AS4T

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1608 Rev.12 P. 1 / 5

THERMOCOUPLE ALARM

(dual or quad alarm trip; eld-congurable)

MODEL

AS4T

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

This equipment is for use in general industrial environments, therefore may not be suitable for applications which

require higher level of safety (e.g. safety or accident prevention systems)or of reliability (e.g. vehicle control or combustion control systems).

For safety, installation and maintenance of this equipment

must be conducted by qualified personnel.

■ PACKAGE INCLUDES:

Signal conditioner

(body + base socket + CJC sensor) ................................. (1)

■ MODEL NO.

Confirm that the model number described on the product is

exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

■ SYMBOLS USED ON THE PRODUCT AND IN THIS MANUAL

The symbol indicated on the equipment, means that

the user must refer to the related parts in the manual for

safe operation of the equipment. It is essential to read the

instructions wherever the symbol appears in the manual.

WARNING: is reserved for conditions and actions that

can cause serious or fatal injury.

CAUTION : is reserved for conditions and actions that can

cause injury or instrument damage.

WARNING

■ INSULATION CLASS

Basic insulation (Signal input or output to Power input: 300

V) is maintained.

If insulation failure may result in equipment, hazardous

voltage (maximum 240 V) may result to signal input and

then electric shock may cause.

Prior to installation, prepare supplemental insulation

(equivalent basic insulation) between signal input and external circuits.

CAUTION

■ REGARDING SAFETY

If equipment is not used in a manner not specified by MSystem, the protection provided by the equipment may be

impaired.

■ CONFORMITY WITH LOW VOLTAGE DIRECTIVE OR UL

•This equipment is suitable for use in a Pollution Degree

2 environment and in Installation Category II (transient

voltage 2500 V).

•Altitude up to 2000 meters.

•The equipment must be mounted inside a panel.

•The equipment must be installed such that appropriate

clearance and creepage distances are maintained to conform to EU/UL requirements. Failure to observe these

requirements may invalidate the EU/UL conformance.

■ CONFORMITY WITH EMC DIRECTIVE

•Insert a noise filter for the power source connected to the

unit. TDK-Lambda Noise Filter Model RSNA-2006 or

equivalent is recommended.

•The actual installation environments such as panel configurations, connected devices, connected wires, may affect

the protection level of this unit when it is integrated in a

panel system. The user may have to review the CE requirements in regard to the whole system and employ additional protective measures to ensure the CE conformity.

■ SIGNAL INPUT

This terminal is used for signal input.

Do not connect or measure to the circuits including transient voltage 2500 V.

Refer to “INPUT SPECIFICATIONS” in detail.

■ OUTPUT TERMINAL

Never use the output terminal under any load that exceeds

the rated values. Otherwise it will impair prescribed performance and cause burning of the equipment itself.

■ WIRING

•For wiring connection, refer to “TERMINAL CONNECTIONS” and wire correctly. Fire, electric shock and failure cause if wire are incorrectly connected.

•Wire using vinyl insulated power cable that meet input

voltage and load current for equipment and screw by an

adequate torque.

Loose screws may abnormally generate heat and fire

may cause. (Proper tightening torque [N·m] : 0.98 – 1.18)

•Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

•Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

AS4T

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1608 Rev.12 P. 2 / 5

POINTS OF CAUTION

■ POWER INPUT RATING & OPERATIONAL RANGE

Locate the power input rating marked on the product and

confirm its operational range as indicated below:

■ AC Power

M2: 100 – 240 V AC, 50 – 60 Hz, maximum 6 VA

(85 – 264 V AC, 47 – 66 Hz)

■ DC Power

R: 24 V DC (24 V ±10%), maximum 3.5 W

P: 110 V DC (85 – 150 V), maximum 3.5 W

■ GENERAL PRECAUTIONS

Before you remove the unit from its base socket or mount it,

turn off the power supply and input signal for safety.

■ ENVIRONMENT

•Indoor use

•When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

•Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

•Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■ AND ....

•The unit is designed to function as soon as power is supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

•Never use the internal relay under any load that exceeds

the rated contact values including the switching capacities (contact voltage and contact current).

Otherwise it will impair prescribed performance (insulation failure, contact welding, contact failure) and cause

burning of the Relay itself.

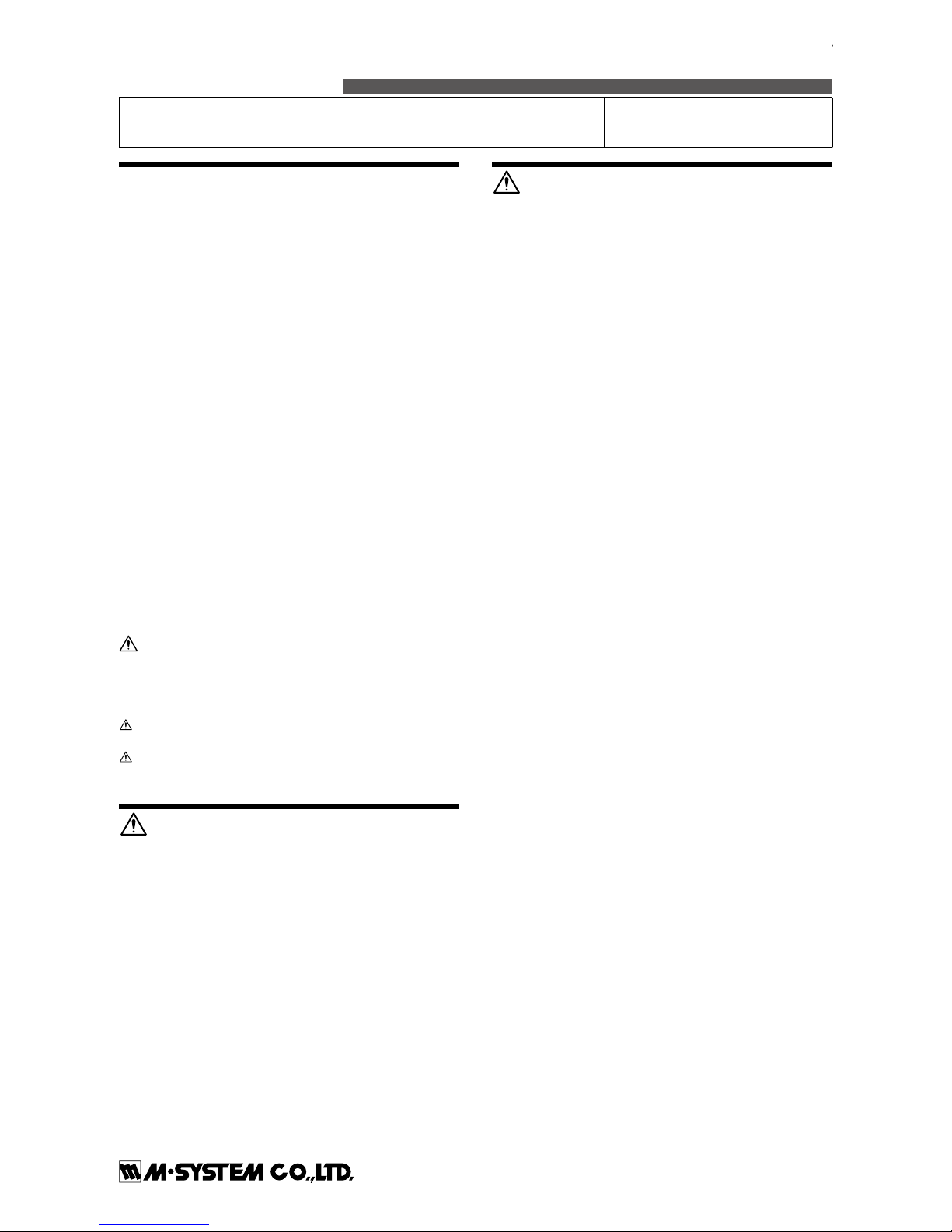

COMPONENT IDENTIFICATION

Body

Specifications

Base Socket

Connection Diagram

CJC

Sensor

INPUT SPECIFICATIONS

Input resistance: 1 MΩ min.

Burnout sensing: 45 nA ±10%

Default setting: K (CA) -100.0 – +999.9°C

T/C

USABLE RANGE

CONFORMANCE

LIMIT

°C °F °C °F

(PR) *

K (CA) *

E (CRC) *

-52 to +1860

-272 to +1472

-272 to +1020

-61.6 to +3380

-458 to +2682

-458 to +1868

150

-200

-200

302

-328

-328

J (IC)

T (CC) *

B (RH) *

-260 to +1300

-272 to +500

24 to 1920

-436 to +2372

-458 to +932

75.2 to 3488

-260

-200

450

-436

-328

842

R *

S *

C

(WRe 5-26)

-100 to +1860

-100 to +1860

-52 to +2416

-148 to +3380

-148 to +3380

-61.6 to +4381

150

150

-52

302

302

-61.6

N

U

L

P

(Platinel II)

-272 to +1400

-252 to +600

-252 to +1000

-52 to +1496

-458 to +2552

-422 to +1112

-422 to +1832

-61.6 to +2725

-200

-252

-252

-52

-328

-422

-422

-61.6

* For temperatures ranges near the lower limit of the usable range, the

transmitter may not satisfy the described accuracy.

OUTPUT SPECIFICATIONS

■ Quad Alarm

Relay rating: 120 V AC @ 1 A (cos ø = 1)

240 V AC @ 0.5 A (cos ø = 1)

30 V DC @ 1 A (resistive load)

■ Dual Alarm

Relay rating: 120 V AC @ 5 A (cos ø = 1)

240 V AC @ 2.5 A (cos ø = 1)

30 V DC @ 5 A (resistive load)

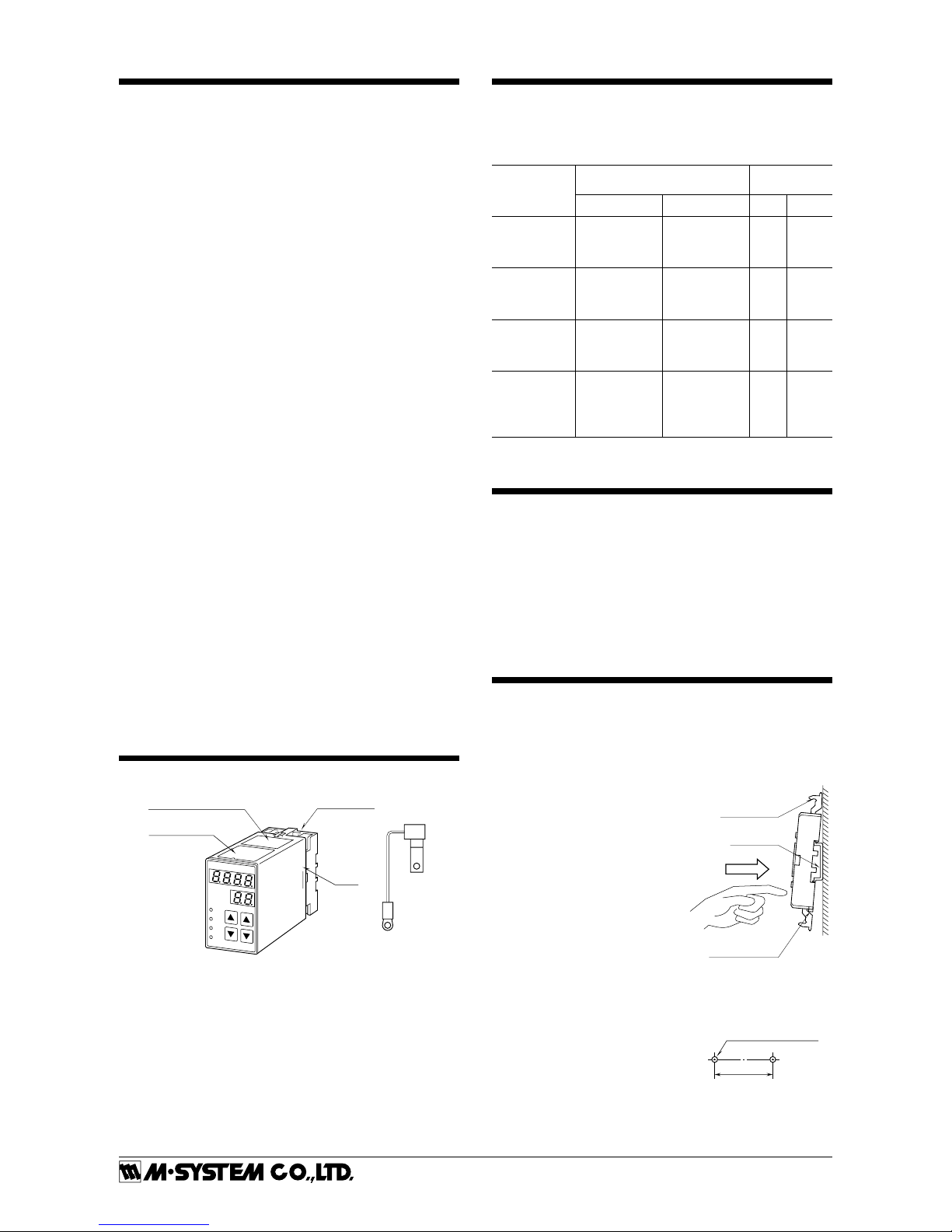

INSTALLATION

Detach the yellow clamps located at the top and bottom of

the unit to separate the body from the base socket.

■

Clamp

(top & bottom)

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

Shape and size of the base socket

are slightly different with various

socket types.

DIN RAIL MOUNTING

Set the base socket so that its

DIN rail adaptor is at the bottom. Position the upper hook at

the rear side of base socket on the

DIN rail and push in the lower.

When removing the socket, push

down the DIN rail adaptor utilizing a minus screwdriver and pull.

■

2-M4or4.5(.18)dia.hole

40±0.2

MOUNTING HOLES

(TOP VIEW)

WALL MOUNTING

•Install using M4 screw with referring to the right dimension.

•Install by screw that is securely

fastened or equivalent means.

AS4T

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1608 Rev.12 P. 3 / 5

FRONT VIEW & PROGRAMMING

■

L1

L2

L3

L4

ALARM

DATA

ITEM

DATA

ITEM

ITEM No. Display

DATA UP-DOWN Keys

ITEM No. UP-DOWN Keys

*Monitor LEDs

DATA Display

*L3 or L4 does not turn on for dual output type.

PROGRAMMING PROCEDURE

1 ) Press ITEM UP or DOWN key until ITEM display indicates “01”.

2 ) Press DATA UP or DOWN key and choose “1” or “2” on DATA

display.

1 : Only alarm setpoints are modifiable.

2 : All parameters are modifiable.

3 ) Press ITEM UP or DOWN key until ITEM display shows the

ITEM No. you need to change.

4 ) Press DATA UP or DOWN key and choose a DATA No. or value

you need on DATA display.

5 ) Repeat above 3 and 4. (Entered data is stored when you move to

a new ITEM.)

6 ) Press ITEM UP or DOWN key until ITEM display indicates “01”.

7 ) Press DATA UP or DOWN key and choose “0” on the display.

8 ) Press ITEM UP or DOWN key until ITEM display indicates “P”.

DATA display shows process input.

(You can now check data setting by choosing ITEM No.)

Note: DO NOT press UP and DOWN keys simultaneously.

ITEM

MDF.

CODE

DATA

CONTENTS DEFAULT SETTING

P N/A -272 – 2416*

1

Process input display in engineering unit ----

L1

L2

L3

L4

1, 2

1, 2

1, 2

1, 2

-272 – 2416*

1

-272 – 2416*

1

-272 – 2416*

1

-272 – 2416*

1

L1 alarm setpoint in engineering unit

L2 alarm setpoint in engineering unit

L3 alarm setpoint in engineering unit *

2

L4 alarm setpoint in engineering unit *

2

Quad: 20.0

Quad: 30.0

Quad: 70.0

Quad: 80.0

Dual: 20.0

Dual: 80.0

01 0, 1, 2 Modification code

0 : Data indication only.

1 : Only ITEM L1 – L4 are modifiable.

2 : All parameters are modifiable.

1

02 N/A 00 – 99 Status indication (“0” is normally indicated.)

0: Normal 1: Memory error 10: Out of input range -15 – +115%

03 N/A 3 Input type 3: Thermocouple

04 2 0 – 99 Power ON-delay time (seconds) 5

05 2 0 – 99 Alarm ON-delay time (seconds) 0

06 2 0, 1, 2, 3 , 4 Moving average (sampling cycle: 100 msec.)

0: No, 1: 4 samples, 2: 8 samples, 3: 16 samples, 4: 32 samples

0

07

08

09

10

2

2

2

2

0, 1

0, 1

0, 1

0, 1

L1 trip operation

L2 trip operation

L3 trip operation

L4 trip operation

(0: Lo, 1: Hi)

(0: Lo, 1: Hi)

(0: Lo, 1: Hi) *

2

(0: Lo, 1: Hi) *

2

Quad: 0

Quad: 0

Quad: 1

Quad: 1

Dual: 0

Dual: 1

11 2 -1, 0, 1 – 60 Power-saving mode

-1 : Continuous display upon startup

0 : Continuous display after the last access

1 – 60: Time before display turned off (minutes)

10

12

13

14

15

2

2

2

2

0, 1

0, 1

0, 1

0, 1

L1 coil at alarm (0: Energized, 1: De-energized)

L2 coil at alarm (0: Energized, 1: De-energized)

L3 coil at alarm (0: Energized, 1: De-energized)*

2

L4 coil at alarm (0: Energized, 1: De-energized)*

2

0

0

0

0

16 N/A ---- Version No. indication ----

17

18

19

20

2

2

2

2

0.0 – 2416

0.0 – 2416

0.0 – 2416

0.0 – 2416

L1 hysteresis (deadband) in engineering unit

L2 hysteresis (deadband) in engineering unit

L3 hysteresis (deadband) in engineering unit *

2

L4 hysteresis (deadband) in engineering unit *

2

1.0

1.0

1.0

1.0

21 2 0, 1 Burnout (0: Downscale, 1: Upscale) 1

22 2 -272 – 2416*

1

Upper range temperature limit

Display blinking with higher temperature

999.9

PV blinking at upscale burnout

AS4T

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1608 Rev.12 P. 4 / 5

ITEM

MDF.

CODE

DATA

CONTENTS DEFAULT SETTING

23 2 -272 – 2416*

1

Lower range temperature limit

Display blinking with lower temperature

-100.0

PV blinking at downscale

burnout

24 2 0, 1, 2 Temperature unit (0: °C, 1: °F, 2: K) 0

25 2 0 – 12 Thermocouple type

0: (PR), 1: K (CA), 2: E (CRC), 3: J (IC), 4: T (CC), 5: B (RH)

6: R, 7: S, 8: C (WRe 5-26), 9: N, 10: U, 11: L, 12: P (Platinel II)

1: K (CA)

*1. It operates simultaneously with the display unit of ITEM 24. Refer to the table 1 for available setting range.

*2. Quad alarm trip type only

Table 1: USABLE RANGE

T/C

USABLE RANGE

°C °F K

(PR) *

1

-52.0 – +1860 -61.6 – +3380 221.2 – 2133

K (CA) *

1

-272 – +1472 -458 – +2682 1.2 – 1745

E (CRC) *

1

-272 – +1020 -458 – +1868 1.2 – 1293

J (IC) -260 – +1300 -436 – +2372 13.2 – 1573

T (CC) *

1

-272 – +500.0 -458 – +932.0 1.2 – 773.2

B (RH) *

1

24.0 – 1920 75.2 – 3488 297.2 – 2193

R *

1

-100.0 – +1860 -148.0 – +3380 173.2 – 2133

S *

1

-100.0 – +1860 -148.0 – +3380 173.2 – 2133

C (WRe 5-26) -52.0 – +2416 -61.6 – +4381 221.2 – 2689

N *

1

-272 – +1400 -458 – +2552 1.2 – 1673

U -252 – +600.0 -422 – +1112 21.2 – 873.2

L -252 – +1000 -422 – +1832 21.2 – 1273

P (Platinel II) -52.0 – +1496 -61.6 – +2725 221.2 – 1769

*1. For temperatures ranges near the lower limit of the usable range, the transmitter may not satisfy the described accuracy.

*2. Minimum step

-199.9 to 999.9: 0.1

Not greater than -200, not lower than 1000: 1

CONNECTIONS

■ EXTERNAL DIMENSIONS unit: mm (inch)

• When mounting, no extra space is needed between units.

5678

21

1110

80 (3.15)

40 (1.57)

50 (1.97)

7.8 (.31)

2–4.5 (.18) dia.

MTG HOLE

25 (.98) deep

11

–

M3.5

SCREW

39

4

For wiring connection, refer to “TERMINAL CONNECTIONS” and wire correctly.

Fire, electric shock and failure cause if wire are incorrectly connected.

80 (3.15)

50 (1.97) 103 (4.06)

132 (5.20)

20

(.79)

[3.3 (.13)]

35.4 (1.39)

CLAMP

(top & bottom)

DIN RAIL

35mm wide

■ TERMINAL ASSIGN

78

21

1110

39

7 (.28)

CJC SENSOR

(model: CJM)

5

4

6

AS4T

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1608 Rev.12 P. 5 / 5

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the connection diagram on top of the unit.

Attach the CJC sensor together with input wiring to the

input terminals. The CJC sensor is not interchangeable.

Check that its serial number is the same as that of the unit.

U(+)

V(–)

POWER

7

8

10

11

9

2

3

1

L2 OUTPUT

L1 OUTPUT

N.C.

N.O.

COM

N.C.

N.O.

COM

■ SPDT RELAY

U(+)

V(–)

POWER

7

8

10

11

9

2

3

1

L4 OUTPUT

L1 OUTPUT

COM

L3 OUTPUT

L2 OUTPUT

COM

■ N.O. RELAY ■ N.C. RELAY

10

11

9

2

3

1

L4 OUTPUT

L1 OUTPUT

COM

L3 OUTPUT

L2 OUTPUT

COM

+

–

T / C

CJC

SENSOR

metal leg

model: CJM

comp. leadwire

5

4

6

+

–

+

–

T / C

CJC

SENSOR

metal leg

comp. leadwire

5

4

6

+

–

CHECKING

1 ) Terminal wiring: Check that all cables are correctly

connected according to the connection diagram.

2 ) Power input voltage: Check voltage across the termi-

nal 7 – 8 with a multimeter.

3 ) Input: Check across the terminals 5 – 6 with a sensi-

tive voltmeter to show a normal emf voltage value.

If the thermocouple or its extension wires are broken,

the PV display indicates the upper range temperature

limit and blinks (the lower range limit with downscale)

due to burnout function. Check leadwires in such a

case.

4 ) Alarm operations: Check the alarm operations refer-

ring to the figure below.

5 ) Output load: Check that the output rating road is: 240

V AC / 120 VA or 30 V DC / 30 W (240 V AC / 600 VA

or 30 V DC / 150 W for dual alarm, Output Code 5) at

the maximum. For maximum relay life with inductive

load, external protection is recommended.

050 100

Input

(%)

LL LHHH

L2 (1–2)

ON

L3 (1–3)

ON

L4 (9–11)

ON

OFF

OFF

L1 (9–10)

ON

OFF

OFF

Alarm Trip Operation Terminal No. in parentheses

Example with quad N.O. contacts (LL, L, H, HH)

Trip Operation in Power Failure

• Output code 2: All relays turn off.

• Output code 3: All relays turn on.

• Output code 5: Terminals 1 –3, 9 – 11 turn on.

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes.

• H (HH) Setpoint

Increase the input signal from a value lower than the setpoint and check that the relay trips at the H (or HH) setpoint within the setpoint accuracy described in the data

sheet.

• L (LL) Setpoint

Decrease the input signal from a value higher than the setpoint and check that the relay trips at the L (or LL) setpoint

within the setpoint accuracy described in the data sheet.

When the setpoints are shifted, please contact M-System’s

Sales Office or representatives.

LIGHTNING SURGE PROTECTION

In order to protect the unit from lightning surges entering

through power supply cables, use of appropriate lightning

surge protectors are recommended. Please contact M-System.

Loading...

Loading...