Chillers and inverter air/water heat pumps

with axial fans

TECHNICAL MANUAL

NGSi 05÷15

38178800879

Original in

structions in Italian language

TECHNICAL MANUAL

Chillers and inverter air/water heat pumps with axial fans

38178800879

Ed.A

Any waste electrical and electronic equipment must not be disposed of with ordinary household waste; it must be dealt with in accordance with the

legal requirements for WEEE under European Directive 2002/96/EC and the subsequent amendments 2003/108/EC, requesting instructions from

the relevant Local Authority, or from the dealer if the product is replaced with another of the same type.

TECHNICAL MANUAL

- Contents

NGSi 05÷15

1

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

CONTENTS

CONTENTS...........................................................................................................................................................1

Chapter 1

PURPOSE AND CONTENTS OF THIS MANUAL .....................................................................................................4

1.1 Conserving the manual .................................................................................................................... 4

1.2 Symbols used in the manual ............................................................................................................ 4

Chapter 2

STANDARDS OF REFERENCE...............................................................................................................................4

Chapter 3

PERMITTED USE..................................................................................................................................................4

Chapter 4

GENERAL SAFETY REGULATIONS ......................................................................................................................5

4.1 Occupational health and safety........................................................................................................ 5

4.2 Personal protective equipment ........................................................................................................ 5

4.3 Safety signs...................................................................................................................................... 6

4.4 Refrigerants safety datasheet ........................................................................................................... 6

Chapter 5

TECHNICAL FEATURES.......................................................................................................................................7

5.1 Frame............................................................................................................................................... 7

5.2 Refrigerant circuit............................................................................................................................ 7

5.3 Compressors .................................................................................................................................... 7

5.4 Air side exchanger........................................................................................................................... 7

5.5 Fans ................................................................................................................................................. 7

5.6 User heat exchangers....................................................................................................................... 7

5.7 Control panel ................................................................................................................................... 8

5.8 Control system................................................................................................................................. 8

5.9 Monitoring and protection devices .................................................................................................. 8

5.10 Water circuit .................................................................................................................................... 8

5.11 Fan speed regulation........................................................................................................................ 8

Chapter 6

VERSIONS AVAILABLE ........................................................................................................................................ 8

6.1 Optional accessories ........................................................................................................................ 8

Chapter 7

INSTALLATION ....................................................................................................................................................8

7.1 General ............................................................................................................................................ 8

7.2 Lifting and handling ........................................................................................................................ 9

7.3 Positioning and spaces required for technical purposes ................................................................ 9

7.4 Water connections ........................................................................................................................... 9

7.4.1 Connecting to the condensate drain ............................................................... 10

7.4.2 Service tap ...................................................................................................... 10

7.4.3 System drainage ............................................................................................. 10

7.4.4 Water system diagram .................................................................................... 10

7.5 5-9 kW chiller diagram.................................................................................................................. 11

7.6 12-15 kW chiller diagram ............................................................................................................ 11

7.7 Electrical connections.................................................................................................................... 12

7.7.1 Connection terminal board ............................................................................ 12

Chapter 8

START-UP .......................................................................................................................................................... 14

Chapter 9

USER - CONTROL INTERFACE .........................................................................................................................14

9.1 Menu structure............................................................................................................................... 15

9.1.1 Analogue inputs menu .................................................................................... 15

9.2 Parameters category ...................................................................................................................... 16

9.3 Setpoints settable by the user ........................................................................................................ 16

9.4 Display........................................................................................................................................... 16

9.5 LEDs.............................................................................................................................................. 16

9.6 Modifying the dynamic setpoint.................................................................................................... 17

9.7 Modifying the setpoint from 0-10V input ..................................................................................... 17

TECHNICAL MANUAL

- Contents

NGSi 05÷15

2

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

9.8 Hydraulic pump operation .............................................................................................................18

9.8.1 Operation on call from temperature controller (Default) ..............................18

9.8.2 Operation on call from temperature controller with periodic activation .......19

9.8.3 Continuous operation .....................................................................................19

9.8.4 Pump proportional adjustment .......................................................................19

9.9 Heaters for antifreeze protection (if AK accessory is installed) ....................................................20

9.10 Remote on-off and remote summer-winter switching ...................................................................20

9.11 Remote water temperature probe ...................................................................................................20

9.12 Domestic hot water production enable ..........................................................................................20

9.12.1 Probe storage in heating mode ....................................................................... 21

9.12.2 Domestic hot water production call from digital input ..................................21

9.13 Domestic hot water accumulation in hot mode .............................................................................22

9.14 System backup heaters...................................................................................................................23

9.15 Systems backup heater in defrost mode.........................................................................................23

9.16 Domestic hot water backup heater .................................................................................................23

9.17 Backup heaters selection mode......................................................................................................23

9.18 Activation of backup and hot water tank heaters in joint operation mode/compressor replacement mode23

9.19 System season indication ...............................................................................................................30

9.20 Fan and dissipation control ............................................................................................................30

9.20.1 Ventilation control in chiller mode ................................................................. 30

9.20.2 Ventilation control in heating mode ...............................................................30

9.21 Defrost cycle ..................................................................................................................................31

9.22 Compressor crankcase heater.........................................................................................................31

9.23 Functions which can be enabled with Hi-T accessory...................................................................31

9.23.1 Screed function ...............................................................................................31

9.23.2 Disinfection (Legionella prevention) ..............................................................31

9.24 Handbook for installation configurations ......................................................................................31

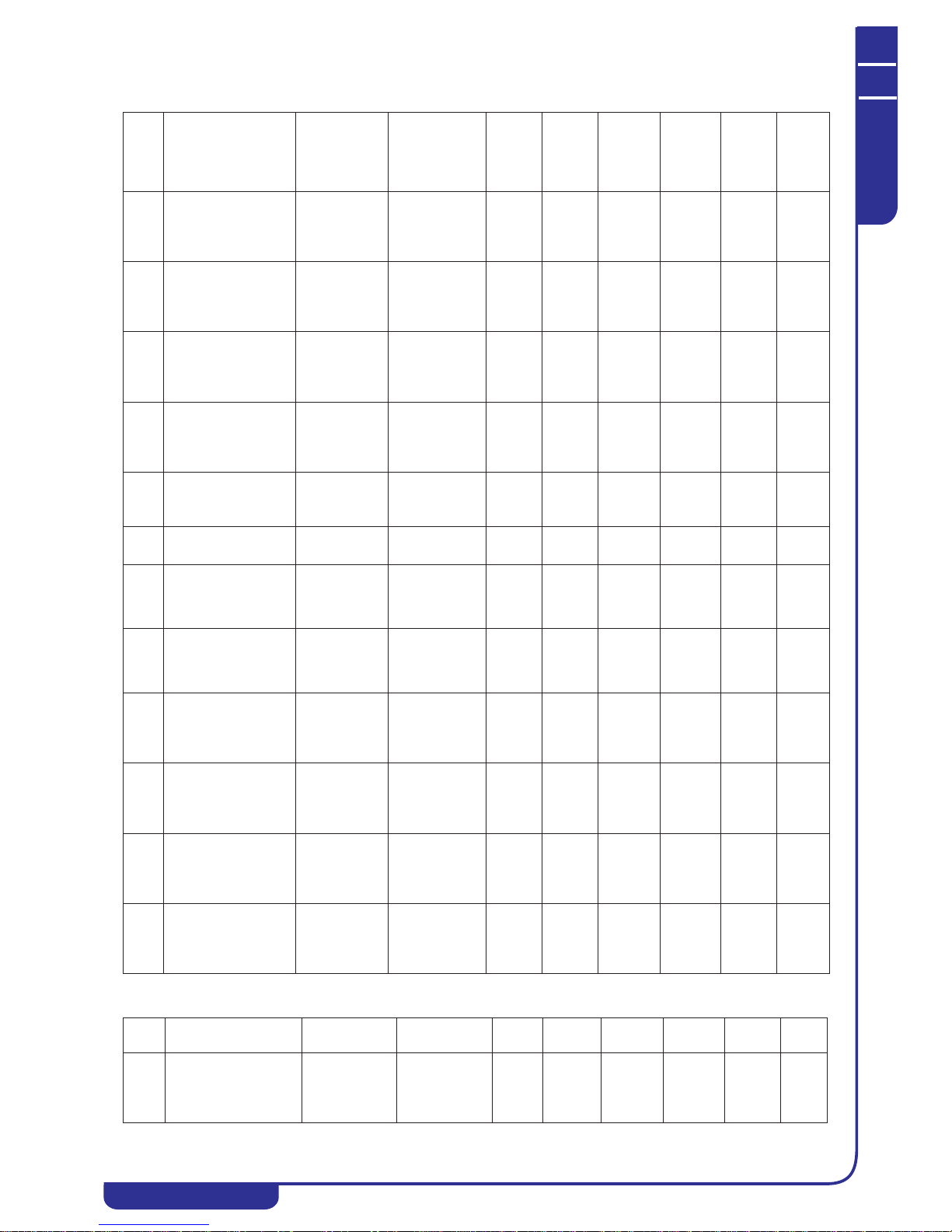

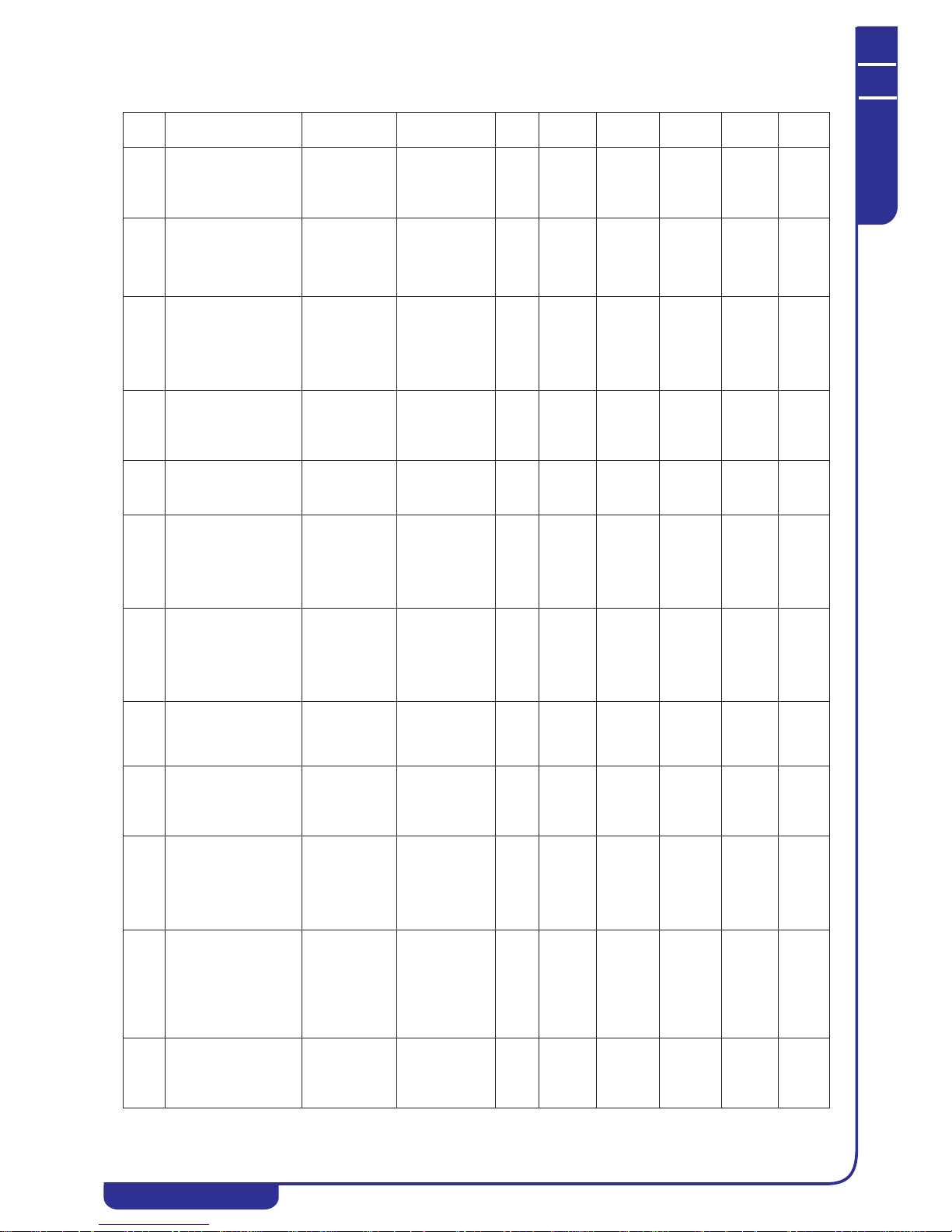

9.25 Tables of settings which can be made by the user and installer ....................................................31

9.26 Alarms............................................................................................................................................38

9.26.1 Flow switch E06 .............................................................................................. 38

9.26.2 High temperature E18 ....................................................................................38

9.26.3 Antifreeze E05 ................................................................................................. 38

9.26.4 Probe alarms ................................................................................................... 38

9.26.5 Inverter timeout E80 .......................................................................................38

9.26.6 Remote ON/OFF E00 ...................................................................................... 38

9.26.7 High pressure E01 .......................................................................................... 38

9.26.8 High pressure switch HP (in series with compressor delivery line probe) E64 38

9.26.9 Low pressure E02 ........................................................................................... 38

9.27 No voltage......................................................................................................................................38

9.28 User cutout alarm table ..................................................................................................................38

Chapter 10

LENGTH SHUT-DOWNS......................................................................................................................................39

Chapter 11

ROUTINE CHECKS AND MAINTENANCE............................................................................................................39

11.1 Environmental protection ..............................................................................................................40

Chapter 12

TAKING THE UNIT OUT OF SERVICE ................................................................................................................40

Chapter 13

TECHNICAL DATA .............................................................................................................................................40

Chapter 14

ELECTRICAL DATA OF UNIT AND CONTROL DEVICES.....................................................................................42

Chapter 15

HEAT PUMP WORKING HEADS..........................................................................................................................42

15.1 Mod. NGSi 05................................................................................................................................42

15.2 Mod. NGSi 07................................................................................................................................43

15.3 Mod. NGSi 10................................................................................................................................43

15.4 Mod. NGSi 15................................................................................................................................43

Chapter 16

OPERATING LIMITS...........................................................................................................................................44

16.1 Evaporator water flow rate ............................................................................................................44

16.2 Chilled water production (summer operation) ...............................................................................44

TECHNICAL MANUAL

- Contents

NGSi 05÷15

3

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

16.3 Hot water production (winter operation)....................................................................................... 44

16.4 Room air temperature and summary table .................................................................................... 44

Chapter 17

CORRECTION FACTORS FOR THE USE OF GLYCOL.........................................................................................45

Chapter 18

DIMENSIONS......................................................................................................................................................45

18.1 Mod. NGSi 05 ............................................................................................................................... 45

18.2 Mod. NGSi 07 ............................................................................................................................... 46

18.3 Mod. NGSi 10-15 .......................................................................................................................... 46

Chapter 19

ELECTRIC WIRING DIAGRAMS ......................................................................................................................... 47

19.1 Mod. NGSi 05-07 .......................................................................................................................... 47

19.2 Mod. NGSi 10 ............................................................................................................................... 48

19.3 Mod. NGSi 15 ............................................................................................................................... 49

Chapter 20

CRH REMOTE KEYPAD (OPTIONAL ACCESSORY)...........................................................................................50

20.1 Connecting the CRH keypad to the minichiller ............................................................................ 50

Chapter 21

DOUBLE SETPOINT KIT (OPTIONAL ACCESSORY) ...........................................................................................50

21.1 Scope and field of application ....................................................................................................... 50

21.2 Kit components and technical data................................................................................................ 51

21.3 Humidity switch mode operation .................................................................................................. 51

21.4 Minichiller settings........................................................................................................................ 52

21.5 Installation notes............................................................................................................................ 52

21.6 Settable setpoints ........................................................................................................................... 52

21.7 Switching functions ....................................................................................................................... 53

21.8 Electrical wiring diagram .............................................................................................................. 53

21.8.1 Wiring diagram, configuration without external relay .................................. 53

21.8.2 Wiring diagram, configuration with external relay ....................................... 54

21.9 Humidity switch connections ........................................................................................................ 54

21.10 Standard water system diagram..................................................................................................... 55

TECHNICAL MANUAL

Chapter 1 - Purpose and contents of this manual

NGSi 05÷15

4

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

CHAPTER 1

PURPOSE AND CONTENTS OF THIS MANUAL

The manual of NGSi units contains all the necessary information for optimal use of the equipment in conditions of safety for the

operator, as required by the Machinery Directive 2006/42/EC and subsequent amendments.

This manual is intended to provide the information required for the selection, installation, use and maintenance of NGSi units. The

instructions it contains are intended for the operator who uses the unit; even if he is not specifically skilled, the information he will find here

will enable him to use it effectively.

The manual describes the equipment at the time of sale and is therefore to be considered appropriate to it, notwithstanding any subsequent

technological improvements made by MTA to the capabilities, ergonomics, safety and functionality of its products.

MTA therefore does not accept any obligation to update the manuals of previous versions of its equipment.

Users are urged to comply strictly with the information in this manual, especially that relating to safety and routine maintenance.

1.1 Conserving the manual

The manual must always accompany the unit to which it refers. It must be kept in a safe place, protected from dust and damp and easily

accessible to the operator, who must consult it whenever he is in any doubt regarding the use of the equipment.

MTA reserves the right to modify the manual together with its products, without any obligation to update materials already delivered.

Disclaims any liability for any inaccuracies in the manual, if due to printing errors or copying errors.

Any updates sent to the customer must be kept attached to this manual.

MTA is at customers’ service for the provision of more detailed information the topics covered by this manual, or information concerning

the use and maintenance of its equipment, on request.

1.2 Symbols used in the manual

CHAPTER 2

STANDARDS OF REFERENCE

The equipment covered by MTA and its individual component units have been designed in accordance with the relevant harmonised EC

standards and the other European and domestic standards, applicable in accordance with the Machinery Directive issued by the Council of

the European Communities (2006/42/EC and subsequent amendments).

The following have also been complied with:

• EN ISO 12100 standard

• EN ISO 13857 standard

• UNI EN 378-1, 378-2, 378-3 and 378-4 standards

• UNI EN 12735-1 standard

• CEI EN 60204-1 standard

• EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3, EN 62233 standards

• Community Directives 97/23/EC, 2006/95/EC, 2004/108/EC, 2002/95/EC and 2002/96/EC

CHAPTER 3

PERMITTED USE

• The company excludes all contractual and extra-contractual liability for damage caused to persons, animals or things, by

incorrect installation, adjustment and maintenance, improper use or partial or superficial reading of the information

contained in this manual.

• These units have been designed for heating and/or cooling water. A different application, unless expressly authorized by the

manufacturer, is to be considered improper and therefore not permitted.

• The location, the water and electrical systems must be determined by the system designer and must take into account both

the purely technical needs as well as any applicable local legislation and specific authorizations.

• The execution of all work must be performed by qualified and experienced personnel, who knows the rules in force in

different countries.

Indicates operations dangerous for people and/or for the correct operation of the equipment.

Indicates operations which must not be carried out.

Indicates information with which the operator must comply to ensure that the equipment performs well in conditions of

safety.

TECHNICAL MANUAL

Chapter 4 - General safety regulations

NGSi 05÷15

5

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

CHAPTER 4

GENERAL SAFETY REGULATIONS

Before starting any type of procedure on the NGSi units, every operator must be perfectly familiar with operation of the equipment and its

controls and have read and understood all the information in this manual.

4.1 Occupational health and safety

It is reminded that the European Union has issued directives concerning the safety and health of workers, among which: 89/391/EEC,

89/686/EEC, 89/655/EEC, 86/188/EEC and 77/576/EEC that each employer has obligation to respect and enforce. Users are therefore

reminded that:

4.2 Personal protective equipment

During use and maintenance of NGSi units, personal protective equipment must be used, including:

The removal of and/or tampering with any safety device is strictly forbidden.

Children or unassisted disabled persons are not allowed to use the equipment.

Do not touch the equipment when barefoot or parts of the body are wet or damp.

Do not pull, detach or twist the electrical cables coming from the equipment, even if it is disconnected from the mains power

supply.

Do not stand with feet, sit and/or lean on any type of object on the equipment.

Do not spray or pour water directly on the equipment.

It is prohibited to dispose of, abandon or leave within reach of children packaging materials (cardboard, staples, plastic bags,

etc.) because it can be a potential source of danger.

All routine or unplanned maintenance operations must be carried out with the equipment at a standstill and disconnected

from the electricity supply.

Do not place hands or fit screwdrivers, spanners or other tools on moving parts.

The person in charge of the equipment and the maintenance operative must receive appropriate training and instruction to

enable them to perform their tasks in conditions of safety.

Operators must be familiar with personal protection equipment and the safety rules contained in national and international

laws and standards.

Tampering with or replacement of parts of the equipment not specifically authorised by the manufacturer is forbidden.

Procedures of this kind relieve the manufacturer of all liability under civil or criminal law.

The use of components, consumables or parts other than those recommended by the manufacture and/or specified in this

manual may be dangerous for operators and/or cause damage to the equipment.

The operator’s workstation must be kept clean and tidy and free of any objects which may restrict his freedom of movement.

The workplace must be suitably lit for the planned procedures. Insufficient or excessive lighting may be a source of risks.

Ensure that workplaces are well ventilated at all times and that extraction system are always in operation, in good condition

and compliant with the relevant legal requirements.

Clothing: Anyone performing maintenance on or using the system must wear clothing compliant with the relevant essential

safety requirements. He must also wear safety footwear with non-slip soles, especially in areas with slippery floors.

Gloves: Suitable protective gloves must be worn during cleaning and maintenance procedures.

TECHNICAL MANUAL

Chapter 4 - General safety regulations

NGSi 05÷15

6

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

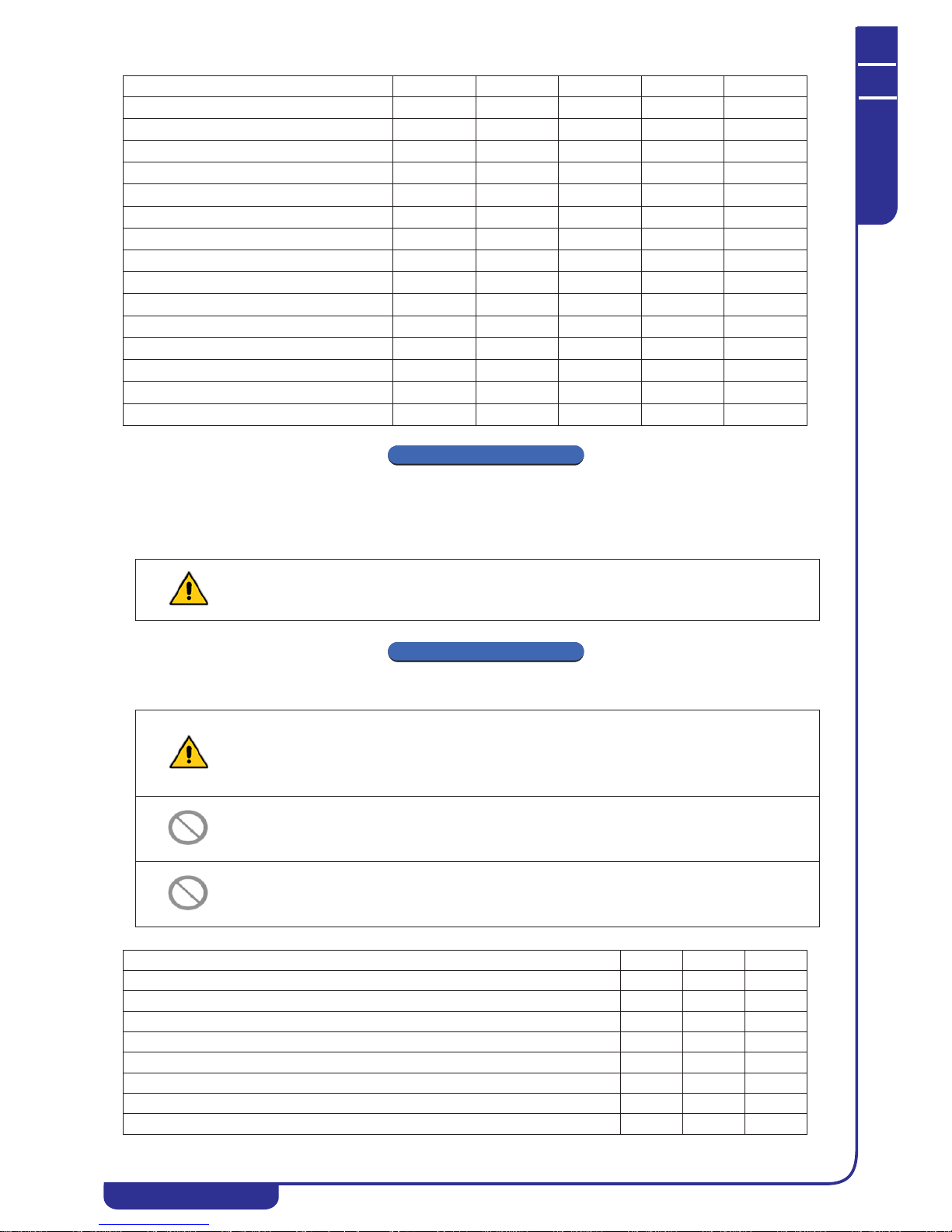

4.3 Safety signs

The unit carries the following safety signs, with which personnel must comply:

4.4 Refrigerants safety datasheet

Mask and goggles: A mask to protect the airways and protective goggles must be worn during cleaning operations.

General hazard.

Dangerous voltage.

Moving parts.

Surfaces which may cause injuries.

Denomination: R410A (50% Difluoromethane (R32); 50% Pentafluoroethane (R125).

INDICATION OF HAZARDS

Major hazards: Suffocation.

Specific hazards: Rapid evaporation can cause cold burns.

FIRST AID MEASURES

General information: Do not attempt to administer liquids or solids to persons who have lost consciousness.

Inhalation: Move victims to the open air.

Use oxygen or artificial respiration if necessary.

Do not administer adrenaline or similar substances.

Contact with the eyes: Wash thoroughly with plenty of clean water for at least 15 minutes and seek medical assistance.

Contact with the skin: Wash immediately in plenty of clean water.

Remove contaminated clothing immediately.

FIRE-FIGHTING MEASURES

Means of extinction: Any.

Specific hazards: Pressure rise.

Specific methods: Cool containers with water spray.

MEASURES IN THE EVENT OF ACCIDENTAL LEAKAGE

Individual precautions: Evacuate personnel to safe muster points.

Provide adequate ventilation.

Use personal protective equipment.

Environmental precautions: Evaporates.

Cleaning methods: Evaporates.

HANDLING AND STORAGE

Handling technical

measures/precautions:

Ensure the presence of sufficient ventilation and/or air extraction means in the workplace.

Recommendations for safe use: Do not breath fumes or aerosol.

Storage: Close hermetically and store in a cool, dry and well-ventilated place.

Store in its original containers. Incompatible products: explosive materials, inflammable materials,

organic peroxide.

CONTROL OF EXPOSURE/INDIVIDUAL PROTECTION

Control parameters: AEL (8-h and 12-h TWA) = 1000 ml/m3 for each of the two components.

Respiratory protection: For rescue and maintenance work in tanks, use autonomous breathing apparatus.

The vapours are heavier than air and can cause suffocation, reducing the oxygen available for breathing.

Protection of the eyes: Safety spectacles.

Protection of the hands: Rubber gloves.

Hygiene measures: Do not smoke.

TECHNICAL MANUAL

Chapter 5 - Technical features

NGSi 05÷15

7

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

CHAPTER 5

TECHNICAL FEATURES

NGSi series water chillers and heat pumps are designed for residential and commercial applications. They are extremely versatile and when

operating in heat pump mode they are able to produce hot water at a temperature of 55°C for environmental heating and domestic use. The

brushless INVERTER compressor, combined with an electronic expansion valve, pump and variable speed fan, optimises the power

consumption and operating efficiency of the refrigerating components.

5.1 Frame

All NGSi units are in hot-galvanised sheet metal, painted with polyurethane powder enamels baked at 180°C to ensure the best resistance to

atmospheric agents. The frame is free-standing with removable panels for easier inspection and maintenance of the internal components. All

screws and rivets for outdoor installations are in galvanised steel.

5.2 Refrigerant circuit

The refrigerant circuit has been manufactured with components supplied by top international producers and in accordance with the UNI EN

13134 standard on braze-welding procedures. The refrigerant gas used is R410A. The refrigerant circuit includes: 4-way reverse cycle valve,

electronic expansion valve, liquid separator (07, 10 and 15 models), liquid receiver, inspection valves for maintenance and checks, PED

standard safety device (high pressure pressure switch), pressure transducers for accurate control of evaporating and condensing pressures and

filters to prevent fouling of the thermal expansion valve.

5.3 Compressors

The DC inverter compressors are of rotary hermetic (05 and 07 models), twin rotary (10 model) and scroll (15 model) types, specifically

designed for use with R410A refrigerant; they are all equipped with thermal overload protection and mounted on rubber dampers.

The compressors are installed in a separate chamber, out of the air stream, to reduce noise.

The crankcase heater is powered up when the compressor is off by at least 30 minutes and if the discharge temperature is below 20°C (with

hysteresis of 2.0°C). The crankcase heater is disabled when the compressor restarts. It is recommend to plug the unit in and put it on standby at least 6 hours before it starts operation.

Compressors can be inspected through the front panel, which allows maintenance to be performed even with the unit in operation.

5.4 Air side exchanger

The air side heat exchangers are constructed with copper tubes and aluminium fins. The copper tubes have a diameter of 7 mm in the 05 and

07 models and 5/16” in the 10 and 15 models; the aluminium fins are 0.1 mm thick. The tubes are mechanically expanded into the aluminium

fins to improve the heat exchange factor. The geometry of these exchangers guarantees low air side pressure drop, meaning that fans

operating at low rpm can be used (reducing the unit’s noise level).

5.5 Fans

The unit is fitted with plastic axial fans with aerofoil blades. They are all statically and dynamically balanced and supplied complete with

safety grille as required by the EN 60335 standard (safety of household and similar electrical appliances). The fans are installed on the unit

on rubber dampers to reduce the noise level. All electric motors used are of 8 pole modulating brushless type (200/1000 rpm). The motors are

directly coupled and equipped with integral thermal overload protection. Motors all have IP X4 protection rating.

5.6 User heat exchangers

The user heat exchangers are of braze-welded plate type and are in AISI 316 stainless steel, insulated with closed-cell material in the factory;

they can be equipped with antifreeze heaters (AK optional accessory). Each evaporator is protected by an antifreeze protection temperature

probe, which starts up the water circulator, even with the unit switched off, if the conditions set on the control unit occur.

PHYSICAL AND CHEMICAL PROPERTIES

Colour: Colourless.

Odour: Slight.

Boiling point: -52.8°C at atmospheric pressure.

Flash point: Non-flammable.

Relative density: 1.08 kg/l at 25°C.

Solubility in water: Negligible.

STABILITY AND REACTIVITY

Stability: No reactivity if used in compliance with the relative instructions.

Materials to avoid: Strong oxidants. Incompatible with magnesium, zinc, sodium, potassium and aluminium.

The incompatibility becomes more serious if the metal is in powder form or if the surfaces have recently

not been protected.

Hazardous decomposition

products:

These products are halogen compounds, hydrofluoric acid, carbon oxides (CO, CO2) and carbonyl

halides.

TOXICOLOGICAL INFORMATION

Acute toxicity: (R32) LC50/inhalation/4 hours/lab.rats >760 mg/l

(R125) LC50/inhalation/4 hours/lab.rats >3480 mg/l

Local effects: Concentrations significantly above the TLV can cause narcotic effects.

Inhalation of products in decomposition can lead to respiratory difficulty (pulmonary oedema).

Long-term toxicity: No carcinogenic, teratogenic, or mutagenic effects observed in laboratory animals.

ECOLOGICAL INFORMATION

Global warming potential GWP

(R11=1):

1.730

Ozone depletion potential ODP

(R11=1):

0

Considerations on disposal: usable with reconditioning.

TECHNICAL MANUAL

Chapter 6 - Versions available

NGSi 05÷15

8

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

5.7 Control panel

The control panel is constructed in compliance with the relevant European standards. The panel is accessed by removing the front and side

panels and top of the unit with the aid of a suitable tool. The panel control protection rating is IP24. The panel also comprises a terminal

board with clean contacts for remote ON-OFF switching, summer/winter switching, the auxiliary heater, the domestic hot water sensor,

control of a remote 3-way valve and contacts for the remote control panel and double set point operation.

5.8 Control system

All NGSi units are equipped with a microprocessor with overheating control by means of the electronic thermostatic valve operated in

response to the signals sent by the pressure transducers. The CPU also controls the water temperature setting, antifreeze protection,

compressor timing, alarm reset, alarm control and operating LEDs. On request, the microprocessors can be connected to BMS remote control

systems and the simpler HNS system with our terminals. The control system, combined with the use of INVERTERS and the on-board

sensors, monitors performance of the inverter compressor, circulator and fan (2 fans in 10 and 15 models) and adapts its constantly and

swiftly as required.

The INVERTER system reduces the system’s minimum water content from the conventional 12-15 litres/kW of chilling power to the

ABSOLUTE figures of 18 litres for the 05, 25 litres for the 07, 35 litres for the 10 and 45 litres for the 15 model in the NGSi series.

Thanks to these exceptionally low water contents, NGSI series units are suitable for systems without water tanks, with obvious

benefits in terms of reduction in unit size, installation space requirements, heat loss and system installation and maintenance costs.

5.9 Monitoring and protection devices

All units are supplied as standard with the following monitoring and protection devices: return water temperature probe on the system water

return line,

operating and antifreeze probe on the pipe delivering water to the system, high pressure transducer, low pressure

transducer, compressor inlet and outlet temperature probes, compressor thermal protection devices, fan thermal protection devices, water

side flow switch to protect the evaporator and high pressure switch.

5.10 Water circuit

NGSi chiller units have an integral water circuit including the circulator pump, suitable for the use of chilled water and directly controlled by

the unit’s own control unit. The circulator, always of modulating type, has an induction motor. The water circuit also includes the expansion

vessel, the safety valve (6 bar) and the automatic air bleeder valve.

5.11 Fan speed regulation

The fan speed is controlled by the microprocessor in order to optimise the evaporation/condensation pressure for summer/winter operation,

to enable the unit to operate correctly.

CHAPTER 6

VERSIONS AVAILABLE

NGSi - reversible heat pump with integrated hydronic system (expansion vessel, safety valve, pressure gauge, modulating circulator pump,

flow switch, automatic air bleeder valve. intake/discharge valve).

Models available: 05, 07, 10 and 15.

6.1 Optional accessories

Hi-T - Multi-function touch screen remote control that integrates the centralized management of the minichiller and of the HNS system, the

functions of USB port, humidity and temperature sensors. It is also equipped with an extremely intuitive interface that simplifies the use of

the control.

CRH - Remote control panel for installation in the room for remote control of the unit, with extra functions in addition to those provided on

the unit, also able to control our hydronic terminals.

AG - Rubber dampers for installation underneath the unit to cushion any vibrations.

AK - Antifreeze kit (this accessory must be installed in the factory and must be specified when ordering). It comprises a heating cable wound

around the base of the unit near to the condensation coil and a Mylar heating element on the faces of the plate heat exchanger.

KDS - Double setpoint kit (already integrated in the Hi-T) for the management of a second working setpoint on the system side.

CHAPTER 7

INSTALLATION

7.1 General

When installing or servicing the unit, staff must comply strictly with the instructions provided in this manual and those on the unit itself, and

always take all necessary precautions. Failure to follow instructions may be dangerous.

MTA must be notified of the damage within 8 days. The Customer must draw up a written report in the event of significant damage.

WARNING:

The INVERTER control system is able to manage minimum system water contents of 18 litres for the 05 model, 25 litres for

the 07 model, 35 litres for the 10 model and 45 litres for the 15 model. These figures in litres are absolute values, and not values

per kW of rated power.

WARNING:

All the operations described below must only be performed by QUALIFIED STAFF. Before doing any work on the unit,

make sure that the electricity supply is disconnected.

On receipt of the unit, inspect it for damage: it left the factory in perfect condition. Any damage must be reported to the

forwarder at once and noted on the Delivery Sheet before it is signed.

TECHNICAL MANUAL

Chapter 7 - Installation

NGSi 05÷15

9

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

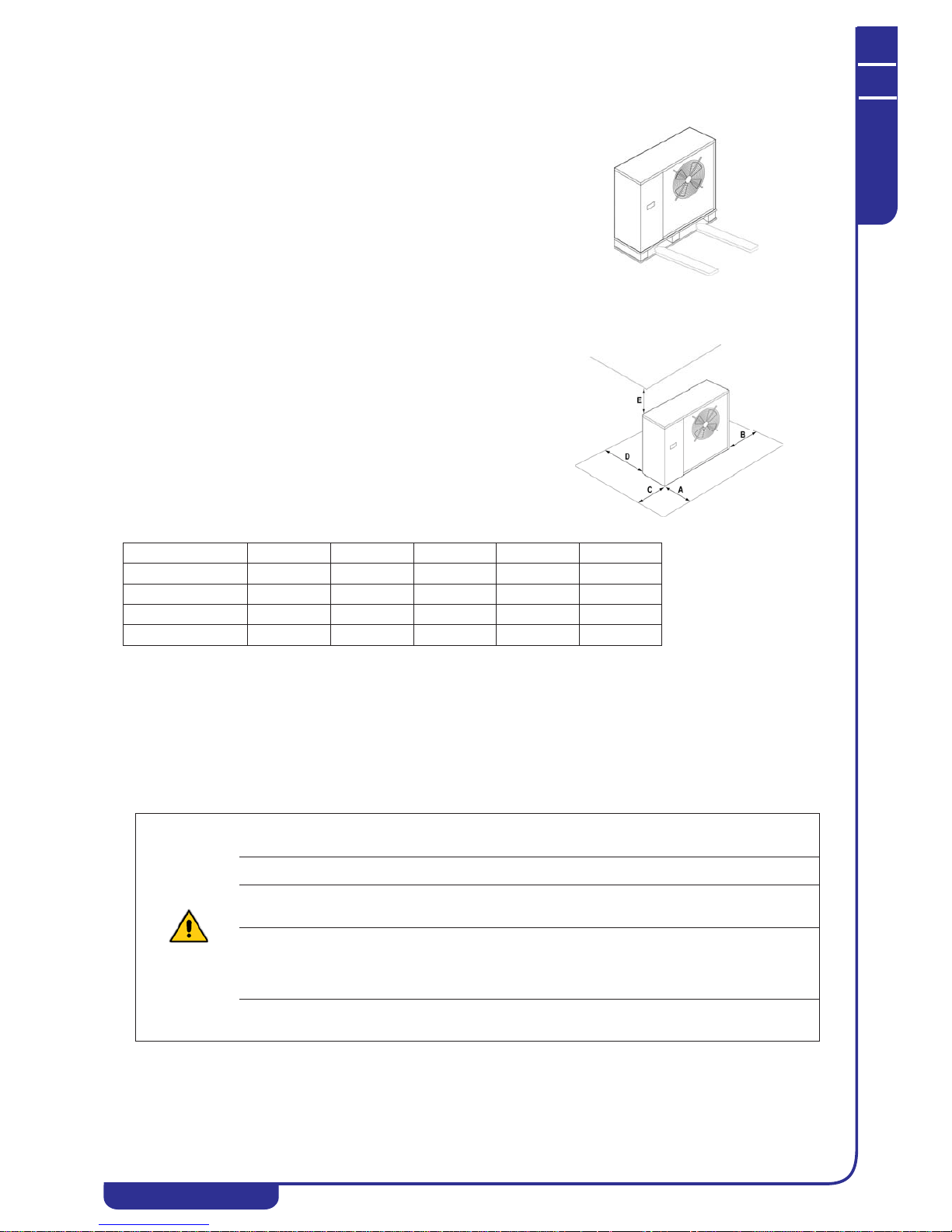

7.2 Lifting and handling

7.3 Positioning and spaces required for technical purposes

* Recommended installation and maintenance space

** Recommended servicing and maintenance space

7.4 Water connections

The water connections must be made in accordance with national or local regulations; the pipelines may be in steel, galvanised steel or PVC.

The size of the pipelines must be carefully calculated for the unit’s rated flow rate and the pressure drops in the water circuit. All water

connections must be insulated with closed cell material of suitable thickness. The chiller must be connected to the pipeline by means of

flexible couplings. The following components should be installed in the water circuit:

• Well thermometer for measuring the temperature in the circuit.

• Manual gate valves for shutting off the chiller from the water circuit.

• Y-shaped metal filter (on the system return line) with metal mesh of no more than 1 mm.

• Loading assembly and discharge valve where necessary.

When unloading and positioning the unit, the greatest care must be taken to

avoid sharp or violent movements, to protect the internal components. Units can

be lifted with the aid of a forklift truck, or with slings, taking care not to damage

the side and top panels. The unit must always be kept horizontal during these

operations.

All NGSi series models are designed and built for outdoor installation; they

should therefore never be covered with canopy roofs or placed close to trees or

walls to ensure that air is not recycled through them. A plinth of suitable size for

the unit should be provided. Units transmit only a low level of vibration to the

ground, but vibration damping supports should be placed between the base frame

and the supporting surface. It is also important to avoid problems of recirculation

of air between the intake and delivery sides to avoid impairment of the unit’s

performance or even a shut-down of normal operation. To ensure this, the

minimum operating spaces detailed below must be left.

MOD. A B* C D E**

NGSi 05 1,500 500 400 400 500

NGSi 07 1,500 500 400 400 500

NGSi 10 1,500 500 400 400 500

NGSi 15 1,500 500 400 400 500

WARNING:

when deciding pipeline sizes, take care not to exceed the maximum system side pressure drop shown in the technical data

table in Section

“Technical data” (see working head values).

WARNING:

Connect the pipes to the connections using always the double key system.

WARNING:

The system return pipeline must be connected to the point marked “WATER INTAKE”; otherwise, the evaporator might

freeze.

WARNING:

A metal filter with (mesh of no more than 1 mm) must be installed on the system return pipeline labelled “WATER

INTAKE”. If the flow switch is tampered with or modified, or if the metal mesh filter is not installed on the system, all

warranty cover is forfeited at once. The filter must be kept clean, so the user must check after installation that it is still clean,

and then inspect it regularly.

All units leave the factory complete with flow switch (mounted in the factory). If the flow switch is modified or removed, or if

the water filter is not fitted in the unit, the warranty will lose all validity. Refer to the wiring diagram provided with the unit

for connection of the flow switch.

TECHNICAL MANUAL

Chapter 7 - Installation

NGSi 05÷15

10

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

7.4.1 Connecting to the condensate drain

All NGSi units are built so that the base of the unit acts as a condensate collection basin. A plastic union is supplied as standard for

connection to the fitting provided underneath the base, to allow connection of a pipe to drain off the condensate.

The base of the hydronic kit of each unit (on the right-hand side panels) of each unit also has a hole to allow drainage of any condensate

which may percolate from the water system pipes. Since these pipes are well insulated, the amount of condensate produced is minimal, and

therefore the connection of a drain pipe to this hole is not essential.

7.4.2 Service tap

If it becomes necessary to top up the system or adapt the glycol concentration, it is possible to use the service valve. Unscrew the cap of the

service tap and connect a hose connection to the 14 mm (inner diameter) hose connected to the water network, and then load the system by

unscrewing the ring nut. After the operation, re-tighten the nut and screw on the cap. It is in any case recommendable for loading the system,

to use an external tap whose prearrangement is made by the installer.

7.4.3 System drainage

If it is necessary to fully discharge the unit, first close the inlet and outlet manual gate valves (not supplied) and then remove the tubes

arranged externally on the water inlet and outlet so as to drain the liquid contained in the unit (to make this operation easy, it is

recommended to externally install on the water input and output two drain valves interposed between the unit and the manual gate valves).

7.4.4 Water system diagram

Condensate drain union Union connected to the unit Condensate drain union fitting

KEY

A Plate heat exchanger

B Flow switch

CService tap

D Circulator pump

E Expansion vessel

F Air bleed valve

G Safety valve

H Pressure gauge

Ring nut

Cap with gasket

A

B

H

G

F

E

D

C

TECHNICAL MANUAL

Chapter 7 - Installation

NGSi 05÷15

11

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

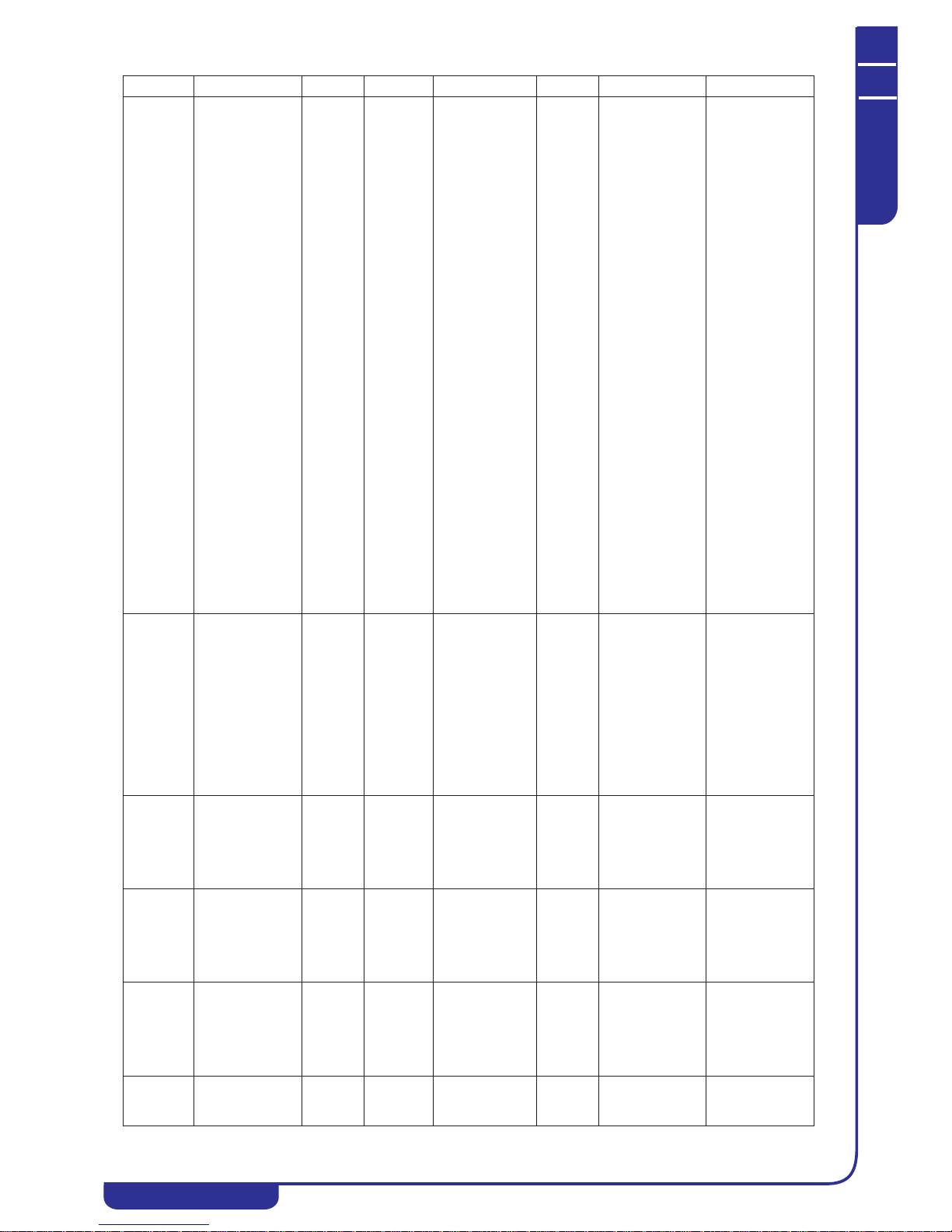

7.5 5-9 kW chiller diagram

7.6 12-15 kW chiller diagram

C Compressor

CLS Compressor liquid separator

ST Compressor intake temperature

DT Compressor outlet temperature

HP High pressure transducer

Pr High pressure switch

LP Low pressure transducer

LS Liquid separator (on 07, 10 and 15 models only)

4WV Cycle reverser valve

LR Liquid receiver

EEV Electronic expansion valve

FL Filter

M Axial fan

SE External air temperature

P Circulator installed on unit

IN Water intake temperature

OUT Water outlet temperature

C Compressor

CLS Compressor liquid separator

OS Oil separator (on 10 and 15 models only)

ST Compressor intake temperature

DT Compressor outlet temperature

HP High pressure transducer

Pr High pressure switch

LP Low pressure transducer

LS Liquid separator (on 07, 10 and 15 models only)

4WV Cycle reverser valve

LR Liquid receiver

EEV Electronic expansion valve

NRV Check valve (may be fitted on some models)

FL Filter

M Axial fan

SE External air temperature

P Circulator installed on unit

IN Water intake temperature

OUT Water outlet temperature

CP Capillary

WARNING:

The unit must be installed in a manner which allows maintenance and repairs. The warranty does not cover costs of the

platforms or handling equipment required for any work on the unit.

All maintenance and inspection procedures must only be performed by QUALIFIED STAFF.

Before doing any work on the unit, make sure that the electricity supply is disconnected.

WARNING:

The unit contains several moving components. Take great care when working in their vicinity, even if the electricity supply is

disconnected.

The compressor heads and delivery pipeline are often at quite high temperatures. Take special care when working in the

vicinity of the heat exchanger coils.

The aluminium fans are particularly sharp and may cause serious injuries.

SE

EEV

LR

IN

OUT

4WV

DT

LP

HP

ST

M

P

C

LS

OS

FL FL

NRV

CP

CLS

Pr

TECHNICAL MANUAL

Chapter 7 - Installation

NGSi 05÷15

12

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

7.7 Electrical connections

Check that the electricity supply corresponds to the unit’s rated data (voltage, phases and frequency) marked on the nameplate on its righthand panel. The electrical connection must be made in accordance with the wiring diagram supplied with the unit and with the local and

international regulations (provide a magneto-thermal master switch, differential security breakers for each line, suitable ground connection

for the system, etc.). The power supply cables, electrical protection devices and line fuses must be of the size stated in the unit’s wiring

diagram and in the electrical data in the technical specification table (see Section

“Technical data”).

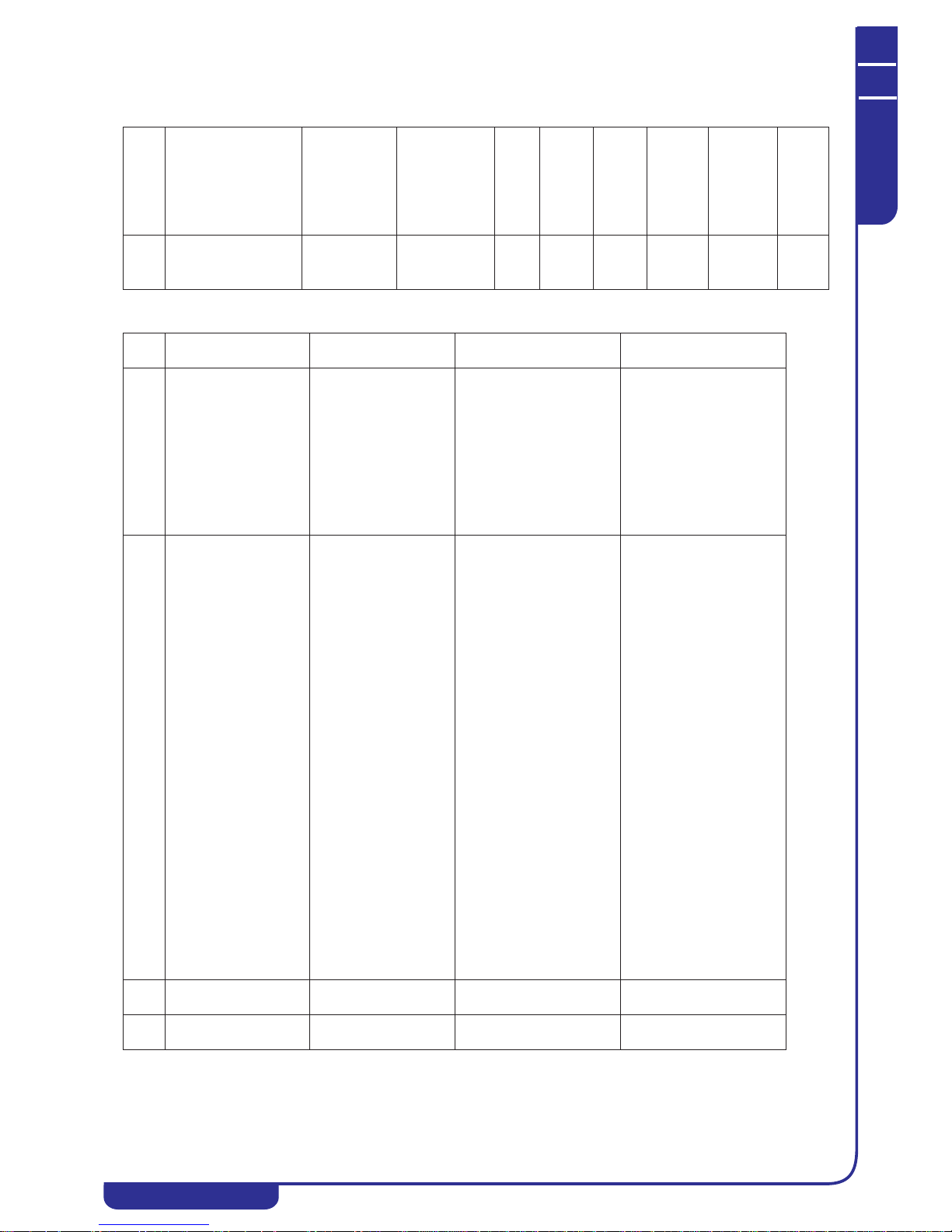

7.7.1 Connection terminal board

The electrical connections must be made by qualified staff. The connection terminal board underneath the plastic cover on the same side

as the water connections (for the 10 and 15 models, the protective casing must be removed). When connecting the terminal board, comply

with the instructions provided below (the drawing is guideline).

The connections described below are standard. Other connections are described in the table in Point 9.25.

After maintenance procedures, put the panels back in place, securing them with the fixing screws.

WARNING:

There must be no variations in the power supply voltage in excess of ±10% of the nominal value. If this tolerance is not

complied with, please contact our technical department.

WARNING:

The electricity supply must comply with the stated limits: otherwise, the warranty becomes null and void immediately. Before

starting any work on the unit, make sure that the electricity supply is disconnected.

WARNING:

The flow switch (B in the water system diagram above and installed in the factory) must ALWAYS be connected as stated in

the wiring diagram. Never bridge the flow switch connections on the terminal board. No warranty cover will be provided if

the flow switch connections have been modified or incorrectly connected.

WARNING:

The remote control panel is connected to the chiller by 4 cables with gauge 1.5 mm

2

. The power supply cables must be

separate from the remote control cables. Maximum distance 50 metres.

WARNING:

The remote control panel cannot be installed in an area with strong vibrations, corrosive gases, excess dirt or high humidity

levels. Leave the area close to the cooling system unobstructed.

The connections to the terminal board must only be made by qualified staff.

Terminal Type Connection

GND power supply

1-Ph/N/PE

230V, 50Hz

(3-Ph/N/PE

400 Vac, 50Hz in the 15kW size)

connect the ground cable

N1 power supply

1-Ph/N/PE

230V, 50Hz

(3-Ph/N/PE

400 Vac, 50Hz in the 15kW size)

connect the mains neutral cable

L1 power supply

1-Ph/N/PE

230V, 50Hz

(3-Ph/N/PE

400 Vac, 50Hz in the 15kW size)

connect the mains live cable (in three-phase versions, there

are two additional terminals, L2 and L3).

TECHNICAL MANUAL

Chapter 7 - Installation

NGSi 05÷15

13

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

NC1 digital output

230 Vac with exchange contact

NC terminal for supply of power (230V AC) to 3-way valve

for domestic hot water heater (only used for 3-way valves

with 3-point power supply, for switching to system side)

(for other configurations see Point 9.25)

N digital output

230 Vac with exchange contact

neutral terminal for supply of power (230V AC) to 3-way

valve for domestic hot water heater (for other

configurations see Point 9.25)

NO1 digital output

230 Vac with exchange contact

NO terminal for supply of power (230V AC) to 3-way valve

for domestic hot water heater (for switching the valve to the

heater side) (for other configurations see Paragraph 9.25)

NC2 digital output

230 Vac with exchange contact

NC terminal for supply of power (230V, 50Hz, 5A resistive

load, 1 A inductive load) to 3-way valve for double setpoint

for radiators (optional to be used only on series V2, see

Point

“Double setpoint kit (optional accessory)”) (for

other configurations see Point 9.25)

N2 digital output

230 Vac with exchange contact

neutral terminal for supply of power (230V AC) to 3-way

valve for double setpoint for radiators (optional to be used

only on series V2, see Point

“Double setpoint kit (optional

accessory)”

) (for other configurations see Point 9.25)

NO2 digital output

230 Vac with exchange contact

NO terminal for supply of power (230V, 50Hz, 5A resistive

load, 1 A inductive load) to 3-way valve for double setpoint

for radiators (optional to be used only on series V2, see

Point

“Double setpoint kit (optional accessory)”) (for

other configurations see Point 9.25)

R+ serial communication connection of modbus + signal for remote keypad

R-

serial communication connection of modbus - signal for remote keypad

GNDR serial communication modbus for remote keypad ground reference connection

12V+ power supply output 12Vac, 50Hz remote keypad power supply output (12V, 50Hz, 500mA)

12V- power supply output 12Vac, 50Hz remote keypad power supply output (12V, 50Hz, 500mA)

SE analogue (ST8) / digital (DI7) input input for humidity switch for double setpoint control

(optional) (for other configurations see Point 9.25)

SE analogue (ST8) / digital (DI7) input input for humidity switch for double setpoint control

(optional) (for other configurations see Point 9.25)

AEHN digital output (DO3) 230Vac neutral output for backup heater for domestic hot water

(230V, 50Hz, 5A) (for other configurations see Point 9.25)

AEH digital output (DO3) 230 Vac phase output for backup heater for domestic hot water

(230V, 50Hz, 5A) (per for other configurations see Point

9.25)

SAN analogue input (ST9) / digital (DI8) input for domestic hot water heater probe (for other

configurations see Point 9.25)

SAN analogue input (ST9) / digital (DI8) input for domestic hot water heater probe (for other

configurations see Point 9.25)

DO5N digital output (DO5) 230 Vac neutral output (optional to be used only if the machine has

not the antifreeze kit “AK” included) (for other possible

configurations see Point 9.25)

DO5 digital output (DO5) 230 Vac phase output (optional to be used only if the machine has

not the antifreeze kit “AK” included) (for other possible

configurations see Point 9.25)

DO4N digital output (DO4) 230 Vac neutral output (230V, 50Hz, 5A resistive load,

1 A inductive load) (optional to be used only if the machine

has not the antifreeze kit “AK” included) (for other possible

configurations see Point 9.25)

DO4 digital output (DO4) 230 Vac phase output (230V, 50Hz, 5A resistive load, 1 A inductive

load) (optional to be used only if the machine has not the

antifreeze kit “AK” included) (for other possible

configurations see Point 9.25)

SW digital input input for remote summer/winter mode switching (closed=

summer mode / open= winter mode)

SW digital input input for remote summer/winter mode switching (closed=

summer mode / open= winter mode)

onoff digital input remote on/off input (closed=unit on / open=unit off)

Terminal Type Connection

TECHNICAL MANUAL

Chapter 8 - Start-up

NGSi 05÷15

14

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

CHAPTER 8

START-UP

Before start-up:

• Check that system diagrams and manuals for the unit installed are available.

• Check that electrical and water system diagrams of the system to which the unit is connected are available.

• Check that the water circuit stop taps are turned on.

• Check that the water system has been filled and pressurised and the air has been vented.

• Check that all the water system connections have been made correctly and all the instructions on the decals have been

followed.

• Check that arrangements have been made for the drainage of condensate.

• Check the electrical connection and that all the terminals are secure.

• Check that the electrical connections have been made in accordance with the relevant standards, including the ground

connection.

• The voltage must be as stated on the unit nameplate.

• Check that the power supply voltage is within the tolerance limits (±10%).

• Check that the compressor heaters are receiving power correctly.

• Check that there are no gas leaks.

• Before switching on the system, check that all the enclosing panels are in place and secured with the screws provided.

CHAPTER 9

USER - CONTROL INTERFACE

onoff digital input remote on/off input (closed=unit on / open=unit off)

0-10V+ analogue input (ST10) 0-10V (+) signal input for setpoint modification

0-10V- analogue input (ST10) 0-10V (-) signal input for setpoint modification

WARNING:

The unit must be connected to the electrical mains and set in STANDBY mode (powered up) by turning on the master switch

at least 12 hours before start-up, to allow the heater to warm up the compressor crankcase as required (the heaters are

automatically powered up when the master switch is on). The heaters are operating correctly if the compressor crankcase

temperature has risen to 10÷15°C above room temperature within a few minutes.

WARNING:

Never stop the unit temporarily by turning off the master switch; this must only be done to disconnect the unit from the power

supply for lengthy stoppages (e.g. seasonal lay-offs, etc.). When the power supply is disconnected the crankcase heaters no

longer receive power, leading to the risk of a compressor breakdown when the unit is started up.

WARNING:

Do not modify the electrical connections to the unit; otherwise, warranty cover is forfeited at once.

WARNING:

Summer/winter operating mode must be selected at the start of the relative season. Frequent switching back and forth

between these modes is not recommended, as it may damage the compressors.

WARNING:

When the unit is installed and commissioned, check that it operates correct in both heating and cooling modes.

Selects the operating mode and resets alarms which can be rearmed manually. The sequence at consecutive

pressures on the key is:

off Æ cool ÆheatÆ off

If domestic hot water is enabled, the sequence is:

offÆ cool Æ cool+san Æ heat Æheat+sanÆ off

During parameter setting, it moves BACK one level.

Accesses the parameter setting menu, allowing setting of the summer, winter and domestic hot water setpoints.

Terminal Type Connection

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

15

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

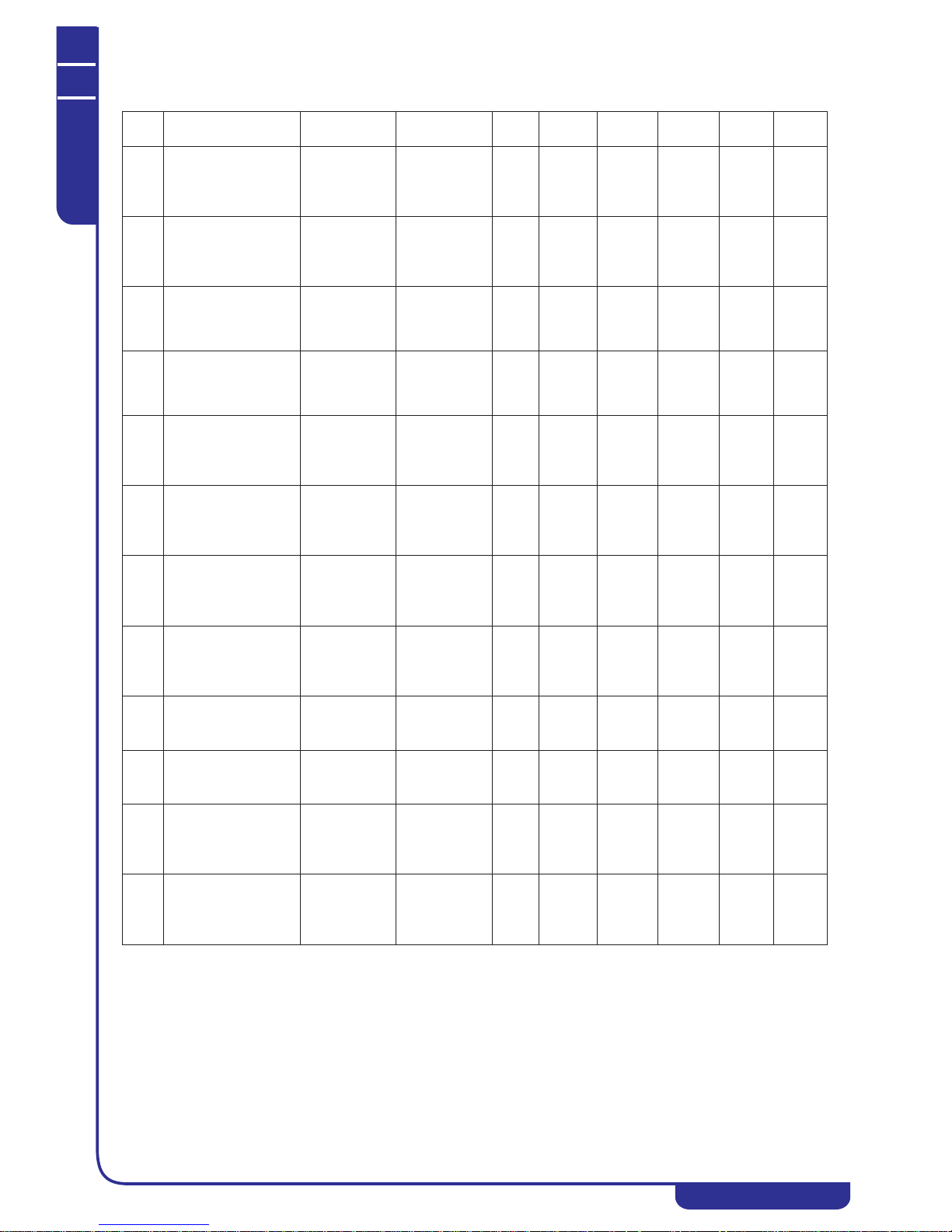

9.1 Menu structure

Level 0 (U) = always visible

Level 1 (M) = visible if the maintenance password (H80) or the manufacturer password is entered

Level 2 (C) = visible only if the manufacturer password is entered

Level 3 (A)= visible only through Modbus

9.1.1 Analogue inputs menu

Entering the maintenance password in the analogue inputs menu “tP” at level 1 of the menu structure of the control installed on the unit, it is

possible to read the values of the probes:

t01: water intake temperature (°C);

t02: water outlet temperature (°C);

t03: compressor intake temperature (°C);

t04: compressor outlet temperature (°C);

t05: high pressure (bar);

t06: low pressure (bar);

t07: outdoor air temperature (°C);

t09: domestic hot water temperature (°C) (if domestic hot water production is enabled).

UP key. In parameter setting mode, used to move to a higher level menu or to increase the value of a parameter

when in “modify” mode.

DOWN key. In parameter setting mode, used to move to a lower level menu or to decrease the value of a

parameter when in “modify” mode.

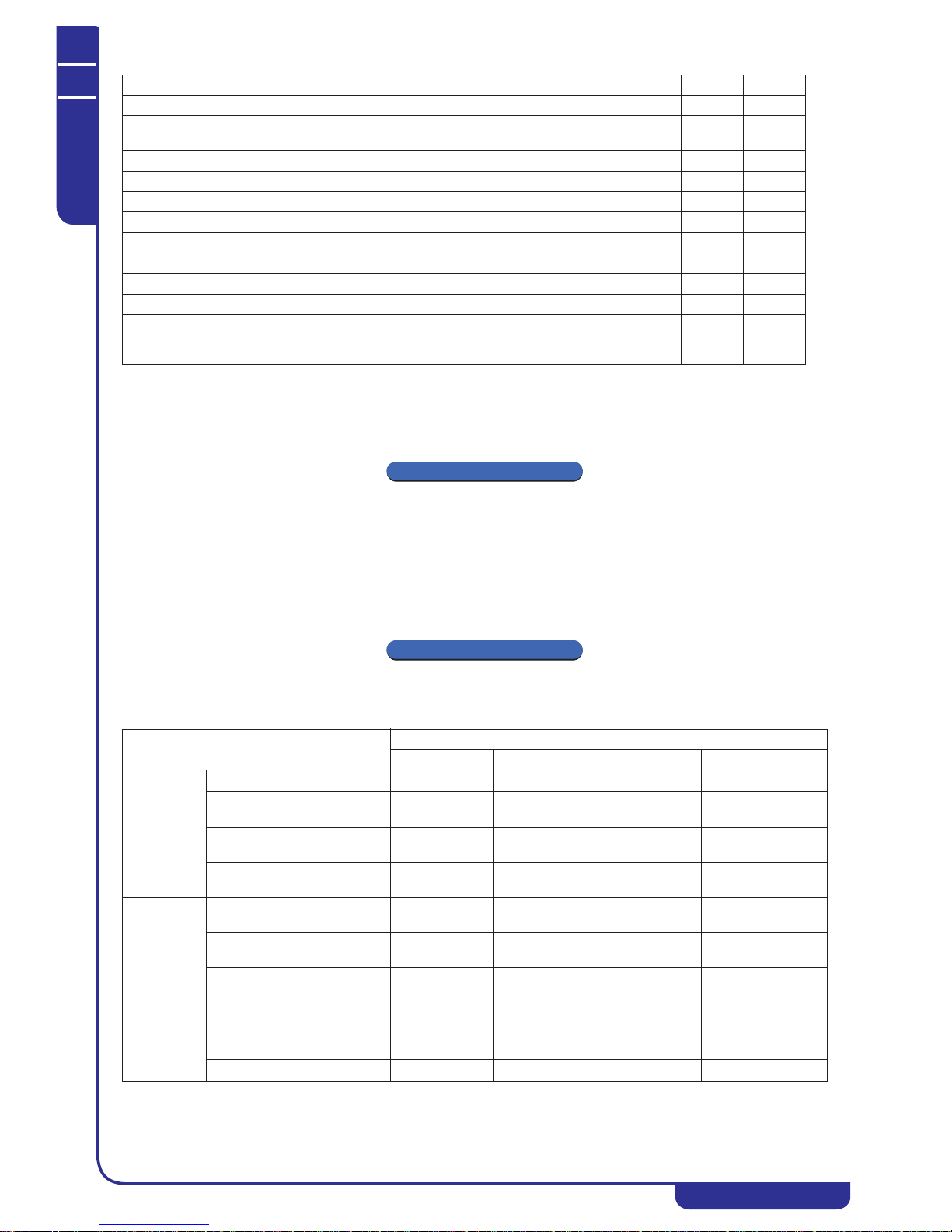

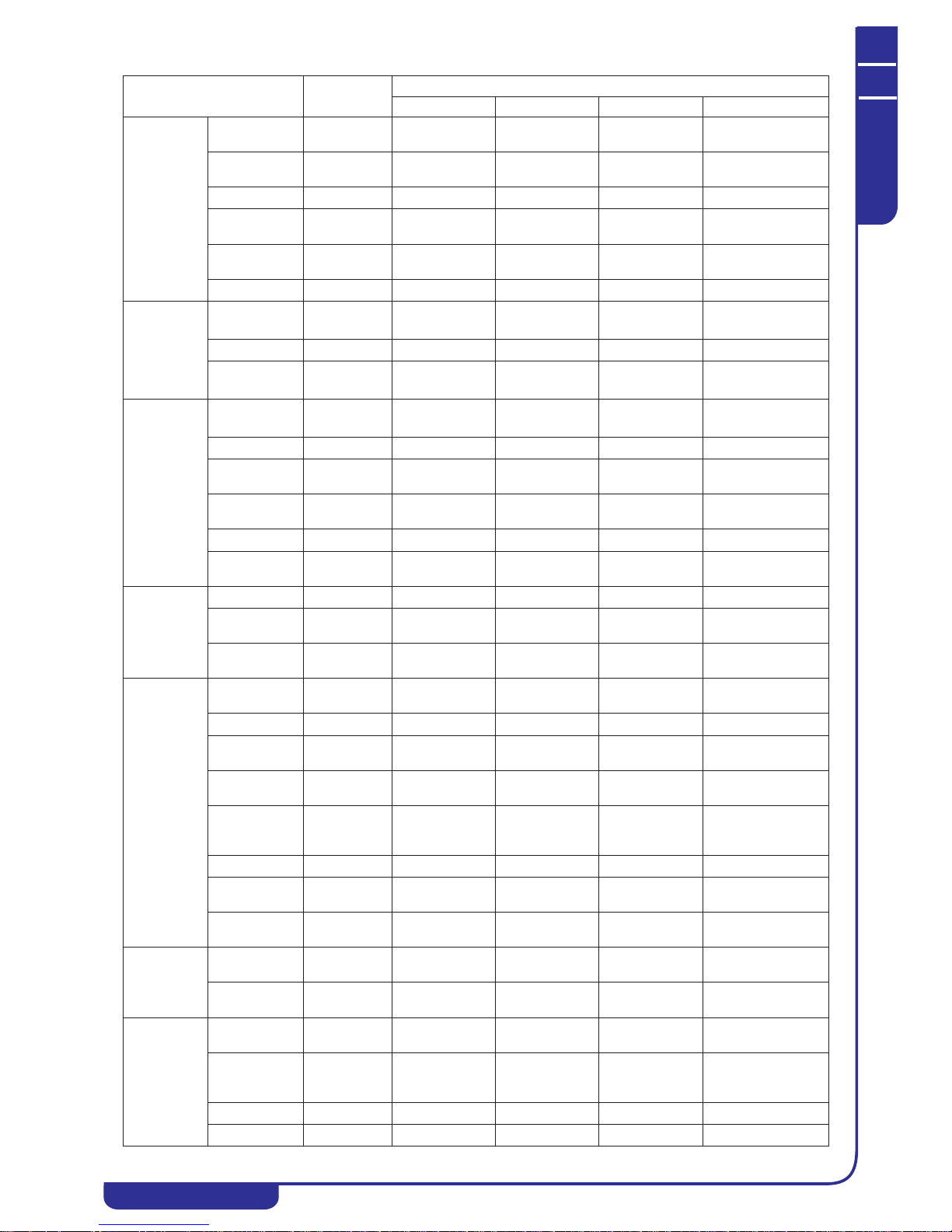

Level 0 Level 1 Level 2 Level 3 Level 4

Adjustment probe

Acve alarm

U Setpoint:

SEt

Label Set cooling:

Coo

Cooling setpoint value

Label Set heang:

HEA

Heang setpoint value

M

Analogue Input:tP

Input code:

t01-t04

Analogue Input value

UAlarms:

Err

Acve alarms code:

E00

M

Digital Inputs: Id Input code:

i01-i05

Digital input status

M Parameters:

PAr

Parameters category

Parameter index Parameter value

U Password:

PSS

Password value

M

Operaon Hours:

Ohr

Compressor hours 1:

OH1

Number of hours

Compressor hours 2:

OH2

Number of hours

Pump hours:

OHP

Number of hours

U = user

M = maintainer

C = manufacturer

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

16

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

9.2 Parameters category

9.3 Setpoints settable by the user

The second setpoint is only operational if the relative optional kit has been purchased.

9.4 Display

Normally, the display shows the water output temperature in tenths of a degree Celsius or the alarm code if at least one alarm has been

tripped. With several alarms present, the first one is shown and the second one appears after the first has been reset. In menu mode, the

contents of the screen depend on the function being used.

9.5 LEDs

Description

Group identification

code

Parameter index

Configuration

CnF H01-

Compressor

CP C01-

Fan

FAn F01-

Alarms

ALL A01-

Adjustment

Re b01-

Pump

PUP P01-

Electric heaters

Fro r01-

Defrosting

dFr d01-

Electronic valve

EEu U01-

Offset

OFF o01-

Setpoint type

Setpoint

(summer/winter)

Summer

default (range)

Winter

default (range)

First setpoint [°C]

Coo/Hea 7 (5÷18) 45 (35÷55)

Second setpoint [°C]

Co2/He2 18 (7÷23) 35 (25÷45)

Hot water setpoint [°C]

San 48 (25÷55)

Compressor LED • ON with compressor in operation.

• OFF with compressor not running.

• FLASHING if compressor start delay timer is running.

Domestic hot

water LED

• ON with domestic hot water valve active.

• OFF with domestic hot water valve not active.

Defrost LED • ON with defrosting active.

• OFF with defrosting disabled or completed.

• FLASHING if defrosting interval timer is running.

Antifreeze heater

LED

• LED ON with antifreeze heater (optional) in operation.

Pump LED • LED ON with pump in operation.

Alarm LED • LED ON with an alarm tripped.

Heating mode

LED

• LED ON with unit in heating mode.

Cooling mode

LED

• LED ON with unit in cooling mode.

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

17

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

9.6 Modifying the dynamic setpoint

The regulator allows the setpoint to be modified by adding an offset to the external air temperature probe reading. To use this function, the

user has to set the values of parameters b08 to b14 following the instructions provided below (modifications to be made by the installer).

Parameters of regulator PAr->rE->

• b08 = dynamic setpoint enabled=1 / disabled=0 (must be disabled if weather compensation from the optional CRH remote

keypad is used).

• b09 = cooling maximum offset.

• b10 = heating maximum offset.

• b11 = External temperature setting in cooling mode.

• b12 = External temperature setting in heating mode.

• b13 = Temperature delta in cooling mode.

• b14 = Temperature delta. in heating mode.

Modifying the setpoint in relation to the external temperature:

9.7 Modifying the setpoint from 0-10V input

Another type of adjustment allows to change the set-point by adding (or subtracting) a value according to the 0-10V input (if enabled). To

enable the function, set H21=40, and if necessary change the value of the parameter b15 (0-10 range), taking into consideration that:

• with 0 Volt input the current setpoint will be: (Coo/Hea) setpoint set – b15/2

• with 5 Volt input the setpoint will be the one set (Coo/Hea)

• with 10 Volt input the current setpoint will be: (Coo/Hea) setpoint set – b15/2

Cooling

Heating

Ext. temp. set.

Ext. temp. set.

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

18

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

The 0-10V signal must be applied to 0-10V+ and 0-10V terminals (see wiring diagrams).

NOTE

In “cool” mode, considering that the chiller setpoint by default is set to 7°C, the parameter b15 must not have a value greater than or equal

to 6 to ensure that the new setpoint set from the 0-10V input can achieve values below the antifreeze activation threshold (4°C).

9.8 Hydraulic pump operation

The hydraulic pump can be set according to one of the three following types of operation:

• operation on call of the temperature controller (default)

• operation on call from the temperature controller with periodic activation

• continuous operation

The pump is switched off immediately if the flow switch alarm is activated in manual reset.

The pump instead is always on if the antifreeze heaters are operating or if the hydraulic pump in antifreeze mode operation is activated.

The operation in antifreeze mode is activated if the adjustment temperature drops below P04 °C (default 5°C), it is disabled if the adjustment

temperature rises above P04+P05 °C (Default value of P05=2.0°C).

The pump adjustment is proportional (see Point 9.8.4).

9.8.1 Operation on call from temperature controller (Default)

In this user mode (P03=1, default), the pump is activated upon request of the temperature controller; and after a time delay of 20 seconds

from the pump start up, also the compressor activates. In power off, instead, the pump is switched off with a delay time of 120 seconds from

the call with the temperature controller in off status (off status coinciding with the compressor power off).

With flow switch alarm active in automatic reset the pump is however turned on even if the compressor is off.

If the machine operation is enabled from the remote “on-off” digital input (see Point 9.10), the circulator is immediately activated for a time

of 2 minutes, regardless of the temperature control inside the unit (the activated water recirculation allows the correct activation of the

temperature control).

0 - 10 V Input [V]

New setpoint [°C]

Setpoint set

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

19

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

9.8.2 Operation on call from temperature controller with periodic activation

The function is disabled if P17=0 (default). If the pump is set into operation on call from the temperature controller (P03=1, default), it is

activated periodically for a time defined by the parameter P17 (in seconds) after a count whose duration can be set by the parameter P16 (in

minutes), activated when the pump is switched off when the temperature control is met.

With flow switch alarm active in automatic reset the pump is however turned on even if the compressor is off.

The periodic function is also interrupted in the case of intervention of the antifreeze regulator that forces the pump activation.

9.8.3 Continuous operation

In this operation mode, which is active if P03=0, the pump is always on. It is powered off only with the unit OFF.

9.8.4 Pump proportional adjustment

The pump speed is varied according to the temperature difference between the exchanger intake water and discharge water, according to the

diagram below, where:

P07: modulating pump maximum speed (%)

P08: modulating pump minimum speed (%)

P09: modulating pump intake/discharge water Delta T set (°C)

P10: Modulating pump Delta (°C)

Temperature controller

Compressor

Pump

Time

Time

Time

Power on delay between

pump and compressor

Power off delay between

compressor and pump

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

20

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

In domestic hot water production the pump is forced to the maximum speed.

9.9 Heaters for antifreeze protection (if AK accessory is installed)

The antifreeze heaters on the faces of the evaporator plates come on even with the unit off (but powered up) when the output water

temperature drops below r02 °C (default 4°C) in “heat” mode or below r03 °C (default 4°C) in “cool” and “OFF” mode. The heaters are

switched off when the temperature reading of the output water probe exceeds r02+r06 in “heat” or r03+r06 in “cool” mode and in “OFF”

(default value r06=2.0°C). The heating cable on the base of the machine is activated, instead, when the outside air temperature drops below

3°C or the machine goes into defrost (after a set delay). It is disabled when the outdoor temperature exceeds 5°C.

9.10 Remote on-off and remote summer-winter switching

The terminal board has two digital inputs for operating the unit by means of a remote enabling signal.

9.11 Remote water temperature probe

In some system solutions (e.g. heat pump in parallel with the hot water tank on the same hydronic circuit and bypass diverter valve) it may

be necessary to remotely control the system temperature probe so that the controller installed on the unit can successfully process the system

management.

To configure the remote probe set H19=41 and H44=0 and connect the probe to the SE-SE terminals, or set H20=41 and H45=0 to use the

SAN-SAN terminals).

9.12 Domestic hot water production enable

To activate the domestic hot water function, connect a probe to be inserted in the tank to the SAN-SAN terminals (enabled as analogue

input). After fitting and connecting the temperature probe, the domestic hot water function has to be enabled by setting parameter H10 with

the value 1 and parameter H20 with the value 6 to enable the analogue input for the probe. These settings are accessed by entering the

maintenance password and accessing parameters PRG->PSS->PAr->Cnf->H10/H20 (modifications to be made by the installer).

If the domestic hot water temperature is below the relative setpoint (set at 48°C by default, which can be modified by accessing the PRG-

>Set->SAN menu) the unit activates the domestic hot water valve and the compressor switches to the minimum frequency for a time of 2

minutes, giving the valve time to divert the flow of water to the domestic hot water tank. After the switching time, the compressor is set at

the maximum frequency starting the modulation at one degree before the setpoint and switching off one degree after. Once the setpoint is

reached, the valve returns to the rest position and compressor operation is controlled in the usual way.

If a 3-way switching valve with 3-point power supply is used, it must be connected to terminals NO1, N and NC1.

If a 3-way switching valve with 2-point power supply (with return spring) is used, it must be connected to terminals NO1 and N.

Contact NO1 closed means that the valve is excited and is diverting the flow of water to the domestic hot water tank.

Contact NO1 open means that the valve is not excited and is diverting the flow of water to the user.

SW-SW:

Input for remote summer/winter mode switching.

To enable this function, set parameter H76 with the value 1.

The parameter is protected by a password (it can only be modified by the installer).

With open contact the machine is in “heat” mode, with closed contact the machine switches to “cool” mode.

onoff-onoff:

Remote on-off input.

This function is already enabled by default.

Remove the jumper from the terminal board to set the unit in standby status (in this status the display of control

installed on the unit shows “E00”).

When the contact closes, the machine comes out of the standby mode and the circulator is turned on for 2 minutes.

If the domestic hot water operation is enabled, the remote on-off function has no effect on the production of ACS,

it disables only the operation in heating and chiller mode on the system side (in this status the display installed on

the unit shows “SAN”).

TECHNICAL MANUAL

Chapter 9 - User - Control Interface

NGSi 05÷15

21

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

When the system switches from user water to domestic hot water, the working probe changes its function from “water outlet probe” to

“domestic hot water probe”. When the system switches from winter to domestic hot water operation, the compressor does not switch off and is

turned up to the maximum frequency set by the controller, while if it switches from summer to domestic hot water, the compressor is switched

off and waits for the safety pause time.

9.12.1 Probe storage in heating mode

When the system switches from user water to domestic hot water, the working probe changes its function from “water outlet probe” to

“domestic hot water probe”. For this reason, in hot mode, before entering into domestic hot water mode, the last value read by the probe is

stored.

After the domestic hot water temperature control is met, the reference temperature on the system side returns to the temperature previously

stored. The storage function stops:

• in the moment in which the temperature read by the probe becomes lower than the stored value;

• or after the expiry of a time equal to b06 seconds (default 45 seconds).

9.12.2 Domestic hot water production call from digital input

Alternatively to the temperature probe use, the activation of the domestic hot water function can be performed by closing a digital input of