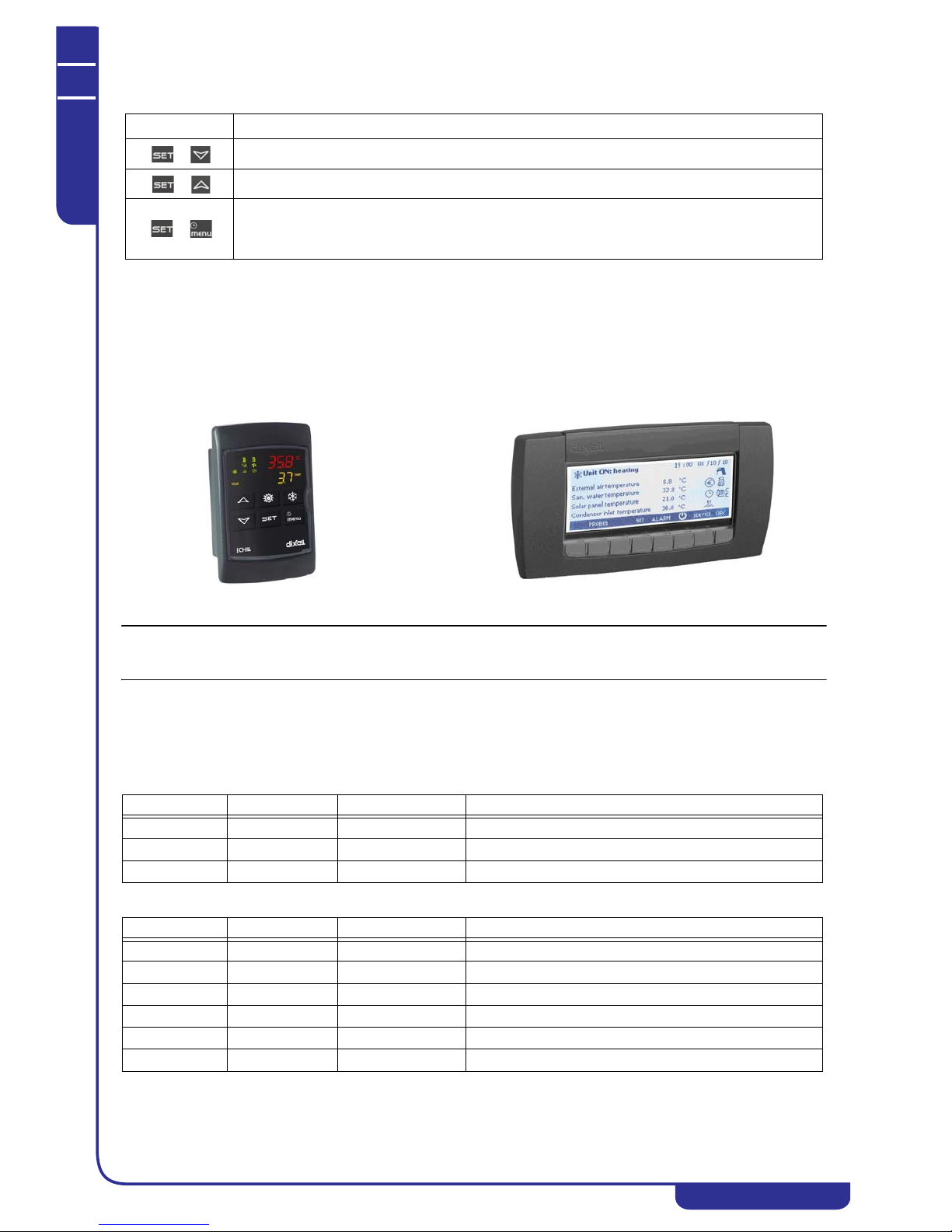

On the models TAEevo Tech 015÷351 the electronic control unit is installed on the door of the electrical panel, while on

models TAEevo Tech 381÷802 it is fitted inside the electrical panel while the door is equipped with LCD graphic display.

NOTE

To convert the semi-graphic LCD display on the door of the electrical panel (mod. TAEevo Tech 381÷802) to remote control,

the relevant remote control kit must be ordered.

0.1 Unit start/stop

The unit can be switched on and off as follows:

• From the keypad (local or remote)

• From a digital input configured as remote ON/OFF

NOTE

In case of a power loss, when pow er is restored the unit will be ON if it was ON at the time of power loss, and OFF if it was

OFF.

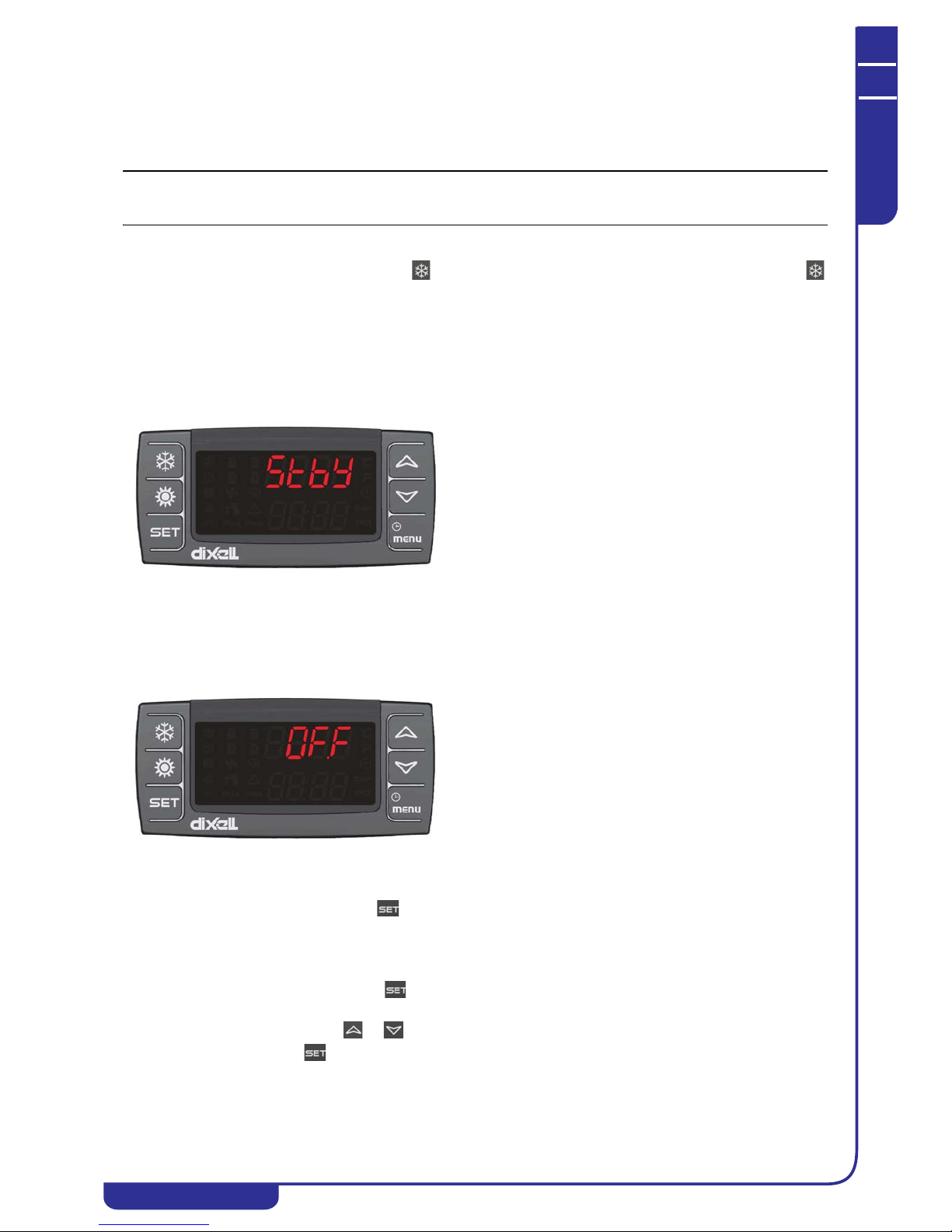

0.1.1 Start from the keypad

From unit OFF (stand-by) press and release button to switch the unit on or off in chiller mode. With the unit on LED

is lit.

Stand-by mode is set each time the unit is switched off from chiller operating mode. Also in stand-by the controller makes it

possible to:

• Display the measured values.

• Manage the alarm situation by displaying and signalling active alarms.

When the unit is in stand-by the controller shows the label

on the display.

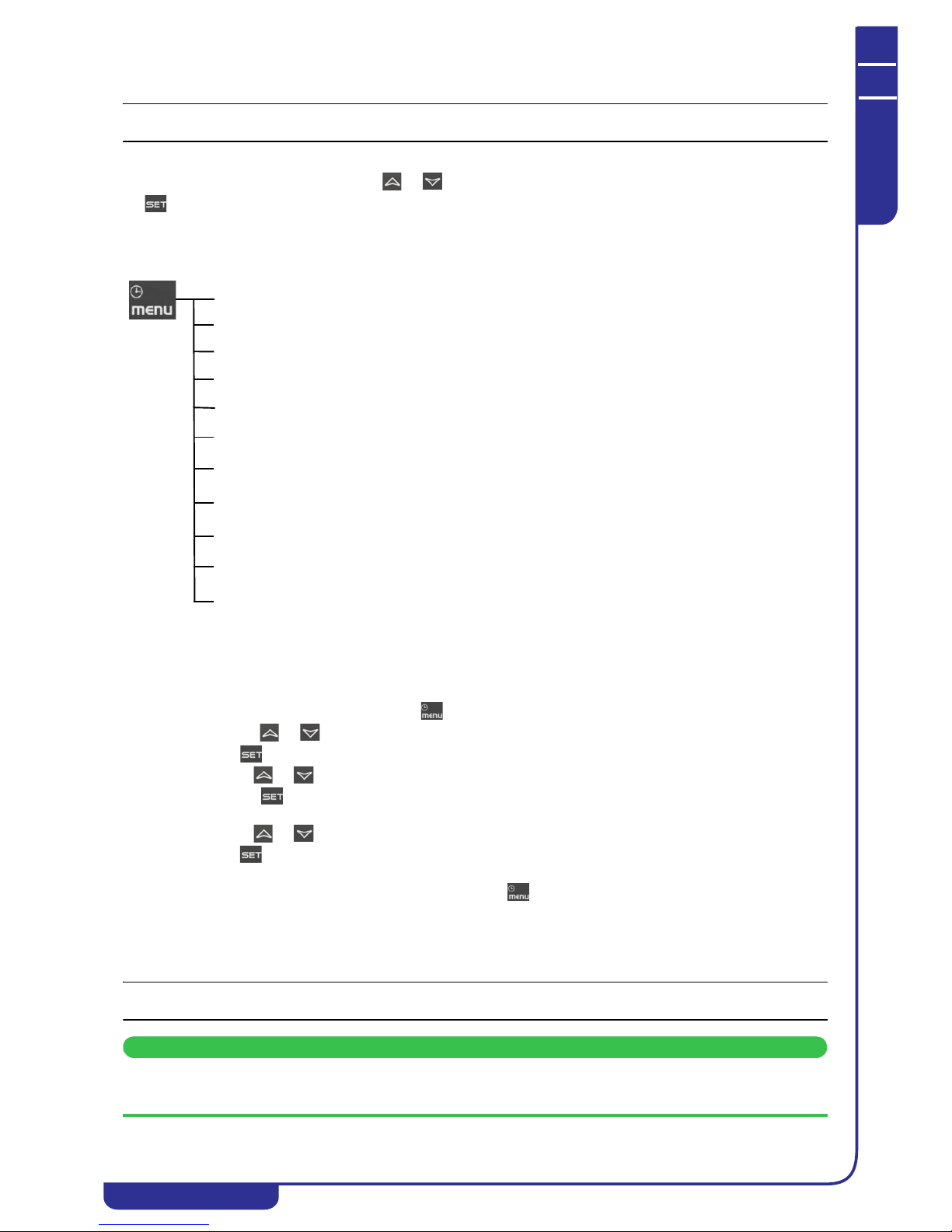

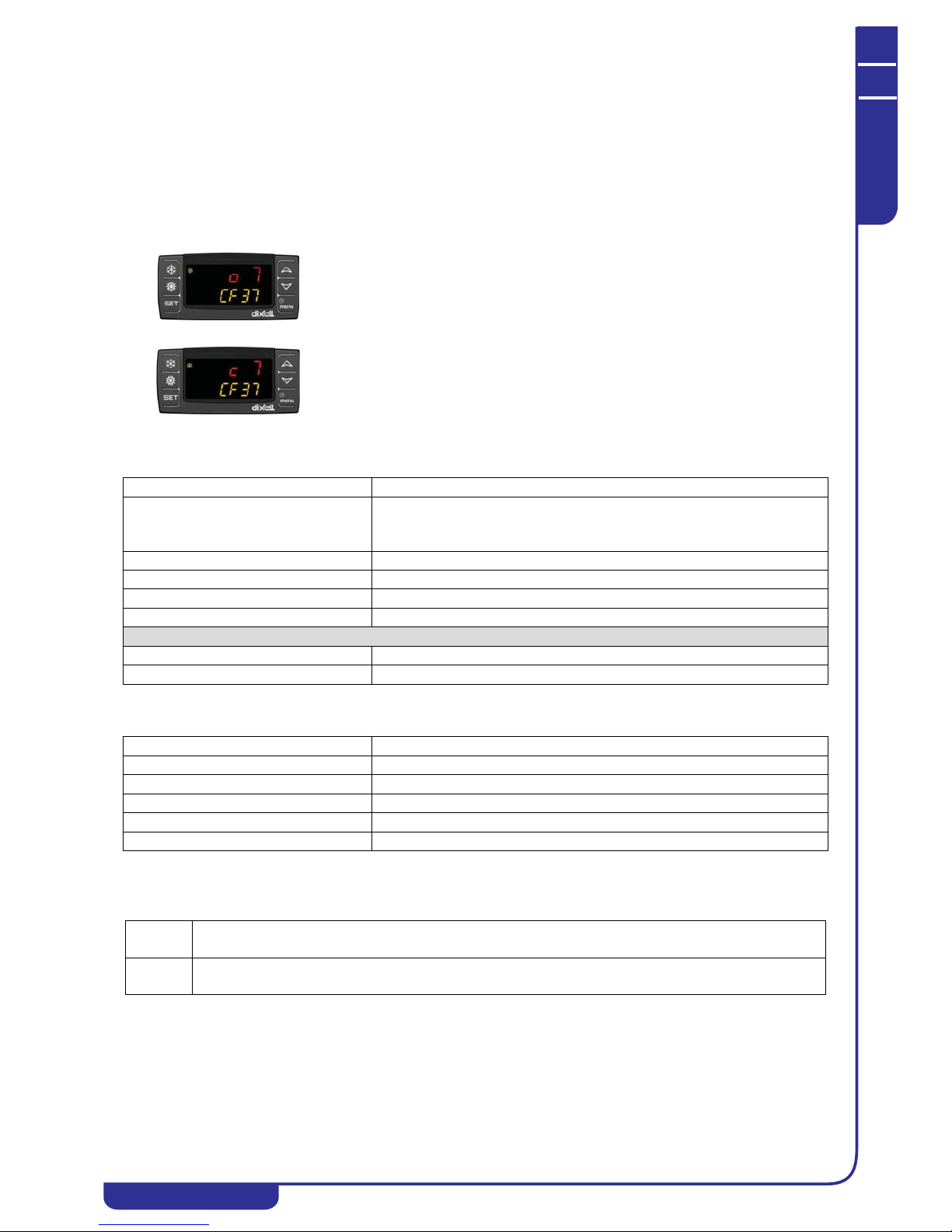

Electronic control TAEevo Tech 015÷351

LCD graphic display TAEevo Tech 381÷802

OPERATING AND MAINTENANCE MANUAL

- User’s quick guide

TAEevo Tech 015÷802 60 Hz UL

3

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

0.1.2 Start-up from a digital input

The unit can be switched on/off from a digital input configured as remote On/OFF.

The power-off command (local or remote) always assumes priority with respect to the power-on command. If the unit is

powered-off with a local command it must be powered back on with a local command.

When the unit is in OFF status from a digital input the controller shows the label

. on the display.

For details concerning the connection, refer to the electrical diagram.

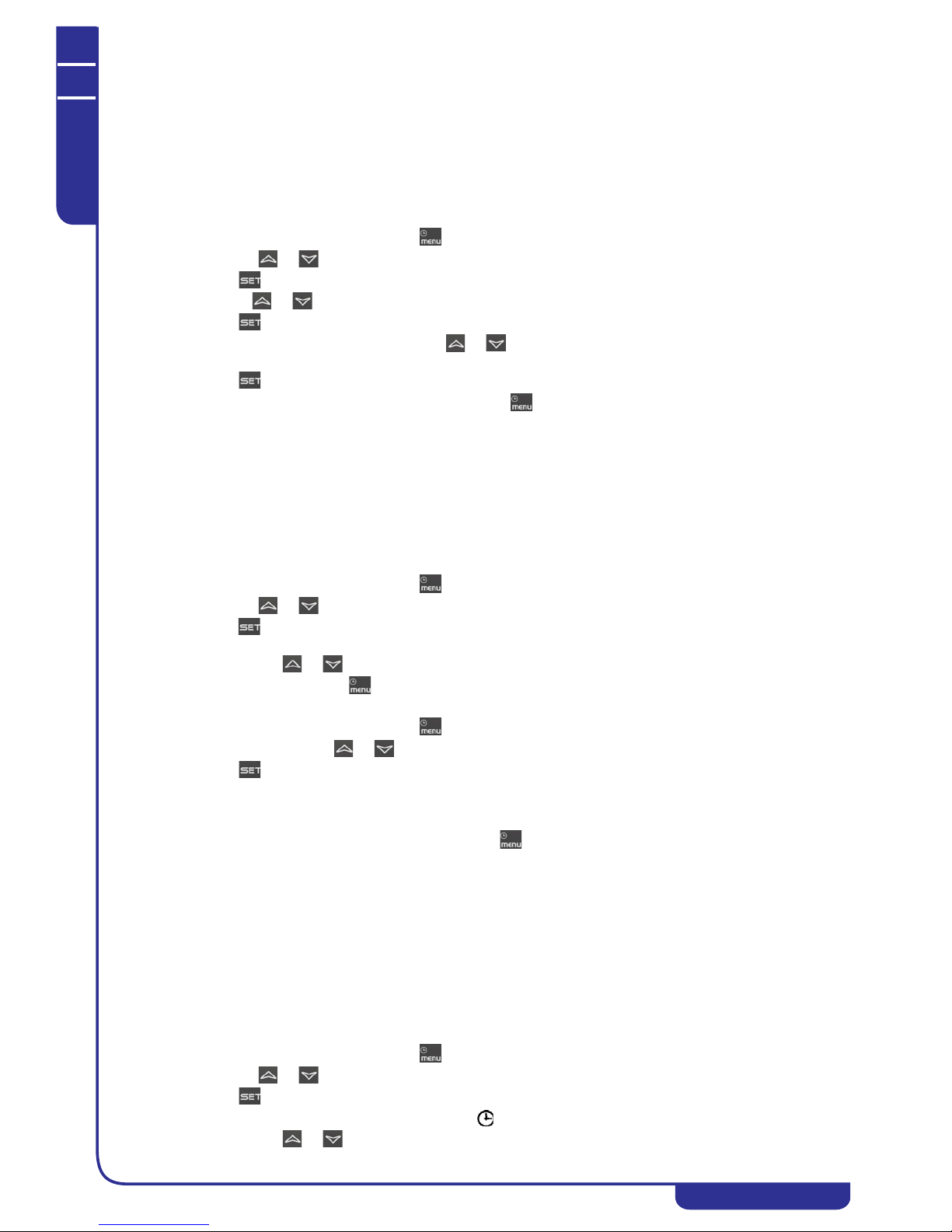

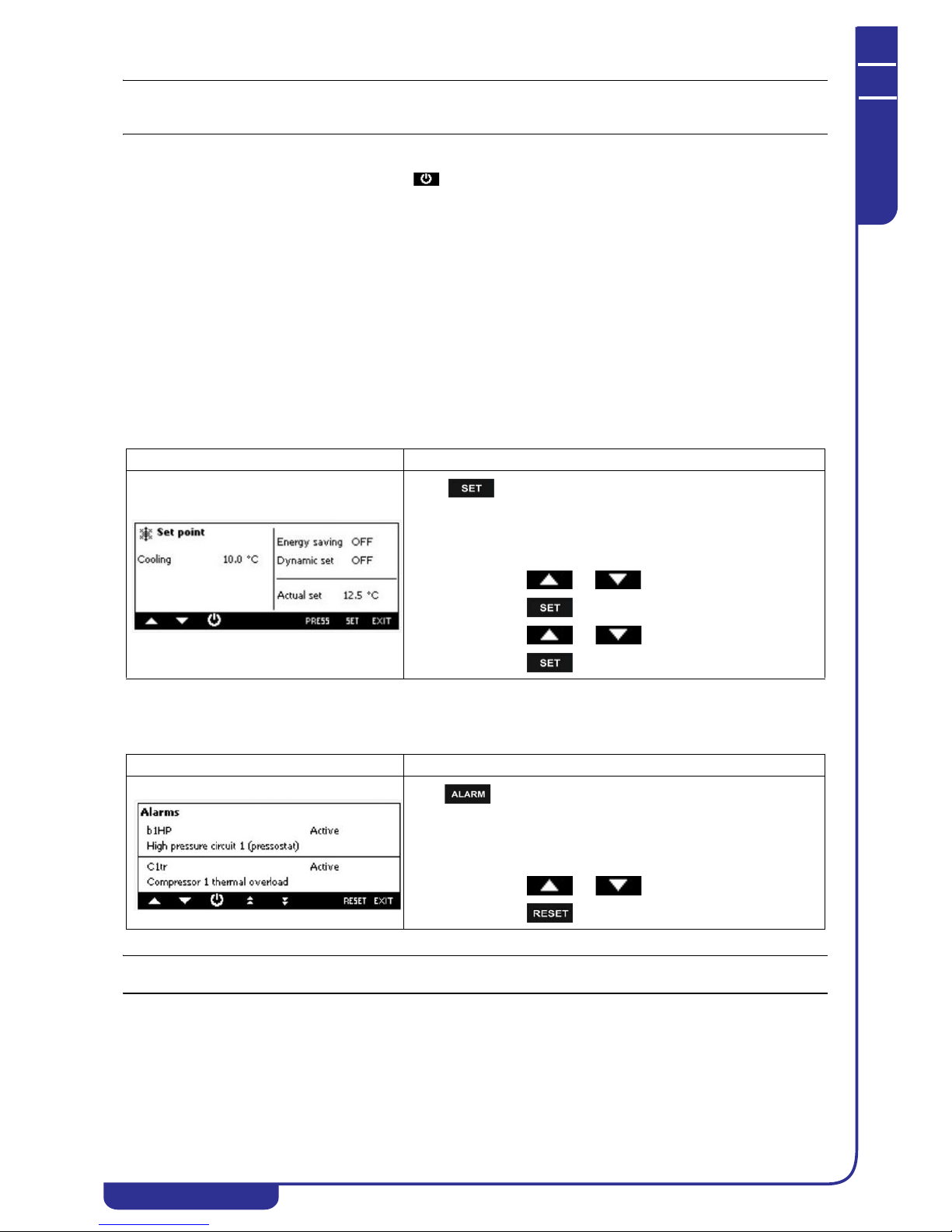

0.2 Setpoint

0.2.1 Display the setpoint

To display the setpoint press and release the key.

With the unit in stand-by the lower display will show SetC (chiller set).

The upper display will show the set value.

0.2.2 Change the setpoint

To change the unit working setpoint press the key for at least 3 seconds and the working setpoint SetC (chiller set) will

appear in flashing mode.

The setpoint can be changed using the or buttons.

To save the new setpoint, press or wait for the time-out to exit programming mode.

0.3 Alarms display and reset

ATTENTION

With this procedure you can reset all the alarms except for the compressor thermal cut-out alarms for which the

password will be required: 14.

To open the functions menu proceed as follows:

• Open the functions menu by pressing the button

• With the or buttons select the ALrM function

•Press .

If no alarms are present, pressing button is not enabled.

• The lower display shows the label with the alarm code; the upper display, if the alarm displayed is resettable,

shows the label rSt or no if the alarm condition is still present.

• Pressing in correspondence with label rSt resets the alarm and the system goes to the next one; if this too

is resettable, press to reset it and go to the next one.

• If you want to scroll through all the alarms present press or .

To exit the ALrM function and return to normal display mode press or wait for the time-out.

With the unit in StbY (stand-by) and the LED flashing, press and scroll with buttons or to select the ALrM

function and press button to display the active alarm.

NOTE

To reset the compressor thermal alarms refer to the specific heading.

OPERATING AND MAINTENANCE MANUAL

- Table of Contents

TAEevo Tech 015÷802 60 Hz UL

4

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

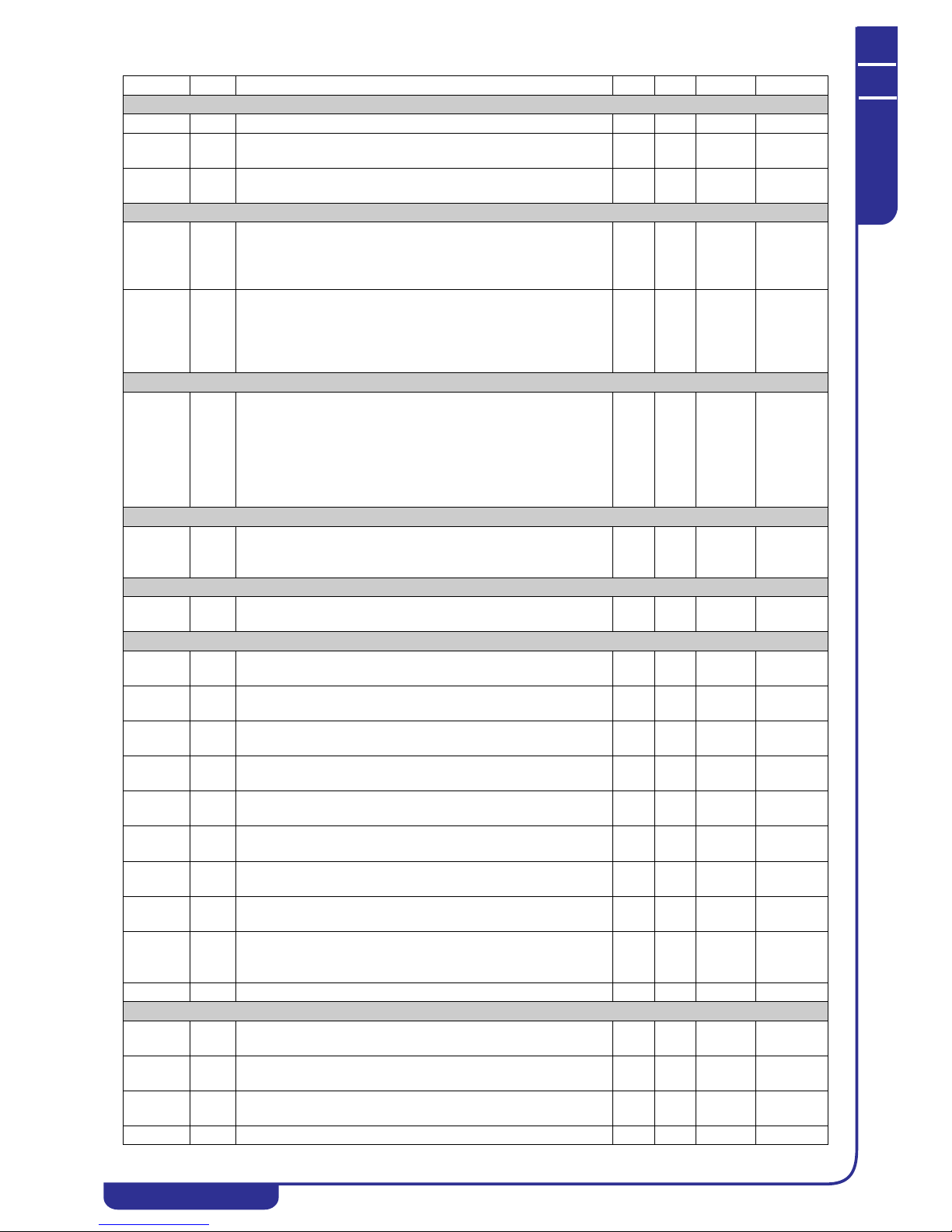

TABLE OF CONTENTS

USER’S QUICK GUIDE .........................................................................................................................1

0.1 Unit start/stop....................................................................................................................2

0.1.1 Start from the keypad ..........................................................................................................2

0.1.2 Start-up from a digital input ................................................................................................3

0.2 Setpoint .............................................................................................................................3

0.2.1 Display the setpoint ............................................................................................................. 3

0.2.2 Change the setpoint .............................................................................................................3

0.3 Alarms display and reset................................................... ........................................... ..... 3

TABLE OF CONTENTS.........................................................................................................................4

Chapter 1

GENERAL INFORMATION....................................................................................................................8

1.1 How to interpret the model ...............................................................................................9

1.2 How to interpret the alphanum eric strin g .......................................................................10

Chapter 2

SAFETY..............................................................................................................................................11

2.1 General............................................................................................................................11

2.2 User circuit liquids....................................................... ................................................... 11

2.3 Lifting and transport precautions.................................................................................... 11

2.4 Precautions to be adopted during installation ................................................................. 13

2.5 Precautions to be adopted during operation.................................................................... 13

2.6 Maintenance precautions ................................................................................................ 13

2.7 Disposal, disassembly and recycling .............................................................................. 15

2.8 Refrigerant gases....................................................................................................... ...... 15

2.8.1 Refrigerants safety datasheet ............................................................................................15

Chapter 3

TECHNICAL DATA.............................................................................................................................17

3.1 Data for standard units....................................................................................................17

3.1.1 Dimensions ...................................... ..................................................................................17

3.1.2 Characteristics of pumps and fans .................................................................................... 18

3.1.3 Sound level measurements .................................................................................................18

Chapter 4

DESCRIPTION....................................................................................................................................20

4.1 Components .................................................................................................................... 20

4.1.1 Refrigerant circuit .............................................................................................................20

4.2 Compressors.................................................................................................................... 20

4.3 Condenser ....................................................................................................................... 20

4.4 Evaporator....................................................................................................................... 21

4.5 Tank ................................................................................................................................ 21

4.6 Pump ...............................................................................................................................21

4.7 Fans.................................................................................................................................21

4.7.1 Axial ...................................... ......... ...... ......... ....... ......... ....... ......... ........ ....... ....... ...............21

4.8 Cabinet............................................................................................................................ 22

4.9 Materials in contact with the liquid to be cooled............................................................ 22

4.10 Overall dimensions and minimum clearances with respect to walls..............................22

4.11 Electrical circuit..............................................................................................................22

Chapter 5

INSTALLATION..................................................................................................................................23

5.1 Inspection........................................................................................................................23

5.2 Location .......................................................................................................................... 23

5.3 Freeze protection ............................................................................................................. 24

5.3.1 Operating limits ............. ................................................................... ................................. 24

5.4 Hydraulic connections .................................................................................................... 25

5.4.1 Evaporator water limit features ...................... .................................................................. 27

5.5 Expansion vessel.............................................................................................................27

5.6 Electrical connections..................................................................................................... 28

OPERATING AND MAINTENANCE MANUAL

- Table of Contents

TAEevo Tech 015÷802 60 Hz UL

5

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

5.7 Phase Monitor ............................................. ....................................................................29

Chapter 6

STARTING..........................................................................................................................................30

Chapter 7

ELECTRONIC CONTROLLER ............................................................................................................. 32

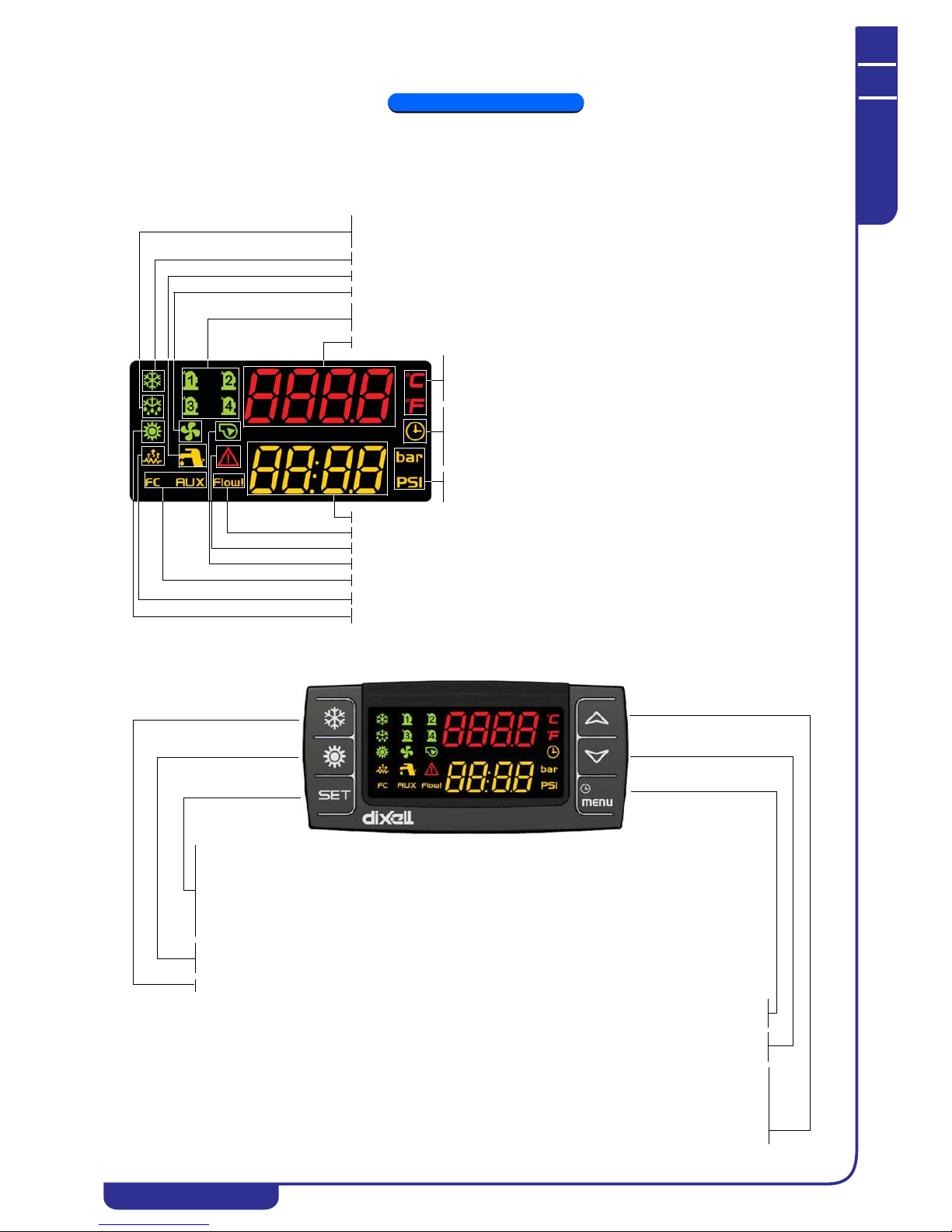

7.1 User interface ..................................................................................................................32

7.2 Function of buttons .........................................................................................................32

7.2.1 Function of combined buttons ......................................................... ...................................33

7.3 Remote terminal..............................................................................................................33

7.4 Probes key .......................................................................................................................33

7.5 Unit start/stop..................................................................................................................34

7.5.1 Start from the keypad .........................................................................................................34

7.5.2 Start from a digital input ...... .............................................................................................34

7.6 Setpoint ........................................................................................................................... 34

7.6.1 Display the setpoint ............ ................................... ............................................................34

7.6.2 Change the setpoint ...........................................................................................................34

7.7 Dynamic setpoint function ..............................................................................................35

7.8 How to display the internal values of a circuit................................................................36

7.9 Functions menu button “Menu”......................................................................................36

7.9.1 CrEn - Enable or disable the single circuit .......................................................................36

7.9.2 COEn - Enable or disable the single compressor ..............................................................37

7.9.3 COSn - Display and reset the number of compressor starts ..............................................37

7.9.4 Hour - Display and reset the running hours of the loads ..................................................37

7.9.5 Cond - Display of percentage / number of condensing steps ............................................38

7.9.6 POEn - ENABLE or DISABLE the operation of a water pump using the key ...................38

7.10 uS - Tank heater probe display........................................................................................38

7.11 Alarms.............................................................................................................................39

7.11.1 Alarms display and reset (ALrM function) ........................................................................39

7.11.2 How to mute the buzzer ........... ...........................................................................................39

7.11.3 General alarms list ........................................................................... .................................39

7.11.4 Indications table . .. ..................................................................... ........................................41

7.11.5 Probe faulty .................... ....................................................................................................41

7.11.6 High pressure switch alarm ...............................................................................................41

7.11.7 High pressure switch alarm and/or compressor thermal alarm ........................................42

7.11.8 Low pressure switch alarm ....... .................................... .....................................................42

7.11.9 High pressure .....................................................................................................................43

7.11.10Low pressure ......................................................................................................................43

7.11.11Anti-freeze alarm ...............................................................................................................44

7.11.12Chiller mode anti-freeze alarm ..........................................................................................44

7.11.13Level sensor and/or flow meter alarm ...............................................................................44

7.11.14Compressors thermal alarm ..............................................................................................46

7.11.15Fan thermal alarm .............................................................................................................46

7.11.16High condensing pressure unloading indication in chiller mode ......................................47

7.11.17High condensing pressure recovery disabling indication .................................................47

7.11.18Evaporator inlet high water temperature unloading indication ........... .............................48

7.11.19Evaporator water pump group thermal alarm ..................................................................48

7.11.20Phase monito r alarm ................................................................................... ......................49

7.11.21Compressors maintenance alarm ......................................................................................49

7.11.22Pumps maintenance alarm .................................................................................................49

7.11.23EEprom alarm ....................................................................................................................49

7.11.24Unit configuration alarm ...................................................................................................50

7.12 iCHILL input/output configurations ...............................................................................52

7.12.1 Configuration of analogue inputs PB1 - PB2 – PB5 – PB6 ..............................................52

7.12.2 Configuration of analogue inputs PB3 - PB4 ....................................................................52

7.12.3 Configuration of digital inputs ID1 – ID11 .......................................................................53

7.12.4 Configuration of digital outputs RL1- RL8 ................................ ........................................54

7.12.5 Configuration of proportional outputs OUT1 and OUT2 (0 – 10 VOLT) .........................55

7.12.6 Configuration of proportional outputs OUT3 and OUT4 (0 – 10 VOLT/PWM) ...............55

7.12.7 Display in programming mode of polarity of digital inputs / outputs ...............................56

7.12.8 Remote terminal alarm ......................................................................................................56

7.12.9 Remote terminal alarm ......................................................................................................56

7.12.10Alarm relay / open - collector / buzzer notes ............................. .................................... ....56

7.12.11Diagnostic of alarms that switch from automatic to manual .............................................57

OPERATING AND MAINTENANCE MANUAL

- Table of Contents

TAEevo Tech 015÷802 60 Hz UL

6

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

7.12.12Display and delete the alarms log in the memory (ALOG function) ........... ......................57

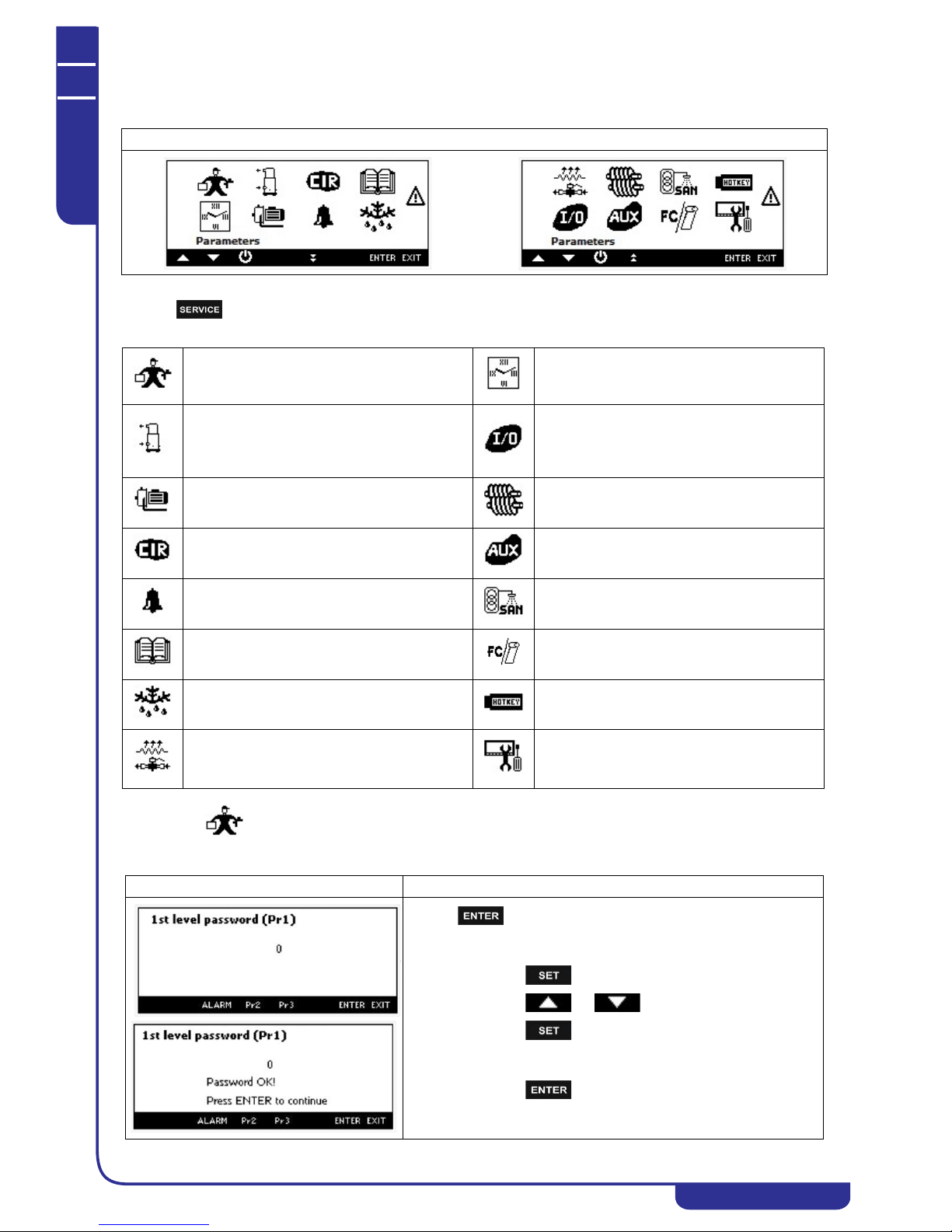

7.13 Programming from keypad............................................................................................. 57

7.13.1 Access to parameters ....................... ..................................................................... .............58

7.13.2 How to change a parameter value ....................................................................................59

7.14 Use of the hot-key (function UPL) .................................................................................59

7.14.1 Programming the board with the hot-key ..........................................................................59

7.14.2 Hot-key programming ....................................................................................................... 59

7.15 Unit adjustment and control............................................................................................59

7.15.1 Compressors control ...................................................................... ............................... ....59

7.15.2 Choice of compressors control type .................................................................................. 59

7.15.3 Proportional control .......................................................................................................... 59

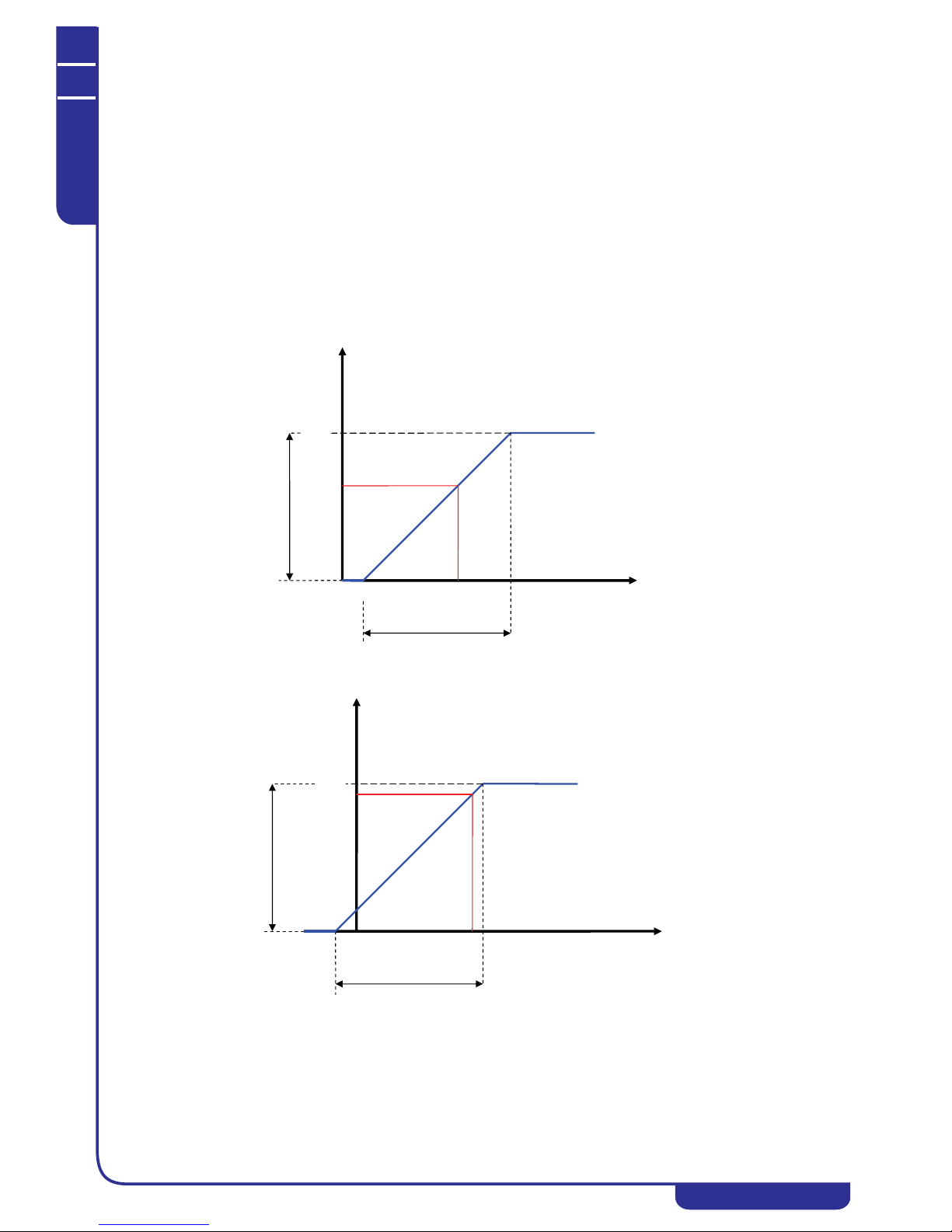

7.15.4 Compressors proportional control diagram .....................................................................60

7.15.5 Neutral zone control (factory setting) ............................................................................... 60

7.15.6 Compressors rotation ................................... .................................. ...................................60

7.15.7 Forced compressors rotation ......................................... .. .................................... .............60

7.15.8 Compressors starting time limitation ................................................................................ 61

7.16 Unloading function ......................................................................................................... 61

7.17 Fans control........................................................................................ ... ..........................61

7.17.1 Units configured with “STEP” fans ................................................... ............................... 61

7.17.2 Fan control diagrams ........................................................................................................ 61

7.18 Hydraulic unit ................................................................................................................. 61

7.19 Anti-freeze pump management (if ambient probe is installed) ...................................... 61

7.20 ModBus...........................................................................................................................62

7.21 Automatic restart.............................................................................................................62

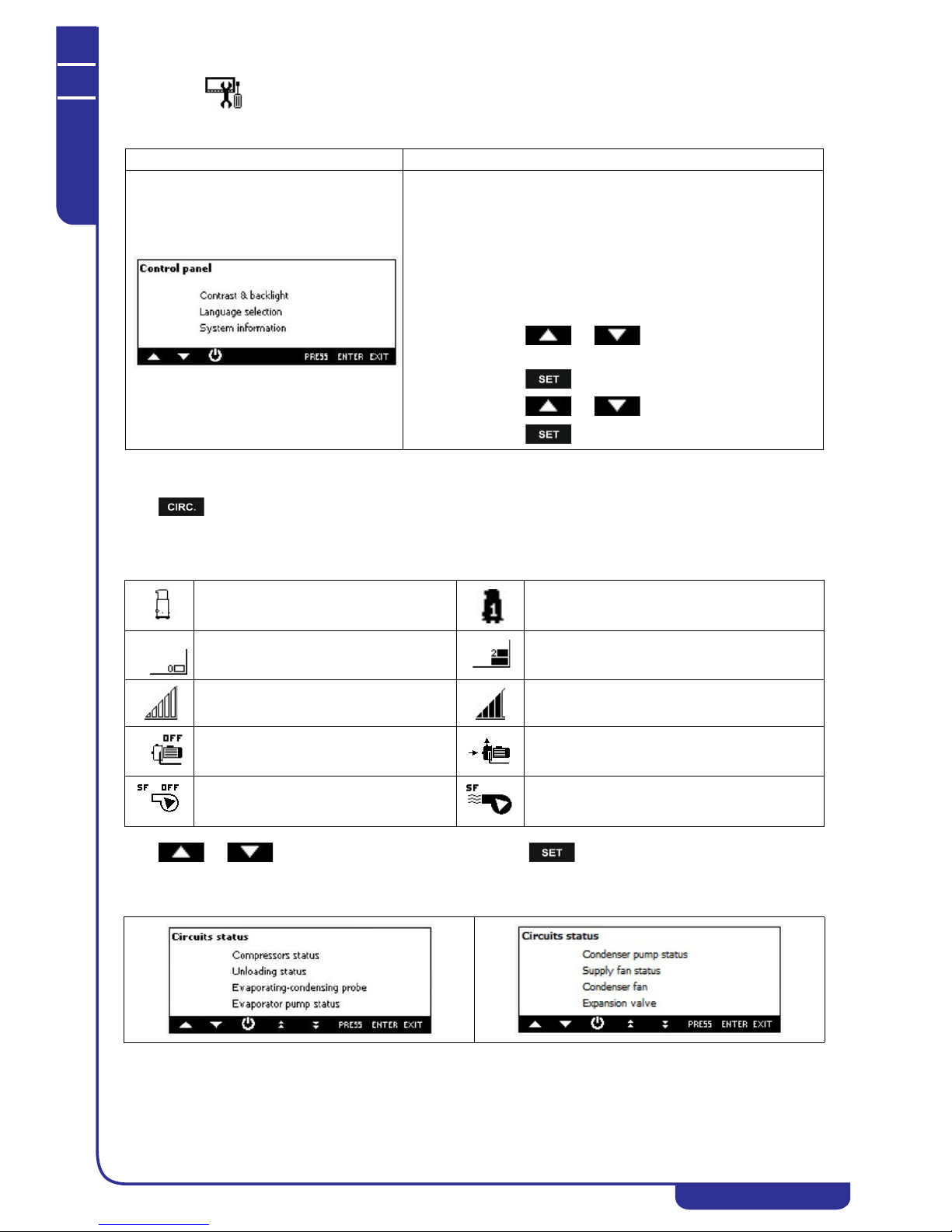

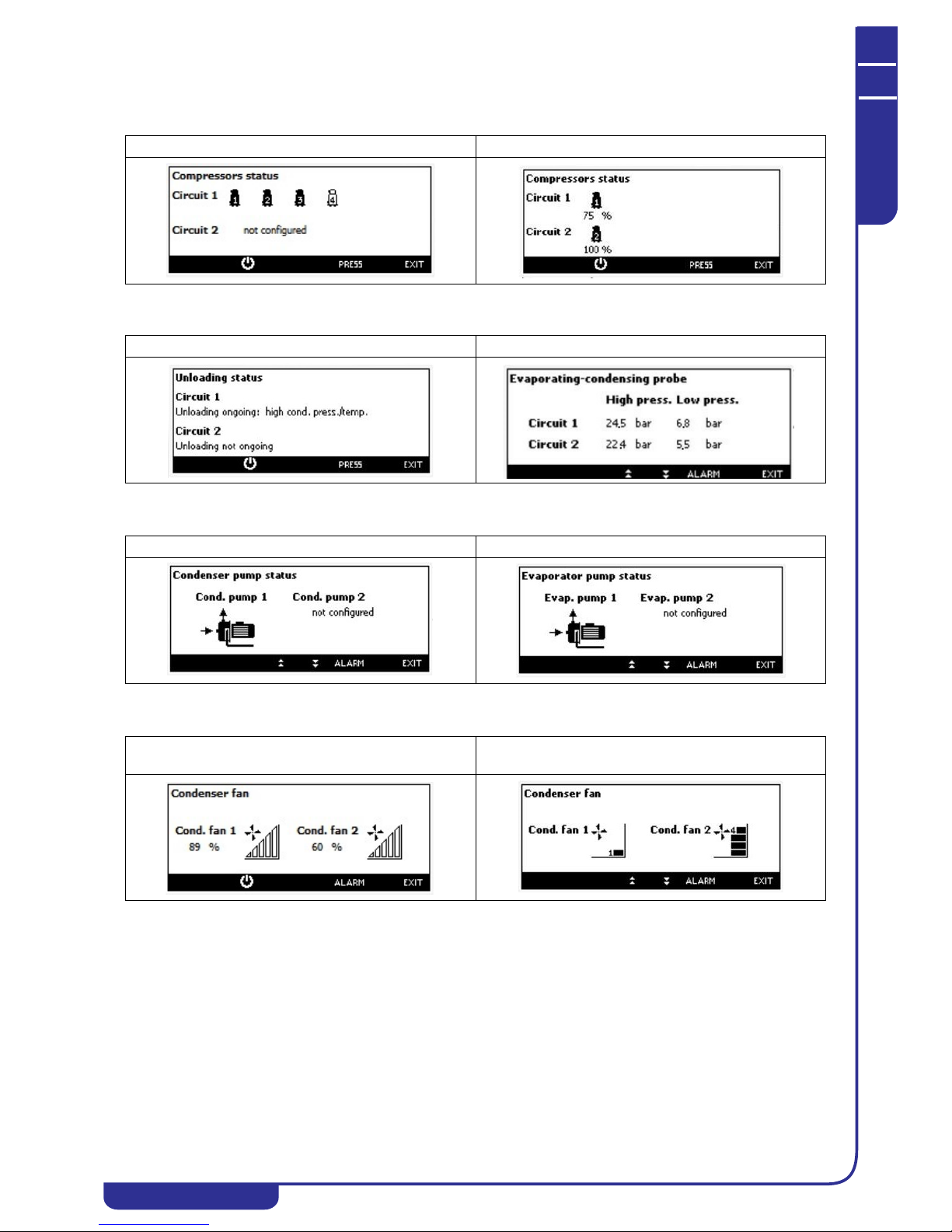

7.22 Control with LCD graphic display..................................................................................6 2

7.23 Function of buttons.........................................................................................................63

7.24 Probes visualization........................................................................................................63

7.25 Unit start/stop.................................................................................................................. 63

7.25.1 Start from the keypad ........................................................................................................64

7.25.2 Start-up from a digital input ..............................................................................................64

7.26 Visualization / modification of the set point...................................................................64

7.27 Alarm visualization.................................. .......................................... .............................64

7.28 Menu service visualization .............................................................................................65

7.29 Parameters programming................................................................................................ 65

7.30 Compressor maintenance................................................................................................ 66

7.31 Water pump maintenance ...............................................................................................66

7.32 Circuit maintenance........................................................................................................67

7.33 Alarm visualization and reset ......................................................................................... 67

7.34 Alarm log visualization................................................................... ................................68

7.35 Electric heater visualization............................................................................................ 68

7.36 I/O status......................................................................................................................... 68

7.37 Auxiliary output visualization ........................................................................................69

7.38 Parameters programming with Hot Key.........................................................................70

7.39 Keyboard configuration.................................................................................................. 71

7.40 Circuit Information .........................................................................................................71

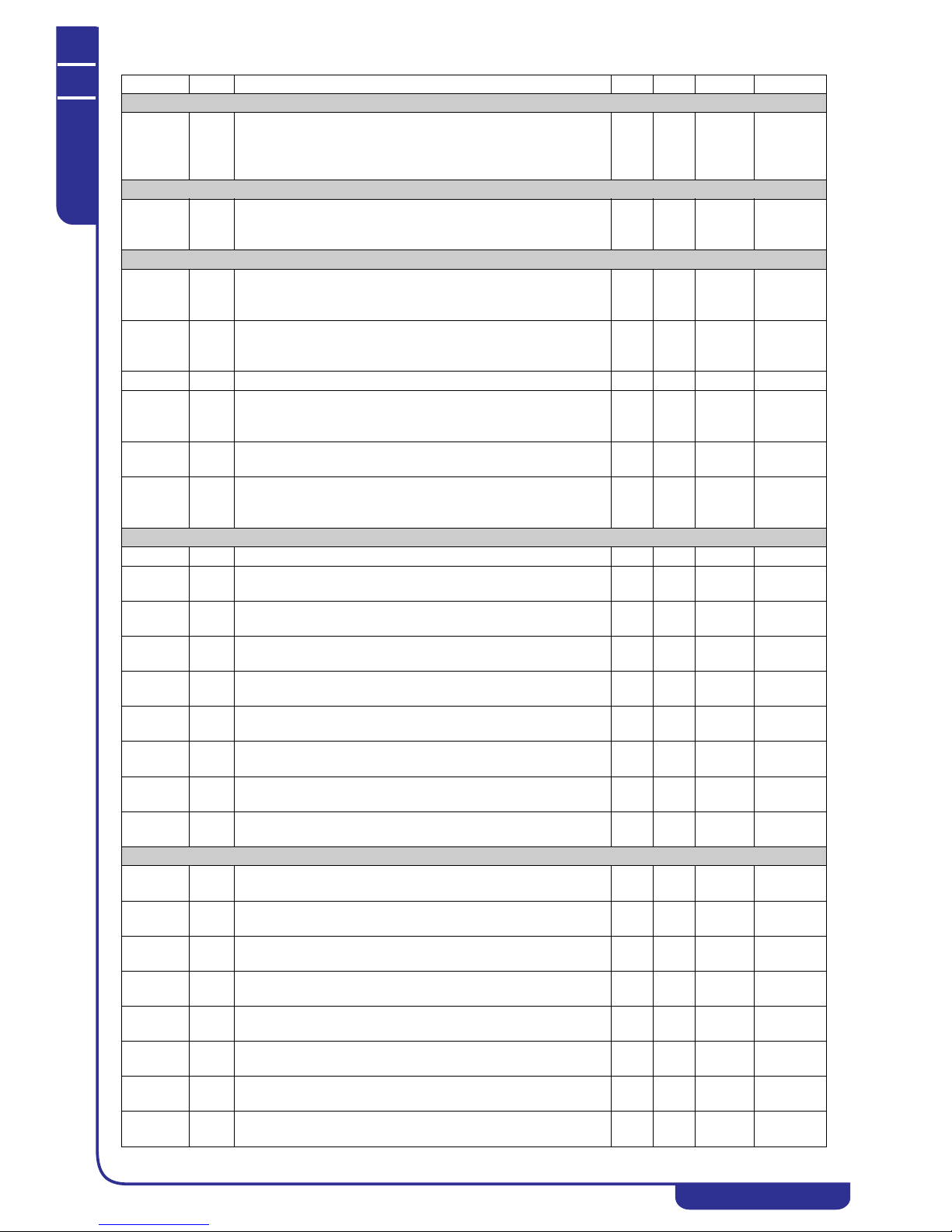

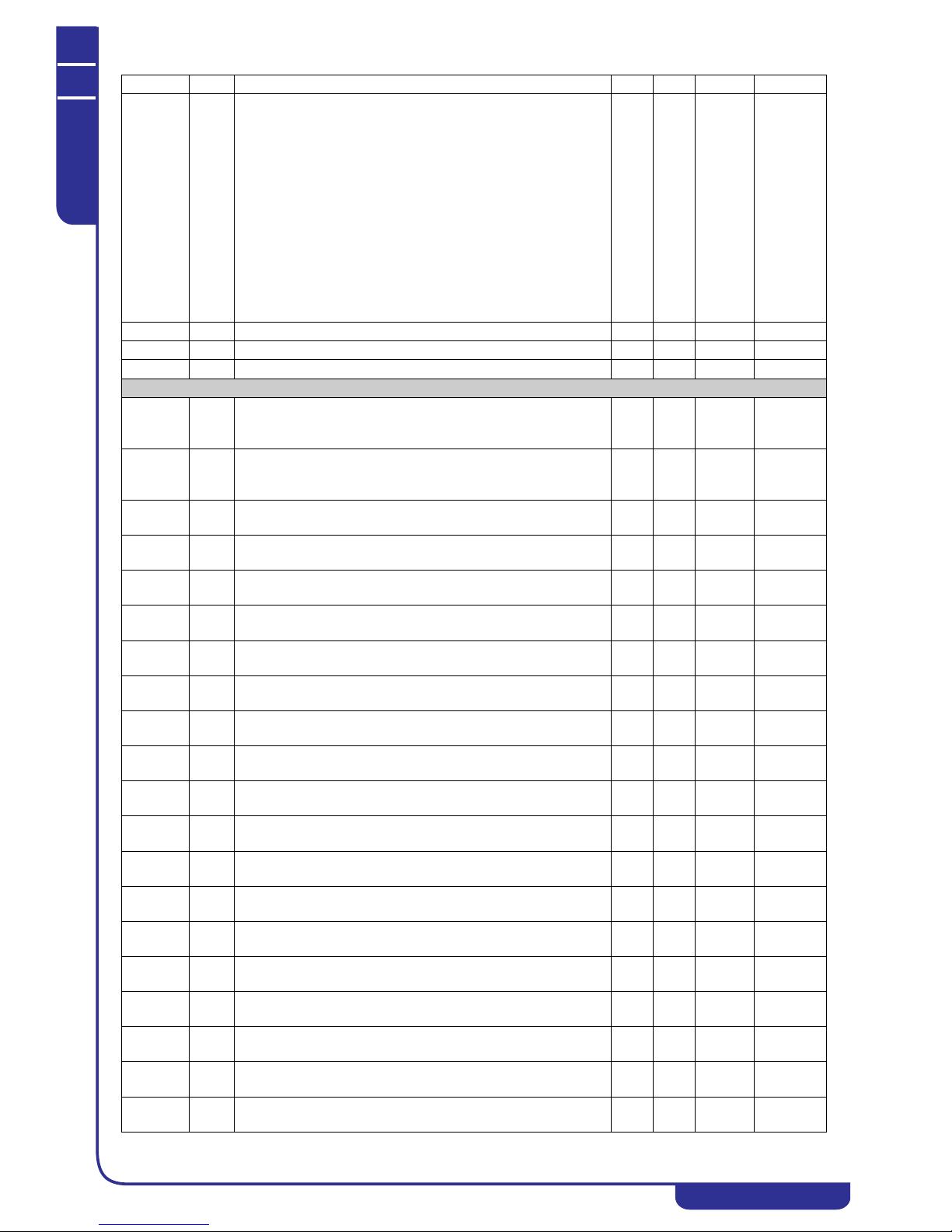

7.41 Parameters description-settings ...................................................................................... 73

7.41.1 Description of parameters .................................................................................................73

7.41.2 Parameters setting ...........................................................................................................105

7.41.3 Parameters dependent on remote terminal kit ................................................................ 181

Chapter 8

OTHER COMPONENTS.....................................................................................................................182

8.1 Compressor motor protection ....................................................................................... 182

8.2 Refrigerant high and low pressure switches .................................................................182

8.3 Fan pressure switches ................................................................................................... 182

8.4 Pressure transducers.................................... .......................................... ........................183

8.5 Level sensor .................................................................................................................. 183

Chapter 9

OPERATION AND MAINTENANCE ...................................................................................................184

9.1 Operation ......................................................................................................................184

9.2 Maintenance....................................................... ........................................... ...............184

9.3 Access to the unit..........................................................................................................184

OPERATING AND MAINTENANCE MANUAL

- Table of Contents

TAEevo Tech 015÷802 60 Hz UL

7

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

9.4 Draining the process water circuit.................................................................................185

9.5 Pressure limiting valve (option)....................................................................................186

9.5.1 General notes of safety ....................................................................................................186

9.5.2 General notes ............................... ....................................................................................186

9.5.3 Range of application ........................................................................................................186

9.5.4 Installation and assembly ........................................................ .. .................................... ..186

9.5.5 Setting ..............................................................................................................................187

9.5.6 Operating and maintenance .............................................................................................187

9.5.7 Warranty ................................. ................................................. ........................................187

9.5.8 Marking ................................... ............. .............. ............. ........... .............. ............. ...........187

9.6 Maintenance Schedule...................................................................................................188

Chapter 10

TROUBLESHOOTING........................................................................................................................189

Chapter 11

RISK ANALYSIS: RESIDUAL RISK....................................................................................................194

OPERATING AND MAINTENANCE MANUAL

Chapter 1 - General information

TAEevo Tech 015÷802 60 Hz UL

8

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

CHAPTER 1

GENERAL INFORMATION

The units described in this manual may be referred to below as “WATER CHILLERS”.

This manual is addressed to personnel responsible for installing, using and servicing the unit.

The units were constructed using components made by premium quality manufacturers and the entire design, production and

control process was carried out in compliance with standard ISO 9001.

In the majority of applications the liquid in the user circuit is water so henceforth the term “WATER” will be utilised, even if

the liquid in the user service is different (for example mixtures of water and ethylene or propylene glycol).

Hereinafter the expression “PRESSURE” is used to indicate relative pressure.

The electrical panel has been designed following UL508A standard rule (Industrial Control Panels).

The compressors and fans carry the cURus marking.

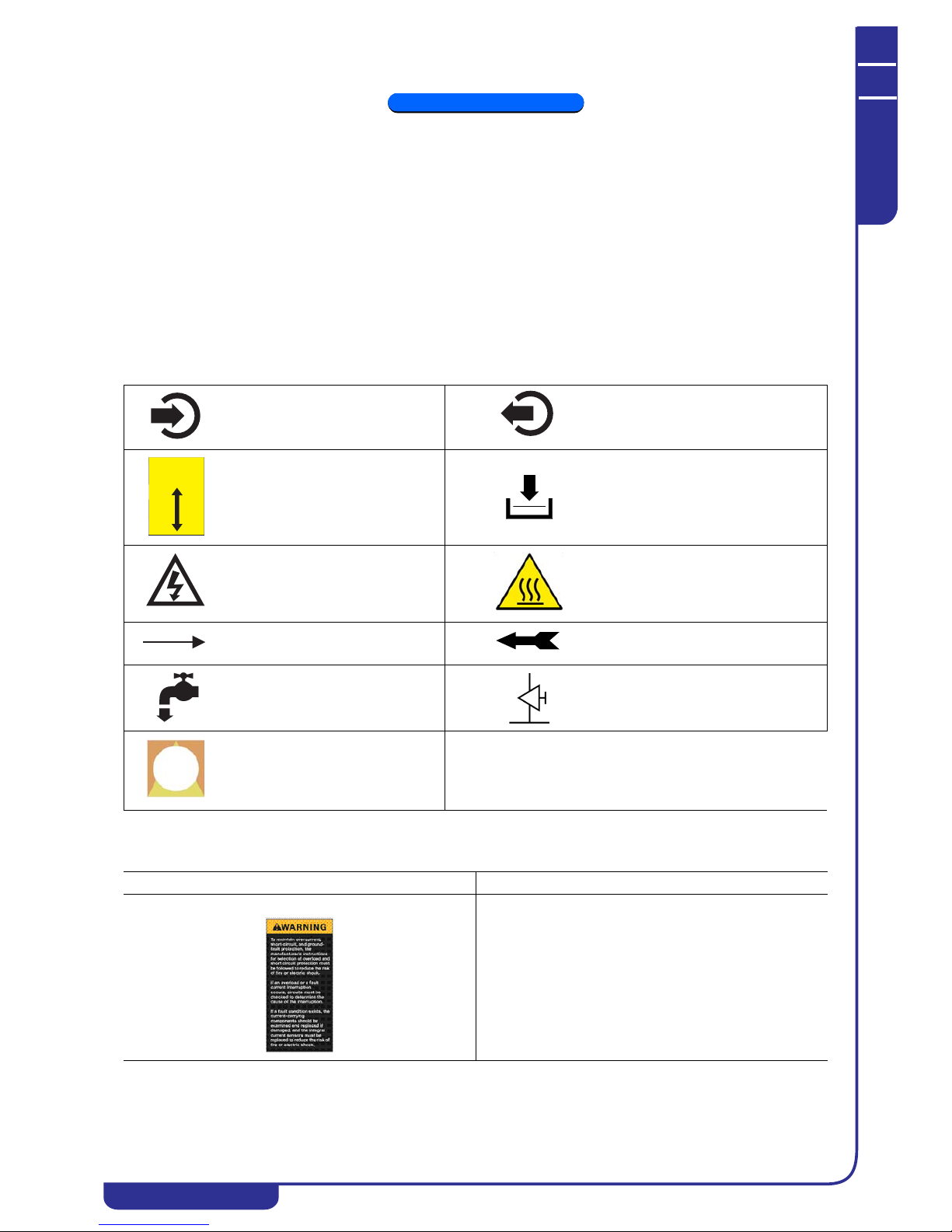

The following symbols are to be found on the decals affixed to the unit and also in the dimensional drawings and refrigerant

circuit diagrams.

The meaning of each symbol is indicated below:

The following warning symbols are shown on the stickers on the unit. If requested, the same stickers are available also in

French. Their meaning is the following:

Process water inlet Process water outlet

Indication of the axis of reference for

lifting operations

Drain point to empty the unit of water

Electric shock hazard

Risk of burns from contact with hightemperature surfaces

Direction of flow of refrigerant fluid

and water circuit

Rotation direction of pump (if installed)

and fans

Water filling point Air bleed valve

Opening to be used for the insertion

of bars for the purpose of lifting the

unit

WARNING SYMBOL DESCRIPTION

To maintain overcurrent, short-circuit, and ground-fault

protection, the manufacturer’s instructions for selection of

overload and short circuit protection must be followed to

reduce the risk of fire or electric shock.

In an overload or a fault current interruption occurs, circuits

must be checked to determine the cause of the interruption.

If a fault condition exists, the current-carrying components

should be examined and replaced if damaged, and the

integral current sensors must be replaced to reduce the risk

of fire or electric shock.

ASSE DI SOLLEVAMENTO

AXIS OF EQUILIBRIUM

GLEICHGEWICHTSACHSE

EMPLACEMENT DE FORCHES

PUNTO DE ELEVACION

OPERATING AND MAINTENANCE MANUAL

Chapter 1 - General information

TAEevo Tech 015÷802 60 Hz UL

9

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

1.1 How to interpret the model

ATTENTION

This manual, which is addressed to users, installers, and service personnel, supplies all the technical information

required to install and work with the unit and to perform the routine maintenance operations required to maximise its

working life.

Use only genuine parts when carrying out routine maintenance or repairs.

Requests for SPARE PARTS and any INFORMATION concerning the unit must be made to your dealer or nearest service

centre, specifying the MODEL and SERIAL NUMBER shown on the unit’s dataplate and on the last page of this manual.

Hazardous voltage.

All doors must be closed before energizing the panel.

Read and understand operator’s manual before using this

machine.

Failure to follow operating instructions could result in death

or serious injury.

Moving parts can crush and cut.

Do not operate with guard removed.

Follow lockout procedure before servicing.

Hazardous voltage.

Disconnect power before servicing or cleaning.

MODEL DESCRIPTION

Number of refrigerant circuits

Guideline power of compressor expressed in HP

E = hermetic compressor

A = air-cooled condenser

T = tank; chiller with storage tank.

WARNING SYMBOL DESCRIPTION

TAEevo Tech XX Y

OPERATING AND MAINTENANCE MANUAL

Chapter 1 - General information

TAEevo Tech 015÷802 60 Hz UL

10

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

1.2 How to interpret the alphanumeric string

The alphanumeric string is shown on the metal data plate on the cover page of this manual.

This symbol shown alongside appears in some refrigerant circuit diagrams and electrical

diagrams. This symbol refers to the alphanumeric string reported in the manual. The upper

box (X) identifies the position of the string, the lower box (Y) identifies the assigned value.

The empty alphanumerical string is circled in the adjacent figure; each

position in the upper row is associated with an alphanumeric value in the

lower row (0, 1, 2, A, B, etc.) and each character is associated with a

specific feature of the unit.

POS. VALUE DESCRIPTION

REFRIGERANTE 1 3 R410A

VOLTAGE 2 0 400/3/50

1 460/3/60

N 400/460/3/50-60

UNIT AMBIENT TEMPERATURE 3 0 STANDARD

1 -20°C

COMPRESSOR START-UP 4 0 DIRECT

2 SOFT STARTER

EVAP. FREEZE PROTECTION 5 0 NO

1YES

VERSION 6 STD STANDARD

ELECTRONIC THERMOSTATIC

VALVE

07 NO

1YES

LASER 8 A YES

BNO

C TEMPERATURE FINE REGULATION

FAN 9 A AXIAL

B CENTRIFUGAL

G HIGH PRESSURE AXIAL FLOW FANS

FAN CONTROL 10 1 ELECTRONIC CONTROL

3 ON/OFF

PRE-PAINTED CONDENSING COILS 11 0 NO

1YES

PUMP

13

R SP - Predisposed P3

IP3

LP5

PP3+P3

QP5+P5

TANK MATERIAL

14

1 Fe+Fe

2 Aisi+NoF

WATER BYPASS

15

1 OVERLOAD VALVE

2NO

KIT TYPE

16

A NO KIT

B TANK KIT

PRODUCT TYPE

1

7

0 STANDARD

X SPECIAL

0

1

12

CONDENSER COIL PROTECTION

NONE

FILTERS

OPERATING AND MAINTENANCE MANUAL

Chapter 2 - Safety

TAEevo Tech 015÷802 60 Hz UL

11

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

CHAPTER 2

SAFETY

This unit is designed to ensure the best guarantees of safety and efficiency in its intended use, on the condition that it is

installed, commissioned, and serviced in compliance with the instructions given in this manual.

The manual must therefore be studied by all those who want to install, use or maintain the unit.

The unit contains electrical components that operate at mains voltage and also moving parts.

All work on the unit must be carried out only after disconnecting the electrical supply. Maintenance operations involving

work inside the unit must be performed by skilled and adequately qualified perso nnel equipped with suitable pr otection

means (active and passive, e.g. work gloves) to ensure maximum safety.

Keep unauthorized persons (e.g. children) away from the place of installation of the unit.

2.1 General

When handling or maintaining the unit and all auxiliary equipment, personnel must operate with care observing all

instructions concerning health and safety at the installation site.

ATTENTION

Numerous accidents that occur during operation and maintenance of the units are caused by failure to comply with

basic safety rules and precautions.

An accident can often be avoided by recognising a situation that is potentially hazardous.

The user must ensure that all personnel involved in operating and servicing the unit have read and understood all the

warnings, precautions, prohibitions and notes given in this manual and affixed to the unit. Improper operation or maintenance

of the unit and auxiliary equipment can be dangerous and can cause serious or fatal accidents.

We cannot anticipate every possible circumstance which might constitute a potential hazard.

The warnings in this manual are therefore not all-inclusive.

If the user adopts operational procedures or uses tools or working procedures that are not specifically recommended, he must

take care to ensure that the unit and the auxiliary equipment are not damaged or made unsafe and that no risks emerge in

relation to persons or property. Any improper use of the unit will relieve the manufacturer from any liability for possible

personal injury or property damage.

Arbitrary modifications made to the unit will automatically invalidate all forms of guarantee provided by the manufacturer.

ATTENTION

The hot / chilled water prod uced by units canno t be used for hygiene/sanitary or food applications. If it is

used for the above purposes, the installer must install an intermediate exchanger.

If the intermediate exchanger is not present, the installer must affix a warning notice to the eff ect “non potable

water”.

2.2 User circuit liquids

The user circuit liquids must be compatible with the materials used for the construction of the unit’s hydraulic circuit.

The expression “liquids” means: water, water with additives and/or glycol. Additive and glycol suppliers must guarantee

compatibility with the materials. For further information refer to “4.9 Materials in contact with the liquid to be cooled”.

ATTENTION

If the liqui ds in the user circuit contain hazardous substances (such as glycol, for example), any liquid that is expelled

from a leakage area must be collected because it is noxious for the environment. The disposal of hazardous liquids must be

handled by specialised companies authorised for the treatment of hazardous wastes.

2.3 Lifting and transport precautions

Avoid injury by using a hoist to lift heavy loads.

Check all chains, hooks, shackles and slings are in good condition and are of the correct capacity.

They must be tested and approved according to local safety regulations.

Cables, chains or ropes must never be attached directly to lifting eyes.

Always use an appropriate shackle or hook properly positioned. Arrange lifting cables so that there are no sharp bends.

Use a spreader bar to avoid lateral loading of hooks and eyebolts.

When a load is lifted from the ground keep well clear of the area beneath the load and the immediately surrounding area.

OPERATING AND MAINTENANCE MANUAL

Chapter 2 - Safety

TAEevo Tech 015÷802 60 Hz UL

12

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

Keep lifting acceleration and speed well within safety limits and never leave a suspended load attached t o a hoist any longer

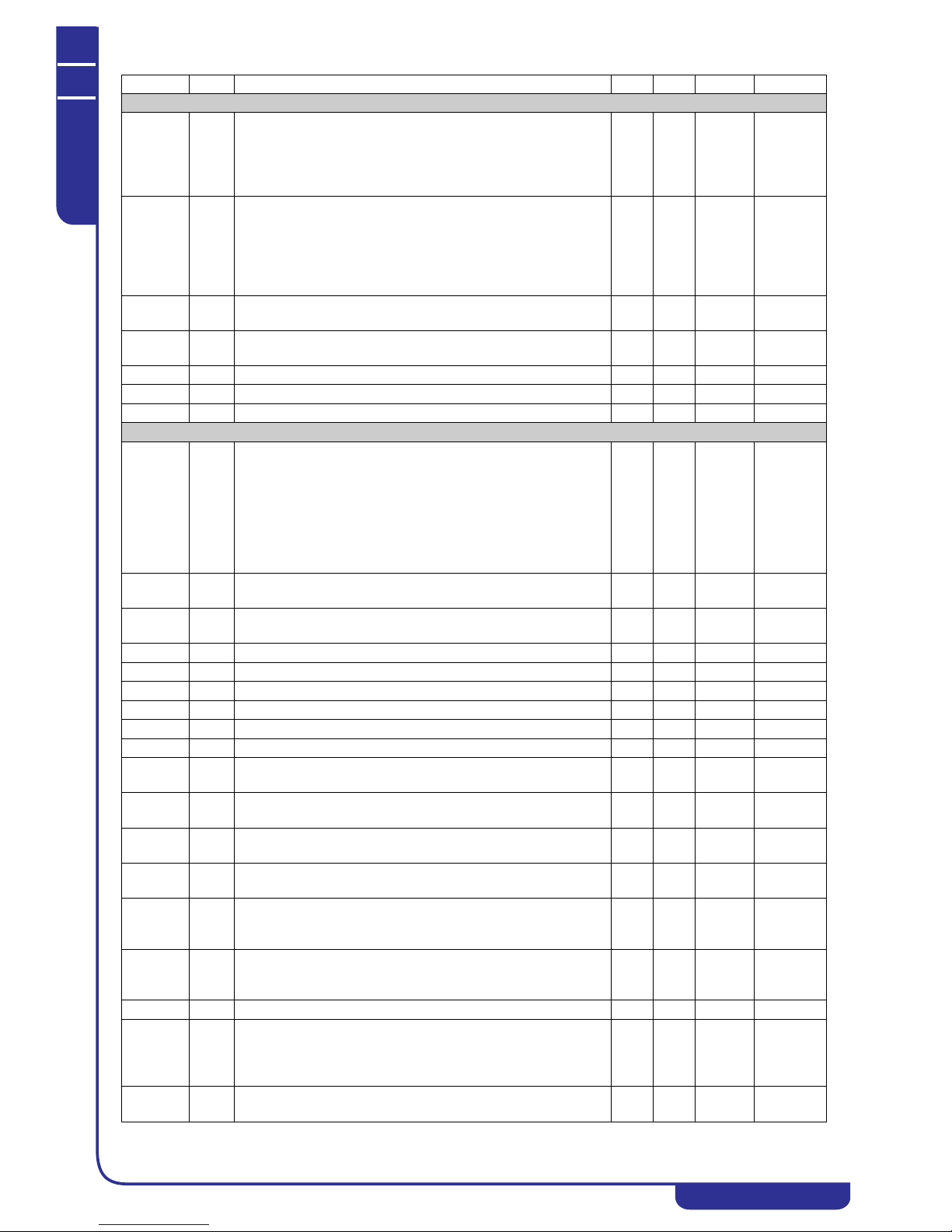

than strictly necessary. The weight values shown in the following table were obtained with the unit empty, pump P3and axial

fans.

The manufacturer does not supply load spreaders, lifting straps or hooks with the unit.

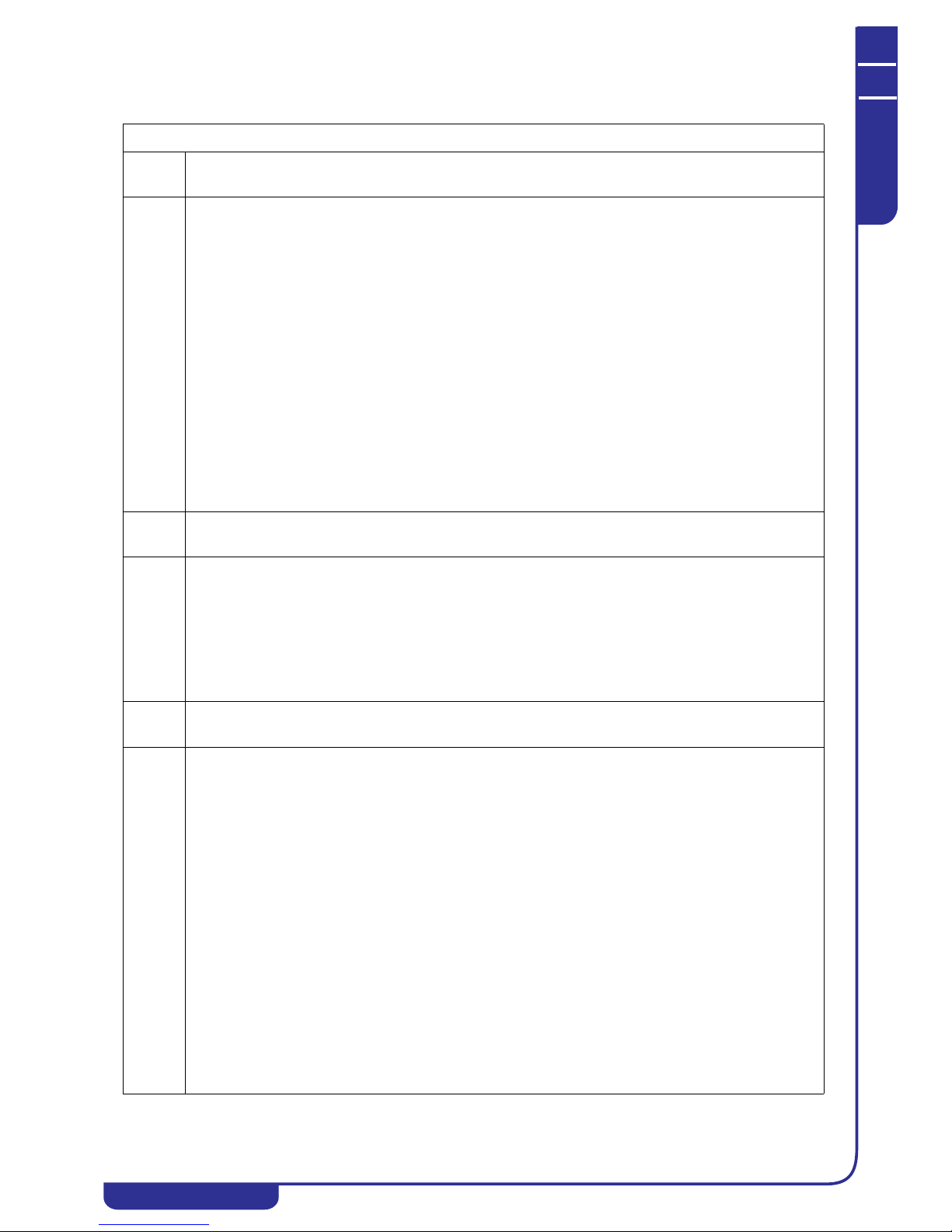

Model TAEevo Tech 402÷602

Model TAEevo Tech 015 020 031 051 081 101 121 161 201 251

Weight (kg) 144 149 208 2 31 341 385 399 415 595 678

Weight (lb) 317 328 459 5 09 752 849 880 915 1312 1495

Model TAEevo Tech 301 351 381 401 402 502 602 702 802

Weight (kg) 711 722 995 1080 1197 1246 1282 1585 1605

Weight (lb) 1567 1592 2194 2381 2639 2747 2826 3494 3538

Model TAEevo Tech 015÷161 Model TAEevo Tech 201÷401

OPERATING AND MAINTENANCE MANUAL

Chapter 2 - Safety

TAEevo Tech 015÷802 60 Hz UL

13

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

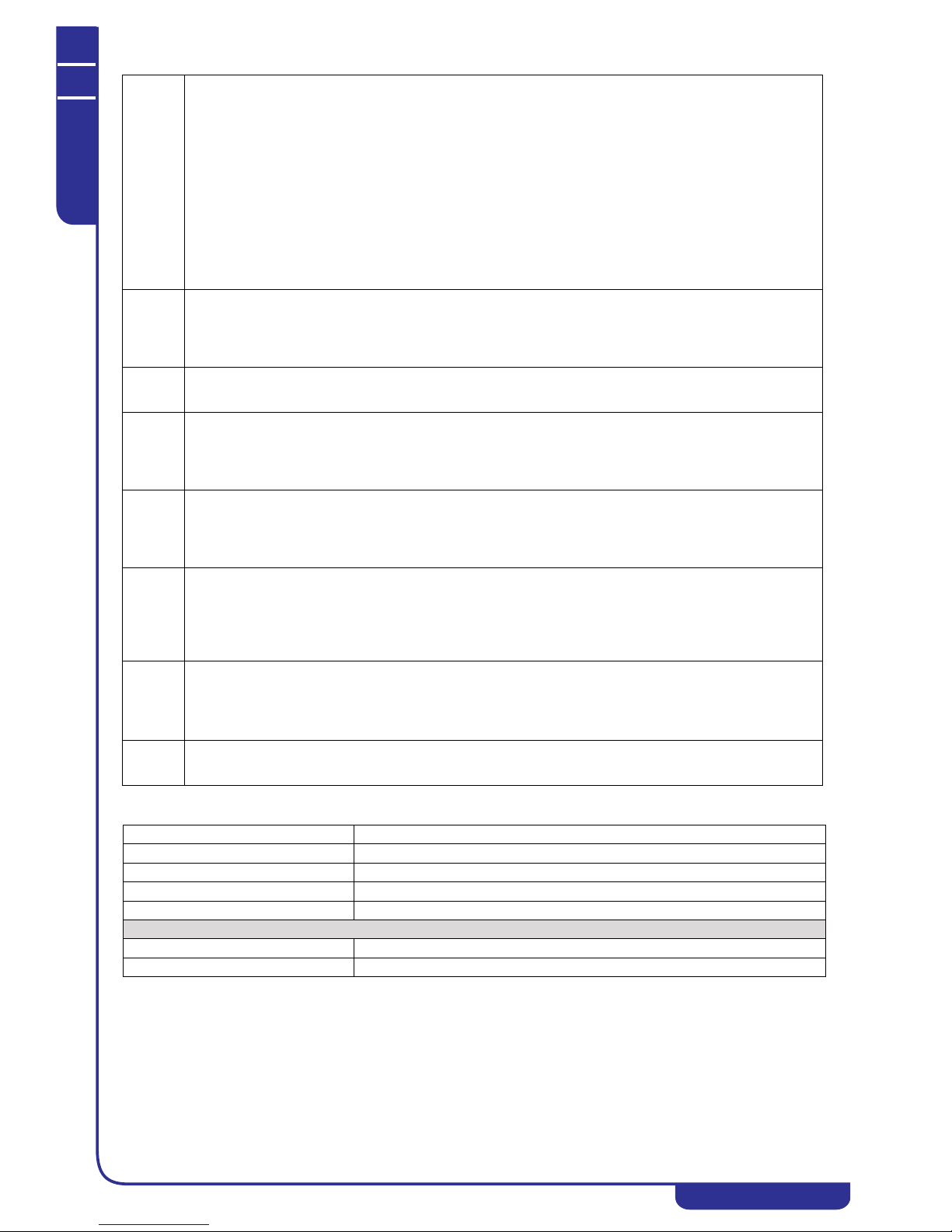

Model TAEevo Tech 702÷802

NOTE

Weight values are guideline, with the water circuit empty. The values may vary in relation to the configuration of the unit

(pump type, supply type, and ventilation type).

2.4 Precautions to be adopted during installation

The connections to be prearranged concern the process water circuit. For connection to the mains electrical supply consult

the technical documentation attached to the unit.

2.5 Precautions to be adopted during operation

The unit must be operated by competent personnel under the guidance of a qualified supervisor.

All water pipelines must be painted or clearly marked in compliance with local safety prescriptions in force in the place of

installation.

ATTENTION

Do no t remove or tamper with safety devices, protections, or the insulating materials installed in the unit and in the

auxiliary equipment.

All electrical connections must comply with local codes.

The unit and its auxiliary equipment must be connected to earth and protected against short circuits and overloads.

When mains power is switched on, lethal voltages are present in the electrical circuits and extreme caution must be exercised

if any work must be carried out on the electrical system.

Do not open the electrical equipment guard panels while the circuit is energized. Operations that require intervention with the

electrical circuit energized must be performed only by qualified personnel using appropriate equipment and wearing apparel

and devices designed to protect against electrical hazards.

2.6 Maintenance precautions

ATTENTION

When it is necessary to discharge waste material do not pollute water pipelines, groundwater or watercourses.

Avoid the combustion of materials that could produce fumes that are toxic and harmful when released into the atmosphere.

Protect the environment by using only approved methods of disposal.

Keep a written record of all work carried out on the unit and the auxiliary equipment. The frequency and the nature of the

work required over a period can reveal adverse operating conditions that should be corrected.

4OOKP

OPERATING AND MAINTENANCE MANUAL

Chapter 2 - Safety

TAEevo Tech 015÷802 60 Hz UL

14

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

ATTENTION

Use only the refrigerant specified on the data pl ate of the unit.

Make sure that all instructions concerning operation and maintenance are strictly followed and that the complete unit, with all

accessories and safety devices, is kept in good working order. The accuracy of pressure and temperature gauges must be

regularly checked. If values are discovered that exceed the permissible tolerances, the gauges must be replaced.

ATTENTION

Do not perform weldin g procedures or other operations that can produce heat in the vicinity of elements containing oil

or flammable liquids. Systems which may contain oil or flammable liqui ds must be completely purged and cleaned, e.g. w ith

steam, before carrying out such operations.

Components in the vicinity must be protected with non-inflammable material and, if the operation is to be performed close to

parts of the lubrication system or in the vicinity of components that may contain oil or inflammable liquids, the system must

first be purged.

Never use an open flame as a light source to inspect parts of the unit.

For all units establish a suitable time interval for cleaning procedures.

ATTENTION

If replacement parts are needed use only original spares.

Take care not to damage pressure limiting devices.

All guards must be refitted after carrying out repair or maintenance work.

ATTENTION

Check the direction of rotation of the motors (the pump, if installed) when starting the unit for the first time and after

work has been performed on the electrical connections or on the power supply sectioning device.

Do not use flammable liquids to clean the unit when it is running. If chlorinated hydrocarbon non-flammable fluids are used

for cleaning, safety precautions must be taken against any toxic vapours that may be released.

ATTENTION

Before removing any panels or dismantling any part of the unit, carry out the following operations:

- Isolate the unit from the electrical power supply by disconnecting the supply upstream of the power feeding line.

- Lock out the disconnect switch in the “OFF” position by fitting a padlock.

- Affix a tag to the disconnect switch handle stating “WORK IN PROGRESS - DO NOT SWITCH ON”.

- Do not set the electrical power switch to ON or attempt to start the unit if it has been tagged out with a warning sign.

Coloured tracers can be used in service-maintenance operations.

Inspect all refrigerant circuit unions including connectors, flanges, and more generally all critical po ints (open unions) in

order to prevent possible leakage of refrigerant gas.

OPERATING AND MAINTENANCE MANUAL

Chapter 2 - Safety

TAEevo Tech 015÷802 60 Hz UL

15

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

2.7 Disposal, disassembly and recycling

The product was designed and built with recyclable materials.

The correct waste sorting for the subsequent start-up of the equipment disposed of for recycling, treatment and for

compatible environmental disposal, contributes to prevent possible negative consequences on the environment and health. It

also favour the recycling of the materials the equipment is made up with.

The unit may include all or some of the materials listed below:

• Refrigerant fluid R410A

• Copper parts

• Aluminium parts

• Carbon Steel parts

• Stainless Steel parts

•PVC parts

• CFC-free synthetic insulating material

• polystyrene parts

• Polyester oil

•Brass

During dismantling, the compressor, pumps, fans, exchangers (if working) can be recovered for possible re-use thanks to

specialised centres.All materials must be recycled or disposed of in compliance with the corresponding national regulations.

Refrigerant, oil and possible anti-freeze solutions recycling must be done by specialised companies in compliance with the

corresponding local and national legislation.

Electrical and electronic materials cannot not be disposed of together with domestic general waste. They must be disposed of

in special collection centres.

Units must be treated at a centre specialised in re-conditioning, recycling and recovery of materials.

2.8 Refrigerant gases

The units are charged with R410A refrigerant

Do not replace or mix one gas with another because different gases are not mutually compatible.

To clean out a very heavily contaminated refrigerant system, e.g. after a refrigerant compressor burnout, a qualified

refrigeration engineer must be consulted to carry out the task.

The manufacturer’s instructions and local safety regulations should always be observed when handling and storing high

pressure gas cylinders.

2.8.1 Refrigerants safety datasheet

Denomination: R410A (50% Difluoromethane (R32); 50% Pentafluoroethane (R125)).

INDICATION OF HAZARDS

Major hazards: Suffocation.

Specific hazards: Rapid evaporation can cause frostbite.

FIRST AID MEASURES

General information: Do not attempt to administer liquids or solids to persons who have lost consciousness.

Inhalation: Move victims to the open air. Use oxygen or artificial respiration if necessary.

Do not administer adrenaline or similar substances.

Contact with the eyes: Wash thoroughly with plenty of clean water for at least 15 minutes and seek medical

assistance.

Contact with the skin: Wash immediately in plenty of clean water. Remove contaminated clothing immediately.

FIRE-FIGHTING MEASURES

Means of extinction: Any.

Specific hazards: Pressure rise.

Specific methods: Cool containers with water spray.

MEASURES IN THE EVENT OF ACCIDENTAL LEAKAGE

Individual precautions: Evacuate personnel to safe muster points. Provide adequate ventilation. Use personal

protective equipment.

Environmental precautions: Evaporates.

Cleaning methods: Evaporates.

HANDLING AND STORAGE

Handling

Technical measures/ precautions: Ensure the presence of sufficient ventilation and/or air extraction means in the

workplace.

Recommendations for safe use: Do not breath fumes or aerosol.

Storage: Close hermetically and store in a cool, dry and well-ventilated place. Store in its original

containers. Incompatible products: explosives, flammable materials, organic peroxide

OPERATING AND MAINTENANCE MANUAL

Chapter 2 - Safety

TAEevo Tech 015÷802 60 Hz UL

16

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

CONTROL OF EXPOSURE/INDIVIDUAL PROTECTION

Control parameters: AEL (8-h and 12-h TWA) = 1000 ml/m3 for each of the two components.

Respiratory protection: For rescue and maintenance work in tanks use autonomous breathing apparatus. The

vapours are heavier than air and can cause suffocation, by reducing the oxygen available

for breathing.

Protection of the eyes: Safety spectacles.

Protection of the hands: Rubber gloves.

Hygiene measures: Do not smoke.

PHYSICAL AND CHEMICAL PROPERTIES

Colour: Colourless.

Odour: Faint.

Boiling point: -52.8°C at atmospheric pressure.

Flash point: Non-flammable.

Relative density: 1.08 kg/l at 25°C.

Solubility in water: Negligible.

STABILITY AND REACTIVITY

Stability: No reactivity if used in compliance with instructions.

Materials to avoid: Highly oxidising materials. Incompatible with magnesium, zinc, sodium, potassi um and

aluminium.

Incompatibility is more critical if the metal is present in the form of powder or if surfaces

have been recently unprotected.

Hazardous decomposition

products:

These products are halogen compounds, hydrofluoric acid, carbon monoxides (CO,

CO2), carbonyl halides.

TOXICOLOGICAL INFORMATION

Acute toxicity: (R32) LC50/inhalation/4 hours/lab. rats 760 ml/l

(R125) LC50/inhalation/4 hours/lab. rats 3480 mg/l

Local effects: Concentrations significantly above the TLV can cause narcotic effects.

Inhalation of products in decomposition can lead to respiratory difficulty (pulmonary

oedema).

Long-term toxicity: No carcinogenic, teratogenic, or mutagenic effects observed in laboratory animals.

ECOLOGICAL INFORMATION

Global warming potential GWP

(R11=1):

1730

Ozone depletion potential ODP

(R11=1):

0

Considerations on disposal: Usable with reconditioning.

OPERATING AND MAINTENANCE MANUAL

Chapter 3 - Technical data

TAEevo Tech 015÷802 60 Hz UL

17

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

CHAPTER 3

TECHNICAL DATA

The data plate affixed to the unit bears the following technical data:

ATTENTION

The performance of the unit depends mainly on the flow rate and temperature of water in the user circuit, and the

condenser thermal exchange fluid temperature. These values are defined at the time of the offer.

3.1 Data for standard units

3.1.1 Dimensions

See attached drawings.

MODEL and CODE The mode l number and the code identify the size of the unit and the type of

construction.

MANUAL Code number of the manual.

SERIAL NUMBER Construction number of the unit.

MANUFACTURING YEAR Year of unit’s final testing.

VOLTAGE/PHASE/FREQUENCY Electrical power supply characteristics.

MAX CURRENT DRAW (I max) Unit current draw in limit operating conditions.

SHORT CIRCUIT CURRENT Short circuit current.

HIGHER MOTOR FLA Max. absorbed current.

INSTALLED POWER (P max) Unit power input in limit operating conditions

PROTECTION RATING According to European standard EN 60529 / NEMA 250 international standard.

ELECTRICAL DIAGRAM Identifies the electrical diagram number.

REFRIGERANT Refrigerant fluid in the unit.

REFRIGERANT QUANTITY Quantity of refrigerant fluid contained in the unit.

USER CIRC. FLUID Type of user fluid utilised by the unit (normally water)

MAX ALLOWABLE PRESSURE (PS) Max. design p ressure of the user circuit.

ALLOWABLE TEMPERATURE (TS) Minimum and maximum values of temperature of the user circuit; this should not be

confused with the maximum working temperature which is established when the

offer is made.

CONDENSER COOLING FLUID Fluid used by the unit to cool the condenser.

MAX WORKING PRESSURE Max. design pressure of the condenser cooling circuit (this data is not present if the

unit is air cooled condensed).

MAX. TEMPERATURE Condenser cooling circuit maximum design temperature (this information is not

given if the unit’s condenser is air-cooled).

SOUND PRESSURE LEVEL Free field sound pressure level in hemispherical radiation conditions (open field) at

a distance of 1 m from the condenser side of the unit and a height of 1.6 m from the

ground.

AMBIENT TEMPERATURE Minimum and maximum values of ambient air temperature.

WEIGHT Approximate weight of the unit before packing.

OPERATING AND MAINTENANCE MANUAL

Chapter 3 - Technical data

TAEevo Tech 015÷802 60 Hz UL

18

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

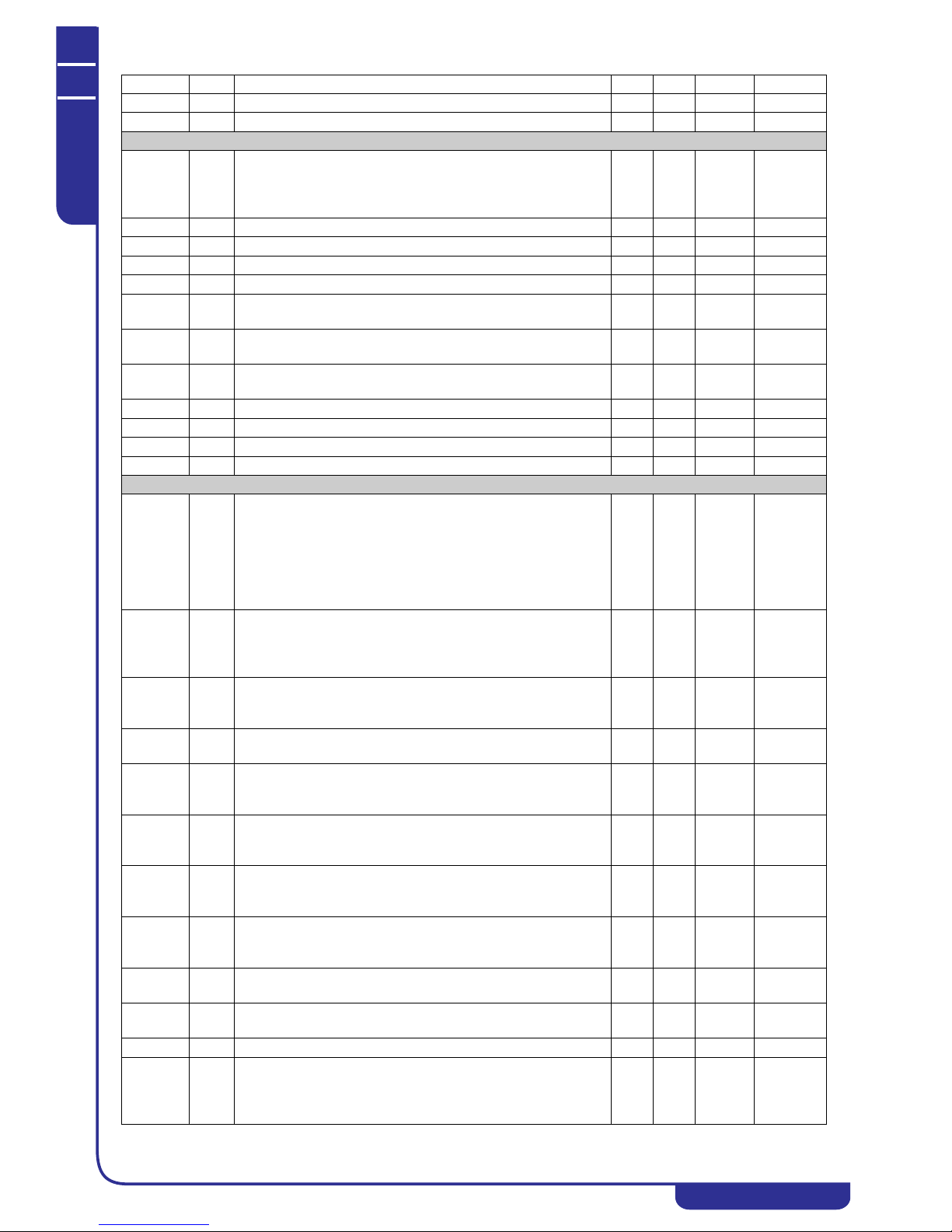

3.1.2 Characteristics of pumps and fans

NOTE

The values in the table may vary in relation to the unit model and configuration. In this case refer to the offer data.

NOTE

The pressure head is the pressure head available in the user’s premises. The installed pump my differ with respect to the

standard pump. For the flow rate and pressure head values two numbers are specified: the first refers to nomin al conditions

and the second refers to maximum conditions.

3.1.3 Sound level measurements

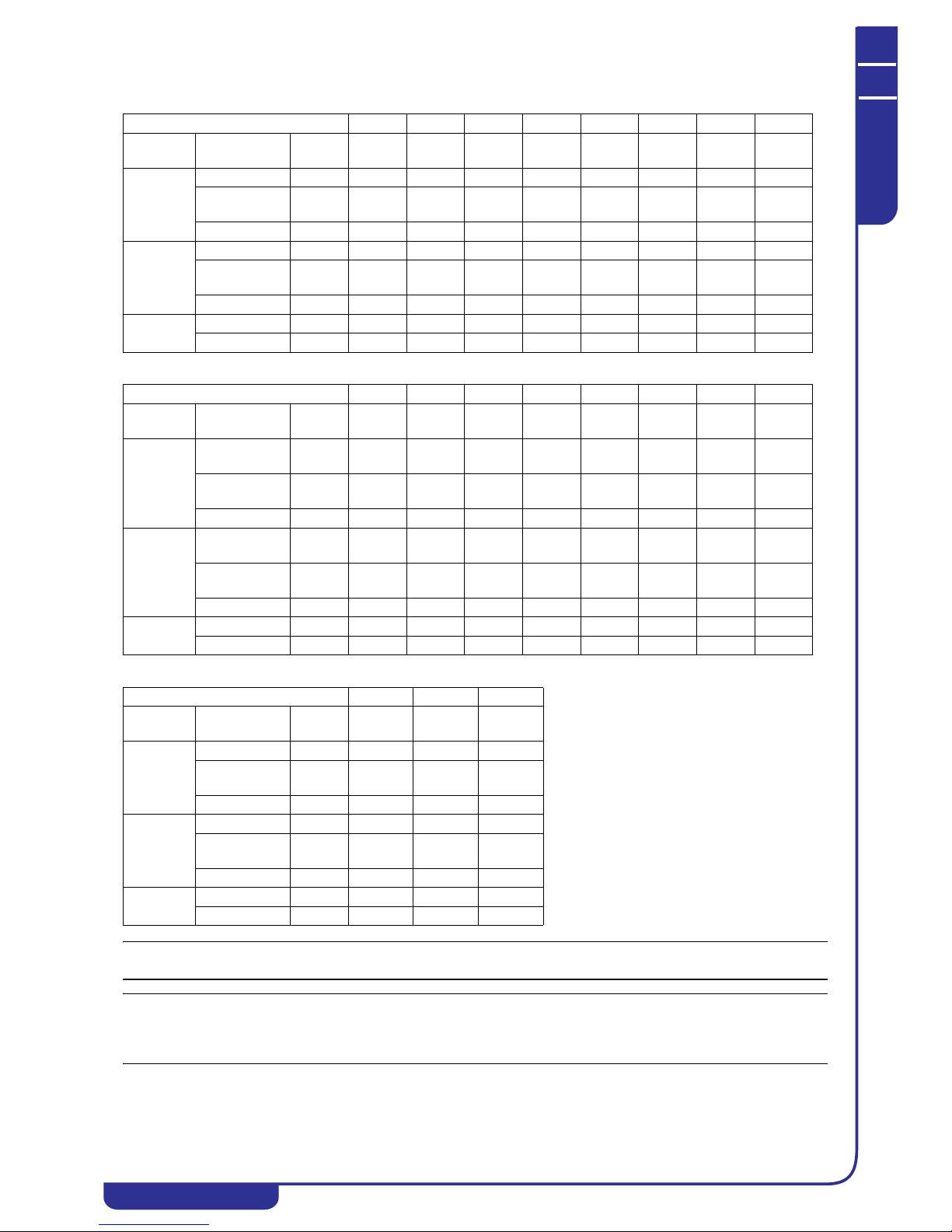

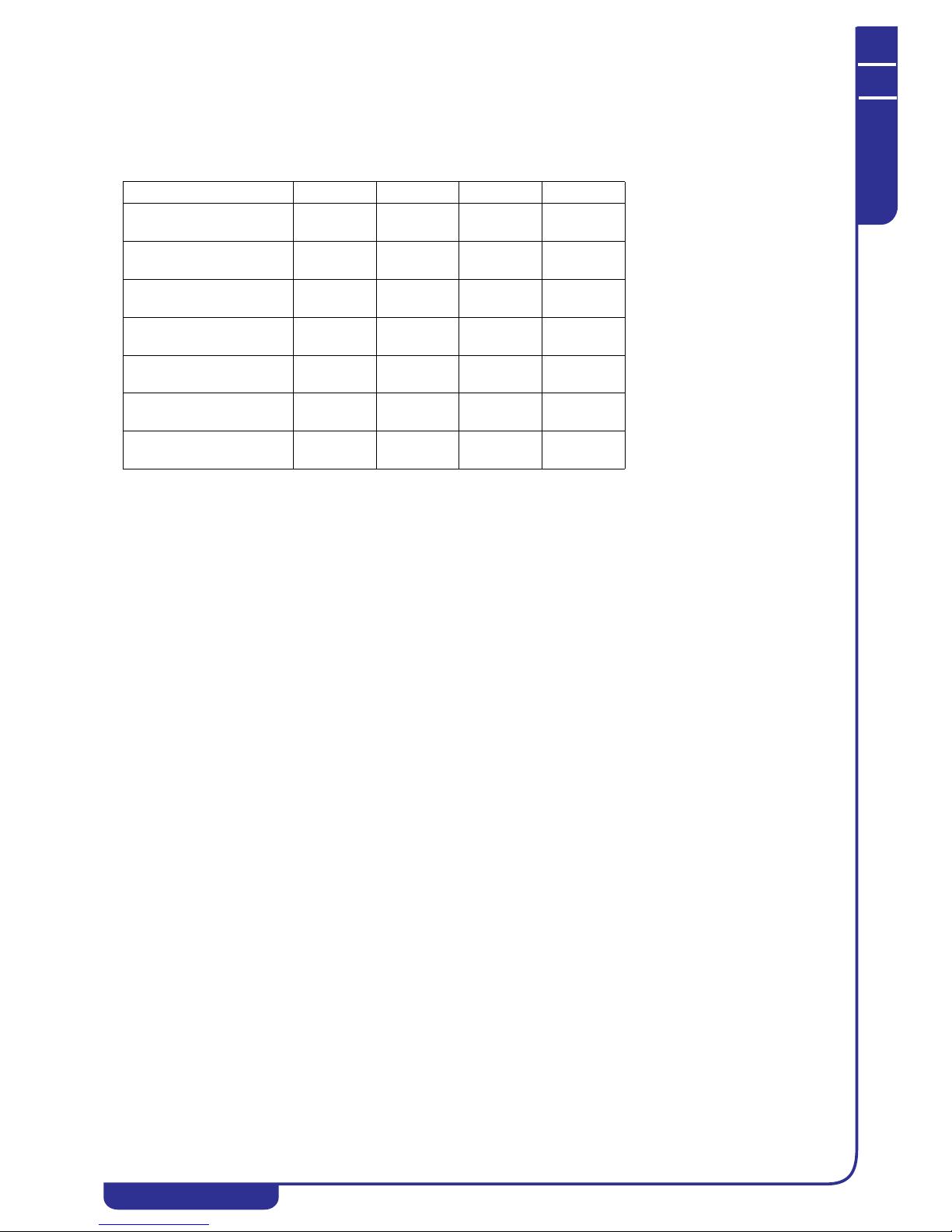

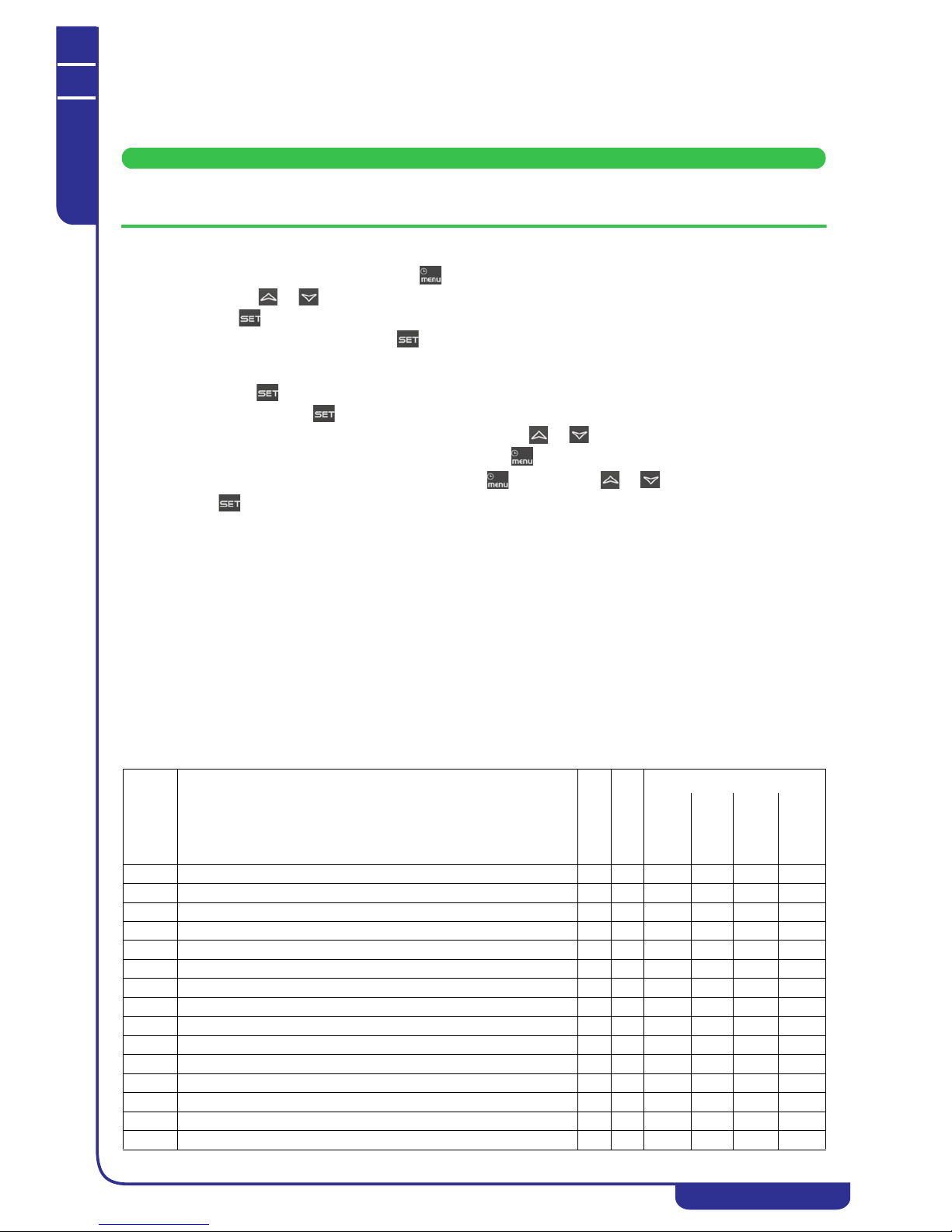

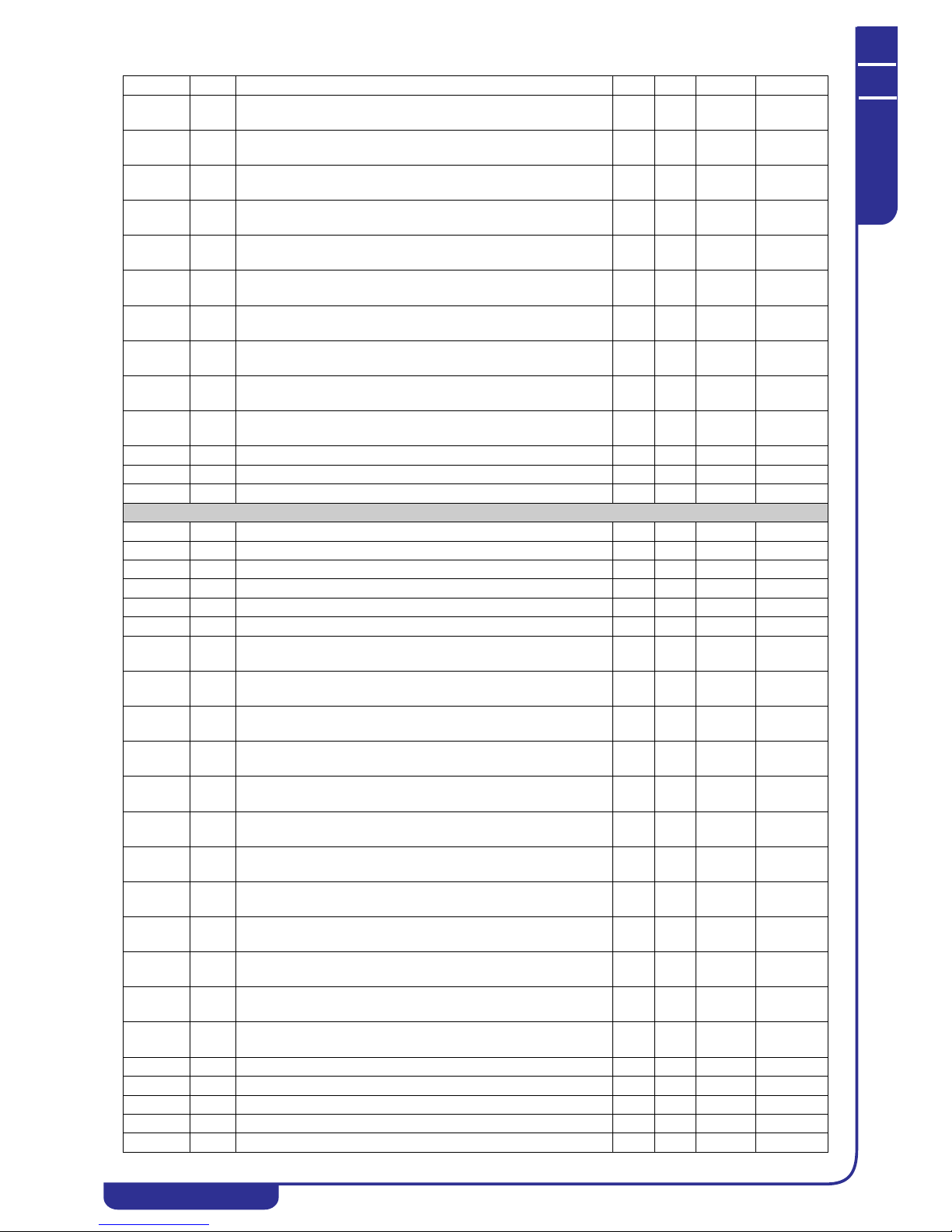

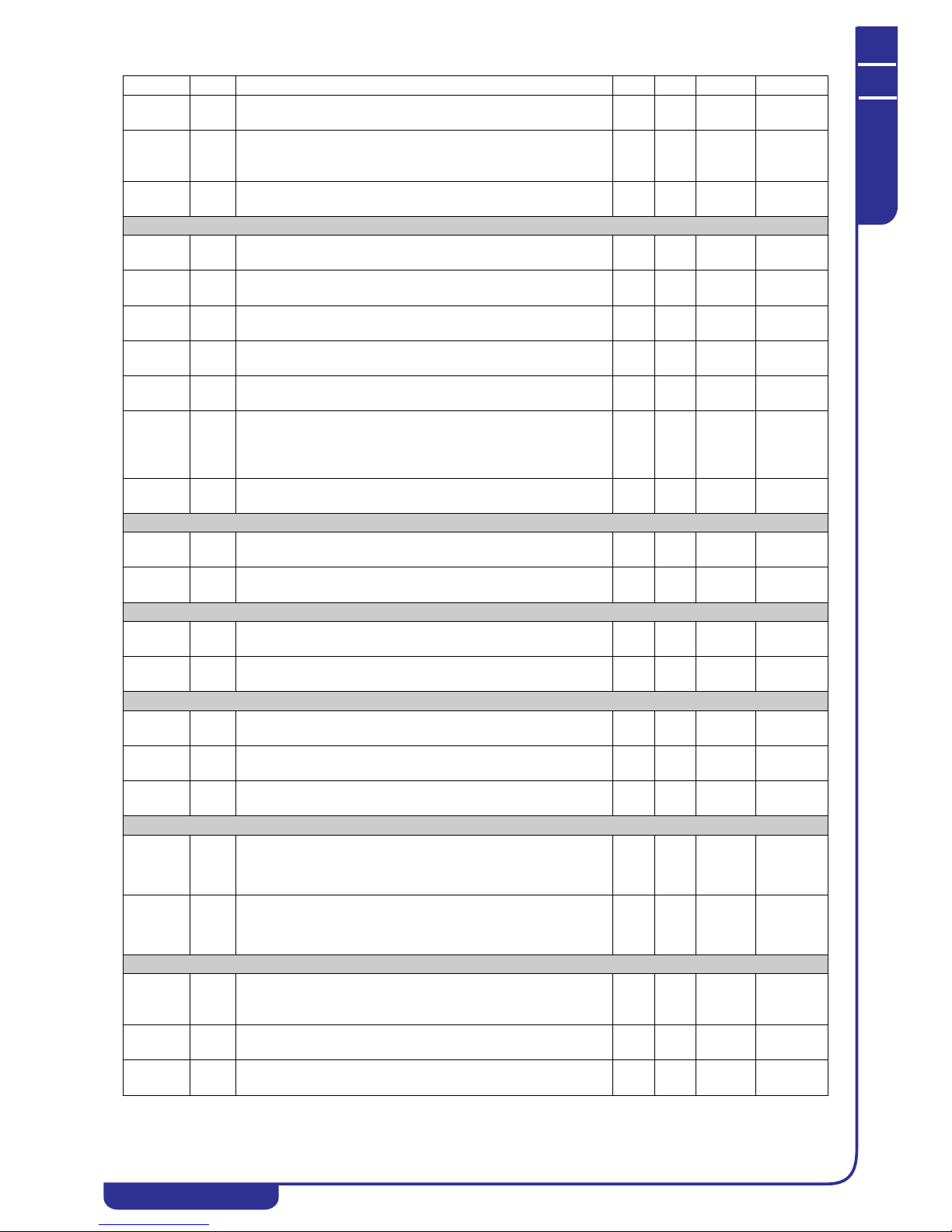

Model TAEevo Tech 015 020 031 051 081 101 121 161

Tank

capacity

water volume (gal) 16 16 30 30 37 67 67 67

Pump P3

water flow rate (gpm) 2.0/21.1 2.0/21.1 3.8/21.1 4.8/21.1 9.5/42.3 12.1/42.3 15.2/85.4 18.0/85.4

pump pressure

head

(PSI) 44.9/25.4 44.9/25.4 44.1/28.7 43.7/29.9 4 3.1/22.2 42.4/25.8 42.5/23.4 42.3/24.4

rated power (kW) 0.75 0.75 0.75 0.75 0.9 0.9 1,85 1,85

Pump P5

water flow rate (gpm) 2.0/26.4 2.0/26.4 3.8/26.4 4.8/26.4 9.5/66.0 12.1/66.0 15.2/66.0 18.0/66.0

pump pressure

head

(PSI) 85.7/44.9 85.7/44.9 84.3/50.6 83.4/49.2 8 7.5/50.1 86.6/56.9 85.4/56.9 84.2/57.5

rated power (kW) 1.5 1.5 1.5 1.5 3.0 3.0 3.0 3.0

Axial flow

fan

No. of fans 11111222

total airflow (cfm) 2795 2470 4530 3590 5825 9945 9415 9415

Model TAEevo Tech 201 251 301 351 381 401 402 502

Tank

capacity

water volume (gal) 92.5 92.5 92.5 92.5 108 108 1 32 132

Pump P3

water flow rate (gpm) 19.0/84.5 19.0/84.5

26.5/

105.7

30.9/

105.7

39.5/

220.1

43.9/

220.1

37.9/

220.1

37.9/

220.1

pump pressure

head

(PSI) 42.4/28.9 42.4/28.9 45.9/19.3 45.2/18.5 5 2.2/20.4 52.1/20.4 52.4/25.0 52.4/25.0

rated power (kW) 1.8 1.8 2.2 2.2 4 4 4 4

Pump P5

water flow rate (gal)

19.0/105.7 19.0/105.7

26.5/

105.7

30.9/

105.7

39.5/

220.1

43.9/

220.1

37.9/

220.1

37.9/

220.1

pump pressure

head

(PSI) 75.6/47.7 75.6/47.7 74.8/47.8 74.0/47.0 7 7.6/42.9 77.2/42.9 77.7/47.6 77.7/47.6

rated power (kW) 4 4 4 4 7.5 7.5 7.5 7.5

Axial flow

fan

No. of fans 22332222

total airflow (cfm) 1 1535 11415 15625 15625 2 5662 24367 25895 25070

Model TAEevo Tech 602 702 802

Tank

capacity

water volume (gal) 132 179 179

Pump P3

water flow rate (gpm) 37.9/220.1 69.2/220.1 81.3/220.1

pump pressure

head

(PSI) 52.4/25.0 62.7/36.0 61.4/36.0

rated power (kW) 4 5.5 5.5

Pump P5

water flow rate (gal) 37.9/220.1 69.2/378.6 81.3/378.6

pump pressure

head

(PSI) 77.7/47.6 70.0/30.9 69.7/30.9

rated power (kW) 7.5 11.0 11.0

Axial flow

fan

No. of fans 2 3 3

total airflow (cfm) 24 285 43967 42378

OPERATING AND MAINTENANCE MANUAL

Chapter 3 - Technical data

TAEevo Tech 015÷802 60 Hz UL

19

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

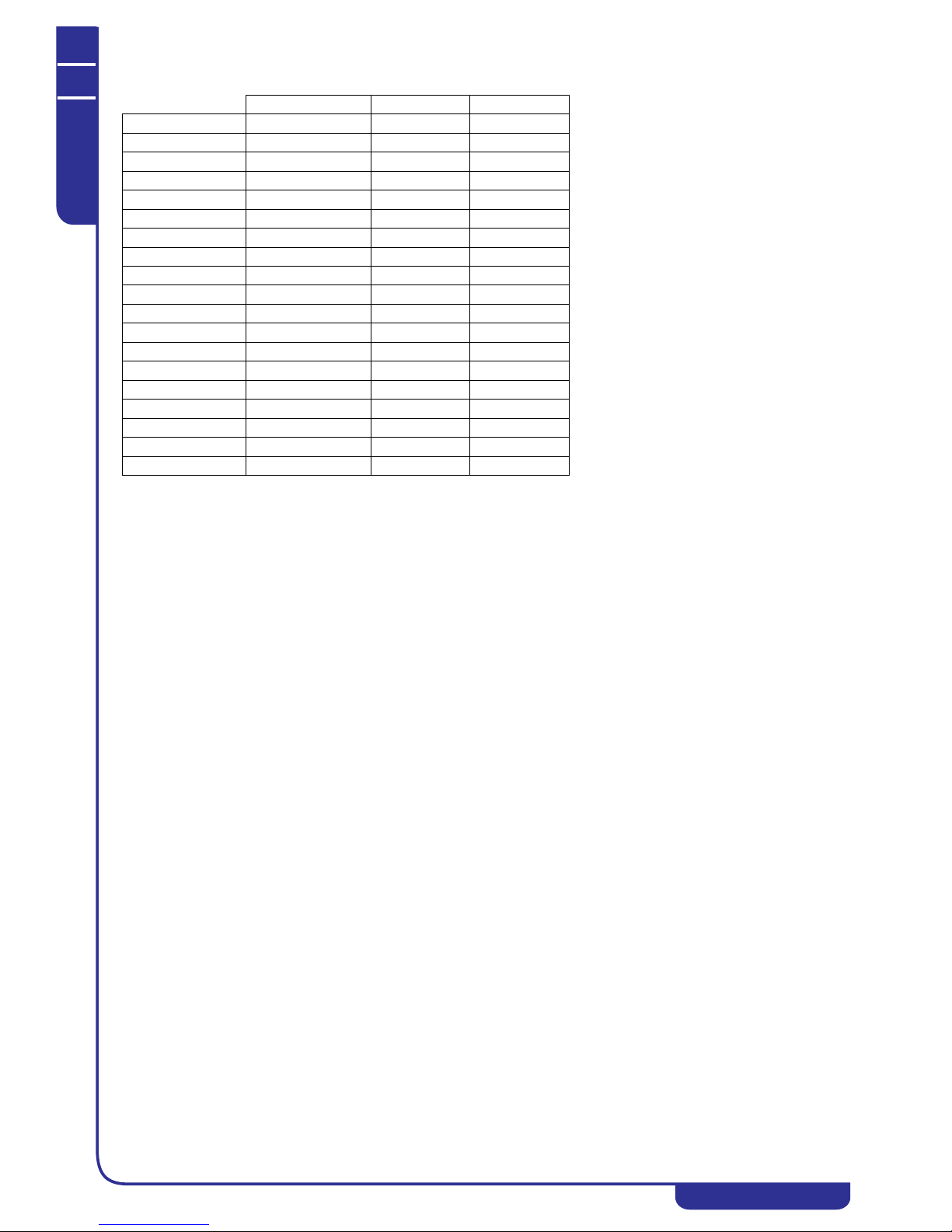

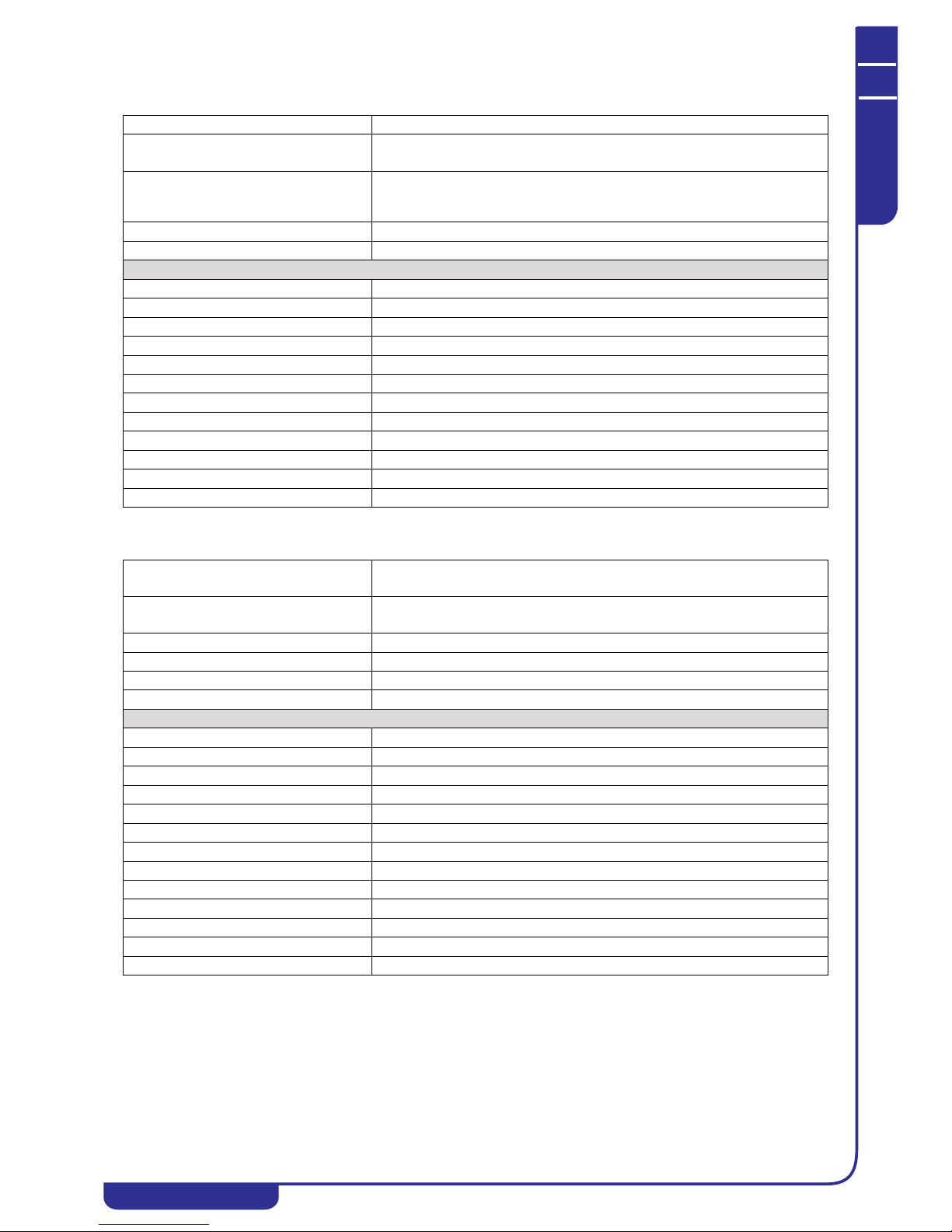

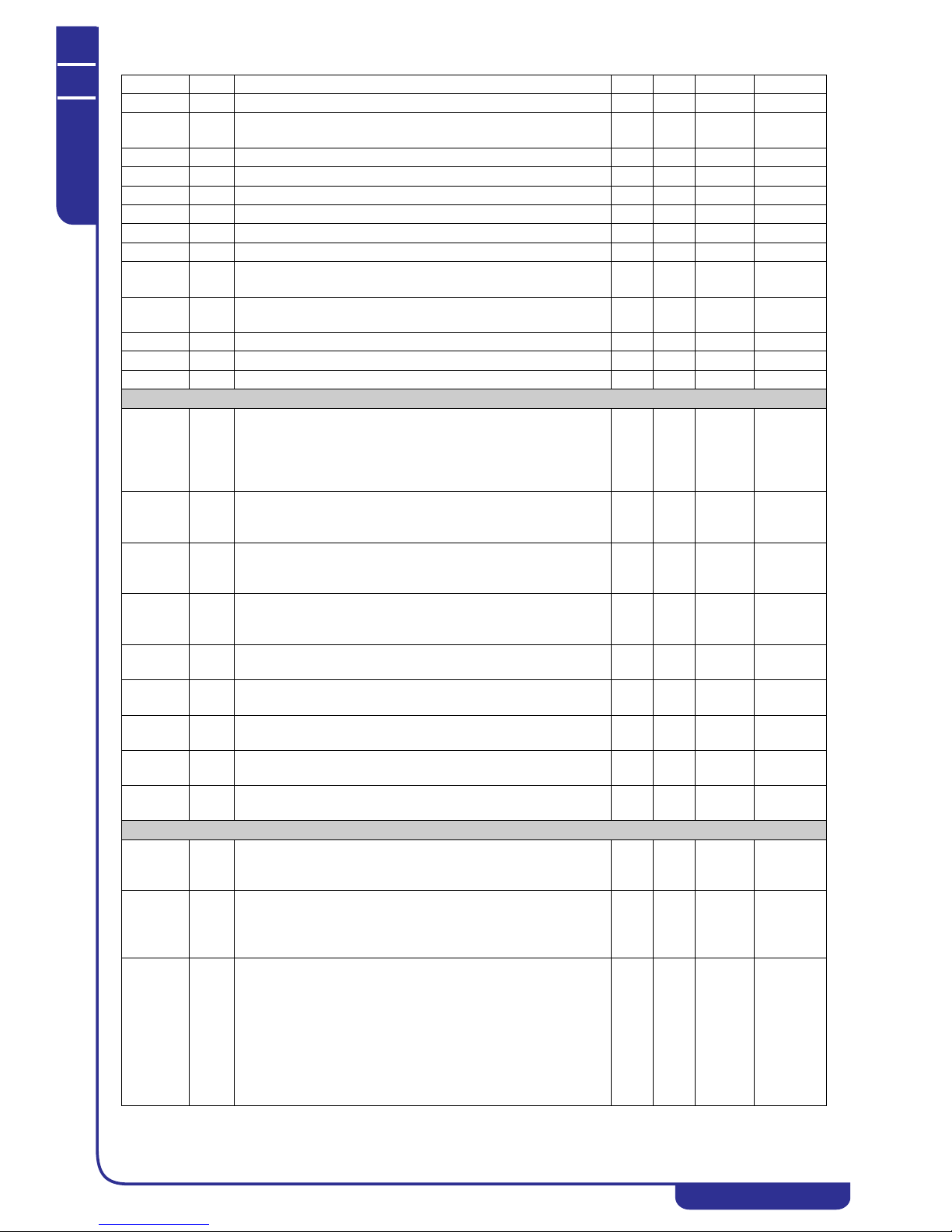

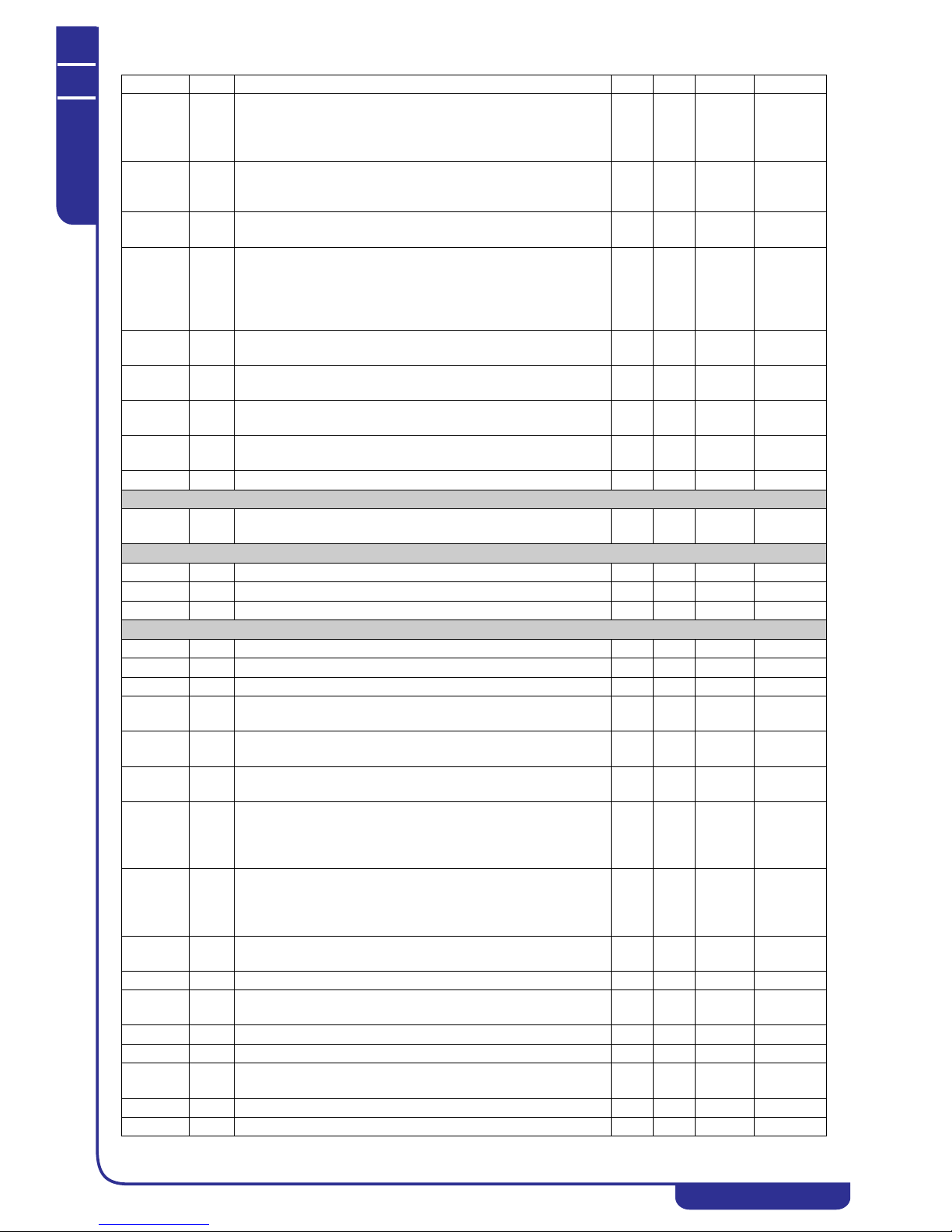

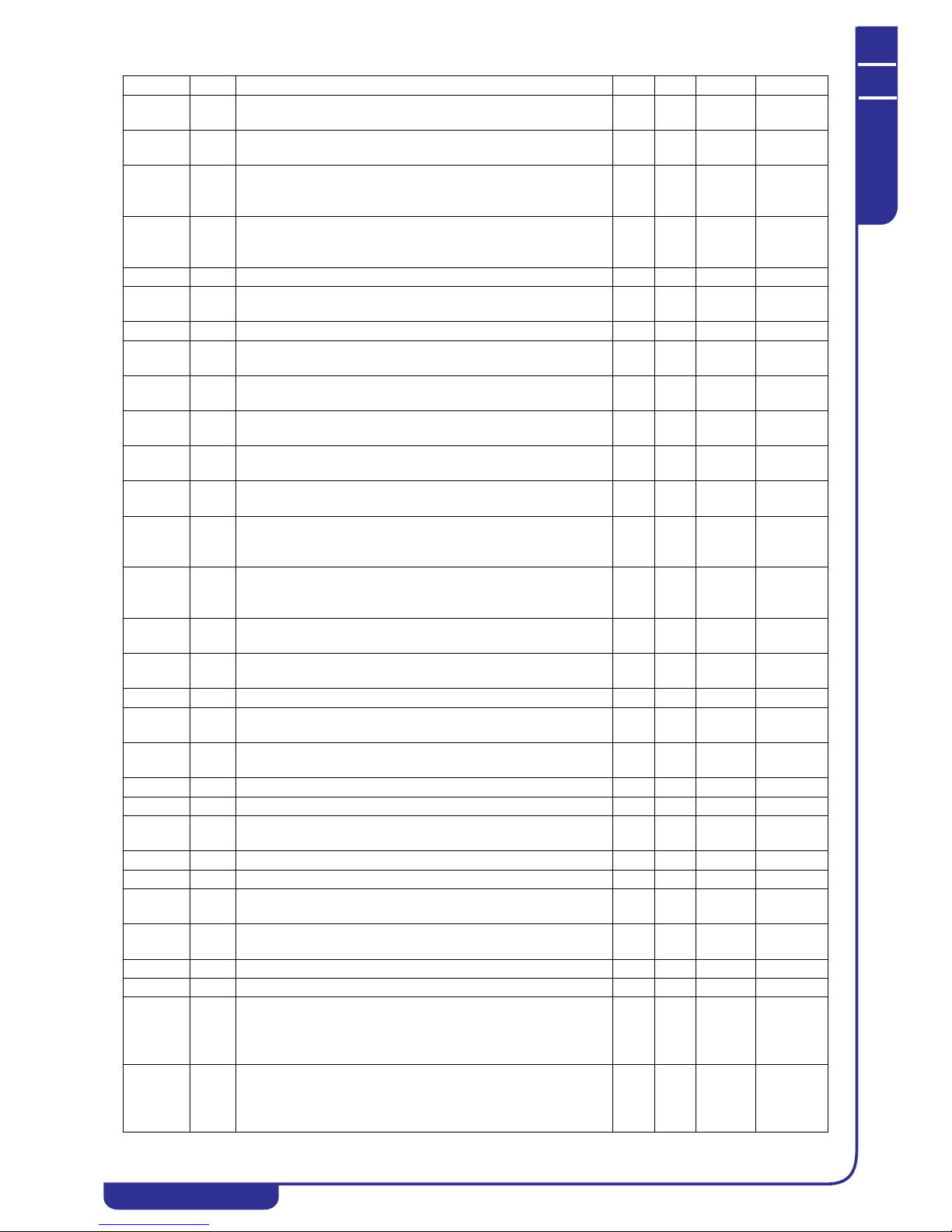

* at distance of 1 m (3.2 FT)

** global

Test conditions

Noise levels refer to operation of the unit at full load in nominal conditions.

Sound pressure level in hemispherical irradiation conditions at a distance of 1 m (3.2 FT) from the condensers side of the unit

and height of 1.6 m (5.2 FT) from the ground. Values with tolerance of ± 2 dB.

Sound pressure level: according to ISO 3744.

Fan Lp dB(A) * Lw dB(A) **

TAEevo Tech 015 axial 69,5 82,5

TAEevo Tech 020 axial 68,9 81,9

TAEevo Tech 031 axial 69,6 82,6

TAEevo Tech 051 axial 70,7 83,7

TAEevo Tech 081 axial 70,9 83,9

TAEevo Tech 101 axial 72,0 85,0

TAEevo Tech 121 axial 71,2 84,2

TAEevo Tech 161 axial 72,1 85,1

TAEevo Tech 201 axial 74,2 87,2

TAEevo Tech 251 axial 74,1 87,1

TAEevo Tech 301 axial 75,6 88,6

TAEevo Tech 351 axial 75,3 88,3

TAEevo Tech 381 axial 78.0 91,0

TAEevo Tech 401 axial 80.2 93,2

TAEevo Tech 402 axial 79,5 92,5

TAEevo Tech 502 axial 79,6 92,6

TAEevo Tech 602 axial 79,3 92,3

TAEevo Tech 702 axial 79.4 92,4

TAEevo Tech 802 axial 80.6 93,6

OPERATING AND MAINTENANCE MANUAL

Chapter 4 - Description

TAEevo Tech 015÷802 60 Hz UL

20

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

CHAPTER 4

DESCRIPTION

4.1 Components

Data for materials are referred to standard units. Non-standard materials may be utilised in order to meet specific

requirements. In this case refer to the offer data.

The units are basically composed of the following parts:

• Refrigerant compressor

• Condenser

• Evaporator

•Tank

•Pump

• Frame/cabinet

• Electronic controller

4.1.1 Refrigerant circuit

TAEevo Tech 015÷401 models feature a single refrigerant circuit with one or two compressors connected in parallel

(tandem).

TAEevo Tech 402÷802 models feature two refrigerant circuits with two compressors connected in parallel (tandem).

Each refrigerant circuit, is equipped with the following components:

• refrigerant fluid utilised R410A;

• hermetic scroll compressor;

• pressure switch for fans with On/Off control (only TAEevo Tech 015÷401);

• high and low refrigerant pressure switches;

• high pressure transducer for fan speed control and for unloading (modes TAEevo Tech 402÷802);

• thermostatic lamination valve complete with external pressure equalizer;

• filter dryer;

• liquid sight-glass;

• refrigerant pressure gauges (from TAEevo Tech 031);

• schrader service valves.

For more information consult the attached diagrams.

4.2 Compressors

The compressors are of the SCROLL type and are characterised by high energy efficiency, low vibration and consequent very

low noise during normal operation.

The compressors are cooled by the refrigerant on the suction line, protected against possible overheating of the windings by

an internal module that monitors windings temperature, and protected upline by thermal magnetic cutouts. These components

are housed in an enclosed compartment, but they are readily accessible.

NOTE

During the short periods of starting and stopping the compressor you may hear a metallic noise due respectively to the initial

contact between the coils and to the momentary reversal of their rotation. This noise is absolutely normal and does not affect

the reliability of the compressor.

ATTENTION

At the time of the first start following a prolonged stoppage lasting several days, ensure the crankcase heater of each

compressor is switched on at least 12 hours before pressing the start button.

NOTE

TAEevo Tech 402÷802 units can be optionally fitted with compressor stating with a Soft Starter.

The Soft Starter is linked to each compressor and it serves to limit peak current at the time of compressor starting.

- Units equipped with soft starters can operate up to a maximum ambien t temperature of 40°C, beyond which the unit simply

stops, without tripping any alarms.

- The soft starters are not compatible with capacitive devices (e.g. power factor correction capacitors) installed between the

soft starter and the compressor motor. Any static or dynamic power factor correction systems installed upline from the main

power circuit breaker must not operate simultaneously with staring of the soft starter.

4.3 Condenser

Condensation occurs in finned core coils composed of copper tubes and headers, corrugated aluminium fins, and galvanized

sheet metal shoulders.

OPERATING AND MAINTENANCE MANUAL

Chapter 4 - Description

TAEevo Tech 015÷802 60 Hz UL

21

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

4.4 Evaporator

The evaporator is of the finned core type; water flows in contact with the finned surface at velocities such as to ensure low

pressure drops, while the refrigerant flows through the tubes.

In these models the exchanger is protected from the risk of ice formation caused by low evaporation temperatures, with antifreeze strategies handled by the electronic controller. The evaporator water outlet temperature is controlled by a probe. If

negative room/water temperatures are required, a mixture of water and glycol must be used.

To drain the circuit refer to “9.4 Draining the process water circuit”.

4.5 Tank

The storage tank is cylindrical.

The tank can be protected against freezing by means of an electric heater managed by the electronic controller. A level sensor

in the tank serves to signal low water level conditions. The standard supply includes anti-condensation cladding, a drain

valve and an air bleed valve.

An internal bypass between the water delivery and return connections makes it possible to read the anti-freeze probe if the

unit’s process water inlet and outlet connections are inadvertently closed. In this case the unit stops due to tripping of the

anti-freeze alarm and the shut-off valves must be reopened.

The bypass serves exclusively to allow an anti-freeze alarm to trip (if present) and to allow the pump to run with a reduced

water flow rate without damage. It is advisable to avoid repeated anti-freeze alarm trip cycles in the foregoing conditions.

4.6 Pump

The unit is equipped with centrifugal pumps that can be of two different types, characterised by their ability to provide

different pressure heads depending on requirements (3 and 5 barg / 43.5 and 7 2.5 PSI pump). The unit can also be su pplied

without an installed pump. The electrical characteristics of the compatible pump are specified in the wiring diagram.

The pump seals are in silicon carbide/silicon carbide/EPDM.

ATTENTION

Bleed the circuit by unscrewing the bleed cap on the pump whenever the hydraulic circuit is filled. See 5.4 “Hydraulic

connections”.

NOTE

The pump must never run dry.

4.7 Fans

4.7.1 Axial

The fans are of the axial flow type, comprising a diecast aluminium fan wheel with sickle shaped blades.

The protection rating of the fans is IP54.

All fans feature insulation class F to ensure they are compatible with outdoor operation in all climates. Fan assembly is

completed by an upper safety grille (supporting the fan).

For models TAEevo Tech 031÷802 it is possible to fit a semi-transparent

container kit, secured to the rear of the unit. In steady state conditions the

water level in the container must be approximately at the half-way point. In

this case water filling is performed via the container kit.

OPERATING AND MAINTENANCE MANUAL

Chapter 4 - Description

TAEevo Tech 015÷802 60 Hz UL

22

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

4.8 Cabinet

The entire plinth, the uprights, and the outer panels are made of galvanized carbon steel sheet and are assembled by means of

screws and/or rivets. All panels undergo phosphor degreasing treatment followed by ep oxy polyester power coating.

The frame is designed to allow easy access to all components of the unit.

4.9 Materials in contact with the liquid to be cooled

Standard chillers: carbon steel, copper, aluminium, zinc, brass, stainless steel and plastic materials

specifically:

• evaporator with copper tubes, aluminium fins and galvanized sheet metal shoulders;

• carbon steel tank.

Chillers with non-ferrous hydraulic circuit (TAEevo Tech 015÷401): stainless steel (AISI 304), copper, brass and plastic

materials.

Specifically:

• with copper tubes and fins and brass shoulders;

• tank in AISI 304 stainless steel.

The pump mechanical seals are in silicon carbide/silicon carbide/EPDM.

4.10 Overall dimensions and minimum clearances with

respect to walls

See the enclosed electrical diagrams.

4.11 Electrical circuit

Refer to Chapter 5 “Installation” for information on electrical hook-ups and consult the attached diagrams.

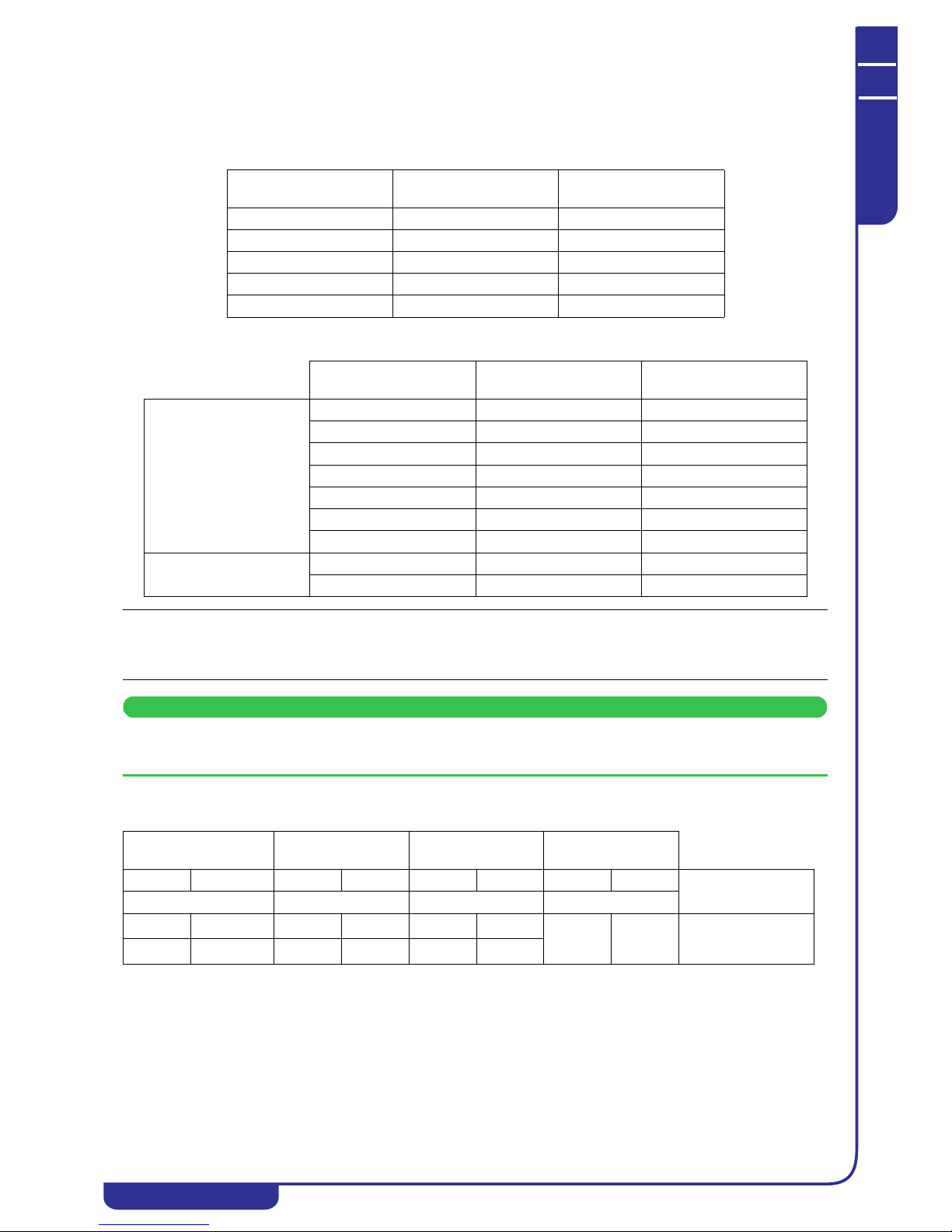

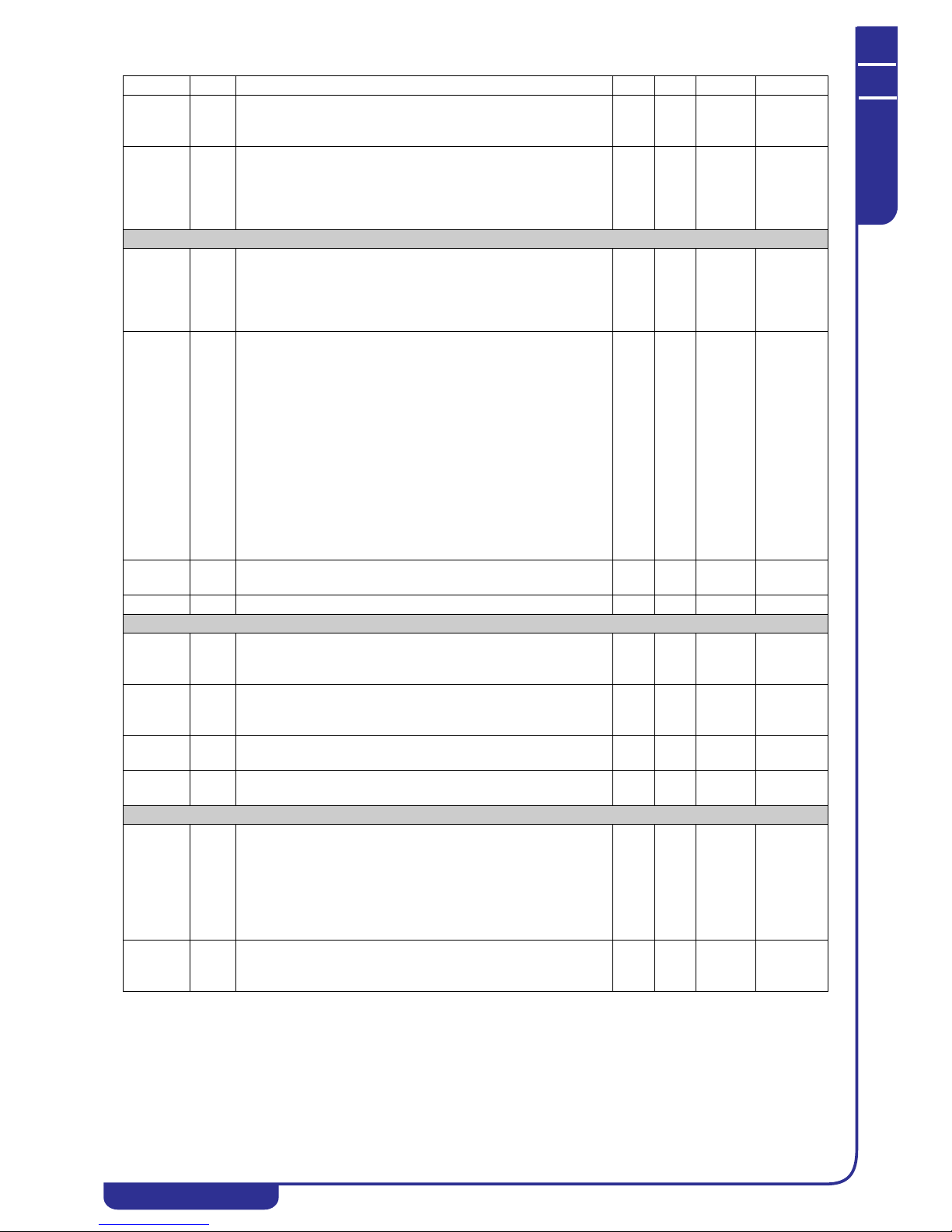

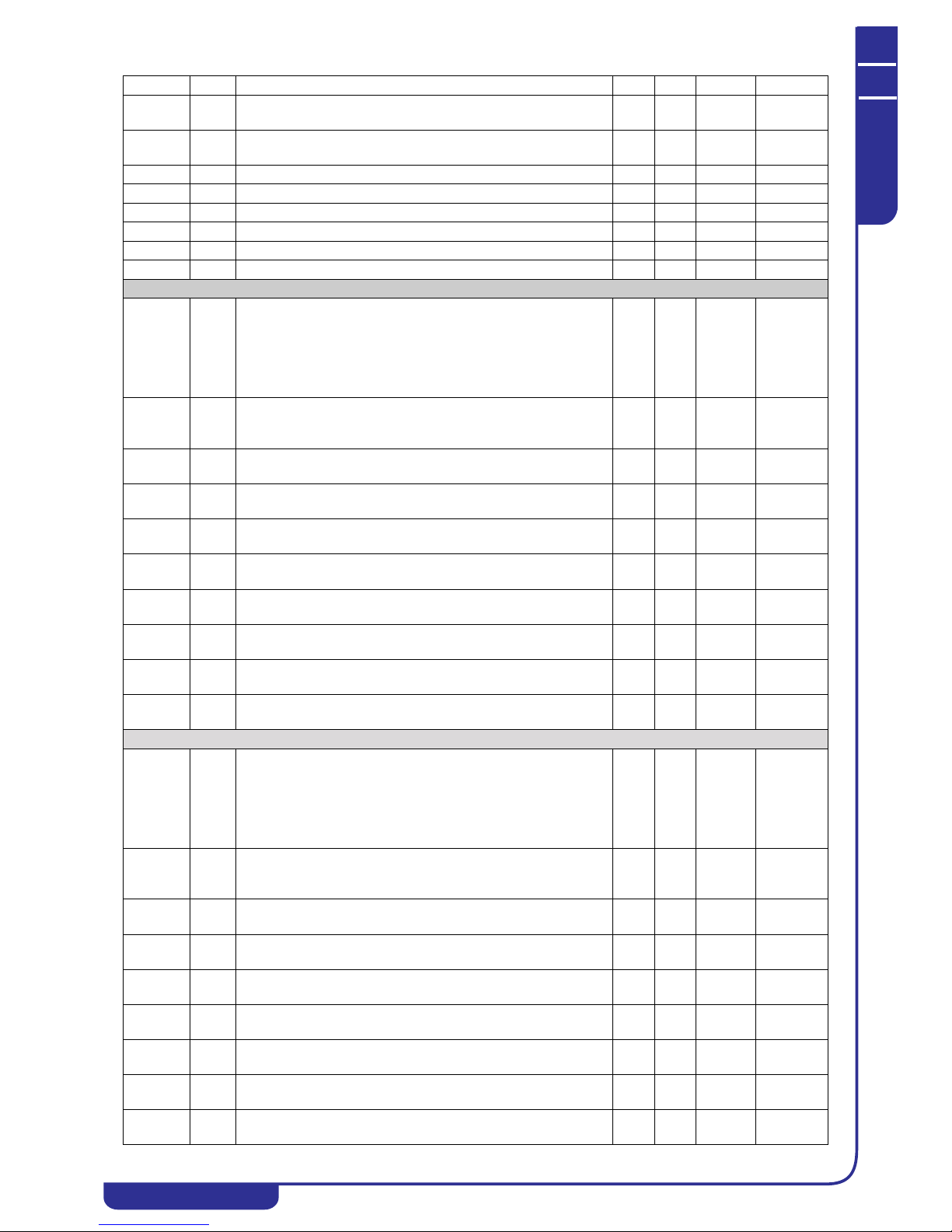

Model Width Depth Height

TAEevo Tech 015÷020

(mm)

(in)

560

22

1265

49.8

794

31.2

TAEevo Tech 031÷051

(mm)

(in)

660

26

1310

51.6

1400

55.1

TAEevo Tech 081÷161

(mm)

(in)

760

29.9

1865

73.4

1447

57

TAEevo Tech 201÷351

(mm)

(in)

865

34

2255

88.8

2065

81.3

TAEevo Tech 381÷401

(mm)

(in)

1150

45.2

2790

110

2091

82.3

TAEevo Tech 402÷602

(mm)

(in)

1255

49.4

3295

129.7

2140

84.2

TAEevo Tech 702÷802

(mm)

(in)

1251

49.2

3350

131.9

2153

84.7

OPERATING AND MAINTENANCE MANUAL

Chapter 5 - Installation

TAEevo Tech 015÷802 60 Hz UL

23

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

CHAPTER 5

INSTALLATION

ATTENTION

Before installing or operating these units, ensure that all personnel involved have read and understood Chapter 2

“Safety”. The unit must be installed in accordance with current national legislation in the country of use.

5.1 Inspection

As soon as the unit has been unpacked check it carefully for damage.

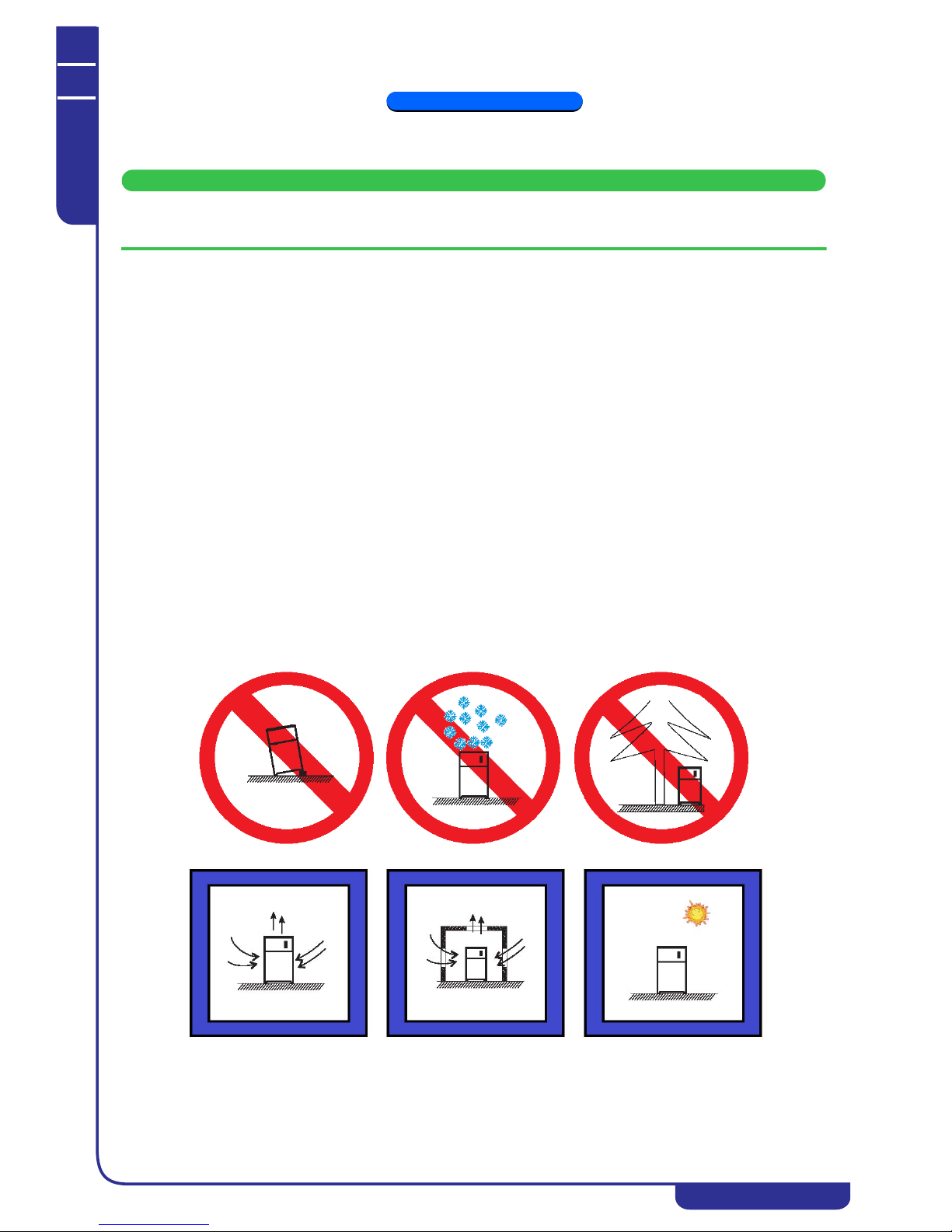

5.2 Location

1. The unit can be installed either outdoors or in an enclosed environment, depending on the degree of IP protection

of the electrical panel and the unit itself.

2. If the unit is installed indoors the place of installation must be well ventilated. In certain cases it may be necessary

to install ventilation fans or extractor fans in order to reduce room temperature.

3. The ambient air must be clean, avoid sea ambients (brackish air), and not contain flammable gas or corrosive

solvents.

4. The minimum and maximum working ambient temperature are specified on the unit data plate. Ensure that the

unit is not installed in flows of hot air emitted by other equipment.

In extremetemperature conditions, the protection devices may trip.

5. Do not obstruct or interfere with the air flow produced by the unit; comply strictly with the minimum spaces/

distances specified in the installation drawings.

6. The machine must be installed on a perfectly horizontal flat surface, built and calculated to withstand the

machine’s operating weight, especially in the contact points highlighted in the installation drawing. In the event

of installations which fail to comply with the above requirements, the manufacturer’s warranty cover will

immediately become null and void and the unit could malfunction or even lock out.

7. Leave free space around the unit for access during service interventions (see Attachments).

8. Do not install the plant in sites exposed to strong winds; if unavoidable, install suitable windscreens.

See point 1.

OPERATING AND MAINTENANCE MANUAL

Chapter 5 - Installation

TAEevo Tech 015÷802 60 Hz UL

24

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

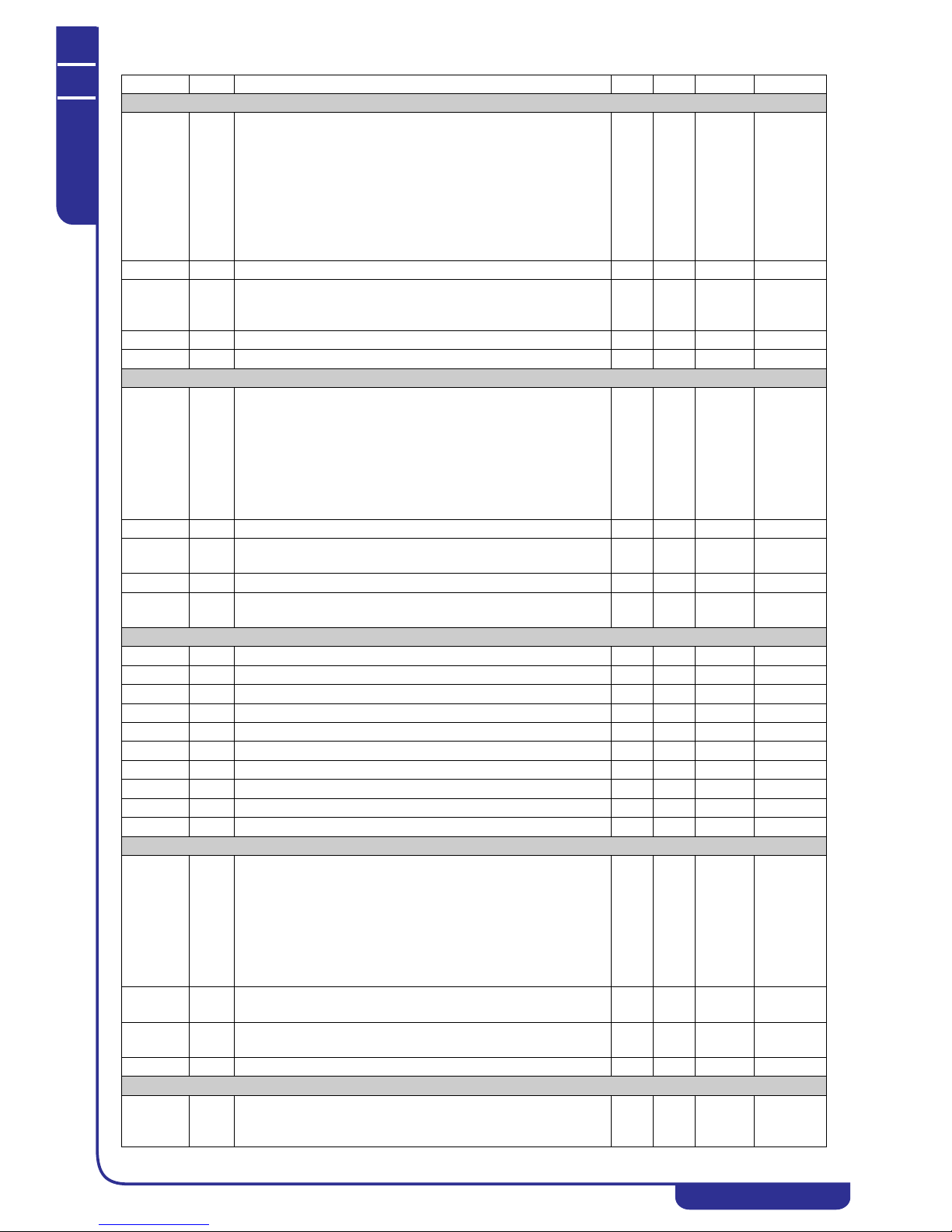

5.3 Freeze protection

Even if the minimum operating temperature is higher than 0°C/32°F, during shutdown periods in the cold season the unit may

be subject to temperatures that are lower than 0°C/32°F.

In such cases if the water is not drained out of the unit ethylene or propylene glycol antifreeze should be added to the water

in the following percentages:

In accordance with the chilled water outlet temperature, to avoid the formation of ice ethylene or propylene glycol antifreeze

should be added to the water in the following percentages:

NOTE

The water flow rate must correspond to the value stated in the technical specifications or in the selection software.

The conditions specified in the table do not guarantee anti-freeze protection with the machine operating in bypass mode

between water delivery and return, and with the machine water inlet and outlet fittings shut off.

ATTENTION

The anti-freeze setting is 4°C/39°F. To reduce the anti-freeze setting edit parameter AL26.

For water outlet temperatures lower than 6 °C you must add a suitable quantity of antifreeze solution.

5.3.1 Operating limits

The operating limits are decided at the time of sale. Refer to the data specified in the contract.

Ambient T up to

[°C] (°F)

Ethylene Glycol

[% by weight]

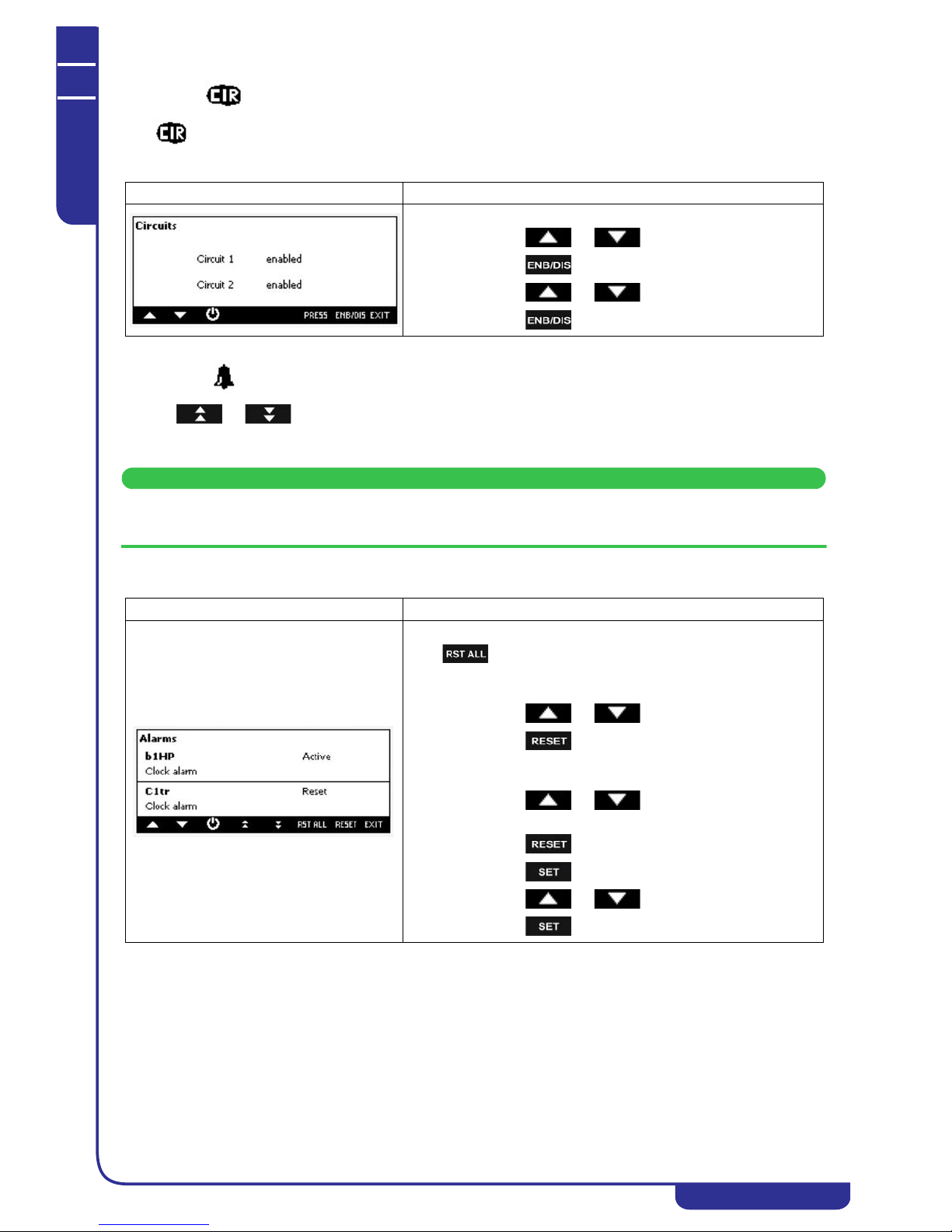

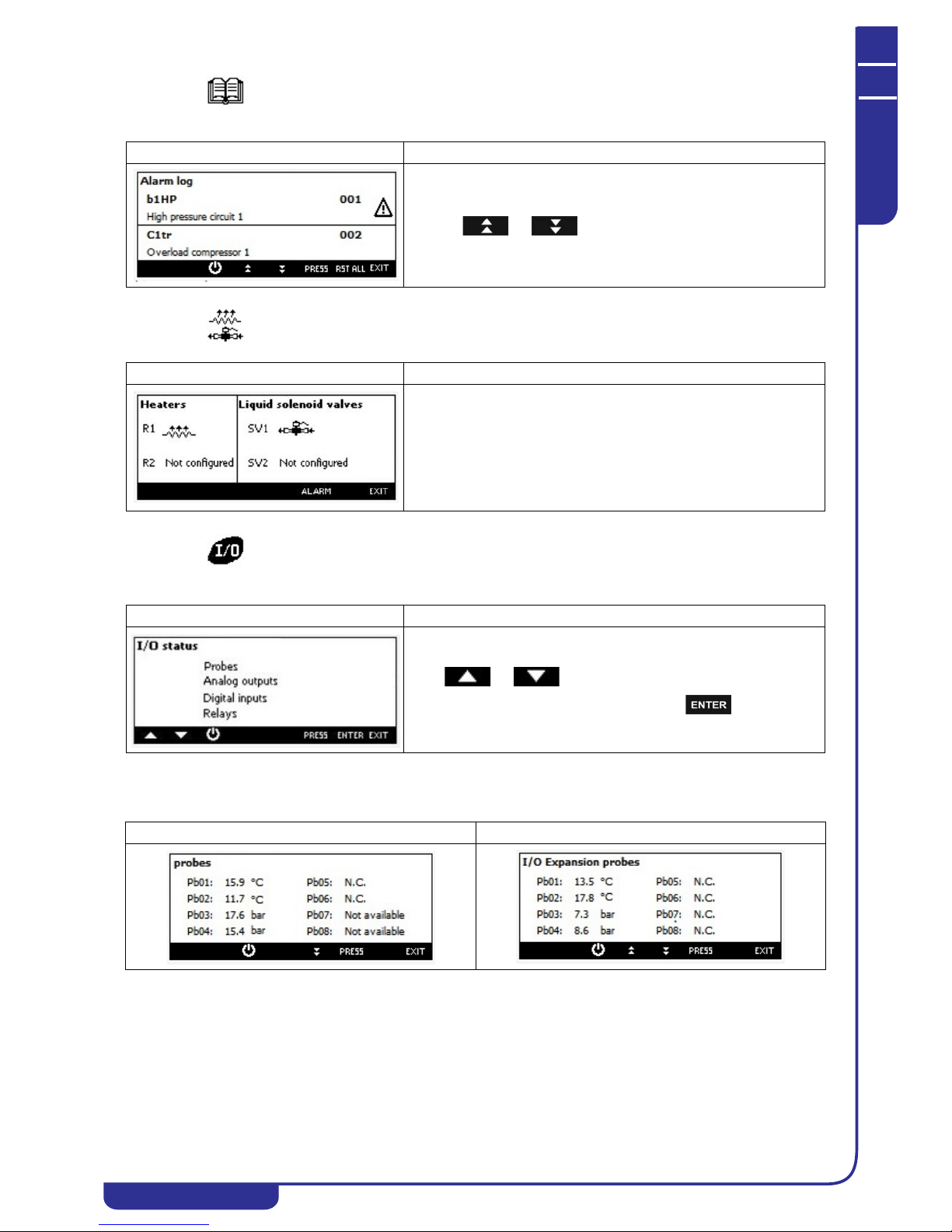

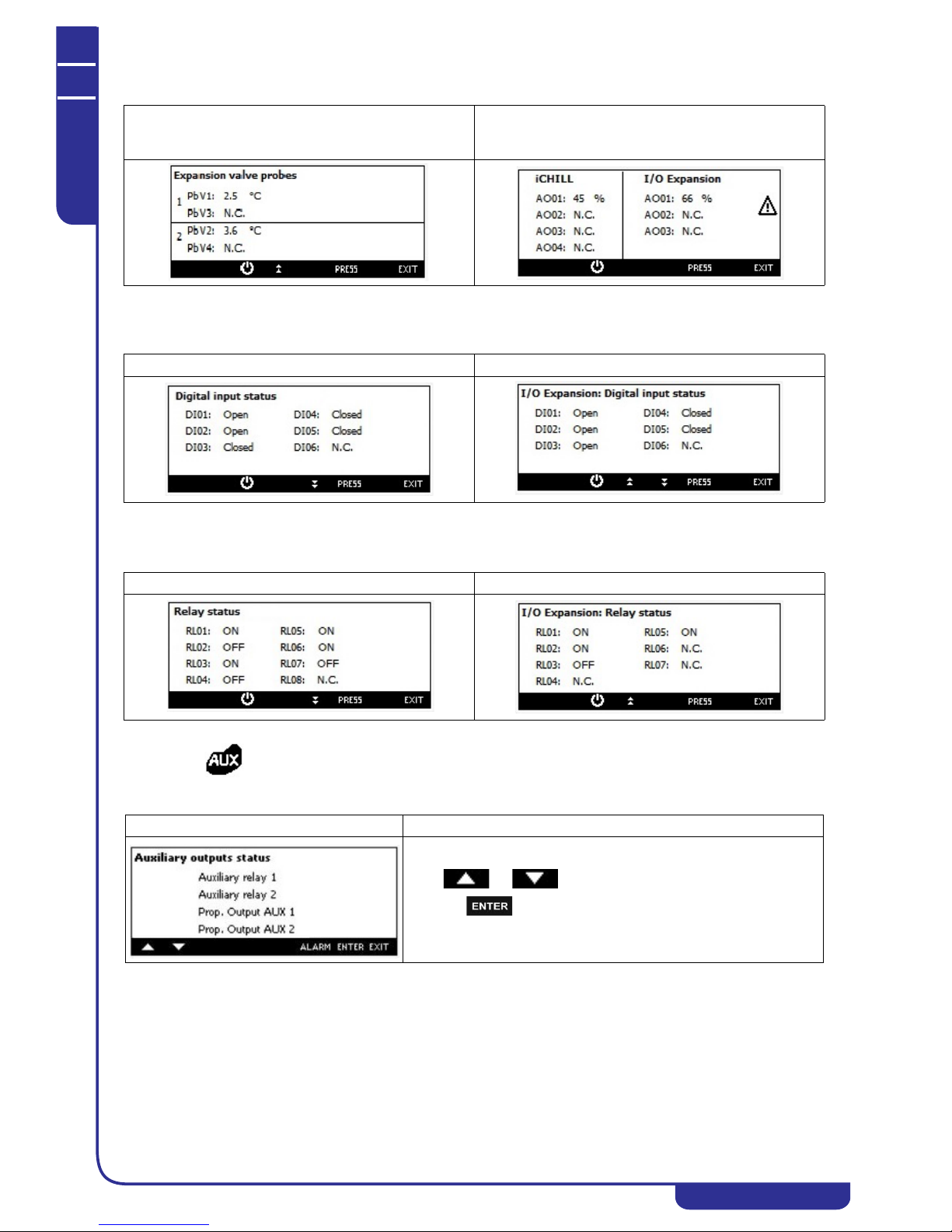

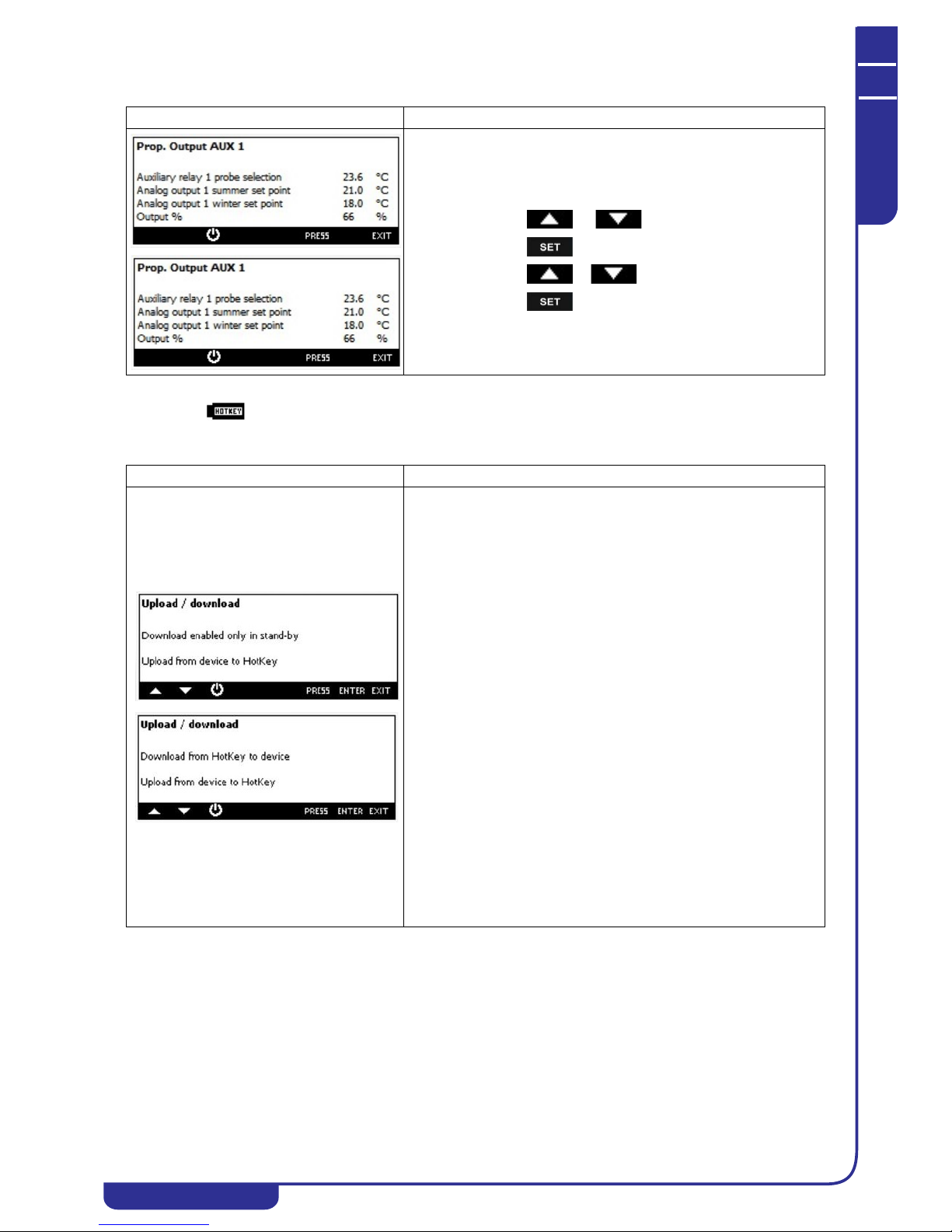

Propylene Glycol