Page 1

R3-WT1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8388 Rev.3 P. 1 / 5

MULTI POWER INPUT MODULE

MODEL

R3-WT1

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

the contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Multi power input module .............................................(1)

■ MODEL NO.

Confirm that the model number described on the product is

exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

In order to set up the software setting of this module, PC

Configurator Software (model: R3CON) is required. For

more information, please refer to the users manual for the

R3CON.

The R3CON PC Configurator Software is downloadable at

MSystem’s web site: http://www.m-system.co.jp.

POINTS OF CAUTION

■ HOT INSERTION/REMOVAL OF MODULES

•Removing or replacing modules does not affect other modules on the same backplane. It is possible to replace them

without removing the power supply. However, replacing

multiple modules at once may greatly change line voltage

levels. We recommend that you replace them one by one.

■ ENVIRONMENT

•Indoor use

•When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

•Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

•Environmental temperature must be within -10 to +55°C

(14 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■ WIRING

•Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

•Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■ AND ....

•The unit is designed to function as soon as power is supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

INSTALLATION

Use the Installation Base (model: R3-BSx).

Page 2

R3-WT1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8388 Rev.3 P. 2 / 5

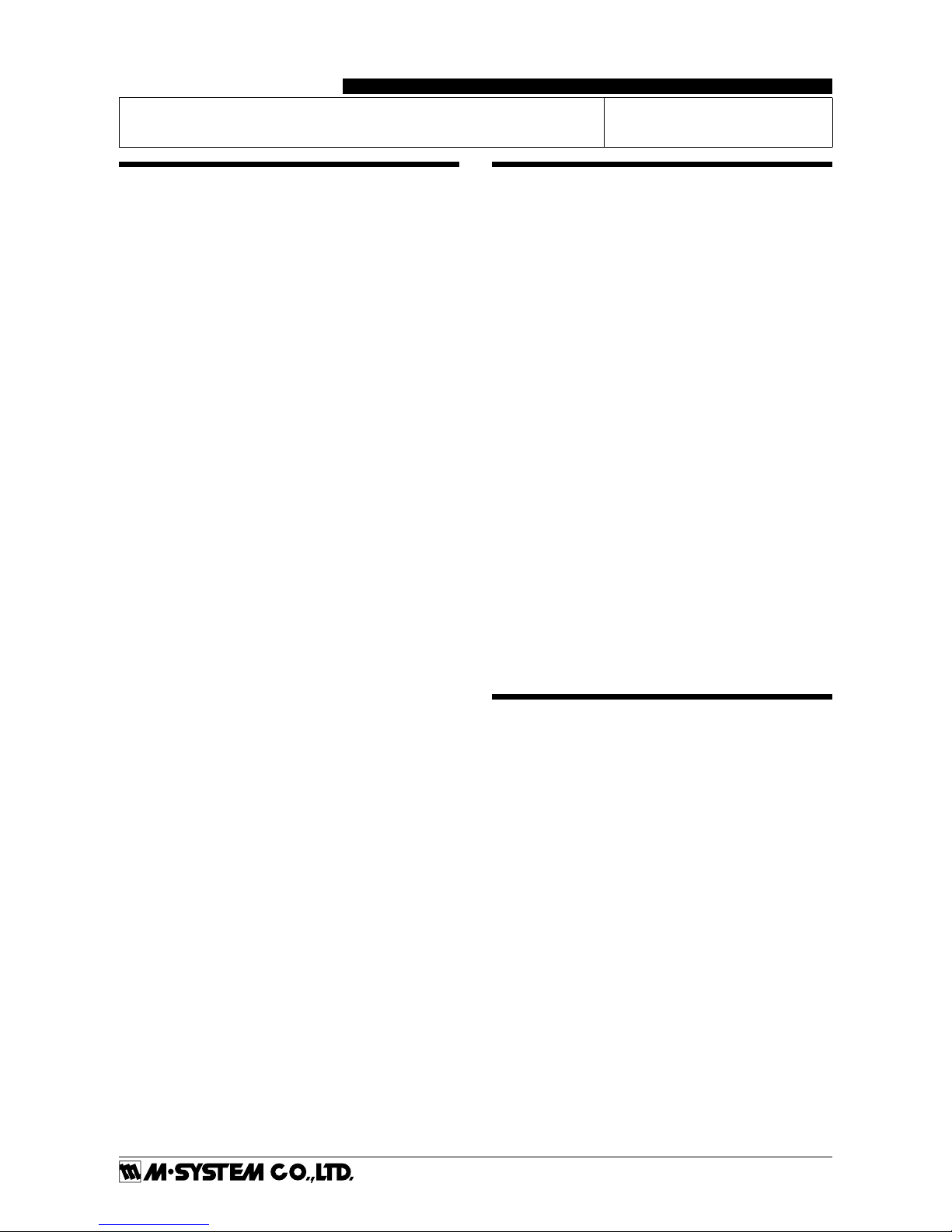

COMPONENT IDENTIFICATION

■ FRONT VIEW

RUN LED

ERR LED

1

2

3

4

5

6

7

8

9

10

■ SIDE VIEW

ON

8

7

6

5

4

3

2

1

SW1SW2

ON

8

7

6

5

4

3

2

1

SW3

ON

4

3

2

1

■ SIDE DIP SW

(*) Factory setting

Be sure to turn off the power supply to the module whenchanging settings. Reset the count after setting changes.

• SW1, SW2

Count Reset Enable : Back to 0 at overflow

Disable : Halt at 999 999 999

Power Factor may start hunting around 1.

SW FUNCTION

0 : OFF(*)

1 : ON

SW1-2 active energy count reset disable enable

SW1-3 active energy

bidirectional current

disable enable*

1

SW1-6 active energy count reset disable enable

SW1-7 active energy

bidirectional current

disable enable*

1

SW2-1 power factor LEAD polarity normal inverted

*1. Both active energy count reset and reactive energycount re-

set are fixed at ‘disable.’

The count stops at ±999 999 999.

When the bidirectional current computation is enabled,the

outgoing active energy and the LEAD reactive energy become 0.

Power Factor Polarity

0

-1.0

1.0

COS

q

DEG

90-90-180

(LEAD)

180

(LAG)

Inverted

Normal

• SW3

The maximum available active energy count is 109.

SW

0 : OFF(*)

1 : ON

SW3-1 ---- count reset

How to Reset

Set the SW3-1 to ON and turn on the power supply. Wait

until the RUN LED (red) starts flashing and the ERR LED

(green) turns on. Then turn the power supply off and reset

the SW3-1 to OFF.

Turn all switches off other than the above.

■ STATUS INDICATOR LED

RUN indicator: Bi-color (red/green) LED;

Red when the bus A operates normally;

Green when the bus B operates normally;

Amber when both buses operate normally.

ERR indicator: Bi-color (red/green) LED;

Red with the input abnormality;

Green in normal operating conditions.

Page 3

R3-WT1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8388 Rev.3 P. 3 / 5

PC CONFIGURATOR

The following parameters can be set with using PC Configurator Software (model: R3CON):

•Enter fine 0% adjustment value

•Enter fine 100% adjustment value

•Low-end cutout value in %

•Primary voltage

•Primary voltage, Exponent (10

n

)

•Primary current

•Primary current, exponent 10

n

•Active/Reactive Power, span value

•Active/Reactive Power, exponent 10

n

•Active Energy unit, exponent 10

n

•Minimum totalized value

•Maximum totalized value

•Reactive Energy unit, exponent 10

n

•Minimum totalized value

•Maximum totalized value

TRANSMISSION DATA DESCRIPTIONS

ADDRESS CONTENTS

n Active power *

2

n + 1 Reactive power *

2

n + 2 Power factor *

2

n + 3 Frequency *

2

n + 4 Incoming active energy (lower bits) *

3

n + 5 Incoming active energy (upper bits)

n + 6 Outgoing active energy (lower bits) *

3

n + 7 Outgoing active energy (upper bits)

n + 8 LAG reactive energy (lower bits) *

3

n + 9 LAG reactive energy (upper bits)

n +10 LEAD reactive energy (lower bits) *

3

n +11 LEAD reactive energy (upper bits)

n +12 0

n +13 0

n +14 0

n +15 0

R3CON type ID WT1****

Network module 4, 8, 16

data allocation

mode example *

1

n = I/O address on the installation base

Factory setting = 1 kWh and 1 kvarh per bit.

Data address depends upon the data allocation mode as

indicated below:

4 (n thr. n+3)

8 (n thr. n+7)

16 (n thr. n+15)

*1. Fixed at 16 for the R3-NPx.

*2. 16-bit data

*3. 32-bit data

I/O DATA DESCRIPTIONS

■ 16-BIT DATA

■

0

15

16-bit binary data. Minus values are represented in 2’s complements.

32-BIT DATA

1631

0

15

stigid rewolstigid reppu

32-bit binary data. Minus values are represented in 2’s complements.

Page 4

R3-WT1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8388 Rev.3 P. 4 / 5

TERMINAL CONNECTIONS

Connect the unit as in the diagram below.

■ DIMENSIONS mm (inch)

130 (5.12)

52.5 (2.07)

109 (4.29)

7.9

(.31)

1

2

3

4

5

6

7

8

9

10

10–M3.5

SCREW

POSITIONING

GUIDE

TERMINAL

COVER

■ CONNECTION DIAGRAM

BUS CONNECTOR

INTERNAL

POWER

INTERNAL

BUS A

INTERNAL

BUS B*

VOLTAGE

INPUT

1

3

4

2

LOAD

123

SOURCE

P2V

P1Uvu

FUSE

VT

Vv

P3

Uu

CURRENT

INPUT

5

7

8

6

LOAD

123

SOURCE

k

l

CT

L

K

1L

1S

3L

3S

k

l

L

K

■ 3-PHASE/3-WIRE

BUS CONNECTOR

INTERNAL

POWER

INTERNAL

BUS A

INTERNAL

BUS B*

■ SINGLE-PHASE/3-WIRE

BUS CONNECTOR

INTERNAL

POWER

INTERNAL

BUS A

INTERNAL

BUS B*

■ SINGLE-PHASE/2-WIRE

VOLTAGE

INPUT

1

3

4

2

LOAD

12

SOURCE

P2

P1

5

7

8

6

VUv

u

VT

FUSE

CURRENT

INPUT

LOAD

12

SOURCE

1L

1S

k

l

L

K

CT

*For dual redundant communication.

VOLTAGE

INPUT

1

3

4

2

LOAD

1N2

SOURCE

P0V

P1Uvu

FUSE

VT

Vv

P2

Uu

CURRENT

INPUT

5

7

8

6

LOAD

1N2

SOURCE

k

l

CT

L

K

1L

1S

2L

2S

k

l

L

K

Page 5

R3-WT1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8388 Rev.3 P. 5 / 5

WIRING INSTRUCTIONS

■ SCREW TERMINAL

Torque: 0.8 N·m

■ SOLDERLESS TERMINAL mm (inch)

Refer to the drawing below for recommended ring tongue

terminal size. Spade tongue type is also applicable. Solderless terminals with insulation sleeve do not fit.

Applicable wire size: 0.75 – 2 mm

2

3.7 (.15) dia.

6 min.

(.24)

14.5 (.57) max.

7 max.

(.28)

3.5 (.14) max.

Loading...

Loading...