Page 1

©Copyright MST Global 2019

User Manual

Revision A, March 2019

Page 2

©

Rev

Revision History

ision Change

A Initial release

AXON Digital Platform

User Manual

Revision A

Date

March 2019

2019 MST Global Commercialin Confidence

ii

Page 3

A

XON Digital Platform

User Manual

Revision A

Copyright and Disclaimer

Copyright

Published in Sydney by: Mine Site Technologies Pty Ltd (MST Global)

ABN: 93 002 961 953 ACN: 002 961 953

Global Head Office : Level 5, 113 Wicks Road, Nor th Ryde, NSW 2141 Australi a

Telephone: +61 (0)2 9491 6500

Copyright © 2019 Mine Site Technologies Pty Ltd (MST Global). All rights reserved. MST Global

reserves the right to make changes to speci ficatio ns and infor matio n in this manual without pri or not i ce.

MST Global ac cepts no respo n s ibility for any err ors or omissions contained in this manu al.

This publication is subject copyright . No part of it may in any form or by any means (electronic,

mechanical, microcopying, photocopying, recording or otherwise) be reproduced, stored in a retrieval

system or transmitted without prior written permission of the copyright owner. Enquiries should be

addressed to MST Global.

Warning

Unauthorised reproducti on o f, alteratio n o f contents, or dist ri buti on to thi r d parti es, in w ho l e or in part is

an infringement of copyright MST Global will actively pursue any breach of its copyright.

Disclaimer

Information contained in this documen t has been de veloped by Mine Site Technologies Pty Ltd (MST

Global). Every care has been taken by the staff of MST to ensure the content of this manual is rel evant

and up to date at the time of publication. Content is subject to change without notice. Technical updates

as associated with this manual will be supplied to the customer at MST Global’s earliest convenience.

This manual is published and distributed on the basi s that the publ i sher is no t responsi bl e for the re sul ts

of any actions taken by users of the information contained in this manual. MST Global does not accept

responsibility for errors or d amag es resulting fr om misrepresentation, misinterpretation or deviation from

instructions by any person in regard to the information contained in this manual. The information is

supplied on the condition that the recipient will make their own determination as to the suitability of the

information for their pu rposes prior to use.

© 2019 MST Global Commercial in Confidence

iii

Page 4

A

Contact Information

Australia

Sydney

Level 5, 113 Wicks Road

North Ryde

Sydney NSW 2113

Tel: +61 (0)2 9491 6500

United States

Denver

13301 W 43rd Drive

Golden, Denver

Colorado 80403

Tel: +1 303 951 0570

Tuscon

Tel: +1 520 495 0185

Chile

Santiago

Vitacura 2771, 0f 503

Las Condes,

Santiago 7550134

Tel: +56 (2) 2 656 7673

Russia

Moscow

Office 318a

Lesnaya, 43

Moscow 127055

Tel: +7 (499) 978 72 11

South Africa

Centurion

Unit 1, Oxford Office Park

3 Bauhinia St

Gauteng 0046

Tel: +27 (0) 12 345 6100

China

Hangzhou

Building 5

1413 Moganshan Road

Hangzhou 310011

Tel: +86 571 8580 3320 Ext 206

XON Digital Platform

User Manual

Revision A

© 2019 MST Global Commercial in Confidence

iv

Page 5

A

XON Digital Platform

User Manual

Revision A

About This Manual

This manual describes features and functions of the MST AXON Digital Platform product family. It

provides information about hardware, installation, configuration an d how to trou bl eshoot any i ssue s. You

will find it easier to use the manual if you are familiar with networking systems and have an

understanding of electronics in a network environment.

Conventions used in the manual

This publication uses the followi ng conv en ti ons to highli ght and conv ey i nforma ti on :

Text that requires input from an operator is boldfaced.

Operator interface screen control names are boldfaced.

Keyboard input keys are CAPITALISED.

Icons

Icons are used in the manual to highlight specific information as shown the table below.

Icon Description

NOTE: The NOTE icon indicates importan t in formation or

references to the user.

IMPORTANT: The IMPORTANT icon con tai ns in formation to prevent

damage to the product and injury to the user.

CAUTION: The CAUTION icon indicates to stop and pay attention

or an action not to be performed.

© 2019 MST Global Commercial in Confidence

v

Page 6

A

Additional Support

For additional support pl ea se visit our website www.mstglobal.com

NOTE: The information provided in this document ("Information") is presented in good faith

and believed to be correct as at the date of this document. MST makes no representations

as to the accuracy or completeness of the Information. The Infor m a ti on is suppl i ed on the

condition that the recipient will make their own determination as to the suitability of the

Information for their purposes prior to use. Under no circumstances will MST be responsible

for any damages whatsoever resulting from the use of, or reliance upon, the Information.

XON Digital Platform

User Manual

Revision A

© 2019 MST Global Commercial in Confidence

vi

Page 7

b

AXON Digital Platform

User Manual

Revision A

Contents

Revision History ......................................................................................................................... ii

Copyright and Disclaimer ........................................................................................................ iii

Copyright ............................................................................................................................................... iii

Warning ................................................................................................................................................. iii

Disclaimer .............................................................................................................................................. iii

Contact Information .................................................................................................................. iv

About This Manual ..................................................................................................................... v

Conventions used in the manual ............................................................................................................ v

Icons ....................................................................................................................................................... v

Additional Support ................................................................................................................................. vi

Chapter 1: Understanding AXON Digital Pl atform .................................................................. 1

1.1 Typical System Layout ................................................................................................................ 1

Chapter 2: AXON Core unit ....................................................................................................... 2

2.1 Hardware Overview .................................................................................................................... 3

2.3 Connectivity ................................................................................................................................ 4

2.3.1 Composite Fibre Ports ........................................................................................................ 4

2.3.2 Copper Ethernet Ports ........................................................................................................ 6

2.3.3 Expansion sockets .............................................................................................................. 6

Chapter 3: AXON Air module .................................................................................................... 7

3.1 Hardware Overview .................................................................................................................... 8

3.3 Daisy Chaining of AXON Air units ............................................................................................... 9

Chapter 4: Network System Design ..................................................................................... 10

4.1 Installation Types and Coverage .............................................................................................. 10

4.2 Power Requirements ................................................................................................................ 10

4.3 Choosing Antennas ................................................................................................................... 11

4.4 Placement of AXON Air units .................................................................................................... 12

4.5 Placement of Antennas ........................................................................................................... 12

© 2019 MST Glo

al CommercialinConfidence

vi

Page 8

A

XON Digital Platform

User Manual

Revision A

4.6 Determining distance between AXON Air modules ................................................................... 13

Chapter 5: Installation .......................................................................................................... 15

5.1 AXON Core Mounting Options .................................................................................................. 15

5.2 AXON Air Mounting Options .................................................................................................... 17

5.3 Antenna Mounting Options ....................................................................................................... 18

5.4 Installation Schemes ................................................................................................................. 20

5.4.1 Installation in a Straight Drive............................................................................................ 20

5.4.2 Installation in a no line of sight scenario ........................................................................... 21

5.4.3 Installation in large underground openings, e.g. Crusher Building .................................... 22

5.4.4 Installation at an Intersection ............................................................................................ 23

5.5 Connecting Power to AXON Core ............................................................................................. 24

5.6 Handling composite cable during installation ............................................................................ 24

5.7 Connecting Composite Cable to AXON Core ........................................................................... 25

5.8 Standard Composite and Fibre Cable Lengths ......................................................................... 25

5.9 Connecting Ethernet Cable to AXON Core ............................................................................... 25

5.10 Connecting Antennas to AXON Air .......................................................................................... 26

5.11 Manual Reset and Reboot ....................................................................................................... 27

Chapter 6: Understanding VLANs ....................................................................................... 28

6.1 Understanding Trunk and Access Ports ................................................................................... 29

6.1.1 Trunk Ports ....................................................................................................................... 29

6.1.2 Access Ports ..................................................................................................................... 29

6.1.3 Port Allocation ................................................................................................................... 31

6.2 VLANs and Wireless Networks ................................................................................................. 31

6.3 Native VLAN ............................................................................................................................. 32

Chapter 7: Configuration Using the Web Interface ............................................................ 34

7.1 Logging onto the Web Browser Interface .................................................................................. 34

7.2 Status Screen ........................................................................................................................... 50

7.2 Configuration Screen ................................................................................................................ 51

7.3 Status Tab ................................................................................................................................ 52

7.3.1 Obtaining Device Information ............................................................................................ 52

7.4 Settings > System > Actions ..................................................................................................... 54

© 2019 MST Global Commercial in Confidence

viii

Page 9

A

7.4.1 Upload/download settings ................................................................................................. 54

7.4.2 Update firmware ................................................................................................................ 55

7.4.4 Reboot .............................................................................................................................. 55

7.4.5 Change password ............................................................................................................. 55

7.4.2 Setting the Time ................................................................................................................ 56

7.5 Setting Tab ............................................................................................................................... 59

7.5.1 Managing Automatic TFTP Configuration ......................................................................... 59

7.5.2 Configuring SNMP S ettings .............................................................................................. 60

7.5.3 Setting Up the LAN ........................................................................................................... 61

7.5.4 Configuring Wireless Radio ............................................................................................... 64

XON Digital Platform

User Manual

Revision A

7.5.5 Configuring Wireless Networks ......................................................................................... 67

7.5.6 Configuring EAP (Extensible Authentication Protocol) ...................................................... 69

7.5.7 Configuring Asset Tracking and Location Based Services ................................................ 70

7.5.8 Configuring Ethernet Switch Ports .................................................................................... 72

7.5.9 Defining VLANs ................................................................................................................. 74

7.5.10 Configuring the VLAN Port Map ........................................................................................ 75

Chapter 8: Centralised Configuration Management ........................................................... 76

8.1 Device Management Overview ................................................................................................. 77

8.1.1 Site Configuration .............................................................................................................. 77

8.1.2 AP Config Templates ........................................................................................................ 78

8.1.3 Access Point ..................................................................................................................... 80

8.2 TFTP Server Overview ............................................................................................................. 83

8.2.1 Editing Site Configuration Files ......................................................................................... 84

8.2.2 Editing Device Configuration Files .................................................................................... 85

8.3 TFTP Parameters ..................................................................................................................... 86

Appendix A: Troubleshooting Guide .................................................................................. 98

Appendix B: Composite Cable Testing ........................................................................ 100

B1: Visual Inspection of the Fibre Optic Cable ............................................................................. 100

B2: Measuring and Testing for Power Loss .................................................................................. 100

Appendix C: Ethernet Cable Specifications .................................................................... 102

© 2019 MST Global Commercial in Confidence

ix

Page 10

A

XON Digital Platform

User Manual

Revision A

Appendix D: Device Discovery ......................................................................................... 103

Appendix E: Connecting a PC to an Network Device ..................................................... 105

Appendix F: Maintenance Check List .............................................................................. 107

Appendix G: Acronyms ..................................................................................................... 108

Appendix H: AXON Core Specifications ......................................................................... 125

Appendix I: AXON Air Specifications ............................................................................ 127

Appendix J: Hardware Warranty ...................................................................................... 130

Appendix K: AXON AIR Installation Addendum .............................................................. 131

© 2019 MST Global Commercial in Confidence

x

Page 11

A

©

XON Digital Platform

User Manual

Revision A

Chapter 1: Understanding AXON Digital Platform

Mine Site Technologies' AXON Famil y o f hardware product s consi sts o f the AXON Core unit and a

number of expansion modules that can be added to it.

There is also a substantial external software offering (sold separately) that complements and

expands AXON hardware, makin g it a true Digit al Plat form for mine di giti zation, automation and

productivity enhancement. Please contact MST for more information in relation to the associated

MST software products.

Currently, in addition to AXON Core, MST offers AXON Air, daisy-chainable, Wi-Fi Access Point with

tracking capability. Two more modules will be added to the family within the next six months.

1.1 Typical System Layout

An example of a typical AXON system deployment is shown on the Figure 1 below.

The first AXON Core in line connects to an Ethernet switch and a power supply via a JB11 junction

box. All subsequent units are connected in series down the mine tunnel by the composite cable.

Optional extension modules and radios, such as AXON Air Wi-Fi access points, are fitted as required.

When the mine tunnel splits into different sections, an additional AXON Core is branched out from the

main network. AXON Core or AXON Air devices can also be positioned in Wi-Fi ‘hot spots’ such as

crib areas and refuge bays. One of the AXON Core devices on the diagra m has an optional PoE+

and power distribution module attached to it, allowing for a bigger number of client devices (such as

cameras) to be connected.

A client device can connect to the network wirelessly when in proximity of AXON Air or directly to

AXON Core via a CAT5 cable.

Figure 1: AXON system layout

2019 MST Global CommercialinConfidence

1

Page 12

©

A

XON Digital Platform

User Manual

Revision A

Chapter 2: AXON Core unit

Topics:

Hardware Overview

Connectivity

This chapter presents the features a nd fun c ti on s o f the AXON Core unit and shows how it integra t es

within a network.

Mine Site Technologies' AXON Core is the main building block of the MST AXON product family. It

consists of a managed fibre optic Ethernet switch with several PoE+ outputs, power management

circuitry for client devices and two sockets for external expansion modules. AXON Core provides

wired network access for mining envi ronments that do not require Intrinsic al ly Safe equipment.

AXON Core has the following key features:

Three, Fibre Optic, Full duplex, Gigabit Ethernet ports

Four 1Gbps copper Ethernet ports with Power over Ethernet (PoE+) supply capability.

Two sockets for external expansion modules (PoE, managed power, automation control, sensors,

etc.)

Rigid hard plastic enclosure, suitable for mining environment, sealed to comply with an Ingress

Protection rating of IP65

Composite cabling system incorporating fibre optic data and DC pow er

Low power design, with a wide input voltage from 20-60VDC

VLAN (IEEE 802.1Q) protocol support

RSTP (802.1W) protocol support

LLDP (802.1AB) protocol support

MST Device Discovery protocol support

SNMP (read only) protocol support

QoS (P802.1p) protocol support

For detailed specifications on AXON Core, see AXON Core Specifications.

2019 MST Global CommercialinConfidence

2

Page 13

A

©

XON Digital Platform

User Manual

Revision A

2.1 Hardware Overview

The features and functions of AXON Core are ill ustrated in Figure 2: AXON Core layout and the

accompanying table.

5

6

3

8

7

4

12

10

1

1

2

9

13 13

4

5

11

10

10

6

14

1

Figure 2: AXON Core layout

Key Description Function

15

14

1

2

Composite ( fibre + power) cable

port

Connector for data transmi ssi on and / or DC power

distribution. There are three ports : A, B and C

Power and Status LED Power and Status LED

3 Power warning LED Power warning LED

4 PoE+ port status dual colour LEDsPoE+ port status dual colour LEDs

5 PoE+ port activity LEDs PoE+ port activity LEDs

6 Fibre port status LEDs Fibre port status LEDs

7 Radio port status LED Radio port status LED

8 Radio port activity LED Radio port activity LED

9 PoE+ AXON Air port

PoE+ port typically used by AXON Air module. It can

also be used for other purposes

10 PoE+ Ethernet ports

External Ethernet por t with IEEE 802.3at PoE+ supply

capability for powering client devices.

2019 MST Global CommercialinConfidence

3

Page 14

A

©

A

A

XON Digital Platform

User Manual

Revision A

11 Factory defaults button

12 Reset button (RED) Pressing this button will cause switch core reset without

13 Mounting holes Rear mounting bracket with holes for mounting AXON

14 Covered Expansion Socket Expansion socket covered with a protective cover.

15 SD card Inserting a card from another switch and power cycling

Factory reset button for the unit. Pressing it for 5…15

seconds will cause factor y reset

losing the device configuration.

Core on the wall or roof.

XON Core will install switch configuration stored on the

card

2.3

Connectivity

AXON Core has three types of network connectio ns:

Composite Fibre Ports

Ethernet Ports

Expansion interfaces

2.3.1 C om posite Fibre Ports

AXON Core unit has three composite fibre port connectors with a crush protection cover. Each

connector consists of tw o electrical contact s and a duplex L C single mode optic fibre (SM OF)

receptacle as shown in Figure 3: Composite fibre ports.

NOTE: A protective cover o r a mating cabl e connector must be attach ed to unused

ports to maintain the IP65 (Ingress Protection) rating of the unit

Figure 3: Composite fibre port s

Each port can be connected in one of the following ways:

Port connection Description

Protective covers

DC power only connection

DC power cable to connect the PSU to the electrical

contacts on an AXON Core. By convention, this cable is

connected to port A.

2019 MST Global CommercialinConfidence

4

Page 15

A

©

A

A

Fibre only connection

XON Digital Platform

User Manual

Revision A

fibre optic cable terminated to the fibre contacts of the AXON

Core composite connector.

Fibre and DC power connection

composite cable providing fibre optic connectivity and power

to AXON Core.

Fibre optic cabling provides numerous benefits over Ethernet cabling, with superior signal integrity

and no signal interference from high-powered electronics. It also enables units to be spaced over

longer distances wi tho ut the di stance limitation of Ethe rnet cabling.

By default, port A is configured as the upstrea m port and ports B, C as the dow nstrea m ports. The

difference between upstream and downstream ports is the orientation of the fibre that is used for

transmitti n g and receiving data. This is illustrated in Figure 4: Fibre orientation of Upstream and

Downstream ports.

Figure 4: Fibre orientation of Upstream and Downstream ports

Due to the difference in the fibre orientation, M ST composite cable an d fib r e optic cab l e can only be

connected between ports on AXON Core devices marked with a tick in the matrix below.

Port A

Port A Port B Port C

Port B

Port C

Single- and Multi-Mode Cables

AXON Core is supplied from the factory with 1000BASE-LX single-mode SFP modules. Customers

wishing to interface to other cable standards, e.g. 100BASE-FX single or multi-mode, should con t act

MST to arrange replacement of the appropriate SFP modules.

2019 MST Global CommercialinConfidence

5

Page 16

A

©

XON Digital Platform

User Manual

Revision A

NOTE: If replacing the single-mode SFP modules wi th mul ti-mode modules, the

single-mode patch lead between the SFP module and the MST Composite Cable

connector on the inside of the housing needs to be replaced w i th a multi-mode

patch lead.

JB11 junction boxes can be connected inline between any two units in the chain

to supply power. There is no need to isolate AXON Core units to a single power

source.

IMPORTANT: If an SFP is changed, the device must be rebooted or reset to

detect the change.

2.3.2 Copper Ethernet Ports

AXON Core has four external Copper Ethernet ports that enable connection to other networking

devices.

The four Ethernet ports also provide IEEE 802.3at PoE+ (Power over Ethernet) injector functionality,

allowing a singl e cable to be used for data a nd power to network devi ces. Each Ethernet port's

functionality can be configured by the w eb browser inte r face, or by centralised configuration

management.

One of these four ports, located on the top of AXON Core, will typically be used for AXON Air module

connection, but can also be used for any other purpose. Similarly, any of the other PoE+ ports can be

used to connect AXON Air module.

For more information on configuring Ethernet ports, see Chapter 7: Configuration Using the Web

Interface

2.3.3 Expansion sockets

AXON Core has two expansion sockets on its front panel that allow adding optional expansion

modules to it.

Expansion socket

cover

2019 MST Global CommercialinConfidence

Expansion socket

interface

6

Page 17

©

A

XON Digital

Platform

User

Chapter 3: AXON Air module

Topics:

Hardware overview

Daisy Chaining of AXON Air units

This chapter presents the features and func ti on s o f the AXON Air module and shows how it

integrates with the AXON Core unit and the networ k.

Mine Site Technologies' AXON Air is a key member and an important building block within the MST

AXON family of products, it provides wireless network access for mining environments that do not

require Intrinsically Safe equipment and consists of a Wi-Fi Access Point and 2-port Ethernet switch

for daisy chaining. AXON Air supports meshing (802.11s protocol) and can be used as a mesh

gateway or a wireless bridge between two wired subnets.

AXON Air has the following features:

One Wi-Fi Radio, 802.11 a/b/g/n, 2 x 2 MIMO, 2.4 or 5Ghz

6 x SSIDs

VLAN (IEEE 802.1Q) protocol support

LLDP (802.1AB) protocol support

SNMP (read only) protocol support

QoS (P802.1p) protocol support

WEP/ WPA/ WPA2 security protocols support

Two 1Gbps Ethernet ports with proprietary Power over Ethernet power supply capability

The unit gets its power from the upstream PoE ports and pas ses it throu gh to the next access

point in the chain via the downstream port. AX ON Ai r negotiates a P oE + Cl ass 4 power

requirement, whilst drawing 4W nominally.

Rigid hard plastic enclosure, suitabl e for mini ng environment sealed to comply wi th an Ingress

Protection rating of IP65

For detailed specifications on AXON Air, see AXON Air Specifications

2019 MST Global CommercialinConfidence

7

Page 18

©

A

A

XON Digital Platform

3.1 Hardware Overview

The features and functions of AXON Ai r are illustrated in Figure 2: AXON Air layout and the

accompanying table.

User Manual

Revision A

Figure 2: AXON Air layout

Key Description Function

1 Upstream PoE+ Ethe rnet po rt

2 Downstream PoE+ Ethernet p ort

1xGbps Ethernet port with IEEE 802.3at PoE+ input

capability

1xGbps Ethernet port with IEEE 802.3at PoE+ supply

capability for power i ng next - i n- line AXON Air unit

3 Default configuration button Pressing the button for 10 or more seconds and

power cycling AXON Air at the same time will cause

4

factory reset

ntenna connector N-type female Antenna connectors

5 Power On LED Power On LED

6 Wi-Fi Activity LED Wi-Fi Activity LED

2019 MST Global CommercialinConfidence

8

Page 19

©

A

A

XON Digital Platform

7 Downstr eam PoE L ED Downstream PoE activity LED

8 Upstream PoE LED Upstream PoE activity LED

9 Tracking activity LED Tracking activity LED

10 External Antenna External 2.5dB, omnidirectional antenna

User Manual

Revision A

11

ntenna swivel mounting area Mounting area used to accommodate optional

antenna swivel mechanism (sold separately).

12 Mounting holes Two mounting holes on the top of the module

3.3 Daisy Chaining of AXON Air units

Each AXON Air features a two-port Ethernet switch, which enables daisy chaining of individual AXON

Air units via a CAT5 cable. The maximum distance in between AXON Air nodes in such scenario is

100 meters. A maximum of three AXON Air units can be daisy chained together.

The unit gets its power from one of its upstrea m P oE port and passes i t thr ough to the next access

point in the chain via the downstream port. AXON Air negotiates a PoE+ Class 4 power requirement,

whilst drawing 4W nominally.

The AXON Air operational parameters can be configured through its o wn web brow ser interface or via

the centralised configuration management. For more information, see Chapter 7: Configuration U sing

the Web Interface

2019 MST Global CommercialinConfidence

9

Page 20

©

A

XON Digital Platform

User Manual

Revision A

Chapter 4: Network System Design

Topics:

Installation Types and Coverage

Power Requirements

Choosing Antennas

Placement of AXON Air units

Pla c eme nt of Antenn as

Determining distance between AXON Air modules

This chapter describes network system design for underground mines.

A MST System Engineer will usually design and preconfigure a network based on the requirements

and layout of each mine site. This will involve a visual inspection of the mine site to identify user

areas, and determine access point locations. A RF (Radio Frequency) site survey is also conducted

to understand the behaviour of radio waves in the mine. The following factors help determine network

design:

Wireless coverage re quirements of the mi ne

Quantity and type of wireless client devi ces conne cted to the network

Wired client devices connected to the network and their location

Interconnection to the mine's exi sti ng corpo rate network

Policies for network protocol between networks

Cabling requirements

Antenna types to use w ith each unit an d mounti ng method for ea ch antenna

Mounting location and installation method for each network device.

4.1

Installation Types and Coverage

Wireless network coverage can be described as:

Wi-Fi hotspot — Network coverage is provided in key areas, such as crib areas and refuge bays.

Full coverage — Seaml ess wi reless cov era ge by strate gical ly placi ng AX ON Air units so their

radio fields overlap.

An AXON Air can communicate at wireless distances of 150-30 0 metres, depending on the chosen

antenna,geometry and geology of the mine.

4.2

Power Requirements

The power requirements for a networ k are unique to each site installation. Det ermining power

requirements can be complex and is dependent on various factors such as the number of AXON Core

units, PoE devices, branches in the network and composite cable lengths.

2019 MST Global CommercialinConfidence

10

Page 21

©

A

A

A

A

v

XON Digital Platform

User Manual

Revision A

NOTE: A site inspection conducted by a MST System Engineer will help determine

the power requirements for your network.

AXON Core is designed t o opera te a t a w i de v ol tage ran ge, fro m a mi ni mu m o f 20VDC u p to 60VDC.

Each AXON Core in a network can interna lly step u p the incoming voltage to 48VD C in order to

supply power to its connected PoE devices. AXON Core needs to receive a minimum input of 20VDC

to power PoE devices.

56VDC power supplies are used for large networks to maximise the distance between power

supplies. For instances where the AXON Core switches are deployed in isolation or in remote

location a 24V DC UPS can be used.

External power supply reco mmendations:

Using Uninterrupted Power Supplies is not mandatory; however, it will increase the uptime and

protect the network from power surges and fluctuations. Fluctuations may cause damage to the

network and auxiliary equipment. The recommended UPS is AXO N Force UPS.

4.3

Choosing Antennas

Antennas are connected via N-Type connectors to each AXON Air to provide wi reless network

coverage. The type of wireless coverage, surrounding geology, tunnel topology and surface of the

roadway/tunnel are all factors that will determine the choice of antenna. A minimum of two antennas

is required for each AXON Air. There two most popular directional antenna patterns:

Omnidirectional antenn as — radiate equ ally in all direct ions for a short ran ge, providing

immediate coverage in an open area.

Directional antennas — radiate in a specific direction over a longer range. A higher gain antenna

will have a longer range an d is more directional. It is important that directional antennas are

aligned properly betw een AXON Air units to en su re conti nuou s coverage between uni ts.

The antenna radiation pa ttern and polarisa tion need to be con sidered to prov ide suitable wirel ess

coverage in an area.

Antennas commonly used with AXON Air are shown below.

ntenna Type Illustration Description

Omnidirectional 2.5dbi

rubber whips

lower gain antenna that radiates equally in

all directions. It provides direct cov erage in an

open area.

Panel antenna

panel antenna is a directional antenna, with

a wide horizontal beamwidth and narrower

ertical beamwidth. They are suited for

covering an open area in one direction.

2019 MST Global CommercialinConfidence

11

Page 22

©

A

A

Y

A

Diversity panel antenna

agi directional antenna

XON Digital Platform

User Manual

Revision A

diversity panel antenna contains two panel

antennas in one housing with a 90° rotation

between them. It is used for providin g bett er

signal reception in difficult areas, and more

accurate Wi-Fi tag location when Wi-Fi

tracking is implemented. Diversity antennas

use both antenna connections on a WAC.

Ya gi antenna is high gain directiona l

antenna. They are ideally suited for line of

sight tunnel communications. Yagi antennas

need to be aimed accurately and avoid

obstacles in their RF beam path.

4.4

Placement of AXON Air units

In underground environments, many factors can influence finding a suita ble location for moun ting of

the AXON Air access point and antennas connect ed to it. This docu men t wi l l only consi der the signal

propagation aspects, se e AXON Air Mounting Options for more advice.

4.5

It is recommended to attach the antennas directl y , or with a short good qu al i ty coax i al cable, to the

access point. The antenna can be connected up to 20m away from the access point when at

minimum CNT or LMR 400 antenna cable is used. At 2.4 GHz the loss of this cable is approximately

2.1 dB per 10m. It will reduce the effectiveness of the antenna however it may be acceptable with the

use a of high gain antenna. The coaxial connection should be kept as short as possible to minimise

signal attenuation. Large r anten na s / longe r cabl e feeds can re qui re l i ne am pl i fie rs, and possi bl y bidirectional splitter / combi ner s for dual antenna systems.

In surface installation to ensure EN 60950-1 compli an ce, AXON Air, the antenna and all cabli ng m ust

be installed in a location that eliminates the chance of the system being struck by lightning. If an

antenna needs to be installed in a location whe re i t could be struc k by lightni ng, then an app ropri ate

lightning arrestor must be placed in-line with the antenna and cabling such that AXON Air is not

subject to overvoltage due to lightning.

Antenna placement underground is dependent on the surrounding geology, tunnel topology and

stratum type. The recommended place men t o f antennas is as foll ows:

Tip 1: Directionality

Antennas should be mounted and angled to give optimum transmission along curves and dips as

shown below in Figure 5: Angling antennas.

Placement of Antennas

Figure 5: Angling antennas

2019 MST Global CommercialinConfidence

12

Page 23

©

A

XON Digital Platform

User Manual

Tip 2: Obstructions

Antennas should be mounted to avoid signal obstructio n fro m roc k, veh i cles, equipment and

machinery as show n in Figure 6: Antenna mounting to avoid obstructions.

Revision A

Figure 6: Antenna mounting to avoid obstructions Tip 3: RF Field Overlap

Multiple antennas should be mounted to av oid crossing signal paths as shown in Figure 7: Antenna

directivity.

Figure 7: Antenna directivity

The positioning of the antennas is crucial when Wi-Fi tags are used for asset tracking and locati on

services. Wi-Fi tags wil l not be read when there are anten na standi ng wave nulls. Antennas need to

be positioned to have best reception of tag messages. For Antenna mounting options, see Antenna

Mounting Options

4.6 Determining distance between AXON Air modules

Line of Sight Distances

In line of sight, each AXON Air has a maximum wireless range of 300 metres (984 feet) using high

gain directional antennas . AXON Air unit s are gen erall y i nstall ed wi th a 100 metre (328 feet) ov erla p

of the radio field as shown in Figure 8: Wireless channel layo ut and distances around curves

2019 MST Global CommercialinConfidence

13

Page 24

A

©

XON Digital Platform

User Manual

Revision A

This ensures sufficient coverage between AXON Air units.

AXON Air units within ran ge of each other must be configured w ith different Wi-Fi channels. B y default

every fifth channel is used (channels 1, 6 and 11) to prevent signal overlap, minimising the possibility

of inter-modulation or inter ference. There are ci rcumstances in which the configuration may all ow all

radios to be operating on the same channel. Rapid handover and mobi l e dev i ce battery consu mptio n

may improve in this configuration.

Figure 8: Wireless channel layout and distances around curves

In situation where line of sight (LoS) between the receiving device and AXON Air cannot be achieved

due to the physical layout of the tunnel, the distan ce betw ee n the AP’s may need to be reduced.

Below is a typical example of such situation. The AXON Air AP’s are spaced 100 m apart to

overcome the curvature of the spiral decli ne

There are many variances in a tunnel, which

influence the RF signal propa gation, the si z e

and curvature being the most prevalent. The

surface of the walls, steel mesh, water and

objects in the RF path are all factors to take

into consideration when planning the system

design. Another important factor to consider

is movement of vehicles, large vehicle such

as trucks can shadow a large area of the

section of the tunnel, effectiv ely bl ocking the

roadway and the RF path. In many cases, it

is advantageous to trial a section to get a

better understanding of the Wi-Fi

propagation in the specific environ ment . A

Wi-Fi survey is a good measure to insure

good coverage.

2019 MST Global CommercialinConfidence

14

Page 25

©

AXON Digital Platform

User Manual

Revision A

Chapter 5: Installation

Topics:

AXON Core Mounting Options

Antenna Mounting Options

Installation Schemes

Connecting power to AXON Core

Handling Composite Cable During Installation

Connecting Composite Cable to AXON Core

Standard Composite and Fibre Cable Lengths

Connecting Ethernet Cable to AXON Core

Connecting Antennas to AXON Air

Manual Reset and Reboot

This chapter describes mountin g opti on s, installation schemes, and antenna and cable connecti o ns.

Fibre connector assembly and cable termi nati on are bey ond the scope of thi s manua l .

IMPORTANT: The electronic components in each AXON Core have been designed to

be isolated from the enclosure and local electrical earth. This ensures there is no

5.1

Standard mounting options for AXON Core are described in the table below.

The mounting plate for AXON Core is designed for ease of installation and future convenient

removal/replacement. The key holes in the mounting plate allow AXON Core to be attached or removed

from the plate with ease; there is no need to remove the mounting plate when exchanging an AXON

Core in place of a new one.

AXON Core Mounting Options

current passing between grounds of different potentials (known as galvanic isolation).

Galvanic isolation must always be maintained, with the AXON Core ground terminals

isolated from electrical earth , and all antenna and an tenna cab l e connec ti o ns prope rl y

insulated.

Application Installation

Mounting the AXON Core Mounting plate to a

rock bolt

The AXON Core mounting plate has two 25mm

holes to mount it to a rock bolt on the mine's

rock face. It is secured to the rock bolt with a

Mounting the AXON Core Mounting plate with 12

mm rock anch or or thr e aded ba r .

25mm nut.

Drill 13 mm hole and use appropriate chemical

anchor to secure the anchor rod

Mounting AXON Core to the mesh The four corner mounting points on a mounting

plate can be cable-tied to the mesh in a mine

tunnel.

2019 MST Global CommercialinConfidence

15

Page 26

©

A

XON Digital Platform

User Manual

Revision A

The AXON Core mounting plate

Step 1. Drill 13 mm hole Step 2. Inject glue

Step 4. Mount the AXON Core

Plate Step 3. Insert both Anchors

2019 MST Global CommercialinConfidence

16

Page 27

©

A

XON Digital Platform

User Manual

Revision A

Step 5. install AXON Core & Air

CAUTION: The above mounting method maybe not suitable for your particular

situation. If in doubt consult with your Geo-Technical team or your supervisor.

The AXON Core mounting plate can be

mounted in various convenient ways.

On this picture you can see a preferred

way of using two 12 mm chemical

anchors.

Any combination may be used to fix the

plate e.g. 24 mm rock bolt and 12mm

chem anchor.

5.2

AXON Air Mounting Options

The AXON Air wireless access point is commonly mounted onto the AXON Core unit as depicted at

Step 5 in the previous paragraph. There will be situations where it is advantageous to mount AXON Air

in a different location to AXON Core or where AXON Core is not required, e.g. when AXON Air is

chained to another AXON Air. For this purpose, a separate mounting plate is included with AXON Air.

A convenient way to mount AXON Air is to use a mounting post as shown on the photo below. The

procedure is similar to the AXON Core mounting method shown above. The 12mm threaded anchor (WMNT-025) is glued into a hole in the rock wall and the yellow mounting post ( W-MNT-019 ) wi th A XO N

Air attached to it is screwed on top of the anchor. A M12 nut can be used to counter lock the pole,

stopping it from spinning, if required.

The mounting plate has two key holes that are used for wall or rock face mountin g.

AXON Air Mounting Bracket

2019 MST Global CommercialinConfidence

17

Page 28

©

A

XON Digital Platform

User Manual

Revision A

Note: When mounting AXON Air wireless access points, it is important to

consider the distance from the antenna to sur rounding objects. As a rule

generally, antenna should not be placed within 400 mm of RF reflecting objects

or materials that contain metal.

CAUTION: The above mounting method maybe not suitable for your particular

situation. If in doubt consult with your Geo-Technical team or your supervisor.

5.3

Antenna Mounting Options

Antenna mounting is dependent on the location and cov erage requi red . E xamples of antenna installatio n

options are described and illustrated in the table below.

Mounting Option Description Picture

Omni directional

antenna directly

attached to AXON Air

AXON Air is supplied with 2x

2.5 dBi Omni directional

antennas. Which install

directly to the enclosure.

Directional Helical

antenna 15 dBi

(Poynting) directly

attached to AXON Air

Example of a directional

Helical antenna directly

attached to AXON Air. This

is the preferred mou nting

method and has the

advantage of a short RF

cable.

2019 MST Global CommercialinConfidence

18

Page 29

©

A

Mounting a Yagi

antenna or panel

antenna to the mine

tunnel roof.

In instances where it is

required to separate the

antenna from AXON Air, an

antenna can be connected

via an (up to) 20 m Coaxial

cable.

A hole is drilled into the

tunnel roof and the mounting

pole is secured using

chemset adhesive. The Yagi

antenna is attached to the

mounting pole using Uclamps

XON Digital Platform

User Manual

Revision A

Mounting a Yagi

antenna or panel

antenna at a portal

Mounting a panel

antenna on the rock

face or mesh

In situation where the drilling

is not possible or prohibited,

specialised mounts can be

manufactured.

The panel antenna is cable

tied to the mesh, ensure the

antenna is not obstructed by

objects and avoid mounting

it close (400 mm or less) to

large steel structures.

2019 MST Global CommercialinConfidence

19

Page 30

©

A

XON Digital Platform

User Manual

Revision A

5.4

Installation Schemes

The installation and placement of antennas and AXON Core units will depend on the wireless coverage

type, rock type and tunnel topology. A few examples of installation schemes in a mine are described and

illustrated in the following sections.

5.4.1 Installation in a Straight Drive

An example of a straight driv e installation sche me is show n in Figure 9: Installation scheme in a straight

drive.

In this example, multiple AXON Core units are fitted with AXON Air access points utilising 15dBi helical

antenna. This creates constant coverage as may be required by a vehicle traveling along the roadway.

Figure 9: Installation scheme in a straight drive

2019 MST Global CommercialinConfidence

20

Page 31

©

A

XON Digital Platform

User Manual

Revision A

5.4.2 Installation in a no line of sight scenari o

A curved decline installation scheme as shown in Figure 10

One of the advance d futures of AXON Air is the ability to b e powered from anoth er AXON Air. This adds

great flexibility in network desi gn. In the ex ample bel ow a AXON Core network switch is collocated i n the

electrical cuddy, this is con venient as the composite cable can be run through a borehole from the

surface and then further to the lower level s. It is not recommend to chain more tha n 3 AXON Air u ni ts

from one PoE+ port on AXON Core. The maximum length of Ethernet cable between AXON Air units is

100 meters, this gives 300 meters if 3 units were chained.

Figure 10: Installation scheme in a curved decline

2019 MST Global CommercialinConfidence

21

Page 32

©

A

XON Digital Platform

User Manual

Revision A

5.4.3 Installation in large underground openings, e.g. Crusher Building.

In large openings, it is advan tageous to use omni- di rectiona l or semi-di recti on al anten na. The exam pl e

here shows AXON Core unit with AXON Air module providing wireless network coverage and PoE

connectivity. AXON Core functi onal i ty i s ex pand ed wi th two optional (soon to be rel eased) pl ugin

modules. Firs t called AXON Control providing autom a t ion capability and the second called AXON

Power, which expands the total number of AXON Core PoE ports to seven.

On the diagram below, there are six IP cameras connected to AX ON Cor e, tw o of which monitor t he

crusher and the other four monitor t rucks reversing towards the crush er. AXON Control module connects

to the sensor measuring the temperature of the main bearing of the crasher, it also drives the crusher

dust suppression solenoid valve via one of its relay outputs. The automation logic, driving the relay is

enabled by the MST SENSA Director software. The dust suppression is turned on only when a truck is

present.

Figure 11: Installation scheme in a Crusher Building

2019 MST Global CommercialinConfidence

22

Page 33

©

A

XON Digital Platform

User Manual

Revision A

5.4.4 Ins tallation at an Intersection

An example installation scheme for an intersection is shown in Figure 12: Install ati on Scheme at an

intersection.

At intersection where fibre connection i s requi red to be conti nued i n all directions, tw o AXON Core

Nodes are required. The distan ce fro m the in terse cti on depends on the s p eci fic re qui rements.

It may be appropriate to move one AXON core with AXON Air attached to it (B) as far as 400 m into the

northern spore roadway and the other (A) in the orthogonal direction closer to the intersection.

A traffic light solution can be implemented if an optional AXON Control module is used inside of the unit

(A). It can be programmed to operate independently of the network.

B

N

A

Figure 12: Installation Scheme at an intersection

2019 MST Global CommercialinConfidence

23

Page 34

©

A

XON Digital Platform

User Manual

Revision A

5.5

Connecting Power to AXON Core

The AXON family of products includes three ru ggedi zed mining uninterrupted power supplies, for f ul l

composite cable installation in operational areas AXON Force is an ideal UPS. The main electrical

benefit is that the output power is 56V DC constant, regardless if mains power is available or not. Most

common UPSs will supply 56V DC if mains power is on; however, the output voltage will drop back to 48

V DC when mains power is off. This means that the DC power design has to consider worst-case

scenario.

MST strongly recommends the use of UPS in underground implementation, as it will ensure clean

reliable DC power and guarantied uptime.

Composite cable can be inserted into other AXON Cores while the system is powered; this allows the

system to be expanded as necessary. Power usage levels should be evaluated prior to adding more

units downstream to ensure that the v ol tage rail doe s not drop too low . A minimum of 20VDC is required

for AXON Core to supply PoE to other dev ices. If the voltage drops below 20 V , additi on al po wer is

required.

The DC power system is dose not allows more than one DC Supply/UPS to be

connected to the same composite cable. This is r e ferred to as “cell” cell s are

interconnected via optical fibre connection only. This typical for DC systems. If

double redundant power is required, please contact MST.

Connect the composite fibre/power cable to a DC power source with correct termination. Note that the

DC supply must be between 20 and 60VDC. Refer to the power supply requirements Section 4.2.

Turn on the DC power supply and verify that the green power ligh t is on. If there i s no green light, refer to

Troubleshooting Guide.

5.6

Handling composite cable during installation

The composite cable is ruggedly buil t for the mining envi ronmen t . How ev er the foll ow i ng precautionary

measures should be noted during instal l ation:

Never pull or create tension on the cable. Unreel the cable from the cable reel, or allow the weight of

the cable to unreel as the vehicle is moving as shown in Figure 13: Handling composite cable.

Do not bend the cable at sharp angles; excessive bending can fracture or break the fibre optic cable.

Do not step on the cable.

2019 MST Global CommercialinConfidence

24

Page 35

©

A

XON Digital Platform

User Manual

Revision A

Figure 13: Handling composite cable

5.7

Connecting Composite Cable to AXON Core

A composite cable is connected to the fibre port of AXON Core. Once connected, it will auto detect

devices and their settings.

IMPORTANT: Protect al l conne ctors and sockets from dust and grit, with minimal

exposure during installation. Any unused sockets must be cov ered by the sup pl i ed

dust caps at all times during installation. Any unused sockets must be covered by

the supplied dust caps at all times.

Branch fibre network out requires simpl y con necting composite cables to the addition al fibre por ts. The

connected fibre ports wil l cause the correspondi ng fibre port LEDs to become active. If you are adding

AXON Core units to an existing system, please consult your MST System Engineer to ensure power

requirements are being met.

5.8

Standard Composite and Fibre Cable Lengths

While custom cable runs can be made whe re necessary, it is faster and cheaper to use standard cable

lengths supplied by MST. Please contact MST for the latest listing of available cable lengths.

5.9

Connecting Ethernet Cable to AXON Core

The external Ethernet po rts are loca ted on the un derside o f AXON Core, and are used to connect to

Ethernet devices (such as computers, Ethernet controlled PLCs, ha rd-wired Etherne t Phones and IP v ideo

devices). An Ethernet cable with a RJ45 connector is used to connect PoE de vices. Ethernet cables are

required to meet specifications for use in a mining environment in Ethernet Cable Specifications

2019 MST Global CommercialinConfidence

25

Page 36

©

A

Procedure Illustration

1. Unscrew the protective cover on the

Ethernet port.

2. Insert the Ethernet cable (with a bayonet

back-shell)

3. Align the protective cover on the cable to the

notch in the mating jack on AXON Core, and

twist to lock the connector into the Ethernet port

4. Securely fasten the cable lead against the

wall/ceiling.

IMPORTANT:

Check that all unused Ethernet ports

remain protected with the supplied

covers.

XON Digital Platform

User Manual

Revision A

5.10

Connecting Antennas to AXON Air

Antennas can be connected directly to the coaxial (RP-TNC) jacks on the unit or mounted remotely by

using coaxial cables. Coaxial cable length should be kept as short as possible (ideally less than 10m) to

minimise signal loss.

IMPORTANT: All cable and antenna connections must be electrically insulated using selfamalgamating rubber tape.

To ensure EN 60950-1 compliance, AXON Air, the antenna and all cabling must be installed in a

location that eliminates the chance of the system being struck by lightning. If an antenna needs to

be installed in a location where it could be struck by lightning, then an appropriate lightning arrestor

must be placed in-line with the antenna and cabling such that AXON Air is not subject to

overvoltages due to lightning.

2019 MST Global CommercialinConfidence

26

Page 37

©

A

XON Digital Platform

User Manual

Revision A

5.11

Manual Reset and Reboot

The AXON Core switch fabric can be manually reset or the whole device can be loaded with default

settings as described below .

Description Picture

Locate and identify the switch Reset Button (RED).

Press and release to reset the switch core

Description Picture

Locate and identify the Default Factory Settin gs

Button (BLACK).

To reset AXON Core to factory default settings,

pres s a n d ho ld th e b u t to n f o r 5 … 15 se c on d s.

2019 MST Global CommercialinConfidence

27

Page 38

©

A

XON Digital Platform

User Manual

Revision A

Chapter 6: Understanding VLANs

Topics:

Understanding Trunk and Access Ports

VLANs and Wireless Networks

Native VLAN

This chapter explai ns the principles behind a Virtual Local Area Network (VLA N). It is important to

understand VLANs to properly configure the network and power distribution module.

A VLAN is a collection of nodes grouped according to their function or application, rather than their

physical location. They are grouped in order to separate and prioritise data within a network, as shown in

Figure 14: VLANs. VLANs are created when multiple applications, such as voice, telemetry, data and

video, are required in a mining network.

Figure 14: VLANs

2019 MST Global CommercialinConfidence

28

Page 39

©

A

XON Digital Platform

User Manual

Revision A

6.1

Understanding Trunk and Access Ports

VLANs can be assigned to trunk ports and acces s ports on a netw or k. Th ese two types of alloca tion

determine how data is transmitted and relayed.

6.1.1 Trunk Ports

Trunk ports typically provide a connection between network switches, and can carry data for multiple

VLANs. They will only tran smi t frames (packets of data) that belong to the port's assigned VLAN s. To

identify the VLAN of each frame, a network switch adds a tag to the fram e (know n as 802.1Q trunking).

The tag contains the followi ng in forma ti on :

VLAN ID — allows the network swi tch receiving a frame to identify the VLAN it belongs to.

Priority ID — allows the network switch to prioritise distribution when multiple frames are being

transmitted. Priority ID ranges from 0-7, where 7 is the highest priority.

When a network swi tch receives a tagged frame, the ta g is read to determine the VLAN it belon gs to. The

tag is removed and distributed to devices connected on the same VLAN.

When the network switch receives multiple frames, it will prioritise the distribution of frames based on the

Priority ID in the VLAN ID tag. For more information on configuring VLANs, see Defining VLANs

6.1.2 Access Ports

Access ports connect client devices such as PCs and laptops to the network switch, and can only be

assigned to a single VLAN. Access ports can only send and rec ei ve untagged frames, with those frames

allocated to the relev ant VLAN inside the switch. Any tagged fra mes sent to an access port will be dropped.

An example of VLAN traffic flow through trun k and access ports is shown in Figure 15: VLAN traffic flow

and described below.

Figure 15: VLAN traffic flow

2019 MST Global CommercialinConfidence

29

Page 40

©

A

XON Digital Platform

User Manual

Revision A

1. A PC sends an untag ged frame into access port 6 (C ontrol V LAN) on netw ork and power

distribution module 1. The frame is sent to other access ports on the Control VLAN (access

port 5).

2. network and power distribution module 1 tags the frame with VLAN ID = 4 and Priority = 5

and sends it thro ugh the trunk ports to network and power distribution module 2.

3. network and power distribution module 2 receives the tagged frame, and identifies the frame

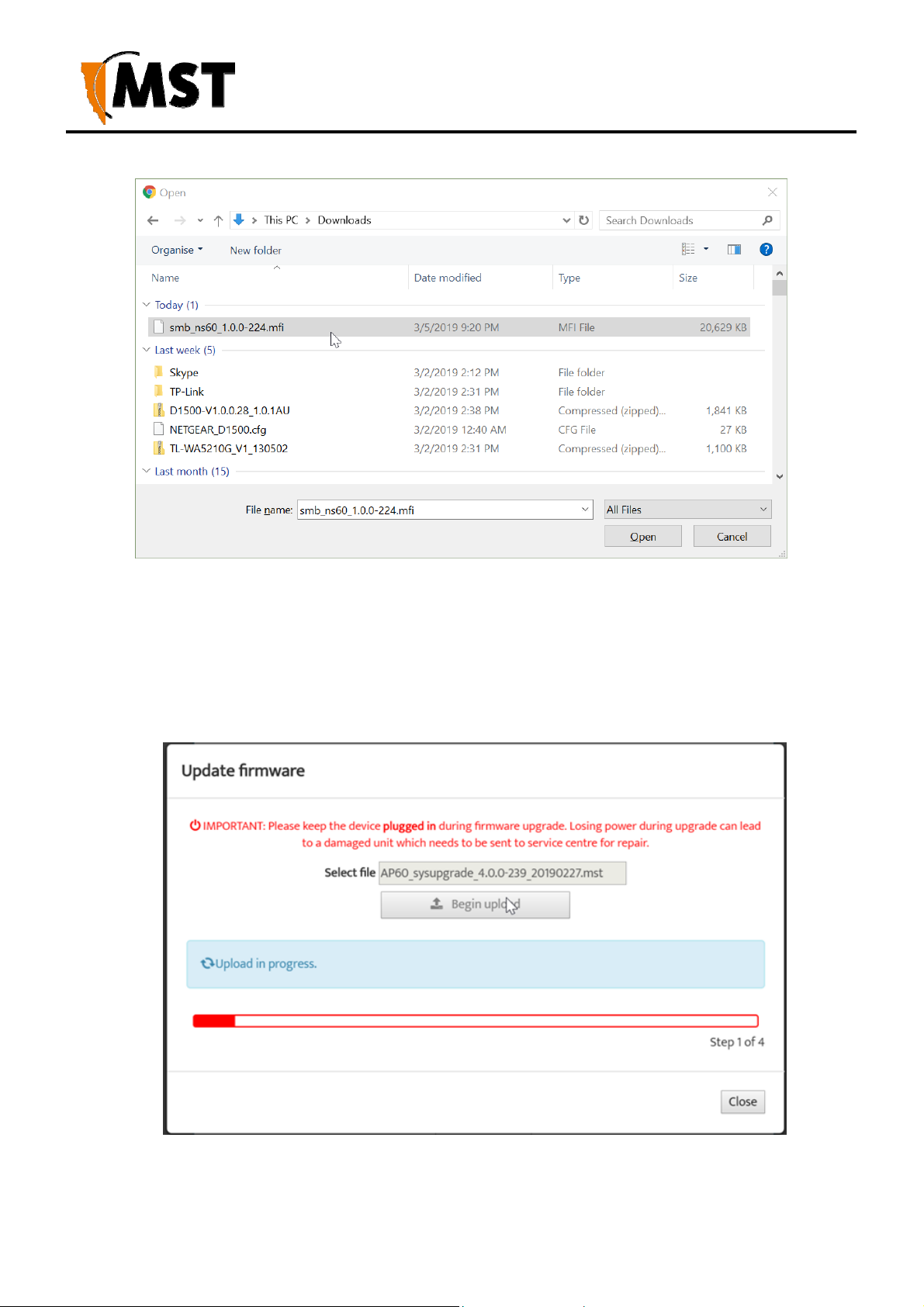

belonging to the Control VLAN.

4. network and power distribution module 2 removes the tag and sends the frame to all ports

on the Control VLAN (access ports 5 and 7).

5. If network and power distribution module 1 receives multiple frames, they are tagg ed and

sent via trunk ports to network and power distribution module 2.

6. network and power distribution module 2 receives the frames and prioritises distribution.

2019 MST Global CommercialinConfidence

30

Page 41

©

A

XON Digital Platform

User Manual

Revision A

6.1.3 Port Allocation

Physical ports on A XON Core can be configured t o be either a t runk port or acce ss port using the web

browser interface or editing site configurati on files w hen Trivi al File Trans fer Protocol ( TFTP) is used.

AXON Core default configuration has ports 1-8 alloca ted as trunk ports . Ports 1-4 are usual ly connected

to othe r AXON Core units, and ports 5-8 are connected to WAPs or other PoE devices. For more

information on configuring ports and VLA N memb ership, see Configu ri ng the VLAN Port Map

6.2

VLANs and Wireless Networks

The network and power distribution module can have up to four wireless Service Set

Identifiers (SSIDs) per WAC. Each SSID is associated with a single VLAN and functions as

an access port on that VLAN. An example of a wireless network is shown in Figure 16: An

example of VLAN and wireless networks and described below.

Figure 16: An example of VL AN and wireless networ ks

1. An untagged frame is s ent from a Laptop 1 thr ough a wireless network (SSID = Data) on the

network switch.

2. The frame is tagged by the network switch and is sent through the trunk port to the WAP.

3. The WAP identifies the tagged frame as belonging to the Data VLAN and removes the tag.

4. The untagged frame is sent via the wireless network (SSID = Data) to Laptop 2.

2019 MST Global CommercialinConfidence

31

Page 42

©

A

XON Digital Platform

User Manual

Revision A

6.3

Native VLAN

Trunk ports on the network and power distribution modul e also sup po rt a Native VLAN. The Native

VLAN is where untagged frames will be allocated. On the network switch, the native VLAN is always the

Infrastructure VLAN. Thi s all ows cl ien t dev ices such a s PCs or l aptops to access an d ma nage the

network switch when they are connected via a trunk port.

The Infrastructure VLAN i s mandatory in the netw ork switch and cannot be deleted.

An example of native VLAN functionality is illustrated in Figure 17: An example of native VLAN and

described below.

Figure 17: An example of native VLAN

1. The PC sends an untagged frame to Trunk port 3 on network and power distribution module

1.

2. The frame is allocated to the Infrastructure VLAN.

3. The management CPU of network and power distribution module 1 is always an Access port

on the Infrastructure VLAN and will receive the frame.

4. The untagged frame would also go to network and power distribution module 2 via the Trunk

ports between the network switch units.

5. network and power distribution module 2 allocates the untagged frame to the Infrastructure

VLAN.

6. The management CPU of network and power distribution module 2 is always an Access port

on the Infrastructure VLAN and will receive the frame.

2019 MST Global CommercialinConfidence

32

Page 43

©

A

XON Digital Platform

7. Any frame leaving the Management CPU is placed on the Infrastructure VLAN.

8. All frames on the Infrastructure VLAN are sent out untagged on Trunk ports.

User Manual

Revision A

2019 MST Global CommercialinConfidence

33

Page 44

©

A

XON Digital Platform

User Manual

Revision A

Chapter 7: Configuration Using the Web Interface

Topics:

Logging in

Status Tab

Configuration Tab

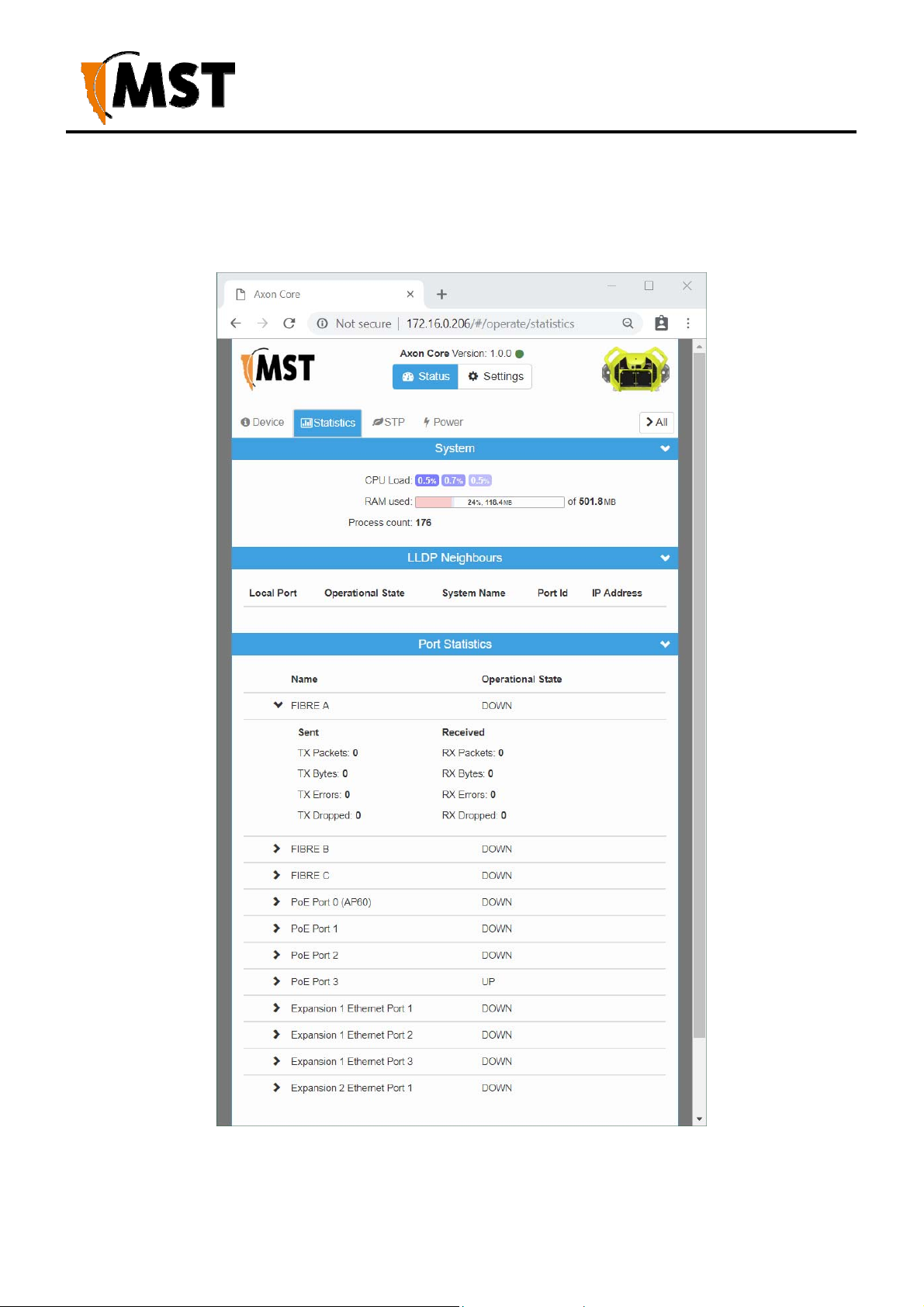

This chapter describes how to configure a network device using a web browser. Please note that

screenshots may vary slightly from those shown, depending on your current firmw are v ersio n.

AXON Core and AXON Air have a built-in web-server that is accessible by a PC to configure settings. A

PC can access the web browser interface by making a TCP/IP connection to the device. For more

information, see C onnect ing a PC to an Network Device.

The IP address of the network device can be located and configured using the MST Device Scanner

tool. For more information on how to use the Device Scanner, see Device Discovery.

7.1

Logging onto the Web Browser Interface

The web browser interface has a login front screen with access at two levels:

ADMIN — Allows settings to be viewed and modified. The default password is ‘admin’.

USER — Allows settings to be viewed but not modified. By default, there is no password.

NOTE:

By default, AXON Core is configured to use DHCP. To find the IP address of a newly

connected device, use the MST Device Scanner.

Devices running early versions of firmware may default to 192.168.1.100.

To log in to the web browser interface:

1. Launch your web browser and enter http://<IP address> in the address field.

2. The login screen is displayed.

2019 MST Global CommercialinConfidence

34

Page 45

©

A

XON Digital Platform

User Manual

Revision A

3. In the Sign in dialog box, en t e r ad min a s u se rn a me a nd t he p a ss wo rd . The factory default

password is admin.

4. Click Sign In. The Device Status screen will be displayed.

STATUS

1. Device

a. General

i. Name – Unique name of the device by which it is known on the network and

managements console. OS hostname .

ii. Uptime – Elapsed time since startup

iii. Time – Current time

iv. Site Change Number – Version of the applied site-wide configuration file

v. Device Change Number – Version of the applied device specific

configuration file

b. Firmware Details

i. Name – Name of the firmware component

ii. Build version – Unique identifier of the release in the form (major.minor.release-build)

2019 MST Global CommercialinConfidence

35

Page 46

©

A

XON Digital Platform

User Manual

Revision A

c. Network

i. IP Address – current ma na gement IP address of the device, configured or acquired

from DHCP

ii. Subnet mask

iii. Gateway

d. Device Information

i. Model – Internal MST equipment code

ii. Revision

iii. Manufacture date

iv. MAC

v. Serial

e. Temperatures (AXON Core only)

i. Power management CPU

ii. Switch CPU

iii. Power brick – POE 54V step-up/step-down power supply temperature

iv. Switch mode power supply – 3.3V power supply temperature

2. Wireless (AXON Air only)

2019 MST Global CommercialinConfidence

36

Page 47

©

A

XON Digital Platform

User Manual

Revision A

a. Radio

i. Enabled – Yes or No

ii. Channel – Channel currently in use

iii. Regulatory domain – Country code where the device is installed.

Determines which channels will be available to comply with local

regulation.

b. Access points

i. SSID

ii. Enabled

iii. BSSID

iv. Security

2019 MST Global CommercialinConfidence

37

Page 48

©

A

3. Statistics

XON Digital Platform

User Manual

Revision A

c. Mesh

i. Mesh state

ii. Associated stations

iii. Mesh paths

d. Mesh map – displays nodes participating in the mesh with corresponding diagnostic

information

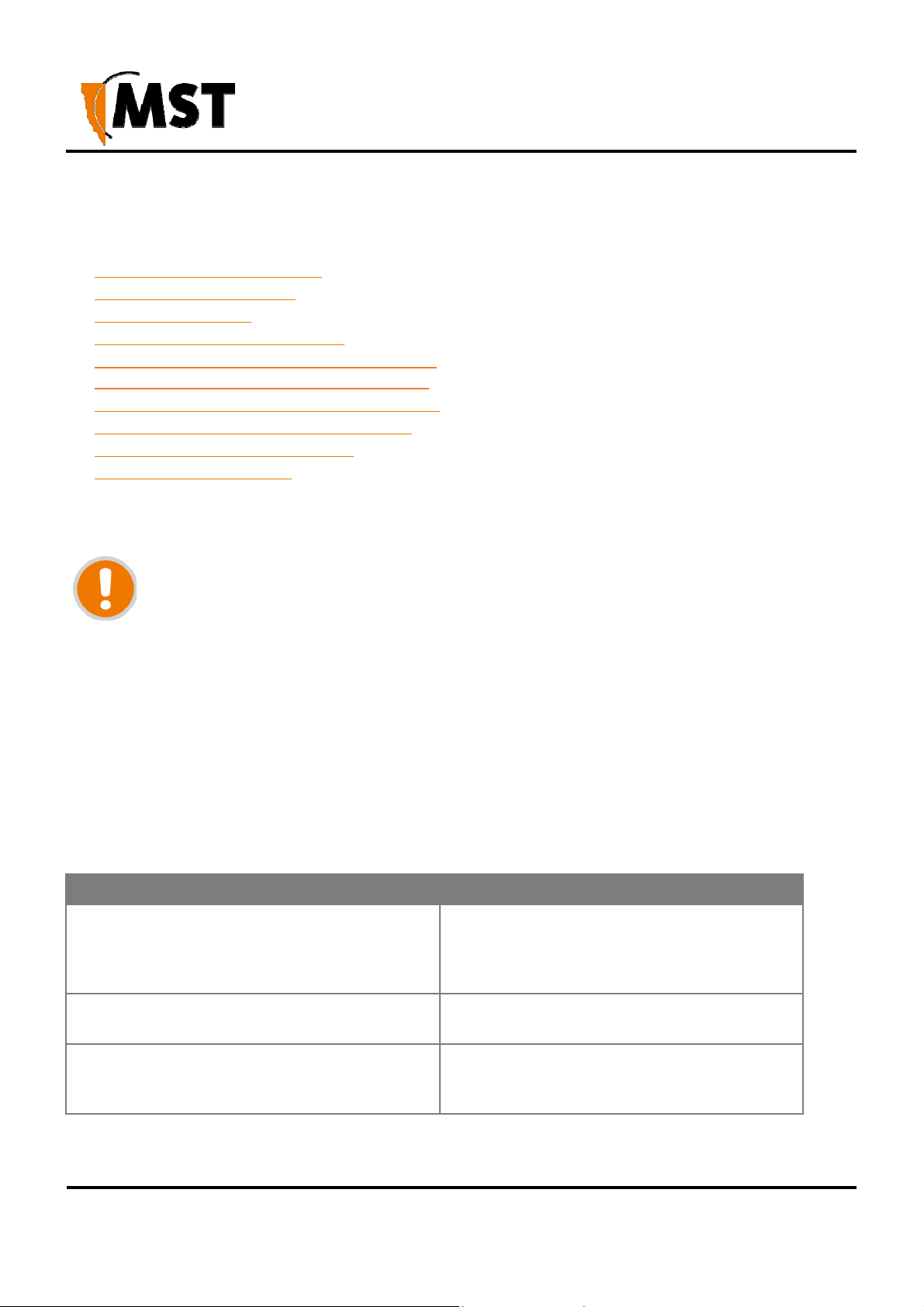

a. System

i. CPU load – shows 1 minute, 5 minute and 15 minute CPU load average

ii. RAM used – shows percentage and MB used memory, total available

RAM. Mouse over shows free MBs.

iii. Process count

2019 MST Global CommercialinConfidence

38

Page 49

©

A

XON Digital Platform

User Manual

Revision A

b. LLDP Neighbours – lists all directly connected wired devices

i. Local port – identifies local port to which a remote device is connected

ii. Operational state – UP or DOWN

iii. System name – the name of the remote host

iv. Port Id –port identifier on the remote system to which the local device is

connected

v. IP Address – IP address of the neighbouring device (http link to device

management web page)

c. Port Statistics

i. Name – Local port identifi er

ii. Operational state – UP or DOWN

iii. Sent, Received:

1. TX Packets – number of packets sent and received

2. TX Bytes – number of bytes sent and received

3. TX Errors – numbe r of errors sent and received

4. TX Dropped – number of dropped packets on send and recei v e

4. STP (AXON Core only)

2019 MST Global CommercialinConfidence

39

Page 50

©

A

–

v

XON Digital Platform

User Manual

Revision A

a. General

b.

5. Power

i. Version

ii. Bridge ID Priority iii. Bridge ID Address

iv. Root I D Priority

v.

Root ID Address

Ports

i. Local Port – port identifie r

ii. Link Up – yes/no

iii. Priority

iv. Cost

v. State– Disable or Forwarding

i. Role –Disabled, Designated PortorRoot Port

2019 MST Global CommercialinConfidence

40

Page 51

©

A

XON Digital Platform

User Manual

Revision A

a. Each Controller

i. Port Name

ii. Enabled – Yes or No

iii. Port Status – Off (unplugged), Good (plugged in, powered), Failure (tripped, over-

current). In case of failure, additional reason for failed status will be shown

iv. Power Threshold – Currently negotia ted CLA S S for the plug ged in dev i ce

b. Measurements

i. Input Voltage

ii. Composite Port A-C – Current flow through the composite po rt in Amps.

Positive value shows current entering, and negative value shows current

leaving the device.

iii. Power CPUs – Current consumption of the management CPU plus the

microcontroller

iv. Power POE – Current consumption of all POE devices including voltage

step-up / step-down overheads

v. Power Total – Combined total consumption for the whole AXON Core

device (CPUs + POE supply).

2019 MST Global CommercialinConfidence

41

Page 52

©

A

6. Tracking (AXON Air only)

a. Live Tag Reads

XON Digital Platform

User Manual

Revision A

i. Search Mac Address – type part of the tag MAC address to filter the l i st

ii. MAC Address – shows the MAC address of the tag recognised

iii. RSSI – Relative Signal Strength Index – the value in dB of the signal

strength received

2019 MST Global CommercialinConfidence

42

Page 53

©

A

XON Digital Platform

User Manual

Revision A

iv. Sequence – the sequence number of the fra me broadca st by the tag.

Keeps increasing by one with each ‘chirp’ (chirp period is configurable on

the tag)

v. Exciter ID – In addition to periodical l y broadca sting a frame, tags can also

broadcast when excited by the vicinity of an exciter in which case the

exciter ID will be shown

vi. Time since seen – time elapsed since the last ti m e a signal from the tag

was received

SETTINGS

All pages are showing currently configured values. To modify, use Configure button to enter edit mode

and Save or Cancel to finish.

1. Network

a. Network

2019 MST Global CommercialinConfidence

43

Page 54

©

A

XON Digital Platform

User Manual

Revision A

i. Name – Descriptive name for easier management (e.g. Infrastructure,

Voice, Data, etc.)

ii. VLAN ID – Unique VLAN TAG ID between 1 and 4095

iii. Priority – Value 0 to 7

iv. Enabled – Yes or No

b. VLAN Port Map – Allows port configuration and assigning ports to VLANs

i. Port – Local port identifier (Fibre, PoE, Expansion, …)

ii. Enable – Yes or No

iii. Speed & Duplex – Data transfer speeds and Half/Full duplex settings.

Default: Auto negotiated.

iv. Mode: Trunk or Access – Traffic send and received from Trunk will

contain VLAN tags, traffic on Access port not contain VLAN frames. See

VLAN configuration tutorial.

2. Wireless (AXON Air only)

2019 MST Global CommercialinConfidence

44

Page 55

©

A

XON Digital Platform

User Manual

Revision A

a. Radio

b. Access points

c. Mesh

i. Enabled – Yes or No

2019 MST Global CommercialinConfidence

45

Page 56

©

A

ii. SSID – The SSID of the mesh network

iii. Security mode – Open (no security) or SAE

iv. Pre-shared key – Password for SAE security

v. RSSI threshold –

vi. Mode operation – None, Gate Announcements or Path Requests & Replies

3. STP (AXON Core only)

a. STP/RSTP Settings