MSA Safety 10128627, 10128628, 10128642, 10153984, 10128644 User Manual

Operating Manual

GALAXY® GX2

Automated Test System

Order No.: 10127150/02

WARNING

Read this manual carefully before using the instrument. The instrument will perform as designed

only if it is used and maintained in accordance with the manu facturer's in struction. Otherwise, it

could fail to perform as designed and persons who rely on this instrument for their safety could

sustain serious personal injury or death.

WARNING

Refer to the applicable gas detector(s) operating manual for proper set-up and operatio n.

Follow all local regulations and internal requirements relating to both the GALAXY GX2 System

and the gas detector. Misuse can result in serious personal injury or death.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

United States

Phone 1-800-MSA-2222

Fax 1-800-967-0398

For your local MSA contacts please go to our website www.MSAsafety.com

MSA AUER

MSA

Contents

Contents

1 Safety Regulations ................................................................................................................... 5

1.1 Correct Use .......................................................................................................................... 5

1.2 Product Warranty ................................................................................................................. 6

2 Introduction .................................. ...................................... .................................... .................... 8

2.1 Power Supply ..................................................................................................................... 10

2.2 The Test Stand .................................................................................................................. 10

SD or SDHC Memory Card Slot ...................................................................................... 11

Test Stand Networked to a PC ........................................................................................ 11

Test Stand is Stand-Alone ............................................................................................... 12

USB Drives ...................................................................................................................... 13

2.3 Ethernet Interface .............................................................................................................. 13

2.4 Software Options ................... ... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ... .... ..... 14

2.5 Cylinder Holder (electronic) ............................................................................................... 14

2.6 Optional Printer ............................ ... ... .... ... ... ... .... ... ... ... ....................................... ... ... ......... 15

2.7 Optional Multi-Unit Charger ......................... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 15

2.8 Special Conditions for Use with Reactive Gases ............................................................... 16

3 Installation .................................... ................................ ................................... ......................... 18

3.1 Connect Units in a Bank .................................................................................................... 19

3.2 Connect a Test Gas Source Without a Cylinder Holder ..................................................... 20

3.3 Network Test Stands .......................................................................................................... 20

3.4 Removing Gas Seal for Certain ALTAIR and ALTAIR Pro Instruments . ... .... ... ... ... ... .... ... .. 21

3.5 Desktop Mounting .............................................................................................................. 22

3.6 Wall Mounting .................................................................................................................... 24

3.7 SD or SDHC Memory Card Option .................................................................................... 25

4 Setting Up the GALAXY GX2 System .................................................................................... 26

4.1 Initial Setup ........................................................................................................................ 26

4.2 Security Setup .................................................................................................................... 28

4.3 Home Screen ............................... ... ... .... ... ... ... .... ...................................... .... ... ... ... ... ......... 28

4.4 General Setup ................. ... .... ... ... ... ... .... ... ....................................... ... ... ... .... ... ... ... ... ......... 30

4.5 GX2 Configuration ....................... ... ... .... ... ....................................... ... ... ... .... ... ... ... ... .... ..... 31

Backlight/Volume Setup .................................................................................................. 31

GALAXY GX2 Setup ....................................................................................................... 36

GX2 Gas Setup ............................................ .... ... ... ... .... ...................................... ... .... ... .. 39

Network Setup (Optional) ................................................................................................ 42

Port Setup (Optional) ...................................................................................................... 43

4.6 Instrument Configuration ....................................................................................................43

Instrument Setup ............................................................................................................. 45

US

GALAXY GX2 Automated Test System

3

Contents

Sensor Setup ............. ... .... ... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... ... ... ..47

Save Settings ............ ... .... ...................................... .... ... ... ... .... ... .....................................49

Load/Delete Settings ...................................................................................................... 49

Update Settings ...............................................................................................................50

4.7 Cylinder Configuration ............ ... .......................................... .......................................... ..... 50

Cylinder Setup ........................................................ .... ... ... ... .... ... ... ... ... .... ........................51

Expiration Setup ............................................ ... ... ... .... ... ... ... .... ... ..................................... 52

Special Conditions for Use with 100% LEL or Greater Methane Calibration Gas .......... 53

5 Using the GALAXY GX2 System ............................................................. ... .... ... ... ... .... ... ... ... .. 54

5.1 Turning on the System .......................................................................................................54

5.2 Inserting the Instrument ............... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... ... ..... 54

5.3 Running a Test ...................................................................................................................55

5.4 Classic Mode ...... .... ... ... ... .... ... ....................................... ... ... ... .... ... ... .................................. 59

5.5 Automated Testing Features .............................................................................................59

GALAXY GX2 Always Ready Feature .............................................................................59

MSA

Time of Day Automated Testing .....................................................................................60

5.6 E-mail Notification .................................................. ... .... ... ... ... .... ... ... .................................. 61

5.7 Overdue Calibration and Bump Notification .......................................................................61

6 Troubleshooting .............................................................. .... ... ... ... .... ... ... ... ... .... ........................ 62

6.1 Instrument Will Not Initiate a Bump or Calibration ..................... ... ... ... ... .... ... ... ... ...............62

6.2 Instrument Fails Zero Calibration or Bump ........................................................................ 63

6.3 Instrument Fails Span Calibration or Bump .......................................................................63

6.4 Instrument Records Do Not Display ................. ....................................................... ........... 63

6.5 Cylinder Data Does Not Display ....................... .......................... ......................... ............... 64

6.6 Test Stand Yellow LED ......................................................................................................64

6.7 System Error Messages ..................................................................................................... 66

6.8 Automated Testing Does Not Occur .................................................................................. 67

Time of Day is set on the GALAXY GX2 but no test occurred ......................................... 67

My Altair 4X didn't calibrate when it was supposed to .....................................................67

7 Maintenance (Cleaning and Part Replacement) .................................................................... 68

7.1 Corrective Maintenance .....................................................................................................68

7.2 Replacement Parts and Accessories ................................................................................. 68

7.3 Fresh Air Filter Replacement .............................................................................................72

7.4 O-Ring Seal Replacement (Cylinder Holder) ..................................................................... 73

7.5 Inlet Seal Replacement (ALTAIR 5/5X Gas Detector) .......................................................73

7.6 Rubber Insert Replacement (ALTAIR Gas Detector) ......................................................... 75

8 Technical Specifications ......................................................................................................... 76

9 GALAXY GX2 Default Parameters ..........................................................................................77

4

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

1 Safety Regulations

1.1 Correct Use

Read this manual carefully before using the instrument. The instrument will perform as designed

only if it is used and maintained in accordance with the manufacturer's instruction. Otherwise, it

could fail to perform as designed and persons who rely on this instrument for their safety could

sustain serious personal injury or death.

Safety Regulations

WARNING

WARNING

(1) Do not use silicone-type lubricants in assembling the GALAXY

Test System and do not allow silicone vapors to be drawn into the flow system while in

operation. Silicone can desensitize the combustible gas sensor, thereby giving erroneously

low readings.

(2) Use the GALAXY GX2 System only in non-hazardous environments free of combustible

concentrations of gases and vapors. System use with 100% LEL or greater me thane is described in chapter 4.7 under Special Conditions for Use with 100% LEL or Greater Methane

Calibration Gas.

(3) Use only genuine MSA replacement parts when performing any maintenance procedures

on the GALAXY GX2 System. Substitution of components can seriously impair

performance.

Failure to follow the above can result in serious personal injury or loss of life.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits a re designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipme nt g enerates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio com munications. Op eration of this equipm ent

in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

®

GX2 Automated

NOTICE

This is a class A product in accordance with CISPR 22. In a domestic environment, this product

may cause radio interference, in which case the user may be required to take adequate

measures.

US

GALAXY GX2 Automated Test System

5

Safety Regulations

FCC Warning Statements

Changes or modifications not expressly approved by the manufacturer could void the user's

authority to operate the equipment.

Industry Canada (IC) Warning Statements

The installer of this radio equipment must ensure that the antenna is located or pointed such that

it does not emit RF field in excess of Health Canada limits for the general population; consult

Safety Code 6, obtainable from Health Canada's website www.hc-sc.gc.ca/rpb.

1.2 Product Warranty

The warranties made by Mine Safety Appliances Company with respect to the produ ct are voided

if the product is not used and serviced in accordance with the instructions in this manual. Protect

yourself and others by following them. We encourage our customers to contact MSA regarding

this equipment prior to use or for any additional information relative to use or repairs.

ITEM WARRANTY PERIOD

GALAXY GX2 Test Stand,

Cylinder Holder and Multi Unit

Charger

Optional Receipt/ Sticker Printer 1 year from ship date

MSA warrants that this product will be free from mechanical defects and faulty workmanship for a period of two (2)

years from date the product is first used, provided it is

maintained and used in accordance with MSA's instructions and/or recommendations. Warranty shall not exceed

two years and six months from the date of manufacture.

MSA

This warranty does not cover filters, fuses, etc. Certain other accessories not specifically listed

here may have different warranty periods. This warranty is valid only if th e pr oduct is main ta ined

and used in accordance with Seller's instructions and/or recommendations. The Se ller shall be released from all obligations under this warranty in the event repairs or modifications are made by

persons other than its own or authorized service personnel or if the warranty claim results from

physical abuse or misuse of the product. No agent, employee or representative of the Seller has

any authority to bind the Seller to any a ffirmation, representation or wa rranty concerning this product. Seller makes no warranty concerning components or accessories not manufactured by the

Seller, but will pass on to the Purchaser all warranties of manufacturers of such components.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED OR

STATUTORY, AND IS STRICTLY LIMITED TO THE TERMS HEREOF. SELLER

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE.

6

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Safety Regulations

Exclusive Remedy

It is expressly agreed that Purchaser's sole and exclusive remedy for breach of the above warranty, for any tortious conduct of Seller, or for any other cause of action, shall be the replacement at

Seller's option, of any equipment or parts thereof, which after examination by Seller is proven to

be defective. Replacement equipment and/or parts will be provided at no cost to Purchaser,

F.O.B. Seller's Plant. Failure of Seller to successfully replace any nonconforming equipment or

parts shall not cause the remedy established hereby to fail of its essential purpose.

Exclusion of Consequential Damage

Purchaser specifically understands and agrees that under no circumstances will seller be liable to

purchaser for economic, special, incidental or consequential damages or losses of any kin d whatsoever, including but not limited to, loss of anticipated profits and any other loss caused by reason

of nonoperation of the goods. This exclusion is app licable to claims for breach of warranty, tortious

conduct or any other cause of action against seller.

US

GALAXY GX2 Automated Test System

7

Introduction

2 Introduction

Congratulations on purchasing the GALAXY GX2 Automated Test System, the next generation

Test Stand and instrument management system from MSA. This system is used exclusively with

the ALTAIR

to represent that entire line of ALTAIR gas detection instruments.

In this manual the user will learn to install and configure the GALAXY GX2 Test Stand and optional

attachments, and test gas detectors. Maintenance, Troubleshooting, and Technical Specifications

sections are also provided.

The Test Stand uses a sophisticated internal processor and simple to use touch screen display

for the configuration of calibration parameters and gas detector settin gs, and for gath ering instrument data.

Each Test Stand and optional attachments can be wall or desk mounted to serve the needs of the

user. Constructed of durable composite polymers, this equipment is designed for normal indoor

applications and operates within a broad temperature range of 0º to 40ºC in non-condensing humidity atmospheres.

The principal components of the GALAXY GX2 System include the Test Stand and optional electronic or non-electronic Cylinder Holder, Multi-Unit Charger, and Receipt/ Sticker Printer. These

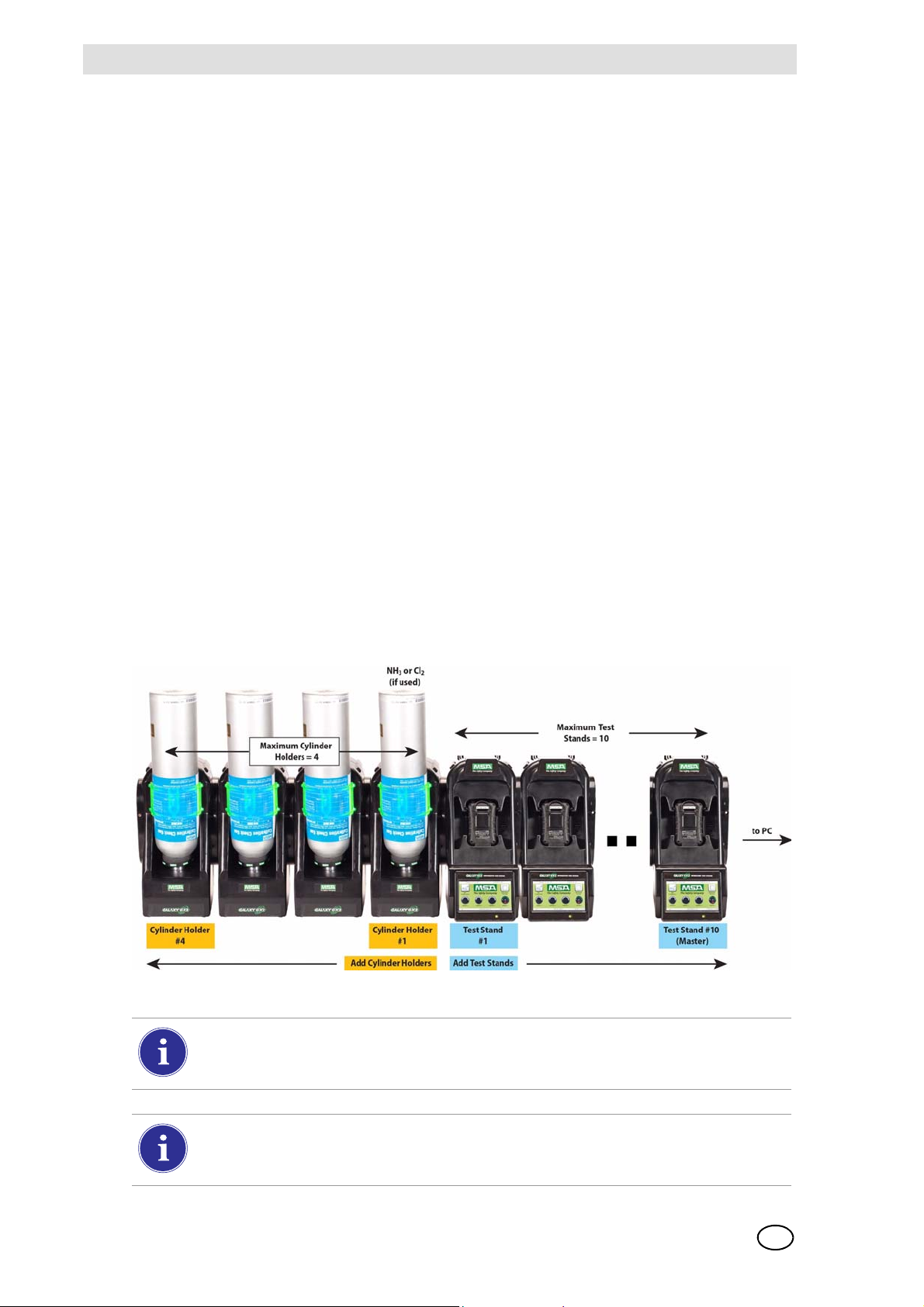

components [ Fig. 1] are designed to be attached (excluding the printer), to avoid accidental

separation during operation.

®

family of gas detectors. This manual uses the terms instrument and gas detector

MSA

Fig. 1 The GALAXY GX2 Automated Test System

8

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Introduction

The Test Stand is a standalone unit that can accommodate one gas detector of the ALTAIR family.

However, each Test Stand contains the plumbing and electronic ports to simultaneo usly connect

a total of 10 Test Stands and four Cylinder Holders (electronic or non-electronic).

For applications where multiple Cylinder Holders are connected, the Test Stand Expanded Sole-

noid option must be ordered. This option allows the Test Stand to open a nd clo se up to fo ur Cylinder Holder valves for gas detectors that may require multiple cylinders for test purposes. For

example, an ALTAIR 5/5X with the standard 4 sensors plus a toxic sensor likely requires two gas

cylinders.

The electronic Cylinder Holder is designed to read a Radio Frequency Identification (RFID) tag

embedded in a plastic ring on MSA test gas cylinders. The RFID tag contains cylinder parameters

that are necessary for successful calibration operations, providing the customer with an exceptionally easy setup experience. Gas cylinder information is automatically populated without user

intervention when using the RFID-tagged gas cylinders.

If MSA test gas cylinders are not used, the non-electronic version of the Cylinder Holder is available. This configuration [ Fig. 2] requires the user to manually enter cylinder parameters.

Fig. 2 Non-electronic Cylinder Holder and Test Stand.

A USB port is provided on the Test Stand that may be used with the GALAXY GX2 USB key to

change instrument settings via the touch scree n. This function allows for convenient fleet

management capabilities. The port may also be used for an optional Receipt/ Sticker Printer, to

print calibration/bump stickers or paper receipts after an instrument test.

The primary functions of the Test Stand are to calibrate and bump the ALTAIR family of gas detectors.

A Bump Test (or Function Check) is a qualitative check conducted by applying a known challe nge

gas to the instrument. The purpose of this check is to confirm sensor functionality and to verify the

integrity of the flow path to the sensor(s). Perform a bump test prior to each day's use.

US

GALAXY GX2 Automated Test System

9

Introduction

A successful calibration consists of the adjustment of the sensor('s) output to match the precise

concentration value of a known traceable calibration cylinder. A calibration can be performed at

any time to ensure maximum accuracy. A calib ration should be performed periodically at regular

intervals and immediately if the unit fails a bump test.

See the instrument manual for specific conditions that require a more frequent bump or calibr ation

interval. Also see the instrument manual for information on ch ecking the gas detector alarm functions.

In the following sections of this manual the user will learn how to install the GALAXY GX2

Automated Test System, set up its functionality, and perform instrument tests. The hardware, software, and configuration options anticipate the user's needs and provide superb efficiency in this

next generation Automated Test System.

GALAXY GX2 System Features and Options

The GALAXY GX2 System automatically identifies the type of gas detector inserted into the Test

Stand. Based on user-defined settings, the Test Stand then per forms bump tests and/or calibrates

the instrument. The data collected from each test event is stored to a memory card

[ chapter 2.2] and/or optional MSA Link™ Pro software application for data analysis (refer to the

MSA Link Pro end-user manual).

MSA

2.1 Power Supply

The Test Stand supplies power to the attached electronic Cylinder Holders. The Test Stand and

Multi-Unit charger are powered indivi dually by one of the following methods:

- Power Module: Input power requirements: 100 - 240 VAC, 47 - 63 Hz

(Several different prong types are available for world-wide AC sockets).

- Optional Vehicle Module 12/24 VDC (For use in a cigarette lighter socket).

NOTICE

Use of a power supply not specified by MSA will void the instrument warranty and could cause

damage to the GALAXY GX2 System.

2.2 The Test Stand

The Test Stand performs the following functions:

- Bump or calibration testing per user setup.

- Records test results to the optional memory card and to an optional networked PC interface.

- Sends gas detector Instrument Periodic and/or Session da talogs to a networked PC inte rface.

- Provides optional instrument charging capability.

- USB key allows gas detector settings to be changed securely, with the touch of the Test Stand

screen.

- Permits printing of test results to an instrument sticker or receipt, with the optional Receipt/

Sticker Printer.

- Sends e-mail notification of system alerts per user setup.

10

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Introduction

1

2

3

4

5

6

An LED indicator shows the status of the Test Stand:

- Green light indicates that the Test Stand hardware and software are fully functional.

- Blinking green light indicates that the Test Stand is performing the user specified test or data-

log download.

- Blinking yellow light indicates that the Test Stand is in error and cannot be used for gas detec-

tor testing. Diagnostic information is available as de scribed on the "GX2 Status" screen on the

Test Stand and in the Troubleshooting section of this manual [ chapter 6].

- Red light indicates that the last calibration or bump test failed.

Fig. 3 Test Stand Physical Features

1 Touch Screen Display 4 SD Card Port

2 Status LED 5 USB Port

3 Test Stand to Test Stand connector 6 Gas plugs

SD or SDHC Memory Card Slot

A memory card port is provided on the Test Stand for calibration and bump record storage. An

SD or SDHC memory card can be purchased from MSA (preferred) or from the following manufacturers:

- Kingston

- SanDisk

- Lexar

- Wintec

The data on an SD or SDHC memory card is encrypted for use with MSA Link™ Pro application.

There is also an application available on the MSA website to create a printable version of the SD

card records (MSA GALAXY GX2 SD Card Reader.exe).The type and amount of data recorded

to the memory card is contingent on whether the Test Stand is networked.

Test Stand Networked to a PC

If the network connection is lost, only calibration and bump r ecords are saved to the memory card.

If networked and e-mail alerts are configured with MSA Link Pro, the Test Stand will generate an

email alert once the memory card reaches 90% and again at 99% capacity.

US

GALAXY GX2 Automated Test System

11

Introduction

Test Stand is Stand-Alone

If the GALAXY GX2 Test Stand is not networked to MSA Link Pro, the memory card will save each

calibration and bump test record. Incomplete records will not be saved.

Once a memory card reaches full capacity, the Test Stand will be in fault and prohibit any unit from

performing tests in that bank, until corrected. The Test Stand can be configured to erase the

memory card, or the user can insert a replacement.

The memory card should only be removed when no test activity is occurring. Events that

occur while no memory card is installed will not be stored in the Test Stand.

If no memory card is used, only the most recent bump or calibration record is stored to

the Test Stand internal memory.

An optional end cap [ Fig. 4] can be placed over the port to protect the memory card and all

external connections.

MSA

Fig. 4 Optional End Cap

12

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Introduction

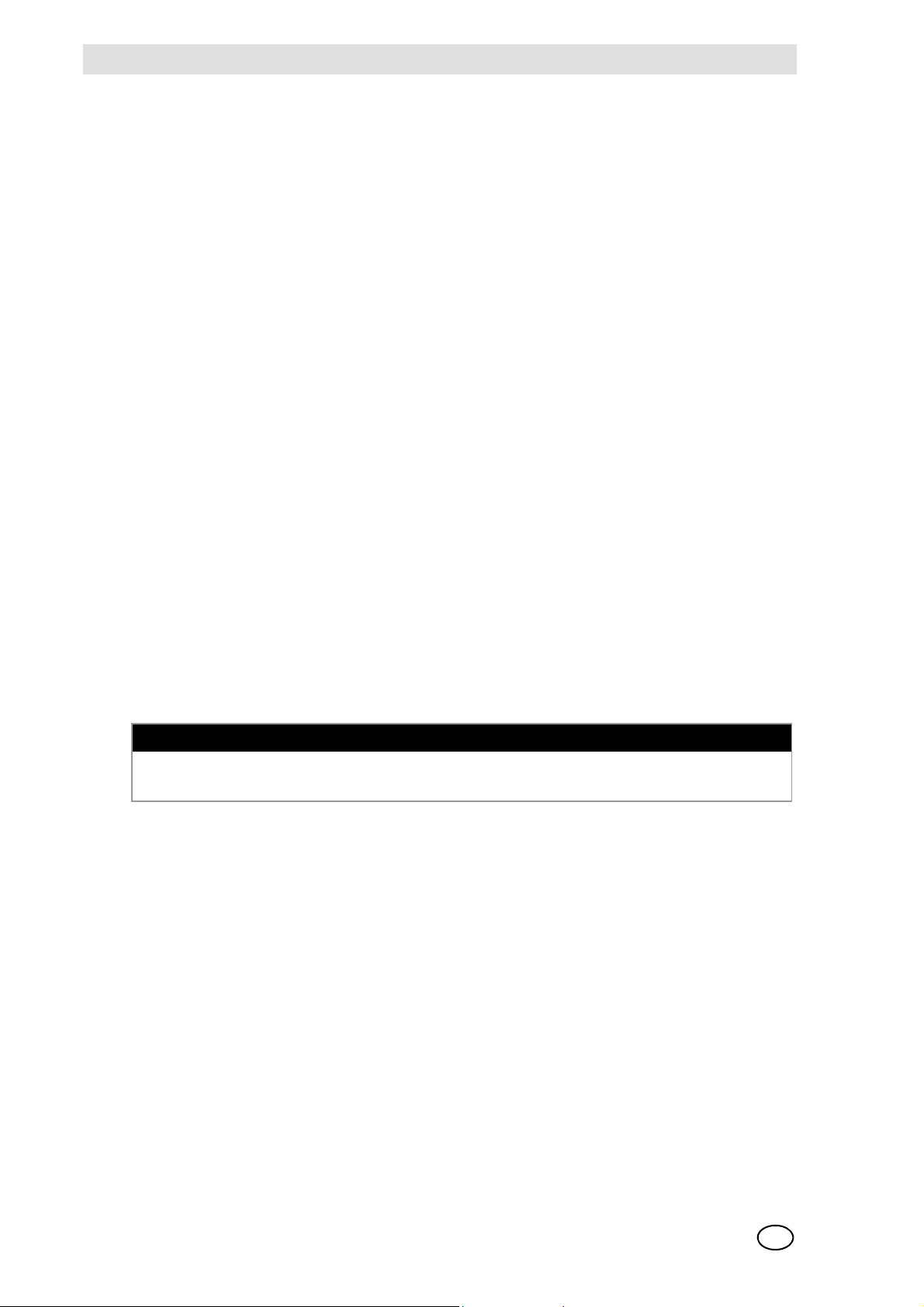

USB Drives

Two optional USB Keys [ Fig. 5] are available for purchase with the GALAXY GX2

Automated Test System:

- GALAXY GX2 USB Key: This key is inserted in the USB port on the Test Stand in order to

change gas detector settings. The key ensures only authorized users can chan ge settings o n

ALTAIR gas detectors; a security step in addition to the four-digit password.

- MSA Link Pro Key: This key is used to enable the MSA Link Pro application on a single PC.

More information about this key can be found in the software prod uct end-user manual.

Fig. 5 GALAXY GX2 USB Key and MSA Link Pro Key

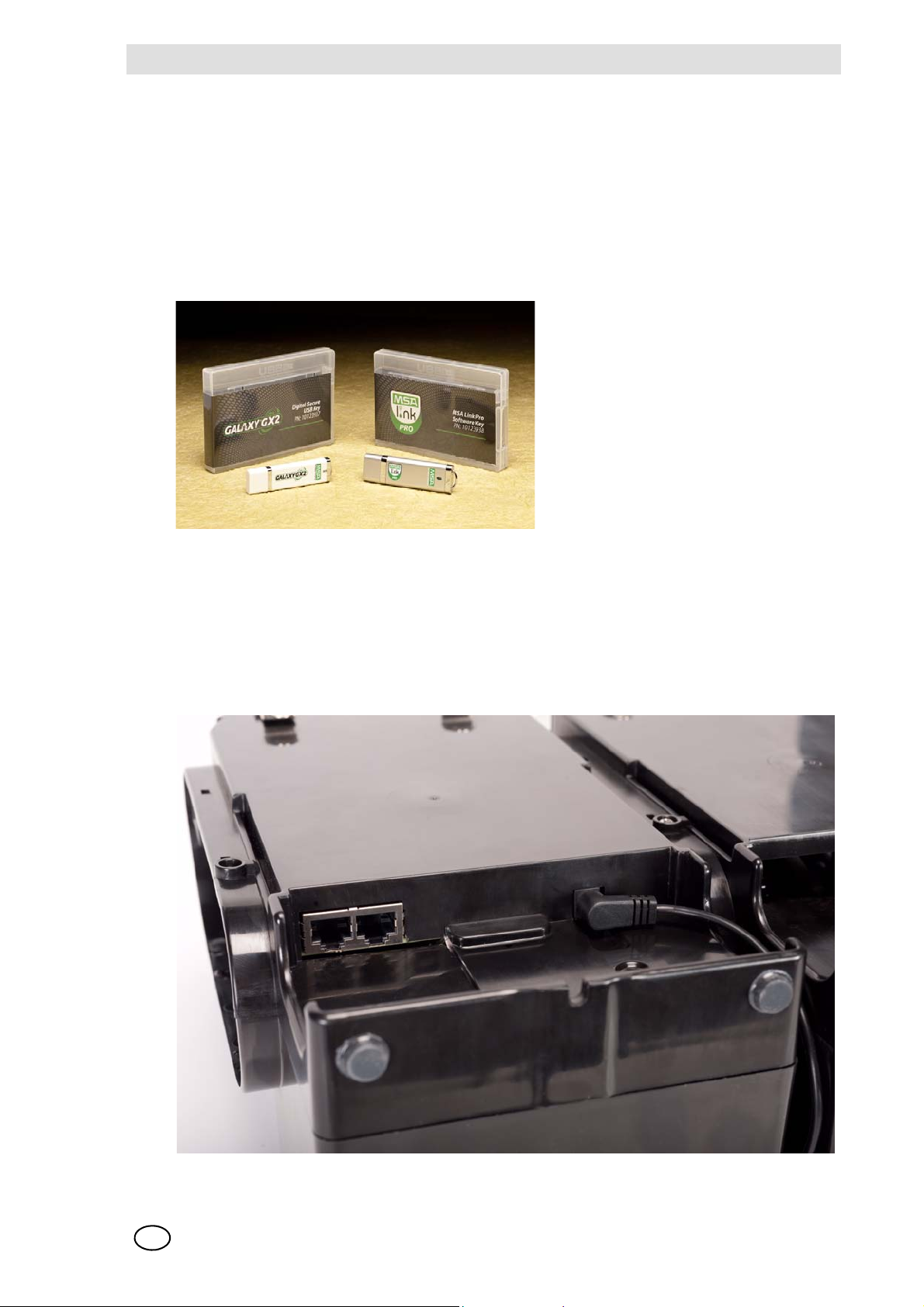

2.3 Ethernet Interface

Two Ethernet Interfaces are provided on the rear of the GALAXY GX2 Test Stand [ Fig. 6]. The

ports allow for the connection and communication distribution between multiple Test Stands. If

networking to a computer, one Ethernet port on the Master Test Stand is used to communicate

with the MSA Link Pro software application.

Fig. 6 Test Stand Ethernet jacks

US

GALAXY GX2 Automated Test System

13

Introduction

1

2

3

2.4 Software Options

The GALAXY GX2 System functions as a standalone system, but the optional MSA Link Pro software application can be used to network the Test Stand to a PC through an Ethernet cable. This

application provides a best-in-class user interface and data analysis toolset to quickly identify issues or concerns that require user action.

MSA Link Pro software provides the user:

- Database storage of instrument Periodic and Session datalogs.

- Automatic or customized reports from the collected data.

- Single glance notification of instruments that are overdue for calibration or bump test.

- Email notifications of GALAXY GX2 System and instrument warnings and error messages.

- Single setting configuration of all GALAXY GX2 units in a bank.

No need to individually configure each Test Stand.

Users may use the free MSA Link software application and an IR dongle

[ chapter 7.2] to communicate directly with their gas detector. MSA Link software

allows a user to upload and download instrument settings, and download datalogs.

MSA

To learn more about installing and using MSA Link Pro software, refer to the software product enduser manual.

2.5 Cylinder Holder (electronic)

The electronic Cylinder Holder can accommodate one test gas cylinder and includes:

Fig. 7 Cylinder Holder Physical Features

1 Light Band 2 RFID Tag 3 Internal Pressure Regulator & Sensor

14

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Introduction

Multi-Color Light Band

Indicates gas bottle functionality.

- Green indicates a bottle is

completely functional, and gas

parameters are within pressure

and expiration date limits.

- Yellow indicates low calibration

gas, or gas is nearing its expiration date.

- A blinking yellow light band indi-

cates a hardware problem with

the cylinder holder.

- Red indicates an empty calibra-

tion gas bottle, or that gas has

expired.

RFID Tag Gas

Identification

Reads the RFID tag of

the MSA test gas cylinder and transmits:

- the gas type

- gas concentration

- expiration date

- lot number

- cylinder part number

to the Test Stand. The

RFID tag is only available on MSA-branded test

gas cylinders shown in

the Maintenance section

[ chapter 7].

Pressure Regulator & Sensor

Reads the pressure of the gas

cylinder and transmits that

information to the Test Stand.

- When gas pressure drops to

approximately 99 psi

(6.89 bar) a warning will

display and the display

numbers appear yellow.

- Once pressure drops to ap-

proximately 49 psi (3.45 bar)

the display numbers appear

red.

- Once pressure drops to less

than 5 psi (0.34 bar) the

Test Stand will prohibit testing with that cylinder.

2.6 Optional Printer

The Printer can print calibration and bump result receipts and calibrations stickers for gas detectors [ Fig. 7]. The Receipt/ Sticker Printer uses a USB cable to connect to the port of the farthest

right Test Stand [ Fig. 3].

Labels are available in two formats [ chapter 7.2]:

- Format #1: Calibration Sticker only (2 cm x 2 cm square label).

- Format #2; Receipt and Sticker combined.

Fig. 8 Optional Printer

2.7 Optional Multi-Unit Charger

There are two configurations of the optional Multi-Unit Charger (MUC). The ALTAIR 4/4X MUC

can simultaneously charge up to four ALTAIR 4/4X gas detectors. Similarly the ALTAIR 5/5X MUC

can charge four 5/5X gas detectors. Each Multi-Unit Charger contains its own power supply and

US

GALAXY GX2 Automated Test System

15

Introduction

does not connect electrically to the Test Stand. The housing is designed to physically connect to

each other, whether bench-top or wall-mounted (if desired).

The light indicators on the Multi-Unit Charger are defined as follows:

- Red indicates that the unit is charging

- Green indicates that the unit is fully charged or no unit is inserted.

Verify the Multi-Unit Charger indicator lights red when an instrument is inserted. A fully

charged instrument will momentarily flash red and the indicator will light green. If the red

light does not engage the instrument may not be seated properly on the charging prong.

Instruments whose battery is completely discharged will need to be trickle-charge

prior to normal charging operations. Such instruments will show a green LED during the

trickle-charge period until normal charging is initiated, at which time the red LED wil l be

active.

There can be as much as a 10 minute window between when the instrument battery indicator

shows charged and the Multi-Unit charger status indicator changes. The instrument indicator is

the most accurate and will indicate the true charge state of the battery.

MSA

Fig. 9 Multi-Unit Charger (Altair 4/4X and 5/5X only)

2.8 Special Conditions for Use with Reactive Gases

If using a Test Stand and Cylinder Holder for calibrating or bump testing a gas Detector configured with a chlorine or ammonia sensor:

16

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Introduction

- Place the chlorine or ammonia gas cylinder in the Cylinder Ho lde r clo ses t to th e Test Sta nd .

- Only one reactive gas Test Stand is allowed in a bank.

- If connecting other Test Stands to the right of the reactive stand, plug the reactive gas outlet

port with a white gas plug before mating the next Test Stand. Otherwise, inaccurate calibration

could result on the reactive sensor.

- Before the first use with reactive toxic gas, condition the regulator and Test Stand with

the gas, by running the calibration twice in sequence. If using chlorine, perform this procedure daily before use.

If not using GALAXY GX2 Cylinder Holders:

- Use a dedicated pressure regulator on the reactive toxic gas cylinder (for chlorine or ammonia,

use P/N 10034391). Label the pressure regulator "FOR CHLORINE USE ONLY" or

"FOR AMMONIA USE ONLY", as applicable (label stickers are provided with regulator).

- Use the shortest possible tubing running from the reactive toxic gas pressure regulator to the

Test Stand's "CYLINDER 1" port.

- Before the first use with reactive toxic gas, condition the regulator and Test Stand with

the gas by running the calibration twice sequentially; for chlorine, perform this pro cedure daily before use.

- Many gases have a cross-sensitivity to other gases. Ens ure that test cylinder gases do not

contain other interfering gases.

The GALAXY GX2 System does not support the calibration or bump testing of chlorine dioxide

(ClO

) sensors due to the reactive nature of the gas. Manual calibration of ClO2 sensors is rec-

2

ommended using a very short tubing length.

US

GALAXY GX2 Automated Test System

17

Installation

3 Installation

The GALAXY GX2 System is a simple to install system that can be desktop or wall mounted. Setup requires simple tools and just a few minutes of time.

Carton Contents

The GALAXY GX2 System will be shipped with the following:

- Test Stand (including gas plugs, barbs and fresh air filter)

- Power Supply (if ordered)

- Spare Parts Kit (gas tubing barbs and plugs)

- Ethernet Cable (short cable for connection between Test Stands)

- Product CD

- Quick Start Guide

- Screen Protector (installed on the display screen)

- DIN Rail clip kit

Tools Needed

MSA

- Phillips head (cross-head) screwdriver.

As stated in the Introduction, the GALAXY GX2 System is designed for the connection of up to

10 Test Stands and four Cylinder Holders [ Fig. 10]. Test Stands must be assembled sequentially on the right-hand side of the first. Cylinder Holder(s) must be installed on the left-hand side

of the first Test Stand.

Fig. 10 Test Stands and Cylinder Holders properly installed in a bank

18

Test gas cylinders containing Chlorine or Ammonia must be installed according to the

directions in the Special Conditions for Use with Reactive Gases section

[ chapter 2.8].

When installing the GALAXY GX2 System, please consider the environmental needs of

your facility. If the customer desires, the GALAXY GX2 System can be used in a

ventilated area to assist in disbursing the test gas exhaus t.

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

This manual provides steps for desktop and wall mounting. The following sections describe the

proper installation for various GALAXY GX2 configurations:

- Connect Units in a Bank (Test Stands and Cylinder Holders) [ chapter 3.1]

- Connect a Test Gas Source Without a Cylinder Holder (optional) [ chapter 3.2]

- Network Test Stands (optional) [ chapter 3.3]

- Removing Gas Seal for Certain ALTAIR and ALTAIR Pro Instruments [ chapter 3.4]

- Desktop Mounting [ chapter 3.5]

- Wall Mounting [ chapter 3.6]

- SD or SDHC Memory Card Option [ chapter 3.7]

3.1 Connect Units in a Bank

(1) On the left-hand side of the Test Stand, ensure all five barb fitting s are in pla ce and straight-

ened before connecting a Cylinder Holder or another Test Stand.

Installation

(2) Once the barb fittings and connectors are fully a ligned, firmly push the two units together until

the screw holes in the flange align.

(3) Insert one of the supplied screws into the front and two screws into the back of the flange.

US

GALAXY GX2 Automated Test System

19

Installation

(4) If connecting multiple Test Stands, remove the white gas plugs [ Fig. 3] from all units ex-

cept the farthest right Test Stand. If using ammonia or chlorine test gas, read the re striction

found under chapter 2.8 “Special Conditions for Use with Reactive Gases” regarding the

white plugs.

(5) Continue adding Test Stands to the right and Cylinder Holders to the left [ Fig. 10].

When connecting two or more Test Stands ensure the white plugs are secured on the

right side of the farthest right unit to prevent gas leakage.

MSA

3.2 Connect a Test Gas Source Without a Cylinder Holder

If high-pressure, high-capacity test gas cylinders are preferred, an optional demand regulator

(p\n 710289) is available for cylinders with pressure less than (<) 30 00 p si. Testing fr om an inde pendent gas source will require additional setup effort, as described in the Cylinder Configuration

section [ chapter 4.7].

(1) On the left-hand side of the Test Stand, en sure all five bar b fittings are in place and str aight-

ened.

(2) Place the user-supplied regulator onto the gas cylinder and secure a length of tubing onto its

outlet.

(3) Securely fit the end of the tubing over the appropriate barb fitting on the GALAXY GX2

Cylinder Holder.

3.3 Network Test Stands

Test Stands that are banked together should be connected through the provided Ethernet cab le.

The Master Test Stand is the one located on the furthest right of the bank.

(1) Insert the short Ethernet cable into the left side jack of each Test Stan d (1) and co nnect it to

the right side jack of the neighboring unit (2) [ Fig. 11].

One interconnect Ethernet cable is included with each Test Stand.

20

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Installation

3

2

1

Fig. 11 Test Stand Ethernet connections

1 Master Test Stand 3 Test Stand to Test Stand port

2 MSA Link Pro port

(2) If connecting the bank to a computer with the MSA Link Pro software, use a customer-

supplied Ethernet cable and connect via the Master Test Stand Ethernet port #1 shown

above.

(3) If not connecting to either a network connection or a PC the interconnecting Ethernet cable

must be inserted into port 1 on the Master Test Stand.

3.4 Removing Gas Seal for Certain ALTAIR and ALTAIR Pro Instruments

All ALTAIR/ALTAIR Pro Test Stands will be shipped with a black rubber base seal and a green

rubber gas seal. The green seal is used only for ALTAIR H

The seal should be removed and stored for ALTAIR O

and all ALTAIR Pro instruments.

2

S and ALTAIR CO instruments.

2

Fig. 12 Altair and Altair Pro Inlet Seals

US

GALAXY GX2 Automated Test System

21

Installation

3.5 Desktop Mounting

(1) Place the GALAXY GX2 System on a flat, stable surface.

(2) Insert the power supply into the power jack [s ee chapter 4.1 for first-time power up initializa-

tion].

MSA

The Test Stand display pivots for ease of viewing.

(3) If using the Electronic Cylinder Holder the clear light band should illuminate once step 2 is

complete. If illumination does not occur firmly push the units together to ensure the connectors are fully seated.

22

GALAXY GX2 Automated Test System

US

MSA AUER

MSA

Installation

(4) If using MSA Cylinder Holders, the left most Cylinder Holder should have a fresh air filter

attached to the top port.

(5) If not using MSA Cylinder Holders, the left most Test Stand should have a fresh air filter

attached to the top port.

(6) Ensure the white plugs are inserted into the five gas connection fittings on the right side of

the farthest right test stand.

US

GALAXY GX2 Automated Test System

23

Installation

3.6 Wall Mounting

When wall mounting the Test Stand (and applicable Cylinder Holder), MSA recommends steps

1-5 from the Desktop Mounting section [ chapter 3.5] above be completed prior to in stalling on

the DIN Rail. For a large configuration of Test Stands and Cylinder Holders, MSA recommends

several people be used for installing or uninstalling from the DIN rail.

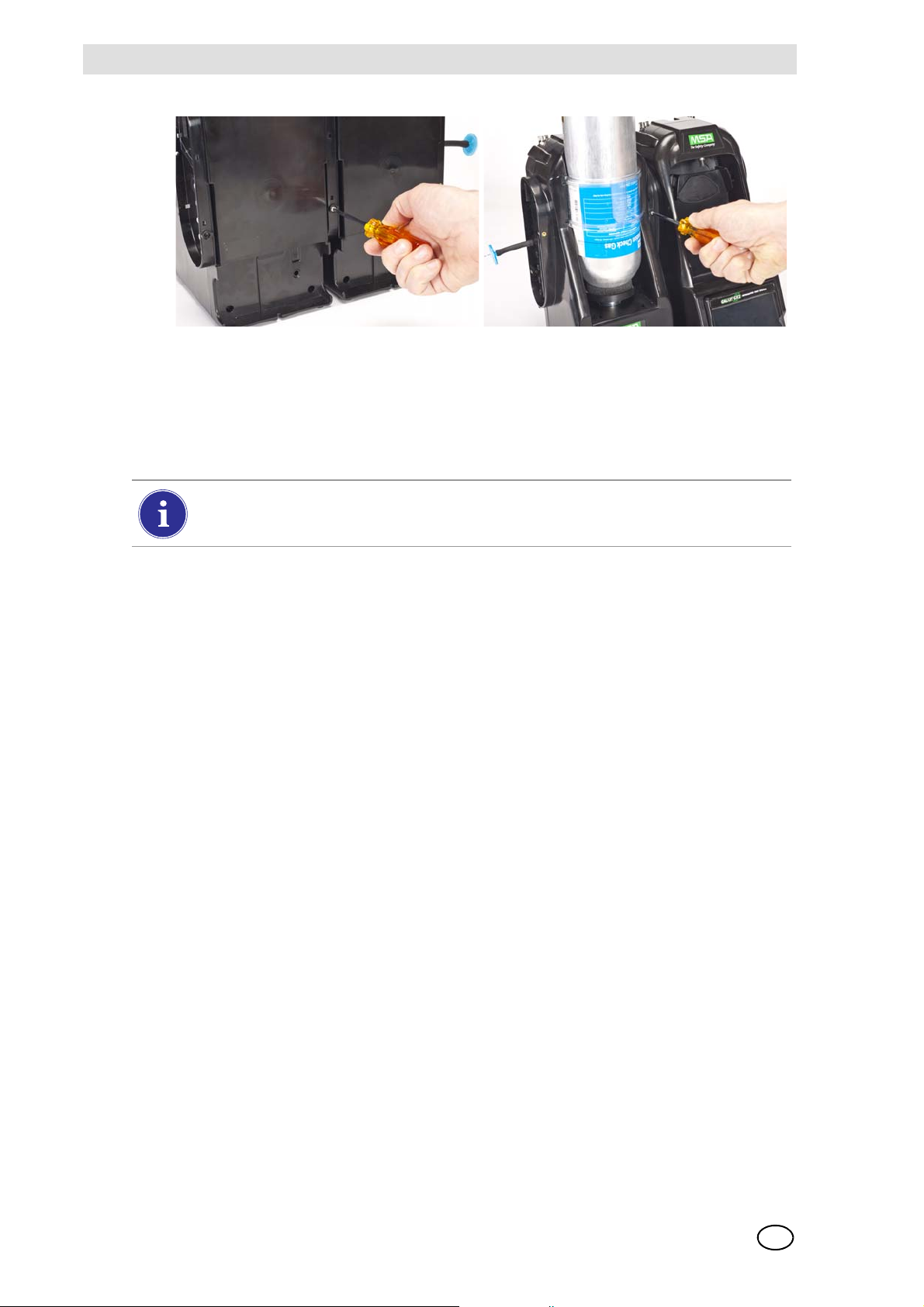

(1) Complete steps 1-5.

(2) Secure the optional DIN rail Clips to the rear of the GALAXY GX2 System, using the included

screws.

MSA

(3) Mount the DIN rail (Type Omega) to the wall by securing it with wall anchors or other suitable

fasteners.

(4) Align the bottom of the DIN rail clips on the lower edge of the wall-mounted DIN rail and snap

the upper part of the clip into place.

(5) To remove from the DIN rail, pull the top of the clip forward to release from the top rail and

push down on the unit to remove from the lower edge of the rail.

24

GALAXY GX2 Automated Test System

US

Loading...

Loading...