MSA Safety 10116926, 10165446, 10116924 User Manual

Operating Manual

ALTAIR® 5X PID

Multigas Detector

Order No.: 10165710/02

CR 800000039893

MSAsafety.com

WARNING!

Read this manual carefully before using the device. The device will perform as designed only if it is

used and maintained in accordance with the manufacturer's instruction. Otherwise, it could fail to

perform as designed and persons who rely on this device for their safety could sustain serious personal

injury or death.

It is imperative that this operating manual be read and observed when using the product. In particular,

the safety instructions, as well as the information for the use and operation of the product, must be

carefully read and observed. Furthermore, the national regulations applicable in the user's country

must be taken into account for safe use.

Alternative use, or use outside this specification will be considered as non-compliance. This also

applies especially to unauthorized alterations to the product and to commissioning work that has not

been carried out by MSA or authorized persons.

See ALTAIR 5X PID CD or visit MSAsafety.com for the Declaration of Conformity (DoC) information

(#1000006537).

This product incorporates Bluetooth

The Bluetooth word mark and logos are registered trademarks owned by Bluetooth SIG, Inc., and any

use of such marks by MSA is under license. Other trademarks and trade names are those of their

®

wireless technology.

respective owners.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

USA

Phone 1-800-MSA-2222

Fax 1-800-967-0398

For your local MSA contacts please go to our website www.MSAsafety.com

©

MSA 2020. All rights reserved

Contents

1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Liability Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Safety and Precautionary Measures. . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 PID Theory and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Device Hardware Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 On-Screen Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Viewing Additional Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 Sensor Missing Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7 Monitoring Toxic Gases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.8 Monitoring Oxygen Concentration . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.9 Monitoring Combustible Gases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.10 Monitoring VOC Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.11 Displaying Current Response Factor . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Environmental Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Turning ON and Fresh Air Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fresh Air Setup (FAS) at device Turn-ON. . . . . . . . . . . . . . . . . . . . . 31

4.3 Special Consideration for Oxygen Sensor . . . . . . . . . . . . . . . . . . . . 31

4.4 Measurement Mode [Normal Operation]. . . . . . . . . . . . . . . . . . . . . . 32

4.5 Device Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Calibration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Instrument Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6 Bluetooth Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7 MSA Link Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.8 Function Tests on the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.9 Bump Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

US

ALTAIR® 5X PID

3

4.10 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Zero Calibration Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Finishing Successful Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.11 Time of Day Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.12 Device Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.2 Verifying Pump Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3 Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 Maintenance Procedure - Replacing or Adding a Sensor . . . . . . . . . 52

5.5 Replacing the Pump Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.6 Cleaning the Device Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.8 Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.9 PID Sensor Cleaning and Maintenance Procedure . . . . . . . . . . . . . 55

6 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.1 Factory-set Alarm Thresholds and Setpoints . . . . . . . . . . . . . . . . . . 61

6.2 Performance Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3 Calibration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.4 Combustible Gas Cross Reference Factors for General-Purpose

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.1 Marking, Certificates and Approvals According to the Directive

2014/34/EU (ATEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.2 Marking, Certificates and Approvals According to IECEx . . . . . . . . . 66

8 XCell Sensor Patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.1 US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.2 Outside US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.3 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10 PID Response Factor Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ALTAIR® 5X PID

US

4

11 Flow Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.1 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.2 Bump Test/ Informational Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.3 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.4 Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.5 Calibration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.6 Alarm Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.7 Sensor Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.8 Instrument Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.9 Sensor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.10 VOC Gas Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12 Changeable Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

ALTAIR® 5X PID

US

5

1 Safety Regulations

1.1 Correct Use

The ALTAIR 5X PID Multigas Detector, hereafter also referred to as device, is for use by trained and

qualified personnel. The device is designed to be used when performing a hazard assessment to:

• Assess potential worker exposure to combustible and toxic gases and vapors as well as low level

of oxygen.

• Determine the appropriate gas and vapor monitoring needed for a workplace.

The ALTAIR 5X PID Multigas Detector can be equipped to detect:

• Combustible gases and certain combustible vapors.

• Volatile organic compounds (VOC).

• Oxygen-deficient or oxygen-rich atmospheres.

• Specific toxic gases for which a sensor is installed.

• CSA only: While the device can detect up to 30 % oxygen in ambient air, it is approved for use

only up to 21 % oxygen.

Outside the US: Oxygen for monitoring inertization applications. The device is suitable and certified for

the measurement of the oxygen concentration in gas mixtures for inertization according toEN 50104

but without alarm function.

WARNING!

Perform a blocked flow test before each day's use.

It is recommended that a Bump Test is performed before each day's use; adjust if necessary.

Perform a Bump Test more frequently if exposed to silicone, silicates, lead-containing compounds,

hydrogen sulfide, or high contaminant levels.

Recheck calibration if unit is subjected to physical shock.

Use only to detect gases/vapors for which a sensor is installed.

Do not use to detect combustible dusts or mists.

For accurate catalytic combustible readings, make sure adequate oxygen is present

(>10 % O

Never block pump inlet, except to perform a sampling system safety test.Have a trained and qual-

ified person interpret device readings.Risk of Explosion: Do not remove battery pack or recharge

Li Ion battery in a hazardous location.Do not alter or modify device.

Use only MSA-approved sampling lines.

Do not use silicone tubing or sampling lines.

Wait sufficient time for the reading; response times vary based on gas and length of sampling line.

Properly identify the VOC gas being measured before using VOC response factors or setting

alarm values (exposures, STEL, TWA)

Recognize that the VOC display readings are in increments of 0.1ppm from 0-999 ppm, then

1 ppm increments from 1000-2000 ppm with a Response Factor of one for the 0-2000 ppm PID

sensor.

Ensure installed PID lamp corresponds to the PID lamp setting on the display shown at startup.

Incorrect use can cause death or serious personal injury.

).

2

Safety Regulations

US

It is imperative that this operating manual be read and observed when using the product. In particular,

the safety instructions, as well as the information for the use and operation of the product, must be

ALTAIR® 5X PID

6

carefully read and observed. Furthermore, the national regulations applicable in the user's country

must be taken into account for safe use.

Alternative use, or use outside this specification will be considered as non-compliance. This also

applies especially to unauthorized alterations to the product and to commissioning work that has not

been carried out by MSA or authorized persons.

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately or not as intended.

The selection and use of this product must be under the direction of a qualified safety professional who

has carefully evaluated the specific hazards of the jobsite where it will be used and who is completely

familiar with the product and its limitations. The selection and use of this product and its incorporation

into the safety scheme of the jobsite is the exclusive responsibility of the employer.

Product liability claims, warranties also as guarantees made by MSA with respect to the product are

voided, if it is not used, serviced or maintained in accordance with the instructions in this manual.

1.3 Safety and Precautionary Measures

WARNING!

Carefully review the following safety limitations and precautions before placing this device in

service.Incorrect use can cause death or serious personal injury.

• Check function (see chapter 4.8 "Function Tests on the Device") each day before use. MSA

recommends carrying out a routine inspection prior to each day's use.

• It is recommended that a Bump Test is performed before each day's use (see chapter 4.9 "Bump

Test") to verify proper device operation. The device must pass the bump test. If it fails the test,

perform a calibration (see chapter 4.10 "Calibration") before using the device.

• The ALTAIR 5X PID Detector is designed to detect gases and vapors in air only.

• Bluetooth Operation is dependent upon signal availability of the wireless service(s) necessary to

maintain the communication link. Loss of wireless signal will prevent communication of alarms and

other information to linked devices. Take appropriate precautions in the event a loss of wireless

signal occurs.

Safety Regulations

WARNING!

It is very important to have an understanding of PID basics when changing PID settings. Failure to

properly identify the VOC gas being measured and/or failures to select the correct Response Factor

alarm values (exposure, STEL, TWA) that match the desired Response Factor and/or the correct lamp

will result in erroneous readings or erroneous alarm limits that could cause death or serious personal

injury.

• Perform a Bump Test more frequently if the device is subjected to physical shock or high levels of

contaminants. Also, check calibration more frequently if the tested atmosphere contains the

following materials, which may desensitize the combustible gas sensor and/or VOC sensor (PID)

and reduce its readings:

– Organic silicones

– Silicates

– Lead-containing compounds

– Sulfur compound exposures over 200 ppm or exposures over 50 ppm for one minute

– High concentration of VOC gas may affect CO sensor performance

ALTAIR® 5X PID

US

7

Safety Regulations

• The minimum concentration of a combustible gas in air that can ignite is defined as the Lower

Explosive Limit (LEL). A combustible gas reading of XXX indicates the atmosphere is above

100 % LEL, and an explosion hazard exists. Move away from hazardous area immediately.

• Do not use the catalytic or electrochemical sensors to test for combustible or toxic gases in the

following atmospheres as this may result in erroneous readings:

– Oxygen-deficient or oxygen-rich atmospheres

– Reducing atmospheres

– Furnace stacks

– Inert environments

– Atmospheres containing combustible airborne mists/dusts.

• Do not use the catalytic combustible sensor of the ALTAIR 5X PID Multigas Detector to test for

combustible gases in atmospheres containing vapors from liquids with a high flash point (above

38 °C, 100 °F) as this may result in erroneously low readings.

• Allow sufficient time for device to display accurate reading. Response times vary based on the

type of sensor being utilized ( chapter 6.2 "Performance Specification"). Allow a minimum of

1 second per foot (3 seconds per meter) of sample line to allow the sample to be drawn through

the sensors.

• Sampling lines made from 0.062 inch (1.57 mm) inner diameter tubing provide fast transport times

to the device; however, they must be limited to 50 feet (15 m) in length.

• Sampling of reactive toxic gases (Cl

line and probe kits listed in chapter 9 "Ordering Information".

• Sampling lines made from 0.125 inch (3 mm) inner diameter tubing must be limited to 100 feet (30

m) in length.

• All device readings and information must be interpreted by someone trained and qualified in interpreting device readings in relation to the specific environment, industrial practice and exposure

limitations.

Observe Proper Battery Maintenance

Use only battery chargers made available by MSA for use with this device; other chargers may damage

the battery pack and the device. Dispose of in accordance with local health and safety regulations.

Be Aware of Environmental Conditions

A number of environmental factors may affect the sensor readings, including changes in pressure,

humidity and temperature. Pressure and humidity changes also affect the amount of oxygen actually

present in the atmosphere.

Be Aware of the Procedures for Handling Electrostatically Sensitive Electronics

The device contains electrostatically sensitive components. Do not open or repair the device without

using appropriate electrostatic discharge (ESD) protection. The warranty does not cover damage

caused by electrostatic discharges.

, ClO2, NH3) must only be done with the reactive gas sample

2

US

ALTAIR® 5X PID

8

Safety Regulations

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including any interference that may cause undesired

operation.

WARNING!

This is a class A product in accordance with CISPR 22. In a domestic environment, this product may

cause radio interference, in which case the user may be required to take adequate measures.

This Class A digital apparatus complies with Canadian ICES-003.

Be Aware of the Warranty Regulations

The warranties made by MSA The Safety Company with respect to the product are voided if the

product is not used and maintained in accordance with the instructions in this manual. Please protect

yourself and others by following them. We encourage our customers to write or call regarding this

equipment prior to use or for any additional information relative to use or service.

Be Aware of the Product Regulations

Follow all relevant national regulations applicable in the country of use.

ALTAIR® 5X PID

US

9

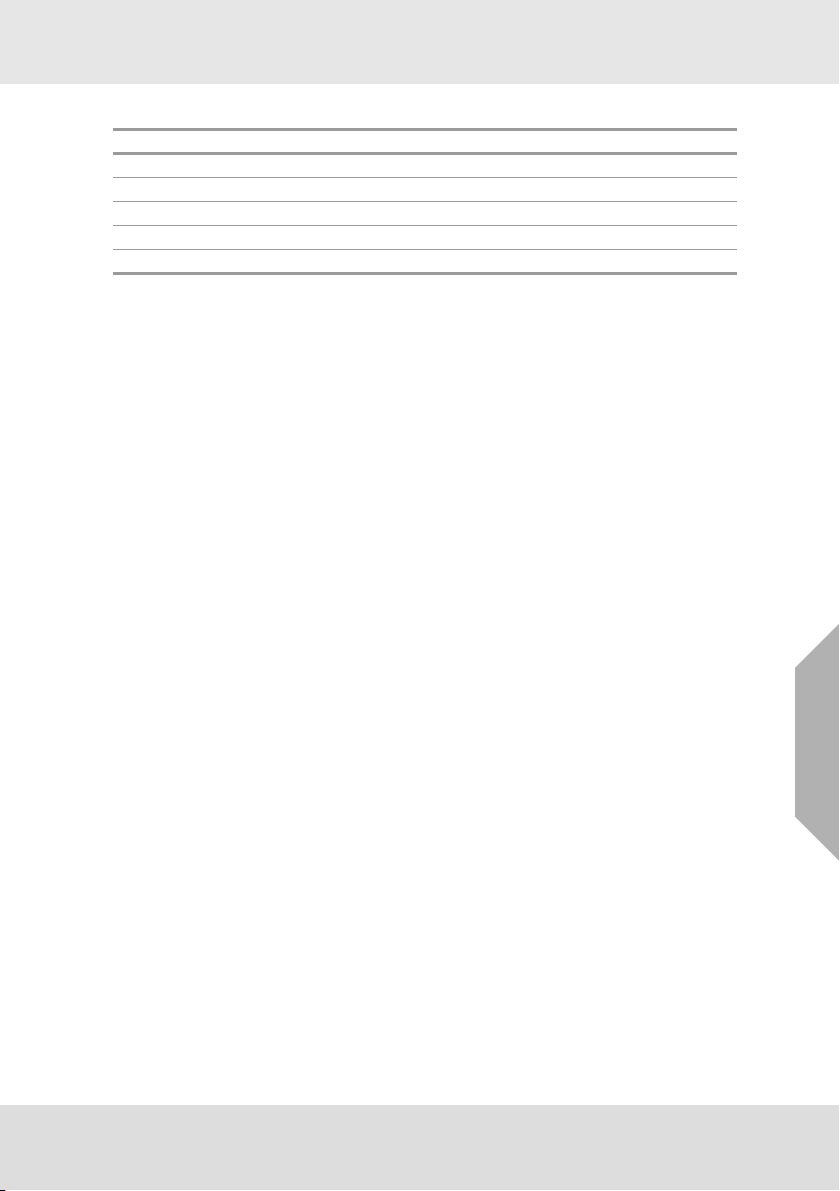

1.4 Warranty

ITEM WARRANTY PERIOD

Chassis and electronics Three years

XCell COMB, O

XCell Cl

Series 20 ClO

PID sensors One year

This warranty does not cover filters, fuses, etc. As the battery pack ages, there will be a reduction in

usable device run time. Certain other accessories not specifically listed here may have different

warranty periods. This warranty is valid only if the product is maintained and used in accordance with

Seller's instructions and/or recommendations.

The Seller shall be released from all obligations under this warranty in the event repairs or modifications are made by persons other than its own or authorized service personnel or if the warranty claim

results from physical abuse or misuse of the product. No agent, employee or representative of the

Seller has any authority to bind the Seller to any affirmation, representation or warranty concerning this

product. Seller makes no warranty concerning components or accessories not manufactured by the

Seller, but will pass on to the Purchaser all warranties of manufacturers of such components.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED OR STATUTORY, AND IS STRICTLY LIMITED TO THE TERMS HEREOF. SELLER SPECIFICALLY

DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE.

Exclusive Remedy

It is expressly agreed that Purchaser's sole and exclusive remedy for breach of the above warranty, for

any tortious conduct of Seller, or for any other cause of action, shall be the replacement at Seller's

option, of any equipment or parts thereof, which after examination by Seller is proven to be defective.

Replacement equipment and/or parts will be provided at no cost to Purchaser, F.O.B. Seller's Plant.

Failure of Seller to successfully replace any nonconforming equipment or parts shall not cause the

remedy established hereby to fail of its essential purpose.

Exclusion of Consequential Damage

Purchaser specifically understands and agrees that under no circumstances will seller be liable to

purchaser for economic, special, incidental or consequential damages or losses of any kind whatsoever, including but not limited to, loss of anticipated profits and any other loss caused by reason of nonoperation of the goods. This exclusion is applicable to claims for breach of warranty, tortious conduct

or any other cause of action against seller.

, H2S, CO, SO2, NO2, and IR sensors Three years

2

, NH3 sensors Two years

2

, HCN, NO, NO2, PH3 sensors One year

2

Safety Regulations

US

ALTAIR® 5X PID

10

PID Theory and Definitions

2 PID Theory and Definitions

To support the safe and effective operation of the ALTAIR 5X PID, MSA believes operators should have

a working knowledge of how the device functions, not just how to make it work. The information

presented in this section supplements the hands-on operational instruction provided in the rest of the

manual for the PID.

PID Theory

A photoionization detector (PID) uses an ultraviolet lamp to ionize the compound of interest. A current

is produced in proportion to the concentration of the VOC present, and the concentration of the

compound is shown on the device display.

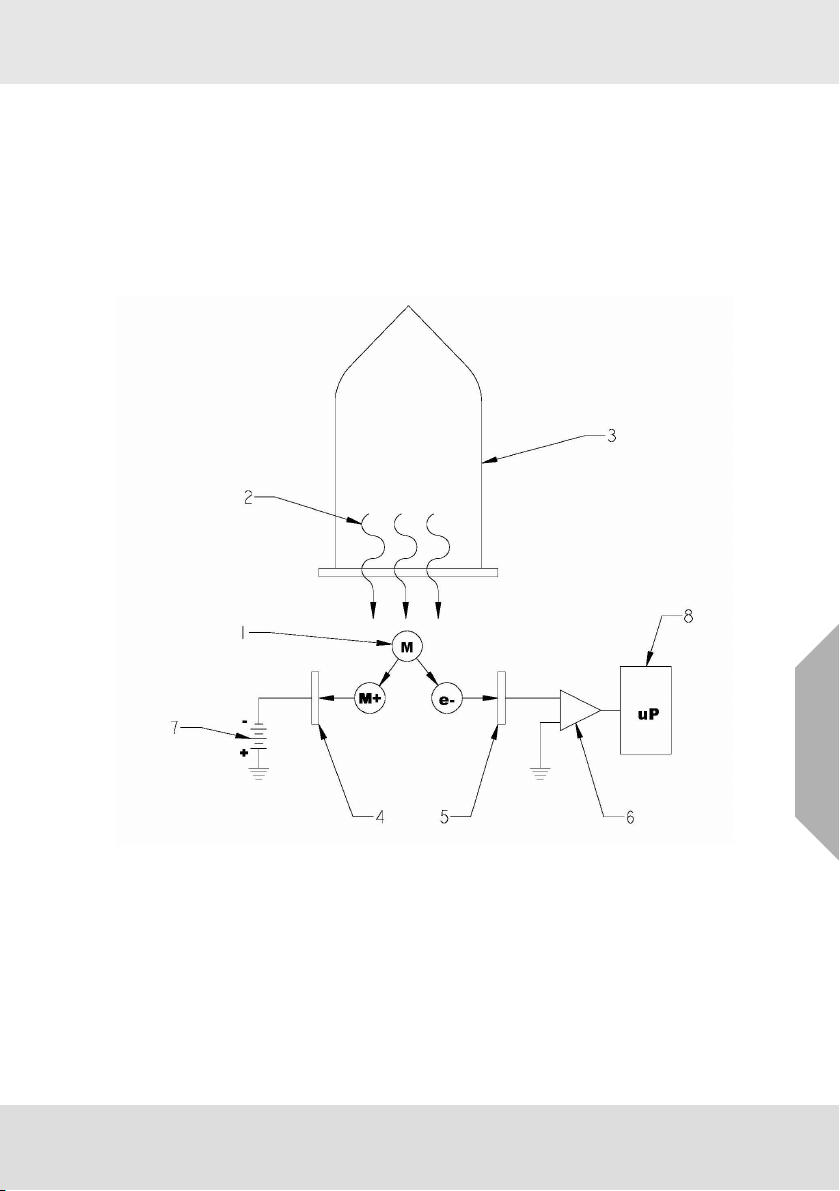

Fig. 1 Typical photoionization sensor design

1 Molecules of Interest 5 Electrodes

2 High energy Vacuum Ultra Violet (VUV) radiation 6 Amplifier

3 UV lamp 7 DC Source

4 Electrodes 8 Microprocessor

Zero Gas

Zero gas is a reference gas used during calibration to zero the device. When a zero gas with no hydrocarbon content is introduced to the device, the detector will still respond with a small signal. This signal

is a result of secondary background processes. During calibration, zero gas is applied to quantify the

ALTAIR® 5X PID

US

11

PID Theory and Definitions

background ionization current.When only measuring concentration changes relative to a reference

ambient environment, fresh air can be used as the zero gas. When background hydrocarbon vapors

are present, MSA recommends using zero gas air.

Span Gas

Span gas is a reference gas used during calibration to determine the slope (response per unit concentration) of the calibrated response curve.

For the 0-2000 ppm PID sensor the only allowable calibration gas is 100 ppm isobutylene.

See Chapter 4.10 "Calibration" for calibration instructions.

Response Factors

When a compound is ionized by photoionization, the ionized molecules are collected and converted to

a current. This response is a characteristic property of the specific compound which is influenced by

its molecular structure. The slope of the response curve (defined in picoamperes per ppm) is different

for different chemicals. To properly report the concentration for a given sample gas, the ALTAIR 5X PID

uses response factors. See Chapter 10 "PID Response Factor Table", for instructions on using the preprogrammed list of response factors.

WARNING!

It is very important to have an understanding of PID basics when changing PID settings. Failure to

properly identify the VOC gas being measured and/or failures to select the correct Response Factor

alarm values (exposure, STEL, TWA) that match the desired Response Factor and/or the correct lamp

will result in erroneous readings or erroneous alarm limits that could cause death or serious personal

injury.

The response factor is defined as the ratio of the detector response for isobutylene to the detector

response for the sample gas. Response factors for a wide range of substances have been determined

experimentally. These response factors are programmed into the device. Note that the calibrated

response curve, and all programmed response factors are relative to isobutylene. Isobutylene has a

response factor of one.

The response factor is a multiplier that compensates for the difference between the response of the

sample gas and the response of isobutylene at 100ppm. Whenever the device detects the presence

of a VOC, it uses the response factor for the user-assigned target gas to convert the signal to the

correct, concentration. This is done by multiplying the equivalent isobutylene response by the response

factor for the set sample gas. The isobutylene response curve is calculated at every calibration.

If the response factor is known, a device calibrated with isobutylene can be used to calculate the actual

concentration of a target gas.

Calculating a Response Factor

To determine a response factor for a target chemical, perform the following simple procedure:

(1) Calibrate the ALTAIR 5X PID using isobutylene as the span gas.

(2) On the device, set the sample gas name to isobutylene.

(3) Apply a known concentration of the target chemical to the device and note the concentration

reported in the display.

The response factor for the target chemical relative to isobutylene:

US

RF target gas =

Actual known concentration

Concentration reported by device

ALTAIR® 5X PID

12

PID Theory and Definitions

For example:

An operator is using a device that has been calibrated on isobutylene. The sample gas is set to isobutylene. While using this device to sample for hexane, the display reads 100 ppm. Since the response

factor for hexane is 4.5, the actual concentration of hexane is:

Actual hexane concentration = 4.5 x 100 ppm = 450 ppm.

For example:

A device is calibrated on isobutylene, and has isobutylene defined as the sample gas. When sampling

106 ppm of benzene in air, the device reports a concentration of 200 ppm. In this example, the

response factor for benzene relative to isobutylene would be:

RF benzene =

When surveying, if benzene is selected as the sample gas in the Response Factor page, 0.53 will be

used by the device as a response factor. The device will use this response factor to automatically

correct the displayed concentration into PPM benzene.A target gas with a response factor between

zero and one implies that the device has a higher detector response for that gas when compared to

isobutylene. If the response factor is greater than one, the device has a lower detector response for

this gas when compared to isobutylene.

WARNING!

It is very important to select the correct lamp setting during PID setup since PID response factors for

a target chemical relative to isobutylene are different depending on what energy PID lamp is installed.

See Chapter 4.5 "Device Setup" for setup instructions. Failure to follow this warning can result in inaccurate readings that could lead to serious injury or death.

106 ppm known concentration benzene

200 ppm reported

=0.53

US

ALTAIR® 5X PID

13

3 Description

1

1

2

3

4

6

5

7

11

8 9

10

12

13

3.1 Overview

Description

Fig. 2 Device view

LEDs

1

2 red "Alarm", 1 green "Safe" and 1 yellow "Fault"

2Horn 9Pump inlet

3 Display 10 Filter

4 Button 11 RFID tag

5q Button 12 Charging port

6 Button 13 Charge Status LED

7 Bluetooth Status LED

The device monitors gases in ambient air and in the workplace.

The ALTAIR 5X PID is available with a maximum of five sensors, which can display readings for six

separate gases (one Two-Tox Sensor provides both CO and H

in a single package).

The ALTAIR 5X PID Multigas Detector is only available with a color display.

The alarm levels for the individual gases are factory-set and can be changed through the

Instrument Setup Menu. These changes can also be made through MSA Link Software. Ensure that

the latest version of the MSA Link software has been downloaded from MSA’s website

www.msasafety.com.

It is recommended that after making changes using MSA Link software, the device should be turned

OFF and ON.

8 IRDA communi cation port

US

S or CO and NO2 sensing capabilities

2

ALTAIR® 5X PID

14

While the device can detect up to 30 % oxygen in ambient air, it is approved for use only up to 21 %

oxygen.

3.2 Device Hardware Interfaces

Device operation is dialog driven from the display with the aid of the three function buttons

( Fig. 2 "Device view").

The device has three buttons for user operation. Each button can function as a "soft key", as defined

on the display directly above the button.

Button Definitions

Button Description

q The q button is used to turn the device ON or OFF and to confirm user action selections.

The button is used to page down through data screens or to decrease the values in setup mode.

This button is also used to initiate a Bump Test for the installed sensors, directly from the

LED Description

RED (Alarm)

GREEN (Safe)

YELLOW (Fault)

BLUE

(Bluetooth Status)

MEASURING page.If the user is granted access to the MotionAlert setting feature, this button can

be used to activate the InstantAlert

See chapter 4.5 "Device Setup" for the means to allow/disallow user access.

The button is used to reset Peak, STEL, TWA and alarms (where possible) or perform calibration in measuring mode. It is also used as page up or to increase the values in setup mode.

When the button and the button are pressed simultaneously while in normal measure mode, the

Setup mode can be entered after the password is confirmed.

LED Definitions

The red alarm LEDs are visual indications of an alarm condition or any type of error in the

device.

The Safe LED flashes once every 15 seconds to notify the user that the device is ON and

operating under the conditions defined below:

• The green SAFE LED is enabled

• Combustible reading is 0 % LEL or 0 % Vol

• Oxygen (O

• All other sensor readings are 0 ppm

• No gas alarms are present (low or high)

• Device is not in Low Battery warning or alarm

• STEL and TWA readings are 0 ppm

This option can be turned OFF through the MSA Link software.

The Fault LED activates if any of several fault conditions are detected during device operation. This includes:

• A device memory error

• A sensor determined to be missing or inoperative

• A pump fault

These faults are also indicated by activation of device alarm LEDs, horn, and vibrating

alarm.

The blue LED is a visual indication of the Bluetooth connection status.

• Off = Bluetooth board OFF or Undiscoverable

• Fast Flash = Discoverable Mode

• Slow Flash = Connected

) reading is 20.8 %

2

TM

alarm.

Description

US

ALTAIR® 5X PID

15

3.3 Alarms

The device is equipped with multiple alarms for increased user safety:

Icon Alarm

Description

Vibrating Alarm

Horn

InstantAlert™

Alarm

MotionAlert™

Alarm

Stealth Mode

Sensor Life

Alarm

Backlight

The device vibrates when any alarm condition is active. This can be turned OFF

through the SETUP- ALARM OPTIONS menu ( chapter 4.5 "Device Setup").

The device is equipped with an audible alarm.

The horn can be turned OFF through the SETUP- ALARM OPTIONS menu

( chapter 4.5 "Device Setup").

The InstantAlert exclusive feature allows the user to manually activate an audible

alarm to alert those nearby to potentially dangerous situations. Holding the

button for approximately 5 seconds while in Normal Measure Mode activates

the InstantAlert alarm. Access to this feature may be restricted by user settings.

See chapter 4.5 "Device Setup" for means to allow/disallow user access.

If MotionAlert is turned ON ( chapter 4.5 "Device Setup"), the device activates a

"Man Down" alarm if motion is not detected within 30 seconds. The Alarm LEDs

flash, and the horn activates with an increasing audible frequency. MotionAlert is

always turned OFF when the device is turned OFF.

Access to this feature may be restricted by user settings. See chapter 4.5 "Device

Setup" for means to allow/disallow user access.

Stealth Mode disables the visual, audible and vibrating alarms. MSA recommends

that this feature be left in its default "OFF" state. Stealth mode can be turned ON

through the SETUP - INSTRUMENT OPTIONS menu ( chapter 4.5 "Device

Setup"). On the display, all three alarm icons are shown as OFF.

The device evaluates the condition of the sensors during Calibration.

As the end of a sensor’s life approaches, a warning is provided. While the sensor

is still fully functional, the warning gives the user time to plan for a replacement

sensor to minimize downtime. The Sensor Life indicator displays during ongoing

operations as a reminder of a sensor’s pending end of life.

When a sensor’s end-of-life is reached, sensor calibration will not be successful,

and the user is then alerted by a Sensor Life Alarm. A flashing Sensor Life

indicator displays during ongoing operations until the sensor is replaced and/or

successfully calibrated.

On the display, each displayed gas will have its own Sensor Life indicator. If a

sensor is in end-of-life warning, its indicator will be an orange . If a sensor has

reached end-of-life, it is in alarm and its Sensor Life indicator will be a continuous

blinking red .

See chapter 4.10 "Calibration" for additional details on Sensor Life determination

and indication.

The backlight automatically activates when any front panel button is pressed and

remains ON for the duration of user-selected timeout.

This duration can be changed using the SETUP - INSTRUMENT SETUP

( chapter 4.5 "Device Setup") or through MSA Link software.

US

ALTAIR® 5X PID

16

Icon Alarm

This operating beep activates every 30 seconds by momentarily beeping the horn

and flashing the alarm LEDs under the following conditions:

• Operating beep is enabled

Operating

Beep

• Device is on normal Measure Gases page

• Device is not in battery warning

• Device is not in gas alarm.

The Operating Beep can be disabled using the SETUP - INSTRUMENT OPTIONS

( chapter 4.5 "Device Setup") or through MSA Link software.

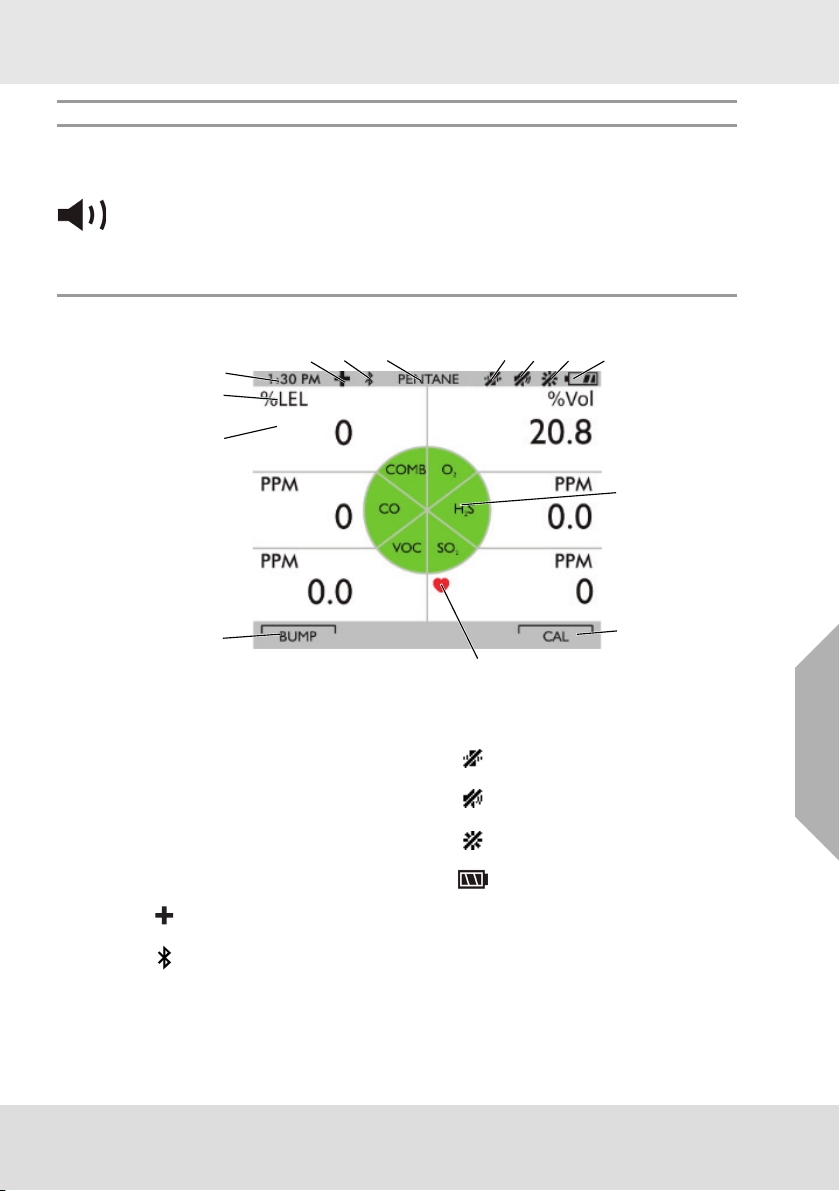

3.4 On-Screen Indicators

4

3

2

67

5

89

Description

10

11

12

1

14

Fig. 3 Color display

1 "Soft Key" Indicator 8 Vibration alarm OFF

2 Gas reading 9

3 Gas Concentration Units 10 LED OFF

4 Current Time 11 Battery charge level

5 Motion Alert symbol ON 12 Gas Type

6 Bluetooth ON 13 "Soft Key" Indicator

Combustible Gas Type/ VOC Gas

7

Type alternates

(the display switches between each

type every few seconds)

ALTAIR® 5X PID

14 Sensor Life Indicator

Horn OFF or successful Bump Test/

Calibration Indicator

13

US

17

Description

Battery Charge Level Indicator

The battery condition icon continuously displays in the upper right-hand corner of the display. A bar

represents the charging level of the battery.

The nominal run-time of the device (COMB, O

12 hours. Actual run-time will vary depending on ambient temperature, battery and alarm conditions.

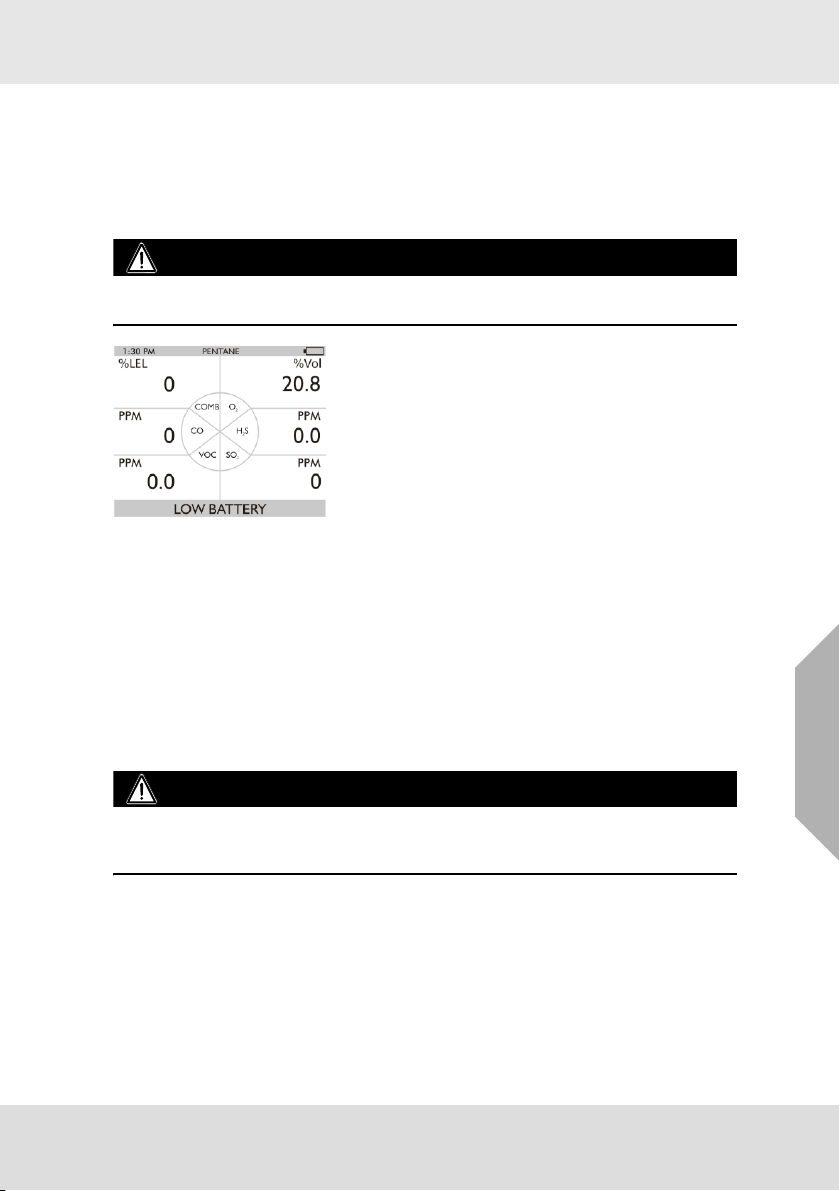

Low Battery Warning

WARNING!

If battery warning alarm activates while using the device, leave the area immediately as the end of

battery life is approaching. Failure to follow this warning can result in serious personal injury or death.

Fig. 4 Battery Warning

The duration of remaining device operation during a Low Battery Warning depends on ambient

temperatures, battery condition alarm status. Nominal battery life is 30-60 minutes after the Battery

Warning activates.

When the device goes into battery warning the:

• battery life indicator continuously blinks

• alarm sounds and alarm LEDs flash every 30 seconds

• Safe LED no longer flashes

• device continues to operate until it is turned OFF or battery shutdown occurs.

Battery Shut Down

, CO, H2S, and PID sensor) at room temperature is

2

US

WARNING!

If battery alarm displays, stop using the device as it no longer has enough power to indicate potential

hazards, and persons relying on this product for their safety could sustain serious personal injury or

death.

The device goes into battery shutdown mode 60 seconds before final shutdown (when the batteries

can no longer operate the device):

•"BATTERY ALARM” flashes on the display

• Alarm sounds

• Alarm LEDs flash

• Fault LED is on

• No other pages can be viewed; after approximately one minute, the device automatically turns

OFF.

ALTAIR® 5X PID

18

Description

Fig. 5 Battery Shut Down

When battery shutdown condition occurs (shown in Fig. 5):

(4) Leave the area immediately.

(5) Recharge or replace the battery pack.

Battery Charging

WARNING!

Risk of explosion: Do not recharge device in hazardous area.

WARNING!

Use of any charger, other than the charger supplied with the device, may damage or improperly charge

the batteries.

For users in Australia/ New Zealand: The charge cradle is a Class A product. In a

domestic environment, this product may cause radio interference, in which case, the

user may be required to take adequate measures.

The charger is capable of charging a completely depleted pack in less than six hours in normal, roomtemperature environments.

Allow very hot or cold devices to stabilize for one hour at room temperature before

attempting to charge.

• Minimum and maximum ambient temperature to charge the device is 10 °C (50 °F) and 35 °C

(95 °F), respectively.

• For best results, charge the device at room temperature 23 °C (73 °F).

To Charge the Device

• Firmly insert the charger connector into the charge port on the back of the device.

• An LED in the battery pack is used to indicate on the charge status.

Red = charging, Green = charged, yellow = fault

• If a problem is detected during charging (LED turns yellow):

Disconnect the charger momentarily to reset the charge cycle.

• The battery pack may be charged separately from the device.

• During periods of non-use, the charger may remain connected to the device/battery pack.

ALTAIR® 5X PID

US

19

The charger must be disconnected for the device to operate.

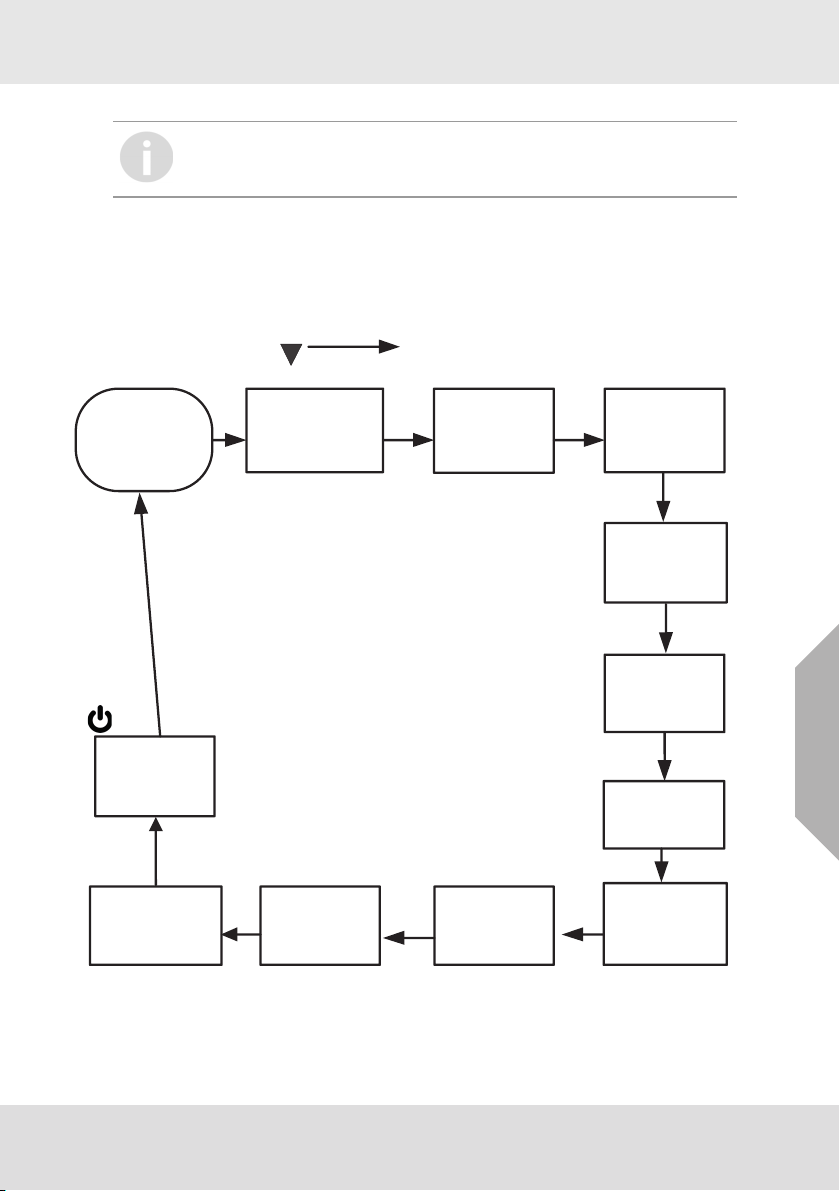

PEAK * MIN

STEL *

1

TWA *

1

BUMP TEST ?

DATE

LAST CAL

DATE *

CAL DUE

DATE *

MOTION

ALERT

STATUS *

MAIN

MEASURE

PAGE

Advance on

Advance on

* IF ENABLED

1

NOT VALID FOR ALL SENSORS

* 1

DISCOVERY

MODE*

CHANGE

VOC

GAS*?

3.5 Viewing Additional Pages

The Main Screen appears at device turn-ON.

Additional displays can be viewed by pressing the button to move to the screen as indicated by the

"soft key".

The sequence of pages are as follows and are described below:

Description

ALTAIR® 5X PID

US

20

Description

Bump Test (BUMP page)

This page allows the user to perform an automated Bump Test on the device. To perform the test, the

(YES) button is pressed. See chapter 4.9 "Bump Test" for details on performing the Bump Test.

If the button is pressed, the Bump Test is not performed, and the display shows the next page in

the sequence (PEAK).

If the button is pressed, the Bump Test is not performed, and the display reverts back to the normal

MEASURE page.

Peak Readings (PEAK page)

This page shows the highest levels of gas recorded by the device since turn-ON or since peak readings

were reset.

To reset the peak readings:

(1) Access the PEAK page.

(2) Press the button.

This page can be de-activated through MSA Link software.

Minimum Readings (MIN page)

This page shows the lowest level of oxygen recorded by the device since turn-ON or since the MIN

reading was reset. It is only shown if an oxygen sensor is installed and enabled.

To reset the MIN reading:

(1) Access the MIN page.

(2) Press the button.

Short Term Exposure Limits (STEL page)

WARNING!

If the STEL alarm activates, leave the contaminated area immediately; the ambient gas concentration

has reached the preset STEL alarm level. Failure to follow this warning will cause over-exposure to

toxic gases and persons relying on this product for their safety could sustain serious personal injury or

death.

This page shows the average exposure over a 15-minute period.

When the amount of gas detected by device is greater than the STEL limit:

• Alarm sounds, alarm lights flash.

• Alarm LEDs flash

•“STEL ALARM” message flashes.

To reset the STEL:

ALTAIR® 5X PID

US

21

(3) Access the STEL page.

(4) Press the button.

The STEL alarm is calculated over a 15-minute exposure.

STEL calculation examples:

Assume the device has been running for at least 15 minutes:

15 minute exposure of 35 ppm:

Description

(15 minutes x 35 ppm)

15 minutes

10 minute exposure of 35 ppm and 5 minutes exposure of 15 ppm:

(10 minutes x 35 ppm) + (5 minutes x 5 ppm)

15 minutes

This page can be de-activated through MSA Link software.

Time Weighted Average (TWA page)

WARNING!

If the TWA alarm activates, leave the contaminated area immediately; the ambient gas concentration

has reached the preset TWA alarm level. Failure to follow this warning will cause over-exposure to toxic

gases and persons relying on this product for their safety could sustain serious personal injury or death.

This page shows the average exposure over 8 hours since the device was turned ON or since the TWA

reading was reset. When the amount of gas detected is greater than the eight-hour TWA limit:

• Alarm sounds

• Alarm LEDs flash

•“TWA ALARM” message flashes.

To reset the TWA Readings:

(5) Access the TWA page.

(6) Press the button.

The TWA alarm is calculated over an eight-hour exposure.

= 35 ppm

= 25 ppm

US

ALTAIR® 5X PID

22

TWA calculation examples:

1 hour exposure of 50 ppm:

Description

(1 hour x 50 ppm) + (7 hours x 0 ppm)

8 hours

4 hour exposure of 50 ppm and 4 hour exposure of 100 ppm:

(4 hours x 50 ppm) + (4 hours x 100 ppm)

8 hours

12 hour exposure of 100 ppm:

(12 hours x 100 ppm)

8 hours

This page can be de-activated through MSA Link software.

Date Display

Current date appears on the display in the format: MM-DD-YY.

Last cal page

Displays the device last successful calibration date in the format: MM-DD-YY. This page can be deactivated through MSA Link software or the SETUP - CAL OPTIONS page.

Cal due page

Displays the days until the device's next calibration is due (user selectable). This page can be de-activated through MSA Link software or the SETUP - CAL OPTIONS page.

Discoverable Mode page

Allows the user to put the device into Bluetooth discoverable mode in order to pair with another device.

This page can be deactivated through the SETUP - INSTRUMENT OPTIONS page.

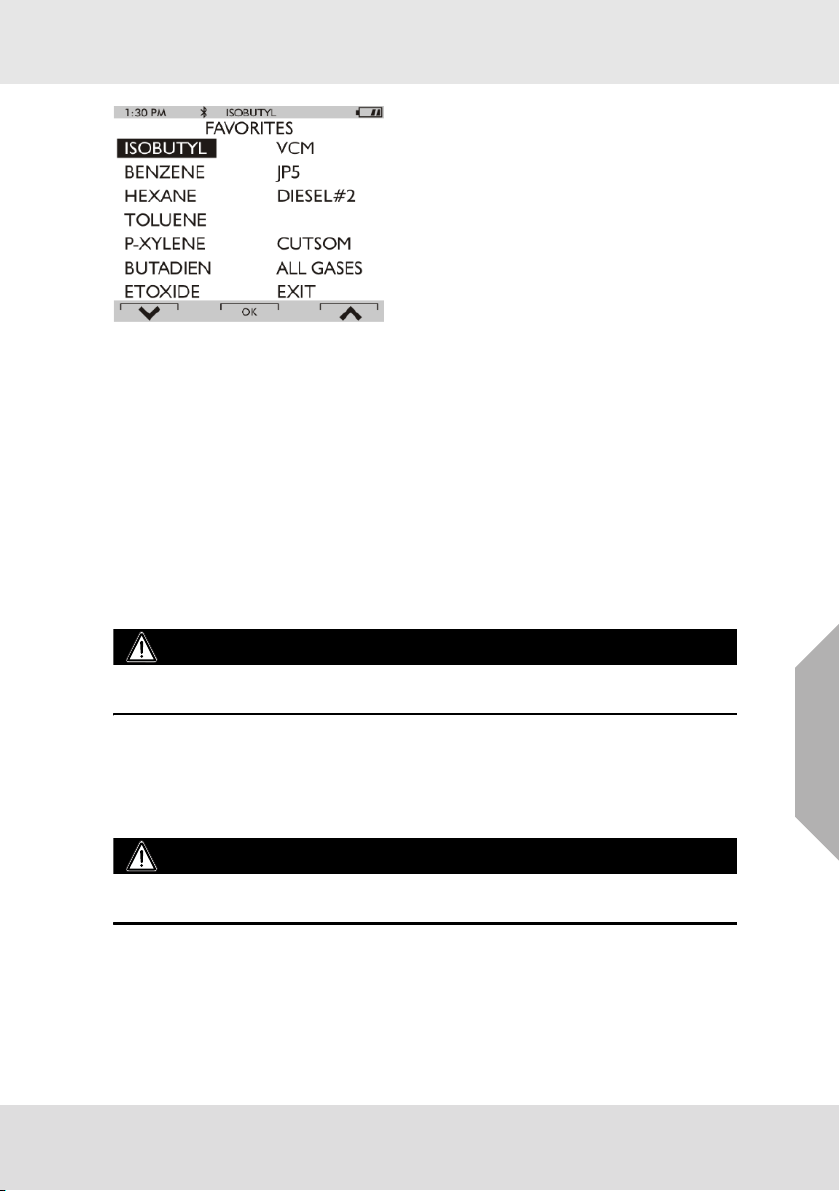

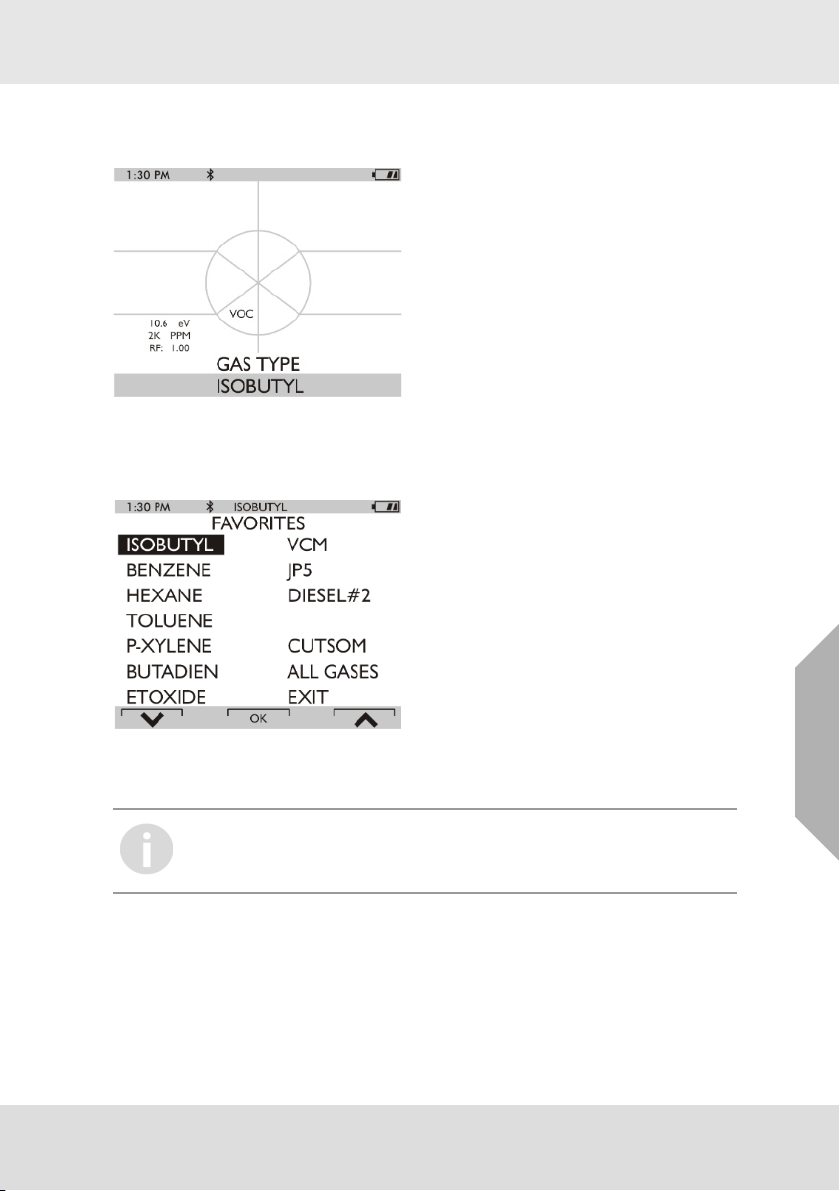

Change VOC Gas? Page

This page is selectable if the "Menu Enable" feature is ON as described in section 4.5 "Device Setup".

This page contains the 10 Favorite PID gases, the All Gases list and the Custom Gas list. An example

of this screen is shown below:

= 6.25 ppm

= 75 ppm

= 150 ppm

US

ALTAIR® 5X PID

23

Motion Alert Activation Page

When the MotionAlert feature is active, the + symbol appears. The device enters pre-alarm when no

motion is detected for 20 seconds. This condition can be cleared by moving the device. MotionAlert is

turned OFF each time the device is powered OFF. After 30 seconds of no motion, the full MotionAlert

alarm is triggered. This alarm can only be cleared by pressing the button. This page displays if it

was selected in Setup Mode. To activate or deactivate the MotionAlert feature, press the button

while the MOTIONALERT ACTIVATION page is displayed.

3.6 Sensor Missing Alarm

Enabled PID and XCell sensors are continuously monitored for proper function. If, during operation,

the PID or an XCell sensor is detected as failed or disconnected, this alarm message appears.

•"SENSOR MISSING" flashes on the display.

• The problematic sensor is indicated.

• The alarm sounds and the Fault and Alarm LEDs flash.

• The alarm can be silenced by pressing the button; no other pages can be viewed.

Description

WARNING!

When this alarm occurs, the device is inoperative for measuring gases. The user must exit the

hazardous area, the device must be powered down, and the sensor situation must be corrected.

3.7 Monitoring Toxic Gases

The device can monitor the concentration of a variety of toxic gases in ambient air. Which toxic gases

are monitored depends on the installed sensors.

The device displays the gas concentration in parts per million (ppm), mol/mol or mg/m

Measuring page. Gas units are selected in the SETUP - INSTRUMENT OPTIONS page.

WARNING!

If an alarm is triggered while using the device, leave the area immediately.Remaining in the area under

such circumstances can cause serious personal injury or death.

The device has four gas alarms:

•HIGH Alarm

• LOW Alarm

•STEL Alarm

•TWA Alarm

ALTAIR® 5X PID

3

on the

US

24

Description

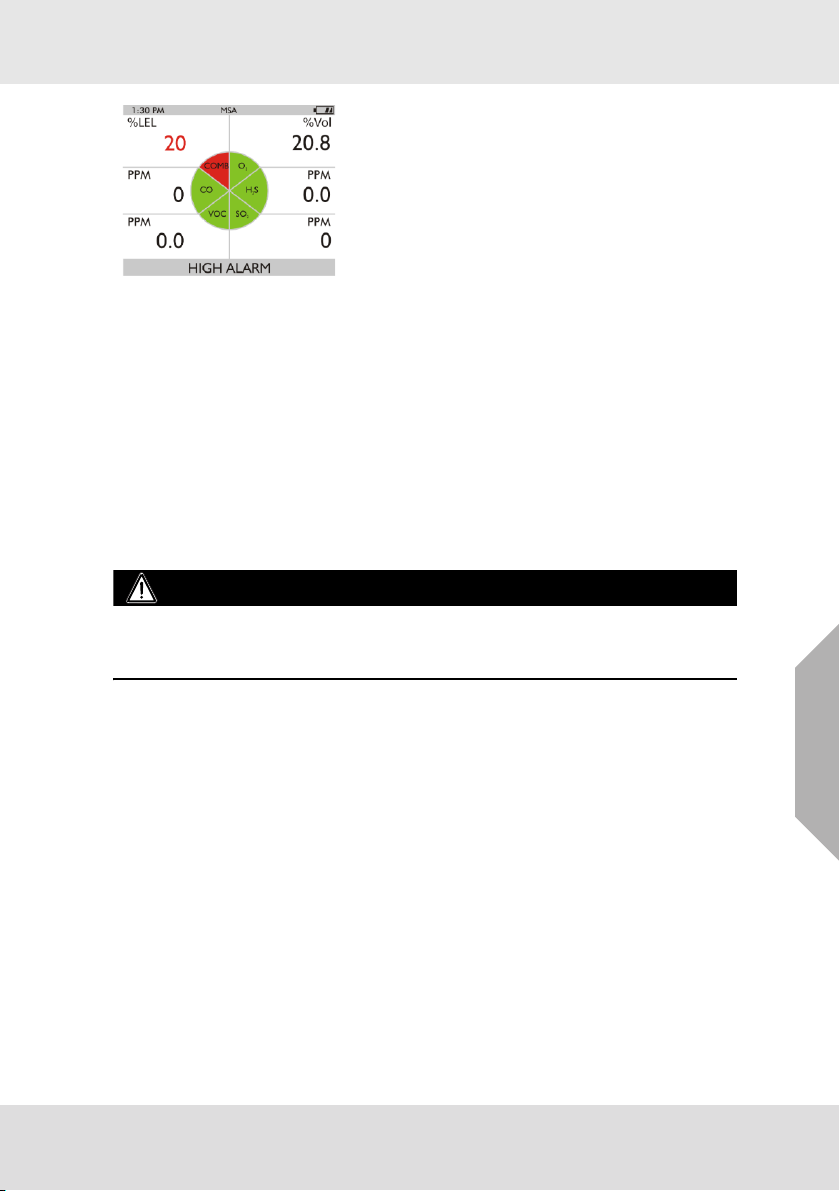

Fig. 6 Alarm Conditions (here High Alarm)

The carbon monoxide channel in the device is equipped with an internal filter. The purpose of this filter

is to protect the CO sensor from acid gases (H2S, SO2, etc.) and from the hydrocarbons that the device

is intended to measure, including the calibration gas, isobutylene. In normal use, an interferent signal

for calibration or bump checking the device should not be observed on the CO channel. However,

exposure to large amounts of certain hydrocarbons (either long exposure times or high concentrations)

can overwhelm the filter and appear as signals on the CO channel.

In normal operation, after the hydrocarbon exposure is ended, the filter is designed to outgas absorbed

hydrocarbons at a rate that will not cause a signal on the CO channel. However, if the unit is exposed

to high temperature (>40°C), this desorption rate increases and spurious signals may be observed on

the CO channel due to gassing of previously absorbed hydrocarbons. Typically the CO sensor will

recover within 24 hours but extremely high exposures can extend this time. After the recovery period

if the CO sensor can no longer be calibrated or shows an elevated reading that cannot be brought to

zero with a zero calibration, the CO sensor should be replaced.

WARNING!

Extremely high levels of VOCs will send the CO sensor into alarm and the sensor may not

recover or the recovery period will be significant.

Take the impact on sensor performance into account when installing sensors.

If the gas concentration reaches or exceeds the alarm set point or the STEL or TWA limits, the:

• alarm message displays and flashes in combination with the corresponding gas concentration

• backlight turns on

• alarm sounds (if active)

• alarm LEDs flash (if active)

• vibrating alarm triggers (if active)

3.8 Monitoring Oxygen Concentration

The device monitors the oxygen concentration in ambient air. The alarm set points can be set to activate on two different conditions:

• Enriched - oxygen concentration > 20.8% or

• Deficient - oxygen concentration < 19.5%.

While the device can detect up to 30% oxygen in the ambient air, it is approved for use only up to 21%

oxygen-content.

ALTAIR® 5X PID

US

25

WARNING!

If an alarm activates while using the device, leave the area immediately.

Remaining in the area under such circumstances can cause serious personal injury or death.

When the alarm set point is reached for either of the above conditions:

• the alarm message displays and flashes in combination with the corresponding gas concentration

• backlight turns on

• alarm sounds (if active)

• alarm LEDs flash (if active)

• vibrating alarm triggers (if active)

The LOW alarm (oxygen deficient) is latching and will not automatically reset when the O

tion rises above the LOW set point. To reset the alarm press the button. If the alarm is latching, the

button silences the alarm for five seconds. Alarms can be made latching or unlatching via MSA Link

software.

False oxygen alarms can occur due to changes in barometric pressure (altitude), humidity or extreme

changes in ambient temperature.

It is recommended that an oxygen calibration be performed at the temperature and pressure of use.

Be sure that the device is in known fresh air before performing a calibration.

3.9 Monitoring Combustible Gases

The device can be equipped with a catalytic combustible sensor that detects a variety of combustible

gases up to 100 % LEL and displays the reading as either % LEL or % CH

WARNING!

If an alarm is triggered while using the device, leave the area immediately.Remaining in the area under

such circumstances can cause serious personal injury or death.

.

4

Description

concentra-

2

The catalytic combustible sensor has two alarm setpoints:

•HIGH Alarm

• LOW Alarm

If the gas concentration reaches or exceeds the alarm set point, the device:

• alarm message displays and flashes in combination with the corresponding gas concentration:

• backlight turns on

• alarm sounds (if active)

• alarm LEDs flash (if active)

Gas Exposure of 100 % LEL

When gas reading exceeds 100 % of the lower explosive limit (LEL), the catalytic combustible sensor

enters a Lock Alarm state and displays “XXX” in place of the actual reading.

WARNING!

A catalytic combustible gas reading of "XXX” indicates the atmosphere could be above 100 %LEL or

5.00 % Vol CH4 and an explosion hazard exists. Move away from contaminated area immediately.

ALTAIR® 5X PID

US

26

The user can clear the LockAlarm state only by turning the device OFF, and then ON again in a fresh

air environment. When catalytic combustible gas reading digits appear, the device is available again

for measuring gases.

Check national standard values for 100 % LEL.

3.10 Monitoring VOC Gases

The device is equipped with a PID sensor that detects a variety of VOC gases. The device displays

the gas concentration in parts per million (ppm), µmol/mol or mg/m3 on the Measuring page.

WARNING!

If an alarm is triggered while using the device, leave the area immediately.

Remaining in the area under such circumstances can cause serious personal injury or death.

The device has four gas alarms:

•HIGH Alarm

• LOW Alarm

•STEL Alarm

•TWA Alarm

If the gas concentration reaches or exceeds the alarm set point or the STEL or TWA limits, the:

• alarm message displays and flashes in combination with the corresponding gas concentration

• backlight turns on

• alarm sounds (if active)

• alarm LEDs flash (if active)

• vibrating alarm triggers (if active)

To reset the alarm press the button.

False VOC alarms can occur due to changes in barometric pressure (altitude), humidity or

extremechanges in ambient temperature.

It is recommended that a VOC calibration be performed at the temperature, humidity and pressure of

use.

Be sure that the device is in known fresh air before performing a calibration. For optimal lamp strike,

the PID lamp should be started within the normal temperature range.

Description

US

When the device is calibrated in an dry, air conditioned environment and taken to a high

temperature and high humidity outdoor environment, a VOC Low or High alarm may be

triggered by this sudden change. It is recommended that the PID sensors be cleaned

prior to this transition to avoid this situation, or to acclimate the sensor to the outdoor

conditions in a known safe area.

ALTAIR® 5X PID

27

3.11 Displaying Current Response Factor

The current Response Factor (RF) is displayed at device startup along with the PID lamp potential in

eV value, sensor range and VOC gas type.

During operations, the RF can be displayed through several menus. If the Menu Enable option is On,

use the button on the Main Measuring page to scroll through the menu options and select YES on

"Change VOC Gas?". Selecting any gas on this page will display the 8 character gas name, the

Response Factor, the Maximum Value of the VOC gas and the current High and Low Alarm values.

Description

The Maximum Value is calculated by multiplying the sensor range by the RF. For example, the

Max Value for Hexane is 2000 *4.5 = 9000 ppm. The maximum value cannot exceed 9999 ppm .

It is the responsibility of the user to change the VOC Low and High Alarms as appropriate

for the applied RF. The selection of the alarm limits must be under the direction of a qualified safety professional who has carefully evaluated the specific hazards of the jobsite

where it will be used and who is completely familiar with the product and its limitations.

A complete list of the 8 character gas name and Response Factors for all VOC gases is contained in

chapter 10 "PID Response Factor Table".

ALTAIR® 5X PID

US

28

Loading...

Loading...