MSE HARRIER, HARRIER R, HARRIER RH User Manual

HARRIER

and

HARRIER R

User Manual

Please read this before use

MSB10352/2-56

MSB10352R/2-5

2

SIGNS

WARNING!

Warning of potential injury or health risk.

DANGER!

Risk of electric shock with potential for severe injury or death as a consequence.

DANGER!

Biohazard with potential for risk to health or death as a consequence.

DANGER!

Risk of explosion with potential for severe injury or death as a consequence.

This manual was prepared with special care.

MSE CENTRIFUGES LTD may change the manual at any time

and

without notice because of improvements, typographical errors, inaccuracies of current information

or improvements to facilities.

You can find the current version of the user manual on our website under: www.mseuk.com

DOWNLOADS section.

3

Content

1 APPLICATION ......................................................................................................................................... 5

2 TECHNICAL SPECIFICATION .................................................................................................................... 6

3 INSTALLATION ....................................................................................................................................... 7

4 SAFETY NOTES ....................................................................................................................................... 9

5 OPERATING ......................................................................................................................................... 15

6 CENTRIFUGING .................................................................................................................................... 19

7 TEMPERATURE CONTROL .................................................................................................................... 32

8 PARAMETERS OF CENTRIFUGATION .................................................................................................... 34

4

9 MENU .................................................................................................................................................. 45

10 MAINTENANCE .................................................................................................................................... 54

11 TROUBLESHOOTING ............................................................................................................................ 59

12 GUARANTEE ........................................................................................................................................ 61

13 DISPOSAL ............................................................................................................................................ 62

14 MANUFACTURER’S INFO ..................................................................................................................... 63

15 ANNEXES ............................................................................................................................................. 64

OPTIONAL ACCESSORIES

DECLARATION OF DECONTAMINATION - REPAIR

DECLARATION OF DECONTAMINATION - RETURN

STATEMENT OF CONFORMITY

• DECLARATION OF CONFORMITY (ROHS 2 2011/65/EU)

• CONVERSION TABLE FOR RPM/RCF (NOMOGRAM)

5

1 Application

The Harrier/R/RH centrifuges are benchtop laboratory centrifuge for in vitro diagnostic (IVD).

Devices are used for separation samples taken from people's, animals’ and plants’ components of

different densities, under the influence of the centrifugal force, to provide information about their

biological state (Harrier – ventilated, Harrier R – with cooling, Harrier RH – with cooling and heating).

Its construction ensures easy operation, safe work and wide range of applications

at laboratories engaged in routine medical analyses, biochemical research works etc.

In the centrifuge, it is prohibited to centrifuge caustic, inflammable and explosive

preparations.

6

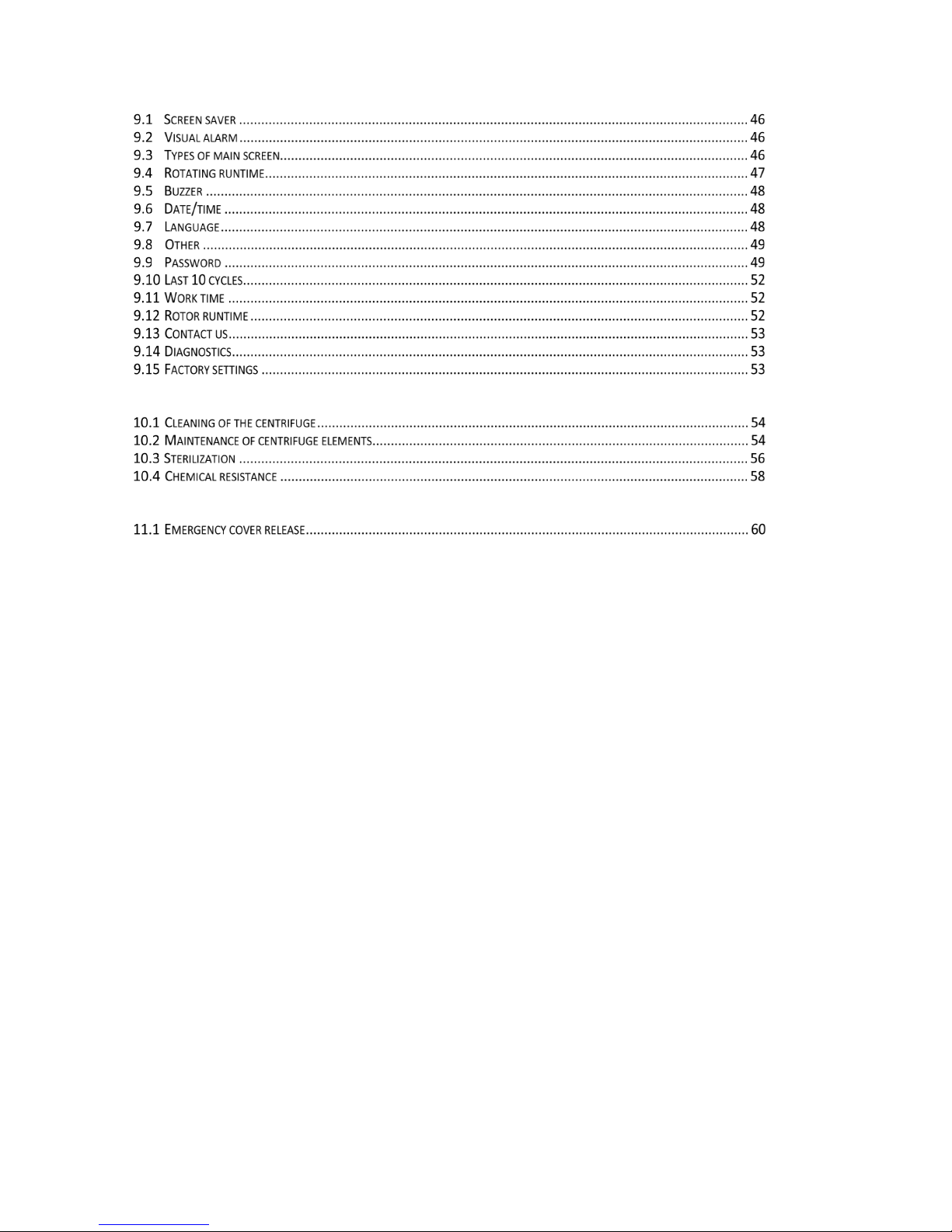

2 Technical specification

manufacturer

MSE Centrifuges Ltd, Mytogen House, 11 Browning Road, Heathfield TN21 8DB

Type

Harrier

Harrier R/RH

mains voltage (L1+N+PE)

230V

100V

110V

120V

127V

230V

100V

110V

120V

127V

±10

±5

±10

±5

mains frequency,

50/60Hz

50Hz/60Hz

50Hz

60Hz

60Hz

power consumption (max.)

600W

980W

current protection [A]

T 6,3A

T 10A

T 10A

T 16A

cooling medium

-

R507 (CFC/HCFC free)

Harrier

Harrier R

Harrier RH

capacity (max.)

1000 ml

speed – RPM

90 ÷ 18000 rpm (step 1 rpm)

relative centrifugal force – RCF

30065 x g (step 1 x g)

Torque, or else the unit need to be

changed (max.)

19148 Nm

running time

00:00:01 ÷ 99:59:59 – [hours, min., sec] (step 1s)

time counting

as start button is pressed / as preselected speed is reached

short-time operation mode – SHORT

yes

continuous operation mode – HOLD

yes

user programmes

100

adjustable temperature

-

-20 ÷ 40°C*

(step 1°C)

-20 ÷ 55°C*

(step 1°C)

initial cooling/heating

PROG 99 (90 ÷ 2500 RPM)

no/ no yes / no yes / yes

guaranteed temperature with max.

rotor speed

-

≤4°C

cooling/heating without centrifuging

no

yes/ no

yes / yes

cooling/heating with centrifuging

no

yes /no

yes / yes

acceleration (ACEL)

10 linear curves

deceleration (DECEL)

10 linear curves

programmable non-linear curves:

Acceleration

10

Deceleration

10

USB communication

yes

Electromagnetic compatibility

according to PN-EN 61326-1:2006

ambient conditions

PN-EN 61010-1 (p.1.4.1)

set-up site indoors only

ambient temperature

2° ÷ 40°C

humidity (maximum relative

humidity)

< 80%

installation category II EN 61010-1

pollution degree 2 EN 61010-1

safety area 300 mm

degree of protection IP21 IP20 IP20

height (H)

380 mm 380 mm

width (W)

443 mm 443 mm

depth (D)

545 mm 695 mm

height with open cover (Hoc)

768 mm 768 mm

noise level

56 dB

weight 230V

41,8 kg

64,8 kg

65,7 kg

weight 120V

45 kg

70,9 kg

71,8 kg

*time and possibility of obtaining a set temperat ure is depende nt on multiple factors, including: roto r type, esta blished RPM, a mbient temperature; accuracy: - ±1*C

appropriate for place of temperature sensor

Menu languages: ENGLISH, FRENC H, GERMAN, SPANISH, ITALI AN, PORTUGUES E, RUSSIAN, SWEDISH, CZECH, POLISH

7

3 Installation

Open the package. Remove the box containing the accessories. Take out centrifuge from the container.

Keep the box and packing materials in case of service shipping.

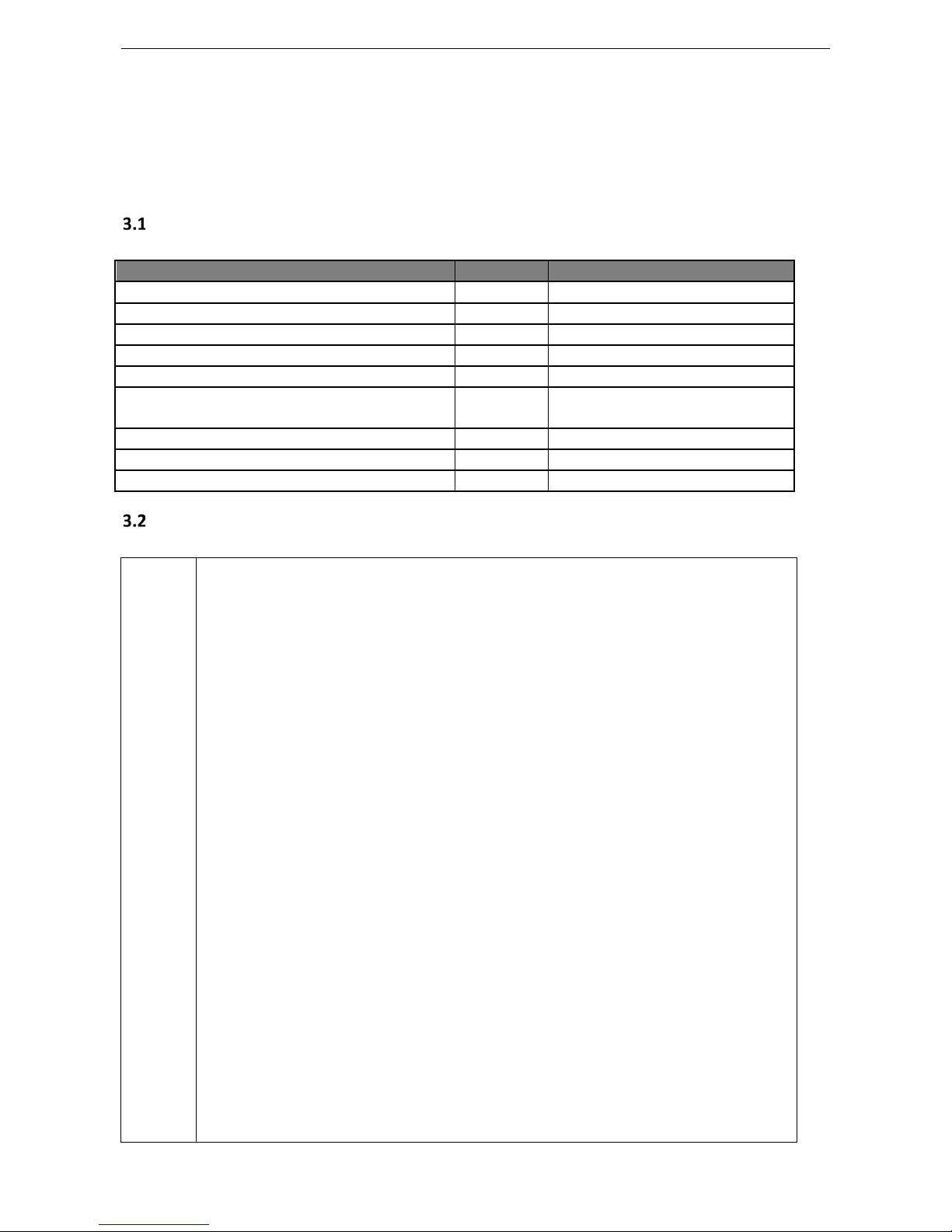

Content of the package

Name

pcs.

cat no.

centrifuge HARRIER/R/RH

1

see name plate

complete clamp 1 17664

spanner for the rotor

1

17665

spanner for emergency opening of the cover

1

17162

power cord 230V / 120V

1

17866/17867

fuse WTA T 6,3A 250V / WTA T10A 250V

/WTA T16A 250V

2 17862/17863/17864

Vaseline 20ml 1 17201

USB A-A cable 1 16655

user manual 1 20352/R/RH/EN

Location

Ensure safe location.

The centrifuge shall not be located near source of heat and shall not be

subjected to direct sunlight.

Centrifuge should be located on a stable and flat-levelled table top.

Centrifuge should be set horizontally on a rigid base.

It is necessary to ensure a ventilation zone of a minimum of 30cm round the

centrifuge from every direction. Do not obstruct ventilation holes !

Benching/Table for centrifuge should have a safety zone of a minimum of

30cm round the centrifuge from every direction (this is needed in case of

malfunction according to EN 61010-020).

Benching/Table for centrifuge should be free of restraints.

Parameters of the centrifuge refer to the above temperatures (see 2.Technical

specification).

When changing from cold to warm, condensation of water will occur inside the

centrifuge. It is therefore important that sufficient time be provided for drying

out of the centrifuge prior to further use of the centrifuge (min. 4 hours).

Do not position the centrifuge so that it is difficult to operate the power

switch.

Supply voltage given on the name plate has to be consistent with local supply

voltage. MSE CENTRIFUGES LTD laboratory centrifuges are 1

st

class safety

devices and they are provided with the three-core cable with the plug resistant

to dynamic loadings. Mains socket shall be provided with the safety pin

(protective earth (PE)).

It is recommended to install emergency cut-out that shall be located far from

8

the centrifuge, near the exit or beyond the room.

Before switching on, check whether the centrifuge is connected to power

supply correctly. It is compulsory to use the power cord recommended by the

manufacturer (17866 for 230V, 17867 for 120V)

Before use, check whether the device is correctly intalled.

Current protection

The centrifuge is equipped with thermal current protection. Fuse is situated in the

plug-in socket unit at the back of the centrifuge.

9

4 Safety notes

Operating personnel

The laboratory centrifuge can be operated by authorised laboratory personnel after

familiarisation with the user manual.

User manual shall be always held near the centrifuge.

The centrifuge should not be misused.

If the centrifuge is used in a manner not specified by the manufacturer, the

protection provided by the device may be impaired.

Guarantee

The warranty period is 24 months (unless otherwise specified in the purchase

documents).

The service life of the centrifuge specified by the manufacturer is

10 years.

After termination of the warranty period, it is necessary to carry out yearly technical

inspections of the centrifuge.

The Manufacturer reserves the right to make technical changes in manufactured

products.

The maximum period of storage of for centrifuges that are not used is 1 year. After

this period, a technical inspection of the centrifuge should be carried out by service

personnel authorised by the manufacturer.

10

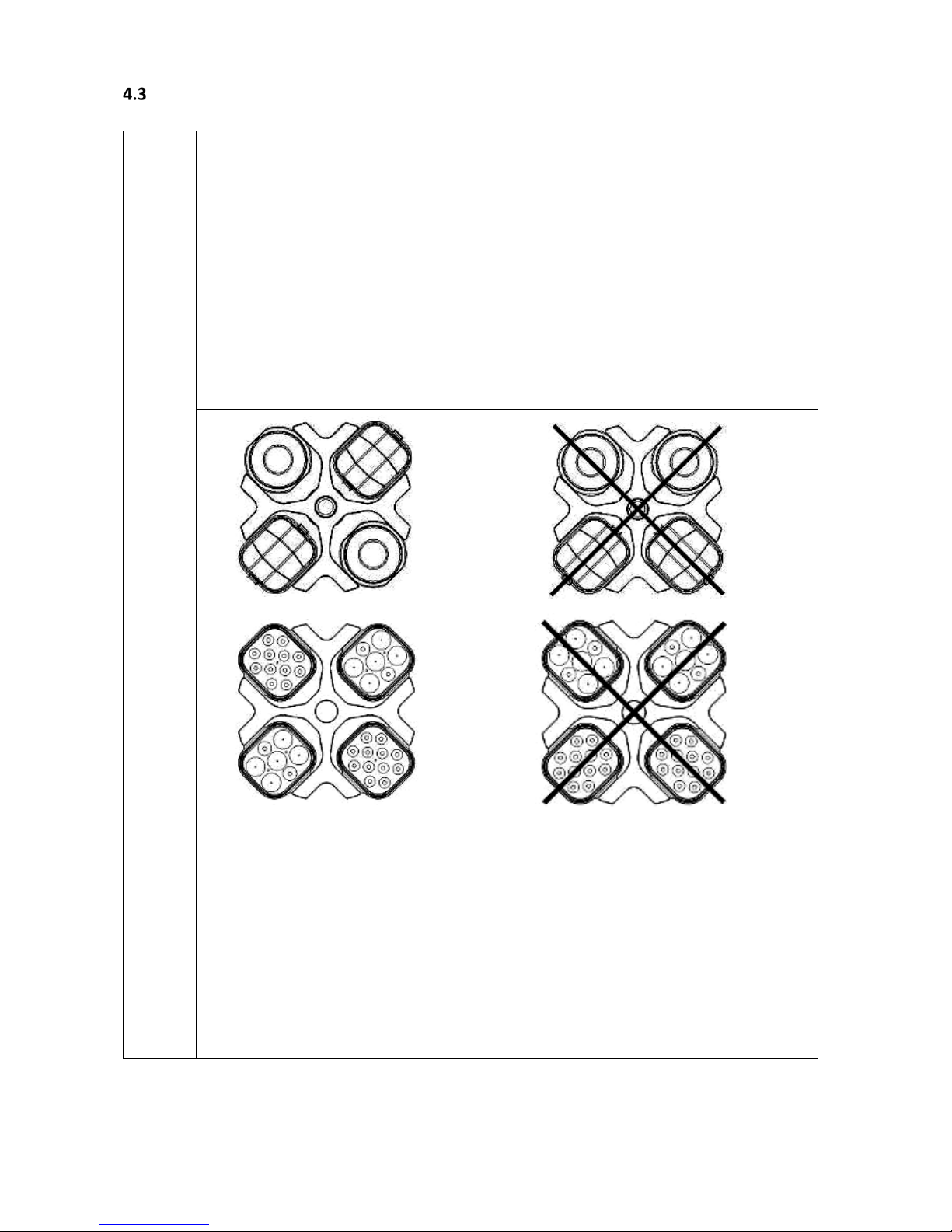

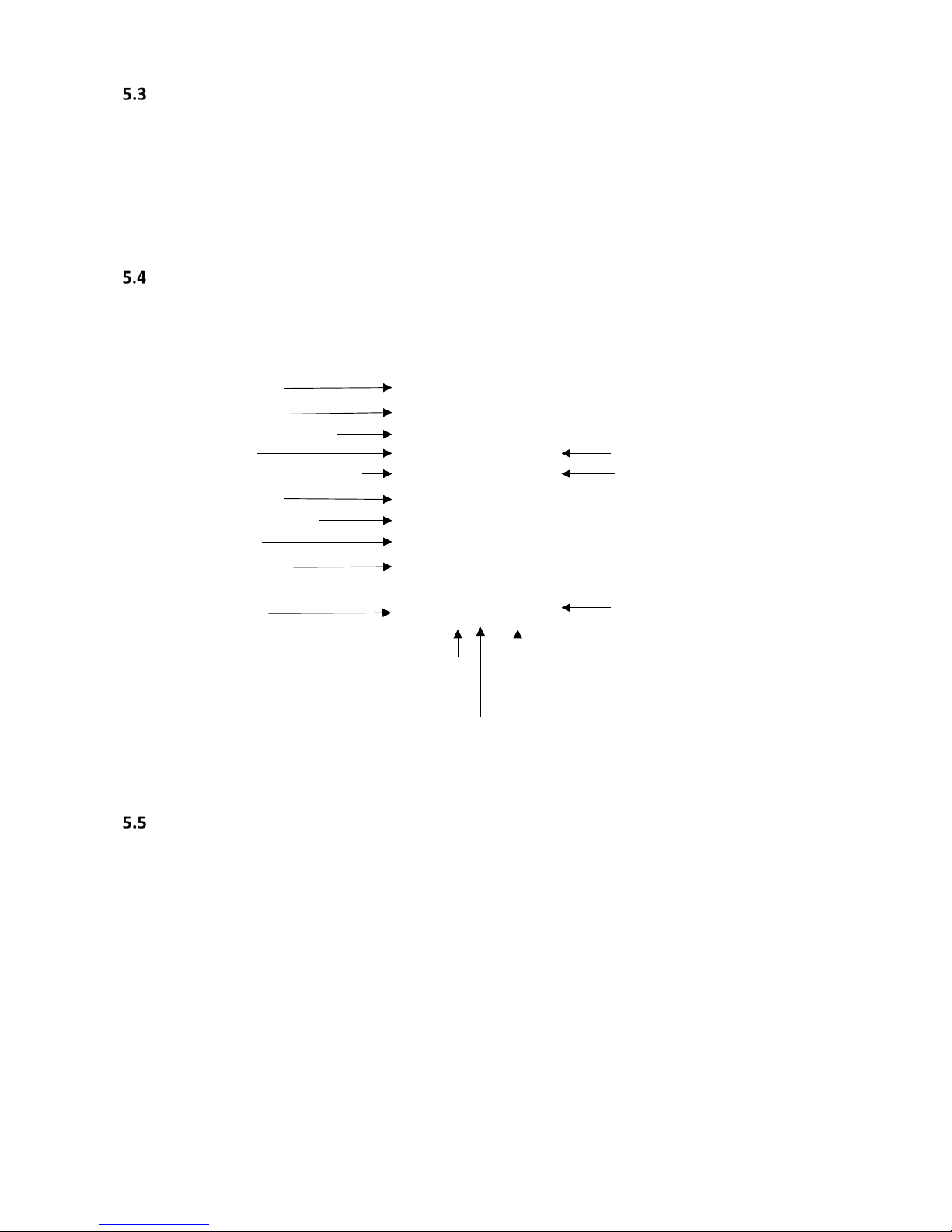

Loading the rotor

Fix the rotor firmly on the motor axis.

Avoid unbalance.

Load opposite buckets with the same accessories.

Centrifugation of the test tubes of different sizes:

There is a possibility to centrifuge test tubes of different sizes; however, it is

absolutely necessary in such cases that opposite buckets and round carriers

be the same.

The mass of different containers with test tubes spun at the same time has

to be comparable. Swing-out rotors must be equipped with all ( two or four

– dependent on the type of rotor) buckets.

Lubricate the swing-out rotor journal pins.

CORRECT

WRONG

CORRECT

WRONG

It is necessary to insert test tubes symmetrically on the opposite sides.

11

FILLING TUBES

Fill test tubes outside the centrifuge.

Please pay special attention to the quality and proper thickness of the glass test

tubes walls. Those must be test tubes for centrifuges.

Fill test tubes outside the centrifuge.

Safety hints

ROTORS MAINTENANCE

Lubricate the swing-out rotor trunnion pins.

Use only accessories in good condition.

Protect equipment against corrosion using accurate preventive maintenance.

HS ACCESSORIES MAINTENANCE

Make sure that rubber O-

rings are lightly coated with silicone grease. Use high

vacuum grease, e.g. type „C” by LUBRINA.

HAZARDOUS MATERIALS

MSE Centrifuges accessories are not biotight. For centrifuging infectious materials, it

is necessary to use hermetically closed tubes meeting demands of biotightness,

in order to prevent germs migration into the centrifuge and beyond it.

It is not allowed to subject to

centrifugation toxic or infectious materials with

damaged leak proof seals of the rotor or test-tube. Proper disinfection procedures

have to be carried out after dangerous substances have

contaminated the

centrifuge or its accessories.

EXPLOSIVE AND COMBUSTIBLE MATERIALS

It is not allowed to centrifuge explosive and inflammable materials.

It is not allowed to centrifuge substances prone to reacting as a result of a high

energy supply during centrifugation.

The centrifuge can not be operated in

explosion-endangered areas.

It is not allowed to centrifuge materials capable of generating inflammable or

explosive mixtures when subjected to air.

12

Maintenance conditions

START-UP

Prior to switching the centrifuge on, the user must read carefully all sections of this

user manual in order to ensure smooth operation and avoid damages of this device

or its accessories.

In order to protect the centrifuge against unbalance, fill in the test tubes up to the

same weight.

TRANSPORTATION

Centrifuge must not be transported with the rotor mounted on the shaft.

GENERAL HINTS

Only original rotors, tubes and spare parts must be used.

In case of faulty operation of the centrifuge, please contact MSE CENTRIFUGES LTD

Service Department or its authorised representatives.

It is not allowed to switch the centrifuge on if it is not installed properly or rotor

is not fitted correctly.

CENTRIFUGES SUBSTANCES

It is not allowed to exceed load limit set by the manufacturer. Rotors are intended

for fluids of average homogeneous density equal to 1,2 g/cm3

or smaller when

centrifugation is carried out at maximum speed. When fluids of higher density are

used, it is necessary to change the density of the centrifuge’

s sample

in PARAM/DENSITY field.

13

INSPECTION PROCEDURES CARRIED OUT BY THE OPERATOR

The operator has to pay special attention to the fact that key centrifuge parts are not

damaged for safety reasons. This is specifically important for:

Centrifuge accessories and especially structural changes, corrosion, preliminary

cracks, abrasion of metal parts.

Screw connections.

Inspection of seals of the buckets if such are used. Special attention must be paid to

all of the rubber (seals) parts. In the case of damage or visible structural changes

defective parts must be replaced for new immediately (Set of seals Cat. No. 18591

available from the manufacturer).

Yearly technical inspection of the centrifuge (after lapse of guarantee).

Only the manufacturer-specified buckets, included in the equipment list, as well as

centrifuge tubes, which diameter, length and durability are suitable, should be used

for spinning in this centrifuge. The use of equipment made by other manufacturers

should be consulted with the manufacturer of the centrifuge.

It is not permitted to lift or shift the centrifuge during operation or rest on it.

It is not permitted to stay in the safety zone (30 cm distance around the centrifuge)

neither leave objects, e.g. glass vessels within this zone.

It is not permitted to put any objects on the centrifuge

COVER OPENING

It is not permitted to open the cover manually in emergency procedure when rotor is

still turning.

14

ROTORS

It is not permitted to use the rotors and round carriers with signs of corrosion

or other mechanical defects.

It is not permitted to centrifuge highly corrosive substances which may cause

material impairment and lower mechanical properties of rotor and round

carriers.

It is not permitted to use rotors and accessories not agree

d by the

manufacturer. Only

use commercial glass and plastic test tubes which are

specifically made for centrifuging in this laboratory centrifuge. Do not use poor

quality elements.

Cracking of glass vessels and test tubes could result

in dangerous vibration of the centrifuge.

It is not permitted to carry out centrifugation with the rotor caps taken off or

not screwed tight.

Residual risk

The centrifuge is built according to state-of-the-art standards and recognised safety regulations.

Nevertheless, there still remains some level of residual risk due to improper operation and malfunctions. It

is possible to decrease residual risk by applying strictly the user manual conditions and correcting any

malfunction which could threaten safety immediately.

15

5 Operating

Centrifuge overview

The new generation of MSE CENTRIFUGES LTD’s laboratory centrifuges is provided with state-of-theart microprocessor control systems, very durable and quiet asynchronous brushless motors and accessories

consistent with requirements of the present-day user.

Centrifuge description

5

4

3

2

Fig.2. Right side of centrifuge

1 2

1. Power switch

2. USB

3. Control panel

4. Cover

5. Sight glass

6.

Emergency lid

opening

1. Plug-in socket

2. Fuse socket

Fig.1. General view

Fig.3. Assembly of angle rotor

Fig.4. Mains socket

back of the centrifuge

1. Motor shaft

2. Rotor

3. Rotor lid

4. Clamp bolt/rotor

nut

4

3

2

1

6

1

16

Construction

The centrifuge has a rigid self-supporting structure. The housing is made of sheet aluminium, the

back is made of steel sheet. Front and cover are made of ABS type plastic. The cover is fixed on steel axles

of hinges and from the front, it is locked with an electromagnetic lock blocking any possibility of opening

during centrifugation. The rotation chamber casing is made of thick steel sheet. The rotation chamber is

made of stainless steel sheet.

Name plate

Rotor and accessories installation

Connect the centrifuge to the mains (master switch on the back of the centrifuge).

Turn on the centrifuge (button on the side of the centrifuge).

Open the cover of the centrifuge by pressing the COVER key (see section Centrifuging/Control

Panel). Prior to putting the rotor in, please ensure that the rotating chamber is free of impurities,

e.g. such as dust, glass splinters, residues of fluids that must be taken away.

Fit the rotor on the motor shaft screwing it tight on the cone.

Screw-in the clamp for fixing the rotor (clockwise). Ensure it is tight with the supplied spanner for

the rotor.

Swing-out rotors have to be provided with the buckets in all seats. Please remember that every

buckets swings individually and freely. Bucket suspension studs (trunnoin pins) should be lubricated

periodically with petroleum jelly.

Centrifuge model

Catalogue number

Power supply parameters

Rating power

Type and mass of refrigerant

Maximum speed

Date of manufacturing

Serial number

Information about

manufacturer

CE compliance

Fuse type

R

efrigerant does

not contain CFC.

Product should

not be disposed

with other waste.

Dispose according

to national law.

Pay attention when you are seeing this symbol.

Operating of centrifuge may be potentially

harmful.

In Vitro

Diagnostic

device

Read user

manual

17

In case of rotors designed with the cover (angled rotor), they must not be used without the rotor

lid. Rotor covers must be closed tightly. Rotor covers ensure smaller drags of the rotors, proper

setting of the test-tubes and airtight sealing.

Please only use buckets intended for the selected types of the rotor.

Fill test tubes outside the centrifuge.

In case of centrifuging in an angle rotor, test tubes (buckets) have to be filled properly in order to

prevent spillage of fluids during centrifuging.

Tubes must be filled so that the material does not

escape.

Please fill tubes according to below formula:

Max liquid level < Tube height −

Internal tube diameter

2

Additionaly please adhere to the manufacturer's restrictions about the filling of the test tube.

It is recommended to equalise vessels loads as much as possible in order to ensure

minimal vibrations during operation.

In order to prolong the lifetime of the rotor and gaskets, rotors will need to be lubricated with the

maintenance oil, while gaskets and threaded parts will need to be lubricated with petroleum jelly.

For replacement of the rotor, please unscrew clamp and then grab the rotor with both hands at

opposite sides, taking it away from drive shaft by pulling it up.

Control device

The microprocessor control unit of the centrifuge allows the selecting, programming and registering

of the work parameters.

centrifugal force

liquid

Internal tube diameter

18

Setting parameters

The data setting and read-out system are part of a hermetically closed keyboard with distinctly

accessible operation points. Easily readable displays confirm the selected features and facilitate the

operator’s programming and recording of parameters and condition of the centrifuge.

The centrifuge is provided with the USB interface that enables connection of the centrifuge to an

external PC unit with the printer and recording of the centrifugation parameters.

Safety features

Lid lock

The centrifuge can only be started when the lid is properly closed. Similarly, the lid can only be

opened once the rotor has stopped. In case of emergency opening of the lid during operation, the

centrifuge will be immediately switched-off and the rotor will slow to a complete stop.

Unbalance detecting

Should loads of opposite buckets or carriers in rotors be unbalanced, the drive will be switched-off

during acceleration or operation of the centrifuge and an error message will be displayed.

Rotor verification and checking compatibility with loaded programme

Upon starting centrifuging, the unit verifies the type of the rotor installed and in the case of its

incompatibility with the type indicated in the application or absence of the rotor, the spinning process will

stop with simultaneous displaying of an error message. The conformity of the type of the rotor is signalled

with a single audible signal. If the auto-identification (see 9.8 Other) option is checked, the proper rotor will

be automatically chosen, without the user input.

Rest state inspection

Opening of the centrifuge’s cover by pressing the COVER button is possible, but only when the

rotor is in a state of rest. Use the inspection glass to ensure the rotor is in the rest state. When the rotor is

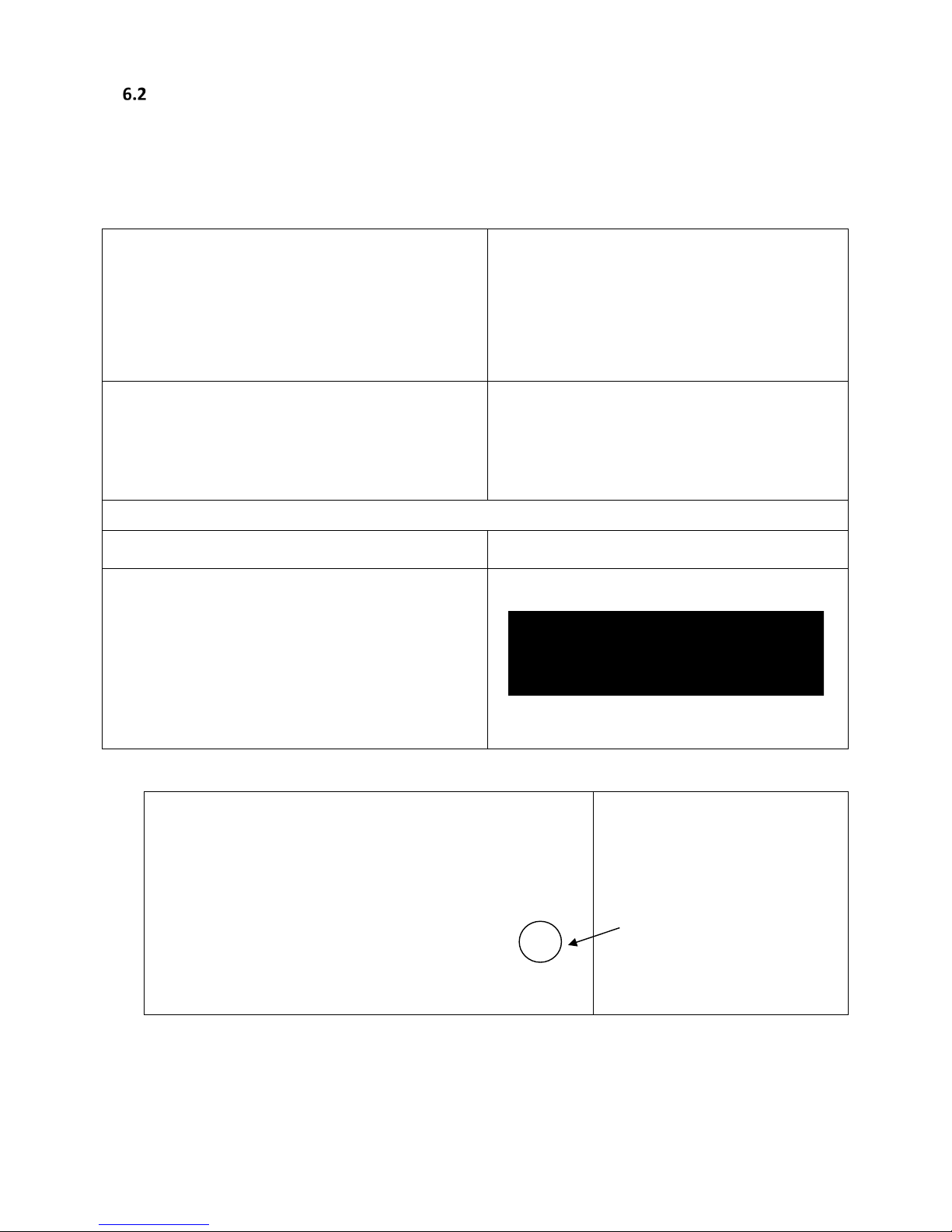

being stopped, the brake symbol (see 6.2) is visible and goes off when it stops. The opening of the

emergency cover during rotor running is prohibited.

Checking of excessive temperature

If the temperature in rotation chamber exceeds 50°C (Harrier) / 65°C (Harrier R/RH) caused by, for

example, a malfunction of the cooling system, the drive will be switched off and an error message will be

displayed. The reboot is only possible after the device has cooled down.

Increase in temperature (Harrier only)

In uncooled centrifuges, the temperature in the rotor chamber, rotor and sample can increase to

above 40°C, based on the run time, g-force (rcf)/speed and ambient temperature.

19

6 Centrifuging

The switching ON/OFF of the power is carried out via the master switch situated on the right side wall

of the centrifuge. All other settings on the centrifuge are done by means of the control panel.

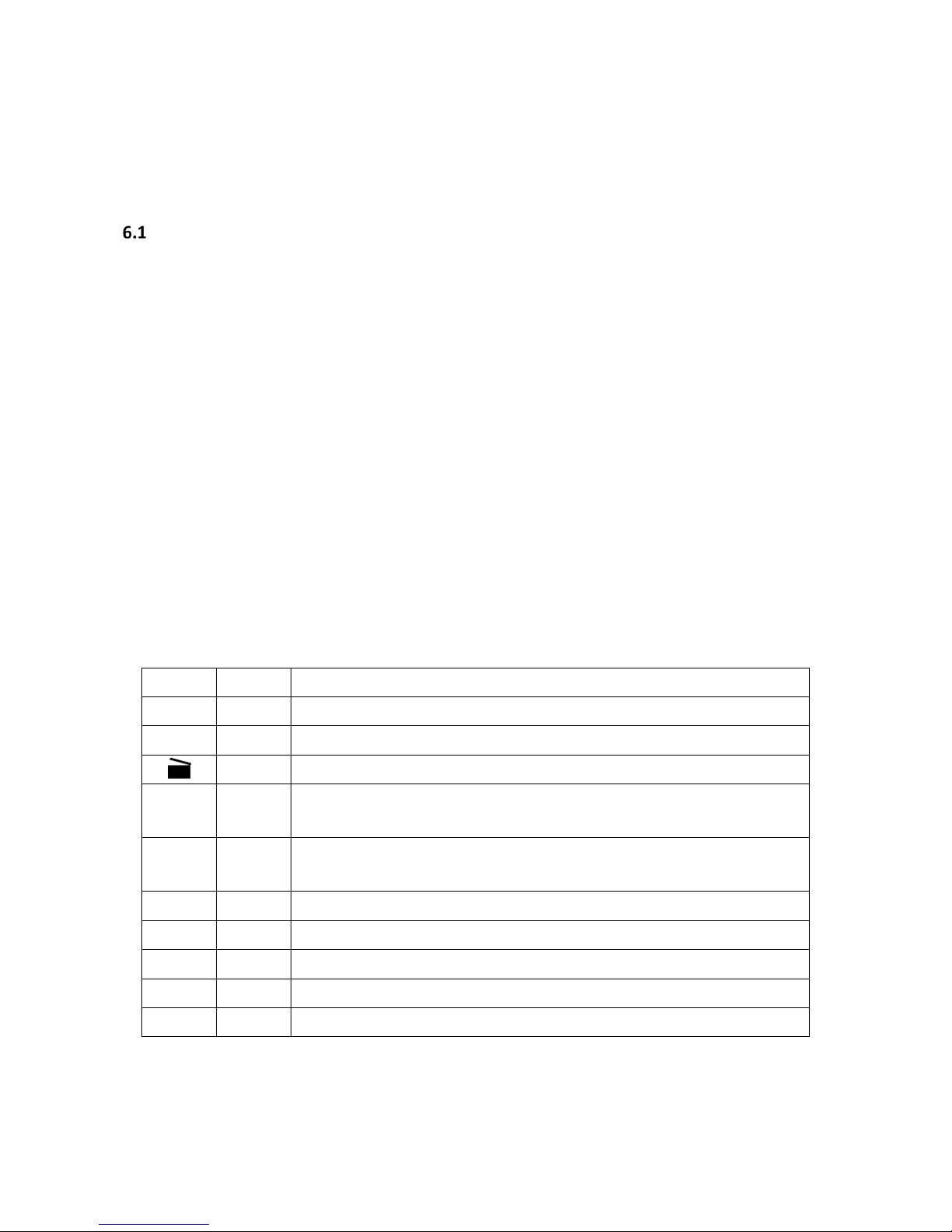

Control panel

The control panel placed on the front casing provides the control of the centrifuge operation.

Control panel

►►

SHORT1

short-time centrifuging

►

START

start centrifugation run

STOP2

end centrifugation run

LID

lid opening

FAST

COOL

start fast cooling mode, precool (Harrier R and Harrier RH only)

BACK/

OPTIONS

exit the current menu / mode type, choose options for simplified display (press and

hold for 1 s.)

▲

UP

navigation in-menu / increasing values

▼

DOWN

navigation in-menu / decreasing values

◄

LEFT

navigation in-menu

►

RIGHT

navigation in-menu

SET

SET

changing parameters / confirming changes

1

the centrifuge is working as long as the key is pressed

2

pressing once – will stop the centrifuging with acceleration features set in the current programme,

pressing twice – will make the centrifuging as fast as possible (quickest feature). During the setting of

parameters, you can use this button for exiting zones on the primary screen without introducing changes.

20

Display

The display is located in the centre of the control panel. The main screen variants are presented

below. In the user manual, examples of screens from the Harrier R/RH are shown. For Harrier (without

refrigeration), the temperature is not shown. The flashing of field on display mean it is ready to set. The

flashing of fields is visualised as highlighted in the user manual.

After switching on of centrifuge, the welcome

screen will appear. On the next screen, it is then

possible to set up parameters.

Simplified display mode is set as default, it is

possible to switch to normal (see chapter 9.3)

display mode (with two sub modes shown

below).

Normal display

RPM display mode

o

RCF display mode

Switching between RPM and RCF display mode

For normal display,

switch between RPM and RCF

display mode by pressing and

holding the key for 1s:

then select demand

mode.

Loading...

Loading...