Page 1

INSTRUCTION MANUAL

SERVO-TOP II ELECTRONIC ACTUATOR

(linear type)

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ SAFETY PRECAUTIONS

Before use, please read all the following precautions carefully to ensure the safety. These safety precautions, classified into “WARNING” and “CAUTION” according to the degree of damage that each item could cause, are imperative

to prevent an accident. After reading, be sure to keep this

manual always in a visible and accessible place for the user.

WARNING Suggesting that failure to observe the pre-

cautions could result in death or serious personal injury.

CAUTION Suggesting that failure to observe the precautions could result in personal injury or damage to the

property.

WARNING

Be sure to replace the terminal box cover which houses

the power input terminals on before turning on the power

supply. It could cause electric shock.

Power fuse: A glass tube power fuse (5.2 dia × 20 mm)

of the rating as shown below is incorporated for safety.

Be sure to remove the power supply before replacing it.

Replacing the fuse without turning off the power supply

could cause electric shock.

AC power: Medium time lag, M 3A 250V

DC power: Medium time lag, M 4A 125V

Remove power supply to the actuator before wiring to it.

It could cause electric shock.

DO NOT loosen the set screw fixing the lever of angle sensor. Loosening it may cause a malfunction. It could cause

electric shock, burn, and injuries.

DO NOT step onto the actuator. DO NOT rest a heavy

object on or against it. It could cause injury.

When installing the PSN outdoor or where it is exposed

to rain or water drops, adequate precaution must be done

for preventing water from entering inside through wiring

conduits. It could cause electric shock.

DO NOT mount the PSN in such direction that the output

stem is at the top of the actuator. It could cause electric

shock.

Be surer that the power supply is removed. Hand or arm

could be caught and cause injury.

When the operation is completed, be sure to remove the

handle and cover the stem with a rubber cap. Hand or

arm could be caught and cause injury.

Inside the cover, the metal plate mounting printed wiring boards located above the motor is also installed for

heat dissipation. The motor and the plate may become extremely hot during operation. DO NOT touch them with

bare hands. It could cause burn injury.

The adjustments which are paint locked are for factory

use only and should be changed only by qualified M-System personnel. M-System is not liable for any malfunction or inconvenience caused by unauthorized change of

them by the user. Otherwise it could cause breakdown.

■ PACKAGE INCLUDES:

SERVO-TOP II body ...........................................................(1)

Indicator (when the stem button is selected;

attached to the actuator body with a Scotch tape) ............(1)

Note: Yoke and other components necessary to attach the

PSN to a valve are to be provided by the customer.

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation and connection,

hardware setting, and basic maintenance procedures.

With the emergency shutdown option selected, please also

refer to PSN1/PSN3 Instruction Manual for this option

(EM-4857-A).

When you need to change software settings, please refer to

the Operation Manual for Model PU-2x (EM-9255), Section

B. This unit is factory adjusted and calibrated according to

the Ordering Information included in the product package.

If you do not need to change the pre-adjusted setting, you

can skip the sections on PU-2x programming in this manual

and the Operation Manual for Model PU-2x.

MODEL

CAUTION

PSN1/PSN3

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 1 / 9

Page 2

POINTS OF CAUTION

■ CONFORMITY WITH EU DIRECTIVES

• This equipment is suitable for Pollution Degree 2 and

Installation Category II (transient voltage 2500V). Reinforced insulation (Signal or metallic housing or seq.

signals or battery status (with failsafe function only) to

power: 300V) is maintained. Prior to installation, check

that the insulation class of this unit satisfies the system

requirements.

• Altitude up to 2000 meters.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to conform to CE requirements. Failure to observe these requirements may invalidate the CE conformance.

• Install lightning surge protectors for those wires connected to remote location. Refer to “LIGHTNING SURGE

PROTECTION” section below.

■ POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

100 – 120V AC rating: 90 – 132V, 47 – 66 Hz,

approx. 240VA (200VA for PSN3)

200 – 240V AC rating: 180 – 264V, 47 – 66 Hz,

approx. 240VA (200VA for PSN3)

24V DC rating: 24V ±10%, approx. 3A

PSN1 / PSN3

■ SCREW TORQUE

• The torque for tightening screws for the cover is between

2.4 – 3.1 N·m (1.8 – 2.3 ft·lb).

■ DESIGNING YOKE

• When a foreign object is caught in the valve, a thrust as

great as 7500 N (1686 lb) could be applied to the yoke.

Observe enough strength when designing mechanical

components such like the yoke.

• When the PSN is used on a steam stream in temperature

control, its temperature may rise beyond ambient temperature caused by a heat conducted or radiated from piping. Use a longer yoke for effective heat dissipation and

apply insulation material.

■ OPERATING CONDITION

• Depending on operating condition, internal temperature

may rise extremely high.

• When operating continuously with such a condition, it

causes short life span or damage and may impair expected performance.

• Operate with an enough margin such as shortening the

operational duty time ratio.

■ GENERAL PRECAUTIONS

• DO NOT install signal wires and power supply wires together in one duct because it may cause a malfunction

due to inductive noises. If they must be installed together, use shielded cables.

• If input signals are to be turned on/off with power supplied to the actuator, be sure to set the abnormal low input operation mode.

■ ENVIRONMENT

• Inside building. If outside, keep away from direct sunlight.

• Operating temperature -25 to +55°C (-13 to +131°F) for

PSN1; -15 to +55°C (5 to 131°F) for PSN3.

• Operating humidity 30 to 85% RH (non-condensing)

• Vibration 2 G (19.6 m/s

2

) max.

• The actuator must be installed in a place where maintenance and inspection can be conducted. Observe at least

15 cm (5.9 in.) of open space at the top of its cover for

maintenance and inspection.

• Keep away from hazardous atmosphere such like explosive or corrosive gases.

■ SOUND ACCOMPANYING MOTOR ROTATION

• The PSN’s stepping motor inherently generates whistling

sound during normal operation according to its rotating

frequency, larger with lower frequencies. DO NOT be

alarmed.

■ PID CONTROL SIGNAL

• Choose PID parameters carefully so that the MV remains

as stable as possible. Unstable control shortens the life of

actuator and valve.

■ GASKET

• Be sure to return the gasket when you close the cover

after wiring or adjustments.

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 2 / 9

Page 3

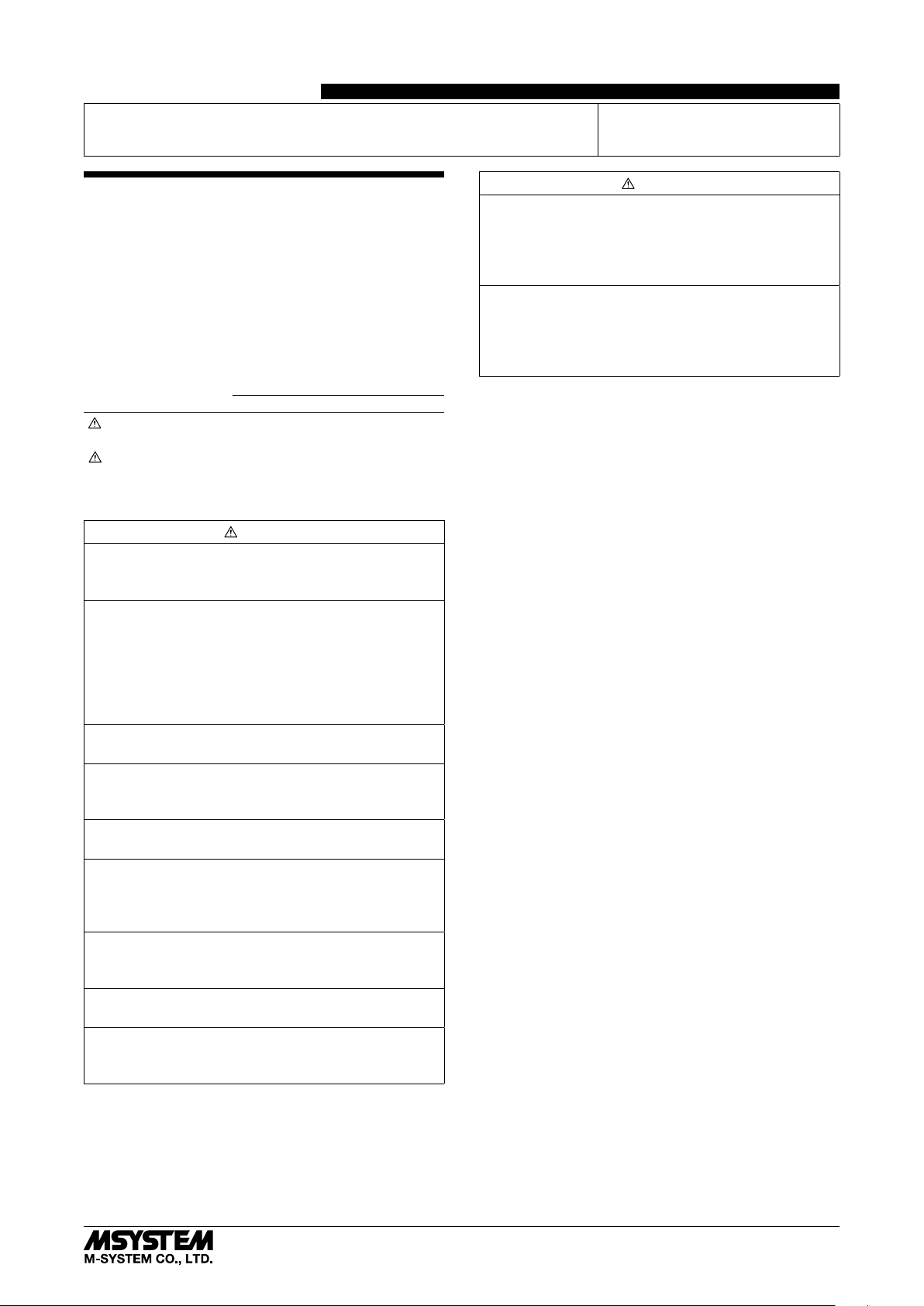

COMPONENT IDENTIFICATION

Stepping Motor

Temperature Sensor

Modular Jack

Control PCB

PSN1 / PSN3

Input Resistor (for current input)

SW-1 –8

Manual Operation

Angle Sensor

Sealing Spring

Ground

Terminal

Gasket

FUSE

POWER

INPUT

ALARM

UP

DOWN

1

2

U(+)

POWER

V(–)

1 EXTEND / RETRACT

2 ACCORDING TO SW1 / STOP

3 REVERSE / DIRECT

4

5 RETRACTED POSITION SET

6 EXTENDED POSITIN SET

7

8 RUN / PU

POWER

INPUT

ALARM

UP

(RETRACT)

DOWN

(EXTEND)

OPEN / CLOSE

SEQUENTIAL

INPUT

SIGNAL

POSITION

SIGNAL

FORCED

COMMAND

CONTROL

+

COM1

+

RETRACT

EXTEND

OPEN / CLOSE SIGNAL

RETRACTED

OPEN / CLOSE SIGNAL

EXTENDED

ALARM

COM2

COM1

12

3

4

5

6

7

8

9

10

11

Fuse

: Power LED (green LED turns on when applied)

: Input LED (green LED turns on when applied)

: Alarm LED (red LED turns on with alarm)

: UP Control Button

: DOWN Control Button

Output Stem

Figure 1. Component Identication

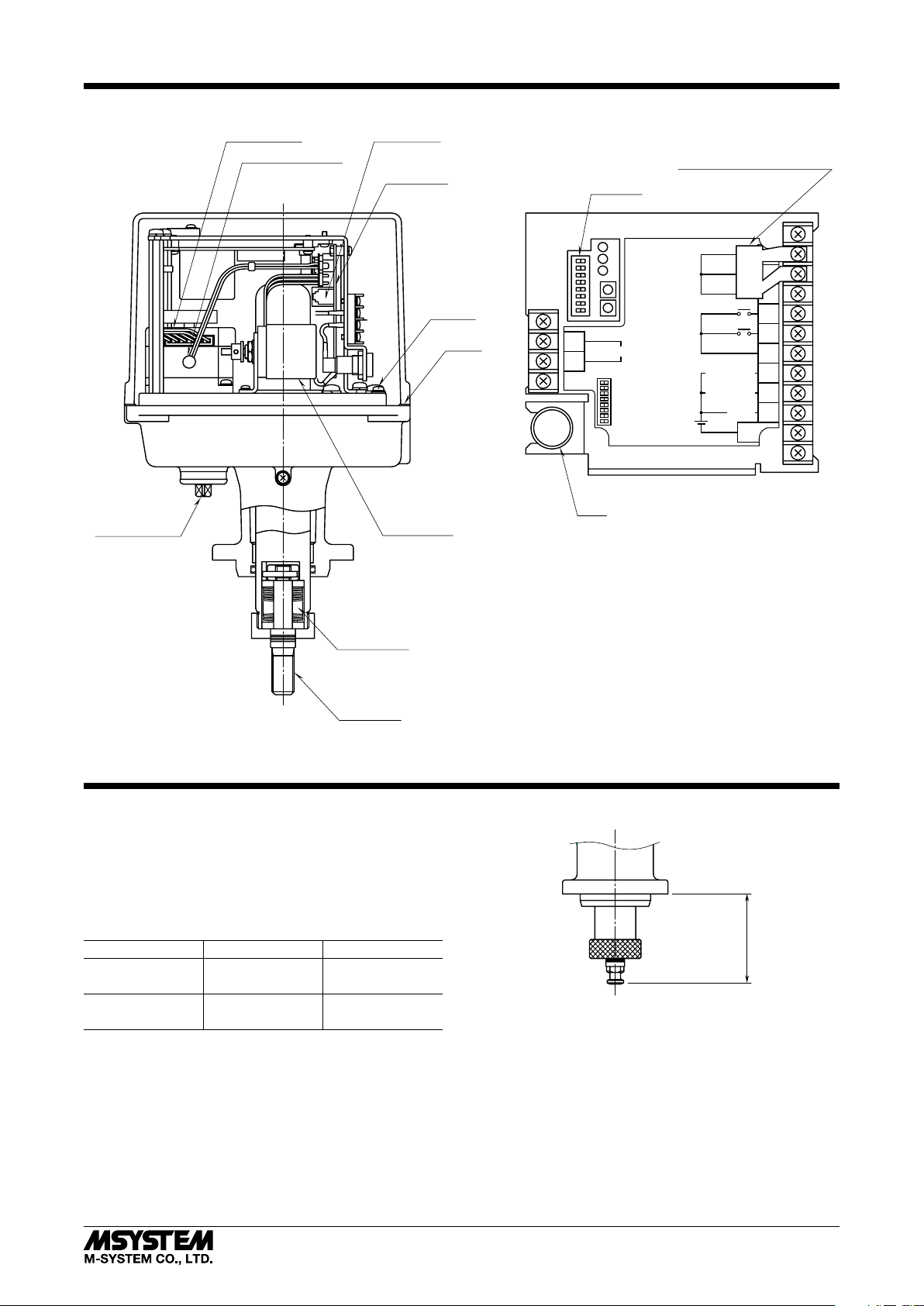

OUTPUT STROKE & ADJUSTABLE RANGE

The servo-control PCB compares input signal (position setpoint signal) and actual position signal from the position

sensor, and drives the motor to reduce the deviation.

When a full-close signal is provided, the output stem is

pressed onto the sealing spring after the valve is fully

closed, until the sealing pressure reaches a preset value.

MODEL L (mm) L (inch)

PSN1-4x1 66 to 106 2.60 to 4.17

PSN1-4x2 52 to 92 2.05 to 3.62

PSN3-6x1 66 to 126 2.60 to 4.96

PSN3-6x2 52 to 112 2.05 to 4.41

Yoke Surface

L

Figure 2. Operational Range of the Output Stem

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 3 / 9

Page 4

PSN1 / PSN3

INSTALLATION

Valve, yoke and other components necessary to connect the

PSN to the valve are provided by the customer.

DO NOT CHANGE the ex-factory settings of the PSN. The

following procedure should be done with the power supply

removed, except when otherwise specified.

(General Procedure)

1) Apply power input and 0% input signal (100% for direct

action) in order to expose the output stem to the maximum degree.

2) Set the valve stem at the lowest position.

3) Connect the PSN to the yoke.

4) Screw the valve stem into the output stem until there is

little opening between them.

For applying a sealing pressure, refer to flexure values in

Table 3 (e.g. 1 mm for applying 1500 N for PSN1-x1) and

screw it until the opening equals the value.

5) Fix both stems with a lock nut.

6) Apply power input and approx. 50% input signal and

check that there is no opening between the yoke and

valve bonnet.

Fix the yoke and the valve.

7) Connect the indicator and other components if necessary.

SERVO-TOP II

Bolt

Output Stem

Indicator

Scale Plate

Valve Stem

Button

Lock Nut

Yoke

Valve Bonnet

40°

40°

ø9 (.35)

ø14 (.55)

Figure 3. Stem Details

ø15 (.59)

140°

ø10

(.39)

ø15 (.59)

R1

6 (.24)4 (.16)

1 (.04)

6 (.24)

16 (.63)

Figure 5. Connecting the PSN with a Valve, Example

ELECTRICAL CONNECTIONS

Remove the cover of the PSN body and wire to the terminal

block according to Figure 6.

The PSN requires the power input (1 – 2) and input signal

(3 – 4) connections for operating.

INPUT SIGNAL

POSITION SIGNAL

FORCED

OPEN/CLOSE

COMMAND

SEQUENTIAL

CONTROL

+

3

*

R

COM1

RETR.

EXT.

(EXT.)

COM2

4

5

MODULAR JACK

+

8

6

7

9

10

11

12

COM1

FULL OPEN

/CLOSE

(RETR.)

ALARM

*Input resistor attached for a current input.

APPLICABLE SOLDERLESS TERMINAL

3.2 (.13) dia min.

U(+)

1

2

POWER

V(–)

PU-2x

Figure 4. Indicator Details

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

5.9 (.23)

4.6 (.18) min.

Figure 6. Connection Diagram

EM-4857 Rev.10 P. 4 / 9

max.

Page 5

ADJUSTMENT PROCEDURE

Open the PSN body cover and adjust the full-open and

-closed positions referring to Figure 1. Other adjustments

can be also conducted as explained below: switching actuator action, safety operation at abnormally low input, and

positions for the open/close limiters and for the full-open/

close signal, and restart limiting timer.

For adjusting positions for the open/close limiters and for

the full-open/close signal, and restart limiting timer, the

PU-2x is required.

■ OPERATION AT ABNORMALLY LOW INPUT (SW-1, SW-2)

When the input goes down to 0.37±0.1V DC or below, the

PSN goes to the abnormal low input operation. It is set to

stop the actuator at the factory. Refer to Table 1.

PSN1 / PSN3

■ FULL-OPEN/CLOSED POSITIONS

1) Turn ON the SW-8 in order to put the PSN in the local

calibration mode, and the input signal is disregarded.

2) Turn ON the SW-5 and adjust the fully retracted end

pressing UP/DOWN control buttons.

3) When the output stem reaches a desired position, turn

OFF the SW-5. The position is memorized as the fully

retracted end.

4) Turn ON the SW-6 and adjust the fully extended end

pressing UP/DOWN control buttons.

5) When the output stem reaches a desired position, turn

OFF the SW-6. The position is memorized as the fully

extended end.

6) Turn OFF the SW-8 in order to put the PSN in the operating mode. Apply input signals and confirm the fullopen/closed positions.

Table 1. Abnormal low input operation & switch positions

MODE SW-1 SW-2

Stop

Fully Extend

Fully Retract

*1

OFF

ON

ON

OFF

OFF

*1. SW-1 position is disregarded in STOP mode.

SW-1...SW-8

O

1

N

2

3

4

5

6

7

8

UP Control Button

DOWN Control Button

FUSE

U(+)

1

V(–)

2

POWER

INPUT

ALARM

POSITION SIGNAL

UP

DOWN

FORCED

OPEN/CLOSE

POWER

COMMAND

SEQUENTIAL

CONTROL

1 CLOSE/OPEN

2 ACCORDING TO SW1/STOP

3 REVERSE/DIRECT

4

5 FULL-OPEN POSITION SET

6 FULL-CLOSED POSITION SET

7

8 RUN/PU

INPUT SIGNAL

COM1

OPEN

CLOSE

COM1

FULL OPEN

FULL CLOSE

ALARM

COM2

12

+

3

4

–

5

6

7

8

9

10

11

Figure 7. Adjustments, Details

■ ACTUATOR ACTION (SW-3)

Use SW-3 for switching the actuator action. It is set to “REVERSE” at the factory. Refer to Table 2.

Table 2. Actuator action

MODE SW-3 ACTION

Direct ON Output stem retracted with decreasing

input. (Valve stem pulled out.)

Reverse OFF Output stem extended with decreas-

ing input. (Valve stem pushed in.)

In DIRECT action, the input signal 0 – 100% corresponds to

the position output signal 20 – 4mA DC.

■ SEALING SPRING

For applying a sealing pressure when the valve is fully

closed, adjust flexure of the sealing spring when calibrating

the fully opened/closed positions.

For applying a sealing pressure at the both ends, such like

the case of a three-way valve, adjust flexure of the sealing

spring at the both ends.

Excessive flexure may shorten life of the actuator and

spring. Observe the maximum flexure at the maximum

pressure.

The output stem is provided with scales by millimeters.

Output Stem

Sealing Pressure

Scale

Figure 8. Sealing Spring

TYPE MAXIMUM

PRESSURE

1500 N use

3000 N use

5000 N use

1500 N use

3000 N use

5000 N use

(N)

1500

3000

5000

(lb)

337

674

1124

FLEXURE AT

MAXIMUM

PRESS. (mm)

1

1

0.5

(inch)

0.04

0.04

0.02

SET

PRESS.

(N)

1170

2410

3980

(lb)

263

542

895

RATED

SPRING

(N/mm)

330

590

2040

(lb/in.)

1880

3370

11600

Note: The seal spring starts flexing when a pressure exceeding

the set pressure is applied. Control pressure within 80%

of the set pressure except when the valve is fully closed.

If excessive pressure is applied within the control range,

flexure of the spring may jeopardize the linearity.

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 5 / 9

Page 6

PU-2x ADJUSTMENTS

■ DISPLAY

ITEM No.

G

I

D

• Response Messages

NG: No good

The PU-2x may not be securely connected.

Check connection of the modular jack.

ER: Communication error

Turn the SW-8 ON.

• Data Indicator

OK: OK

DATA-ERR: Invalid data input

NON-ITEM: ITEM No. not applicable

■ PROGRAMMABLE ITEMS

Table 4. Programmable items ( ) for PSN3

ITEM

No.

ITEM

10 Full-open/-closed

position (retracted)

11 Full-open/-closed

position (extended)

12 Retracted side limit 75 – 105 0.1 100

13 Extended side limit -5 – 25 0.1 0

14 Full-open/-closed

output (retracted)

15 Full-open/-closed

output (extended)

16 Split ON/OFF 0 or 1 0

17 Split type LO/HI 0 or 1 0

18 Split point 30 – 70 0.1 50

19 Opening/closing

speed limit

20 Deadband 0.1 – 5 0.1 0.5

21 Restart limiting timer 0 – 30*

22 Speed in shutdown*

23 Position in shutdown*

*2. ROM version 1.05 or later

*3. Settings are enabled with ‘Failsafe’ option.

■ ROM VERSION INDICATION

Press ITEM 99 in the local calibration mode in order to display the ROM version of the PSN.

■ HOW TO PROGRAM THE PSN

1) Apply power supply voltage to the PSN.

2) Turn ON the SW-8 in order to put the PSN in the local

calibration mode, and the input signal is disregarded.

3) Connect the modular jack cord of the PU-2x to the PSN.

ITEM display is blank.

4) Indicating Current Setting

Key in the ITEM No. that you want to check. (N = 0 to 9)

Press [ITEM] [N] [N].

Response Messages

()

Data to be entered

or Messages

USABLE

RANGE

MINIMUM

INCREMENT

8 – 100 0.1 100

0 – 92 0.1 0

75 – 100 0.1 98

0 – 25 0.1 2

1 – 50 1 16 (24)

2

3

1 – 50 1 16 (24)

3

0 – 100 0.1 0

LCD Display

2

0.1*

DEFAULT

2

PSN1 / PSN3

5) Indicating New ITEM No.

Press [ITEM] [N] [N] or press [UP] or [DOWN].

6) Modifying Current Setting

Display the ITEM No. that you want to change, and press

[DATA], new setting, and [ENTER].

If an irrelevant setting is entered, the PU-2x indicates

“DATA-ERR” on its message display. Key in an appropriate setting again.

7) Remove the modular jack cord of the PU-2x.

8) Turn OFF the SW-8 in order to return the PSN in the

operating mode. Apply input signals and confirm every

setting.

Note 1: DO NOT remove power to the PSN with the PU-2x

connected to it.

Note 2: Be sure to remove the PU-2x before driving the motor

(in the operating mode).

■ EXPLANATIONS ABOUT THE PROGRAMMABLE ITEMS

1) Full-Open/-Closed Positions (ITEM No.10, 11)

Key in a percentage value within 0% for the extended

end, and 100% for the retracted end.

[Extended End] > [Retracted End]

2) Extended/Retracted Limits (ITEM No.12, 13)

The adjustable ranges shown in Table 4 are applicable

against the stroke determined by the full-open/-closed

positions as 100%.

3) Full-Open/-Closed Outputs (ITEM No.14, 15)

The adjustable ranges shown in Table 4 are applicable

against the stroke determined by the full-open/-closed

positions as 100%.

4) Split Range (ITEM No.16 to 18)

Refer to Figure 9 and determine the type and point of

split range.

When the split range is set to OFF (ITEM No.16), the

split range type and point (ITEM No.17, 18) are invalid.

Split Range Type Set to “LO”

(Set to “DIRECT” Action)

Split Range Type Set to “HI”

(Set to “REVERSE” Action)

Retracted End

OUTPUT STEM

Extended End

POSITION

0

INPUT (%)

30 70

Figure 9. Split Range

Thick, solid lines indicate

examples of I/O characteristics,

while broken lines indicate

limits of adjustable range.

100%50

Adjustable Split Point Range

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 6 / 9

Page 7

PSN1 / PSN3

5) Opening/Closing Speed Limit (ITEM No.19)

Opening/closing speed affects the thrust. Refer to Tables

5 – 6 and Figures 10 – 11 for checking required thrust

and attainable speed.

Acceleration or deceleration is not included in the speed.

Acceleration or deceleration respectively requires approx. 0 to 2 sec.; takes longer with faster speed.

Table 5. PSN1 opening/closing speed limit

SPEED

SCALE [A]

SPEED [V]

(mm/s)

OPERATION

TIME (s/20 mm)

THRUST

N lb

1 0.30 66.0 3000 674

2 0.54 37.3 3000 674

16 2.03 9.9 3000 674

35 4.05 4.9 2500 562

44 5.01 4.0 2000 450

50 5.65 3.5 1600 360

Speed [V] achieved by Speed Scales [A] other than mentioned

above can be approximately calculated by the following equation:

Speed [V] = 0.106 × Speed Scale [A] + 0.323, where 2 ≤ A ≤ 50

Table 6. PSN3 opening/closing speed limit

SPEED

SCALE [A]

SPEED [V]

(mm/s)

OPERATION

TIME (s/20 mm)

THRUST

N lb

1 0.22 92.6 5000 1124

2 0.38 52.3 5000 1124

10 0.99 20.2 5000 1124

13 1.22 16.4 4500 1012

16 1.44 13.8 4000 899

20 1.75 11.4 3500 787

24 2.05 9.7 3000 674

28 2.35 8.5 2500 562

33 2.73 7.3 2000 450

36 2.96 6.8 1500 337

41 3.34 6.0 1000 225

48 3.87 5.2 500 112

50 4.02 5.0 350 79

Speed [V] achieved by Speed Scales [A] other than mentioned

above can be approximately calculated by the following equation:

Speed [V] = 0.076 × Speed Scale [A] + 0.231, where 2 ≤ A ≤ 50

3500

3000

2500

2000

1500

THRUST (N)

1000

500

Thrust

Speed

7

6

5

4

3

SPEED (mm/s)

2

1

6000

Thrust

5000

4000

3000

THRUST (N)

2000

1000

0

02010 30 40 50

SPEED SCALE

Speed

5

4

3

SPEED (mm/s)

2

1

0

Figure 11. PSN3 Speed v.s. Thrust

6) Deadband (ITEM No.20)

Deadband is adjustable as % of the maximum stroke

within 0.1 to 5%.

7) Restart Limiting Timer (ITEM No.21)

The timer is provided to protect the motor from overheat-

ing, preventing it from restarting for a certain interval

once the motor has been stopped within deadband.

When the high temperature protection is activated in a

high temperature ambient, adjust the timer to a longer

interval.

Adjustable range is within 0 to 30 sec.

MANUAL OPERATION

■ WHEN POWER IS AVAILABLE TO SUPPLY TO PSN

1) Turn on the power supply.

2) Turn on the SW-8 to put the PSN into the local calibration mode.

3) Use UP/DOWN buttons to manually operate the PSN.

4) Turn off the SW-8 after turning off the power supply.

■ USING THE MANUAL OPERATION STEM

1) Be sure that the power supply is removed.

2) The output stem is designed to go up when the manual

operation stem turns clockwise (seen from the operation

stem side). Turn the handle with a torque under 1 N·m

or 0.74 ft·lb (1.5 N·m or 1.48 ft·lb for PSN3) in checking

the stem position with the indicator.

3) The output stem moves by 10 mm per approx. 24 turns

(approx. 25 turns for PSN3) of the manual operation

stem.

4) When the operation is completed, be sure to remove the

handle and cover the stem with a rubber cap.

5) Be sure that the handle is not attached before turning on

the power supply.

6) Use a 8-mm spanner as a handle.

0

02010 30 40 50

SPEED SCALE

Figure 10. PSN1 Speed v.s. Thrust

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

0

EM-4857 Rev.10 P. 7 / 9

Page 8

PROTECTIVE FUNCTIONS

■ ERROR DETECTION

• When the position signal is deviated from the input signal but the output stem is stuck due to overload or certain

malfunction, the PSN repeats starting the motor at the

maximum torque for several items. If the stem is still

stuck after that, the PSN outputs an alarm signal (LED

turned ON) and stops power supply to the motor.

• In order to reset the PSN, apply several times 0% and

100% input signals in turn, or turn off and on the power

supply.

• In case the alarm is off frequently, check for foreign obstacles in the valve, inappropriate adjustments, or retightened gland packing or other possible causes of the

overload.

• e sure to remove the cause of alarm in order to ensure

appropriate life span.

■ ABNORMAL TEMPERATURE INCREASE PROTECTION

• When the incorporated temperature sensor detects an abnormal temperature increase in the motor, the PSN outputs an alarm signal (LED blinks in 0.5-sec. ON – 0.5-sec.

OFF sequence) and stops power supply to the motor until

the temperature decreases to an acceptable level.

• The PSN is designed to automatically recover power supply to the motor. It take longer to recover normal operation when ambient temperature is higher.

PSN1 / PSN3

■ PROTECTIVE FUSE

• A fuse is incorporated for protection against overcurrent

in the control PCB and motor.

• If the power LED does not turn on with the power supplied to the actuator, check the fuse status.

• If a replaced fuse is blown quickly, it is possible that the

control PCB and/or motor are damaged. Consult M-System or M-System’s representative.

■ MOTOR PREHEAT FUNCTION

When the PSN detects a temperature lower than 0°C or

32°F (approximate) on the surface of its motor, the PSN supplies current to the motor in order to warm up and maintain

its surface temperature at 5°C or 41°F (approximate).

Maintain the power supply ON when the PSN is used in the

ambient temperature below 0°C or 32°F.

MAINTENANCE

For effective use and longer life of the PSN, regular checking appropriate for its operating conditions are recommended. Refer

to the following table.

ITEM CHECKING POINT HOW TO PROCEED

Functioning Apply input 0%, 50%, 100%, then back to 50%, 0%.

Check the actuator operations and positions at each

input value.

Abnormal sound No abnormal sound is heard during operation. Repair or calibration

Connector

Leadwire

Inside humidity, rust No condensation. No rust.

Screws Check that screws and bolts are securely fastened. Re-tighten them.

Nut Check that the nut at the valve stem is not loose. Re-tighten it and calibrate.

The connector is firmly connected.

No breakdown of leadwires.

The insulation covers are not torn, not bruised.

If there is water inside, check the packing.

For repair or parts replacement, contact M-System or representatives.

■ LUBRICATION

There is no need of oiling the PSN in normal operating conditions.

■ REGULAR TEST RUNNING

If the valve is not frequently operated, run a test operation regularly (once a week, for example) to check proper functions.

Repair or calibration

If the alarm indicator LED is on, check that the

valve operates lightly and smoothly.

Repair or calibration

Remove water, dry the case and inside parts.

Replace rusted parts. Calibration.

If the packing is damaged, replace it.

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 8 / 9

Page 9

PSN1 / PSN3

TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE HOW TO PROCEED

Not functioning Power and/or

input indicator

OFF

Power and input

indicator ON

Unstable functioning Operating speed is too fast. Secure the required thrust by slowing.

Alarm indicator ON Overload caused by a foreign object caught

Alarm indicator blinking Motor temperature is abnormally high. Use the restart limiting timer. Review MV

For repair or parts replacement, contact M-System or representatives.

Power and/or input signal is not supplied. Check power and input signals, remove the

causes of malfunction and secure the sig-

nals.

Wiring error. Check the wiring.

Bad contact. Check the connector and other connecting

sections.

Fuse melted. Replace it with a new one.

The actuator is in local calibration mode

(SW-8 ON).

Improper adjustments of full-open/-closed

positions.

Control PCB damaged. Repair and calibration.

Motor damaged. Repair and calibration.

Abnormality in power voltage or input

signal.

Power voltage is too low or fluctuating. Secure the required level of voltage.

Input is unstable. Check the controller and cables. Eliminate

Angle sensor is damaged. Repair and calibration.

in the valve.

Actuator mechanism damaged. Repair and calibration.

Wiring of the temperature sensor is broken

or the connector is detached.

Turn SW-8 OFF.

Adjust the full-open/-closed positions.

Remove the causes of malfunction and

secure the signals.

noise.

Remove the causes of overload.

value from the controller.

Check the connector and leadwires.

LIGHTNING SURGE PROTECTION

M-System offers a series of lightning surge protectors for

protection against induced lightning surges. Please contact

M-System to choose appropriate models.

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4857 Rev.10 P. 9 / 9

Loading...

Loading...