MSSC Smart-Jet BLUE User Manual

T H E R M A L I N K J E T C O D E R

USER’S MANUAL

Pro Pack Solutions, Inc.

770-554-1187

SAFETY INFORMATION ................................................................................................................................................ 4

PRODUCT WARRANTY ................................................................................................................................................. 4

ABOUT MACHINE ........................................................................................................................................................ 4

TECHNICAL SPECIFICATIONS ........................................................................................................................................... 5

Machine details .......................................................................................................................................................... 5

Keyboard .................................................................................................................................................................... 5

Android devices .......................................................................................................................................................... 5

MACHINE OVERVIEW ...................................................................................................................................................... 6

Indicator LED .............................................................................................................................................................. 6

Connecting Port .......................................................................................................................................................... 7

Keyboard .................................................................................................................................................................... 7

Operation menu with keyboard ................................................................................................................................. 8

Operation menu with PC software ........................................................................................................................... 11

GETTING STARTED ..................................................................................................................................................... 17

INSTALLATION PROCEDURES ..................................................................................................................................... 18

MOUNTING BRACKETS .................................................................................................................................................. 18

EXTERNAL DEVICES CONNECTIONS ........................................................................................................................... 22

EXTERNAL SENSOR ........................................................................................................................................................ 22

ENCODER ...................................................................................................................................................................... 23

COMBINE EXTERNAL SENSOR AND ENCODER ............................................................................................................... 24

ALARM .......................................................................................................................................................................... 25

INPUT AND OUTPUT...................................................................................................................................................... 25

RS485 PROTOCOL ......................................................................................................................................................... 25

QUICK STARTUP ........................................................................................................................................................ 27

REQUIRED COMPONENTS ............................................................................................................................................. 27

Setup machine .......................................................................................................................................................... 27

Keyboard setup ......................................................................................................................................................... 28

Bluetooth setup (for connection to Android devices) ............................................................................................... 28

PC connection setup ................................................................................................................................................. 31

Setup external devices (Optional) ............................................................................................................................. 31

Create first messages ............................................................................................................................................... 31

KEYBOARD OPERATION ............................................................................................................................................. 33

MESSAGE ......................................................................................................................................................................... 33

OPERATION ...................................................................................................................................................................... 42

SETTINGS ......................................................................................................................................................................... 43

PC APPLICATION INTRODUCTION .............................................................................................................................. 54

SOFTWARE REQUIREMENT ................................................................................................................................................... 54

HARDWARE SETUP ............................................................................................................................................................. 54

SOFTWARE SETUP .............................................................................................................................................................. 54

Install application ..................................................................................................................................................... 54

Install driver .............................................................................................................................................................. 56

Install driver on Window 8 ....................................................................................................................................... 62

SOFTWARE USING .............................................................................................................................................................. 67

Printer Controller Interface ....................................................................................................................................... 67

Create new message ................................................................................................................................................ 67

APPENDIX.................................................................................................................................................................. 78

INK CARTRIDGES MAINTENANCE .................................................................................................................................. 78

Print head cleaning ................................................................................................................................................... 78

Wiping ...................................................................................................................................................................... 78

Important notes ........................................................................................................................................................ 79

Purging ..................................................................................................................................................................... 79

INK CARTRIDGE STORAGE PROCEDURE ........................................................................................................................ 80

Important handling cautions .................................................................................................................................... 80

UPDATE FIRMWARE INSTRUCTIONS ............................................................................................................................. 81

Prepare USB flash ..................................................................................................................................................... 81

Update firmware ...................................................................................................................................................... 82

Update logo .............................................................................................................................................................. 82

Update font .............................................................................................................................................................. 82

Machine default ....................................................................................................................................................... 83

TROUBLE SHOOTING ................................................................................................................................................. 83

SAFETY INFORMATION

Have to STOP machine before plug/ unplug cartridge.

Avoid using with the high voltage, strong impact to the coder.

Limit store the coder in the high dusty working environment.

The working temperature of the coder is 5oC – 50oC.

PRODUCT WARRANTY

The Product warranty for machine is effective for 12 months from delivery date. Brackets,

keyboard, power supply, and anti-shock mechanism are excluded from the warranty.

The warranty is VOID if:

Any non-original parts and unapproved OEM inks are used.

The product has been altered or modified without approval from us.

Print head damage is a result of improper installation.

Damage occurs from an accident, such as but not limited to, being dropped, being sprayed

with water or other liquids, caused by a natural disaster, caused by stocking or shipping

conditions.

Unapproved, wrong or unstable power supply is used.

ABOUT MACHINE

Thank you for purchasing the Smart-Jet BLUE Thermal Inkjet Coder, a product of MSSC LLC,

US. This printer is designed for packaging printing applications powered by HP Thermal Inkjet

Technology.

Machine boasts to be able to control via PC connection to print variable data and barcodes,

Bluetooth connection via mobile devices running on Android operating systems, and wireless

keyboard. Each option provides a full set of applications.

Machine produces crisp text, logos, variable data and barcodes on porous and non-porous media

by automatically recognizes aqueous and solvent inks and applies the appropriate printing

parameters.

The complete system includes one machine, power supply with On/Off switch, wireless keyboard,

mounting brackets and necessary software for PC and Bluetooth operations.

USER MANUAL V02 | Updated 18-Jan-2016 4

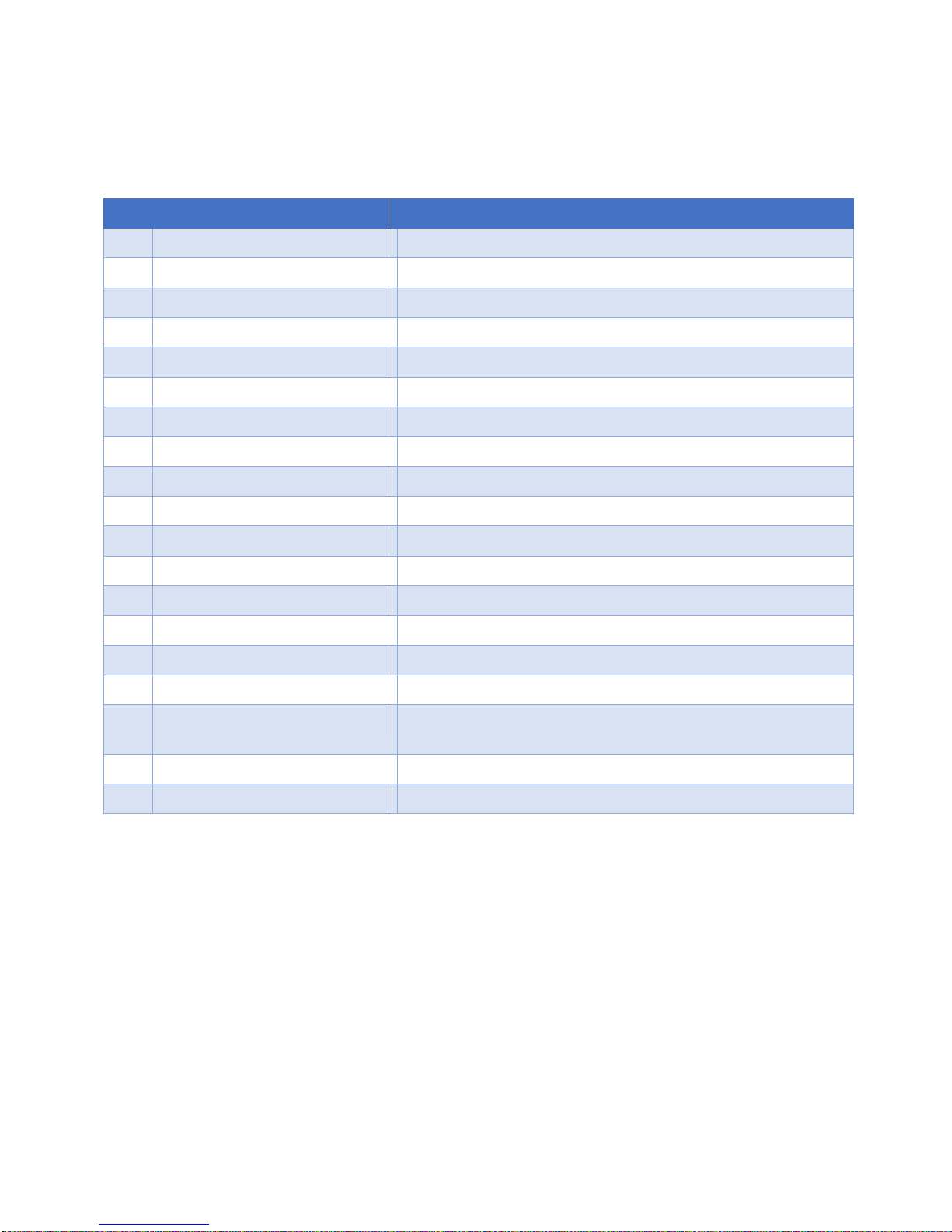

No

Description

Specifications

1

Model

Smart-Jet BLUE

2

Display

LCD 2.8” automatic rotation

3

Dimensions (Lx W x H)

107.5 x 74.5 x 83 mm / 4.23 x 2.93 x 3.27 in

4

Weight

450g

5

Power supply

AC 100V – 240V, 50/60Hz, 1.4A

6

Maximum power consumption

48W

7

Maximum printing resolution

600x600dpi

8

Print speed

76m/min@300x300dpi

9

Optical density

5 levels

10

Operation selection

PC, Wireless keyboard, Bluetooth

11

Message memory

100 messages

12

Ink solution

Aqueous and Solvent

13

Menu language

Multiple / selectable

14

Printable characters

Windows True Fonts

15

No. of lines

Maximum 6 lines

16

Character height

Maximum 12.7mm / 0.5”

17

Printability

Alphanumeric, logos, date/time, expiry date, Julian date,

shift code, data and barcodes

18

Operating temperature

50C – 500C

19

External connections

External sensor, encoder, alarm kit, etc.…

TECHNICAL SPECIFICATIONS

Machine details

Keyboard

The Machine is currently compatible with all wireless USB 2.0 keyboards available in the market.

Android devices

Control machine via Bluetooth connection by using Android devices from 4.0 up to.

USER MANUAL V02 | Updated 18-Jan-2016 5

MACHINE OVERVIEW

Items

Detail

[1] Sensors

Default setting is don’t recognize black conveyor

Internal sensor: Red light.

External sensor: Green light.

Sensor is activated when receives signals

[2] Error

Reports errors during operation.

[3] Bluetooth/PC

Remains ON when being connected

[4] Printing Status

Remains ON when it’s on printing mode.

[5] Ink Low

Remains ON to indicate ink low.

Indicator LED

USER MANUAL V02 | Updated 18-Jan-2016 6

Items

Detail

[1] USB FLASH

USB 2.0 flash for updating firmware, fonts and logo

[2] USB KEYBOARD

For USB 2.0 wireless keyboard receiver

[3] USB PC PORT

For PC connection with USB 2.0 cable A-B

[4] DB15 EXTENDED PORT

Extend port for external sensor, encoder, alarm, etc…

[5] 12VDC PORT

Power supply

No

Key

Use

1

Enter

Confirm, save or apply

2

ESC

Go to previous session

3

/

Move your cursor to left/right

4

/

Move your cursor up/down

5

Shift

Press and hold “Shift” to input capitalized characters

6

Insert

Press “Insert” to insert Symbol, Logo, Counter, Date, Expired, Time,

String, Barcode, and Shift into the message

7

Backspace

Delete your message from the left

8

Tab

Move your cursor faster

9

Home/End

Move your cursor to Home/End

Connecting Port

Keyboard

USER MANUAL V02 | Updated 18-Jan-2016 7

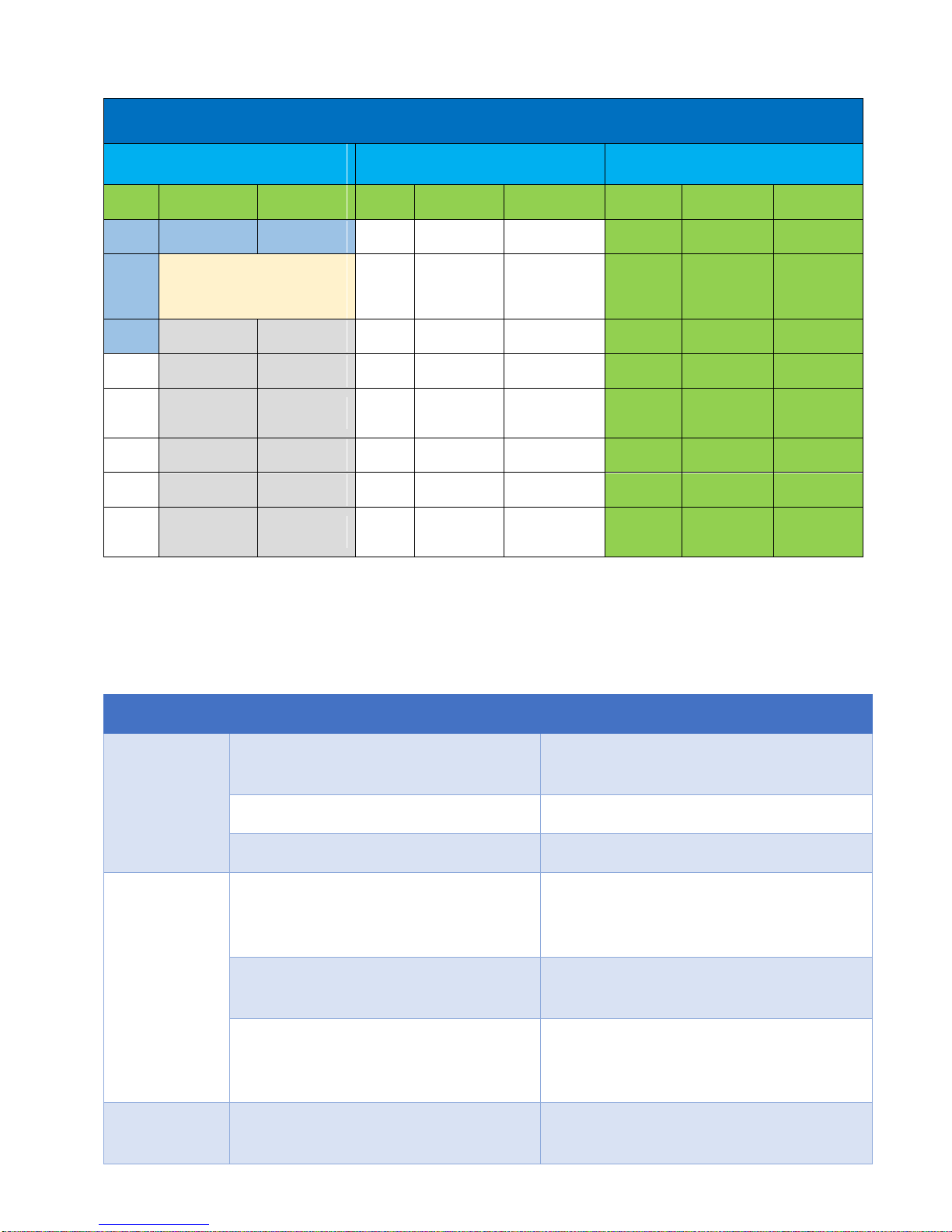

Main Menu

Message

Operation

Setting

Open

Create new

Information

Purge

Start/Stop

Connect PC

Speed

Resolution

Density

Use

Select font

Select size

Delay

Cartridge

Update logo

Edit

Insert Menu

(Popup menu when press Inset)

String

Random Jet

Print Side

Delete

Symbol

Logo

Sensor

Direction

Print Mode

Counter

Date

Unit

Bluetooth

Update Font

Expired

Time

Roll over

hour

System

Clock

Rotate

String

Barcode

Password

Default

Language

Shift Code

IO Signal

Coder Name

RS485

LCD

Backlight

Reset

About

Menu

Sub Menu

Description

Open

Use

Use the existing messages on the

machine memory for printing.

Edit

Edit the existing message.

Delete

Delete existing messages.

Create new

Select font

Select kind of font you need to use on

messages. Support two kind of font:

Upper Case font and Normal font

Select size

Select size of messages: support up to 6

sizes.

Insert menu (Symbol, Logo, Counter,

Date, Expired, Time, String, Barcode,

Shift Code)

Insert some needed component to your

messages.

Information

Show all information needed to monitor

your printing process.

Operation menu with keyboard

From the main screen of machine, use arrow keys to move the cursor to the desired

object. Press Enter to save and apply settings. Otherwise, press ESC.

Message

USER MANUAL V02 | Updated 18-Jan-2016 8

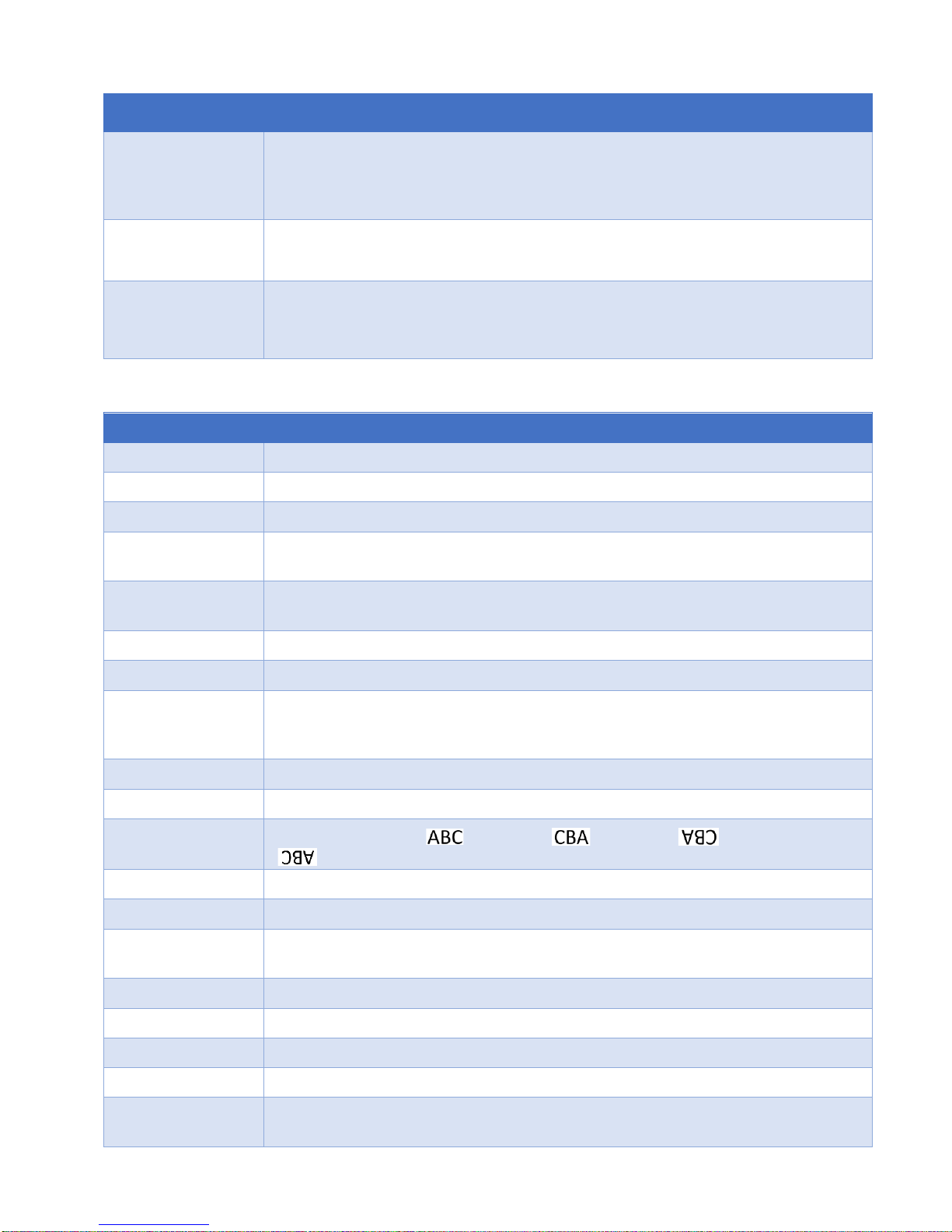

Operation

Menu

Description

Start / Stop

Start or Stop printing job. Combine and press CTRL + SHIFT + ENTER on

keyboard to fast Start / Stop print.

Purge

All of nozzle on cartridge will push out ink. After purged you will see 2 lines of

ink on substrate.

Connect PC /

Disconnect PC

Connect or Disconnect machine from PC.

Please stop print first, before go to Connect PC menu.

Menu

Description

Speed

Set print speed for the machine or select to enable encoder.

Resolution

Set your desired resolution.

Density

Set optical density of the print.

Delay

Set the distance since the sensor receives signal to the start of printing. Or

the delay distance after printer take a print command.

Cartridge

Display the current level of ink in the cartridge. Or kind of current cartridge is

plugged to machine.

Update Logo

Update logo or image from USB to the machine memory.

String

Set the chain of data to insert into the print.

Random Jet

Prevents the print head from clogging due to the extended down time

between prints. This will be useful when you print on Solvent base ink with

decap time is low.

Print Side

Select nozzle side on the cartridge: Odd, Even, or Auto switch

Sensor

Select External or Internal sensor.

Directions

set print direction: : left right, : right left, : reverse left right,

: reverse right left.

Print Mode

Select printing mode: Sensor mode and Continuous mode.

Unit

select desired measurement inch/mm.

Bluetooth

Turn on Bluetooth connection to help you can search the printer via app on

Android devices.

Update Fonts

Update different font sizes for machine via USB flash contain of full firmware.

Rollover hour

Set different date depending on specific production hour.

System clock

Set time and date for your system clock.

Rotate

Select your screen modes: Auto-rotate or Lock rotate.

Password

Set to authorize different level of users, or to protect the machine from

unauthorized users.

Settings

USER MANUAL V02 | Updated 18-Jan-2016 9

Default

Reset machine to factory default.

Language

Select your interface language. Or add more interface language from USB

flash.

IO signals

The extend button to re-start machine. This will help in some special case.

Custom string

Update the custom strings via USB flash that are created from application on

PC. This useful to printing with any language without connecting to PC.

Coder name

This name will be showed once you use the Android app to search or

connect.

RS485

Enable the RS485 protocol on machine. To help you able to control multiple

printer by one Controller (PLC, PC, Laptop…) on RS485 network.

LCD Backlight

Adjust the time that turn on the light of screen. Your screen will become black

but all activity still working. Turn on screen by press any key on keyboard.

Reset

Reset the memory of Counter variable on message. The memory of Counter

will help you save the current value of Counter event you stop print or

machine is turned off.

About

Display current firmware version on printer and allow your update new

firmware to machine.

USER MANUAL V02 | Updated 18-Jan-2016 10

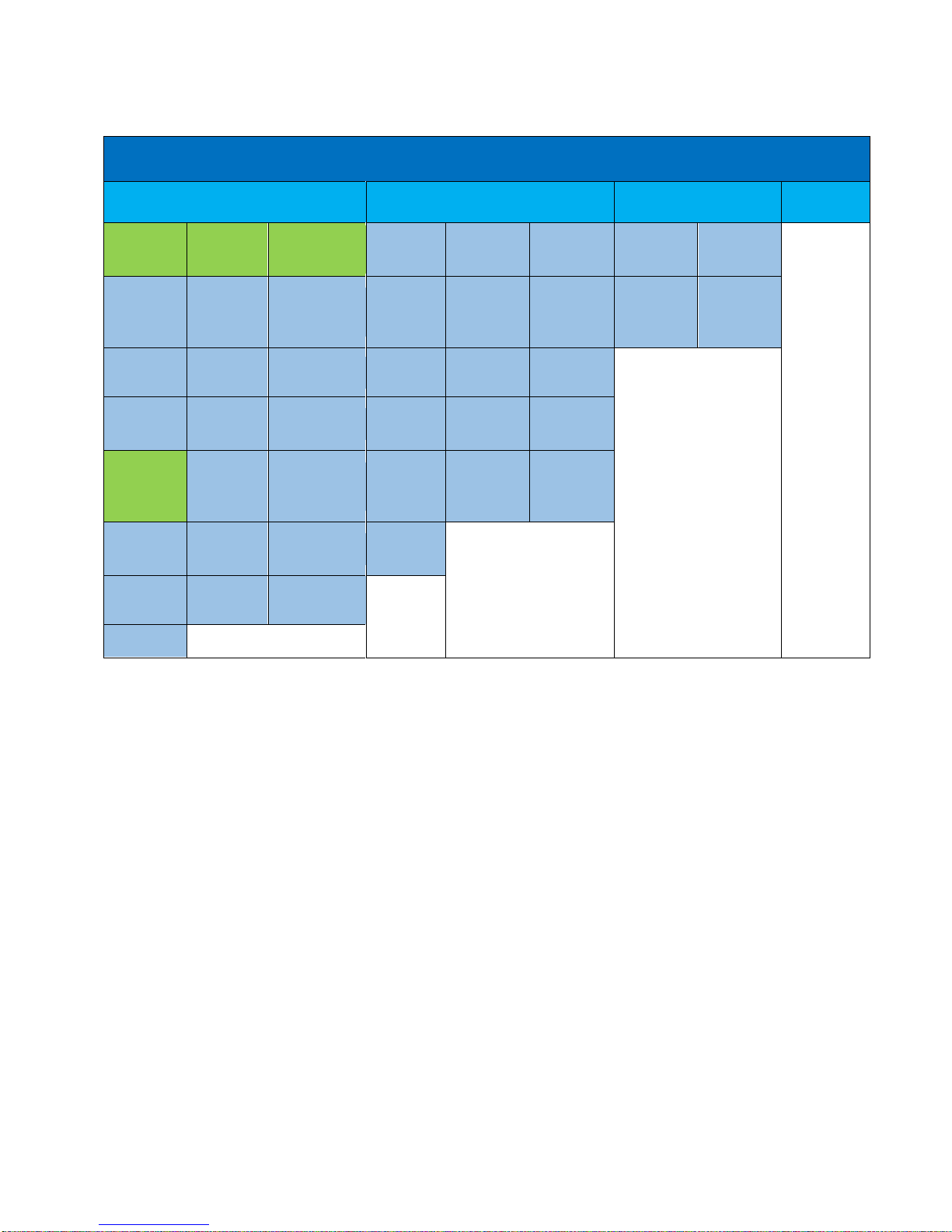

PC Application Menu

Printer Control Screen

Designing Screen

Tools

About

Print Head

Setup

Printer

Setup

Printing

Status

New

Template

Edit

Template

Open

Template

Purge

Ink Cost

Switch

nozzle

Unit

Connection

Status

Save

Template

Export

Template

to TIFF

Delete

Event Log

Convert

Logo

Random

Jet

Direction

Speed m/min

Cut

Copy

Paste

Encoder

Density

Page Index

Mouse

Selected

Hand

Selected

Shape

Printer

Controller

Resolution

DPI

Start Page /

End Page

Text

Insert

Serial

Number

Insert

Shift Code

Insert

Print

Printing

Mode

Ink Level

Image

Insert

Pause

Sensor

Setup

No Repeat

Data

Stop

Operation menu with PC software

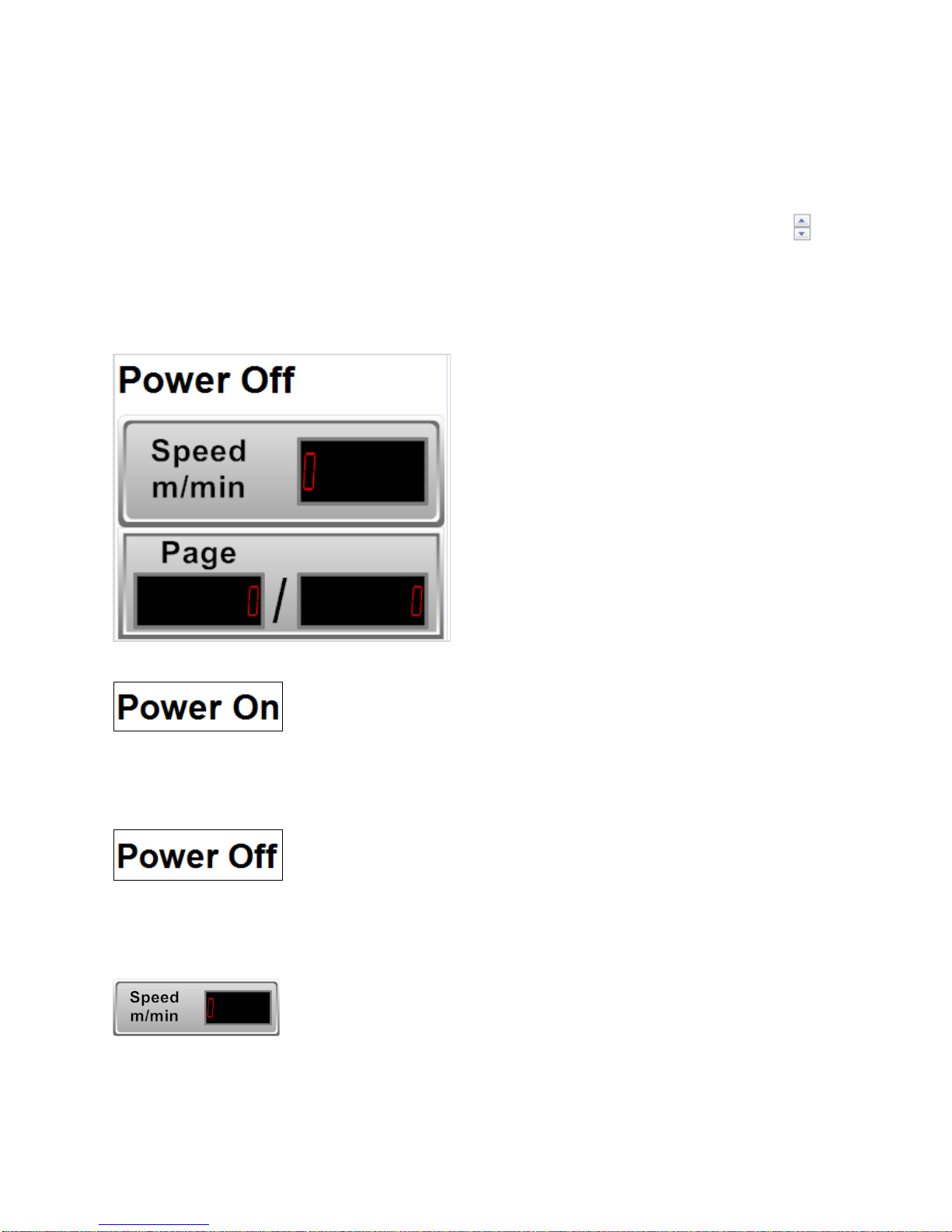

Printer Control Screen

Setting all printing parameters for the message before start printing.

Be sure to stop the printing mode before setting the parameters.

Print Head Setup

Switch Nozzle

Select nozzle sides, ODD or EVEN.

Turn on ODD to print on the odd side (with 300x300dpi).

Turn on EVEN to print on the even side (with 300x300dpi).

Auto Switch Nozzle

Select ON for automatically changing nozzles between ODD and EVEN. And then select the number

of changing. Otherwise, select OFF.

Random Jet

Periodically purge to clean the print head.

USER MANUAL V02 | Updated 18-Jan-2016 11

Turn ON Status and set the time for purging in the Time by click up or down at or input the

desired value.

This value is adjustable from 5s to 1,000s.

Encoder

Encoder is recommended to optimize maximum print quality.

Turn ON Encoder to operate Machine with encoder. Print speed of Machine will be automatically

synchronized with conveyor speed.

Turn OFF Encoder to disable encoder. Input your desired speed at Speed to synchronize with the

speed of the conveyor.

Max Speed: shows the maximum speed you can achieve with the current resolution and density.

NOTES:

Ensure your encoder is working if it is ON and can detect the objects.

To make a test print without conveyor, turn OFF encoder.

Printer Setup

Unit

Select your measurement Inches or Millimeters.

Direction

Select your print direction Left to Right or Right to Left.

Select Rotate View to print upside down.

Rotate View

Upside down the current design of your message.

Density

Select your desired optical density. There are 5 levels to select.

Resolution DPI

Select your desired resolution

Printing Mode

Select your printing mode: Continuous Mode or Sensor Mode.

Sensor Mode

Machine prints when sensor is triggered.

Select Internal to print with a built-in sensor on Machine.

Set Delay before and Delay after print to have your message printed at the desired position.

Select External to print with external sensor

USER MANUAL V02 | Updated 18-Jan-2016 12

Input distance from external sensor to the print head, set Delay before and Delay after print to

have your message printed at the desired position.

Continuous Mode

Machine will print continuously when a sensor is triggered for the first time.

When Continue mode is applied, distance between the messages on the same object should to be

set.

Go to Fixed Length to input the value or select the value by click up or down at button .

Go to Repeat All and select Times to input how many prints to be repeated. Otherwise, select

Unlimited.

Printing Status

Machine is connected to PC.

Machine is disconnected from PC.

Displays the current speed of conveyor synchronized by encoder.

USER MANUAL V02 | Updated 18-Jan-2016 13

Displays the number of pages printed (left) per the total pages to print (right).

Select page to start / end printing, apply for counter, barcode. The data will continue to be printed

from the start page.

Printer Controller

Print: Select to print

Pause: Select to temporary stop printing

Stop: stop printing.

This must be applied before adjusting parameters or editing the message.

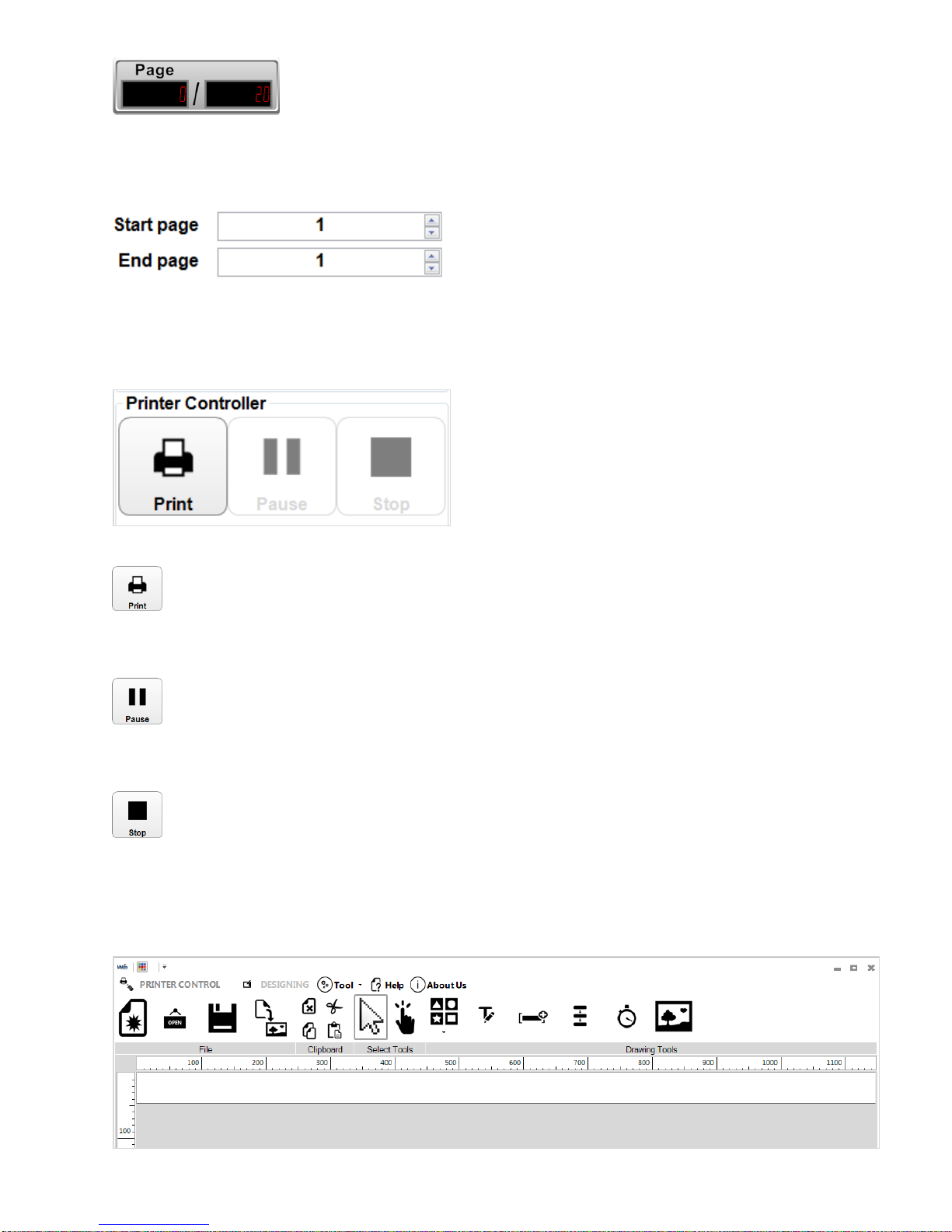

Designing messages

USER MANUAL V02 | Updated 18-Jan-2016 14

New template: Create new message with free template design.

Open: Open message from PC.

Save template: Save message to PC.

Export to .tiff files: Export message in Tiff format.

Delete: Delete object.

Cut: Cut object.

Copy: Copy object.

Paste: Paste object.

Select Tool: Select to function and edit each object on the message.

Hand Pan: Move designing area to right/left to function on the hidden area in case your

message is not fully displayed on the screen.

Shapes: Select image to insert into message: Line, Rectangle, Square, Circle and Oval.

Static Text: Insert characters and barcodes.

Serial Number: Insert counter.

Shift Code: insert shift code.

Image: Insert image or logo.

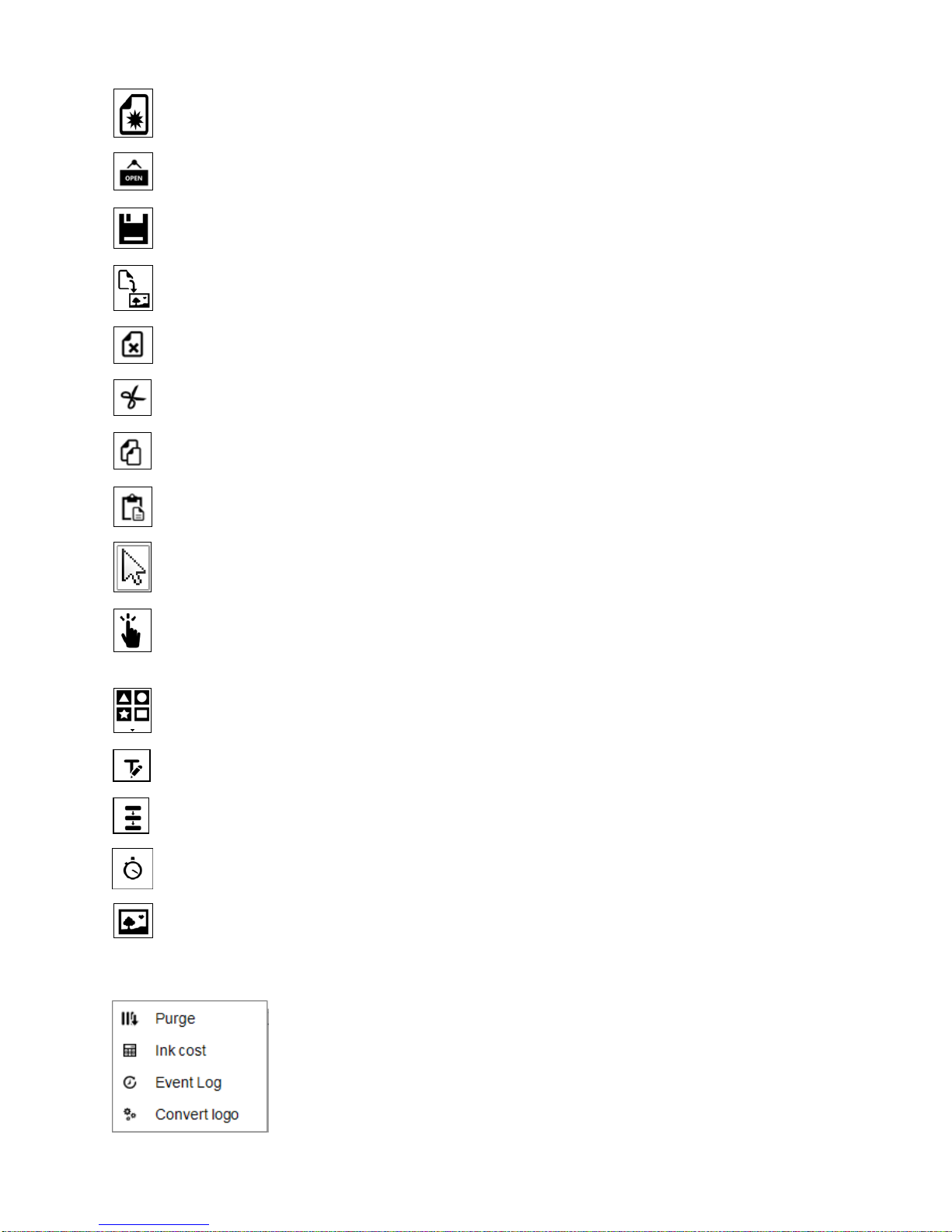

Tools

USER MANUAL V02 | Updated 18-Jan-2016 15

Purge: all of nozzle on cartridge will push out some ink. This will help clean all cartridge.

Ink Cost: calculate number of printing job, ink price, price for each print.

Event Log: view all of action that user did on application.

Convert logo: use to convert photo / image / logo / text to HEX file and update to the printers.

USER MANUAL V02 | Updated 18-Jan-2016 16

GETTING STARTED

Install the machine on your conveyor according to the installation instructions.

See the Quick Installation Guide (included inside package) for more information.

Set print direction and appropriate throw distance to obtain best print quality (1-3 mm).

Insert ink cartridge.

Plug the power cord into an appropriate power source to start up the machine.

Insert keyboard receiver to keyboard port, turn on wireless keyboard.

USER MANUAL V02 | Updated 18-Jan-2016 17

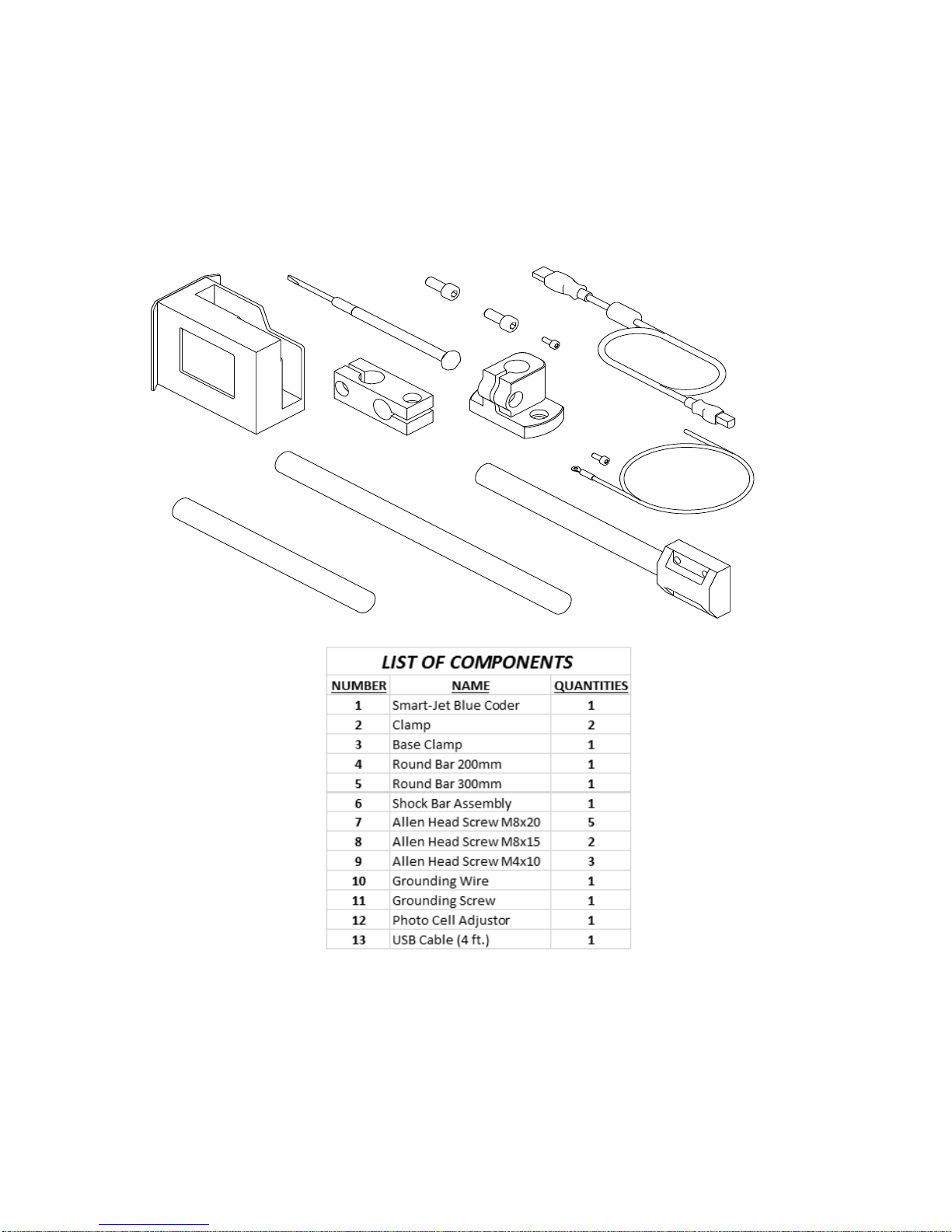

1

2

3

4

5

6

7

8

9

10

11

12

13

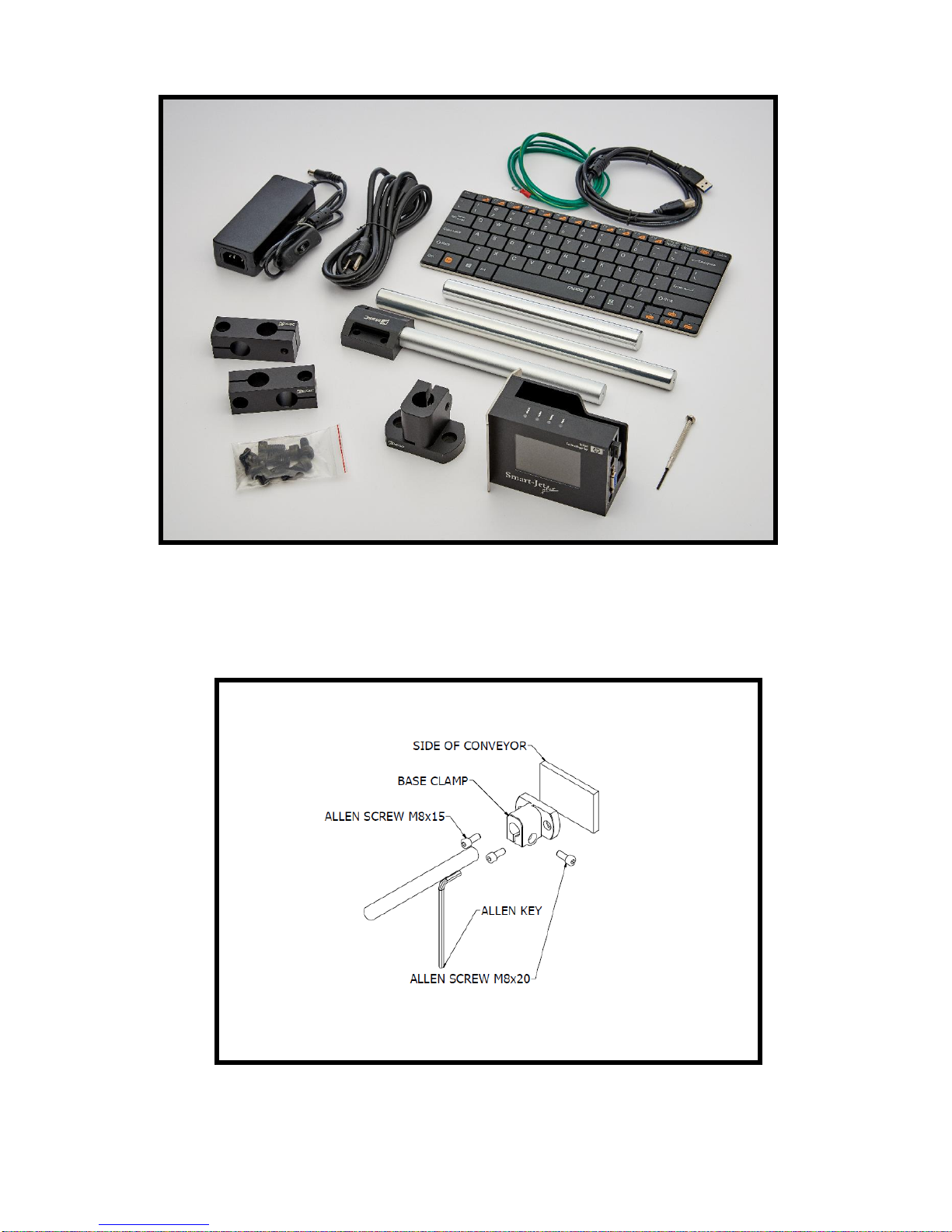

INSTALLATION PROCEDURES

MOUNTING BRACKETS

Step 1

Skid plate adjust depending on direction of your production line.

Select direction to mount machine on the conveyor. Skid plate can be assembled as A or B position

depending on the direction of the products on the conveyor.

Default machine will be set at B position.

USER MANUAL V02 | Updated 18-Jan-2016 18

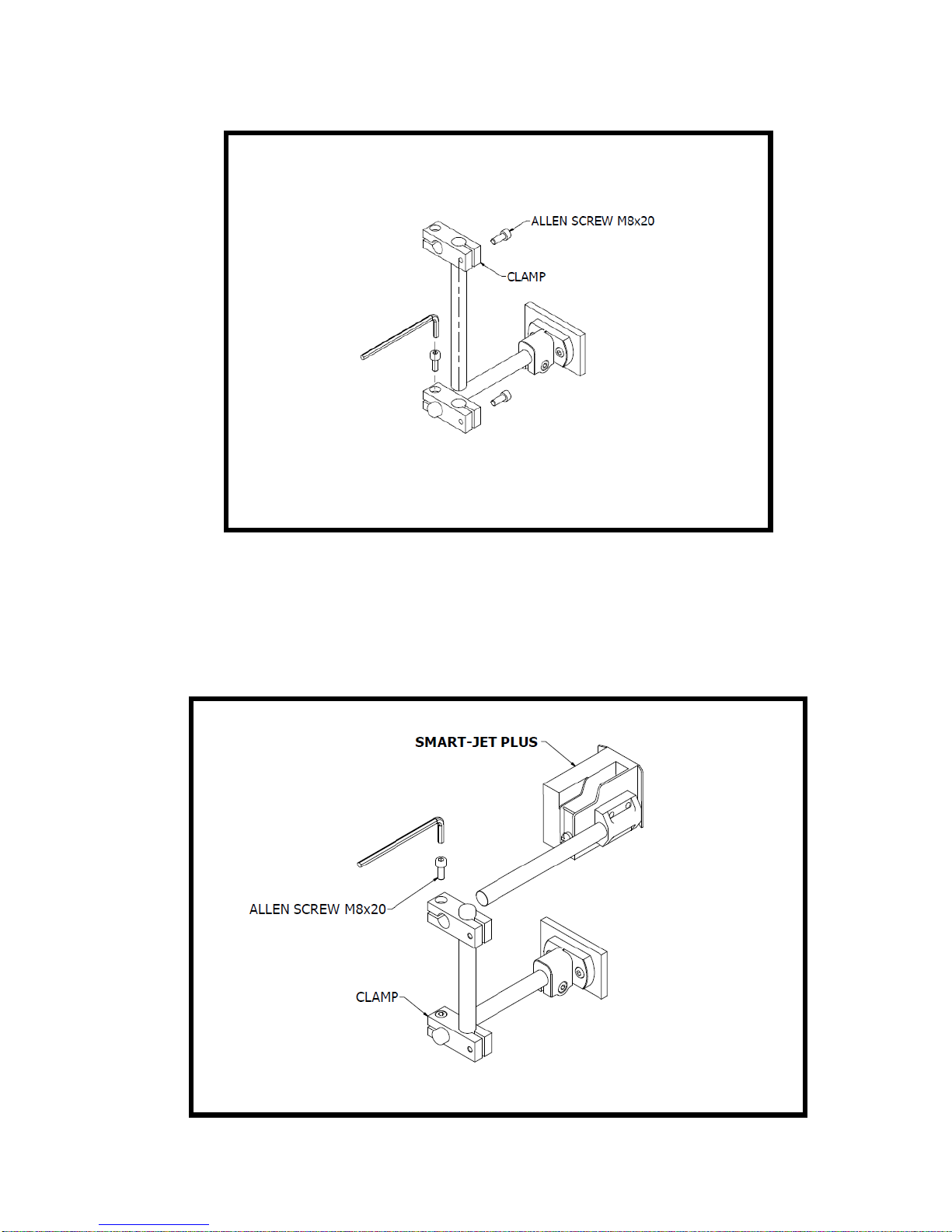

Step 1: Installing the clamps to the side of the conveyor

USER MANUAL V02 | Updated 18-Jan-2016 19

Step 2: Installing the clamps to the round bar

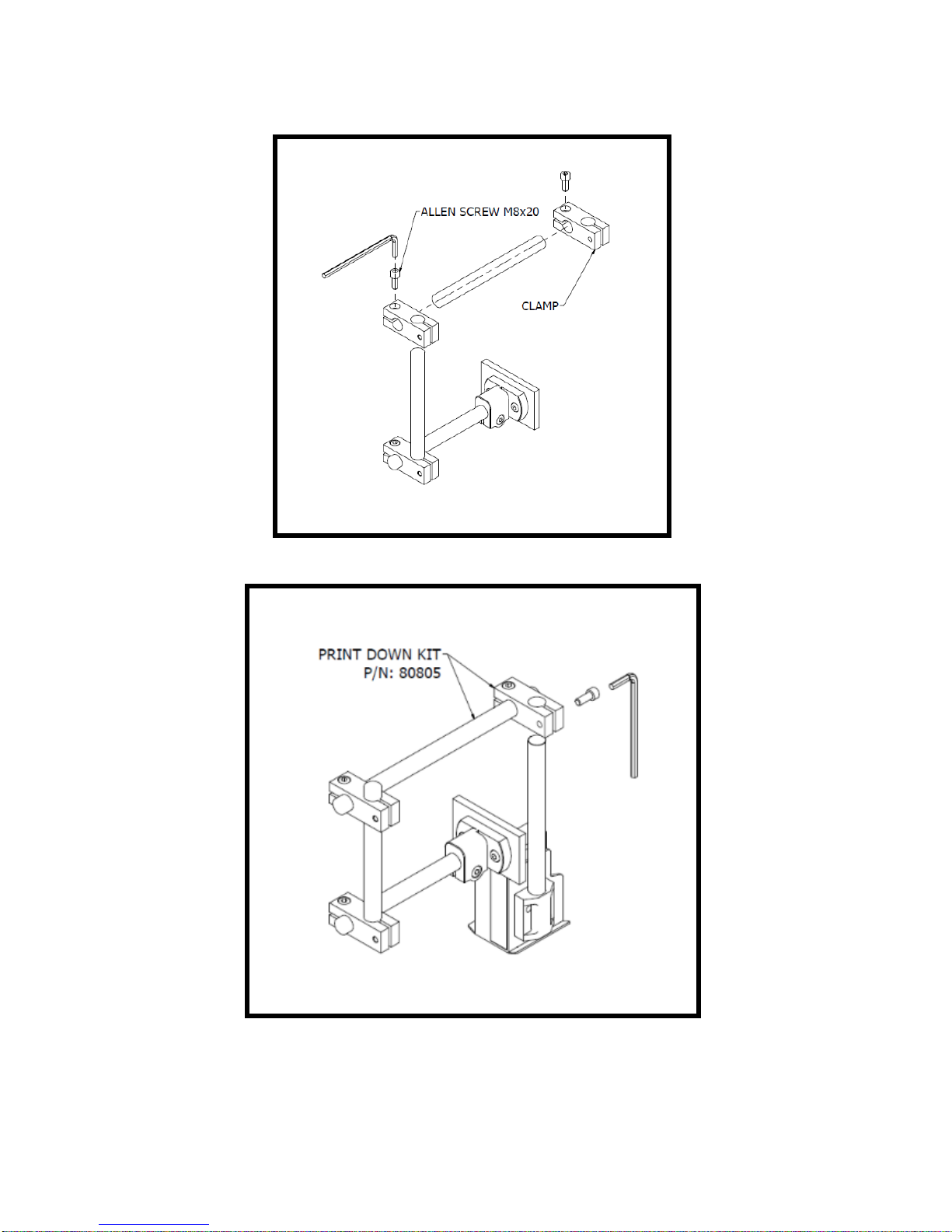

MOUNTING OPTIONS

Select the suitable bar length

Horizontal setup

USER MANUAL V02 | Updated 18-Jan-2016 20

Vertical setup

Step 1:

Step 2:

NOTES:

Make sure the brackets are mounted firmly to avoid vibration and sway of the print head. This

will affect the print quality.

USER MANUAL V02 | Updated 18-Jan-2016 21

EXTERNAL DEVICES CONNECTIONS

NOTES:

Machine is able to operate with External Sensor, Encoder, Alarm at a time. Consult your

supplier for further supports on the settings and connections.

To connect machine with External Sensor, Encoder, Alarm, etc…, additional connector DB15

(male) will be required.

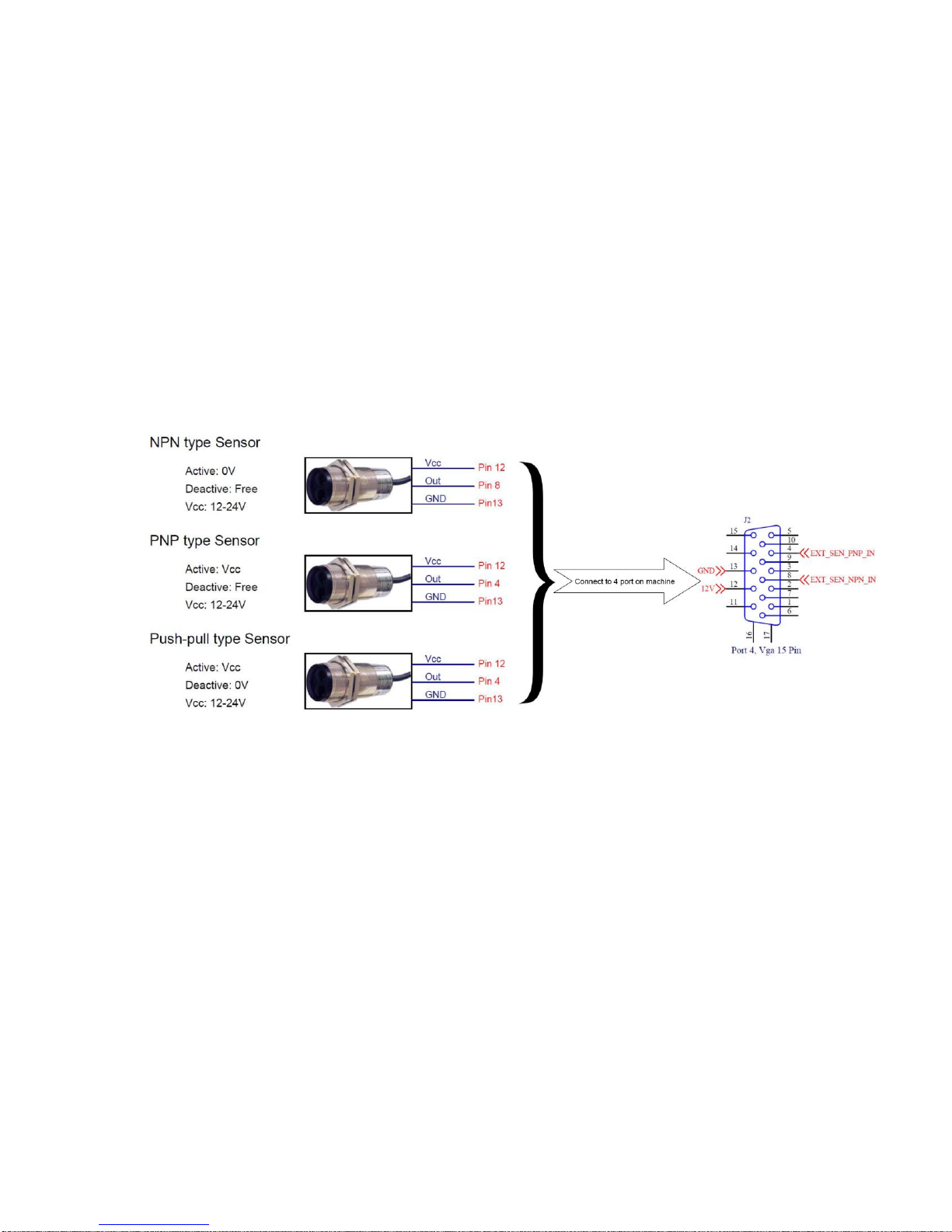

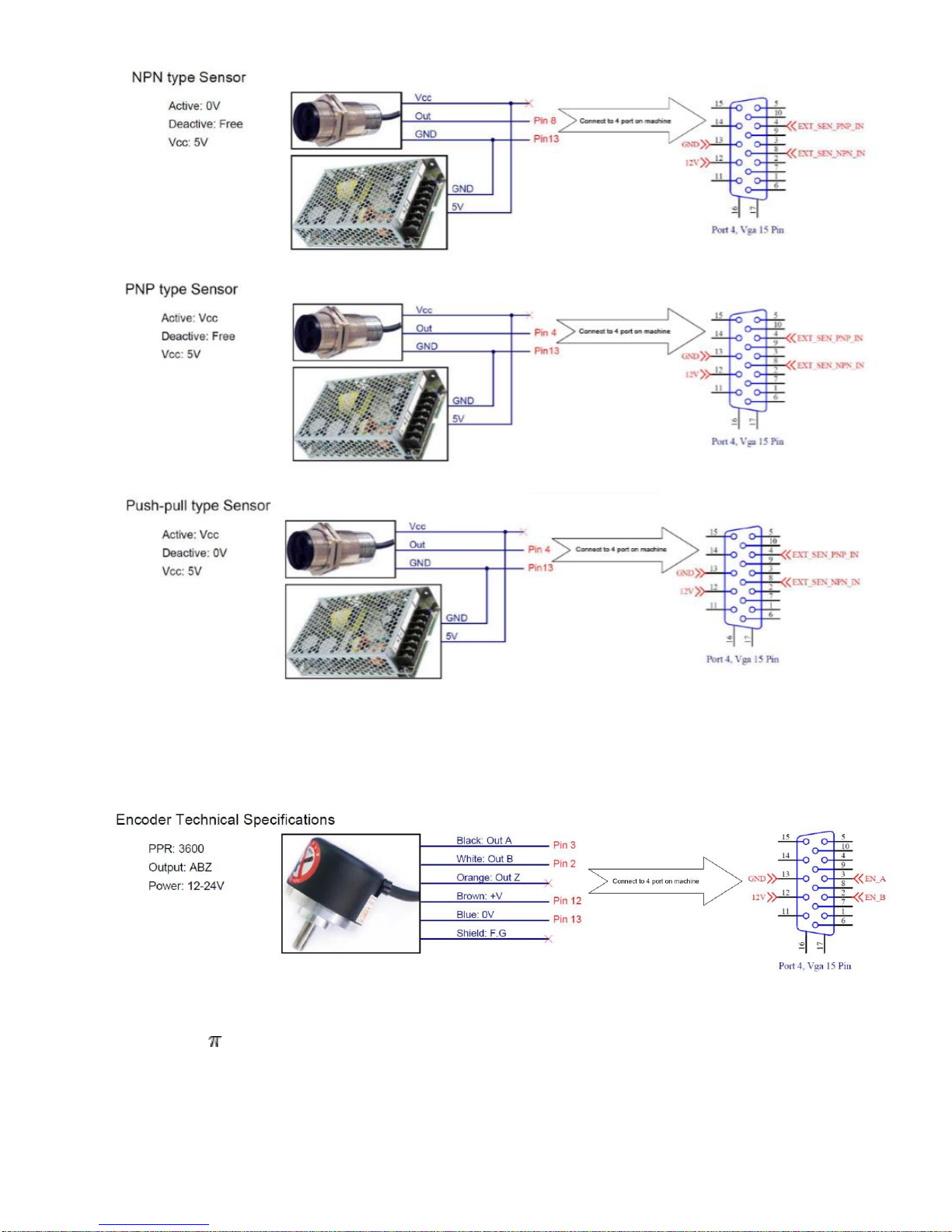

EXTERNAL SENSOR

Machine supports NPN, PNP and Push-pull sensor types.

Connect sensor using power supply on machine.

Connect sensor to machine using external power supply. Below demonstration is for external

power supply of 5V.

USER MANUAL V02 | Updated 18-Jan-2016 22

ENCODER

An encoder is recommended to ensure the best print quality regardless the inconsistent speed of

conveyor.

To calculate wheel diameter (D) depend on resolution (R) is:

D = R/( x 600) (inches).

Example: Encoder has R = 3600 (PPR),

D = 1.90985 inches ~ 48.5 mm.

USER MANUAL V02 | Updated 18-Jan-2016 23

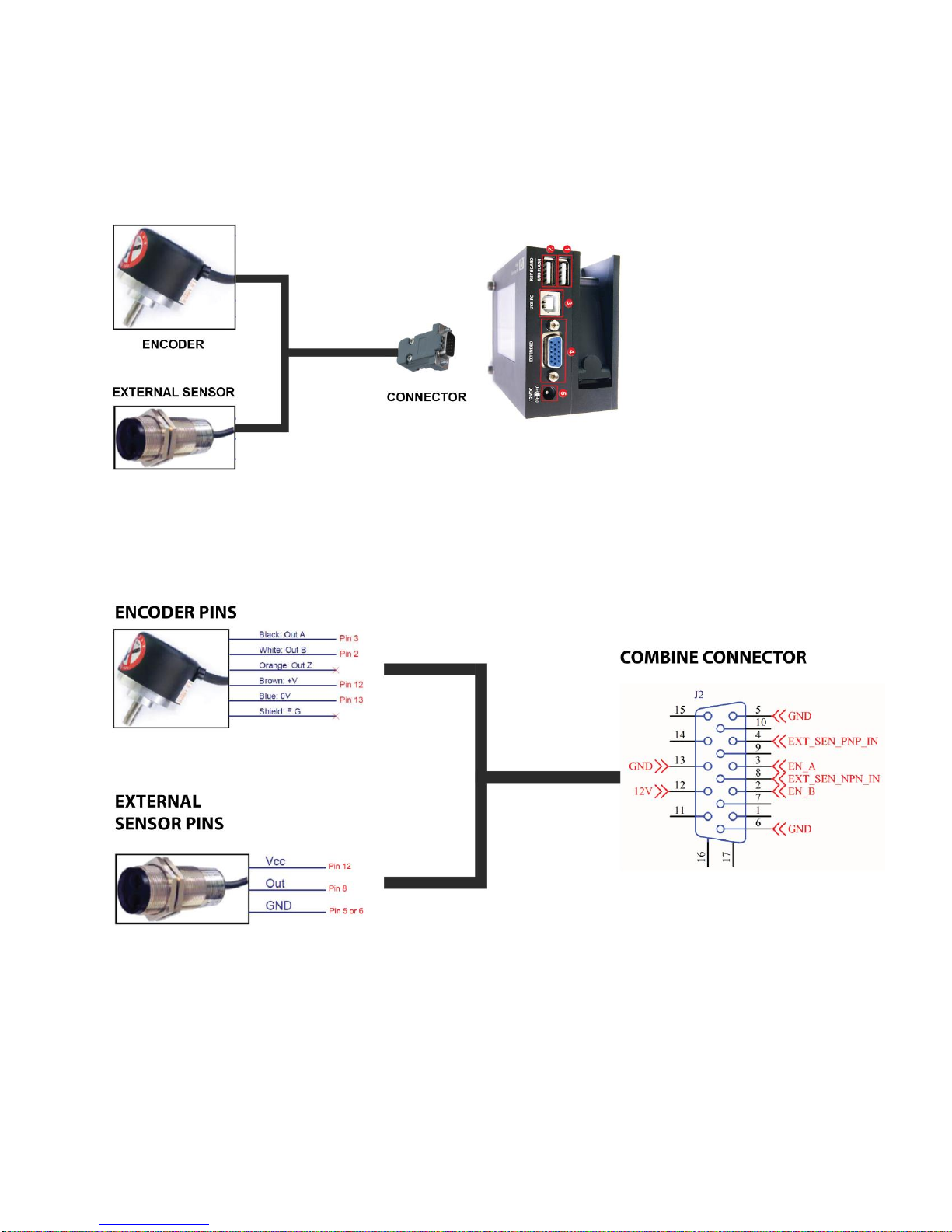

COMBINE EXTERNAL SENSOR AND ENCODER

In some case you need to use external sensor and encoder to get perfect printing quality. But the

machine have one extended port only. Please do as following instruction to take external sensor and

encoder work together with machine.

See picture for this situation.

See this picture for connection pins.

NOTES:

PIN12 (12V) use for both of Encoder and External sensor.

USER MANUAL V02 | Updated 18-Jan-2016 24

ALARM

Allow users to monitor operation of Machine from distance via the light signals from the Alarm.

INPUT AND OUTPUT

Input: To trigger some functions (reset counter …). Accept NPN or dry contact.

Output: NPN signal. Active when some even occur (each print …).

RS485 PROTOCOL

Allow control machine via RS485 network from other devices like: PLC, PC…

Before use this protocol you need to set parameter on machine as below.

Step 1

Connect PIN 1 (RS485B) and PIN 11 (RS485A) to RS485 network as picture below.

Machine extended port detail:

USER MANUAL V02 | Updated 18-Jan-2016 25

Loading...

Loading...