MSL MSF-390 Maintance Manual

MSL COMPRESSOR Co., Ltd.

553, Seorun-dong, Pocheon-si, Gyunggi-do, South Korea 487-030

T) 82-31-541-7000 F) 82-31-542-2999 www.mslcomp.com

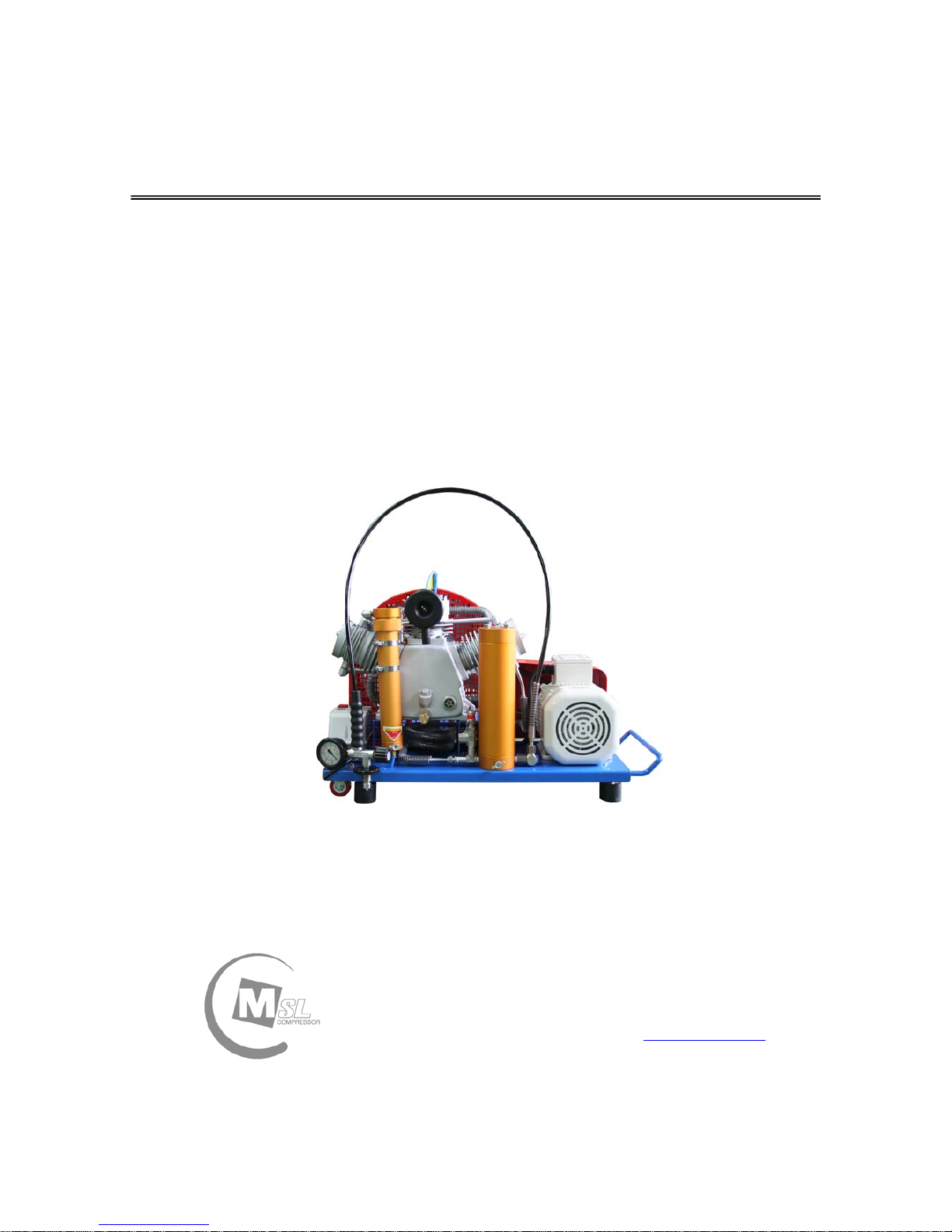

MSF-390

Rev.05

AIR COMPRESSOR MANUAL

OPERATION & MAINTENANCE

- 2 -

General Notice

This operation manual contains the operating and maintenance procedures necessary to

safely run your MSL Compressor. We strongly recommend that you read this manual

thoroughly prior to operation and follow all the safely precautions precisely. Damage

resulting from any deviation from these instructions is excluded from warranty and liability

for this product. Be sure to pay attention to the following points.

1. Fill only tanks with a valid hydrostatic test date

2. Never exceed the working-pressure rating indicated on the tank

3. Do proper maintenance of the filtration system

4. Do regular drainage of the condensate

5. Avoid contaminated air to reach the air intake

6. Do not exceed maximum rpm

Description of Function

The MSF-390 is a 3 stage compressor designed to fill scuba tanks with compressed air.

Air is supplied through air intake filter. The air then enters the 1st stage with a tiny

quantity of oil-vapour and is compressed to 3 bar. From there it passes a cooling pipe to

the 2nd stage, where it is compressed to 45 bar. After that the water and oil are removed

in a (mechanical-expansional) separator and the air is cooled in the next cooling-pipe

before entering stage 3. There it is compressed to the final pressure of 220 bar and then

led to the next filter, where again oil and water are separated through expansion before

the air passes through an activated carbon filter. The filter exit-port is connected to a high

pressure hose, which ends with a pressure-gauge and a tank-connection (filling-valve

assembly).

Each stage has its own safety valve, set and sealed by the manufacturer. The final one is

adjusted from 220 to 330 bar, depending on specification.

Starting the compressor for the first time

1. Place compressor with keeping a distance of at least 50 cm from any walls (Air Temp.

max 40 ℃)

2. Make sure your location is properly vented due to exhaust gases (Engine type)

3. Check oil level on Engine

4. Check fuel level on Engine

5. Check connections

6. Check oil level on compressor

7. Check if air filter cartridge is in place

8. Make sure all filling valves are closed

9. Start compressor

10. Run compressor to max. pressure

11. Check if safety valve opens at Max. pressure

12. Check compressor unit for air leaks

13. Check drain valves of water separators

14. Turn off compressor

15. Release pressure by filling valves

- 3 -

WARNING

WARNING

Safety Precautions

Please refer to the Safety Precautions and use accordingly. The precautions specifically

mentioned in this reading material are of great importance concerning safety, so please follow

as noted. The dangers of misuse are divided into three categories.

DANGER

: Ignoring this notice may result in death and/or fatal injury and can face

extreme danger.

WARNING

: Ignoring this notice may result in death and/or fatal injury.

CAUTION

: Ignoring this notice may result in injury and damage to property.

CAUTION

■ Use only tanks that have been inspected, and never pass the pressure limit as

noted on the tank.

■ Do not use contaminated gases. Do not use in an area with heavy dust.

■ When not in use, keep in an open area.

■ Filter should be replaced regularly as noted in the instruction manual.

(Important: Refer to filter replacement instructions prior to replacement)

■ Do not inject oil or fuels during use.

■ To prevent overheating, cool down compressor after 30 minute operating.

■ User should master instructions and safety precautions in this manual prior to

using the equipment.

■ Installation area needs to be free of chemicals and debris.

■ Installation surface needs to be free of erosion.

■ Install in an area with open air flow and minimal exposure to weather conditions.

WARNING

■ Owner of the equipment should always emphasize precaution to the operator.

■ Accidents should be avoided through careful observation of abnormalities such

as irregular noise from the equipment.

■ Equipment parts should not be altered or relocated in any form.

■ Failure to use recommended parts may result in accidents.

■ Do not remove or alter safety stickers or safety valves.

■ Always examine equipment for missing and irregular parts.

■ Notify us in the event of any discovery of defects, after posting a sign alerting

the equipment out of order.

■ Machinery should always be operated in right lighting. Lighting too bright or too

dark may lead to accidents in operating the equipment.

■ Always check the status of oil and need for changing of oil.

■ Always check the power supply current for the equipment.

- 4 -

DANGER

■ Do not touch the equipment during operation.

■ Do not use flammable cleaners during maintenance.

■ Do not climb the equipment.

■ Operators should always wear a safety suit, gloves, headwear, and other items

for safety. Jewelry should not be worn during operation.

■ Equipment should be installed on a level and flat surface.

SAFETY EQUIPMENT AND INDICATORS

◩ SAFETY EQUIPMENT

■ Safety Valve ■ Pressure Switch

■ Electrical Overload Meter ■ Pressure Gauge

■ Pulley Safety Net

■ water drain

No INDICATOR

1

Overheat

2

Electrical Shock

3

Warning

4

Ear Protection Required

5

Clear hands from V-belt

6

Refer to manual, oil needed.

7

Operation temperature limit.

8

Drain

9

Horizontal Placed

◩ SAFETY INDICATORS

AIR COMPRESSOR MANUAL

- 5 -

■ Possible oil/gas mixture release in the event of an oil leak.

■ Possible electrical shock from water and humidity.

■ Possible accidents from operating the equipment not in accordance to the instructions.

■ Possible high decibel noise.

■ Possible fire hazards in haphazard handling of fuels.

■ Possible drive belt friction.

■ Possible erosion near the cooling fan.

■ Possible injury from a missing valve in the course of compression

1.

Safety principles

2.

The regulation of safety prior to operation

3.

Technical Data

4.

Applied model

5.

Installation

6.

Operation

7.

Maintenance

8.

Troubleshooting

9.

Preventive Maintenance

10.

Warranty Policy

OTHER DANGERS.

◩ TABLE OF CONTENTS

page no.

◩ APPENDIX (PART LIST)

-. PART LIST

-. AIR FLOW DIAGRAM

-. ELECTRIC DIAGRAM

AIR COMPRESSOR MANUAL

- 6 -

1. Safety Principles

1-1 General Notice

■ The user must observe safety principles to prevent accident during operation.

■ The user must pay attention to preventive maintenance table to prevent accident.

■ Read the operation manual of your compressor and its drive engine carefully.

1-2 Safety Principles

■ This machine is designed and constructed for only breathing air compressor so, user

has not to use for other purposes.

■ Allow only qualified personnel to operate the compressor.

■ Take care that the intake air is pure and free of toxic gases and exhaust fumes.

■ Machine operation can be stopped by pressing Emergency Stop Switch

in dangerous

situations.

■ Do not place any objects on compressor while in operation.

■ Make sure no person or object can accidentally touch any moving parts while

running.

■ All work on compressor must be carried out while compressor is plugged off and

depressurized.

■ Check regularly for leaks by brushing all fittings and couplings with a soap solution.

■ Never weld high pressure tubing.

■ Filling-hoses must be in perfect condition; special attention should be paid to he

connecting fittings

■ Units installed with electric motor must be disconnected the power-cable prior to

any work.

■ Make sure no person is within one meter of the drain-hoses before draining the

condensate

■ Do not touch the exhaust while the engine is running and within ten minutes after

shutting down.

■ The main power supply must always disconnected after operation.

■ The power transmission belt guards should not be opened except checking

main power supply.

■ The operator should wear ear protection if exposed to the noise of the running

compressor for the extended periods of time.

AIR COMPRESSOR MANUAL

- 7 -

2. The regulation of safety prior to operation

2-1 Installation of product should be in shade area, well-ventilated and clean area.

2-2 Use proper power to operate the product based on Manufacturer's advisory voltage

and electric current.

2-3 Use standard lubrication oil recommended by the manufacturer and change oil

periodically.

2-4 Do not let strange material taken in the air intake port.

2-5 Manual drain type product should be drained periodically by opening the drain valve

of condensate.

* Auto drain type product designed to drain condensate automatically based on

periodical setting.

2-6 Do not adjust pressure regulator, safety valve and other parts set without

manufacturer's confirmation.

2-7 Use air purification filter recommended by manufacturer.

2-8 Use air intake filter recommended by manufacturer.

Loading...

Loading...