Page 1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 1 / 7

INSTRUCTION MANUAL

RELAY CONTACT OUTPUT MODULE, 8 points

(Modbus)

MODEL

R7M-DC8C

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Discrete output module.......................................................(1)

Terminating resistor (110Ω, 0.25W) ...................................(1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■ CONFORMITY WITH EU DIRECTIVES

•This equipment is suitable for Pollution Degree 2 and

Measurement Category II (output, transition voltage

1500V) with the maximum operating voltage 125V.

*1

Ba-

sic insulation (output to power: 150V)

*2

is maintained.

Prior to installation, check that the insulation class of

this unit satisfies the system requirements.

*1. For use in Measurement Category I (output, transition

voltage 1500V) with the maximum operating voltage

250V.

*2.

For use in Measurement Category I, 300V.

•The equipment must be mounted inside the instrument

panel of a metal enclosure.

•Altitude up to 2000 meters.

•The equipment must be installed such that appropriate

clearance and creepage distances are maintained to conform to CE requirements. Failure to observe these requirements may invalidate the CE conformance.

•The actual installation environments such as panel configurations, connected devices and connected wires may

affect the protection level of this unit when it is integrated in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure CE conformity.

■ POWER INPUT RATING & OPERATIONAL RANGE

•Locate the power input rating marked on the product and

confirm its operational range as indicated below:

24V DC rating: 24V ±10%, approx. 60mA

■ GENERAL PRECAUTIONS

•Before you remove the unit or mount it, turn off the power

supply and output signal for safety.

■ ENVIRONMENT

•Indoor use.

•When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

•Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

•Environmental temperature must be within -10 to +55°C

(14 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■ WIRING

•Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

•Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■ AND ....

•The unit is designed to function as soon as power is supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

Page 2

R7M-DC8C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 2 / 7

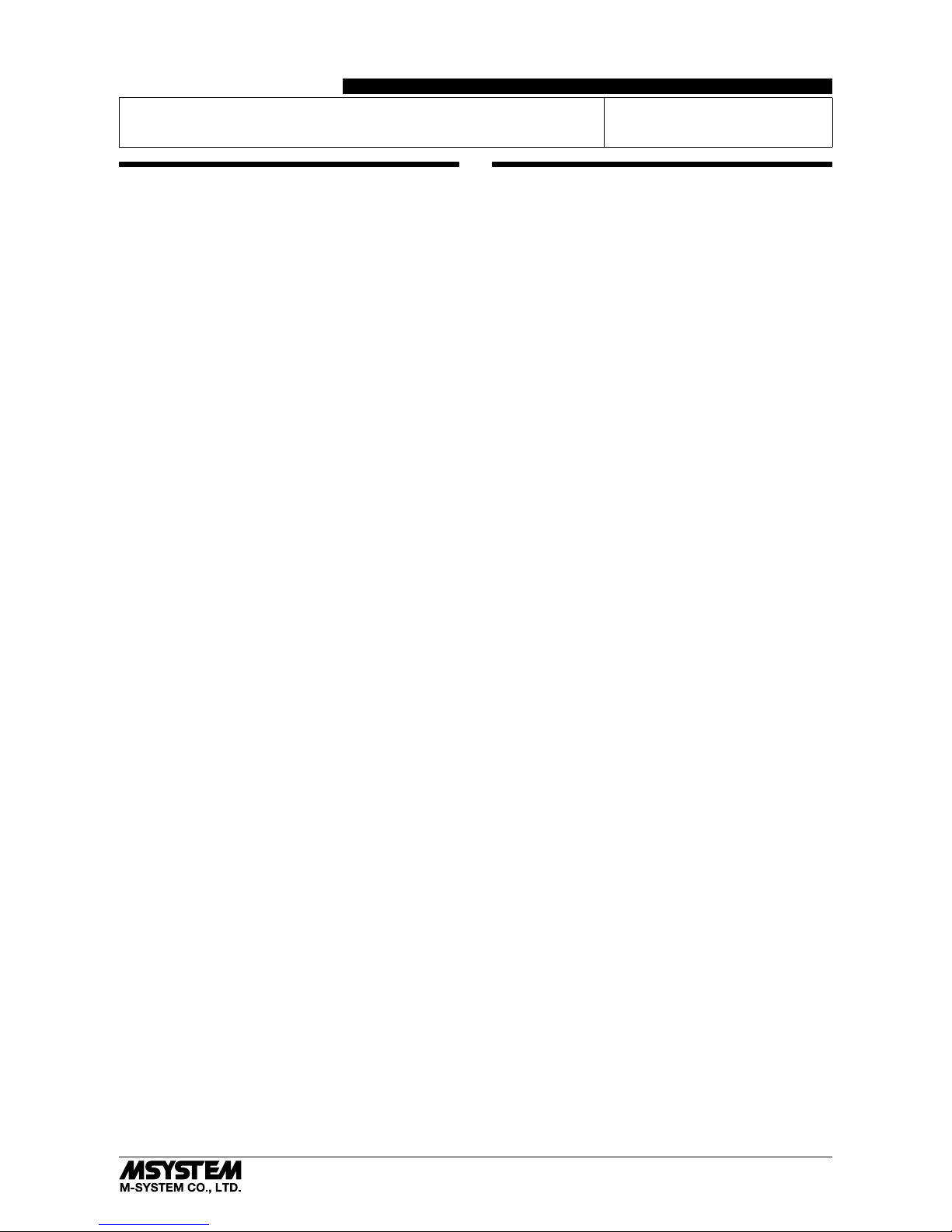

COMPONENT IDENTIFICATION

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

ERR

RD

RUN SD

PWR

X10 X1

NODE ADD. B.RATE

1 2 3 4 5 6 7 8

0 1 2 3 4 5 6 7 8 9 A B C D E F

4567

123

10 11 12 13

2341

15 16 17 18

7896145

(A) Status Indicator LED

(B) Node Address Setting Rotary SW

(C) Baud Rate Setting Rotary SW

(D) Operating Mode Setting DIP SW (SW1)

(E) Discrete Output Status Indicator LED

(F) Modbus, Power Supply Terminals

(G) Output Terminals

(F) (G)

(B)(A) (C) (D) (E)

■ STATUS INDICATOR LED

ID COLOR FUNCTION

PWR Red

Turns on when the internal 5V is supplied

normally.

RUN Red

Turns on when the data is received normally.

ERR Red

Turns on when the received data is

abnor-

mal. Blinks when setting is abnormal.

SD Red Turns on when the module is transmitting.

RD Red Turns on when the module is receiving.

■ NODE ADDRESS

Node Address is selected between 1 and 99 in decimal. The

left switch determines the tenth place digit, while the right

switch does the ones place digit of the address.

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

Node Address Setting (x1)

Factory setting : 00

Node Address Setting (x10)

■ BAUD RATE

Baud Rate is selected with the rotary switch.

5

4

3

2

1

0

9

8

7

6

Baud Rate Setting

0 : 38.4 kbps (factory setting)

1 : 19.2 kbps

2 : 9600 bps

3 : 4800 bps

■ OPERATING MODE

(*) Factory setting

• Output at the Loss of Communication (SW1-4)

SW1-4 OUTPUT AT THE LOSS OF COMMUNICATION

OFF Reset the output (turned off)

ON

Hold the output (*)(maintains the last data received

normally)

Note : Be sure to set unused SW1-1 through 1-3 and 1-5 through

1-8 to OFF.

■ DISCRETE OUTPUT STATUS INDICATOR LED

LED indicators show the signal status.

ON : LED ON

OFF : LED OFF

■ POWER SUPPLY, MODBUS TERMINAL ASSIGNMENT

4DA5DG6

+24V

1DB2

SLD3FG

7

0V

NO. ID FUNCTION, NOTES

1 DB ---2 SLD Shield

3 FG FG

4 DA ---5 DG ---6 +24V Power input (24V DC)

7 0V Power input (0V)

■ OUTPUT TERMINAL ASSIGNMENT

10

+24V11Y012Y1

10V2

COM03COM0

13

Y2

4

COM0

14

Y3

5

COM0

15

Y4

6

COM1

16

Y5

7

COM1

17

Y6

8

COM19COM1

18

Y7

NO.

ID FUNCTION

NO.

ID FUNCTION

1 0V 0V 10 +24V 24V DC

2 COM0 Common 0 11 Y0 Output 0

3 COM0 Common 0 12 Y1 Output 1

4 COM0 Common 0 13 Y2 Output 2

5 COM0 Common 0 14 Y3 Output 3

6 COM1 Common 1 15 Y4 Output 4

7 COM1 Common 1 16 Y5 Output 5

8 COM1 Common 1 17 Y6 Output 6

9 COM1 Common 1 18 Y7 Output 7

Page 3

R7M-DC8C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 3 / 7

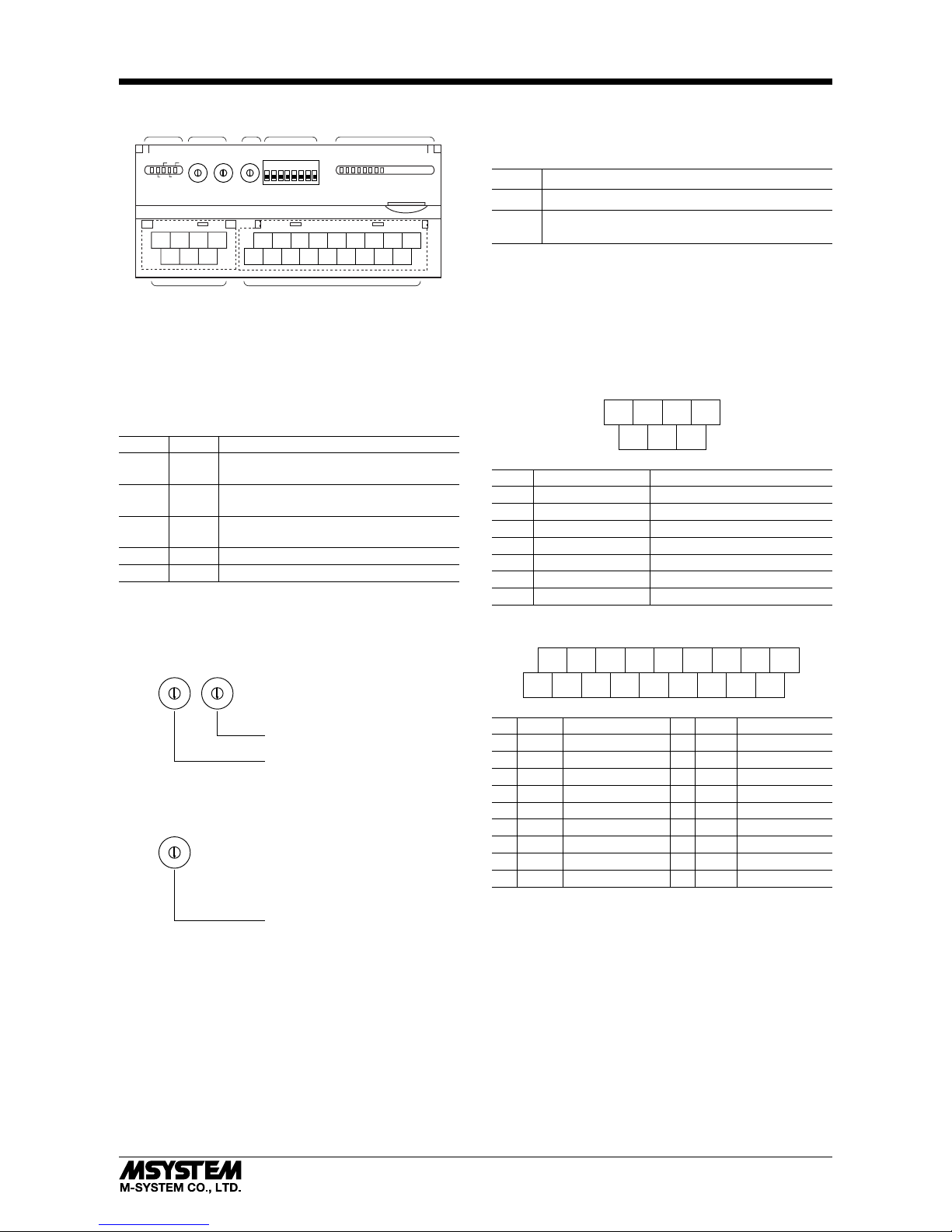

WIRING INSTRUCTIONS

■ SCREW TERMINAL

Torque: 0.5 N·m

■ SOLDERLESS TERMINAL

Refer to the drawing below for recommended ring tongue

terminal size. Spade tongue type is also applicable. Solderless terminal:

Applicable wire size: 0.25 to 1.65 mm

2

(AWG 22 to 16)

Recommended manufacturer: Japan Solderless Terminal

MFG. Co., Ltd, Nichifu Co., Ltd

6 (.24) max

3.3 (.13) max

mm (inch)

CONNECTION DIAGRAM

Connect the unit as in the diagram below.

4 Points / common

10

14

1

2

5

11

+

24V

Y0

0V

Y3

COM0

COM0

+

–

+

–

18

6

9

15

Y4

Y7

COM1

COM1

+

–

+

–

8 Points / common

10

14

1

2

5

11

+

24V

24V DC

Y0

0V

+

–

Y3

15

Y4

18

Y7

COM0

COM0

6

9

COM1

COM1

+

–

+

–

24V DC

+

–

5

2

6

4

7

13

8

9

14

12

15

11

16

17

18

COM0

COM0

COM0

Y0

Y1

Y2

Y3

COM0

COM1

COM1

COM1

Y4

Y5

Y6

Y7

COM1

3

4

1

2

5

3

FG

6

7

24 V DC

0 V

SLD

DG

DB

DA

10

1

0 V

+

24 V

■ Output Connection Example

In order to improve EMC performance, bond the FG

terminal to ground.

Caution: FG terminal is NOT a protective conductor terminal.

MASTER CONNECTION

■ MASTER CONNECTION

Tx+/Rx+

Tx–/Rx–

SG

Rx+

Rx–

Host PC

DA

DB

DG

SLD

FG

Remote Unit

DA

DB

DG

SLD

FG

Remote Unit

TERMINATOR TERMINATOR

Be sure to connect the terminating resistor included in the product package to the unit at both ends of transmission line.

The terminator must be connected across DA and DB.

The Host PC can be located other than at the extreme ends of transmission line.

Page 4

R7M-DC8C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 4 / 7

EXTERNAL DIMENSIONS unit: mm (inch)

4567

123

10 11 12 13

2341

15 16 17 18

78

9

6145

30 (1.18)

[5 (.20)]

3 (.12)5.5 (.22)

DIN RAIL

35mm wide

54 (2.13)

17 (.66)

50 (1.97)

18.5 (.73)

115 (4.53)

7–M3 SCREW

TERMINALS

for Modbus, POWER

18–M3 SCREW

TERMINALS

for OUTPUT

6 (.24)

6 (.24)

CONFORMITY WITH CE MARKING

■ CE MARKING

CE marking requires to integrate safety regulations existed in each country in EU territory and to secure smooth distribution

of products of which safety is guaranteed. It is mandatory by law that products distributed and sold in EU territory to have

CE mark which shows that the product conforms with the requirements of EU Directive. Each EU Directive describes the

scope of apparatuses to which that EU Directive is applied. M-System’s R7M must conform with EMC Directive.

Each Directive states only basic requirements. In order to mark the CE on an assembled machinery equipment, its manufacturer needs to check the overall conformity with Directives applicable to it.

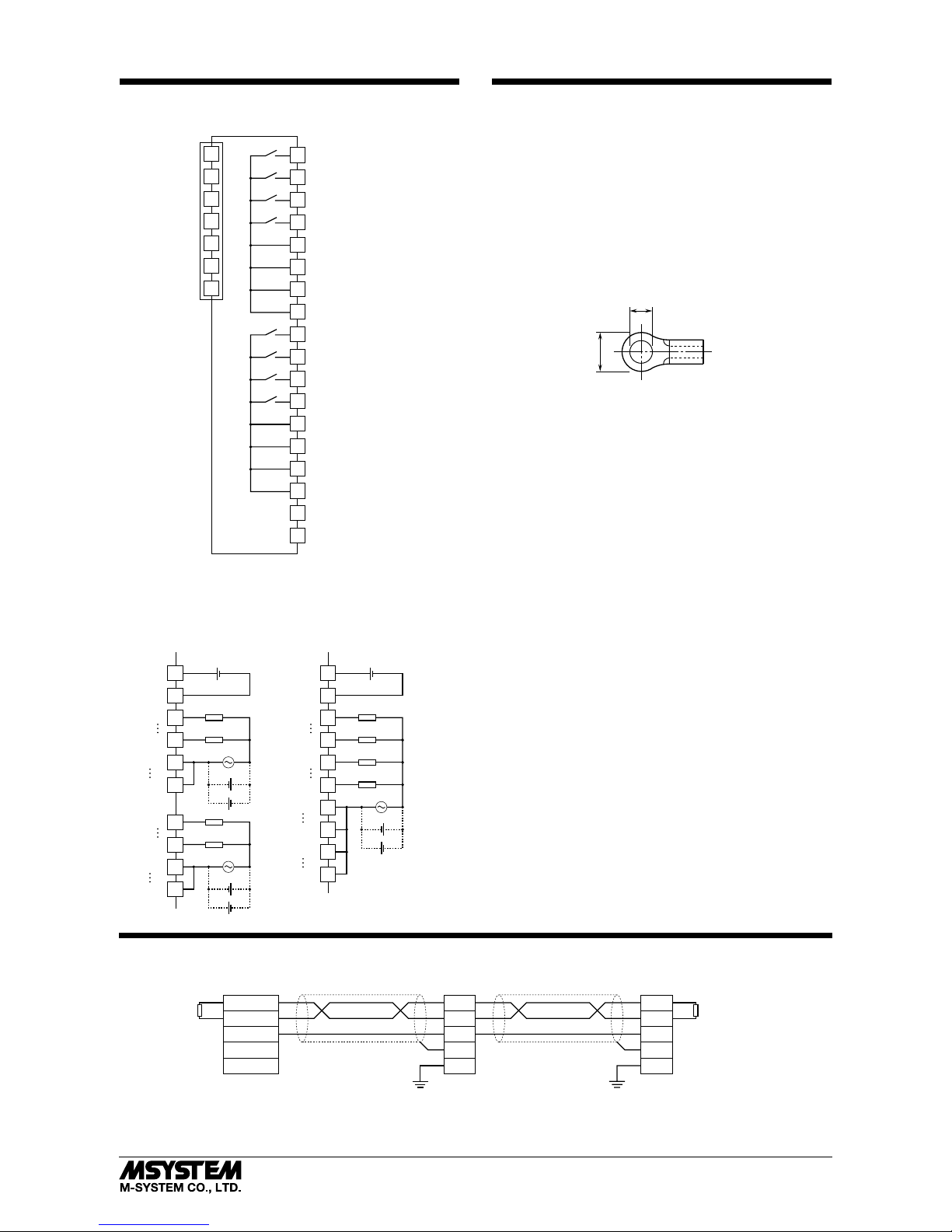

■ WARNINGS AND CAUTIONS WHEN INSTALLING THE R7M

The R7M needs to be installed in a control panel. This is effective not only to ensure general safety but also to contain noise

emissions by the R7M inside the control panel. We conduct a series of testing to see that the product conforms to EMC Directive while it is installed in the control panel.

Warning and cautions when installing R7M are stated below.

•Use control panels with an internal panel plate, both made of metal, when installing the R7M.

•Make sure to adequately ground the control panel and the internal panel plate with a thick cable to maintain low imped-

ance at high frequency.

•Use shielded cables for the signals taken out of the control panel.

•Choose a thick and short cable to ground the FG terminal of the R7M module to the internal panel plate of the control panel.

•Note: If electromagnetic radiation disturbance increases by grounding the FG terminal, remove the grounding.

•When painting the internal plate of the control panel, apply masking to expose metal surface to secure conductivity at the

sections where the following parts are attached:

- Bolts attaching the internal panel to the control panel

- Ground for the FG of the R7M module

- Earth clamp on the shielded cable

•Noise emissions inside the control panel might leak through its openings. Design them as small as possible. Recommended

diameter is 10 cm or less.

Supplement:

Additional measures may be taken depending upon actual installation sites. These points of cautions are illustrated in the

next page.

•Prevent noise leakage by wrapping cables using shield covers, shield tubes and flexible conduits etc. if noise leaks through

the cable outlet.

•Use an electromagnetic shield gasket and block up the gap between the control panel cabinet and its cover, if noise leaks

through it.

•Connecting the internal panel plate and the cover of the control panel to the main cabinet using an earth strap may be

effective to strengthen the grounding.

•Electromagnetically shielded control panel cabinet is effective for shielding.

Page 5

R7M-DC8C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 5 / 7

Use (e.g.) a shield cover

when noise leaks through

the opening.

To external apparatus

Keep the opening

for cabling as small as

possible.

Install an electromagnetically

shielded gasket when

noise leaks through

the opening.

Shielding is strengthened

by using an electromagnetically shielded

control panel.

By connecting the

internal panel plate

and the panel cover with

an earth strap, grounding

may be strengthened and

EMC may be improved.

Ground the control panel

at low impedance using

(e.g.) braided wires.

Keep the opening for

ventilation as small as

posible.

Attach an electromagnetically shielded

filter when noise leaks

through the opening.

Install the R7M Series inside

a control panel.

Attachment part of earth

clamp should be fixed with

screw in conduction with the

internal panel plate.

• Points of cautions applicable when installing the R7M Series

Page 6

R7M-DC8C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 6 / 7

■ WARNINGS AND CAUTIONS WHEN LAYING CABLES

Signal cables connected to the R7M contain high-frequency components. Since these cables has the same effect as an antenna, they emit these high-frequency components to the external space as noise or overlaps noise from the external space

on themselves.

Cables with shielding should be used for the signal line due to the above reason.

EMC conformance test is conducted in the condition that shielded cables and earth clamps are used with the R7M.

Warning and cautions when laying cables are stated below. These points of cautions are illustrated in the next page.

•Use shielded cables for those signal cables installed out of the control panel and for thermocouple and RTD extension wires.

•All the network cables connected to R7M should be shielded.

•Use shielded cables for network communication.

•Expose the shield at a part of the cable cover, clip it with an earth clamp, and ground it to the internal panel of the control

panel. A drain wire connected to the panel in a pig-tail form cannot maintain low impedance against high-frequency noise,

thus grounding (noise shielding) in this form will not be effective.

Supplement:

Additional measures may be taken depending upon actual installation sites. These points of cautions are illustrated in the

next page.

•Keep cables as short as possible. It prevents noise emissions from the cables and noise overlapping to the cables.

•Attach a ferrite core to reduce noise impact to the signal cables susceptible to the noise. Ferrite core can be attached close

to the cable outlet of the control panel or close to the I/O terminal or connector, whichever is more effective. Also, the impact

might be reduced by winding the cable around the ferrite core for extra turns or attaching multiple ferrite cores.

•Keep cables which are easily affected by noise away from those which can be a noise source.

•Keeping physical distance (farther than 20 cm from motor drive cables, farther than 10 cm for other groups).

Motor Drive

Cable

Power Supply

Cable

DC Signal Cable

Network Cable

Analog Signal

Cable

Often being a noise source Often subject to noise interference.

In the following are examples of effective ways to lay cables separately:

•Dividing off by a grounded metal plate

•Grouping into separate grounded metal pipes or cable shields.

Wires on each side of a filter should not be too close to each other. Noise could ride onto the other side of cable.

Extra attention needs to be paid at the following parts.

•Noise filter that is enclosed in power cables.

•Ferrite core that is attached to signal cables.

•Noise limiting circuit (surge quenching circuit, transient absorber circuit, etc.) that is enclosed in signal cables.

Page 7

R7M-DC8C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-7803-U Rev.4 P. 7 / 7

Noise

Filter

Motor

Drive Cable

Maintain distance between

cables and noise sources.

Grounding in pig tail form

is not effective.

• Points of cautions applicable when wiring the R7M Series

To external apparatus

Keep the cable as

short as possible.

To external apparatus

Shielded

Cable

Earth

Clamp

Remove a part of the shielded

cable cover and ground it

to the internal panel

plate using an earth

clamp.

To connect with

apparatuses outside

the control panel via

Modbus, ground the

cable shield using

an earth clamp.

Keep the wires away from

each other at both ends of

the filter.

Loading...

Loading...