MTA HAST 090 N, HAST 110 N, HAST 080 N, HAST 140 N, HAST 070 SN Maintenance And Operating Manual

...

HEAT PUMPS

MAINTENANCE AND OPERATING MANUAL

HAS T 070÷140

38178801085

Original instructions in Italian language

MAINTENANCE AND OPERATING MANUAL

Quick guide

HAS T 070÷140

1

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

QUICK GUIDE

0.1 Power up and power down

Power up the machine.

At the time of commissioning, follow the machine configuration instructions (see "6.2.1 First power-up").

The display switches on and the main mask appears.

Check the unit status and the presence of blocking alarms.

Hold down the key for 2 sec

. The pump, if installed, will start running and the unit's refrigerant compressors will start

after a preset time lag.

To stop the unit hold down the key for 2 seconds.

The electronic controller and the display will remain on.

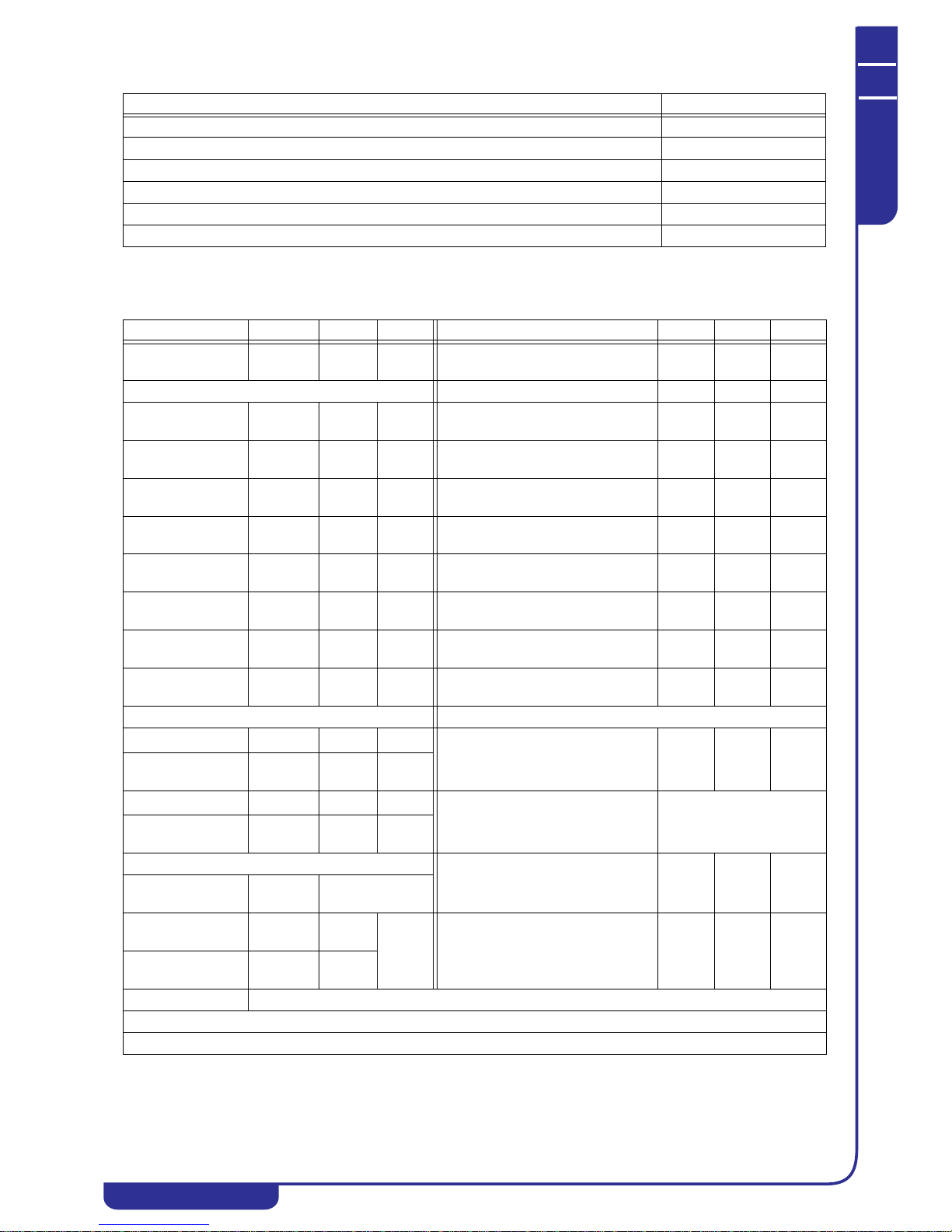

0.2 Keys

Summary table showing all types of keys present on the controller.

Key Function

Scroll through masks

Scroll and select the fields in a mask / increase and decrease the value of a field

Scroll the parameters on different circuits (pronged press)

Scroll the masks in the ALARM menu

Access the I/O menu (see "6.3 I/O menu")

Access the SET menu (see "6.4 Setpoints Menu")

Access the USER menu (see "6.5 User Menu")

Access the reserved menu (see "6.7 Reserved menu")

Access the ALARM menu (see "6.8 Alarms")

Power the unit on and off (see "6.2.4 Powering up the unit")

Exit a menu

Activate a field/confirmation

Alarms reset in ALARM menu (see "6.8 Alarms")

Access to EX/MD submenu from I/O menu (optional, see "6.3 I/O menu")

MAINTENANCE AND OPERATING MANUAL

Quick guide

HAS T 070÷140

2

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

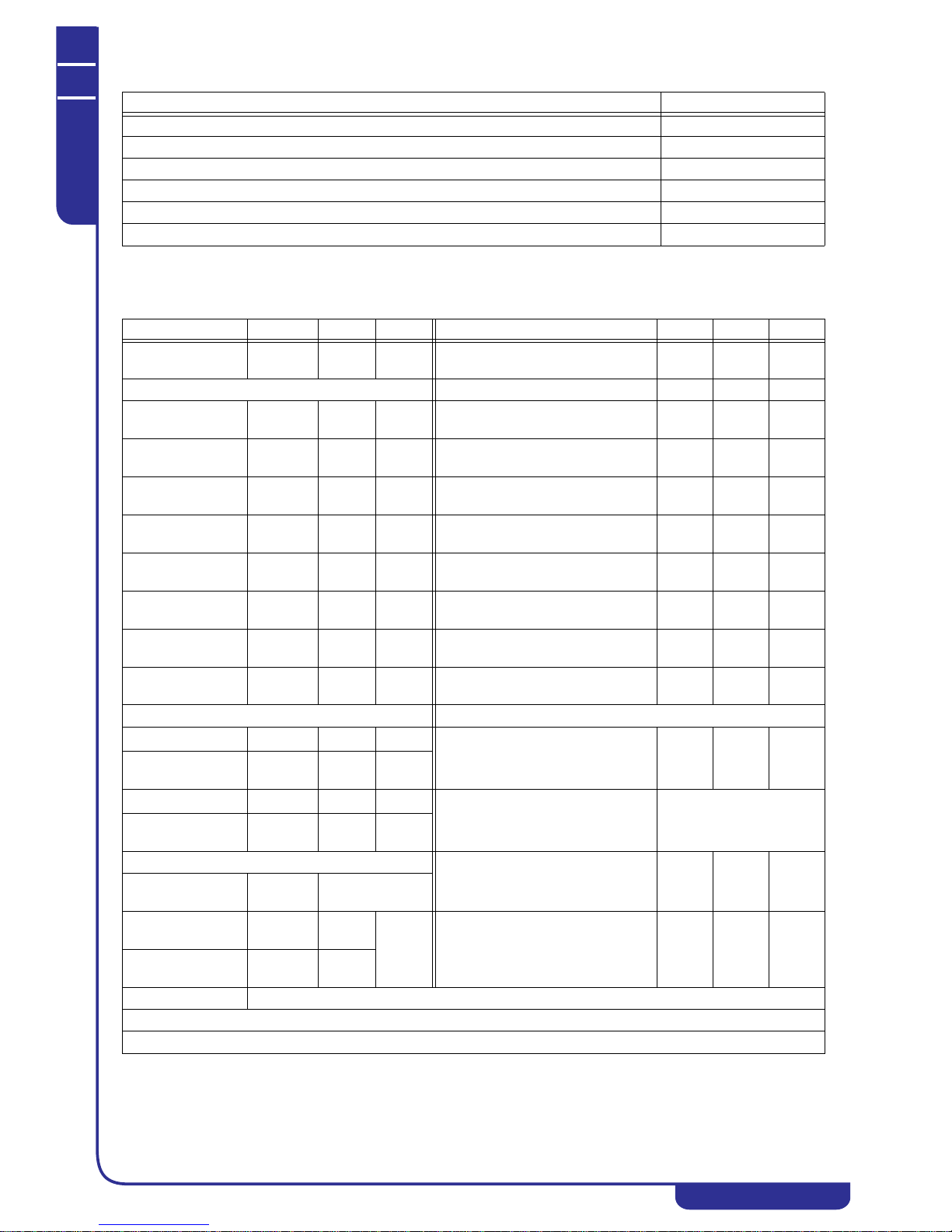

0.3 Changing the setpoint

0.4 Alarms

The unit can be either on or off.

Press in the main menu to open the setpoint menu.

Scroll through the menu with the keys until reaching mask ST02.

Use the key to select the setpoint.

Press .

Use the keys to set the value.

Press to confirm.

Press to quit the menu.

The presence of active alarms is signalled by the icon.

Press the key to enter the mask to display the alarms.

The mask contains a list of active alarms. Use the keys to scroll

the list.

The symbol shows that the alarm is resettable.

Press to reset an individual alarm.

Press and keep it pressed for 2 seconds to reset all active alarms.

Press to quit the mask.

MAINTENANCE AND OPERATING MANUAL

Contents

HAS T 070÷140

3

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

CONTENTS

QUICK GUIDE ......................................................................................................................................1

0.1 Power up and power down...............................................................................1

0.2 Keys..................................................................................................................1

0.3 Changing the setpoint.......................................................................................2

0.4 Alarms ..............................................................................................................2

CONTENTS...........................................................................................................................................3

G

ENERAL INFORMATION....................................................................................................................5

1.1 How to interpret the model...............................................................................5

1.2 How to interpret the codes ...............................................................................5

1.3 Data plate..........................................................................................................6

1.4 Declaration of conformity ................................................................................6

1.5 Performance data..............................................................................................7

1.6 Noise ................................................................................................................7

1.7 How to interpret the alphanumeric string.........................................................7

TECHNICAL PARAMETERS FOR HEAT PUMP SPACE HEATERS AND HEAT PUMP

COMBINATION

HEATERS.....................................................................................................................7

S

AFETY ..............................................................................................................................................32

2.1 General ...........................................................................................................32

2.2 General precautions........................................................................................33

2.2.1 Precautions during lifting and transport ........................................................33

2.2.2 Precautions to be adopted during operation ..................................................33

2.2.3 Disposal .......................................................................................................... 33

2.2.4 Precautions for maintenance and repair ........................................................33

2.3 Refrigerants .................................................................................................... 34

DESCRIPTION ....................................................................................................................................35

3.1 Operating principle.........................................................................................35

3.2 Components....................................................................................................35

3.2.1 Compressors ...................................................................................................35

3.2.2 Condensers ......................................................................................................35

3.2.3 Fans ................................................................................................................36

3.2.4 Evaporator ......................................................................................................36

3.2.5 Heat recovery and desuperheater ...................................................................36

3.2.6 Liquid receiver ...............................................................................................37

3.2.7 Cycle reversal valve .............................................................................. ..........37

3.3 Hydraulic system (optional)...........................................................................38

3.4 Cabinet ...........................................................................................................39

3.5 Protection rating .............................................................................................39

3.6 Electrical circuit .............................................................................................39

3.7 Overall dimensions.........................................................................................39

INSTALLATION ..................................................................................................................................40

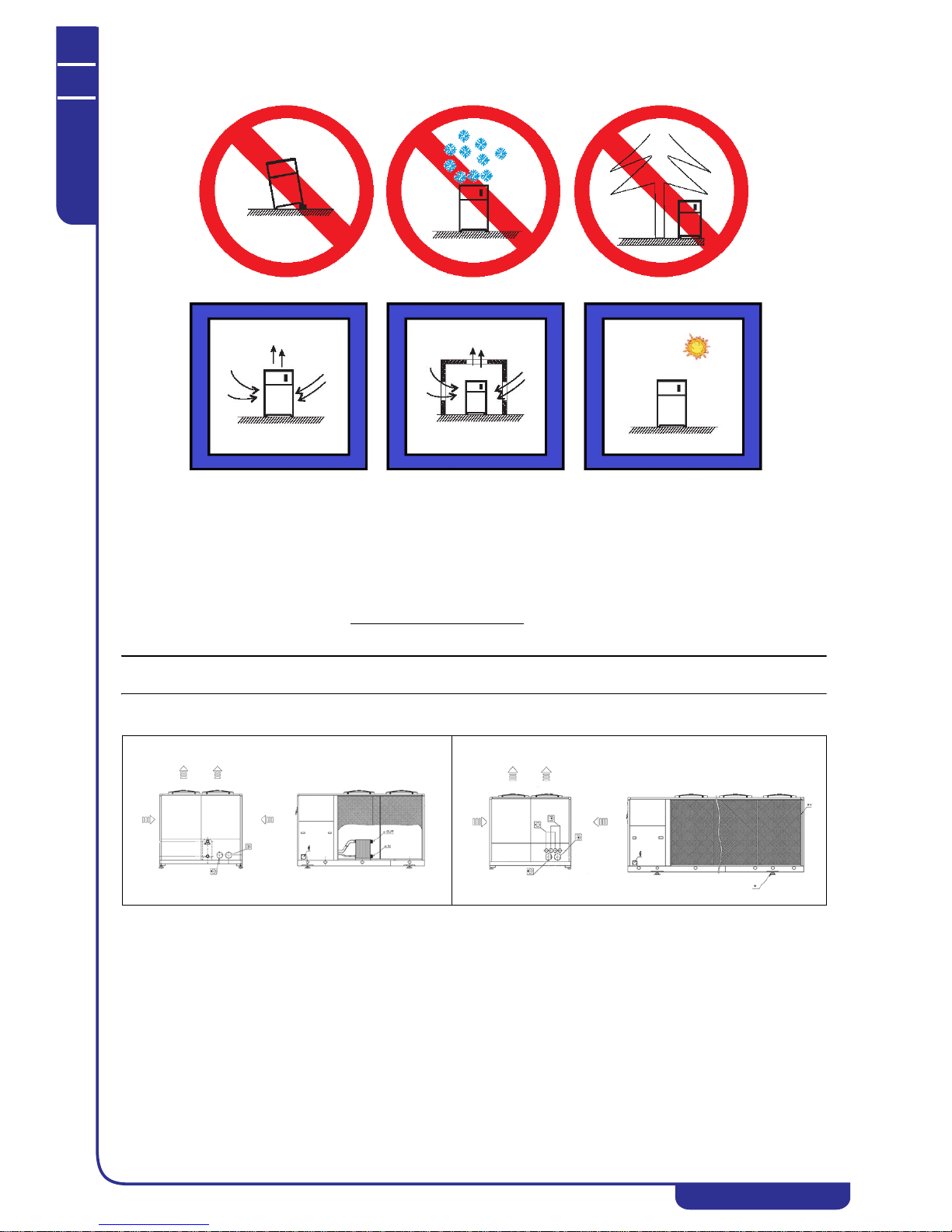

4.1 Foreword ........................................................................................................40

4.2 Symbols..........................................................................................................40

4.3 Installation......................................................................................................40

4.3.1 Inspection ................... ........................ ......................... ........................ ............ 40

4.3.2 Location .......................................................................................................... 40

4.3.3 Hydraulic connections ....................................................................................41

4.3.4 Freeze protection ............................................................................................44

4.3.5 Electrical connections .....................................................................................45

4.3.6 Phase Monitor .............. ...................................................................................45

START-UP ..........................................................................................................................................46

E

LECTRONIC CONTROLLER .............................................................................................................47

6.1 Technical features ..........................................................................................47

6.1.1 Controller connectivity ...................................................................................47

6.1.2 Display ..................... .......................................... .......................................... ...48

6.1.3 Auxiliary hardware .........................................................................................49

MAINTENANCE AND OPERATING MANUAL

Contents

HAS T 070÷140

4

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

6.2 Using the display ........................................................................................... 50

6.2.1 First power-up ................................................................................................ 50

6.2.2 Main menu ...................................................................................................... 51

6.2.3 Display menus ................................................................................................ 51

6.2.4 Powering up the unit ......................................... .............................................51

6.2.5 Power-on from a digital input ........................................................................ 51

6.2.6 Power-on by supervision system ........................................... ......................... 51

6.2.7 Keys ................................................................................................................ 52

6.2.8 Icons ............................................................................................................... 53

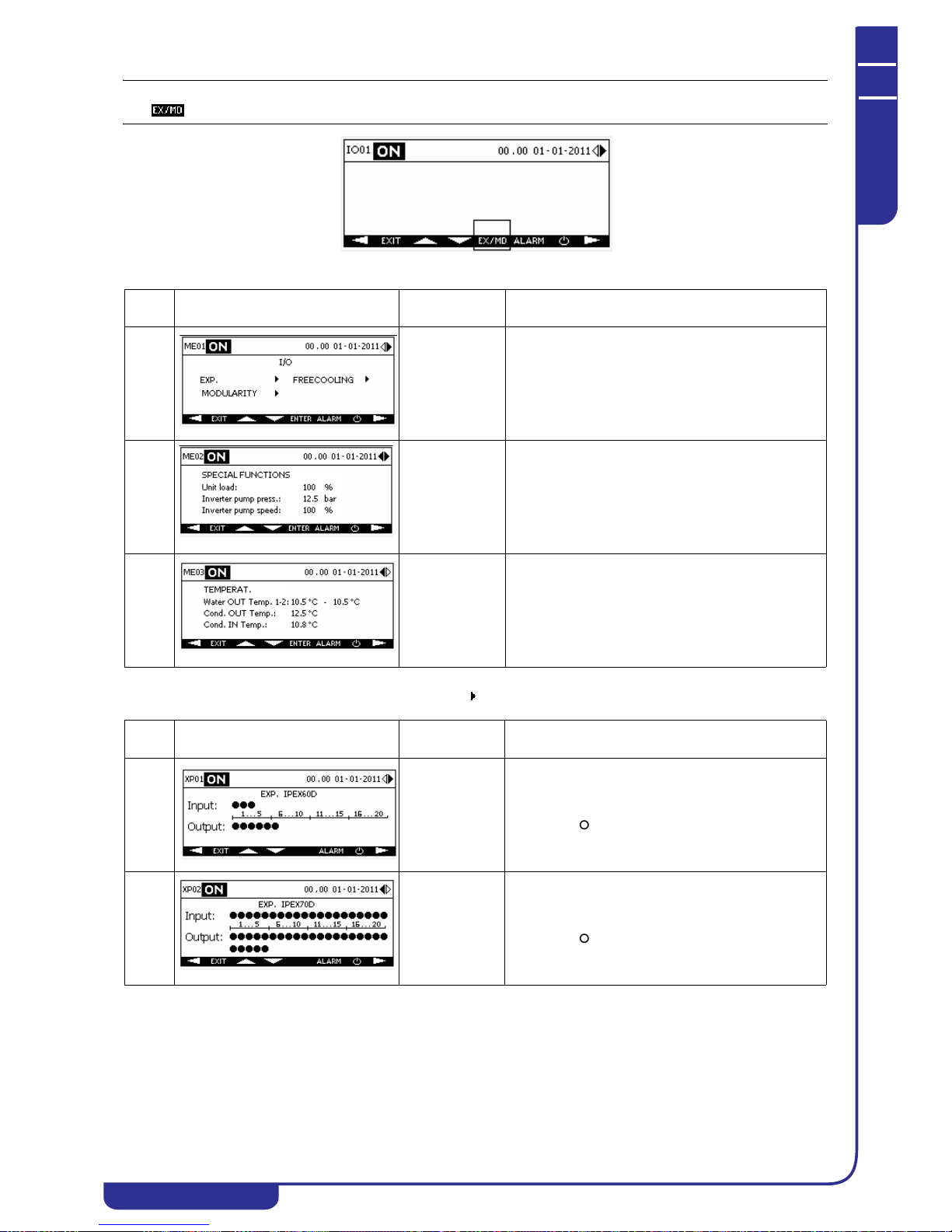

6.3 I/O menu ........................................................................................................ 54

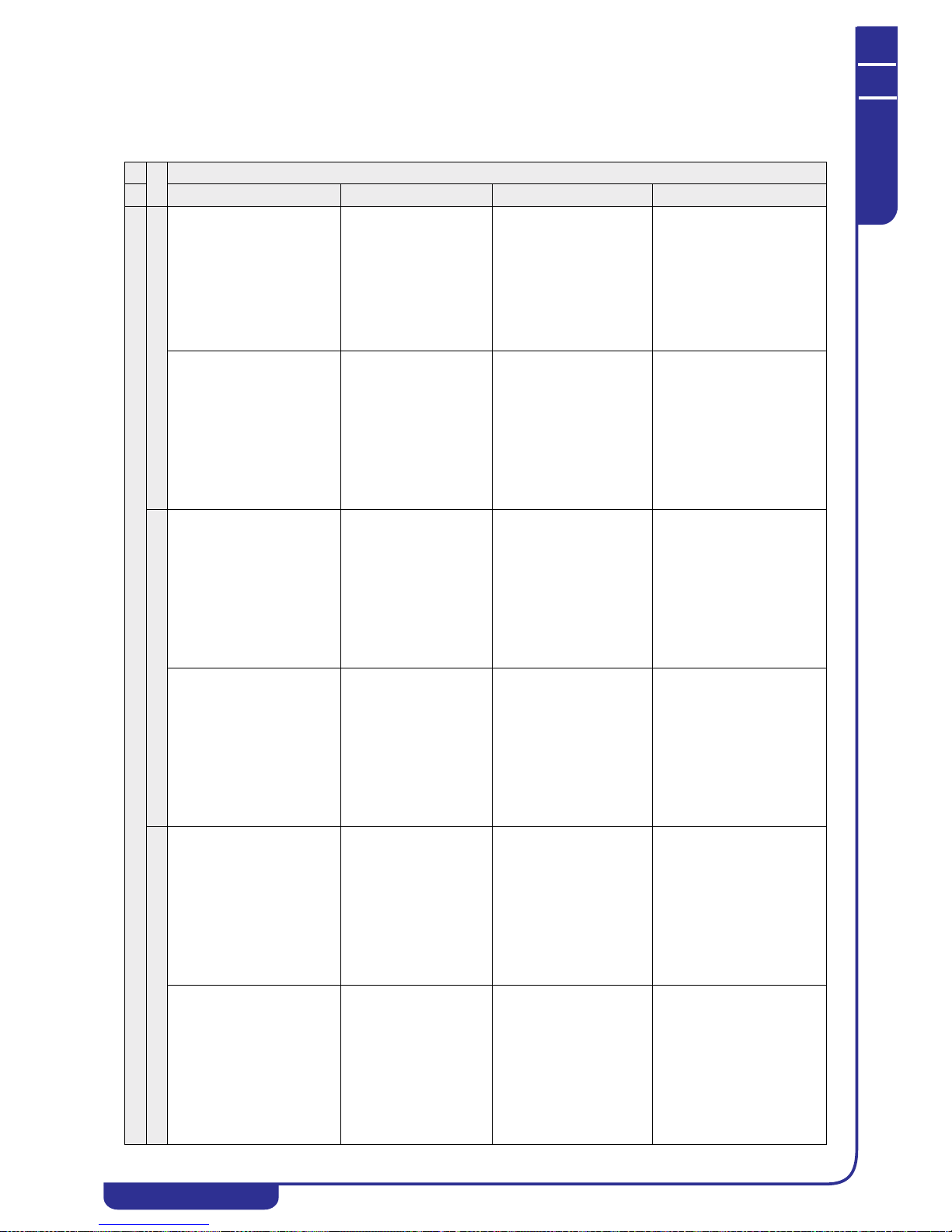

6.3.1 EX/MD auxiliary I/Os ....................................... .............................................55

6.4 Setpoints Menu .............................................................................................. 57

6.5 User Menu...................................................................................................... 59

6.5.1 Autostart ......................................................................................................... 60

6.5.2 Display language ............................................................................................60

6.5.3 Buzzer ............................................................................................................. 60

6.5.4 Backlighting and contrast ........................................................................... .. . 60

6.6 Alarm Menu................................................................................................... 60

6.7 Reserved menu............................................................................................... 61

6.7.1 Reserved menu icons ......................................................................................61

6.7.2 Access to menu functions .... ................................. ................................. ..........62

6.7.3 Configuration ................................................................................................. 63

6.7.4 Compressors .................. ...................................... .................................... ....... 63

6.7.5 Fans ........................... ............................................... ...................................... 6 5

6.7.6 Anti-freeze ...................................................................................................... 67

6.7.7 Heat recovery ................................................................................................. 68

6.7.8 Regulation ...................................................................................................... 70

6.7.9 Defrost ..................... .............................................. ......................................... 7 2

6.7.10 Operating hours ........................................... .................................................. 73

6.7.11 Manual procedure ..........................................................................................73

6.7.12 Alarms set ......... .............................................................................................. 74

6.7.13 Log ............................. .......................... ........................... ........................... .....74

6.7.14 Pumps ............................................................................................................. 74

6.7.15 Date/time ........................................................................................................ 75

6.7.16 Time bands .....................................................................................................75

6.7.17 Modularity ...................................................................................................... 75

6.7.18 Supervision ........................................................ ............................................. 76

6.7.19 Unloading ....................................................................................................... 76

6.7.20 Special functions ............................................................................................. 77

6.7.21 Free-cooling ................................................................................................... 79

6.7.22 Other settings ........................................... ...................................................... 80

6.8 Alarms............................................................................................................ 80

6.8.1 Buzzer ............................................................................................................. 80

6.8.2 Alarms list ............. ............................................................... ........................... 80

FUNCTIONS AND COMPONENTS OF THE UNIT .................................................................................89

7.1 Electronic thermostatic valve (optional)........................................................ 89

7.2 High pressure switches (HP).......................................................................... 89

7.3 Temperature and pressure transducers........................................................... 89

7.3.1 Pressure transducers .......... ................................................................ ............90

7.4 Flow switch.................................................................................................... 90

7.5 Level sensor ................................................................................................... 90

7.6 Forced ventilation of the electrical board ...................................................... 91

7.7 Antifreeze control .......................................................................................... 91

OPERATION AND MAINTENANCE .....................................................................................................92

8.1 Operation ....................................................................................................... 92

8.2 Maintenance................................................................................................... 92

8.2.1 Access to the unit's internal compartments ................................................. ...92

8.2.2 Emptying of the evaporator ............................................................................93

8.2.3 Planning of checks and maintenance operations ........................................... 94

TROUBLESHOOTING .........................................................................................................................95

R

ISK ANALYSIS: RESIDUAL RISK......................................................................................................98

A

PPENDIX........................................................................................................................................101

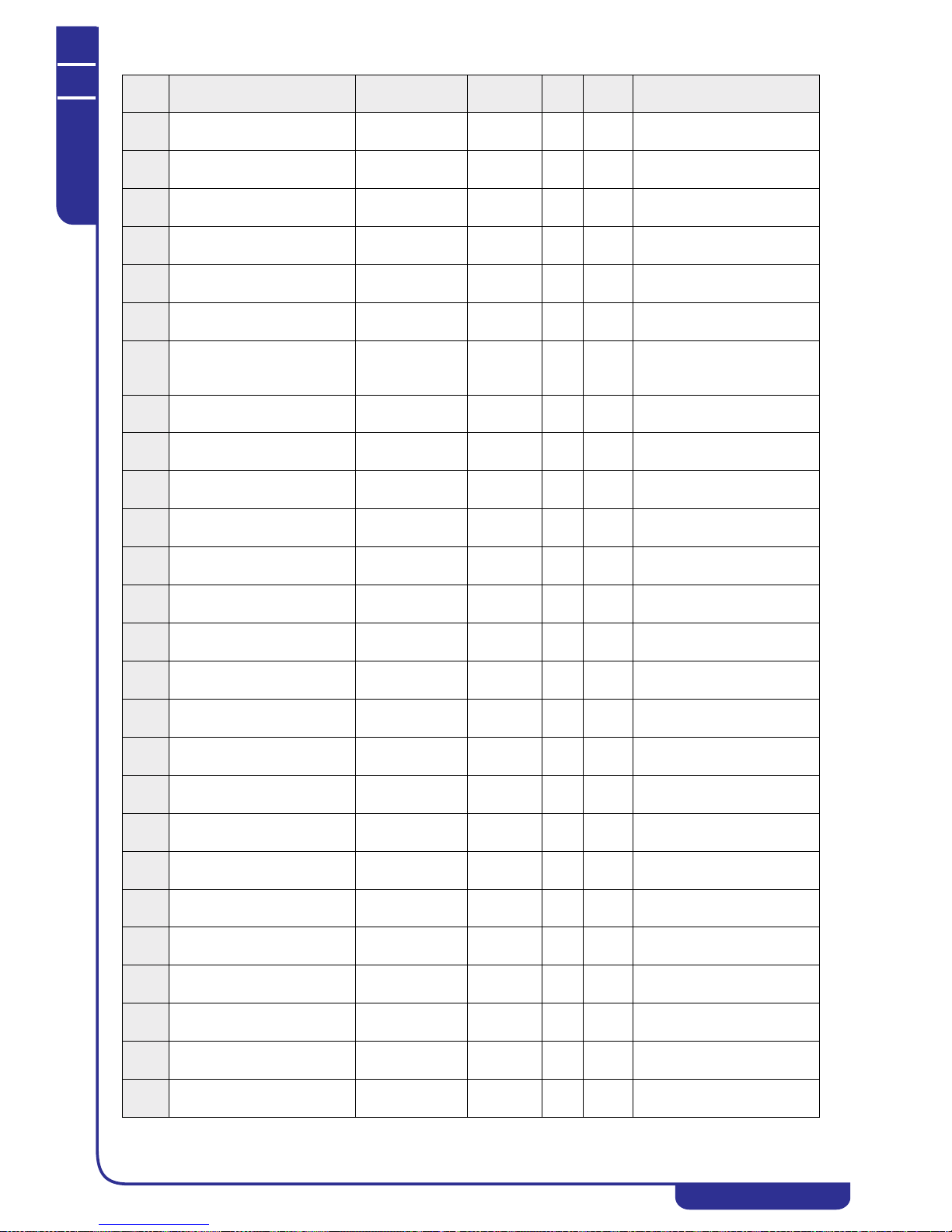

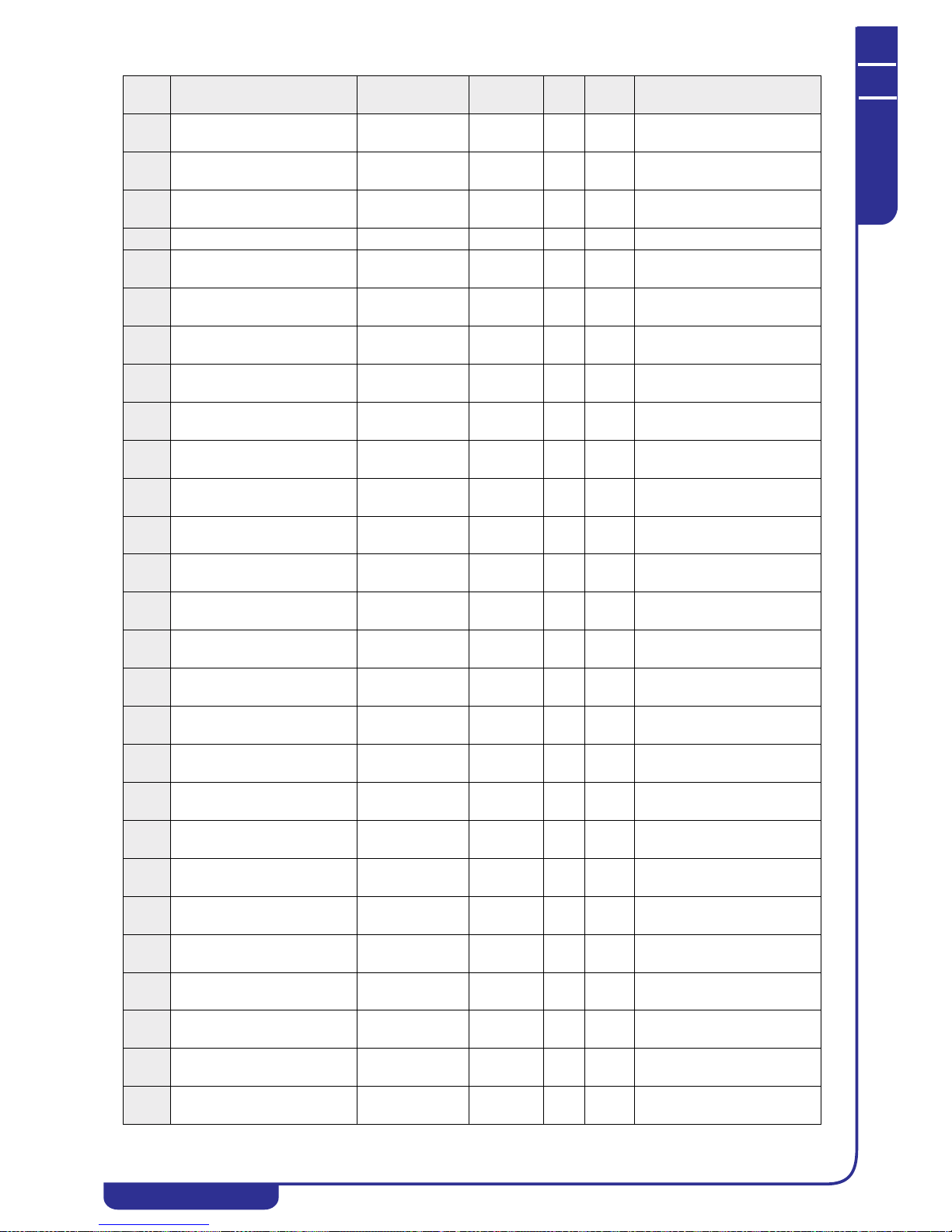

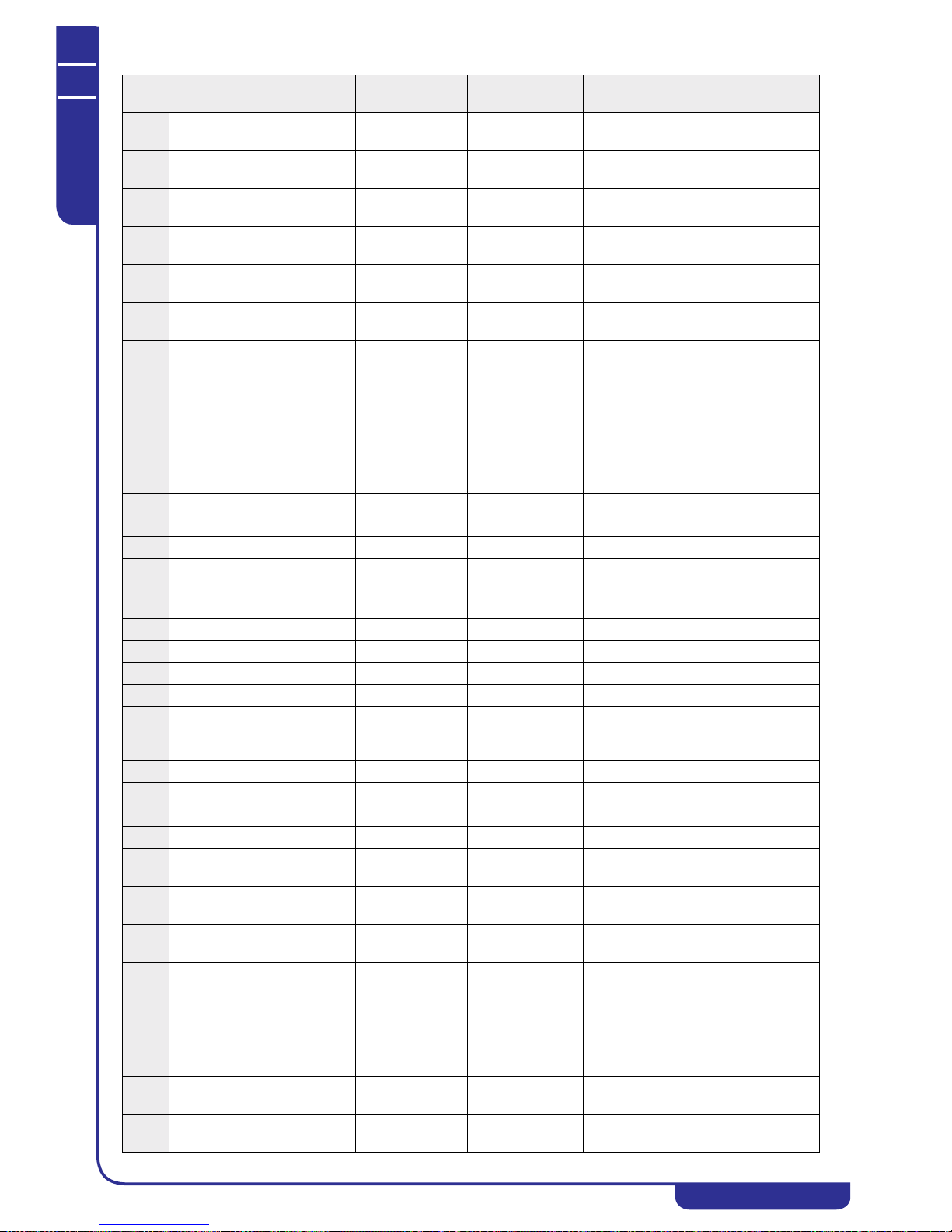

10.1 Settings table ................................................................................................ 101

MAINTENANCE AND OPERATING MANUAL

General information

HAS T 070÷140

5

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

CHAPTER 1

GENERAL INFORMATION

These units are designed to cool or heat a liquid (WATER in the majority of applications).

The term “WATER” is used for the sake of simplicity to identify the liquid to be cooled, even if the liquid involved is not

water (for example mixtures of water and ethylene or propylene glycol).

The liquid to be cooled must be compatible with the materials used.

This analysis must be carried out when installing the unit.

ATTENTION

Requests for spare parts and any information must be addressed to the local dealer or service centre, specifying

the MODEL and SERIAL NUMBER shown on the unit's nameplate and on the last page of this manual.

1.1 How to interpret the model

1.2 How to interpret the codes

MODEL DESCRIPTION

H AS T

Unit version (N, SN or SSN)

Nominal power of compressor expressed in HP

HAries Tech model

H = Heat pump

/N

Low noise operation value: standard. Fan rotation speed approx. 900 rpm. Compressors compartment only

partially acoustically insulated.

/SN

Low noise operation value: medium. Fan rotation speed approx. 700 rpm. Acoustically insulated compressors

compartment.

/SSN

Low noise operation value: high. Fan rotation speed approx. 700 rpm. Compressors compartment with high

efficiency acoustic insulation.

MAINTENANCE AND OPERATING MANUAL

General information

HAS T 070÷140

6

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

1.3 Data plate

The data plate affixed to the unit shows the main technical data.

1.4 Declaration of conformity

MODEL and CODE Identify the size of the unit (see Chapter 1 “General information“) and the

type of construction.

MANUAL Code number of this manual.

SERIAL NUMBER Unit serial number or manufacturing number.

YEAR OF CONSTRUCTION Year of unit's final testing.

VOLTAGE/PHASES/FREQUENCY Power supply specifications.

MAX CURRENT INPUT

I

MAX

Unit current input in limit working conditions

INSTALLED POWER

P

MAX

Unit power input in limit working conditions

PROTECTION RATING Protection rating of the entire unit, according to European standard EN

60529.

REFRIGERANT Type of refrigerant charge with which the unit is filled.

REFRIGERANT CHARGE Quantity of refrigerant supplied to the circuit.

MAX. REFRIGERANT PRESS. HP SIDE Refrigerant circuit design pressure (high pressure side).

MAX. REFRIGERANT PRESS. LP SIDE Refrigerant circuit design pressure (low pressure side).

USER CIRC. FLUID Fluid cooled or heated by the unit (usually: water).

MAX. WORKING PRESSURE User circuit maximum design pressure.

MAX TEMPERATURE User circuit maximum design temperature - not to be confused with the

maximum working temperature, which is specified at the time of the offer.

SOUND PRESSURE LEVEL Free field sound pressure level in hemispherical radiation conditions

(open field) at a distance of 1 m from the condenser side of the unit and a

height of 1.6 m from the ground.

AMBIENT TEMPERATURE Thermal exchange air minimum and maximum temperature values.

WEIGHT Approximate weight of the unit without packaging.

List:

a) Name of manufacturer

b) Definition of responsibility

c) Type of unit

d) Model of the unit

e) Serial or construction number of the unit

f) Directives and standards

g) PED

h) Officer responsible for technical file

i) Particulars of the officer responsible for the technical file

j) Place and date

M.T.A. S.p.A.

V

IA ARTIGIANATO

,2-Z

ONA INDUSTRIALE

- 35026CONSELVE (PD)- ITALY

Dichiarazione di conformità CE / UE

a) Noi:

b) Dichiariamo sotto la nostra sola responsabilità che la macchina

c) Tipo:

d) Modello:

e) Matricola:

f) è conforme a quanto prescritto dalle Direttive e norme:

x Direttiva Macchine 2006 /42/CE

- UNI EN ISO 12100

- CEI EN 60204-1 : 2006-09

x Direttiva Compatibilità Elettromagnetica 2 014/30/UE

- CEI EN 61000-6-1 : 2007-10

- CEI EN 61000-6-3 : 2007-11

- CEI EN 61000-6-2 : 2006-10

- CEI EN 61000-6-4 : 2007-11

g) inoltre è stata progettata, costruita e ispezionata conformemente

ai requisiti richiesti dalla Direttiva PED 2014/68/UE

-EN 378

x l’insieme ricade in categoria:

x la procedura di valutazione di conformità utilizzata è secondo il modulo:

(rif. Allegati II e III della Direttiva 2014/68/UE)

x l’organismo notificato i ncaricato della sorveglianza del sistema di qualità:

x estremi dell'Attestato di approvazione del sistema qualità:

x la macchina è considerata insieme ai fini della direttiva PED. Le attrezzature in pressione che la

compongono e le relative procedure di valutazione di conformità sono le seguenti:

Gli altri componenti non recano la marcatura CE in quanto rientrano nelle prescrizioni dell’Art. 1

par. 2 f della Direttiva 2014/68/UE

h) che la persona autorizzata alla costituzione del fascicolo tecnico è:

indirizzo:

i) Nome:

Cognome: Posizione:

j)

Luogo, Data Firma

Allegati: Lista dei pericoli considerati secondo l’Allegato I della Direttiva Macchine

MUT002/H

FACS

I

MI

LE

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

7

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

1.5 Performance data

The performance of the unit depends mainly on the flow rate and the temperature of chilled water (CHILLER) or heated

water (HEAT PUMP) and on the ambient temperature.

Performance values are defined at the time of the contract, refer to the offer data if necessary.

1.6 Noise

Data concerning noise levels are shown in the appendix to the manual.

1.7 How to interpret the alphanumeric string

ATTENTION

See the tabl e concerning the alphanumeric string in th e appendix.

The alphanumeric string is shown on the metal data plate on the cover page of this manual.

TECHNICAL PA RAMETERS FOR HEAT PUMP SPACE HEATERS AND HEAT PUMP

COMBINATION HEATERS

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

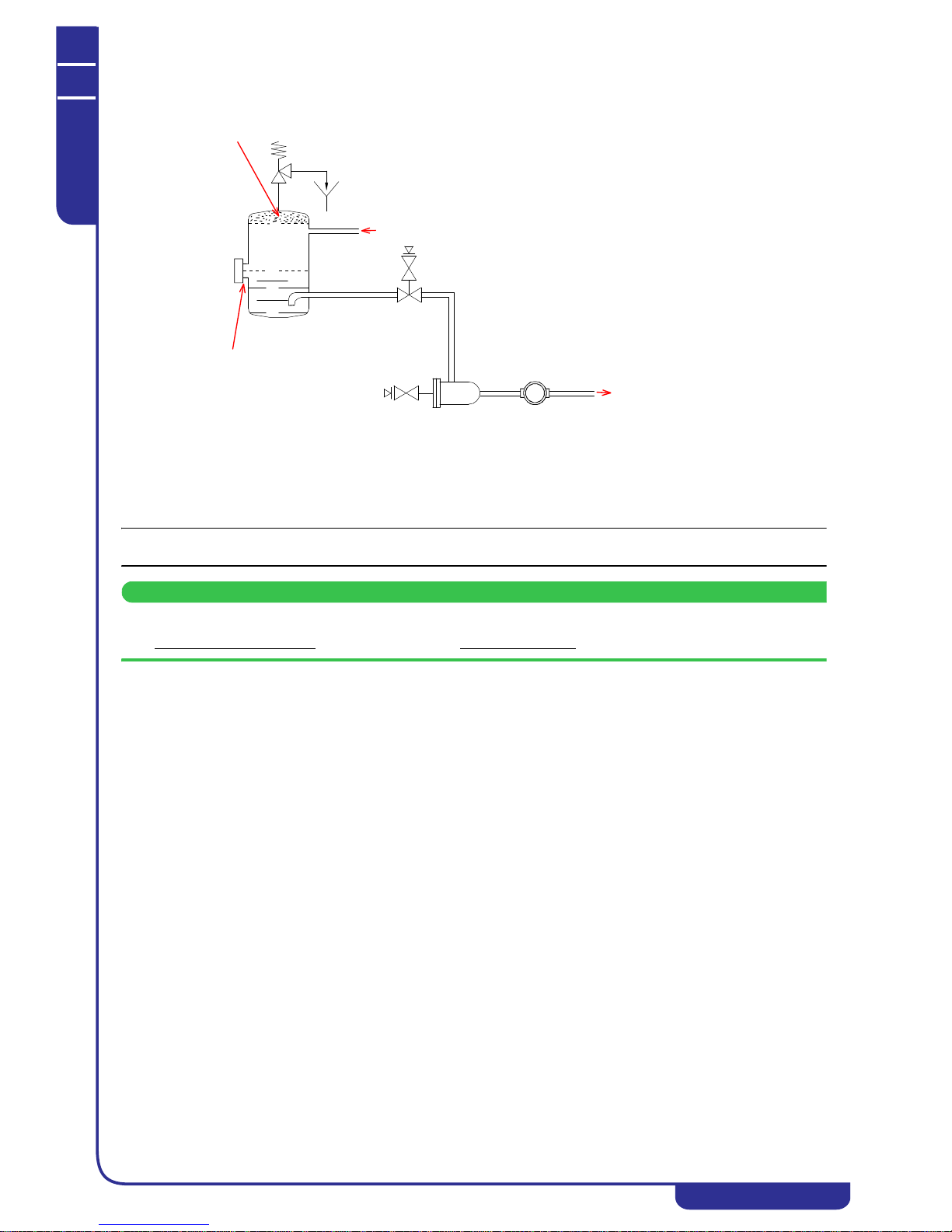

This symbol shown alongside appears in some refrigerant circuit diagrams and electrical

diagrams. This symbol refers to the alphanumeric string reported in the manual. The upper

box (X) identifies the position of the string, the lower box (Y) identifies the assigned value.

The empty alphanumerical string is circled in the adjacent figure; each

position in the upper row is associated with an alphanumeric value in the

lower row (0, 1, 2, A, B, etc.) and each character is associated with a

specific feature of the unit.

Model/Version HAS T 0 7 0 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 163,15 kW

Seasonal space heating energy

efficiency

ηs 117,69 %

Seasonal coefficient of performance SCOP 3,02 --

T

j

= – 7 °C

Pdh 124,75 kW Tj = – 7 °C

COPd

or PERd

2,48 -- o %

T

j

= + 2 °C

Pdh 160,48 kW Tj = + 2 °C

COPd

or PERd

3,43 -- o %

T

j

= + 7 °C

Pdh 184,53 kW Tj = + 7 °C

COPd

or PERd

4,14 -- o %

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

8

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

T

j

= + 12 °C

Pdh 212,30 kW Tj = + 12 °C

COPd

or PERd

4,98 -- o %

Tj = bivalent

temperature

Pdh 131,78 kW Tj = bivalent temperature

COPd

or PERd

2,67 -- o %

Tj = operation limit

temperature

Pdh 115,24 kW Tj = operation limit temperature

COPd

or PERd

2,23 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

0,92 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 44800

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

93,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

Model/Version H A S T 080 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 195,06 kW

Seasonal space heating energy

efficiency

ηs 123,86 %

Seasonal coefficient of performance SCOP 3,17 --

T

j

= – 7 °C

Pdh 149,06 kW Tj = – 7 °C

COPd

or PERd

2,62 -- o %

T

j

= + 2 °C

Pdh 191,89 kW Tj = + 2 °C

COPd

or PERd

3,61 -- o %

T

j

= + 7 °C

Pdh 220,53 kW Tj = + 7 °C

COPd

or PERd

4,35 -- o %

T

j

= + 12 °C

Pdh 253,74 kW Tj = + 12 °C

COPd

or PERd

5,24 -- o %

Item Symbol Value Unit Item Symbol Value Unit

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

9

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Tj = bivalent

temperature

Pdh 157,55 kW Tj = bivalent temperature

COPd

or PERd

2,81 -- o %

Tj = operation limit

temperature

Pdh 137,37 kW Tj = operation limit temperature

COPd

or PERd

2,36 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,10 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 43000

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

92,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

Item Symbol Value Unit Item Symbol Value Unit

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

10

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 90 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 209,48 kW

Seasonal space heating energy

efficiency

ηs 125,67 %

Seasonal coefficient of performance SCOP 3,22 --

T

j

= – 7 °C

Pdh 160,05 kW Tj = – 7 °C

COPd

or PERd

2,67 -- o %

T

j

= + 2 °C

Pdh 205,95 kW Tj = + 2 °C

COPd

or PERd

3,66 -- o %

T

j

= + 7 °C

Pdh 236,51 kW Tj = + 7 °C

COPd

or PERd

4,41 -- o %

T

j

= + 12 °C

Pdh 272,13 kW Tj = + 12 °C

COPd

or PERd

5,32 -- o %

Tj = bivalent

temperature

Pdh 169,20 kW Tj = bivalent temperature

COPd

or PERd

2,86 -- o %

Tj = operation limit

temperature

Pdh 147,41 kW Tj = operation limit temperature

COPd

or PERd

2,40 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,16 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 47800

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

93,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

11

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 100 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 220,71 kW

Seasonal space heating energy

efficiency

ηs 125,65 %

Seasonal coefficient of performance SCOP 3,22 --

T

j

= – 7 °C

Pdh 168,57 kW Tj = – 7 °C

COPd

or PERd

2,67 -- o %

T

j

= + 2 °C

Pdh 216,82 kW Tj = + 2 °C

COPd

or PERd

3,65 -- o %

T

j

= + 7 °C

Pdh 248,78 kW Tj = + 7 °C

COPd

or PERd

4,41 -- o %

T

j

= + 12 °C

Pdh 286,02 kW Tj = + 12 °C

COPd

or PERd

5,31 -- o %

Tj = bivalent

temperature

Pdh 178,26 kW Tj = bivalent temperature

COPd

or PERd

2,86 -- o %

Tj = operation limit

temperature

Pdh 155,19 kW Tj = operation limit temperature

COPd

or PERd

2,41 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,18 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 47800

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

93,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

12

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 110 N

Air-to-water heat pump: SI

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: SI

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 250,79 kW

Seasonal space heating energy

efficiency

ηs 118,43 %

Seasonal coefficient of performance SCOP 3,04 --

T

j

= – 7 °C

Pdh 191,44 kW Tj = – 7 °C

COPd

or PERd

2,54 -- o %

T

j

= + 2 °C

Pdh 246,87 kW Tj = + 2 °C

COPd

or PERd

3,45 -- o %

T

j

= + 7 °C

Pdh 283,27 kW Tj = + 7 °C

COPd

or PERd

4,14 -- o %

T

j

= + 12 °C

Pdh 325,11 kW Tj = + 12 °C

COPd

or PERd

4,95 -- o %

Tj = bivalent

temperature

Pdh 202,56 kW Tj = bivalent temperature

COPd

or PERd

2,72 -- o %

Tj = operation limit

temperature

Pdh 175,99 kW Tj = operation limit temperature

COPd

or PERd

2,30 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,37 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 67200

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

93,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

13

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 120 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 289,65 kW

Seasonal space heating energy

efficiency

ηs 124,39 %

Seasonal coefficient of performance SCOP 3,18 --

T

j

= – 7 °C

Pdh 221,07 kW Tj = – 7 °C

COPd

or PERd

2,67 -- o %

T

j

= + 2 °C

Pdh 285,09 kW Tj = + 2 °C

COPd

or PERd

3,63 -- o %

T

j

= + 7 °C

Pdh 327,22 kW Tj = + 7 °C

COPd

or PERd

4,34 -- o %

T

j

= + 12 °C

Pdh 375,6 kW Tj = + 12 °C

COPd

or PERd

5,19 -- o %

Tj = bivalent

temperature

Pdh 233,95 kW Tj = bivalent temperature

COPd

or PERd

2,86 -- o %

Tj = operation limit

temperature

Pdh 203,32 kW Tj = operation limit temperature

COPd

or PERd

2,42 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,39 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 64500

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

92,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

14

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 130 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 308,76 kW

Seasonal space heating energy

efficiency

ηs 124,50 %

Seasonal coefficient of performance SCOP 3,19 --

T

j

= – 7 °C

Pdh 235,88 kW Tj = – 7 °C

COPd

or PERd

2,67 -- o %

T

j

= + 2 °C

Pdh 303,51 kW Tj = + 2 °C

COPd

or PERd

3,63 -- o %

T

j

= + 7 °C

Pdh 348,25 kW Tj = + 7 °C

COPd

or PERd

4,34 -- o %

T

j

= + 12 °C

Pdh 399,68 kW Tj = + 12 °C

COPd

or PERd

5,18 -- o %

Tj = bivalent

temperature

Pdh 249,38 kW Tj = bivalent temperature

COPd

or PERd

2,86 -- o %

Tj = operation limit

temperature

Pdh 217,43 kW Tj = operation limit temperature

COPd

or PERd

2,41 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,41 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,41 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 64500

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

92,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

15

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 140 N

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 345,13 kW

Seasonal space heating energy

efficiency

ηs 130,16 %

Seasonal coefficient of performance SCOP 3,33 --

T

j

= – 7 °C

Pdh 264,31 kW Tj = – 7 °C

COPd

or PERd

2,80 -- o %

T

j

= + 2 °C

Pdh 337,56 kW Tj = + 2 °C

COPd

or PERd

3,79 -- o %

T

j

= + 7 °C

Pdh 387,37 kW Tj = + 7 °C

COPd

or PERd

4,53 -- o %

T

j

= + 12 °C

Pdh 445,18 kW Tj = + 12 °C

COPd

or PERd

5,41 -- o %

Tj = bivalent

temperature

Pdh 278,76 kW Tj = bivalent temperature

COPd

or PERd

3,00 -- o %

Tj = operation limit

temperature

Pdh 244,62 kW Tj = operation limit temperature

COPd

or PERd

2,53 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,60 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,52 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 64500

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

92,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

16

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 070 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 158,83 kW

Seasonal space heating energy

efficiency

ηs 122,44 %

Seasonal coefficient of performance SCOP 3,14 --

T

j

= – 7 °C

Pdh 121,64 kW Tj = – 7 °C

COPd

or PERd

2,57 -- o %

T

j

= + 2 °C

Pdh 155,56 kW Tj = + 2 °C

COPd

or PERd

3,56 -- o %

T

j

= + 7 °C

Pdh 178,52 kW Tj = + 7 °C

COPd

or PERd

4,31 -- o %

T

j

= + 12 °C

Pdh 205,23 kW Tj = + 12 °C

COPd

or PERd

5,19 -- o %

Tj = bivalent

temperature

Pdh 128,29 kW Tj = bivalent temperature

COPd

or PERd

2,77 -- o %

Tj = operation limit

temperature

Pdh 112,63 kW Tj = operation limit temperature

COPd

or PERd

2,31 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

0,87 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 33000

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

86,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

17

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 080 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 189,19 kW

Seasonal space heating energy

efficiency

ηs 127,47 %

Seasonal coefficient of performance SCOP 3,26 --

T

j

= – 7 °C

Pdh 144,78 kW Tj = – 7 °C

COPd

or PERd

2,70 -- o %

T

j

= + 2 °C

Pdh 185,29 kW Tj = + 2 °C

COPd

or PERd

3,71 -- o %

T

j

= + 7 °C

Pdh 212,53 kW Tj = + 7 °C

COPd

or PERd

4,48 -- o %

T

j

= + 12 °C

Pdh 244,22 kW Tj = + 12 °C

COPd

or PERd

5,40 -- o %

Tj = bivalent

temperature

Pdh 152,81 kW Tj = bivalent temperature

COPd

or PERd

2,89 -- o %

Tj = operation limit

temperature

Pdh 133,75 kW Tj = operation limit temperature

COPd

or PERd

2,43 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,02 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 31600

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

85,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

18

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 090 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 204,00 kW

Seasonal space heating energy

efficiency

ηs 129,48 %

Seasonal coefficient of performance SCOP 3,31 --

T

j

= – 7 °C

Pdh 156,03 kW Tj = – 7 °C

COPd

or PERd

2,74 -- o %

T

j

= + 2 °C

Pdh 199,85 kW Tj = + 2 °C

COPd

or PERd

3,76 -- o %

T

j

= + 7 °C

Pdh 229,15 kW Tj = + 7 °C

COPd

or PERd

4,55 -- o %

T

j

= + 12 °C

Pdh 263,35 kW Tj = + 12 °C

COPd

or PERd

5,49 -- o %

Tj = bivalent

temperature

Pdh 164,77 kW Tj = bivalent temperature

COPd

or PERd

2,94 -- o %

Tj = operation limit

temperature

Pdh 144,01 kW Tj = operation limit temperature

COPd

or PERd

2,48 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,08 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 35600

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

86,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

19

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 100 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 214,69 kW

Seasonal space heating energy

efficiency

ηs 129,00 %

Seasonal coefficient of performance SCOP 3,30 --

T

j

= – 7 °C

Pdh 164,12 kW Tj = – 7 °C

COPd

or PERd

2,74 -- o %

T

j

= + 2 °C

Pdh 210,18 kW Tj = + 2 °C

COPd

or PERd

3,74 -- o %

T

j

= + 7 °C

Pdh 240,69 kW Tj = + 7 °C

COPd

or PERd

4,53 -- o %

T

j

= + 12 °C

Pdh 276,43 kW Tj = + 12 °C

COPd

or PERd

5,47 -- o %

Tj = bivalent

temperature

Pdh 173,40 kW Tj = bivalent temperature

COPd

or PERd

2,93 -- o %

Tj = operation limit

temperature

Pdh 151,43 kW Tj = operation limit temperature

COPd

or PERd

2,48 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,10 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 35600

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

86,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

20

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 110 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 243,68 kW

Seasonal space heating energy

efficiency

ηs 123,15 %

Seasonal coefficient of performance SCOP 3,15 --

T

j

= – 7 °C

Pdh 186,24 kW Tj = – 7 °C

COPd

or PERd

2,64 -- o %

T

j

= + 2 °C

Pdh 239,12 kW Tj = + 2 °C

COPd

or PERd

3,58 -- o %

T

j

= + 7 °C

Pdh 273,99 kW Tj = + 7 °C

COPd

or PERd

4,30 -- o %

T

j

= + 12 °C

Pdh 314,13 kW Tj = + 12 °C

COPd

or PERd

5,16 -- o %

Tj = bivalent

temperature

Pdh 196,82 kW Tj = bivalent temperature

COPd

or PERd

2,82 -- o %

Tj = operation limit

temperature

Pdh 171,58 kW Tj = operation limit temperature

COPd

or PERd

2,39 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,27 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 49500

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

86,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

21

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 120 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 280,95 kW

Seasonal space heating energy

efficiency

ηs 128,27 %

Seasonal coefficient of performance SCOP 3,28 --

T

j

= – 7 °C

Pdh 214,69 kW Tj = – 7 °C

COPd

or PERd

2,76 -- o %

T

j

= + 2 °C

Pdh 275,53 kW Tj = + 2 °C

COPd

or PERd

3,73 -- o %

T

j

= + 7 °C

Pdh 315,66 kW Tj = + 7 °C

COPd

or PERd

4,47 -- o %

T

j

= + 12 °C

Pdh 361,89 kW Tj = + 12 °C

COPd

or PERd

5,36 -- o %

Tj = bivalent

temperature

Pdh 226,92 kW Tj = bivalent temperature

COPd

or PERd

2,95 -- o %

Tj = operation limit

temperature

Pdh 197,81 kW Tj = operation limit temperature

COPd

or PERd

2,50 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,30 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 47400

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

85,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

22

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 130 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 298,86 kW

Seasonal space heating energy

efficiency

ηs 127,63 %

Seasonal coefficient of performance SCOP 3,27 --

T

j

= – 7 °C

Pdh 228,74 kW Tj = – 7 °C

COPd

or PERd

2,74 -- o %

T

j

= + 2 °C

Pdh 292,68 kW Tj = + 2 °C

COPd

or PERd

3,71 -- o %

T

j

= + 7 °C

Pdh 335,08 kW Tj = + 7 °C

COPd

or PERd

4,44 -- o %

T

j

= + 12 °C

Pdh 384,19 kW Tj = + 12 °C

COPd

or PERd

5,32 -- o %

Tj = bivalent

temperature

Pdh 241,39 kW Tj = bivalent temperature

COPd

or PERd

2,93 -- o %

Tj = operation limit

temperature

Pdh 211,38 kW Tj = operation limit temperature

COPd

or PERd

2,48 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,30 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,41 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 47400

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

85,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

23

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 140 SN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 333,21 kW

Seasonal space heating energy

efficiency

ηs 132,60 %

Seasonal coefficient of performance SCOP 3,39 --

T

j

= – 7 °C

Pdh 255,56 kW Tj = – 7 °C

COPd

or PERd

2,85 -- o %

T

j

= + 2 °C

Pdh 324,21 kW Tj = + 2 °C

COPd

or PERd

3,85 -- o %

T

j

= + 7 °C

Pdh 371,12 kW Tj = + 7 °C

COPd

or PERd

4,60 -- o %

T

j

= + 12 °C

Pdh 425,80 kW Tj = + 12 °C

COPd

or PERd

5,51 -- o %

Tj = bivalent

temperature

Pdh 269,13 kW Tj = bivalent temperature

COPd

or PERd

3,05 -- o %

Tj = operation limit

temperature

Pdh 237,30 kW Tj = operation limit temperature

COPd

or PERd

2,58 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

1,30 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,52 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 47400

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m

3

/h

Sound power level,

outdoors

L

WA

85,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

24

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.

For low temperature heat pumps, parameters shall be declared for low-temperature application.

Parameters shall be declared for average climate conditions.

Model/Version HAST 070 SSN

Air-to-water heat pump: YES

Water-to-water heat pump: NO

Brine-to-water heat pump: NO

Low-temperature heat pump: YES

Equipped with a supplementary heater: NO

Heat pump combination heater: NO

Item Symbol Value Unit Item Symbol Value Unit

Rated heat output Prated 155,05 kW

Seasonal space heating energy

efficiency

ηs 125,85 %

Seasonal coefficient of performance SCOP 3,22 --

T

j

= – 7 °C

Pdh 118,88 kW Tj = – 7 °C

COPd

or PERd

2,64 -- o %

T

j

= + 2 °C

Pdh 151,24 kW Tj = + 2 °C

COPd

or PERd

3,66 -- o %

T

j

= + 7 °C

Pdh 173,28 kW Tj = + 7 °C

COPd

or PERd

4,43 -- o %

T

j

= + 12 °C

Pdh 198,94 kW Tj = + 12 °C

COPd

or PERd

5,34 -- o %

Tj = bivalent

temperature

Pdh 125,23 kW Tj = bivalent temperature

COPd

or PERd

2,84 -- o %

Tj = operation limit

temperature

Pdh 110,37 kW Tj = operation limit temperature

COPd

or PERd

2,37 -- o %

Bivalent

temperature

Tbiv -5 °C

For air-to-water heat pumps:

Operation limit temperature

TOL -10 °C

Degradation coefficient

Cdh 0,9 —

Heating water operating limit

temperature

WTOL 55 °C

Power consumption in modes other than active mode Supplementary heater*

Off mode

P

OFF

0kW

Rated heat output Psup -- kW

Thermostat-off

mode

P

TO

0,82 kW

Standby mode

P

SB

0,02 kW

Type of energy input --

Crankcase heater

mode

P

CK

0,30 kW

Other items

For air-to-water heat pumps: Rated

air flow rate, outdoors

- 24600

m

3

/h

Capacity control

fixed/

variable

fixed

Sound power level,

indoors

L

WA

--

dB(A)

For water-/brine-to-water heat

pumps: Rated brine or water flow

rate, outdoor heat exchanger

---

m3/h

Sound power level,

outdoors

L

WA

80,0

Contact details M.T.A. S.p.A. Via Artigianato, 2 - 35026 Conselve (PD) Italy

Parameters are declared with variable water temperature output.

*if available

MAINTENANCE AND OPERATING MANUAL

Technical parameters for heat pump space heaters and heat pump combination heaters

HAS T 070÷140

25

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

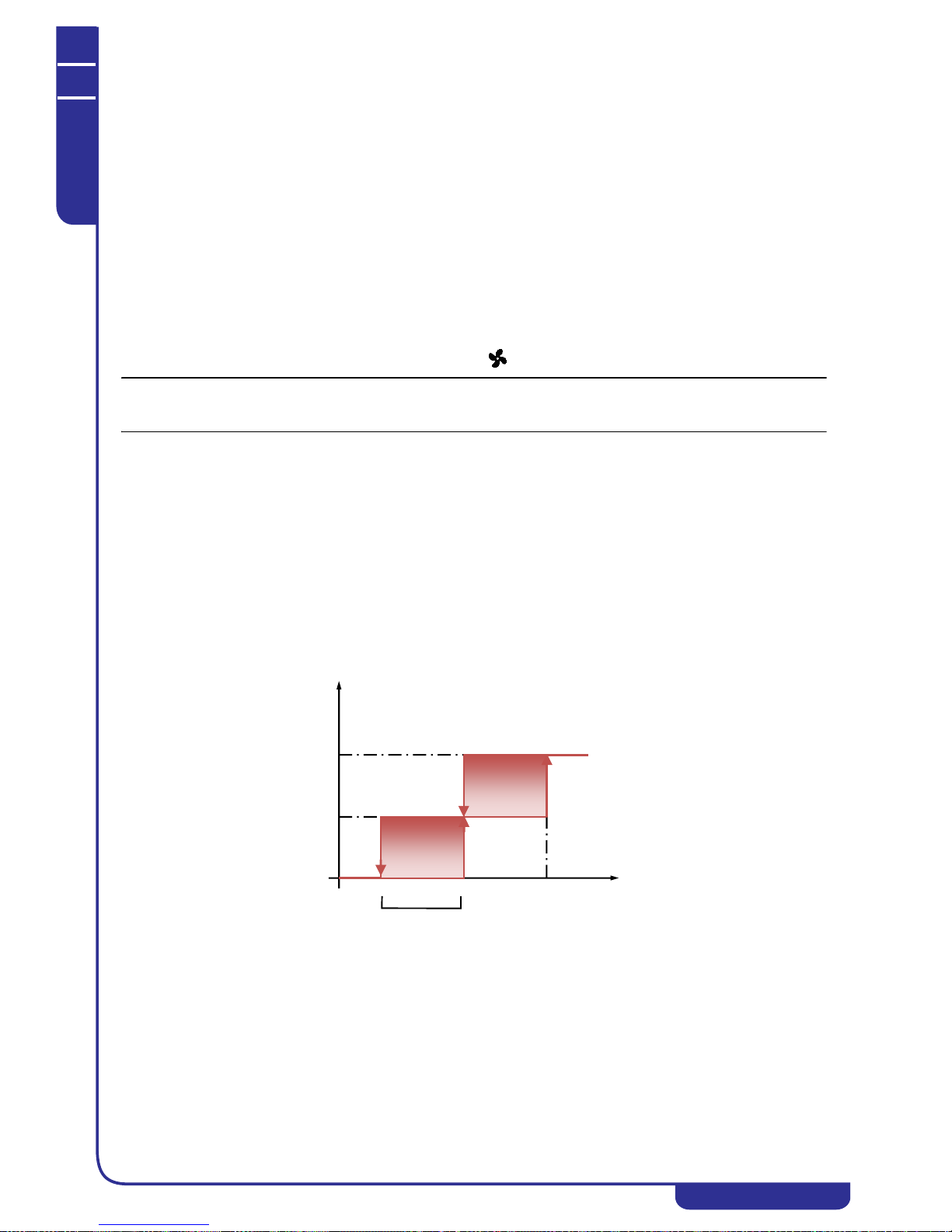

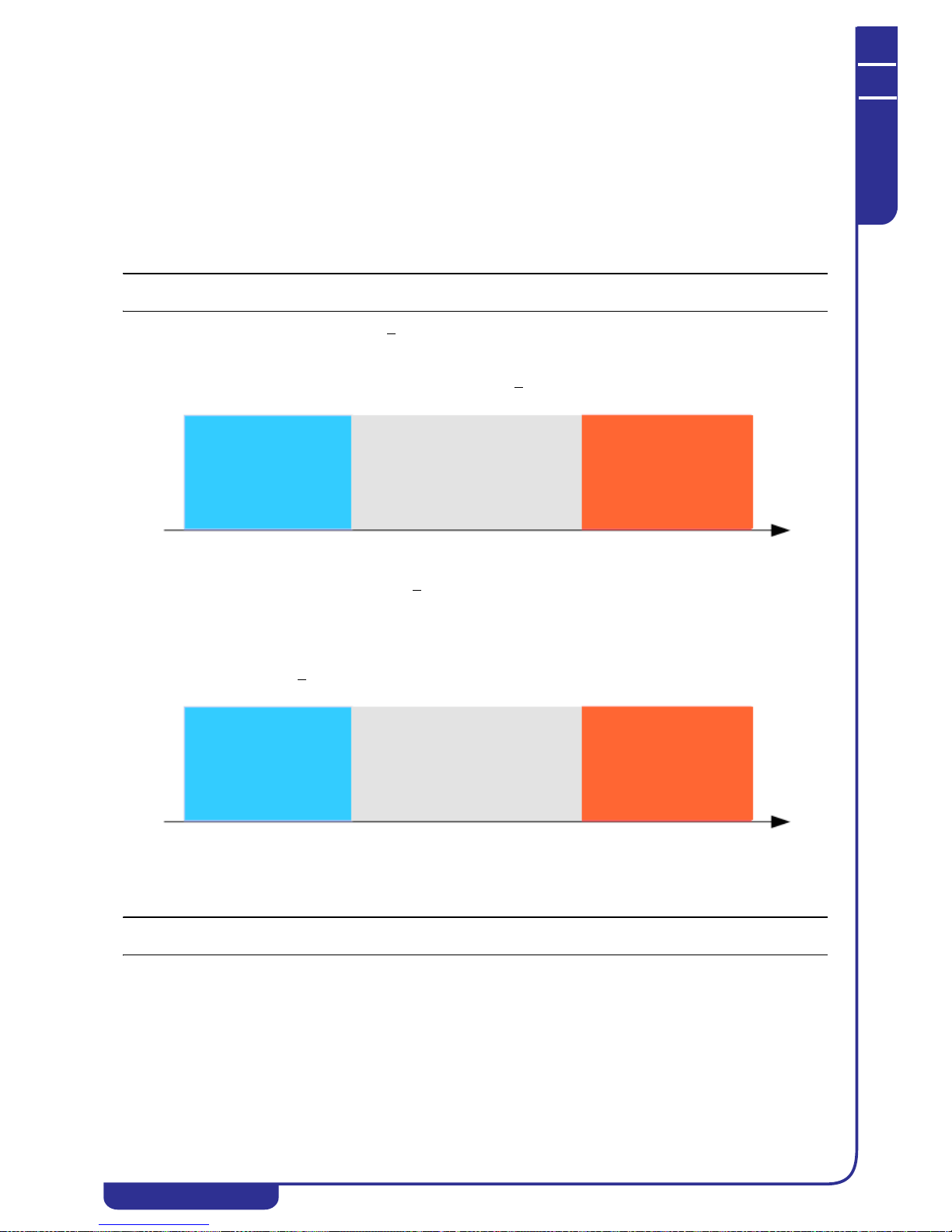

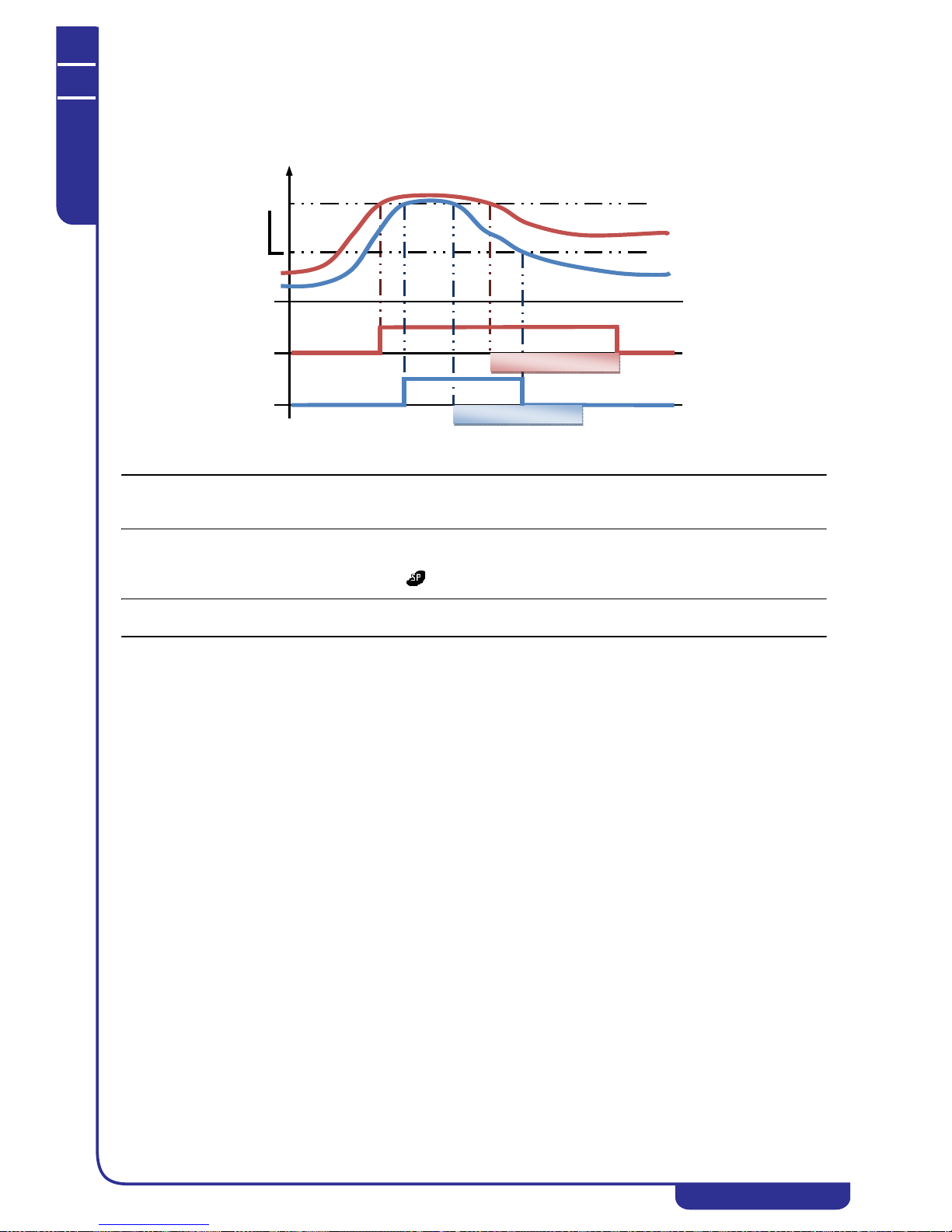

Parameters shall be declared for medium-temperature application, except for low-temperature heat pumps.