Page 1

75ET

EM-7354-0003A Rev.1P. 1 / 4

BEFORE USE ....

Thank you for choosing M-System. Before use, check the

package you received as below.

If you have any problems or questions with the product,

please contact M-System's Sales Office or representatives.

This product is for use in general industrial environments,

therefore may not be suitable for applications which require

higher level of safety (e.g. safety or accident prevention

systems) or of reliability (e.g. vehicle control or combustion

control systems).

For safety, installation and maintenance of this product must

be conducted by qualified personnel.

■ PACKAGE INCLUDES:

Touch Panel Paperless Recorder................................ (1)

Installation fastener ................................................... (4)

CD-ROM (software and users manual) ..................... (1)

■ MODEL NO.

Check that model No. described on specification label is

exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when you

use this product, including installation, connection and basic

maintenance procedures. For more details, refer to the users

manual included in the CD-ROM.

POINTS OF CAUTION

This product is not designed for use in classified locations.

DO NOT use this product in explosive atmosphere.

■ POWER INPUT

• Power input rating & operational range: Check the power

rating for the unit on the specification label.

Rating 24V DC: 24V ±20%, max. 50W

• Supplying any level of power other than specified above can

damage the 75ET or the power source.

• The power cables and the signal I/O cables for the 75ET

must be located separately.

• The main circuit cables (high voltage and high current), the

signal I/O cables, and the power cables should not be bundled

together or placed near each other.

• To increase noise resistance of the power input wires, twist

the strands before connecting.

■ SAFETY PRECAUTION

• Before you remove the module, turn off the power supply

and input signal for safety.

• Do not use the 75ET in an environment where flammable

gases are present. This may result in an explosion.

• Do not disassemble or modify the 75ET in any way. Doing

so may result in a fire or an electrical shock.

• Do not strike the panel of the 75ET with a hard, heavy or

pointed object, or press the panel with excessive force. Doing

so may result in panel damage or injury.

• Do not block the 75ET's ventilation openings or use it in

areas where heat accumulates. Additionally, do not store or

use it under high-temperature conditions.

• Do not store or use the 75ET in locations subject to direct

sunlight, or where excessive dust or dirt is present.

• The 75ET is a precision instrument. Do not store or use it

where large shocks or excessive vibration can occur.

• Do not store or use the 75ET in environments subject to

chemical evaporation (such as that of organic solvents), or

where there are chemicals and/or acids present in the air.

• Do not use paint thinner or organic solvents to clean the

75ET.

• Do not turn off the power supply to the 75ET during

recording. The CF Card may be destroyed.

■ ENVIRONMENT

• Indoor use

• Standard installation for the 75ET is in a vertical panel. If

the 75ET is to be installed in a slanted panel, the panel should

not incline more than 30 degrees from the vertical.

• Environmental temperature must be within 0 to 50°C (32

to 122°F) with relative humidity within 30 to 85% RH in order

to ensure adequate life span and operation.

■ LCD PANEL

• The LCD panel’s liquid contains an irritant. If the panel is

damaged and the liquid contacts your skin, rinse immediately the contact area with running water for at least 15

minutes. If the liquid gets in your eyes, rinse immediately

your eyes with running water for at least 15 minutes and

consult a doctor.

• The following phenomena are LCD characteristics, and

NOT a product defect:

- LCD screen may show uneven brightness depending

upon displayed images or contrast settings.

- The LCD screen pixels may contain minute blank-andwhite-colored spots.

- The color displayed on the LCD screen may appear

different when seen from outside the specified viewing

angle.

- When the same image is displayed on the screen for a

long time period, an afterimage may appear when the

image is changed. If this happens, turn off the 75ET and

wait 10 seconds before restarting it.

• To prevent an afterimage:

- Set the screensaver when you plan to display the same

image for a long time period.

- Plan to change the screen image periodically so that the

same image does not remain for the long time period.

INSTRUCTION MANUAL

MODEL

75ET

PAPERLESS RECORDER

(12.1-inch touch panel)

Page 2

75ET

EM-7354-0003A Rev.1P. 2 / 4

INSTALLATION

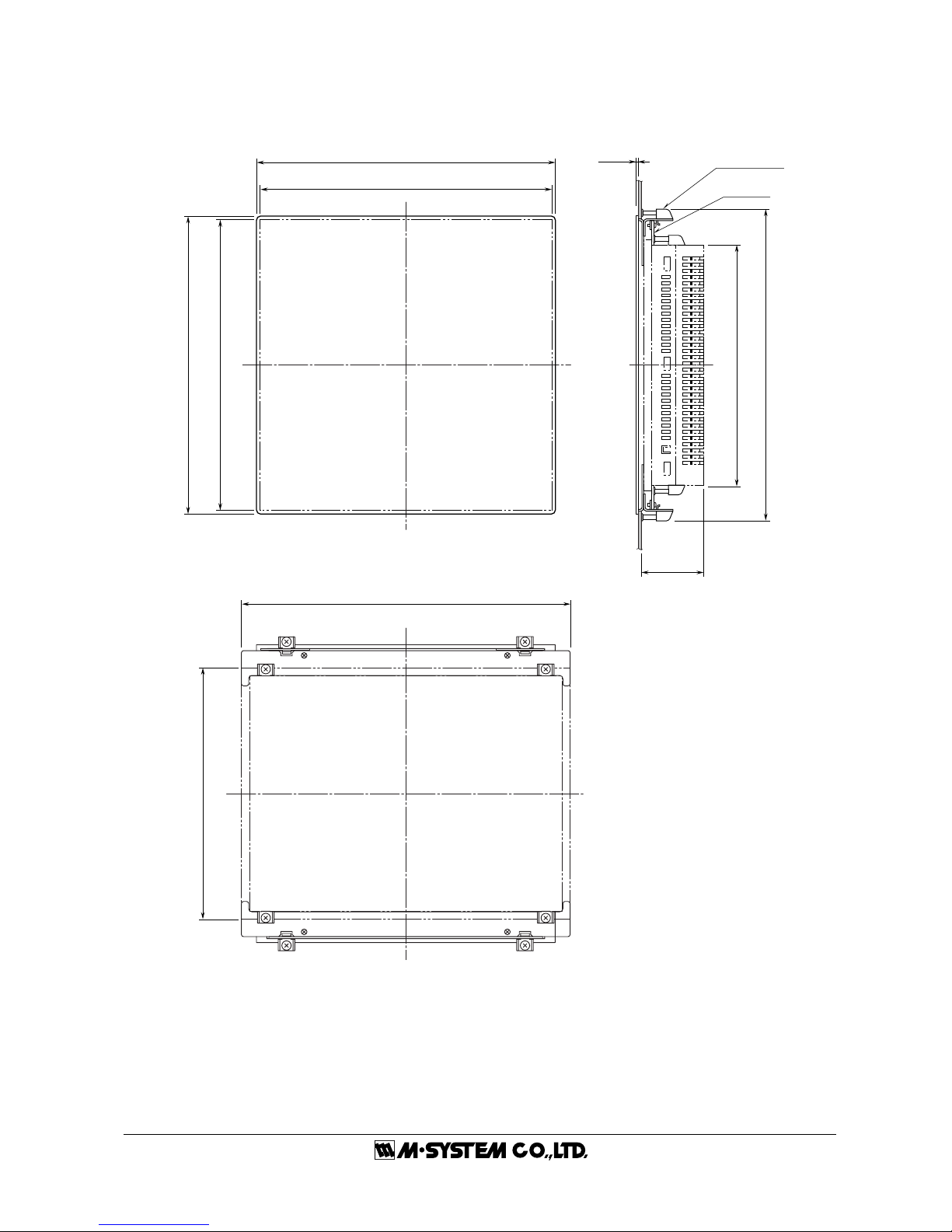

Use the mounting attachments included in the product package. Refer to the panel cutout dimensions as shown below. For use

with Panel Mount Adaptor (model: A-75), refer to the instruction manual for the model.

The A-75 panel cutout conforms to DIN 43700.

For each maintenance, operation and sufficient ventilation, at the minimum of 100 mm must be observed between the 75ET unit

and adjacent structures or equipment.

■ 75ET PANEL CUTOUT mm ■ A-75 ADAPTOR PANEL CUTOUT mm

EXTERNAL DIMENSIONS mm (inch)

■ 75ET

281

281

+2

0

+2

0

Panel thickness: 1.6 – 6.0 mm

Panel thickness: 1.6 – 10.0 mm

227.5

+1

0

4–R3 max.

301.5

+1

0

317 (12.48)

246 (9.59) (screen area)

243 (9.57)

184.5 (7.26) (screen area)

227 (8.94)

50 (1.97)8 (.31)

Page 3

75ET

EM-7354-0003A Rev.1P. 3 / 4

■ A-75 PANEL MOUNT ADAPTOR

288 (11.34)

317 (12.48) (75ET)

■ REAR VIEW

■ FRONT VIEW ■ SIDE VIEW

281 (11.06) (panel cutout)

288 (11.34)

281 (11.06) (panel cutout)

227 (8.94) (75ET)

305 (12.01)

2 (.08)

243 (9.57) (75ET)

INSTALLATION

FASTENER

ADAPTOR

PLATE B

(rear side)

61 (2.40)

Page 4

75ET

EM-7354-0003A Rev.1P. 4 / 4

TERMINAL CONNECTIONS

Connect the module as in the diagram below.

■ CONNECTION DIAGRAM ■ RS-232C INTERFACE

1

5

6

9

ABBR.

PIN NO. EXPLANATION OF FUNCTION

1 Not Used.

BB (RD) 2 Received Data

BA (SD) 3 Transmitted Data

CD (ER) 4 DTE Ready

AB (SG) 5 Signal Common

CF (CD) 6 Received Line Signal Detector

CA (RS) 7 Request to Send

CB (CS) 8 Clear to Send

9 Do Not Connect.

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

product was originally purchased if such product has been used under normal operating conditions and properly maintained, M-System's sole liability, and purchaser's exclusive remedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System Co., Ltd., 5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN, Phone: (06) 6659-8201, Fax: (06) 6659-8510, E-mail: info@m-system.co.jp

CF CARD SLOT

MODULAR JACK

D-SUB CONNECTOR

10BASE-T

RS-232C

+

–

FG

POWER

GROUND

Page 5

1

7xETBLD USERS MANUAL EM-7353-0003C

PAPERLESS RECORDING SYSTEM 7xET SERIES

PC CONFIGURATOR

Model: 7xETBLD

Users Manual

Page 6

2

7xETBLD USERS MANUAL EM-7353-0003C

Contents

1. GENERAL DESCRIPTIONS ........................................................................ 3

1.1 7xETBLD FEATURES ................................................................................................................. 3

1.2 SYSTEM REQUIREMENTS ........................................................................................................ 3

1.3 PROGRAMMING FUNCTIONS ................................................................................................... 3

2STARTING & USING THE 7xETBLD .......................................................... 4

2.1 CONNECTING THE 7xET ........................................................................................................... 4

2.2 INSTALLING / UNINSTALLING THE 7xETBLD........................................................................... 4

2.2.1 INSTALL........................................................................................................................... 4

2.2.2 UNINSTALL...................................................................................................................... 4

2.3 STARTING / STOPPING THE 7xETBLD..................................................................................... 5

2.4 SETTING ON THE 7xETBLD ...................................................................................................... 6

2.4.1 COMMUNICATION SETTING.......................................................................................... 6

2.4.2 STORING RATE ...............................................................................................................6

2.4.3 DATA STORING METHOD............................................................................................... 6

2.4.4 START MODE .................................................................................................................. 6

2.4.5 TEMPERATURE UNIT..................................................................................................... 6

2.4.6 DATA STORING FORM.................................................................................................... 7

2.4.7 DIGITAL DISPLAY METHOD ........................................................................................... 7

2.4.8 DISPLAY RATE ................................................................................................................ 7

2.4.9 CHART SPEED................................................................................................................7

2.4.10 DIGITAL DISPLAY............................................................................................................ 7

2.4.11 GRAPH............................................................................................................................. 7

2.4.12 DATA FILE USED VOLUME............................................................................................. 7

2.4.13 SCREEN SAVER ............................................................................................................. 7

2.4.14 NODE SETTING ..............................................................................................................7

2.4.15 PEN SETTING ................................................................................................................. 8

2.4.16 PEN SELECT ................................................................................................................. 12

2.5 FILE OPERATION BUTTONS ................................................................................................... 13

2.5.1 FILE READ..................................................................................................................... 13

2.5.2 FILE WRITE ................................................................................................................... 13

2.5.3 SETTING TO CSV.......................................................................................................... 13

2.5.4 CF DATA CREATE ......................................................................................................... 13

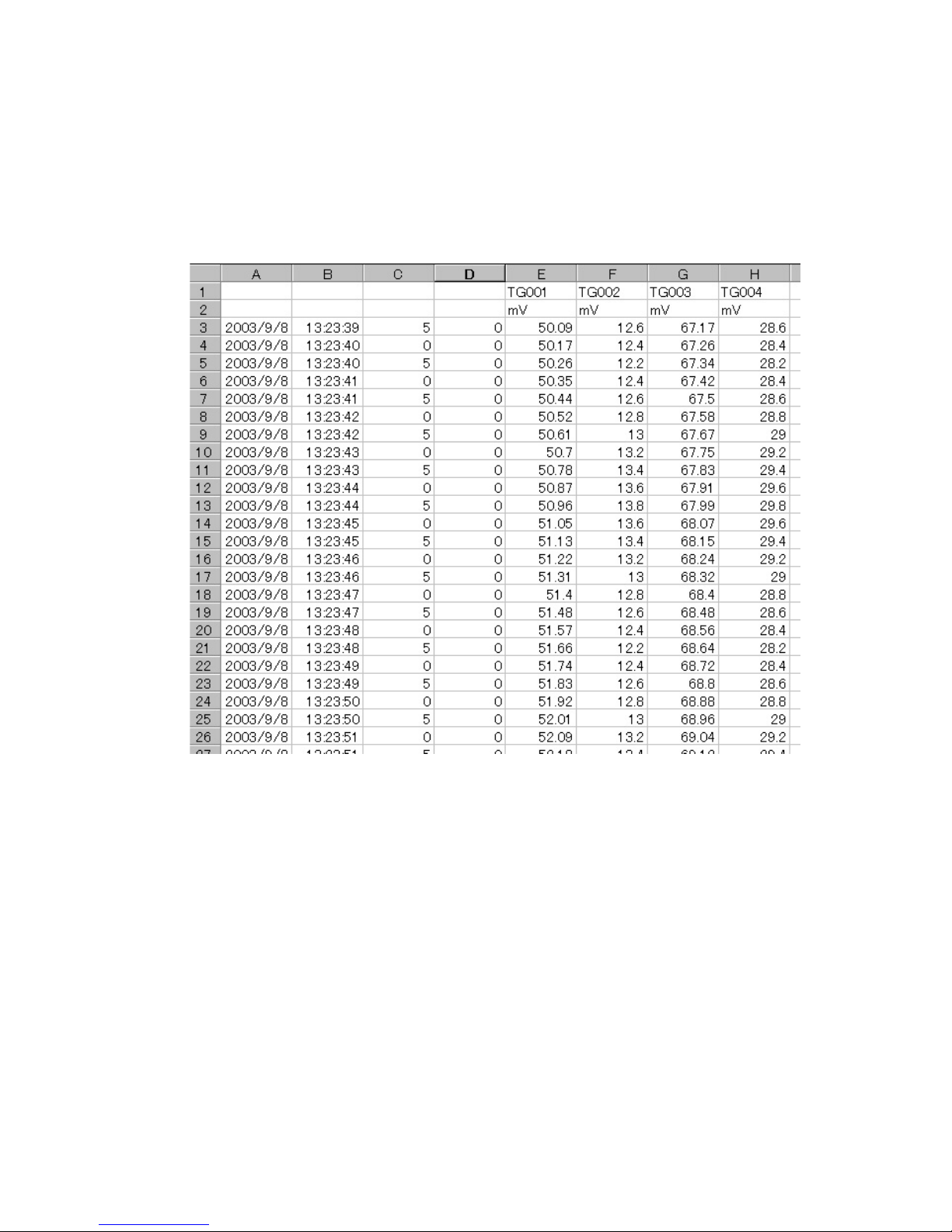

2.5.5 CF DATA TO CSV .......................................................................................................... 14

2.5.6 CF DATA TO MRD.......................................................................................................... 15

2.5.7 DATA VERSION CONVERT........................................................................................... 15

2.6 ONLINE OPERATION BUTTONS ............................................................................................. 16

2.6.1 UPLOAD......................................................................................................................... 16

2.6.2 DOWNLOAD (All)........................................................................................................... 16

2.6.3 DOWNLOAD (Runtime) ................................................................................................. 16

2.6.4 REMOTE START / STOP ............................................................................................... 16

2.6.5 PULSE COUNT PRESET .............................................................................................. 17

2.6.6 REMOTE CSV TOOL..................................................................................................... 17

2.6.7 REMOTE MRD TOOL .................................................................................................... 18

APPENDIX-A ETHERNET CABLE ................................................................................................... 18

Page 7

3

7xETBLD USERS MANUAL EM-7353-0003C

1. GENERAL DESCRIPTIONS

Thank you for choosing M-System’s Paperless Recording System.

The Model 7xETBLD is an easy PC Configuration T ool Software which enables the user to configure the 7xET Series

Touch Panel Paperless Recorders (models: 73ET, 74ET and 75ET) remotely via Ethernet.

This users manual describes PC requirements for the software and its use. For detailed information about the

functions of the 7xET Series, please refer to its respective manual.

Descriptions in this manual is applicable to the 7xETBLD Ver. 3.00x.

1.1 7xETBLD FEATURES

The 7xETBLD enables the user to set parameters to a 7xET remotely via Ethernet simply by specifying its IP

address. It can also upload preset 7xET configuration remotely.

Specific set of configurations can be saved on the PC and then reloaded on the program later when necessary.

The 7xET’s recording operations can be started/stopped by commands from the 7xETBLD program.

1.2 SYSTEM REQUIREMENTS

PC: IBM PC/AT compatible

OS: Window 2000 or XP

Screen area: 1024 x 768 pixels

Display color: 65000 colors (16-bit high color)

Ethernet media: 10BASE-T (73ET is compatible with 100BASE-TX)

1.3 PROGRAMMING FUNCTIONS

Parameters: Communication setting, Storing rate, Data storing method, Start mode,

Temperature unit, Data storing form, Digital display type, Display rate,

Chart speed, Digital display (auto hide), Graph (chart direction),

Data file used volume, Screen saver,

Node setting, Pen setting (common, analog, discrete, alarm)

Pulse count preset: Preset individual pens

Preset all pens

Communication: Download (configuration to the 7xET)

Upload (configuration from the 7xET)

File read / write

Remote start / stop

CF Data create: Creating 7xET.7xDA and 7xET.7xCA files on the CF Card.

CF Data to CSV: Converting data at the specific time period stored in the CF Card into a CSV file.

Getting the time-specific data via Ethernet and converting it into a CSV file.

CF Data to MRD: Converting data at the specific time period stored in the CF Card into a MRD file

which is readable on the MSR128 (file name: yymmdd.MRD).

Getting the time-specific data via Ethernet and converting it into a MRD file.

Data Version Convert: Converting old-version files into the latest-version ones.

Setting to CSV: Saving the 7xETBLD parameters in CSV format.

Page 8

4

7xETBLD USERS MANUAL EM-7353-0003C

2STARTING & USING THE 7xETBLD

2.1 CONNECTING THE 7xET

Confirm that the PC on which the 7xETBLD is used is connected to the 7xET via Ethernet. The 7xET’s IP address

must be properly set in advance. Please refer to the 7xET users manual for detailed information about IP address

setting.

The 7xETBLD Ver. 3.00x is applicable to the following versions of the 7xET Series.

73ET: Ver. 6.00x

74ET: Ver. 3.00x

75ET: Ver. 3.00x

2.2 INSTALLING / UNINSTALLING THE 7xETBLD

If you already have the 7xETBLD program installed in your PC, remove it following the procedure explained in 2.2.2

before installing a new one.

2.2.1 INSTALL

1. Insert the Paperless Recorder Software Package CD (model: CHARTLSP2) into the CD-ROM drive on your PC.

The 7xETBLD Install Program automatically starts up. If the program does not start up automatically, open

Control Panel and choose Add/Remove Programs.

2. Locate the setup program under the 7xETBLD folder in the CD

3. Start Setup.exe. and follow instructions on the screen.

4. With the installation complete, ‘7xETBLD’ menu is created in ‘Programs’ menu.

2.2.2 UNINSTALL

1. Press Start on the task bar and choose Control Panel from Settings menu. (Double-click My Computer icon on

the desktop and choose Control Panel.)

2. Double-click Add/Remove Programs and follow instructions on the screen.

Page 9

5

7xETBLD USERS MANUAL EM-7353-0003C

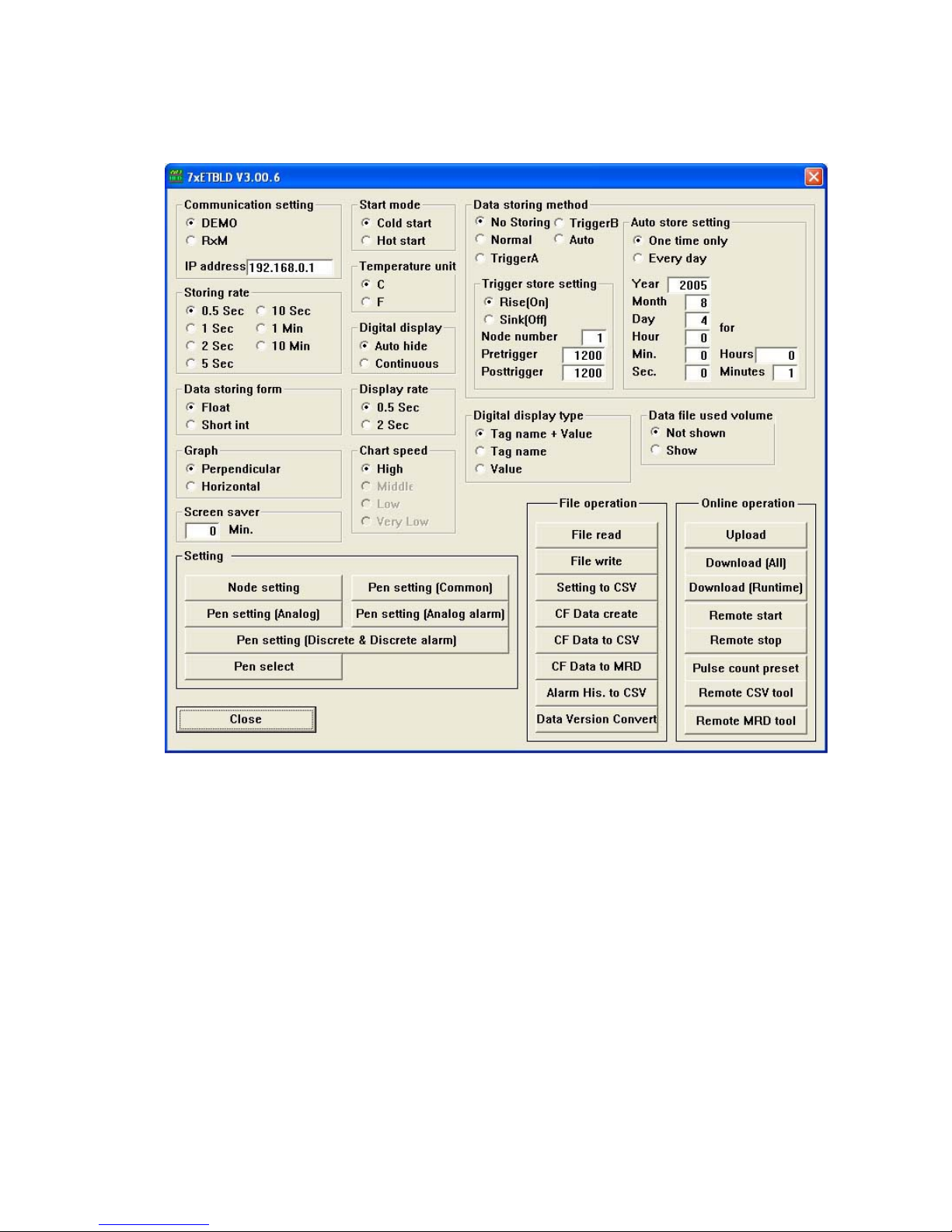

2.3 STARTING / STOPPING THE 7xETBLD

Press Start on the task bar, choose Programs and locate 7xETBLD. Start 7xETBLD.exe and the 7xET PC Configurator

window appears on the screen as shown in Figure 1. Alternately, double-click 7xETBLD.exe shortcut icon on the

desktop to start the program.

Figure 1: 7xET PC Configurator window.

In order to quit the window, click [Close] button at the right-bottom.

Page 10

6

7xETBLD USERS MANUAL EM-7353-0003C

2.4 SETTING ON THE 7xETBLD

2.4.1 COMMUNICATION SETTING

DEMO: Y ou can run the 7xET program without actual signal input for learning, evaluation and demonstra-

tion when you choose DEMO.

RxM: Choose this option when you connect R1M/R2M via Modbus RTU.

IP address: Enter 7xET’s static IP address. 192.168.0.1 entered in the field upon the first startup is M-Sys-

tem’s ex-factory setting.

2.4.2 STORING RATE

Choose among 0.5 sec., 1 sec., 2 sec., 5 sec., 10 sec., 1 min., and 10 min.

2.4.3 DATA STORING METHOD

There are four (4) storing modes as explained below:

No storing: Sampled data are plotted on the screen but no recording is executed.

Normal: Recording is manually initiated and stopped. Data is continuously stored while the recording is on.

Trigger (A): Remote trigger. Data is automatically recorded while the external trigger condition (input) is true.

Trigger (B): Event Recording. The 7xET detects an external event by trigger signal, and stores preset number

of samples before and after the moment of event.

Auto: Recording is automatically initiated and stopped at a predefined time.

Trigger (A), remote trigger mode setting

Remote trigger mode is applicable only to the R1M or R2M series I/O modules.

Data is automatically recorded while the external trigger condition (input) is true.

Condition: Specify whether the recorder should identify On or Off of the contact signal as trigger condi-

tion. For example, when the Condition is set to On, the 7xET stores data while the signal is On

and stops recording when it is turned to Off.

Node Number: Specify which R1M/R2M device connected to the 7xET is used to trigger. Enter numbers and

alphabets on the alphanumeric keypad which opens by pressing the current selection.

Trigger (B), event recording mode setting

Event recording mode is applicable only to the R1M or R2M series I/O modules.

Recording is automatically initiated according to predetermined trigger conditions and preset number of samples

before and after the moment of event are stored.

Rise or Sink: Specify whether the recorder should identify a rise or sink of the contact signal as trigger.

Node number: Specify which R1M/R2M device connected to the PC is used to trigger.

Pretrigger / Posttrigger: 1200 samples at the maximum for each can be stored. Specify numbers of samples to

be stored before (Pretrigger) and after (Posttrigger) the event respectively.

Pretrigger recording is applicable only when the storing rate is set to 0.5 or 1 sec.

Auto store setting

Either ‘One time only’ or ‘Every day’ option can be selected.

When you choose ‘One time only’ option, data is stored once at a predefined time. With ‘Every day’ option, the 7xET

runs recording once per day at a predefined time.

Specify time and duration of a recording cycle, including a date for ‘One time only’ recording. For ‘Every day’

recording, you do not need to specify ‘Year,’ ‘Month’ or ‘Day.’

2.4.4 START MODE

Cold Start: At a restart, the 7xET stands by showing the initial view.

Hot Start: At a restart, the 7xET automatically starts recording.

2.4.5 TEMPERATURE UNIT

Choose either °C (Celsius) or °F (Fahrenheit).

Page 11

7

7xETBLD USERS MANUAL EM-7353-0003C

2.4.6 DATA STORING FORM

Float (floating point): Selected when you need to store data including decimal fractions. The 4-byte-long

data is better in data precision but the total storable time in the CF Card becomes

shorter compared from Short Int.

Short int (short integer): Integer data with hypothetical fixed decimal point. The 2-byte-long data is not as pre-

cise (one decimal place) as Float type is, but the total storable time in the CF Card is

longer.

2.4.7 DIGITAL DISPLAY METHOD

Tag name + Value: The momentary value and the tag name of the data plotted on the screen.

Tag name: The tag name of the data plotted on the screen.

Value: The momentary value of the data plotted on the screen.

2.4.8 DISPLAY RATE

Choose between 0.5 sec. and 2 sec.

2.4.9 CHART SPEED

Choose among High, Middle, Low and Very Low.

When you choose 0.5 sec. for the storing rate and/or the display rate, only High speed is selectable.

2.4.10 DIGITAL DISPLAY

Specify either to show or hide the digital display on the Record view. With ‘Horizontal’ graph direction, only ‘Regular’

can be specified.

Auto Hide: Digital display is automatically hidden in 30 seconds after it appears on the screen. Click the area

of the display to call it up.

Regular: Digital display remains on the screen.

2.4.11 GRAPH

Specify the plotting direction, Perpendicular or Horizontal.

2.4.12 DATA FILE USED VOLUME

Specify either to show or hide the bargraph indicator on the Overview.

2.4.13 SCREEN SAVER

Enter a desired time in minutes to initiate the screen saver. With the time set to zero (0), the screen saver is

deactivated.

2.4.14 NODE SETTING

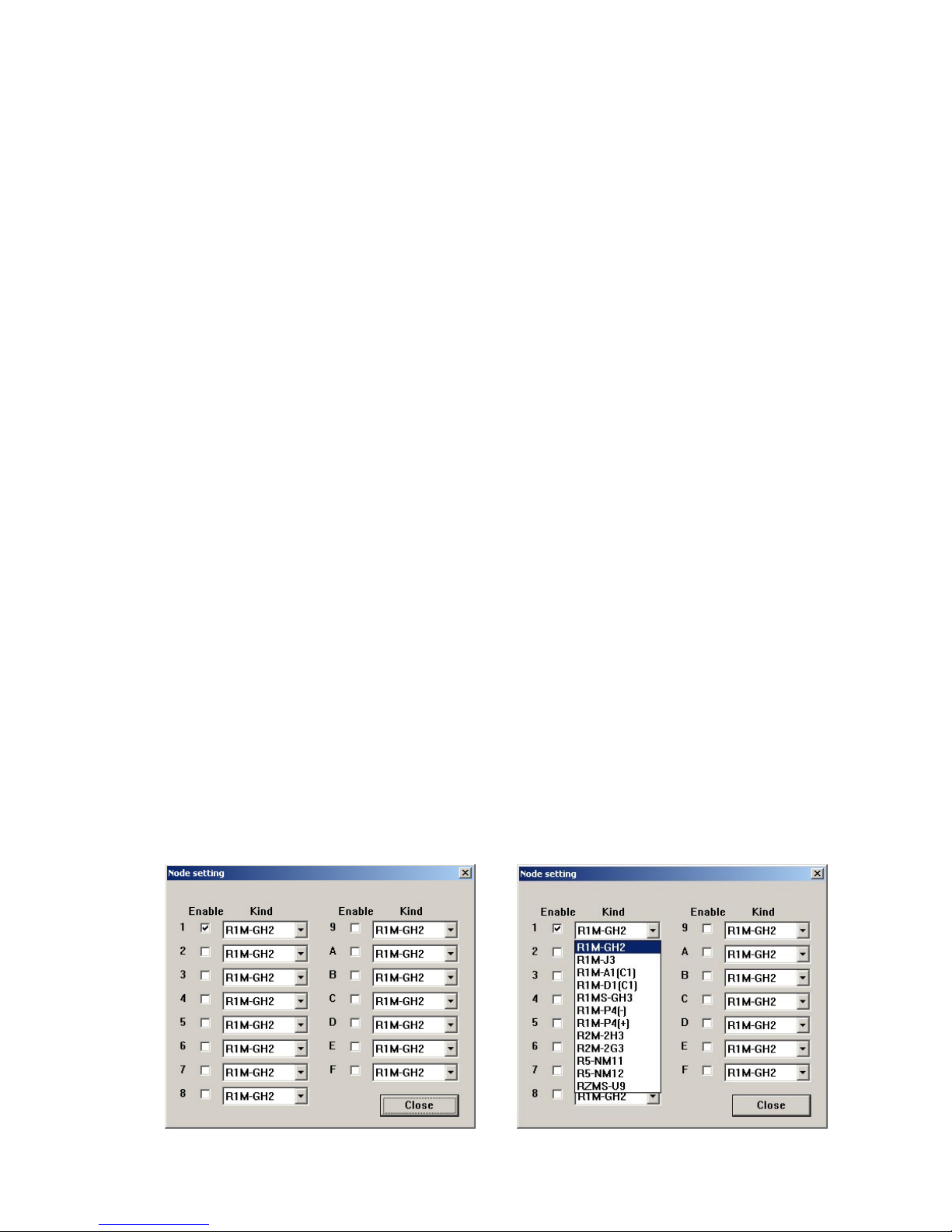

Pressing [Node setting] button opens the window shown in Figure 2a.

Enter ✔ mark to enable specific node numbers. Then specify I/O module type as shown in Figure 2b.

Figure 2a: Node setting (1) Figure 2b: Node setting (2)

Page 12

8

7xETBLD USERS MANUAL EM-7353-0003C

2.4.15 PEN SETTING

Pen setting (Common)

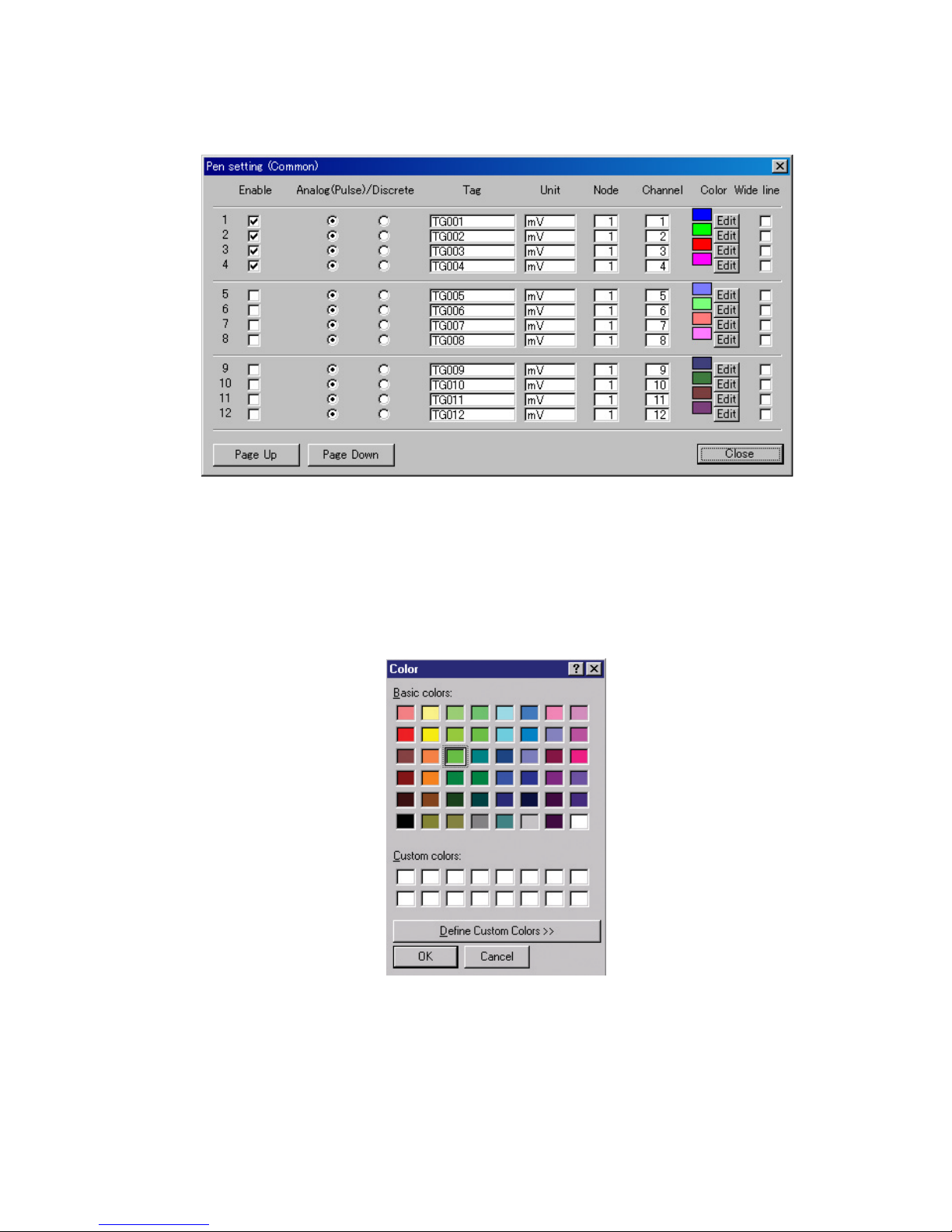

Pressing [Pen setting (Common)] button opens the window shown in Figure 3.

Figure 3: Pen setting (Common).

Enable: Enter ✔ mark to activate specific pens.

Analog (Pulse)/Discrete: Choose Analog or Discrete signal for each pen.

Tag / Unit: Enter tag names and engineering unit. Up to 8 alphanumerical characters for Tag, 4 charac-

ters for Unit.

Node / Channel: Enter node and channel numbers.

Color: Pressing [Edit] button opens the window shown in Figure 4. Select a color from the palette.

You can also compose a new color.

Figure 4: Color.

Wide Line: Enter ✔ mark to use a wide line on the screen for the pen.

Page Up / Page Down: Pressing this button shows next / previous 12 pens.

Close: Use [Close] button to quit the window. Clicking [X] button at the right-top of the window simply

resets the present setting to a default one.

Pens not selected to be ‘Enabled’ in Pen Setting (Common) are not shown in the views for Pen Setting (Analog) or

Pen Setting (Discrete & Discrete Alarm). Analog signal pens are not shown in Pen Setting (Discrete & Discrete

Alarm) view. Likewise, discrete signal pens are not shown in Pen Setting (Analog).

Page 13

9

7xETBLD USERS MANUAL EM-7353-0003C

Pen setting (Analog)

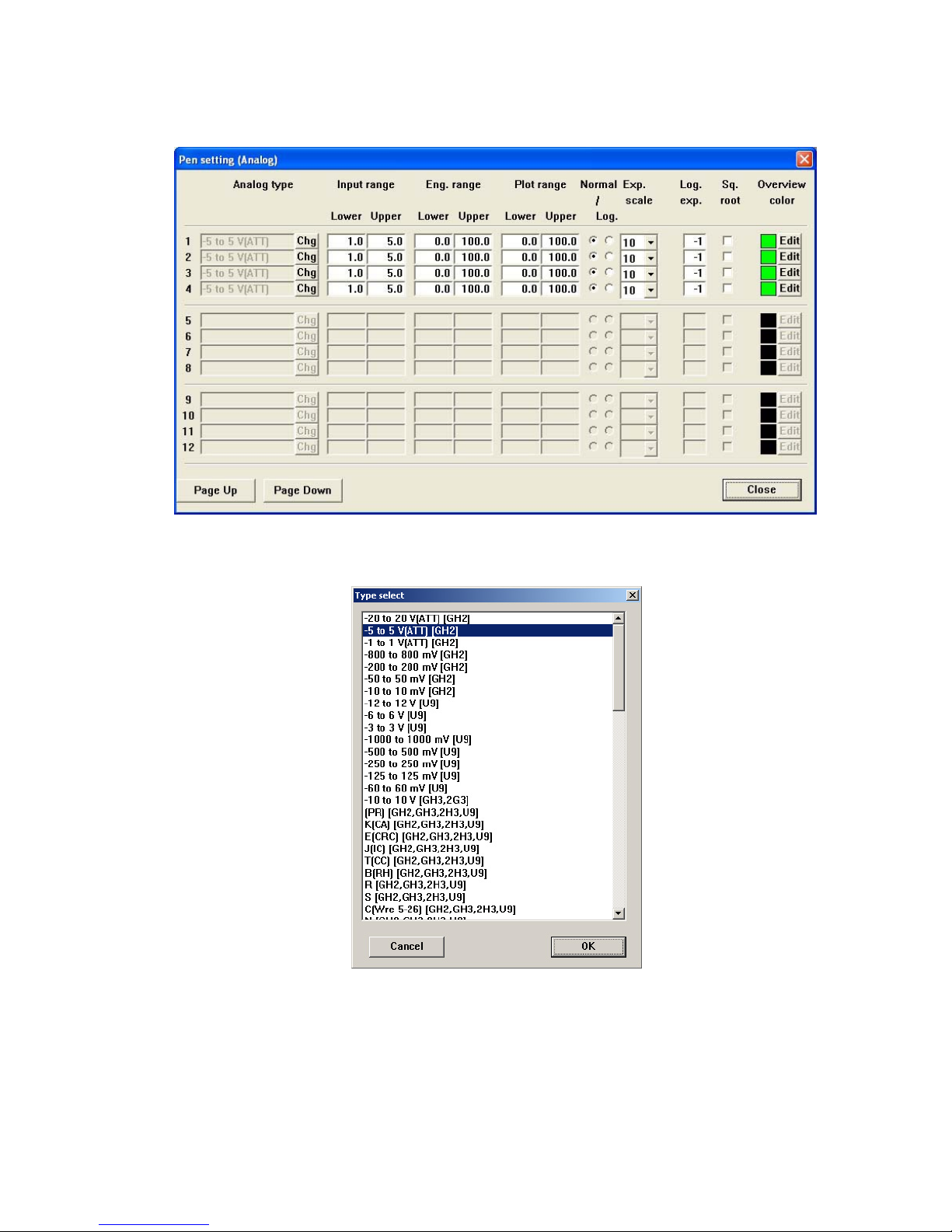

Pressing [Pen setting (Analog)] button opens the window shown in Figure 5.

Set channels to which ‘Analog’ is selected in ‘Pen setting (Common)’ window.

Figure 5: Pen setting (Analog).

Analog type: Choose an analog input type for each pen. In order to change setting, press [Chg] button

and choose a new type from the list shown in ‘Type select’ window as in Figure 6.

Figure 6: Type select.

Input range: Specify within the actual upper and lower ranges referred to as 0% and 100% respectively .

This range is the maximum range plotted on the screen. For a thermocouple/RTD input,

this setting is unavailable.

Engineering range: Specify the scaled range in actual engineering unit. The engineering range is shown on

the digital meter when actual recording is running. For a thermocouple/RTD input, this

setting is unavailable.

Plot range: Values in engineering unit for the plot range displayed on the chart. These values are

usually the same as Engineering Range values. Set a narrower range when you want to

enlarge a particular section of the Engineering Range.

Page 14

10

7xETBLD USERS MANUAL EM-7353-0003C

Normal / Log.: When Normal plotting is selected, the plot area is divided equally. When Logarithmic is

selected, the plot area is divided in specified scale of exponents of 10.

Exponential scale: Specify how many divisions you wish to have in the plot range among 10, 5, 4, 2, and 1.

Log. plot pos. exponent: Specify the lower limit of exponent within -9 to 8.

Square Root: Input data is square-root-extracted when this setting is enabled.

Overview color: Specify the analog data bargraph color used on the Overview. Press [Edit] to call up the

color palette.

Pen setting (Analog alarm)

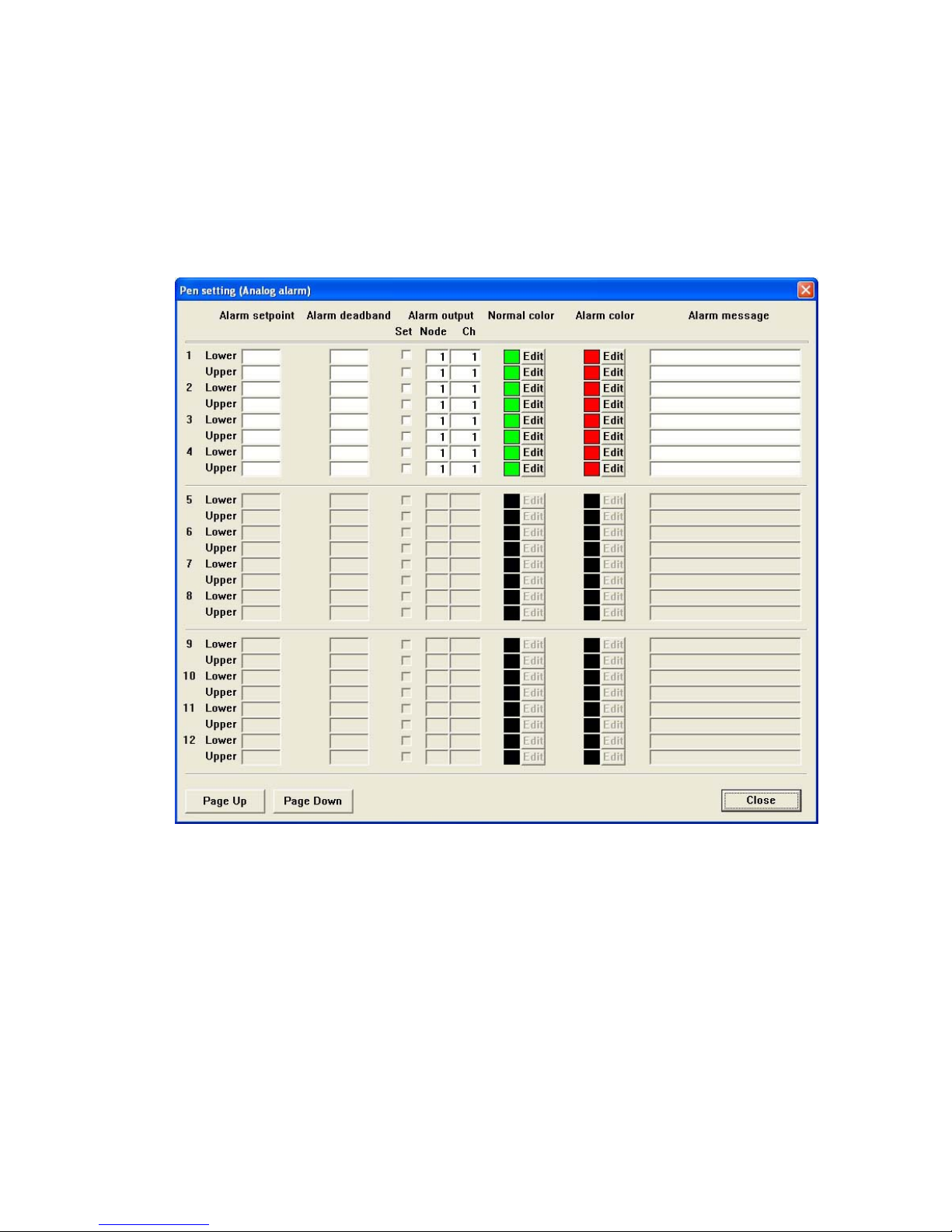

Pressing [Pen setting (Analog alarm)] button opens the window shown in Figure 7.

Figure 7: Pen setting (Analog alarm)

Alarm setpoint: Specify Lower (Low) and Upper (High) setpoints in engineering unit within the Engineering

Range. Leave the fields blank if you do not need an alarm output.

Alarm deadband: Alarms are reset when the signal goes out of the alarm zone by the deadband values

specified for each alarm setpoint. Leave the fields blank if you do not need a deadband.

Lower / Upper alarm output: Alarm contact outputs can be provided to external output devices. Enable the

function by entering ✔ mark in ‘Set’ box for the pen and specify node number and channel

number of the output module.

Normal & Alarm color: Colors specified for normal and alarm conditions are used for digital indicator values on

the Record view. Press Edit and use the color palette to specify the colors.

Alarm message: Specify the comment for the alarm trip used in the Alarm History. Max. 10 characters.

Page 15

11

7xETBLD USERS MANUAL EM-7353-0003C

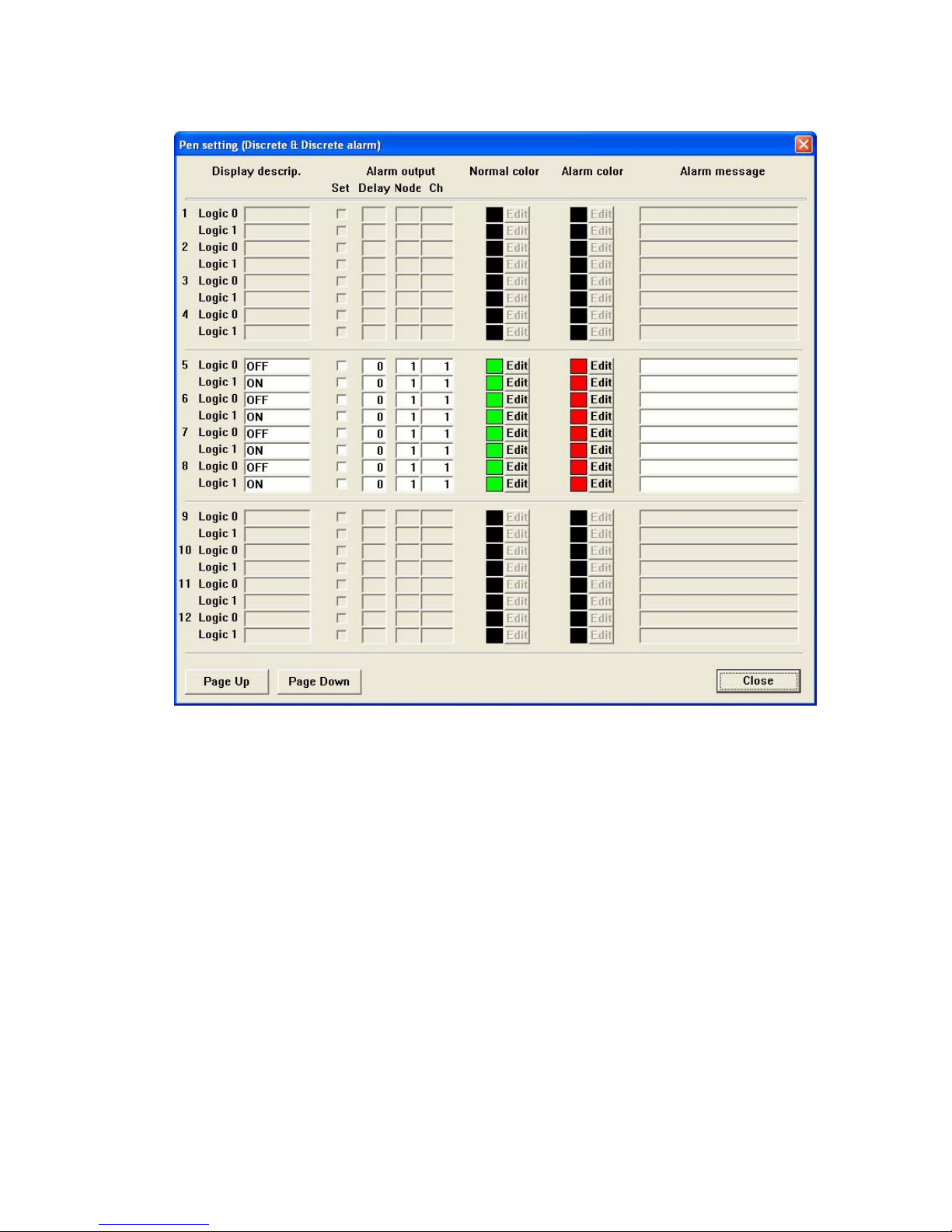

Pen setting (Discrete)

Pressing [Pen setting (Discrete)] button opens the window shown in Figure 8.

Figure 8: Pen setting (Discrete).

Display description: Specify message assigned respectively to Logic 0 and Logic 1 status with up to 5 charac-

ters. The message is shown on the digital meter instead of analog value.

Logic 0 & Logic 1 alarm output: Alarm contact outputs can be provided to external output devices. Enable the

function by entering ✔ mark in ‘Set’ box for the pen and specify node number and channel

number of the output module.

Normal & Alarm color: Colors specified for normal and alarm conditions are used for digital indicator on the

Record view. Press Edit and use the color palette to specify the colors.

Alarm message: Specify the comment for the true/false status for each Logic 0 and 1 bit used in the Alarm

History. Max. 10 characters.

Page 16

12

7xETBLD USERS MANUAL EM-7353-0003C

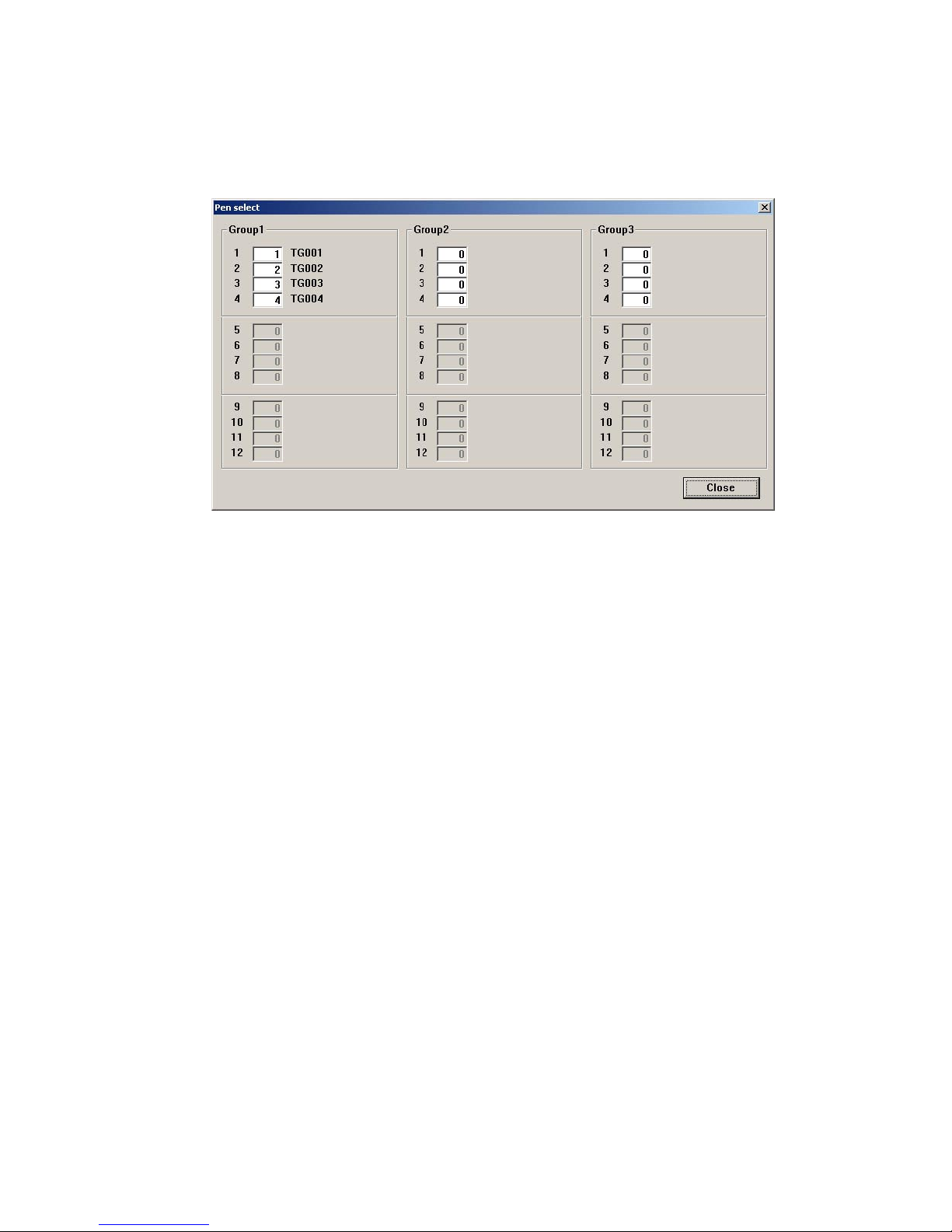

2.4.16 PEN SELECT

Pen Select is used to assign signal channels to be plotted on the screen (Figure 9).

Max. 36 pens (three groups) can be plotted on the screen except that it is limited to 12 pens when the storing rate

and/or display rate are set to 0.5 sec.

Enter the channel No. in the field and the tag name for the pen is indicated to the right. Enter 0 when you do not want

to assign any pen to the channel.

Figure 9: Pen select.

Page 17

13

7xETBLD USERS MANUAL EM-7353-0003C

2.5 FILE OPERATION BUTTONS

2.5.1 FILE READ

When you need a specific set of parameter settings, press [File read] and choose one of the parameter files saved

as in 2.5.2.

2.5.2 FILE WRITE

Parameters set on the 7xETBLD can be saved in a file with user-specified file name (up to 8 characters).

Parameter contents uploaded from the 7xET also can be saved in the same manner.

When you use a file created on the 7xETBLD for the 7xET, the file name must be 7xET.7xPA. Add .7xP A at the end

of the file name.

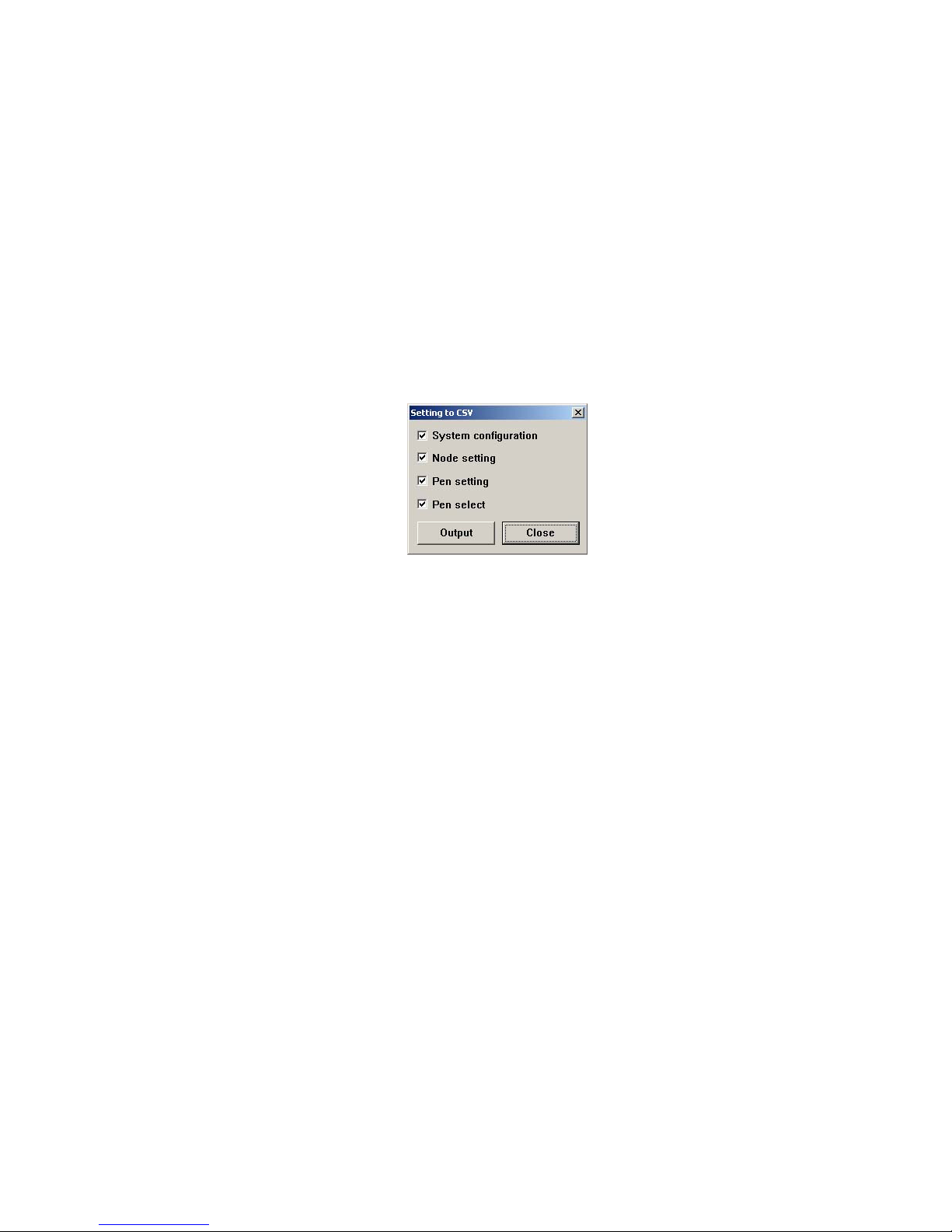

2.5.3 SETTING TO CSV

Parameters set on the 7xETBLD can be saved in the CSV format.

Parameter contents uploaded from the 7xET also can be saved in the same manner.

Pressing [Setting to CSV] opens up the window shown in Figure 10 on the screen.

Figure 10. Setting to CSV.

System configuration: Communication setting, Storing rate, Data storing method, Start mode,

Temperature unit, Data storing form, Digital display type, Display rate,

Chart speed, Digital display (auto hide), Graph (chart direction),

Data file used volume, Screen saver,

Node setting, Pen setting (common, analog, discrete, alarm)

Node setting: Node number and device

Pen configuration: Common pen setting, Analog pen setting, Analog alarm setting, Discrete pen and

alarm setting

Pen select Pen number and tag name

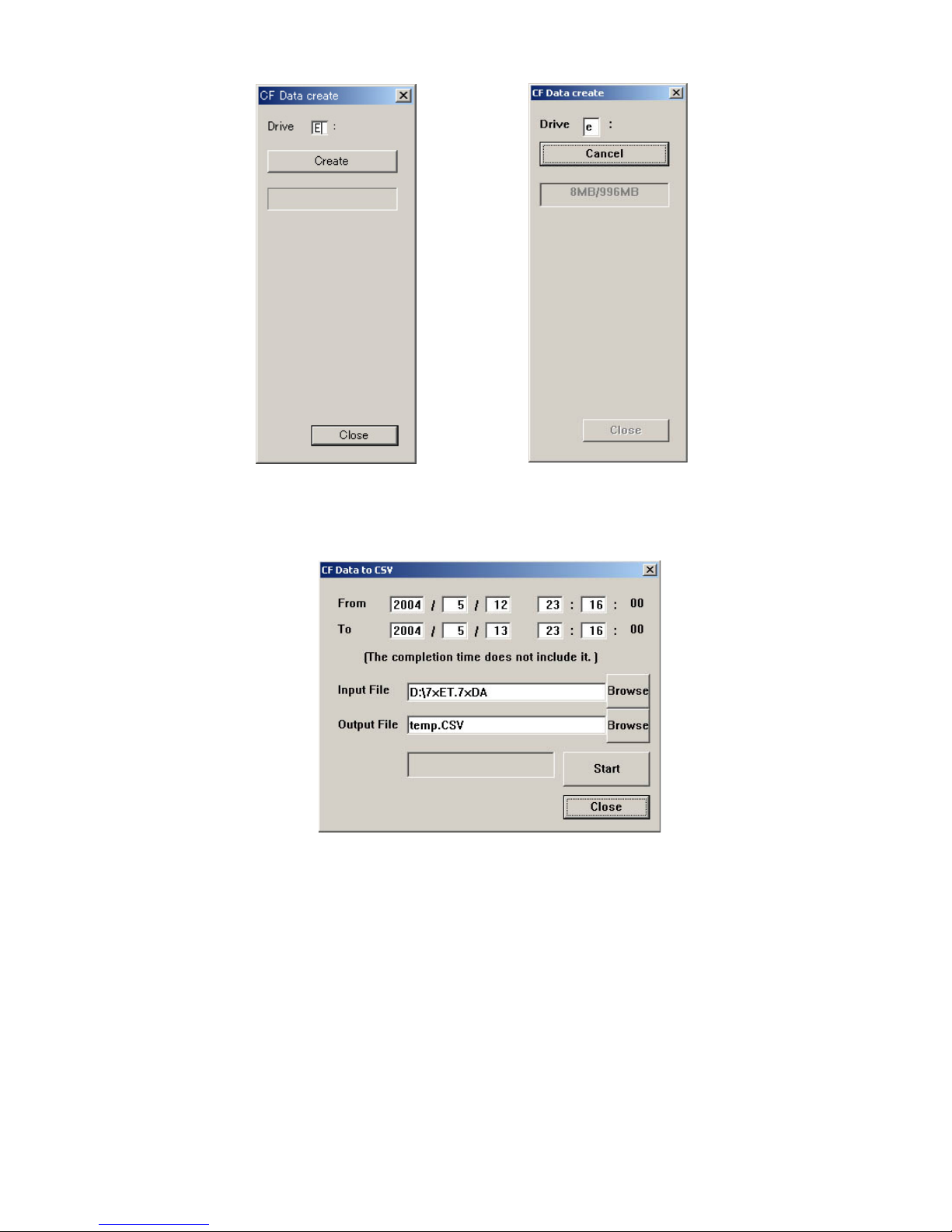

2.5.4 CF DATA CREATE

The 7xET automatically creates a data area dedicated to store data files when it starts up. It can also be created on

the PC using the 7xETBLD.

Press [CF Data create] and the window shown in Figure 11 appears on the screen.

Enter the drive ID where you have a CF Card and press [Create]. Then the window is replaced with the one shown

in Figure 12.

Pressing [Cancel] stops creating the file.

The field below the [Cancel] button shows two figures: file size to be created on the right, file size being created on

the left.

When the operation is complete, [Congratulations!] appears on the screen.

Page 18

14

7xETBLD USERS MANUAL EM-7353-0003C

Figure 11. CF Data create Figure 12. CF Data create in file creating process

2.5.5 CF DATA TO CSV

Pressing [CF Data to CSV] button opens the dialog box CF Data to CSV (Figure 13).

Figure 13: CF Data to CSV.

Insert the CF Card to a card reader.

Specify the date and time to start and stop reading. (Seconds cannot be specified.)

Specify in ‘Input File’ field the file name you want to convert.

Specify in ‘Output File’ field the directory path and the CSV file name.

Click [Start].

Remark 1: The data at the time index specified in ‘To’ field is Not included in the converted file. For example, if you

specify ‘T o 10:00:00’ with 1-minute storing rate, the data is converted up to 9:59:00. If you need the data at 10:00:00,

specify ‘To 10:01:00.’

Remark 2: Data stored in Float form are converted into values with two decimal points.

Page 19

15

7xETBLD USERS MANUAL EM-7353-0003C

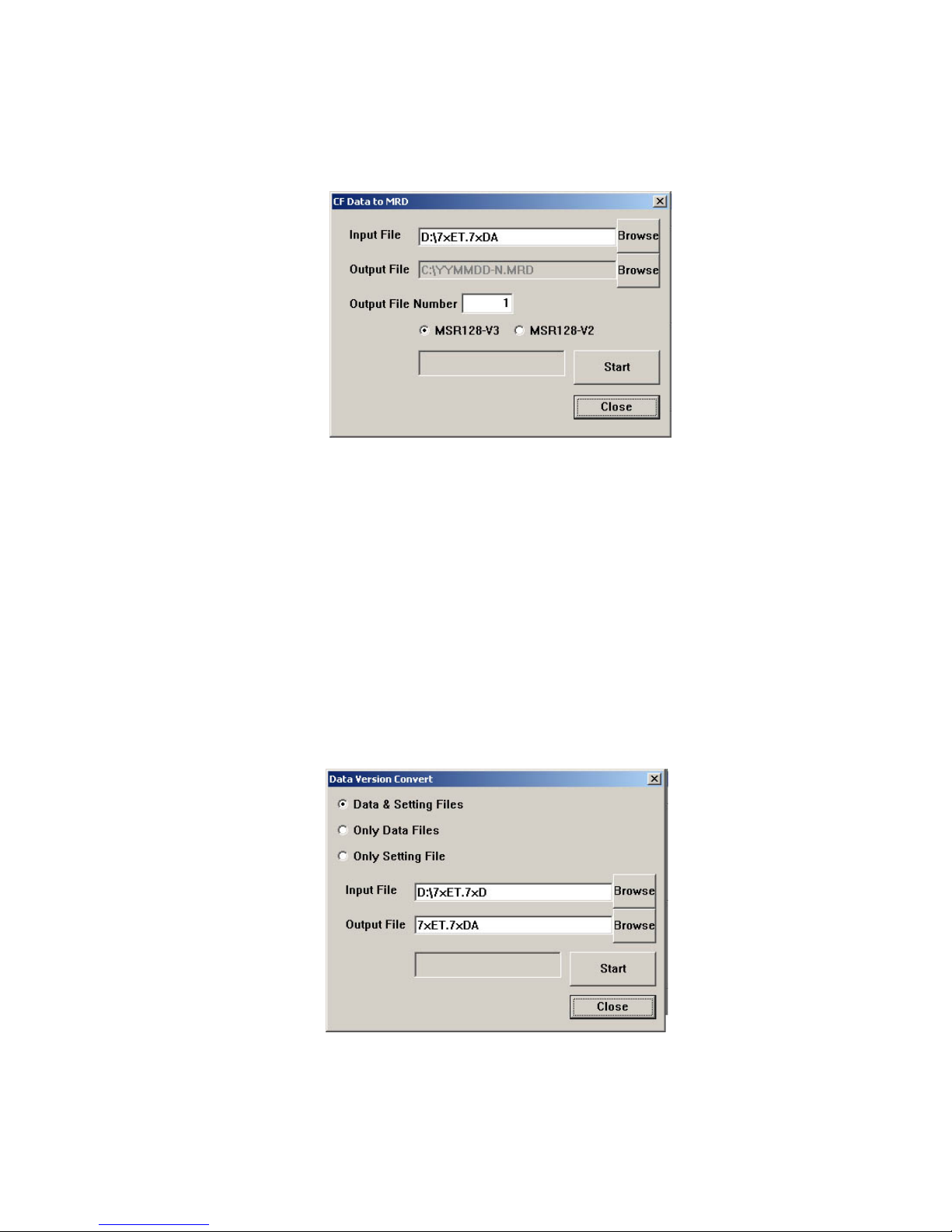

2.5.6 CF DATA TO MRD

Data stored by the 7xET can be converted into the format compatible with the MSR128-V2 or MSR128-V3 (MRD

File) so that the data can be displayed on the MSR128 software.

This procedure is not required for the MSR128-V4.

Pressing [CF Data to MRD] button opens the dialog box CF Data to MRD (Figure 14).

Figure 14: CF Data to MRD.

Insert the CF Card to a card reader.

Specify in ‘Input File’ field the 7xET file name you want to convert.

Specify in ‘Output File’ field the directory path where the converted MRD file is to be saved.

Specify in ‘Output File Number’ the number to be added at the end of the new file name (‘N’ of the file name based

on the date ‘YYMMDD-N.’) N = 1 through 9999.

Choose the target MSR128 software version.

Click [Start].

2.5.7 DATA VERSION CONVERT

The 7xET creates/uses three types of file: Data File, Setting File and Control File.

The older version files can be converted into the new version files compatible with the 7xET/0003 (73ET V er.6.00x,

74ET Ver.3.00, 75ET Ver.3.00).

73ET Ver.4.0x, 74ET Ver.1.0x, 75ET Ver.1.0x

(1) Pressing [Data Version Convert] button opens the dialog box Data Version Convert (Figure 15).

Figure 15: Data Version Convert.

Page 20

16

7xETBLD USERS MANUAL EM-7353-0003C

(2) Specify the type of files you want to convert.

Data & Setting Files: All files stored in the 7xET are converted.

Only Data Files: Data Files and Control File are converted.

Only Setting File: Only the Setting File is converted.

(3) Specify in ‘Input File’ field the 7xET file name you want to convert. If you have selected ‘Data & Setting Files’ to

be converted, specify only the data file name.

(4) Specify in ‘Output File’ field the directory path and the file name.

(5) Click [Start]. When the message “” disappears, the conversion of Data File and Control File is complete. For the

Setting File, go through the following procedure.

(6) Click [File Read] and upload the Setting File.

(7) Click [File Write] to store the file again. Now the file is compatible with the 7xET/0003.

73ET Ver.5.0x, 74ET Ver.2.0x, 75ET Ver.2.0x

There is no need of converting Data and Control files. Go through the above procedure (6) and (7) to convert the

Setting file.

2.6 ONLINE OPERATION BUTTONS

Online Operation Buttons are accessible only when the 7xET is connected to a PC installed with the 7xETBLD via

Ethernet. Before using these functions, confirm that an appropriate IP address is set to the 7xET.

2.6.1 UPLOAD

The 7xETBLD can read the current settings on the 7xET. Enter IP address of the 7xET in ‘Communication setting’

and press [Upload] button. When the upload is successfully done, ‘Congratulations!’ appears on the screen. Uploading

can be executed only while recording is stopped.

2.6.2 DOWNLOAD (All)

Pressing [Download] button downloads the current settings configured on the 7xETBLD to the 7xET. When the

download is successfully complete, ‘Congratulations!’ appears on the screen. Downloading can be executed only

while recording is stopped.

2.6.3 DOWNLOAD (Runtime)

The following parameters, runtime programmable items, can be downloaded even while recording.

Digital display pen numbers

Digital display

Graph

Screen saver

Pen color (Pen setting, common)

Wide line (Pen setting, common)

Plot range (Pen setting, analog)

Logarithmic plot position exponent (Pen setting, analog)

Pen setting (analog alarm)

Pen setting (discrete alarm)

Display pens setting

When the download is successfully complete, ‘Congratulations!’ appears on the screen.

2.6.4 REMOTE START / STOP

You can remotely start / stop the 7xET with these control buttons. When you need to change and download settings,

the 7xET can be stopped at any time.

Page 21

17

7xETBLD USERS MANUAL EM-7353-0003C

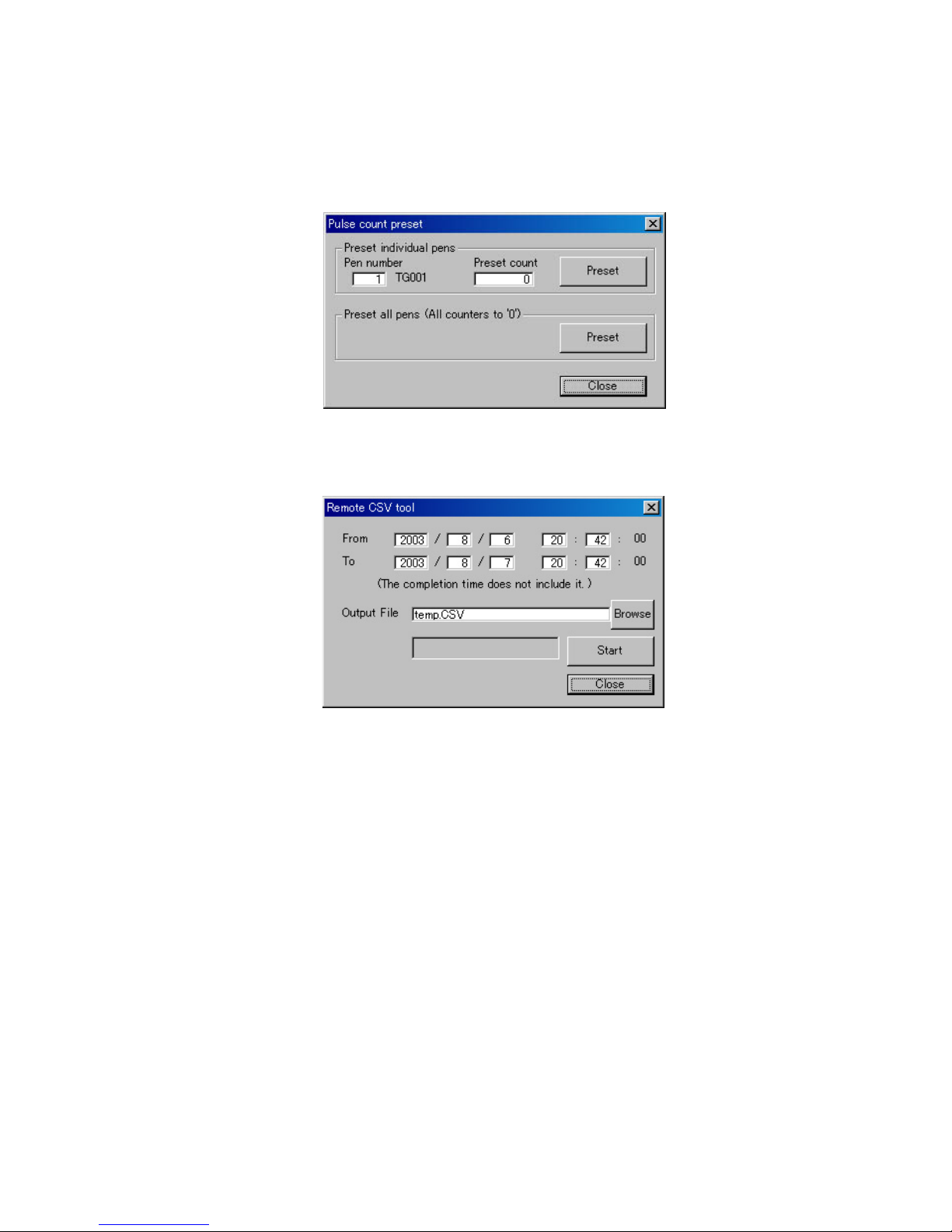

2.6.5 PULSE COUNT PRESET

The accumulated count data on the R1M-P4 can be reset to preset values on the 7xETBLD menu.

Click [Pulse Count Preset] to open the dialog box to open the Pulse Count Preset (Figure 16).

Preset individual pens: Specify the pen number and desired preset value and click Preset, and the R1M-P4

data for the specific channel are reset.

Preset all pens: Used to reset all count values to zero.

Figure 16: Pulse count preset.

2.6.6 REMOTE CSV TOOL

‘CF Data to CSV’ file conversion can be executed also via Ethernet.

Figure 17: Remote CSV Tool.

Specify the date and time to start and stop reading. (Seconds cannot be specified.)

Specify in ‘Output File’ field the directory path and the CSV file name.

Click [Start].

Remark 1: The data at the time index specified in ‘To’ field is Not included in the converted file. For example, if you

specify ‘T o 10:00:00’ with 1-minute storing rate, the data is converted up to 9:59:00. If you need the data at 10:00:00,

specify ‘To 10:01:00.’

Remark 2: Data stored in Float form are converted into values with two decimal points.

Page 22

18

7xETBLD USERS MANUAL EM-7353-0003C

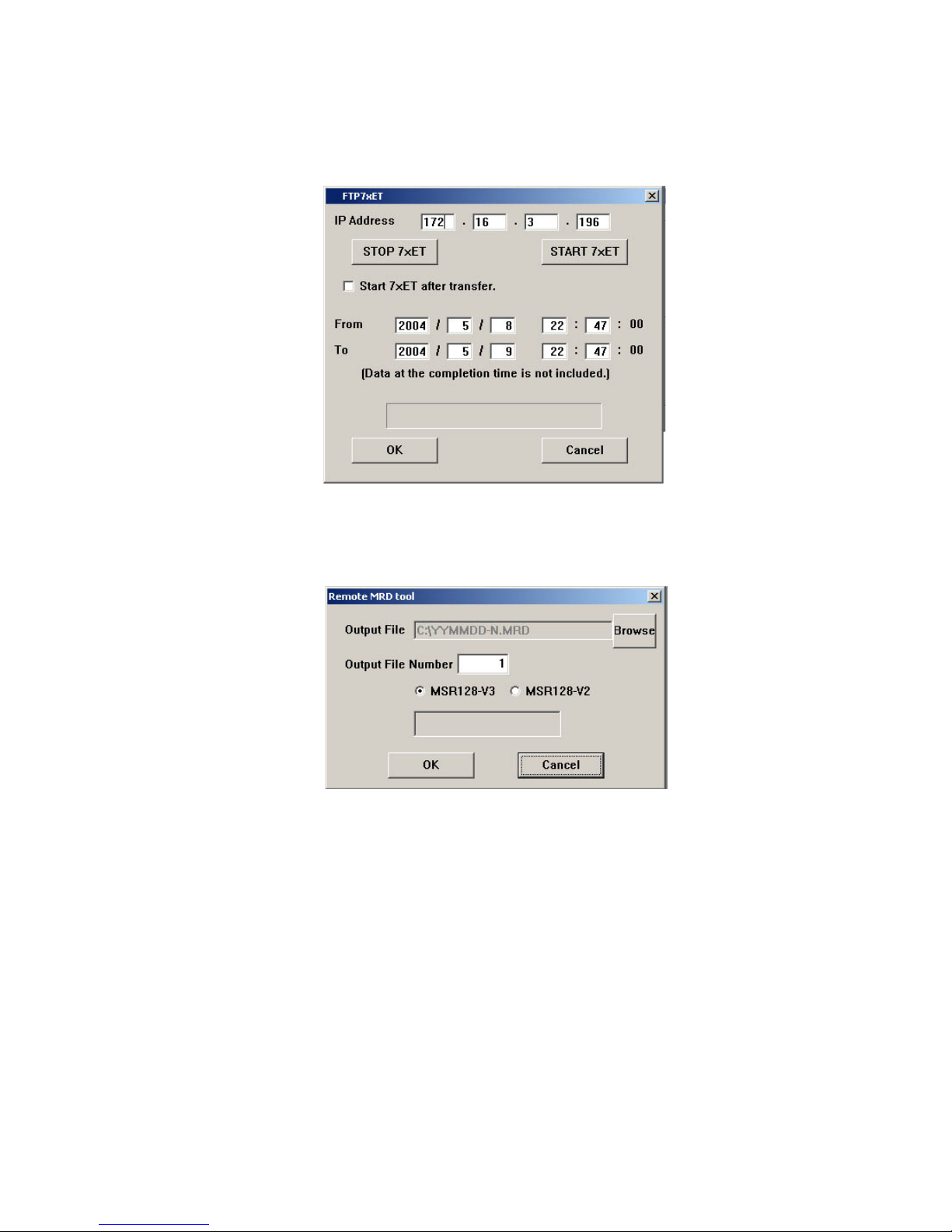

2.6.7 REMOTE MRD TOOL

‘CF Data to MRD’ file conversion can be executed also via Ethernet.

Data stored by the 7xET can be converted into the format compatible with the MSR128-V2 or MSR128-V3 (MRD

File) so that the data can be displayed on the MSR128 software.

This procedure is not required for the MSR128-V4.

Figure 18: FTP7xET.

Specify the IP address of the 7xET where the data is stored.

Specify the date and time to start and stop reading. (Seconds cannot be specified.)

Click [OK] starts file transfer. When the transfer is complete, ‘Remote MRD Tool’ window appears on the screen.

Figure 19: Remote MRD Tool.

Specify in ‘Output File’ field the directory path where the converted MRD file is to be saved.

Specify in ‘Output File Number’ the number to be added at the end of the new file name (‘N’ of the file name based

on the date ‘YYMMDD-N.’) N = 1 through 9999.

Choose the target MSR128 software version.

Click [OK].

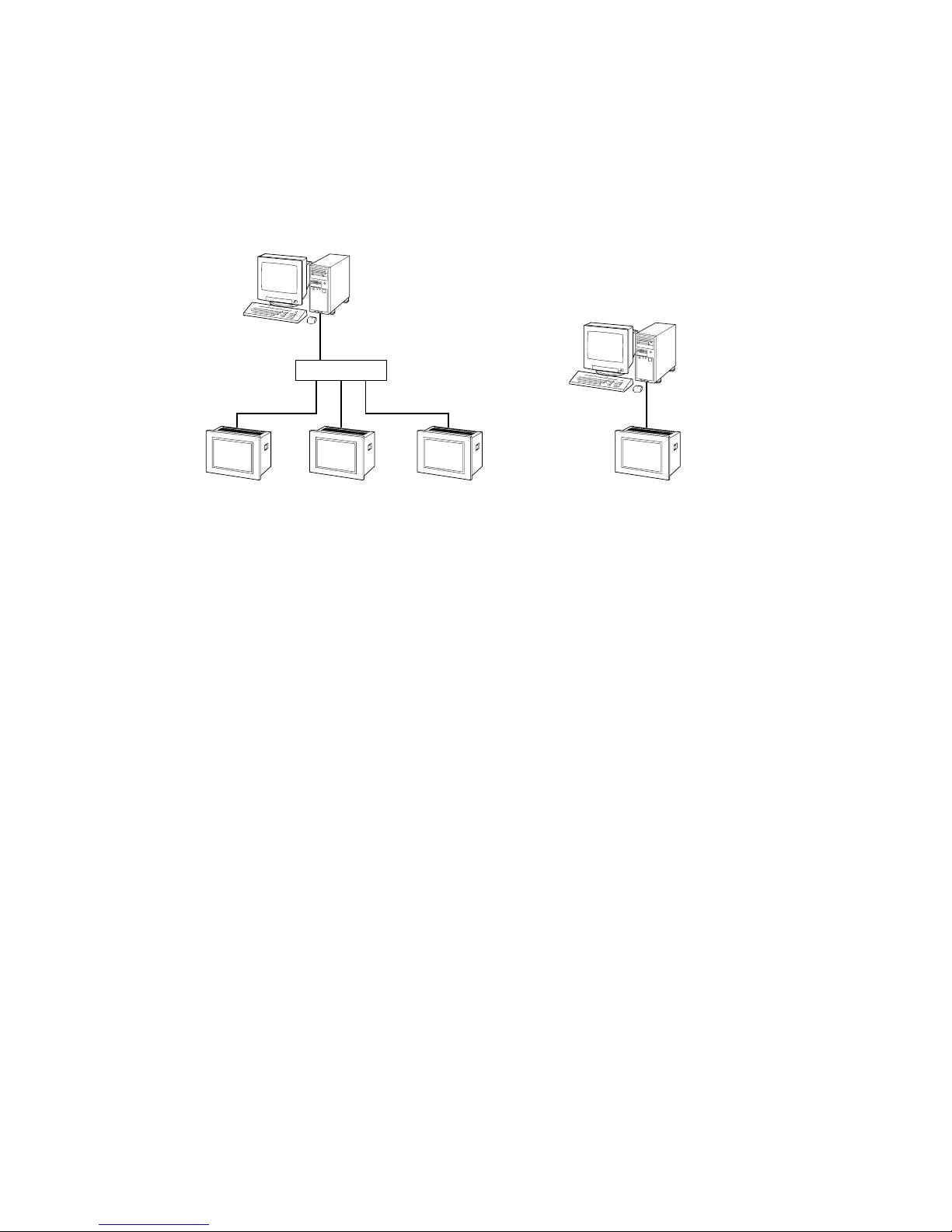

APPENDIX-A ETHERNET CABLE

Different cable types are used depending on how the 7xET and the PC installed with the 7xETBLD are connected via

Ethernet.

CONNECTION VIA ETHERNET HUB/SWITCH

Use a ‘Straight Through’ cable between each device and the hub. (Figure A-1)

DIRECT CONNECTION

Use a ‘Crossover’ cable between the PC and the 7xET. (Figure A-2)

Figure A-1. Figure A-2.

If the 7xETBLD shows “Connect Error” saying Ethernet connection is unavailable, confirm the connection on the

Windows MS-DOS.

Confirm Connect Error type

Page 23

19

7xETBLD USERS MANUAL EM-7353-0003C

7xET

Ethernet

Straight Through Cable

Ethernet

Straight Through Cable

7xET7xET

Hub / Switch

7xET

Ethernet

Crossover Cable

Page 24

20

7xETBLD USERS MANUAL EM-7353-0003C

Page 25

1. What is covered.

M-System Co., Ltd. (“M-System”) warrants, only to the original

purchaser of new M-System products purchased directly from MSystem, or from M-System’s authorized distributors or resellers, for its

own use not for resale, that the M-System products shall be free from

defects in materials and workmanship and shall conform to the specifications set forth in the product catalogue applicable to the M-System

products for the Warranty Period (see Paragraph 5 below for the

Warranty Period of each product).

THE ABOVE WARRANTY IS THE ONLY WARRANTY APPLICABLE TO THE M-SYSTEM PRODUCTS AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.

2. What is not covered.

This warranty does not cover any M-System product which has been:

(1) modified, altered or subjected to abuse, misuse, negligence or

accident; (2) improperly installed or installed in conjunction with any

equipment for which it was not designed; or (3) damaged or destroyed

by disasters such as fire, flood, lightning or earthquake.

In no event shall M-System be liable for any special, incidental, consequential or other damages, costs or expenses (including, but not limited

to, loss of time, loss of profits, inconvenience or loss of use of any

equipment).

3. Remedies.

If a defective product is returned to M-System in accordance with the

procedures described below, M-System will, at its sole option and

expense, either: (1) repair the defective product; (2) replace the

defective product; or (3) refund the purchase price for the defective

product paid by the purchaser. Except as otherwise provided by

applicable state law, these remedies constitute the purchaser’s sole and

exclusive remedies and M-System’s sole and exclusive obligation under

this warranty.

M-SYSTEM WARRANTY

4. Warranty Procedure.

If the purchaser discovers a failure of the M-System products to

conform to the terms of this warranty within the Warranty Period, the

purchaser must promptly (and, in any event not more than 30 days after

the discovery of such failure) notify the relevant party as described

below either by telephone or in writing at the below address to obtain an

Authorized Return (AR) number and return the defective product to the

relevant party. The designated AR number should be marked on the

outside of the return package and on all correspondence related to the

defective product. The purchaser shall return, at purchaser’s expense,

defective products only upon receiving an AR number. In order to avoid

processing delays, the purchaser must include: copies of the original

purchase order and sales invoice; the purchaser’s name, address and

phone number; the model and serial numbers of the returned product;

and a detailed description of the alleged defect.

5. Warranty Period.

Signal Conditioner: 36 months from the date of purchase.

M-Rester: 12 months from the date of purchase.

Valve Actuator: 18 months from the date of shipment from

M-System or 12 months from the date of its

installation, whichever comes first.

Other Products: 36 months from the date of purchase.

M-SYSTEM CO., LTD.

5-2-55, Minamitsumori, Nishinari-ku,

Osaka 557-0063 JAPAN

Phone: (06) 6659-8201

Fax: (06) 6659-8510

E-mail: info@m-system.co.jp

Page 26

1

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

PAPERLESS RECORDING SYSTEM

TOUCH PANEL

PAPERLESS RECORDER

Model: 73ET / 74ET / 75ET

Users Manual

Page 27

2

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

Contents

1. GENERAL DESCRIPTIONS ........................................................................ 4

1.1 7xET FEATURES & FUNCTIONS ............................................................................................... 4

1.2 SYSTEM CONFIGURATIONS ..................................................................................................... 6

1.3 HARDWARE SPECIFICATIONS ................................................................................................. 7

1.3.1 SYSTEM COMPONENTS................................................................................................ 7

1.3.2 COMPONENT IDENTIFICATION ..................................................................................... 7

1.4 INSTALLATION............................................................................................................................ 9

1.4.1 INSTALLATION REQUIREMENTS .................................................................................. 9

1.4.2 PANEL CUTOUT (unit: mm) ........................................................................................... 10

1.4.3 INSTALLATION PROCEDURE ....................................................................................... 11

1.5 I/O MODULES ........................................................................................................................... 12

1.5.1 INPUT DEVICE SELECTIONS ...................................................................................... 12

1.5.2 CONNECTING I/O MODULES TO THE 7xET ............................................................... 12

1.5.3 CONFIGURING THE R1M, R2M & RZMS-U9 MODULES ............................................ 14

1.6 CF CARD ................................................................................................................................... 16

1.6.1 HOW TO INSERT AND REMOVE THE CF CARD......................................................... 17

1.6.2 REPLACING THE CF CARD ......................................................................................... 17

2. STARTING UP THE 7xET.......................................................................... 18

2.1 MENU OPTIONS ....................................................................................................................... 18

2.2 USING A BLANK CF CARD FOR 74ET & 75ET ....................................................................... 19

2.3 STARTING UP ........................................................................................................................... 19

3. SETTING THE 7xET .................................................................................. 20

3.1 COMMUNICATION SETTING ................................................................................................... 20

3.2 STORING RATE ........................................................................................................................ 20

3.3 DISPLAY RATE.......................................................................................................................... 21

3.4 CHART SPEED ......................................................................................................................... 21

3.5 GRAPH ...................................................................................................................................... 21

3.6 DIGITAL DISPLAY TYPE........................................................................................................... 21

3.7 DIGITAL DISPLAY ..................................................................................................................... 22

3.8 START MODE............................................................................................................................ 22

3.9 TEMPERATURE UNIT .............................................................................................................. 22

3.10 DATA STORING FORM ............................................................................................................. 22

3.11 SCREEN SAVER....................................................................................................................... 23

3.12 DATE TIME................................................................................................................................ 23

3.13 DATA FILE USED VOLUME SETTING ..................................................................................... 23

3.14 CJC (Cold Junction Compensation) SETTING .......................................................................... 24

3.15 DATA STORING METHOD ........................................................................................................ 24

3.15.1 TRIGGER (A) STORING MODE (REMOTE TRIGGER) ................................................ 25

3.15.2 TRIGGER (B) STORING MODE (EVENT RECORDING).............................................. 26

3.15.3 AUTO STORING MODE ................................................................................................ 26

3.16 NODE SETTING ........................................................................................................................ 27

Page 28

3

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

3.17 PEN SETTING ........................................................................................................................... 28

3.17.1 PEN SETTING (COMMON) ........................................................................................... 28

3.17.2 PEN SETTING (ANALOG) ............................................................................................. 30

3.17.3 PEN SETTING (ANALOG ALARM) ................................................................................ 35

3.17.4 PEN SETTING (DISCRETE) .......................................................................................... 36

3.17.5 CONFIRMING CHANGES ............................................................................................. 37

4. RECORD .................................................................................................... 38

4.1 TREND VIEW ............................................................................................................................ 38

4.1.1 PEN PANEL ................................................................................................................... 38

4.1.2 CHART ........................................................................................................................... 39

4.1.3 DIGITAL DISPLAY.......................................................................................................... 40

4.1.4 CONTROL BUTTONS.................................................................................................... 41

4.2 OVERVIEW ............................................................................................................................... 42

4.2.1 GROUP & TIME INDICATOR......................................................................................... 42

4.2.2 DATA INDICATORS ........................................................................................................ 43

4.2.3 CONTROL BUTTONS.................................................................................................... 44

4.3 BARGRAPH............................................................................................................................... 44

4.3.1 GROUP & TIME INDICATOR......................................................................................... 45

4.3.2 BARGRAPH ...................................................................................................................45

4.3.3 DIGITAL DISPLAY.......................................................................................................... 46

4.3.4 CONTROL BUTTONS.................................................................................................... 46

4.4 TRIPLE VIEW (74ET & 75ET only) ........................................................................................... 47

5. RETRIEVE.................................................................................................. 48

6 ALARM HISTORY ...................................................................................... 51

7 R5/R3 SERIES I/O MODULES................................................................... 53

7.1 R5-NM1 ..................................................................................................................................... 53

7.1.1 CONFIGURING THE R5-NM1 HARDWARE ................................................................. 53

7.1.2 CONNECTING TO THE 7xET ........................................................................................ 54

7.1.3 SETTING UP THE 7xET SPECIFICALLY FOR R5 SERIES .......................................... 55

7.2 R3-NM1 ..................................................................................................................................... 57

7.2.1 CONFIGURING THE R3-NM1 HARDWARE ................................................................. 57

7.2.2 CONNECTING TO THE 7xET ........................................................................................ 58

7.2.3 SETTING UP THE 7xET SPECIFICALLY FOR R3 SERIES .......................................... 59

8. FILE ............................................................................................................ 61

8.1 7xET FILES ............................................................................................................................... 61

8.2 DATA STORAGE TIME.............................................................................................................. 62

APPENDIX – 1. IP ADDRESS SETTING ........................................................................................... 63

APPENDIX – 2. BACKLIGHT FAILURE ............................................................................................. 63

APPENDIX – 3. VERSION INDICATION ............................................................................................ 63

Page 29

4

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

1. GENERAL DESCRIPTIONS

Thank you for choosing M-System’s Paperless Recording System.

The system consists of a 7xET Series Touch Panel Paperless Recorder, Models 73ET, 74ET and 75ET and RxM

Series I/O Modules, Models R1M and R2M. The 7xET Series, with its functions and operability similar to conventional chart recorders, can easily replace them. It is also a flexible and economical solution, in conjunction with

independent I/O modules which can accept either DC voltage/current, thermocouple, or RTD.

Data are stored electronically on a CF Card. Remote recording via Ethernet is also possible using the PC Recorder

Software MSR128.*

This users manual explains how to install the 7xET Series Recorder, connect to the RxM Series I/O Modules and

operate the Paperless Recorder Software on the 7xET Touch Panel.

If you intend to use the 7xET in the following environments or conditions, redundant and/or failsafe system designs

should be used to ensure the proper degree of reliability and safety.

- Environments or conditions which are not defined in this manual

- Nuclear power control devices, railway control devices, aircraft control devices, transportation vehicles,

fuel control equipment, medical equipment, recreational equipment, safety equipment, and other critical

equipment for which safety must be secured according to relevant laws.

- Those devices which inherently require extremely high level of safety and reliability.

*Explanations regarding the MSR128 given in this manual are applicable to the MSR128-V4, Ver 4.00 or higher. For using the MSR128-V4

or even the MSR128 of earlier versions, refer to respective users manuals.

■ COMPACT FLASH (CF) CARD

A CF Card is required to start up the 7xET.

M-System will not guarantee the product’s described performance if a CF Card other than purchased from M-

System, or specified below, is used.

Recommended CF Card: Manufacturer: Hagiwara Sys-Com

Model No.: MCF10P-xxxxS (Alternative Model No. CFI-xxxxDG)

Capacity: 128 MB through 512 MB

1.1 7xET FEATURES & FUNCTIONS

Model 7xET is a touch panel display, installed with M-System’s Paperless Recorder Software. The Windows-CE

based recording/logging system is most suitable for exporting data to other Windows based applications, such as

Microsoft Excel.

The 7xET transfers, in real time via Ethernet, data from local I/O modules connected via Modbus RTU to a host PC

installed with the MSR128 PC Recorder Software. It can also store data in a CF card, portable and usable on an

independent PC for later analysis.

■ DATA RECORDING FUNCTIONS

Number of channels: Max. 128 points from I/O modules connected via RS-232C (Modbus RTU) and expanded

via RS-485

Sampling rate: 0.5 sec.

Storing rate: 0.5 sec., 1 sec., 2 sec., 5 sec., 10 sec., 1 min., or 10 min.

Data form: Binary, floating or short integer

Data storage: CompactFlash (CF) Card

■ DATA DISPLAY FUNCTIONS

• Trend View — Shows data stored in real time on the trend graphs.

Display channels*1: Max. 12 points per view

Display rate: 0.5 sec. or 2 sec.

Chart direction: Vertical or horizontal

Data type: High speed, middle speed, low speed or very low speed

Number of display views: 3 views

Page 30

5

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

• Overview — Shows real-time data for all channels.

Display channels: 32 points

Display rate: 0.5 sec. or 2 sec.

Data display items: Analog: Tag name, alarm status, momentary value (bargraph)

Discrete: Tag name, alarm status, momentary value

Detailed data display: Analog: Tag name, momentary value (bargraph + digital indicator), alarm event date/time

(trigger & reset)

Discrete: Tag name, momentary value, alarm event date/time

Used data file volume: Unused data file volume can be indicated.

Number of display views: 4 views

• Bargraph View — Shows data stored in real time on the bargraphs.

Display channels*1: Max. 12 points per view

Display rate: 0.5 sec. or 2 sec.

Bar direction: Vertical or horizontal

Number of display views: 3 views

• Retrieve View — Shows data stored in the CF Card.

Number of display views: 3 views

Time index search: By scrolling the window or by specifying the time index

Engineering unit indicators: When a part of the screen for a specific time index is touched, digital indicators appear on

the screen indicating the data at the specified time.

• Alarm History — Shows alarm event information.

Number of display views: 1 view

Displayed events: 16 events

Data display items: Alarm event date/time (trigger & reset), tag name, pen No., alarm message

Search: By scrolling the window or by specifying the time index

Accept: Individual or all events

Update: Automatic or manual

• Triple View (available with the 74ET and the 75ET only) — Shows Trend, Overview and Alarm History on

the same screen.

• Settings View

■ ALARM

Alarm setting: Analog: Upper (high) and lower (low) alarm setpoints are selectable for each channel.

Discrete: ON or OFF bit status alarm for each channel.

Deadband: Analog: Deadband (hysteresis) is selectable in engineering unit value.

Discrete: Delay time can be specified.

Alarm history record: Stored in the CF Card: Date/time of alarm events (trigger & reset), tag name and pen No.,

alarm message

■ ETHERNET CONNECTIVITY

Ethernet communication: Transmits data of specific channels stored in real time to a host PC installed with the PC

Recorder Software Model MSR128*

2

.

Configurator software (model: 7xETBLD)*2 can be used to set the 7xET parameters.

Number of host PC: Max. 2 PCs

*1. Number of channels depends upon the storing interval and the display interval. The number is limited to four (4)

when either the storing rate or the display rate is set to 0.5 seconds.

*2. Refer to the respective instruction manuals included in the CD-ROM for detailed information.

CAUTION !

Data record may miss certain number of samples if the Ethernet cable is disconnected and reconnected during

recording. Be sure to secure the cable during recording.

Page 31

6

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

1.2 SYSTEM CONFIGURATIONS

■R1M, R2M, RZMS

RS-232C

PC Recorder

(model: R1M-GH

or R1MS-GH3)

PC Recorder

(model: R1M-D1)

PC Recorder

(model: R1M-P4)

RS-485

PC Recorder

(model: R1M-A1)

RS-232C

Interlink / Reverse

Cable

PC Recorder

(model: R2M)

RS-232C/RS-485

Converter

(model: R2K-1)

Insert an RS-232C/RS-485 Converter for isolation

to expand the RS-485 line to a long distance.

PC Recorder

(model: RZMS-U9)

Paperless Recorder

(model: 73ET, 74ET, 75ET)

■MONITORING AT THE MSR128-V4 VIA ETHERNET

Paperless Recorder

(models: 73ET, 74ET, 75ET)

RS-485

Ethernet

PC Recorder

(model: R1M-GH)

PC Recorder

(model: R1M-A1)

PC Recorder

(model: R1M-D1)

RS-232C/RS-485 Converter

(model: R2K-1)

Card Reader

CF Card

■READING DATA FROM CF CARD AT THE MSR128-V4

Paperless Recorder

(models: 73ET, 74ET, 75ET)

RS-485

PC Recorder

(model: R1M-GH)

PC Recorder

(model: R1M-A1)

PC Recorder

(model: R1M-D1)

RS-232C/RS-485 Converter

(model: R2K-1)

Page 32

7

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

1.3 HARDWARE SPECIFICATIONS

1.3.1 SYSTEM COMPONENTS

■ PAPERLESS RECORDERS (OS: Windows CE 3.0)

73ET: 5.7-inch Touch Panel Unit

74ET: 7.4-inch Touch Panel Unit

75ET: 12.1-inch Touch Panel Unit

■ ACCESSORIES INCLUDED IN THE PRODUCT PACKAGE

Paperless Recorder Software Package (model: CHARTLSP2)

Installation Fasteners

■ ACCESSORIES & RELATED PRODUCTS

Panel Mount Adaptors (for DIN-size panel cutout)

For 73ET: Model A-73

For 74ET: Model A-74

For 75ET: Model A-75

PC Recorder I/O Modules (R1M, R2M and RZMS Series)

Remote I/O Modules (R3 and R5 Series)

1.3.2 COMPONENT IDENTIFICATION

■ 73ET

■FRONT VIEW

■REAR VIEW

■RIGHT SIDE VIEW

Touch Panel

Switching screens, controls

Power Terminals

10BASE-T

Modular Jack

Ethernet interface

■LEFT SIDE VIEW

Power Indicator LED

ON with power supplied.

CF Card Slot

CompactFlash Card interface

RS-232C Connector

I/O interface

FG

–+

FG

NL

Page 33

8

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

■ 74ET

■FRONT VIEW

■REAR VIEW

■LEFT SIDE VIEW

10BASE-T Modular Jack

Ethernet interface

Touch Panel

Switching screens, controls

CF Card Slot

CompactFlash Card interface

Status Indicator LED

Green: Power ON/Normal

(Red to Green at startup)

Orange: Backlight failure

Red: System error

Serial Interface (COM1, COM2)

RS-232C connector (COM2 unused)

Power Terminals

Connect to 24V DC

Unidentified connectors and sockets are unused.

Page 34

9

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

■ 75ET

1.4 INSTALLATION

1.4.1 INSTALLATION REQUIREMENTS

•For easy maintenance, operation and sufficient ventilation, at the minimum of 100 mm must be observed between

the 7xET unit and adjacent structures or equipment.

Figure 1.4.1a: Maintenance space requirements.

■BOTTOM VIEW

■REAR VIEW

■LEFT SIDE VIEW ■FRONT VIEW

Touch Panel

Switching screens, controls

Status Indicator LED*

Green: Power ON/Normal

(Red to Green at startup)

Orange: Backlight failure

Red: System error

Serial Interface (COM1, COM2)

RS-232C connector (COM2 unused)

Power Terminals

CF Card Slot

CompactFlash Card interface

10BASE-T Modular Jack

Ethernet interface

*Located behind the panel

mount adaptor (if used).

Unidentified connectors and sockets are unused.

100 mm

100 mm

100 mm

100 mm

100 mm

100 mm 100 mm

Paperless Recorder

Page 35

10

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

• Ambient temperature: 0 to 50°C (except for 73ET for 0 to 45°C)

Ambient humidity: 30 to 85% RH

Ambient temperature refers to both the temperatures behind the panel and over the panel.

•We recommend to mount the 7xET on a vertical panel. With a slanted panel, the 7xET must not incline more than 30

degrees from the vertical. If the 7xET is to be installed in greater angle, use a forced-air cooling system to maintain

the ambient temperature lower than 50°C.

Figure 1.4.1b: Mounting angle.

• Horizontal (rotated) installation is not allowed.

1.4.2 PANEL CUTOUT (unit: mm)

■ 73ET ■ 74ET

■ 75ET

30°30

°

30° or less

from vertical

156

Panel thickness: 1.6 – 10.0 mm

123.5

+1

0

+1

0

4–R3 max.

Panel thickness: 1.6 – 10.0 mm

204.5

+1

0

159.5

+1

0

4–R3 max.

Panel thickness: 1.6 – 10.0 mm

227.5

+1

0

4–R3 max.

301.5

+1

0

Page 36

11

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

1.4.3 INSTALLATION PROCEDURE

■ INSTALLATION GASKET

The 7xET unit should always be installed using the pre-fitted installation gasket, even at locations where water

resistance is not required.

The installation gasket must be installed properly to ensure a sufficient water-resistance level.

When properly installed, the gasket uniformly extends approximately 2 mm out of the groove.

■ INSTALLING THE 7xET ONTO THE PANEL

1. Insert the 7xET unit into the cutout section of the panel with the touch screen facing outward.

2. Insert the installation fastener hooks into the four (4) insertion slots, two (2) on the top and two (2) on the bottom.

3. Slide the fastener toward the rear of the 7xET.

4. Slowly tighten each fastener attachment screw in sequence until all fasteners are evenly and securely tightened.

The appropriate torque for tightening an attachment screw is 0.5 N·m.

For use with Panel Mount Adaptors (models: A-73, A-74, A-75), refer to the respective instructions.

■ CONNECTING TO THE POWER SOURCE

WARNING !

Turn the main power supply off prior to connecting the 7xET power terminals. Failure to do so may result in an

electrical shock.

CAUTION !

Observe the operational voltage range as indicated below . Supplying any other le vel of po wer can damage the 7xET

unit or the power source.

73ET 100 – 240V AC rating: Operational voltage range 85 – 264V AC

24V DC rating: 24V DC ±10%

74ET 24V DC rating: 24V DC ±20%

75ET 24V DC rating: 24V DC ±20%

• Power Supply Cable

To reduce line-to-line and line-to-ground noise as much as possible, use a low-noise power supply.

The wires for the 7xET’s power supply, I/O devices, and any motor-driven equipment must be installed separately.

To increase the noise resistance, use a twisted-pair cable for power supply.

Do not bind together or place near each other the main circuit cables (high voltage and high current), I/O signal

cables, and power supply cables.

To reduce noise, keep the power supply cables as short as possible.

• Grounding

Use a grounding resistance of less than 100Ω.

The grounding for the 7xET unit should be independent of other devices. Use exclusive grounding or a common

grounding point.

Insertion slots

Top view: Two more insertion slots at the bottom.

Installation panel

Hook

Page 37

12

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

• Wire Connection

Use thick wires (max. 2 mm

2

) for the power supply. Always start braiding close to the terminal ends.

Use the sleeve-type ring terminals as shown to the right.

Connection Procedure

1. Confirm that the mains supply is off.

2. Remove the ter minal block cover’s attachment screws.

3. Remove the ter minal block cover.

4. Remote the screws from the three (3) middle terminals.

5. Align the power wires (braided) and the grounding (FG).

6. Re-insert and tighten the terminal screws. (Torque 0.5 – 0.6 N·m)

7. Reattach the terminal block cover and tighten its screws. (Torque 0.5 – 0.6 N·m)

1.5 I/O MODULES

1.5.1 INPUT DEVICE SELECTIONS

Table 1.5.1 shows a list of usable I/O modules for the 7xET.

Table 1.5.1: I/O modules usable with the 7xET.

1.5.2 CONNECTING I/O MODULES TO THE 7xET

I/O modules directly next to the 7xET are connected via RS-232C. (Use COM1 only for the 74ET and the 75ET.)

Tables 1.5.2a and 1.5.2b show the RS-232C connector pin assignments.

Table 1.5.2a: 73ET pin assignment. Table 1.5.2b: 74ET and 75ET pin assignment.

max.

6.0 mm

min. ø3.2 mm

1

5

6

9

ABBR.

PIN NO. EXPLANATION OF FUNCTION

1 Not Used.

BB (RD) 2 Received Data

BA (SD) 3 Transmitted Data

CD (ER) 4 DTE Ready

AB (SG) 5 Signal Common

CF (CD) 6 Received Line Signal Detector

CA (RS) 7 Request to Send

CB (CS) 8 Clear to Send

9 Do Not Connect.

ABBR.

PIN NO. EXPLANATION OF FUNCTION

CF (CD) 1 Received Line Signal Detector

BB (RD) 2 Received Data

BA (SD) 3 Transmitted Data

CD (ER) 4 DTE Ready

AB (SG) 5 Signal Common

CC (DR) 6 Data Set Ready

CA (RS) 7 Request to Send

CB (CS) 8 Clear to Send

CE (CI) 9 Calling Indicator

MODEL R1M R2M RZMS-U9 R3-NM1 R5-NM1

DC Voltage

R1M-GH2*

1,*2

R2M-2G3*

3

R3-SV R5-SV

Analog DC Current

R1MS-GH3*1,*

3

No R3-SS/-DS R5-SS/-DS

Input Thermocouple R2M-2H3*

3

RZMS-U9*1,*3R3-TS R5-TS

RTD R1M-J3 No R3-RS R5-RS

Potentiometer No No

CT No No No R3-CT No

PT No No No R3-PT No

Contact Input R1M-A1 No No R3-DA R5-DA

Contact Output

R1M-D1

No No R3-DC R5-DC

(open collector)

Pulse Input (totalizing counter)

R1M-P4

No No No No

R1M-A1C1

*1. Resistor module (model: REM3-250) is required to convert the current signal into voltage.

*2. Trigger contact input (1 point) is available.

*3. Trigger contact input (1 point) and alarm contact output (1 point) are available.

Page 38

13

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

The R1M/R2M is connected to 7xET’s COM port via a straight RS-232C cable included in the product package.

Second and more R1M, up to 15 in total, can be connected via RS-485 twisted-pair cables as shown in Figure 1.5.2.

When the line between the R1M and the PC needs to be extended via RS-485, insert an RS-232C/RS-485 converter

(model: R2K-1) to prevent noise interference and connect the converter to the PC via a straight RS-232C cable.

If you need to connect an R2M module with an R1M module on the RS-485 network, use an RS-232C interlink/

reverse cable.

Figure 1.5.2: System configuration example for the R1M/R2M series.

RS-485, Modbus RTU

RS-232C

straight

RS-485

RS-232C

Interlink/reverse

R1M-GH2

DC/TC INPUTS

16 points

1 trigger input

R2K-1

R2M-2H3

TC INPUTS

8 points

7xET

R1M-J3

RTD/POT INPUTS

8 points

R1M-A1

CONTACT INPUTS

32 points

R1M-D1

CONTACT OUTPUTS

(open collector)

32 points

Page 39

14

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

1.5.3 CONFIGURING THE R1M, R2M & RZMS-U9 MODULES

MODEL R1M-GH2

The Model R1M-GH2 needs hardware setting to specify the type/level of input signals.

Figure 1.5.3a: R1M-GH2 bottom view.

Table 1.5.3a: R1M-GH2 DIP switch setting.

SW311 SW305 SW304 SW303 SW302

SW405 SW404 SW403 SW402

SW301

O

N

2

1

3

4

5

6

7

8

SW702

SW702 is fixed to

the position 3.

DO NOT CHANGE.

SW411 SW401 SW308 SW307 SW306

SW408 SW407 SW406

O

N

2

1

3

4

5

6

7

8

INPUT SWITCHES SETTING NOTES

Thermocouple SW301 – SW308 (ch 1 – ch 8) Set to position "1." Attentuation OFF

SW401 – SW408 (ch 9 – ch 16)

SW311 (ch 1 – ch 8) OFF

SW411 (ch 9 – ch 16)

Voltage input, 0.8 V or less SW301 – SW308 (ch 1 – ch 8) Set to poisition "1." Attentuation OFF

SW401 – SW408 (ch 9 – ch 16)

SW311 (ch 1 – ch 8) ON

SW411 (ch 9 – ch 16)

Voltage input, above 0.8 V * SW301 – SW308 (ch 1 – ch 8) Set to position "3." Attentuation ON

SW401 – SW408 (ch 9 – ch 16)

SW311 (ch 1 – ch 8) ON

SW411 (ch 9 – ch 16)

*Factory default setting

Page 40

15

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

MODEL R1M-P4

The Model R1M-P4 needs hardware setting to specify the display type for either totalized or momentary value.

Figure 1.5.3b: R1M-P4 bottom view.

MODEL RZMS-U9

The Model RZMS-U9 needs hardware setting to specify the A/D conversion mode, service channel numbers, cold

junction compensation, line noise filter frequency , and burnout type for temperature inputs . Cold junction compensation could be specified on the 7xET program.

Switch Positions

1 through F: At the startup, the combination of settings as shown in the table below is enabled.

0: PC configuration mode (PC Configuration Software RZMSCFG, under development).

At the startup, last software setting before the power is turned off is enabled.

Figure 1.5.3c: RZMS-U9 rear view.

Table 1.5.3b: RZMS-U9 rotary switch setting.

SW602

SW602 is fixed to

the position 3.

DO NOT CHANGE.

Momentary

SW604

Totalized

(factory default)

Totalized or Momentary

Display Selector

RS-485 Connector

Configurator Jack

Address Setting

Rotary SW

Operating Mode

Setting Rotary SW

RS-232C

9-pin Connector

Power / FG Terminals

A/D SERVICE COLD JUNCTION

LINE NOISE

BURNOUT (T/C and RTD)

CONVERSION CHANNEL COMPENSATION FILTER All Channels

Individual

MODE NUMBERS (T/C)

FREQUENCY

NONE UP DOWN

Channels

With 50/60 Hz 1 2 3

50 Hz 4 5 6

Medium 12 60 Hz 7 8 9

Without 50 Hz A B C

60 Hz D E F

Software setting Software setting Software setting Software setting 0

for all channels (12 or 6) for individual for all channels Software

(

Fast, Medium, Slow

) channels (50, 60, 50/60 Hz) setting

Remark 1: Factory setting is ‘1.’

Page 41

16

73ET/74ET/75ET USERS MANUAL EM-7353-0003B Rev.5

RS-485

Connector

Power Terminals

Address Setting

Rotary SW

Configurator

Jack

Specification Label

RS-232C

9-pin Connector

Configurator

Jack

RS-232C

9-pin Connector

Address Setting

Rotary SW

NODE NUMBER

Node number setting (1 – F, up to 15 nodes) is required at the rear rotary switch when more than one module is

connected. Each module must ha ve an unique node n umber . Before changing the node number, be sure to turn off

the power supply to the module.

Figure 1.5.3d: R1M rear view. Figure 1.5.3e: R2M rear view.

Figure 1.5.3f: RZMS-U9 rear view.

1.6 CF CARD

A CF Card is required to operate the 7xET. Use one manufactured by Hagiwara Sys-Com. Recommended card

types are indicated under Section 1. GENERAL DESCRIPTIONS.

CAUTION !

• DO NOT extract the CF Card while recording.

• The 7xET may still be accessing the CF Card for a while after the recording has been stopped. DO NOT remove

power to the 7xET while recording and immediately after the recording has been stopped (1 or 2 minutes).

•Prior to inserting the CF Card, carefully check the orientation of the CF Card (front face) and the connector. Incorrect

orientation may damage the card or destroy its data.

Figure 1.6: CF card dimensions and front/reverse sides identification.

RS-485 Connector

Configurator Jack

Address Setting

Rotary SW

Operating Mode

Setting Rotary SW

RS-232C

9-pin Connector

Power / FG Terminals

42.80 ±0.10 mm

36.40 ±0.08 mm

Wide Narrow

FRONT SIDE

The CF Card is keyed with guide grooves of uneven width at

each side in order to prevent insertion in an wrong orientation.

Page 42

17