Above-the-Neck

Protection Solutions

Compatible safety products to protect your head, face, hearing, and vision

MSAsafety.com

1

Above-the-Neck Protection Solutions

Above-the-Neck Protection Solutions

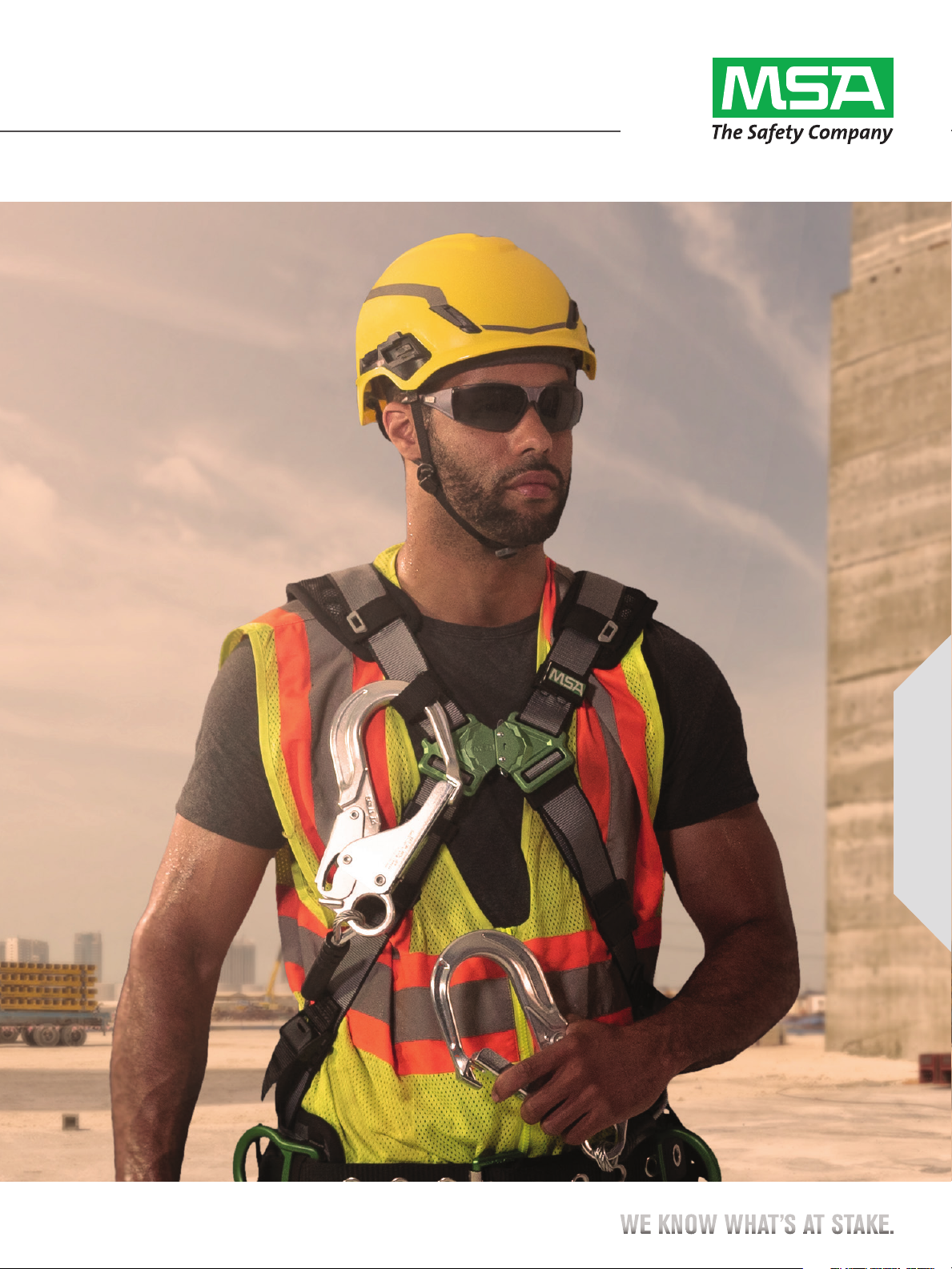

Join the millions around the globe

who choose MSA: For safety. For value.

This catalog highlights MSA’s comprehensive head, eye, face and

hearing (HEFH) protection line. Our hard hats, eye/face protection

products, helmet accessories, hearing protection products—and

more—provide seamless safety solutions to protect workers

around the world. For a complete product listing, see the most

recent MSA Safety Equipment Catalog, call our award-winning

customer service department, or visit MSAsafety.com.

Save money, increase revenue

and reduce inventory costs with our

comprehensive Above-the-Neck

safety solutions:

“Try It” sample program oers100+

•

leading MSA products, including

V-Gard Hard Hats, V-Gard Accessories,

left/RIGHT earmus, and Sightgard®

eyewear–completely FREE of charge!

Look for the that tells you which products

are in the program.

Our products are tested by engineers in our own

•

test facilities. They are also certied and/or

tested by qualied, third-party test houses.

Table of Contents

V-Gard® Protective Hard Hats .......................................................................................... 4–6

V-Gard GREEN Hard Hats .................................................................................................6

Replacement Suspensions for MSA Hard Hats .............................................................................7

Hard Hat Customization ............................................................................................... 8–9

V-Gard NFL Hard Hats ...............................................................................................10–11

V-Gard Freedom Series and Specialty Hard Hats ..........................................................................12

V-Gard Hydro Dip Hard Hats .............................................................................................13

V-Gard 500 Hard Hats ...................................................................................................14

Topgard® Hard Hats ....................................................................................................14

SmoothDome® Hard Hats ...............................................................................................15

Thermalgard® Hard Hats ................................................................................................15

Skullgard® Hard Hats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Super-V® Hard Hats .....................................................................................................16

2

2

Comfo-Cap® Hard Hats ..................................................................................................17

Bump Caps .............................................................................................................17

V-Gard H1 Safety Helmets ...........................................................................................18–19

V-Gard Accessory System ...........................................................................................20–29

V-Gard Frames ...............................................................................................20–22

V-Gard Visors ................................................................................................23–27

V-Gard Headgear ................................................................................................28

V-Gard Chin Protectors ...........................................................................................29

V-Gard Accessory System Kits .....................................................................................29

V-Gard Frameless Barrier .........................................................................................30

V-Gard Accessory Replacement Parts ..............................................................................30

Welding Shield and Adapters ........................................................................................31–32

Hard Hat Accessories ...............................................................................................33–35

Hearing Protection .................................................................................................36–37

Sightgard® Protective Eyewear ......................................................................................38–43

Sightgard Safety Glasses .....................................................................................38–41

Sightgard Safety Goggles ....................................................................................42–43

Eyewear Accessories .............................................................................................43

ANSI/ISEA Z89.1-2014 and CSA Z94.1-2015 (Industrial Head Protection Standards)

ANSI/ISEA Z89.1-2014 and CSA Z94.1-2015 voluntary industry standards establish

industrial helmet types and classes, providing performance and testing requirements.

These standards include specications for helmets designed to oer protection from top

and/or lateral impact.

Three classes included in these standards indicate helmet electrical insulation rating:

Class E (Electrical) – Helmets intended to reduce the danger of exposure to high-voltage

electrical conductors, proof-tested at 20,000 volts.

Class G (General) – Helmets intended to reduce the danger of exposure to low-voltage

electrical conductors, proof-tested at 2,200 volts.

Class C (Conductive) – Helmets do not provide protection from electrical conductors.

Industrial head protection test requirements per ANSI/ISEA Z89.1-2014 and CSA Z94.1-2015

are separated by helmet type: Type I helmets protect wearers from top impact, while Type II

helmets protect wearers from top and lateral impact. Test requirements for ANSI/ISEA Z89.12014 and CSA Z94.1-2015 are available from the Industrial Safety Equipment Association

(www.safetyequipment.org) and www.CSA.ca, respectively.

In addition to three non-mandatory tests for reverse donning [ ], lower temperature

[LT] and high-visibility [HV], the ANSI/ISEA Z89.1-2014 standard also includes these

provisions:

n Section 5: Accessories and Replacement Components

Revised standard includes language to further support the premise that accessory/

component manufacturers are responsible for proving that their products do not

cause helmets to fail.

n Section 6: Instructions and Markings

Clarication language was added to help customers understand that “useful service

life” for helmets is not required by the Standard, although helmet manufacturers

may choose to include it.

n Section 7.3.3 Higher Temperatures (HT)

Revision enables additional protection in response to needs of users who may

work within hot environments. Optional preconditioning at higher temperatures

of 60°C ± 2°C (140°F ± 3.6°F) has been added. (In the 2009 Standard, temperature

conditioning was 48.8°C ± 2°C (120°F ± 3.6°F).) If a helmet has been

pre-conditioned to 60°C ± 2°C (140°F ± 3.6°F), the helmet will be marked as HT.

In addition, new updates allow for exibility and inclusion of emerging and current

best manufacturing materials for higher temperature protection.

NOTE: the Standard does not address pre-conditioning that could be needed for temperature and

radiant heat extremes. To ensure that you have the proper head protection level needed for your

specic heat application, check with the manufacturer for stated usage of any helmet.

Non-Mandatory

ANSI/ISEA Z89.1-2014 Tests

Reverse Donning [ ]

To enable a helmet to be worn in

reverse, or a swing ratchet suspension

to be used in a helmet, that particular

helmet must be marked with the

“double-arrowed circle” to indicate that

it meets the non-mandatory reverse

donning test.

Lower Temperature [LT]

The traditional low temperature test

for a helmet is -18°C or 0°F. Helmets

that meet ANSI Z89.1 requirements

for LOWER temperatures (-30°C or

-22°F) can be marked with LT by the

manufacturer.

High-Visibility [HV]

Helmets that meet non-mandatory

requirements for high-visibility, including

special tests forchromaticity and

luminescence for added visibility, can be

marked with HV by the manufacturer.

Higher Temperature [HT]

The traditional pre-conditioning

temperature test for a helmet is 48.8°C

± 2°C (120°F ± 3.6°F). Helmets that

meet ANSI Z89.1 requirements for

HIGHER temperatures pre-conditioned

to 60°C ± 2°C (140°F ± 3.6°F) can be

marked with HT by the manufacturer.

HT does not indicate pre-conditioning

that could be needed to validate

temperature and radiant heat extremes.

3

3

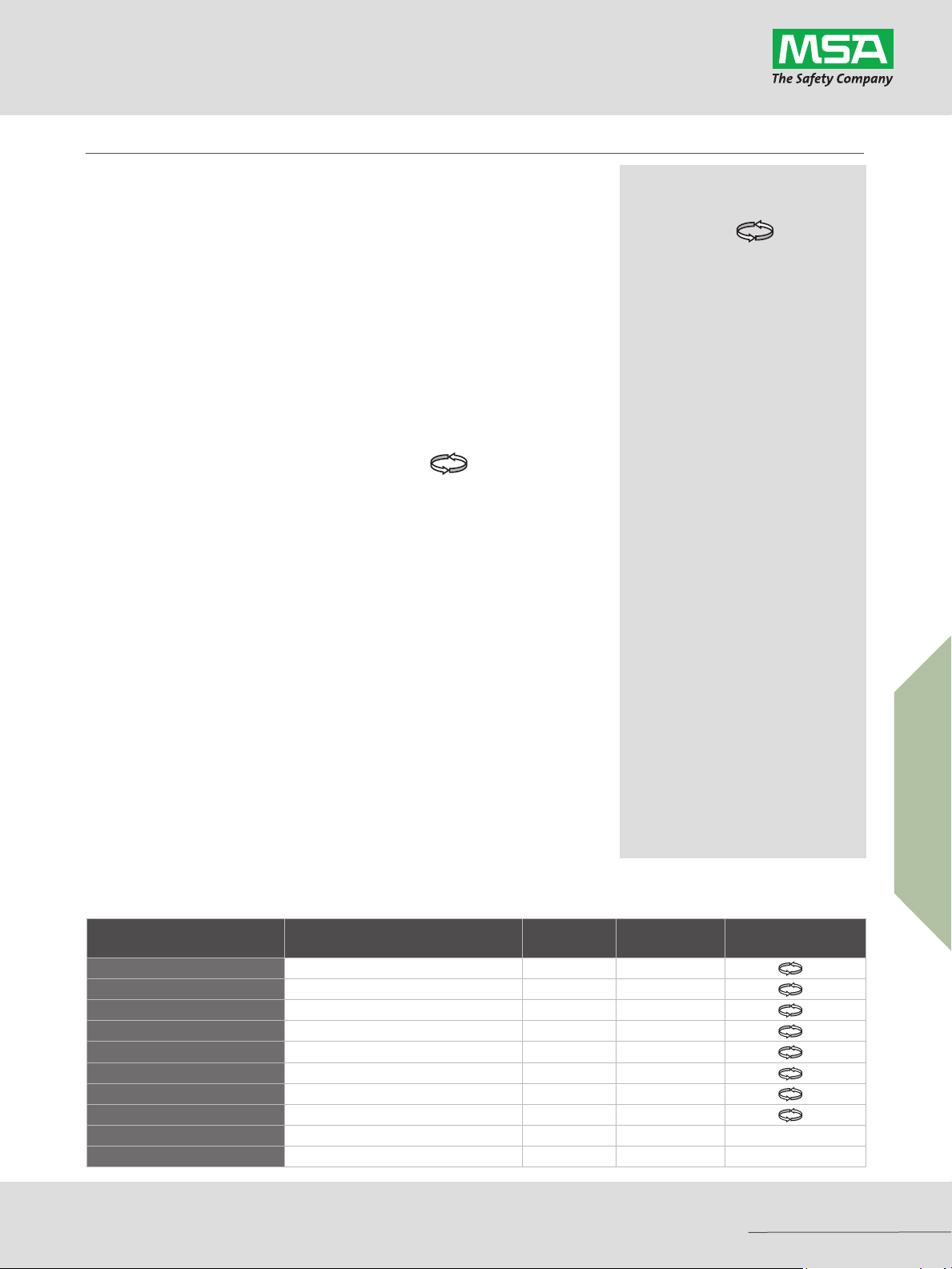

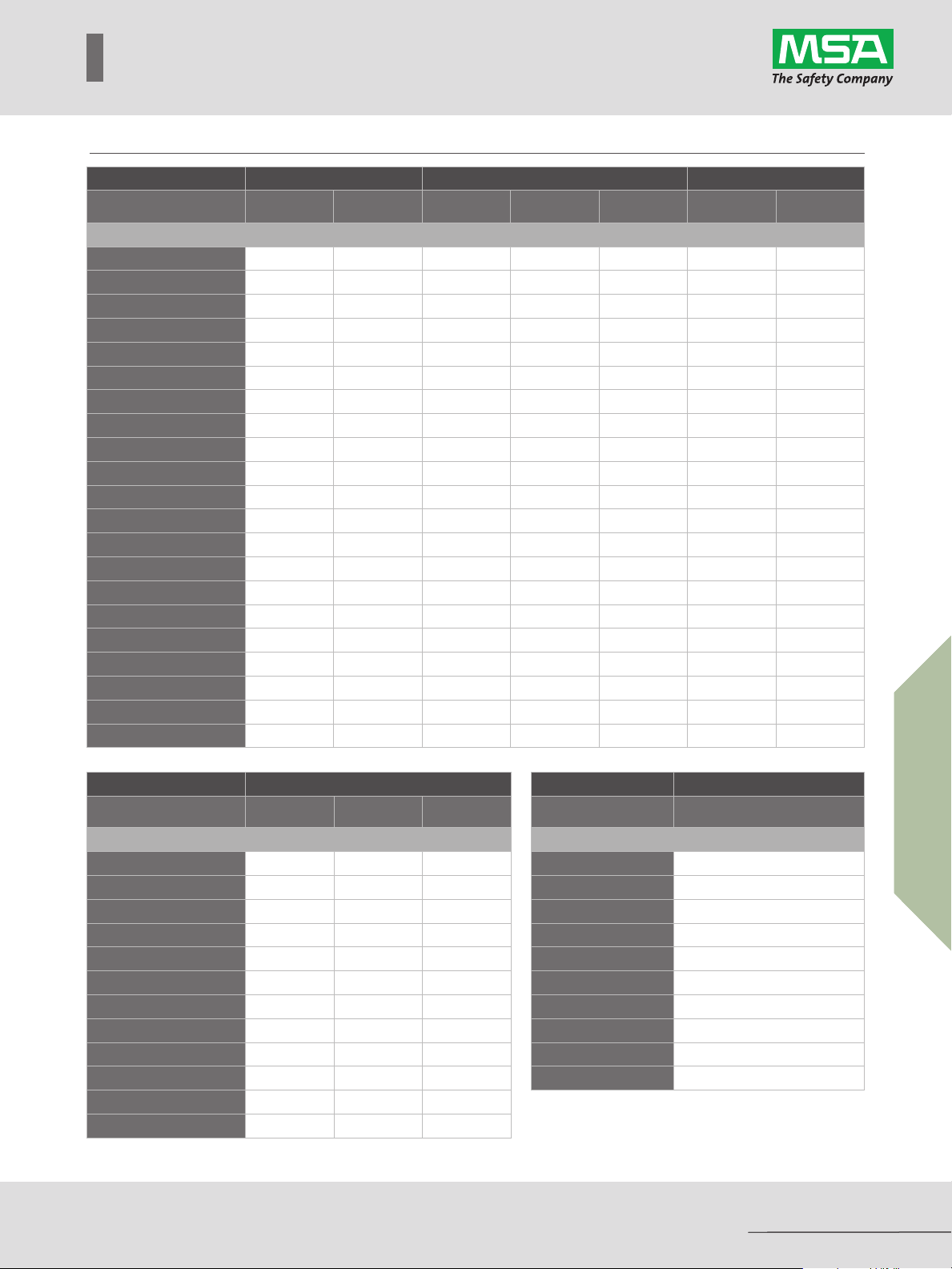

All MSA hard hats have been tested per the mandatory and non-mandatory ANSI/ISEA Z89.1-2014 and CSA Z94.1-2015 requirements,

as indicated. MSA oerings include:

MSA Hard Hat Standard(s) Type Class

V-Gard Cap/Hat ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class E HT/ /LT/HV

V-Gard GREEN Cap/Hat ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class E HT/ /LT/HV

V-Gard 500 Vented Cap/Hat ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class C HT/ /LT/HV

V-Gard 500 Non-Vented Cap/Hat ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class E HT/ /LT/HV

SmoothDome Cap ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class E HT/ /LT/HV

Topgard Cap/Hat ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class E HT/ /LT/HV

Thermalgard Cap ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type I Class G HT/ /LT/HV

Skullgard Cap/Hat ANSI/ISEA Z89.1-2014 Type I Class G HT/ /LT/HV

Super-V Cap ANSI/ISEA Z89.1-2014; CSA Z94.1-2015 Type II Class E HT/LT/HV

Comfo Cap ANSI/ISEA Z89.1-2014 Type I Class G HT/LT

For additional ANSI/ISEA Z89.1-2014 update details, please refer to MSA white paper ANSI/ISEA Z89.1-2014 American

National Standard for Industrial Head Protection (ID0600-66-MC / August 2014). This white paper is available as a FREE

download on any MSA industrial helmet page when you visit www. MSAsafety.com.

ANSI Z89

Non-Mandatory Tests

MSAsafety.com

MSAsafety.com

Above-the-Neck Protection Solutions

KNOW?

DID YOU

Above-the-Neck Protection Solutions

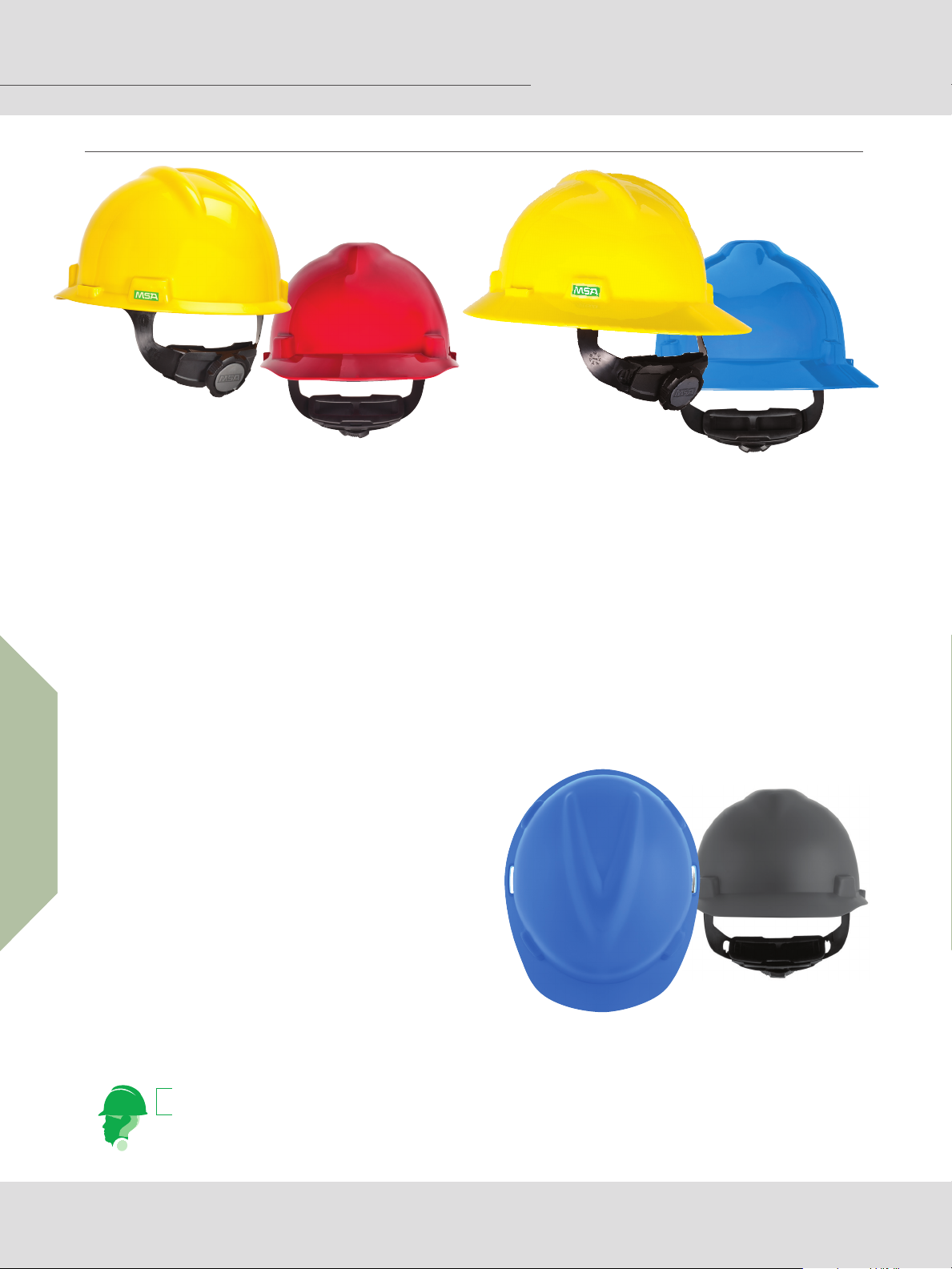

V-Gard Hard Hats

V-Gard Cap

with Fas-Trac III Suspension

V-Gard Full-Brim Hat

with Fas-Trac III Suspension

Gloss Finish

Classication ................................................................... Type I

Application ....................................................................... General purpose

Shell Material .................................................................. Polyethylene

Styles .................................................................................... Slotted cap; slotted full-brim hat

Colors ................................................................................... Cap-Style:

Sizes ...................................................................................... Cap-Style: small (6 – 71⁄8”); standard (61⁄2 – 8”); large (7– 81⁄2”)

Standards .......................................................................... ANSI/ISEA Z89.1-2014 (Class E); CSA Z94.1-2015 (Class E)

Certication ..................................................................... Third-party by SEI

Customization ................................................................ Imprinting and striping available (see pages 8–9)

Replacement Suspensions ..................................... See page 7

44

Matte Finish

Classication ................................. Type I

Application ..................................... General purpose

Shell Material ................................ Polyethylene

Styles .................................................. Slotted cap only

Colors ................................................. Cap-Style:

Full-Brim Hat:

Full-Brim Hat: standard (61⁄2 – 8”)

nnnnnnnn

nnnnnnnnnnnnnnnnnnnn

nnnnnnnnnn

Sizes .................................................... Cap-Style: standard (61⁄2 – 8”)

Standards ........................................ ANSI/ISEA Z89.1-2014 (Class E);

CSA Z94.1-2015 (Class E)

Certication ................................... Third-party by SEI

Customization .............................. Imprinting and striping available

(see pages 8–9)

Replacement Suspensions ... See page 7

All V-Gard Helmets have UV inhibitor molded right in.

Did you know that MSA oers a complete line of MSA hard hat accessories?

See pages 20–36 for more information.

V-Gard Hard Hats

Small V-Gard Slotted Cap Standard V-Gard Slotted Cap Large V-Gard Slotted Cap

Color

w/ Staz-On®

Suspension

COMPLETE VGARD ASSEMBLIES GLOSS FINISH

WHITE 466354 477477 463942 10057441 475358 473284 477482

BLUE 466355 477478 463943 10057442 475359 476928 477483

YELLOW 466356 477479 463944 10057443 475360 473285 477484

ORANGE — — 463945 10057444 475361 — —

RED — — 463947 10057446 475363 — —

GREEN — — 463946 10057445 475362 — —

GRAY — — 463948 10057447 475364 — —

HIVIZ® ORANGE

HIVIZ YELLOWGREEN

2

2

— — 488148 10057420 488146 — 489364

— — — 10061514 10061512 — —

BRIGHT LIME GREEN — 489368 815558 — 815565 — —

DARK CANADIAN BLUE — — — — 802972 — —

GOLD — — 464852 — 475365 — —

ROBIN’S EGG BLUE — — 463111 — 495853 — —

BROWN — — 464658 — 495854 — —

SILVER — — 484340 — 495855 — —

TAN — — 461180 — — — —

BLACK — — 475235 — 492559 — —

LIGHT BUFF — — 478237 — 495856 — —

PURPLE — — 488398 — 495858 — —

PINK — — — — 495862 — —

HOT PINK — — 10155231 — 10155230 — —

w/ Fas-Trac® III

Suspension

w/ Staz-On

1

Suspension

w/ 1 Touch®

Suspension

1

w/ Fas-Trac III

Suspension

w/ Staz-On

1

Suspension

w/ Fas-Trac III

Suspension

1

V- Gard Slotted Full-Brim Hat (Std)

Color

w/ Staz-On

Suspension

w/ 1 Touch

Suspension

1

w/ Fas-Trac III

Suspension

COMPLETE VGARD ASSEMBLIES GLOSS FINISH

WHITE 454733 10058321 475369

BLUE 454732 10058320 475368

YELLOW 454730 10058318 475366

ORANGE 454734 10058322 496075

RED 454736 10058324 475371

GREEN 454735 10058323 475370

GRAY 454731 10058319 475367

HIVIZ® ORANGE

HIVIZ YELLOWGREEN

2

489360 10058326 10021292

2

— 10061516 10061515

BRIGHT LIME GREEN 815562 — 815570

DARK CANADIAN BLUE — — 802975

HOT PINK 10156374 — 10156373

1

Certied to CSA.

2

V-Gard Cap/Hat meets voluntary standard for hi-visibility as prescribed by ANSI/ISEA Z89.1-2014.

Look for ocial hi-visibility marking [HV] on the helmet’s ANSI label.

V- Gard Slotted Cap (Std)

1

Color

w/ Fas-Trac III

Suspension

1

5

5

5

COMPLETE VGARD ASSEMBLIES MATTE FINISH

WHITE 10203081

BLUE 10203082

YELLOW 10203083

ORANGE 10203087

RED 10203086

GREEN 10203085

GRAY 10203084

HIVIZ® ORANGE

HIVIZ YELLOW

2

2

10203089

10203088

BLACK 10203092

MSAsafety.com

MSAsafety.com

Above-the-Neck Protection Solutions

KNOW?

DID YOU

Above-the-Neck Protection Solutions

V-Gard Hard Hat Special Assemblies

Standard V-Gard Slotted Cap V- Gard Slotted Full-Brim Hat

Color

SPECIAL VGARD ASSEMBLIES

HIVIZ ORANGE w/yellow-green stripe

HIVIZ YELLOWGREEN w/red-orange stripe

HIVIZ YELLOWGREEN w/silver stripe

WHITE w/lamp bracket and cord holder (Class C) 460018 — — 460069 — 815009

WHITE w/American Flag 474159 — — — — —

VGARD ASSEMBLY WITH SWINGRATCHET SUSPENSION

WHITE 10004689 Standard-size V-Gard Cap, w/Swing-Ratchet Suspension

w/ Staz-On

Suspension

2

— 10102195 10102193 — — —

2

— 10102234 10102233 — — —

2

— 10102196 10102194 — — —

w/ 1 Touch

Suspension

1

w/ Fas-Trac III

Suspension

w/ Staz-On

1

Suspension

w/ 1 Touch

Suspension

1

w/ Fas-Trac III

Suspension

1

V-Gard w/Swing-Ratchet Suspension

V-Gard w/Lamp Bracket and Cord Holder

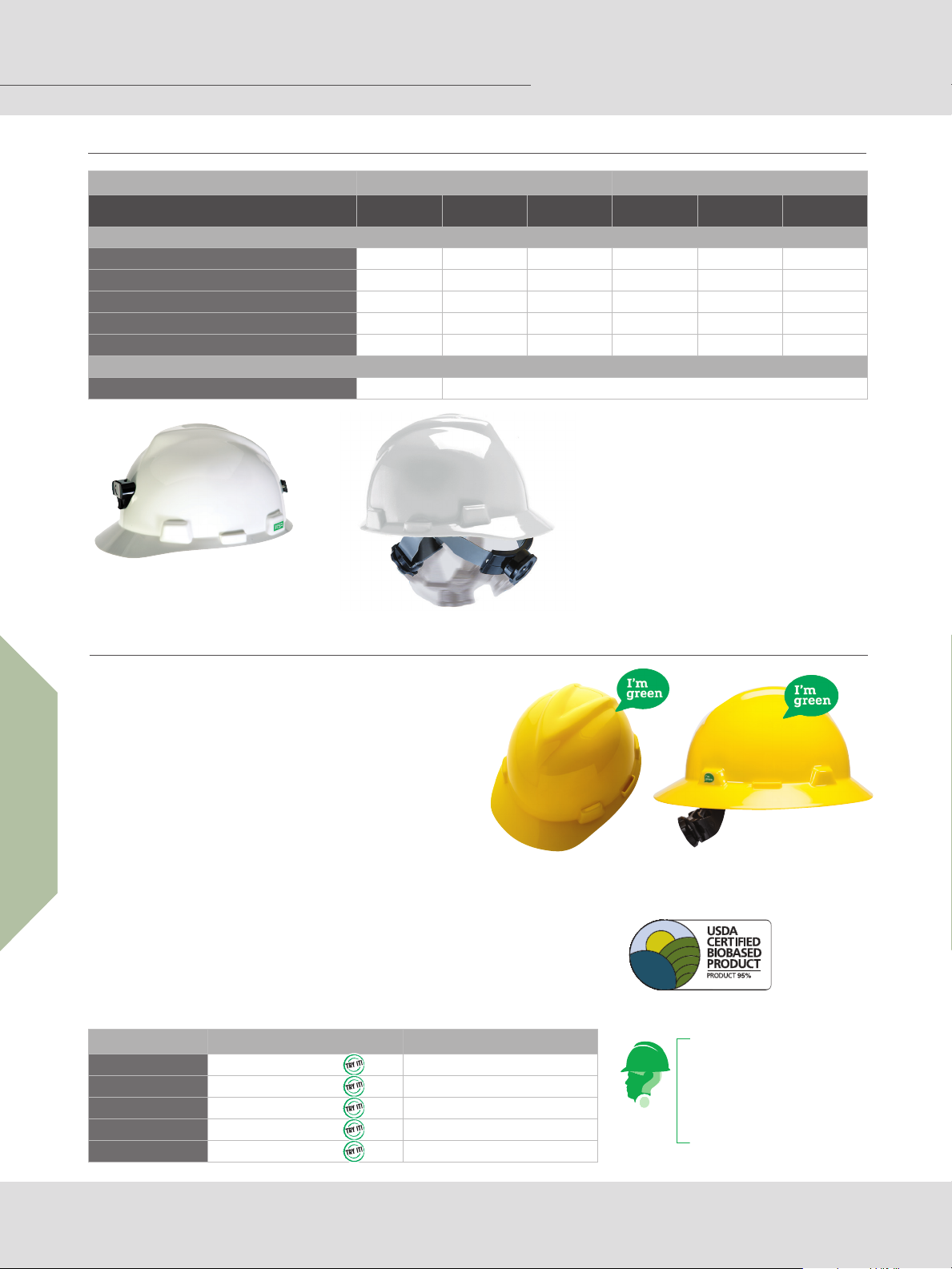

V-Gard® GREEN Hard Hats: the world’s rst hard hat made from renewable resources

V-Gard GREEN hard hats are constructed of renewable green

high-density polyethylene (GHDPE); traditional V-Gard Helmets

are manufactured through standard HDPE production methods.

V-Gard GREEN hard hats provide the same appearance and

quality as MSA V-Gard hard hat. Test results for V-Gard GREEN

helmet shells indicated 95% bio-based content.

66

Classication ................................. Type I

Application ..................................... General purpose

Shell Material ................................ Green high-density polyethylene (GHDPE)

Styles .................................................. Slotted cap with 4-point Fas-Trac® III Suspension; slotted full-brim hat with 4-point Fas-Trac® III Suspension

Colors .................................................

Sizes .................................................... Standard (61⁄2 – 8”)

Standards ........................................ ANSI/ISEA Z89.1-2014 (Class E); CSA Z94.1-2015 (Class E)

Certication ................................... Third-party by SEI; USDA Biobased Certied

Customization .............................. Imprinting and striping available (see pages 8–9)

Replacement Suspensions ... See page 7

nnnn

V-Gard GREEN Slotted Cap V- Gard GREEN Slotted Full-Brim Hat

WHITE 10150199 10160923

YELLOW 10150200 10160924

BLUE 10150221 10160925

GREEN 10150222 10160926

RED 10150223 10160927

1

Certied to CSA.

2

V-Gard Cap/Hat meets voluntary standard for hi-visibility as prescribed by ANSI/ISEA Z89.1-2014.

Look for ocial hi-visibility marking [HV] on the helmet’s ANSI label.

On average, production of each

V-Gard GREEN helmet removes

approximately 2 lbs. of CO

from the

2

atmosphere, according to the GHDPE

material supplier.

Replacement Suspensions for MSA Hard Hats

MSA Fas-Trac® III Ratchet Suspension

The MSA Fas-Trac III Suspension helps to reduce pressure headaches and pulled hair,

and stays on your head.

Sweatband fully covers headband and worker’s forehead

Three levels of nape strap adjustment for customized t

Lower nape strap improves retention

Smooth ratchet rotation and secure hold

Learn how the Fas-Trac III Suspension can relieve your headaches.

Visit www.MSAsafety.com/fastrac.

Fas-Trac III 1 Touch Staz-On Swing Ratchet

HELMET TYPE (SIZE)

VGARD CAP OR HAT STANDARD 10148708 10061123 10087218 816645

VGARD CAP SMALL 10148706 — 467386 —

VGARD CAP LARGE 10148707 — 492566 —

VGARD 500 CAP STANDARD 10148708 10061123 10087218 816645

VGARD 500 HAT STANDARD 10148708 — 10087218 —

SMOOTHDOME CAP STANDARD 10148708 10061123 10087218 816645

TOPGARD CAP OR HAT STANDARD 10153384 10061127 — 816648

THERMALGARD CAP STANDARD 10153384 10061127 — —

SKULLGARD CAP OR HAT STANDARD 10153385 10061128 454231 816654

SKULLGARD CAP LARGE 10126693 — 468096 —

SUPERV CAP STANDARD 10126683 — — —

VANGUARD CAP STANDARD 10153386 — — —

COMFOCAP STANDARD 10153385 10061128 454231 —

➍

SUSPENSION TYPE (4-point, unless otherwise noted)

u

➋

➌

1

7

7

The Fas-Trac III Suspension sweatband accessory keeps workers cool and dry.

Part No. Product Specics

10153518 • For use with MSA Fas-Trac® III Suspension

Use only the indicated MSA suspension in your MSA helmet. Do not mix suspension sizes and helmet sizes (i.e., putting a standard sized

suspension in a large helmet or any other mismatched combination). Do not use competitor suspensions in MSA helmets. Inspect your

suspension frequently. Suspensions should be replaced every 12 months, regardless of inspection results. Replace immediately (along with

the helmet), if an impact has occurred. Failure to follow these instructions will reduce the energy absorbing ability of the protective helmet to

receive impact, and could result in serious injury or death.

1

Swing ratchet size is 61⁄2” through 75⁄8”

• Optional, moisture-wicking and washable

• Can be attached/replaced while suspension is assembled in helmet

• Sold ONLY in packages of 10

MSAsafety.com

MSAsafety.com

Above-the-Neck Protection Solutions

Helmet Customization For 30+ Years

Practice makes perfect logos:

• MSA uses inks and processes that create durable logos.

We have never had a complaint about a logo “scratching

o” in the 30+ years we have been in the logo business!

• It can be tricky to avoid logo distortion due to the curvature

of the hard hat. That’s why MSA Logo Express® Service employs

graphic designers who process logos onto hard hats. These

skilled artisans ensure each logo is placed properly so it not

only endures, but also accurately represents your brand and

logo in color, size and shape–despite the curve of the hard hat.

• MSA oers multiple printing services from simple one-color

logo to digital photos, in up to four locations

• We don’t require “color-separated” artwork for 1+ color logos;

nor do we require customers to identify the PMS colors in their

logos. Our graphic artists can manage that, if you do not have

these details.

• Re-ordering is easy because we keep your logo on le until

you change it

1

.

Our Process

Once your order has been received by the MSA Logo Express

Service Design center we get to work. Files are imported from

your on-line hard hat conguration, assessed for usability and

colors separated (if the PMS colors have not been identied)

and layout nalized. Should you choose to personalize your

hard hat, don’t forget to complete form ID# 0617-17 and

submit with your order.

Delivery

Once the layout process is complete, our factory craftsman get

to work on your order. Your order for a new hard hat logo should

8

ship within eight (8) days from our Murrysville, PA plant from the

date we receive your approval on the artwork

2

.

Minimum Order Quantities (MOQ)

MSA requires MOQs, by hard hat type, for logoing and striping.

Qualifying MOQs of custom-imprinted or striped hard hats

must be of the same size, model and options (i.e., color and

suspension). MOQs are:

• 20 for V-Gard, SmoothDome®, Topgard, Comfo Cap Hard Hats,

and Nexus Climbing Helmets

• 16 for Skullgard or Thermalgard® Hard Hats

• 12 for Super-V and Vanguard Hard Hats

• 40 for Bump Caps

Striping

Add any of 27+ dierent reective and retro-reective stripes

to your hard hat. MSA reective stripes help enhance the

visibility of workers in daytime conditions, while retro-reective

3

stripes

oer additional enhancement in nighttime or low-light

conditions. Stripes are available in various sizes and shapes,

and can be placed on all types of MSA hard hats.

Keep in mind too, that while you can order more stripes for

self-application, MSA does not recommend doing this. The reason

for this is MSA pre-treats all hard hats prior to striping with an

electrical discharge treatment to enhance the ability of the stripes

adhesive bonds.

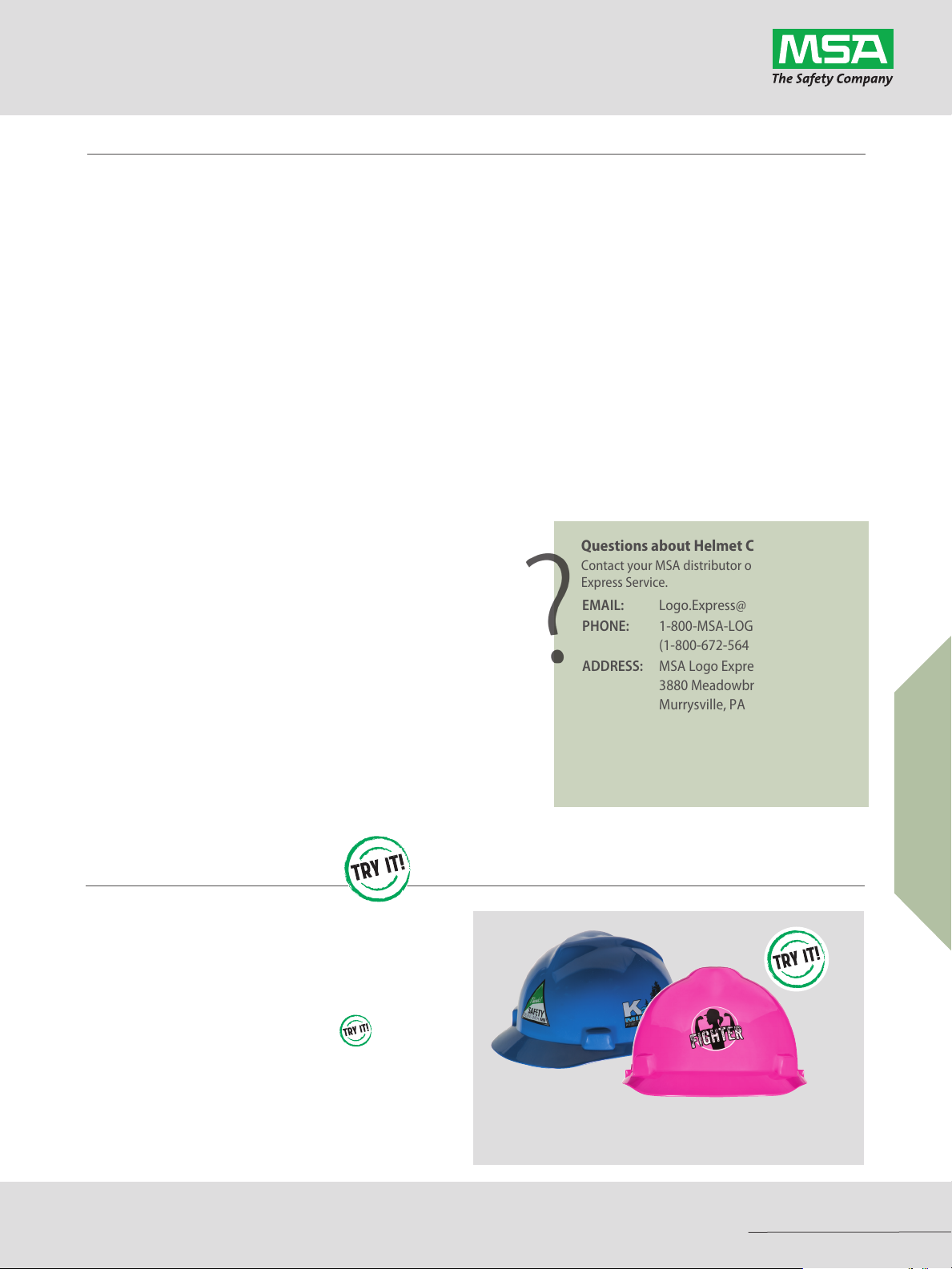

Stock Logos and Slogans

With 23 “pre-built” stock logos and slogans, MSA oers more

“o-the-shelf” hard hat graphics than anyone in the industry.

Our newest stock logos honor breast cancer survivors and

ghters everywhere. They were designed specically for use on

our new Hot Pink V-Gard, but work well on just about any MSA

hard hat! Standard logos make it easy for you to place emphasis

on safety, patriotism or personnel identication without having

to develop your own artwork. They can be can be used alone or

with your customized logo and striping.

Hard Hat Color Choices

MSA oers more stocked color options than competitors.

In fact, in our popular V-Gard hard hat, we oer 21 stocked colors,

including our newest: Hot Pink! There are non-stocked color

options available for all MSA hard hats; a qualifying MOQ of 100

hard hats is required.

Personalization

The same quality and precision that MSA logos have become

famous for is now available with personalization. You can add

your name, ID#, title, or anything else with this additional option.

Pricing

Please refer to your local distributor for pricing details on standard

and non-standard charges that may apply to your order.

1

Files are purged from MSA’s system if no logoed hard hat order is received within three (3) years of the rst order.

2

Orders for repeat logos ship within seven (7) days. This includes 2-3 days for order processing, and 5 days for production.

DID YOU

KNOW?

You can create a shell color of your choice.

You need only order a qualifying MOQ

of 500 hard hats or more.

Placing Customized Hard Hat Orders

Steps to complete your on-line logo conguration order:

1. Visit: http://webapps2.msasafety.com/logoexpress/#/intrologin

2. Select “No” when asked are you a distributor.

3. Select “Customize Now”.

4. Choose a standard.

5. Select your hard hat and click ”Customize It”.

6. Choose your size.

7. Choose your suspension (Fas-Trac III is recommended).

8. Choose your shell color.

9. Choose any striping you wish to include.

10. Upload your logo or chose from a stock logo.

• Logos cannot be trademarked or of any sports team

without the written consent of the logo owner.

• For optimum quality and turnaround, please submit

artwork as a vector le format.

• Acceptable formats include: CDR, AI, and EPS. Don’t have

a vector le? We also accept these formats: JPG, PDF, TIFF,

PNG, BMP and GIFs.

11. Place your order.

If you are the end user:

• Save and email.

• Review terms and click “Accept”.

• Complete form and send email to:

- Distributor Name

- Distributor Email

If you are a Channel Partner, you can place the order once you have

completed the logoing process OR you can enter in the code emailed

to you by the end user to nalize the ordering process.

Should you choose to personalize your hard hat, please complete

form ID #0617-17-MC and submit with order.

Please see “MSA Logo Express® Service

Artwork Guidelines” (ID 0617-06-MC) for details

on artwork submission. We can deliver your

custom hard hats faster if we have our preferred

artwork le formats, but we will work with

whatever you give us to recreate your logo.

Submit an electronic le of your artwork by email

(Logo.Express@MSAsafety.com) or by US Postal

Service:

MSA Logo Express

3880 Meadowbrook Rd.

Murrysville, PA 15668-1753

Be sure to include a copy of the completed Order

Form with your artwork submission.

Questions about Helmet Customization?

Contact your MSA distributor or MSA Logo

Express Service.

EMAIL: Logo.Express@msasafety.com

PHONE: 1-800-MSA-LOGO

?

ADDRESS: MSA Logo Express

us.msasafety.com/logoexpress

(1-800-672-5646)

3880 Meadowbrook Rd.

Murrysville, PA 15668-1753

Visit us on the web:

KEYWORD: Logo

9

The “Try-It” Sample Program

The “Try It” sample program oers some of the most

popular MSA head, eye, face and hearing protection

products, including V-Gard Helmets, V-Gard Accessories,

left/RIGHT Hearing Protection, and Sightgard® Eyewear—

completely FREE of charge! Look for the that tells

you which products are included in the program.

See what a logoed V-Gard Cap, Hat or 500 Helmet looks like. Pre-designed

logoed hard hat samples are available through the FREE sample Try It program.

Contact your MSA sales representative for more details.

MSAsafety.com

Above-the-Neck Protection Solutions

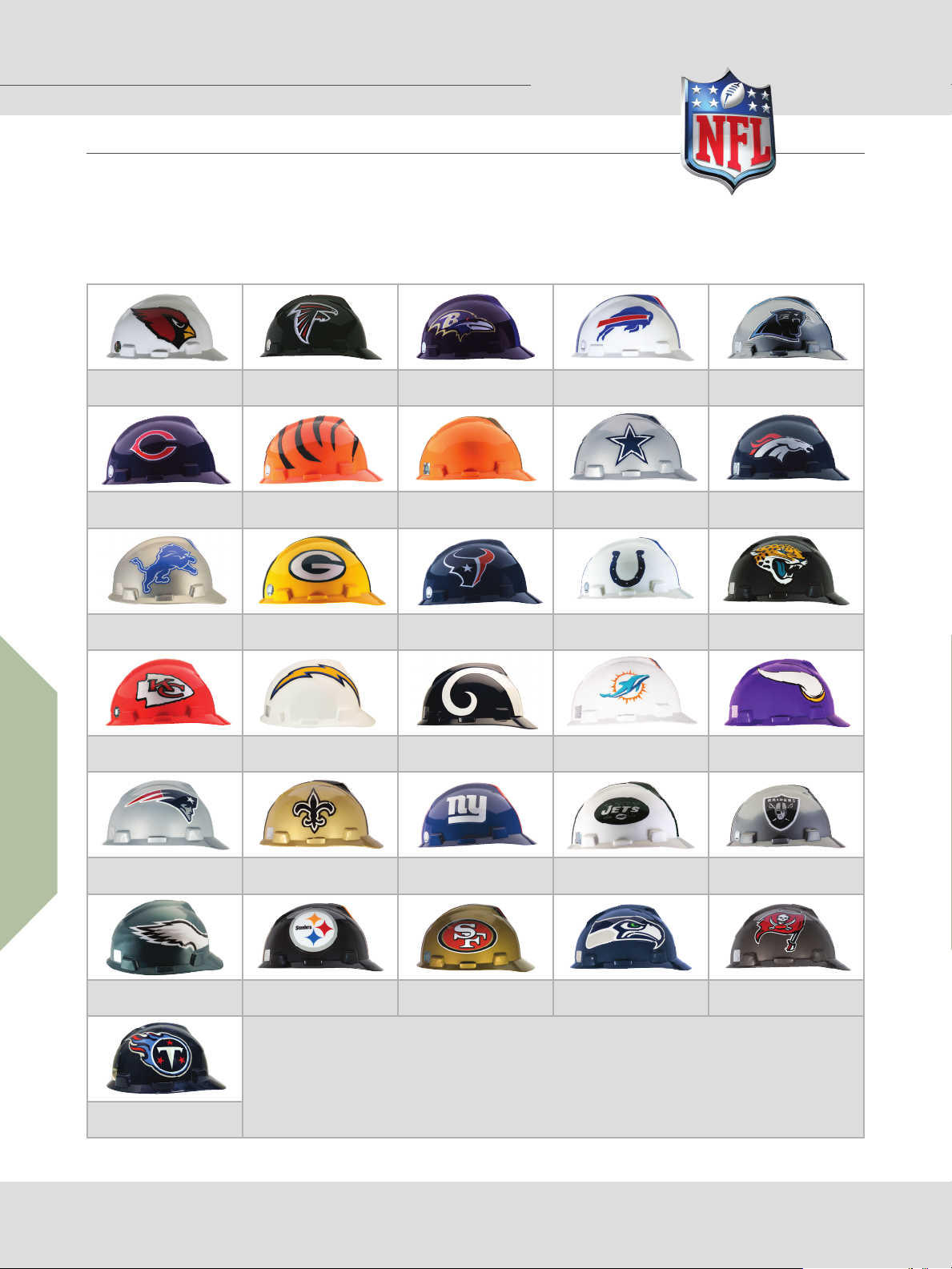

Ocially Licensed NFL V-Gard Hard Hats

Classication ...........................Type I

Application ...............................General purpose

Shell Material ..........................Polyethylene

Styles ............................................Slotted cap/hat

V-Gard NFL Cap-Style Hard Hats

Arizona Cardinals

Part No. 818384

Chicago Bears

Part No. 818389

Detroit Lions

Part No. 818394

Atlanta Falcons

Part No. 818385

Cincinnati Bengals

Part No. 818390

Green Bay Packers

Part No. 818395

Suspension ...............................Fas-Trac III

1

Sizes .............................................. Standard (6

⁄2 – 8”)

Standards ..................................ANSI/ISEA Z89.1-2014 (Class E); CSA Z94.1-2015 (Class E)

Certication .............................Third-party by SEI

Baltimore Ravens

Part No. 818386

Cleveland Browns

Part No. 818391

Houston Texans

Part No. 10031348

Bualo Bills

Part No. 818387

Dallas Cowboys

Part No. 818392

Indianapolis Colts

Part No. 818396

Carolina Panthers

Part No. 818388

Denver Broncos

Part No. 818393

Jacksonville Jaguars

Part No. 818397

10

Kansas City Chiefs

Part No. 818398

New England Patriots

Part No. 818401

Philadelphia Eagles

Part No. 818406

Los Angeles Chargers

Part No. 818408

New Orleans Saints

Part No. 818402

Pittsburgh Steelers

Part No. 818407

Los Angeles Rams

Part No. 818411

New York Giants

Part No. 818403

San Francisco 49ers

Part No. 818409

Miami Dolphins

Part No. 818399

New York Jets

Part No. 818404

Seattle Seahawks

Part No. 818410

Minnesota Vikings

Part No. 818400

Oakland Raiders

Part No. 818405

Tampa Bay Buccaneers

Part No. 818412

Tennessee Titans

Part No. 818413

NFL Properties, the NFL and its Member Clubs make no express or implied claims with respect to eectiveness and safety of these products and have not manufactured or endorsed these products in

any way.

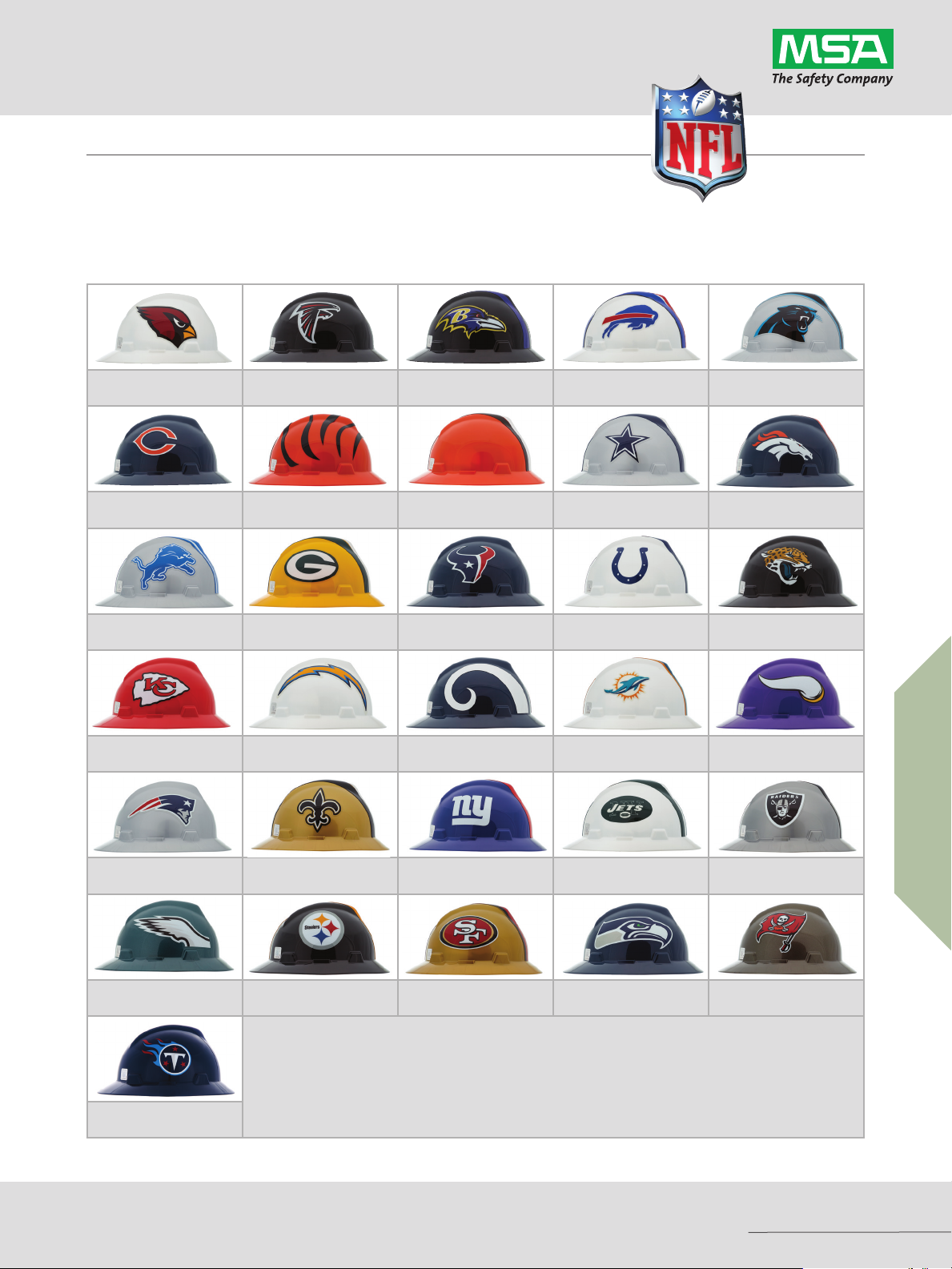

Ocially Licensed NFL V-Gard Hard Hats

Classication ...........................Type I

Application ...............................General purpose

Shell Material ..........................Polyethylene

Styles ............................................Slotted cap/hat

V-Gard NFL Full-Brim Hard Hats

Arizona Cardinals

Part No. 10194742

Chicago Bears

Part No. 10194747

Detroit Lions

Part No. 10194752

Atlanta Falcons

Part No. 10194743

Cincinnati Bengals

Part No. 10194748

Green Bay Packers

Part No. 10194753

Suspension ...............................Fas-Trac III

1

Sizes .............................................. Standard (6

⁄2 – 8”)

Standards ..................................ANSI/ISEA Z89.1-2014 (Class E); CSA Z94.1-2015 (Class E)

Certication .............................Third-party by SEI

Baltimore Ravens

Part No. 10194744

Cleveland Browns

Part No. 10194749

Houston Texans

Part No. 10194754

Bualo Bills

Part No. 10194745

Dallas Cowboys

Part No. 10194750

Indianapolis Colts

Part No. 10194755

Carolina Panthers

Part No. 10194746

Denver Broncos

Part No. 10194751

Jacksonville Jaguars

Part No. 10194769

Kansas City Chiefs

Part No. 10194770

New England Patriots

Part No. 10194773

Philadelphia Eagles

Part No. 10194778

Los Angeles Chargers

Part No. 10194780

New Orleans Saints

Part No. 10194774

Pittsburgh Steelers

Part No. 10194779

Los Angeles Rams

Part No. 10194811

New York Giants

Part No. 10194775

San Francisco 49ers

Part No. 10194781

Miami Dolphins

Part No. 10194771

New York Jets

Part No. 10194776

Seattle Seahawks

Part No. 10194782

Tennessee Titans

Part No. 10194813

NFL Properties, the NFL and its Member Clubs make no express or implied claims with respect to eectiveness and safety of these products and have

not manufactured or endorsed these products in any way.

Minnesota Vikings

Part No. 10194772

11

Oakland Raiders

Part No. 10194777

Tampa Bay Buccaneers

Part No. 10194812

MSAsafety.com

Above-the-Neck Protection Solutions

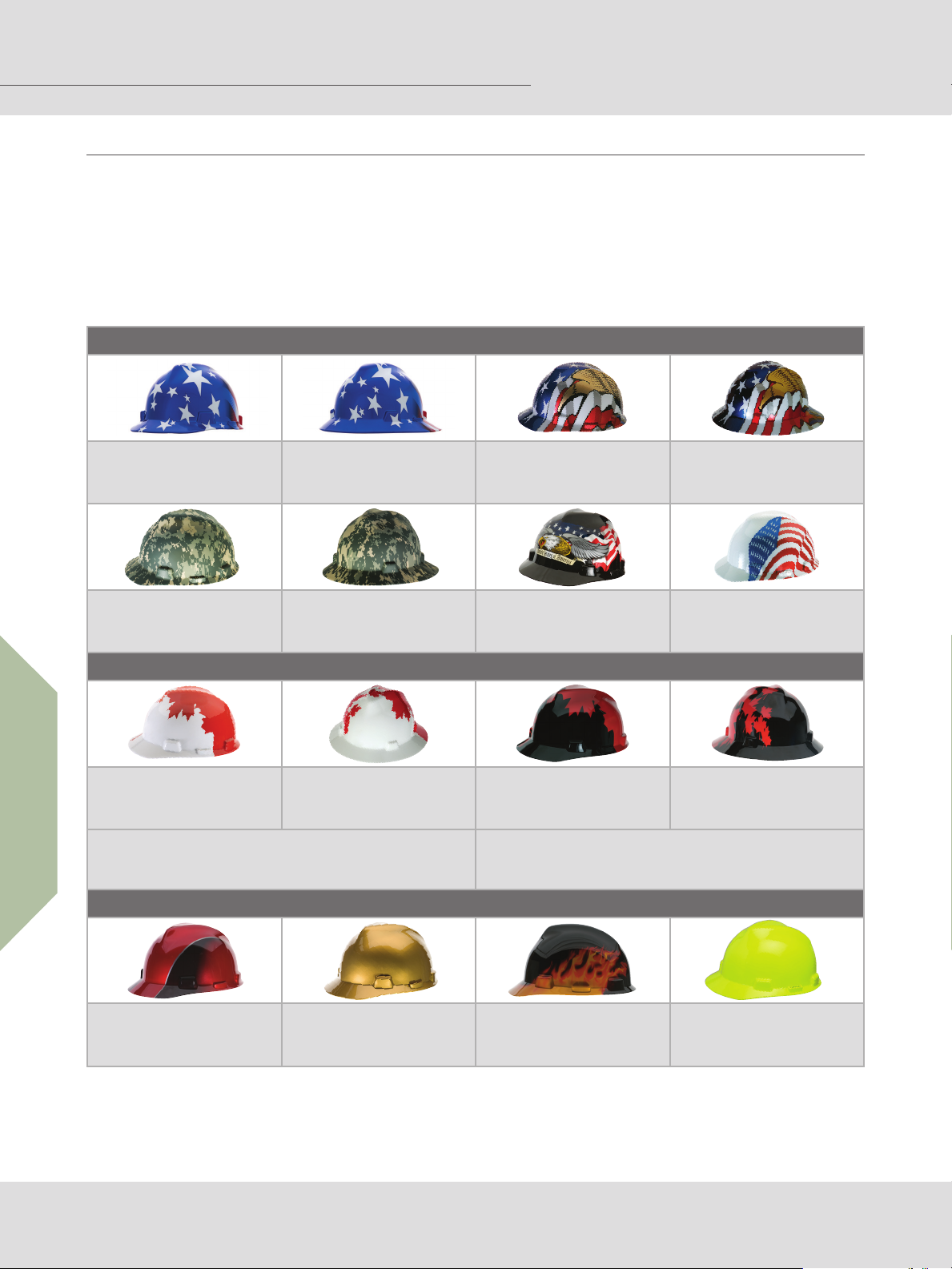

Freedom Series™ and Specialty V-Gard Hard Hats

Classication .........................Type I

Application .............................General purpose

Shell Material ........................Polyethylene with thermoformed graphics

Styles ..........................................Slotted cap;

Slotted full-brim hat (Freedom Series only)

Suspension .............................Fas-Trac III

1

Sizes ............................................Standard (6

⁄2 – 8”)

American Freedom Series Assemblies

American Stars and Stripes

V-Gard Slotted Cap

Part No. 10052945

Camouage

V-Gard Slotted Cap

Part No. 10103908

American Stars and Stripes

V-Gard Slotted Hat

Part No. 10071157

Camouage

V-Gard Slotted Hat

Part No. 10104254

Standards ................................ANSI/ISEA Z89.1-2014 (Class E);

CSA Z94.1-2015 (Class E)

Certication ...........................Third-party by SEI

Customization ......................Imprinting and striping available

(see pages 8–9)

Replacement

Suspensions ...........................See page 7

American Flag w/2 Eagles

V-Gard Slotted Cap

Part No. 10052947

American Eagle

V-Gard Slotted Cap

Part No. 10079479

American Flag w/2 Eagles

V-Gard Slotted Hat

Part No. 10071159

Dual American Flag

V-Gard Slotted Cap

Part No. 10050611

12

Canadian Freedom Series Assemblies

White w/Red Maple Leaf

V-Gard Slotted Cap

Part No. 10050613

Camouage w/Canadian Flag on front1

V-Gard Slotted Cap

Part No. 10104925

Specialty V-Gard Assemblies

Rally Cap

V-Gard Slotted Cap

Part No. 10103908

White w/Red Maple Leaf

V-Gard Slotted Hat

Part No. 10082234

Metallic Gold

V-Gard Slotted Cap

Part No. 10103908

Black w/Red Maple Leaf

V-Gard Slotted Cap

Part No. 10082233

Black Fire

V-Gard Slotted Cap

Part No. 10103908

Black w/Red Maple Leaf

V-Gard Slotted Hat

Part No. 10082235

Extreme Hi-Viz Cap2

V-Gard Slotted Cap

Part No. 10103908

1

Not pictured

2

Extreme Hi-Viz Cap meets high-visibility requirements of ANSI/ISEA 107.

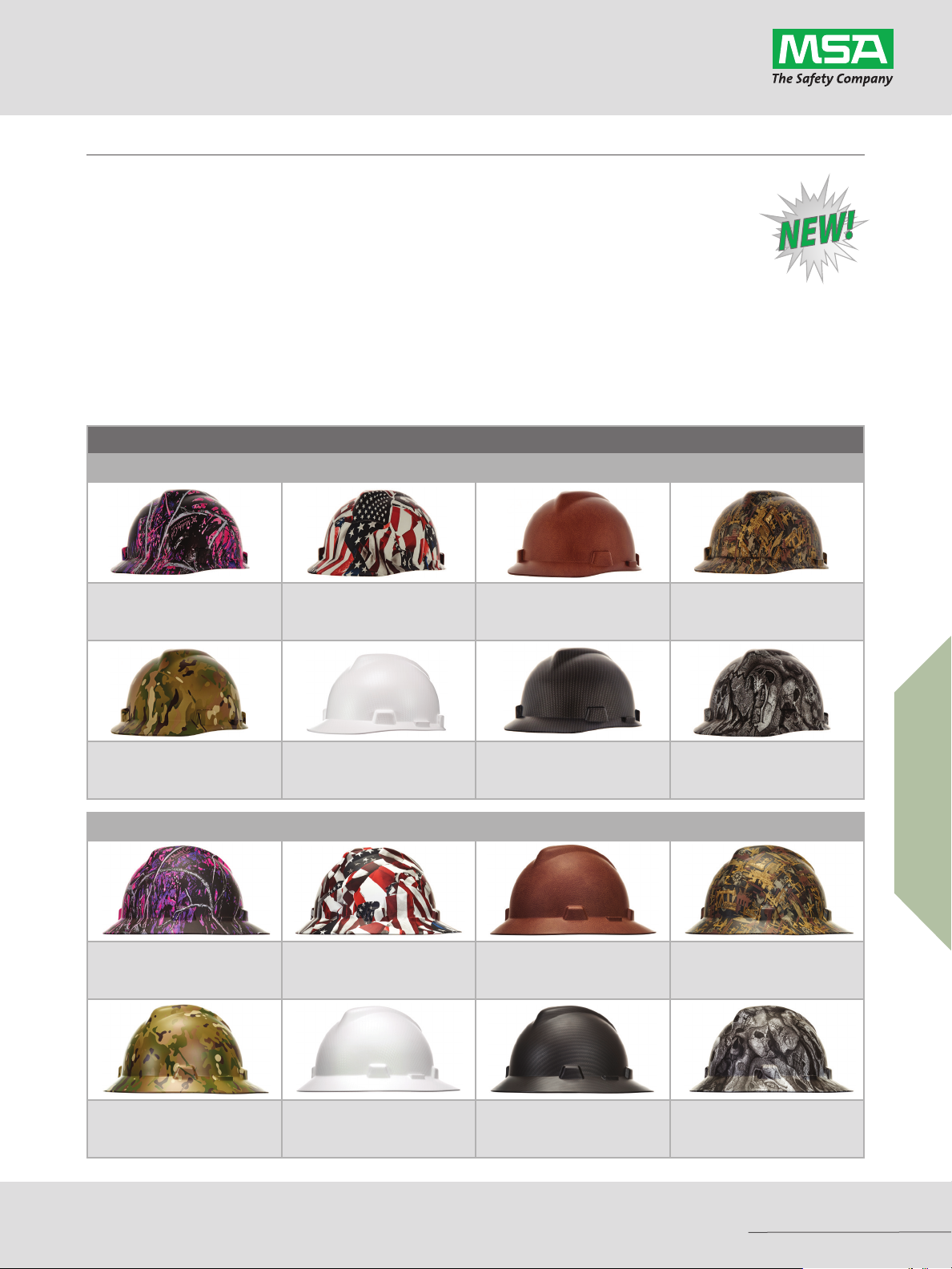

Hydro Dip V-Gard Hard Hats

Classication .........................Type I

Application .............................General purpose

Shell Material ........................Polyethylene

Styles ..........................................Slotted cap;

Slotted full-brim hat

Suspension .............................Fas-Trac III

1

Sizes ............................................Standard (6

⁄2 – 8”)

Standards ................................ANSI/ISEA Z89.1-2014 (Class E);

CSA Z94.1-2015 (Class E)

Certication ...........................Third-party by SEI

Customization ......................Imprinting and striping available

(see pages 8–9)

Replacement

Suspensions ...........................See page 7

The #1 Selling Hard Hat Has a New Look!

The features that have set the MSA V-Gard as a world leader in head protection remain: comfort, durability, customization, and

support. The hydro dip nish provides a new twist on style, without sacricing safety or performance. Choose from eight dierent

standard looks, with the ability to customize to your specic design.* All V-Gard hydro dip hard hats come with the rst-in-class comfort

of the Fas-Trac® III Suspension and are products of the U.S.

HYDRO DIP VGARD ASSEMBLIES

Standard Cap Styles

Muddy Girl

V-Gard Slotted Cap

Part No. 10204770

One Nation

V-Gard Slotted Cap

Part No. 10204771

Italian Leather

V-Gard Slotted Cap

Part No. 10204773

Oileld Camo

V-Gard Slotted Cap

Part No. 10204774

Multi Camo

V-Gard Slotted Cap

Part No. 10204775

Standard Full-Brim Hat Styles

Muddy Girl

V-Gard Slotted Hat

Part No. 10204779

Multi Camo

V-Gard Slotted Hat

Part No. 10204784

*Restrictions apply

Silver Carbon Fiber

V-Gard Slotted Cap

Part No. 10204776

One Nation

V-Gard Slotted Hat

Part No. 10204780

Silver Carbon Fiber

V-Gard Slotted Hat

Part No. 10204785

Sport Carbon Fiber

V-Gard Slotted Cap

Part No. 10204777

Italian Leather

V-Gard Slotted Hat

Part No. 10204782

Sport Carbon Fiber

V-Gard Slotted Hat

Part No. 10204786

Devil’s Kanyon

V-Gard Slotted Cap

Part No. 10204778

Oileld Camo

V-Gard Slotted Hat

Part No. 10204783

Devil’s Kanyon

V-Gard Slotted Hat

Part No. 10204787

MSAsafety.com

13

Above-the-Neck Protection Solutions

14

V-Gard 500 Hard Hats

V-Gard 500 Cap

with Fas-Trac III Suspension

Vented V-Gard 500 Caps and Hats provide cooling vents for

improved air circulation and comfort; Non-Vented V-Gard 500

Caps and Hats provide dielectric head protection.

Classication .............................Type I

Application .................................General purpose

Shell Material ............................Polyethylene

Styles ..............................................Vented or non-vented slotted cap

Vented or non-vented hat

Colors .............................................

Sizes ................................................Standard (61⁄2 – 8”)

Standards ....................................ANSI/ISEA Z89.1-2014

(Vented Class C; Non-Vented Class E)

CSA Z94.1-2015

(Vented Class C; Non-Vented Class E)

Certication ...............................Third-party by SEI

DESCRIPTION

VENTED CAP

WHITE 10034018 10034027

YELLOW 10034020 10034029

GREEN 10034023 10034032

HIVIZ ORANGE

HIVIZ YELLOWGREEN

NONVENTED CAP

WHITE 10034088 10034097

VENTED FULLBRIM HAT

WHITE 10167911 10167950

YELLOW 10167913 10167952

GREEN 10167916 10168438

HIVIZ ORANGE

HIVIZ YELLOWGREEN

NONVENTED FULLBRIM HAT

WHITE 10168521 10168589

nnnnnn

w/4-Point Fas-Trac III

Suspension

BLUE 10034019 10034028

RED 10034022 10034031

1

10034026 10034035

1

10074819 10074820

BLUE 10167912 10167951

RED 10167915 10168437

1

10167921 10168453

1

10167931 10168461

w/6-Point Fas-Trac III

Suspension

Topgard® Hard Hats

White w/lamp bracket

Topgard Cap

with Fas-Trac III Suspension

Classication ................................. Type I

Application ..................................... General purpose;

elevated temperature

Shell Material ................................ Polycarbonate

Styles .................................................. Slotted cap;

Non-slotted full-brim hat

Colors .................................................

nnnnnnn

Sizes .................................................... Standard (61⁄2 – 8”)

Standards ........................................ ANSI/ISEA Z89.1-2014 (Class E)

CSA Z94.1-2015 (Class E)

Certication ................................... Third-party by SEI

DESCRIPTION

TOPGARD SLOTTED CAP STANDARD SIZE

WHITE 454728 475385

YELLOW 454721 475378

GRAY 454722 475379

BLUE 454723 475380

ORANGE 454725 475382

GREEN 454726 475383

RED 454727 475384

BRIGHT ORANGE — 804396

WHITE W/LAMP BRACKET

AND CORD HOLDER

TOPGARD NONSLOTTED HAT STANDARD SIZE

WHITE 454719 475393

YELLOW 454712 475387

GRAY 454713 —

BRIGHT ORANGE — 804397

w/ 1 Touch

Suspension

448914 —

1

w/ Fas-Trac III

Suspension

Customization: Imprinting and striping available—see pages 8–9 Replacement Suspensions: See page 7

1

V-Gard Cap/Hat meets voluntary standard for hi-visibility as prescribed by ANSI/ISEA Z89.1-2014. Look for ocial hi-visibility marking [HV] on the helmet’s ANSI label.

KNOW?

DID YOU

SmoothDome® Hard Hats

KNOW?

DID YOU

Thermalgard® Hard Hats

SmoothDome Cap

with Fas-Trac III Suspension

Classication ................................. Type I

Application ..................................... General purpose; welding

Shell Material ................................ Polyethylene

Styles .................................................. Vented or non-vented slotted cap

Colors .................................................

nnnnnnnn

Sizes .................................................... Standard (61⁄2 – 8”)

Standards ........................................ ANSI/ISEA Z89.1-2014 (Class E)

CSA Z94.1-2015 (Class E)

Certication ................................... Third-party by SEI

DESCRIPTION

WHITE 10074067 10084078

BLUE 10074068 10084079

YELLOW 10074069 10084080

ORANGE 10074070 10084081

RED 10074071 10084082

GREEN 10074072 10084083

GRAY 10074073 10084084

HIVIZ ORANGE

HIVIZ YELLOWGREEN

HIVIZ ORANGE

W/YELLOWGREEN STRIPE

HIVIZ YELLOWGREEN W/

ORANGE STRIPE

HIVIZ ORANGE

W/SILVER STRIPE

HIVIZ YELLOWGREEN

W/SILVER STRIPE

w/4-Point Fas-Trac III

Suspension

1

10074077 10084088

1

10074084 10084095

10095987 10095988

1

10095989 10095990

1

10096141 —

1

10096142 —

1

w/6-Point Fas-Trac III

Suspension

Thermalgard Cap

with Fas-Trac III Suspension

Classication ................................. Type I

Application ..................................... General purpose;

elevated temperature

2

Shell Material ................................ Glass-reinforced nylon

Styles .................................................. Slotted cap

Colors .................................................

nnnnnnn

Sizes .................................................... Standard (61⁄2 – 8”)

Standards ........................................ ANSI/ISEA Z89.1-2014 (Class G)

CSA Z94.1-2015 (Class G)

Certication ................................... Third-party by SEI

DESCRIPTION

YELLOW 486964 486959

WHITE 486965 486960

RED — 486961

ORANGE 486967 486962

BLUE 486968 486963

BRIGHT ORANGE 800359 800360

GREEN 487399 814343

STEEL GRAY — 10095325

w/ 1 Touch

Suspension

w/ Fas-Trac III

Suspension

NFPA 70E is a work practice; it is not a standard

and does not specify any test methods. No products

“meet” NFPA 70E—users simply follow the practice

of NFPA 70E. For head protection, NFPA 70E

recommends that users wear Class E hard hats in

following this work practice.

15

MSA helmets marked LT meet voluntary

requirements for “Lower Temperature.”

Helmets marked LT are conditioned to -22°F

and then tested for impact and penetration,

as outlined in the Standard. Any helmet NOT

marked with LT is tested to 0°F.

Customization: Imprinting and striping available—see pages 8–9 Replacement Suspensions: See page 7

1

Topgard Caps and Hats have been tested to radiant heat loads producing temperatures up to, but not exceeding, 275°F.

2

Thermalgard Caps and Hats have been tested to radiant heat loads producing temperatures up to, but not exceeding, 350°F.

MSAsafety.com

Above-the-Neck Protection Solutions

16

Skullgard® Hard Hats

Skullgard Cap, natural,

with Fas-Trac III

Suspension

Classication .................... Type I

Application ........................ General purpose; elevated temperature

Shell Material ................... Phenolic

Styles ..................................... Non-slotted cap; full-brim hat

Colors ....................................

Sizes ....................................... Cap:

Small (6 – 71⁄8”);

Standards ........................... ANSI/ISEA Z89.1-2014 (Class G)

Certication ...................... Third-party by SEI

DESCRIPTION

SKULLGARD CAP (STANDARD SIZE)

NATURAL TAN 454617 475395 816651

HIVIZ REDORANGE

SKULLGARD HAT (STANDARD SIZE)

NATURAL TAN 454664 475407 —

ALTERNATIVE SKULLGARD ASSEMBLIES

SKULLGARD

CAP

SKULLGARD

HAT

nnnnnnn

Standard (61⁄2 – 8”);

Large (7 – 81⁄2”)

Hat:

Standard (61⁄2 – 8”)

w/ Staz-On

Suspension

WHITE 454618 475396 —

YELLOW 454619 475397 —

RED 454620 — —

GREEN 454621 — —

GRAY 454622 — —

BLUE 454623 — —

ORANGE 454626 — —

2

458702 — —

WHITE 454665 475408 —

YELLOW 454666 — —

GREEN 454668 — —

ORANGE 454673 — —

w/ Staz-On

Suspension

82018 475405 Large size, natural tan

460409 — Standard size, with lamp bra-

460389 — Standard size, with lamp bra-

w/ Fas-Trac III

Suspension

— 10104377 Small size, natural tan

— 482002

w/ Fas-Trac III

Suspension

cket and cord holder,

natural tan

With welder’s lugs,

natural tan

cket and cord holder,

natural tan

w/ Swing-Ratchet

3

3

3

Suspension

Super V® Hard Hats

Super-V Cap, white,

with Fas-Trac III

Suspension

1

Classication .................................

Application ..................................... Lateral protection

Shell Material ................................

Styles ..................................................

Colors .................................................

Sizes ....................................................

Standards ........................................

CSA Z94.1-2015 (Class E)

Certication ................................... Third-party by SEI

DESCRIPTION w/Fas-Trac III Suspension

SUPER V ASSEMBLIES

NAVY GRAY C217097

HIVIZ ORANGE

Use only MSA’s Fas-Trac III Sus pen sion designed for Super-V Helmets. Use of

any other suspension will reduce the energy-absorbing ability of the protective

helmet, which can result in serious personal injury or death.

Type II (ANSI and CSA)

Polyethylene

Slotted cap w/foam liner

nnnnnnnnnn

Standard (61⁄2 – 73⁄8”)

ANSI/ISEA Z89.1-2014 (Class E);

WHITE C217091

YELLOW C217093

RED C217095

ORANGE C217094

BLUE C217092

2

GREEN C217096

GOLD C217098

BLACK C217140

SILVER 10025227

C217100

Customization: Imprinting and striping available—see pages 8–9 Replacement Suspensions: See page 7

1

Skullgard caps and hats have been tested to radiant heat loads producing temperatures up to, but not exceeding, 350°F.

2

Hi-Viz red-orange Skullgard Cap meets voluntary standard for hi-visibility as prescribed by ANSI/ISEA Z89.1-2014. Look for ocial

hi-visibility marking [HV] on the helmet’s ANSI label.

3

Alternative Skullgard Assemblies that include welder’s lugs or lamp bracket and cord holder are certied to Class C electrical rating.

Comfo-Cap® Hard Hats

Bump Caps

Classication ............ Type I

Application ................ Mining

Shell Material ........... Polycarbonate

Styles ............................. Non-slotted cap w/ lamp bracket & cord holder

Colors ............................

nnnnnn

Sizes ............................... Standard (61⁄2 – 8”)

Standards ................... ANSI/ISEA Z89.1-2014 (Class G)

Certication .............. Third-party by SEI

DESCRIPTION w/Staz-On w/Fas-Trac III

COMFO CAP ASSEMBLIES

WHITE 91522 475336

BLUE 91586 —

YELLOW 91585 —

ORANGE 91589 —

RED 91590 —

GREEN 91584 —

BLACK 82769 —

Customization: Imprinting and striping available—

see pages 8–9

Replacement Suspensions: See page 7

Classication ............ Non

Application ................ Non-impact

Shell Material ........... Polyethylene

Styles ............................. Non-slotted cap w/ plastic suspension

Colors ............................

nnnnn

Sizes ............................... Standard (61⁄2 – 8”)

Standards ................... Not applicable

Certication .............. None

DESCRIPTION w/Plastic Suspension

BUMP CAP ASSEMBLIES

WHITE 10033652

BLUE 10033650

YELLOW 10033651

ORANGE 10033654

RED 10033653

GREEN 10033655

Bump caps are not safety helmets and do not meet OSHA or ANSI/ISEA Z89.1

requirements. DO NOT use bumps caps for impact protection, for sports or

when an ANSI-compliant helmet is required.

Customization: Imprinting and striping available

(locations limited)

17

1

Super V Cap meets voluntary standard for hi-visibility as prescribed by ANSI/ISEA Z89.1-2014.

Look for ocial hi-visibility marking [HV] on the helmet’s ANSI label.

MSAsafety.com

Above-the-Neck Protection Solutions

V-Gard H1 Safety Helmets

18

V-Gard H1 Safety Helmet

with vents

The V-Gard H1 Safety Helmet and accessories provide exceptional

comfort and ease of use in a stylish low-prole design. A complete

above-the-neck platform for all applications.

• Fas-Trac® III Pivot ratchet suspension for superior comfort,

adjustability and range of motion

• Non-contact foam liner maximizes air ow & breathability

for optimal cooling and hygiene

• Vented options for optimal air ow and cooling

• Field replaceable 4-point chinstrap with multiple adjustment

points for customized t and comfort

• Premium sweatband with sweat-wicking fabric, breathable foam

and Velcro® attachment for easy eld replacement

• Patented “push-button” accessory attachment rail and universal

lighting clips for quick installation and removal

• Convenient rescue whistle integrated into the chin strap buckle

DESCRIPTION

WHITE 10194783 10194791

RED 10194784 10194792

BLUE 10194785 10194793

GREEN 10194786 10194794

YELLOW 10194787 10194795

HIVIZ YELLOW GREEN 10194788 10194796

ORANGE 10194789 10194797

BLACK 10194790 10194798

GRAY 10204341 10204342

w/ pivoting Fas-Trac III Suspension

TRIVENT

V-Gard H1 Safety Helmet

without vents

Classication .............................Type I

Markets .........................................Utilities; oil, gas and petrochemical;

general industry; construction

Application .................................General Industry; construction;

working-at-heights; conned space;

rescue

Shell Material ............................HDPE (high-density polyethylene)

Styles ..............................................Trivent; no vent

Colors .............................................

nnnnnnnn

Sizes ................................................Standard 61⁄2 – 8” (52–64 cm)

head circumference

Standards ....................................See chart on page 19

w/ pivoting Fas-Trac III Suspension

VGARD H1 SAFETY HELMET ASSEMBLIES

NO VENT

Customization: Stylish dark gray reective striping standard. Imprinting available—see pages 8–9

Accessories: See page 19

V-Gard H1 Safety Helmets

V-Gard H1 Safety Helmets: Standards

STANDARD Aspect TRIVENT NO VENT

ANSI/ISEA Z89.12014

TYPE 1

CSA/CAN Z94.115

TYPE 1

EN 12492:2012 MOUNTAINEERING STANDARD

EN 397:2012 + A1:2012

EN 50365:2002 1000V A.C.

FOR USE ON LOW VOLTAGE INSULATIONS

* Pending approval.

V-Gard H1 Safety Helmet Accessories

Class C (Conductive 0 V ac)

Class E (20,000 V ac)

-22° F (-30° C) (Lower Temperature)

140°F ± 3.6°F (60°C ± 2°C) (Higher Temperature)

Class C (Conductive 0 V ac)

Class E (20,000 V ac)

—

-22° F (-30° C) (Lower Temperature)

440 V ac (Electrical Resistance)

—

■

■

■ ■

■

■

■

■*

■

■

■

PART NO. 10194818 10194819 10194820

PRODUCT NAME H1 Clear Face Shield H1 Mesh/Forestry Face Shield V-Gard H1 Half-Face Spectacles

COLOR Clear Mesh Clear

PRODUCT

SPECIFICS

APPROVALS • ANSI/ISEA Z87.1-2015

• Clear polycarbonate contoured visor

for closer t and improved resistance to

impact and splash hazards

• Simple push button donning and dong

on the V-Gard H1 Safety Helmet—

no additional frames or adapters required

• Dual pivot hinge maintains a low prole

to the helmet when stowed for improved

eld of vision and wind resistance

• Anti-fog coating and frameless design

improves visibility

• CSA Z94.3

• EN 166

• Steel mesh contoured visor for closer t

and improved protection from ying chips

and other light debris

• Simple push button donning and dong

on the V-Gard H1 safety helmet—

no additional frames or adapters required

• Dual pivot hinge maintains a low prole

to the helmet when stowed for improved

eld of vision and wind resistance

• ANSI/ISEA Z87.1-2015

• EN 1731

• Clear polycarbonate contoured spectacles

for closer t and improved resistance to

impact and splash hazards

• Simple push button donning and dong

on the V-Gard H1 safety helmet—

no additional frames or adapters required

• Dual pivot hinge maintains a low prole

to the helmet when stowed for improved

eld of vision and wind resistance

• Anti-fog coating and frameless design

improves visibility

• ANSI/ISEA Z87.1-2015

• CSA Z94.3

• EN 166

MSAsafety.com

19

Above-the-Neck Protection Solutions

V-Gard Accessory System: V-Gard Frames for Cap-Style Hard Hats

V-Gard Universal Cap Frame

PART NO. 10190639 10190640

DEBRIS

CONTROL

PRODUCT

SPECIFICS

With debris control Without debris control

Easy to Use

• Add and remove accessories

• Quicker visor installation and removal

• Green color coded parts

Built to Last

• Innity joints

• Universal strap

• Debris control

Reducing Complexity

• Designed to work with all MSA V-Gard

cap-style hard hats

Easy to Use

• Add and remove accessories

• Quicker visor installation and removal

• Green color coded parts

Built to Last

• Innity joints

• Universal strap

Reducing Complexity

• Designed to work with all MSA V-Gard

cap-style hard hats

PART NO. 10187163

PRODUCT

SPECIFICS

PART NO. 10187251

PRODUCT

SPECIFICS

Replacement debris wiper

Replacement rubber strap

20

V-Gard Frames for General Purposes

Markets: General industry, manufacturing, repair and maintenance,

construction, oil and gas, forestry, shipbuilding, metalworking,

automotive, mining

Applications: Chipping, splash, chiseling, drilling, grinding,

machining, power fastening, sanding, sawing

PART NO. 10115730 10121266

MATERIAL High density polyethylene (HDPE) High density polyethylene (HDPE)

DEBRIS

CONTROL

PRODUCT

SPECIFICS

Includes replaceable debris control which creates tight seal

between frame and cap

• Fits all MSA Slotted Caps

• Stowable slot adaptors secure frame tightly in slotted MSA

caps, and allow frame to work with or without earmus

• Sliding adjustment bladesallow visor to work with most halfmask respirators and other PPE worn under a visor

Standards

AS/NZS 1337

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 10

Use V-Gard Frames ONLY with V-Gard Visors, to ensure compliance with safety standards. Misuse can result in death, permanent

impairment of sight, or other serious injury.

1

: ANSI/ISEA Z87.1-2015; CSA Z94.3; EN 166; and

Debris control sold separately

• Fits all MSA Slotted Caps

• Stowable slot adaptors secure frame tightly in slotted MSA

2

caps, and allow frame to work with or without earmus

• Sliding adjustment blades allow visor to work with most

half-mask respirators and other PPE worn under a visor

3

2

1

Standards requirements met by each V-Gard Frame/V-Gard Visor combination designated on each V-Gard Visor.

2

Patent pending

3

MSA recommends the use of debris control on V-Gard frames when wearing BOTH large V-Gard molded Visors and cap-mounted earmus.

4

MSA does not recommend the use of the V-Gard Universal Frame with the MSA SmoothDome when using cap-mounted mus and large V-Gard molded Visors.

The V-Gard Frame for Slotted Caps should be worn with this particular combination.

V-Gard Accessory System: V-Gard Frames for Cap-Style Hard Hats

V-Gard Frames for Elevated Temperature Applications

Markets: Food manufacturing/canneries, steel mills, construction,

open-pit mining, agriculture, oil/gas/petrochemical reneries,

rubber manufacturing, and steam tunnels

Applications: Food processing, machine operation, maintenance,

millwright, cutting, punching, extrusion, drilling, blasting, casting/

conveying, chemical mixing, sanding

PART NO. 10115821 10121267 10116552

MATERIAL Polycarbonate – all non-metal construction Polycarbonate – all non-metal construction Polycarbonate – all non-metal construction

Features: Tested to withstand temperatures of 350°F (176.7°C),

reducing warping, cracking or crazing

1

Standards

: ANSI/ISEA Z87.1-2015; CSA Z94.3; EN 166;

and AS/NZS 1337

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 10

DEBRIS

CONTROL

PRODUCT

SPECIFICS

Replaceable debris control

tested against EN 166 hot solids

requirements

• Stowable slot adaptors secure frame

tightly in slotted MSA caps, and allow

frame to work with or without earmus

• Sliding adjustment blades

allow visor to work with most half-mask

respirators and other PPE worn under

a visor

Debris control sold separately

• Stowable slot adaptors secure frame

tightly in slotted MSA caps, and allow

2

frame to work with or without earmus

• Sliding adjustment blades

allow visor to work with most half-mask

respirators and other PPE worn under

a visor

3

Replaceable debris control

tested against EN 166 hot solids

requirements

• Heavy duty at rubber strap allows easy

and secure placement on all MSA caps,

including non-slotted models

• Design allows use with other PPE,

including MSA earmus and respirators

4

V-Gard Accessory System: V-Gard Frames for Full-Brim Hard Hats

V-Gard Frames for General Purposes V-Gard Frames for Elevated Temperature Applications

Markets: General industry, manufacturing, repair

and maintenance, construction, oil and gas, forestry,

shipbuilding, metalworking, automotive, mining

Applications: Chipping, splash, chiseling, drilling,

grinding, machining, power fastening, sanding, sawing

1

Standards

: ANSI/ISEA Z87.1-2015; CSA Z94.3; EN 166;

and AS/NZS 1337

Certication: Third-party by Intertek, INSPEC

International Ltd., CSA International and SAI Global Ltd.

Min Order Qty: 10

Markets: Food manufacturing/canneries, steel mills, construction, open-pit

mining, agriculture, oil/gas/petrochemical reneries, rubber manufacturing,

and steam tunnels

Applications: Food processing, machine operation, maintenance, millwright,

cutting, punching, extrusion, drilling, blasting, casting/conveying, chemical

mixing, sanding

Features: Tested to withstand temperatures of 350°F (176.7°C), reducing

warping, cracking or crazing

1

Standards

: ANSI/ISEA Z87.1-2015; CSA Z94.3; EN 166; and AS/NZS 1337

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 10

21

PART NO. 10116627

MATERIAL High density polyethylene (HDPE)

DEBRIS

CONTROL

PRODUCT

SPECIFICS

1

Standards requirements met by each V-Gard Frame/V-Gard Visor combination designated on each V-Gard Visor.

2

Patent pending

3

MSA recommends the use of debris control on V-Gard frames when wearing BOTH large V-Gard molded Visors and cap-mounted earmus.

4

MSA does not recommend the use of the V-Gard Universal Frame with the MSA SmoothDome when using cap-mounted mus and large V-Gard molded Visors.

The V-Gard Frame for Slotted Caps should be worn with this particular combination.

Oered without debris control ONLY

• Heavy duty at rubber strap allows easy and

secure placement on all MSA hats, including

non-slotted models

• Design allows use with other PPE, including

MSA earmus and respirators

• Fits MSA Full-Brim Safety Helmets

PART NO. 10116628

MATERIAL Polycarbonate – all non-metal construction

DEBRIS

CONTROL

PRODUCT

SPECIFICS

Oered without debris control ONLY

• Heavy duty at rubber strap allows easy and secure placement

on all MSA hats, including non-slotted models

• Design allows use with other PPE, including MSA earmus and respirators

• Fits MSA Full-Brim Safety Helmets

MSAsafety.com

Above-the-Neck Protection Solutions

V-Gard Accessory System: V-Gard Frames for MSA Slotted Full-Brim Hard Hats

Markets: Oil, gas & petrochemical, manufacturing, repair and

maintenance, construction, general industry, forestry, shipbuilding,

metalworking, automotive, mining

Standards

Certication/Testing: CSA International and Intertek

Min Order Qty: 10

Applications: Chipping, splash, chiseling, drilling, grinding,

machining, power fastening, sanding, sawing

V-Gard Frames for General Purposes Debris Control

1

: ANSI/ISEA Z87.1-2015 and CSA Z94.3

22

PART NO. 10154622 10154604

MATERIAL Polybutylene terephthalate (PBT) Polybutylene terephthalate (PBT)

DEBRIS

CONTROL

PRODUCT

SPECIFICS

Sold with replaceable debris control

which creates tight seal between

frame and hat

• Fits MSA Slotted Full Brim Hats

• Sliding adjustment blades allow

visor to work with most half-mask

respirators and other PPE worn

under a visor

• Patented Inni-just allows

lift/closure adjustment using

grippable knobs that can’t

be lost

Debris control sold separately

• Fits MSA Slotted Full Brim Hats

• Sliding adjustment blades allow

visor to work with most half-mask

respirators and other PPE worn

under a visor

• Patented Inni-just allows

lift/closure adjustment using

grippable knobs that can’t

be lost

PART NO. 10116628

MATERIAL All rubber construction

DEBRIS

CONTROL

PRODUCT

SPECIFICS

V-Gard Accessory System: V-Gard Metal Frames for Hard Hats

V-Gard Frames for General Purposes and Elevated Temperature Applications

Markets: Manufacturing; construction; steel/smelting operations

Applications: Machine operation, maintenance, millwright,

extrusion, drilling, blasting, casting/conveying

Standards

Certication: Third-party by Intertek, CSA International (as marked)

1

: ANSI/ISEA Z87.1-2015; CSA Z94.3

Exceeds EN requirements for molten metal

• Debris Control for V-Gard Slotted Full Brim

Hat Frames

PART NO. 10158799 10158800 10176739

MATERIAL Heavy-duty anodized aluminum Heavy-duty anodized aluminum Heavy-duty anodized aluminum

PRODUCT

SPECIFICS

• For use with MSA cap-style hard hats

• Spring coil for fast loading of frame to

helmet

• Three visor resting positions

• Locking device holds visor securely in the

down position

• For use with MSA Skullgard Caps

• Spring coil for fast loading of frame to

helmet

• Three visor resting positions

• Locking device holds visor securely in the

down position

• For use with MSA full-brim hard hats

• Spring coil for fast loading of frame to

helmet

• Three visor resting positions

• Locking device holds visor securely in the

down position

MSA does not recommend V-Gard Metal Frames for use where electrical hazards, including but not limited to arc ash, could occur.

1

Standards requirements met by each V-Gard Frame/V-Gard Visor combination designated on each V-Gard Visor.

V-Gard Visors: General Purpose

Markets: General industry, manufacturing, repair and maintenance,

construction, oil and gas, forestry, shipbuilding, metalworking,

automotive, mining

Applications: Chipping, splash, chiseling, drilling, grinding,

machining, power fastening, sanding, sawing

PART NO. 10144486 10115836 10115837

MATERIAL Polycarbonate – clear Polycarbonate – clear Polycarbonate – clear

FEATURES • Maximum UV protection

PRODUCT

SPECIFICS

• Impact-rated (Z87+)

• 5” (14.61 cm) x 17” (43.2 cm) x .04” (1.02 mm)

• Nitrometer; for use with V-Gard Retractable

or Standard Chin Protectors

• Contoured visor; closer t and improved

resistance to impact and splash hazards

• Approved to ANSI and CSA

does not meet EN standards

2

standards;

• 8” (20.3 cm) x 17” (43.2 cm) x .04” (1.02mm)

• Contoured visor; closer t and improved

resistance to impact and splash hazards

Standards

MSA 1B); AS/NZS 1337 (except as noted)

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 10

1

: ANSI/ISEA Z87.1-2015; CSA Z94.3 and EN 166 (2C-1.2

• 8” (20.3 cm) x 17” (43.2 cm) x .04” (1.02mm)

• Nitrometer; for use with V-Gard Retractable

or Standard Chin Protectors

• Contoured visor; closer t and improved

resistance to impact and splash hazards

PART NO. 10120108 10115863 10115839

MATERIAL Polycarbonate – clear Polycarbonate – clear Polycarbonate with antifog/anti-scratch

FEATURES • Maximum UV protection

PRODUCT

SPECIFICS

PART NO. 10115841 10115842

MATERIAL Polycarbonate with antifog/anti-scratch coatings

FEATURES • Maximum UV protection

PRODUCT

SPECIFICS

• Impact-rated (Z87+)

• 8” (20.3 cm) x 17” (43.2 cm) x .04” (1.02mm)

• Bulk pack of 20

• Contoured visor; closer t and improved

resistance to impact and splash hazards

for humid conditions – clear

• Impact-rated (Z87+)

• Slightly thicker for industrial impact applications

• 8” (20.3 cm) x 17” (43.2 cm) x .06” (1.52mm)

• Nitrometer; for use with V-Gard Retractable or Standard Chin

Protectors

• Contoured visor; closer t and improved resistance to impact

and splash hazards

• 9.5” (24.1 cm) x 17” (43.2 cm) x .04” (1.02mm)

• Contoured visor; closer t and improved

resistance to impact and splash hazards

Polycarbonate with anti-fog/antiscratch coatings

for humid conditions – green tint to reduce glare

• 8” (20.3 cm) x 17” (43.2 cm) x .06” (1.52mm)

• Contoured visor; closer t and improved resistance to impact

and splash hazards

• Not for use where a Shade infrared (IR) visor is required

coatings for humid conditions – clear

• Maximum UV protection

• Impact-rated (Z87+)

• Slightly thicker for industrial impact

applications

• 8” (20.3 cm) x 17” (43.2 cm) x .06” (1.52mm)

• Contoured visor; closer t and improved

resistance to impact and splash hazards

23

1

Standards requirements met by each V-Gard Frame/V-Gard Visor combination designated on each V-Gard Visor.

MSAsafety.com

V-Gard Visors: General Purpose

Markets: General industry, manufacturing, repair and maintenance,

construction, oil and gas, forestry, shipbuilding, metalworking,

automotive, mining

Applications: Chipping, splash, chiseling, drilling, grinding,

machining, power fastening, sanding, sawing

PART NO. 10115840 10117783

MATERIAL Polycarbonate – clear Polycarbonate – clear

FEATURES • Maximum UV protection

PRODUCT

SPECIFICS

• Impact-rated (Z87+)

• Slightly thicker for industrial impact applications

• 8” (20.3 cm) x 17” (43.2 cm) x .06” (1.52mm)

• Contoured visor; closer t and improved resistance to impact and

splash hazards

Standards

MSA 1B); AS/NZS 1337 (except as noted)

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 10

1

: ANSI/ISEA Z87.1-2015; CSA Z94.3 and EN 166 (2C-1.2

• 8” (20.3 cm) x 17” (43.2 cm) x .06” (1.52mm)

• Flat nitrometer; for use with V-Gard Retractable or Standard

Chin Protectors

• Wider design; improved resistance to impact and splash hazards

• Does not meet CSA Z94.3

V-Gard Visors: General Purpose (Non-Impact)

Markets: General industry, manufacturing, repair and maintenance,

construction, oil and gas, forestry, shipbuilding, metalworking,

automotive, mining

Applications: Flying chips and other light debris

Standards

Certication: Third-party by Intertek, INSPEC International Ltd., and

SAI Global Ltd.

Min Order Qty: 10

1

: ANSI/ISEA Z87.1-2015; EN 1731-F; and AS/NZS 1337

24

PART NO. 10116557 10116558 10158822

MATERIAL Epoxy-coated steel mesh (20 x 20) — black, plastic edged Epoxy-coated steel mesh (20 x 20) —

FEATURES • General protector (Z87)

PRODUCT

SPECIFICS

1

Standards requirements met by each V-Gard Frame or Headgear/V-Gard Visor combination designated on each V-Gard Visor.

• Not for impact hazards

• 8” (20.3 cm) x 17” (43.2 cm)

• Not for use against splash, impact, elevated

temperatures or UV hazards

• Can be worn with earmus

• 8” (20.3 cm) x 17” (43.2 cm)

• Nitrometer; for use with V-Gard Retractable

or Standard Chin Protectors

• Not for use against splash, impact,

elevated temperatures or UV hazards

• Can be worn with earmus

aluminum-bound mesh

• 8” (20.3 cm) x 16.5” (41.9 cm)

• Not for use against splash, impact, electrical

or UV hazards

V-Gard Visors: Heavy Duty Chemical and Splash

KNOW?

DID YOU

KNOW?

DID YOU

Markets: General industry, heavy manufacturing, laboratories,

chem/petrochemical, agriculture, pharmaceutical, oil and gas,

mining

Applications: Chipping, splash, chemical mixing, grinding,

machining, power fastening, sanding, sawing

PART NO. 10115855 10115856 10115851

MATERIAL Propionate – clear Propionate – clear Propionate – clear

FEATURES • Impact-rated (Z87+)

• Please refer to MSA’s Chemical Application Quick Reference Guide (ID 0670-007-MC) for chemical performance details

PRODUCT

SPECIFICS

• 8” (20.3 cm) x 17” (43.2 cm) x .098” (2.5mm)

• Extra-thick to help prevent warping,

cracking or crazing under tough conditions

• 8” (20.3 cm) x 17” (43.2 cm) x .098” (2.5mm)

• Nitrometer; for use with V-Gard Retractable

or Standard Chin Protectors

• Extra-thick to help prevent warping,

cracking or crazing under tough conditions

Standards

and AS/NZS 1337

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 5

V-Gard propionate Visors oer both chemical resistance and impact protection, unlike most propionate visors on the market.

Not only are they marked with Z87+, but the clear visors are also compliant with EN166, meaning they were tested at a velocity

nearly 32% faster than ANSI/ISEA Z87.1-2010. V-Gard green tint propionate Visors also oer maximum UV protection.

1

: ANSI/ISEA Z87.1-2015; EN 166 (MSA 1B 3); CSA Z94.3

• 9.25” (23.5 cm) x 18” (45.7 cm) x .098”

(2.5mm)

• Extra-thick to help prevent warping,

cracking or crazing under tough conditions

• Extended length and width for greater

coverage of neck and face

V-Gard Visors: Elevated Temperature with High-Performance Anti-fog/Anti-scratch Coatings

Markets: Food manufacturing/canneries, steel mills, construction,

open-pit mining, agriculture, oil/gas/petrochemical reneries,

rubber manufacturing, steam tunnels

Applications: Hot/humid conditions, chipping, splash, chiseling,

drilling, grinding, machining, power fastening, sanding, sawing,

Standards

CSA Z94.3 and AS/NZS 1337

Certication: Third-party by Intertek, INSPEC International Ltd.,

CSA International and SAI Global Ltd.

Min Order Qty: 5

outdoor work

PART NO. 10115853 10115854

MATERIAL Polycarbonate with EN 166 performance-rated anti-fog/

FEATURES • Maximum UV protection

PRODUCT

SPECIFICS

anti-scratch coatings for hot/humid conditions (N,K marks,

respectively) – clear

• Impact-rated (Z87+)

• Thick for heavy-duty industrial impact applications

• 10.375” (26.4 cm) x 17” (43.2 cm) x .098” (2.5 mm)

• Molded visor for superior optics under heavy duty use

• Extended length for greater coverage of neck/face

• Performs well against many chemicals. Refer to MSA›s Chemical

Application Quick Reference Guide (ID 0670-007-MC) for details

1

: ANSI/ISEA Z87.1-2015; EN 166 (2C-1.2 MSA IBT9KN);

Polycarbonate with EN 166 performance-rated anti-fog/

anti-scratch coatings for hot/humid conditions (N,K marks,

respectively) – green tint to reduce glare

• 10.375” (26.4 cm) x 17” (43.2 cm) x .098” (2.5 mm)

• Molded visor for superior optics under heavy duty use

• Extended length for greater coverage of neck/face

• Not for use where a Shade IR visor is required

25

V-Gard molded, green and clear visors (whether propionate or polycarbonate) oer superior optical quality and resistance to

many chemicals. For details on optics, please refer to the MSA White Paper, “Optical Quality Requirements and V-Gard® Visors”

(ID 0302-32 MC) available for download from MSA’s Asset Library.

1

Standards requirements met by each V-Gard Frame or Headgear/V-Gard Visor combination designated on each V-Gard Visor.

MSAsafety.com

Above-the-Neck Protection Solutions

KNOW?

DID YOU

V-Gard Visors: Elevated Temperature

Markets: Food manufacturing/canneries, steel mills, construction,