Page 1

INSTRUCTION MANUAL

FREQUENCY SCALER

(eld-programmable; built-in excitation)

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner (body + base socket) .............................(1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection,

hardware setting and basic maintenance procedures.

When you need to change software settings, please refer to

the Operation Manual for Model PU-2x (EM-9255), Section

B.

This unit is factory adjusted and calibrated according to the

Ordering Information included in the product package. If

you don’t need to change the pre-adjusted setting, you can

skip the sections on hardware setting and calibration in this

manual and the Operation Manual for Model PU-2x.

MODEL

■ AND ....

•The unit is designed to function as soon as power is supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

JFR2

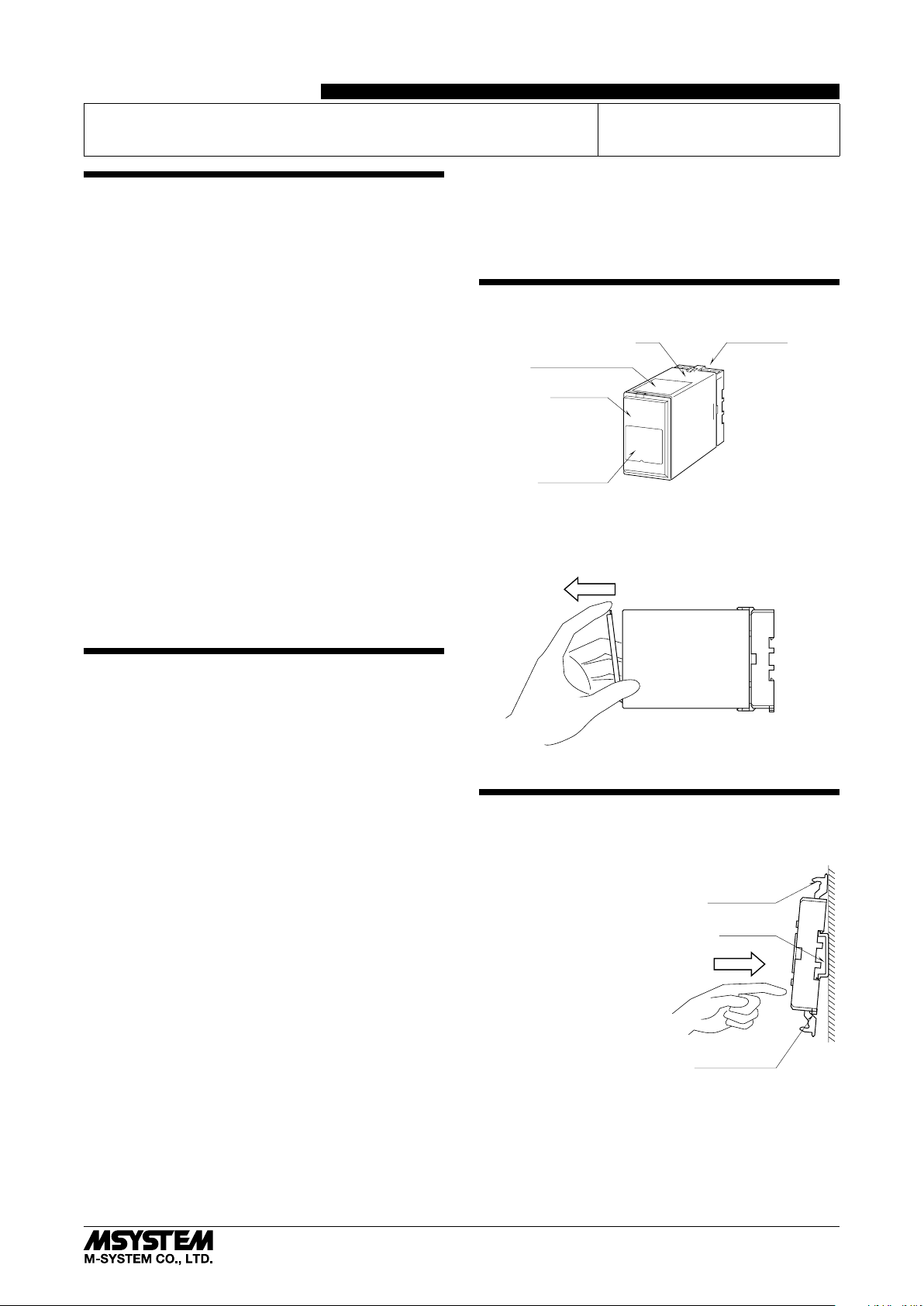

COMPONENT IDENTIFICATION

Body Base Socket

Connection Diagram

Front Cover

Specifications

■ HOW TO OPEN THE FRONT COVER

Position your finger on the hook at the top of front cover

and pull.

POINTS OF CAUTION

■ POWER INPUT RATING & OPERATIONAL RANGE

•Locate the power input rating marked on the product and

confirm its operational range as indicated below:

85 – 132V AC rating: 85 – 132V, 47 – 66 Hz, approx. 6VA

12V, 24V and 48V DC rating: Rating ±10%, approx. 3.3W

110V DC rating: 85 – 150V, approx. 3.3W

■ GENERAL PRECAUTIONS

•Before you remove the unit from its base socket or mount

it, turn off the power supply and input signal for safety.

■ ENVIRONMENT

•Indoor use.

•When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

•Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

•Environmental temperature must be within -5 to +60°C

(23 to 140°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■ WIRING

•Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

•Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

The shape of base socket may be different

for some models.

INSTALLATION

Detach the yellow clamps located at the top and bottom of

the unit to separate the body from the base socket.

■ DIN RAIL MOUNTING

Set the base socket so that its

DIN rail adaptor is at the bottom. Position the upper hook

at the rear side of base socket

on the DIN rail and push in

the lower. When removing

the socket, push down the

DIN rail adaptor utilizing a

minus screwdriver and pull.

■ WALL MOUNTING

Refer to “EXTERNAL DIMENSIONS.”

DIN Rail Adaptor

Shape and size of the base socket

are slightly different with various

socket types.

Clamp

(top & bottom)

DIN Rail

35mm wide

Spring Loaded

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 1 / 8

Page 2

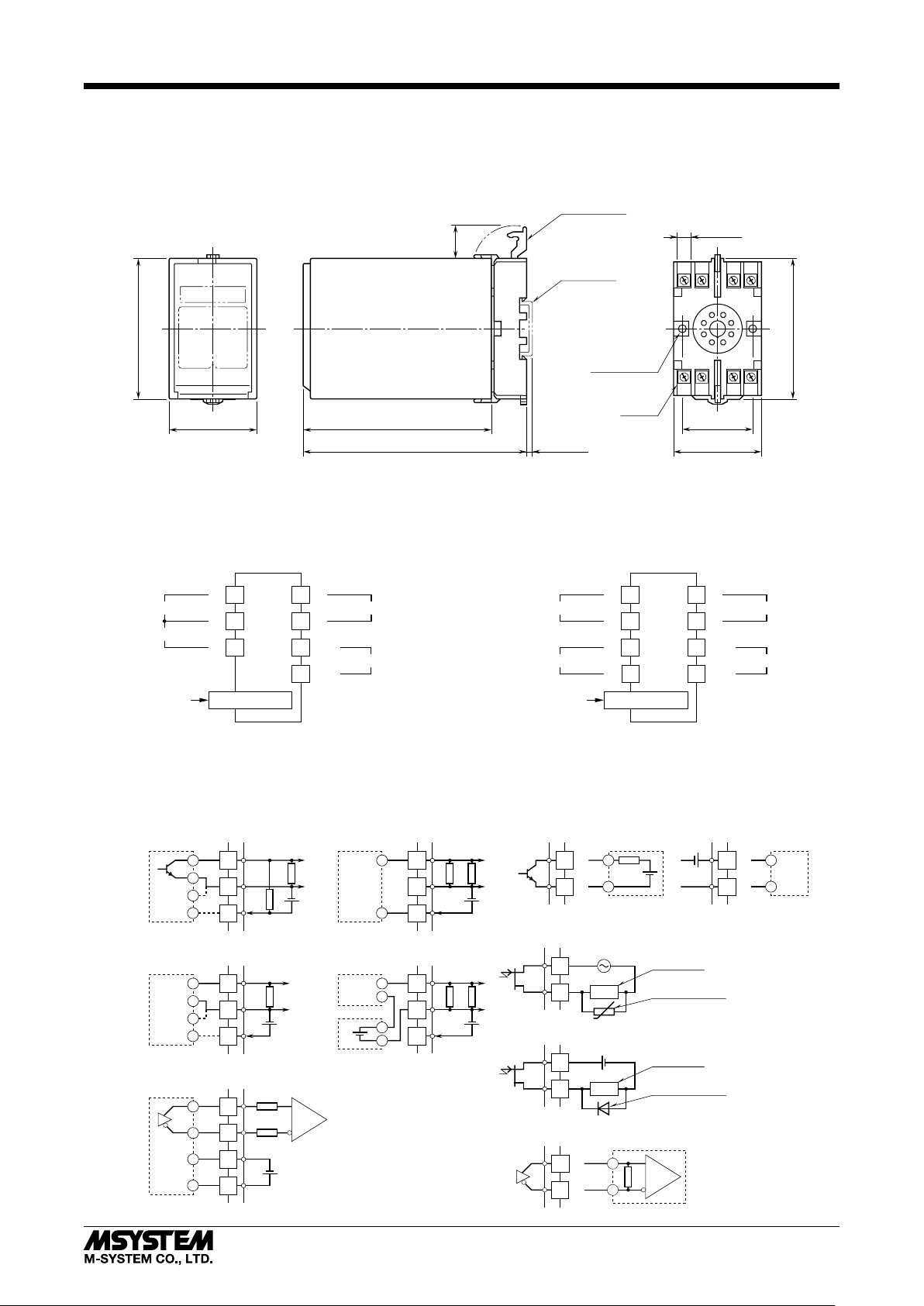

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the connection diagram on the top of the unit.

■ EXTERNAL DIMENSIONS unit: mm (inch)

CLAMP

(top & bottom)

20

(.79)

DIN RAIL

35mm wide

JFR2

7.8 (.31)

3456

80 (3.15)

50 (1.97) 107 (4.21)

127 (5) [3.3 (.13)]

■ CONNECTION DIAGRAM

■ OPEN COLLECTOR, MECHANICAL CONTACT,

VOLTAGE PULSE or 2-WIRE CURRENT PULSE INPUT

+

INPUT

SENSOR EXCITATION

PU-2x

With 24V excitation and open collector/mechanical contact input,

the voltage across the terminals 3 – 4, divided in the waveform shaper,

is of approx. 16V.

3

–

4

+

5

MODULAR JACK

+

1

2

7

8

OUTPUT

–

U(+)

POWER

V(–)

2–4.5 (.18) dia.

MTG HOLE

15 (.59) deep

8–M3.5

2187

SCREW

40 (1.57)

50 (1.97)

• When mounting, no extra space is needed between units.

■ RS-422 LINE DRIVER INPUT

INPUT

SENSOR EXCITATION

PU-2x

+

3

–

6

+

5

–

4

MODULAR JACK

+

1

2

7

8

OUTPUT

–

U(+)

POWER

V(–)

80 (3.15)

Input Connection Examples

■ Open Collector or

Mechanical Contact

+

3

–

4

–

PWR

+

5

5kΩ

■ Voltage Pulse

+

3

–

4

–

PWR

+

5

■ RS-422 Line Driver Pulse

+

3

–

6

–

PWR

4

+

5

Vsns

Vsns

Output Connection Examples

■ 2-Wire Current Pulse

• Built-in Excitation

2-WIRE

PICK-UP

Vsns

• External DC Supply

2-WIRE

PICK-UP

DC SUPPLY

–

100Ω

3

4

+

5

–

100Ω

3

+

4

+

5

–

■ Open Collector

+

1

–

Vsns

2

■ Noncontact AC/DC Switch

• AC Powered

1

2

Vsns

• DC Powered

+

–

LOAD

U

1

LOAD

2

+

–

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

■ RS-422 Line Driver Pulse

+

1

–

2

+

–

■ Voltage Pulse

Relay or

Counter Coil

Varistor or Spark

Quenching Circuit

Relay or

Counter Coil

Spark Quenching

Diode

+

–

+

+

1

–

–

2

EM-1581 Rev.4 P. 2 / 8

Page 3

EXPLANATIONS OF TERMS & FUNCTIONS

■ LOW-END CUTOUT

The output frequency is forcibly set to 0 Hz when the input

frequency is below the low-end cutout setting by the PU-2x

Programming Unit. It is selectable from 0.3 to 100% of the

selected input frequency range (e.g. 30 Hz – 10 kHz for the

input frequency range 0 – 10 kHz). Use the same unit as

that for the input.

The low-end cutout is reset when the input frequency exceeds the cutout value by 1%. For example, with the input

frequency range 0 – 100 kHz, the input span frequency 10

kHz and the low-end cutout set to 1 kHz; the output equals

0 Hz while the input is within 0 – 1 kHz. When it goes

higher than 1.1 kHz, the output becomes proportional to the

input.

When the input frequency range setting is changed, the

low-end cutout value is automatically reset to the default

value, 0.3% of the range.

■ SCALING FACTOR, INPUT SPAN FREQUENCY & OUT-

PUT SPAN FREQUENCY

The scaling factor, rate of output frequency divided by input

frequency, are determined by two parameters: input span

frequency and output span frequency.

Although there are also input zero frequency and output

zero frequency, they are fixed to zero (0) Hz.

The output frequency is limited up to 115% of the output

span frequency.

JFR2

■ DETECTING PULSE EDGE

• Open Collector & Mechanical Contact:

OFF (input monitor LED ON) to ON (input monitor LED

OFF)

• Voltage Pulse

A pulse rise detected when the input voltage goes above

the detecting level (input monitor LED ON); a pulse sink

detected when it goes below the level (input monitor LED

OFF).

• Two-wire Current Pulse

The input resistor (100 Ω) converts the current signal (0 –

25 mA) into 0 – 2.5 V. A pulse rise detected when the voltage goes above the detecting level (input monitor LED ON);

a pulse sink detected when it goes below the level (input

monitor LED OFF).

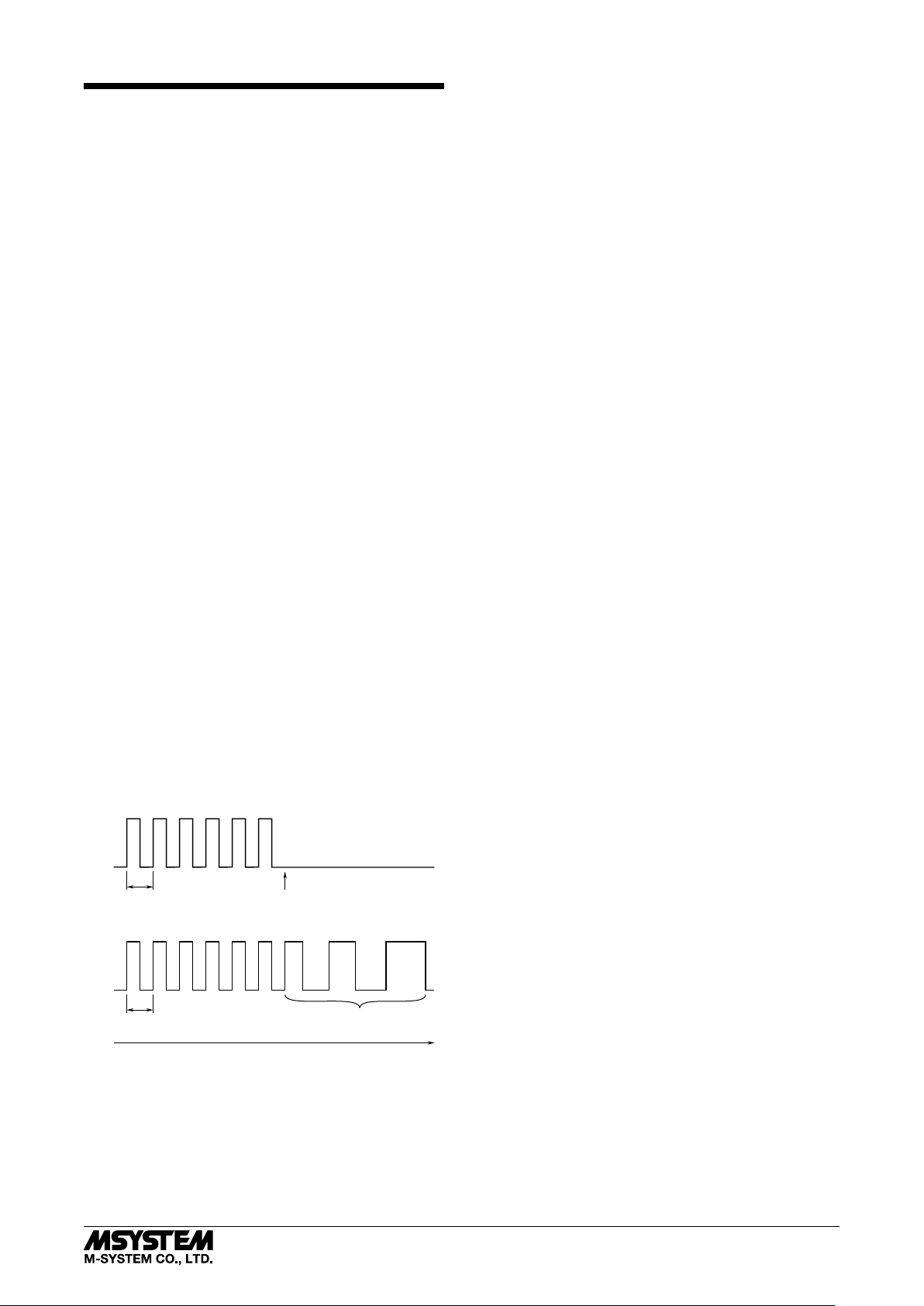

■ INPUT/OUTPUT WAVEFORMS

The figure below shows an example of the output waveform

when the input is changed from 100% to 0% (0 Hz), with no

conversion to one-shot.

The output, as shown in the figure, does not drop to 0 Hz immediately after the input does, but rather decreases gradually down to 0 Hz.

The time required for the output reaches 0 Hz is longer

when the input frequency range is lower.

In general, it becomes shorter when the low-end cutout

value is greater.

INPUT

Input 100% Input 0%

OUTPUT

Output 100%

Output frequency decreasing

Time

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 3 / 8

Page 4

HARDWARE SETTING & CALIBRATION

Modular Jack

Input Monitor LED

3

2

4

1

Detecting Level Adj.

Detecting Level Adj. Pin

Pulse Amplitude Selector

5

0

SW3

6

9

7

8

1

2

3

4

5

SW1

6

7

8

1

2

3

4

SW2

5

6

7

8

Sensor Excitation Adj.

■ PULSE AMPLITUDE (rotary switch) (*) Factory setting

For RS-422 line driver pulse, this setting is invalid.

For voltage pulse input, select the pulse amplitude (Vp-p)

among the switch positions 0 through 6. For open collector,

mechanical contact or two-wire current pulse input, set the

switch to 7. DO NOT SET to 8 or 9. The power supply to the

unit must be turned off when changing the setting.

SW PULSE AMPLITUDE MAX. INPUT VOLTAGE

0

1

2

3

4

5

6*

7 (*)

1

50 – 100 Vp-p

25 – 50 Vp-p

10 – 25 Vp-p

5 – 10 Vp-p

1 – 5 Vp-p

0.5 – 1 Vp-p

0.1 – 0.5 Vp-p

Open collector, Mechanical contact or

Two-wire current pulse

*1. Maximum frequency limited 50 kHz.

Unused

Unused

Input Type Selectors

ON

1

2

3

4

5

6

7

8

50V

50V

25V

10V

5V

1V

0.5V

JFR2

■ DIP SWITCH SETTING (*) Factory setting

For RS-422 line driver pulse, the noise filter setting is invalid.

SW2 is not used. Turn all switches to OFF.

The power supply to the unit must be turned off when

changing the setting.

• Input Type

ON

OFF

OFF

SW1

OFF

ON

OFF

INPUT TYPE

Open collector (*)

Mechanical contact

1 2 3 4 5 6

ON OFF ON OFF OFF ON

Voltage pulse OFF OFF ON OFF OFF ON

Two-wire current pulse OFF ON ON OFF OFF ON

RS-422 line driver pulse OFF OFF OFF ON ON OFF

• Noise Filter

Choose an appropriate noise filter setting according to input

frequency. (The unit may not function within the described

accuracy level if no filter is used.)

‘High’ setting is used for input ranges ≤ 1 Hz.

‘Low’ setting is used for input ranges ≤ 1 kHz.

NOISE FILTER SW1-7 SW1-8

High

Low (*)

None

■ CAUTION FOR RS-422 LINE DRIVER PULSE

For RS-422 line driver pulse, the input amplitude, detecting level and noise filter settings are all invalid. However,

in order to prevent errors in setting, set these switches as

follows:

Input amplitude = 50 – 100 Vp-p (SW=0)

Detecting level = 0V

Noise filter = None

■ EXAMPLE 1: VOLTAGE PULSE with Amplitude 5 Vp-p, DC Offset 2.5 V, Input Frequency 1 kHz

Input type: Voltage pulse

Input frequency: 1 kHz (range and span frequency selected with the PU-2x)

Input amplitude: 1 – 5 Vp-p

Detecting level:

2.5 V (DC Offset × Sensitivity Scale = 2.5 × 1/1 = 2.5 V)

(Set to the offset value after it is scaled by the sensitivity

scale.)

Noise filter: Low

The rotary switch and DIP switch are configured as shown to

SW3 SW1 SW2

5

6

4

7

3

8

2

1

0

ON

9

12345678

the right.

■ EXAMPLE 2: VOLTAGE PULSE with Amplitude 30 Vp-p, DC Offset 15 V, Input Frequency 50 Hz

Input type: Voltage pulse

Input frequency: 100 Hz (range and span frequency selected with the PU-2x)

Input amplitude: 25 – 50 Vp-p

Detecting level:

1.5 V (DC Offset × Sensitivity Scale = 15 × 1/10 = 1.5 V)

(Set to the offset value after it is scaled by the sensitivity

scale.)

Noise filter: High

The rotary switch and DIP switch are configured as shown to

SW3

4

3

2

1

5

6

7

8

9

0

SW1 SW2

ON

12345678

the right.

ON

12345678

Not Used (All OFF)

ON

1 2345678

Not Used (All OFF)

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 4 / 8

Page 5

■ DETECTING LEVEL

Determine the appropriate detecting level referring to the flow chart below.

START

JFR2

Voltage pulse input or

Two-wire current pulse input?

Yes

Confirm the Sensitivity Scale in Table 1

below.

Assign the value in the following equation.

1

Detecting Level (V)*

DC Offset (V)*

Adjust the detecting level to the value

calculated above following the procedure

explained below.

*1. Rounded off to one decimal place.

*2. For 2-wire current pulse, divide a current input (mA)

by 10 and convert it into voltage (V).

=

2

× Sensitivity Scale

No

Table 1

SW PULSE AMPLITUDE SENSITIVITY SCALE

0

1

2

3

4

5

6

7

50 – 100 Vp-p

25 – 50 Vp-p

10 – 25 Vp-p

5 – 10 Vp-p

1 – 5 Vp-p

0.5 – 1 Vp-p

0.1 – 0.5 Vp-p

Open collector

Mechanical contact

1/20

1/10

1/5

1/2

1

5

10

1

Two-wire current pulse

A specific sensitivity scale is applied according to the pulse

amplitude setting. The scaled input voltage is then compared to the detecting voltage level (0 – 5 V).

The scaled H level voltage must be equal to or higher than

the detecting level so that the pulse state is accurately detected. (Refer to the instruction manual for detailed information about adjusting the detecting level.)

Open collector input or

Mechanical contact input?

Yes

Adjust the detecting level

appropriate for the sensor

excitation voltage.

Excitation

≥ 10V DC

7 – 10V DC

5 – 7V DC

Detect. Level

2V

1.5V

1V

No

Adjust the detecting level

to 0V appropriate for

RS-422 line driver pulse

input.

• Setting Examples

Voltage pulse (DC Offset = Pulse Amplitude / 2)

PULSE

AMPLITUDE (Vp-p)

50

50

30

25

15

10

7.5

5

3.5

2

1

0.5

AMPLITUDE

RANGE (Vp-p)

50 – 100

25 – 50

25 – 50

10 – 25

10 – 25

5 – 10

5 – 10

1 – 5

1 – 5

1 – 5

0.5 – 1

0.1 – 0.5

DETECTING

LEVEL (V)

1.3

2.5

1.5

2.5

1.5

2.5

1.9

2.5

1.8

1

2.5

2.5

Two-wire current pulse (DC Offset = Pulse Amplitude / 2)

PULSE

AMPLITUDE (mAp-p)

15 (1.5 Vp-p)

25 (2.5 Vp-p)

AMPLITUDE

RANGE

Set to open collector,

mechanical contact or

two-wire current pulse

DETECTING

LEVEL (V)

0.8

1.3

Set DC offset to 0 V for 100 Vp-p pulse input.

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 5 / 8

Page 6

• How to Change the Detecting Level

Input Monitor LED

Voltmeter

Detecting Level Adj.

Detecting Level Adj. Pin

3

2

4

1

5

0

SW3

6

9

7

8

1

2

3

4

5

SW1

6

7

8

1

2

3

4

SW2

5

6

7

8

V

–

Connect to Terminal 4

of the base socket.

A voltmeter of class 0.5 or better accuracy with pointed

probes is required.

1) Connect the negative probe of voltmeter to the terminal 4

of base socket.

2) If you need a noise filter, set the SW1-7 and SW1-8 in

advance.

3) Connect the positive probe to the test pin and turn the

Detecting Level Adjustment until the meter shows desired value.

4) Apply input signals and check that input monitor LED

(PL1) blinks according to the input signal.

If the LED does not blink, the detecting level may be out

of pulse amplitude range. Check the pulse amplitude

and the DC offset again and readjust the detecting level.

JFR2

■ SENSOR EXCITATION ADJUSTMENT

You can change the sensor excitation voltage with the sensor excitation adj. located behind the front cover. If you

need to change it, check that the required current is within

the specification.

• How to Change the Excitation

A voltmeter and ammeter of class 0.5 or better accuracy are

required.

SENSOR EXC.

Ammeter

A

V

PU-2x

Voltmeter

–

4

+

5

MODULAR JACK

+

1

OUTPUT

–

2

7

U(+)

POWER

8

V(–)

1) Connect the voltmeter across the terminal 5 – 4.

2) Connect the ammeter to terminal 5.

3) Turn the potentiometer until the meter shows the desired value.

Check that the current value indicated on the ammeter

is within the allowable limit. If the value is greater than

the limit, lower the voltage value or connect a separate

power source. Otherwise, the transmitter may fail.

24

12

VOLTAGE (V)

5

25

Voltage (V) × Current (A) ≤ 600mW

60 120

CURRENT (mA)

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 6 / 8

Page 7

JFR2

SOFTWARE SETTING

Please refer to the Operation Manual for Model PU-2x (EM-9255), Section B: (B-1) INTRODUCTION, (B-2) GENERAL OPERATION DESCRIPTION, (B-3) OPERATION FLOW CHART for general information.

[GROUP 01]

ITEM MDFY. INPUT DATA DISPLAY DEFAULT CONTENTS

01 S N/A MAINTENANCE SWITCH

0 MTSW: MON.MODE 0: Data indication only.

1 MTSW: PRG.MODE 1: All ‘P’ marked parameters are modifiable.

02 P Alphanumeric TG: XXXXXXXXXX N/A Tag name entry (10 characters max.)

03 P Numeric (%) OUTPER XXX.XX N/A Output in % and simulated output

05 D No input INPPER XXX.XX N/A Input in %

06 D No input INPFRQ XXX.XX N/A Input frequency (unit as in ITEM 11)

07 D No input N/A

SW: IN_V 1/20 SW = 0, Voltage pulse, Sensitivity scale = 1/20

SW: IN_V 1/10 SW = 1, Voltage pulse, Sensitivity scale = 1/10

SW: IN_V 1/5 SW = 2, Voltage pulse, Sensitivity scale = 1/5

SW: IN_V 1/2 SW = 3, Voltage pulse, Sensitivity scale = 1/2

SW: IN_V 1/1 SW = 4, Voltage pulse, Sensitivity scale = 1/1

SW: IN_V 5/1 SW = 5, Voltage pulse, Sensitivity scale = 5/1

SW: IN_V 10/1 SW = 6, Voltage pulse, Sensitivity scale = 10/1

SW: IN_OC, mA SW = 7, Open collector, mechanical contact or two-wire

SW: no use SW = 8, (not used)

SW: no use SW = 9, (not used)

SW: IN_RS-422 DIP switch set to RS-422 line driver pulse

11 P 5

0 INRNG: 10 mHz 0 – 10 mHz

1 INRNG: 100 mHz 0 – 100 mHz

2 INRNG: 1.0 Hz 0 – 1.0 Hz

3 INRNG: 10 Hz 0 – 10 Hz

4 INRNG: 100 Hz 0 – 100 Hz

5 INRNG: 1.0 kHz 0 – 1.0 kHz

6 INRNG: 10 kHz 0 – 10 kHz

7 INRNG: 100 kHz 0 – 100 kHz

12 P Numeric INSPN XXXXXX 1.0000 Input span frequency (unit as in ITEM 11)

13 P 6

0 OUTRNG: 1 mHz (5)* 0 – 1 mHz

1 OUTRNG: 10 mHz 0 – 10 mHz

2 OUTRNG: 100 Hz 0 – 100 mHz

OUTRNG: 1.0 Hz 0 – 1.0 Hz

OUTRNG: 10 Hz 0 – 10 Hz

OUTRNG: 100 Hz 0 – 100 Hz

OUTRNG: 1.0 kHz 0 – 1.0 kHz

7 OUTRNG: 10 kHz 0 – 10 kHz

14 P Numeric OUTSPN XXXXXX 1.0000 Output span frequency (unit as in ITEM 13)

(20.00)*

15 P Numeric DRPOUT XXXXXX 0.3 Low-end cutout frequency (unit as in ITEM 11)

18 P Numeric SMPL RATE XXX 1 Averaging non-uniform pulses

Input specification selected with the front rotary switch

current pulse

Input frequency range

Output frequency range

*( ) Output code R: Noncontact AC/DC switch

*( ) Output code R: Noncontact AC/DC switch

Deadband fixed at 1% (Low-end cutout is reset when

the input exceeds the setting by 1%.)

Input pulses are divided and then multiplied by the

ratio so that the output waveform is uniform (stable).

Range ≤ 0 – 100 Hz : Ratio 1 – 255

0 – 1 kHz : 1 – 25

0 – 10 Hz : 1 – 2

0 – 100 Hz : Not selectable (fixed at 1)

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 7 / 8

Page 8

ITEM MDFY. INPUT DATA DISPLAY DEFAULT CONTENTS

19 P Numeric (%) FINZER XXX.XX 0.00 Fine zero adjustment

OUTPER XXX.XX Indicates the output in % when data is input.

20 P Numeric (%) FINSPN XXX.XX 100.00 Fine span adjustment

OUTPER XXX.XX Indicates the output in % when data is input.

Modication Code

D : No modification (writing) possible. Used only for monitoring (reading).

S : Modifiable at any time.

P : Modifiable only when the MAINTENANCE SWITCH is in the ‘PRG’ mode.

ROM Version Indication

[GROUP 00] [ITEM 99]

CHECKING

1) Terminal wiring: Check that all cables are correctly connected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

7 – 8 with a multimeter.

3) Check input signal.

4) Sensor excitation: Check that the load for the sensor excitation is within the permissible limit.

5) Output: Check that the load resistance meets the described specifications.

JFR2

LIGHTNING SURGE PROTECTION

M-System offers a series of lightning surge protectors for

protection against induced lightning surges. Please contact

M-System to choose appropriate models.

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1581 Rev.4 P. 8 / 8

Loading...

Loading...