MSSC qm7500 Technical Manual

4ECHNICAL-ANUAL

-33#-C$ONOUGH,AKE2OAD#OLLINSVILLE),53!4EL4EL&AX

¹-33#!LL2IGHTS2ESERVED0RINTEDIN53! 1-2EV!$

Table of Contents

QM7500 Technical Manual

Table of Contents . . . i

Introduction . . . 1

Maintenance . . . 2

Startup . . . 2

Shutdown . . . 2

Troubleshooting . . . 3

Servicing . . . 6

Preparing the QM7500 for Servicing . . . 6

Special Notes for Reassembling the QM7500 Printhead . . . 6

Standard QM7500 Assembly . . . 7

Printhead Assembly . . . 8

Controller Assembly . . . 9

Backflushing a Nozzle . . . 10

Backflushing a Valve . . . 11

Replacing the Nozzle Block . . . 11

Optional 7 mm, 15 mm, and 20 mm Nozzle Blocks . . . 12

Replacing a Valve . . . 12

Replacing the Regulator . . . 13

Replacing the Valve/Photocell Board . . . 15

Replacing the Display . . . 17

Replacing the Battery . . . 18

Replacing the Circuit Board . . . 19

Parts List . . . 20

Introduction . . . 20

QM7500 100/240V with US Power Cord . . . 21

QM7500 100/240V with International Power Cord . . . 21

QM7500 100/240V Arabic . . . 21

QM7500 100/240V Chinese . . . 21

QM7500 Printhead Assembly . . . 23

QM7500 Controller Assembly . . . 25

Consumables – Porous . . . 26

Other Components . . . 26

QM31930/03093 Rev AD Table of Contents i

QM7500 Technical Manual

Introduction This QM7500 Technical Manual provides you with complete maintenance,

troubleshooting and servicing information for the MSSC QM7500 Ink Jet Printer. It

also contains a replacement parts list.

CAUTION: This manual is designed for use by qualified technicians only. Any

unauthorized repairs will void your warranty. Unless you are a qualified

technician, do not attempt maintenance that is not discussed in the QM7500

Owners Manual (PN QM32004). You may accidentally damage components

resulting in injury or damage to the equipment.

For more information or assistance contact your local distributor or MSSC

Technical Support any time at (573) 437-7030; FAX: (573) 437-4030.\

QM31930/03093 Rev AD Introduction 1

QM7500 Technical Manual

Maintenance Startup

At beginning of each shift:

1) With the spray cap on the solvent bottle, spray the nozzles with solvent. In

harsh environments, you may need to spray the nozzles more often than once

per shift.

2) Purge the printhead.

3) Check the ink level in the bottle; install a new bottle if necessary. In harsh

environments, or if print quality declines, replace the ink bottle with solvent

and purge solvent through the unit.

Shutdown

If you are shutting down the unit for less than two weeks, simply turn off the

controller. You do not need to purge the printheads with ink or solvent. Also, do not

remove any ink that may have caked on the nozzle block. This will keep

contaminants from entering the nozzles. When you restart the unit, follow the daily

maintenance procedures on page 2.

If you are shutting down the unit for more than two weeks purge the printheads

with porous solvent. Leave the solvent in the ink lines until you restart the unit.

2 Maintenance QM31930/03093 Rev AD

QM7500 Technical Manual

Troubleshooting

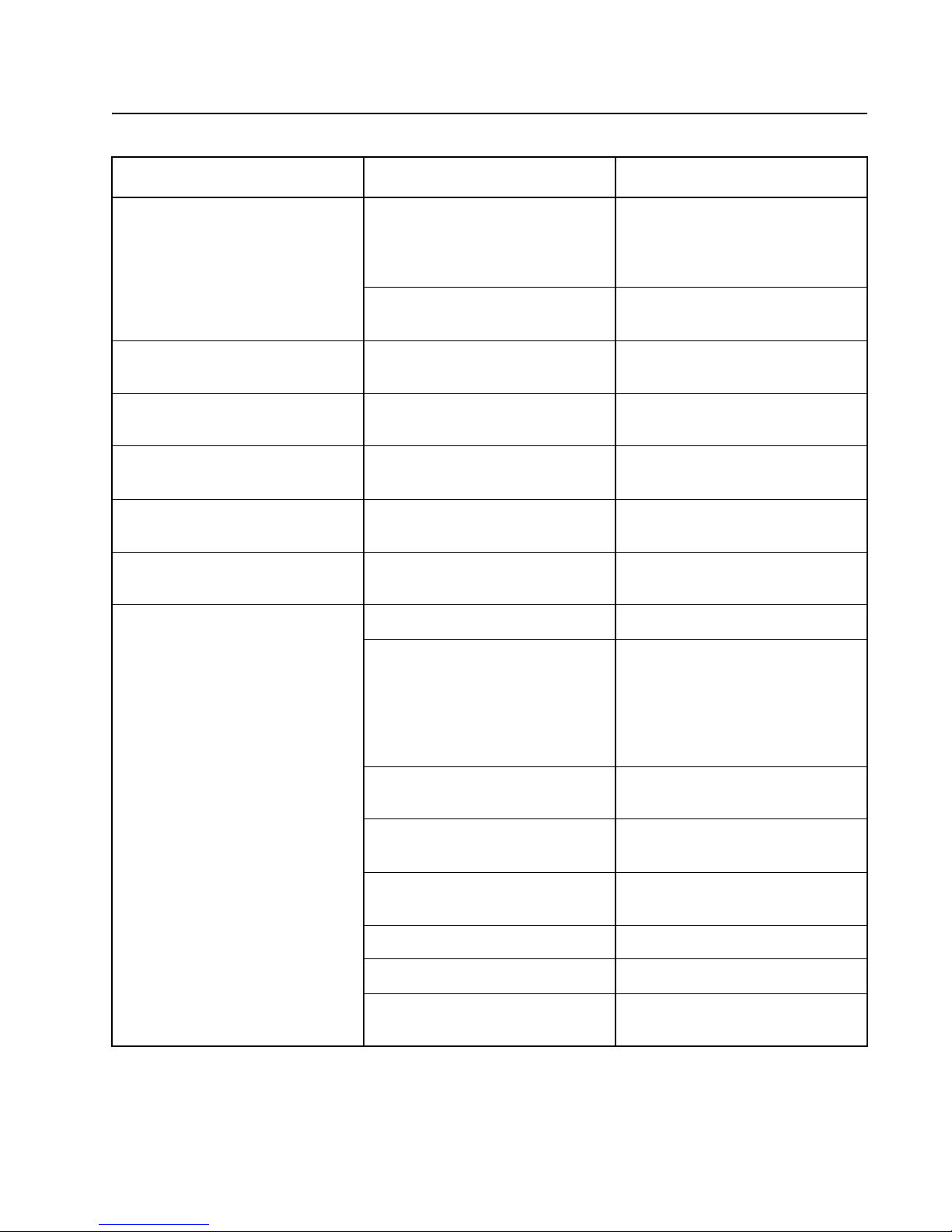

Problem Possible Cause Solution

Row of keys fail to work. Chips loose on the circuit board. Make sure the RAM chip (U8) and

the software (U7) are properly

installed, and that the Zilog chip is

not loose.

Printed circuit board is defective. Replace the printed circuit board.

(See page 19.)

The green light is on, but the unit

will not print.

The unit prints intermittently. Wires disconnected from the

The print light is constantly

orange.

Wires loose from the barrel

terminals.

barrel terminals.

Printhead photocell board

defective.

Reseat any loose wires in the

barrel terminals. (See Figure A.)

Reseat any loose wires in the

barrel terminals. (See Figure A.)

Replace the printhead photocell

board. (See page 15.)

The machine resets itself. V alve shorted out. Replace the defective valve. (See

page 12.)

The unit will purge but not print. Wires loose from the barrel

terminals.

Reseat any loose wires in the

barrel terminals. (See Figure A.)

A dot or dots missing. Unit ran out of ink. Replace the ink bottle.

Nozzle clogged. 1.Spray the nozzle block with

solvent.

2.Backflush the nozzle. (See

page 10.)

3.Replace nozzle block. (See

page 11.)

Tube and jewel assembly in the

nozzle block cracked,

Replace the nozzle block. (See

page 11.)

QM31930/03093 Rev AD Troubleshooting 3

Worn valve. Increase dot size to temporarily

adjust for worn valve.

Valve became loose from the

valve board.

Reseat the valve on the valve

board.

V alve is defective. Replace the valve. (See page 12.)

Ink line became loose. Reattach the ink line.

Wires loose from the barrel

terminals.

Reseat the wires in the barrel

terminals. (See Figure A.)

QM7500 Technical Manual

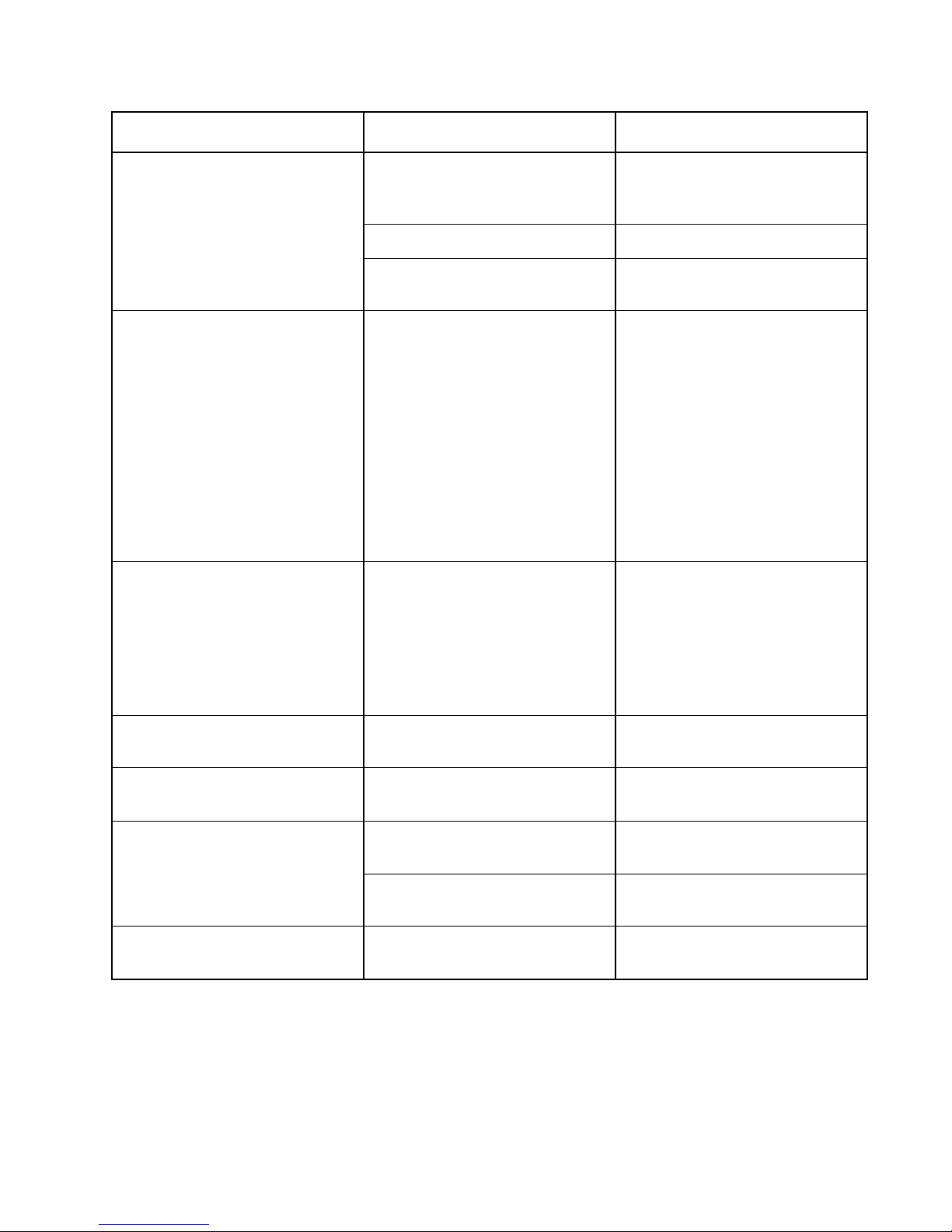

Problem Possible Cause Solution

One or more valves fail to work,

resulting in missing dots

The unit comes on and the print

key is orange.

The dots are splattering on the

print sample.

Cable from the controller to the

printhead touched the valve board

causing a short.

Secure the cable from the

controller to the printhead with a

tie wrap.

V alve is defective. Replace the valve. (See page 12.)

V alve/photocell board is defective. Replace the valve/photocell

board. (See page 15.)

Unit locked up. 1.Unplug the power supply from

the unit, then plug it back in.

2.Zap the controller by keying in Z

A P Shift A.

CAUTION: Zapping the controller

will result in the loss of all print

parameter settings (dot size,

character width, print delay). These

will need to be reset after the ZAP

routine.

Note: Always perform the ZAP

routine after replacing softwar e.

Printhead too far away from the

product.

Position the printhead as close as

possible to the product without

rubbing against it and no further

than 3/8" (9.5 mm) away.

Note: Avoid contact between the

printhead and the product as this

may cause print quality to suffer.

No power. Unit is not properly plugged in. Plug unit into an appropriate

power source.

Ink is leaking from the regulator. Regulator is cracked or defective. Replace the regulator. (See

page 13.)

The bottle will not engage when

replacing the bottle.

Regulator is not properly seated in

the saddle of the printhead base.

Reseat the regulator in the

printhead base.

Regulator is cracked. Replace the regulator. (See

page 13.)

Display screen is blank or garbled. Display is defective. Replace the display. (See

page 17.)

4 Troubleshooting QM31930/03093 Rev AD

QM7500 Technical Manual

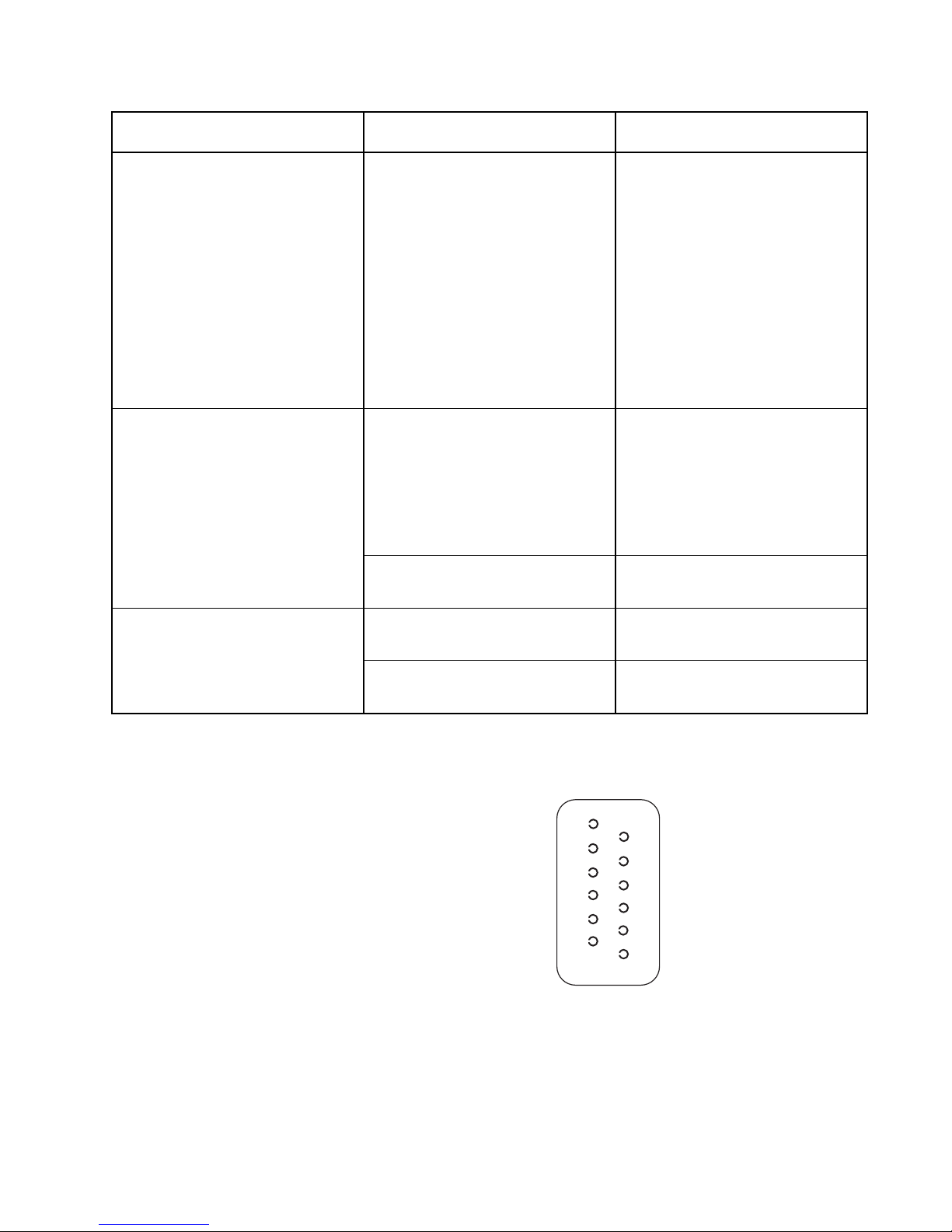

Problem Possible Cause Solution

Prints unrecognizable characters

when displayed correctly.

Message prints backwards or is

too long.

Power supply has recycled and

the QM7500 has defaulted to the

Hebrew language.

1.Type in th e correct language

code for the language you are

using. (If English is the

language being used type

ENGL.)

2.Zap the controller by keying in

ZAP Shift A.

CAUTION: Zapping the controller

will result in the loss of all print

parameter settings (dot size,

character width, print delay). These

will need to be reset after the ZAP

routine.

One of the two photocells are

dirty.

1.Clean the photocells.

2.Manually set the conveyor

direction, eliminating the need

for two photocells. See your

Owner’s Manual for instructions

on setting the conveyor

direction.

Photocell is defective. Replace the photocell boa rd. (See

page 15.)

Keyboard is not responding. Contacts on the PC board are

dirty.

Contacts on the back of the

keypad are dirty.

Figure A: Barrel Terminal Wiring Diagram

light brown

pink

brown

white

red

yellow

Clean the contacts.

Clean the contacts.

purple

gray

green

orange

blue

black

QM31930/03093 Rev AD Troubleshooting 5

Loading...

Loading...