Page 1

MSAsafety.com

User Instructions

Workman FP Stryder

Beam Anchor

Model Number / Número de modelo /

Numéro de modèle / Número do modelo:

10144431

□ 10144432 □

TM

Order No.: 10145808/03

Print Spec.: 10000005389 (F)

CR 800000030551

Page 2

WAR NING!

National standards and state, provincial and federal laws require the user to be trained before

using this product. Use this manual as part of a user safety training program that is appropriate

for the user's occupation. These instructions must be provided to users before use of the

product and retained for ready reference by the user. The user must read, and understand (or

have explained), and heed all instructions, labels, markings and warnings supplied with this

product and with those products intended for use in association with it. FAILURE TO DO SO

MAY RESULT IN SERIOUS INJURY OR DEATH.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

USA

Phone 1-800-MSA-2222

Fax 1-800-967-0398

For your local MSA contacts please go to our website www.MSAsafety.com

©

MSA 2018. All rights reserved

Page 3

1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Usage Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Safety and Precautionary Measures to be Adopted . . . . . . . . 4

1.5 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Attachment Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Crossbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 D-Ring Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Compatibility of System Parts . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Planning the Use of Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Inspection Before Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Making Proper Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Moving Around the Work Area . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Connecting the Workman FP Stryder . . . . . . . . . . . . . . . . . . . 9

4 Cleaning, Maintenance and Storage . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Inspection Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Procedure for Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Corrective Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Inspection Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

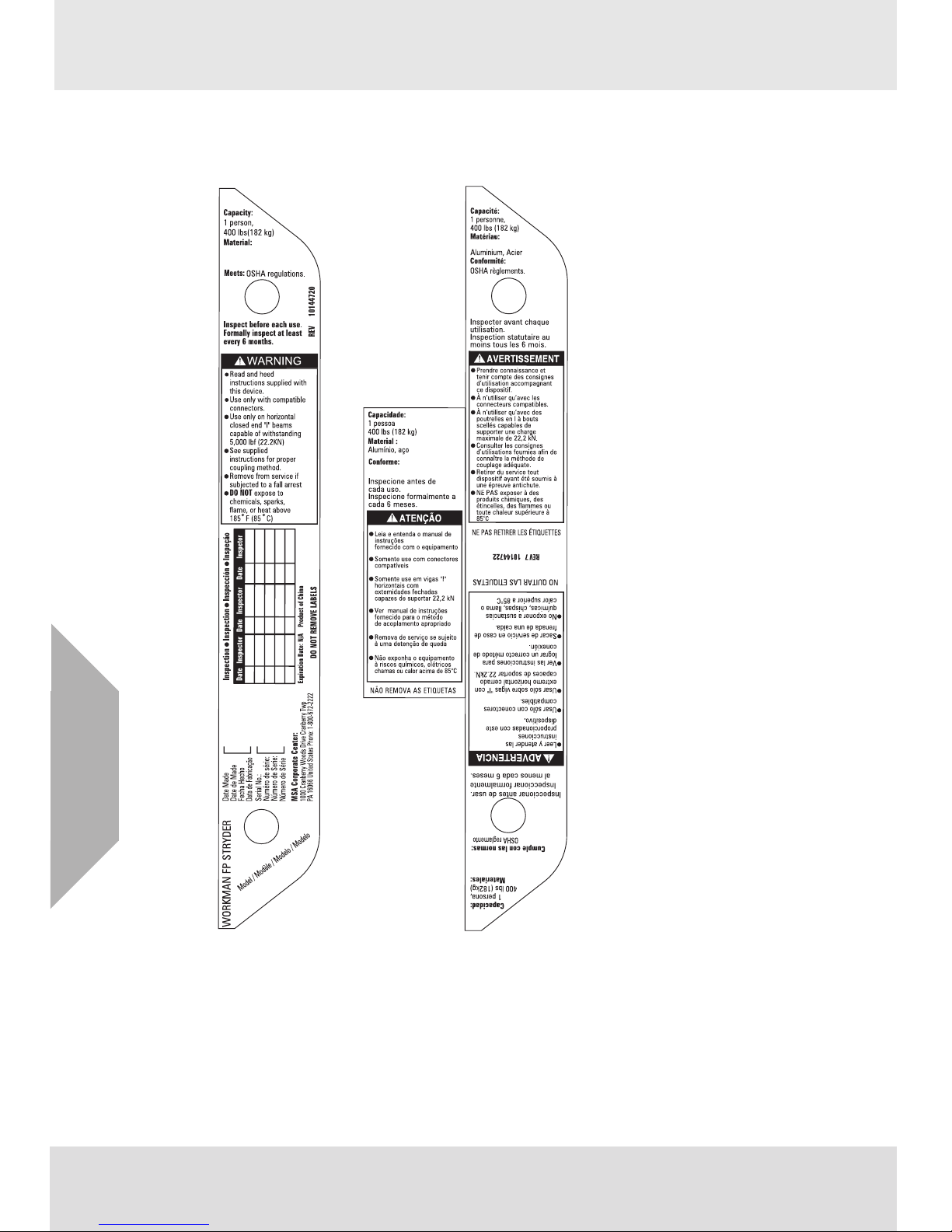

6 Markings And Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

US

WORKMAN FP STRYDER

3

Page 4

1 Safety Regulations

1.1 Correct Use

The Workman FP Stryder is designed for use by one person working at an elevated work level. The

Workman FP Stryder links the user to an I-beam anchorage point. It allows the worker to utilize existing

I-beam as temporary anchors, without the need for drilling or permanently attaching anchorages. It

moves with the worker allowing for continuous tie off.

Failure to follow any warning in this user instructions can result in serious personal injury or death.

1.2 Compliance

• ANSI Z359.18, Type A; OSHA requirements

• The product may comply with standards shown. See product label for specific compliance notifications. '

• Anchorage connectors labeled with ANSI Z359.18 have been tested in compliance with the

requirements of ANSI/ASSE Z359.7.

NOTE: ANSI compliance and testing covers only the hardware and does not extend to the anchorage

and substrate to which the anchorage connector is attached.

1.3 Usage Limitations

The following application limitations must be considered and planned for before using the

Workman FP Stryder.

1.3.1 Physical Limitations

Persons with muscular, skeletal, or other physical disorders should consult a physician before using.

Pregnant women and minors must never use the Workman FP Stryder. Increasing age and lowered

physical fitness may reduce a person’s ability to withstand shock loads during fall arrest or prolonged

suspension. Consult a physician if there is any question about physical ability to safely use this product

to arrest a fall or suspend.

US

1.3.2 Hazards

Chemical hazards, heat and corrosion may damage the Workman FP Stryder. More frequent inspections are required in these environments. Do not use in environments with temperatures greater than

185 ºF (85 ºC).

The following could cause damage to product:

• DO NOT use where lanyard or shock absorber may be exposed to sharp or abrasive edges or

sheared, expanded metal, or frame cut steel. Sharp edges may cut a lanyard or shock absorber

during a fall. Cover all sharp or abrasive edges with padding or sheathing before working above

edge.

• Do not install where equipment may encounter electrical hazards or moving machinery.

• Do not leave the Workman FP Stryder installed in environments which could cause damage or

deterioration to the product. Refer to sections 4.3 "Maintenance" and 5 "Inspection" for care and

inspection details. Do not leave unattended loads on the Workman FP Stryder.

• Avoid using Workman FP Stryder adjacent to moving machinery, electrical hazards or abrasive

surfaces or in the presence of excessive heat, open flame or molten metal.

• Do not use the Workman FP Stryder near energized equipment of where contact with high voltage

power lines may occur. Metal components of the Workman FP Stryder may provide a path for electrical current to flow, resulting in an electrical shock or electrocution.

• Remove any surface contamination such as, but not limited to, concrete, stucco, roofing material,

etc. that could accelerate cutting or abrading of attached components.

• Unauthorized alterations, relocations or additions to the anchorage connector are not permitted.

4

WORKMAN FP STRYDER

Page 5

1.4 Safety and Precautionary Measures to be Adopted

• It is the responsibility of the purchaser of the Workman FP Stryder to assure that product users

are made familiar with these user instructions and trained by a competent person. Training must

be conducted without undue exposure of the trainee to hazards. MSA offers training programs,

please contact for training information.

• DO NOT alter this equipment or intentionally misuse it. DO NOT use fall protection equipment for

purposes other than those for which it was designed. DO NOT use fall protection equipment for

towing, hoisting or material handling.

• If PPE is resold, it is essential that instructions for use, maintenance, and periodic examination are

provided in the language of destination.

• Use the Workman FP Stryder only on horizontal beams.

1.5 Warranty

Express Warranty – MSA warrants that the product furnished is free from mechanical defects or

faulty workmanship for a period of one (1) year from first use or eighteen (18) months from date of

shipment, whichever occurs first, provided it is maintained and used in accordance with MSA’s

instructions and/or recommendations. Replacement parts and repairs are warranted for ninety (90)

days from the date of repair of the product or sale of the replacement part, whichever occurs first.

MSA shall be released from all obligations under this warranty in the event repairs or modifications

are made by persons other than its own authorized service personnel or if the warranty claim results

from misuse of the product. No agent, employee or representative of MSA may bind MSA to any affirmation, representation or modification of the warranty concerning the goods sold under this contract.

MSA makes no warranty concerning components or accessories not manufactured by MSA, but will

pass on to the Purchaser all warranties of manufacturers of such components. THIS WARRANTY IS

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, AND IS STRICTLY

LIMITED TO THE TERMS HEREOF. MSA SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedy - It is expressly agreed that the Purchaser’s sole and exclusive remedy for

breach of the above warranty, for any tortious conduct of MSA, or for any other cause of action, shall

be the repair and/or replacement, at MSA’s option, of any equipment or parts thereof, that after examination by MSA are proven to be defective. Replacement equipment and/or parts will be provided at

no cost to the Purchaser, F.O.B. Purchaser’s named place of destination. Failure of MSA to successfully repair any nonconforming product shall not cause the remedy established hereby to fail of its

essential purpose.

Exclusion of Consequential Damages - Purchaser specifically understands and agrees that under

no circumstances will MSA be liable to Purchaser for economic, special, incidental, or consequential

damages or losses of any kind whatsoever, including but not limited to, loss of anticipated profits and

any other loss caused by reason of the non-operation of the goods. This exclusion is applicable to

claims for breach of warranty, tortious conduct or any other cause of action against MSA.

For additional information please contact the Customer Service Department at 1-800-MSA-2222

(1-800-672-2222).

US

WORKMAN FP STRYDER

5

Page 6

2 Description

8 7

1

2

11

3

4

6

10

9 5

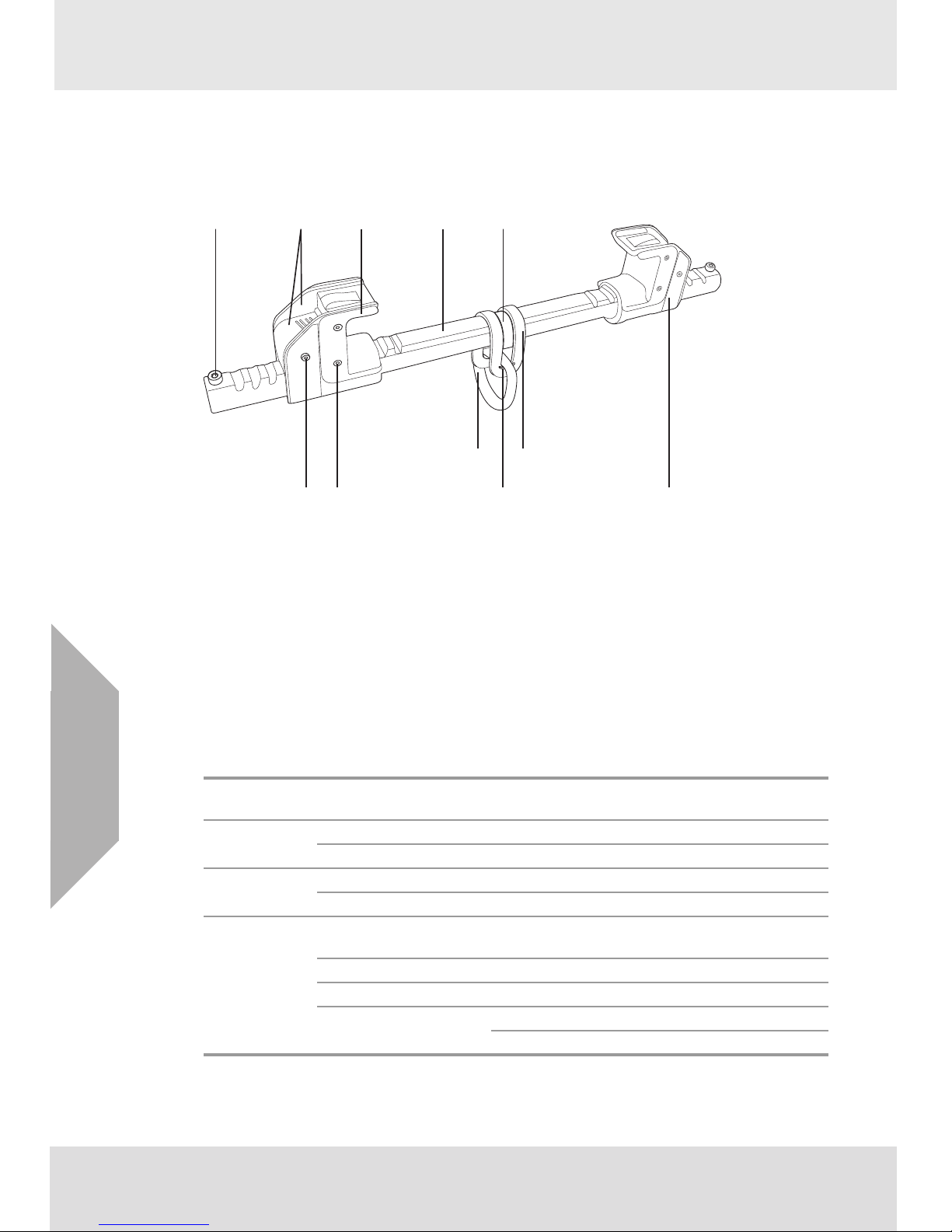

The Workman FP Stryder is an I-beam anchorage connector. The intended purpose of each element

of the Workman FP Stryder is given in sections 2.2 "Attachment Elements" through 2.4 "D-Ring

Connector" below. See inspection diagram for location of elements.

1 Jaw and locking button-2

2 D-ring-1

3 D-ring connector-1

4 Spacer-1

5 Cross bar-1

6 Glide pad-2

7 Barrel screw (-4) and bolt (-6)

8Pin-2

9Screw-2

10 Label-2

11 Load indictor

US

2.1 Specifications

Capacity

Weight

Flange capacity

Materials of

construction

When used as part of a personal fall arrest system, fall arrest forces must not exceed 1800 Ibf (8 kN).

6

400 lbs (182 kg) including weight of the user plus tools, clothing and other userborne objects.

Model 10144431 5 lbs (2.3kg)

Model 10144432 11.9 lbs (5.4 kg)

Model 10144431 4.00 inch (10.2cm) to 13.5 inch (34.3cm)

Model 10144432 14.00 inch (35.6cm) to 23.5 inch (59.7cm)

Housing, Button, Spring,

pin, D-ring connector

Glide pads Teflon impregnated thermal plastic.

D-ring Alloy steel

Crossbar

WORKMAN FP STRYDER

Stainless steel

Model 10144431 Aluminum alloy

Model 10144432 Alloy steel

Page 7

2.2 Attachment Elements

2.2.1 D-Ring

Used for connection to a lanyard element of a personal fall arrest system.

2.2.2 Jaw

Used for connection to the I-beam anchorage.

2.3 Crossbar

The crossbar connects and provides the means for adjustment of the jaws, and anchors the D-ring

connector.

2.4 D-Ring Connector

The D-ring connector connects the D-ring to the crossbar, and provides an integral load indicator.

2.5 Compatibility of System Parts

2.5.1 Compatibility of Components and Subsystems

Workman FP Stryder are designed to be used with other MSA Approved products. Use of the

Workman FP Stryder with products made by others that are not approved in writing by MSA may

adversely affect the functional compatibility between system parts and the safety and reliability of the

complete system.

2.5.2 Compatibility of Connectors

Connectors, such as D-rings, snaphooks, and carabiners must be rated at 5000 Ibf (22.2kN) minimum

capacity. MSA connectors meet this requirement. Connecting hardware must be compatible in size,

shape and strength. Non-compatible connectors may accidentally disengage (“roll out”). Always verify

that the connecting D-ring on the Workman FP Stryder is compatible with the snaphook, or carabiner

of the lanyard subsystem.

2.5.3 Anchorages

The acceptable anchorage for the Workman FP Stryder is a horizontal I-beam. The I-beam must be

configured so that the Workman FP Stryder cannot come off the end of the beam Anchorages for

personal fall arrest systems must either: (a) have a strength capable of supporting and withstanding at

least 5,000 pounds (22.2 kN) in the directions permitted by the system without failure, or (b), must be

certified by a professional engineer as having the required strength for fall arrest or travel restraint, as

applicable. See ANSI Z359.18 for definition of certification. See ANSI Z359.187 for definition of certificate. When more than one personal fall arrest system is attached to an anchorage, the anchorage

strengths set forth in (a) and (b) must be multiplied by the number of systems attached to the

anchorage. This requirement is consistent with OSHA requirements under CFR 1910, subpart F,

Section 1910.66, Appendix C. Do not proceed with installation and user of the anchorage connector if

an assessment of strength cannot be made.

US

WORKMAN FP STRYDER

7

Page 8

3Use

WARNING!

The anchorage to which the Workman FP Stryder is attached must be rated in the direction of

intended use. See section 2.5.3 "Anchorages" for details on anchorage strength and loading

details.

When installing or removing the Workman FP Stryder, limit exposure to fall hazards. A separate

independent fall arrest system may be required.

Ensure that fall clearance is sufficient to meet governing standards or subsystem component

requirements.

Work directly under the anchorage/anchorage connector at all times. A full body harness is the

only acceptable body holding device that can be used in a fall arrest system.

MSA Fall Protection products may not be used while under the influence of drugs or alcohol.

3.1 Planning the Use of Systems

3.1.1 Free Fall Distance, Total Fall Distance and System Elongation

WARNING!

DO NOT exceed the allowable free fall distance or exceed the maximum fall arrest forces as specified

by governing standards or subsystem components.

The capacity of the Workman FP Stryder must be greater or equal the sub-system components.

US

1) Free fall distance. See user instructions and label of compatible deceleration device (i.e. SRL,

lanyard, etc.) for allowable free fall distance.

2) Total fall distance. The sum of the free fall distance and deceleration distance plus a 3 ft (0.92 m)

safety margin.

3) Deceleration distance. Must not exceed 3.5 ft (1.1m).

3.1.2 Pendulum (Swing) Falls

WARNING!

Prevent swing falls and impact with objects in or adjacent to the fall path.

Always remove obstructions below the work area to ensure a clear fall path. Keep work area free from

debris, obstructions, trip hazards, spills or other hazard which could impair the safe operation of the fall

protection system. DO NOT use the Workman FP Stryder unless a qualified person has inspected the

workplace and determined that identified hazards can neither be eliminated nor exposures to them

prevented.

Swing fall hazards must be minimized by anchoring directly above the user’s work space. The force of

striking an object in a pendular motion can cause serious injury. Always minimize swing falls by working

as directly below the anchorage point as possible.

3.1.3 Rescue and Evacuation

The user must have a rescue plan and the means at hand to implement it. The plan must take into

account the equipment and specific training necessary to affect prompt rescue under all foreseeable

conditions. If the rescue be from a confined space, the provisions of OSHA regulation 1910.146 and

ANSI Z117.1 must be taken into account. It is recommended to provide means for user evacuation

without assistance of others. This will usually reduce the time to get to a safe place and reduce or

prevent the risk to rescuers.

8

WORKMAN FP STRYDER

Page 9

3.2 Inspection Before Each Use

Inspect the Workman FP Stryder to verify it is in serviceable condition. Examine entire device for signs

of cracking or deformation. See Section 10 for inspection details. Do not use a Workman FP Stryder if

inspection of it reveals an unsafe condition.

3.3 Making Proper Connections

WARNING!

Do not rely on feel or sound to verify proper snaphook or carabiner engagement. Ensure that gate and

keeper are closed before use.

When connecting the D-ring of the Workman FP Stryder to a lanyard subsystem, be certain accidental

disengagement (“rollout”) cannot occur. Rollout is possible when interference between a snaphook and

the mating connector causes the snaphook’s gate or keeper to accidentally open and release. Rollout

occurs when a snaphook is snapped into an under sized ring such as an eye bolt or other non-compatibly shaped connector. Only self closing, self locking snaphooks and carabiners should be used to

reduce the possibility of rollout when making connections. Do not use snaphooks or connectors that

will not completely close over the attachment object. Do not make knots in a lanyard. Do not hook a

lanyard back onto itself. Snaphooks and carabiners must not be connected to each other. Do not attach

two snaphooks into one D-ring. Always follow the manufacturer’s instructions supplied with each

system component.

3.4 Moving Around the Work Area

The Workman FP Stryder is designed to move along the flange of the I-beam anchorage, following the

user movements. Move around carefully to prevent loss of balance in the event the Workman FP

Stryder binds or contacts an obstacle in the path of movement.

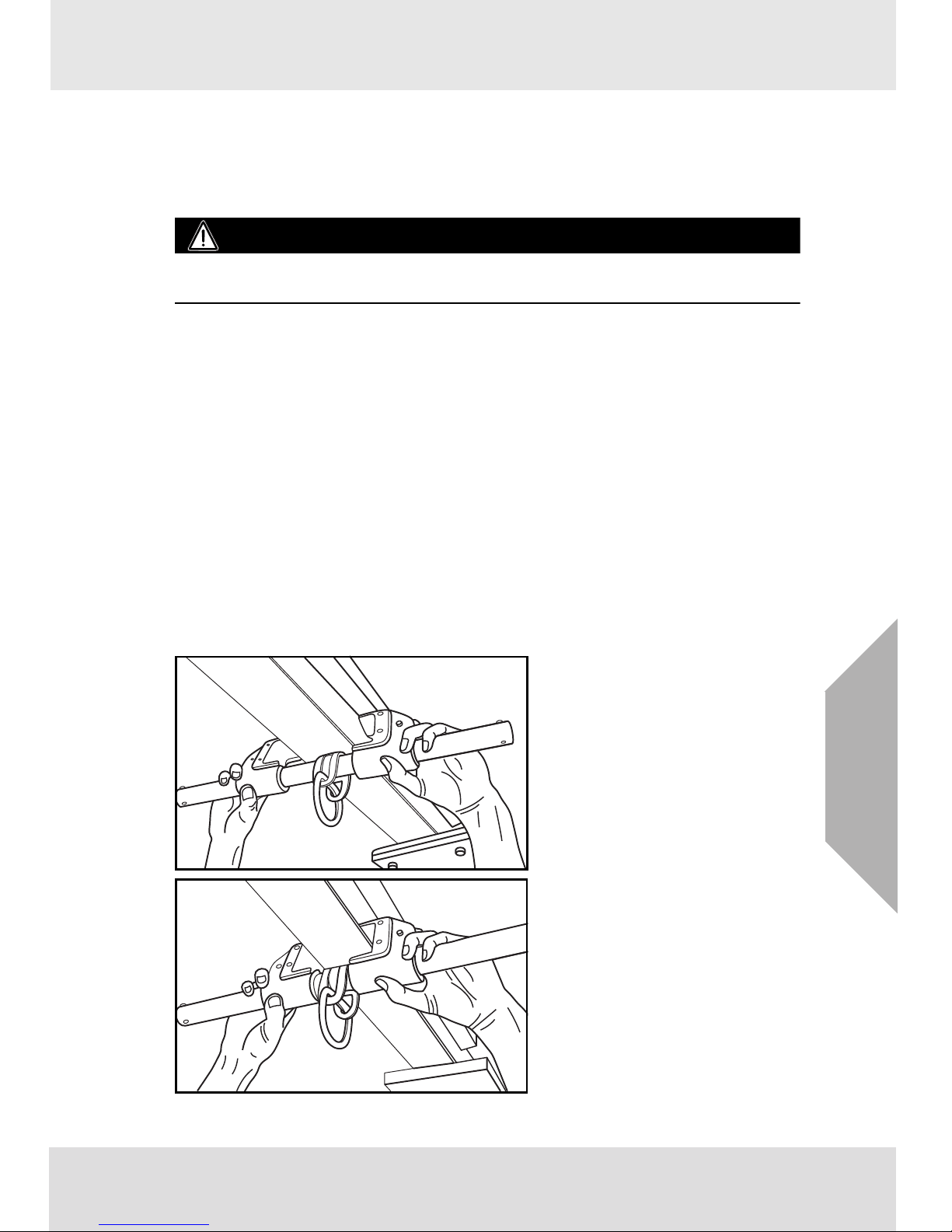

3.5 Connecting the Workman FP Stryder

The Workman FP Stryder may be used in above or below beam applications.

(1) To use the Workman FP Stryder,

depress the buttons to unlock the

jaws and slide the jaws far enough

apart to fit over the flange of the Ibeam anchorage.

(2) Push the jaws together to capture

the flange of the

I-beam. Release the buttons to lock

the jaw to the crossbar. Fine adjust

the jaws to fit, by alternating locking

the jaws in the differently placed slot

in the crossbar.

US

WORKMAN FP STRYDER

9

Page 10

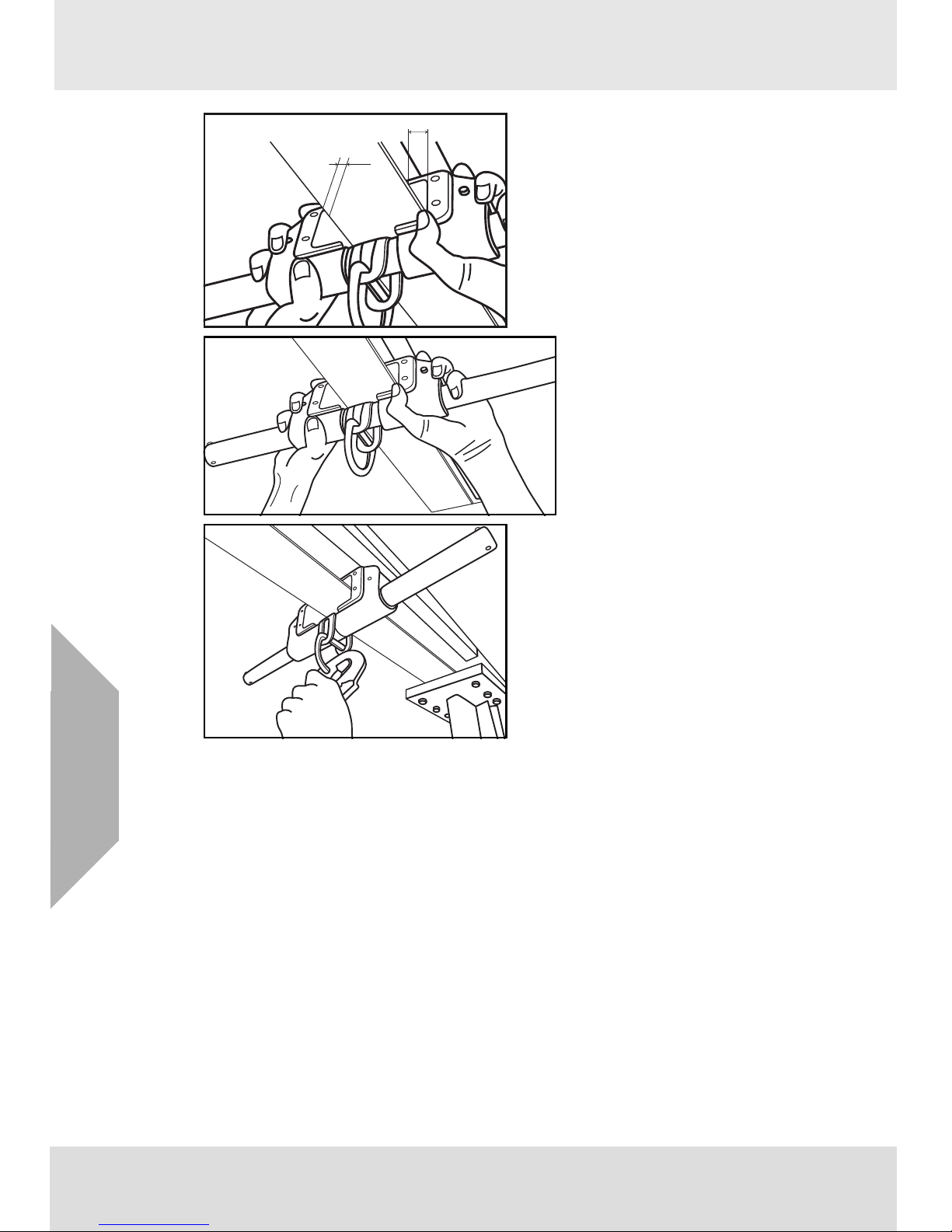

(3) The maximum total clearance

A

B

between the jaws and the flange is

0.5 inch (12.7 mm).

Maximum total clearance = A+B

Maximum total clearance <0.5 inch

(12.7 mm)

(4) Verify the jaws are locked into the

crossbar.

(5) The user can then connect the

snaphook or carabiner of their

lanyard subsystem to the D-ring of

the Workman FP Stryder.

Be certain the snaphook or carabiner gate is completely closed

and locked.

US

10

WORKMAN FP STRYDER

Page 11

4 Cleaning, Maintenance and Storage

4.1 Cleaning Instructions

Use a clean damp (not wet) cloth to remove dirt or contamination which may cause corrosion or

hamper readability of labels. Wipe off any moisture before returning the device to service. Remove any

surface contamination such as concrete, stucco, roofing material, etc., that could accelerate cutting or

abrading of attached components. The frequency of cleaning should be determined by inspection and

by severity of the environment. In highly corrosive environments cleaning should be done every two or

three days. Never use solvents to clean the device as they may damage the plastic components. Don’t

use abrasives to scour the device as they may damage the surface and the labels. To remove oil or

grease, use a mild dishwater detergent on a damp cloth or sponge and follow by repeated swabbing

with a clean cloth to remove all soap residue. Never immerse the product in water or other liquid.

4.2 Storage

Store the device in a clean, dry place indoors. Store the product away from heat and steam and never

allow it to rest for lengthy periods of time on concrete or ash floors as the lime sulfur and ash can cause

corrosion.

4.3 Maintenance

User maintenance consists of cleaning and drying the device and replacement of the glide pad. All

other maintenance or repair/work must be done at the factory or by an authorized person. (Authorization by MSA must be written).

WORKMAN FP STRYDER

US

11

Page 12

US

5Inspection

5.1 Inspection Frequency

WARNING!

If the Workman FP Stryder is damaged or is subjected to fall arrest forces or impact forces, it must be

immediately removed from service and marked as "UNUSABLE" until it has been destroyed.

The Workman FP Stryder must be inspected by the user before each use. Additionally, the Workman

FP Stryder must be inspected by a competent person other than the user at intervals of no more than

six months. The competent person inspection is referred to as Formal Inspection. An inspection log

must be filled out during the Formal Inspection, see section 5.4 "Inspection Log". In addition, the

inspection log on the Workman FP Stryder label must be marked or punched to indicate when the last

Formal Inspection occurred.

The program administrator shall maintain documentation of equipment inspections. This documentation shall include, at a minimum, the identity of the equipment, inspection date, name of the competent

or qualified person conducting the inspection and the result of that inspection.

The program administrator shall sett inspection criteria for the equipment. Such criteria shall equal or

exceed the most restrictive of the criteria established by the ANSI Z359.18 standard or the manufacturer‘s user instructions. Keep inspection criteria current in relationship to changing patterns or conditions of use.

5.2 Procedure for Inspection

Perform the following steps in sequence. If in doubt about any inspection point, consult MSA or a

competent person who is qualified to perform a Formal Inspection as described in section 11.

(1) Inspect the Workman FP Stryder labels to verify that they are present and legible. See Section 6

"Markings And Labels" for the specific labels that should be present and the information

contained thereon. Check the Formal Inspection Log to be sure a Formal Inspection has been

performed within the last six months. If the Log does not indicate that a Formal Inspection has

been performed within the last six months, or if any labels are missing or illegible, remove the

device from use and mark it as “UNUSABLE” until a Formal Inspection is performed by a competent person.

(2) Check the auto close action of the button. Depress button with thumb, and ensure auto closing.

If button fails these functional tests, return to maintain from service.

(3) Check for structural defects and corrosion. Verify that are no missing, loose screw or altered

parts; that there are no cracks, deformations, or excessive corrosion.

(4) Inspect the D-ring for deformation, damage, fractures, cracks, corrosion, deep pitting, burrs,

sharp edges, cuts, deep nicks, evidence of excessive heat or chemical exposures. Check the

pin with screw for no deformation, fractures, cracks, corrosion, pitting and nicks. Verify the screw

in the pin tightly. If the screws which connected with pins are loose, remove the device from use

and make It “UNUSABLE”. Check the entire assembly for evidence of inadequate maintenance

of equipment, alteration, excessive wear, or any condition that calls to question the suitability of

the equipment for its intended purpose.

(5) Inspect the load indicating D-ring connector for activation. If the device has been exposed to a

fall arrest force the window will be deformed, remove the device from use and make it “UNUSABLE”.

(6) Inspect each component and subsystem of the complete system in accordance with the associ-

ated manufacturer’s instructions. See section 3.1 "Planning the Use of Systems" for a description of the makeup of the different types of subsystem and systems.

12

WORKMAN FP STRYDER

Page 13

5.3 Corrective Action

WARNING!

Unauthorized alterations, relocations or additions to the anchorage connector are not permitted.

Only MSA or persons or entities with written authorization from the manufacturer may make repairs to

the Workman FP Stryder. No unauthorized repairs, modifications, alterations, relocations, and/or additions are permitted.

When inspection reveals sign of inadequate maintenance, the Workman FP Stryder must be immediately removed from service and marked as “UNUSABLE” until destroyed or subjected to corrective

maintenance. Defects, damage, excessive wear, malfunction and aging are generally not repairable.

If detected immediately remove the Workman FP Stryder from use and mark it as “UNUSABLE” until

destroyed. For final disposition, submit the Workman FP Stryder to a competent person who is authorized to perform Formal Inspection. If there is any question as to reliability, contact MSA, or a service

center authorized in writing by MSA, before further use of the device.

5.4 Inspection Log

Model No.: Inspector:

Serial No.:

Date Made: Disposition:

Comments:

Inspection

Date:

WORKMAN FP STRYDER

US

13

Page 14

6 Markings And Labels

8

regulações OSHA

(10144431)

Aço (10144432)

Acier 10144432

10144431

Acero (10144432)

Aluminio, Acero (10144432)

Steel (10144432)

Aluminium, Steel (10144431)

The labels must be present, legible and securely attached to the Workman FP Stryder. The labels are

located on the sides of the jaws.

US

14

WORKMAN FP STRYDER

Page 15

WORKMAN FP STRYDER

15

US

Page 16

For local MSA contacts, please visit us at MSAsafety.com

Because every life has a purpose...

Page 17

MSAsafety.com

Model Number / Número de modelo /

Numéro de modèle / Número do modelo:

10144431

□ 10144432 □

Instrucciones para el usuario

Workman FP Stryder

TM

Anclaje para viga

N.º de referencia: 10145808/03

Espec. de impresión: 10000005389 (F)

CR 800000030551

Page 18

ADVERTENCIA!

Conforme a la normativa nacional y a las legislaciones estatales, provinciales y federales, el

usuario debe recibir formación antes de utilizar este producto. Utilice este manual como parte

de un programa de formación sobre la seguridad del usuario que sea adecuado para el puesto

de trabajo del usuario. Es necesario proporcionar estas instrucciones a los usuarios antes del

uso del producto y conservarlas a mano para que el usuario pueda consultarlas. El usuario

debe leer y comprender (o deben explicarle) todas las instrucciones, etiquetas, marcados y

advertencias suministrados con este producto y con los productos que se vayan a utilizar en

combinación con el mismo. EL INCUMPLIMIENTO DE ESTA RECOMENDACIÓN PUEDE

CONLLEVAR LESIONES GRAVES O LETALES.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

EE. UU.

Teléfono: 1-800-MSA-2222

Fax: 1-800-967-0398

Para consultar sus contactos locales de MSA, visite nuestra página web www.MSAsafety.com

©

MSA 2018. Todos los derechos reservados

Page 19

WORKMAN FP STRYDER

3

ES

1 Normativas de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Uso correcto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Conformidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Limitaciones de uso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Medidas preventivas y de seguridad a adoptar . . . . . . . . . . . . 4

1.5 Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Descripción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Elementos de acoplamiento . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Cruceta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Conector de la argolla en D . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Compatibilidad de las piezas del sistema . . . . . . . . . . . . . . . . 7

3 Uso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Planificación del uso de los sistemas . . . . . . . . . . . . . . . . . . . 8

3.2 Inspección antes de cada uso . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Realización de conexiones correctas . . . . . . . . . . . . . . . . . . . 9

3.4 Desplazamiento por el área de trabajo . . . . . . . . . . . . . . . . . . 9

3.5 Conexión del Workman FP Stryder . . . . . . . . . . . . . . . . . . . . . 9

4 Limpieza, mantenimiento y almacenamiento . . . . . . . . . . . . . . . 11

4.1 Instrucciones de limpieza . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Inspección . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Frecuencia de inspección . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Procedimiento para la inspección . . . . . . . . . . . . . . . . . . . . . 12

5.3 Acción correctiva . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Registro de inspección . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Marcados y etiquetas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 20

ES

WORKMAN FP STRYDER

4

1 Normativas de seguridad

1.1 Uso correcto

El Workman FP Stryder está diseñado para ser utilizado por una persona durante trabajos en altura.

El Workman FP Stryder une al usuario con un punto de anclaje de una viga en I. Permite al trabajador

utilizar una viga en I disponible como anclaje temporal sin necesidad de perforar ni de acoplar anclajes

de forma permanente. Se mueve junto con el trabajador permitiendo un amarre continuo.

Si se hace caso omiso de cualquiera de las advertencias de las presentes instrucciones para el

usuario, podrían sufrirse lesiones personales graves o letales.

1.2 Conformidad

• ANSI Z359.18, tipo A; requisitos OSHA

• El producto puede cumplir las normas indicadas. Consulte en la etiqueta del producto las

notificaciones específicas sobre la conformidad. '

• Los conectores de anclaje etiquetados con ANSI Z359.18 han sido probados de conformidad con

los requisitos de ANSI/ASSE Z359.7.

NOTA: la conformidad y las pruebas según ANSI cubren únicamente el hardware y no abarcan el

anclaje ni la superficie a la que está fijado el conector de anclaje.

1.3 Limitaciones de uso

Es preciso tener en cuenta y planificar las siguientes limitaciones de aplicación antes de utilizar el

Workman FP Stryder.

1.3.1 Limitaciones físicas

Las personas que sufran enfermedades musculares, del esqueleto o físicas deben consultar a un

médico antes de utilizar el equipo. Las mujeres embarazadas y las personas menores de edad no

deben utilizar nunca el Workman FP Stryder. Cuanta más edad tenga el usuario y cuanto peor sea su

estado físico, mayor será la probabilidad de que se reduzca su capacidad de resistir cargas de impacto

durante la retención de una caída o una suspensión prolongada. Consulte a un médico si tuviera

alguna duda sobre la capacidad física de utilizar con seguridad este producto como retención de una

caída o para aplicaciones en suspensión.

1.3.2 Peligros

Los peligros químicos, el calor y la corrosión pueden provocar daños en el Workman FP Stryder. En

este tipo de entornos se precisan inspecciones más frecuentes. No utilice el dispositivo en entornos

con temperaturas superiores a 85 ºC (185 ºF).

Lo siguiente puede provocar daños en el producto:

• NO utilice el dispositivo en los casos en los que elemento de amarre o el amortiguador de

impactos puedan verse expuestos a bordes afilados o abrasivos, a metal expandido cizallado o a

acero de corte de bastidor. Los bordes afilados pueden cortar un elemento de amarre o un

amortiguador de impactos durante una caída. Cubra todos los bordes afilados o abrasivos con

acolchado o revestimiento antes de trabajar por encima del borde.

• No instale el equipo donde este pueda estar sometido a peligros eléctricos o máquinas en

movimiento.

• No deje el Workman FP Stryder montado en entornos en los que pueda sufrir daños o

deteriorarse. Consulte en los apartados 4.3 "Mantenimiento" y 5 "Inspección" la información

detallada sobre el cuidado y la inspección. No deje cargas desatendidas en el Workman FP

Stryder.

• Evite utilizar el Workman FP Stryder junto a máquinas en movimiento, peligros eléctricos o

superficies abrasivas, así como en presencia de un calor excesivo, llama abierta o metal fundido.

• No utilice el Workman FP Stryder cerca de equipos bajo tensión o en lugares donde pueda entrar

en contacto con líneas eléctricas de alta tensión. Los componentes metálicos del Workman FP

Stryder pueden conducir corriente eléctrica, lo que podría provocar una descarga eléctrica o

electrocución.

Page 21

WORKMAN FP STRYDER

5

ES

• Elimine de la superficie cualquier suciedad, p. ej., hormigón, yeso, material de cubierta, etc. que

pudiera acelerar el corte o la abrasión de los componentes acoplados.

• Está prohibido realizar alteraciones, reubicaciones o anexos no autorizados en el conector de

anclaje.

1.4 Medidas preventivas y de seguridad a adoptar

• Es responsabilidad del comprador del Workman FP Stryder asegurarse de que los usuarios se

familiaricen con estas instrucciones para el usuario y de que reciban formación por parte de una

persona competente. Durante la formación, el aprendiz no debe verse expuesto a peligros de

forma indebida. MSA ofrece programas de formación. Póngase en contacto con la empresa para

recibir información sobre la formación.

• NO altere el equipo ni lo someta intencionadamente a un uso indebido. NO utilice un equipo de

protección anticaídas para fines distintos a aquellos para los que ha sido concebido. NO utilice un

equipo de protección anticaídas para arrastrar, elevar o manipular materiales.

• Si un EPI se volviera a vender, deberán proporcionarse instrucciones de uso, mantenimiento e

inspección periódica en el idioma del país de destino.

• Utilice el Workman FP Stryder únicamente en vigas horizontales.

1.5 Garantía

Garantía expresa – MSA garantiza que el producto suministrado estará exento de defectos

mecánicos y de fallos de funcionamiento durante un período de un (1) año a partir del primer uso o

de dieciocho (18) meses a partir de la fecha de envío, cualquiera que se produzca antes, siempre y

cuando se mantenga y utilice conforme a las instrucciones y/o recomendaciones de MSA. Los

repuestos y reparaciones cuentan con una garantía de noventa (90) días a partir de la fecha de

reparación del producto o la venta del repuesto, cualquiera que se produzca antes. MSA queda

exenta de toda obligación contraída con esta garantía si personas distintas a las de su propio

personal o a las del servicio autorizado realizasen reparaciones o modificaciones, o si se reclama la

garantía por mal uso del producto. Ningún agente, empleado o representante de MSA puede

vincular a MSA a ninguna afirmación, representación o modificación de la garantía relativa a los

productos vendidos con este contrato. MSA no ofrece garantía alguna por los componentes o

accesorios que no hayan sido fabricados por MSA, aunque transferirá al comprador todas las

garantías del fabricante de dichos componentes. ESTA GARANTÍA SUSTITUYE A CUALQUIER

OTRA GARANTÍA, YA SEA EXPRESA, IMPLÍCITA U OBLIGATORIA, Y SE LIMITA

ESTRICTAMENTE A LOS TÉRMINOS DE ESTE DOCUMENTO. MSA RECHAZA

ESPECÍFICAMENTE TODA RESPONSABILIDAD DE CUALQUIER GARANTÍA DE

COMERCIABILIDAD O DE IDONEIDAD PARA UN FIN DETERMINADO.

Recurso exclusivo - Se acuerda de forma expresa que el recurso único y exclusivo del comprador,

por incumplimiento de la anterior garantía, por cualquier conducta dolosa de MSA o por cualquier

otra causa de acción, será la reparación y/o cambio a criterio de MSA, de cualquier equipo o pieza

del mismo que, tras haber sido examinado por parte de MSA, se haya probado como defectuoso.

El reemplazo de equipos y/o piezas se realizará sin costo alguno para el comprador, FOB en el

destino indicado por el comprador. El incumplimiento de MSA de reparar satisfactoriamente

cualquier producto no conforme no será causa de la pérdida del propósito esencial del recurso aquí

establecido.

Exclusión de daños indirectos - El comprador entiende y acepta específicamente que, bajo

ninguna circunstancia, MSA será responsable ante el comprador por los daños o las pérdidas

económicas, especiales, incidentales o resultantes de ninguna clase, incluida pero sin limitarse a

ella, la pérdida de beneficios anticipados y cualquier otra pérdida causada por la falta de

operatividad de los productos. Esta exclusión se aplica a las reclamaciones por incumplimiento de

la garantía, conducta dolosa o cualquier otra causa de acción contra MSA.

Para obtener información adicional, póngase en contacto con el departamento de atención al cliente

en el 1-800-MSA-2222 (1-800-672-2222).

Page 22

ES

WORKMAN FP STRYDER

6

2 Descripción

El Workman FP Stryder es un conector de anclaje para vigas en I. El propósito previsto de cada uno

de los elementos que conforman el Workman FP Stryder se indica a continuación en los apartados del

2.2 "Elementos de acoplamiento" al 2.4 "Conector de la argolla en D". Consulte en el diagrama de

inspección la ubicación de los elementos.

2.1 Especificaciones

En caso de utilizarse como parte de un sistema anticaídas personal, las fuerzas de parada en la caída

no deben superar los 8 kN (1800 Ibf).

1 Mordaza y botón de bloqueo-2

2 Argolla en D-1

3 Conector de la argolla en D-1

4 Separador-1

5 Cruceta-1

6 Almohadilla de deslizamiento-2

7 Tornillo de cilindro (-4) y perno (-6)

8 Pasador-2

9 Tornillo-2

10 Etiqueta-2

11 Indicador de carga

8 7

1

2

11

3

4

6

10

9 5

Capacidad

182 kg (400 lbs) incluido el peso del usuario más herramientas, ropa y otros

objetos transportados por el usuario.

Peso

Modelo 10144431 2,3 kg (5 lbs)

Modelo 10144432 5,4 kg (11,9 lbs)

Capacidad del

borde

Modelo 10144431 10,2 cm (4,00 pulg.) a 34,3 cm (13,5 pulg.)

Modelo 10144432 35,6 cm (14,00 pulg.) a 59,7 cm (23,5 pulg.)

Materiales de

construcción

Carcasa, botón, resorte, pasador,

conector de la argolla en D

Acero inoxidable

Almohadillas de deslizamiento Termoplástico impregnado con teflón

Argolla en D Aleación de acero

Cruceta

Modelo 10144431 Aleación de aluminio

Modelo 10144432 Aleación de acero

Page 23

WORKMAN FP STRYDER

7

ES

2.2 Elementos de acoplamiento

2.2.1 Argolla en D

Se utiliza para la conexión a un elemento de amarre de un sistema anticaídas personal.

2.2.2 Mordaza

Se emplea para la conexión al anclaje de la viga en I.

2.3 Cruceta

La cruceta conecta y permite ajustar las mordazas, a la vez que ancla el conector de la argolla en D.

2.4 Conector de la argolla en D

El conector de la argolla en D conecta la argolla en D a la cruceta y proporciona un indicador de carga

integral.

2.5 Compatibilidad de las piezas del sistema

2.5.1 Compatibilidad de componentes y subsistemas

Los Workman FP Stryder están diseñados para ser utilizados con otros productos autorizados por

MSA. El uso del Workman FP Stryder con productos de otros fabricantes que no hayan sido

autorizados por escrito por parte de MSA puede afectar negativamente a la compatibilidad funcional

entre los componentes del sistema y a la seguridad y la fiabilidad del sistema completo.

2.5.2 Compatibilidad de conectores

Los conectores, como pueden ser las argollas en D, los ganchos de seguridad y los mosquetones,

deben presentar una capacidad mínima de 22,2 kN (5000 lbf). Los conectores de MSA cumplen este

requisito. Los dispositivos de conexión deben ser compatibles en tamaño, forma y resistencia. Los

conectores no compatibles pueden desengancharse accidentalmente ("separación accidental").

Compruebe siempre que la argolla en D de conexión del Workman FP Stryder es compatible con el

gancho de seguridad o el mosquetón del subsistema del elemento de amarre.

2.5.3 Anclajes

El anclaje aceptable para el Workman FP Stryder es una viga en I horizontal. La viga en I debe estar

configurada de modo que el Workman FP Stryder no pueda salir del extremo de la viga. Los anclajes

para sistemas anticaídas personales deben: (a) presentar una resistencia capaz de soportar y

aguantar al menos 22,2 kN (5000 lbs) en las direcciones permitidas por el sistema sin fallar, o (b) estar

certificados por un ingeniero profesional que asegure que presentan la resistencia necesaria para la

retención de caídas o la contención de desplazamiento según sea aplicable. Consulte en ANSI

Z359.18 la definición de la certificación. Consulte en ANSI Z359.187 la definición del certificado. Si se

acopla más de un sistema anticaídas personal a un anclaje, las resistencias de anclaje establecidas

en (a) y en (b) más arriba deberán multiplicarse por el número de sistemas anticaídas personales

acoplados. Este requisito satisface las estipulaciones OSHA de CFR 1910, subparte F, sección

1910.66, anexo C. No realice el montaje ni utilice el conector de anclaje en caso de no poderse evaluar

la resistencia.

Page 24

ES

WORKMAN FP STRYDER

8

3 Uso

ADVERTENCIA!

El anclaje al que está acoplado el Workman FP Stryder debe estar clasificado para la dirección

de uso previsto. Consulte en el apartado 2.5.3 "Anclajes" la información sobre la resistencia de

anclaje y la carga.

Al montar o retirar el Workman FP Stryder, limite los riesgos de sufrir caídas. Puede ser necesario

utilizar un sistema anticaídas independiente.

Asegúrese de que la distancia de caída es suficiente para cumplir las normativas en vigor o los

requisitos de los componentes del subsistema.

Trabaje directamente bajo el anclaje/conector de anclaje en todo momento. Un arnés anticaídas

es el único dispositivo de sujeción corporal admitido para el uso en un sistema anticaídas.

Los productos de protección anticaídas de MSA no pueden utilizarse bajo los efectos de las

drogas o del alcohol.

3.1 Planificación del uso de los sistemas

3.1.1 Distancia de caída libre, distancia de caída total y alargamiento del sistema

ADVERTENCIA!

NO exceda la distancia de caída libre permitida ni las fuerzas máximas de parada en la caída

especificadas por las normativas en vigor o los componentes del subsistema.

La capacidad del Workman FP Stryder debe ser igual o mayor que la de los componentes del

subsistema.

1) Distancia de caída libre. Consulte en las instrucciones para el usuario y en la etiqueta del

dispositivo de deceleración compatible (p. ej., SRL, elemento de amarre, etc.) la distancia de

caída libre permitida.

2) Distancia de caída total. La suma de la distancia de caída libre y de la distancia de deceleración

más un margen de seguridad de 0,92 m (3 ft).

3) Distancia de deceleración. No debe superar los 1,1 m (3,5 ft).

3.1.2 Caídas tipo péndulo (con balanceo)

ADVERTENCIA!

Evite las caídas con balanceo y los impactos contra objetos situados en la trayectoria de caída

o en sus inmediaciones.

Es necesario eliminar cualquier obstáculo situado debajo del área de trabajo con el fin de garantizar

una trayectoria de caída despejada. Mantenga la zona de trabajo libre de suciedad, obstáculos,

peligros de tropiezo, derrames u otros peligros que pudieran mermar el funcionamiento seguro del

sistema de protección anticaídas. NO utilice el Workman FP Stryder a no ser que una persona

cualificada haya inspeccionado el lugar de trabajo y haya determinado que los peligros identificados

no pueden eliminarse o que no es posible evitar la exposición a los mismos.

Minimice el peligro de caída por balanceo realizando el anclaje directamente por encima de la posición

de trabajo del usuario. La fuerza al golpear un objeto en movimiento pendular puede provocar lesiones

de gravedad. Minimice siempre las caídas con balanceo trabajando lo más directamente posible

debajo del punto de anclaje.

Page 25

WORKMAN FP STRYDER

9

ES

3.1.3 Rescate y evacuación

El usuario debe disponer de un plan de rescate y de los medios necesarios para implementarlo. El

plan debe tener en cuenta los equipos y la formación específica necesarios para llevar a cabo un

rescate inmediato en todas las condiciones predecibles. Si el rescate tiene lugar desde un espacio

confinado, deberán tenerse en cuenta las disposiciones de la regulación OSHA 1910.146 y ANSI

Z117.1. Se recomienda poner a disposición medios para la evacuación de usuarios sin la asistencia

de terceras personas. Por lo general, esto disminuirá el tiempo necesario para llegar a un lugar seguro

y reducirá o evitará el riesgo para las personas encargadas del rescate.

3.2 Inspección antes de cada uso

Inspeccione el Workman FP Stryder para verificar que se encuentra en perfecto estado operativo.

Examine el dispositivo completo para descartar grietas o deformación. Consulte en el apartado 10 la

información detallada sobre la inspección. No utilice un Workman FP Stryder si la inspección revela

un estado no seguro.

3.3 Realización de conexiones correctas

ADVERTENCIA!

Para comprobar el acoplamiento correcto de los ganchos de seguridad o de los mosquetones, no

confíe en el tacto o el sonido. Asegúrese de que el pestillo y el retenedor estén cerrados antes del uso.

Al conectar la argolla en D del Workman FP Stryder a un subsistema de elemento de amarre,

asegúrese de que no puede desengancharse accidentalmente ("separación accidental"). Puede

producirse una separación de este tipo si interferencias entre un gancho de seguridad y el conector

de acoplamiento hacen que el pestillo o el retenedor del gancho de seguridad se abran y liberen

accidentalmente. Se produce una separación accidental cuando un gancho de seguridad se engancha

en una argolla sin las dimensiones suficientes como puede ser un cáncamo u otro conector con una

forma no compatible. Al realizar las conexiones, utilice únicamente ganchos de seguridad y

mosquetones con autoenclavimiento y cierre automático para recudir la posibilidad de que se

produzca una separación accidental. No utilice ganchos de seguridad o conectores que no se cierren

completamente sobre el objeto acoplado. No realice nudos en los elementos de amarre. No enganche

un elemento de amarre a sí mismo. Los ganchos de seguridad y los mosquetones no deben

conectarse entre sí. No acople dos ganchos de seguridad a una misma argolla en D. Siga siempre las

instrucciones del fabricante suministradas con cada componente del sistema.

3.4 Desplazamiento por el área de trabajo

El Workman FP Stryder está diseñado para moverse por el borde del anclaje de la viga en I siguiendo

los movimientos del usuario. Muévase con cuidado para evitar perder el equilibrio en caso de que el

Workman FP Stryder se enganche o entre en contacto con un obstáculo en la trayectoria de

movimiento.

3.5 Conexión del Workman FP Stryder

El Workman FP Stryder puede utilizarse por encima o debajo de vigas.

(1) Para utilizar el Workman FP Stryder,

pulse los botones para desbloquear

las mordazas y deslice las mordazas

alejándolas lo suficiente para que se

ajusten sobre el borde del anclaje de

la viga en I.

Page 26

ES

WORKMAN FP STRYDER

10

(2) Comprima las mordazas para

atrapar el borde de la viga en I.

Suelte los botones para bloquear la

mordaza en la cruceta. Ajuste con

precisión las mordazas

bloqueándolas de forma alternativa

en la ranura situada en otra posición

de la cruceta.

(3) La distancia total máxima entre las

mordazas y el borde es de 12,7 mm

(0,5 pulg.).

Distancia total máxima = A+B

Distancia total máxima < 12,7 mm

(0,5 pulg.)

(4) Compruebe que las mordazas están

bloqueadas en la cruceta.

(5) A continuación, el usuario puede

conectar el gancho de seguridad o el

mosquetón del subsistema del

elemento de amarre a la argolla en D

del Workman FP Stryder.

Asegúrese de que el pestillo del

gancho de seguridad o del

mosquetón esté completamente

cerrado y bloqueado.

A

B

Page 27

WORKMAN FP STRYDER

11

ES

4 Limpieza, mantenimiento y almacenamiento

4.1 Instrucciones de limpieza

Utilice un paño húmedo (no mojado) para eliminar la suciedad o la contaminación que podrían

provocar corrosión o reducir la legibilidad de las etiquetas. Seque toda humedad con un paño antes

de volver a poner en servicio el dispositivo. Elimine de la superficie cualquier suciedad, p. ej.,

hormigón, yeso, material de cubierta, etc. que pudiera acelerar el corte o la abrasión de los

componentes acoplados. La frecuencia de limpieza debe estipularse mediante una inspección y

teniendo en cuenta las condiciones del entorno. En entornos muy corrosivos debería efectuarse una

limpieza cada dos o tres días. No utilice nunca disolventes para limpiar el dispositivo puesto que los

componentes de plástico podrían resultar dañados. No utilice abrasivos para limpiar el dispositivo ya

que podrían dañar la superficie y las etiquetas. Para eliminar el aceite o la grasa, utilice un lavavajillas

suave con un paño húmedo o una esponja y, seguidamente, emplee un paño limpio para eliminar todo

residuo de jabón. No sumerja nunca el producto en agua u otros líquidos.

4.2 Almacenamiento

Almacene el dispositivo es una estancia interior limpia y seca. Almacene el producto alejado del calor

y del vapor y no permita que permanezca durante periodos de tiempo prolongados sobre suelos de

hormigón o con ceniza ya que el polisulfuro de calcio y la ceniza pueden provocar corrosión.

4.3 Mantenimiento

El mantenimiento que debe efectuar el usuario consiste en limpiar y secar el dispositivo y en sustituir

la almohadilla de deslizamiento. El mantenimiento o las reparaciones y trabajos restantes deben

realizarse en fábrica o por una persona autorizada. (MSA debe otorgar la autorización por escrito).

Page 28

ES

WORKMAN FP STRYDER

12

5 Inspección

5.1 Frecuencia de inspección

ADVERTENCIA!

Si el Workman FP Stryder estuviera dañado o si se hubiera visto expuesto a fuerzas de parada en la

caída o a fuerzas de impacto, deberá ponerse fuera de servicio de inmediato y marcarse como

"INSERVIBLE" hasta destruirse.

El usuario debe inspeccionar el Workman FP Stryder antes de cada uso. Además, el Workman FP

Stryder debe inspeccionarse por una persona competente diferente al usuario en intervalos no

superiores a seis meses. La inspección efectuada por una persona competente se conoce como

inspección oficial. Es preciso cumplimentar un registro de inspección durante la inspección oficial,

véase el apartado 5.4 "Registro de inspección". Asimismo, es necesario marcar o perforar el registro

de inspección de la etiqueta del Workman FP Stryder para indicar cuándo se ha realizado la última

inspección oficial.

El administrador de programas debe llevar una documentación de las inspecciones de los equipos.

Dicha documentación debe incluir al menos la identidad del equipo, la fecha de inspección, el nombre

de la persona competente o cualificada que ha realizado la inspección y el resultado de la inspección.

El administrador de programas debe estipular los criterios de inspección para el equipo. Dichos

criterios deben ser iguales o superar los criterios más restrictivos establecidos por la norma ANSI

Z359.18 o por las instrucciones para el usuario del fabricante. Mantenga los criterios de inspección

acordes al cambio de los patrones o de las condiciones de uso.

5.2 Procedimiento para la inspección

Lleve a cabo los siguientes pasos en orden. Si tuviera alguna duda respecto a algún punto de la

inspección, consulte a MSA o a una persona competente cualificada para efectuar una inspección

oficial según se describe en el apartado 11.

(1) Inspeccione las etiquetas del Workman FP Stryder para verificar que están disponibles y

legibles. Consulte en el apartado 6 "Marcados y etiquetas" las etiquetas específicas deben estar

presentes así como la información que deben incluir. Consulte el archivo de inspección oficial

para asegurarse de que se ha efectuado una inspección oficial durante los últimos seis meses.

Si el registro no muestra que se ha realizado una inspección oficial durante los últimos seis

meses o si faltara alguna etiqueta o estuviera ilegible, retire el dispositivo del servicio y

márquelo como "INUTILIZABLE" hasta que una persona competente lleve a cabo una

inspección oficial.

(2) Compruebe la acción de cierre automático del botón. Pulse el botón con el pulgar y asegúrese

de que cierra automáticamente. Si el botón no superara estas pruebas funcionales, devuelva el

dispositivo para que el servicio técnico realice el mantenimiento.

(3) Descarte la presencia de defectos estructurales y de corrosión. Compruebe que no falten

tornillos y que no estén flojos, que no haya componentes alterados, grietas, deformaciones o

una corrosión excesiva.

(4) Inspeccione la argolla en D para descartar deformaciones, daños, fisuras, grietas, corrosión,

picaduras profundas, rebabas, bordes afilados, cortes, incisiones o signos de una exposición a

un calor excesivo o a productos químicos. Compruebe el pasador con tornillo para descartar la

presencia de deformación, fisuras, grietas, corrosión, picaduras e incisiones. Verifique que el

tornillo se ajusta firmemente en el pasador. Si los tornillos unidos a los pasadores están sueltos,

retire el dispositivo del servicio y márquelo como "INUTILIZABLE". Compruebe el conjunto

completo para descartar evidencias de un mantenimiento inadecuado del equipo, alteraciones,

un desgaste excesivo o cualquier estado que ponga en duda la idoneidad del equipo para su fin

previsto.

(5) Inspeccione una posible activación en el indicador de carga del conector de la argolla en D. Si

el dispositivo hubiera estado expuesto a una fuerza de parada en la caída, la ventana estará

deformada. En este caso, retire el dispositivo del servicio y márquelo como "INUTILIZABLE".

(6) Inspeccione cada componente y subsistema del sistema completo según las instrucciones

correspondientes del fabricante. Consulte en el apartado 3.1 "Planificación del uso de los

sistemas" una descripción de la composición de los diferentes tipos de subsistemas y sistemas.

Page 29

WORKMAN FP STRYDER

13

ES

5.3 Acción correctiva

ADVERTENCIA!

Está prohibido realizar alteraciones, reubicaciones o anexos no autorizados en el conector de anclaje.

Únicamente MSA o personas o entidades con autorización escrita del fabricante pueden realizar

reparaciones en el Workman FP Stryder. No están permitidos reparaciones, modificaciones,

alteraciones y/o anexos.

Si la inspección revela signos de un mantenimiento inadecuado, el Workman FP Stryder debe retirarse

de inmediato del servicio y marcarse como "INUTILIZABLE" hasta destruirse o someterse a un

mantenimiento correctivo. Por lo general, los defectos, los daños, el desgaste excesivo, los fallos de

funcionamiento y el envejecimiento no pueden repararse. Si detectara alguna de estas deficiencias,

retire de inmediato el Workman FP Stryder del servicio y márquelo como "INUTILIZABLE" hasta

destruirlo. Para la eliminación definitiva, remita el Workman FP Stryder a una persona competente

autorizada para realizar una inspección oficial. Si hubiera alguna duda sobre la fiabilidad del

dispositivo, póngase en contacto con MSA o con un centro de servicio autorizado pro escrito por MSA

antes de continuar utilizando el dispositivo.

5.4 Registro de inspección

N.º de modelo: Inspector:

N.º de serie: Fecha de inspección:

Fecha de fabricación: Disposición:

Comentarios:

Page 30

ES

WORKMAN FP STRYDER

14

6 Marcados y etiquetas

Las etiquetas deben estar presentes, legibles y fijadas de forma segura al Workman FP Stryder. Las

etiquetas están ubicadas en los laterales de las mordazas.

8

regulações OSHA

(10144431)

Aço (10144432)

Acier 10144432

10144431

Acero (10144432)

Aluminio, Acero (10144432)

Steel (10144432)

Aluminium, Steel (10144431)

Page 31

WORKMAN FP STRYDER

15

ES

Page 32

For local MSA contacts, please visit us at MSAsafety.com

Because every life has a purpose...

Page 33

MSAsafety.com

Model Number / Número de modelo /

Numéro de modèle / Número do modelo:

10144431

□ 10144432 □

Instructions d’utilisation

Workman FP Stryder

TM

Ancrage sur poutre

Réf. : 10145808/03

Référence impression : 10000005389 (F)

CR 800000030551

Page 34

AVERTISSEMENT!

Les normes nationales et les lois locales, régionales et fédérales imposent que l’utilisateur soit

formé avant d’utiliser ce produit. Utilisez ce manuel dans le cadre d’un programme de

formation à la sécurité de l’utilisateur adapté à l’occupation de l’utilisateur. Ces instructions

doivent être procurées aux utilisateurs avant l’utilisation du produit et conservées pour

consultation ultérieure par l’utilisateur. L’utilisateur doit lire, comprendre (ou se faire expliquer)

et tenir compte de l’ensemble des instructions, étiquettes, marquages et avertissements

accompagnant ce produit et les produits destinés à être utilisés en combinaison avec ce

produit. LE NON-RESPECT DE CES CONSIGNES PEUT ENTRAÎNER DES BLESSURES

GRAVES, VOIRE MORTELLES.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

États-Unis

Tél. 1-800-MSA-2222

Fax 1-800-967-0398

Pour obtenir les coordonnées de vos représentants MSA locaux, veuillez consulter le site Internet

www.MSAsafety.com

©

MSA 2018. Tous droits réservés

Page 35

WORKMAN FP STRYDER

3

FR

1 Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Utilisation correcte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Conformité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Limites d’utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Mesures et précautions de sécurité à adopter . . . . . . . . . . . . . 4

1.5 Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Éléments de fixation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Barre transversale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Connecteur pour anneau en D . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Compatibilité des éléments du système . . . . . . . . . . . . . . . . . 7

3 Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Utilisation planifiée des systèmes . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Inspection avant chaque utilisation . . . . . . . . . . . . . . . . . . . . . 9

3.3 Exécution correcte des connexions . . . . . . . . . . . . . . . . . . . . . 9

3.4 Déplacements dans la zone de travail . . . . . . . . . . . . . . . . . . . 9

3.5 Connexion du Workman FP Stryder . . . . . . . . . . . . . . . . . . . . 9

4 Nettoyage, maintenance et stockage . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Instructions de nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Stockage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Fréquence d’inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Procédure d’inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Mesure corrective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Journal d’inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Marquages et étiquettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 36

FR

WORKMAN FP STRYDER

4

1 Consignes de sécurité

1.1 Utilisation correcte

Le Workman FP Stryder est conçu pour être utilisé par une personne travaillant à un niveau élevé.

Le Workman FP Stryder relie l’utilisateur à une poutre en I servant de point d’ancrage. Il permet au

travailleur d’utiliser une poutre en I existante comme ancrage temporaire sans avoir à percer ou à fixer

des ancrages permanents. Il se déplace avec le travailleur pour assurer une fixation continue.

Le non-respect d’un avertissement donné dans les présentes instructions d’utilisation peut entraîner

des blessures graves, voire mortelles.

1.2 Conformité

• ANSI Z359.18, type A ; exigences OSHA

• Le produit peut être conforme avec les normes indiquées. Reportez-vous à l’étiquette du produit

pour les notifications de conformité spécifiques.

• Les connecteurs d’ancrage portant un étiquetage ANSI Z359.18 ont été testés conformément aux

exigences de la norme ANSI/ASSE Z359.7.

REMARQUE : la conformité ANSI et les tests s’appliquent uniquement au matériel et ne s’étendent ni

à l’ancrage ni au support auquel le connecteur d’ancrage est fixé.

1.3 Limites d’utilisation

Les limites d’application suivantes doivent être prises en compte et prévues avant l’utilisation du

Workman FP Stryder.

1.3.1 Limitations physiques

Les personnes atteintes de troubles musculaires, squelettiques ou physiques de tout autre type

doivent consulter un médecin avant d’utiliser le produit. Le Workman FP Stryder ne doit jamais être

utilisé par des femmes enceintes et des mineurs. L’âge et une forme physique réduite peuvent

diminuer la capacité d’une personne à supporter les chocs d’arrêt de chute ou une suspension

prolongée. Consultez un médecin s’il existe le moindre doute concernant votre aptitude physique à

utiliser ce produit en toute sécurité pour l’arrêt d’une chute ou la suspension.

1.3.2 Dangers

Les risques chimiques, la chaleur et la corrosion peuvent endommager le Workman FP Stryder. Des

inspections plus fréquentes sont nécessaires dans ces environnements. N’utilisez pas le produit dans

des environnements présentant des températures supérieures à 185 ºF (85 ºC).

Le produit risque d’être endommagé dans les cas suivants :

• N’utilisez PAS le produit si la longe ou l’absorbeur de chocs risque d’être exposé à des bords

tranchants ou abrasifs, à des métaux déployés blindés ou à un châssis en acier découpé. Les

bords tranchants risquent de sectionner la longe ou l’absorbeur de chocs lors d’une chute.

Couvrez tous les bords tranchants ou abrasifs avec un rembourrage ou un revêtement avant de

travailler au-dessus d’un bord.

• N’installez pas le produit à un emplacement où l’équipement peut être mis en danger par des

risques électriques ou des machines en mouvement.

• Ne laissez pas le Workman FP Stryder installé dans des environnements qui pourraient

endommager ou détériorer le produit. Reportez-vous aux sections 4.3 "Maintenance" et 5

"Inspection" pour des informations détaillées concernant l’entretien et l’inspection. Ne laissez pas

de charges sans surveillance sur le Workman FP Stryder.

• Évitez d’utiliser le Workman FP Stryder à proximité de machines en mouvement, de risques

électriques ou de surfaces abrasives ou en présence d’une chaleur excessive, de flammes nues

ou de métal en fusion.

• N’utilisez pas le Workman FP Stryder à proximité d’équipements sous tension ou s’il existe un

risque de contact avec des lignes d’alimentation à haute tension. Les composants métalliques du

Workman FP Stryder peuvent permettre au courant électrique de passer, ce qui entraîne un risque

de choc électrique ou d’électrocution.

Page 37

WORKMAN FP STRYDER

5

FR

• Éliminez toutes les contaminations de surface qui pourraient accélérer la coupure ou l’abrasion

des composants fixés, comme par exemple (mais sans s’y limiter) : béton, stuc, matériaux de

couverture, etc.

• Il est interdit d’effectuer des modifications, déplacements ou ajouts non autorisés sur le

connecteur d’ancrage.

1.4 Mesures et précautions de sécurité à adopter

• Il est de la responsabilité de l’acheteur du Workman FP Stryder de garantir que les utilisateurs du

produit sont familiarisés avec ces instructions d’utilisation et formés par une personne

compétente. La formation doit être menée sans exposer inutilement la personne formée aux

dangers. MSA offre des programmes de formation ; veuillez nous contacter pour obtenir des

informations concernant la formation.

• Ne modifiez PAS cet équipement et n’en faites PAS intentionnellement mauvais usage. N’utilisez

PAS l’équipement de protection antichute à des fins autres que celles pour lesquelles il a été

conçu. N’utilisez PAS l’équipement de protection antichute pour le tractage, le levage ou la

manutention de matériaux.

• Si l’EPI est revendu, il est essentiel que les instructions d’utilisation, de maintenance et

d’inspection périodique soient fournies dans la langue du pays de destination.

• N’utilisez le Workman FP Stryder que sur des poutres horizontales.

1.5 Garantie

Garantie explicite – MSA garantit que le produit livré ne présente aucun défaut mécanique ni défaut

de fabrication pendant un (1) an à compter de la date de première utilisation ou dix-huit (18) mois à

compter de la date d’expédition dudit produit, selon la première éventualité, à condition que celui-ci

soit entretenu et utilisé conformément aux consignes et/ou recommandations de MSA. Les pièces

de rechange et les réparations sont garanties pendant quatre-vingt-dix (90) jours à compter de la

date de réparation du produit ou de la vente de la pièce de rechange, selon la première éventualité.

La présente garantie n’impose aucune obligation à MSA en cas de réparations ou de modifications

effectuées par des personnes autres que son propre personnel d’entretien autorisé ou si la

réclamation est liée à une mauvaise utilisation du produit. Aucun agent, employé ni représentant de

MSA n’est autorisé à attribuer à MSA une quelconque affirmation, représentation ou modification de

garantie concernant les biens vendus selon les termes de ce contrat. MSA n’accorde pas de garantie

sur les composants ou les accessoires non fabriqués par MSA, mais transmettra à l’acquéreur toutes

les garanties des fabricants de ces composants. CETTE GARANTIE REMPLACE TOUTES LES

AUTRES GARANTIES EXPLICITES, IMPLICITES OU STATUTAIRES, ET SE LIMITE

STRICTEMENT AUX CONDITIONS DE CE CONTRAT. MSA SE DÉGAGE NOTAMMENT DE

TOUTE RESPONSABILITÉ DE GARANTIE DE QUALITÉ MARCHANDE OU D’ADAPTATION À

UNE APPLICATION PARTICULIÈRE.

Recours exclusif - Il est expressément décidé que le seul et unique recours de l’acquéreur en cas

de non-respect de la garantie ci-dessus, en cas de comportement inadapté de MSA ou pour toute

autre cause, sera la réparation et/ou le remplacement, au choix de MSA, de l’équipement ou de ses

pièces qui auront été jugés défectueux par MSA. L’équipement et/ou les pièces de rechange seront

fournis gratuitement à l’acquéreur en FOB, lieu de destination convenu pour l’acquéreur. L’échec de

MSA quant à la réparation correcte d’un produit non conforme ne saurait être assimilé à un nonaccomplissement de l’objectif premier du recours en question.

Exclusion des dommages indirects - L’acquéreur comprend et accepte expressément qu’en

aucun cas MSA ne sera tenu responsable d’éventuels dommages ou pertes économiques, spéciaux,

accidentels ou indirects d’aucune sorte causés à l’acquéreur, y compris mais sans se limiter à la

perte de bénéfices anticipés et à toute autre perte causée par le non-fonctionnement des produits.

Cette exclusion s’applique aux demandes d’indemnisation pour rupture de garantie, pour conduite

délictueuse ou pour tout autre motif d’action à l’encontre de MSA.

Pour de plus amples informations, veuillez contacter le service clientèle au 1-800-MSA-2222

(1-800-672-2222).

Page 38

FR

WORKMAN FP STRYDER

6

2 Description

Le Workman FP Stryder est un connecteur d’ancrage sur poutre en I. L’usage prévu de chaque

élément du Workman FP Stryder est décrit dans les sections 2.2 "Éléments de fixation" à 2.4

"Connecteur pour anneau en D" ci-après. Reportez-vous au schéma d’inspection pour la localisation

des éléments.

2.1 Caractéristiques

En cas d’utilisation au sein d’un système stop chute personnel, les forces d’arrêt de chute ne doivent

pas dépasser 1800 Ibf (8 kN).

1 Mâchoire et bouton de verrouillage-2

2 Anneau en D-1

3 Connecteur pour anneau en D-1

4 Séparateur-1

5 Barre transversale-1

6 Patin-2

7 Vis cylindrique (-4) et boulon (-6)

8 Goupille-2

9 Vis-2

10 Étiquette-2

11 Indicateur de charge

8 7

1

2

11

3

4

6

10

9 5

Capacité

400 lbs (182 kg) en comptant le poids de l’utilisateur et des outils, vêtements et

autres objets portés par l’utilisateur.

Poids

Modèle 10144431 5 lbs (2,3 kg)

Modèle 10144432 11,9 lbs (5,4 kg)

Capacité de la

bride

Modèle 10144431 4,00 pouces (10,2 cm) à 13,5 pouces (34,3 cm)

Modèle 10144432 14,00 pouces (35,6 cm) à 23,5 pouces (59,7 cm)

Matériaux de

construction

Boîtier, bouton, ressort, goupille,

connecteur pour anneau en D

Acier inoxydable

Patins Thermoplastique imprégné de Téflon

Anneau en D Alliage d’acier

Barre transversale

Modèle 10144431 Alliage d’aluminium

Modèle 10144432 Alliage d’acier

Page 39

WORKMAN FP STRYDER

7

FR

2.2 Éléments de fixation

2.2.1 Anneau en D

Permet d’établir la connexion à l’élément à longe d’un système stop chute personnel.

2.2.2 Mâchoire

Utilisée pour la connexion à la poutre en I d’ancrage.

2.3 Barre transversale

La barre transversale assure la connexion, permet d’ajuster les mâchoires et ancre le connecteur pour

anneau en D.

2.4 Connecteur pour anneau en D

Le connecteur pour anneau en D permet de connecter l’anneau en D à la barre transversale et fournit

un indicateur de charge intégral.

2.5 Compatibilité des éléments du système

2.5.1 Compatibilité des composants et des sous-systèmes

Le Workman FP Stryder est conçu pour être utilisé avec d’autres produits approuvés MSA. L’utilisation

du Workman FP Stryder avec des produits d’autres fabricants qui ne sont pas approuvés par écrit par

MSA peut avoir un impact négatif sur la compatibilité fonctionnelle des éléments du système, ainsi que

sur la sécurité et la fiabilité du système complet.

2.5.2 Compatibilité des connecteurs

Les connecteurs, tels que les anneaux en D, les mousquetons automatiques et les mousquetons,

doivent présenter une capacité minimale de 5000 Ibf (22,2 kN). Les connecteurs MSA répondent à

cette exigence. Le matériel de connexion doit être compatible en termes de dimensions, de forme et

de résistance. Les connecteurs incompatibles risquent de se détacher accidentellement

(« déroulement »). Vérifiez toujours que l’anneau en D de connexion du Workman FP Stryder est

compatible avec le mousqueton automatique ou le mousqueton du sous-système à longe.

2.5.3 Ancrages

L’ancrage acceptable pour le Workman FP Stryder est une poutre en I horizontale. La poutre en I doit

être configurée de manière à ce que le Workman FP Stryder ne puisse pas se détacher au bout de la

poutre. Les ancrages pour systèmes stop chute personnels doivent : (a) présenter une résistance

capable de supporter au moins 5000 livres (22,2 kN) dans les directions permises par le système sans

défaillance, ou (b) doivent être certifiés par un ingénieur professionnel comme offrant la résistance

requise pour l’arrêt de chute ou la retenue en déplacement, le cas échéant. Reportez-vous à la norme

ANSI Z359.18 pour la définition de la certification. Reportez-vous à la norme ANSI Z359.187 pour la

définition du certificat. Si plusieurs systèmes stop chute personnels sont fixés à un ancrage, les

résistances d’ancrage données aux points (a) et (b) doivent être multipliées par le nombre de systèmes

fixés à l’ancrage. Cette exigence coïncide avec les exigences OSHA conformément à CFR 1910,

sous-partie F, section 1910.66, annexe C. Ne procédez pas à l’installation et à l’utilisation du

connecteur d’ancrage s’il est impossible d’évaluer la résistance.

Page 40

FR

WORKMAN FP STRYDER

8

3 Utilisation

AVERTISSEMENT!

L’ancrage auquel le Workman FP Stryder est fixé doit être évalué dans la direction d’utilisation

prévue. Reportez-vous à la section 2.5.3 "Ancrages" pour des informations détaillées sur la

résistance de l’ancrage et les sollicitations.

Lors de l’installation ou du retrait du Workman FP Stryder, limitez l’exposition aux risques de

chute. Un système stop chute indépendant séparé peut s’avérer nécessaire.

Vérifiez que le tirant d’air est suffisant pour répondre aux normes applicables ou aux exigences

des composants du sous-système.

Travaillez en permanence directement sous l’ancrage/le connecteur d’ancrage. Un harnais