Page 1

TM

Service & Troubleshooting

M&S Systems is committed to producing high

quality audio products for the home. If you have

any questions or problems with the speaker

systems or the system is not operating properly,

contact your WaveGuide installer or call M&S

Systems at (800) 366-9422.

TM

In-Wall & Ceiling Speakers

2861 Congressman Lane

Dallas, TX 75220

800.877.6631

www.mssystems.com

Owner’s Manual

Part Numbers

WG100C WG100W

WG150C WG150W

115986

Page 2

TM

TM

Introduction

WaveGuide ceiling and in-wall speakers are

designed to provide clear, sharply-focused audio

reproduction while remaining unobtrusive in the

background. These speakers bring out the best in any

home theater or whole-house stereo system. These

products also offer many features, including:

• 1” Asymmetrical Aluminum Dome Tweeter

• Slide switches for bass and treble control

(+/-3dB)

• Cam-lock mounting system with isolated

rubber pads to reduce vibration

• Kevlar cone for low distortion and smooth

response

• Molded in IR lens that allows installation of an

infra-red receiver through the speaker baffle

• Gasket around the baffle to provide an

acoustic seal

Description

Ceiling Speakers

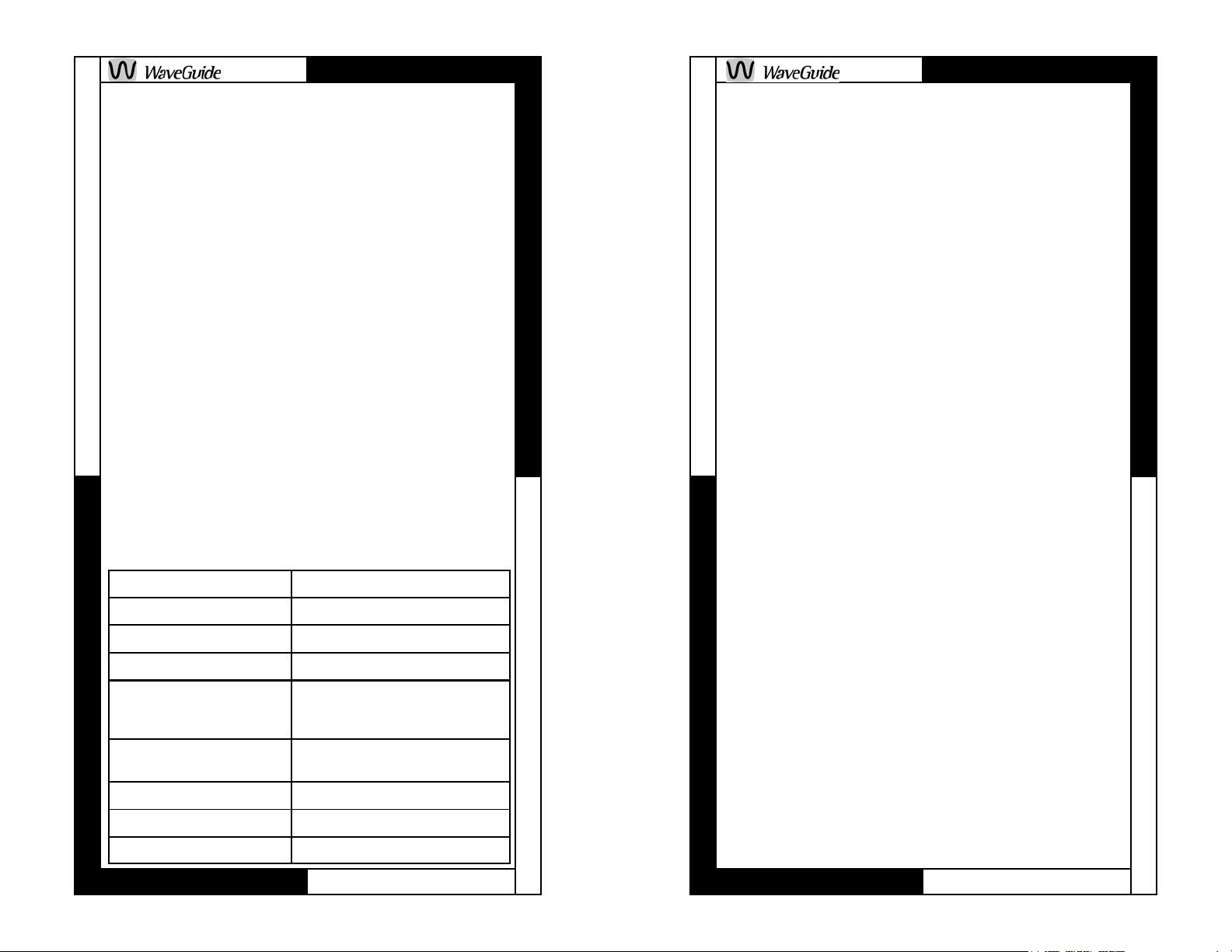

WG100C

Frequency Response 50Hz to 20kHz (+/-3db)

Maximum Power Rating 100 Watts

Impedance Rating 8-Ohms

Overall Speaker Dimension 9” Diameter

Specifications 6” Kevlar cone woofer;

Mounting Dimension w/o

Mounting Ring

Mounting Ring Dimension 8 3/16” Diameter

Grille Aluminum

Color White

(Sold in Pairs)

1” asymmetrical aluminum dome

tweeter

7 1/2” Diameter

WARRANTY

M&S Systems™ Limited 10-Year Warranty for WaveGuide™

Speakers and AirVac™ Gold Power Units

M&S Systems offers a 10-Year Warranty on our WaveGuide™

speakers and AirVac™ Gold power units. This warranty is identical

to the M&S Systems™ 2-Year Warranty, with the exception that this

warranty covers the WaveGuide™ speakers and AirVac™ Gold

power units for 10 years instead of 2. The M&S Systems™ 10-Year

Warranty applies ONLY to the WaveGuide™ speakers and

AirVac™ Gold power units and to no other M&S Systems™, M&S™

8- ohm or AirVac™ products.

M&S Systems Limited 2-Year Warranty

M&S Systems warrants its products to be free of defects for 2 years.

Except for the WaveGuide™ Speakers and AirVac™ Gold power

units (See above). The warranty period begins on either (a) the date

of purchase or installation date of this product or (b) the date of

closing on a new residence in which this product was originally

installed.

The warranty extends to the original user of the product and to each

subsequent owner of the product during the term of the warranty.

M&S™ will repair or replace, at its option, parts and materials at no

charge. Parts supplied under this warranty may be new or rebuilt at

the option of M&S Systems™.

If during the warranty period the product appears to have a defect,

please call our toll free service number (800-366-9422) prior to

dismantling. Dismantling the product prior to calling our service

number may void the warranty. Before returning any product to M&S

Systems™, obtain a Return Authorization Number (RAN) from our

service department. M&S Systems will return the repaired

product freight prepaid within the continental United States. ANY

PRODUCT RETURNED TO M&S SYSTEMS WITHOUT A RAN

NUMBER WILL BE REFUSED.

This limited warranty is in lieu of any other warranties, express or

implied, including any implied warranty of merchantability or fitness

for a particular purpose or otherwise, and of any other obligations or

liability on the seller’s part. This limited warranty does not cover

damage caused by improper installation, acts of God, criminal acts,

the violation of applicable building or electrical codes or the use of

non-M&S wire, cable (excluding CAT5 and RG-6) or wall housings.

Under no circumstances shall M&S Systems™ be liable for

consequential, incidental or special damages arising in connection

with use, or inability to use this product. In no event shall M&S

Systems™ liability hereunder exceed the cost of the product

covered hereby. No person is authorized to assume for us or

obligate us for any other liability in connection with the sale of this

product. Some states do not allow the exclusion or limitation of

consequential, incidental or special damages, so the above

limitation or exclusion may not apply to you. This limited warranty

gives you specific legal rights, and you may also have other rights,

which vary from state to state.

Page 2

Page 2

Page 23

Page 3

TM

TM

red wire in the red terminal and the black wire in

the black terminal. See figure 10. Make sure that

none of the strands from the black and red wires

are touching each other. This can create a short

circuit that can damage your electronics. Mount

the baffle to the frame using the 6 screws

provided. Do not over tighten the mounting

screws.

Step 12. After the speaker is mounted,

adjustments to the swivel tweeter (small speaker)

can be made by either directing the sound

visually or by using a musical source to

determine the best sound coverage for the

listening area. To position the tweeter, press at

the outside edge of the tweeter housing (DO

NOT PRESS ON THE CONE DIRECTLY).

Note the crease in the asymmetrical tweeter

provides the highest directional response in this

direction. See figure 11 on page 14.

If you require to disperse the sound in a 360degree pattern you must position the line in the

tweeter in a horizontal position. See figure 12 on

page 15.

The combination of switch settings allow you to

boost and cut bass and treble +/-3dB. Adjust the

speaker level to accommodate for room

acoustics. See figure 13 on page 15.

Step 13. Divide each adhesive bead strip in half.

(Adhesive bead strips are in the clear self-closing

bag). Place strips on the edge of the grille as

shown in figure 14 on page 15. Reinstall the grille

on the speaker.

Step 14. Adhere the WaveGuide logo to the grille

with the pressure sensitive tape.

WG150C

Frequency Response 35Hz to 20kHz (+/-3db)

Maximum Power Rating 150 Watts

Impedance Rating 8-Ohms

Overall Dimensions 10 7/8” Diameter

Specifications 8” Kevlar cone woofer;

1” asymmetrical aluminum dome

tweeter

Mounting Dimension w/o

Mounting Ring

Mounting Ring Dimension 10 1/16” Diameter

Grille Aluminum

Color White

In-Wall Speakers

9 5/8” Diameter

(Sold in Pairs)

WG100W

Frequency Response 50Hz to 20kHz (+/-3db)

Maximum Power Rating 100 Watts

Impedance Rating 8-Ohms

Overall Dimensions 9” W x 12 5/16” H

Specifications 6” Kevlar cone woofer;

1” asymmetrical aluminum dome

tweeter

Mounting Dimension w/o

Mounting Ring

Mounting Ring Dimension 7 15/16” W x 11” H

Grille Aluminum

Color White

7 1/2” W x 10 13/16” H

Page 22

Page 3

Page 3

Page 4

TM

TM

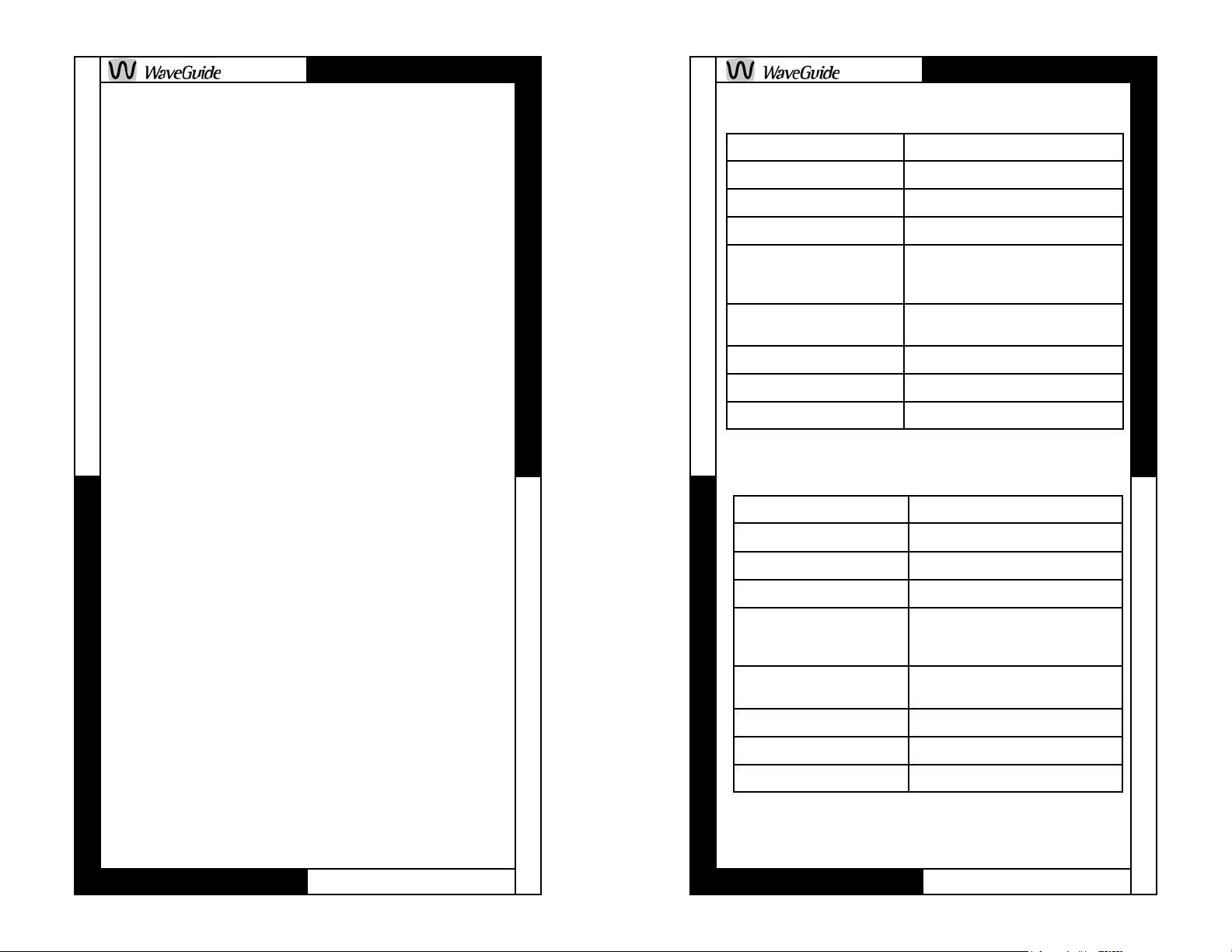

WG150W

Frequency Response 35Hz to 20kHz (+/-3db)

Maximum Power Rating 150 Watts

Impedance Rating 8-Ohms

Overall Dimensions 10 1/4” W x 14 15/16” H

Specifications 8” Kevlar cone woofer;

1” asymmetrical aluminum dome

tweeter

Mounting Dimensions w/o

ring

Mounting Ring Dimension 9 3/16” W x 13 3/16” H

Grille Aluminum

Color White

8 11/16” W x12 3/4” H

Unpacking Your Speakers

Before you unpack your speakers, be extra

careful not to touch the cone and tweeter

materials. After carefully unpacking your

speakers, the carton and the packing material

should be saved for possible use later. If any

speaker appears to be damaged, do not attempt

to repair or to connect the unit to the amplifier.

Repack the speaker and notify your distributor or

M&S Systems for replacement or repair.

Speaker Location

Ceiling Installation

Careful consideration must be given to the

speaker location to realize the full frequency

range. Ceiling speakers should be spaced 6 to 8

feet (6 feet for 8-foot ceilings and 8 feet for 10-

tearing wallpaper. Then use a drywall or keyhole

saw to cut along the scored line. Make sure that

you do not cut the hole larger than the outline.

Step 7. Be sure to clear any insulation material

from the speaker back.

Step 8. After you have determined the speaker

locations secure a 16 gauge 2 conductor cable to

the stud using an insulated staple. Leave at least

18 inches of additional cable for connection

during final speaker installation. Run the other

end of the speaker cable to the audio source.

Step 9. Prepare the speaker wiring by stripping

off approximately 3 inches of the outer jacket

(care should be taken so the insulation on the

wires inside the jacket are not damaged) also

strip approximately 3/8 inch off the ends of the

two inside conductors. Twist the ends of the

stranded cable so the wires are tight.

Step 10. Follow the instructions included with the

volume control and amplifier.

Step 11. You are now ready to install the frame.

Remove the paint mask. Be careful not to touch

the speaker cones and tweeters when

removing the paint mask in order to prevent

any damage. Remove the baffle from the frame

and fasten the frame to the drywall. Index the

mounting tabs to make sure that all tabs will clear

the opening. Insert the frame in the wall and

tighten the tabs with the screws on the front of

the baffle. Attach the speaker cable to the

speaker by pressing down on the red (+) or black

(-) gold-plated push terminals and inserting the

Page 4

Page 21

Page 5

TM

TM

sound. When the sound is deeper and more

hollow sounding, you are between studs.

When the sound is sharper and more flat

sounding, you are close or over a stud.

• Identify studs by the position of electrical

outlets or switches. There may be a stud

directly to the left or right of these electrical

fixture. This gives you a point of

measurement since studs are either 24 or 16

inches on center in newer houses, 12 inches

in older homes.

Step 2. When you are sure of where the wall’s

studs are (and are completely sure there isn’t an

electrical cable, water pipe or heating duct in that

vicinity of the wall), use a level and position the

cardboard mounting template, and draw around

the outer perimeter with a pencil.

Step 3. Drill a 1-inch hole in the center of the

pencil outline which you have just drawn, just

deep enough to fully penetrate the drywall.

Step 4. Obtain a length of stiff wire such as a

straightened wire cost hanger. Bend it so that

the last 6 or 8 inches is at a right angle to the

rest.

Step 5. Insert the bent part into the 1-inch hole

you just drilled and probe to the left and the right

to confirm that a stud is not too close on either

side. Move the wire around in a circular motion to

check clearances above and below the hole as

well.

Step 6. If there are no obstructions, carefully

score the penciled outline of the template with a

sharp utility knife to avoid chipping paint or

foot ceilings and above) apart but no closer than

2 feet to any adjacent wall. Avoid placing

speakers in air return cavities. Some type of

protection will be required for the back of the

speaker if blown insulation is used. The following

is a partial list of ways to protect the speaker:

• Use an RE-16 speaker cover

• Use a piece of wood that will cover at least 3

feet on either side of the speaker opening.

The ends may be partially closed to keep the

blown insulation from reaching the speaker,

however, a minimum gap of 2 inches at each

end is better than a sealed box

• Use a piece of bat insulation at least 3 inches

thick over the back of the speaker. This

insulation should not have a backing or if it

does, the backing must be installed facing

away from the speaker.

• Use a fine mesh to cover the back of the

speaker to protect against bulk type insulation

materials. This will not work with insulation

containing fine powders.

Do not install speakers in joist cavities containing

120/240V appliances, within 18 inches of dimmer

light fixtures, security wiring and other control

wiring.

In-wall Installation

Careful consideration must be given to the

speaker location to realize the full frequency

range. In-wall speakers should be spaced 6 to 8

feet apart but no closer than 2 feet to any

adjacent wall or ceiling. Typical height from the

floor would be in the 4 to 6 foot range. Avoid

placing speakers in air return wall cavities,

outside walls or walls containing plumbing.

To reduce vibration into a room on the back side

Page 20

Page 5

Page 6

TM

TM

of the speaker, use a piece of bat insulation at

least 3 inches thick in the stud cavity. This

insulation should not have a backing or if it does,

the backing must be installed facing away from

the speaker. The insulation should extend about

2 ft. on either side of the speaker opening.

Do not install speakers in outside walls, stud

cavities containing 120/240V appliances, within

18 inches of dimmers, security wiring and other

control wiring.

Speaker Installation

for New Construction

Ceiling Speakers

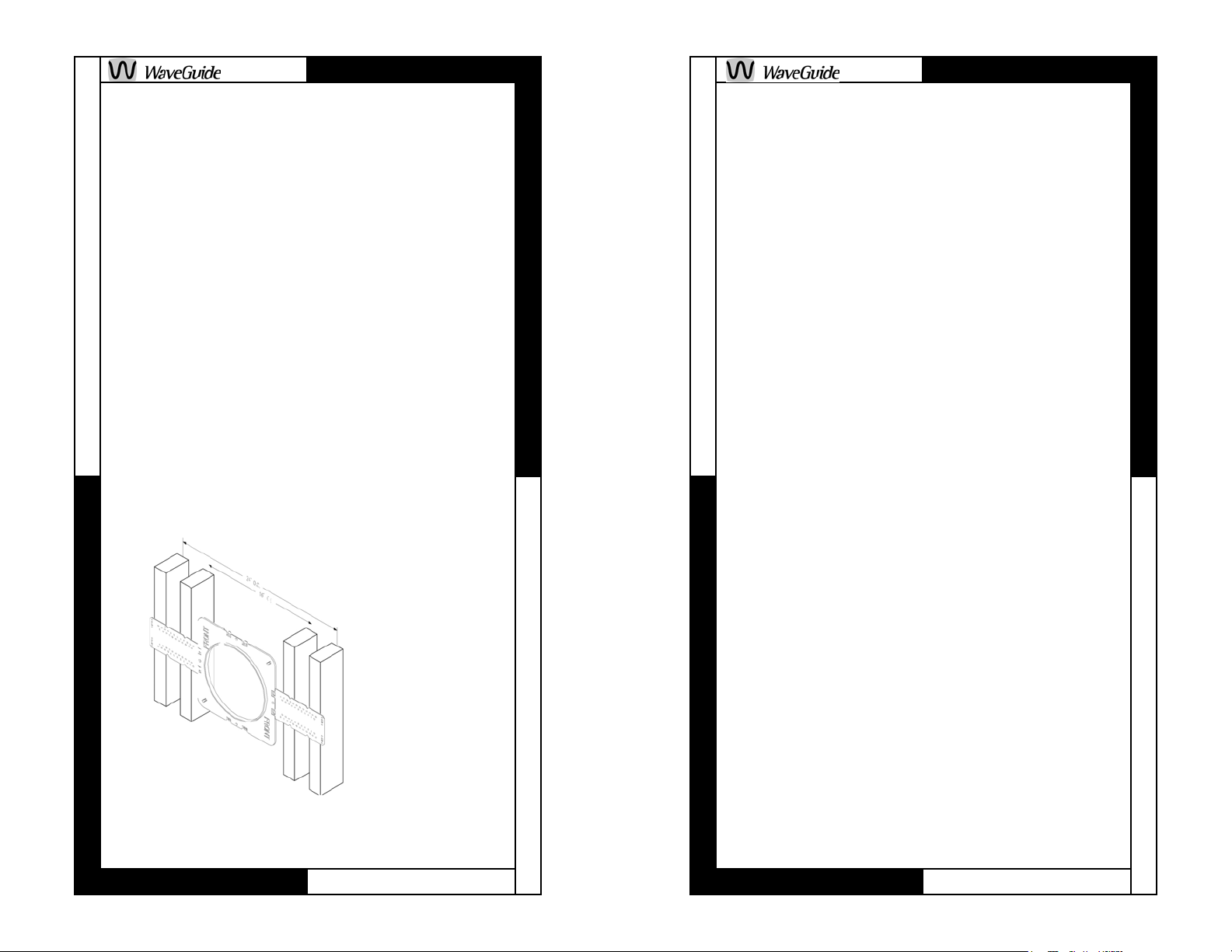

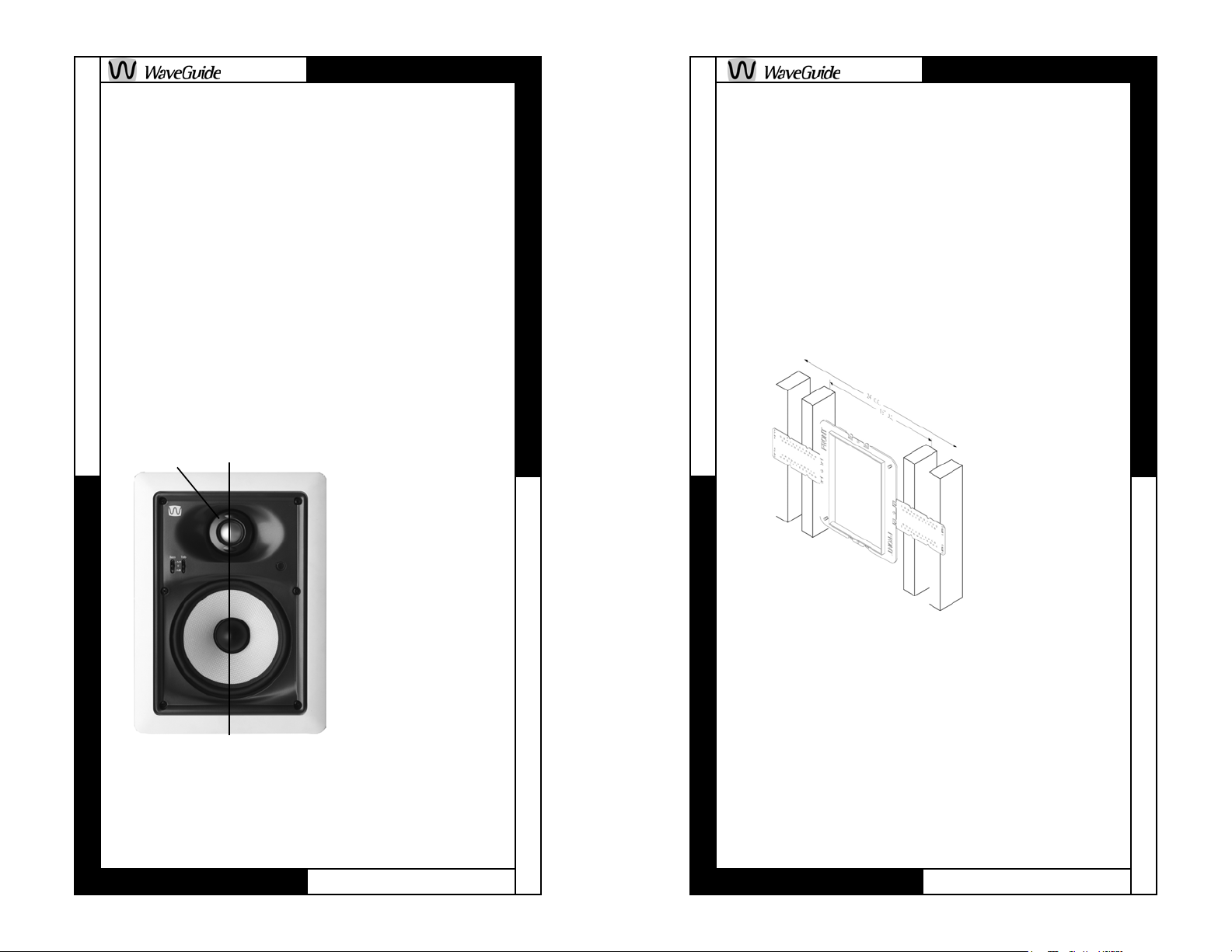

Step 1. Speaker mounting rings are used in the

pre-construction phase of speaker installation

during construction of new homes and additions.

WaveGuide mounting rings are designed to

provide drywall installers the correct cut-out

pattern for the

speakers. The

mounting rings

have “flaps” that

are nailed/

screwed/

stapled onto the

joist. See figure

1. Once the wall

board is

FIGURE 1

When installing the mounting ring, note that there

are holes molded into the mounting ring for

installed, the

opening is cut

out to mount

the speaker.

If you require to disperse the sound in a 360degree pattern you must position the line in the

tweeter in a horizontal position. See figure 5 on

page 10.

The combination of switch settings allow you to

boost and cut bass and treble +/-3dB. Adjust the

speaker level to accommodate for room

acoustics. See figure 6 on page 10.

Step 13. Divide each adhesive bead strip in half.

(Adhesive bead strips are in the clear self-closing

bag). Place strips on the edge of the grille as

shown in figure 7 on page 10. Reinstall the grille

on the speaker.

Step 14. Adhere the WaveGuide logo to the grille

with the pressure sensitive tape.

Repeat steps for the second speaker.

In-wall Speakers

For existing construction, the use of rough-in

rings can not occur. The following steps outline

how to locate a section between two wall studs,

mark the outer boundaries of the hole, drill a

small hole in the center to verify the location and

then cut the main hole.

Step 1. Determine the location of the wall studs

so the speaker can be centered approximately

between them. There are several ways to go

about this:

• Use an electronic stud finder. Many stud

finders can also indicate the location of live

AC wiring.

• Tap on the wall and listen to the resulting

Page 6

Page 19

Page 7

TM

TM

stranded cable so the wires are tight.

Step 10. Follow the instructions included with the

volume control and amplifier.

Step 11. You are now ready to install the

speaker. Remove the paint mask from the baffle.

Be careful not to touch the speaker cones and

tweeter when removing the paint mask in

order to prevent any damage. Attach the

speaker cable to the speaker by pressing down

on the red (+) or black (-) gold-plated push

terminals and inserting the red wire in the red

terminal and the black wire in the black terminal.

See Figure 3 on page 8. Make sure that none of

the strands from the black and red wires are

touching each other. This can create a short

circuit that can damage your electronics. Index

the mounting tabs to make sure that all tabs will

clear the opening. Insert the speaker in the

ceiling and tighten the tabs with the screws on

the front of the grille. DO NOT OVERTIGHTEN

THE SCREWS, the screws should only be tight

enough to secure the speaker.

Step 12. After the speaker is mounted,

adjustments to the swivel tweeter (small speaker)

can be made by either directing the sound

visually or by using a musical source to

determine the best sound coverage for the

listening area. To position the tweeter, press at

the outside edge of the tweeter housing (DO

NOT PRESS ON THE TWEETER CONE

DIRECTLY).

Note the crease in the asymmetrical tweeter

provides the highest directional response in this

direction. See figure 4 on page 9.

speaker wire tie-off.

TIPS FOR NEW CONSTRUCTION

• If possible, run speaker wires after AC

wiring is in place to avoid additional noise

caused by close proximity of wiring.

• Secure the speaker wires against a joist with

insulated staples, being careful not to pierce

the wire insulation. Allow slack for building

material expansion.

• Horizontal wire runs should be routed through

holes drilled at equal heights in the joist.

• Do not install the actual speaker until the wall

board is in place. Until then leave several feet

of wire secured to the back of the mounting

ring. The excess wire can be removed during

final installation.

• During the drywall installation, make sure the

speaker cut-out hole does not extend farther

than 1/4 inch from the inside of the mounting

ring. The flat rough-in rings and flaps are thin

enough that they won’t interfere with wall

board installation.

FIGURE 2

Step 2. After

you have

determined

the speaker

locations

using the

guidelines

above, secure a 16

gauge 2conductor

cable to the

mounting ring

Page 18

Page 7

Page 8

TM

TM

tabs (see figure 2), such as the M&S Systems

MS16X, for attachment to the speakers after the

dry wall has been installed. Leave at least 18

inches additional cable for the connection during

final speaker installation. Run the other end of

the speaker cable to the audio source.

NOTE: Make a drawing of each speaker location.

This will assist you in locating the wires if they

have been covered after the wall board has been

installed.

Step 3. This is the finish-out stage. Prepare the

speaker wiring by stripping off approximately 3

inches of the outer jacket (care should be taken

so the insulation on the wires inside the jacket

are not damaged) also strip approximately 3/8

inch off the ends of the two inside conductors.

Twist the ends of the stranded cable so the wires

are tight.

Step 4. Follow the instructions included with the

volume control and amplifier.

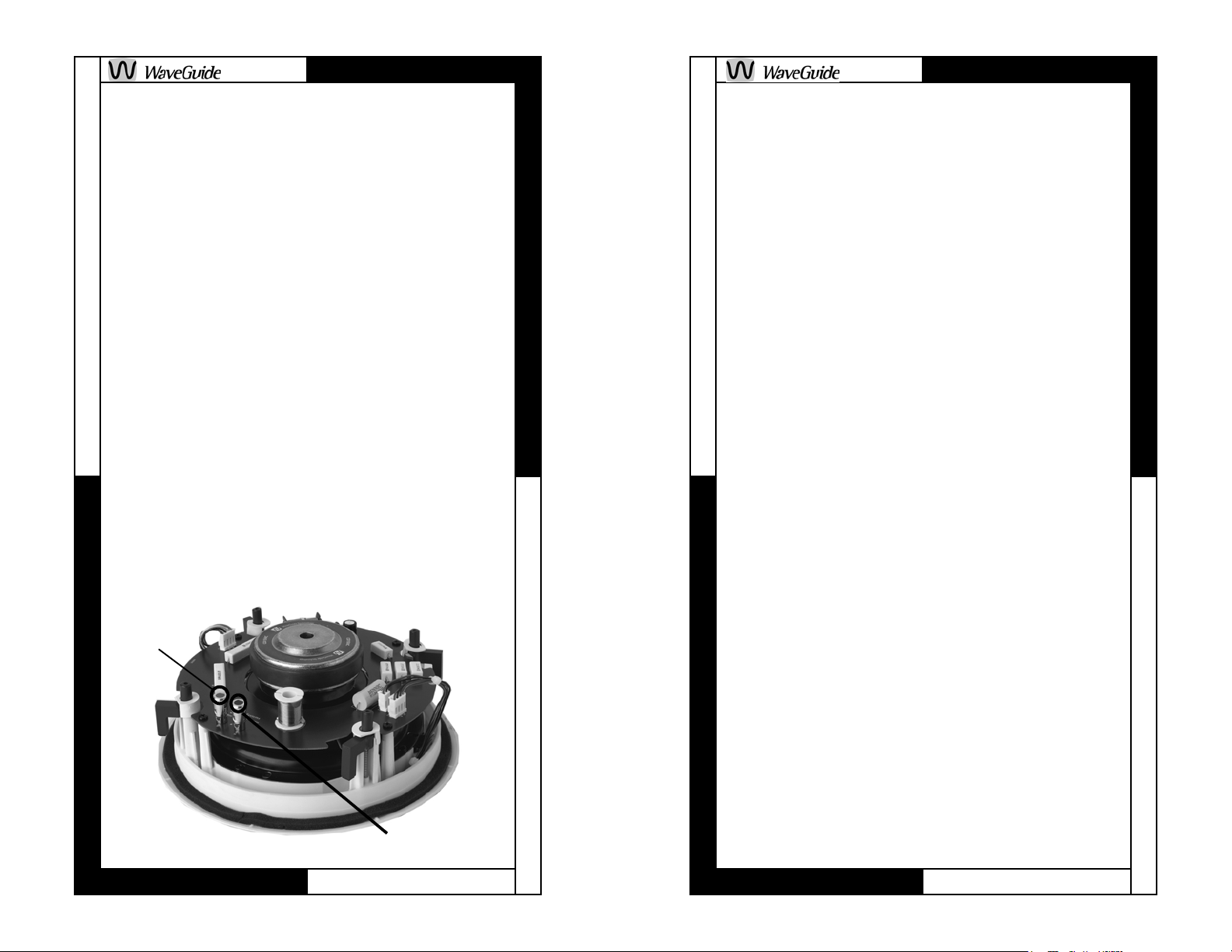

Step 5. You are now ready to install the speaker.

FIGURE 3

Positive

(red)

Negative (black)

pencil outline which you have just drawn, just

deep enough to fully penetrate the drywall.

Step 4. Obtain a length of stiff wire such as a

straightened wire cost hanger. Bend it so that the

last 6 or 8 inches is at a right angle to the rest.

Step 5. Insert the bent part into the 1-inch hole

you just drilled and probe to the left and the right

to confirm that a joist is not too close on either

side. Move the wire around in a circular motion to

check clearances above and below the hole as

well.

Step 6. If there are no obstructions, carefully

score the penciled outline of the template with a

sharp utility knife to avoid chipping paint or

tearing wallpaper. Then use a drywall or keyhole

saw to cut along the scored line. Make sure that

you do not cut the hole larger than the outline.

Step 7. Be sure to clear any insulation material

from the speaker back.

Step 8. After you have determined the speaker

locations secure a 16 gauge 2 conductor cable to

the joist using an insulated staple. Leave at least

18 inches of additional cable for connection during final speaker installation. Run the other end of

the speaker cable to the audio source.

Step 9. Prepare the speaker wiring by stripping

off approximately 3 inches of the outer jacket

(care should be taken so the insulation on the

wires inside the jacket are not damaged) also

strip approximately 3/8 inch off the ends of the

two inside conductors. Twist the ends of the

Page 8

Page 17

Page 9

TM

TM

Speaker Installation

for Existing Construction

Ceiling Speakers

For existing construction, the use of mounting

rings can not occur. The following steps outline

how to locate a section between two joists, mark

the outer boundaries of the hole, drill a small hole

in the center to verify the location and then cut

the main hole.

Step 1. Determine the location of the joists so the

speaker can be centered approximately between

them. There are several ways to go about this:

• Use an electronic stud finder. Many finders

can also indicate the location of live AC

wiring.

• Tap on the wall and listen to the resulting

sound. When the sound is deeper and more

hollow sounding, you are between joists.

When the sound is sharper and more flat

sounding, you are close or over a stud.

• Identify joists by the position of electrical

light fixtures. There may be a joist directly to

the left or right of these electrical fixture. This

gives you a point of measurement since joists

are either 24 or 16 inches on center in newer

houses, 12 inches in older homes.

Step 2. When you are sure of where the ceiling’s

joists are (and are completely sure there isn’t an

electrical cable, water pipe or heating duct in that

vicinity of the wall), position the cardboard

mounting template, and draw around the outer

perimeter with a pencil.

Step 3. Drill a 1-inch hole in the center of the

Remove the paint mask from the baffle. Be

careful not to touch the speaker cones and

tweeter when removing the paint mask in

order to prevent any damage. Attach the

speaker cable to the speaker by pressing down

on the red (+) or black (-) gold-plated push

terminals and inserting the red wire in the red

terminal and the black wire in the black terminal.

See Figure 3. Make sure that none of the strands

from the black and red wires are touching each

other. This can create a short circuit that can

damage your electronics. Index the mounting

tabs to make sure that all tabs will clear the

opening. Insert the speaker in the ceiling and

tighten the tabs with the screws on the front of

the grille. DO NOT OVERTIGHTEN THE

SCREWS, the screws should only be tight

enough to secure the speaker.

Step 6. After the speaker is mounted,

adjustments to the swivel tweeter (small speaker)

can be made by either directing the sound

visually or by using a musical source to

determine the best sound coverage for the

listening area. To position the tweeter, press at

FIGURE 4

the outside

edge of the

tweeter housing

(DO NOT

PRESS ON THE

TWEETER

CONE

DIRECTLY).

Note (see

figure 4) the

tweeter

horn

Crease position

crease in the

asymmetrical

Page 16

Page 9

Page 10

TM

TM

tweeter

horn

FIGURE 5

tweeter provides

the highest

directional

response in this

direction.

See figure 5. If

you require to

disperse the

sound in a 360degree pattern

you must

position the line

crease position

in the tweeter in

a horizontal

position.

See figure 6. The

combination of switch

settings allow you to

boost and cut bass

and treble +/-3dB.

Adjust the speaker

level to accommodate

FIGURE 6

for room acoustics.

Step 7. Divide each

adhesive bead strip

in half. (Adhesive

bead strips are in the

clear self-closing

bag). Place strips on

the edge of the grille

FIGURE 7

as shown in figure 7.

Reinstall the grille on

the speaker.

Step 8. Adhere the WaveGuide logo to the grille

with the pressure sensitive tape.

Repeat the steps for the second speaker.

Tweeter horn

Crease position

FIGURE 12

FIGURE 13

Step 7. Divide each

adhesive bead strip

in half. (Adhesive

bead strips are in the

clear self-closing

bag). Place strips on

the edge of the grille

as shown in figure

14. Reinstall the grill

on the speaker.

Step 8. Adhere the

WaveGuide logo to

the grille with the

pressure sensitive

tape.

Repeat the steps for

the second speaker.

FIGURE 14

Page 10

Page 15

Page 11

TM

TM

touching each other. This can create a short

circuit that can damage your electronics. Mount

the baffle using the 6 screws provided. DO NOT

OVERTIGHTEN THE SCREWS, the screws

should on only be tight enough to secure the

speaker.

Step 6. After the speaker is mounted,

adjustments to the swivel tweeter (small speaker)

can be made by either directing the sound

visually or by using a musical source to

determine the best sound coverage for the

listening area. To position the tweeter, press at

the outside edge of the tweeter housing (DO

NOT PRESS ON THE CONE DIRECTLY).

Note the crease in the asymmetrical tweeter

provides the highest directional response in this

Tweeter horn

direction. See figure

11.

If you require to

disperse the sound

in a 360-degree

pattern you must

position the line in

the tweeter in a

horizontal position.

See figure 12.

The combination of

switch settings allow

you to boost and cut

bass and treble +/3dB. Adjust the

Crease position

FIGURE 11

speaker level to

accommodate for

room acoustics. See

figure 13.

In-wall Speakers

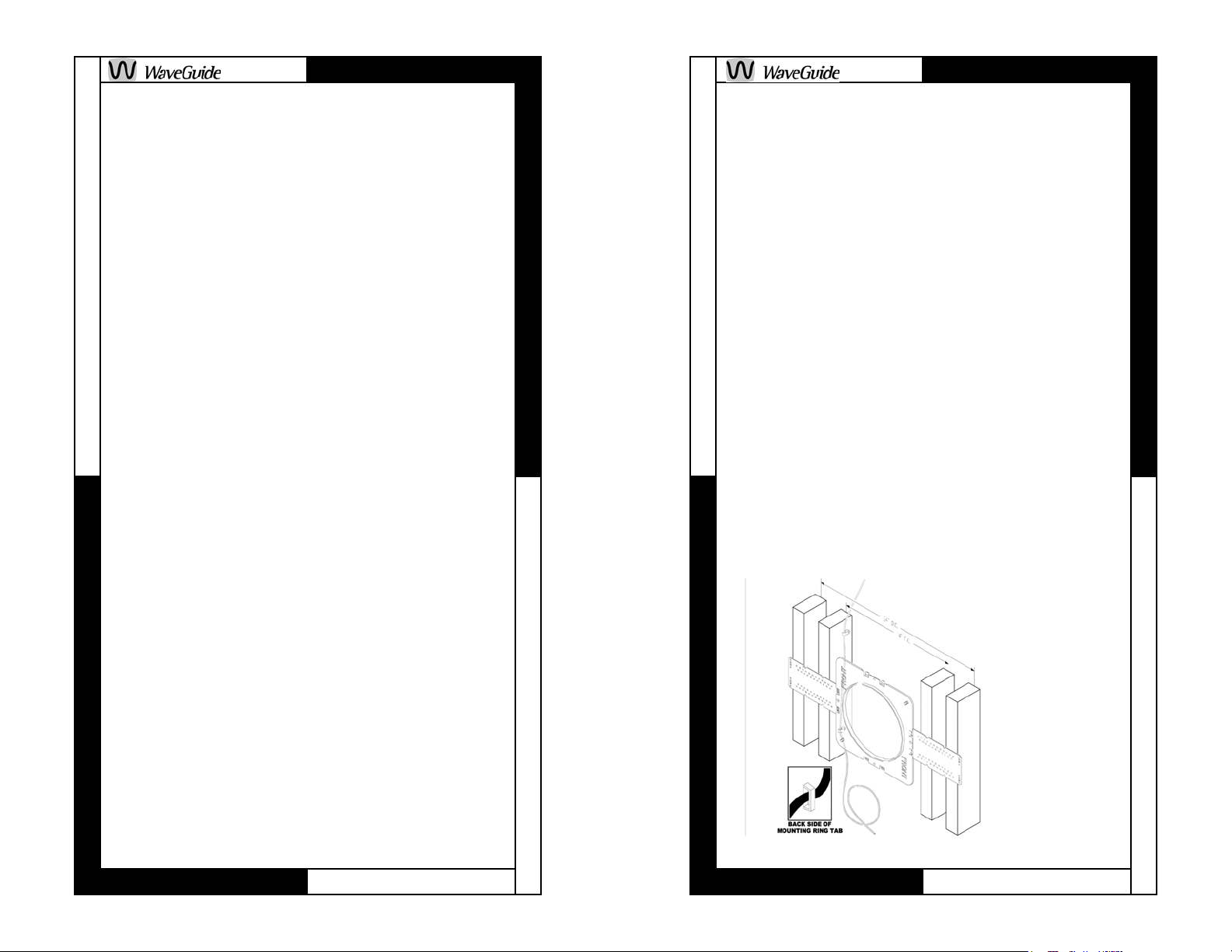

Step 1. Speaker mounting rings are used in the

pre-construction phase of speaker installation

during construction of new homes and additions.

WaveGuide mounting rings are designed to

provide drywall installers the correct cut-out

pattern for the speakers. The rings have “flaps”

that are nailed/screwed/stapled onto the studs.

See figure 8.

Once the wall board is installed, the opening is

cut out and the speaker frame is inserted into the

mounting ring.

When installing

the mounting

ring, note that

there are holes

molded into the

mounting ring

for speaker

wire tie-off.

FIGURE 8

TIPS FOR NEW CONSTRUCTION

• Use a small level to verify that the mounting

ring is straight.

• If possible, run speaker wires after AC

wiring is in place to avoid additional noise

caused by close proximity of wiring.

• Secure the speaker wires against a stud with

insulated staples, being careful not to pierce

the wire insulation. Allow slack for building

material expansion.

Page 14

Page 11

Page 12

TM

TM

• Horizontal wire runs should be routed through

holes drilled at equal heights in the studs.

• Do not install the actual speaker until the wall

board is in place. Until then leave several feet

of wire secured to the back of the mounting

ring. The excess wire can be removed during

final installation.

During the drywall installation, make sure the

speaker cut-out hole does not extend farther than

1/4 inch from the inside of the mounting ring. The

flat rough-in rings and flaps are thin enough that

they won’t interfere with installation.

Step 2. After you have determined the speaker

locations using the guidelines above, secure a 16

gauge 2 conductor cable to the mounting ring

tabs (see figure

9), such as the

M&S Systems

MS16X, for attachment to the

speakers after

the dry wall has

been installed.

Leave at least

18 inches

additional cable

for the

connection

during final

FIGURE 9

speaker

installation.

Run the other end of the speaker cable to the

audio source.

NOTE: Make a drawing of each speaker location.

This will assist you in locating the wires that have

been covered after the sheet rock has been

installed.

Step 3. This is the finish-out stage. Prepare the

speaker wiring by stripping off approximately 3

inches of the outer jacket (care should be taken

so the insulation on the wires inside the jacket

are not damaged) also strip approximately 3/8

inch off the ends of the two inside conductors.

Twist the ends of the stranded cable so the wires

are tight.

Step 4. Follow the instructions included with the

volume control and amplifier.

Step 5. You are now ready to install the frame.

Remove the paint mask. Be careful not to touch

the speaker cones and tweeters when

removing the paint mask in order to prevent

any damage. Remove the baffle from the frame

and fasten the frame to the pre-construction

bracket. Attach the speaker cable to the speaker

by pressing down on the red (+) or black (-) goldplated push terminals and inserting the red wire

in the red terminal and the black wire in the black

terminal. See figure 10. Make sure that none of

the strands from the black and red wires are

Negative

(black)

Positive

(red)

FIGURE 10

Page 12

Page 13

Loading...

Loading...