Page 1

Space-saving Signal Conditioners M3-UNIT Series

UNIVERSAL TRANSMITTER

(field- and PC-configurable)

Model: M3LU2

OPERATING MANUAL

1M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 2

CONTENTS

1. INTRODUCTION .....................................................................................4

1.1 PACKAGE .............................................................................................................................4

2. SAFETY PRECAUTIONS (Be sure to observe.).....................................5

3. POINTS OF CAUTION ...........................................................................7

3.1 BEFORE USE .... ..................................................................................................................7

3.2 CONFORMITY WITH EU DIRECTIVES ............................................................................... 7

3.3 ENVIRONMENT ...................................................................................................................7

3.4 WIRING ................................................................................................................................8

3.5 HANDLING CAUTIONS ........................................................................................................ 8

4. FEATURES AND PREPARATION PROCEDURE OF M3LU2 ..............9

4.1 FEATURES OF M3LU2 ........................................................................................................9

4.2 PREPARATION PROCEDURE .............................................................................................9

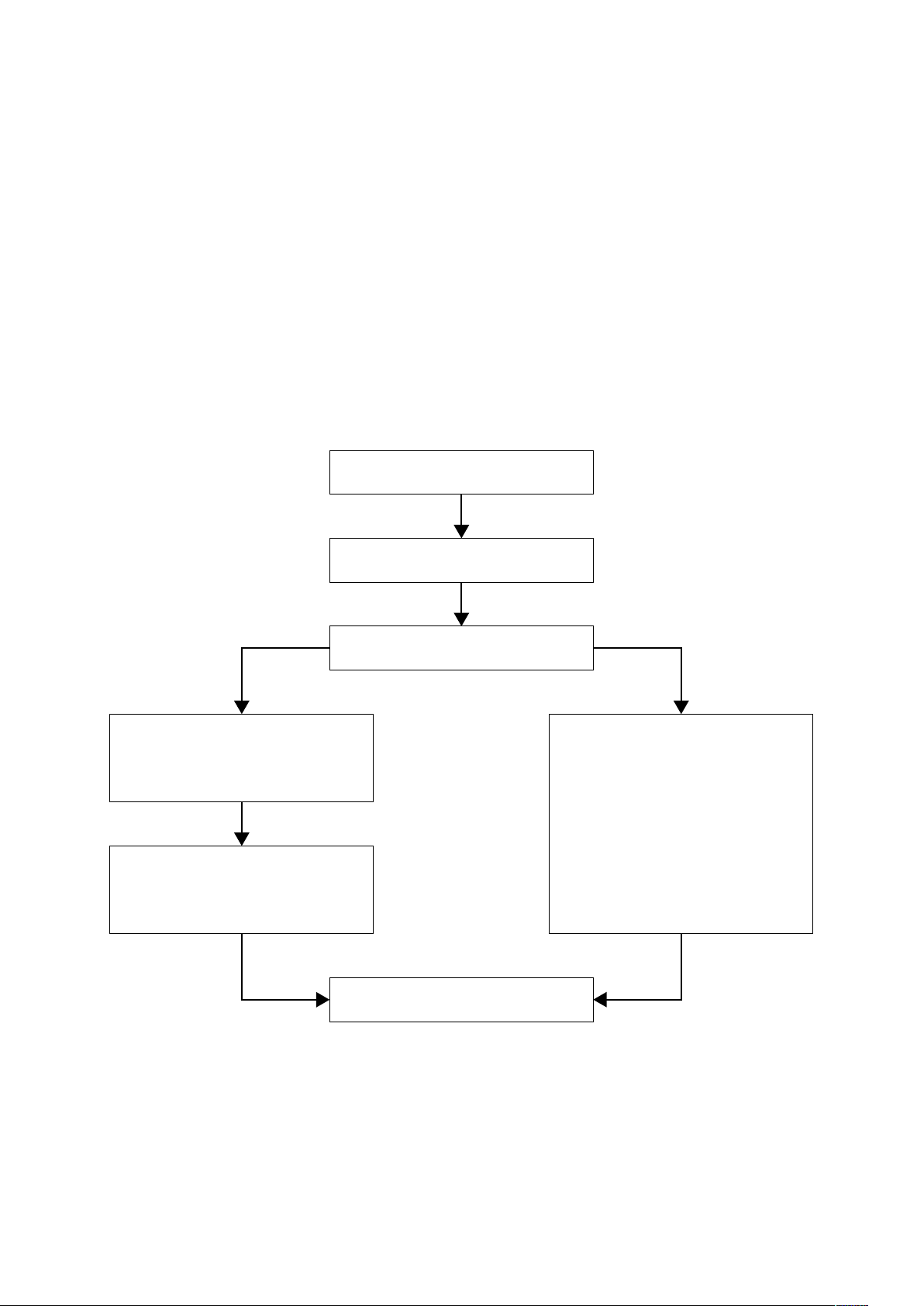

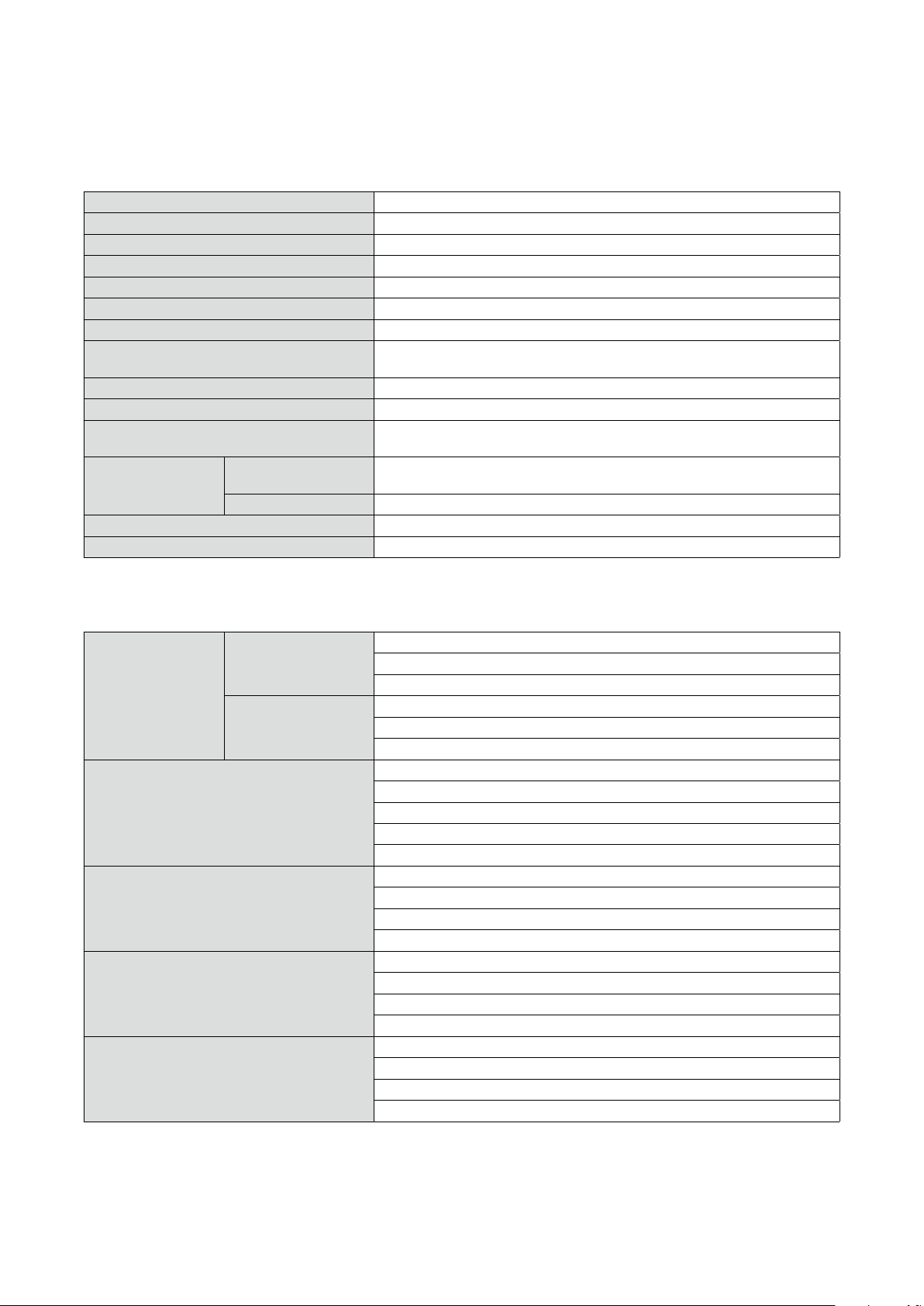

5. COMPONENT IDENTIFICATION .........................................................10

5.1 FRONT AND SIDE VIEWS ................................................................................................. 10

5.1.1 STATUS INDICATOR LED ....................................................................................... 11

5.2 INTERNAL VIEW ................................................................................................................13

6. HOW TO OPEN THE COVER ..............................................................14

7. DIP SWITCH CONFIGURATION ..........................................................15

7.1 DIFFERENCE BETWEEN DIP SW CONFIGURATION AND PC CONFIGURATION ......... 15

7.2 DIP SWITCH SELECTION PER I/O SPECIFICATION AND FUNCTION ............................ 15

7.2.1 CONFIGURATION MODE ....................................................................................... 16

7.2.2 INPUT TYPE (JP2) .................................................................................................. 16

7.2.3 INPUT (DIP SWITCHES) ........................................................................................ 16

7.2.4 OUTPUT TYPE .......................................................................................................20

7.2.5 FRONT CONTROL BUTTON LOCK .......................................................................20

8. WIRING ................................................................................................. 21

8.1 CAUTION IN WIRING .........................................................................................................21

8.2 WIRING INSTRUCTIONS ...................................................................................................21

8.3 TERMINAL ASSIGNMENT ................................................................................................. 23

8.4 TERMINAL CONNECTIONS ..............................................................................................24

8.4.1 WIRING INPUT.......................................................................................................24

8.4.2 WIRING OUTPUT...................................................................................................26

8.4.3 WIRING POWER ....................................................................................................26

2M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 3

9. INSTALLATION ....................................................................................27

10. CALIBRATION ....................................................................................28

10.1 CALIBRATION FLOW .......................................................................................................28

10.2 INPUT & OUTPUT RANGING ..........................................................................................29

10.2.1 OUTLINE OF I/O RANGING .................................................................................29

10.2.2 MAXIMUM RANGE, MINIMUM SPAN AND DEFAULT VALUE OF INPUT ...........31

10.2.3 MAXIMUM RANGE, MINIMUM SPAN AND DEFAULT VALUE OF OUTPUT .......32

10.2.4 OPERATION PROCEDURE OF I/O RANGING....................................................33

10.3 FINE ADJUSTMENT MODE .............................................................................................36

10.3.1 OUTLINE OF FINE ADJUSTMENT ......................................................................36

10.3.2 OPERATION PROCEDURE OF FINE ADJUSTMENT .........................................37

11. CHECKING, MAINTENANCE, INITIALIZATION OF PARAMETERS .39

11.1 CHECKING ........................................................................................................................ 39

11.2 MAINTENANCE ................................................................................................................ 39

11.3 INITIALIZATION OF PARAMETERS .................................................................................39

12. APPENDICES ..................................................................................... 40

12.1 SPECIFICATIONS ............................................................................................................40

12.1.1 GENERAL SPECIFICATIONS ...............................................................................40

12.1.2 INPUT SPECIFICATIONS .....................................................................................40

12.1.3 OUTPUT SPECIFICATIONS .................................................................................41

12.1.4 INSTALLATION ......................................................................................................41

12.1.5 PERFORMANCE ..................................................................................................41

12.1.6 STANDARDS & APPROVALS ...............................................................................42

12.1.7 I/O TYPE, MAXIMUM RANGE & ACCURACY ......................................................42

12.1.8 CALCULATION EXAMPLES OF OVERALL ACCURACY .....................................44

12.2 PC CONFIGURATOR SOFTWARE ..................................................................................45

12.3 MODEL NUMBERING ......................................................................................................46

12.4 EXTERNAL DIMENSIONS ...............................................................................................47

3M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 4

1. INTRODUCTION

Thank you for your choosing M-System. Read this manual carefully to ensure that you use the product correctly and safely.

1.1 PACKAGE

Check contents of the package you received as outlined below.

•Signal conditioner

•Accessories

I/O range and tag name label sheet Instruction manual CJC sensor

(mounted on a Euro type connector terminal

block)

*1 Ordering Information Sheet is included when input or output is specied in ordering.

4M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 5

2. SAFETY PRECAUTIONS (Be sure to observe.)

The following signs are used in this manual to provide precautions required to ensure safe usage of the unit. Please understand these signs and graphic symbols, read the manual carefully and observe the description.

The following signs show seriousness of safety hazard or damage occurred when used wrongly with the signs ignored.

Indicates a potentially hazardous situation which, if not avoided, may result in

serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, may result in

injury or in property damage.

Indicates prohibitions. Indicates mandatory cautions. Indicates cautions.

PROHIBITION

WET HANDS

Make sure for safety that only qualied personnel

perform the wiring.

• Failure to do so may result in a re, electric

shock or injury.

Do not touch the terminals while the power is on.

•Doing so may result in electric shock.

Check the connection diagram carefully before

wire connection.

• Failure to do so may result in malfunction, a re

or electric shock.

Tighten the terminal screws of the Euro type connector terminal blocks with a specied torque.

• Excessive fastening may result in damage of

the screws and loose screws may occasionally

result in ignition.

Do not operate buttons with a wet hand or nger.

•Doing so may result in electric shock.

Do not splash water on the unit.

• Doing so may result in a re, electric shock or

injury.

Provide safety measures outside of the unit to

ensure safety in the whole system if an abnormality occurs due to malfunction of the unit or another

external factor affecting the unit’s operation.

Stop using the unit immediately if smokes, unusual

smell or abnormal noises come(s) from it.

• Using the unit continuously may result in a re

or electric shock.

Stop using the unit if it is dropped or damaged.

• Using the unit continuously may result in a re

or electric shock.

Do not throw the unit into the re.

• Doing so may result in rupture of the electronic

component.

5M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 6

Never discompose or remodel the unit.

• Doing so may result in electric shock, malfunction or injury.

Do not press buttons with a pointed object.

•Doing so may result in malfunction of the unit.

PROHIBITION

TO CONTACT

Do not connect or remove the unit while its power

is on.

• Doing so may result in, electric shock, malfunction or injury.

Do not allow ne shavings or wire scraps to enter

the unit in machining screws or wiring.

•Doing so may result in malfunction of the unit.

Do not open the housing cover while the power or

the input is applied.

• Doing so may result in electric shock, malfunction or injury.

Do not touch the printed circuit board or the electronic components in opening the cover.

•Doing so may result in malfunction of the unit.

Do not connect other cables to the COMM (congurator jack) port than the dedicated one.

•Doing so may result in malfunction of the unit.

Use a minus screwdriver and tweezers in setting

the switches.

• Failure to do so may result in malfunction of

the unit.

Do not pull the wires to separate the Euro type

connector terminal blocks from the body.

• Doing so may result in damage of the unit or

injury.

Do not use the unit with the cover open.

•Doing so may result in malfunction of the unit.

Do not pull the wires connecting to the unit.

• Doing so may result in electric shock, damage

of the unit or injury.

Do not use the unit in the atmosphere where combustible gas is present.

• Doing so may result in inammation, ignition or

smoke.

Do not cover the ventilation slits with cables, etc.

•Doing so may result in malfunction or heating.

6M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 7

3. POINTS OF CAUTION

3.1 BEFORE USE ....

The unit is for use in general industrial environments, therefore may not be suitable for applications which require higher

level of safety (e.g. safety or accident prevention systems) or of reliability (e.g. vehicle control or combustion control systems).

For safety, installation and maintenance of this unit must be conducted by qualied personnel.

If the unit is not used in a manner not specied by M-System, the protection provided by the equipment may be impaired.

3.2 CONFORMITY WITH EU DIRECTIVES

This product conforms to the following Low Voltage and EMC Directives.

Electromagnetic Compatibility (EMC) Directive (2004/108/EC)

EMI EN 61000-6-4: 2007/A1: 2011

EMS EN 61000-6-2: 2005

Low Voltage Directive (2006/95/EC)

EN 61010-1: 2010

Installation Category II

Pollution Degree 2

Input or output to power: Reinforced insulation (300 V)

Input to output: Basic insulation (300 V)

•This equipment is suitable for Pollution Degree 2 and Installation Category II. Reinforced insulation (signal input or output

to power input: 300 V) and basic insulation (signal input to output: 300 V) are maintained. Prior to installation, check that

the insulation class of this unit satises the system requirements.

•Altitude up to 2000 meters.

•The equipment must be mounted inside a panel.

•The actual installation environments such as panel congurations, connected devices, connected wires, may affect the

protection level of this unit when it is integrated in a panel system. The user may have to review the CE requirements in

regard to the whole system and employ additional protective measures to ensure the CE conformity.

This product conforms to the EMC Directive for electrical and electronic apparatus intended for use in industrial environments. If it is used in the residential environments, it may cause radio interference, and the user is requested to take

appropriate measures.

3.3 ENVIRONMENT

Install the unit within the installation specications.

•Indoors use

•Environmental temperature must be within -25 to +60°C (-13 to 140°F) with relative humidity within 30 to 95% RH without

condensing.

•Altitude up to 2000 meters.

•Provide sufficient space around the unit for heat dissipation.

•Install the unit in a well-ventilated place in order to prevent internal temperature rise.

•Refer to “Clustered mounting” to install several units. In mounting the unit with other equipments side by side, provide

sufficient space between them, according to the dimensions in the clustered mounting.

•Do not use the unit under the following environments:

– Where the unit is exposed to direct sunlight, rain or wind. (The unit is not designed for outdoor use.)

– Where condensation may occur due to extreme temperature changes.

– Where corrosive or ammable gas is present.

7M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 8

– Where heavy dust, iron powder or salt is present in the air.

– Where organic solvent such like benzine, thinner, and alcohol, or strong alkaline materials such like ammonia and

caustic soda may attach to the unit, or where such materials are present in the air.

– Where the unit is subject to continuous vibration or physical impact.

– Where there are high-voltage lines, high-voltage equipments, power lines, power equipments, equipments with trans-

mission unit such like a ham radio equipment, or equipments generating large switching surges around the unit.

3.4 WIRING

•In order to prevent potential electric shock, wire the unit after turning off the power supply and making sure that the power

is not supplied to the cable.

•Be sure to conrm the name and polarity of each terminal before wiring to the Euro type connector terminal blocks.

•Do not connect anything to unused terminals.

3.5 HANDLING CAUTIONS

•The unit is designed to function as soon as power is supplied, however, a warm up for 10 minutes is required for satisfying complete performance described in the data sheet.

•Use the unit within the noted supply power voltage and rated load.

•The last measured values are held in mode transition. Take this into consideration when conguring the control system.

•Clean the surface of the unit with wet soft cloth. Do not use organic solvent such like benzine, thinner and alcohol. Doing

so may result in deformation or discoloration of the unit.

•When abnormality is found such like smokes, unusual smell and abnormal noises coming from the unit, immediately cut

the power supply and stop using it.

8M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 9

4. FEATURES AND PREPARATION PROCEDURE OF M3LU2

4.1 FEATURES OF M3LU2

The M3LU2 is a eld congurable signal transmitter using a simulator and an indicator, without a PC or a dedicated setting

unit.

For instance, select an input type and range with the DIP switches on the unit to set input. Then apply a desired minimum

or maximum input from the simulator and press a front button to memorize the value as minimum or maximum value. Easy

and reasonable M-System’s one-step calibration (hereafter called ‘One-Step Cal’) realizes automatic I/O ranging and calibration only by pressing a button once.

4.2 PREPARATION PROCEDURE

Before using the unit, perform the calibration according the following ow. The procedure depends on the conguration

options or modes.

•Two conguration modes are available with the model M3LU2-x/A, eld conguration using the DIP SW / control

buttons (hereafter called ‘DIP SW conguration’) and the PC conguration.

•The model M3LU2-x/B is for the DIP SW conguration only.

CONFIGURING DIP SW & JP2

DIP SW conguration PC conguration

INPUT RANGING

• With front control buttons and a simulator.

OUTPUT RANGING

• With front control buttons, a simulator

and a multimeter.

WIRING & MOUNTING ON DIN RAIL

POWER ON

I/O SETTING AND CALIBRATION

• Using the PC Congurator Software

(model: M3LUCFG).

STARTING OPERATION

9M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 10

5. COMPONENT IDENTIFICATION

5.1 FRONT AND SIDE VIEWS

(1)

(2)

(3)

(4)

(7)

(5)

(9)

(8)

(6)

(1) LED1 (LD1), LED2 (LD2) and LED3 (LD3)

The blinking pattern (ON/blink/OFF) of the tri-color (green/amber/red) LEDs indicates a mode or an operation status of

the transmitter.

(2) MODE, UP and DOWN Buttons

Used for the I/O ranging and ne adjustments by ‘One-Step Cal’, and for reset of the parameters to the default status.

The functions of the buttons are shown in the following table.

BUTTON FUNCTION

MODE

UP

DOWN

Used to move on to the I/O Ranging Mode, Fine Adjustment Mode and RUN Mode, and to reset the

parameters to the default status.

Used to congure 100% input in the Input Ranging Mode and 100% output in the Output Ranging

Mode, and to increase the output in the Fine Adjustment Mode.

Used to congure 0% input in the Input Ranging Mode and 0% output in the Output Ranging Mode, and

to decrease the output in the Fine Adjustment Mode.

(3) Congurator jack

Used to connect with a PC using the PC Congurator Software (model: M3LUCFG) for various settings, I/O ranging

and ne adjustments.

Connect a dedicated cable between the congurator jack and the PC.

(4) Cover for congurator jack

Slide the cover to connect the cable to the congurator jack. Close the cover in the normal operation.

(5) Specication label

The model No., power input and serial No. (SER NO) are printed on the label.

(6) Connection diagram

The connection diagram for each terminal is shown.

(7) DIP SW setting

The DIP switch settings are shown.

(8) I/O range label

When I/O range indication is necessary, write in the congured ranges on the I/O range label included in the product

package and put it on the side of the unit.

(9) Tag name label

When a tag No. is specied, the unit(s) will be shipped with the tag name label put on the above position.

10M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 11

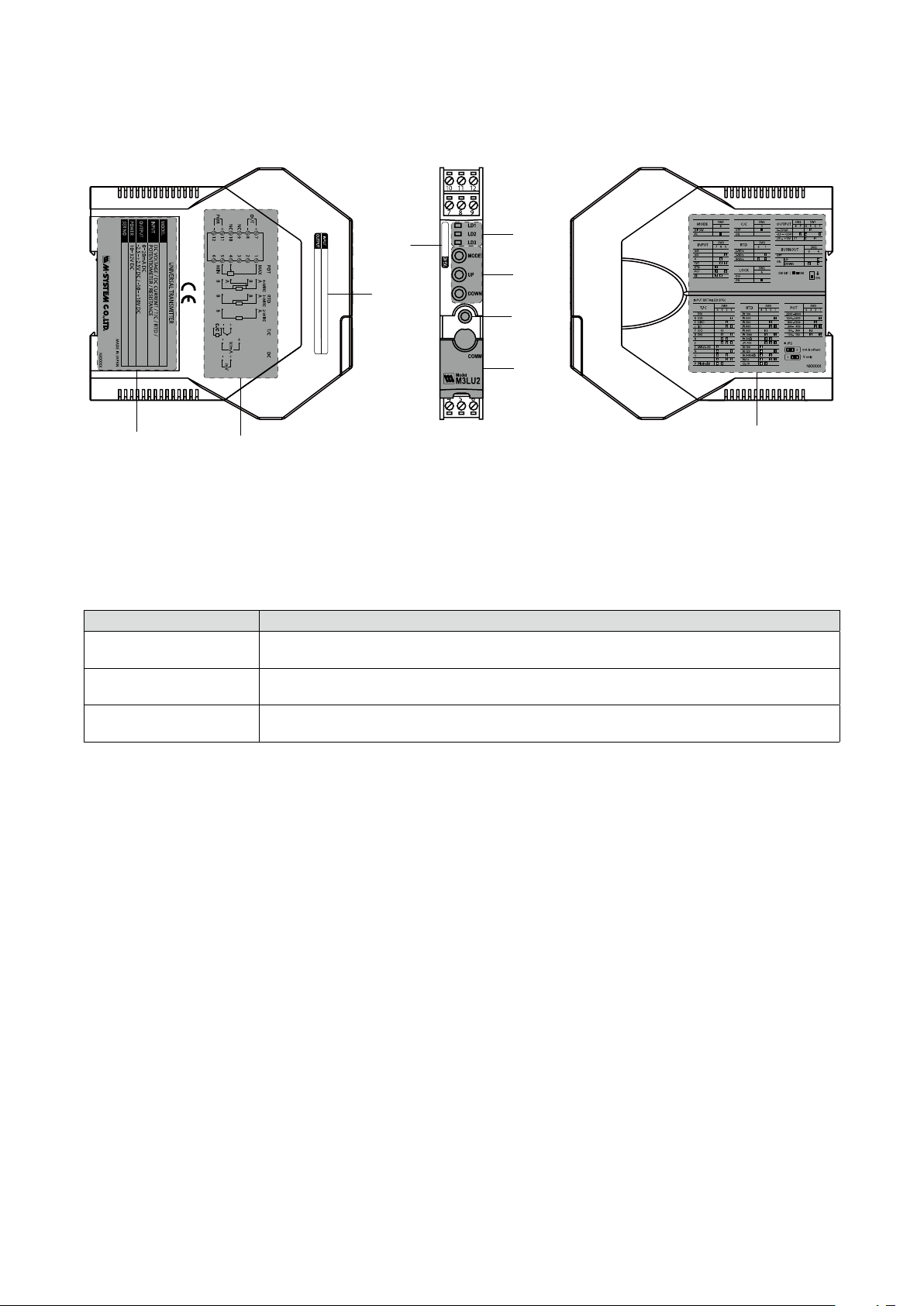

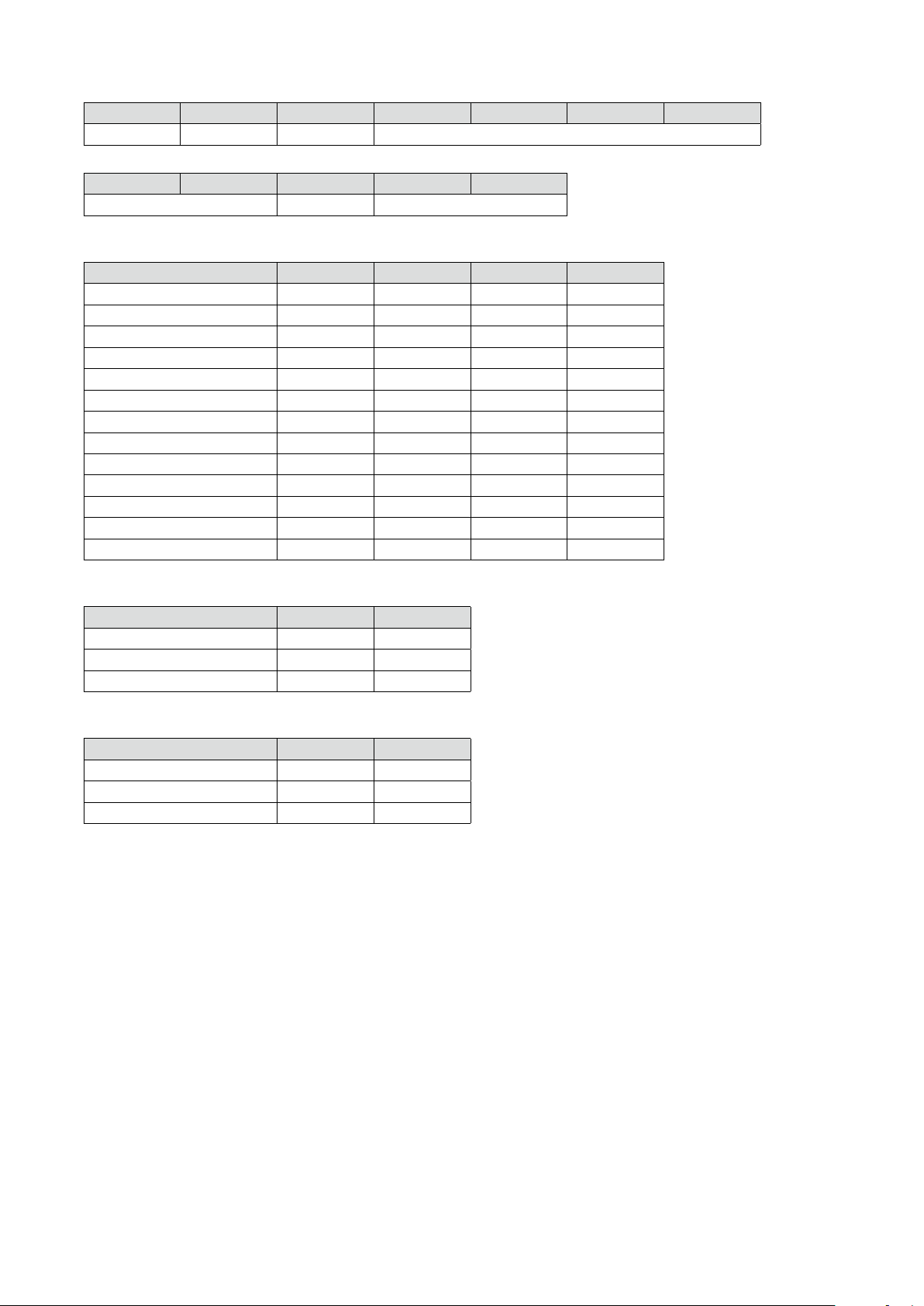

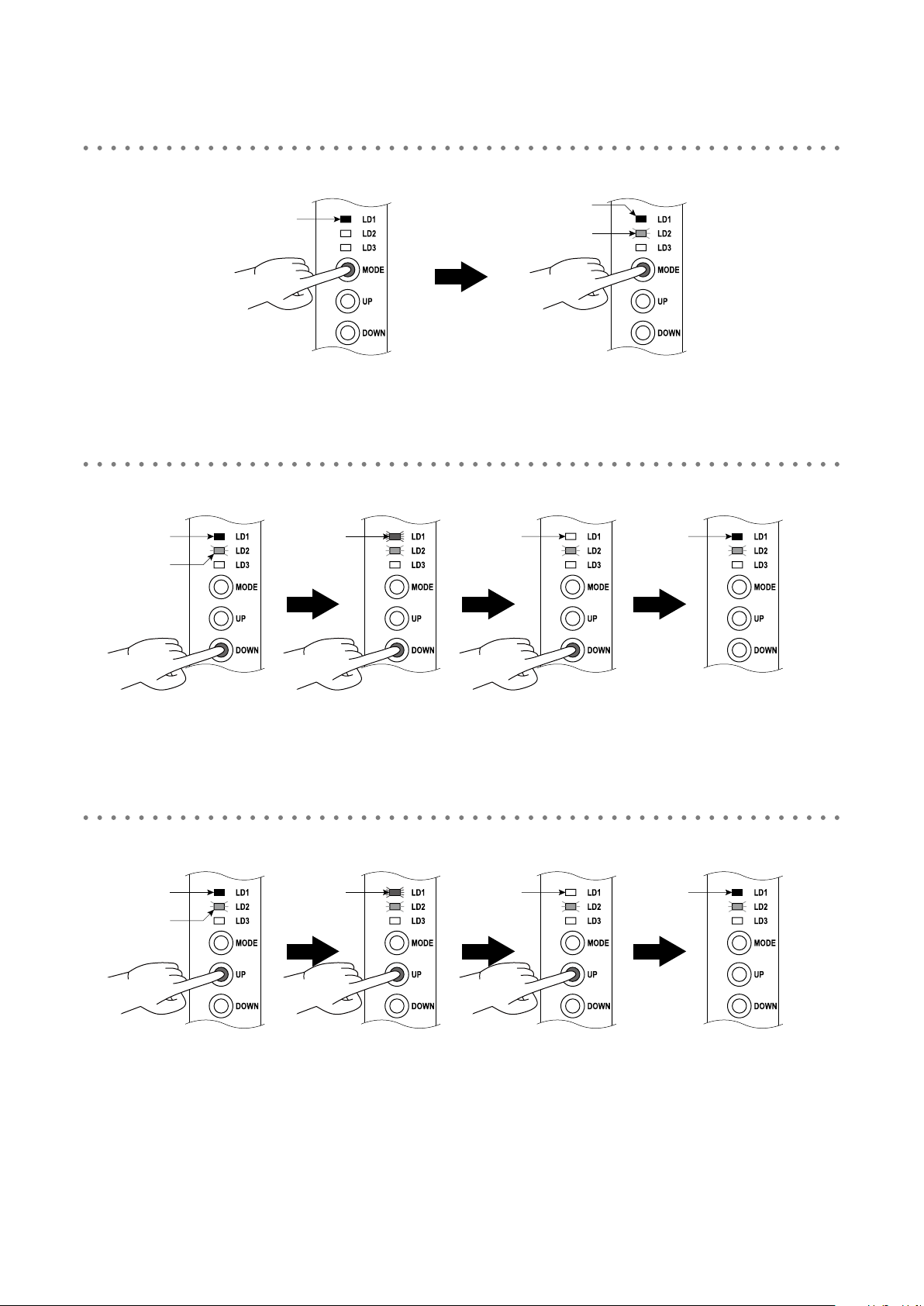

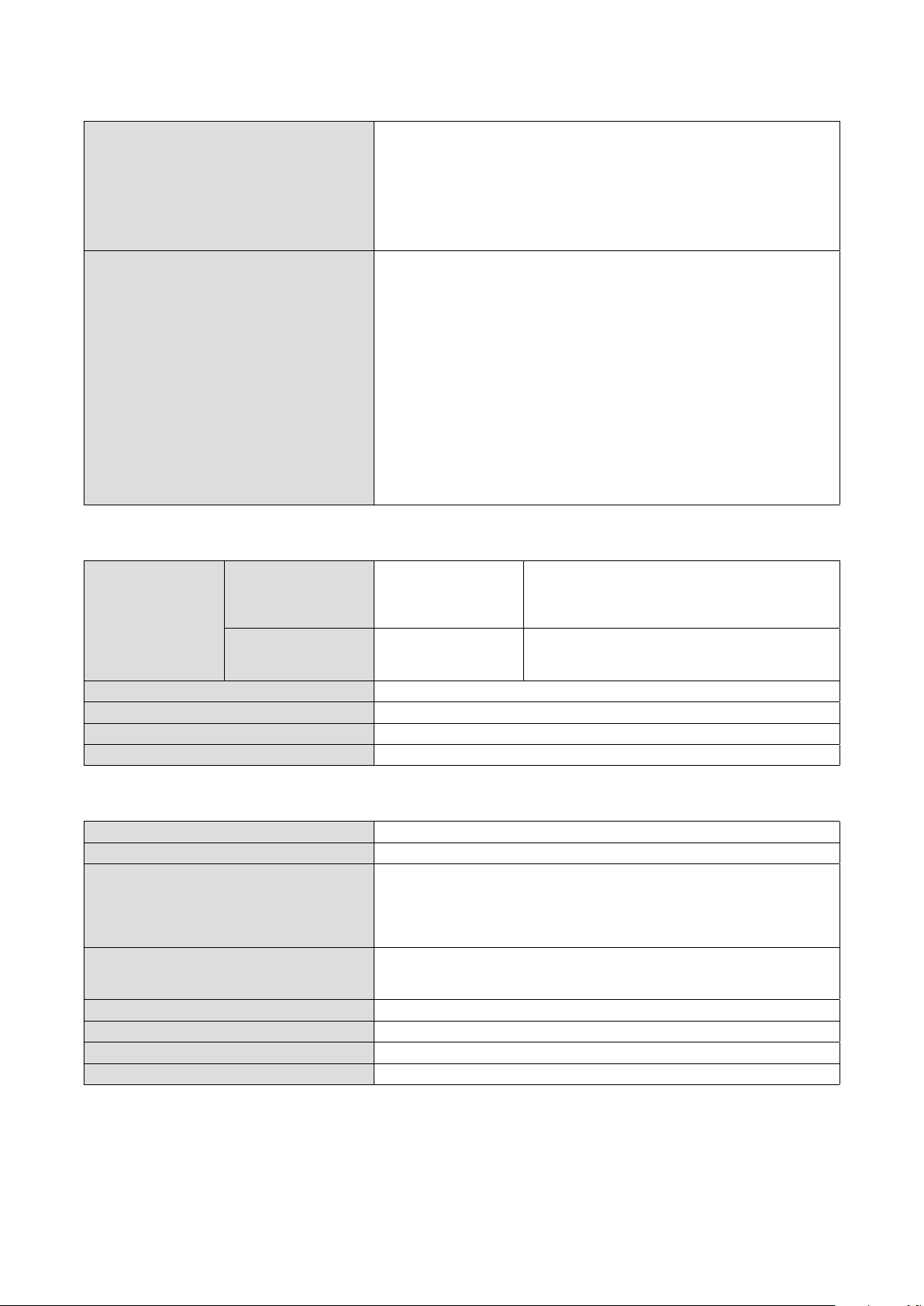

5.1.1 STATUS INDICATOR LED

Combinations of the three front LEDs (LD1, LD2 and LD3) indicates the transmitter’s operating status by different blinking

patterns. The patterns depend on the conguration modes, DIP SW conguration and PC conguration.

Examples are shown below.

LED COLOR PATTERN

Red

Amber

Green

R

A

G

ON

Blink

OFF

■ NORMAL OPERATION (RUN) MODE

Combination of the LEDs and their blinking patterns indicate normal or abnormal operation of the unit, and are useful to

identify error modes.

•Normal operation (RUN) mode

DIP SW CONFIGURATION PC CONFIGURATION

•Error mode

ERROR DIP SW CONFIGURATION PC CONFIGURATION

Output saturated

Burnout

DIP SW error

System error

The output is below -15% or above +115%. Check the setting and input.

The sensor or the input wiring is disconnected. Check the sensor and wiring.

DIP SW conguration is inappropriate. Check the SW settings.

Indicates the CPU’s communication error.

11M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 12

■ I/O RANGING MODE & FINE ADJUSTMENT MODE

The LED status in the I/O ranging and ne adjustments using the ‘One-Step Cal’ is shown in the following tables.

MODE LED MODE LED

Input ranging

Output ranging Fine span adjustment

Fine zero adjustment

NOTE

In the I/O ranging and ne adjustments using the PC Congurator Software (model: M3LUCFG), the LEDs are not according to the above tables.

12M3LU2 OPERATING MANUAL EM-2653-B Rev.0

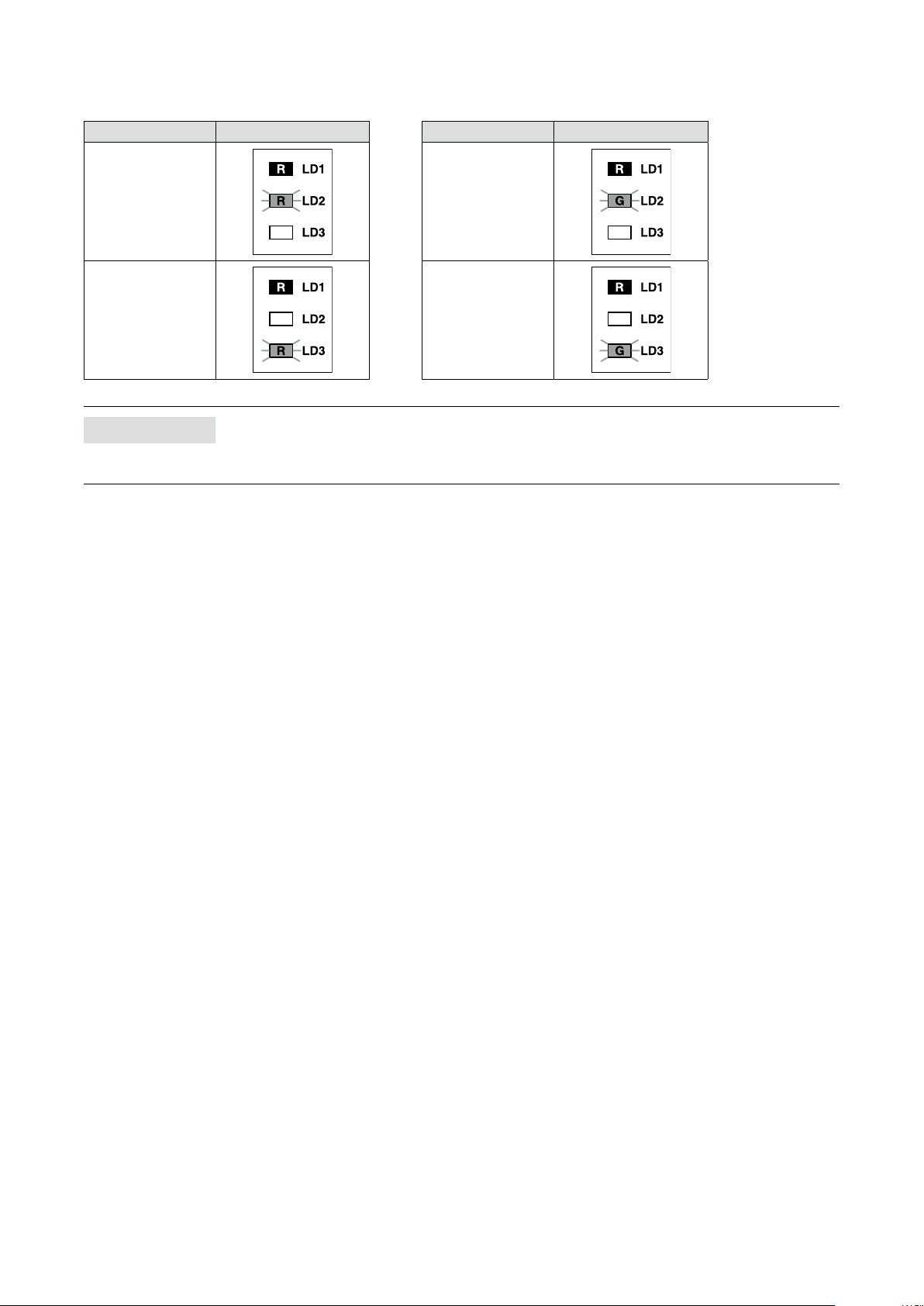

Page 13

5.2 INTERNAL VIEW

(1) SW1

(2) SW2 (3) SW3

(4) JP2

(1) SW1

Sets output type.

(2) SW2

Sets wires, cold junction compensation, burnout, front control button lock and output type.

(3) SW3

Sets input type, sensor type and conguration mode.

(4) JP2

Sets input type.

13M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 14

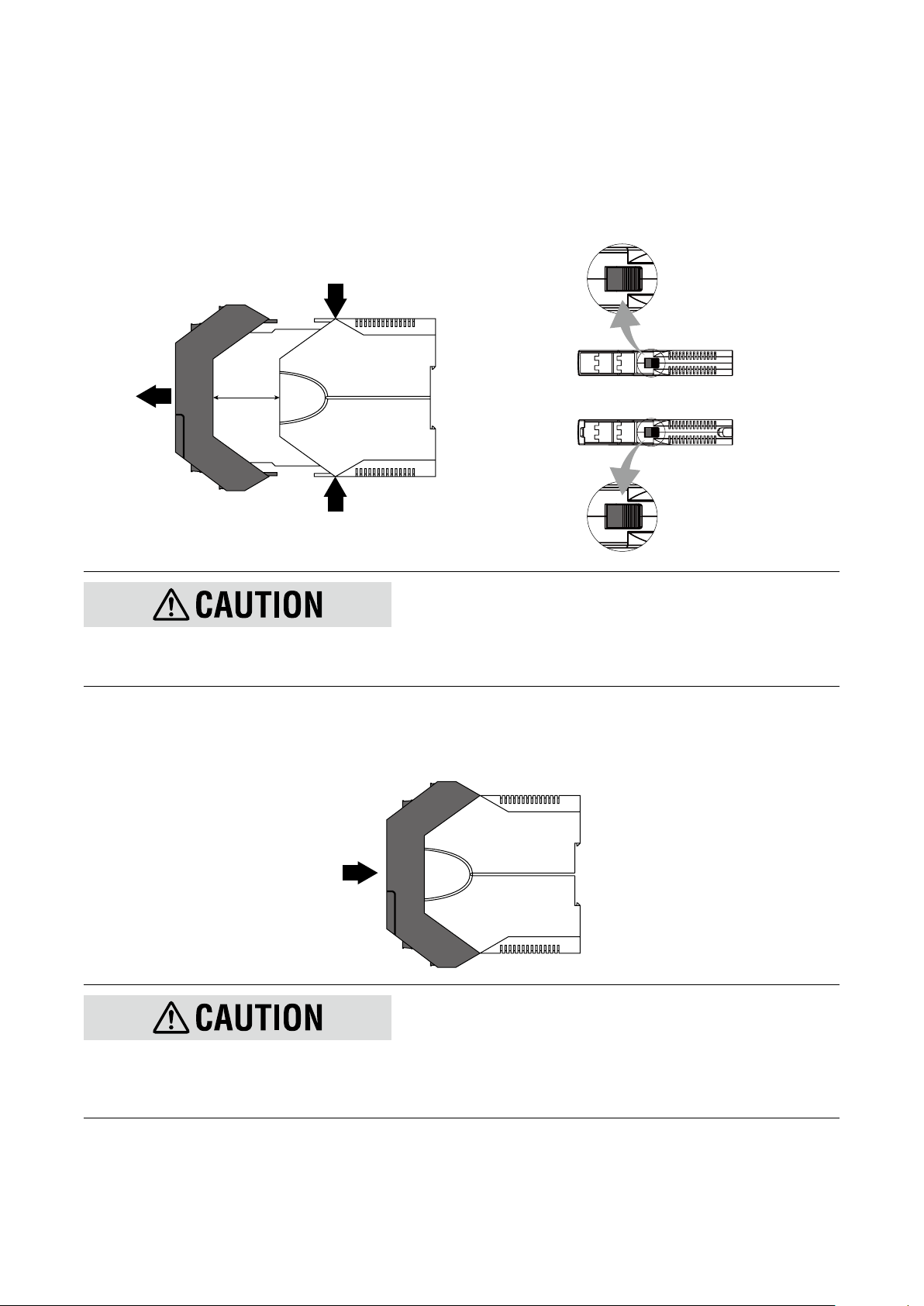

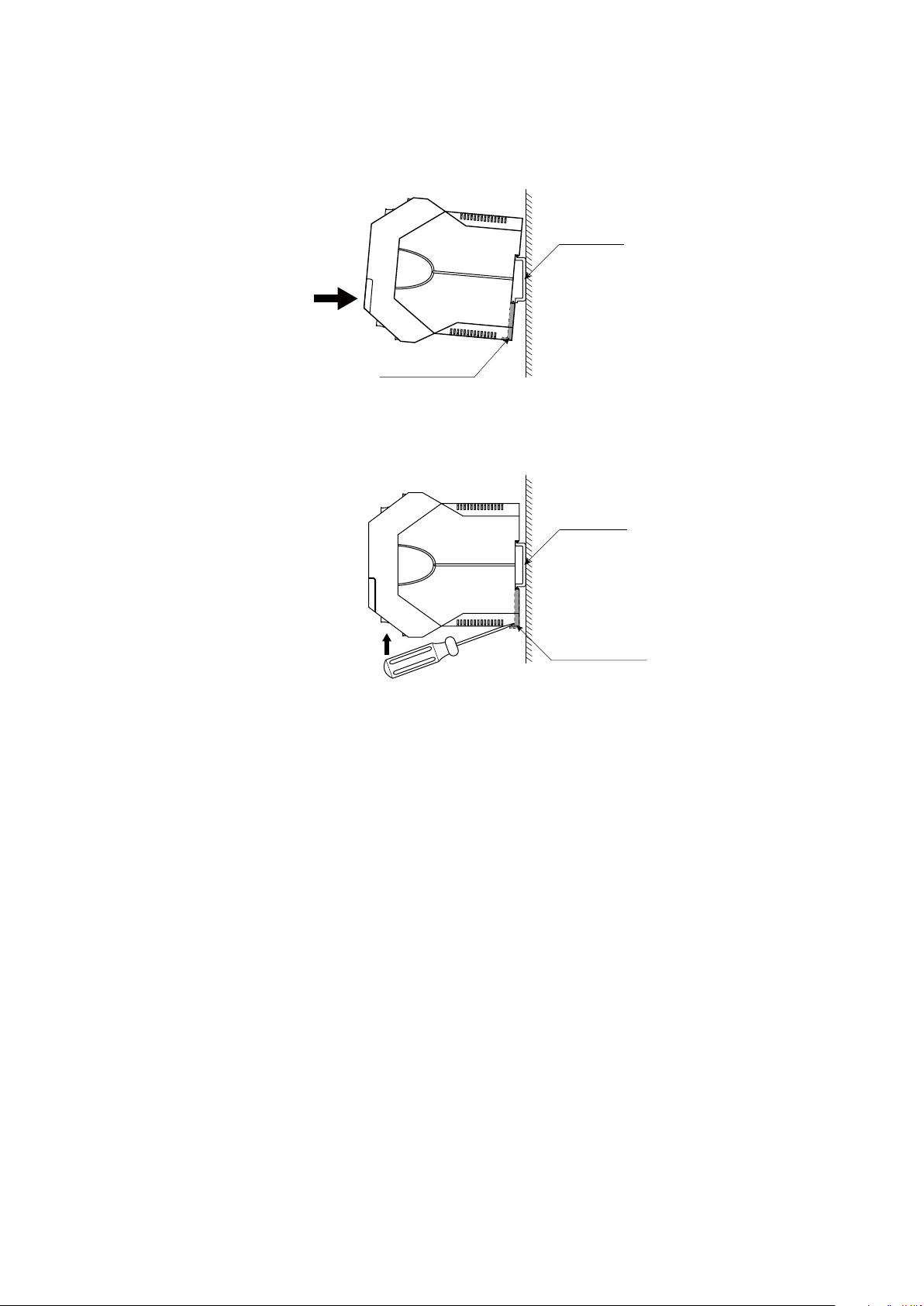

6. HOW TO OPEN THE COVER

■

Open the housing cover to set the DIP switches and JP2 inside the cover.

■ HOW TO OPEN THE COVER

(1) Hold the locks at the top and bottom of the unit.

(2) Slide the housing cover gently to open until it hits the latching inside the unit (approx. 3.5 cm).

Top

Front

Approx. 3.5 cm

Lock

Lock

Bottom

■

Lock

Lock

•Do not open the cover while the power or the input is applied.

•Do not touch the printed circuit board or the electronic components in opening the cover.

•Do not pull beyond where the cover is latched.

■ HOW TO CLOSE THE COVER

(1) Push the front to close the cover.

Front

•Before closing the cover, make sure that there is not a conductive foreign material attached on the printed cir-cuit board.

•Be sure to close the cover after setting.

•Be careful not to get your hand or nger caught in the cover.

•Do not force the cover closed. Doing so may result in damage of the electronic components.

14M3LU2 OPERATING MANUAL EM-2653-B Rev.0

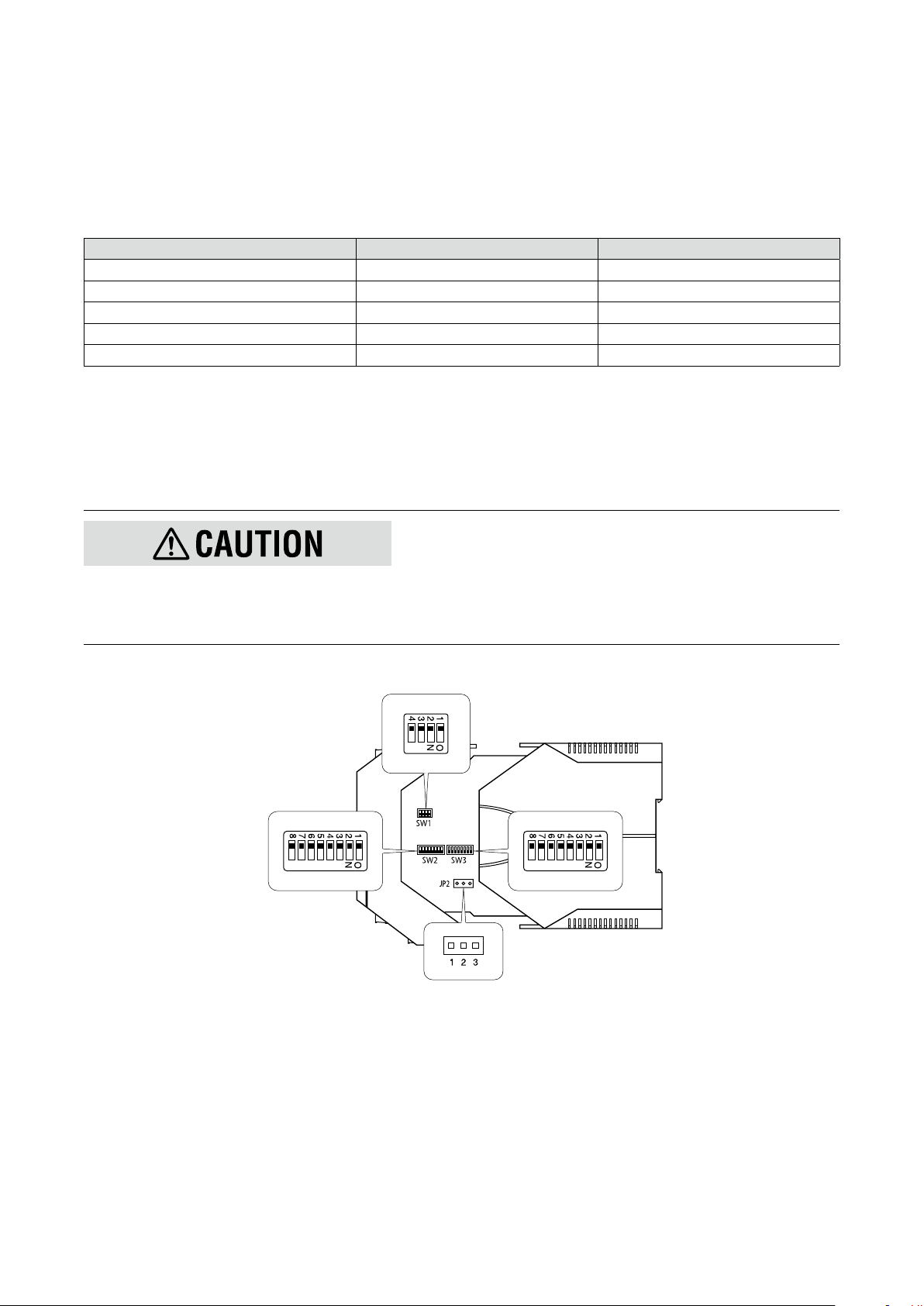

Page 15

7. DIP SWITCH CONFIGURATION

SW1

This chapter describes the conguration of the I/O specications and functions using the DIP switches and the JP2.

For the PC conguration, some DIP switch settings are necessary.

7.1 DIFFERENCE BETWEEN DIP SW CONFIGURATION AND PC CONFIGURATION

The following table shows the difference between the DIP SW conguration and PC conguration.

CONFIGURATION ITEM DIP SW CONFIGURATION PC CONFIGURATION

Conguration mode SW3-8 OFF SW3-8 ON

JP2 for input type Required Required

DIP SW for input Required ----

Output type Required Required for SW1-1 through 1-4

Front control button lock As necessary As necessary

7.2 DIP SWITCH SELECTION PER I/O SPECIFICATION AND FUNCTION

Congure the DIP switches and JP2 according to your I/O specications and functions.

The unit reads the DIP-switch-calibrated conguration only once after the power supply is turned on. Set the switches with

the power supply removed. Some tools are needed to set the DIP switches and JP2.

•Set the switches and JP2 with the power supply removed.

•Use tweezers or longnose pliers to switch the JP2.

•Use a minus screwdriver with the blade edge 0.8 mm (0.03”) to set the DIP switches.

•Do not touch other electronic components except for the JP2 and DIP switches.

SW2 SW3

JP2

15M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 16

7.2.1 CONFIGURATION MODE

With the model M3LU2-x/A, select the conguration mode (conguration method of I/O specications), DIP SW conguration or PC conguration, as shown in the following table. With the model M3LU2-x/B, turn the SW3-8 OFF.

DIP SW conguration: sets I/O specications with the DIP switches inside the cover and the front control buttons.

PC conguration: sets I/O specications with the PC Congurator Software (model: M3LUCFG).

MODE SW3-8

DIP SW OFF

PC ON

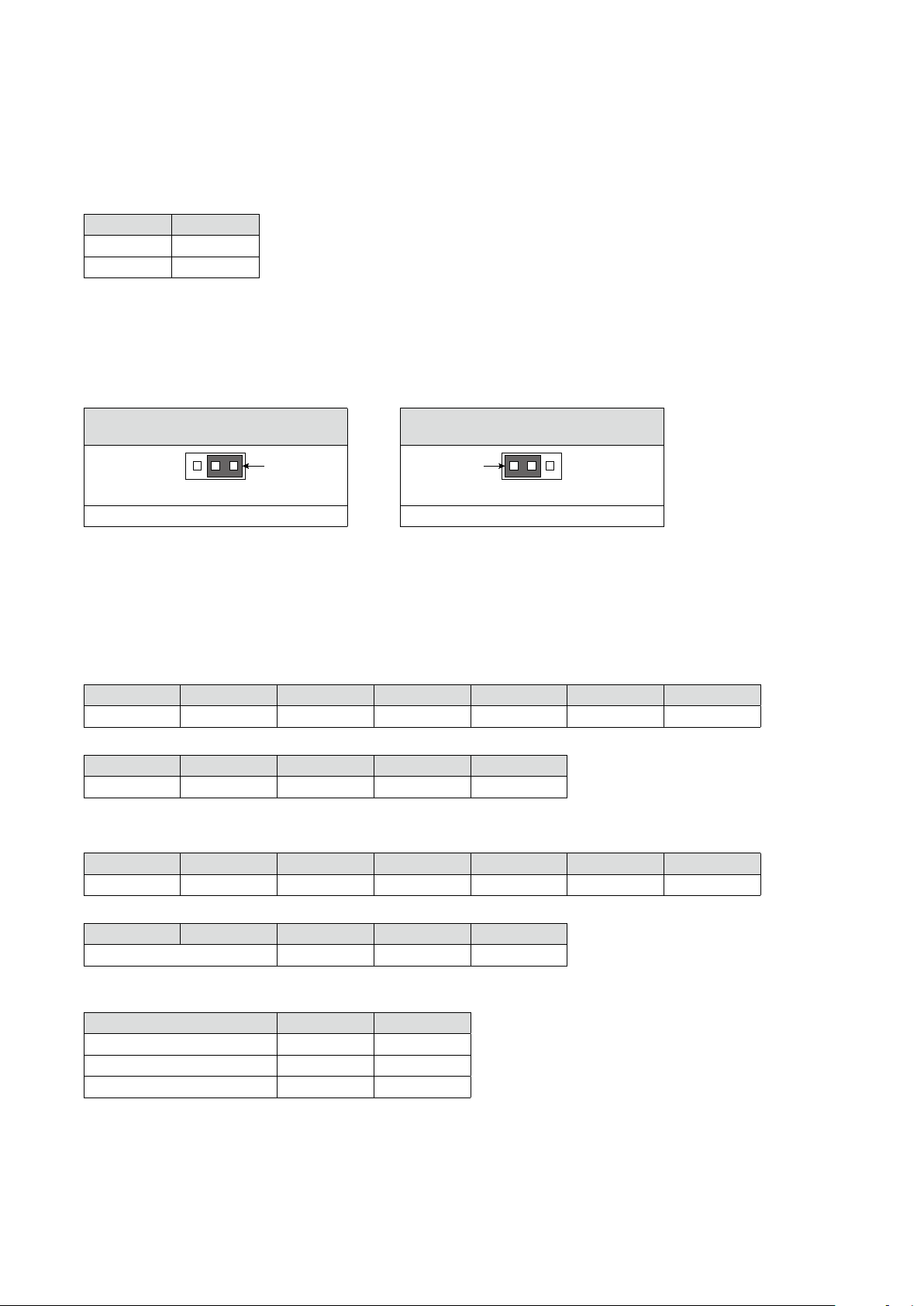

7.2.2 INPUT TYPE (JP2)

Switch the JP2 jumper according to the input specications.

Note that the JP2 setting is required with the PC conguration.

DC VOLTAGE [V] RANGE POSITION

[maximum range: -10 to +10 V DC]

Jumper

12

3

Switch the JP2 jumper to the 2-3 position. Switch the JP2 jumper to the 1-2 position.

NORMAL POSITION

(other than DC voltage [V] range)

Jumper

12

3

7.2.3 INPUT (DIP SWITCHES)

Set the DIP switches (SW2-1 through 2-5, SW3-1 through 3-7) according to the input specications. These settings are not

required with the PC conguration.

7.2.3.1 DC current input

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

OFF OFF OFF OFF OFF OFF OFF

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

OFF OFF OFF OFF OFF

7.2.3.2 DC voltage input (mV) [maximum range: -1000 to +1000 mV DC]

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

OFF OFF ON OFF OFF OFF OFF

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

Refer to Burnout OFF OFF OFF

•Burnout

BURNOUT SW2-5 SW2-4

No burnout OFF OFF

Upscale OFF ON

Downscale ON ON

16M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 17

7.2.3.3 DC voltage input (V) [maximum range: -10 to +10 V DC]

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

OFF ON OFF OFF OFF OFF OFF

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

OFF OFF OFF OFF OFF

7.2.3.4 Thermocouple input

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

OFF ON ON Refer to Thermocouple type

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

Refer to Burnout Refer to Cold junction compensation OFF OFF

•Thermocouple type

T/C SW3-4 SW3-3 SW3-2 SW3-1

(PR) OFF OFF OFF OFF

K (CA) OFF OFF OFF ON

E (CRC) OFF OFF ON OFF

J (IC) OFF OFF ON ON

T (CC) OFF ON OFF OFF

B (RH) OFF ON OFF ON

R OFF ON ON OFF

S OFF ON ON ON

C (WRe 5-26) ON OFF OFF OFF

N ON OFF OFF ON

U ON OFF ON OFF

L ON OFF ON ON

P (Platinel II) ON ON OFF OFF

•Burnout

BURNOUT SW2-5 SW2-4

No burnout OFF OFF

Upscale OFF ON

Downscale ON ON

•Cold junction compensation

COLD JUNCTION COMPENSATION SW2-3

Enable OFF

Disable ON

17M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 18

7.2.3.5 RTD input

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

ON OFF OFF Refer to RTD type

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

Refer to Burnout OFF Refer to RTD wires

•RTD type

RTD SW3-4 SW3-3 SW3-2 SW3-1

Pt 100 (JIS ’97, IEC) OFF OFF OFF OFF

Pt 200 OFF OFF OFF ON

Pt 300 OFF OFF ON OFF

Pt 400 OFF OFF ON ON

Pt 500 OFF ON OFF OFF

Pt 1000 OFF ON OFF ON

Pt 50 Ω (JIS ’81) OFF ON ON OFF

JPt 100 (JIS ’89) OFF ON ON ON

Ni 100 ON OFF OFF OFF

Ni 120 ON OFF OFF ON

Ni 508.4 Ω ON OFF ON OFF

Ni-Fe 604 ON OFF ON ON

Cu 10 @25°C ON ON OFF OFF

•Burnout

BURNOUT SW2-5 SW2-4

No burnout OFF OFF

Upscale OFF ON

Downscale ON ON

•RTD wires

WIRES SW2-2 SW2-1

2-wire OFF OFF

3-wire OFF ON

4-wire ON ON

18M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 19

7.2.3.6 Resistance input

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

ON ON OFF OFF OFF OFF OFF

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

Refer to Burnout OFF Refer to Resistance wires

•Burnout

BURNOUT SW2-5 SW2-4

No burnout OFF OFF

Upscale OFF ON

Downscale ON ON

•Resistance wires

WIRES SW2-2 SW2-1

2-wire OFF OFF

3-wire OFF ON

4-wire ON ON

7.2.3.7 Potentiometer input

SW3-7 SW3-6 SW3-5 SW3-4 SW3-3 SW3-2 SW3-1

ON OFF ON Refer to Potentiometer (total resistance)

SW2-5 SW2-4 SW2-3 SW2-2 SW2-1

Refer to Burnout OFF OFF OFF

•Potentiometer (total resistance)

POTENTIOMETER

(TOTAL RESISTANCE)

2500 to 4000 Ω OFF OFF OFF OFF

1200 to 2500 Ω OFF OFF OFF ON

600 to 1200 Ω OFF OFF ON OFF

300 to 600 Ω OFF OFF ON ON

150 to 300 Ω OFF ON OFF OFF

80 to 150 Ω OFF ON OFF ON

SW3-4 SW3-3 SW3-2 SW3-1

•Burnout

BURNOUT SW2-5 SW2-4

No burnout OFF OFF

Upscale OFF ON

Downscale ON ON

19M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 20

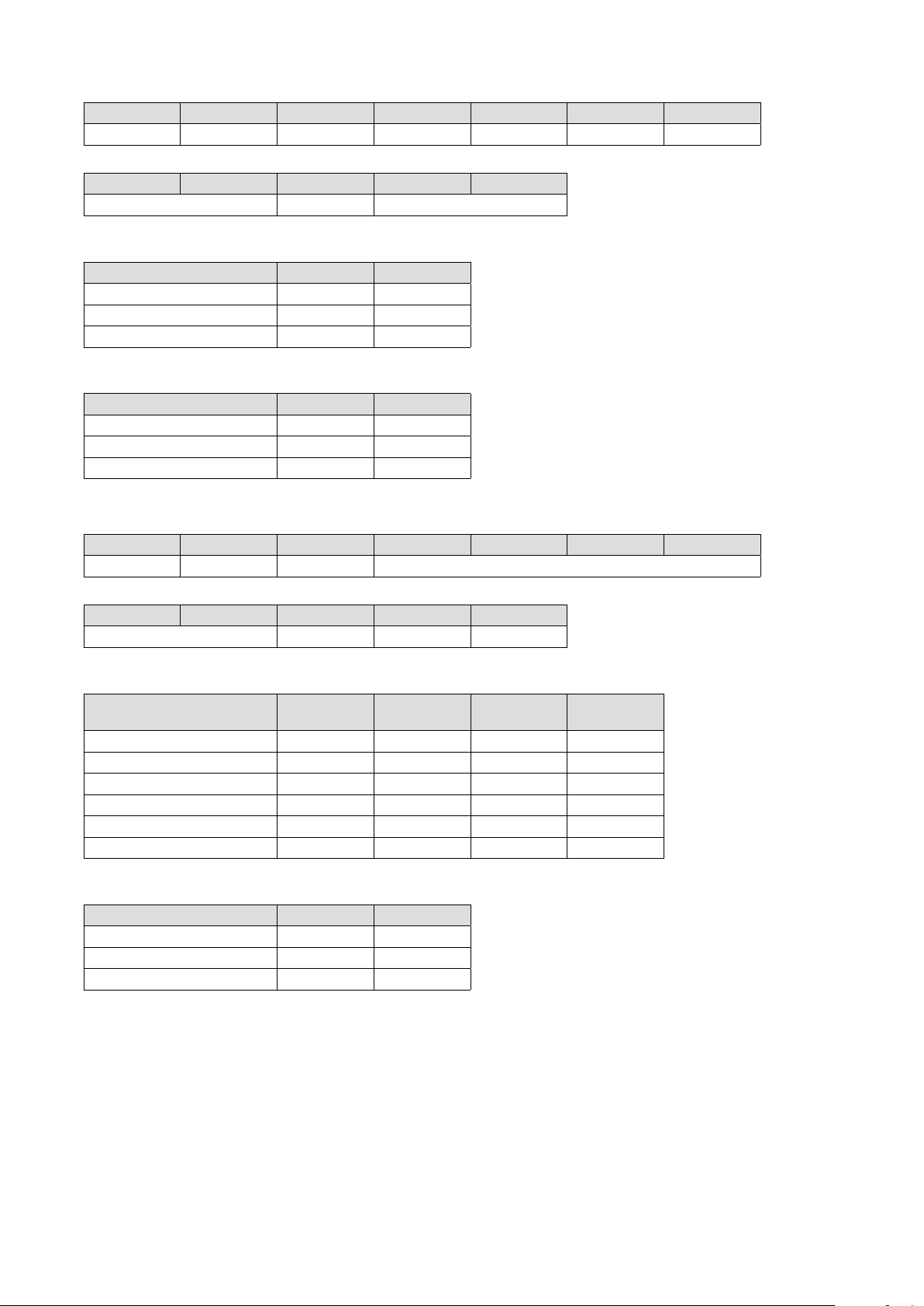

7.2.4 OUTPUT TYPE

Set the DIP switches (SW1-1 through 1-4, SW2-7 and 2-8) according to the output specications.

The DIP switch settings (SW1-1 through 1-4) are required with the PC conguration.

7.2.4.1 DIP SW conguration

•DC current output

SW1-4 SW1-3 SW1-2 SW1-1 SW2-8 SW2-7

OFF ON OFF OFF OFF OFF

•DC voltage output (narrow spans) [maximum range: -2.5 to +2.5 V DC]

SW1-4 SW1-3 SW1-2 SW1-1 SW2-8 SW2-7

ON OFF OFF ON OFF ON

•DC voltage output (wide spans) [maximum range: -10 to +10 V DC]

SW1-4 SW1-3 SW1-2 SW1-1 SW2-8 SW2-7

ON OFF ON OFF ON OFF

7.2.4.2 PC conguration

•DC current output

SW1-4 SW1-3 SW1-2 SW1-1

OFF ON OFF OFF

•DC voltage output (narrow spans) [maximum range: -2.5 to +2.5 V DC]

SW1-4 SW1-3 SW1-2 SW1-1

ON OFF OFF ON

•DC voltage output (wide spans) [maximum range: -10 to +10 V DC]

SW1-4 SW1-3 SW1-2 SW1-1

ON OFF ON OFF

7.2.5 FRONT CONTROL BUTTON LOCK

You can lock the button operation on the front panel to prevent inadvertent operation.

LOCK SW2-6

Unlock OFF

Lock ON

20M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 21

8. WIRING

8mm

8mm

8.1 CAUTION IN WIRING

•Make sure for safety that only qualied personnel performs the wiring.

•In order to prevent potential electric shock, wire the unit after turning off the power supply and making sure that the

power is not supplied to the cable.

•Be sure to conrm the name and polarity of each terminal before wiring to the Euro type connector terminal blocks

(hereafter called ‘terminal block(s)’).

•Take measures to reduce noise as much as possible, e.g. by using shielded twisted pair wires for the input signal.

Ground the input shield to the most stable earth to prevent noise troubles.

•Do not connect anything to unused terminals.

•M-System offers a series of lightning surge protectors for protection against induced lightning surges. Please con-

tact M-System to choose appropriate models.

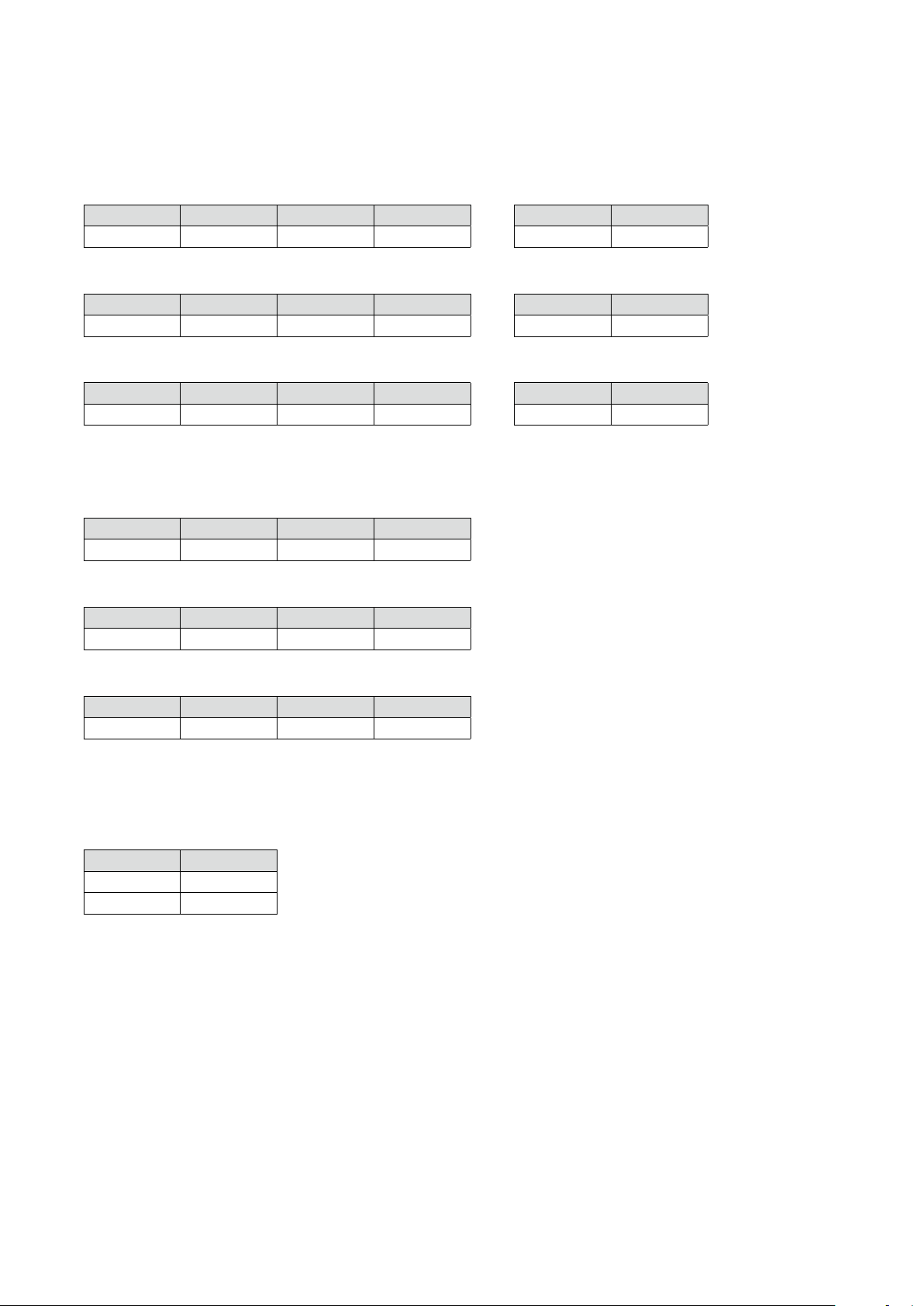

8.2 WIRING INSTRUCTIONS

■ APPLICABLE WIRE SIZE

•Solid: 0.25 to 2.5 mm

•Stranded: 0.25 to 2.5 mm

2

(0.55 to 1.75 dia.)

2

(0.55 to 1.75 dia.)

8mm

•Tinning wire ends may cause contact failure and therefore is not recommended.

•Expose wire conductors by 8 mm (0.31”).

■ RECOMMENDED FERRULE

The following Phoenix Contact terminals are recommended.

•For single-wire •For twin-wire

CROSS-SECTION AREA MODEL CROSS-SECTION AREA MODEL

0.2 to 0.25 mm

0.25 to 0.34 mm

0.34 to 0.5 mm

0.5 to 0.75 mm

0.75 to 1.0 mm

1.0 to 1.5 mm

2

2

2

2

2

2

AI 0,25-8 YE 0.34 to 0.5 mm

AI 0,34-8 TQ 0.5 to 0.75 mm

AI 0,5-8 WH 0.75 to 1.0 mm

AI 0,75-8 GY 1.0 to 1.5 mm

AI 1,0-8 RD

AI 1,5-8 BK

2

2

2

2

AI-TWIN 2X 0,5-8 WH

AI-TWIN 2X 0,75-8 GY

AI-TWIN 2X 1,0-8 RD

AI-TWIN 2X 1,5-8 BK

Recommended manufacturer: Phoenix Contact GmbH & Co., KG

21M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 22

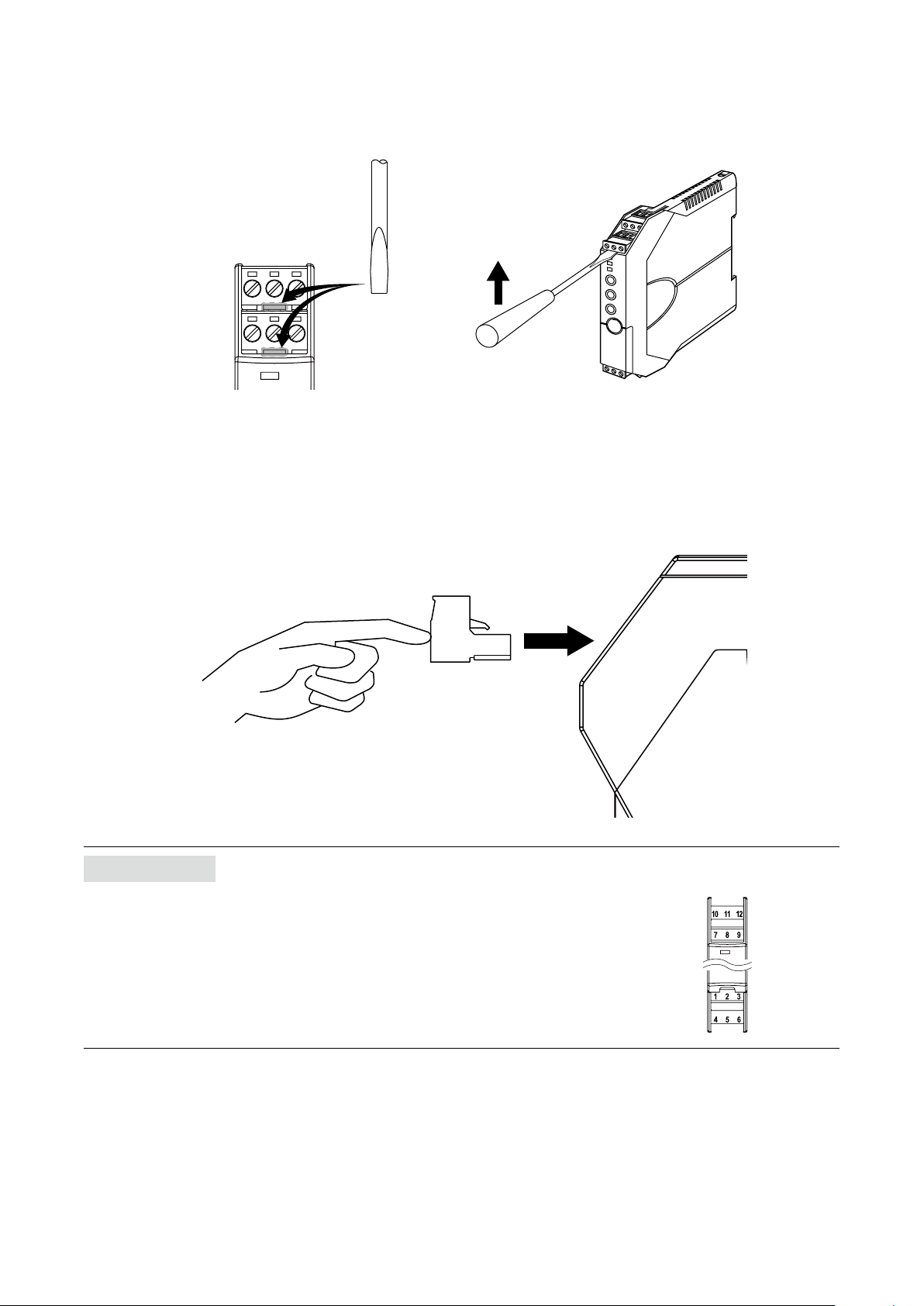

■ INSTALLATION/SEPARATION OF TERMINAL BLOCK

•Separation

Insert a minus screwdriver between the terminal block and the housing body, pull up the driver and pull out the terminal

block.

•Installation

Push the terminal block until it clicks into place.

NOTE

Match the terminal numbers of the terminal blocks with those indicated on the transmitter body in installing the blocks (gure on the right).

22M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 23

■ WIRING TO TERMINAL BLOCK

Insert a wire into the dead end of a terminal block and x it with a minus screwdriver with the blade edge 0.6 mm (0.02”)

and the blade width 3.5 mm (0.14”) (torque: 0.5 – 0.6 N∙m).

NOTE

•For a thermocouple input, replace the terminal block (4 – 5 – 6)

with the one connected with the CJC sensor included in the

package. Fasten the input wire and the CJC sensor together

on the terminal 5.

•Do not use a ferrule with insulating sleeve.

•Insert a wire under the CJC sensor (gure on the right).

CJC sensor (model: CJM)

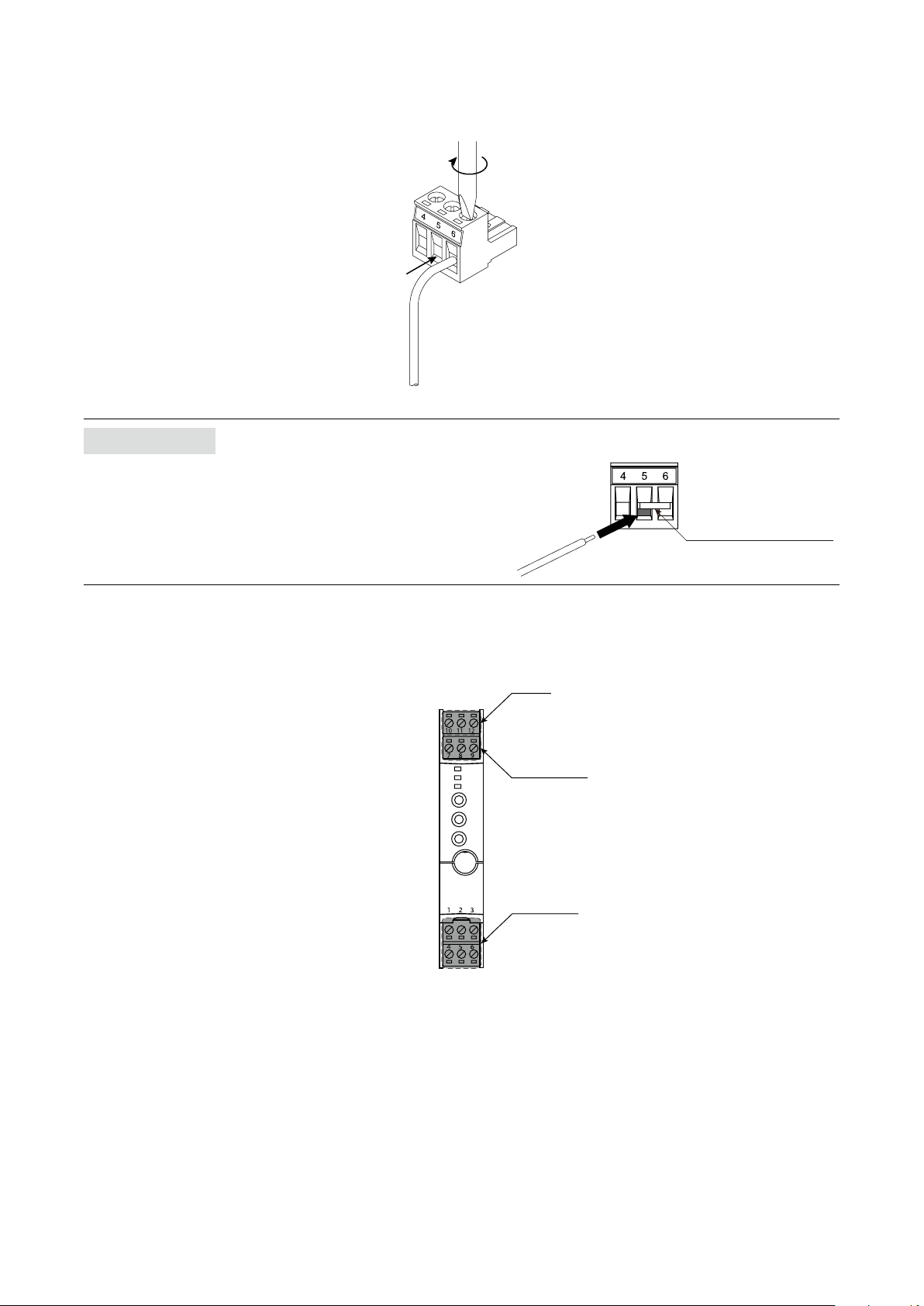

8.3 TERMINAL ASSIGNMENT

Power

Output signal

Input signal

23M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 24

8.4 TERMINAL CONNECTIONS

■ DC POWERED TYPE

DC

VOLT

mA

mV

–+–

■ AC POWERED TYPE

DC

VOLT

mA

mV

–+–

+

+

T/C

ext. wire

+

–

*1

CJC

SENSOR

T/C

ext. wire

+

–

*1

CJC

SENSOR

2-wire

RTD

3-wire

RTD

A

4-wire

RTD

A

B

+

–

B

B

POT.

max.

+

1

A

B

3

2

3

4

min.

2

5

1

–

A

B

7

8

11

12

+

OUTPUT

–

+

DC POWER

–

*2

6

CONFIGURATOR

2-wire

RTD

3-wire

RTD

A

4-wire

RTD

A

B

+

POT.

max.

A

B

A

–

B

B

B

min.

JACK

+

1

3

2

3

4

2

5

1

–

7

8

10

12

+

OUTPUT

–

U

AC POWER

V

*2

6

CONFIGURATOR

JACK

*1 Replace the Euro Type Connector Terminal Block (4 – 5 – 6) with the one connected with the CJC Sensor, included in the package.

The CJC Sensor is secured to the terminal 6.

Loosen only the terminal 4 – 5 and connect the T/C extension wires.

*2 Be aware that the AC power and DC power connect to different terminals.

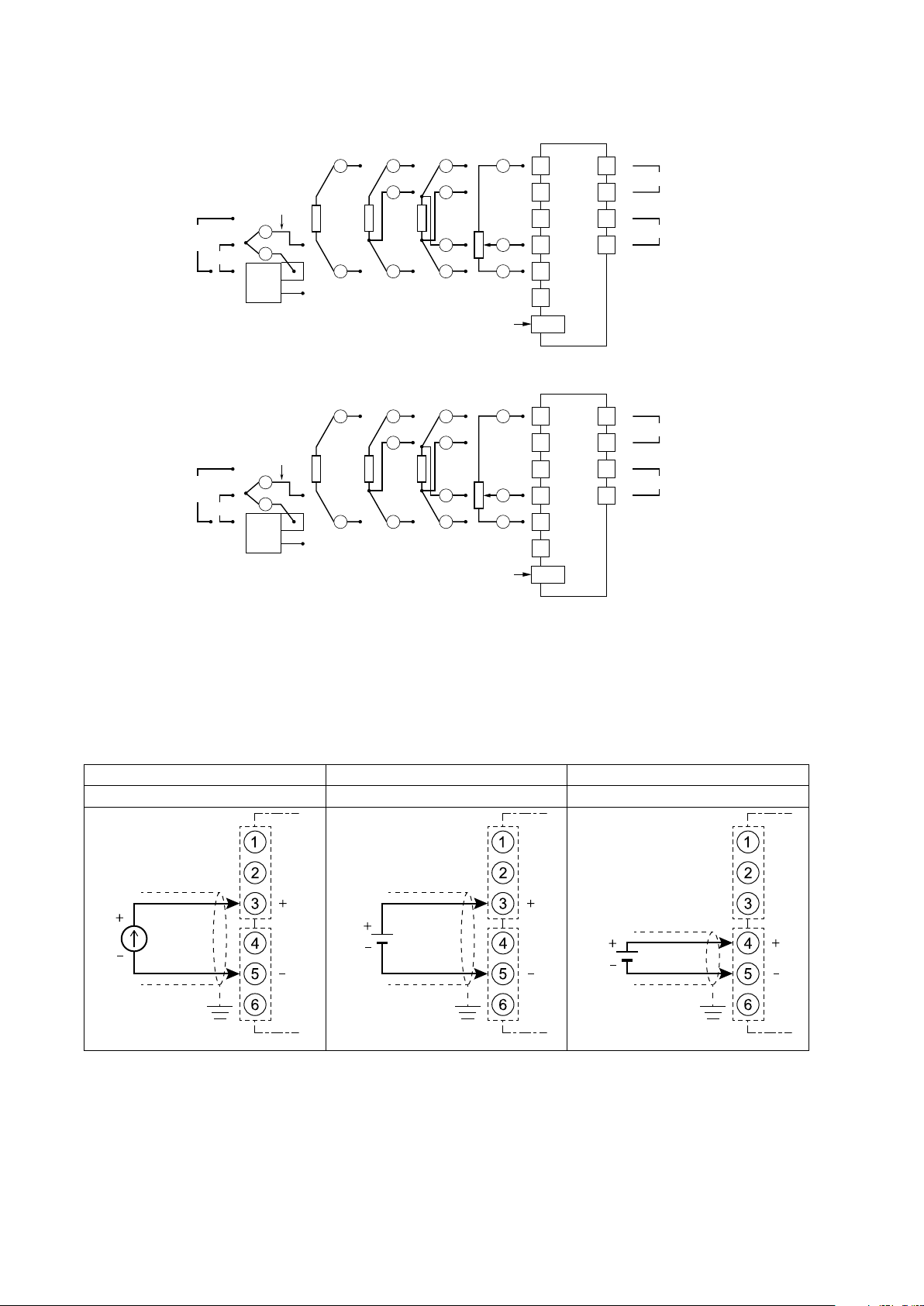

8.4.1 WIRING INPUT

8.4.1.1 DC voltage/current input

Connect DC voltage or current wires.

DC current input DC voltage input (V) DC voltage input (mV)

Maximum range: 0 to 20 mA DC Maximum range: -10 to +10 V DC Maximum range: -1000 to +1000m V DC

DC current

Ground

(resistance

100 ohms or less)

DC voltage (V)

Ground

(resistance

100 ohms or less)

DC voltage (mV)

Ground

(resistance

100 ohms or less)

24M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 25

8.4.1.2 Thermocouple input

RTD or resistance

RTD or resistance

RTD or resistance

Connect a thermocouple or extension wires.

Thermocouple input

Extension

T/C

Ground

(resistance

100 ohms or less)

CJC sensor (model: CJM)

Wire

•Wire the unit with the thermocouple using the extension wires with

the same characteristics as the thermocouple.

•The CJC sensor is calibrated to a particular unit and not interchangeable with another. Match the serial No. of the unit and the

sensor (gure on the right).

•Be careful not to change the temperature around the terminal block.

Take care that wind from a fan does not hit it directly.

•Be careful not to separate the CJC sensor from the terminal block.

Do not loosen the screw on the terminal 6. If you did, connect the

CJC sensor to the terminals 5 and 6.

Serial No.

CJC sensor (model: CJM)

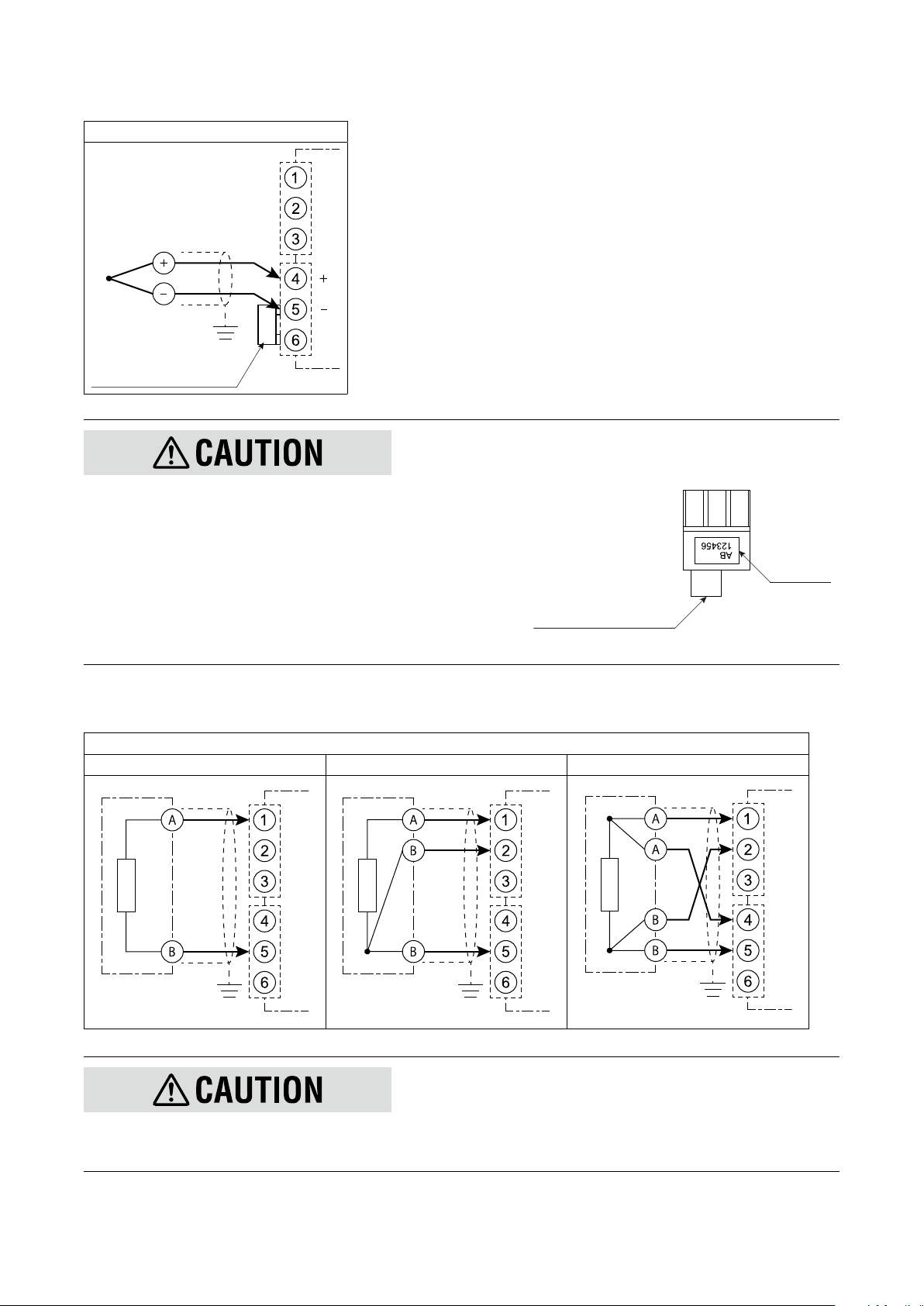

8.4.1.3 RTD/resistance input

Connect a RTD or a resistance. Connect according to the RTD/resistance wires.

RTD/resistance input

2-wire 3-wire 4-wire

Ground

(resistance

100 ohms or less)

Ground

(resistance

100 ohms or less)

Ground

(resistance

100 ohms or less)

•The leadwire resistance including internal resistance such like a lightning surge protector and a barrier must be maximum 20 Ω per wire.

•The excitation is 0.3 mA. Use a RTD with excitation 0.3 mA or more.

25M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 26

8.4.1.4 Potentiometer input

Connect a potentiometer.

Potentiometer input

Potentiometer

Max.

Min.

Ground

(resistance

100 ohms or less)

8.4.2 WIRING OUTPUT

Voltage or current output is provided depending on the output setting.

Output

Output

Ground

(resistance

100 ohms or less)

8.4.3 WIRING POWER

Connect power according to the power input code. The power specications are shown in the following table.

CODE RATING ALLOWABLE RANGE & POWER CONSUMPTION

M2 100 to 240 V AC 85 to 264 V AC, 47 to 66 Hz

Approx. 4 VA at 100 V

Approx. 5 VA at 200 V

Approx. 6 VA at 264 V

R4 10 to 32 V DC 9 to 36 V DC, approx. 3 W

DC power AC power

AC power

DC power

•Be aware that the AC power and DC power connect to different terminals.

•For DC power, conrm the polarity.

26M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 27

9. INSTALLATION

■ DIN RAIL MOUNTING

Set the unit so that its DIN rail adaptor is at the bottom. Position the upper hook at the rear side of the unit on the DIN rail

and push in the lower.

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

■ REMOVAL

Push down the DIN rail adaptor utilizing a minus screwdriver and pull.

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

27M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 28

10. CALIBRATION

‘Calibration’ means I/O ranging or output ne adjustments using the front control buttons. M-System’s ‘One-Step-Cal’ calibration technique realizes automatic I/O ranging and adjustment.

This chapter describes ow and operation procedure of the calibration.

You can also carry out the calibration using the PC Congurator Software (model: M3LUCFG). For detailed information,

refer to the M3LUCFG users manual.

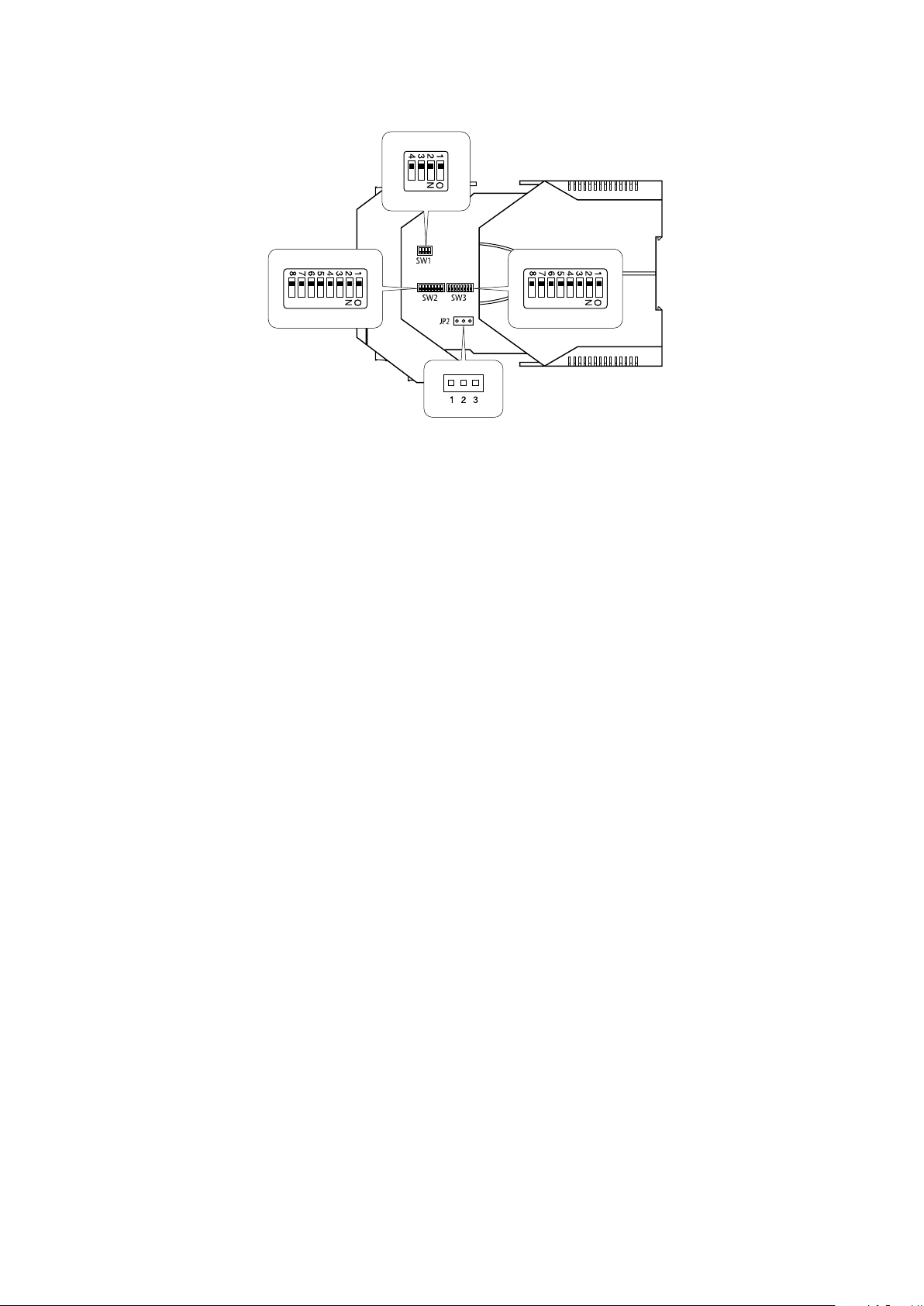

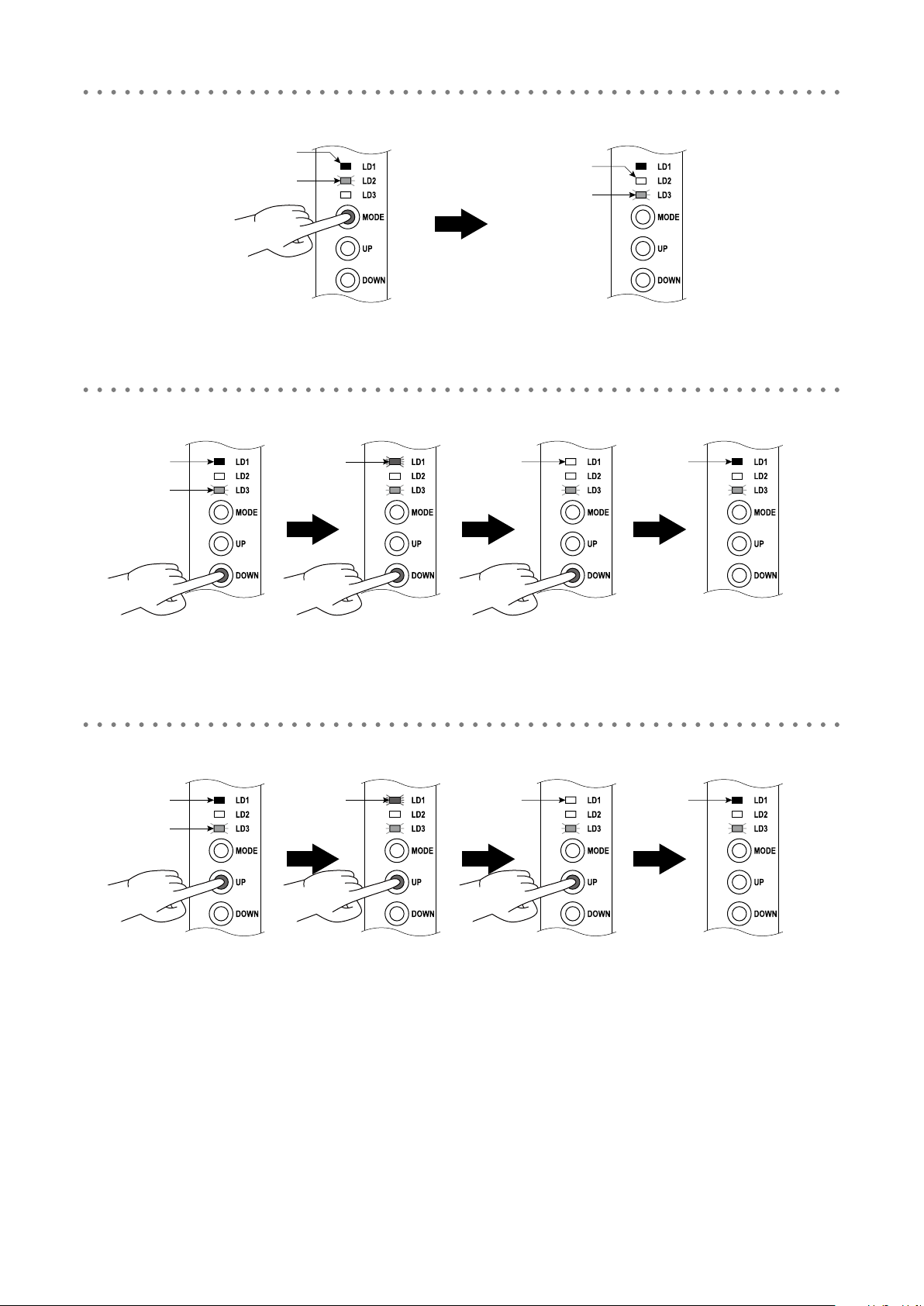

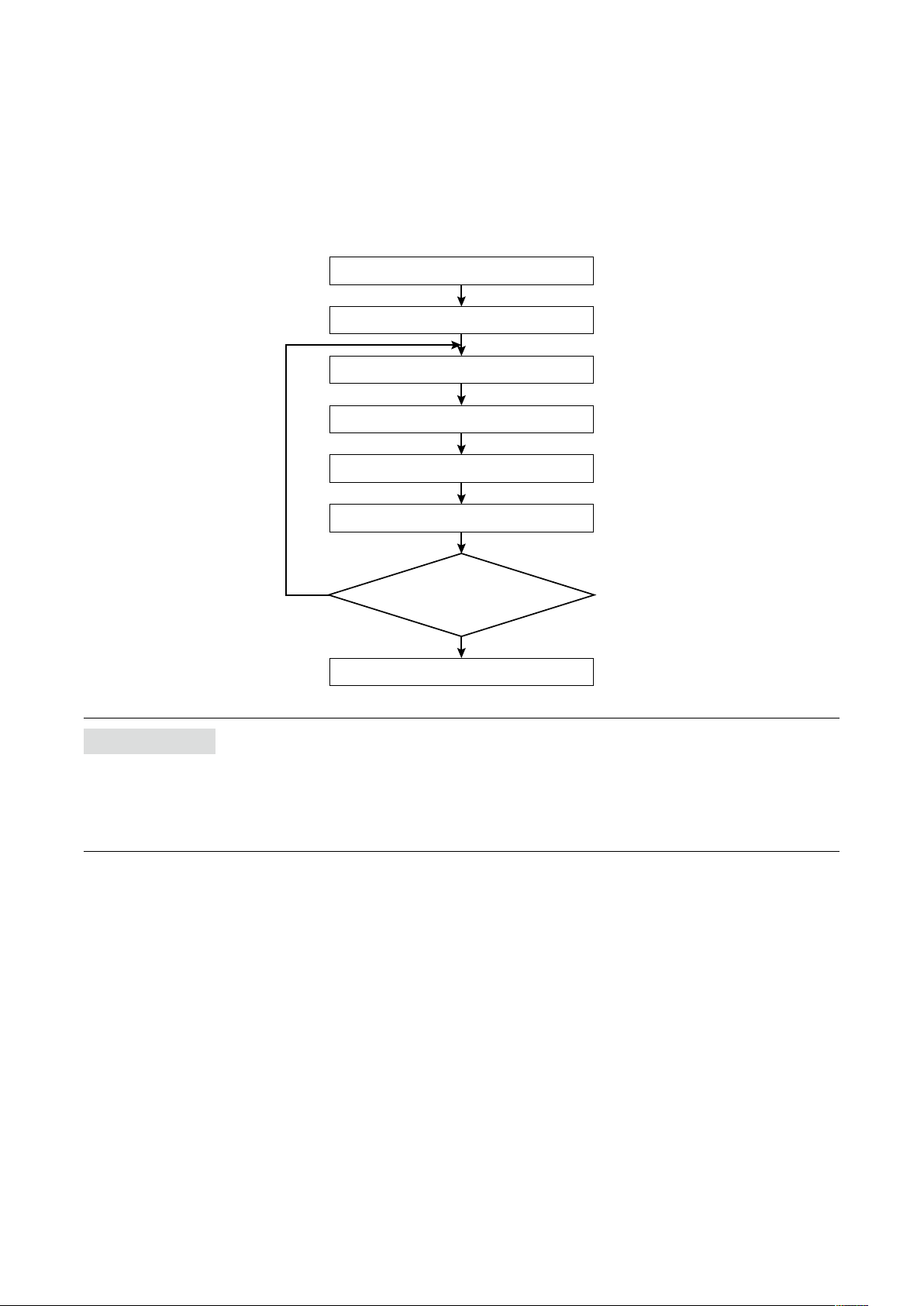

10.1 CALIBRATION FLOW

The calibration includes I/O Ranging Mode and Fine Adjustment Mode. Hold down the MODE button to shift each mode

from the RUN Mode. The mode to shift depends on the time to hold down the button.

The following chart shows the calibration ow.

Hold down

Press

Press

Fine Adjustment ?

1 – 2 s

FINE ZERO

ADJUSTMENT MODE

or

FINE SPAN

ADJUSTMENT MODE

or

RUN MODE

*1

Hold down

Press

Press

I/O Ranging ?

INPUT

RANGING

MODE

OUTPUT

RANGING

MODE

Amber LED

Green LED

Red LED

≥ 5s

Apply simulated

0% input signal.

Apply simulated

100% input signal.

Adjust simulated

input until the output

meter shows

desired 0% output.

Adjust simulated

input until the output

meter shows

desired 100% output.

OFF

ON

Blink

Hold down

Hold down

Hold down

Hold down

MODE button

UP button

DOWN button

*2

0% INPUT

CONFIGURED

*2

100% INPUT

CONFIGURED

*2

0% OUTPUT

CONFIGURED

*2

100% OUTPUT

CONFIGURED

RUN MODE

*1

*1 In the RUN Mode, the green LD1 blinks (PC conguration), or turns on (DIP SW conguration).

*2 When you set 0% or 100% input/output ranges, keep pressing UP or DOWN button until the LD1 blinks for approx. 2 seconds and

turns off, which indicates the setup is complete. When you release the button, the LD1 is returned to ON. Therefore hold down the

button until the LD1 turns OFF.

28M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 29

10.2 INPUT & OUTPUT RANGING

After the DIP switch setting is complete, set up the precise input and output range using the front control buttons. Be sure

that the front control button function is enabled with the DIP switch setting (SW2-6 OFF).

10.2.1 OUTLINE OF I/O RANGING

■ PREPARATION

Mount the DIP-SW-congured M3LU2 on to a DIN rail.

Connect the M3LU2 to a simulator and a multimeter and to a power source according to the terminal connections.

■ INPUT RANGING

•In the Input Ranging Mode, apply the desired minimum input level from the simulator and hold down DOWN button

until the LD1 blinks and then turns OFF.

•Then apply the desired maximum input level and hold down UP button until the LD1 blinks and then turns OFF.

[Example 1] Setting input to 0 – 5 V DC

Maximum input range: -10 to +10 V DC

0% input ranging: apply 0 V DC and hold down DOWN button

100% input ranging: apply 5 V DC and hold down UP button

-10 V

0% input ranging

0 V

0 V

Max. input range

Input ranging

+5 V

+10 V

100% input ranging

5 V

NOTE

•Input ranging is not needed in using the default value.

•100% input ranging value must be greater than 0% value.

•Set the input within the maximum range with the minimum span or more. With inappropriate input level, the input rang-

ing is not carried out even in holding down UP or DOWN button. (The LD1 does not change.)

•There is no stated order of setting 0% and 100% levels or no limitations of entering values for multiple times within one

step of Ranging Mode.

•Signal level is not stored when UP or DOWN button is released before the LD1 turns OFF.

29M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 30

■ OUTPUT RANGING

•In the Output Ranging Mode, increase or decrease the simulated input until the meter shows the desired minimum

output level. Hold down DOWN button until the LD1 blinks and then turns OFF.

•Then increase or decrease the simulated input until the meter shows the desired maximum output level. Hold down

UP button until the LD1 blinks and then turns OFF.

[Example 2] Setting output to 0 – 16 mA DC (input 0 – 5 V DC [Example 1])

Maximum output range: 0 – 20 mA DC

0% output ranging: increase or decrease a simulated input until the meter shows 0 mA DC and hold down

DOWN button.

100% output ranging: increase or decrease a simulated input until the meter shows 16 mA DC and hold

down UP button.

-10 V

0% input ranging

0% output ranging

0 V

0 mA

0 mA

0 V

Max. input range

Input ranging

Max. output range

Output ranging

+5 V

+10 V

100% input ranging

5 V

16 mA

20 mA

100% output ranging

16 mA

IMPORTANT

•Use a simulator to adjust the desired output.

•A different signal from that in the input ranging may be applied.

•Increase or decrease a simulated input while conrming the output with a multimeter.

•Even if the input ranging is performed after the output ranging, another output ranging is not needed.

NOTE

•Output ranging is not needed in using the default value.

•100% output ranging value must be greater than 0% value.

•Set the output within the maximum range with the minimum span or more. With inappropriate output level, the output

ranging is not carried out even in holding down UP or DOWN button. (The LD1 does not change.)

•There is no stated order of setting 0% and 100% levels or no limitations of entering values for multiple times within one

step of the Ranging Mode.

•Signal level is not stored when UP or DOWN button is released before the LD1 turns OFF.

30M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 31

10.2.2 MAXIMUM RANGE, MINIMUM SPAN AND DEFAULT VALUE OF INPUT

The maximum range, minimum span and default value of the input are shown in the following tables. The default value

means initial 0% and 100% input when the DIP switch setting is changed.

10.2.2.1 DC current input

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

0 to 20 mA DC 1 mA 4 to 20 mA DC

10.2.2.2 DC voltage input (mV)

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

-1000 to +1000 mV DC 4 mV 0 to 1000 mV DC

10.2.2.3 DC voltage input (V)

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

-10 to +10 V DC 1 V 1 to 5 V DC

10.2.2.4 Thermocouple input

Minimum span: 20°C (36°F)

Default value: same as conformance range in °C

THERMOCOUPLE °C °F

MAXIMUM RANGE CONFORMANCE RANGE MAXIMUM RANGE CONFORMANCE RANGE

(PR) 0 to 1760 0 to 1760 32 to 3200 32 to 3200

K (CA) -270 to +1370 -150 to +1370 -454 to +2498 -238 to +2498

E (CRC) -270 to +1000 -170 to +1000 -454 to +1832 -274 to +1832

J (IC) -210 to +1200 -180 to +1200 -346 to +2192 -292 to +2192

T (CC) -270 to +400 -170 to +400 -454 to +752 -274 to +752

B (RH) 100 to 1820 400 to 1760 212 to 3308 752 to 3200

R -50 to +1760 200 to 1760 -58 to +3200 392 to 3200

S -50 to +1760 0 to 1760 -58 to +3200 32 to 3200

C (WRe 5-26) 0 to 2315 0 to 2315 32 to 4199 32 to 4199

N -270 to +1300 -130 to +1300 -454 to +2372 -202 to +2372

U -200 to +600 -200 to +600 -328 to +1112 -328 to +1112

L -200 to +900 -200 to +900 -328 to +1652 -328 to +1652

P (Platinel II) 0 to 1395 0 to 1395 32 to 2543 32 to 2543

31M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 32

10.2.2.5 RTD input

Minimum span: 20°C (36°F)

Default value: same as maximum range in °C

RTD °C °F

MAXIMUM RANGE MAXIMUM RANGE

Pt 100 (JIS ’97, IEC) -200 to +850 -328 to +1562

Pt 200 -200 to +850 -328 to +1562

Pt 300 -200 to +850 -328 to +1562

Pt 400 -200 to +850 -328 to +1562

Pt 500 -200 to +850 -328 to +1562

Pt 1000 -200 to +850 -328 to +1562

Pt 50 Ω (JIS ’81) -200 to +649 -328 to +1200

JPt 100 (JIS ’89) -200 to +510 -328 to +950

Ni 100 -80 to +260 -112 to +500

Ni 120 -80 to +260 -112 to +500

Ni 508.4 Ω -50 to +200 -58 to +392

Ni-Fe 604 -200 to +200 -328 to +392

Cu 10 @25°C -50 to +250 -58 to +482

10.2.2.6 Resistance input

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

0 to 4000 Ω 10 Ω 0 to 4000 Ω

10.2.2.7 Potentiometer input

MAXIMUM RANGE

(TOTAL RESISTANCE)

2500 to 4000 Ω 2% of total resistance 0 to 100%

1200 to 2500 Ω

600 to 1200 Ω

300 to 600 Ω

150 to 300 Ω

80 to 150 Ω

MINIMUM SPAN DEFAULT VALUE

10.2.3 MAXIMUM RANGE, MINIMUM SPAN AND DEFAULT VALUE OF OUTPUT

The maximum range, minimum span and default value of the output are shown in the following tables. The default value

means initial 0% and 100% output when the DIP switch setting is changed.

10.2.3.1 DC current output

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

0 to 20 mA DC 1 mA 4 to 20 mA DC

10.2.3.2 DC voltage output (narrow spans)

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

-2.5 to +2.5 V DC 250 mV 0 to 1 V DC

10.2.3.3 DC voltage output (wide spans)

MAXIMUM RANGE MINIMUM SPAN DEFAULT VALUE

-10 to +10 V DC 1 V 1 to 5 V DC

32M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 33

10.2.4 OPERATION PROCEDURE OF I/O RANGING

Perform the I/O ranging in the following procedure.

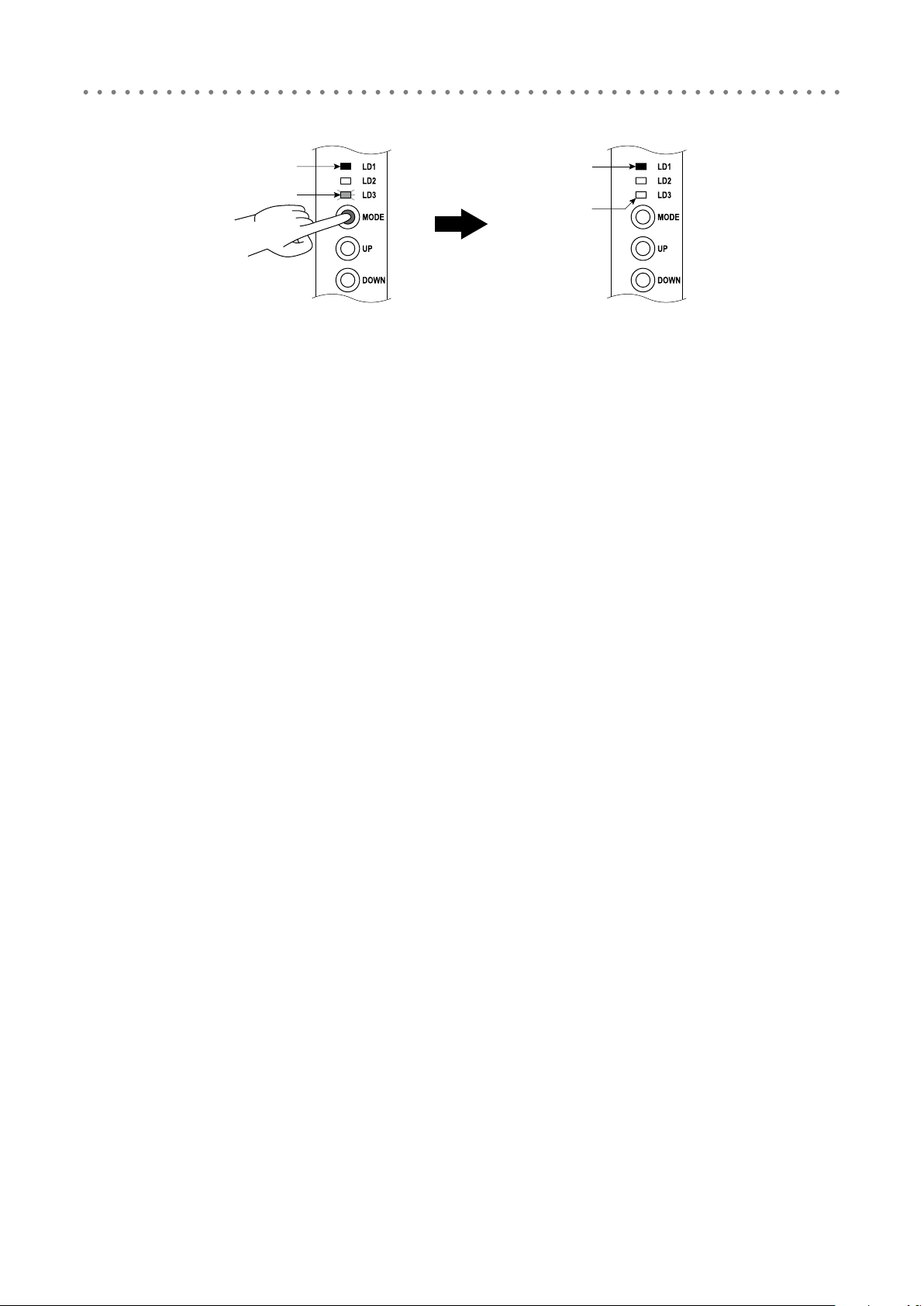

In the RUN Mode, hold down MODE button for 5 seconds or more until the LD1 red LED is ON.

1

Green ON

or

blinking

5 sec. or more

•Conrm that the LD1 green LED is ON (DIP SW conguration) or blinking (PC conguration). Then hold down

MODE button for 5 seconds or more until the LD1 red LED is ON.

•The LD2 red LED starts blinking indicating the Input Ranging Mode.

Apply the desired minimum input level and hold down DOWN button until the LD1 turns OFF.

Red ON

Red blinking

2

Red ON

Red blinking

•Hold down DOWN button, and the LD1 red LED blinks in approx. 2 sec. and then turns OFF in approx. 2 sec.

•The LD1 turning OFF means completion of 0% input ranging. Hold down DOWN button until the LD1 turns OFF.

•Skip to the next procedure when 0% input ranging is not necessary.

Apply the desired maximum input level and hold down UP button until the LD1 turns OFF.

Rapid

red blinking

Approx. 2 sec.

OFF Red ON

Approx. 2 sec.

Release button

0% input ranging completed

3

Red ON

Red blinking

Rapid

red blinking

Approx. 2 sec. Approx. 2 sec.

OFF

Red ON

Release button

100% input ranging completed

•Hold down UP button, and the LD1 red LED blinks in approx. 2 sec. and then turns OFF in approx. 2 sec.

•The LD1 turning OFF means completion of 100% input ranging. Hold down UP button until the LD1 turns OFF.

•Skip to the next procedure when 100% input ranging is not necessary.

33M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 34

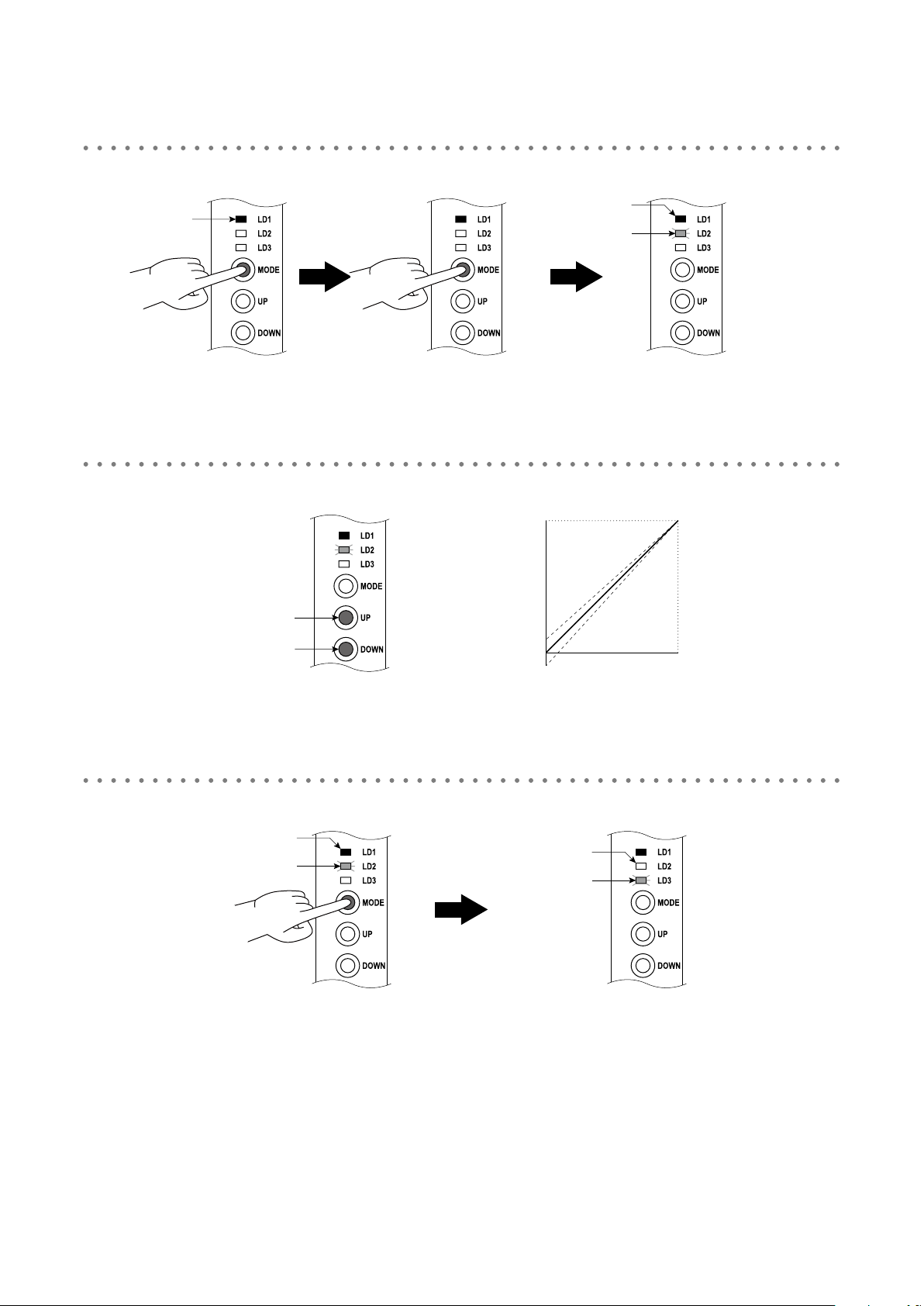

Press MODE button to go on to the Output Ranging Mode.

4

Red ON

Red blinking

Press once

•Press MODE button once to go on to the Output Ranging Mode.

•The LD2 turns OFF and the LD3 red LED starts blinking indicating the Output Ranging Mode.

Increase or decrease the simulated input until the meter shows the desired minimum output level. Hold

down DOWN button until the LD1 turns OFF.

5

OFF

Red blinking

Red ON Red ONOFF

Red blinking

•Hold down DOWN button, and the LD1 red LED blinks in approx. 2 sec. and then turns OFF in approx. 2 sec.

•The LD1 turning OFF means completion of 0% output ranging. Hold down DOWN button until the LD1 turns OFF.

•Skip to the next procedure when 0% output ranging is not necessary.

Increase or decrease the simulated input until the meter shows the desired maximum output level. Hold

down UP button until the LD1 turns OFF.

6

Red ON

Red blinking

Rapid

red blinking

Approx. 2 sec.Approx. 2 sec.

Rapid

red blinking

Approx. 2 sec. Approx. 2 sec.

OFF

Release button

0% ouput ranging completed

Red ON

Release button

100% ouput ranging completed

•Hold down UP button, and the LD1 red LED blinks in approx. 2 sec. and then turns OFF in approx. 2 sec.

•The LD1 turning OFF means completion of 100% output ranging. Hold down UP button until the LD1 turns OFF.

•Skip to the next procedure when 100% output ranging is not necessary.

34M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 35

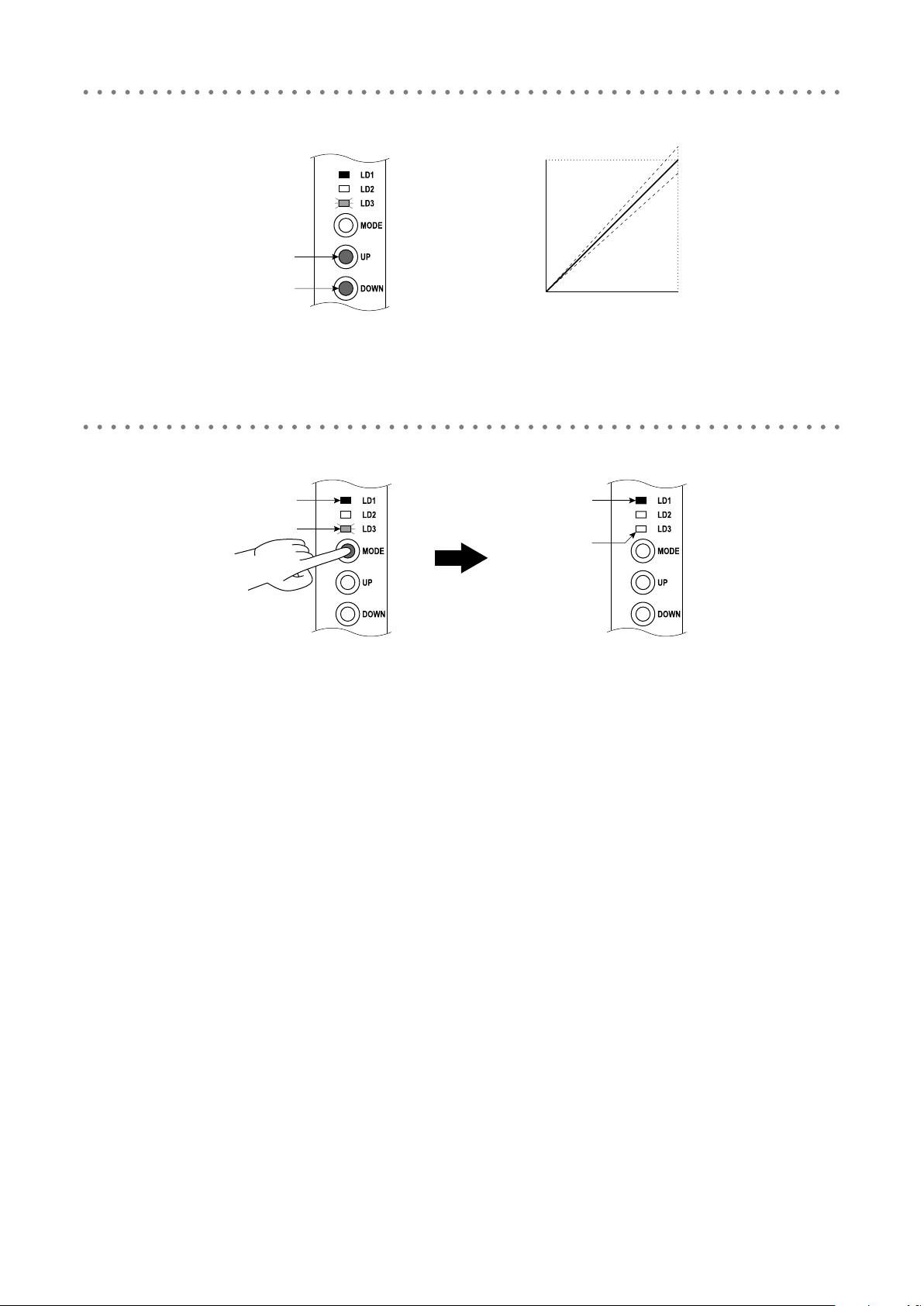

Press MODE button to return to the RUN Mode.

7

Green ON

Red ON

Red blinking

Press once

•Press MODE button once to return to the RUN mode.

•The LD3 turns OFF and the LD1 green LED is ON (DIP SW conguration) or blinking (PC conguration).

or

blinking

OFF

35M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 36

10.3 FINE ADJUSTMENT MODE

Perform the ne zero and span adjustments to correct the deviation between the output signal and a device on site. Be

sure that the front control button function is enabled with the DIP switch setting (SW2-6 OFF).

Note that M-System does not warrant the adjustments by the customer.

Each time the adjustment is performed, signal level is overwritten and is stored even when the power is off.

10.3.1 OUTLINE OF FINE ADJUSTMENT

The following owchart shows the ne zero/span adjustments.

POWER ON

Warming up (10 min. or more)

Moving on to output ne zero adjustment

Adjusting output with UP/DOWN buttons

Moving on to output ne span adjustment

Adjusting output with UP/DOWN buttons

Readjustment

Conrming output value

(operation check)

Adjustment completed

Measurement started

NOTE

•Warm up measuring instruments, equipment and other devices on site for the time specied in each manual, and operate the unit in a stable condition.

•Adjustable ranges are as follows:

Fine zero adjustment -15 to +15%

Fine span adjustment 85 to 115%

36M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 37

10.3.2 OPERATION PROCEDURE OF FINE ADJUSTMENT

Perform the ne adjustment in the following procedure.

Hold down MODE button for 1 to 2 seconds and release the button to go on to the Fine Zero Adjustment

Mode.

1

Green ON

or

blinking

•Conrm that the LD1 green LED is ON (DIP SW conguration) or blinking (PC conguration). Then hold down

MODE button for 1 to 2 seconds and release the button. The LD1 red LED will be ON.

•The LD2 green LED starts blinking indicating the Fine Zero Adjustment Mode.

Use UP (increase) and DOWN (decrease) buttons to adjust the output to 0%. Check the output with a multim-

eter.

2

Hold down

for 1 to 2 sec.

Release button

Output

Red ON

Green blinking

Increase output

Decrease output

•Adjust the output value to 0% regardless of the input.

•Increase the output with UP button, and decrease with DOWN.

•Skip to the next procedure when ne zero adjustment is not necessary.

Press MODE button to go on to the Fine Span Adjustment Mode.

UP (increase)

DOWN (decrease)

↑

↓

Input

3

Red ON

Green blinking

Green blinking

Press once

•Press MODE button once to go on to the Fine Span Adjustment Mode.

•The LD2 turns OFF and the LD3 green LED starts blinking indicating the Fine Span Adjustment Mode.

OFF

37M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 38

Use UP (increase) and DOWN (decrease) buttons to adjust the output to 100%. Check the output with a mul-

↑

timeter.

4

Output

Increase output

UP (increase)

DOWN (decrease)

↓

Decrease output

•Adjust the output value to 100% regardless of the input.

•Increase the output with UP button, and decrease with DOWN.

•Skip to the next procedure when ne span adjustment is not necessary.

Press MODE button to return to the RUN mode.

Input

5

Red ON

Green blinking

Press once

•Press MODE button once to return to the RUN Mode.

•The LD3 turns OFF and the LD1 green LED is ON (DIP SW conguration) or blinking (PC conguration).

Green ON

or

bllinking

OFF

38M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 39

11. CHECKING, MAINTENANCE, INITIALIZATION OF PARAMETERS

11.1 CHECKING

(1) Terminal wiring: Check that all cables are correctly connected according to the connection diagram.

(2) DIP SW setting: Check that the switches are set to appropriate positions.

(3) Power input voltage: Check voltage across the terminal 10 – 12 (AC) or 11 – 12 (DC) with a multimeter.

(4) Input: Check that the input signal is within 0 to 100% of full-scale.

If the DC voltage (mV), thermocouple, RTD, resistance, potentiometer input or their extension wires is/are disconnected, the output goes over 100% (below 0% with downscale protection) due to burnout function. Conrm the status

indicator LED pattern and check leadwires in such a case.

(5) Output: Check that the load resistance meets the described specications.

11.2 MAINTENANCE

Perform the periodic calibration as stated below.

■ CALIBRATION

Warm up the unit for 10 minutes or more, apply 0, 25, 50, 75 and 100% input to the unit, and make sure that the output

is 0, 25, 50, 75 and 100% respectively within the prescribed accuracy. In case the output is deviated from the accuracy,

perform the ne zero/span adjustment.

11.3 INITIALIZATION OF PARAMETERS

You can reset the DIP-SW-congured parameters (I/O ranging and ne adjustments) to the default status. Reset the parameters in the following procedure.

(1) Turn off the power supply to the unit, open the housing cover and set the SW2-1 to OFF and SW2-2 to ON position.

(2) Close the cover and turn on the power while pressing MODE button.

(3) Wait until green LED blinks at the LD1, LD2 and LD3.

(4) Turn off the power, open the cover and reset the SW2-1 and SW2-2 to the previous position.

(5) Close the cover and turn on the power again.

39M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 40

12. APPENDICES

12.1 SPECIFICATIONS

12.1.1 GENERAL SPECIFICATIONS

Construction Small-sized front terminal structure

Connection Euro type connector terminal

Housing material Flame-resistant resin (gray)

Isolation Input to output to power

Overrange output -15 to +115% (negative current output is not available)

Zero adjustment -15 to +15% (front)

Span adjustment 85 to 115% (front)

Burnout (other than current or voltage (V) input) Upscale, downscale or no burnout selectable; Also detects wire breakdown and

overrange input exceeding the electrical design limit for DC input.

Linearization (T/C, RTD input) Standard

Cold junction compensation (T/C input) CJC sensor (included) to be attached to the input terminals

Status indicator LED Tri-color (green/amber/red) LED; Blinking patterns indicate operation status of the

transmitter.

Conguration DIP SW conguration Input type, sensor type, burnout action, RTD/resistance wires, cold junction com-

pensation, output type, conguration mode, front control button lock

PC conguration Refer to 12.2 PC CONFIGURATOR SOFTWARE.

Calibration I/O ranging and ne adjustment via ‘One-Step Cal’ calibration or PC

Congurator connection 2.5 dia. miniature jack; RS-232-C level

12.1.2 INPUT SPECIFICATIONS

Input types and ranges are shown in the following table.

DC Current Input resistance: 50 Ω resistor incorporated

Maximum range: 0 to 20 mA DC

Minimum span: 1 mA

mV & Voltage Input resistance: ≥ 1 MΩ

Maximum range: refer to Table 1

Minimum span: refer to Table 1

Thermocouple Input resistance: ≥ 1 MΩ

Maximum range: refer to Table 2

Burnout sensing: ≤ 4 µA

Conformance range: refer to Table 2

Minimum span: refer to Table 2

RTD (2-wire, 3-wire or 4-wire) Excitation: ≤ 0.3 mA

Maximum range: refer to Table 3

Allowable leadwire resistance: max. 20 Ω per wire

Minimum span: refer to Table 3

Resistance (2-wire, 3-wire or 4-wire) Excitation: ≤ 0.3 mA

Maximum range: 0 to 4000 Ω

Allowable leadwire resistance: max. 20 Ω per wire

Minimum span: 10 Ω

Potentiometer Excitation: ≤ 0.3 mA

Maximum range: refer to Table 5

Allowable leadwire resistance: max. 20 Ω per wire

Minimum span: 2%

40M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 41

12.1.3 OUTPUT SPECIFICATIONS

Output types and ranges are shown in the following table.

DC Current Maximum range: 0 – 20 mA DC

Minimum span: 1 mA

Conformance range: 0 – 23 mA DC

Offset: Lower range can be any specic value within the output range provided

that the minimum span is maintained.

Load resistance: Output drive 15 V max. at 20 mA

(Range: Load resistance)

0 – 20 mA : ≤ 750 Ω

DC Voltage Narrow spans

Maximum range: -2.5 – +2.5 V DC

Minimum span: 250 mV

Conformance range: -3 – +3 V DC

Wide spans

Maximum range: -10 – +10 V DC

Minimum span: 1 V

Conformance range: -11.5 – +11.5 V DC

Offset: Lower range can be any specic value within the output range provided

that the minimum span is maintained.

Load resistance: Output drive 10 mA max.; 5 mA for negative output

(Range: Load resistance)

0 – 10 V : ≥ 1 kΩ

-10 – 0 V : ≥ 2 kΩ

0 – 2.5 V : ≥ 250 Ω

-2.5 – 0 V : ≥ 500 Ω

12.1.4 INSTALLATION

Power comsumption AC power M2: 100 – 240 V AC Operational voltage range 85 – 264 V AC, 47 – 66 Hz

Approx. 4 VA at 100 V

Approx. 5 VA at 200 V

Approx. 6 VA at 264 V

DC power R4: 10 – 32 V DC Operational voltage range 9 – 36 V DC

Ripple 10% p-p max.

Approx. 3 W

Operating temperature -25 to +60°C (-13 to +140°F)

Operating humidity 30 to 95% RH (non-condensing)

Mounting DIN rail

Weight 100 g (3.53 oz)

12.1.5 PERFORMANCE

Accuracy See Table 1 to 6.

Cold junction compensation error ±1.0°C at 0 – 50°C (±1.8°F at 32 – 122°F)

Temp. coefficient ±0.015%/°C [±0.008%/°F] at -5 to +55°C [23 to 131°F] of max. range

±0.03%/°C [±0.016%/°F] for the following conditions:

•DC,T/Cinputspans≤10mV

•RTD,potentiometer,resistancespans≤80Ω

•inanambientexceeding55°C[131°F]orbelow-5°C[23°F]

Response time ≤ 0.2 sec. (0 – 90%, DC input)

(With the Option A, the Sync Filter set to the fastest frequency on the PC Congurator Software. Default is set to have 0.5 sec. response.)

Burnout response ≤ 10 sec.

Line voltage effect ±0.1% over voltage range

Insulation resistance ≥ 100 MΩ with 500 V DC

Dielectric strength 2000 V AC @ 1 minute (input to output to power to ground)

41M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 42

12.1.6 STANDARDS & APPROVALS

EU conformity EMC Directive (2004/108/EC)

EMI EN 61000-6-4: 2007/A1: 2011

EMS EN 61000-6-2: 2005

Low Voltage Directive (2006/95/EC)

EN 61010-1: 2010

Installation Category II

Pollution Degree 2

Input or output to power: Reinforced insulation (300 V)

Input to output: Basic insulation (300 V)

12.1.7 I/O TYPE, MAXIMUM RANGE & ACCURACY

[Table 1] DC input

INPUT TYPE MINIMUM SPAN MAXIMUM RANGE

ACCURACY

DC Current 1 mA 0 to 20 mA DC ±0.1%

DC Millivolt 4 mV -1000 to +1000 mV DC ±10 μV at F.S. input ≤ 50 mV

±40 μV at F.S. input ≤ 200 mV

±60 μV at F.S. input ≤ 500 mV

±80 μV at F.S. input > 500 mV

DC Voltage 1 V -10 to +10 V DC ±0.1%

*1 Or ±0.1% of span, whichever is greater.

[Table 2] Thermocouple input

T/C °C °F

MIN.

SPAN

MAXIMUM

RANGE

ACCURACY

*2

CONFORMANCE

RANGE

MIN.

SPAN

MAXIMUM

RANGE

(PR) 20 0 to 1760 ±1.00 0 to 1760 36 32 to 3200 ±1.80 32 to 3200

K (CA) 20 -270 to +1370 ±0.25 -150 to +1370 36 -454 to +2498 ±0.45 -238 to +2498

E (CRC) 20 -270 to +1000 ±0.20 -170 to +1000 36 -454 to +1832 ±0.36 -274 to +1832

J (IC) 20 -210 to +1200 ±0.25 -180 to +1200 36 -346 to +2192 ±0.45 -292 to +2192

T (CC) 20 -270 to +400 ±0.25 -170 to +400 36 -454 to +752 ±0.45 -274 to +752

B (RH) 20 100 to 1820 ±0.75 400 to 1760 36 212 to 3308 ±1.35 752 to 3200

R 20 -50 to +1760 ±0.50 200 to 1760 36 -58 to +3200 ±0.90 392 to 3200

S 20 -50 to +1760 ±0.50 0 to 1760 36 -58 to +3200 ±0.90 32 to 3200

C (WRe 5-26) 20 0 to 2315 ±0.25 0 to 2315 36 32 to 4199 ±0.45 32 to 4199

N 20 -270 to +1300 ±0.30 -130 to +1300 36 -454 to +2372 ±0.54 -202 to +2372

U 20 -200 to +600 ±0.20 -200 to +600 36 -328 to +1112 ±0.36 -328 to +1112

L 20 -200 to +900 ±0.25 -200 to +900 36 -328 to +1652 ±0.45 -328 to +1652

P (Platinel II) 20 0 to 1395 ±0.25 0 to 1395 36 32 to 2543 ±0.45 32 to 2543

*2 [Accuracy + Cold Junction Compensation Error 1.0°C (1.8°F)] or ±0.1% of span, whichever is greater.

*1

ACCURACY

*2

CONFORMANCE

RANGE

42M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 43

[Table 3] RTD input

RTD °C °F

*3

MIN. SPAN MAXIMUM RANGE

ACCURACY

MIN. SPAN MAXIMUM RANGE

ACCURACY

Pt 100 (JIS ’97, IEC) 20 -200 to +850 ±0.15 36 -328 to +1562 ±0.27

Pt 200 20 -200 to +850 ±0.15 36 -328 to +1562 ±0.27

Pt 300 20 -200 to +850 ±0.15 36 -328 to +1562 ±0.27

Pt 400 20 -200 to +850 ±0.15 36 -328 to +1562 ±0.27

Pt 500 20 -200 to +850 ±0.15 36 -328 to +1562 ±0.27

Pt 1000 20 -200 to +850 ±0.15 36 -328 to +1562 ±0.27

Pt 50 Ω (JIS ’81) 20 -200 to +649 ±0.15 36 -328 to +1200 ±0.27

JPt 100 (JIS ’89) 20 -200 to +510 ±0.15 36 -328 to +950 ±0.27

Ni 100 20 -80 to +260 ±0.15 36 -112 to +500 ±0.27

Ni 120 20 -80 to +260 ±0.15 36 -112 to +500 ±0.27

Ni 508.4 Ω 20 -50 to +200 ±0.15 36 -58 to +392 ±0.27

Ni-Fe 604 20 -200 to +200 ±0.15 36 -328 to +392 ±0.27

Cu 10 @25°C 20 -50 to +250 ±0.50 36 -58 to +482 ±0.90

*3 Or ±0.1% of span, whichever is greater.

[Table 4] Resistance input

MINIMUM SPAN MAXIMUM RANGE

ACCURACY

*4

10 Ω 0 to 4000 Ω ±0.1 Ω

*4 Or ±0.1% of span, whichever is greater.

*3

[Table 5] Potentiometer input

MINIMUM SPAN MAXIMUM RANGE

ACCURACY

*5

(TOTAL RESISTANCE)

2% 2500 to 4000 Ω

±0.1 Ω

1200 to 2500 Ω

600 to 1200 Ω

300 to 600 Ω

150 to 300 Ω

80 to 150 Ω

*5 Or ±0.1% of span, whichever is greater.

[Table 6] Output

OUTPUT TYPE MINIMUM SPAN MAXIMUM RANGE CONFORMANCE RANGE

DC Current

1 mA

*6

0 to 20 mA DC

0 to 23 mA DC

*7

DC Voltage 250 mV -2.5 to +2.5 V DC -3 to +3 V DC

1 V -10 to +10 V DC -11.5 to +11.5 V DC

*6 For current output, overall accuracy degrades another 0.1% with spans ≤ 2 mA.

*7 Negative overrange current below 0 mA is not available.

43M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 44

12.1.8 CALCULATION EXAMPLES OF OVERALL ACCURACY

■ DC INPUT

(1) 0 to 200 mV DC

Absolute value accuracy [Table 1]: 40 μV

40 μV ÷ 200000 μV × 100 = 0.02% < 0.1%

➠ Overall accuracy = ±0.1% of span

(2) 0 to 4 mV DC

Absolute value accuracy [Table 1]: 10 μV

10 μV ÷ 4000 μV × 100 = 0.25% > 0.1%

➠ Overall accuracy = ±0.25% of span

■ THERMOCOUPLE INPUT

(1) K thermocouple, -150 to +1370°C

Absolute value accuracy [Table 2]: 0.25°C

CJC error (1.0°C) added: 1.25°C

1.25°C ÷ (1370°C – -150°C) × 100 = 0.082% < 0.1%

➠ Overall accuracy including CJC error = ±0.1% of span

(2) K thermocouple, 50 to 150°C

Absolute value accuracy [Table 2]: 0.25°C

CJC error (1.0°C) added: 1.25°C

1.25°C ÷ (150°C – 50°C) × 100 = 1.25% > 0.1%

➠ Overall accuracy including CJC error = ±1.25% of span

■ RTD INPUT

(1) Pt 100, -200 to 800°C

bsolute value accuracy [Table 3]: 0.15°C

0.15°C ÷ (800°C – -200°C) × 100 = 0.015% < 0.1%

➠ Overall accuracy = ±0.1% of span

(2) Pt 100, 0 to 100°C

Absolute value accuracy [Table 3]: 0.15°C

0.15°C ÷ 100°C × 100 = 0.15% > 0.1%

➠ Overall accuracy = ±0.15% of span

■ RESISTANCE INPUT

(1) 0 to 1000 Ω

Absolute value accuracy [Table 4]: 0.1 Ω

0.1 Ω ÷ 1000 Ω × 100 = 0.01% < 0.1%

➠ Overall accuracy = ±0.1% of span

(2) 0 to 50 Ω

Absolute value accuracy [Table 4]: 0.1 Ω

0.1 Ω ÷ 50 Ω × 100 = 0.2% > 0.1%

➠ Overall accuracy = ±0.2% of span

■ POTENTIOMETER INPUT

(1) 300 to 800 Ω (total resistance 1000 Ω)

Absolute value accuracy [Table 5]: 0.1 Ω

0.1 Ω ÷ (800 Ω – 300 Ω) × 100 = 0.02% < 0.1%

➠ Overall accuracy = ±0.1% of span

(2) 30 to 80 Ω (total resistance 100 Ω)

Absolute value accuracy [Table 5]: 0.1 Ω

0.1 Ω ÷ (80 Ω – 30 Ω) × 100 = 0.2% > 0.1%

➠ Overall accuracy = ±0.2% of span

44M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 45

12.2 PC CONFIGURATOR SOFTWARE

The I/O settings and calibration are congurable with the PC Congurator Software (model: M3LUCFG). It is convenient

to set the same I/O specications to several units or the items which are not available with the DIP SW conguration or

‘One-Step Cal’ calibration. Whether the I/O settings are available or not depends on the conguration option code and

conguration mode.

A dedicated cable is required to connect the unit to the PC.

PORT PC CONFIGURATOR CABLE MODEL NO.

RS-232-C MCN-CON

USB COP-US

The PC Congurator Software is freely downloadable at M-System’s web site (http://www.m-system.co.jp/).

Software download model No.: M3CFG

■ I/O CONFIGURATION

The following table shows congurable items with the PC Congurator Software. For detailed information on the PC conguration, refer to the M3LUCFG users manual (EM-9197-A).

ITEM M3LU2-x/A M3LU2-x/B

PC CONFIGURATION

(SW3-8 ON)

Input type X ---- ----

Sensor wires X ---- ----

PV range (upper, lower) X ---- ----

PV damping (time constant) X X ----

Burnout X ---- ----

Cold junction compensation X ---- ----

Transfer function X X ----

AO type X ---- ----

AO range (upper, lower) X ---- ----

ADC conversion rate X X X

Custom TC X ---- ----

Custom RTD X ---- ----

Linearization table setting X X ----

DIP SW CONFIGURATION

(SW3-8 OFF)

■ CALIBRATION

‘One-Step Cal’ calibration (I/O ranging) and DAC trimming (ne adjustments) are congurable with the PC Congurator

Software regardless of the conguration option code and conguration mode.

■ REMARKS

For detailed information on the PC conguration, refer to the M3LUCFG users manual (EM-9197-A).

45M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 46

12.3 MODEL NUMBERING

Code number: M3LU2–[1]/[2][3]

INPUT – Field-selectable

DC Current & Voltage

Current: 0 – 20 mA DC

Millivolt: -1000 – +1000 mV DC

Voltage: -10 – +10 V DC

Thermocouple

(PR), K, E, J, T, B, R, S, C (WRe 5-26), N, U, L, P (Platinel II)

RTD

Pt 100, Pt 200, Pt 300, Pt 400, Pt 500, Pt 1000, Ni 100, Ni 120, Ni 508.4 Ω, Ni-Fe 604, Cu 10 @25°C,

Pt 50 Ω, JPt 100

Potentiometer

Total resistance 80 – 4000 Ω

Resistance

0 – 4000 Ω

OUTPUT – Field-selectable

Current

0 – 20 mA DC

Voltage

-2.5 – +2.5 V DC

-10 – +10 V DC

[1] POWER INPUT

AC Power

M2: 100 – 240 V AC (Operational voltage range 85 – 264 V, 47 – 66 Hz)

DC Power

R4: 10 – 32 V DC (Operational voltage range 9 – 36 V, ripple 10% p-p max.)

[2] CONFIGURATION OPTIONS

A: PC and eld congurable

B: Field congurable

[3] OPTIONS

blank: none

/Q: With options (specify the specication)

SPECIFICATIONS OF OPTION: Q

COATING (For the detail, refer to M-System’s web site.)

/C01: Silicone coating

/C02: Polyurethane coating

/C03: Rubber coating

46M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Page 47

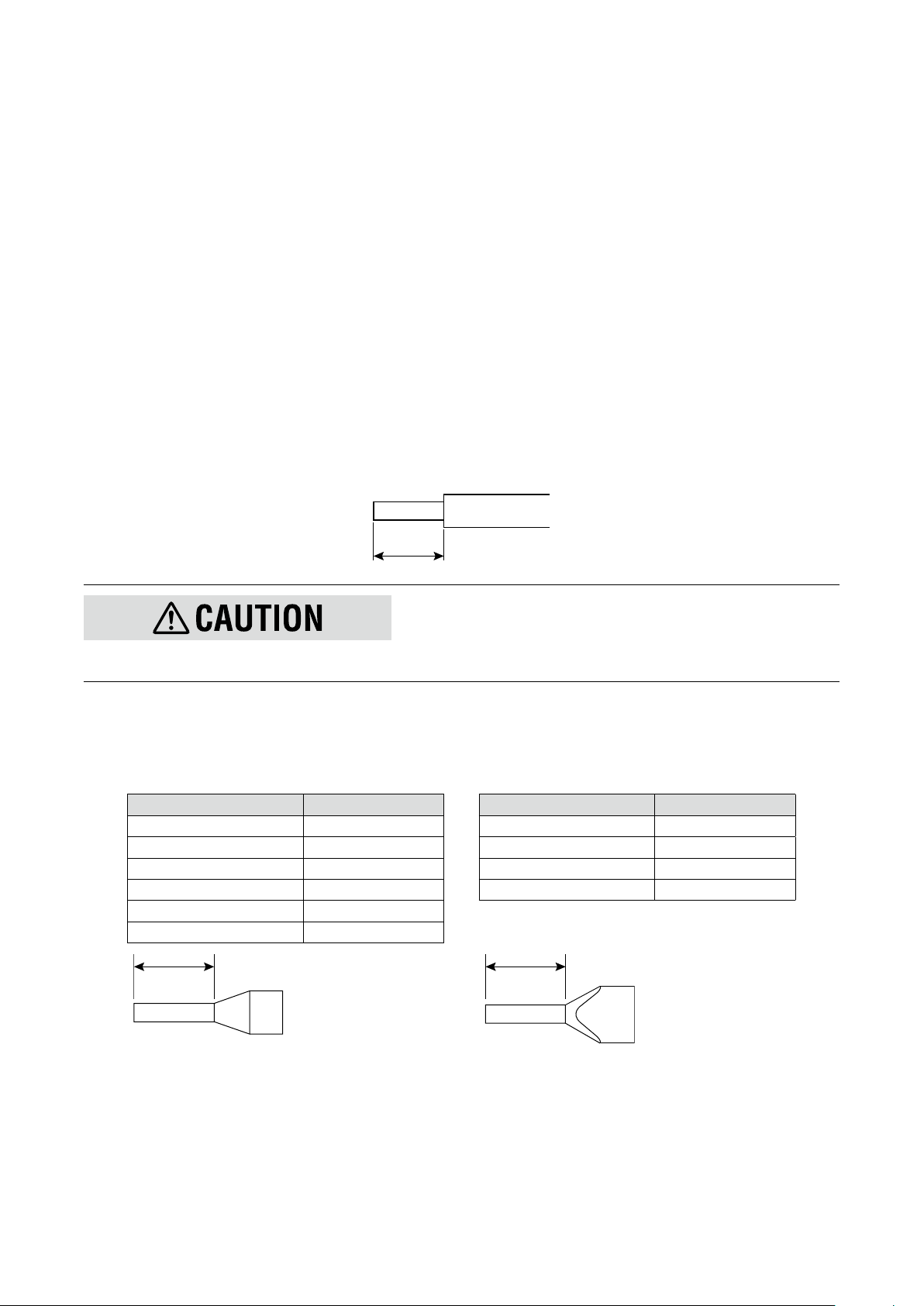

12.4 EXTERNAL DIMENSIONS

10 11 12

789

DIN RAIL

35mm wide

mm (inch)

106 (4.17)

123

456

7

CJC SENSOR

(model: CJM)

* Used only with a thermocouple input

*

18 (.71)

62 (2.44)

(.28)

110.5 (4.35)

[5 (.20)]

• When mounting, no extra space is needed between units

47M3LU2 OPERATING MANUAL EM-2653-B Rev.0

Loading...

Loading...