Page 1

MSI-8000HD

RF Remote Display

Operator’s Manual

159007

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction ............................................................................1

1.1 Safety Section ....................................................................... 2

1.2 Front Panel Descriptions ..................................................... 3

1.3 Specifications ....................................................................... 5

1.4 Features ................................................................................ 6

1.5 FCC Statement ..................................................................... 6

1.6 International RF Certs .......................................................... 6

1.7 Getting Started ..................................................................... 7

1.8 Options .................................................................................. 7

1.9 Unpacking ............................................................................. 8

2.0 Operation ................................................................................9

2.1 Power .................................................................................... 9

2.2 Zero ....................................................................................... 9

2.3 Tare ..................................................................................... 10

3.0 User Defined Function Keys .................................................11

3.1 Off ........................................................................................ 11

3.2 Test ...................................................................................... 11

3.3 Total .................................................................................... 11

3.3.1 Manual Total ...........................................................................12

3.3.2 Auto Total ...............................................................................12

3.3.3 View Total ...............................................................................12

3.4 Net/Gross ............................................................................ 12

3.5 Peak Hold ............................................................................ 13

3.5.1 Capture Peak Force ................................................................13

3.6 2-Units/ 5-Units .................................................................. 14

3.7 Hi-Res ................................................................................. 14

3.8 Print ..................................................................................... 14

3.9 Scan .................................................................................... 14

3.10 Total Remote Devices ........................................................ 15

3.11 Tare ..................................................................................... 15

4.0 Set Up ...................................................................................16

4.1 Menu Map ........................................................................... 16

4.2 Function Keys ..................................................................... 17

4.3 Auto-Off ............................................................................... 18

5.0 COMM Set Up .......................................................................19

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

November 25, 2013

Page 4

5.1 RF Setup ............................................................................. 21

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

5.2 RF Set Up, Dyna-Link And MSI Crane Scales ................... 23

5.3 MSI8000 With Multiple Sensors ......................................... 23

5.4 Summing Modes ................................................................. 24

5.4.1 Modes .....................................................................................24

5.5 Behavior Of Zero And Tare In Multiple Channel Systems 25

5.6 Printer Set Up ..................................................................... 25

5.7 Control Modes .................................................................... 26

5.8 Standard Print Strings ........................................................ 26

5.9 COMM Port Hardware ........................................................ 28

5.10 Service Counters ................................................................ 29

5.11 Relays .................................................................................. 31

5.11.1Relay Options .........................................................................31

5.12 Antenna Options ................................................................. 33

5.12.1Antennas Available for a MSI-8000HD ....................................34

6.0 Appendix ..............................................................................36

6.1 Troubleshooting .................................................................. 36

6.2 Error Codes ......................................................................... 39

6.3 Mechanical Dimensions ..................................................... 40

6.4 Firmware Update Procedure .............................................. 40

The MSI Limited Warranty ............................................................43

ii MSI-8000HD Operator’s Manual

Page 5

1.0 Introduction

The MSI-8000HD RF Remote Display is a wireless remote display for viewing weight

from several compatible MSI Crane Scales and Dyna-Links. It is fully sealed for

outdoor use in most ambient conditions. Using a Remote Display enhances the safety

and usability of the MSI’s Dyna-Link and Crane Scale systems. The RF Remote

Indicator allows load monitoring from a distance and adds the ability to print and

store data.

The MSI-8000H

hours (typical) of continuous use between charges.

If you have any questions or comments please contact

D uses a rechargeable Lithium Polymer battery providing up to 36

Measurement Systems International:

Phone (toll free): 1-800-874-4320

Authorized distributors and their employees can view or download this

manual from the Measurement Systems International distributor site at:

www.msiscales.com.

Introduction 1

Page 6

1.1 Safety Section

Important

WARNING

WARNING

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided could

result in death or serious injury,

exposed when guards are removed.

Indicates information about procedures that, if not observed, could

result in damage to equipment or cor

General Safety

Do not operate or work on this equipment unless you have read and

understand the instructions and warni

any Measurement Systems International dealer for replacement

manuals. Proper care is your responsibility.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT stand near the load being lifted as it is a potential falling hazard. Keep a safe

di

stance.

DO NOT use for purposes other then weight taking or

DO NOT use any load bearing component that is worn beyond 5% of the original

dimension.

DO NOT use any associated lifting product if any of the load bearing components are

racked, deformed, or show signs of fatigue.

c

DO NOT exceed the rated load limit of the associated Scale/Dynamometer unit, rigging

ements, or the lifting structure.

el

DO NOT allow multi-point contact with the hook, shackle, or lifting eye of the

sociated Scale/Dynamometer unit.

as

DO NOT allow high torque on the Scale/Dynamometer unless it is specifically designed

or high torque.

f

DO NOT make alterations or modifications to the unit or associated load bearing

vices.

de

DO NOT remove or obscure warning labels.

For guidelines on the safe rigging and loading of overhead scales and dynamometers,

rea

d the "MSI Crane Scale Safety and Periodic Maintenance Manual" (available at

www.msiscales.com).

Keep hands, feet and loose clothing away from moving parts.

There are no user serviceable parts within the MSI-8000. Any repairs are to be

pe

rformed by qualified service personnel only.

and includes hazards that are

ruption to and loss of data.

ngs in the this Manual. Contact

dynamic load monitoring.

2 MSI-8000HD Operator’s Manual

Page 7

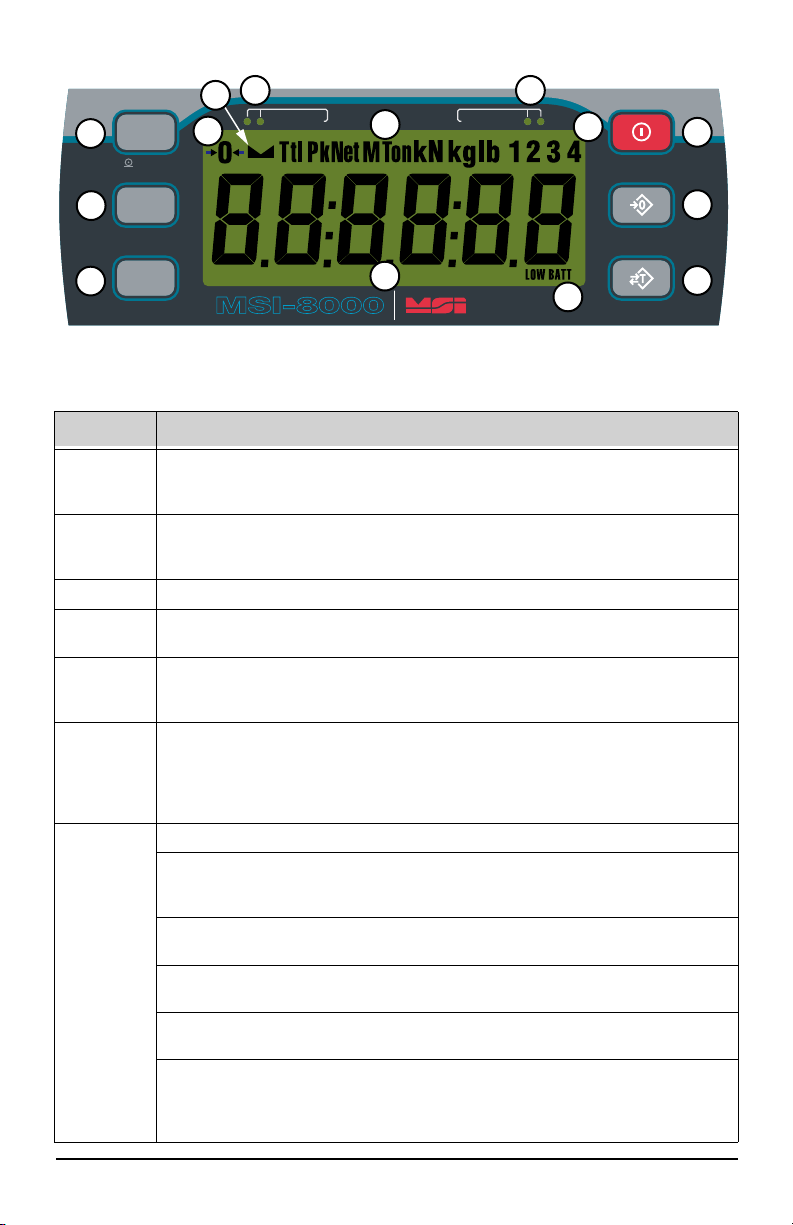

MSI-8000

Measurement Systems

International

TM

FUNCTION

PRINT

ZERO

POWER

TARE

SETPOINTS12

F3

F2

F1

12

Class III/IIIL n

max

=10000

1

2

3

6 8

4

7

9

10

11

12

13

5

14

Figure 1-1. MSI-8000HD Front Panel

1.2 Front Panel Descriptions

Item No Description

1

2

3

4

5

6

7

F1 Key – Programmable to user selectable functions, see Section 3.0.

Default – Peak Hold.

Functions as the ENTER/SELECT key when in setup menus

F2 Key – Programmable to user selectable functions, see Section 3.0.

Default – Display & Function Test

Functions as the scroll key in setup menus

PRINT Key – Defaulted to the Print function.

CENTER-OF-ZERO Annunciator – Indicates the load is within 1/4d of

zero.

STABLE Annunciator – indicates that the load force has settled within the

motion window (usually ±1d).

When this symbol is off, the Scale / Dyna

F1 F2 LED – These blue LEDs are used to indicate various operational

features of functions programmed into the F1 and F2 keys.

Example:

In Peak Hold mode the associated LED wi

reading is captured.

Units and Load Annunciators

TOTAL (Ttl) Annunciator – Indicates the RF

Total accumulated weight. This is a temporary display lasting less than 5

seconds.

PEAK (Pk) Annunciator

– Indicates the RF Linked Device is in the Peak

Hold mode.

NET (Net) Annunciator –

mode. A Tare weight is subtracted from the gross load.

METRIC TON (M) Annunciator

Indicates the RF Linked Device is in the Net load

indicates the RF Linked Device is displaying Metric Tons.

TON (Ton) Annunciator – Ill

uminated alone, indicates the RF Linked Device

is displaying in US Short Tons (1 ton = 2000 lb.). When illuminated along

with the ‘M’ the RF Linked Device is displaying in Metric Tons (1 metric ton =

1000 kg)

-Link will not zero, tare, or totalize.

ll blink whenever a new peak

Linked Device is displaying the

– In conjunction with the Ton annunciator,

Introduction 3

Page 8

Note

Item No Description

7 (cont)

8

9

10

11

12

13

14

F1 and F2 can both be programmed to all available user functions.

If a function key does not work, it is pro

is not setup to support the key.

Example:

If the Function key is set for TOTAL, you mus

Menu of the target scale.

KILONEWTONS (kN) Annunciator – Indicates load display is in

kiloNewtons.

KILOGRAMS (kg) Ann

POUND (lb) Annunciator – I

SETPOINTS – User programmable set points for overload warnings. Set

Points 1 and 2 are high brightness red LEDs

1234 – if the 8000HD has multiple sensors, the number indicates the sensor

being displayed. If more than one number is lit, then the sensors are being

summed.

Example – if both 1 and 2 are lit, then the we

of sensor 1 and sensor 2.

DIGITS – Six 1.22 inch (31 mm) sunlight visible LCD load display.

POWER Key – Turns the unit ON and OFF.

When in setup mode, returns to the no

storing the changes.

ZERO Key – Used to zero out residual load on the scale/Dynalink.

When in the setup mode, drops back one menu level.

At the root menu level, stores the changes and returns to load mode.

Tare K e y – Removes the current load value and puts the system in to the

NET weight mode.

LOW BATT Annunciator – Indicators battery power is low.

The function keys (F1 znd F2) will be displayed as Fx-YYYY, when used to

describe it’s use.

x = function key number, 1 or 2..

YYYY = currently programed function for that key.

unciator – Indicates load display is in kilograms.

ndicates load display is in pounds.

ight displayed equals the sum

rmal weight/load display without

bably because the connected Scale/Dyna-Link

t also setup the TOTAL mode in the Setup

4 MSI-8000HD Operator’s Manual

Page 9

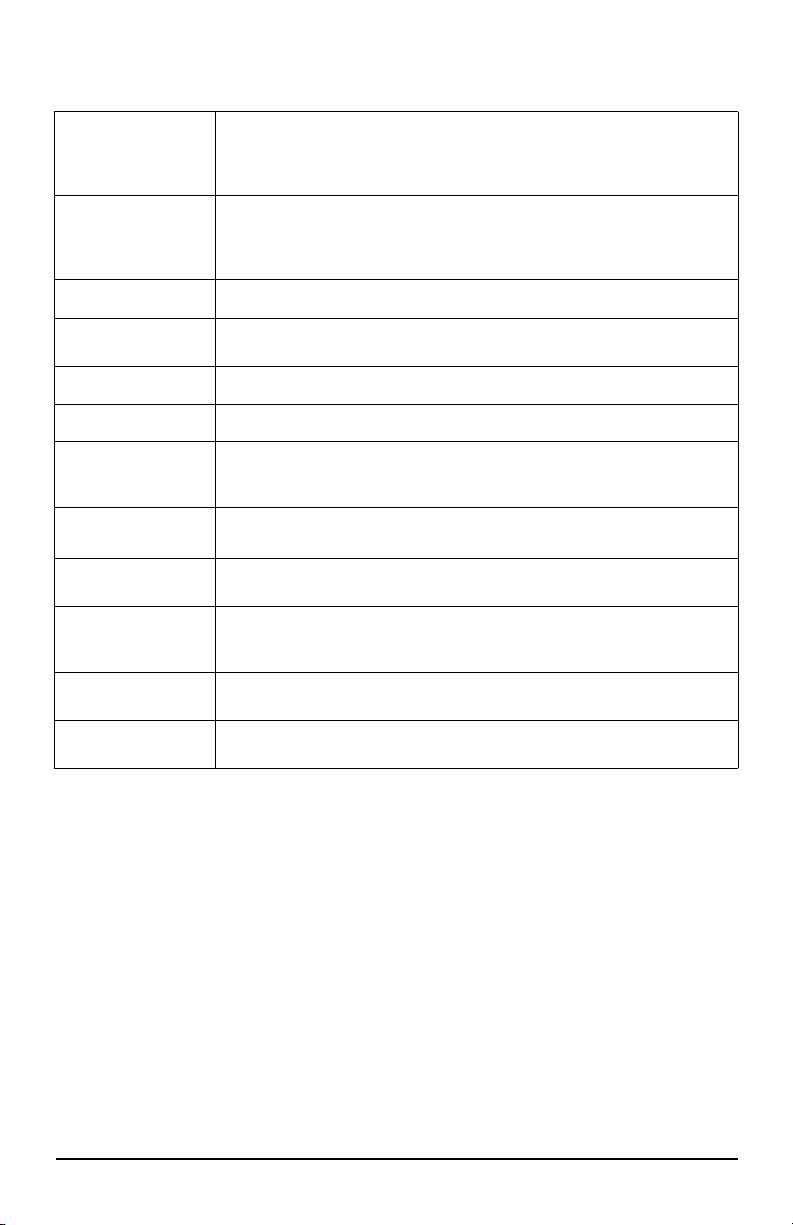

1.3 Specifications

Accuracy

Power

Display

Operating Temp

Operating Time

Enclosure

F1, F2, and F3

Calibration

Auto-Off Mode

Units

Totalization

Set Points

Weight accuracy is dependent on th

or MSI Crane scale. Refer to the appropriate User Guide for

accuracy specifications. The MSI-8000 mirrors the display of the

connected device.

Battery operated by a custom Lithium Polymer cell. Not user

ceable. Estimated number of charges is >300. Life is

repla

prolonged with frequent recharging and not allowing the deep

discharging of the battery.

6 digit, 1 in (26 mm) numeric digits

- 40°F to +122°F (-40°C to +50°C), Rated accuracy range -10°C

to +40°C.

>24 hours typical.

NEMA 4/IP65 with charger port plug installed.

Programmable multifunction buttons for use as TEST, TOTAL,

tal Remote Devices, PEAK, TARE, NET/GROSS, VIEW TOTAL,

To

PRINT and High Res mode

No Calibration parameters are stored in the MSI-8000HD.

However, it can be used to calibrate an RF connected scale

Prolongs battery life by turning the power off after 15, 30, 45, or

minutes (operator determined) of no weight activity

60

kg, lb, Tons (US short ton), Metric Tons, kiloNewtons (other Units

able with custom calibrations). Available units are determined

avail

by the RF Linked Scale/Dyna-Link

Standard: Press button or Automatic; T

X 1000 units

Two internal Set Points with open drain outputs, and two

trabright LEDs on indicator panel.

ul

e linked load unit, a Dyna-Link

OTAL weight up to 99999

Introduction 5

Page 10

1.4 Features

• Designed to meet or exceed all US and International safety and environmental

standards.

• Reliable and easy to use wireless remote display

• No License required. Meets US and International RF Transmission Laws.

• Greater than 24 hours operation when fully charged.

• Automatic Power Off conserves battery life by sensing no activity after 15, 30,

45 or 60 minutes, determined by operator, and turns Power off.

• Rugged construction throughout. IP65 / NEMA 4 for outdoor use. Shock

cushioning on the corners.

•Six, 1

• Selectable for kg / lb. / Tons (US Short) / Metric Tons / kiloNewtons.

• Automatic or manual weight totalization for loading operations.

• Two Set Points can be set for any in-range load/weight value for operator alerts

• ScaleCore Technology providing quick and easy firmware updates and

• Optional Hard-wired link for applications where RF is not allowed.

in (31 mm), LCD digits for clear load readings.

or process control.

calibration / setup backup.

1.5 FCC Statement

Contains FCC ID: OUR-XBEEPRO

The MSI-8000HD complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

i This device may not cause harmful interference.

ii This device must accept any interference received, including interference that

may cause undesired operation.

1.6 International RF Certs

Canada Radio Cert. No.: IC: 4214A-XBEEPRO

Australia & New Zealand: AS4268:3000

Japan: Certificate of Radio Equipment in Japan No.: 08215111/AA/02

Europe and much of Asia:

The product is compliant with the following standards and/or other normative

Safety (article 3.1A) EN60950-1:2001

EMC (article 3.1b) ETSI EN 301 489-1 v1.7.1 (2007-04) In accordance with the

specific requirements of ETSI EN 301 489-17 v1.2.1 (2002-08)

Spectrum (article 3.2) ETSI EN 300 328 v1.7.1 (2006-10)

6 MSI-8000HD Operator’s Manual

documents:

Page 11

1.7 Getting Started

The MSI-8000HD is usually shipped along with a compatible sensor unit such as an

MSI-7300 Dyna-Link 2, or one of MSI’s advanced Crane Scales. MSI ships these

systems pre-configured. If the MSI-8000HD is purchased separately, or is to be used

with a different system, then the RF Transceivers will have to be mated. Follow the

RF Setup Procedure in

Fully charge the battery by plugging the charger into the Charge Port. Depending on

the discharge level of the battery this can take up to 6 hours.

Once the RF Setup is complete for the MSI-8000HD, the system will instantly

connect with the Scale / Dyna-Link. It is advised to do a site survey to identify

operating range and usability of the RF Link. The easiest way to accomplish this is to

position the Scale / Dyna-Link at an average operational height, and then try the link

at various positions and distances. Range may vary by the rotation of the Scale /

Dyna-Link. The RF Transceivers used in the MSI-8000HD are capable of much

further range than the 100’ typical spec, but range is dependent on site and installation

variables.

Section 5.1.

1.8 Options

• Available options for your MSI-8000HD include the following:

• 9-36 VDC Isolated Power Input

• 18-72 VDC Isolated Power Input

• Internal Lithium Ion battery with External charger

• Internal Lithium Ion battery with 90-264 VAC Combination

• 802.11 WiFi (requires 2nd Antenna remotely mounted)

• 100baseT hardwired Ethernet

• Internal Relays (normally open) – see Section 5.11

-Two coil relays

- Two SSR relays - industrial systems

- Two SSR relays - operations where SSR’s are preferred

• One 1Form B Relay (normally closed) – see Section 5.11

• Audible Alarm (not compatible with Battery Versions)

• 4 Channel/Sensor Input

• Gain Antennas to increase RF Range

- 9dBi Mast Mount Omnidirectional

- 9dBi Wall Mount Corner Reflector

- 12dBi Wallmount Corner Reflector

- 5 dBi Vehicle Mount

- 15dBi Mast Mount Yagi, highly directional, for fixed locations only.

• Angle Bracket for desktop and wall mounting.

Introduction 7

Page 12

• Wireless computer interfaces available: The following devices are available to

interface the 8000HD wirelessly to remote Scoreboard Displays, networks, and

directly into a computer using USB.

-USB

- Serial RS-232

- Serial RS-485

- Ethernet Bridge

- WiFi Ethernet

1.9 Unpacking

When unpacking the MSI-8000HD, ensure that all parts are accounted for. Check the

MSI-8000HD for any visible damage and immediately report any damage to your

shipper. It is advisable to use the original shipping container when shipping or

transporting the MSI-8000HD.

8 MSI-8000HD Operator’s Manual

Page 13

2.0 Operation

POWER

ZERO

2.1 Power

To turn on the power.

1. Press

version number will display.

SI-8000HD is ready for use.

The M

, the LCD will show all segments for a display text and the software

2.2 Zero

Sets the zero reading of the Scale/Dyna-Link. Takes out small deviations in zero when

the Scale/Dyna-Link is unloaded. (See Section 2.3 for zeroing (Taring) package,

rigging or pallet weights)

1. Press

zero function to work.

The

MSI-8000HD

Zero - Rules for Use:

• Works in GROSS or NET mode.

• Zeroing while in Net mode will zero the gross load causing the display to show

the neg

• The Scale/Dyna-Link must be stable within the motion window. They will not

zero until the s

that it has a zero request for two seconds. If motion clears in that time, they will

zero.

• The Scale/Dyna-Link will accept a zero setting over

Dyna-Link. Zero settings above 4% of full Scale/Dyna-Link will subtract from

the overall capacity of the Scale/Dyna-Link.

Example

If 100 lb is zeroed on a 1000 lb Scale/Dyna-Link, the overall capacity of the

Scal

e/Dyna-Link will reduce to 900 lb plus the allowed over-range amount.

. The load reading must be stable within the motion window for

stores the zero reading, and can restore it even if power fails.

ative Tare value.

table annunciator is on. The Scale/Dyna-Link will “remember”

the full Range of the Scale/

Operation 9

Page 14

2.3 Tare

TARE

Note

TARE

Note

In scale applications, tare is typically used to zero out a known weight such as

rigging, a container, or pallet and display the load in NET load/weight.

SI-8000HD tare function is defined as a Tare-In/Tare-Out operation.

The M

key stores the current load/weight as a tare value and the

The first press of the

Scale/Dyna-Link subtracts the value from the gross load and changes the display to

NET mode.

The second press of the

GROSS mode.

To Tare and display the NET load

TARE

TARE key will clear the Tare value and revert display to

1. With the weight on the scale/Dyna-li

weight changes to zero and

The weight must be stable with displayed for the tare function to work.

The backup memory in the

restore it even if power fails.

NET is displayed indicating unit is in the NET mode.

nk that needs to be tared, press

MSI-8000HD

stores the tare reading, and can

To Clear the Tare and revert to Gross load

1. Press

, the NET annunciator turns off indicating the unit is in GROSS

mode .

To view the Gross load without clearing the Tare Value, program a function

key to the function “NET/GROSS.”

Tare- Rules for Use:

• Only positive gross load readings can be tared.

• The stable annunciator must be on. The load/force reading must be stable.

• Setting or changing the tare has no effect on the gross zero setting.

• Taring will reduce the apparent over range of the scale.

Example

Taring 100 pounds of rigging on a 1000 lb scale, the scale will overload at a net

loa

d of 900 lb (1000-100) plus any additional allowed overload (usually about

4% or 9d).

. The

10 MSI-8000HD Operator’s Manual

Page 15

3.0 User Defined Function Keys

Note

Note

Note

This section describes each user function available for the F1 and F2 user keys.

The Function Key setup on the

Keys of the connected Scale/Dyna-Link.

To enable the USER key functions, you must set up the USER keys following the

dures in Section 4.0.

proce

In software release 1-XX, F3 is dedicated to the print function and cannot be changed.

T

he functions PRINT (F3) and TARE are available full-time on the MSI-8000HD, they do

not need to be programmed.

3.1 Off

No USER Key Function assigned. The F-Key is disabled.

3.2 Test

The TEST function runs an LCD test in the following order:

• Lights all LCD segments and the LEDs

• Displays the model number (8000)

• Displays the software version number

• Displays the battery level

• Display a test counting from 00000 to 99999

Internal tests are also performed and if any test

Section 6.2 for a description of all error codes.

TEST can be aborted anytime by pushing

The

stepped by pushing

F2 and then using the F1 key to step from display to display.

MSI-8000HD

fails an error code will display. See

ZERO. The test can also be single

is independent of the Function

3.3 Total

For accumulation of multiple weighments, the accumulator uses the displayed load,

so GROSS and NET readings can be added into the same TOTAL.

This feature should not be confused with the ttl.rd (Total Remote Devices)

function, which will add weight from two or more load sensors.

There are four modes of totalizing: manual and three auto modes.

The manual mode requires the TOTAL button to be press

The load will be added to the previously accumulated value. This assures that a

weight/load on the scale is only added to the total once.

All modes require that the load on the scale return below 0.5% (relative to full

scale) of GROSS ZERO or NET ZERO before the next weighment can be

a

dded.

Applied load must be

be totaled.

>

1% of capacity above GROSS ZERO or NET ZERO before it can

ed with the load on the scale.

User Defined Function Keys 11

Page 16

3.3.1 Manual Total

Note

The Fx-TOTAL key under the MANUAL TOTAL mode functions in this manner:

Load is more than 1% of capacity and has not been totaled.

1. Push the

LED blinks to indicate the load value was accepted.

The TOTAL LCD annunciator and the Total wei

number of samples.

2. Current load has been

the 1% threshold is exceeded.

Fx-TOTAL key to add the current load to the TOTAL weight. The Fx

ght is displayed briefly, then the

totaled, push the Fx-TOTAL key to add more weight once

If key is pressed prior to the 1% threshold being met it will display the current

total .

3.3.2 Auto Total

The Fx-TOTAL key under the AUTO TOTAL mode functions as Auto Total On/ Auto

Tota l Off .

The Auto Mode has three variations which are programmed in the

• AutoL

• AutoN

• AutoHig

oad - Any settled load above the ‘Rise above’ threshold will be

automatically totaled. Then the scale must fall below the ‘Drop below’ threshold

before another total is allowed.

orm - This mode takes the last settled load to auto total with. The total

occurs only once the Scale goes below the threshold. This allows the load to be

adjusted without a total occurring. Once load is removed, the Scale uses the last

settled reading for total.

h - Similar to the AutoNorm mode except the Scale uses the highest

settled reading. Useful for loads that can’t be removed all at once.

SETUP menu:

3.3.3 View Total

The Fx-VIEW TOTAL key activates the Total weight display followed by the number

of samples. While the display is showing the Total, Total is cleared by pressing ZERO.

3.4 Net/Gross

Switches the display between Net and Gross modes.

Net weight is defined as Gross weight minus a Tare weight.

To switch between Net Mode and Gross Mode

the Net/Gross function). The Fx-NetGross key will only function if a Tare value has

been established.

Switching back to Gross mode from Net mode will not clear the

allows the operator to use the Gross Mode temporarily without having to reestablish

the tare value. Only clearing or setting a new tare will change the tare value held

before switching into Gross Mode.

12 MSI-8000HD Operator’s Manual

press the Fx-NetGross

Tare value. This

key (setup to

Page 17

3.5 Peak Hold

1) Program a function key to Peak

Hold (P-Hld)

In this example we’ll use F1 for Peak

Hold.

2) Prepare the test stand and test

sample.

3) Press

ZERO to zero out any

residual strain on the link.

4) Press

F1 PkHold Confirm that

the “Pk” annunciator is on.

A small jump in the reading may occur

depending on the stability of your test

device.

5) Apply the test force. The F1 LED

will blink three times when a

new peak value ID is detected.

6) When the force is removed,

the Peak value can be recorded.

7) To run a new test, press

F1 PkHold to clear the Peak

Value. Confirm the “Pk”

annunciator is off. Then repeat

steps 3-6.

Peak Hold

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Pk

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Pk

Example Peak Captured Value

Peak Hold

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Peak Cleared Value

F1

F1

0

ZERO

Peak Hold automatically updates the display when a higher peak weight reading is

established.

The Peak Hold function uses a high speed mode of the A/D converter (220 samples)

allowing

Peak hold is cleared and re-enab

detected, the Fx LED will flash three times. The accuracy of the system in Peak Hold

mode is slightly reduced to .2% of Capacity + 5d. The Filter setting is turned off while

in Peak Hold mode to ensure the fastest acquisition rate.

Example

The Peak Hold function is useful in “Dynamic” and “Fall” tests. Common tests

in

Strain.

3.5.1 Capture Peak Force

it to capture transient loads at a far higher rate than typical Dynamometers.

led with the Fx-Peak Hold Key. When a new peak is

clude “Overall Breaking Strain” (OB€), Breaking Force, and Cycled Breaking

Figure 0-1. Capture Peak Force

User Defined Function Keys 13

Page 18

3.6 2-Units/ 5-Units

Note

Note

Note

The Fx-2.Unit

Selecting the

key will switch the force units between pounds and kilograms.

Fx-5.Unit setting will scroll through all available units: lb, kg, Tons (US

Short), Metric Tons, and kiloNewtons.

3.7 Hi-Res

Only available with the MSI-7300 Dyna-Link (refer to the Dyna-Link manual

PN 152160)

Hi-Res Mode will make the MSI-8000HD more sensitive to motion and movement

resulting in a less stable display. When Hi-Res is on, the filter is automatically set to

the Hi-1 setting (if Hi-2 is already set, then the filter is not changed). This will have a

small effect on settling time. When Hi-Res is turned off, the filter setting resets to the

previous filter setting.

Pressing the

Fx-HiRes

key places the display into a temporary high resolution mode.

The high resolution mode continues until the Fx-HiRes key is pressed again, or power

is cycled. While in the Hi-Res mode the appropriate Fx LED will blink continuously

at a slow rate.

Hi-Res mode does not increase the accuracy, but allows for smaller weight

incrementation to be displayed.

Use Tare or the

ZERO

key to zero out any initial error.

3.8 Print

Pressing the F3-Print key outputs a configured text string to the RS-232 port on the

base of the Dyna-Link.

If an F-Key is programmed as Print and the Pri

nt Setup is configured as continuous,

then the F3-Print key is used for Start Print/Stop Print. See Section 5.6 for more

details on data output.

The Print function is always available on the

F1

necessary to program an

scale will cause the Comm Port on the Remote to output the selected data

string.

or F2 to “Print”. Then pushing F1 or F2 on the

MSI-8000HD

, so it is not

3.9 Scan

Pressing the Fx-Scan key displays RF connected channels in order.

14 MSI-8000HD Operator’s Manual

Page 19

3.10 Total Remote Devices

Note

Pressing the Fx-ttL.rd key displays the summed weight of RF connected sensors.

Sensor summing must be enabled in the COMM Setup Menu. If the “Pairs” or “Both”

modes are enabled in the COMM setup menu, then pressing the Fx-ttL.rd

key will

scroll through the available combinations.

It is a common setup to program

Remote Devices) to allow quick switching between individual channel

isplays (with

d

) or the summed weight (with “ttL.rd”).

F1 for SCAN and F2

for “ttl.rd” (Total

3.11 Tare

The Fx-Tare key is redundant in the MSI-8000HD since it has a permanent TA RE key.

This was done for consistency across the ScaleCore based product line. There is no

need to program a function key to “TARE.”

User Defined Function Keys 15

Page 20

4.0 Set Up

)YQF

)YQF

$2))

2))

Off

Test Display

Total

View Total

Net/Gross

Peak Hold

2 Units

5 Units

Hi Res

Print

Tare

Scan

Total Remote

Devices

F1 & F2 KEY

FUNCTIONS

F2 Key F1

F2 Key F2

Auto Off Time

SETUP MENU

Disabled (default)

15 minutes

30 minutes

45 minutes

1 hour

AUTO OFF TIME

With the Power On, press the F2

key and Power key simultaneously

F2

2))

W(6W

WRW$O

YWWO

Q(W*U

3+/G

8QLW

8QLW

+LU(6

3ULQW

W$UH

6F$Q

WWOUG

4.1 Menu Map

16 MSI-8000HD Operator’s Manual

Figure 4-1. Menu Map

Page 21

4.2 Function Keys

)YQF

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

ENTER/SELECT

ENTER/SELECT

WRWD/

blinking

QHW*U

blinking

3+OG

blinking

2II

blinking

2II

blinking

1)

With the MSI-8000 on, press the

F2 key and the POWER key

simultaneously.

2)

The first item of the Setup Menu

is “Func1”.

To setup F2 instead of F1, scroll to the

next menu item by pressing

F2.

3)

To setup the F1 key press F1.

The current F1 key function is

displayed.

4)

Select the F1 key function by

scrolling through the choices with

the

F2 key. See the list of

available functions on the Setup

Menu Map.

This procedure scrolls through all

available choices for illustration

purposes only.

In this example, we’ll set F1 to the TEST

function.

5)

When the desired F1 Key

function is displayed, press

F1

.

The next item in the Setup Menu

appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the

F2 Key.

Function Key Setup

)YQF

Next Setup Menu Item

Store and return to

weight display

6WRUH

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

7HVW

blinking

6FDQ

blinking

XQLW

blinking

WDUH

blinking

YWWO

blinking

EXIT/SAVE

ZERO

0

Press Simultaneously

SCROLL

XQLW

blinking

SCROLL

+LUHV

blinking

3ULQW

blinking

WWOUG

blinking

SCROLL

SCROLL

WHVW

blinking

0

F1

F2

Exit and Cancel Changes

Exit and Save/Back 1 Level

Enter / Select

Scroll

In Menu Key Functions

The MSI-8000HD has 2 user definable function keys (F1 and F2) on the Front Panel

that can be programmed. F1 is defaulted to Peak Hold and F2 is defaulted to Test.

F3 is currently fixed to the Print

refer to the Section 3.0.

Function keys on the MSI-800

Scale/Dyna-Link.

function. For operational details of each function,

0HD are independent of any Function Key setup on the

Figure 4-2. Function Keys

Set Up 17

Page 22

4.3 Auto-Off

1)

With the MSI-8000 on, press the

POWER and the F2 keys

simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “A-OFF” with

the

F2 key.

3)

To setup the A-Off timing, press

F1. The current Auto-Off time is

displayed.

4)

Select the Auto Off time by

scrolling through the choices with

the

F2 key.

In this example, we’ll set 60 minutes as

the Auto-Off time.

5)

When the desired time is

displayed, press

F1. The next

item in the Setup Menu appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the

F2 Key.

Auto-Off Setup

)YQF$2))

Press Simultaneously

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

ENTER/SELECT

EXIT/SAVE

ZERO

0

ENTER/SELECT

2II

blinking

blinking

blinking

)YQF

Next Setup Menu Item

Store and return to

weight display

6WRUH

blinking

blinking

SCROLL

The A-OFF feature, when enabled, prolongs the battery life by turning POWER off

when the scale is not in use. Any time any button is pressed, or the detected load is in

motion exceeding 10d, the time limit is reset. Therefore, the MSI-8000HD will stay

on indefinitely if the load is changing or any button is pressed at least once. With AOFF disabled, it will remain on; only pressing POWER will turn it off (or when the

battery is depleted).

18 MSI-8000HD Operator’s Manual

Figure 4-3. Auto-Off

Page 23

5.0 COMM Set Up

The MSI-8000HD uses 802.15.4 transceivers to communicate between MSI’s DynaLinks and Crane Scales.

802.15.4 operates in the 2.4GHz systems if:

• Caution is taken to isolate antennas at least 10 feet (3 meters) from the MSI-

8000HD equipment.

• MSI-8000HD based RF systems are peer to peer. For multiple scale connections,

the MSI-8000HD acts as the network coordinator.

The MSI-8000HD uses three numbers to establish a piconet:

• ScaleCore ID - This number is used to uniquely identify each device in a

Piconet. It has a range of 0-254 and must not be duplicated within the same RF

Channel. For the MSI-8000HD as network coordinator, MSI recommends a

number from 20-30.

• RF Channel - Establishes the base network that all interconnected devices must

match. This number must be in the range of 12-23.

• Network ID - This is a 64 bit number that all interconnected devices must match.

The MSI-8000HD limits this number to a max of 6 digits for a range of 0-99999.

Do not use a small number here to help avoid other 802.15.4 networks that

default to a Network ID of 0.

For all devices that must interconnect, the RF Channel and Network ID must match.

The ScaleCore ID must be unique. The Dyna-Link or Crane Scale that is the weight

source should be set to a ScaleCoreID of 0. Then if other slave devices are added,

they can be added in sequence. The MSI-8000HD ID is recommended to be in the

range of 20-30.

COMM Set Up 19

Page 24

0

F1

F2

Exit and Cancel Changes

Exit and Save/Back 1 Level

Enter / Select

Scroll

In Menu Key Functions

PRINT STRINGS

6WUQ*

&QWUO

5DWH

2II

8VHU

/RDG

&RQW

Off(default)

F key

On Stable Load

Continuous

PRINT

CONTROL

Print String Output Rate

Number entry screen

(0-65535 seconds)

Print String Format

Number entry screen

1= Current Wt (Wt-Unit-Mode

)

2= Net Wt (Wt-Unit-Net

)

3= Gross Wt (Wt-Unit-Grs

)

4= Tare Wt (Wt-Unit-Tare

)

5= Total Wt (Wt-Unit-Total

)

6= Total Count (#Samples-TCNT

)

7= Current Wt (no units or mode

)

8=

(Reserved)

9= CR-LF (

)

Affects continuous mode

only

3ULQW

U)

F)QHW

Print

RF

Configure

Network

2Q2II

FLG

&KQO

QHWLG

Enable RF

ScaleCore ID

RF Channel

Network ID

RF

SETUP

Setup Strings

Print Control

Output Rate

Network ID

2Q

2II

Range 1-254, (20-30)

Range 12-23

Range 0 to 999999

RF Network

Number entr

y

screens

W0RUG

WWOUG

Total # of RD’s

Total RD’s

(Remote Sensor

Devices)

CONFIGURE

NETWORK

Range 1-4

(default 1)

$OO

3ULUV

ERWK

2II

Sum all Remote Devices

Sum in Pairs

(requires 4 Remotes)

Sum in Pairs + Grand Total

Off, summing disabled

SUM REMOTE SENSOR DEVICES SETUP

F2

Press Simultaneously

6WU(Q

Transmission

Strength

Range 0 to 4

.

Note

Setting

Transmission Strength should be set to the lowest setting possible to

achieve the transmission required. Both the scale/Dyna-Link and the 8000

s

hould be set at the same transmission strength setting.

RF Power

0 10dBm 137mA Lowest Transmission Power

1 12dBm 155mA (default on 7300s and 8000s)

2 14dBm 170mA

Figure 5-1. COMM Set Up Menu

Level

3 16dBm 188mA

4 18dBm 215mA

20 MSI-8000HD Operator’s Manual

Table 5-1. Transmission Strength Settings

Tran sm it

Current

Note

Page 25

5.1 RF Setup

2Q2II

2Q

1) With the power on, open the

Comm Setup Menu by

pressing the

F1 and F3 keys

simultaneously.

The COMM Setup Menu

appears. The first menu

choice is “Print”.

2) Press

F2 to scroll to the RF

Setup menus.

3) Press

F1 to enter the RF

setup menu.

4) The display reads “OnOff”

Confirm the 8000 RF is on

by pressing F1. If it is off,

use the F2 key to change it

to on. Then push F1.

Off is only used when the 8000 is

hardwired to a Dyna-Link.

5) Press

F1. Next the “Scid”

(ScaleCore ID) screen is

shown

6) Press

F1. The current Scid

number is shown.

If the offered Scid value is correct,

push

F1 and jump to step 10.

In this example we’ll enter 28 as an

SCID number. Any value from 1-254

is acceptable. However, MSI

recommends a value from 20 – 30.

7) To input the SCID value,

press

F2 to start the number

entry process.

8) Use

F2 to change the

number, and

F1 to enter

the number. Add the next

digit by pushing

F2 and

scrolling as required.

Repeat this sequence

until the entire SCID

number is entered.

9) Once the entire SCID

value is entered, press

F1

to finalize the number.

10) The next RF Setup

parameter is “ChnL”

(Channel). Press

F1 to start

the number entry process.

3ULQW

RF Setup Procedure

VFLG

ENTER/SELECT

ENTER/SELECT

SCROLL

U)

example ScID Value

ENTER/SELECT

8 times

fixed

blinking blinking

blinking

blinking

SCROLL

SCROLL

SCROLL

F2

ENTER/SELECT

Error Correction: If you input a wrong value, press ZERO to step

back one digit and reenter.

ENTER/SELECT

fixed

ENTER/SELECT

&KQ/

ENTER/SELECT

Press Simultaneously

SCROLL

ENTER/SELECT

0

F1

F2

Exit and Cancel Changes

Exit and Save/Back 1 Level

Enter / Select

Scroll

In Menu Key Functions

Figure 5-2. RF Set Up

COMM Set Up 21

Page 26

11) The current RF Channel

number is displayed.

If the offered RF Channel value is

correct, push

F1 and jump to step

14.

12) Press

F2 and using the

previous process, enter

the RF Channel number.

Recommended RF Channel numbers

range from 12 to 23. In this example

we’ll use 21 as the RF Channel.

13) When the desired RF

Channel number is

shown and fixed, press

F1.

14) The next RF Setup Menu

item is the “nEtid”

(Network ID). Press

F1

to see the current Net ID

number.

If the offered Network ID value is

correct, push F1 and jump to step

17.

15) Using the numeric entry

process as before, input

a network ID number.

Press

F2 to start a new

number.

Allowed Network ID numbers range

from 0 to 99999. MSI recommends

a random number of at least four

digits to ensure that the 8000

system won’t conflict with any

other 802.11.4 networks (Zigbee).

QHWLG

blinking

blinking

fixed

SCROLL

ENTER/SELECT

ENTER/SELECT

blinking

SCROLL

SCROLL

blinking

blinking

fixed

ENTER/SELECT

ENTER/SELECT

current Net ID blinking

SCROLL

blinking

example value only

SCROLL

Repeat number

entry procedure

16) When the final number is

shown and fixed, press

F1 to store the network

ID.

20) The RF setup menu goes

to the first menu, OnOff.

Press the

ZERO key to

exit out of the RF setup

menus.

21) Press

ZERO again to exit

the COMM setup menu

and store the new RF

network numbers.

6WU(Q

ENTER/SELECT

F1

3ULQW

6WRUH

2Q2II

ENTER/SELECT

F1

0

EXIT/SAVE

ZERO

0

EXIT/SAVE

ZERO

blinking

ENTER/SELECT

F1

17)

The menu displays StrEn.

Press the F1 to enter.

Press F2, us ing the

numeric entry process,

input a transmission

strength number.

19) When the desired number

is displayed, press F1 to

store the number.

18)

Figure 5-3. RF Set Up (Continued)

22 MSI-8000HD Operator’s Manual

Page 27

5.2 RF Set Up, Dyna-Link And MSI Crane Scales

Note

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

SC 0

SC 1

Pair1

(Sum) All

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

SC 0

SC 1

Pair1

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

SC 2

(Sum) All

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

SC 0

SC 1

Pair1

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

SC 2

SC 3

Pair2

(Sum) All

Setting up the MSI-7300 Dyna-Link and other 802.15.4 linked MSI Crane Scales is

the same procedure except for the two button entry method.

MSI-7300 Dyna-Link 2 - P

MSI-3460 Challenger 3 - Press

F1 and F2 simultaneously.

ress

TARE and USER simultaneously.

The 3460 does not have a Print Function. Printing is only available on the linked

MSI-8000HD.

MSI-4260 Port-A-Weigh -

The 4260 does not have a Print Function when the Radio Link is installed.

Printing is only available on the linked

Press TARE and USER simultaneously.

MSI-8000HD

.

The Net ID and RF Channel must exactly match the MSI-8000HD. The ScaleCoreID

(SCID) must be unique. The first Scale/Dyna-Link must have a SCID of 0. In

multiple link systems, setup sequential SCIDS starting at 0.

5.3 MSI8000 With Multiple Sensors

The MSI-8000HD can monitor up to four load sensors (MSI-7300 Dyna-Links are

shown, but MSI-3460s and MSI-4260s can also be used). The sensors are readable

individually, in pairs or summed.

Setting up a multiple sensor network requires the following:

1. Each sensor has a unique SCID. The IDs

This is set in the sensor setup, not in the 8000. See the appropriate User Guide.

2. Using the “Configure Network Menu” [arrow] “T

number of remote sensor devices (RD). This number does not include the MSI-

8000HD or any modems. So the range is 2-4.

3. Setup the desired summing mode using the “Total RDs” menu.

4. Program F1 to the “Scan” function, and F2

must be consecutive, starting with 0.

to the “ttl.rd” function if summed

sensor readings are needed.

otal Number of RDs,” set the

COMM Set Up 23

Page 28

lbkN

MTon

1) Program a function key to Scan.

In this example we’ll use F1 for Scan.

2) The current channel is displayed.

Press

F1 Scan to change the

display to the next channel.

3) The display briefly displays the

scan channel number. Then the

scan channel weight is

displayed.

4) Press

F1 Scan. In a two sensor

system the scan returns to the

first channel, 0.

SCAN

See Function Key setup

on page 15.

lb

MkNTon

6F

Scan Weight Inputs

6F

SCAN

MOMENTARY

MOMENTARY

kg

lb

MkNTon

F1

F1

kg

Figure 5-4. Scan Weight Inputs

Note

5.4 Summing Modes

The summing modes are straight forward and useful for many overhead lifting

applications.

5.4.1 Modes

ALL

All channels are added together. Using the Fx ttl.rd function key, the sum of all

connected sensors are displayed. Pressing the Fx ttl.rd

observing the summed channels by briefly displaying “ttl.rd” (total remote sensor

devices).

If the sum is the only thing the user wants to observe, disable the Scan

function key using the function key setup menu.

PAIRS

Primarily intended for 4 sensor systems. When scrolling through the channels with an

Fx ttl.rd, the channels will be presented as separate weights first and then as pairs.

This display is proceeded by the LCD message “Pair1” and “Pair2.”

BOTH

This mode shows both the pair totals and the overall total. Each press of the

key will scroll through the summed combinations. First “Pair1,” next “Pair2,” then

the sum of all connected sensors is displayed.

OFF

Sensor summing disabled. Even if a function k

24 MSI-8000HD Operator’s Manual

ey is set to “ttl.rd” nothing will happen.

again will confirm that you are

Fx ttl.rd

Page 29

1)

Program a function key to “ttl.rd”

(Total Remote Devices).

In this

example we’ll use

F2 for “ttl.rd”.

2)

The current channel is displayed.

Press

F2 ttl.rd to change the

display to the summed total.

3)

The display briefly displays

“AddAll”. Then summed total

weight is displayed.

4)

Subsequent presses of the

F2 ttl.rd key will show all enabled

sum types.

TOTAL REM

DEVICES

See Function Key setup

on page 15.

kg

lb

M

kN

Ton

$GG$O

View Summed Channels

MOMENTARY

TOTAL REM

DEVICES

3DLU

TOTAL REM

DEVICES

3DLU

MOMENTARY

MOMENTARY

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

F2

F2

F2

Figure 5-5. View Summed Channels

5.5 Behavior Of Zero And Tare In Multiple Channel Systems

Whatever channel that is displayed is considered the “Focus Channel.” Pressing the

ZERO or TAR E keys will only affect the displayed channel. When displaying summed

channels, zero and TARE commands will be sent to all devices that contribute to the

displayed weight. For example, if in the “BOTH” mode, and you are displaying Pair 1

(the sum of SC0 and SC1), pressing ZERO will zero only SC0 and SC1. If displaying

the grand total using the ALL mode, then pressing ZERO will zero all connected

sensors.

Using the TARE function: If one device is tared in the individual display mode, the

summ

ed weight will be the sum of a Net weight and a Gross weight. If the TARE key

is pressed when displaying any of the summed modes, all devices that add to form the

current display are Tared and placed in Net mode.

5.6 Printer Set Up

The RS-232 Comm Port is capable of outputting load data. All the weight modes the

RF linked weight device can measure are available in user formatted form. The

control Mode programs are what cause the MSI-8000HD to print.

The modes are:

1. Assigned F-Key is pressed, one transmission of the s

output.

2. On Load - When the load on the link i

Then the load must return to zero to enable another print output.

3. Continuous - Program the interval in seconds up to 65,535 seconds. Setting the

int

erval to 0 will set an interval as fast as the system can go. To disable printing

set the control mode to “OFF.”

The Comm Port settings are independent of any

They reside only in the MSI-8000HD.

s stable, one transmission will output.

print settings in connected scales.

elected string type is

COMM Set Up 25

Page 30

5.7 Control Modes

The user can select four control modes:

• User

• Load - One

- Printing is controlled by the operator pushing the PRINT key (usually F3).

print occurs when a stable load is reached. The scale must then return

to near zero before another print will occur. Other configurations of “On Load”

are available using the ScCMP application (ScaleCore Configuration

Management Program).

• Cont

inuous - The MSI-8000HD will continuously output the data at a rate

controlled by the “rAtE” (RATE) menu.

• Off - Prin

ting is disabled. Power consumption is lower with print off.

5.8 Standard Print Strings

1 Current load

Fixed output length: 16. Leading zeros suppressed except for the

LSD.

TTTTTTTspUUspMMMMMcrlf

Where TTTTTTT is load data with -sign if necessary. UU is the

units, MMMMM is the load mode which for “1” is either NET or

GROSS

2 Net load Fixed output length:16. Leading ze

LSD.

ros suppressed except for the

TTTTTTTspUUspNETspspcrlf

3 Gross load Fixed output length: 16. Leading zeros suppressed except for the

LSD.

TTTTTTTspUUspGROSScrlf

4 Tar e W e ig ht Fixed output length:16. Leading zeros suppressed except for the

LSD.

TTTTTTTspUUspTA RE crlf

5 To ta l

We

ight

Fixed output length: 16. Leading zeros suppressed except for the

LSD.

TTTTTTTTTspUUspTTLcrlf

6 Number of

Samples

To

t al e d

7 Current

Weight

Mode

8/9 Carriage

n/

Retur

Line Feed.

In the string number entry screen, you can enter combinations of the standard print

strings. For example, to get a NET GROSS TARE printout with a space between

records, simply enter “2349.”

Fixed output length: 16. Leading zeros suppressed except for the

LSD.

spspspspspsp

Net, Gross, Peak, etc

spMMMMMcrlf

Used to add a space between print records.

crlf

SSSSSSSspT- C N T spcrlf

Figure 5-6. Standard Print Strings

26 MSI-8000HD Operator’s Manual

Page 31

Using ScCMP application, custom output strings are possible. See the ScCMP

1) With the MSI-8000 on, press the

F1 key and the F3 keys

simultaneously.

2) The LCD shows “Print”. Press

F1.

3) The sub-menu item “StrnG”

(String) appears. Press

F1

.

4) The current Print Mode format

number is displayed.

5) Setup a print format with one or

more digits representing the data

type required for the print output.

In this example, we’ll set the Print format

for a Net, Gross, Tare output with a

carriage return/line feed between each

print output. The number entry required

will be 2349. The 2 is for Net weight,

the 3 for Gross weight, the 4 for Tare

weight, and the 9 inserts a space before

the next print output.

6) Using the F2 Key, scroll through

the digits until the desired digit

is shown, then press

F1 to enter

the digit value. Repeat for the

remaining digits.

7) When the entire number is

displayed press

F1. The next

item in the Print menu appears,

“Cntrl”.

8) Press

F1 to enter the Print

Control Menu. The last set control

mode will appear.

9) To change the print control mode,

press

F2.

In this example, we’ll set the Print Control

Mode to Continuous.

10) Press F2 key until the desired

print control mode is shown.

11) When the desired print mode is

shown, push

F1 to save. The

next Print setup item, “rAte”

appears. If you have set

Continuous (Cont) as your print

control, proceed to step 12). For

any other Control mode jump to

step 15

Printer / Output Setup

blinking

blinking

fixed

fixed

fixed

&QWUO

ENTER/SELECT

ENTER/SELECT

ENTER/SELECT

Next Print Menu Item

3ULQW

6WUQ

ENTER/SELECT

ENTER/SELECT

blinking

SCROLL

SCROLL

ENTER/SELECT

ENTER/SELECT

xed

blinking

SCROLL

SCROLL

Example Value

blinking

SCROLL

blinking

ENTER/SELECT

2))

SCROLL

2))

SCROLL

8V(U

Function Key PrintsPrint is disabled

SCROLL

/R$G

SCROLL

&RQW

Function Key PrintsPrint is disabled

UDWH

Next Print Menu Item

ENTER/SELECT

1= Current Wt (Wt-Unit-Mode

2= Net Wt (Wt-Unit-Net )

3= Gross Wt (Wt-Unit-Grs

)

4= Tare Wt (Wt-Unit-Tare

)

5= Total Wt (Wt-Unit-Total

)

6= Total Count

(#Samples-TCNT

7= Current Wt

(no units or mode

8= (Reserved)

9= CR-LF (

)

Press Simultaneously

0

F1

F2

Exit and Cancel Changes

Exit and Save/Back 1 Lev

Enter / Select

Scroll

In Menu Key Functions

programming guide for details.

The serial output is configured as 9600 baud, Xon/Xoff handshaking, no hardware

hand

shaking, 1 stop bit, no parity. Other baud rates are possible by special order only.

Figure 5-7. Printer/Output Set Up

COMM Set Up 27

Page 32

12) Press F1 to enter the Print rate

number entry screen. The current

print rate appears on the LCD.

In this example, we’ll set the Print Rate

to an output rate of once every 2

seconds.

13) PressF2 to change the Print rate.

Use F2 to scroll the number,

enter each number with the F1

key.

14) When the entire number is

displayed, press

F1 again to

finalize the seconds entry. The

next Print Menu Item appears,

“String”.

15) Exit the Print Setup Menu by

pressing

ZERO twice. The

message “Store” appears briefly

then normal system operation

starts.

ENTER/SELECT

blinking

Example Value

blinking

SCROLL

blinking

fixed

ENTER/SELECT

SCROLL

ENTER/SELECT

6WUQ

EXIT/SAVE

ZERO

0

EXIT/SAVE

ZERO

0

3ULQW6WRUH

The number represents the print

interval rate in seconds. Use 0 for the

fastest the MSI-8000 can go (~5 times

per second). To set a once a minute

transmission, set the rate to 60. To

set once per hour, set the rate to 3600, etc. Largest possible

entry is 65535 which is >18 hours.

Figure 5.6 Printer/Output Set Up (continued)

5.9 COMM Port Hardware

The MSI-8000HD RS-232 Comm Port is used for software updates, connecting to a

remote display and for connecting to any RS-232 device.

Connector:

connect the MSI-8000HD to a computer. This adapter cable converts the 8000

connector to a standard D9 serial connector. The 503489 cable can be converted to

DTE by using a Null Modem adaptor.

Data Configuration: T

Baud Rate: Prog

updating software is always 38.4k baud

Handshaking: No

handshaking is always on.

It may be necessary to disconnect the shie

prevent ground loops. Ground loops can cause unstable readings. In extreme cases it

may be necessary to use an isolated RS-232 interface.

Serial Cable Schematic, DCE Configuration for connecting to a computer (503489000

1 schematic).

28 MSI-8000HD Operator’s Manual

M12 industrial IP67 rated. An adapter cable (PN 150964) is required to

he data output is fixed at 8-1-N.

rammable for 300 to 230.4<baud in 8 steps. The bootloader for

hardware handshaking is supported. Xon/Xoff software

ld drain wire at the D-9 connector frame to

Page 33

Serial Cable Schematic, DTE Configuration for connecting directly to a DCE printer

or other DCE devices (503489-0002 schematic).

5.10 Service Counters

All MSI’s RF Linked Scales and Dyna-Links maintain two service counters for safety.

The first counter (LFCnt) counts lifts above 25% of capacity. The second counter

(OLCnt) counts the number of times the RF Linked Scale has been overloaded. These

counters serve to warn the user to inspect the load train after a number of overloads or

a long term frequency of high capacity lifts. Service counters can only be reset by the

factory. The power up routine will be interrupted when the lift counter exceeds 16383

lifts or the overload counter exceeds 1023 overloads. Push any key to continue

operation.

Feature only available on MS

counters are available on the Scale/Dyna-Link front panel Test function.

I-8000HD Software release 2.00 and above. Service

COMM Set Up 29

Page 34

1) Program a User Function key to

be TEST (see function key setup).

For this example,

F1 is

programmed as TEST.

2) Press

F1- TEST .

3) Within 2 seconds of pressing the

F1– TEST key, press F1 again

(must be F1 regardless of which key is

programmed as TEST).

The test will sequence through steps 4

to 7 automatically unless you stop it by

pressing

F2 immediately. Then using

F1 and F2 each parameter can be

observed statically.

4) The display flashes “LFCnt” (for

Lift Counter) followed by the

number of times the weight has

exceeded 25% of capacity.

5) Next, the display flashes “OLCnt”

(for Overload Counter) followed

by the number of times the

weight has exceeded capacity.

6) Next,the display flashes the CCal value.

7) The Dynalink / Scale returns to

standard weighing mode. If you

interrupted the auto sequence,

press

ZERO to return to tension

link mode.

/)&QW

2/&QW

Return to standard weight display

ENTER/SELECT

Number of Lifts above 25% of Capacity

Number of Lifts that exceeded Capacity

example value

example value

Start of Test Sequence

All segments on

&&D/

blinking

blinking

example C-Cal value

Access the Service Counters

Fx

Only a MSI factory representative can reset the service counters, as these are an

im

portant safety warning feature. Depending on the circumstances, a thorough load

train inspection is necessary to ensure product safety.

Reference MSI’s “Crane Scale Safety and Period

loading techniques to improve the safety and longevity of your Crane Scale or DynaLink. This publication is available at www.msiscales.com and is included in the CD

shipped with your MSI-8000HD.

Figure 5-8. Access the Service Counters

ic Maintenance Manual” for proper

30 MSI-8000HD Operator’s Manual

Page 35

5.11 Relays

Note

Note

The MSI-8000HD can be equipped with up to three relays for process control or safety

systems.

In the non meter MSI-8000HD, relays are programmed on the unit that the

8000HD is "talking" to.

Two independant relays are installed and are wired out to 4 pins on a M12 connector.

The connecting cables are shown in the table below.

MSI Part No. Description

13287 PVC 4m, rated to 250VRMS, 4A

14626 PVC 10m, rated to 250VRMS, 4A

Alternately they can use a

14622 Straight for cable 4-6mmOD, (RLWS 156256)

14623 Right angle for 4-6mm

14624 Straight for cable 6-8mmOD

14625 Right angle 6-8mmOD

5.11.1 Relay Options

All Relays are Normally Open (1 Form A). Specifications of relay options:

field wireable connector

AC/DC Coil Relay

- AC/DC Coil Relay: 13452 PA1a-5V. 4A Fuse: 13165

- AC Rating: 250VAC @4A.(limited by connector/cordset rating to 4A

cont

inuous)

- DC Rating: 4A @ 30VDC, 0.4A @ 100VDC

Best choice for 90% of applications.

AC/DC SSRs (Solid State Relays).

Better for battery powered units and mates well with 24VDC industrial power

suppl

ies

- AC/DC SSR 60Vpk, 2.7A: 13178 AQZ202D. 2A Fuse: 13193

AC/DC SSRs (Solid State Relays).

For 115VAC operation when SSRs are preferred

.

- AC/DC SSR 200Vpk. 0.9A: 13180 AQZ207D. 0.75A Fuse: 14563

Other Available Relays

- AC/DC SSR 100Vpk, 2A: 13179 AQZ205D. 1.5A Fuse: 14562

- AC/DC SSR 400Vpk, 0.45A: 13181 AQZ204D. 0.375A Fuse: 14564 (Use

lim

ited to 250VRMS due to connector and Cordset limitations)

- DC Only SSRs

- DC SSR 60Vpk, 4A: 13182 AQZ102D. 3A Fuse: 14565

- DC SSR 200Vpk, 1.3A: 14566 AQZ107D. 1A Fuse: 14561

Normally open relays (1 Form A) can be made to function as normally closed

(1 Form B) by programming the setpoint as a less than type. If the 8000HD is

turne

d off or loses power, they will open.

COMM Set Up 31

Page 36

Female

Note: When using DC only SSRs, the positive for

Relay1 is Pin 4 (Black Wire). Positive for Relay2

is Pin 2 (White Wire).

Relay 2

Normally Open

Relay 1

Normally Open

Cordset or Field Wireable Connector

White

Brown

Black

Blue

Internal to the 8000HD

Male

-

+

-

+

4A Max

TVD2

TVD1

1

2

3

4

K2

1

2

3

4

K1

F2

F1

1

4

2

3

1

4

2

3

Note

One 1 Form B (normally closed) SSR is also available.

- AC/DC SSR 400Vpk, 0.5A: 14628 AQZ404. 0.5A Fuse 13539 (Use

lim

ited to 250VRMS due to connector and Cordset limitations).

Requires a minor modification on the Relay board and can only be ordered

by contacting MSI.

32 MSI-8000HD Operator’s Manual

Figure 5-9. Internal Relay Wiring Diagram

Page 37

5.12 Antenna Options

Note

Note

To meet FCC licensing rules, you must use only antennas supplied or

recommended by MSI.

Antenna placement is critical to problem free use of your system.

• Be sure a relatively clear transmission path

connected. Radio signals travel primarily by line of sight (LOS), obstructions

between stations may degrade the system performance.

• When using the long range antenna, mount the antenna

to ensure that you have a clear LOS transmission path. This will ensure the

antenna will clear surrounding obstructions. Do not provide a ground plane for

the antenna.

• Fixed station locations often benefit from

of the other components of the RF network are fixed and/or in the same direction.

Never use a directional antenna on a mobile system.

• If using the standard antenna, ensure the antenna is not blocked by any metal.

T

ransmission is good through most kinds of glass so mounting a meter next to a

window should work fine. If there is no clear line of sight place to mount the

recieving device, consider switching to the long range antenna so the antenna can

be remoted.

• The standard and long range antennas are vertical plane devices. They should be

vertical, pointing

up or down, when high off the ground (like the underside of a

large bridge crane). Do not mount them sideways. The long range 9dBi antenna

is particularly sensitive to off axis mounting. Use a level to ensure the antenna is

exactly 90° perpendicular to the earth.

• Do not mount an omnidirectional antenna next to metallic or concrete s

This can result in reflections and undesired RF characteristics. Use a Corner

Reflector instead.

• After installation, seal the antenna connecti

Failure to seal the antenna may result in liquid destroying the antenna and device

its connected to.

MSI does not recommend extending the coaxial cable beyond 3 meters. At

2.4GHz more loss will result from coax losses than are gained by raising the

ant

enna. If you must extend the antenna, use a very low loss 50 ohm

such as RG-214, RF-195, or other low loss varieties.

For very short extensions (<1m), cables made with RG-316 are suitable.

exists between the devices to be

on an elevated structure

directional antennas when the location

urfaces.

on with an adhesive heat shrink boot.

coax

FCC STATEMENT

FCC ID: HSW-2450M

Note: This unit has been tested and found to comply with the limits for a Class A

dig

ital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at their expense.

COMM Set Up 33

Page 38

5.12.1 Antennas Available for a MSI-8000HD

Adhesive

Heat Shrink

STANDARD ANTENNA

The Standard Antenna is an articulated 1/2 wave 2dBi gain design with a

standard TNC connector that mounts directly on the 8000HD enclosure.

This antenna and coax connector, though

proof. Seal the TNC base with an adhesive heat shrink boot if this

antenna is exposed to rain.

This Antenna should be vertically oriented and is suitable for most short

edium range applications.

to m

LONG RANGE OMNI 9dBi ANTENNA

This omnidirectional high gain antenna is remotely mounted

from the 8000HD with a low loss coaxial cable, it increases

the range up to 4 times.

The antenna must be vertically

Beamwidth (-3dB point) is 14 degrees.

This antenna is supplied with a 10’ (3m) coax cable pre

ched. The 10' cable allows placement of the antenna

atta

above the 8000HD for ease of clearing possible obstacles to

data transmission.

Also available with an N connector for applications

iring longer coax cable lengths.

requ

resistant to water, is not water-

mounted. The vertical

VEHICLE MOUNT WHIP ANTENNA

The Vehicle Mount Whip Antenna mounts directly to the roof of mobile

vehicles and is weatherproof.

This 5 dBi gain whip mounts in a 3/4” hole on the roof of mobile vehicles.

The mount includes 17’ of low loss coax teminated in a TNC Connector.

34 MSI-8000HD Operator’s Manual

Page 39

YAGI Antenna

14dBi Corner Reflector 9dBi Corner Reflector

For maximum range, a 14dBi Gain Yagi Antenna is available

by special order. Please contact MSI for details.

Corner Reflector Antenna

Corner Reflector antennas are often the best

choice for a wall mounted antenna. MSI

offers a 14dBi and a 9dBi Corner Reflector.

Patch Antenna

The patch antenna is for applications where the standard antenna is vulnerable to

physical use or outdoor applications.

The patch antenna is mildly directional

which requires more care in antenna

placement for long range applications. Patch Antennas are available by special order

only. Please contact MSI for details.

COMM Set Up 35

Page 40

6.0 Appendix

6.1 Troubleshooting

Problem Possible Cause Solution

Display is blank

when POWER

button is pressed

Display does not

function properly/

Front panel

buttons do not

function normally/

Scale/Dyna-Link

will not turn off.

Scale/Dyna-Link

does not respond

to tension

changes

Display over

ranges below

100% of capacity

Display drifts AZM (Auto0) is turned

Displayed tension

shows large error

Discharged battery Recharge

Defective battery Replace (factory replacement only

Defective switch or

circuit board

Improperly loaded

software

Faulty Circuit Board Requires Authorized Service

Loose Connectors Requires Authorized Service

Out of calibration Calibrate

Faulty load cell Replace

Load cell connector Check connector and wires

Tar e d Ten si on is

added to load to

determine overload

point

Zero requires

adjustment

Too much tension/

load has been zeroed

off

Rapid temperature

changes such as

moving the scale from

indoors to outdoors

Scale not zeroed

before load is lifted

lb/kg units causing

confusion

Requires recalibration Recalibrate

Requires Authorized Service

Reinstall software

Return to gross tension mode

Rezero the scale

Rezero the scale

Turn A Z M o n

Wait until the scale temperature has

stabilized

Zero the scale with no load attached

Select proper units

Table 6-1. Troubleshooting

36 MSI-8000HD Operator’s Manual

Page 41

Problem Possible Cause Solution

Display reading

not stable

Display toggles

betwe

en “Error”

and “Load”

Display toggles

betwe

en “Error”

and “buttn”

Weight is on the

Scale/Dyna-Link,

RF Remote

Display does not

match

Lo Batt is blinking Battery is low Recharge Battery

Unit turns on,

then immediately

off

Load will not zero System not stable

Load will not Tare

or

Total

Set point lights

k

blin

Manual Total does

not work

Excessive vibration Increase filtering or increase ‘d’ in Cal

Excessive side

loadi

ng

Load cell faulty Check LC connections

Load exceeds

capacity

Faulty Load cell or

wiring

A key is stuck or is

being held down

Units not mated See setting the RF Network address

Battery is low Recharge Battery

Zero out of range Zero range might be limited. Reduce the

System not Stable

Set point is enabled

and the trigger point

has been reached

A function key is not

set to “total”

Ten s io n m us t be

stable

Improve load train symmetry

Reduce tension immediately

Check LC and LC wiring

Check switches for damage

ocedures

pr

Wait for stable symbol

Increase filtering for more stability

tensi

on or use Tare instead

Wait for the stable symbol

on, or if in a mechanically noisy crane,

increase the filtering or reduce the size of

the Scale increment “d.” It is also possible