Page 1

MSAsafety.com

US

Instruction and Safety Manual

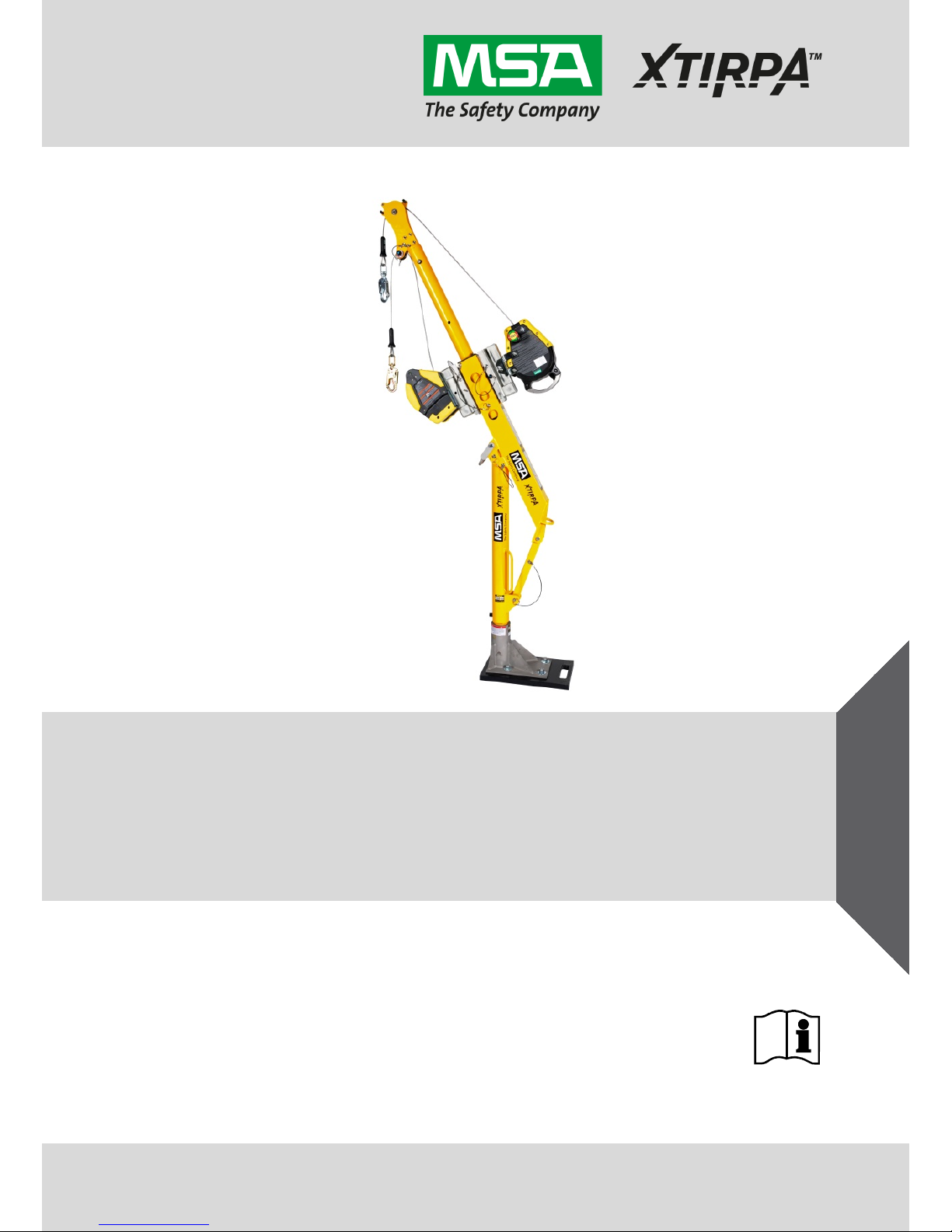

MSA/XTIRPA™ Adapter Base System

24" Reach

Order No.: 10171018/00

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 2

© MSA 2015. All rights reserved

Warning

National standards and state, provincial, and federal laws require

the user to be trained before using this product. Use this manual as

part of a user safety training program that is appropriate for the

user’s occupation. These instructions must be provided to users

before use of the product and retained for ready reference by the

user. The user must read, understand (or have explained), and

heed all instructions, labels, markings, and warnings supplied with

this product and with these products intended f

or use in association

with it. Failure to do so may result in death or serious injury.

XTIRPA™ products are manufactured by Innova Public Utility Products Inc.

Made in Canada.

XTIRPA™ is a Registered Trademark of Innova Public Utility Products Inc.,

used under license in North America and Europe.

Mine Safety Appliances Company

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

United States

For More Information, call 1-800-MSA-2222 or Visit Our Website at

www.MSAsafety.com

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 3

Contents

MSA/XTIRPA™ Adapter Base System 24" Reach 3

US

Contents

1. Safety Regulations .............................................................................. 4

1.1. Correct Use................................................................................ 4

1.2. Usage Limitations ...................................................................... 5

1.2.1 Physical Limitations ................................................................... 5

1.2.2 Hazards ..................................................................................... 6

1.3. Liability Information .................................................................... 6

1.4. Safety and Precautionary Measures to be Adopted ................... 7

1.5. Warranty .................................................................................... 8

2. Description .......................................................................................... 9

2.1. Labels and Markings .................................................................. 9

2.2. System Requirements ............................................................. 11

2.2.1 Compatibility of Components and Subsystems........................ 11

2.2.2 Compatibility of Connectors ..................................................... 12

3. Use ..................................................................................................... 13

3.1. Planning the Use of Systems ................................................... 13

3.1.1 Rescue and Evacuation ........................................................... 13

3.1.2 Free Fall Distance .................................................................... 13

3.2. Pre-Use Inspection .................................................................. 14

3.3. Assembly ................................................................................. 14

4. Cleaning and Maintenance ............................................................... 22

4.1. Cleaning .................................................................................. 22

4.2. Maintenance ............................................................................ 22

5. Inspection .......................................................................................... 23

5.1. Inspection Frequency .............................................................. 23

5.2. Formal Inspection .................................................................... 23

5.3. Procedure for Inspection .......................................................... 23

5.4. Corrective Action ..................................................................... 24

5.5. Inspection Log ......................................................................... 24

6. Storage............................................................................................... 26

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 4

Safety Regulations

4 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

1. Safety Regulations

1.1. Correct Use

The Adapter Base System (hereinafter also called confined space

system) is part of a personal fall arrest, work positioning, personnel

riding, material handling or rescue system for use in confined spaces.

All confined space systems meet applicable OSHA regulations.

The confined space system is designed to be integrated as part of a

complete fall arrest system with a maximum arrest force of 1,800lbf

(8kN). The confined space system is designed to maintain a safety factor

of two, and is to be assembled and used under the supervision of a

qualified person, as required by OSHA. The confined space system is

designed for use by one person.

It is imperative to evaluate the capacity rating of all products incorporated

within the fall arrest system. The capacity of a fall arrest system is the

lowest capacity rating of any product (anchorage connector, SRL, etc.)

integrated in the fall arrest system.

The Adapter Base System anchorage connector is comprised of three

primary components, the davit arm, the mast, and the 3" diameter

adapter base. The Adapter Base System capacity for fall arrest,

personnel riding, rescue, and material handling is as follows:

- 360lbs (163kg) - If using davit arm IN-2210, mast IN-2003, and any

3" diameter adapter base

- 360lbs (163kg) - If using integrated mast and davit arm IN-2295 or

IN-2363, and any 3" diameter adapter base

Capacity for personnel includes the weight of the user plus clothing,

tools, and other user-borne objects.

Free fall distance (limit) must not exceed 6ft (1.8m) in accordance with

OSHA. The Canadian Occupational Health & Safety Act of 1990

specifies that free fall distance must not exceed 5ft (1.5m). The user

must comply with applicable standards and regulations.

When used as part of a personal fall arrest system, fall arresting forces

must not exceed 1,800lbf (8kN).

Warning

If PPE is resold, it is essential that instructions for use maintenance and

periodic examination are provided in the language of destination. Failure

to follow this warning may result in death or serious injury.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 5

Safety Regulations

MSA/XTIRPA™ Adapter Base System 24" Reach 5

US

The Adapter Base System is intended for use by trained and qualified

personnel.

It is imperative that this instruction and safety manual be read and

observed when using the product. In particular, the safety instructions, as

well as the information for the use and operation of the product, must be

carefully read and observed. Furthermore, the national regulations

applicable in the user's country must be taken into account for a safe

use.

Alternative use, or use outside this specification will be considered as

non-compliance. This also applies especially to unauthorized alterations

to the product and to commissioning work that has not been carried out

by MSA or authorized persons.

1.2. Usage Limitations

The following applications limitations must be considered and planned for

before using the confined space system.

1.2.1 Physical Limitations

Persons with muscular, skeletal, or other physical disorders should

consult a physician before using a personal fall arrest system that

includes the confined space system. Pregnant women and minors must

never use these systems.

Increasing age and lowered physical fitness may reduce a person’s

ability to withstand shock loads during fall arrest or prolonged

suspension. Consult a physician if there is any question about physical

ability to safely use this product to arrest a fall or suspend.

Warning

Do not alter this equipment or misuse it. A full body harness is the only

acceptable body holding device that can be used in a fall arrest system.

Failure to follow this warning may result in death or serious injury.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 6

Safety Regulations

6 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

1.2.2 Hazards

Acidic, alkaline, or other environments with harsh substances may

damage the hardware elements in the confined space system. If working

in a chemically aggressive environment, consult MSA to determine

acceptable system components for your specific conditions.

Chemical hazards, heat and corrosion may damage the confined space

system. More frequent formal inspections are required in environments

with chemical hazards, heat and corrosion.

Do not expose to corrosive environments for prolonged periods. Use

extreme caution when working near energized electrical sources.

Maintain a safe working distance (preferably at least 10 feet (3m)) from

electrical hazards. When working near moving machinery parts

(e.g. conveyors, rotating shafts, presses, etc.), make sure that there are

no loose elements in any part of the system.

Any confined space system which shows signs of excessive wear,

deterioration or malfunction must be removed from use and marked

“UNUSABLE” until repaired.

Any confined space system which has been subjected to the forces of a

fall must be immediately removed from service and marked

“UNUSABLE” until submitted to, and released from, formal inspection.

1.3. Liability Information

MSA accepts no liability in cases where the product has been used

inappropriately or not as intended. The selection and use of this product

must be under the direction of a qualified safety professional who has

carefully evaluated the specific hazards of the jobsite where it will be

used and who is completely familiar with the product and its limitations.

The selection and use of this product and its incorporation into the safety

scheme of the jobsite is the exclusive responsibility of the employer.

Product liability claims, warranties also as guarantees made by MSA with

respect to the product are voided, if it is not used, serviced or maintained

in accordance with the instructions in this manual.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 7

Safety Regulations

MSA/XTIRPA™ Adapter Base System 24" Reach 7

US

1.4. Safety and Precautionary Measures to be Adopted

Users of MSA products must be familiar with the user instructions and be

trained by a competent person in:

- workplace hazard identification, evaluation and control

- selection, inspection, use, storage, and maintenance

- usage planning including calculation of free and total fall distance;

maximum arresting force

- compatibility and selection of anchorage/anchorage connectors

including connection to help prevent accidental disengagement

(rollout)

- proper lanyard/harness connection locations

- evacuation and rescue planning and implementation

- consequences of improper use

For Confined Space Applications:

- See OSHA 29 CFR 1910.146

Periodically (at least annually) assess effectiveness of training and

determine the need for retraining or additional training. Contact MSA for

training information.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 8

Safety Regulations

8 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

1.5. Warranty

Express Warranty- MSA warrants that the product furnished is free

from mechanical defects or faulty workmanship for a period of two (2)

years from date of shipment, provided it is maintained and used in

accordance with MSA’s instructions and/or recommendations.

MSA shall be released from all obligations under this warranty in the

event repairs or modifications are made by persons other than its own

authorized service personnel or if the warranty claim results from misu

se

of the product.

No agent, employee or representative of MSA may bind MSA to any

affirmation, representation or modification of the warranty concerning the

goods sold under this contract. MSA makes no warranty concerning

components or accessories not manufactured by MSA, but will pass on

the Purchaser all warranties of manufacturers of such components.

This warranty is in lieu of all other warranties, express, implied or

statutory, and is strictly limited to the terms hereof, MSA specifically

disclaims any warranty of merchantability or fitness for a particular

purpose.

Exclusive Remedy-

It is expressly agreed that the Purchaser’s sole and

exclusive remedy for breach of the above warranty, for any tortious

conduct of MSA, or for any other cause of action, shall be the repair

and/or replacement, at MSA’s option, of any equipment or parts thereof,

that after examination by MSA are proven to be defective.

Replacement equipment and/or parts will be provided at no cost to the

Purchaser, F.O.B. Purchaser’s named place of destination.

Failure of MSA to successfully repair any nonconforming product shall

not cause the remedy established hereby to fail of its essential purpose.

Exclusion of Consequential Damages- The Purchaser specifically

understands and agrees that under no circumstances will MSA be liable

to the Purchaser for economic, special, incidental, or consequential

damages or loses of any kind whatsoever, including but not limited to

loss of anticipated profits and any other loss caused by reason of the

non-operation of the goods. This exclusion is applicable to claims for

breach of warranty, tortious conduct of any other cause of action against

MSA.

For additional information please contact the Customer Service

Department at 1-800-MSA-2222 (1-800-672-2222).

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 9

Description

MSA/XTIRPA™ Adapter Base System 24" Reach 9

US

2. Description

The confined space system is an anchorage connector for users needing

a personal fall arrest, work positioning, personnel riding, material

handling or rescue system for use in confined spaces.

2.1. Labels and Markings

The following labels must be present, legible and securely attached to

the confined space system.

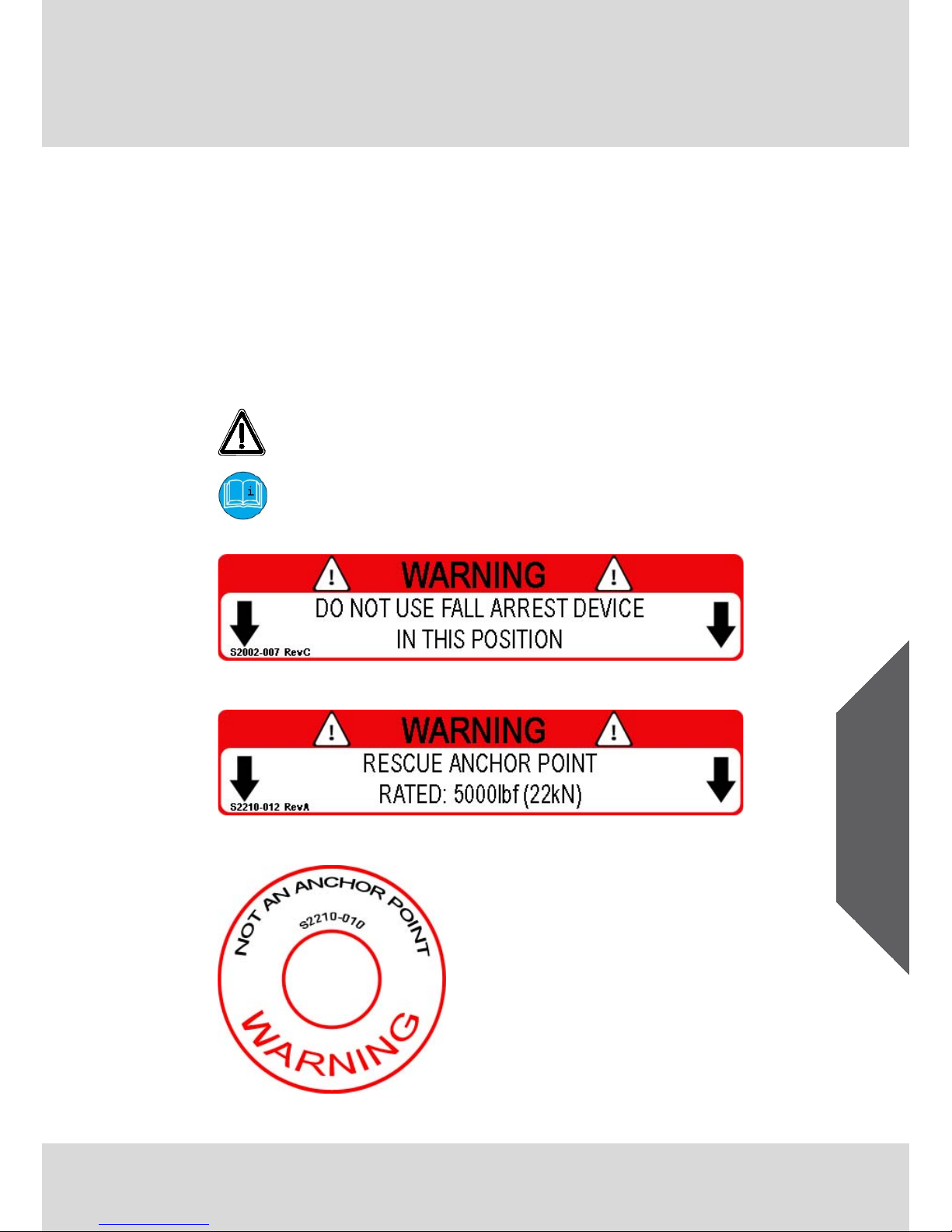

This symbol is used to signalize the user of a potential hazard.

The safety of the worker is in jeopardy. It is imperative to follow

manufacturer’s recommendation.

This symbol asks the user to read and understand the manual

for this product before use.

Fig. 1 Device Positioning Warning Sticker

Fig. 2 Rescue Anchor Point Warning Sticker

Fig. 3 Not an Anchor Point Warning Sticker

Page 10

Description

10 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

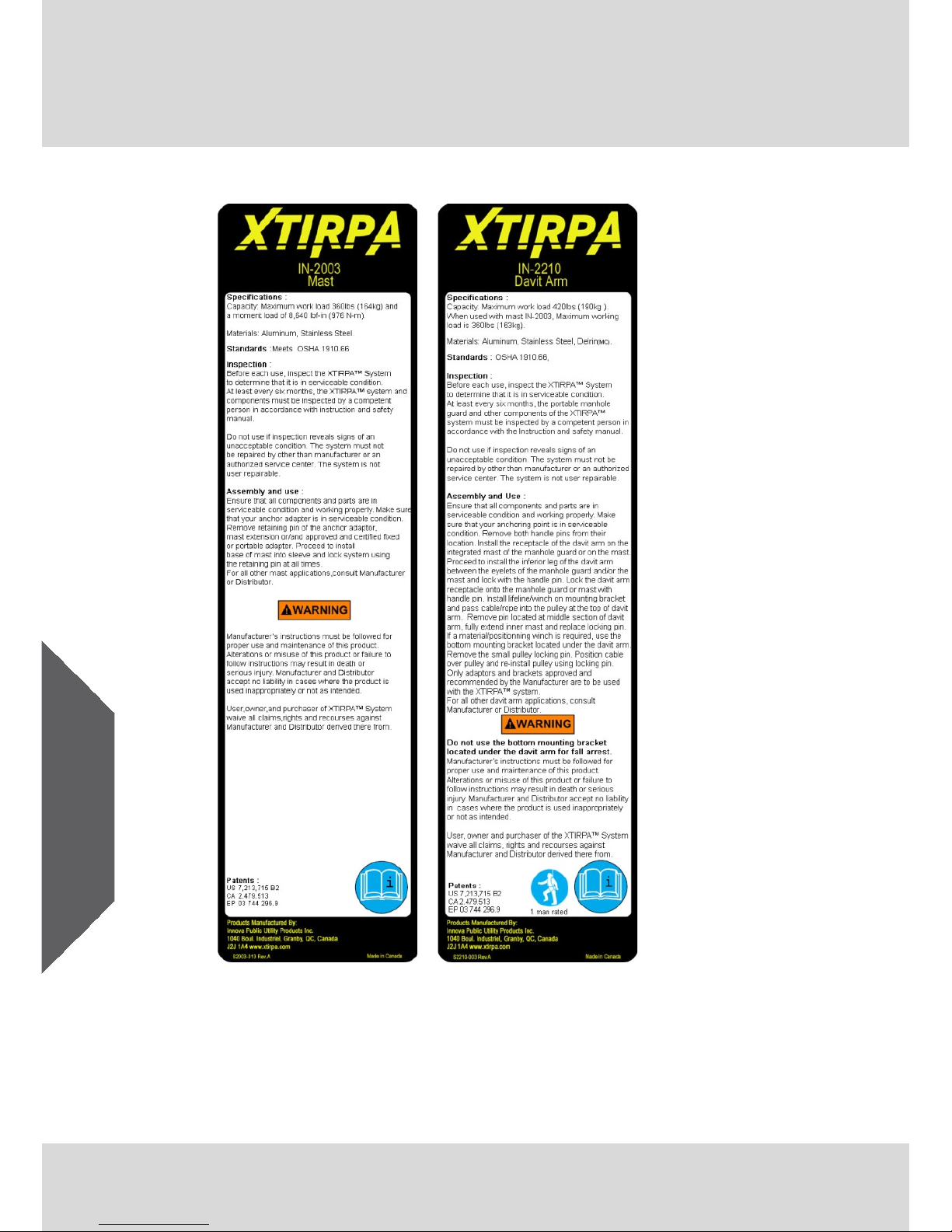

Fig. 4 Mast Label Fig. 5 Davit Arm

Label

Page 11

Description

MSA/XTIRPA™ Adapter Base System 24" Reach 11

US

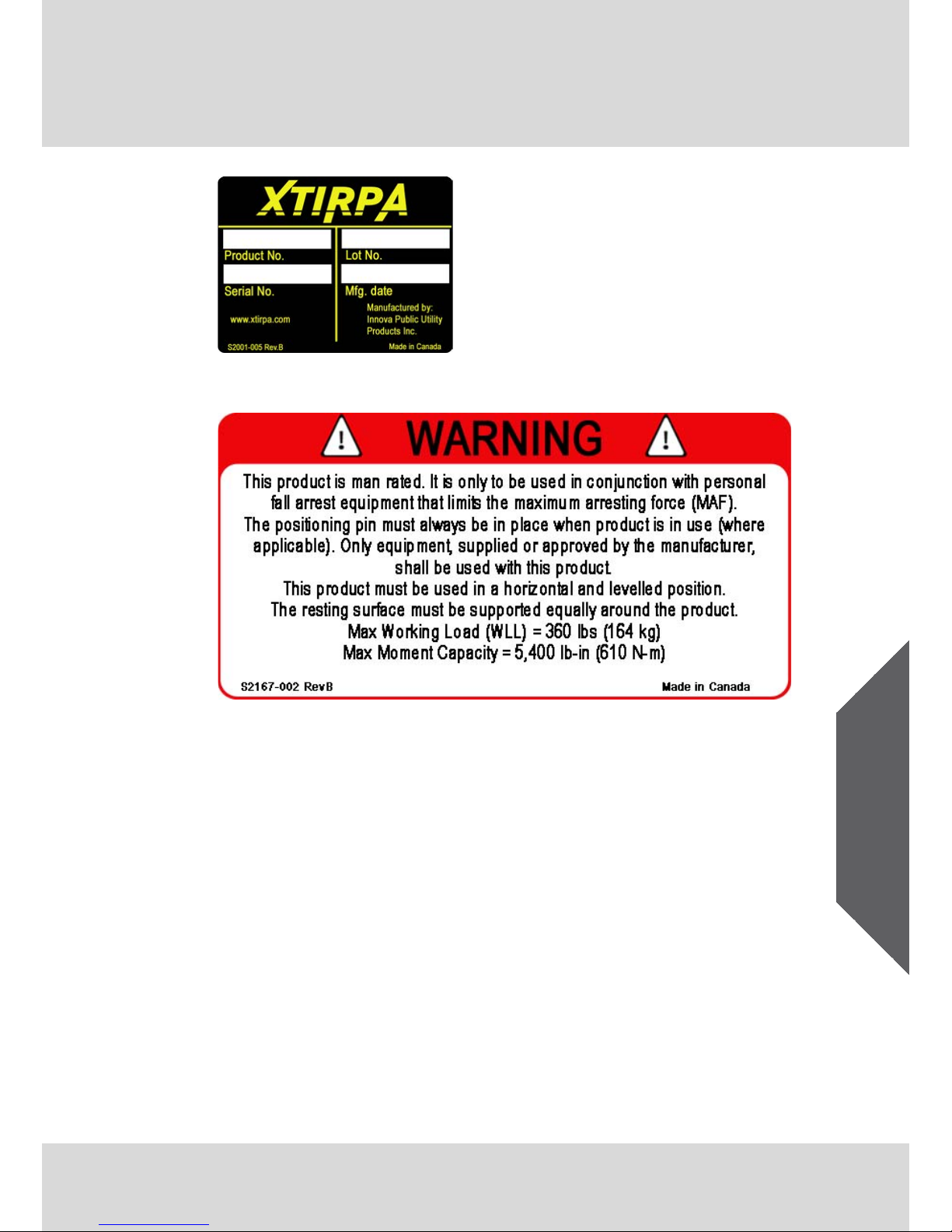

Fig. 6 Product Data Sticker

Fig. 7 Man Rated Label

2.2. System Requirements

2.2.1 Compatibility of Components and Subsystems

The confined space system is designed to be used with MSA fall

protection components and connecting subsystems. MSA fall protection

equipment has been evaluated and tested in accordance with applicable

standards to be compatible when combined in ways stipulated in MSA

product user instructions.

Combining fall protection components and connecting subsystems made

by different manufacturers may adversely affect the functional

compatibility between system parts and the safety and reliability of the

complete system.

It is the responsibility of the employer’s designated competent person to

determine the compatibility of fall protection components and

subsystems. MSA recommends if choosing to combine fall protection

components and connecting subsystems from different manufacturers,

Page 12

Description

12 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

all components and connecting subsystems should be approved to

comply with the applicable ANSI, CSA, or EN standard(s).

For fall arrest applications using the confined space system, the

maximum fall arrest force must not exceed 1,800lbf (8kN). Contact MSA

with any questions regarding compatibility of equipment used with the

confined space system.

2.2.2 Compatibility of Connectors

Connectors such as D-rings, snaphooks, and carabiners must be rated to

5000lbf (22kN) minimum breaking strength. Per ANSI Z359.12 and

CSA Z259.12, connector gates must be able to withstand a load of

3,600lbf (16kN). Connecting hardware must be compatible in size and

shape as to not inadvertently cause their gate mechanisms to open.

Non-compatible connectors may accidentally disengage. Always verify

compatibility of the connecting snaphook or carabiner with harness

D-ring or anchorage connector. Use only self-closing, self-locking

snaphooks and carabiners with the harness.

When using a snaphook to connect to an anchorage or when coupling

components of the system together, be certain accidental

disengagement (rollout) cannot occur.

Rollout is possible when interference between a snaphook and the

mating connector causes the snaphook’s gate or keeper to accidentally

open and release. Rollout occurs when a snaphook is snapped into an

undersized ring such as an eye bolt or other non-compatibly shaped

connector.

Do not use snaphooks or connectors that will not completely close over

the attachment object. Do not make knots in a lanyard. Do not hook the

lanyard back onto itself. Snaphooks and carabiners must not be

connected to each other. Do not attach two snaphooks into one D-ring.

Always follow the manufacturer’s instructions supplied with each system

component.

Warning

Do not rely on feel or sound to verify proper snaphook engagement.

Always check visually for proper engagement. Ensure that gate and

keeper are closed before use. Failure to follow this warning may result in

death or serious injury.

Page 13

Use

MSA/XTIRPA™ Adapter Base System 24" Reach 13

US

3. Use

3.1. Planning the Use of Systems

3.1.1 Rescue and Evacuation

The user must have a rescue plan and the means at hand to implement

it. The plan must take into account the equipment and special training

necessary to affect prompt rescue under all foreseeable conditions.

If the rescue is from a confined space, the provisions of

OSHA regulation 1910.146 must be taken into account.

Although a rescue plan and the means to implement it must always be in

place, it is a good idea to provide means for user evacuation without

assistance of others. This will usually reduce the time to get to a safe

place and reduce or prevent the risk to rescuers.

If the confined space system is to be included as a part of rescue or

evacuation systems, the optional system components required, the time

required to erect the confined space system and attach any optional

components and the anchorage requirements should be considered

when planning these systems.

3.1.2 Free Fall Distance

Do not exceed free fall distance specified by applicable regulations and

standards. When using a shock absorbing lanyard, keep the amount of

slack between the anchorage/anchorage connector and the harness at a

minimum to reduce the free fall distance and the impact force to the user.

Make certain that enough clearance is available in all potential fall paths

to prevent striking an object. The amount of clearance needed depends

upon the type of connecting subsystem used, and the location of the

anchorage or anchorage connector.

Consult the manufacturer’s instructions for the particular connecting

subsystem or component for clearance needed.

Warning

Prevent swing falls and impact with objects in

or adjacent to the fall path.

Always remove obstructions below the work area to ensure a clear fall

path. Work directly under the anchorage/anchorage connector at all

times. Failure to follow this warning may result in death or serious injury.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 14

Use

14 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

Caution

Keep work area free from obstructions, trip hazards, and spills which

could impair the safe operation of the fall-rescue system.

Do not open the confined space access cover before complete

installation of the anchorage connector and all other system

components.

3.2. Pre-Use Inspection

Inspect the confined space system to verify that it is in serviceable

condition. Examine every inch of the confined space system for severe

wear, missing or broken elements, corrosion, or other damage. Do not

use the confined space system if inspection reveals an unsafe condition.

3.3. Assembly

Always work in teams of at least two (2) people (one (1) attendant and

one (1) confined space worker) who are qualified and trained on the

confined space system.

(1.) Remove all components and parts from bags, boxes, or shipping

container and set all on ground. Make sure that components are in

good working condition.

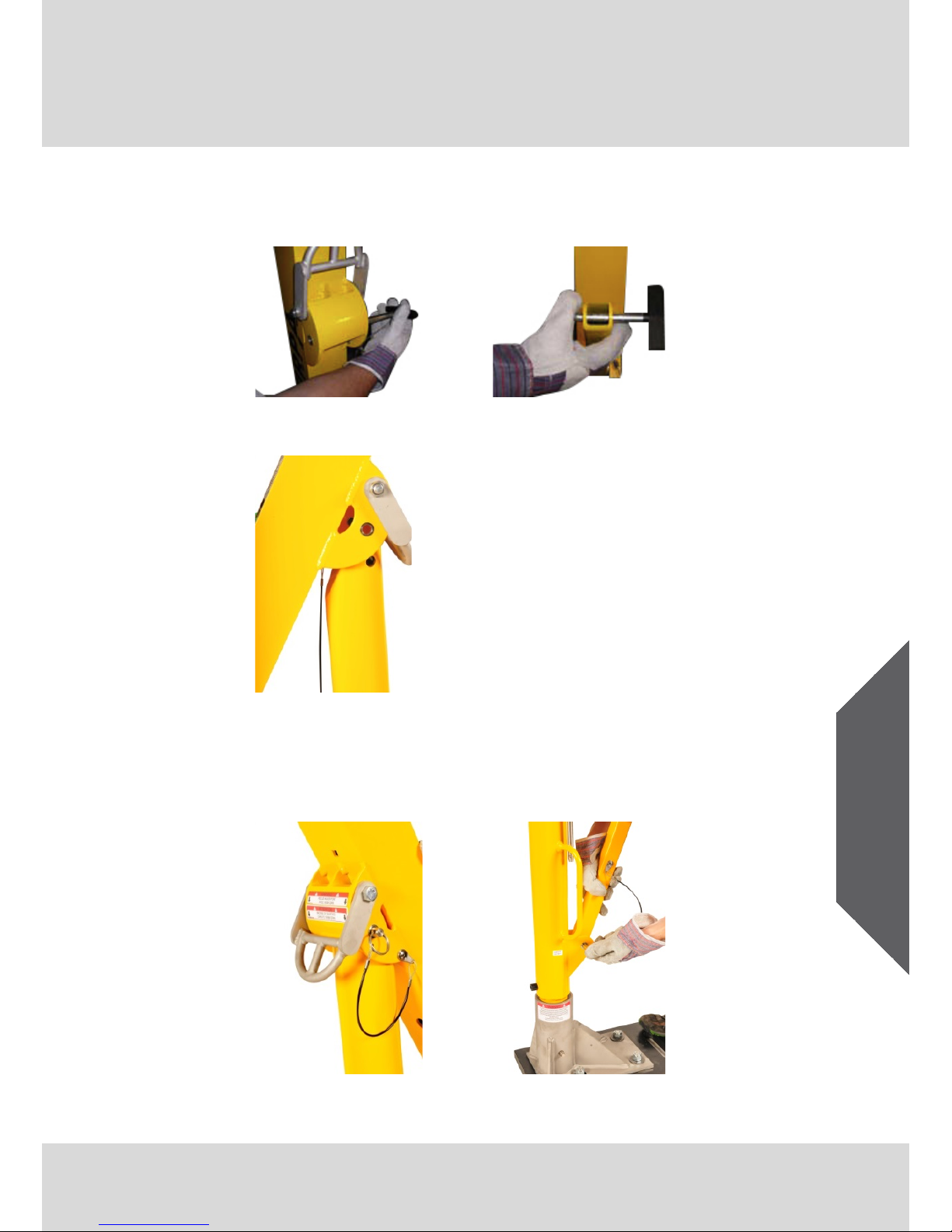

(2.) Insert the mast into the Adapter Base sleeve (A) and lock with a

pin (B). If using integrated mast and davit arm IN-2295 or IN-2363,

proceed to Step 5.

Fig. 8 Step 2A

Fig. 9 Step 2B

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 15

Use

MSA/XTIRPA™ Adapter Base System 24" Reach 15

US

(3.) To install the davit arm on the mast, remove both handle pins from

their locations (A) & (B). Install the receptacle of the davit arm on the

mast (C).

Fig. 10 Step 3A

Fig. 11 Step 3B

Fig. 12 Step 3C

(4.) Lock the davit arm with the first handle pin (A), then install the lower

leg of the davit arm between the eyelets of the mast and lock with

the second handle pin (B).

Fig. 13 Step 4A

Fig. 14 Step 4B

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 16

Use

16 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

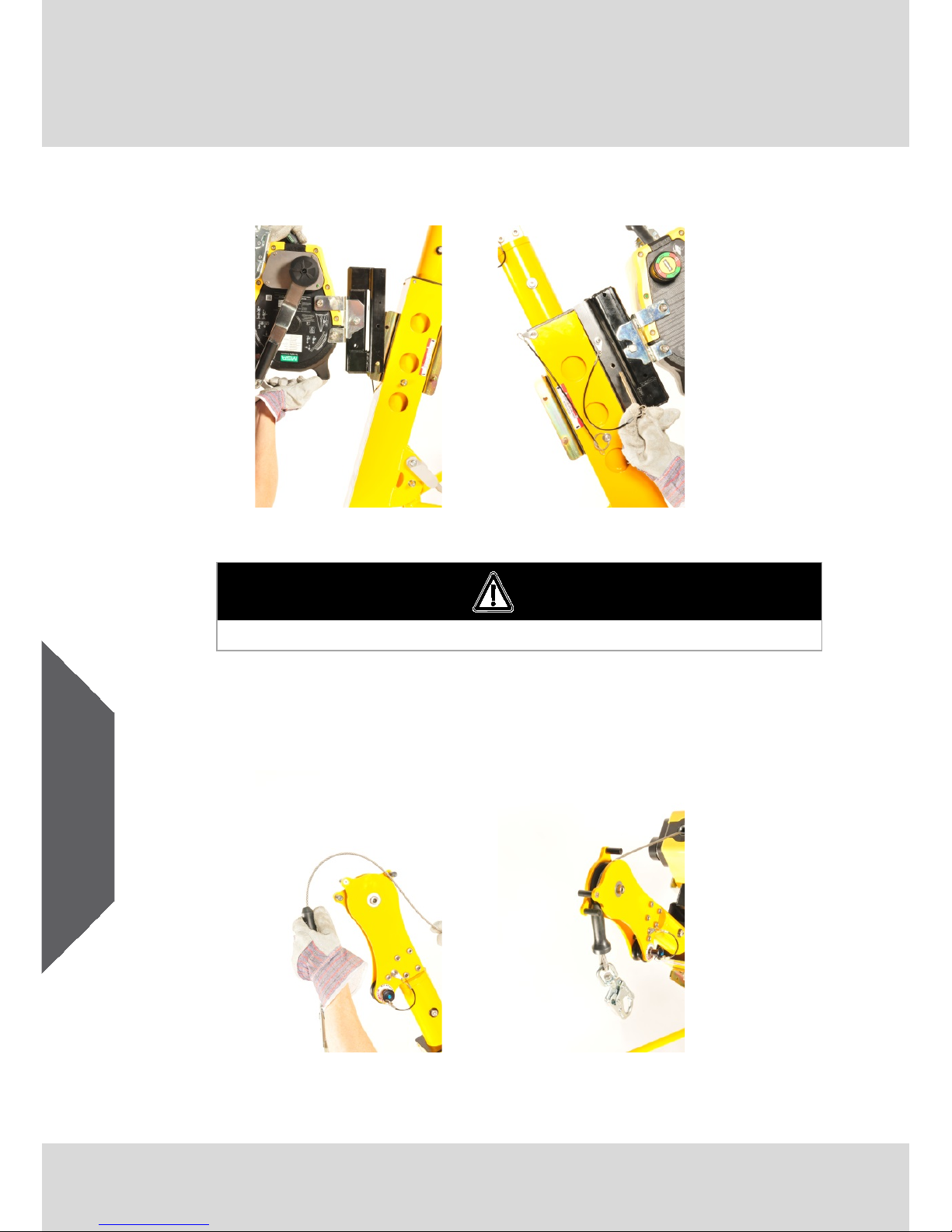

(5.) Install the SRL or winch on the applicable top mounting bracket (A)

and lock with the pin attached to the SRL or winch bracket (B).

Fig. 15 Step 5A

Fig. 16 Step 5B

Warning

Use only MSA approved adapters and brackets.

(6.) If using davit arm IN-2210 and mast IN-2003, pass the cable or rope

lifeline into the pulley located at the top end of the davit arm (A). Be

assured that the cable or rope lifeline is fully seated within the pulley

groove (B).

Fig. 17 Step 6A

Fig. 18 Step 6B

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 17

Use

MSA/XTIRPA™ Adapter Base System 24" Reach 17

US

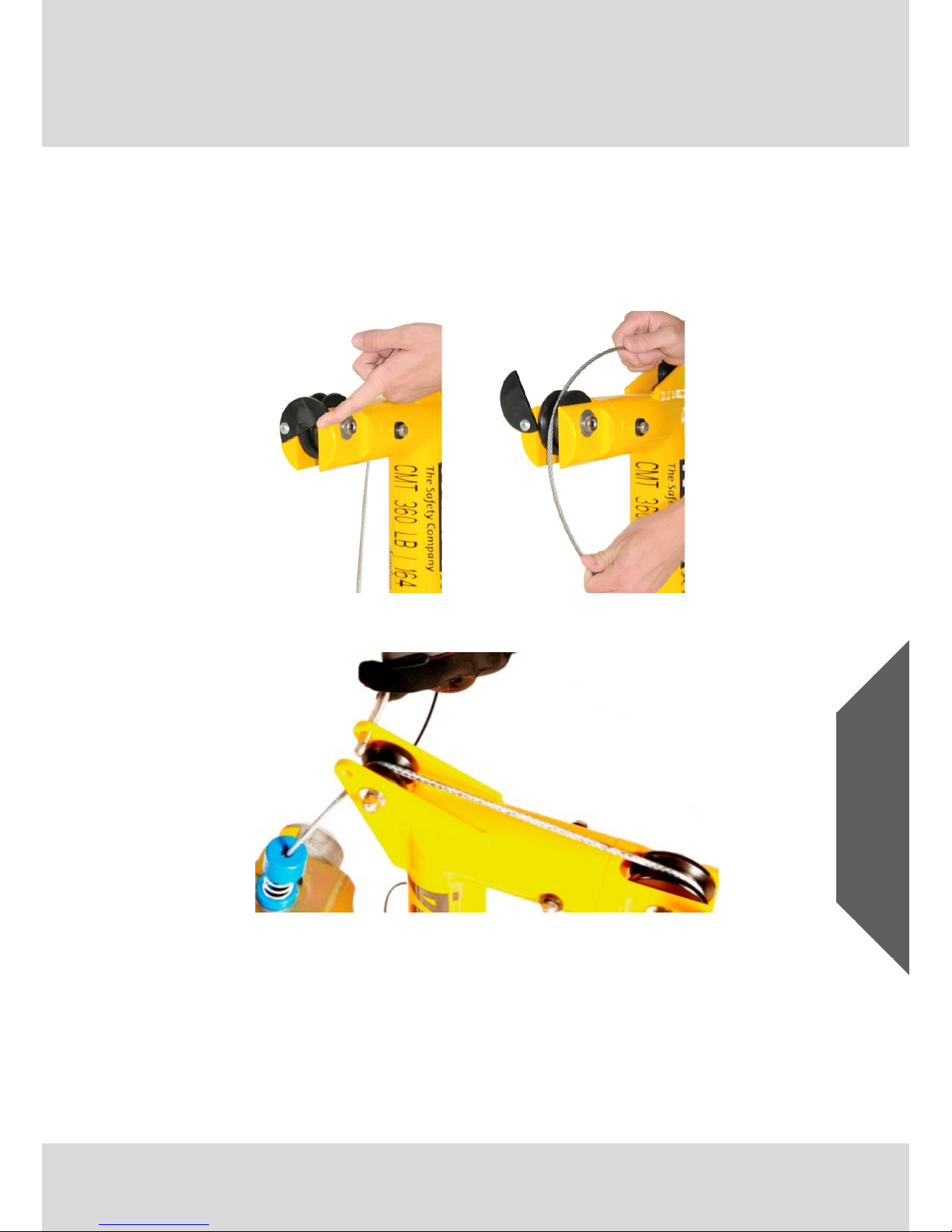

If using the integrated mast and the davit arm IN-2295 or IN-2363,

remove the small pulley pin and rotate the half-moon plate (C) to

pass the cable or rope lifeline into the pulleys (D). Return the half

moon plate to its original position and lock with the small pulley

pin (E). Be assured that the cable or rope lifeline is fully seated

within the pulley groove.

Fig. 19 Step 6C

Fig. 20 Step 6D

Fig. 21 Step 6E

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 18

Use

18 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

(7.) If a material positioning winch is required while using davit arm

IN-2210 and mast IN-2003, use the bottom mounting bracket located

under the davit arm. Install the winch to the mounting bracket (A)

and lock with the pin attached to the winch (B). Remove the small

pulley locking pin (C). Position the cable over the pulley and reinstall using the locking pin (D).

Fig. 22 Step 7A

Fig. 23 Step 7B

Fig. 24 Step 7C

Fig. 25 Step 7D

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 19

Use

MSA/XTIRPA™ Adapter Base System 24" Reach 19

US

Warning

Do not use bottom bracket for fall arrest. Misuse can result in death or

serious injury.

(8.) Remove the locking pin located in the mid section of the davit

arm (A). Extend the inner mast to full extension (B). Replace the

locking pin to secure the davit arm.

Fig. 26 Step 8A

Fig. 27 Step 8B

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 20

Use

20 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

Fig. 28 Adapter Base System 24" Reach

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 21

Use

MSA/XTIRPA™ Adapter Base System 24" Reach 21

US

Warning

Always barricade working area. Failure to do so may result in death or

serious injury.

Warning

Positioning pins must always be in place when in use. Position the cable

or rope lifeline directly over the work area. Position the confined space

system on a hard and level surface. Do not use on soft or loose ground,

such as but not limited to, sand, grass, gravel and rocks. Misuse can

result in death or serious injury.

Warning

Anchorages to which personal fall arrest equipment is attached shall be

capable of supporting at least 5000lbs (22.2kN) per person attached, or

shall be design

ed, installed, and used as part of a complete personal fall

arrest system which maintains a safety factor of at least two, under the

supervision of a qualified person. Failure to do so may result in death or

serious injury.

Warning

Anchorage hardware

must be installed by a qualified person. Anchorage

hardware must be installed according to specification documentation

included with product. Failure to do so may result in death or serious

injury.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 22

Cleaning and Maintenance

22 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

4. Cleaning and Maintenance

4.1. Cleaning

Periodically clean the exterior of the confined space system in use with

water and mild detergent. Clean labels as required. Do not speed dry

with heat. Excessive accumulation of dirt, paint, or other foreign matter

may prevent proper function of the confined space system and, in severe

cases, weaken the material and joints. Questions concerning confined

space system conditions and cleaning should be directed to MSA.

4.2. Maintenance

Equipment which is damaged or in need of maintenance must be tagged

as “UNUSABLE” and removed from service. Corrective maintenance

(other than cleaning) and repair, such as replacement of elements, must

be performed by the MSA factory. Do not attempt field repairs.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 23

Inspection

MSA/XTIRPA™ Adapter Base System 24" Reach 23

US

5. Inspection

5.1. Inspection Frequency

Inspect the confined space system before each use.

5.2. Formal Inspection

MSA requires that all confined space systems be inspected by a

competent person other than the user at intervals of no more than six

months per applicable standard or as specified by a formal fall protection

program.

Record formal inspections in the provided Inspection Log. Do not use the

confined space system with a formal inspection date older than six (6)

months. Tag confined space systems with formal inspection dates older

than six (6) months “UNUSABLE” and remove from service until after

formal inspection.

5.3. Procedure for Inspection

Step 1:

Inspect the confined space system labels to verify that they

are present and legible.

If any labels are missing or illegible, remove the confined

space system from use and mark it as “UNUSABLE” until a

formal inspection is performed by a competent person.

Step 2:

Inspect confined space system for corrosion, cracks,

deformation, fractures, altered or missing elements, burns,

and heat and chemical exposures.

Step 3:

Inspect all metallic parts for deformation, fractures, cracks,

corrosion, deep pitting, burrs, sharp edges, cuts, deep nicks,

missing or loose parts, improper function, and evidence of

excessive heat or chemical exposures.

Step 4:

Inspect all non-metallic parts (i.e. foot pads and labels) for

cut, broken, excessively worn, missing and loose parts.

Labels are to be additionally checked in accordance with

Step 1 above. Inspect for evidence of burns and excessive

heat and chemical exposures.

Step 5:

Inspect each component and subsystem in accordance with

associated manufacturer’s instructions.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 24

Inspection

24 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

Caution

Only MSA or a MSA authorized service center may make repairs to the

confined space system.

5.4. Corrective Action

When inspection reveals signs of an unacceptable condition, the

confined space system must be immediately removed from service and

marked as “UNUSABLE” until destroyed or subjected to maintenance by

the user’s organization.

Damage, excessive wear and/or aging are generally repairable by the

factory. If detected, immediately remove the confined space system from

use and mark it as “UNUSABLE” until repaired.

For final disposition, submit the confined space system to a competent

person who is authorized to perform formal inspection. If there is any

question as to repairability, contact MSA or a MSA authorized service

center before further use of the confined space system.

5.5. Inspection Log

Supplier Address and Contact Details:

Model No:

Serial No:

Date of Manufacture:

Date of Purchase:

Date of First Use:

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 25

Inspection

MSA/XTIRPA™ Adapter Base System 24" Reach 25

US

Examiners

Name/

Signature

Date of Next

Examination

Responsible

for Repair

Name/Signature

Corrective

Action/

Repair

Damage/Wear

Found

Date of

Examination

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 26

Storage

26 MSA/XTIRPA™ Adapter Base System 24" Reach

US

US

6. Storage

Store the confined space system in a clean and dry environment, out of

direct sunlight.

Avoid areas with chemical or toxic vapors, substances or environments.

Do not immerse or leave in direct contact with water, as corrosion and

rust may occur.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 27

Notes

MSA/XTIRPA™ Adapter Base System 24" Reach 27

US

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 28

MSAsafety.com

MX

Manual de instrucciones para un uso seguro

Sistema de base adaptadora

MSA/XTIRPA™ con alcance de 24"

N. º de pedido: 10171018/00

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 29

© MSA 2015 Todos los derechos reservados

Advertencia

Las normativas nacionales, al igual que las leyes estatales,

provinciales y federales establecen que el usuario reciba

capacitación pertinente antes del uso de este producto. Utilice este

manual como parte del programa de capacitación de seguridad

específico para el cargo del usuario. Estas instrucciones deberán

suministrarse al usuario quien deberá leerlas antes del uso del

producto y conservarlas para futuras consultas. El usuario debe

leer, comprender (o hacerse explicar) y respetar todas las

instrucciones, las etiquetas, los marcados y las advertencias que

trae el producto. De lo contrario pueden provocarse lesiones graves

o incluso la muerte.

Los productos XTIRPA™ son fabricados por

Innova Public Utility Products Inc. Hecho en Canadá.

XTIRPA™ es una marca comercial registrada de

Innova Public Utility Products Inc., usada bajo licencia

en Norteamérica y Europa.

Mine Safety Appliances Company

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

Estados Unidos

Para obtener información más detallada, llámenos al 1-800-MSA-2222 o

visite nuestro sitio web www.MSAsafety.com

Page 30

Índice

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 3

MX

Índice

1. Normas de seguridad ......................................................................... 4

1.1. Uso correcto .............................................................................. 4

1.2. Restricciones de uso ................................................................. 5

1.2.1 Restricciones físicas .................................................................. 5

1.2.2 Riesgos ...................................................................................... 6

1.3. Información sobre la responsabilidad ........................................ 6

1.4. Medidas de seguridad y precaución requeridas ........................ 7

1.5. Garantía ..................................................................................... 8

2. Descripción ......................................................................................... 9

2.1. Etiquetas y marcas .................................................................... 9

2.2. Requisitos del sistema ............................................................. 11

2.2.1 Compatibilidad de los componentes y subsistemas ................ 11

2.2.2 Compatibilidad de los conectores ............................................ 12

3. Uso ..................................................................................................... 13

3.1. Planeación del uso de los sistemas ......................................... 13

3.1.1 Rescate y evacuación .............................................................. 13

3.1.2 Distancia de caída libre ........................................................... 13

3.2. Inspección antes del uso ......................................................... 14

3.3. Ensamble ................................................................................. 14

4. Limpieza y mantenimiento ............................................................... 22

4.1. Limpieza .................................................................................. 22

4.2. Mantenimiento ......................................................................... 22

5. Inspección ......................................................................................... 23

5.1. Frecuencia de inspección ........................................................ 23

5.2. Inspección formal ..................................................................... 23

5.3. Procedimiento para la inspección ............................................ 23

5.4. Acción correctiva ..................................................................... 24

5.5. Registro de inspecciones ......................................................... 24

6. Almacenamiento ............................................................................... 26

Page 31

Normas de seguridad

4 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

1. Normas de seguridad

1.1. Uso correcto

El sistema de base adaptadora (en adelante denominado también

"el sistema de espacios confinados") forma parte de un sistema para

la detención de caídas, el posicionamiento en el trabajo, la suspensión,

el desplazamiento de materiales o el rescate, para el uso en espacios

confinados.

Todos los sistemas de espacios confinados cumplen con las normas OSHA.

El sistema de espacios confinados está diseñado para formar parte de un

sistema completo de detención de caídas con una fuerza máxima de

detención de 1800 lbf (8 kN). El sistema de espacios confinados está

diseñado para mantener el factor de seguridad dos, y debe ensamblarse y

utilizarse bajo la supervisión de una persona calificada, tal y como lo exige

OSHA. El sistema de espacios confinados está diseñado para ser utilizado

por una sola persona.

Es obligatorio evaluar la capacidad nominal de todos los productos que

forman parte del sistema de detención de caídas. La capacidad de un

sistema de detención de caídas corresponde a la capacidad nominal más

baja de cualquiera de los productos (conector de anclaje, cuerda

amortiguadora autorretráctil, etc.) que forman parte del mismo.

El conector de anclaje del sistema de base adaptadora consta de tres

componentes principales; el brazo del pescante, el mástil y la base

adaptadora de 3" de diámetro. La capacidad del sistema de base

adaptadora para la detención de caídas, la suspensión, el rescate y el

desplazamiento de materiales es la siguiente:

- 360 lb (163 kg) - Si se usa el brazo de pescante IN-2210, el mástil

IN-2003 y cualquier base adaptadora de 3" de diámetro

- 360 lb (163 kg) - Si está usando el mástil integrado y el brazo de

pescante IN-2295 o IN-2363 y cualquier base adaptadora de 3" de

diámetro

La capacidad para personal incluye el peso del usuario más la ropa, las

herramientas y demás objetos que este lleve puestos.

La distancia de caída libre (límite) no debe superar los 6 pies (1.8 m) de

acuerdo con OSHA. La Ley Canadiense de Salud y Seguridad

Ocupacional de 1990 especifica que la distancia de caída libre no debe

superar los 5 pies (1.5 m). El usuario debe cumplir con todas las normas

y reglamentaciones pertinentes.

Cuando se usa como parte de un sistema personal de detención de

caídas, las fuerzas de detención de la caída no deben superar un valor

de 1800 lbf (8 kN).

Page 32

Normas de seguridad

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 5

MX

Advertencia

Si el EPI se vende a terceros, es esencial entregar junto al mismo las

instrucciones de uso, mantenimiento y revisión periódica en el idioma

de destino. El incumplimiento de esta advertencia puede ocasionar

lesiones graves o incluso la muerte.

El sistema de base adaptadora debe ser utilizado por personal

capacitado y calificado.

Es obligatorio leer este manual y respetarlo durante el uso del producto.

En concreto, es necesario leer y respetar las instrucciones de seguridad

así como la información sobre el uso y el funcionamiento del producto.

Además, para un uso seguro, hay que respetar las normas nacionales

vigentes en el país del usuario.

Cualquier uso alternativo o que no tenga en cuenta estas

especificaciones, se considerará un uso no conforme. Esto concierne

especialmente además cualquier modificación hecha al producto sin

la debida autorización, así como cualquier prueba de conformidad no

realizada por MSA o por personas autorizadas.

1.2. Restricciones de uso

Las siguientes restricciones deben tenerse en cuenta y planificarse

antes de utilizar el sistema de espacios confinados.

1.2.1 Restricciones físicas

Las personas con patologías musculares u óseas o con otros problemas

físicos deben consultar con un médico antes de usar un sistema

personal de detención de caídas en el que esté incorporado el sistema

de espacios confinados. Las mujeres en embarazo y los menores de

edad no deben utilizar estos sistemas bajo ninguna circunstancia.

Una edad avanzada y un estado físico no satisfactorio son factores que

pueden reducir la capacidad de soportar cargas de impacto durante la

detención de una caída o una suspensión prolongada. Consulte con un

médico si tiene dudas sobre la capacidad física para el uso seguro de

este producto para la detención de caídas o la suspensión.

Advertencia

No modifique este equipo ni lo utilice de forma inadecuada. Un arnés

de cuerpo completo es el único dispositivo de sujeción del cuerpo

aceptable que puede utilizarse con los sistemas de detención de caídas.

El incumplimiento de esta advertencia puede ocasionar lesiones graves

o incluso la muerte.

Page 33

Normas de seguridad

6 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

1.2.2 Riesgos

Los ambientes ácidos, alcalinos o con sustancias nocivas pueden

provocar daños en los herrajes del sistema de espacios confinados. Si

se trabaja en un ambiente con sustancias químicas agresivas, consulte

con MSA para determinar cuáles son los componentes más adecuados

según las condiciones específicas.

Las sustancias químicas, el calor y la corrosión pueden estropear el

sistema de espacios confinados. En ambientes con riesgos químicos,

calor y corrosión se requieren inspecciones formales más frecuentes.

Evite la exposición prolongada a ambientes corrosivos. Preste mucha

atención al trabajar cerca de fuentes eléctricas energizadas.

Manténgase a la debida distancia (por lo menos 10 pies (3 m)

preferiblemente) de objetos que comporten riesgos eléctricos. Al trabajar

cerca de partes de maquinaria en movimiento

(p. ej. transportadores, ejes giratorios, prensas, etc.) asegúrese de que

no haya elementos flojos en ninguna de las partes del sistema.

Todo sistema de espacios confinados que presente señales de desgaste

o deterioro excesivo o problemas de funcionamiento debe ponerse fuera

de uso y marcarse como “INUTILIZABLE” hasta su reparación.

Todo sistema de espacios confinados que se haya visto sometido a las

fuerzas de una caída deberá ponerse fuera de servicio de inmediato y

marcarse como “INUTILIZABLE” hasta que pase una inspección formal.

1.3. Información sobre la responsabilidad

MSA declina toda responsabilidad en caso de que el producto se haya

utilizado de forma inadecuada o no conforme a lo previsto. Este producto

debe seleccionarse y utilizarse bajo la dirección de un profesional

calificado en materia de seguridad, quien deberá haber evaluado los

riesgos específicos del sitio en el que va a usarse y estar perfectamente

familiarizado con el producto y sus limitaciones.

La selección y el uso de este producto, así como su incorporación en

el esquema de seguridad del lugar de trabajo, son responsabilidad

exclusiva del empleador.

Toda reclamación de responsabilidad, al igual que todo derecho de

garantía, incluyendo la garantía que ofrece MSA para su producto, se

anulan en caso de un uso o un mantenimiento no conformes con las

instrucciones de este manual.

Page 34

Normas de seguridad

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 7

MX

1.4. Medidas de seguridad y precaución requeridas

Los usuarios de los productos MSA deben familiarizarse con las

instrucciones de uso y recibir una capacitación adecuada por parte

de una persona competente en cuanto a:

- identificación, evaluación y control de los peligros en el lugar

de trabajo

- selección, inspección, uso, almacenamiento y mantenimiento

- planeación del uso incluyendo el cálculo de la distancia de caída

libre y de la distancia total de caída

- compatibilidad y selección del anclaje/conectores de anclaje

incluyendo las conexiones para prevenir la liberación accidental

- ubicación adecuada de la conexión de los cordones/arneses

- planeación e implementación de la evacuación y el rescate

- consecuencias de un uso incorrecto

Para aplicaciones en espacios confinados:

- Véase OSHA 29 CFR 1910.146

Evalúe periódicamente (por lo menos una vez al año) la eficacia de la

capacitación, y determine si es necesario proporcionar capacitación

adicional. Póngase en contacto con MSA para pedir información sobre

la capacitación.

Page 35

Normas de seguridad

8 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

1.5. Garantía

Garantía explícita- MSA garantiza este producto contra defectos

mecánicos y de calidad de fabricación durante un período de dos (2) años

a partir de la fecha de envío, siempre y cuando se hayan respetado las

instrucciones y recomendaciones de MSA para el uso y el mantenimiento.

MSA queda eximida de toda responsabilidad de garantía en caso de

reparaciones o modificaciones por parte de personas no asignadas por la

empresa misma o diferentes del personal autorizado para el mantenimiento,

o en caso de daños debidos a un uso incorrecto del producto.

Ningún agente, empleado ni representante de MSA tiene autoridad alguna

para vincular a MSA a ninguna afirmación, representación o modificación de

la garantía relacionadas con los bienes vendidos bajo este contrato. MSA

no ofrece garantía alguna sobre los componentes o accesorios no

fabricados por MSA; se limitará a transmitir al comprador las garantías de

los fabricantes de dichos componentes.

Esta garantía se otorga en lugar de cualquier otra garantía, ya sea expresa,

tácita o estatutaria, y se limita estrictamente a los términos aquí expuestos.

MSA declina expresamente todo tipo de garantía de comercialización o

idoneidad para un propósito específico.

Recurso exclusivo- Se conviene expresamente que el único y exclusivo

recurso del comprador en caso de incumplimiento de esta garantía, de

cualquier conducta negligente de MSA o cualquier otra causa de acción,

consistirá en la reparación y/o sustitución, a discreción de MSA, del equipo

o de los componentes que, una vez examinados por MSA, resulten

defectuosos.

La sustitución del equipo y/o sus componentes se realizará sin costo alguno

para el comprador, FOB, en el lugar de destino indicado por el mismo.

El incumplimiento de MSA en reparar con éxito el producto no conforme,

no hace que el recurso establecido por este medio falle en su propósito

esencial.

Exclusión de daños consecuenciales- El comprador entiende y acuerda

específicamente que bajo ninguna circunstancia MSA será responsable

ante el comprador por daños o pérdidas económicas, especiales,

incidentales o consecuenciales de cualquier tipo, incluyendo pero sin

limitarse a la pérdida de ganancias anticipadas y cualquier otra pérdida

causada por el funcionamiento incorrecto de los productos. Esta exclusión

se aplica a las reclamaciones por infracciones de la garantía, conductas

ilícitas o cualquier otro hecho que justifique una causa de acción contra

MSA.

Para obtener información complementaria, póngase en contacto con

el Departamento de Servicio al Cliente llamando al 1-800-MSA-2222

(1-800-672-2222).

Page 36

Descripción

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 9

MX

2. Descripción

El sistema de espacios confinados consiste en un conector de anclaje

para usuarios que requieren un sistema para la detención de caídas,

el posicionamiento en el trabajo, la suspensión, el desplazamiento de

materiales o el rescate, para el uso en espacios confinados.

2.1. Etiquetas y marcas

Las siguientes etiquetas deben estar presentes, ser legibles y estar

correctamente enganchadas en el sistema de espacios confinados.

Este símbolo sirve para indicar al usuario un peligro potencial.

La seguridad del trabajador está en riesgo. Es obligatorio seguir

las recomendaciones del fabricante.

Este símbolo le indica al usuario que es necesario leer y

comprender el manual de este producto antes del uso.

Fig. 1 Adhesivo de advertencia del posicionamiento del dispositivo

Fig. 2 Adhesivo de advertencia del punto de anclaje

Fig. 3 Adhesivo de advertencia "No punto de anclaje"

Page 37

Descripción

10 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

Fig. 4 Etiqueta

del mástil

Fig. 5 Etiqueta del brazo

de pescante

Page 38

Descripción

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 11

MX

Fig. 6 Adhesivo con los datos del producto

Fig. 7 Etiqueta de aprobación para el desplazamiento de personas

2.2. Requisitos del sistema

2.2.1 Compatibilidad de los componentes y subsistemas

El sistema de espacios confinados está diseñado para ser utilizado con

componentes y subsistemas de conexión MSA para la protección contra

caídas. El equipo de protección contra caídas de MSA se ha evaluado y

probado en conformidad con las normas pertinentes para asegurar su

compatibilidad cuando se usa en las combinaciones establecidas en las

instrucciones de uso del producto MSA.

La combinación de componentes y subcomponentes de conexión para la

protección contra caídas fabricados por terceros puede comprometer la

compatibilidad funcional entre las partes del sistema y la seguridad y

confiabilidad del sistema entero.

Es responsabilidad de la persona competente asignada por el empleador

determinar la compatibilidad de los componentes y subsistemas para la

protección contra caídas. Si se quieren combinar componentes y

subsistemas de conexión para la protección contra caídas de distintos

fabricantes, MSA recomienda que dichos componentes y subsistemas

estén aprobados conforme a las normas pertinentes ANSI, CSA o EN.

Page 39

Descripción

12 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

Para las aplicaciones de detención de caídas para las que vaya a

utilizarse el sistema de espacios confinados, la fuerza máxima de

detención de la caída no debe superar un valor de 1800 lbf (8 kN).

Póngase en contacto con MSA si tiene dudas en cuanto a la

compatibilidad de los equipos utilizados con el sistema de espacios

confinados.

2.2.2 Compatibilidad de los conectores

Los conectores, como los anillos en D, los ganchos de seguridad y los

mosquetones, deben tener una resistencia a la rotura de mínimo

5000 lbf (22 kN). Conforme a ANSI Z359.12 y CSA Z259.12, los gatillos

de los conectores deben poder soportar una carga de 3600 lbf (16 kN).

Los herrajes de conexión deben ser compatibles en cuanto a tamaño y

forma, de manera tal que no supongan un riesgo de apertura accidental

de los mecanismos del gatillo.

Los conectores no compatibles se pueden desenganchar

accidentalmente. Verifique siempre la compatibilidad del gancho o

mosquetón de conexión con el anillo en D del arnés o el conector de

anclaje. Use únicamente ganchos de seguridad y mosquetones con

cierre y bloqueo automático con el arnés.

Al usar un gancho de seguridad para la conexión a un anclaje, o al

enganchar componentes del sistema entre sí, asegúrese de prevenir la

liberación accidental.

La liberación accidental es posible cuando una interferencia entre un

gancho de seguridad y el conector correspondiente hace que el gatillo

del gancho se abra y se suelte accidentalmente. La liberación accidental

se produce cuando un gancho de seguridad está abrochado en un anillo

de tamaño no adecuado como un perno de argolla o cualquier conector

que tenga una forma no compatible.

No use ganchos o conectores que no se cierren por completo al

engancharlos al objeto. No haga nudos en el cordón. No enganche el

cordón en sí mismo. Los ganchos de seguridad y los mosquetones no

deben conectarse entre sí. No conecte dos ganchos de seguridad en un

mismo anillo en D. Respete siempre las instrucciones del fabricante

entregadas junto a cada componente del sistema.

Advertencia

No hay que fiarse del tacto o del oído para verificar si el gancho se

cierra correctamente. Es necesario controlar visualmente el cierre.

Asegúrese antes del uso de que el gatillo esté perfectamente cerrado.

El incumplimiento de esta advertencia puede ocasionar lesiones graves

o incluso la muerte.

Page 40

Uso

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 13

MX

3. Uso

3.1. Planeación del uso de los sistemas

3.1.1 Rescate y evacuación

El usuario debe tener un plan de rescate y los medios necesarios para

implementarlo. El plan debe tener en cuenta el equipo y la formación

especial que se requieren para poder realizar un rápido rescate en todas

las condiciones previsibles.

Si el rescate se realiza desde un lugar confinado, se deben tener en

cuenta las disposiciones de la norma 1910.146 de OSHA.

Aunque el plan de rescate y los medios para implementarlo deben estar

siempre disponibles, es oportuno procurar al usuario un medio de

evacuación sin la asistencia de otras personas. De esta forma el usuario

podrá llegar más pronto a un lugar seguro y reducir así el riesgo para los

socorristas.

El sistema de espacios confinados forma parte de un sistema de rescate

o evacuación; al planificar dicho sistema se deberán tener en cuenta los

componentes opcionales requeridos, el tiempo necesario para el

montaje del sistema de espacios confinados y para el enganche de los

componentes opcionales y los requisitos de anclaje.

3.1.2 Distancia de caída libre

No supere la distancia de caída libre especificada en las normas y

reglamentaciones pertinentes. Al usar un cordón con amortiguador,

asegúrese de que la unión entre el anclaje/conector de anclaje y el arnés

resulte lo menos floja posible para reducir la distancia de caída libre y la

fuerza de impacto al usuario.

Asegúrese de que haya suficiente espacio en todas las potenciales

trayectorias de caída para evitar golpearse contra algún objeto. La

cantidad de espacio que se requiere depende del tipo de subsistema de

conexión utilizado y de la ubicación del anclaje o del conector de anclaje.

Consulte en las instrucciones del fabricante cuánto espacio se requiere

para el componente o subsistema de conexión en cuestión.

Advertencia

Prevenga las caídas pendulares y los golpes contra objetos en la

trayectoria de caída o junto a ella. Retire siempre los obstáculos que

pueda haber bajo el área de trabajo para asegurar una trayectoria de

caída despejada. Trabaje directamente bajo el anclaje/conector de

anclaje en todo momento. El incumplimiento de esta advertencia puede

ocasionar lesiones graves o incluso la muerte.

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 41

Uso

14 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

Cuidado

Mantenga el área de trabajo libre de obstáculos, riesgos de tropiezo

y líquidos derramados que puedan comprometer la seguridad del uso

del sistema de rescate de caídas.

No abra la tapa del acceso al espacio confinado antes de que se haya

completado la instalación del conector de anclaje y de los demás

componentes del sistema.

3.2. Inspección antes del uso

Revise el sistema de espacios confinados para asegurarse de que esté

en buenas condiciones. Examine detenidamente el sistema de espacios

confinados para asegurarse de que no presente desgaste excesivo,

elementos incompletos o rotos, corrosión u otros daños. No use el

sistema de espacios confinados si se detecta alguna condición no

segura durante la inspección.

3.3. Ensamble

Trabaje siempre en equipos de mínimo dos (2) personas (un (1) asistente

y un (1) trabajador en el espacio confinado) debidamente calificadas

y capacitadas para trabajar con el sistema de espacios confinados.

(1.) Saque todos los componentes y las partes de las bolsas, cajas

o del contenedor de envío y póngalas en el suelo. Asegúrese

de que los componentes estén en buen estado.

(2.) Ponga el mástil en el manguito (A) de la base adaptadora y

bloquéelo con un pasador (B). Si está usando el mástil integrado

y el brazo de pescante IN-2295 o IN-2363, vaya al Paso 5.

Fig. 8 Paso 2A

Fig. 9 Paso 2B

Page 42

Uso

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 15

MX

(3.) Para instalar el brazo de pescante en el mástil, quite los

dos pasadores de sus respectivos alojamientos (A) y (B).

Instale el receptáculo del brazo del pescante en el mástil (C).

Fig. 10 Paso 3A

Fig. 11 Paso 3B

Fig. 12 Paso 3C

(4.) Bloquee el brazo del pescante con el primer pasador (A), monte

entonces la pata inferior del brazo del pescante entre los agujeros

del mástil y bloquéela con el segundo pasador (B).

Fig. 13 Paso 4A

Fig. 14 Paso 4B

Page 43

Uso

16 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

(5.) Instale la cuerda autorretráctil o el cabrestante en el soporte

de montaje superior correspondiente (A) y realice el bloqueo

con el perno conectado en la cuerda autorretrácil o en el soporte

del cabrestante (B).

Fig. 15 Paso 5A

Fig. 16 Paso 5B

Advertencia

Use únicamente adaptadores y soportes aprobados por MSA.

(6.) Si está usando el brazo de pescante IN-2210 y el mástil IN-2003,

haga pasar la línea de vida de cable o cuerda por la polea ubicada

en el extremo superior del brazo del pescante (A). Asegúrese de

que la línea de vida de cable o cuerda quede perfectamente

asentada en la ranura de la polea (B).

Fig. 17 Paso 6A

Fig. 18 Paso 6B

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 44

Uso

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 17

MX

Si está usando el mástil integrado y el brazo de pescante IN-2295

o IN-2363, quite el pasador pequeño de la polea y haga girar la

placa de media luna (C) para hacer pasar la línea de vida de cable

o de cuerda por las poleas (D). Vuelva a poner la placa de media

luna en su posición inicial y bloquéela con el pasador pequeño de

la polea (E). Asegúrese de que la línea de vida de cable o cuerda

quede perfectamente asentada en la ranura de la polea.

Fig. 19 Paso 6C

Fig. 20 Paso 6D

Fig. 21 Paso 6E

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 45

Uso

18 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

(7.) Si se requiere un cabrestante para el posicionamiento de material,

durante el uso del brazo de pescante IN-2210 y del mástil IN-2003,

use el soporte de montaje inferior que se encuentra bajo el brazo

del pescante. Instale el cabrestante en el soporte de montaje (A)

y bloquéelo con el perno conectado en el cabrestante mismo (B).

Quite el perno de bloqueo de la polea pequeña (C). Ubique el cable

sobre la polea y realice nuevamente el montaje con el perno de

bloqueo (D).

Fig. 22 Paso 7A

Fig. 23 Paso 7B

Fig. 24 Paso 7C

Fig. 25 Paso 7D

Page 46

Uso

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 19

MX

Advertencia

No use el soporte inferior para la protección contra caídas. Un uso

incorrecto puede provocar lesiones graves o incluso la muerte.

(8.) Quite el perno de bloqueo que se encuentra en la sección intermedia

del brazo del pescante (A). Alargue el mástil interno por completo

(B). Vuelva a poner el perno de bloqueo para asegurar el brazo del

pescante.

Fig. 26 Paso 8A

Fig. 27 Paso 8B

Page 47

Uso

20 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

Fig. 28 Sistema de base adaptadora con alcance de 24"

Page 48

Uso

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 21

MX

Advertencia

Proteja siempre el área de trabajo. De lo contrario pueden provocarse

lesiones graves o incluso la muerte.

Advertencia

Los pernos de posicionamiento deben estar siempre en su lugar durante

el uso. Ponga la línea de vida de cable o cuerda directamente sobre el

área de trabajo. Ponga el sistema de espacios confinados sobre una

superficie rígida y nivelada. No lo coloque sobre terrenos blandos o no

consistentes, como por ejemplo arena, hierba, grava o piedras, entre

otros. Un uso incorrecto puede provocar lesiones graves o incluso

la muerte.

Advertencia

Los anclajes a los cuales está enganchado el equipo personal de

detención de caídas deben poder soportar por lo menos 5000 lb

(22.2 kN) por cada persona conectada, o deben estar diseñados

e instalados y usarse como parte de un sistema personal de detención

de caídas completo que asegure un factor de seguridad de por lo

menos dos, bajo la supervisión de una persona calificada. De lo

contrario pueden provocarse lesiones graves o incluso la muerte.

Advertencia

Los

herrajes de anclaje deben ser instalados por una persona calificada.

Los herrajes de anclaje deben instalarse de acuerdo con la

documentación específica que se ha entregado con el producto. De lo

contrario pueden provocarse lesiones graves o incluso la muerte.

Page 49

Limpieza y mantenimiento

22 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

4. Limpieza y mantenimiento

4.1. Limpieza

Limpie periódicamente la parte externa del sistema de espacios

confinados con agua y un detergente suave. Limpie las etiquetas

correctamente. No intente acelerar el secado con fuentes de calor. Una

acumulación excesiva de suciedad, pintura u otros materiales extraños

puede comprometer el funcionamiento del sistema de espacios

confinados y, en los casos más graves, debilitar los materiales y los

empalmes. Póngase en contacto con MSA si tiene dudas sobre las

condiciones y la limpieza del sistema de espacios confinados.

4.2. Mantenimiento

Los equipos dañados o que requieren mantenimiento deben llevar

una etiqueta que diga “INUTILIZABLE” y ponerse fuera de servicio.

Las operaciones de mantenimiento correctivo (fuera de la limpieza)

y reparación, como la sustitución de elementos, deben llevarse

a cabo en el establecimiento de MSA. No intente reparar el producto

por sí mismo.

Page 50

Inspección

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 23

MX

5. Inspección

5.1. Frecuencia de inspección

Revise el sistema de espacios confinados antes de cada uso.

5.2. Inspección formal

MSA requiere que todos los sistemas de espacios confinados se

sometan a una inspección por parte de una persona competente,

distinta del usuario, por lo menos cada seis meses, conforme a las

normas pertinentes o, si procede, según lo especifique un programa

formal de protección contra caídas.

Registre las inspecciones formales en el registro de inspecciones que

se le ha suministrado. No use un sistema de espacios confinados cuya

última fecha de inspección formal se remonte a más de seis (6) meses.

Si la fecha de la inspección formal se remonta a más de seis (6) meses,

marque el sistema de espacios confinados como “INUTILIZABLE” y

póngalo fuera de servicio hasta que supere la inspección formal.

5.3. Procedimiento para la inspección

Paso 1:

Revise que las etiquetas del sistema de espacios confinados

estén presentes y resulten perfectamente legibles.

Si las etiquetas están incompletas o resultan ilegibles, ponga

fuera de servicio el sistema de espacios confinados y

márquelo como “INUTILIZABLE” hasta que una persona

competente realice la inspección formal.

Paso 2:

Revise el sistema de espacios confinados para comprobar

que no presente corrosión, grietas, deformación, fracturas,

elementos alterados o incompletos, quemaduras o señales

de exposición al calor o a sustancias químicas.

Paso 3:

Revise todas las partes metálicas para comprobar que no

presenten deformaciones, fracturas, grietas, corrosión,

picaduras profundas, asperezas, bordes cortantes, cortes,

entalladuras profundas, partes sueltas o incompletas, o

señales de exposición excesiva al calor o a sustancias

químicas.

Paso 4:

Revise todas las partes no metálicas (p. ej. los pies

antideslizantes y las etiquetas) para comprobar que no

presenten cortes, roturas, desgaste excesivo o partes

incompletas o flojas.

Las etiquetas deben revisarse además conforme al Paso 1

indicado anteriormente. Revise también que no presenten

quemaduras ni señales de exposición a calor excesivo o a

sustancias químicas.

Page 51

Inspección

24 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

Paso 5:

Revise todos los componentes y subsistemas conforme a las

instrucciones del fabricante correspondiente.

Cuidado

Únicamente MSA o un centro de servicio autorizado por MSA pueden

realizar reparaciones en el sistema de espacios confinados.

5.4. Acción correctiva

Si durante la inspección se detectan condiciones inaceptables,

el sistema de espacios confinados deberá ponerse fuera de servicio

de inmediato y marcarse como “INUTILIZABLE” hasta su eliminación,

o hasta que se someta a mantenimiento por parte de la organización

del usuario.

La fabrica generalmente puede reparar los daños, el desgaste excesivo

y/o el envejecimiento. Si se presentan estas condiciones, ponga el

sistema de espacios confinados fuera de servicio de inmediato y

márquelo como “INUTILIZABLE” hasta que se realicen las reparaciones

necesarias.

Por último, envíe el sistema de espacios confinados a una persona

competente, autorizada para llevar a cabo la inspección formal. En caso

de dudas en cuanto a la viabilidad de reparación, póngase en contacto

con MSA o con el centro de servicio autorizado por MSA antes de seguir

utilizando el sistema de espacios confinados.

5.5. Registro de inspecciones

Dirección del proveedor y datos de contacto:

Modelo n. º:

N. º de serie:

Fecha de fabricación:

Fecha de compra:

Fecha del primer uso:

Page 52

Inspección

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 25

MX

Examinadores

Nombre/

Firma

Fecha

del próximo

examen

Responsable de

la reparación

Nombre/Firma

Acción

correctiva/

Reparación

Daño/desgaste

detectado

Fecha del

examen

Visit: www.thesafetyequipmentstore.com Or Email: besafe@thesafetyequipmentstore.com for Sales & Service.

Page 53

Almacenamiento

26 Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24"

MX

6. Almacenamiento

Almacene el sistema de espacios confinados en un lugar limpio

y seco, protegido de la luz solar directa.

Evite guardarlo en áreas con presencia de sustancias o vapores

químicos o tóxicos.

No lo sumerja ni lo deje en contacto directo con el agua, para evitar

formaciones de óxido y corrosión.

Page 54

Notas

Sistema de base adaptadora MSA/XTIRPA™ con alcance de 24" 27

MX

Page 55

For local MSA contacts, please visit us at MSAsafety.com

Because every life has a purpose...

Loading...

Loading...