Page 1

MODEL: R1M-GH

Remote I/O R1M Series

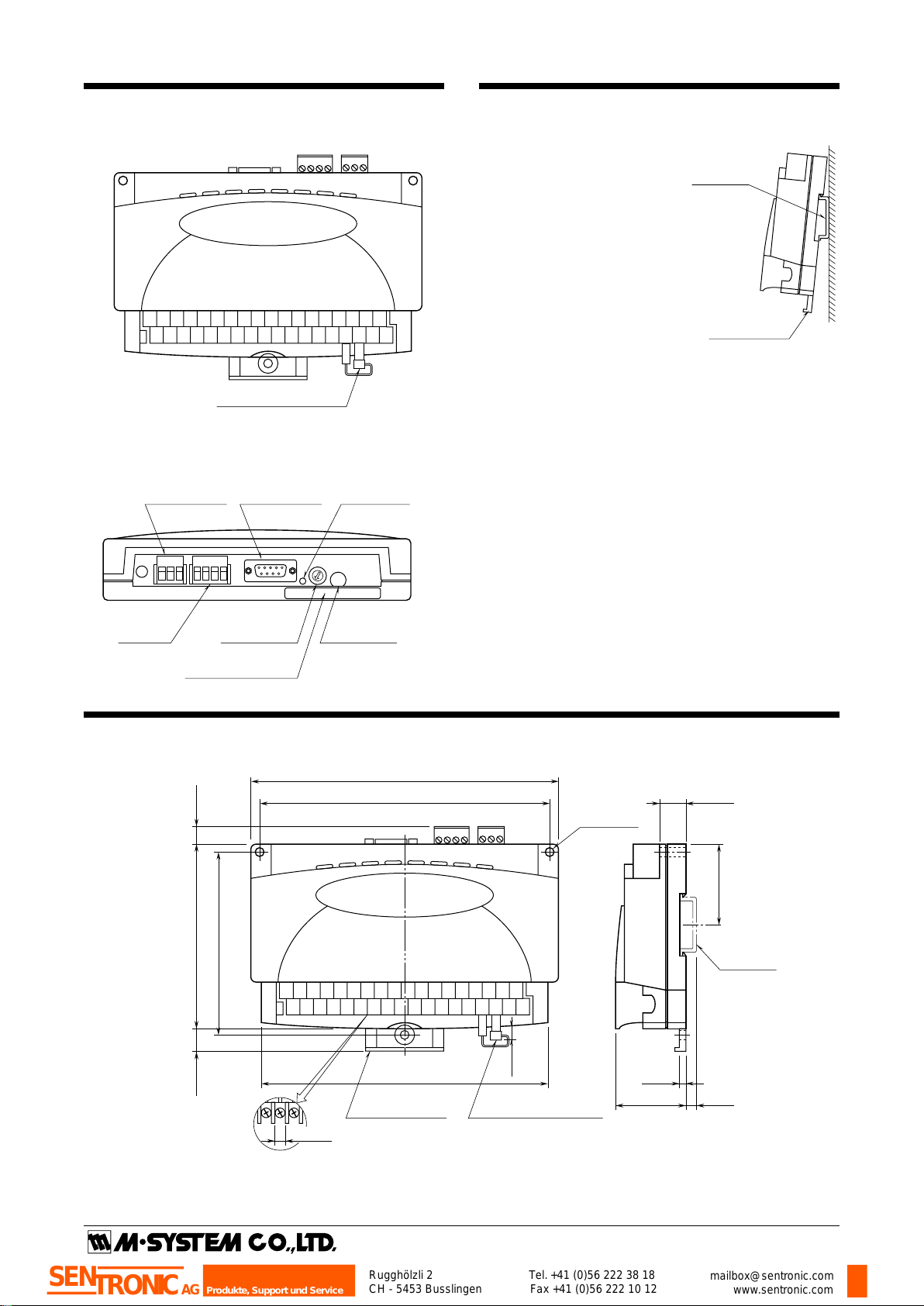

40

(1.57)

115

(4.53)

mm (inch)

175 (6.89)

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

RUN indicator LED: Green light blinks in normal conditions.

THERMOCOUPLE & DC INPUT MODULE

(16 points)

Functions & Features

• 16-point thermocouple or DC inputs

• Easy system expansion via Modbus RTU

MODEL: R1M-GH2T-[1]

ORDERING INFORMATION

• Code number: R1M-GH2T-[1]

Specify a code from below for [1]

e.g. R1M-GH2T-M2

FIELD TERMINAL TYPE

T: M3 screw terminals

[1] POWER INPUT

AC Power

M2: 100 – 240 V AC (Operational voltage range 85 – 264 V,

47 – 66 Hz)

DC Power

R: 24 V DC

(Operational voltage range 24 V ±10 %, ripple 10 %p-p max.)

RELATED PRODUCTS

• Resistor module (model: REM3-250)

• R1X configurator software (model: R1CON)

Downloadable at M-System’s web site.

A dedicated cable is required to connect the module to the

PC. Please refer to the internet software download site or

the users manual for the PC configurator for applicable

cable types.

GENERAL SPECIFICATIONS

Connection

Power input, transmission: Euro type connector terminal

RS-232-C: 9-pin D-sub connector (male)

I/O: M3 screw terminals

Isolation: Input to RS-232-C or RS-485 to power

Address setting: Rotary switch; 1 – F (15 nodes)

COMMUNICATION

Baud rate: 38.4 kbps

Communication: Half-duplex, asynchronous, no procedure

Protocol: Modbus RTU

Protocol: Modbus RTU

Refer to Modbus Protocol Reference Guide (EM-5650) for

supported functions.

■ RS-232-C

Standard: Conforms to RS-232-C, EIA

Transmission distance: 10 meters max.

■ RS-485

Standard: Conforms to RS-485, EIA

Transmission distance: 500 meters max.

Transmission media: Shielded twisted-pair cable (CPEV-S

0.9 dia.)

INPUT SPECIFICATIONS

Input: Thermocouple or DC input, 16 points

(Common negative for DC input)

Measuring Range:

±20 V, ±5 V, ±1 V, ±0.8 V, ±0.2 V, ±50 mV, ±10 mV

Input resistance: 300 kΩ

Thermocouple types: PR, K, E, J, T, B, R, S, C, N, U, L, P

Sampling rate: 100 millisec./16 points

• Trigger input: Dry contact; ON detected at ≤1.5 V

Sensing: Approx. 5 V DC @ 1 mA

INSTALLATION

Power Consumption

•AC: Approx. 10 VA

•DC: Approx. 7 W

Operating temperature: -5 to +60°C (23 to 140°F)

Operating humidity: 30 to 90 %RH (non-condensing)

Mounting: Surface or DIN rail

Weight: 400 g (0.88 lbs)

PERFORMANCE (% of measuring range)

Accuracy

DC input: ±0.3 %

Thermocouple input: See the table on the end of this

section.

Cold junction compensation error: ±3°C or ±5.4°F max.

(at 20°C ±10°C or 68°F ±18°F)

Temp. coefficient: ±0.015 %/°C (±0.008 %/°F)

±0.05 %/°C (±0.03 %/°F) for 10 mV range

Insulation resistance: ≥100 MΩ with 500 V DC

Dielectric strength: 2000 V AC @ 1 minute (input to RS-232C or RS-485 to power to ground)

Page 2

MODEL: R1M-GH

Thermocouple Accuracy

T/C

USABLE RANGE

ACCURACY

°C °F (%)

(PR) 0 to 1770 32 to 3218 ±0.5*

1

K (CA) -270 to +1370 -454 to +2498 ±0.3

E (CRC) -270 to +1000 -454 to +1832 ±0.7

J (IC) -210 to +1200 -346 to +2192 ±0.7

T (CC) -270 to +400 -454 to +752 ±1.0

B (RH) 100 to 1820 212 to 3308 ±0.7*

2

R -50 to +1760

-58 to +3200 ±0.7*

1

S -50 to +1760 -58 to +3200

±0.7*

1

C (

WRe 5-26

) 0 to 2320 32 to 4208 ±0.7

N -270 to +1300 -454 to +2372 ±0.5

U -200 to +600 -328 to +1112 ±0.5

L -200 to +900 -328 to +1652 ±0.3

P (

Platinel II

) 0 to 1395 32 to 2543 ±0.5

*1. ≥400°C or ≥752°F

*2. ≥700°C or ≥1292°F

The described accuracy may be partially not satised when

the temperature ranges below 0°C.

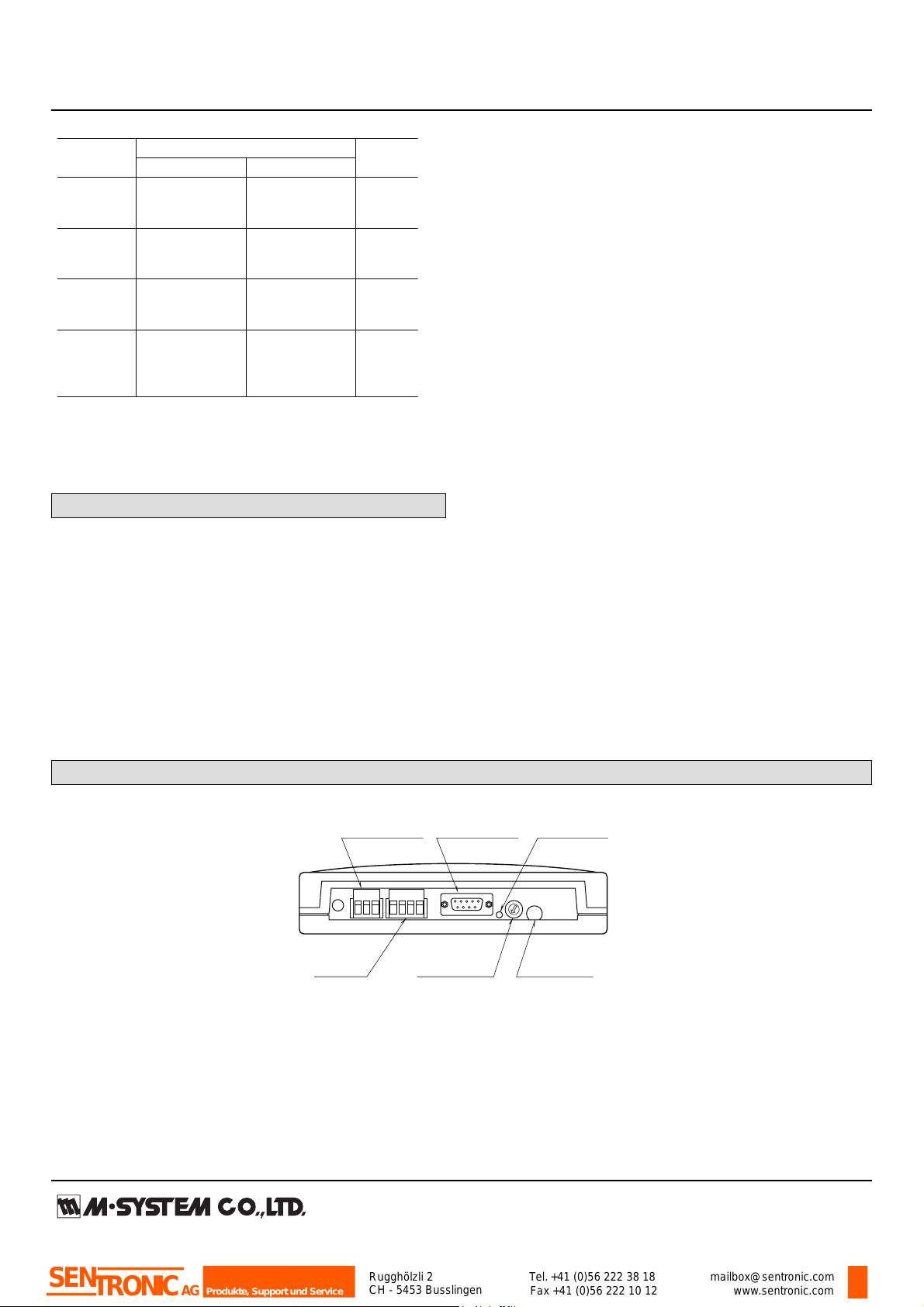

STANDARDS & APPROVALS

RS-485

Connector

Power Terminals

Address Setting

Rotary SW

Configurator

Jack

RUN Indicator

LED

RS-232-C

9-pin Connector

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

CE conformity:

EMC Directive (2004/108/EC)

EMI EN 61000-6-4: 2007

EMS EN 61000-6-2: 2005

Low Voltage Directive (2006/95/EC)

EN 61010-1

Installation Category II

Pollution Degree 2

Input or RS-232-C/RS-485 to power: Reinforced insulation

(300 V)

Input to RS-232-C/RS-485: Basic insulation (300 V)

EXTERNAL VIEW

Page 3

MODEL: R1M-GH

ABBR. PIN NO. EXPLANATION OF FUNCTION

BA (SD) 2 Transmitted Data

BB (RD) 3 Received Data

AB (SG) 5 Signal Common

CB (CS) 7 Clear to Send

CA (RS) 8 Request to Send

1 Not Used.

4 DO NOT connect. Connecting may

6 cause malfunctions.

9

1 5

6 9

■ RS-232-C INTERFACE

CONNECTION DIAGRAM

RS-232-C

T3

T4

T2

T1

T7

T6

T5

Term.

Resist.

Output

Circuit

When the device is located at the end of a transmission line via twisted-pair cable,

(when there is no cross-wiring), close across the terminal T2 –T3 with the attached

jumper pin (or with a leadwire).

When the device is not at the end, remove the jumper pin.

Remark 1: This device is not designed to cancel noise included in the input signals.

Be careful to eliminate such noise by using shielded cables.

Remark 2: Be sure to maintain the same potential at all the common negative

terminals for DC input.

*

9

8

7

6

5

4

3

2

1

10

12

11

13

15

14

16

17

18

20

19

21

22

23

24

25

27

26

28

29

30

31

32

33

35

34

36

TRIGGER INPUT

T/C INPUT

–

+

DC INPUT

INPUT 1

+

–

INPUT 2

INPUT 3

INPUT 4

INPUT 5

INPUT 6

INPUT 7

INPUT 8

INPUT 9

INPUT 10

INPUT 11

INPUT 12

INPUT 13

INPUT 14

INPUT 15

INPUT 16

CJC

Sensor

+

ext. wire

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

Power

Circuit

Input

Circuit

+

–

Shielded Twisted-pair Cable

To Other

I/O Modules

Jumper*

FG

U (+)

V (–)

POWER

D-SUB CONNECTOR

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Note: In order to improve EMC performance, bond the FG terminal to ground.

Caution: FG terminal is NOT a protective conductor terminal.

Page 4

MODEL: R1M-GH

MODBUS WIRING CONNECTION

R1M

T1

T2

T3

T4

R1M

T1

T2

T3

T4

T1

T2

T3

T4

R1M

CONNECTO

R

RS-232-C

RS-485

*

1

*

1

*1. Internal terminating resistor is used when the device is at the end of a transmission line.

*2. Install shielded cables to all sections and ground them at single point.

*

2

FG

RS-485

■ COMMUNICATION PARAMETERS

PARAMETER SPECIFICATION

Data Mode RTU

Baud Rate 9600 / 19200 / 38400 (*) bps

Parity None / Odd (*) / Even

Bit Length 8

Stop Bit 1 (*) / 2

Node Address 1 (*) to 15

Floating Point Data N/A

Interface RS-232-C/ RS-485

(*) Ex-factory setting

■ FUNCTION CODES & SUPPORTED CODES

CODE NAME

01 Read Coil Status X Digital output from the slave

02 Read Input Status X Status of digital inputs to the slave

03 Read Holding Registers X General purpose register within the slave

04 Read Input Registers X Collected data from the field by the slave

05 Force Single Coil X Digital output from the slave

06 Preset Single Registers X General purpose register within the slave

07 Read Exception Status

08 Diagnostics

09 Program 484

10 Poll 484

11 Fetch Comm. Event Counter Fetch a status word and an event counter

12 Fetch Comm. Event Log A status word, an event counter, a message count and a field of event bytes

13 Program Controller

14 Poll Controller

15 Force Multiple Coils X Digital output from the slave

16 Preset Multiple Registers X General purpose register within the slave

17 Report Slave ID Slave type / ‘RUN’ status

18 Program 884/M84

19 Reset Comm. Link

20 Read General Reference

21 Write General Reference

22 Mask Write 4X Register

23 Read/Write 4X Register

24 Read FIFO Queue

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

MODBUS COMMUNICATION

Page 5

MODEL: R1M-GH

■ DATA ADDRESS

ADDRESS

TYPE

DATA

NAME

GH2 J3 A1 D1

FORMAT

Coil (0X) 1 – 32 --- --- --- Y bit DO *

1

33 – 48 Y --- --- --- bit Cold junction compensation SW

(0: Disable, 1: Enable) *

2

Input Status (1X) 1 – 32 Y Y Y --- bit DI *

3

33 – 48 Y Y --- --- bit ADC overrange

Input Register 1 – 16 Y --- --- --- I AI in % (1 – 8 for Type J3)

(3X) 17 – 48 Y Y --- --- F AI per channel in engineering unit

49 – 50 Y --- --- --- F Cold junction temperature *

2

81 – 96 Y Y --- --- I Channel status

513 Y Y Y Y I Bit System Status

0 to 5 Reserved for system use

6 E2PROM diagnostics (0: Normal, 1: Error)

7 ADC error (0: Normal, 1: Error)

8 to 15 Reserved for system use

514 – 521 Y Y Y Y B16 Model No. (“R1M-x”)

522 – 529 Y Y Y Y B16 Serial No.

530 – 537 Y Y Y Y B16 Hardware version No.

538 – 545 Y Y Y Y B16 Firmware version No.

Holding Register 1 – 16 --- --- --- --- I (Reserved for AO in %)

(4X) 17 – 48 --- --- --- --- F (Reserved for AO in engineering unit)

145 – 160 Y Y --- --- I I/O type No.

161 – 176 Y --- --- --- I Burnout type (161 – 168 for Type J3)

(0: No burnout, 1: Upscale, 2: Downscale) *

4

I = 16-bit integer, F = 32-bit floating, B16 = 16-byte char

acter

*1. Discrete output only.

*2. Thermocouple input only.

*3. Trigger contact input for Types GH2 and J3. (Only Address 10001 is enabled.)

*4. Same setting for all channels. For potentiometer inputs, always leave certain residual resistance at 0% side in order to

avoid wrong burnout detection. (0% input or shortcircuit across the terminals 1 – 2 = Wire breakdown at the terminal 3)

Sign

Address n

• 32-bit Floating

Address n+1

Exponent Mantissa

Address n, High-order

• 32-bit Integer, No sign

(R1M-A1)

Address n+1, Low order

High order bytesHigh order bytes Low order bytesLow order bytes

■ INPUT DATA

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Page 6

MODEL: R1M-GH

■ INPUT REGISTERS DESCRIPTION

(1) ANALOG INPUT IN % (30001 to 30016; 30001 to 30008 for J3)

Indicates analog input values in percentage for each channel (1 – 16; 1 – 8 for J3).

(2) ANALOG INPUT IN ENGINEERING UNIT (30017 to 30048; 30017 to 30032 for J3)

Indicates analog input values in engineering unit for each channel (1 – 16; 1 – 8 for J3). The unit is specific to each input type: °C

for temperature, Volts for voltage, and % for potentiometer. The data are 32-bit floating values, which requires two consecutive

registers for one module.

(3) CHANNEL STATUS (30081 to 30096)

Indicates the current status of analog inputs (1 – 16; 1 – 8 for J3). The following list shows the names and descriptions of each bit.

INPUT TYPE & RANGE A/D DATA (Decimal)

DC ±20V ±20000

±5V ±5000

±1V ±10000

±0.8V ±8000

±0.2V ±20000

±50mV ±5000

±10mV ±10000

Thermocouple Temperature x 10

RTD Temperature x 10

Potentiometer 0 – 100Ω ±2000

0 – 500Ω

0 – 1kΩ

0 – 10kΩ

BIT NAME DESCRIPTION

6 Input Overrange Indicates the designated analog input is in overrange, defined as one or

more of the following condition:

• ADC input value 0X0000 or 0XFFFF

• Burnout status for thermocouple input

• Out of range defined in the temperature table (thermocouple and RTD)

• ADC error

0 : Normal

1 : Overrange

7 ADC Error Indicates the status of ADC.

0 : Normal

1 : Error

12 Cold Junction Compensation SW Indicates whether the cold junction compensation is enabled or disabled, for

thermocouple input.

0 : Disable

1 : Enable

Others Reserved For system’s use

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Page 7

MODEL: R1M-GH

■ INPUT REGISTERS DESCRIPTION

Indicates I/O type for each channel. The data are 16-bit integer values.

MODEL I/O I/O TYPE SELECTION USABLE RANGE NOTES

R1MS-GH3 DC input 0X00 -10 to 10 V -10 to 10 V

R2M-2G3

R1M-GH2 DC input 0X00 -20 to 20 V -22.7 to 22.7 V ATT SW ON

0X01 -5 to 5 V -5.6 to 5.6 V ATT SW ON

0X02 -1 to 1 V -1.4 to 1.4 V ATT SW ON

0X03 -800 to 800 mV -860 to 860 mV

0X04 -200 to 200 mV -215 to 215 mV

0X05 -50 to 50 mV -53 to 53 mV

0X06 -10 to 10 mV -13.4 to 13.4 mV

R1M-GH2 T/C input 0X10 (PR) 0 to 1770 °C

R1MS-GH3 0X11 K (CA) -270 to 1370 °C

R2M-2H3 0X12 E (CRC) -270 to 1000 °C

0X13 J (IC) -210 to 1200 °C

0X14 T (CC) -270 to 400 °C

0X15 B (RH) 100 to 1820 °C

0X16 R -50 to 1760 °C

0X17 S -50 to 1760 °C

0X18 C (WRe 5-26) 0 to 2320 °C

0X19 N -270 to 1300 °C

0X1A U -200 to 600 °C

0X1B L -200 to 900 °C

0X1C P (Platinel II) 0 to 1395 °C

R1M-J3 RTD input 0X30 JPt 100 (JIS ’89) -200 to 500 °C

0X31 Pt 100 (JIS ’89) -200 to 660 °C

0X32 Pt 100 (JIS ’97/IEC) -200 to 850 °C

0X33 Pt 50Ω (JIS ’81) -200 to 649 °C

0X34 Ni 508.4Ω -50 to 280 °C

0X35 Pt 1000 -200 to 850 °C

POT input 0X40 0 to 100 ohms 0 to 100 %

0X41 0 to 500 ohms 0 to 100 %

0X42 0 to 1k ohms 0 to 100 %

0X43 0 to 10k ohms 0 to 100 %

R1M-D1 DO 0X60

R1M-A1 DI 0X70

12345678 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 35

T1 T2T3 T4

T5 T6T7

104 (4.09)

10 (.39)

105 (4.13)

14 (.55)

163 (6.42)

36–M3 I/O TERMINALS

165 (6.50) 15.5 (.61)

175 (6.89)

FOR WALL MOUNT.

[6 (.24)]

40 (1.57)

3 (.12)

6.2 (.24)

8 (.31)

CJC SENSOR (model: CJM)

3–5 (.20) dia.

MTG HOLES

46 (1.81)

DIN RAIL

35 mm wide

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

EXTERNAL DIMENSIONS & TERMINAL ASSIGNMENTS unit: mm (inch)

Page 8

MODEL: R1M-GH

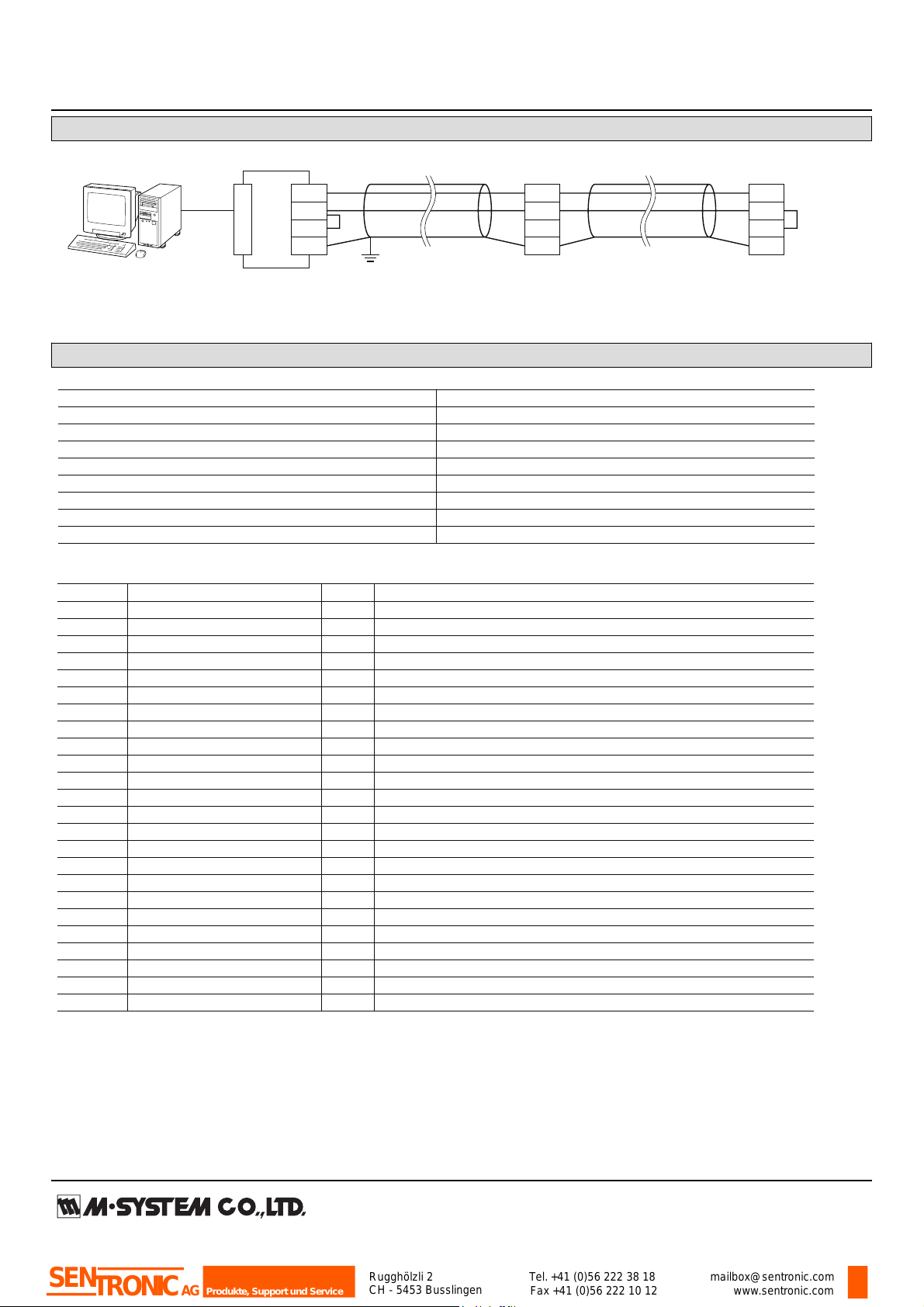

SYSTEM CONFIGURATION EXAMPLES

RS-485

TC/DC Inputs

(model: R1M-GH)

Contact Inputs

(model: R1M-A1)

Contact Outputs

(model: R1M-D1)

When the cable distance between the PC and the R1Ms is long,

insert an RS-232-C/RS-485 Converter for isolation.

RS-232-C

RS-232-C/RS-485

Converter

(model: R2K-1)

Specifications are subject to change without notice.

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Page 9

INSTRUCTION MANUAL

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

R1M-GH

THERMOCOUPLE & DC INPUT MODULE

(16 points)

■ POWER INPUT RATING & OPERATIONAL RANGE

•

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

This product is for use in general industrial environments,

therefore may not be suitable for applications which require

higher level of safety (e.g. safety or accident prevention systems) or of reliability (e.g. vehicle control or combustion control systems).

For safety, installation and maintenance of this product

must be conducted by qualified personnel.

■ PACKAGE INCLUDES:

Remote I/O module (body + CJC sensor) ..................... (1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

For detailed information on Modbus supported functions,

refer to Modbus Protocol Reference Guide (EM-5650).

The R1M is programmable using the PC configurator software. For detailed information on the PC configuration,

refer to the R1CON instruction manual. The R1CON PC

Configurator Software is downloadable at M-System’s web

site: http://www.m-system.co.jp.

Locate

confirm its operational range as indicated below:

100 – 240V AC rating: 85 – 264V, 47 – 66 Hz, approx. 10VA

24V DC rating: 24V ±10%, approx. 7W

■ GENERAL PRECAUTIONS

• Before

and input signal for safety.

■ ENVIRONMENT

• Indoor use

•

When heavy dust or metal particles are present in the air,

install the module inside proper housing with sufficient

ventilation.

• Do

not install the module where it is subjected to continuous vibration. Do not apply physical impact to the module.

• Environmental

(23 to 140°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

• Be

sure that the ventilation slits are not covered with ca-

bles, etc.

■ WIRING

• Wrong connection ma

• Do not connect cables to moving parts or pull them tightly.

• Do

not install cables (power supply, input and output)

close to noise sources (relay drive cable, high frequency

line, etc.).

• Do

not bind these cables together with those in which

noises are present. Do not install them in the same duct.

MODEL

the power input rating marked on the product and

you remove the module, turn off the power supply

temperature must be within -5 to +60°C

y damage the module.

R1M-GH

POINTS OF CAUTION

■ CONFORMITY WITH EC DIRECTIVES

• This equipment is suitable for use in a Pollution Degree

2 environment and in Installation Category II, with the

maximum operating voltage 300V.

Basic insulation

and RS-232C/RS-485. Prior to installation, check that the

insulation class of this unit satisfies the system requirements.

• Altitude up to 2000 meters

•

The equipment must be mounted inside a panel.

• Insert noise filters. Okaya Electric Industries Model SUPE1H or equivalent for the power source connected to the

unit, and TDK Model ZCAT3035-1330 or equivalent for

the RS-232C cable are recommended.

equipment must be installed such that appropriate

• The

clearance and creepage distances are maintained to conform to CE requirements.

• The

actual installation environments such as panel configurations, connected devices, connected wires, may affect the protection level of this unit when it is integrated

in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure the CE conformity.

is maintained between the signal input

■ AND ....

• The

module is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required

for satisfying complete performance described in the data

sheet.

P. 1 / 4EM-5657 Rev.7

Page 10

R1M-GH

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 35

T1 T2 T3 T4

T5 T6 T7

CJC Sensor (model: CJM)

RS-485

Connector

Address Setting

Rotary SW

Configurator

Jack

Specifications Marking

Power Terminals

RS-232C

9-pin Connector

RUN Indicator

LED

DIN Rail Adaptor

DIN Rail

35mm wide

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 35

T1 T2 T3 T4

T5 T6 T7

104 (4.09)

10 (.39)

105 (4.13)

14 (.55)

163 (6.42)

36–M3 I/O TERMINALS

165 (6.50) 15.5 (.61)

175 (6.89)

FOR WALL MOUNT.

[6 (.24)]

40 (1.57)

3 (.12)

6.2 (.24)

8 (.31)

CJC SENSOR (model: CJM)

3–5 (.20) dia.

MTG HOLES

46 (1.81)

DIN RAIL

35 mm wide

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

COMPONENT IDENTIFICATION

■ TOP VIEW

■ REAR VIEW

INSTALLATION

■ DIN RAIL MOUNTING

Set the body so that its DIN rail

adaptor is at the bottom. Pull

down the DIN rail adaptor.

Position the upper hook at the

rear side on the DIN rail and

push in the lower. Push back the

DIN rail adaptor.

■ WALL MOUNTING

Set the body so that its DIN rail

adaptor is at the bottom. Pull

down the DIN rail adaptor.

Refer to “EXTERNAL DIMENSIONS.”

EXTERNAL DIMENSIONS unit: mm (inch)

P. 2 / 4EM-5657 Rev.7

Page 11

R1M-GH

R1M

T1

T2

T3

T4

R1M

T1

T2

T3

T4

T1

T2

T3

T4

R1M

CONNECTOR

RS-232C

RS-485

*

1

*

1

*1. Internal terminating resistor is used when the device is at the end of a transmission line.

*2. Install shielded cables to all sections and ground them at single point.

*

2

FG

RS-485

RS-232C

T3

T4

T2

T1

T7

T6

T5

Term.

Resist.

Output

Circuit

When the device is located at the end of a transmission line via twisted-pair cable,

(when there is no cross-wiring), close across the terminal T2 –T3 with the attached

jumper pin (or with a leadwire).

When the device is not at the end, remove the jumper pin.

Remark 1: This device is not designed to cancel noise included in the input signals.

Be careful to eliminate such noise by using shielded cables.

Remark 2: Be sure to maintain the same potential at all the common negative

terminals for DC input.

*

9

8

7

6

5

4

3

2

1

10

12

11

13

15

14

16

17

18

20

19

21

22

23

24

25

27

26

28

29

30

31

32

33

35

34

36

TRIGGER INPUT

T/C INPUT

–

+

DC INPUT

INPUT 1

+

–

INPUT 2

INPUT 3

INPUT 4

INPUT 5

INPUT 6

INPUT 7

INPUT 8

INPUT 9

INPUT 10

INPUT 11

INPUT 12

INPUT 13

INPUT 14

INPUT 15

INPUT 16

CJC

Sensor

+

ext. wire

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

Power

Circuit

Input

Circuit

+

–

Shielded Twisted-pair Cable

To Other

I/O Modules

Jumper*

FG

U (+)

V (–)

POWER

D-SUB CONNECTOR

1 5

6 9

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

TERMINAL CONNECTIONS

Connect the module referring to the connection diagram.

Attach the CJC sensor together with input wiring to the input screw terminals. The sensor is calibrated for each particular

module and not interchangeable with another. Check the serial numbers of the module and sensor.

MODBUS WIRING CONNECTION

■ RS-232C INTERFACE

ABBR. PINNO. EXPLANATIONOFFUNCTION

BA (SD) 2 Transmitted Data

BB (RD) 3 Received Data

AB (SG) 5 Signal Common

CB (CS) 7 Clear to Send

CA (RS) 8 Request to Send

1 Not Used.

4 DO NOT connect. Connecting may

6 cause malfunctions.

9

P. 3 / 4EM-5657 Rev.7

Page 12

INPUT RANGE SELECTING

SW311 SW305 SW304 SW303 SW302

SW405 SW404 SW403 SW402

SW301

O

N

2

1

3

4

5

6

7

8

SW702

SW702 is fixed to

the position 3.

DO NOT CHANGE.

SW411 SW401 SW308 SW307 SW306

SW408 SW407 SW406

O

N

2

1

3

4

5

6

7

8

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Select switches to match the input signal according to the table below.

INPUT SWITCHES SETTING NOTES

Thermocouple

Voltage input, 0.8V or less

Voltage input, above 0.8V (*)

(*) Factory default setting

SW301 – SW308 (ch 1 – ch 8)

SW401 – SW408 (ch 9 – ch 16)

SW311 (ch 1 – ch 8)

SW411 (ch 9 – ch 16)

SW301 – SW308 (ch 1 – ch 8)

SW401 – SW408 (ch 9 – ch 16)

SW311 (ch 1 – ch 8)

SW411 (ch 9 – ch 16)

SW301 – SW308 (ch 1 – ch 8)

SW401 – SW408 (ch 9 – ch 16)

SW311 (ch 1 – ch 8)

SW411 (ch 9 – ch 16)

Set to position “1”

OFF

Set to position “1”

ON

Set to position “3”

ON

Attenuation OFF

Attenuation OFF

Attenuation ON

R1M-GH

CHECKING

1) Terminal wiring: Check that all cables are correctly connected according to the connection diagram.

2) Power input: Chec

k supply voltage.

3) Input: Check that the input is within 0 – 100% of fullscale.

4) DIP SW setting:

Check that all switches are set correct-

ly.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any calibration.

M-SYSTEM WARRANTY

M-System

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accuracy described in the data sheet. When the output is out of

tolerance, please contact M-System’s Sales Office or representatives.

Loading...

Loading...