MSK MSK4362D, MSK4362HU, MSK4362U, MSK4362S Datasheet

ISO 9001 CERTIFIED BY DSCC

30 AMP, 75V, 3 PHASE

MOSFET BRUSHLESS

M.S.KENNEDY CORP.

4707 Dey Road Liverpool, N.Y. 13088 (315) 701-6751

FEATURES:

75 Volt Motor Supply Voltage

30 Amp Output Switch Capability

100% Duty Cycle High Side Conduction Capable

Shoot-Through/Cross Conduction Protection

Hall Sensing and Commutation Circuitry on Board

"Real" Four Quadrant Torque Control Capability

Good Accuracy Around the Null Torque Point

Isolated Package Design for High Voltage Isolation Plus Good Thermal Transfer

60°/ 120º Phasing Selectable

Plus and Minus 15 Volt Regulated Voltage Outputs are available for Powering Other Circuitry.

MOTOR CONTROLLER

MIL-PRF-38534 QUALIFIED

DESCRIPTION:

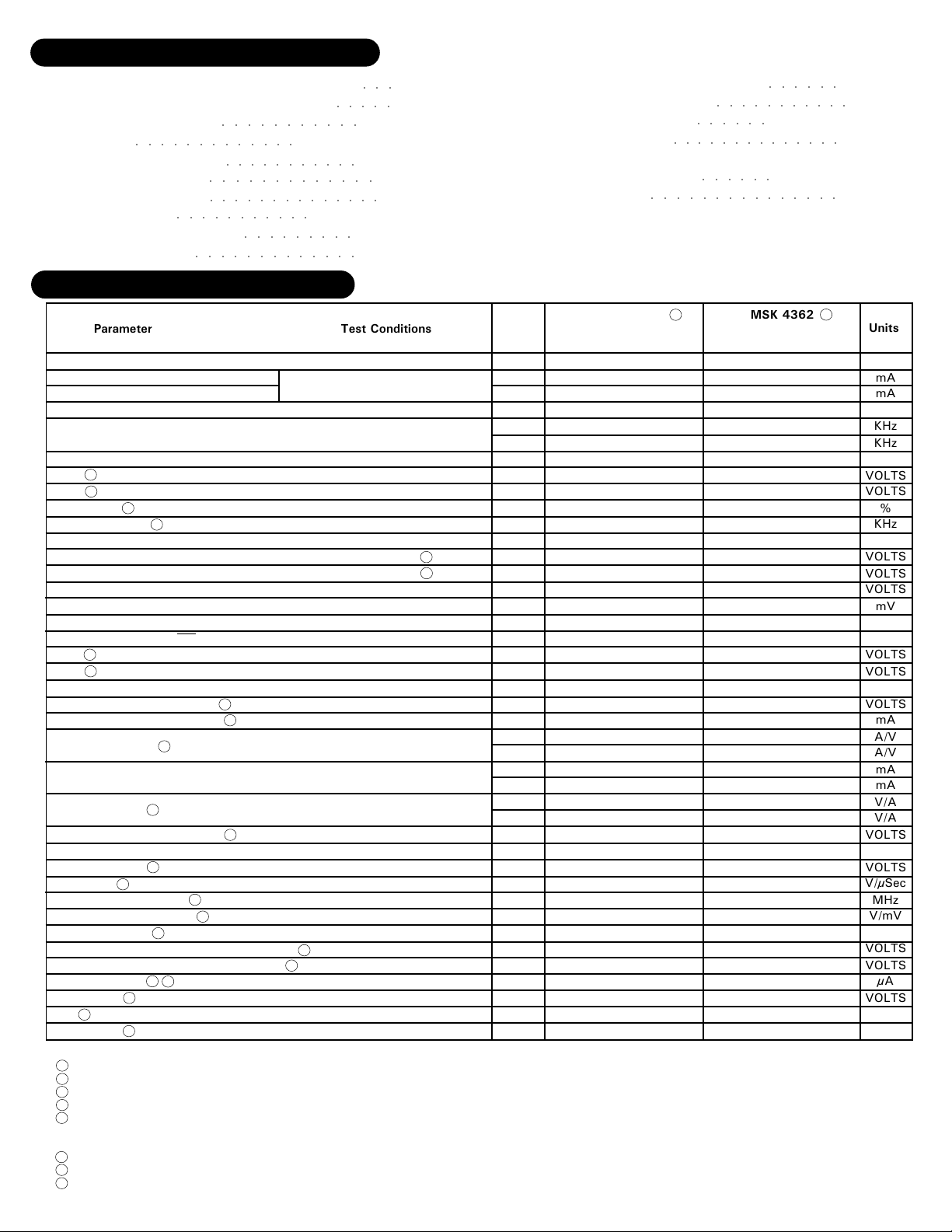

The MSK 4362 is a complete 3 Phase MOSFET Bridge Brushless Motor Control System in a convenient isolated

hermetic package. The hybrid is capable of 30 amps of output current and 75 volts of DC bus voltage. It has the

normal features for protecting the bridge. Included is all the bridge drive circuitry, hall sensing circuitry, commutation

circuitry and all the current sensing and analog circuitry necessary for closed loop current mode (torque) control.

When PWM'ing, the transistors are modulated in locked anti-phase mode for the tightest control and the most

bandwidth. Provisions for applying different compensation schemes are included. The MSK 4362 has good thermal

conductivity of the MOSFET's due to isolated package design that allows direct heat sinking of the hybrid without

insulators.

4362

BLOCK DIAGRAM

TYPICAL APPLICATIONS

3 Phase Brushless DC Motor Control

Servo Control

Fin Actuator Control

Gimbal Control

AZ-EL Control

PIN-OUT INFORMATION

1 REFOUT 13 E/A - 25+REG IN 37 BØ

2 HALL A 14 GND 26 LGND 38 BV+

3 HALL B 15 +Current Command 27 RTN 39 AVS

4 HALL C 16 -Current Command 28 RTN 40 AVS

5 60 /120 17 +15 VIN 29 CVS 41 AØ

6 BRAKE 18 Current Monitor Out 30 CVS 42 AØ

7 CLOCK SYNC 19 -15 VIN 31 CØ 43 AV+

8 DIS 20 -REG IN 32 CØ

9 GND 21 L1 33 CV+

10 N/C 22 -15 VOUT 34 BVS

11 N/C 23 GND 35 BVS

12 E/A OUT 24 +15 VOUT 36 BØ

1

Rev. F 6/00

ABSOLUTE MAXIMUM RATINGS

High Voltage Supply (internal regulators disabled)

High Voltage Supply (using internal regulators)

Current Command Input

Logic Inputs

○○○○○○○○○○○○○

±15VOUT External Load

REFOUT External Load

E/A OUT External Load

Clock SYNC Input

Continuous Output Current

Peak Output Current

○○○○○○○○○○○

○○○○○○○○○○○

○○○○○○○○○○○○○

○○○○○○○○○○○○○○

○○○○○○○○○○○

○○○○○○○○○

○○○○○○○○○○○○○

○○○○○

-0.2V to REFOUT

-0.2V to +15V

ELECTRICAL SPECIFICATIONS

75V

○○○

55V

±13.5V

±25 mA

15 mA

5 mA

30 Amps

41 Amps

Thermal Resistance (Output Switches)

RθJC

Thermal Resistance (Regulator)

RθJC

Storage Temperature Range

TST

Lead Temperature Range

TLD

○○○○○○○○○○○○○○

(10 Seconds)

Case Operating Temperature

TC

Junction Temperature

TJ

○○○○○○○○○○○○○○○

○○○○○○

○○○○○○○○○○○

○○○○○○

○○○○○○

-65°C to +150°C

-55°C to +125°C

1.5°C/W

9°C/W

+300°C

+150°C

Parameter

INPUT CURRENT

+15 VIN

-15 VIN

PWM

Clock Free Running Frequency

CLOCK SYNC INPUT

1

VIL

1

VIH

Duty Cycle

SYNC Frequency

REGULATORS

+15 VOUT

-15 VOUT

REFOUT

-15 VOUT Ripple

LOGIC INPUTS

(Hall A,B,C,Brake,60°/120°,DIS)

VIL

VIH

ANALOG SECTION

Current Command Input Range

Current Command Input Current

Transconductance

Offset Current

Current Monitor

Current Monitor Voltage Swing

ERROR AMP

E/A OUT Swing

Slew Rate

Gain Bandwidth Product

Large Signal Voltage Gain

OUTPUT SECTION

Voltage Drop Across Bridge (1 Upper & 1 Lower)

Voltage Drop Across Bridge (1 Upper & 1 Lower)

Leakage Current

Diode VSD

trr

Dead Time

1

1

1

1

1

1

8

8

1

1

1

1

1

1

1

1

1

1

7

Test Conditions

Output PWM'ing

Current Command=0 Volts

25mA Load

25mA Load

15mA Load

50mA Load

6

6

Group A

Subgroup

Current Command=0Volts

5mA Load

5mA Load

1

1

30 AMPS @ 150°c Junction

All switches off, V+=60V, 150°C Junction

30 AMPS

1

1

4

5,6

-

-

-

-

1,2,3

1,2,3

1,2,3

4

-

-

-

-

4

5,6

1

2,3

4

5,6

-

-

-

-

-

-

-

-

-

-

MSK 4362(H)

Min. Typ. Max.

-

68

-

30

21

18.7

12.5

10

Clock +0

14.25

-14.25

5.82

3.0

-13.5

2.70

2.55

-25

-50

0.300

0.280

-12

-12

6.5

175

22

22

-

-

-

-

-

Clock +3

-

-

-

-

-

-

-

-

-

-

-

3

3

0

0

0.33

0.33

-

-

8

-

6.5

275

-

-

-

-

-

-

-

-

-

-

280

2

25.3

15.75

-15.75

6.57

250

+13.5

3.30

3.45

0.367

0.380

+12

+12

1.83

750

NOTES:

1

Guaranteed by design but not tested. Typical parameters are representative of actual device performance but are for reference only.

2

Industrial grade devices shall be tested to subgroups 1 and 4 unless otherwise specified.

3

Military grade devices ("H" Suffix) shall be 100% tested to Subgroups 1, 2, 3 and 4.

4

Subgroups 5 and 6 testing available upon request.

5

Subgroup 1, 4 TA = TC = +25°C

6

Maximum power dissipation must be limited according to voltage regulator power dissipation.

7

Hybrid powered by external ±15V supplies.

8

Measurements do not include offset current at 0V current command.

2, 5 TA =TC =+125°C

3, 6 TA =TC = -55°C

2

85

40

23

2.5

90

0.8

1.5

25

50

1

2.6

3

Min. Typ. Max.

-

-

20

-

-

12.5

-

10

Clock +0

14.25

-14.25

5.82

-

-

-

3.0

-13.5

-

2.55

-

-50

-

0.280

-

-12

-12

-

-

-

6.5

-

175

-

-

-

-

-

-

-

-

MSK 4362

68

30

22

-

-

-

-

-

-

-

-

-

-

-

-

-

3

-

0

-

0.33

-

-

-

8

6.5

275

-

-

-

-

280

2

2

Units

85

40

24

2.5

mA

mA

KHz

KHz

-

VOLTS

VOLTS

-

90

Clock +3

15.75

-15.75

6.57

250

0.8

+13.5

1.5

3.45

50

0.380

+12

+12

1.83

KHz

VOLTS

VOLTS

VOLTS

mV

VOLTS

VOLTS

-

VOLTS

mA

A/V

A/V

-

mA

mA

-

V/A

V/A

-

VOLTS

VOLTS

V/µSec

-

MHz

-

V/mV

-

VOLTS

1

VOLTS

750

VOLTS

2.6

nSec

-

µSec

-

Rev. F 6/00

%

µA

APPLICATION NOTES

MSK 4362 PIN DESCRIPTIONS

AV+, BV+, CV+ - are the power connections from the hy-

brid to the bus. The pins for each phase are brought out

separately and must be connected together to the V+ source

externally. The external wiring to these pins should be sized

according to the RMS current required by the motor. These

pins should be bypassed by a high quality monolithic ceramic

capacitor for high frequencies and enough bulk capacitance

for keeping the V+ supply from drooping. 78 µF of ceramic

capacitance and 6200 µF of bulk capacitance was used in

the test circuit. The voltage range on these pins is from 16

volts up to 75 volts.

AØ, BØ & CØ- are the connections to the motor phase wind-

ings from the bridge output. The wiring to these pins should

be sized according to the required current by the motor. There

are no short circuit provisions for these outputs. Shorts to

V+ or gound from these pins must be avoided or the bridge

will be destroyed.

AVS, BVS, CVS - are the return pins on the bottom of each

half bridge. They are brought out separately and should be

connected together externally to allow the current from each

half bridge to flow through the sense resistor. The wiring on

these pins should be sized according to the current require-

ments of the motor.

-REF IN - is the input pin for applying power to the internal

-15V DC - DC converter. To use the converter, connect the

-REG IN pin to +15 VOUT pin. If the -15V converter is not

needed, no connection should be made to -REG IN and -15

VOUT. -15 volts will have to be supplied from an external

source to -15VIN. Also, L1 can be left open. See voltage

regulator portion of app. note for additional information.

L1 - is a pin for connecting an external inductor to the DC -

DC converter for generating -15 volts. A 47 µH inductor

capable of running at 250 KHz and about 1 amp of DC cur-

rent shall be used. Connect the inductor between L1 and

GND.

-15 VOUT - is a regulated -15 volt output available for exter-

nal uses. Up to 25 mA is available at this pin. A 100 micro-

farad capacitor should be connected as close to this pin as

possible and returned to GND along with a 0.22 microfarad

monolithic ceramic capacitor. CAUTION: See Voltage Regu-

lator Power Dissipation

-15 VIN - is the input for applying -15 volts to run the low

power section of the hybrid. This pin should be connected to

-15 VOUT if running off of the internal regulator. The re-

quired bypassing of the -15 VOUT pin is sufficient in this

case. For bringing in -15 volts, this pin should be bypassed

with a 10 µF capacitor and a 0.1 µF capacitor as close to this

pin as possible.

RTN - is the power return connection from the module to the

bus. All ground returns connect to this point from internal to

the module in a star fashion. All external ground connections

to this point should also be made in a similar fashion. The

V+ capacitors should be returned to this pin as close as

possible. Wire sizing to this pin connection should be made

according to the required current.

LGND - is an isolated ground connection to the RTN pin of

the hybrid that is connected internally. For any circuitry that

needs to be connected to the RTN pin without the influence

of current flow through RTN should be connected at this

point.

GND - is a ground pin that connects to the ground plane for

all low powered circuitry inside the hybrid.

+REG IN - is the input pin for applying power to the internal

+15V regulator. To use the regulator, connect the +REG IN

pin to the motor bus (V+). See regulator app. note for more

info on input voltage. If the +15V regulator is not needed,

no connection should be made to +REG IN and +15 VOUT.

+15 volts will have to be supplied from an external source to

+15VIN. Absolute maximum voltage on this pin is 55 volts.

See voltage regulator portion of app. note for additional infor-

mation.

+15 VOUT- is a regulated +15 volt output available for ex-

ternal uses. Up to 25 mA is available at this pin. A 100

microfarad capacitor should be connected as close to this pin

as possible and returned to GND along with a 0.22 micro-

farad monolithic ceramic capacitor. CAUTION: See Voltage

Regulator Power Dissipation.

+15 VIN - is the input for applying +15 volts to run the low

power section of the hybrid. This pin should be connected to

+15 VOUT if running off of the internal regulator. The re-

quired bypassing of the +15 VOUT pin is sufficient in this

case. For bringing in external +15 volts, this pin should be

bypassed with a 10 µF capacitor and a 0.1 µF capacitor as

close to this pin as possible.

CURRENT COMMAND (+,-) - are differential inputs for con-

trolling the module in current mode. Scaled at ±3 amps per

volt of input command, the bipolar input allows both forward

and reverse current control capability regardless of motor com-

mutation direction. The maximum operational command volt-

age should be ±10 volts for ±30 amps of motor current.

CURRENT MONITOR- is a pin providing a current viewing sig-

nal for external monitoring purposes. This is scaled at ±3

amps of motor current per volt output, up to a maximum of

±10 volts, or ±30 amps. As ±30 amps is exceeded, the

peaks of the waveform may become clipped as the rails of

the amplifiers are reached. This voltage is typically ±12.5

volts, equating to ±37 amps of current peaks.

E/A OUT - is the current loop error amp output connection.

It is brought out for allowing various loop compensation cir-

cuits to be connected between this and E/A-.

E/A- -is the current loop error amp inverting input connec-

tion. It is brought out for allowing various loop compensa-

tion circuits to be connected between this and E/A OUT.

CLOCK SYNC- is an input for synchronizing to an external

clock. The sync circuit will trigger on the edges of the ap-

plied clock and effectively shorten the period of the internal

oscillator on each cycle. The frequency can be increased

from a free running 22 KHz to 25 KHz maximum. The clock

applied shall be 15 volts amplitude with at least a 10% duty

cycle.

REFOUT- is a 6.25 volt regulated output to be used for pow-

ering the hall devices in various motors. Up to 15 mA of

output current is available.

HALL A, B & C - are the hall input pins from the hall devices

in the motor. These pins are internally pulled up to 6.25

volts. The halls can reflect a 120/240 degree commutation

scheme or a 60/300 degree scheme.

3

IN

Rev. F 6/00

Loading...

Loading...