Page 1

LT VALVE TECHNICAL MANUAL

MSI is a division of Dixie Iron Works, Ltd.

300 West Main St.

Alice, Texas 78332

Phone: 1-800-242-0059

Phone: 1-361-664-6597

Fax: 1-361-664-4840

Email: sales@diwmsi.com

Revision D April 03, 2014

Page 2

MSI LT VALVE TECHNICAL MANUAL

2

TABLE OF CONTENTS

1.0 FEATURES ............................................................................................................. 3

1.1 SAFE-TAP™ GREASE FITTING ............................................................... 4

1.2 GREASEAL™ PLUG ....................................................................................... 5

2.0 EXPLODED VIEW .............................................................................................. 6

2.1 PARTS LIST ...................................................................................................... 7

3.0 ASSEMBLY PROCEDURE – UNISERT™ TYPE ..................................... 8

3.1 ASSEMBLY PROCEDURE – UNISERT™ TYPE (TEXT) .............. 19

3.2 ASSEMBLY PROCEDURE – SPLIT INSERT TYPE ....................... 21

3.3 ASSEMBLY PROCEDURE – SPLIT INSERT TYPE (TEXT) ...... 31

4.0 EXPLODED VIEW (5 INCH ) ..................................................................... 33

4.1 PARTS LIST .................................................................................................... 34

5.0 ASSEMBLY PROCEDURE – UNISERT™ TYPE (5 INCH) ............ 35

5.1 ASSEMBLY PROCEDURE – UNISERT™ TYPE (5 INCH)

(TEXT) ....................................................................................................................... 44

5.2 ASSEMBLY PROCEDURE –SPLIT INSERT TYPE (5 INCH) ... 46

5.3 ASSEMBLY PROCEDURE –SPLIT INSERT TYPE (5 INCH)

(TEXT) ....................................................................................................................... 55

6.0 DISASSEMBLY PROCEDURE ..................................................................... 57

7.0 MAINTENANCE ................................................................................................. 58

8.0 REPAIR AND INSPECTION ........................................................................ 59

8.1 DISASSEMBLY TIPS .................................................................................. 61

8.2 SANDING TIPS ............................................................................................ 62

8.3 ASSEMBLY TIPS .......................................................................................... 63

9.0 STORAGE ............................................................................................................. 64

9.1 SHELF LIFE .................................................................................................... 65

10.0 ACCESSORIES ................................................................................................ 66

10.1 GREASES ....................................................................................................... 67

10.2 GREASE REQUIREMENTS .................................................................... 68

10.3 ACTUATORS ................................................................................................ 69

10.4 RUBBER PRODUCTS ............................................................................... 70

Revision D April 03, 2014

Page 3

MSI LT VALVE TECHNICAL MANUAL

3

1.0 FEATURES

The MSI LT Plug Valve is a lubricated, tapered pocket, quarter-turn plug valve

for rapid full open or close operation. The valve cavity is tapered to ensure uniform

seating of the sealing inserts, providing a reliable seal at the full range of pressures.

The MSI LT Plug Valve and replacement parts are engineered to provide low

operating toque and resistance to the toughest abrasive and corrosive conditions.

MSI offers more end connection choices than any other plug valve

manufacturer in the industry. Connection types such as Hammer Unions, Line Pipe,

API Flanged, Tool Joint, Clamp Hub, and our own metal-to-metal WingSeal (WS20

and WS30) are just a few of the available choices. All sizes of MSI valves can be

outfitted with your choice of end connections or combinations to suit your specific

application. Custom end-to-end lengths are also available on some valves.

Compact Design

Lightweight

Longer lasting internals

Ease of repair

Interchangeability

SafeTap™ grease fitting

UNIsert™ integral insert

GreaSeal™ plug for full 360° greasing

Widest range of end connections in the industry

o Hammer union (all sizes of 602, 1002, 1502, 2002, 2202)

o API Flange & Studded (all sizes and working pressures)

o WingSeal 20 (2.00”ID) & 30 (3.00”ID) *metal-to-metal

o Clamp Hub (all sizes such as B20, GR14, GR31, plus API clamp hubs)

o Threaded Ends (all sizes of Line Pipe, EU, NU, and premium threads)

o Tool Joint (All sizes of IF and ACME unions)

Revision D April 03, 2014

Page 4

MSI LT VALVE TECHNICAL MANUAL

4

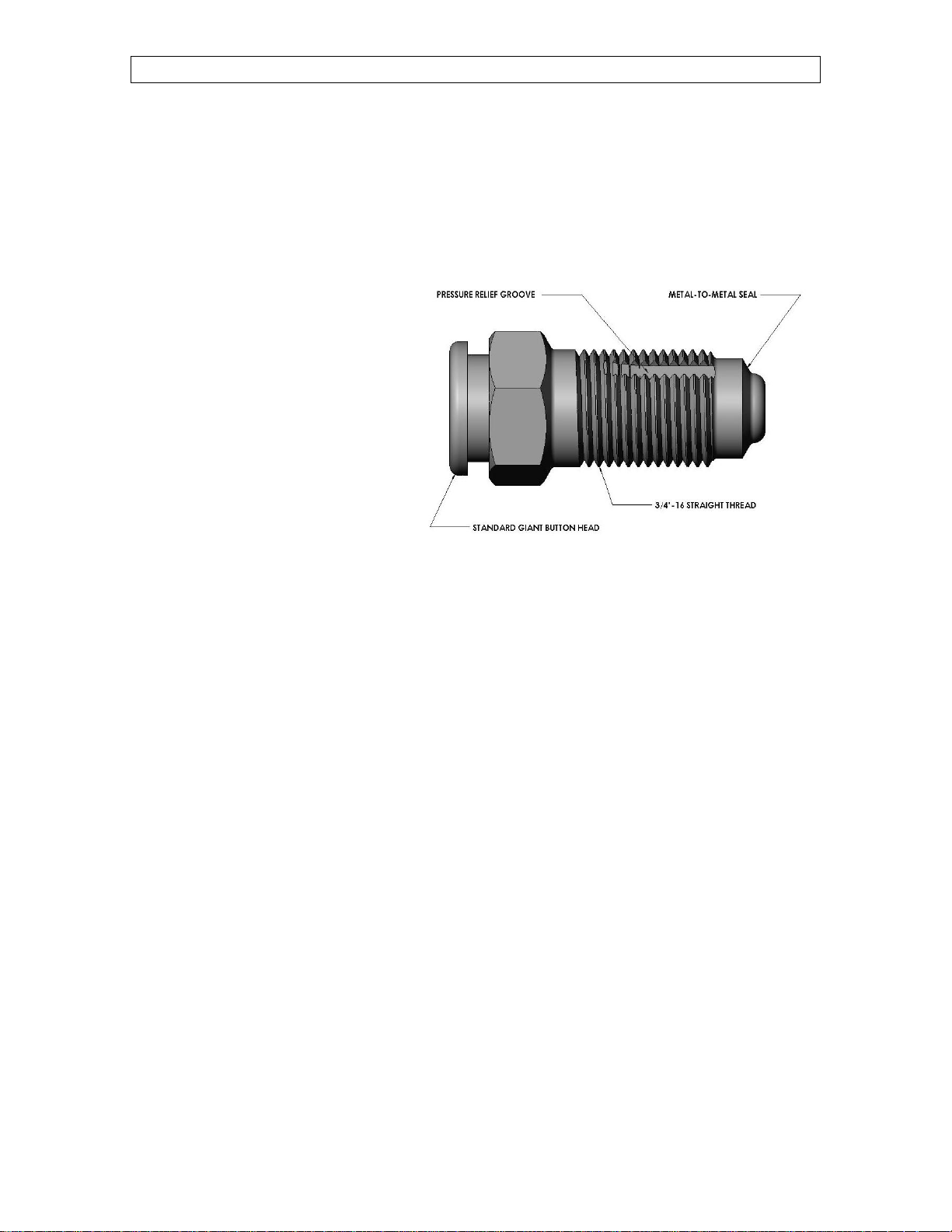

SafeTap™ grease fittings are designed to provide maximum safe operation in the

field. These fittings are standard in all new LT valves. Key features include:

The unique metal-to-

metal seal eliminates

wetted threads and pipe

taps. Since the threads

do not perform a sealing

function they do not

require Teflon tape or

other sealing aids.

The heavier cross section

stands up better to

impacts.

Each fitting has a slot

machined through the

threads which serves as a

pressure relief path in the

event of a leak.

The metal-to-metal seal and the pressure relief slot of the SafeTap™ grease

fitting also allow a means to safely bleed any residual internal pressure.

1.1 SAFETAP™ GREASE FITTING

Revision D April 03, 2014

Page 5

MSI LT VALVE TECHNICAL MANUAL

5

The patented GreaSeal™ plug is designed to provide maximum lubrication in the

harshest field conditions. Key features include:

The only plug that

allows greasing in the

opened or closed

position while in

service.

Dual 360°grease

channels.

Forces grease into 360°

of the seal area when

closed.

Allows for complete

distribution of lubricant

immediately prior to

opening a valve when

exposure to high

temperatures and well

fluids may have

compromised the

existing grease.

Greasing in the closed

position can stop or

significantly slow leaks

in valves with worn or

damaged parts.

Grease fitting installs

from the bottom of the

plug for added

protection from

impacts.

1.2 GREASEAL™ PLUG

Revision D April 03, 2014

Page 6

MSI LT VALVE TECHNICAL MANUAL

6

2.0 EXPLODED VIEW

Revision D April 03, 2014

Page 7

7

2.1 PARTS LIST

NO.

QTY REQ’D

DESCRIPTION

1 2 PLUG BOLT

2 2 WASHER (SMALL)

3 2 WASHER (LARGE)

4 1 HANDLE ADAPTER

5 1 STOP COLLAR

6 1 RESILIENT SEAL

7 1 SAFETAP™ GREASE FITTING

8 1 VALVE BODY

9 2 PLUG SEAL

10a

1

PLUG

10b

1

GreaSeal™ PLUG

11 2 INSERT O-RING

12a

1

UNIsert™

12b

1

INSERT SET (SPLIT)

13 1 ADJUSTING NUT O-RING

14 1 ADJUSTING NUT

15 2 ROLL PIN (OUTER) (LG)

16 2 ROLL PIN (INNER) (SM)

17 1 WING NUT

18 1 NUT RETAINER SET

19 1 SPIRAL RETAINER RING

20 1 STOP BOLT

MSI LT VALVE TECHNICAL MANUAL

Revision D April 03, 2014

Page 8

MSI LT VALVE TECHNICAL MANUAL

8

3.0 ASSEMBLY PROCEDURE – UNISERT™ TYPE

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

o Check surfaces around the

valve bore inside the valve

pocket for sharp edges

that could cause cutting of

the insert o-rings. Then

screw the clean adjusting

nut (14) all the way into

the valve body to make

sure the threads are not

damaged.

o After inspection, remove

the adjusting nut (14),

grease the sealing groove

and install the adjusting

nut o ring (13) in the

groove.

o Check the roll pins (15 &

16) in the valve body by

gently sliding a UNIsert™

(12) into the valve. The

UNIsert™ (12) should

move freely up and down

the length of the roll pin

slots without interference.

Revision D April 03, 2014

Page 9

MSI LT VALVE TECHNICAL MANUAL

9

o Apply a thin film of

lubricant to the recess in

the valve body (8) and

install the plug seal (9)

with the metal back

towards the recess facing

away from the pressure.

o Apply a thin film of

lubricant to the recess in

the adjusting nut (14)

and install the plug seal

(9) with the metal back

towards the recess facing

away from the pressure.

o Check the plug (10)

outside diameter for

surface defects such as

scratches, dings, nicks, or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

Revision D April 03, 2014

Page 10

MSI LT VALVE TECHNICAL MANUAL

10

o Check the surface finish of

the UNIsert™ (12)

making sure it does not

have any scratches, dings,

nicks or sharp edges that

could also affect the

sealing area. See 8.2

SANDING TIPS for repair.

o Inspect the adjusting nut

o-ring (13) for any

possible non-conformity.

o Pack the adjusting nut

(14) plug seal (9) with

valve grease.

Revision D April 03, 2014

Page 11

MSI LT VALVE TECHNICAL MANUAL

11

o Place the UNIsert™ (12)

on the adjusting nut

(14).

o Apply a thin film of grease

to the entire O.D. of the

plug (10).

o Install the lower end of the

plug (10) (opposite the

hex) in the UNIsert™

(12) and adjusting nut

(14) and push down until

the plug shoulders on the

adjusting nut.

Revision D April 03, 2014

Page 12

MSI LT VALVE TECHNICAL MANUAL

12

o Place the insert o-rings

(11) in to the grooves on

the UNIsert™ (12) and

pack with grease to retain

the rings and thoroughly

grease the sealing

surfaces.

o Secure the plug (10) to

the adjusting nut (14)

with the plug bolt (1) and

two washers (2 & 3).

o Lubricate the valve pocket

with valve grease.

Revision D April 03, 2014

Page 13

MSI LT VALVE TECHNICAL MANUAL

13

o Apply thread compound

(Never-Seez) to the

adjusting nut threads and

adjusting nut sealing

surfaces.

o Support the valve so that

the plug (10) hex can

pass through

unobstructed.

o Install the plug (10),

UNIsert™ (12) and

adjusting nut (14)

assembly into the valve

body.

Revision D April 03, 2014

Page 14

MSI LT VALVE TECHNICAL MANUAL

14

o Screw in the adjusting nut

until proper alignment is

obtained between the

valve bore, the UNIsert™

and plug. Do not tighten

beyond proper alignment

as actuating an over

tightened valve could

damage internal parts. If

sight through the bore is

not possible, then screw in

the adjusting nut until ½

or no thread is visible.

o Apply thread compound

(never Seez) to the

threads on the SafeTap™

grease fitting (7).

NOTE: Do not use Teflon

tape on the grease fitting.

o Install SafeTap™ grease

fitting (7) and torque to

80 ft-lbs.

Revision D April 03, 2014

Page 15

MSI LT VALVE TECHNICAL MANUAL

15

o Place spiral retainer ring

(19) on male end (if

required).

o Then place wing nut (17)

on male end and install the

nut retainer set (18) (if

required).

o Secure the retainers with

spiral retainer ring (if

required)

Revision D April 03, 2014

Page 16

MSI LT VALVE TECHNICAL MANUAL

16

o Install stop bolt (20).

o Install stop collar (5).

NOTE: Valves with bores

smaller than 2” do not use

a stop collar, the detent is

integral to the handle

adapter.

o Install the handle

adapter (4).

Revision D April 03, 2014

Page 17

MSI LT VALVE TECHNICAL MANUAL

17

o Secure handle adapter (4) with the plug bolt (1) and washers (2 & 3).

o Remove excess grease from

valve bore.

o Inspect plug alignment and

adjust as necessary with

adjusting nut (14).

Revision D April 03, 2014

Page 18

MSI LT VALVE TECHNICAL MANUAL

18

o Grease the counter bore of the valve body female end and press the resilient

seal (19) lip end towards

the valve in until the lip on

the OD of the seal snaps

into the groove in the back

of the counter bore.

Revision D April 03, 2014

Page 19

MSI LT VALVE TECHNICAL MANUAL

19

3.1 ASSEMBLY PROCEDURE – UNISERT™ TYPE (TEXT)

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

1. Check surfaces around the valve bore inside the valve pocket for sharp edges

that could cause cutting of the insert o-rings. Then screw the clean

adjusting nut (14) all the way into the valve body to make sure the threads

are not damaged.

2. After inspection, remove the adjusting nut (14), grease the sealing groove

and install the adjusting nut o ring (13) in the groove.

3. Check the roll pins (15 & 16) in the valve body by gently sliding a

UNIsert™ (12) into the valve. The UNIsert™ (12) should move freely up

and down the length of the roll pin slots without interference.

4. Apply a thin film of lubricant to the recess in the valve body (8) and install

the plug seal (9) with the metal back towards the recess facing away from

the pressure.

5. Apply a thin film of lubricant to the recess in the adjusting nut (14) and

install the plug seal (9) with the metal back towards the recess facing away

from the pressure.

6. Check the plug (10) outside diameter for surface defects such as scratches,

dings, nicks, or sharp edges that could affect the sealing area. See 8.2

SANDING TIPS for repair.

7. Check the surface finish of the UNIsert™ (12) making sure it does not have

any scratches, dings, nicks or sharp edges that could also affect the sealing

area. See 8.2 SANDING TIPS for repair.

8. Inspect the adjusting nut o-ring (13) for any possible non-conformity.

9. Pack the adjusting nut (14) plug seal (9) with valve grease.

10. Place the UNIsert™ (12) on the adjusting nut (14).

11. Apply a thin film of grease to the entire O.D. of the plug (10).

12. Install the lower end of the plug (10) (opposite the hex/keyway) in the

UNIsert™ (12) and adjusting nut (14) and push down until the plug

shoulders on the adjusting nut.

13. Place the insert o-rings (11) in to the grooves on the UNIsert™ (12) and

pack with grease to thoroughly grease the sealing surfaces.

14. Secure the plug (10) to the adjusting nut (14) with the plug bolt (1) and

two washers (2 & 3).

Revision D April 03, 2014

Page 20

MSI LT VALVE TECHNICAL MANUAL

20

15. Lubricate the valve pocket with valve grease.

16. Apply thread compound (Never-Seez) to the adjusting nut threads and

adjusting nut sealing surfaces.

17. Support the valve so that the plug (10) hex can pass through unobstructed.

18. Install the plug (10), UNIsert™ (12) and adjusting nut (14) assembly

into the valve body.

19. Screw in the adjusting nut until proper alignment is obtained between the

valve bore, the UNIsert™ and plug. Do not tighten beyond proper alignment

as actuating an over tightened valve could damage internal parts. If sight

through the bore is not possible, then screw in the adjusting nut until ½ or no

thread is visible.

20. Apply thread compound (Never-Seez) to the threads on the SafeTap™

grease fitting (7). NOTE: Do not use Teflon tape on the grease fitting.

21. Install SafeTap™ grease fitting (7) and torque to 80 ft-lbs.

22. Place spiral retainer ring (19) on male end (if required).

23. Then place wing nut (17) on male end and install the nut retainer set

(18) (if required).

24. Secure the retainers with spiral retainer ring (if required).

25. Install stop bolt (20).

26. Install stop collar (5). NOTE: Valves with bores smaller than 2” do not

use a stop collar, the detent is integral to the handle adapter.

27. Install the handle adapter (4).

28. Secure handle adapter (4) with the plug bolt (1) and washers (2 & 3).

29. Remove excess grease from valve bore.

30. Inspect plug alignment and adjust as necessary with adjusting nut (14).

31. Grease the counter bore of the valve body female end and press the resilient

seal (19) lip end towards the valve in until the lip on the OD of the seal

snaps into the groove in the back of the counter bore.

Revision D April 03, 2014

Page 21

MSI LT VALVE TECHNICAL MANUAL

21

3.2 ASSEMBLY PROCEDURE – SPLIT INSERT TYPE

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

o Check surfaces around the

valve bore inside the valve

pocket for sharp edges that

could cause cutting of the

insert o-rings. Then screw

the clean adjusting nut

(14) all the way into the

valve body to make sure

the threads are not

damaged.

o After inspection, remove

the adjusting nut (14),

grease the sealing groove

and install the adjusting

nut o ring (13) in the

groove.

o Check the roll pins (15 &

16) in the valve body by

gently sliding a set of

inserts (12) into the

valve. The inserts (12)

should move freely up and

down the length of the roll

pin slots without

interference.

Revision D April 03, 2014

Page 22

22

o Apply a thin film of

lubricant to the recess in

the valve body (8) and

install the plug seal (9)

with the metal back

towards the recess facing

away from the pressure.

o Apply a thin film of

lubricant to the recess in

the adjusting nut (14)

and install the plug seal

(9) with the metal back

towards the recess facing

away from the pressure.

o Check the plug (10)

outside diameter for

surface defects such as

scratches, dings, nicks, or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

MSI LT VALVE TECHNICAL MANUAL

Revision D April 03, 2014

Page 23

MSI LT VALVE TECHNICAL MANUAL

23

o Apply grease to the plug

seal (9) in the adjusting

nut (14).

o Install the lower end of the

plug (10) (opposite the

hex) in the adjusting nut

(14) and push down until

the plug shoulders on the

adjusting nut.

NOTE: For the 0.38” and 1”

valves, do not push the plug

(10) all the way down yet.

o Apply a thin film of grease

to the entire O.D. of the

plug (10).

Revision D April 03, 2014

Page 24

MSI LT VALVE TECHNICAL MANUAL

24

o Check the surface finish of

the inserts (12) making

sure they do not have any

scratches, dings, nicks or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

o Inspect the insert o-rings

(11) for any possible non-

conformity.

o Place the inserts (12)

around the plug (10).

NOTE: For the 0.38” and

1” valves, push the plug

(10) all the way down

now.

Revision D April 03, 2014

Page 25

MSI LT VALVE TECHNICAL MANUAL

25

o Install the insert o-rings

(11) into the insert (12)

grooves and coat with

grease to retain the rings.

o Make sure the entire

sealing surface is

thoroughly greased.

o Secure the plug to the

adjusting nut with the plug

bolt (1) and washers (2

& 3).

Revision D April 03, 2014

Page 26

MSI LT VALVE TECHNICAL MANUAL

26

o Lubricate the valve pocket

with valve grease.

o Apply thread compound

(Never-Seez) to the

adjusting nut threads and

adjusting nut sealing

surfaces.

o Install the plug (10),

inserts (12) and

adjusting nut (14)

assembly into the valve

body.

Revision D April 03, 2014

Page 27

MSI LT VALVE TECHNICAL MANUAL

27

o Support the valve so that

the plug (10) hex can

pass through unobstructed.

o Tighten the adjusting nut

(14) until snug and back

off ¼ turn from snug

position.

o Apply thread compound

(Never Seez) to the

threads on the SafeTap™

grease fitting (7). Install

grease fitting and torque to

80 ft-lbs.

NOTE: Do not use Teflon

tape on the grease

fitting.

Revision D April 03, 2014

Page 28

MSI LT VALVE TECHNICAL MANUAL

28

o Place spiral retainer ring

(19) on male end (if

required).

o Then place wing nut (17)

on male end and install the

nut retainer set (18) (if

required).

o Secure the retainers with

spiral retainer ring (if

required)

Revision D April 03, 2014

Page 29

MSI LT VALVE TECHNICAL MANUAL

29

o Install stop bolt (20).

o Install stop collar (5) and

handle adapter (4).

NOTE: Valves with bores

smaller than 2” do not use

a stop collar, the detent is

integral to the handle

adapter.

o Secure handle adapter

(4) with the plug bolt (1)

and washers (2 & 3).

Revision D April 03, 2014

Page 30

MSI LT VALVE TECHNICAL MANUAL

30

o Remove excess grease from valve bore.

o Inspect plug alignment and

adjust as necessary with

adjusting nut (14).

o Grease the counter bore of

the valve body female end

and press the resilient

seal (19) in until the lip

on the OD of the seal

snaps into the groove in

the back of the counter

bore.

Revision D April 03, 2014

Page 31

MSI LT VALVE TECHNICAL MANUAL

31

3.3 ASSEMBLY PROCEDURE – SPLIT INSERT TYPE (TEXT)

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

1. Check surfaces around the valve bore inside the valve pocket for sharp edges

that could cause cutting of the insert o-rings. Then screw the clean

adjusting nut (14) all the way into the valve body to make sure the threads

are not damaged.

2. After inspection, remove the adjusting nut (14), grease the sealing groove

and install the adjusting nut o ring (13) in the groove.

3. Check the roll pins (15 & 16) in the valve body by gently sliding a set of

insert (12) into the valve. The inserts (12) should move freely up and

down the length of the roll pin slots without interference.

4. Apply a thin film of lubricant to the recess in the valve body (8) and install

the plug seal (9) with the metal back towards the recess facing away from

the pressure.

5. Apply a thin film of lubricant to the recess in the adjusting nut (14) and

install the plug seal (9) with the metal back towards the recess facing away

from the pressure.

6. Check the plug (10) outside diameter for surface defects such as scratches,

dings, nicks, or sharp edges that could affect the sealing area. See 8.2

SANDING TIPS for repair.

7. Apply grease to the plug seal (9) in the adjusting nut (14).

8. Install the lower end of the plug (10) (opposite the hex/keyway) in the

adjusting nut (14) and push down until the plug shoulders on the adjusting

nut. NOTE: For the 0.38” and 1” valves, do not push the plug (10) all

the way down yet.

9. Apply a thin film of grease to the entire O.D. of the plug (10).

10. Check the surface finish of the inserts (12) making sure they do not have

any scratches, dings, nicks or sharp edges that could affect the sealing area.

See 8.2 SANDING TIPS for repair.

11. Inspect the insert o-rings (11) for any possible non-conformity.

12. Place the inserts (12) around the plug (10). NOTE: For the 0.38” and 1”

valves, push the plug (10) all the way down now.

13. Install the insert o-rings (11) into the insert (12) grooves and coat with

grease.

Revision D April 03, 2014

Page 32

MSI LT VALVE TECHNICAL MANUAL

32

14. Make sure the entire sealing surface is thoroughly greased.

15. Secure the plug to the adjusting nut with the plug bolt (1) and washers (2

& 3).

16. Lubricate the valve pocket with valve grease.

17. Apply thread compound (Never-Seez) to the adjusting nut threads and

adjusting nut sealing surfaces.

18. Install the plug (10), inserts (12) and adjusting nut (14) assembly into

the valve body.

19. Support the valve so that the plug (10) hex can pass through unobstructed.

20. Tighten the adjusting nut (14) until snug and back off ¼ turn from snug

position.

21. Apply thread compound (Never Seez) to the threads on the SafeTap™ grease

fitting (7). Install grease fitting and torque to 80 ft-lbs. NOTE: Do not use

Teflon tape on the grease fitting.

22. Place spiral retainer ring (19) on male end (if required).

23. Then place wing nut (17) on male end and install the nut retainer set

(18) (if required).

24. Secure the retainers with spiral retainer ring (if required)

25. Install stop bolt (20).

26. Install stop collar (5) and handle adapter (4). NOTE: Valves with bores

smaller than 2” do not use a stop collar, the detent is integral to the

handle adapter.

27. Secure handle adapter (4) with the plug bolt (1) and washers (2 & 3).

28. Remove excess grease from valve bore.

29. Inspect plug alignment and adjust as necessary with adjusting nut (14).

30. Grease the counter bore of the valve body female end and press the resilient

seal (19) in until the lip on the OD of the seal snaps into the groove in the

back of the counter bore.

Revision D April 03, 2014

Page 33

MSI LT VALVE TECHNICAL MANUAL

33

4.0 EXPLODED VIEW (5” VALVE)

Revision D April 03, 2014

Page 34

MSI LT VALVE TECHNICAL MANUAL

34

NO.

QTY REQ’D

DESCRIPTION

1 1 VALVE BODY

2 2 SAFETAP™ GREASE FITTING

3

12

STUDS 4 12

NUTS

5 2 PLUG SEAL

6a 1 PLUG

6b 1 GreaSeal™ PLUG

7a 1 UNIsert™

7b 1 INSERT SET (SPLIT)

8 2 INSERT O-RING

9 1 O RING, FACE SEAL RING

10 1 SEAL RING

11 1 O RING, ADJUSTING NUT

12 1 ADJUSTING NUT

13 1 FLAT WASHER

14 1 SOCKET HEAD BOLT

15 4 ROLL PIN (OUTER) (LG)

16 4 ROLL PIN (INNER) (SM)

4.1 PARTS LIST (5” VALVE)

Revision D April 03, 2014

Page 35

MSI LT VALVE TECHNICAL MANUAL

35

5.0 ASSEMBLY PROCEDURE – UNISERT™ TYPE (5” VALVE)

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

All assembly steps must be done with the valve pocket in the vertical

position. Any attempt to screw the adjusting nut in with the valve pocket in

the horizontal position could result in damage to the adjusting nut and valve

sealing components.

o Check surfaces around the

valve bore inside the valve

pocket for sharp edges that

could cause cutting of the

insert o-rings. Then screw

the clean adjusting nut

(12) all the way into the

valve body to make sure

the threads are not

damaged.

o After inspection remove the

adjusting nut and check the

roll pins (15 & 16) in the

valve body by gently sliding

the insert (7) into the

valve. The insert (7)

should move freely up and

down the length of the roll

pin slots without

interference.

Revision D April 03, 2014

Page 36

MSI LT VALVE TECHNICAL MANUAL

36

o Apply a thin film of

lubricant to the recess in

the adjusting nut (12)

and install the plug seal

(5) with the metal back

towards the recess facing

away from the pressure.

o Apply grease to the plug

seal (5) in the adjusting

nut (12).

o Grease the sealing groove

and install the adjusting

nut o ring (11) in the

groove.

Revision D April 03, 2014

Page 37

MSI LT VALVE TECHNICAL MANUAL

37

o Apply a thin film of

lubricant to the pocket and

the recess in the valve

body (1) and install the

plug seal (5) with the

metal back towards the

recess facing away from

the pressure.

o Check the plug (6)

outside diameter for

surface defects such as

scratches, dings, nicks, or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

o Support the valve so that

the plug hex can pass

through unobstructed.

Revision D April 03, 2014

Page 38

MSI LT VALVE TECHNICAL MANUAL

38

o Install the plug (6) (hex

side down) in the valve

body.

o Check the surface finish of

the insert (7) making

sure they do not have any

scratches, dings, nicks or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

o Inspect the insert o-rings

(8) for any possible non-

conformity.

Revision D April 03, 2014

Page 39

MSI LT VALVE TECHNICAL MANUAL

39

o Install the insert o-rings

(8) into the insert (7)

grooves and coat with

grease to retain the rings.

o Make sure the entire

sealing surface is

thoroughly greased.

o Apply a thin film of grease

to the entire I.D. of the

insert (7).

Revision D April 03, 2014

Page 40

MSI LT VALVE TECHNICAL MANUAL

40

o Place the insert (7) around

the plug (6) in the valve

body making sure it slides

into the roll pins.

o Apply thread compound

(Never-Seez) to the

adjusting nut threads and

adjusting nut sealing

surfaces.

o Grease the seal ring (10)

groove and insert the o ring

(9) over it.

Revision D April 03, 2014

Page 41

MSI LT VALVE TECHNICAL MANUAL

41

o Place the seal ring (10) on

the top of the insert (7).

o Install the adjusting nut

(12) into the valve body and

tighten until snug and back

off ¼ turn from the snug

position.

o Apply thread compound

(Never Seez) grease to the

plug bolt (14) threads and

tighten it with the allen

wrench on the adjusting nut

side of the plug (6).

Revision D April 03, 2014

Page 42

MSI LT VALVE TECHNICAL MANUAL

42

o Apply thread compound

(Never Seez) to the threads

on the SafeTap™ grease

fitting (2). Install grease

fitting and torque to 80 ftlbs.

NOTE: Do not use Teflon tape

on the grease fitting.

o Remove excess grease from

valve bore.

o Inspect plug alignment and

adjust as necessary with

adjusting nut (12).

Revision D April 03, 2014

Page 43

MSI LT VALVE TECHNICAL MANUAL

43

o Apply Removable

Threadlocker (blue) in the

threads of the stud end and

screw the studs (3) until

tight. Screw the nuts (4)

on the studs (3).

Note: Do not use High

Strength (red) Threadlocker.

Revision D April 03, 2014

Page 44

MSI LT VALVE TECHNICAL MANUAL

44

5.1 ASSEMBLY PROCEDURE- UNISERT™ TYPE (5” VALVE)

(TEXT)

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

All assembly steps must be done with the valve pocket in the vertical

position. Any attempt to screw the adjusting nut in with the valve pocket in

the horizontal position could result in damage to the adjusting nut and valve

sealing components.

1. Check surfaces around the valve bore inside the valve pocket for sharp edges

that could cause cutting of the insert o-rings. Then screw the clean

adjusting nut (12) all the way into the valve body to make sure the threads

are not damaged.

2. After inspection remove the adjusting nut and check the roll pins (15 & 16)

in the valve body by gently sliding the insert (7) into the valve. The insert

(7) should move freely up and down the length of the roll pin slots without

interference.

3. Apply a thin film of lubricant to the recess in the adjusting nut (12) and

install the plug seal (5) with the metal back towards the recess facing away

from the pressure.

4. Apply grease to the plug seal (5) in the adjusting nut (12).

5. Grease the sealing groove and install the adjusting nut o ring (11) in the

groove.

6. Apply a thin film of lubricant to the pocket and the recess in the valve body

(1) and install the plug seal (5) with the metal back towards the recess

facing away from the pressure.

7.

8. Check the plug (6) outside diameter for surface defects such as scratches,

dings, nicks, or sharp edges that could affect the sealing area. See 8.2

SANDING TIPS for repair.

9. Support the valve body (1) so that the plug hex can pass through

unobstructed.

10. Install the plug (6) (hex side down) in the valve body (1).

11. Check the surface finish of the inserts (7) making sure they do not have any

scratches, dings, nicks or sharp edges that could affect the sealing area. See

8.2 SANDING TIPS for repair.

12. Inspect the insert o-rings (8) for any possible non-conformity.

13. Install the insert o-rings (8) into the insert (7) grooves and coat with

grease to retain the rings.

Revision D April 03, 2014

Page 45

MSI LT VALVE TECHNICAL MANUAL

45

14. Make sure the entire sealing surface is thoroughly greased.

15. Apply a thin film of grease to the entire I.D. of the insert (7).

16. Place the insert (7) around the plug (6) in the valve body (1) making sure

it slides into the roll pins.

17. Apply thread compound (Never-Seez) to the adjusting nut threads and

adjusting nut sealing surfaces.

18. Grease the seal ring (10) groove and insert the o ring (9) over it.

19. Place the seal ring (10) on the top of the insert (7).

20. Install the adjusting nut (12) into the valve body (1) and tighten until

snug and back off ¼ turn from the snug position.

21. Apply thread compound (Never Seez) grease to the plug bolt (14) threads

and tighten it with the allen wrench on the adjusting nut side of the plug (6).

22. Apply thread compound (Never Seez) to the threads on the SafeTap™

grease fitting (2). Install grease fittings and torque to 80 ft-lbs.

NOTE: Do not use Teflon tape on the grease fitting.

23. Remove excess grease from valve bore.

24. Inspect plug alignment and adjust as necessary with adjusting nut (12).

25. Apply Removable Threadlocker (blue) in the threads of the stud end and

screw the studs (3) until tight. Screw the nuts (4) over the studs (3)

Note: Do not use Red High Strength Threadlocker.

Revision D April 03, 2014

Page 46

MSI LT VALVE TECHNICAL MANUAL

46

5.2 ASSEMBLY PROCEDURE- SPLIT INSERT TYPE (5” VALVE)

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

All assembly steps must be done with the valve pocket in the vertical

position. Any attempt to screw the adjusting nut in with the valve pocket in

the horizontal position could result in damage to the adjusting nut and valve

sealing components.

o Check surfaces around the

valve bore inside the valve

pocket for sharp edges that

could cause cutting of the

insert o-rings. Then screw

the clean adjusting nut

(12) all the way into the

valve body to make sure

the threads are not

damaged.

o After inspection remove

the adjusting nut and

check the roll pins (15 &

16) in the valve body by

gently sliding a set of

inserts (7) into the valve.

The inserts (7) should

move freely up and down

the length of the roll pin

slots without interference.

Revision D April 03, 2014

Page 47

MSI LT VALVE TECHNICAL MANUAL

47

o Apply a thin film of

lubricant to the recess in

the adjusting nut (12)

and install the plug seal

(5) with the metal back

towards the recess facing

away from the pressure.

o Apply grease to the plug

seal (5) in the adjusting

nut (12).

o Grease the sealing groove

and install the adjusting

nut o ring (11) in the

groove.

Revision D April 03, 2014

Page 48

MSI LT VALVE TECHNICAL MANUAL

48

o Apply a thin film of

lubricant to the pocket and

the recess in the valve

body (1) and install the

plug seal (5) with the

metal back towards the

recess facing away from

the pressure.

o Check the plug (6)

outside diameter for

surface defects such as

scratches, dings, nicks, or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

o Support the valve so that

the plug hex can pass

through unobstructed.

Revision D April 03, 2014

Page 49

MSI LT VALVE TECHNICAL MANUAL

49

o Install the plug (6) (hex

side down) in the valve

body.

o Check the surface finish of

the inserts (7) making

sure they do not have any

scratches, dings, nicks or

sharp edges that could

affect the sealing area.

See 8.2 SANDING TIPS

for repair.

o Inspect the insert o-rings

(8) for any possible non-

conformity.

Revision D April 03, 2014

Page 50

MSI LT VALVE TECHNICAL MANUAL

50

o Install the insert o-rings

(8) into the insert (7)

grooves and coat with

grease to retain the rings.

o Make sure the entire

sealing surface is

thoroughly greased.

o Apply a thin film of grease

to the entire I.D. of the

insert set (7).

Revision D April 03, 2014

Page 51

MSI LT VALVE TECHNICAL MANUAL

51

o Place the inserts (7) around

the plug (6) in the valve

body making sure it slides

into the roll pins.

o Apply thread compound

(Never-Seez) to the

adjusting nut threads and

adjusting nut sealing

surfaces.

o Grease the seal ring (10)

groove and insert the o ring

(9) over it.

Revision D April 03, 2014

Page 52

MSI LT VALVE TECHNICAL MANUAL

52

o Place the seal ring (10) on

the top of the inserts.

o Install the adjusting nut

(12) into the valve body and

tighten until snug and back

off ¼ turn from the snug

position.

o Apply thread compound

(Never Seez) grease to the

plug bolt (14) threads and

tighten it with the allen

wrench on the adjusting nut

side of the plug (6).

Revision D April 03, 2014

Page 53

MSI LT VALVE TECHNICAL MANUAL

53

o Apply thread compound

(Never Seez) to the threads

on the SafeTap™ grease

fitting (2). Install grease

fitting and torque to 80 ftlbs.

NOTE: Do not use Teflon tape

on the grease fitting.

o Remove excess grease from

valve bore.

o Inspect plug alignment and

adjust as necessary with

adjusting nut (12).

Revision D April 03, 2014

Page 54

MSI LT VALVE TECHNICAL MANUAL

54

o Apply Removable

Threadlocker (blue) in the

threads of the stud end and

screw the studs (3) until

tight. Screw the nuts (4)

on the studs (3).

Note: Do not use Red High

Strength Threadlocker.

Revision D April 03, 2014

Page 55

MSI LT VALVE TECHNICAL MANUAL

55

5.3 ASSEMBLY PROCEDURE- SPLIT INSERT (5” VALVE) (TEXT)

NOTE: It is imperative that the workstation being used to assemble the

valve be clean and free of anything that could possibly contaminate the

grease such as metal shavings, dirt, rust, old paint, etc. Do not sand or

deburr near the workstation.

All assembly steps must be done with the valve pocket in the vertical

position. Any attempt to screw the adjusting nut in with the valve pocket in

the horizontal position could result in damage to the adjusting nut and valve

sealing components.

1. Check surfaces around the valve bore inside the valve pocket for sharp edges

that could cause cutting of the insert o-rings. Then screw the clean

adjusting nut (12) all the way into the valve body to make sure the threads

are not damaged.

2. After inspection remove the adjusting nut and check the roll pins (15 & 16)

in the valve body by gently sliding a set of inserts (7) into the valve. The

inserts (7) should move freely up and down the length of the roll pin slots

without interference.

3. Apply a thin film of lubricant to the recess in the adjusting nut (12) and

install the plug seal (5) with the metal back towards the recess facing away

from the pressure.

4. Apply grease to the plug seal (5) in the adjusting nut (12).

5. Grease the sealing groove and install the adjusting nut o ring (11) in the

groove.

6. Apply a thin film of lubricant to the pocket and the recess in the valve body

(1) and install the plug seal (5) with the metal back towards the recess

facing away from the pressure.

7.

8. Check the plug (6) outside diameter for surface defects such as scratches,

dings, nicks, or sharp edges that could affect the sealing area. See 8.2

SANDING TIPS for repair.

9. Support the valve body (1) so that the plug hex can pass through

unobstructed.

10. Install the plug (6) (hex side down) in the valve body (1).

11. Check the surface finish of the inserts (7) making sure they do not have any

scratches, dings, nicks or sharp edges that could affect the sealing area. See

8.2 SANDING TIPS for repair.

12. Inspect the insert o-rings (8) for any possible non-conformity.

Revision D April 03, 2014

Page 56

MSI LT VALVE TECHNICAL MANUAL

56

13. Install the insert o-rings (8) into the insert (7) grooves and coat with

grease to retain the rings.

14. Make sure the entire sealing surface is thoroughly greased.

15. Apply a thin film of grease to the entire I.D. of the insert set (7).

16. Place the inserts (7) around the plug (6) in the valve body (1) making

sure it slides into the roll pins.

17. Apply thread compound (Never-Seez) to the adjusting nut (12) threads and

adjusting nut (12) sealing surfaces.

18. Grease the seal ring (10) groove and insert the o ring (9).

19. Place the seal ring (10) on the top of the inserts (7).

20. Install the adjusting nut (12) into the valve body (1) and tighten until

snug and back off ¼ turn from the snug position.

21. Apply thread compound (Never Seez) grease to the plug bolt (14) threads

and tighten it with the allen wrench on the adjusting nut (12) side of the

plug (6).

22. Apply thread compound (Never Seez) to the threads on the SafeTap™

grease fitting (2). Install grease fittings and torque to 80 ft-lbs.

NOTE: Do not use Teflon tape on the grease fitting.

23. Remove excess grease from valve bore.

24. Inspect plug alignment and adjust as necessary with adjusting nut (12).

25. Apply Removable Threadlocker (blue) in the threads of the stud end and

screw the studs (3) until tight. Screw the nuts (4) over the studs (3)

Note: Do not use Red High Strength Threadlocker.

Revision D April 03, 2014

Page 57

MSI LT VALVE TECHNICAL MANUAL

57

6.0 DISASSEMBLY PROCEDURE

Note: If handle adapter (4) or adjusting nut (14) appears to be stuck or locked,

pressure may be trapped in the valve. This is also known as “pressure locking.” Do

not attempt to disassemble a “pressure locked” valve. See section 8.1

DISASSEMBLY TIPS for pressure relieving procedures.

o Remove the handle adapter (4) and stop collar (5). Turn valve over so

that the adjusting nut (14) is facing up. Leaving the bottom plug bolt (1)

in place, screw out (turning counter-clockwise) the adjusting nut (14). This

will allow the entire internal assembly (adjusting nut (14), plug (10) and

inserts (12)) to be removed from the valve pocket at once.

o Remove the plug bolt (1) that attaches the plug (10) to the adjusting nut

(14).

o Remove the plug (10) and inserts (12).

o Remove the insert o-rings (11), adjusting nut o-ring (13) and plug

seals (9).

o Clean all of the old lubricant and debris from the parts and valve body internal

profile.

Revision D April 03, 2014

Page 58

MSI LT VALVE TECHNICAL MANUAL

58

Valves should be greased as part of a regular maintenance program. Regular

greasing will increase the service life of the internal valve parts. Routine

disassembly and cleaning as part of a maintenance program can prevent

unnecessary damage to the valve body. Dixie Iron Works, Ltd. recommends that

valves be greased after every job or every 5 actuations, whichever one comes first.

Valves should be greased according to the severity of use. Each operating company

should establish guidelines for a greasing and/or disassembly program. These

guidelines should be based on the operating conditions. Special consideration should

be given for conditions in which the following would be involved:

Abrasives in the fluid stream

High flow rates

Caustic or Acidic fluid streams

High Temperature

Fluid Streams that would act as solvents such as condensate

High number of valve actuations

Valves should not be greased while under pressure unless a Greaseal™ plug is being

used. In addition, valves should not be disassembled for repair while part of an

operating arrangement such as a manifold. This should not be attempted even

though the valve may be isolated from the fluid stream by other valves.

If the valve is NOT pressurized, MSI recommends greasing the valve to a minimum

of 3,000 psi greasing pressure. If the valve is pressurized (and a Greaseal™ plug is

being used), the greasing pressure needs to be greater than the internal pressure of

the valve, but always less than the rated working pressure of the valve. The

greasing pump must have pressure measuring capability.

Do not attempt to disassemble a “pressure locked” valve. See section 8.1

DISASSEMBLY TIPS for pressure relieving procedures.

7.0 MAINTENANCE

Revision D April 03, 2014

Page 59

MSI LT VALVE TECHNICAL MANUAL

59

When repairing a MSI plug valve, the following basic guidelines can help

you ensure a good hydrostatic test of the reassembled valve.

Disassemble the valve completely. See section 6.0 DISASSEMBLY PROCEDURES

for detailed instructions on valve disassembly. Remove old grease and debris from

valve pocket with a solvent and inspect for wear or damage such as:

In the adjusting nut seal bore of the pocket: Scratches could be caused by

previous installation of a damaged adjusting nut. Dings can also occur during

assembly. Pitting is usually caused by failure to disassemble and clean valves

after they are in service. Use your fingers to feel for any surface defects

which may either fail to seal against the o-ring or may even damage the oring during assembly.

On the adjusting nut o-ring groove area: Check for scratches, dings, or

pitting. Dings and scratches here are usually caused by careless use of sharp

metal objects when trying to remove old o-rings. Feel for any raised edges

that might scratch the internal seal bore of the valve body and sand or file as

necessary.

On the adjusting nut threads: Check for damaged threads, especially the lead

thread. Use your fingers to check for any raised edges and carefully sand as

needed. Severely damaged threads must be repaired at the factory.

On the pocket walls: Scratches, dings, or pitting, especially in the area

immediately surrounding the valve bore. Use your fingers to feel for any

surface defects which may either fail to seal against the o-ring or may even

damage the o-ring during assembly. Check for any sharp edges around the

valve bore that can cut the insert o-rings. These can be caused by using a

bar when swabbing excess grease or using a bar to carry the valve.

On the internal threads: Check for damaged threads, especially the lead

thread. Use your fingers to check for any raised edges and carefully sand as

needed. Severely damaged threads must be repaired at the factory.

On the plug seal area: Check for scratches, dings, or pitting. Dings and

scratches here are usually caused by careless use of sharp metal objects

when trying to remove old seals.

On the plug outside diameter: Check plug for washout, which will render the

part unusable. Hold part in a well illuminated area and inspect for slight

scratches in plug. If scratches are visible, use a 600 grit sandpaper to

remove them.

On the insert inside diameter: Check segments for washout, which will render the

parts unusable. Hold parts up to a well illuminated area and inspect for slight

scratches in outer and inner diameters of inserts. If scratches are visible, use a 600

grit sandpaper to remove them.

8.0 REPAIR AND INSPECTION

Revision D April 03, 2014

Page 60

MSI LT VALVE TECHNICAL MANUAL

60

If the flow bore is washed and eroded larger than when the bore I.D. was new, the

plug and segment set can only be used when the wear conforms to the guidelines

detailed below. Since the bore will no longer be a perfect circle, you must measure

the largest gap from one side of the bore to the other. If the bore tapers in either

direction, measure the largest dimension. Compare the measurement to the

following maximum acceptable dimensions:

1” Plugs and Inserts – 1.090” max

2” Plugs and Inserts – 2.120” max

3” Plugs and Inserts – 3.120” max

4” Plugs and Inserts – 4.120” max

5” Plugs and Inserts – 5.190” max

Plug valves seal on the downstream side or the side opposite the pressure. The oring in the segment is pressured inward, trying to collapse the inside wall toward the

bore. Dimensions larger than these guidelines will produce walls too thin to support

the working pressure of the valve and these parts should be scrapped.

Because the bore is larger than when new and because the eroded area tends to be

uneven, worn parts create a larger internal upset in the valve which increases

turbulence. This increased turbulence means that the rate of wear will increase

exponentially so special consideration should be given to the application of valves

with worn parts to minimize the possibility of failure during the course of the job.

Continued use of parts with eroded flow bores may reduce the life of the valve body.

MSI recommends that valves with working but washed parts within these guidelines

be used in locations of the rig-up that see less abrasive flow.

See the Minimum Wall Thickness Datasheet for wall thickness inspection

procedures and allowable erosion values.

Revision D April 03, 2014

Page 61

MSI LT VALVE TECHNICAL MANUAL

61

Note: If handle adapter (4) or adjusting nut (14) appears to be stuck or locked,

pressure may be trapped in the valve. This is also known as “pressure locking.” Do

not attempt to disassemble a “pressure locked” valve.

The SafeTap™ grease fitting allows for the safe relief of trapped pressure

within a valve. Extreme caution must be followed when attempting to relieve

a pressure locking situation. Slowly turn the grease fitting ¼ CCW turn to

relieve the pressure. Actuate the valve to ensure all pressure has been

relieved. After the removal of all trapped pressure, you may remove all

components. See section 1.1 SAFETAP™ GREASE FITTING for more

details on the SafeTap™ grease fitting

8.1 DISASSEMBLY TIPS

Revision D April 03, 2014

Page 62

MSI LT VALVE TECHNICAL MANUAL

62

When repairing a MSI plug valve, the following basic guidelines can help

you ensure a successful hydrostatic test of the reassembled valve.

Sanding is necessary to repair blemishes from the sealing surfaces of parts.

Sanding of scratches, dings, and pitting should always be done with 600 grit

sanding cloth that is well lubricated with water or solvent. When sanding

sealing surfaces, it is VERY important to avoid sanding in one spot

continuously; sand evenly across the entire sealing surface. Sand scratches

by moving the sandpaper around the plug, not up and down, along the

length of the plug. If scratches cannot be removed utilizing this technique,

replace the parts. If raised edges or dings in non-sealing areas are too large

to be sanded effectively, you may use a rotary flapper-type sanding wheel.

It is very important that you do not remove any material other than the

actual raised edge. Do not remove any of the base material or you may

permanently damage the valve and render it unsafe for use.

8.2 SANDING TIPS

Revision D April 03, 2014

Page 63

MSI LT VALVE TECHNICAL MANUAL

63

When repairing a MSI plug valve, the following basic guidelines can help

you ensure a good hydrostatic test of the reassembled valve.

If you choose to mix old and new parts, you must make absolutely sure that the old

part does not have any defects. Using 600 grit sanding cloth, wet sand any surface

blemishes as described in section 8.2 Sanding Tips.

See section 3.0 ASSEMBLY PROCEDURES for detailed assembly

instructions.

8.3 ASSEMBLY TIPS

Revision D April 03, 2014

Page 64

64

9.0 STORAGE

Disassemble the valve completely. See section 6.0 DISASSEMBLY PROCEDURES

for detailed instructions on valve disassembly. Remove old grease and debris from

valve pocket with a solvent and inspect for wear or damage per 8.0 REPAIR AND

INSPECTION.

Drain after testing. All equipment should be drained and lubricated after

testing and prior to storage.

All components and assemblies should be cleaned of dirt, rust, and other

contaminants.

Rust Prevention: Equipment should have exposed metallic surfaces protected

with a rust inhibitor which will not become fluid and run at a temperature less

than 125°F (52°C).

Sealing surface protection: Exposed sealing surfaces should be protected from

mechanical damage.

MSI LT VALVE TECHNICAL MANUAL

Revision D April 03, 2014

Page 65

65

9.1 SHELF LIFE

The following is recommended for maximum equipment shelf life:

# of Months in

Storage

Manufacturers Recommendations

0-3 months

Nothing required

3-6 months

Re-grease and operate. Operate by rotating the plug. Check to see

that rotation is smooth without grinding or scraping.

6+ months

Disassemble, rebuild & retest the valve. Replace all internal seals

MSI LT VALVE TECHNICAL MANUAL

Revision D April 03, 2014

Page 66

MSI LT VALVE TECHNICAL MANUAL

66

Use only MSI recommended accessories.

MSI Part Number

Description

VC0393

Valve Operating Bar

10.0 ACCESSORIES

Revision D April 03, 2014

Page 67

MSI LT VALVE TECHNICAL MANUAL

67

Use only MSI recommended greases. Greases intended for gate valves or other

applications may result in failure to achieve a good test and may actually damage

the new parts.

MSI Part Number

Description

Manufacturer's

Website

VC0012

#972 General Service (size K)

Val-Tex

VC0426

#972 General Service (size 5.5)

Val-Tex

VC0669

#972 General Service (size V)

Val-Tex

VC0527

#750 Low Temperature (size J)

Val-Tex

VC0402

#750 Low Temperature (size K)

Val-Tex

VC0357

#700 CO2 / Hi-Temp / Condensate (size J)

Val-Tex

GREASE002 *

1502-S-7 Low Pressure Testing (7 lb can)

Val-Tex

10.1 GREASES

*Val-Tex 1502 grease is for hand application only and not to be pumped. Therefore,

it is to be used only during the assembly process. Inject body grease prior to testing

and after each actuation.

Revision D April 03, 2014

Page 68

MSI LT VALVE TECHNICAL MANUAL

68

Valve Size

Approximate amount of grease “K” size stick

1” VALVE

⅓ STICK

2” VALVE

½ STICK

3” VALVE

1 STICK

4” VALVE

3 STICKS

5” VALVE

5 STICKS

10.2 GREASE REQUIREMENTS

Revision D April 03, 2014

Page 69

MSI LT VALVE TECHNICAL MANUAL

69

MSI uses the following brands of actuators. Information is available by clicking on

the hyperlinks.

Pneumatic

El-O-Matic

Hydraulic

Damcos

Gear Operated

Williams Machine

10.3 ACTUATORS

Revision D April 03, 2014

Page 70

MSI LT VALVE TECHNICAL MANUAL

70

MSI offers many 0-ring and plug seal materials for a variety of environmental and

operating conditions.

10.4 RUBBER PRODUCTS

Revision D April 03, 2014

Loading...

Loading...