Page 1

Instruction Manual

For

CENTAUR 2

CENTRIFUGE

READ BEFORE USE!

Models: MSB020.CX1.5

MSB020.CX1.1

71100-493-4

Page 2

Health and Safety at Work

MSE UK Ltd is required under the Health and Safety at Work Act, 1974 and other UK legislation as designers,

manufacturers, suppliers and importers of articles for use at work to ensure that, as far as is reasonably practicable,

articles which we design, produce, supply or import are safe and without risk to health.

We are required to provide information on the safety and handling precautions to be observed when installing,

operating, maintaining and servicing our products. Such advice is contained in this manual.

We are also obliged to update this information should circumstances change and to operate a system to this end.

We should also like to point out, however that you as users have an important responsibility in the provision

and maintenance of safe working practices and conditions.

Accordingly, we draw the following matters to your attention:

1. This apparatus should only be used as intended and within its design parameters by

suitably qualified and trained personnel who have read and understood the relevant

sections of this manual.

2. This manual should be readily available to such personnel at all times.

3. In addition to that which is written in the manual, normal common-sense safety precautions

must be taken at all times to avoid the possibility of accidents. Particular care is required

when working with apparatus at high temperature or pressure.

4. Installation, maintenance, repairs and servicing should only be carried out by a MSE (UK)

Ltd approved engineer, and suitably trained personnel should only carry out connection to

electrical supplies.

TECHNICAL SUPPORT, WARRANTY SERVICE AND MAINTENANCE

UK customers; if you are in any doubt whatsoever regarding the correct use of this apparatus, or if you require any

technical data or assistance, please contact the MSE UK Ltd Technical Support Department at:

MSE UK Ltd

Worsley Bridge Road Telephone +44 (0) 870 609 4097

Lower Sydenham Fax +44 (0) 208 650 8408

London E-mail: sales@mseuk.co.uk

SE26 5AZ Web Page: www.mseuk.co.uk

OVERSEAS CUSTOMERS: Should contact their local Distributor.

ELECTRICITY SUPPLIES: Voltage and frequency

MSE (UK) Ltd electrical apparatus is offered and labelled in a number of voltage ranges and, where necessary,

different frequencies of mains supply. MSE UK Ltd does not accept any responsibility for the operation of any such

apparatus should it be connected to electricity supplies which are normally outside, or vary outside, the stated

voltage and frequency values for which it is designed, nor for any consequential loss, damage or injury, howsoever

caused.

Page 3

MSE UK Ltd Warranty

Terms and Conditions

We hope that you do not have the need to use the extensive warranty cover that MSE UK Ltd.

extends to you. However should you have a problem, our prompt response is greatly helped if you have

filled in and posted the pre-paid Warranty Registration Card supplied with your new equipment.

This entitles you to a one-year warranty from the date of delivery. During this period, component

parts proven to be defective in materials or workmanship will be repaired or replaced at our expense.

Installation, commissioning and calibration are not covered by this warranty agreement. The MSE

approved service agent must be contacted for warranty determination and direction prior to any work

being carried out.

These warranties are only applicable to new products, and not second hand nor refurbished

products even if repaired by MSE UK Ltd. Any such products are covered by separate warranty terms and

conditions which will be made available on request.

Replacement or repair of component parts or equipment under this warranty shall not extend the

warranty to either the equipment or the component part beyond the original one-year warranty period

unless agreed in writing by MSE UK Ltd.

The above warranties are extended to the original purchaser upon full invoice payment. A

purchase receipt or other proof of purchase may be required before warranty service will be performed.

These warranties only cover failures due to defective workmanship which occur during the normal

operation of the product by the original purchaser, and not failures which result from accident, misuse,

abuse, neglect, mishandling, misapplication, alteration, faulty installation, electrical power fluctuations,

dust, or other environmental extremes, modification or service other than by an approved service agent or

following the written authority of the manufacturer, or damage that is attributable to acts of God.

Expendable items such as motor brushes, door seals, lid seals, "O" rings or lamps are excluded.

MSE UK Ltd, or its approved service agent, reserves the right to repair defective equipment on

the premises of the customer, or at a service station, at the sole discretion of MSE UK Ltd or their

approved agent. In the event of return to an approved service centre the customer is responsible for the

safe packaging of the instrument and notification to the service centre. Neither MSE UK Ltd nor its agents

are responsible for any damage occurring during shipment.

Specification and Material Changes: MSE UK Ltd reserves the right to supply our latest and

improved models at time of shipment.

Taxes: The prices quoted do not include any taxes imposed by the State or Country in which the

purchase was made.

Installation: Installation of all equipment shall be at the expense of the purchaser unless stated

otherwise. Access to the site, and the provision of required utilities e.g. Power, water and drainage to

suitable connections, will be the responsibility of the purchaser, and at the purchaser's expense.

Limitation of liability: In no event, whether as a result of breach of contract or warranty, shall MSE

UK Ltd be liable for any consequential or incidental damages including, but not limited to, loss of profit or

revenues, loss of use of the equipment or any associated equipment, down time costs, costs of substitute

equipment, costs of labour, costs due to delays or claims of purchaser's own customers for such

damages. The purchaser agrees to indemnify MSE Ltd and to hold them harmless from any and all

liability, claims, demands, actions, suits, expenses or costs, including attorney's fees relating to such

consequential or incidental damages.

All expressed and implied warranties, including the warranties of merchantable quality and fitness

for a particular purpose, are limited to the application period of one year.

Validity: Legal rights vary from country to country and states within countries, so some or all of

the exclusions or limitations listed above may not apply, but if any part of these conditions shall be found

to be unenforceable it shall not affect the validity or enforceability of the remainder of the conditions.

Page 4

ELECTRICITY SUPPLY

Before connecting this apparatus to the electricity supply, check the information given

on the apparatus rating plate and ensure that;

A) Your supply is single phase A.C. (alternating current) of the stated frequency

with neutral nominally at earth potential.

B) Your supply voltage is within the stated range.

C) The current rating is within the capacity of your outlet.

D) Your plug or electricity supply circuit is fitted with a suitable fuse.

220v - 240v 110v - 120v

Fuse rating 5 amp see note for 110V - 120V

WARNING! This apparatus must be earthed.

The wires in the mains lead are coloured in accordance with the following code;

220v - 240v 110v - 120v

Live Brown Black

Neutral Blue White

Earth Green and Yellow Green

Connect the wires to a non-reversible 3-pin plug as follows;

Green and Yellow or Green to terminal marked E (Earth), G (Ground), coloured Green

or Green and Yellow or marked with the Earth symbol.

Blue or White wires to terminal marked N (Neutral) or Common or coloured Blue.

Brown or Black wires to terminal marked L (Live) or Phase or coloured Brown.

Note 110v - 120v installations to comply with National and State Wiring Codes.

IMPORTANT Consult an electrician if in any doubt or if your supply system has any of

the following:

No earth.

A coloured code different from the above.

Reversible plugs.

Supply and return leads that are both above earth potential.

NOTE: Do not touch plug pins within two seconds of plug removal from socket.

Page 5

CONTENTS 5

1. IMPORTANT INFORMATION.................................................................................7

2. GENERAL DESCRIPTION.....................................................................................8

2.1 Controls And Indicators..................................................................................9

2.2 Centrifuge Bowl.............................................................................................10

2.3 Opening Lid Manually...................................................................................10

2.4 Specifications.................................................................................................10

3. INSTALLATION....................................................................................................12

3.1 Preparation.....................................................................................................12

3.2 Connecting To 3 Pin Plug.............................................................................12

3.3 Recommendation For Securing Centrifuge................................................13

4. ROTORS AND ACCESSORIES...........................................................................14

4.1 Installation Of Rotor......................................................................................14

4.2 Removal Of Rotor..........................................................................................14

4.3 Loading The Rotor.........................................................................................15

4.4 Rotor Speed....................................................................................................15

4.5 Rotors And Accessories Tables...................................................................16

4.5.1 4 Place Swing out rotor..................................................................................16

4.5.2 4 Place Swing out rotor..................................................................................17

4.5.3 8 Place Swing out rotor..................................................................................18

4.5.4 8 Place Angle rotor.........................................................................................19

4.5.5 12 Place Angle rotor.......................................................................................20

5. OPERATION.........................................................................................................21

5.1 Run Procedure...............................................................................................21

5.2 Stop Procedure..............................................................................................21

5.3 Imbalance.......................................................................................................21

5.4 Motor Thermal Cut-out..................................................................................21

5.5 Power Failure.................................................................................................21

5.6 Lid Safety Circuit...........................................................................................22

6. MAINTENANCE....................................................................................................23

6.1 Cleanliness.....................................................................................................23

6.2 Drive Shaft......................................................................................................23

6.3 Prevention Of Corrosion...............................................................................23

6.4 O-Rings...........................................................................................................23

6.5 Sterilisation ....................................................................................................23

6.6 Disinfecting ....................................................................................................23

6.7 Inspection Or Renewal Of Motor Brushes..................................................23

6.8 Renewing The Fuse.......................................................................................24

6.9 Removal And Replacement Of Centrifuge Bowl ........................................25

6.10 Lid Friction Adjustment.....................................................................25

7. SERVICING...........................................................................................................26

7.1 Calibration Of Speed Control.......................................................................26

7.2 Removal Of The Motor..................................................................................26

Page 6

CONTENTS 6

7.3 Adjustment Of Balance Detector..................................................................27

8. CIRCUIT DESCRIPTION......................................................................................29

8.1 Power Input ....................................................................................................29

8.2 Speed Control................................................................................................29

8.3 Tacho Circuit..................................................................................................29

8.4 Speed Indication............................................................................................30

8.5 Lid Safety Circuit...........................................................................................30

8.6 Balance Circuit...............................................................................................30

9. ESSENTIAL PARTS LIST....................................................................................32

9.1 Body Assembly..............................................................................................32

9.2 Lid and Associated Assembly......................................................................32

9.3 Motor Assembly.............................................................................................33

9.4 PCB ‘A’ Assembly..........................................................................................33

9.5 PCB ‘D’ Assembly..........................................................................................33

9.6 Instrument Chassis Assembly.....................................................................34

10. PRODUCT DISPOSAL - ISO 14001 COMPLIANCE......................................34

11. HOW TO OBTAIN SERVICE ON YOUR FALCON CENTRIFUGE ...............35

Page 7

GENERAL INFORMATION 7

1. IMPORTANT INFORMATION

The following general instructions, and the precautions regarding the

prevention of corrosion in rotors and accessories, as described under

MAINTENANCE, must be noted and carefully observed.

The maximum load should always be checked before commencing any operation. If

the sample has a relative density greater than 1.2, the maximum permissible speed of

the rotor should be calculated as given in this publication, and applied.

Any liquid spilt in the centrifuge should be removed immediately because corrosion is

a major cause of failure in centrifuges. Where particularly corrosive solutions are used,

the samples should be placed in sealed containers and all necessary precautions

observed. The following list gives some examples of corrosive liquids used, particularly

in the biochemical field:

Phenol/cresol/water, chloroform/isoamyl alcohol, salt solutions (especially ammonium

sulphate), solutions of ammonium hydroxide and solutions of acids such as

hydrochloric, trichloroacetic and perchloric acids.

It should be noted that many other substances used in different fields are often equally

corrosive. Users should always check whether or not a substance being used is

corrosive in order to take suitable precautions.

NOTE: The following materials are prohibited:

Flammable or explosive materials

Materials which chemically interact vigorously

The load must be distributed symmetrically round the rotating assembly so that it is

evenly balanced and complies with the manufacturer's instructions in this respect.

After use the sleeves and adaptors in centrifuge rotors should be removed to allow

thorough cleaning of rotors and accessories and so prevent corrosion.

Special care is necessary when using infective material in centrifuges. Containers,

when used with such materials, should be closed while being centrifuged and sterilised

immediately after use, using non-corrosive means.

NOTE: Sealed containers and related components are intended to be part of

biosafety systems such as are specified in international and national

biosafety guide lines, and cannot be relied on as the only means of safeguarding

workers and the environment when handling pathogenic

micro-organisms.

Care should be taken to preserve intact, sets of accessories which have been supplied

as sets, in which all the members possess closely similar weights.

It is advisable to have the centrifuge checked by a competent engineer, preferably the

manufacturer's representative, at least every six months.

Carbon brushes, whilst being of the highest quality obtainable are expressly excluded

from the guarantee. A spare set is included in the accessory pack. The method of

replacement is detailed in section 6.7 of this manual.

Page 8

GENERAL DESCRIPTION 8

2. GENERAL DESCRIPTION

The Centaur 2 centrifuge is CE marked in line with required European Directives

for Electromagnetic and Low Voltage Compatibility, see “Declaration of

Conformity” for EC Directive/standard used.

120v units designed for CSA approval to the following standards:

CAN/CSA C22.2 No. 1010.1-92

CAN/CSA C22.2 No. 1010.2.020-94

INDEPENDENT SPEED SENSING - 120 volt Machines only

To comply with certain USA standards the 120 volt machines are fitted with a

small window in the cover. This permits independent speed check directly from the

rotor with use of an optically coupled tachometer.

Page 9

GENERAL DESCRIPTION 9

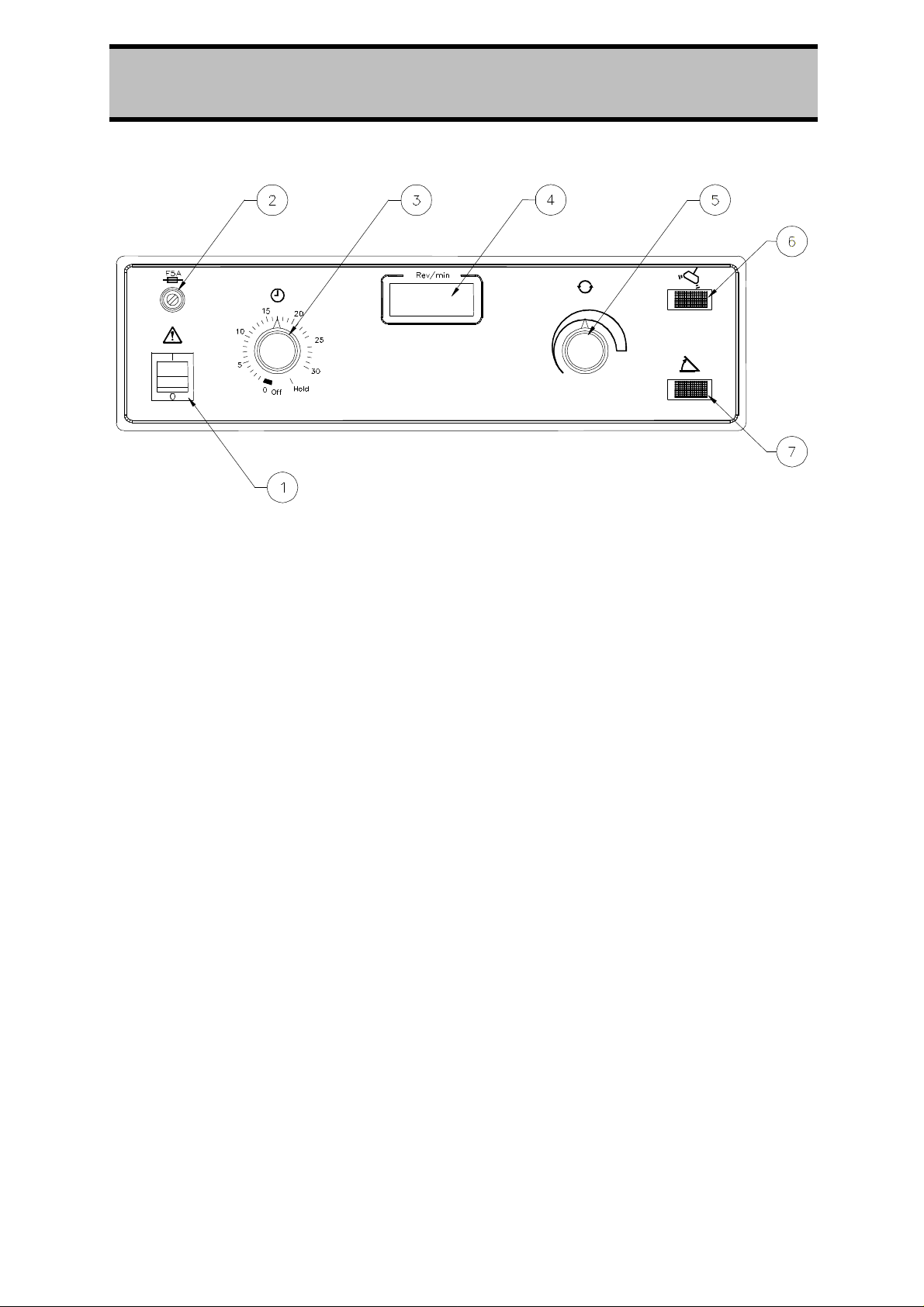

2.1 Controls And Indicators

Figure 1.

Control Panel of the Centaur 2 Centrifuge

1. The Power On rocker switch, when on (switch illuminated) connects power

through to various circuits and components within the centrifuge.

2. The Fuse Holder carries a 20mm long, 5 Amp glass cartridge fuse. It is easily

removable.

3. The Timer control allows a run period up to 30 minutes-selected by turning the

knob clockwise. When the time selected has run out, the rotor will automatically

run down to a stop. If required, the knob may be returned (anti-clockwise) to a

lesser time or to the Off position at will. It cannot be turned anti-clockwise

between the 'Hold' and '30' 'positions. The Hold position switches the centrifuge

for continuous running until manually reset to Off.

4. The Rev/min indicator is a digital display giving continuous read-out of the

rotational speed of the rotor, rounded off to the nearest hundred rev/min, e.g.

2500, 3200.

5.

The Speed control allows selection of any speed between 300 rev/min and the

maximum allowed for the rotor in use (see section 4.5 Rotors And Accessories

Tables) as indicated on the Rev/min digital display.

6. The Imbalance indicator lamp (Red) when on, gives warning that the rotor is

misloaded to a marked degree. In this event, drive to the rotor will cease and

the rotor will run down to a stop. Loading and balance must be checked and

corrected before re-starting the centrifuge.

7. The Lid Unlocked indicator lamp (Amber) when on, indicates that the rotor is

at a standstill and the lid may be opened safely. When the rotor is spinning the

lamp remains off and the lid is locked.

Page 10

GENERAL DESCRIPTION 10

2.2 Centrifuge Bowl

The centrifuge bowl is easily removable for cleaning or disinfection purposes see

section 6 (Maintenance).

2.3 Opening Lid Manually

An electrical interlock prevents the lid being opened while the rotor is turning, or

when the power is disconnected. If access to the rotor is required during a power

failure, insert the Lid Lock Release Key (supplied with accessories) to its fullest

extent, into the small hole on the top of the lid, near the front; move the point

towards the rear against a slight spring pressure to actuate the lid lock

mechanism. Press the lid actuator to the right and open the lid.

The lid is friction-controlled, to remain open at any intermediate position desired.

Front

Figure 2.

Manual Over-ride of Lid Lock

2.4 Specifications

Dimensions

Height 336mm (with lid open - 470mm)

Width 436mm

Depth 487mm

Weight 36kg (without rotor)

Power Supply

Input voltage and frequency.

Cat. No. MSB020.CX1.5 220/240V 50/60 Hz.

Cat. No. MSB020.CX1.1 110/120V 50/60 Hz.

Operating

Humidity MRH 80% up to 31°C decreasing linearly to 50% RH at 40°C

Altitude Up to 2000M

NOTE: Motor, as fitted, contains overtemperature cut-out device.

Page 11

GENERAL DESCRIPTION 11

Accessories Supplied With The Centrifuge

Part No. Description Quantity

32600.019 Fuse 5A (20mm) 1

76600.004 Lid Lock Release Key 1

88110.024 Lid Seal Insertion Tool 1

71100.493 Operating Manual 1

71100.958 Guarantee Card 240V 1

71100.1052 Guarantee Card 120V 1

82120.143 Spindle Nut 1

(for Rotors 34121-607, 34117-603, 34117-604 only)

Page 12

INSTALLATION 12

3. INSTALLATION

IMPORTANT: The rotor must not be fitted when moving or during transit.

3.1 Preparation

Remove the centrifuge from its packing and place it on a rigid, level surface.

Check that the available power supply corresponds to that stated on the voltage

plate fixed to the rear panel of the centrifuge.

NOTE: (i) An electrical interlock prevents the lid being opened unless the

centrifuge is connected to the power supply.

(ii) It is important that, at least, 100mm clearance is allowed at the

sides and rear of the centrifuge when placed in the final operating

position.

NOTE: Laboratory management procedures should require that no person or

any hazardous materials are within a 300mm boundary while the

centrifuge is operating.

3.2 Connecting To 3 Pin Plug

Connect the 3-core cable to a 3-pin plug fitted with a 5 Amp fuse as follows:

WARNING! This equipment must be earthed.

Brown wire to Live (L) Terminal

Blue wire to Neutral (N) Terminal

Yellow/Green wire to Earth (E) Terminal

Connect the centrifuge to the power supply and press the Power switch on. The

Power On and the Lid Unlocked indicators will come on. Push the lid lock actuator

to the right and open the lid.

NOTE: BS EN 61010-2-020 ‘Particular Requirements for Centrifuges’ states that

a remote switch, preferably adjacent to the room exit is a requirement

in case of unit malfunction.

Page 13

INSTALLATION 13

3.3 Recommendation For Securing Centrifuge

A Fixing Kit for securing the Centaur 2 centrifuge to a suitably sound worktop is for

securing centrifuge available from MSE as an optional accessory. It consists of an

anchor bracket which is secured to the bench, or table, by two screws with nuts

and washers; and two screws which screw into the body of the centrifuge to

secure it to the bracket. See Figure 3.

Figure 3

Securing Centrifuge to work surface using Bench fixing Kit

(Part No. 41159.188)

If the restraint kit is not used to secure the centrifuge on the bench then, it is the

recommendation of BS EN61010-2-020 that a clearance of 300mm is allowed

around the base of the centrifuge when in the final operating position.

NOTE: Laboratory management procedures should require that no person or any

hazardous materials are within a 300mm boundary while the centrifuge is

operating.

Figure 3a Recommended Clearances

Note: 75mm if solid surface (i.e. wall) otherwise 300mm

Page 14

ROTORS AND ACCESSORIES 14

4. ROTORS AND ACCESSORIES

4.1 Installation Of Rotor

Before fitting a rotor to the centrifuge ensure that the drive shaft is lightly smeared

with petroleum jelly. Check that the rotor is clean - particularly pockets in angle

rotors.

Locate the rotor on the drive shaft and, ensuring that the correct spindle nut for the

rotor in use is employed (see sections 0 & 4.5), engage and tighten the spindle nut

finger tight.

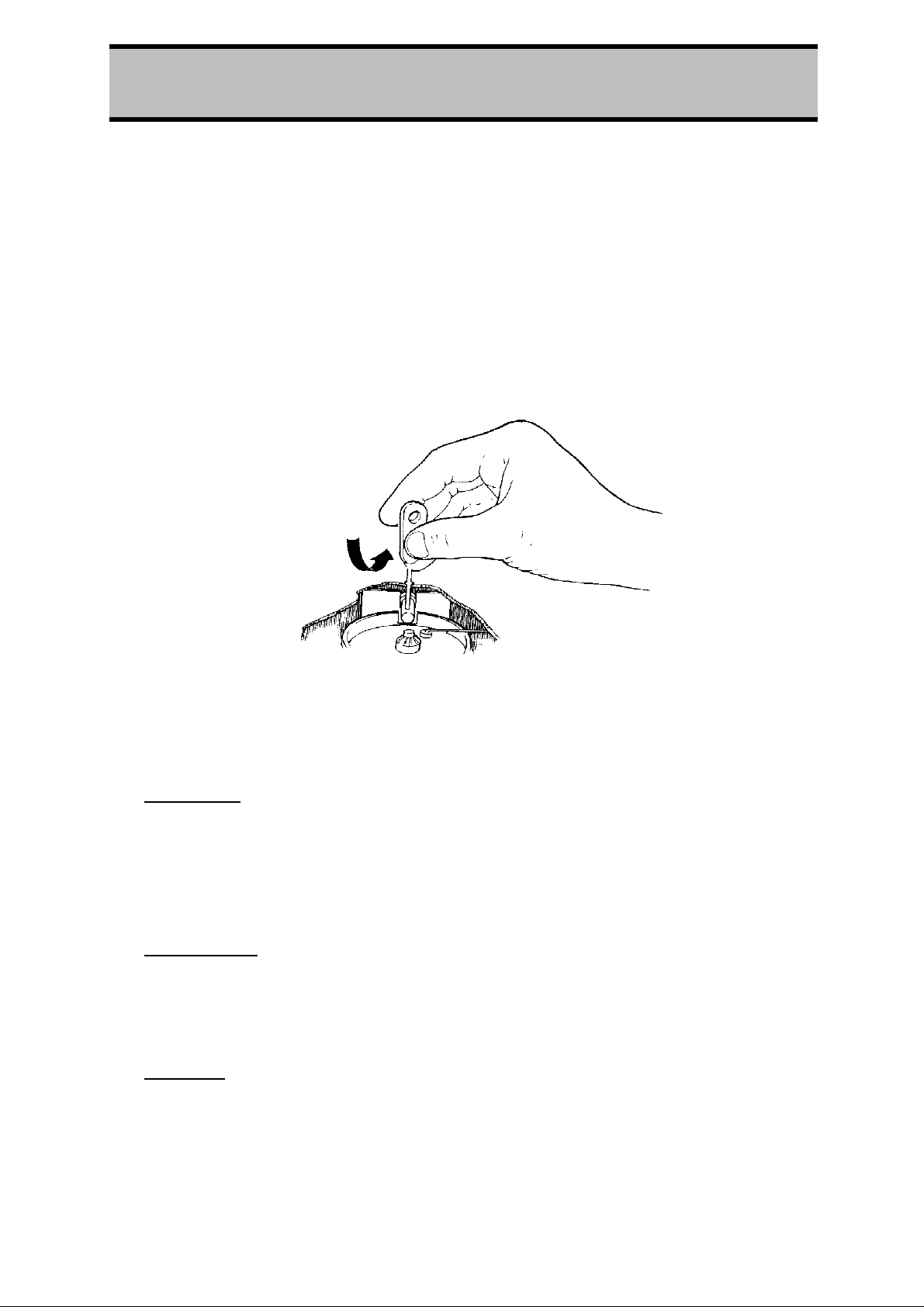

4.2 Removal Of Rotor

Press Power switch off. Open the centrifuge lid. Remove all rotor accessories, i.e.

buckets, trunnions etc. Loosen the spindle nut a few turns, grip the rotor as

illustrated in Figure 4 and pull upwards with the fingers whilst gently rocking the

rotor and applying downward pressure with the thumbs, to release it from the drive

shaft. Remove the nut and lift the rotor free.

Note: Do not attempt to loosen the rotor by tapping on the centrifuge motor

spindle.

Figure 4.

Removing Rotor from Drive Shaft

Page 15

ROTORS AND ACCESSORIES 15

4.3 Loading The Rotor

The rotors must carry a full complement of cups/buckets and/or trunnion rings, but

all cups/buckets need not be loaded. Loads must be placed symmetrically about

the rotor and opposing loads should balance to within 2 grams. Where possible,

balancing by sight is usually sufficient.

Before loading centrifuge tubes ensure that the appropriate colour coded-adapter

or rubber cushion is correctly positioned in the cup/bucket. Check that all tubes

project equally from the upper surface of the rotor.

Finally, if using a swing-out rotor, check that all cups of trunnion rings swing freely.

If necessary, apply a light smear of petroleum jelly to the rotor pivot slots.

Failure to load the rotor correctly can result in serious imbalance and possible

damage to the centrifuge.

Biologically hazardous material should only be centrifuged in sealed

buckets or cups.

4.4 Rotor Speed

Maximum Speeds of rotors (See section 4.5) are calculated on the basis of tubes

filled with a sample of specific gravity 1.2. If liquids of higher specific gravity are

used, the maximum speed of the rotor must be reduced according to the formula:

Where M = New maximum speed

N = Maximum rotor speed at 1.2 specific gravity

S = Specific gravity of sample used

Page 16

ROTORS AND ACCESSORIES 16

4.5 Rotors And Accessories Tables

The centrifuge complies with the requirements of BS4402 only when fitted with one of the following rotors.

* Max. rev/min at 240V or 110V ** Supplied as standard with buckets # Available as spares

Haem. Haematocrit tube Wass. Wasserman glass tube

4.5.1 4 Place Swing out rotor

43124-126

(includes spindle nut)

Cup

(Set of 4)

Sealed Cup

43551-121 - 4 x 200ml 3300 2000 57 116

43551-121 34159-302

43551-121 34159-301

43551-121 34159-304

43551-121 34159-303

43551-121 34159-305

43551-121 34159-306

Open Cup

34421-639 As above As above 3600 2200

Adaptor

(Set of 4)

(brown)

(yellow)

(green)

(grey)

(orange)

(blue)

Rotor

Capacity

4 x 100ml 3300 2000 39.5 113

4 x 50ml 3300 2000 29 113

28 x 15ml 3300 2000 17 110

16 x 10ml DSS 3300 2000 16.5 105

36 x 13∅ mm

48 x 12 ∅ mm

Max.*

Speed

3300 2000 13 110

3300 2000 12 110

Max.

RCF

Max. Tube Size

Dia

(mm)

Ht

(mm)

Page 17

ROTORS AND ACCESSORIES 17

4.5.2 4 Place Swing out rotor

34121-607

Bucket Trunnion Adaptor/

Cushion

Dia

34411-912 34134-604 34142-105** 4 x 100ml 3500 2246 42 125

Sealing cap 34144-308 4 x 50ml 3500 2246 29 120

43561-156 can be 34151-302 8 x 15ml 3500 2246 17 118

used if required 34153-302 20 x 7ml 3500 2246 13 118

34134-605 34142-104** 4 x 50ml 4200 3130 30 118

34411-909 34148-705 4 x 50ml 4200 3130 conical 29 112

Sealing cap assy 34141-114 4 x 1oz 4200 3130 Glass

43561-606 can be 34141-115 4 x 1oz 4200 3130 Sterilin

used if required 34144-307 4 x 15ml 4200 3130 17.5 110

34153-304 24 x Haem 4200 3130 7.7 120

34151-301 8 x Wass 4200 3130 12.7 120

34411-904 34136-102 34142-101** 8 x 15ml 4000 2612 17 120

34136-103 34142-101** 16 x 15ml 3400 2000 17 120

43161-103 16 x 15ml 3400 2000 conical 17 115

34148-101 16 x Haem. 3400 2000 7.7 120

34146-104 16 x 5 or 3ml 3400 2000 13 120

34146-103 16 x 2ml 3400 2000 12 100

34146-102 16 x 0.5 or 1ml 3400 2000 9 100

Rotor

Capacity

Max.*

Speed

Max.

RCF

Max. Tube Size

(mm)

(mm)

Ht

Page 18

ROTORS AND ACCESSORIES 18

4.5.3 8 Place Swing out rotor

43121-111

(includes buckets and spindle nut)

Bucket Trunnion Adaptor/

Cushion

Dia

34411-905# 34142-101** 8 x 15ml 3500 2200 17 115

Rotor

Capacity

Max.*

Speed

Max.

RCF

Max. Tube Size

(mm)

Ht

(mm)

Page 19

ROTORS AND ACCESSORIES 19

4.5.4 8 Place Angle rotor

34117-603

Bucket Trunnion Adaptor/

Cushion

Dia

34411-909 34142-104** 8 x 50ml 4600 3120 29 110

34411-909 34148-705 8 x 50ml 4600 3120 conical 29 110

34411-909 34141-114 8 x 1oz 4600 3120 Glass

34411-909 34141-115 8 x 1oz 4600 3120 Sterilin

34411-909 34144-307 8 x 15ml 4600 3120 17.5 110

34411-909 34153-304 48 x Haem. 4600 3120 7.7 120

34411-909 34151-301 16 x Wass. 4600 3120 12.7 120

Rotor

Capacity

Max.*

Speed

Max.

RCF

Max. Tube Size

(mm)

(mm)

Ht

Page 20

ROTORS AND ACCESSORIES 20

4.5.5 12 Place Angle rotor

34117-604

Bucket Trunnion Adaptor/

Cushion

Dia

34411-904 34142-101** 12 x 15ml 4600 3000 17 110

34411-904 43161-103 12 x 15ml 4600 3000 conical 17 110

34411-904 34148-101 12 x Haem. 4600 3000 7.7 110

34411-904 34146-104 12 x 5 or 3ml 4600 3000 13 120

34411-904 34146-103 12 x 2ml 4600 3000 12 100

34411-904 34146-102 12 x 0.5 or 1ml 4600 3000 9 100

Rotor

Capacity

Max.*

Speed

Max.

RCF

Max. Tube Size

(mm)

(mm)

Ht

Page 21

OPERATION 21

5. OPERATION

5.1 Run Procedure

Ensure that the Rotor is correctly loaded and secured and the Timer set at Off.

Close the lid and press down firmly. Press the Power switch on. The Power On

and the Lid Unlocked indicators will come on.

Select Timer to Hold, for continuous running, or to the time required. The lid will

now be locked - Lid Unlocked indicator off.

Select required speed (between 300 rev/min and the maximum speed of the rotor

in use, see section 4.5) by adjusting the Speed control until the required speed is

indicated on the Rev/min digital display. For repeat runs the Speed control need

not be moved from the position originally selected.

5.2 Stop Procedure

To terminate a run in the Hold mode, set the Timer switch to off and the rotor will

run down smoothly to a stop. In the Time mode the centrifuge will run down

automatically when the selected time has run out. In both modes automatic

braking is applied, and when the rotor has stopped, the Lid unlocked indicator will

come on. Open the lid; the Lid unlocked indicator will go off.

5.3 Imbalance

Should the imbalance indicator lamp come on, the centrifuge will run down. When

the digital panel meter indicates four zero’s, turn the Power switch and Timer to off

and wait thirty seconds, then turn the Power switch on. The lid unlocked indicator

will come on; open the lid; check the balance of the rotor; close the lid and restart

the run.

5.4 Motor Thermal Cut-out

The motor is fitted with a ‘self re-setting’ thermal cut-out to protect the motor from

over-heating. If the thermal cut-out has operated during a run the rotor will stop

and ‘0000’ will be displayed. The centrifuge will return to normal operation once

the motor has cooled.

IMPORTANT: ENSURE THAT THE VENTILATION SLOTS AT THE BACK ARE

NOT OBSTRUCTED IN ANY WAY.

5.5 Power Failure

If the mains power to the centrifuge is interrupted during a run, the rotor will coast

down to a stop and the lid will remain locked. Turn the Timer control to off.

When the power is restored, re-start the run as normal. If it is required to gain

access to the rotor during the power failure, use the Lid Lock Release Key (see

section 2.3).

If power failure occurs and the centrifuge is left unattended, subsequent

restoration of power will cause the centrifuge, if in the Hold mode, to run up to the

originally selected speed. If in the Time mode, the centrifuge will run up to speed

and continue for the time left on the Timer. If the selected time runs out during the

power failure, the lid will remain locked for an inherent delay period of

approximately 3½ minutes from the time of power failure, even if the power is

restored within this period.

Page 22

OPERATION 22

5.6 Lid Safety Circuit

The Lid Safety Circuit has a dual function:

i. It prevents power being switched to the motor until the lid is properly closed.

ii. It imposes a delay of approximately three and a half minutes in the event of a

tacho failure before the Lid Unlocked indicator comes on and the lid can be

opened.

Two micro-switches in the lid form part of the lid safety circuit. These can be

checked for correct operation as follows:

i. Press Power switch on and open the lid. The Lid Unlocked indicator lamp

should be off.

ii. Close the lid. The Lid Unlocked indicator lamp should come on. If the lamp

does not come on, check that the lid is firmly closed as this is the most likely

cause of malfunction .

iii. Switch the Timer to Hold or select a Time. The Lid Unlocked indicator should

go off. If this does not occur, then the Lid Locked microswitch has not

operated. Again, the most likely cause is improper closing of the lid.

Page 23

MAINTENANCE 23

6. MAINTENANCE

DISCONNECT THE CENTRIFUGE FROM THE POWER SUPPLY

User maintenance is minimal, being confined mainly to cleanliness and care of

rotors and accessories. Basic equipment maintenance must be carried out by a

qualified/competent electrician.

6.1 Cleanliness

Ensure that the body of the centrifuge is cleaned periodically to maintain a good

appearance. It is particularly essential to clean out the centrifuge bowl thoroughly,

especially when corrosive materials have been used. A soft cloth dampened in a

solution of mild detergent and warm water will serve for both purposes.

6.2 Drive Shaft

The centrifuge drive shaft should be cleaned periodically with a solvent to remove

excessive grease. When clean, the shaft should be re-lubricated lightly with

petroleum jelly.

6.3 Prevention Of Corrosion

Simple corrosion can usually be detected by eye and appears in the form of

pitting, or white, fluffy deposits on the surface of aluminium rotors. To prevent

corrosion, take care to avoid scratching the surface of rotors and/or accessories.

After use wash rotors, metal buckets, cups, carriers and adaptors in warm soapy

water, dry and store, inverted, in a dry place. Rotors should be protected with MSE

Rotor Spray (Cat. No.17341.151), which is an anti-corrosion and

de-waterising agent.

In addition, rotors should be periodically inspected by a responsible person so that

corrosion can be detected at the onset. Contact MSE (UK) Ltd Technical Support

for further advice on this subject.

6.4 O-Rings

Ensure O-Rings are lightly coated with silicone grease. Check O-Rings regularly

for cuts and abrasions. Seals should be replaced as necessary, or at least once a

year.

6.5 Sterilisation

Except for the 8-place swing-out rotor Cat. No. 43121.111, all rotors, buckets,

sealing caps (O-Rings removed) and the bowl may be sterilised by autoclaving at

120°C. See section 6.9 for bowl removal procedure. If the means available for

disinfection of certain microbiological agents are inadequate, the safety officer

should be consulted and appropriate steps taken

6.6 Disinfecting

The following cleaning fluids may be used

TERMINEX 2 (Available from Arrow Chemicals Ltd.)

VIRKON (Available from Antec International)

These cleaning agents if used as instructed by the manufacturer should not be

harmful to this product, or accessories supplied for use with this product.

WARNING: SOLVENTS OR GRITTY CLEANERS SHOULD NEVER BE USED

EXCESSIVE USE OF WATER SHOULD ALSO BE AVOIDED

6.7 Inspection Or Renewal Of Motor Brushes

Page 24

MAINTENANCE 24

The motor brushes should last for a minimum of 1000 hours of operation.

To renew brushes proceed as follows:

Open the lid and remove the rotor, close the lid, and disconnect the centrifuge

from the power supply.

Turn the centrifuge on to its back Unscrew and remove the two screws securing

the front rubber feet, and the other two screws that locate and secure the

instrument chassis to the base frame. Place corrugated cardboard or other

protection on the upper part of the centrifuge, then withdraw and lay the chassis

on top

Removing The Brushes

Unscrew the brush-retaining cap. The brush is held within a carrier against a

tensator roll spring. If the carrier does not spring free on removal of the cap, a thin,

stiff wire, hooked at one end may be used to assist. Do not use force. Gently

press the arms of the carrier together and withdraw the brush. On withdrawal, note

the position of the roll spring in the carrier in relation to the brush and motor as the

new brush must be fitted in the same manner. It will be seen that a small pin, fitted

near the rear end of the brush locates in a guide slot along one arm of the carrier.

Note that the free end (tongue) of the roll spring is held, near the end of one arm

of the carrier, facing in the direction of fitting.

Fitting New Brushes

Locate the new brush in the carrier with the pin located in the slot and the brush

pushed fully into the carrier against the tension of the roll spring Hold the

assembly together with the roll spring in the same relationship to brush and motor

as when the old brush was removed, and insert the front end into the brush

housing of the motor Take care to ensure that the 'tongue' of the roll spring lies,

facing forward, flat with the carrier (if not, gently press it down with a small

screwdriver) before pushing the assembly home into the brush housing. Note: If

the 'tongue is bent backwards against the carrier upon insertion, it may break off

and the spring will be ineffective Check that the carrier moves freely in and out

against the tension of the spring. Refit the brush-retaining cap and tighten fingertight. Replace and secure the instrument chassis and the rubber feet and turn the

centrifuge the right way up. Run the centrifuge with an unloaded rotor on the drive

shaft to a speed of 1000 rev/min for half-an-hour, to bed in the brushes.

6.8 Renewing The Fuse

To renew the fuse: disconnect the centrifuge from the power supply at the mains

plug. Unscrew the fuse holder cap and remove the fuse. Inspect and replace as

necessary with the correct rating. For 220V/240V model, the plug fuse may also

need to be checked. Fit the new fuse and refit the holder back into the receptacle.

If the fuse blows again during use, contact the local distributor, or MSE (UK) Ltd.

NB - If the fuse blows immediately or blows again during normal use, the power

supply should be disconnected and the service engineer called.

Page 25

MAINTENANCE 25

6.9 Removal And Replacement Of Centrifuge Bowl

To remove the bowl for cleaning or disinfection purposes proceed as follows:

Open the lid, disconnect the centrifuge from the power supply and remove the

rotor (if fitted).

Peel back the lip of the seal above the bowl vent (inside the bowl at right) note

position of the vent then lift the bowl by the vent hole above the seal at this point.

Now lift the bowl by the centre boss and work the seal lip away from around the

entire circumference of the bowl.

To refit the bowl:

Bend the lip of the seal to point upwards at any convenient position. Lower the

base of the bowl on to the seal and work the seal around the side of the bowl so

that the whole seal edge is pointing upwards and embracing the lower part of the

bowl. Lower the bowl, applying slight downward pressure with a twisting motion

and ease downwards until the seal lip is just under the bowl rim, with the vent in

the bowl in original (noted) position.

Insert the lid seal tool (Figure 5.) between the seal and the lip of the bowl and

ease the seal over the lip of the bowl while applying downward pressure on the

bowl centre boss. Work the tool round the rim of the bowl gently easing the seal

over the bowl. Exert further downward pressure on the boss to locate the bowl rim

in the recess of the seal.

Figure 5.

Use of lid seal tool

6.10 Lid Friction Adjustment

If the lid friction collar needs adjustment, e.g., because lid falls slowly downwards,

turn the socket screw, which is visible through the small hole located centrally near

the lower edge of the inside of the lid, using a 4mm socket wrench. Turning

clockwise will tighten, and anti-clockwise will loosen, friction resistance on the lid.

See Figure 6 (upper inset, annotation 20).

Page 26

SERVICING 26

7. SERVICING

This section has been included for the guidance of competent service

engineers only - preferably those trained by MSE (UK) Ltd.

7.1 Calibration Of Speed Control

Disconnect the centrifuge from the power supply Remove the instrument chassis

(see section 6.7 for removal instructions). Refit the two rubber feet temporarily and

set the centrifuge upright with the instrument panel at the front.

Connect 2 frequency metre to test points TP1 (ground) and TP2 (signal) at the

right hand side of the circuit board.

Place a correctly assembled and balanced rotor (see section 4) on the drive shaft,

close the lid and set the speed control and RV2 - PCB 'D' fully anti-clockwise, set

RV3 - PCB 'A' fully clockwise.

Switch on, turn the timer to ‘Hold’ and check that the rotor rotates slowly and the

centrifuge display indicates 100 rpm, if necessary, adjust RV2 - PCB 'A' (min

speed set) to achieve this condition.

Set the speed control fully clockwise, adjust RV1 - PCB 'A' until the frequency

meter reading matches half (1/2) that of the centrifuge display reading, adjustment

clockwise will increase the display reading whilst decreasing the meter reading

and vice-versa for anti-clockwise.

Adjust RV2 - PCB 'D' (max. speed set) so that the centrifuge runs at the highest

speed indicated on both the centrifuge and frequency meter displays.

7.2 Removal Of The Motor

Ensure that there is no rotor on the drive shaft. With the centrifuge turned on to its

back and the instrument chassis removed (section 6.7), remove the remaining

screws around the edges of the base plate. Making a note of terminations and

connections for reference, disconnect plugs and wires and remove the base-platewith-motor. The upper part of the motor is partially secured by the rubber support

disc in the body and can be pulled out.

Remove the three nuts and spring washers which secure the three rubber mounts

to the base plate. Remove the motor assembly from the base plate.

Remove the two hexagon screws, washers and spacers (note arrangement) and

remove the optical detector printed circuit board. Remove the screw in the lower

end of the motor and carefully remove the plastic tacho disc. The motor can now

be detached from the tacho box by removing the three small screws around the

centre of the tacho box.

Carefully note location and position of the motor support bush around the body of

the motor before removal. Remove the motor support bush and fit it to the new

motor as noted, before re-assembly.

Re-assembly of the motor to the tacho box and base plate is a reversal of removal

procedures. Ensure that the tacho disc is centred within the slot of the optical

detector. Ensure also that the three rubber mounts are not twisted during reassembly. Adjust balance detector as described in section 7.3.

Page 27

SERVICING 27

7.3 Adjustment Of Balance Detector

With the centrifuge upright and after operation with a loaded rotor for a few

minutes, to allow the motor to settle in its operating position, insert a 1mm thick

gauge between the microswitch actuator and the side of the tacho-box

(Item 6. Figure 6).

By turning the Balance detector adjusting screw, Item 7, Figure 6 adjust the

microswitch towards the side of the tacho-box until the microswitch just operates

(breaks).

Ensure that the microswitch operates (re-makes) when the gauge is removed.

Page 28

SERVICING 28

Figure 6

Partially Exploded View Of Centaur 2

Page 29

rev

Min

/

2

CIRCUIT DESCRIPTION 29

8. CIRCUIT DESCRIPTION

8.1 Power Input

A.C. mains power is fed to the centrifuge via a double-pole switch SW1, a 5 Amp

fuse FS1 and a filter. The Power switch SW1, when switched on, is illuminated by

a green neon lamp.

8.2 Speed Control

The motor current is phase-controlled by a series triac MR1 which is triggered by

an opto-isolator IC1. The L.E.D. of the opto-oscillator is driven by a section of the

transistor driver IC2 which in turn is fed from two cascaded Schmitt triggers IC4.

The input terminal of the first Schmitt trigger is connected to a 68nF capacitor,

which is discharged to approximately 1 Volt during each mains cross-over by IC2

pins 2, 15 and 3, 14. the Potentiometer RV2 (PCB A) sets the low end of the

speed range and RV2 (PCB D) set the maximum speed. RV4 is for speed control.

The pulse width generated by this circuit is linearly proportional to the speed

control resistance. There is, however, some non-linearity in the speed versus

speed-control angle characteristic because the pulse is used to "chop" a sine

wave in order to vary the speed.

The feedback network R18, MR10 discharges the capacitor to give a narrow

trigger pulse, thus reducing the power requirement on the 12 Volt supply to IC1.

Voltage is fed to the speed control network via the Lid Closed and the Lid Locked

micro-switches SW2 and SW3 and one contact of the Timer switch, SW4/1, so

that the motor is driven only when the lid is closed and locked and the Timer is set

to Hold; or a time is selected. The voltage is stabilised at about 9 Volts by R17,

MR7 and the 8.2 Volts supply.

Relay A is also fed through the two micro-switches and the Timer switch contact.

When Relay A is energised, the motor field and armature are connected in series

with each other and the triac MR1, across the 240 Volts mains input. With Relay A

released (which occurs when the Timer switches off), the armature is shortcircuited and a D.C. voltage is applied to the field. This applies a braking force to

the motor.

8.3 Tacho Circuit

The tacho input is taken from an opto-electronic chopper unit, which gives an

output of

Hz. This input switches VT1 which provides a fixed voltage (≈8V)

square wave to the Speed Indication and Lid Safety Circuits.

Page 30

CIRCUIT DESCRIPTION 30

8.4 Speed Indication

The output of VT1 is fed, via a Schmitt trigger, to a monostable circuit (IC3 pins 4,

5, 6, 8, 9 and 10). The pulse width is fixed by a time constant of 22 nf and a 50k

variable resistor RV1. The output pulses are fed to the digital display unit (PCB D)

where they are integrated to give a D.C. voltage proportional to speed.

The digital display unit consists of a 7107 analogue-to-digital converter/driver I.C.

and its associated components, driving two LED's. The two most significant digits

are driven by the 7107 to indicate the speed. The two least significant digits are

connected through twelve 1k resistors (RN1) to give a fixed 00 display.

8.5 Lid Safety Circuit

When the Timer switch is made, contact SW4/2 applies a voltage to charge up

C8. This sets one input of the NOR gate IC3 pins 11 to 13, to ‘1’, thus deenergising the Lid Solenoid and locking the lid.

When the Timer switches to ‘Off’ the charging current to C8 ceases, but the

discharge time constant is long enough to delay the energising of the solenoid for

about three-and-a-half minutes. This ensures that the lid cannot be opened before

the rotor has stopped.

To allow the lid to be opened as soon as the rotor stops, the circuit comprising:

IC4 pins 1, 2, 3, 4, 5 and 6; IC3 pins 1, 2 and 3, together with VT2, monitors that

the run-down is normal and if so, discharges the capacitor C8. The method

employed uses the outputs of two frequency discriminators: IC4 pins 5 and 6

(directly) and IC4 pins 1, 2, 3 and 4 (after a delay) as inputs to a NOR gate.

If the 60 rev/min discriminator operates sufficiently in advance of the 6 rev/min

circuit, then a pulse is generated by the NOR gate which switches on VT2, to

discharge the capacitor. Under failure conditions no pulse will be generated and

the lid will remain locked for about three-and-a-half minutes.

8.6 Balance Circuit

IC2 pins 4/13 and 5/12 form a bi-stable circuit, which is forced into the required

stable state at switch-on by the capacitor C5. In this stable state pin 13 is near

earth so that Relay A can be energised; and pin 12 is high so that the balance

lamp is off.

If the rotor is unbalanced sufficiently to cause the Balance microswitch to open

momentarily, the bi-stable circuit will switch over to its other stable state. IC2 pin

13 will then be high, de-energising the relay. Pin 12 will be low, switching the

Balance lamp LP2 on and removing the charging current to C8, so that the lid is

unlocked after about three-and-a-half minutes.

The bi-stable can be reset by switching the mains supply off for a few seconds

and then on again.

Page 31

CIRCUIT DESCRIPTION 31

Page 32

PARTS LIST 32

ESSENTIAL PARTS LIST

8.7 Body Assembly

Part No. Description Remarks

93600.078 Bowl Liner

26600.001 Bowl Seal

71500.055 Motor-Support Bush

96500.015 Retaining Ring

73050.002 Rubber Foot

96500.225 Black Plug Button

72100.121 Left-hand Side Panel

72100.120 Right-hand Side Panel

88120.040 Lid Stop

8.8 Lid and Associated Assembly

72900.045 Left-hand Torsion Spring

72900.046 Right-hand Torsion Spring

72100.122 Lid Handle

88120.039 Catch Pin

72900.048 Catch Spring

36020.028 Micro-Switch Lid Closed, SW2

36020.027 Micro-Switch Lid Lock, SW3

60800.001 Solenoid Lid Lock

72900.047 Solenoid Spring Lid Lock

72900.042 Spring Lid Lock

Page 33

PARTS LIST 33

8.9 Motor Assembly

Part No. Description Remarks

34400.159 Motor (for 220/240V - 50/60Hz)

34400.160 Motor (for 100/120V - 50/60Hz)

78070.013 Motor Seal

73030.001 Anti-vibration Mount

82120.143 Spindle Nut For rotors 34121.607

34117.603,

34117.604 only

72100.115 Tacho Disc

61080.036 Optical Tacho PCB Assembly

42050.003 Slotted Optical Switch

8.10 PCB ‘A’ Assembly

61080.043 Printed Circuit Board ‘A’ Assembly

43040.042 Opto-isolator 4N33 IC1

43040.029 Transistor Driver ULN2004 IC2

43030.003 Quad NOR Gate 4001 IC3

43030.002 Schmitt Trigger 74C14 or 40106 IC4

46060.039 Transistor BC184L, 30V 200mA NPN VT1, VT2

46080.013 Triac MR1

42040.012 Diode IN4002 MR2

42030.020 Diode Bridge KBPC 104 400V 2A MR3

42040.013 Diode IN4148 MR4, 5, 7, 8, 9, 10,

11, 12, 13, 14, 15,

16, 17

42020.024 Zener Diode BZX61, 8.2V 1.3W MR6

8.11 PCB ‘D’ Assembly

61080.079 Printed Circuit Board ‘D’ Assembly

43040.043 A to D Converter & LED Driver 7107 IC1

42050.004 2-digit LED.

42020.023 Zener Diode BZV85, 5V1 1.3W MR1

42040.013 Diode IN4148 MR2, 3

Page 34

PARTS LIST 34

8.12 Instrument Chassis Assembly

Part No. Description Remarks

32600.019 Fuse 5A (20mm)

32900.037 Fuse Holder

38700.046 Timer Switch, 30 min, 16A, 250V

44050.035 Potentiometer, Speed Control RV4

76070.099 Knob 28mm Black

76070.095 Knob 28mm Black

76070.096 Cap 28mm Black Speed/Timer Control

76070.097 Pointer 28mm Grey

36040.067 Rocker Switch 240V Power On

36040.068 Rocker Switch 110V

34060.013 Indicator Lamp, Red Imbalance

34020.087 Indicator Lamp, Amber Lid Unlocked

35080.046 Relay RLA

46100.003 Filter

38900.042 Transformer TR1

9. Product Disposal - ISO 14001 Compliance

This product should be treated as industrial waste and disposed of accordingly.

There are no toxic material used in the manufacture of this product. The

majority of materials used in this product are recyclable, and all can be disposed

of safely. Where the product has refrigeration, it is important that prior to

disposal the refrigerant gas is recovered by a qualified person. The insulation

material is non-toxic but could be an irritant. If removed from the product it

should be bagged and disposed of at an authorised site.

Page 35

HOW TO OBTAIN SERVICE 35

10. HOW TO OBTAIN SERVICE ON YOUR CENTRIFUGE

MSE UK Ltd is committed to giving our customers the best possible service. If

your centrifuge should require service at any time please follow these procedures:

All countries except UK, USA and CANADA - Contact your local MSE (UK) Ltd

distributor

UK only For all technical and service enquires contact: -

MSE (UK) Ltd

Worsley Bridge Road

Lower Sydenham

London

SE26 5AZ

Telephone +44 (0) 870 609 4097

Fax +44 (0) 208 650 8408

E-mail: sales@mseuk.co.uk

1. Contact the repairs centre - have the model, serial number, and date of purchase and

fault description available.

2. You will be given a return goods authorisation number and directions for shipping.

3. Remove all rotors, buckets and adapters. Do not ship these items - only the centrifuge.

4. Thoroughly clean and disinfect the centrifuge.

5. Fill out the attached service request form and place inside the centrifuge.

6. Pack in a protective box (preferably that in which the centrifuge was originally supplied).

7. MSE (UK) Ltd will specify the carrier to be used and will give details of how the freight is

to be charged.

Page 36

SERVICE REQUEST FORM

Should it become necessary to have your MSE centrifuge repaired, please take a few

moments to fill out this form, which will help us to ensure you receive the best and fastest

service possible.

Model:

...........................................................................

Serial number:

(on plate at back of unit)

...........................................................................

Date purchased: ...........................................................................

Where purchased: ...........................................................................

Brief description of fault: ...........................................................................

...........................................................................

...........................................................................

Date fault first occurred: ...........................................................................

Date repair centre contacted: ...........................................................................

Authorisation number: ...........................................................................

Condition of centrifuge: ...........................................................................

Has it been disinfected? Yes / No

Disinfectant used: ...........................................................................

Contact name: ...........................................................................

Address: ...........................................................................

...........................................................................

...........................................................................

Telephone Number: ...........................................................................

Signature: .........................................................................................................................

Loading...

Loading...